Patents

Literature

238results about How to "Realize the function of automatic feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic feeding equipment for livestock cultivation

PendingCN110692533AAvoid economic lossImprove unityTransportation and packagingRotary stirring mixersElectric machineryLivestock

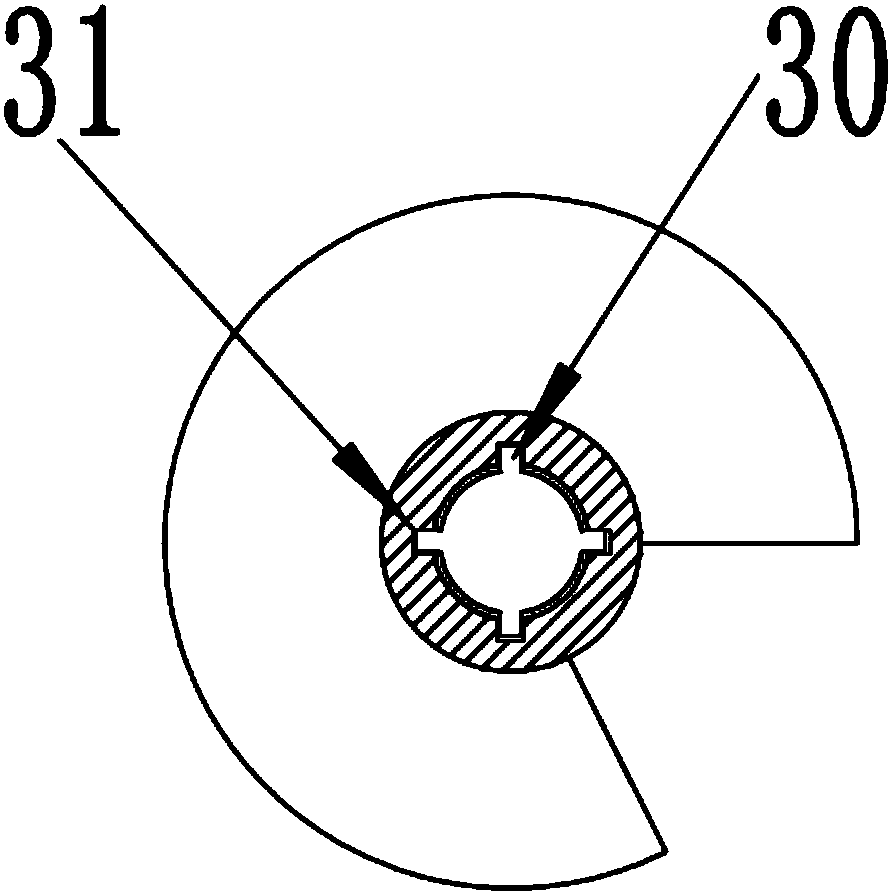

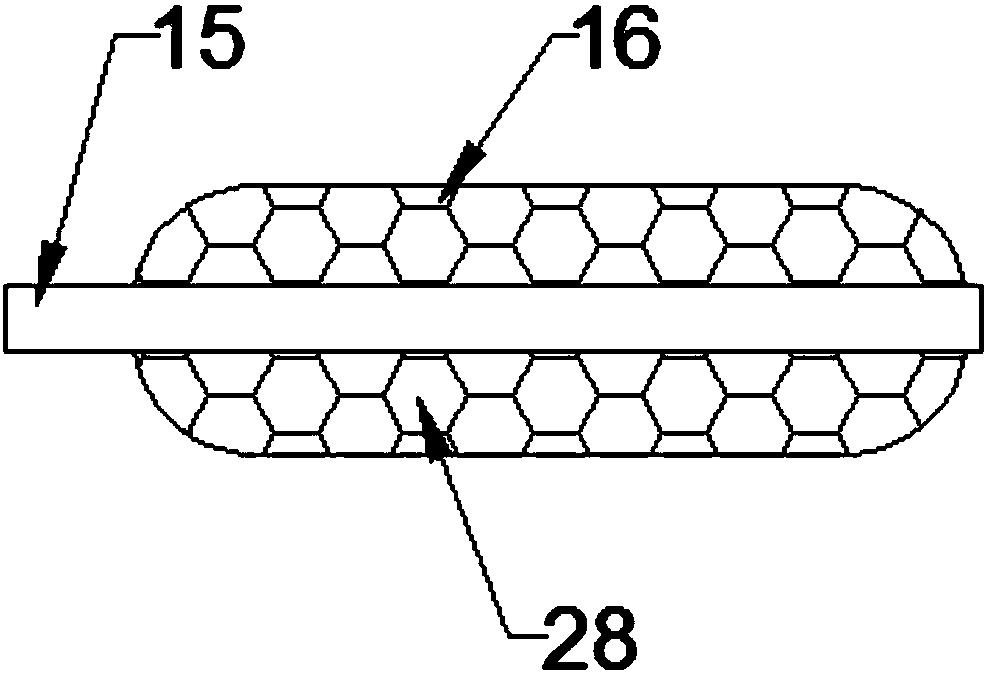

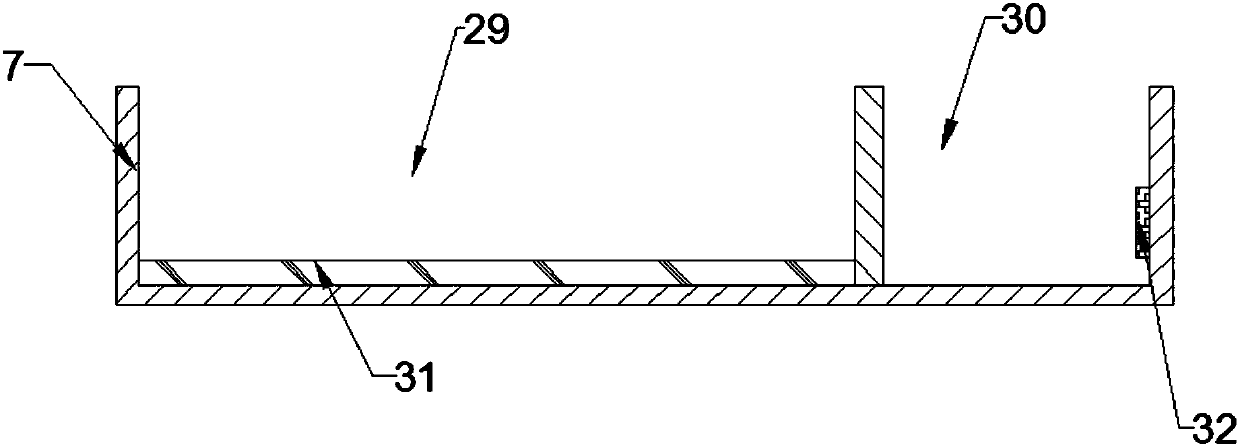

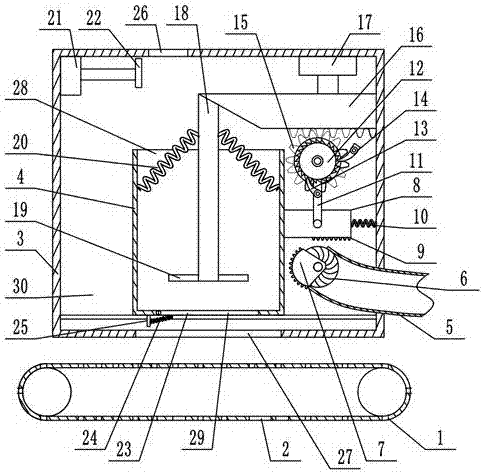

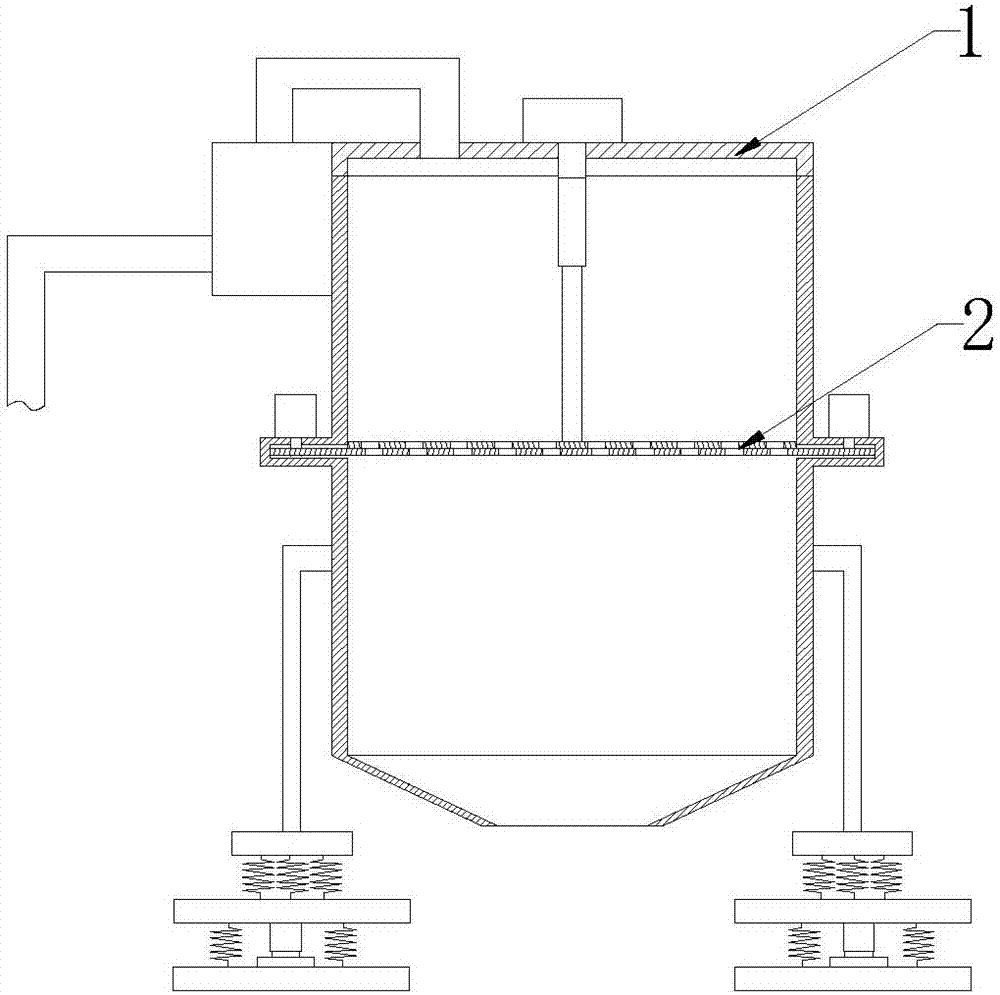

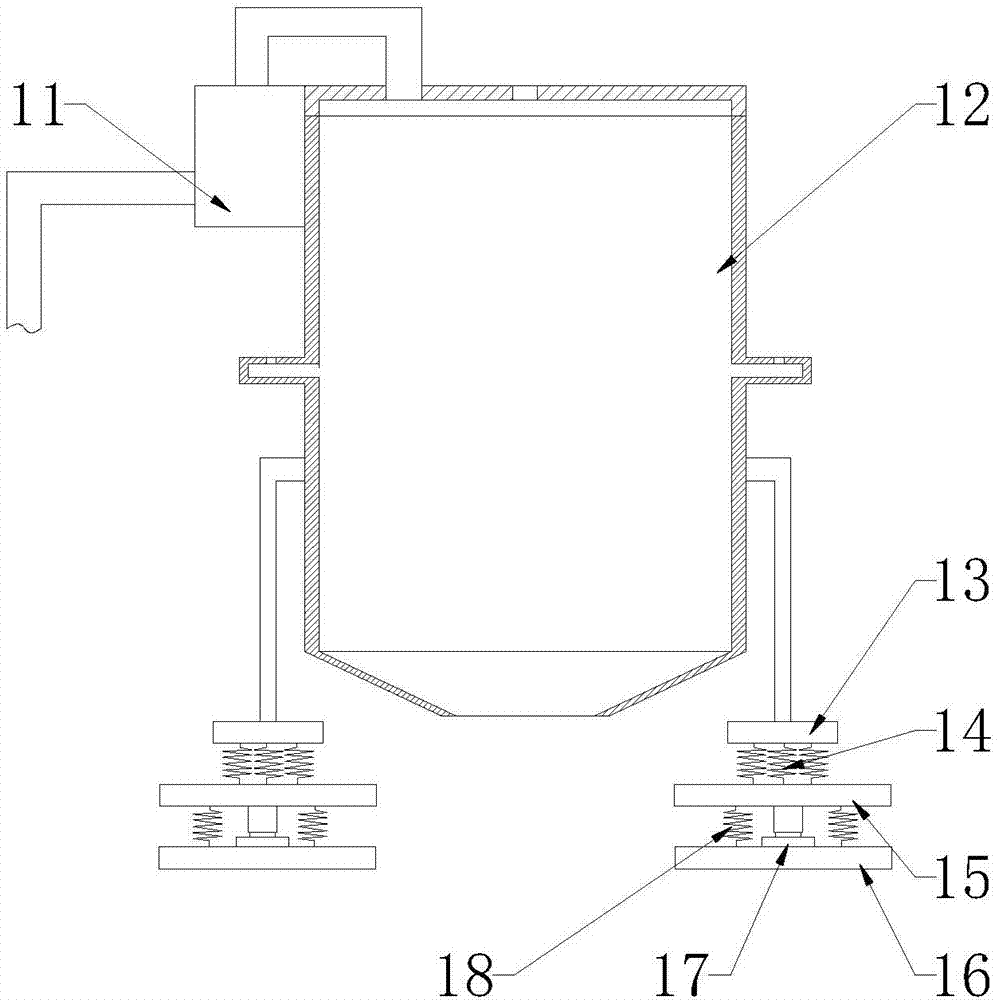

The invention relates to the technical field of automatic equipment, and discloses automatic feeding equipment for livestock cultivation. The equipment comprises an equipment main body, wherein supporting sleeve rods are fixedly mounted on the side surface of the bottom end of the equipment main body; buffer springs are fixedly mounted in inner cavities at the bottom of the supporting sleeve rods;the bottom ends of the buffer springs are fixedly mounted at the top ends of supporting legs; the middle of the bottom end of the equipment main body fixedly sleeves a feeding port; and the feeding port fixedly sleeves a valve. According to the equipment, a blanking plate is arranged at the bottom of the inner cavity of the equipment main body, small holes are formed in the blanking plate, corresponding small holes are further formed in a rotating plate, and a rotating shaft fixedly sleeves the rotating plate, so that when a rotating motor is connected with a power supply to drive the rotating shaft to rotate, the rotating plate is driven to rotate together, and when the small holes on the rotating plate rotate to coincide with the small holes on the blanking plate, feeds on the rotatingplate fall into the feeding port and is discharged, so that the automatic feeding function is realized.

Owner:江门健维自动化设备有限公司

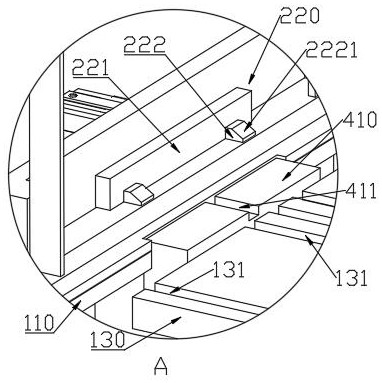

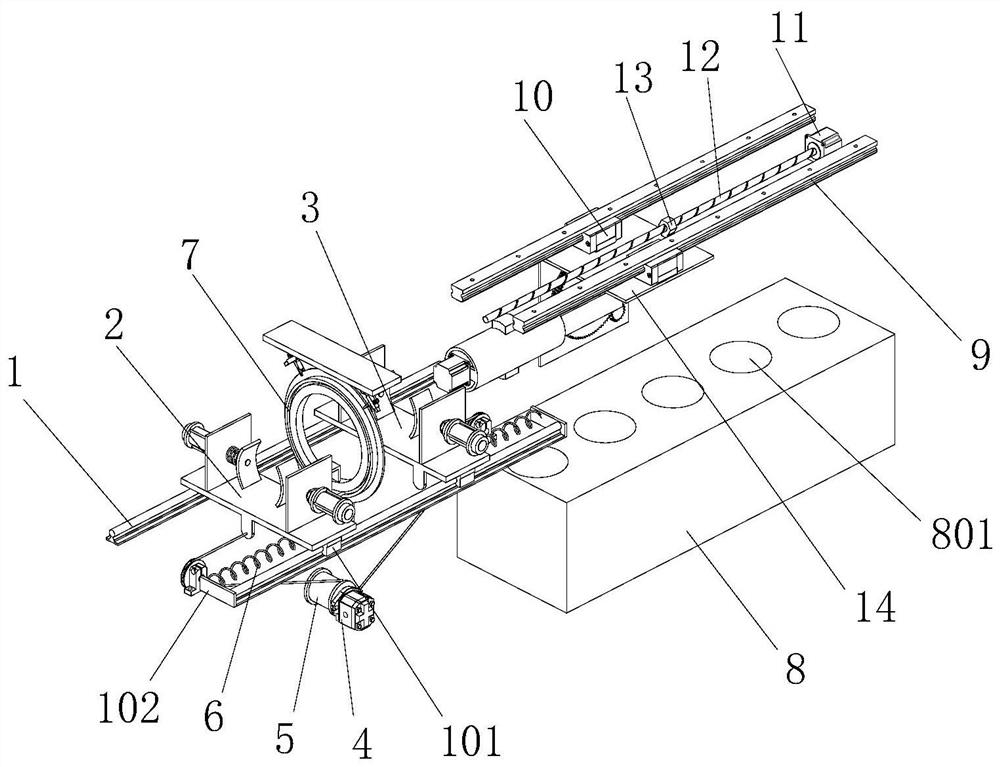

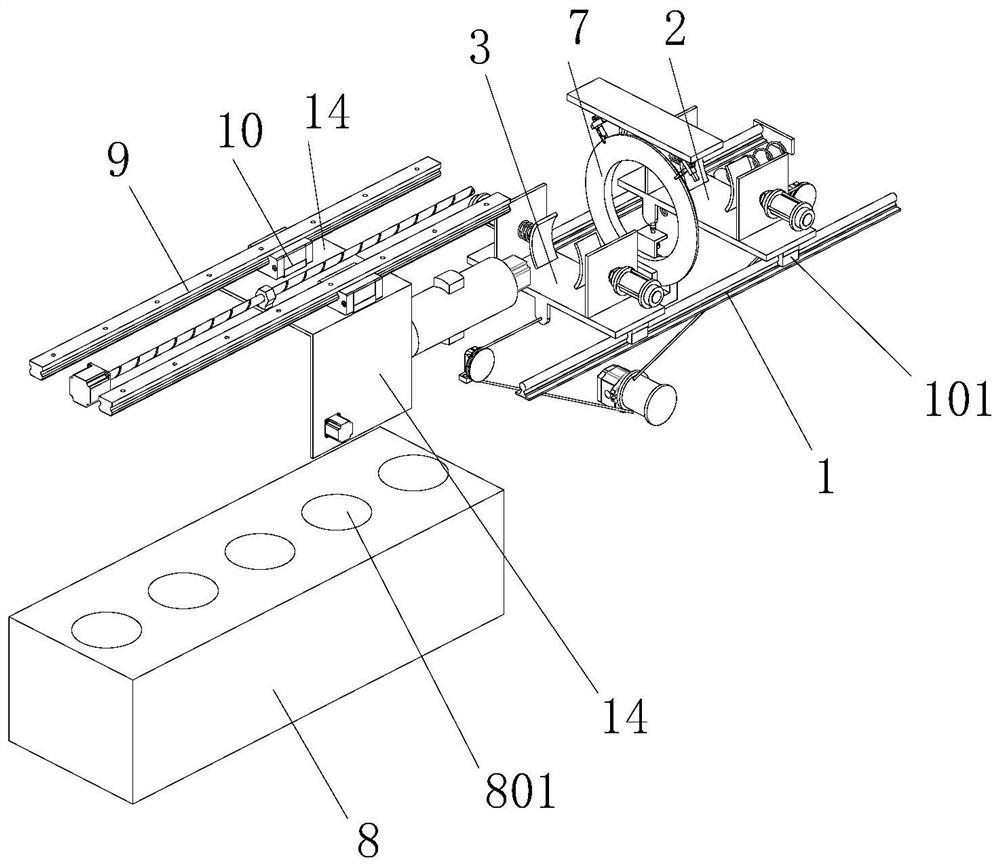

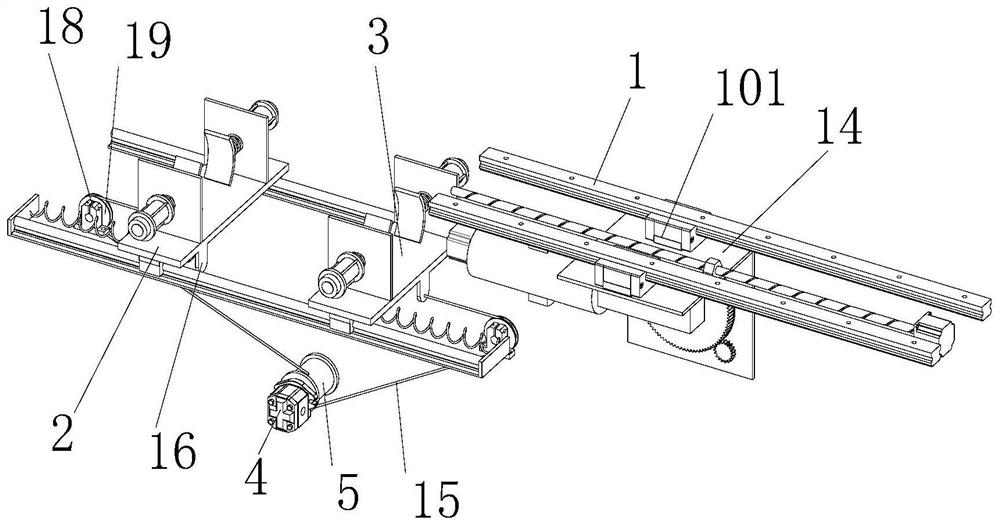

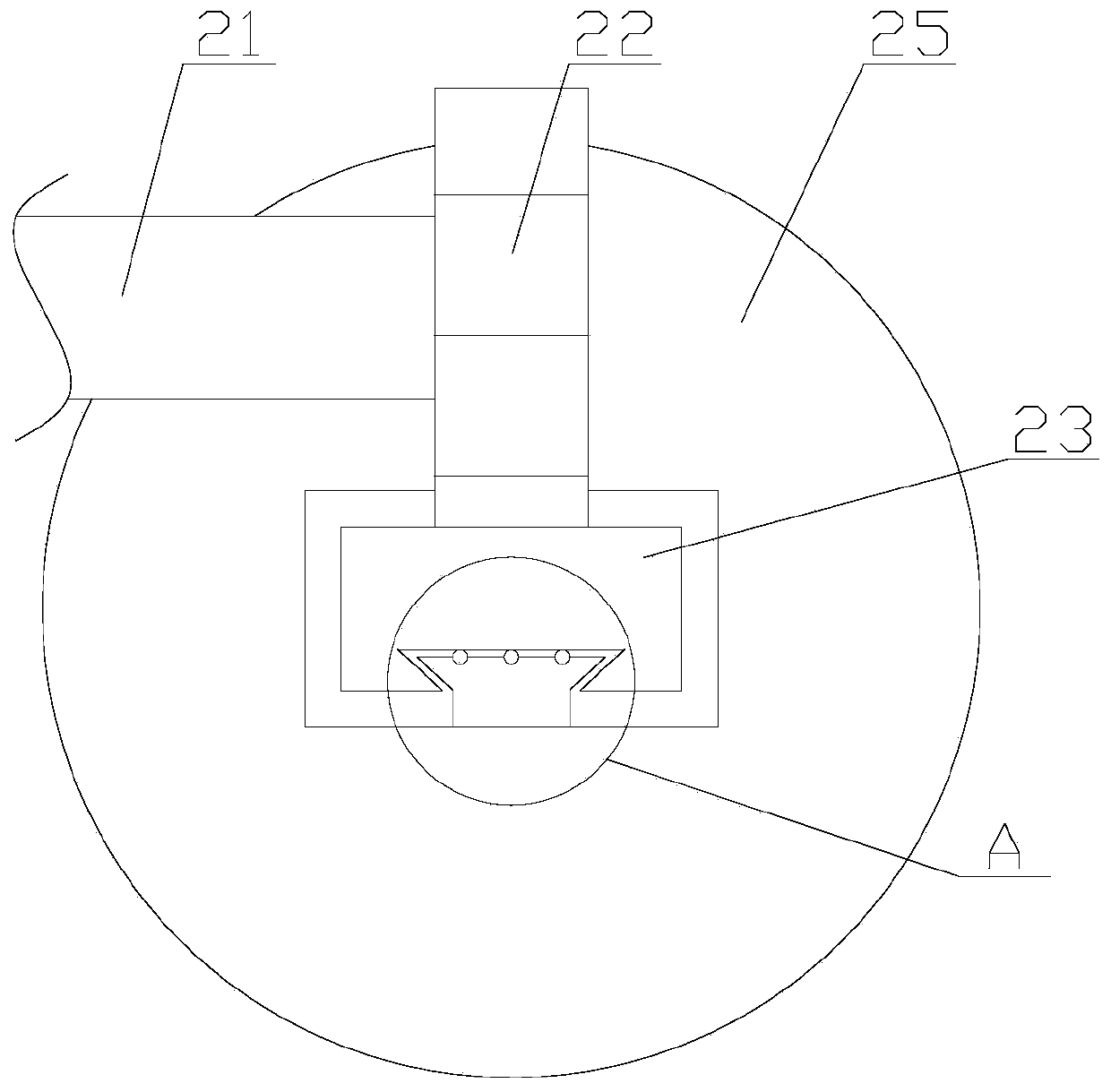

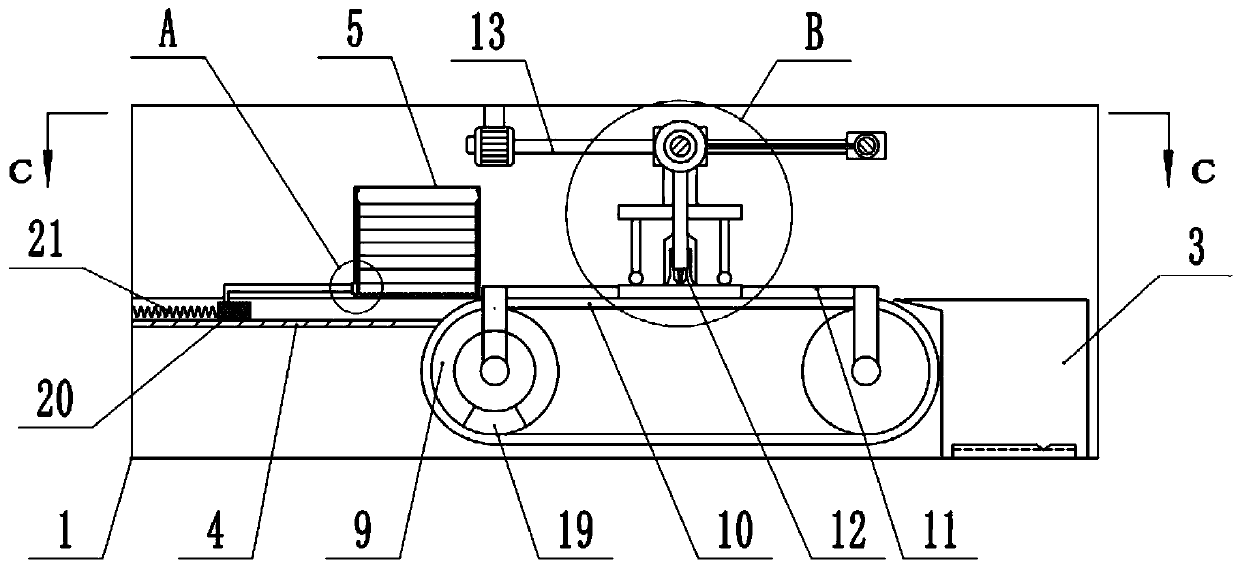

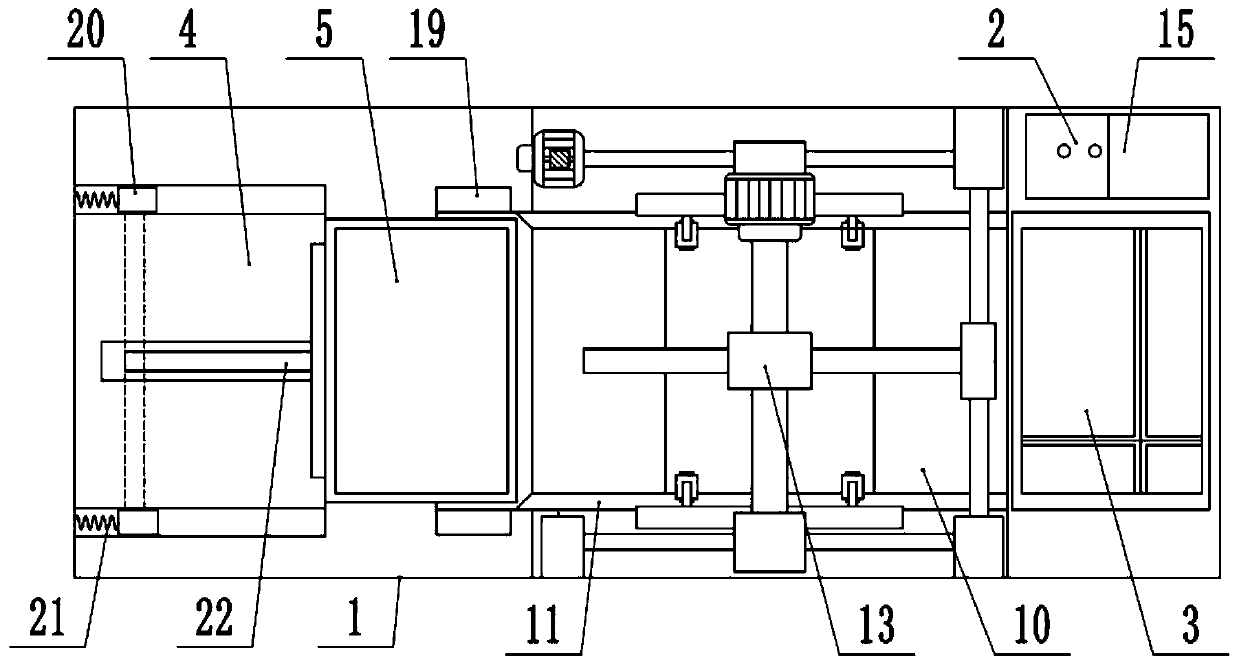

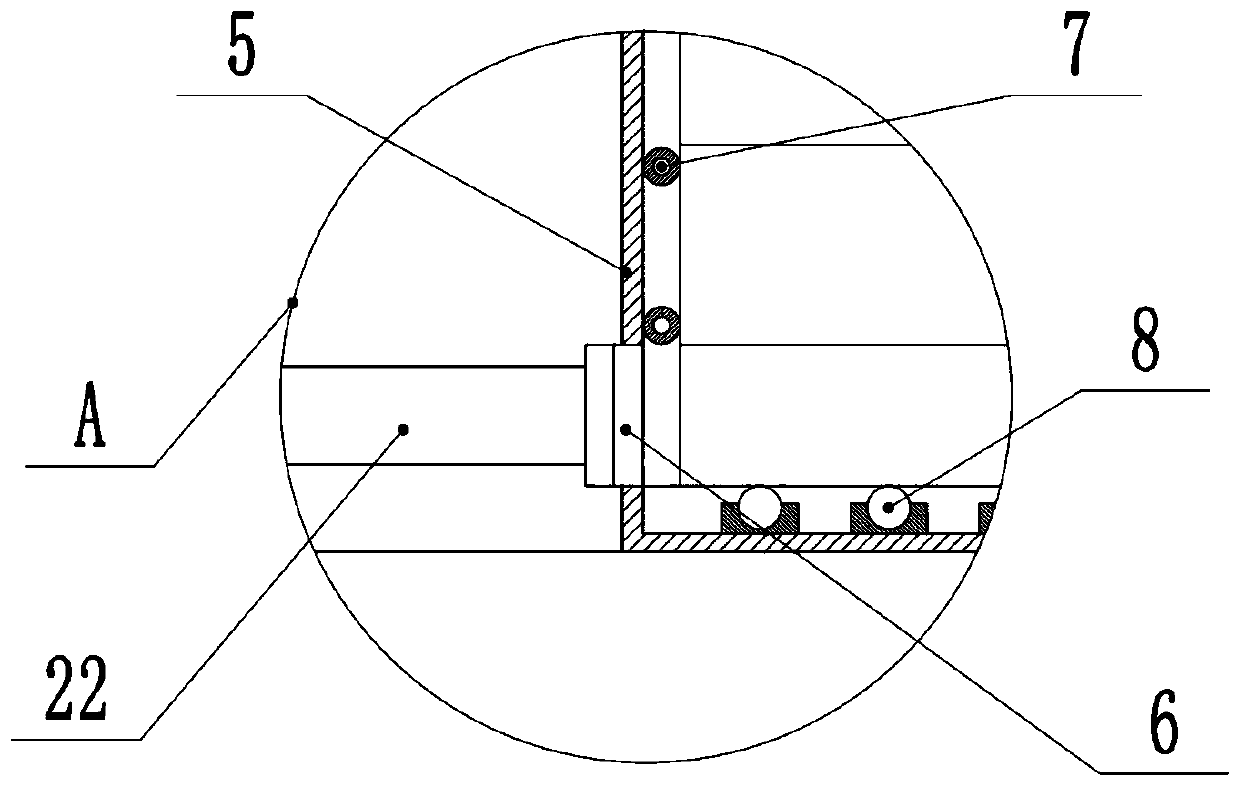

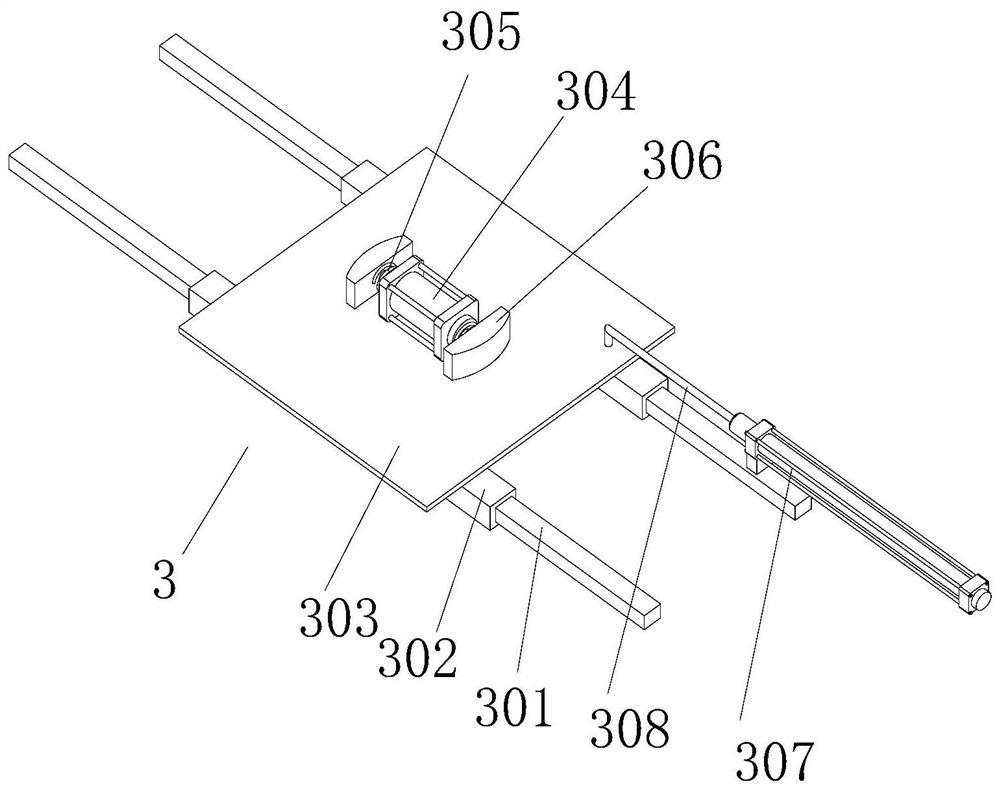

Feeding device for lead frame assembly

ActiveCN112802787ARealize the function of automatic feedingHigh degree of automationSemiconductor/solid-state device manufacturingConveyor partsStructural engineeringLead frame

The invention provides a feeding device for lead frame assembly. The device comprises: a conveying mechanism, which comprises a pair of conveying rails and a driving apparatus, wherein the driving apparatus is provided with a conveying disc in a sliding mode, the top of the conveying disc is provided with a plurality of parallel limiting grooves, and the top face of the rear section of each conveying rail is provided with a heightening strip; a storage mechanism, which is arranged at the front end of the conveying mechanism and used for stacking the frame trays upwards, wherein angle steel is located above the conveying rails, a gap is reserved between the bottom face of the angle steel and the conveying face of the conveying rails, the storage mechanism further comprises a pair of supporting seats, and at least two supporting blocks are arranged on the side wall, facing the middle of the conveying mechanism, of each side baffle, upper inclined surfaces are arranged above the front ends of the supporting blocks, the bottoms of the frame trays are provided with rectangular grooves corresponding to the supporting blocks and provided with ribs corresponding to the limiting grooves, and the ribs are in clearance fit in the limiting grooves; and a lifting mechanism, which comprises a pair of lifting blocks that move up and down in the vertical direction. The frame trays can be automatically output, labor is saved, and production efficiency is effectively improved.

Owner:四川旭茂微科技有限公司

Pipeline welding mechanism

ActiveCN112122812ARealize the function of automatic weldingImprove efficiencyWelding/cutting auxillary devicesAuxillary welding devicesPipe weldingFlange

The invention discloses a pipeline welding mechanism, and belongs to the technical field of welding. The pipeline welding mechanism comprises two fixed guide rails, wherein the two fixed guide rails are fixedly mounted, two sliding blocks are mounted on each fixed guide rail, a first bearing table is fixedly mounted on one sliding block, a second bearing table is fixedly mounted on the other fixedguide rail, traction flanges are arranged on one side of the first bearing table and one side of the second bearing table correspondingly, elastic flanges are mounted on the other side of the first bearing table and the other side of the second bearing table correspondingly, and a fixed pulley is mounted on one side of a fixed shaft base and is rotationally connected with the fixed shaft base. The pipeline welding mechanism is higher in welding efficiency and facilitates large-scale operation.

Owner:安徽滁鑫市政工程有限公司 +1

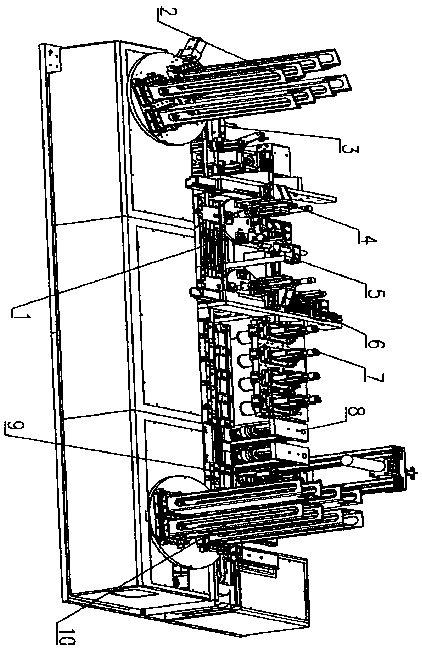

Abdominal pad folding machine

InactiveCN107857157ACompact structureSmall footprintFolding thin materialsAgricultural engineeringSmall footprint

The invention discloses a belly pad folding machine, which comprises a frame, a material discharging device, a material feeding device, a material cutting traction device and a folding and discharging device arranged on the frame in sequence; the folding and discharging device includes a transverse folding mechanism And the longitudinal folding mechanism, the horizontal folding mechanism includes two folding shafts parallel to each other, the folding shafts are provided with a plurality of folding rods, and the folding rods are perpendicular to the folding shaft; the longitudinal folding mechanism includes vertical The half-folding plate is set and perpendicular to the folding shaft, and the position corresponding to the horizontal platform and the half-folding plate is provided with a plate-passing groove, and two side-by-side double-folding transfer rollers are arranged below the plate-passing groove. The invention eliminates the labor cost, has the advantages of accurate material cutting, rapid folding and high efficiency, low equipment cost, compact structure and small occupied space.

Owner:宜昌麦迪科机电设备有限责任公司

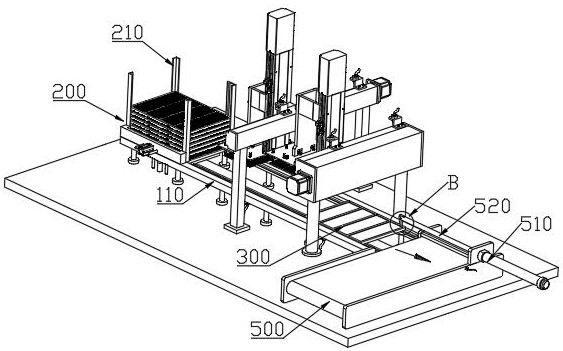

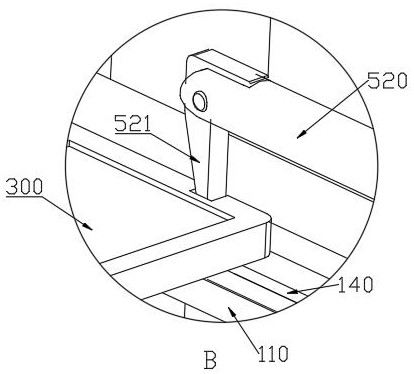

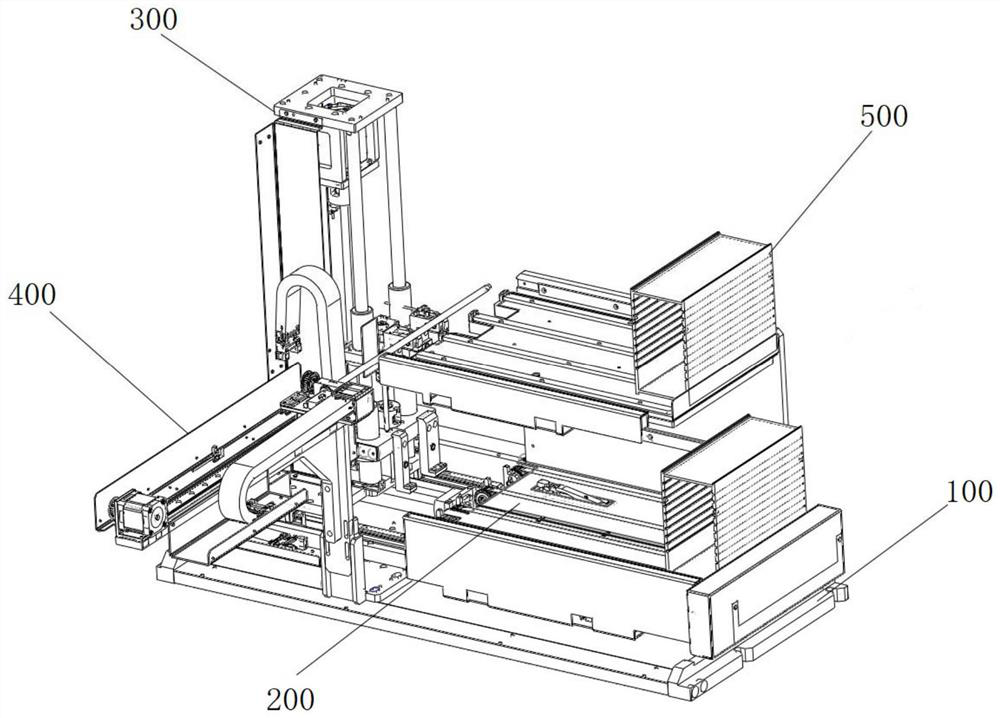

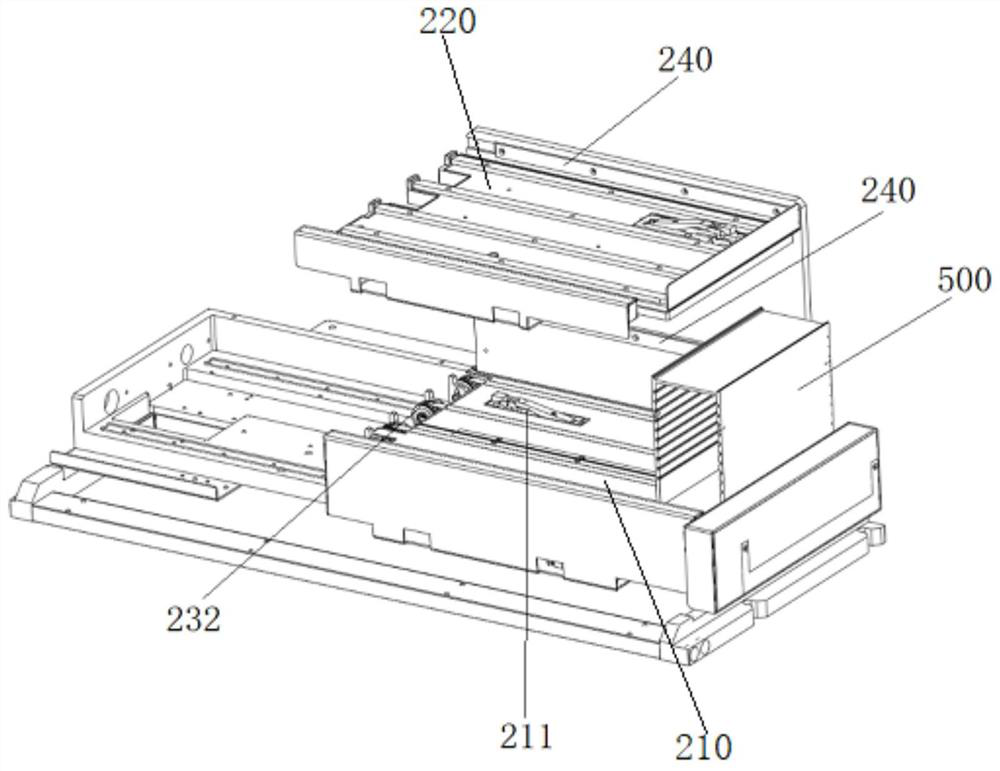

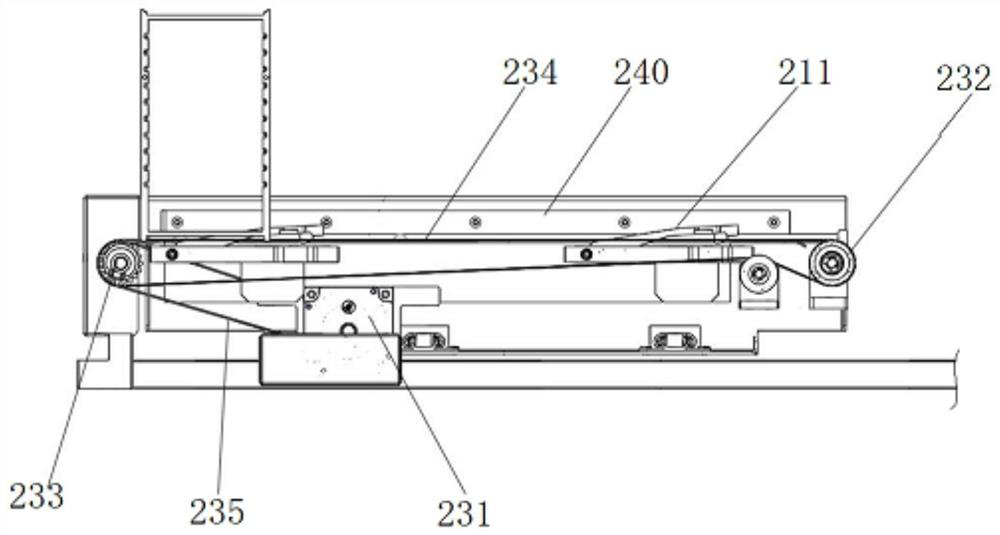

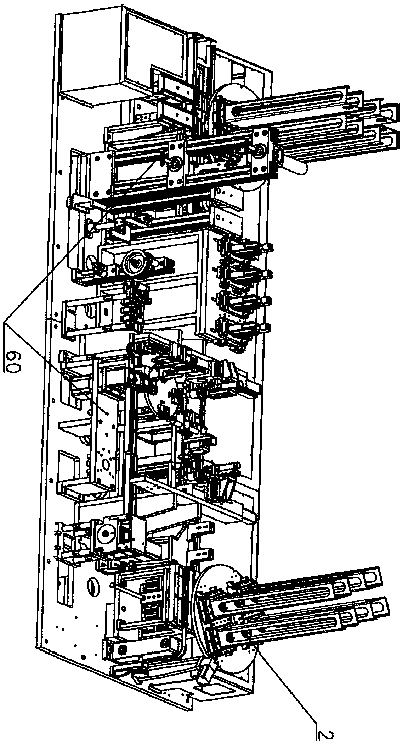

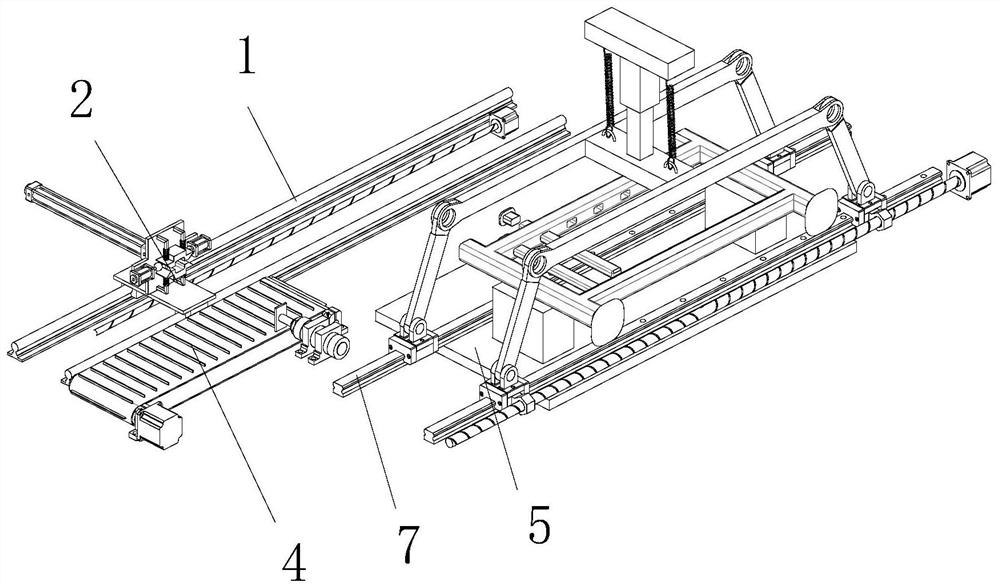

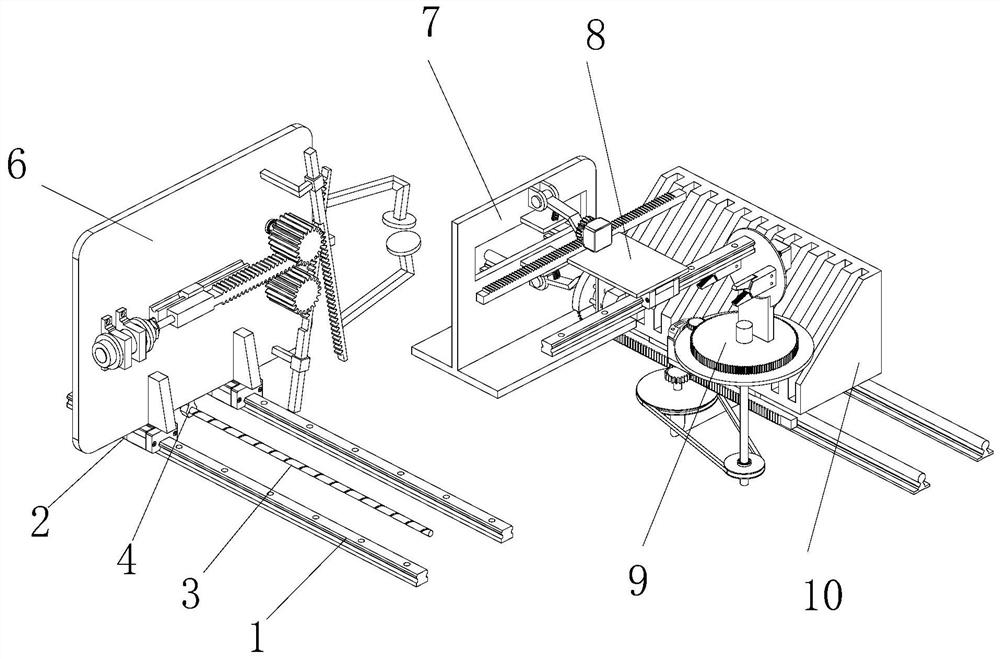

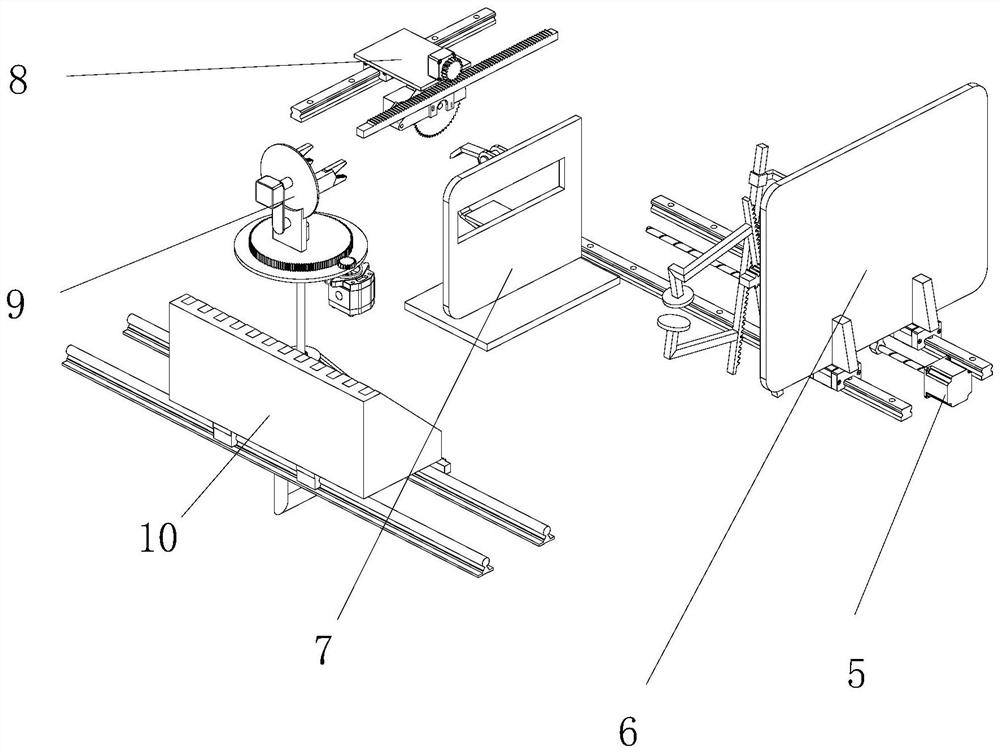

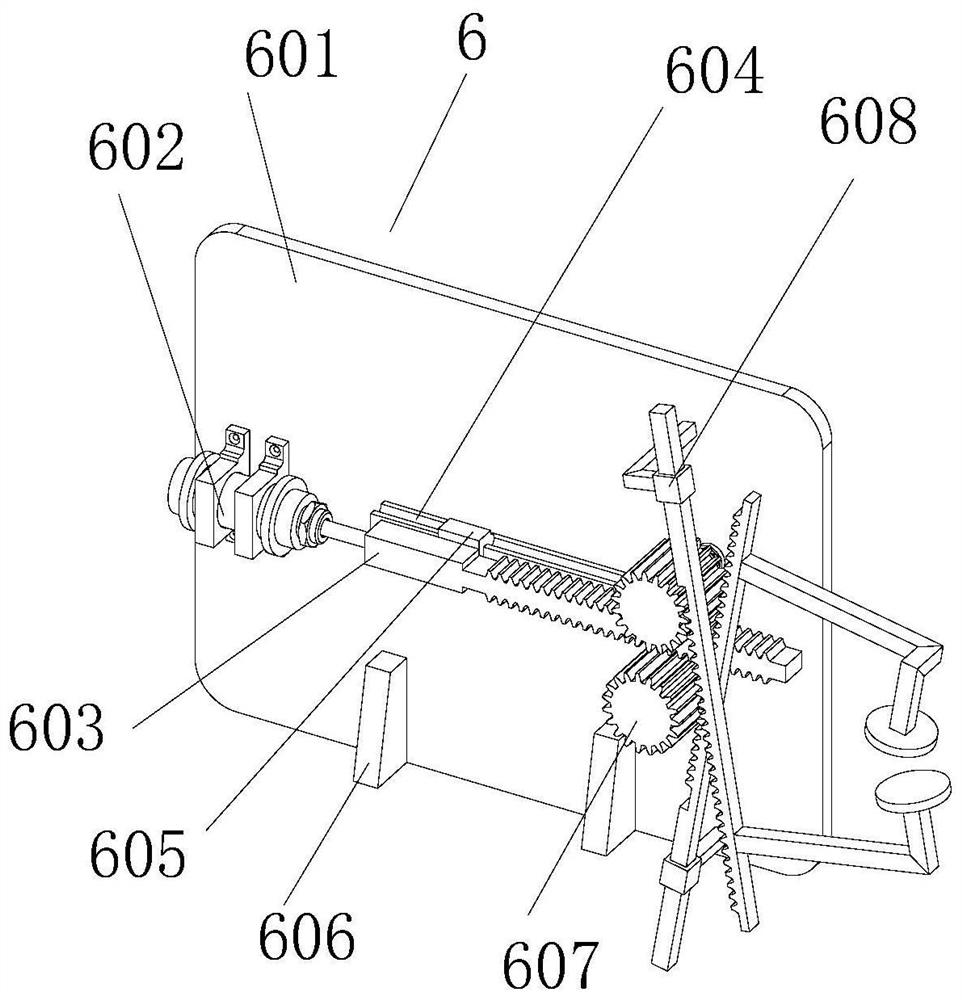

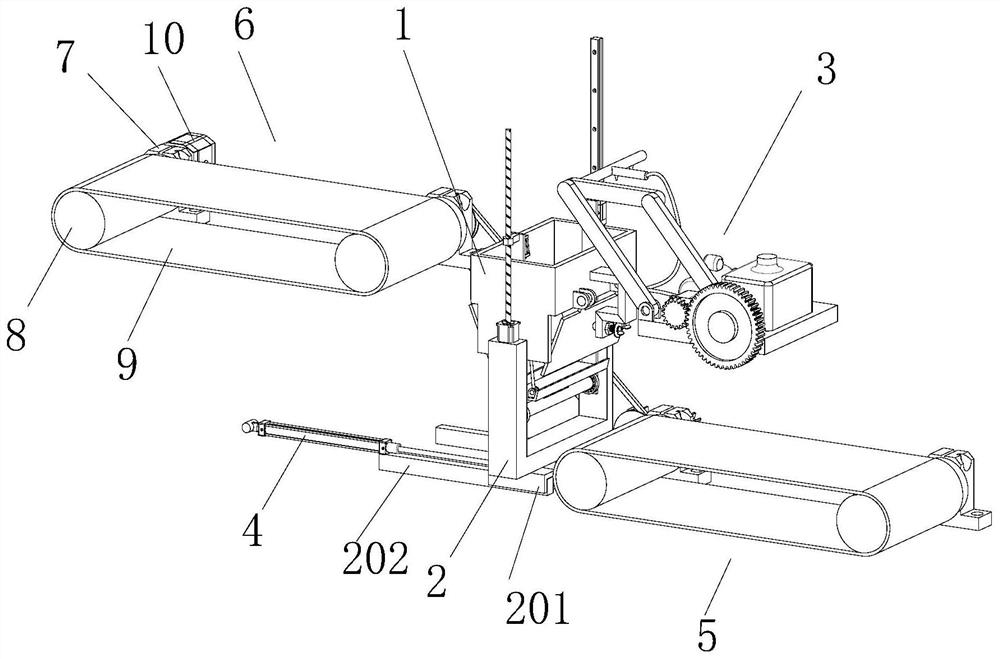

Full-automatic feeding device

InactiveCN111731829ARealize the function of automatic feedingSave time for manual loadingConveyor partsStructural engineeringMechanical engineering

The invention provides a full-automatic feeding device. The full-automatic feeding device comprises a rack, a material conveying mechanism, a material lifting mechanism and a material pushing mechanism are arranged on the rack, wherein the material conveying mechanism comprises a material conveying layer used for conveying a material bin, a recovering layer used for recovering the material bin andmaterial conveying driving assemblies arranged on the material conveying layer and the recovering layer correspondingly, the material lifting mechanism is arranged on one side of the material conveying mechanism, the material lifting mechanism comprises a clamping assembly and a lifting driving assembly used for driving the clamping assembly to move, the clamping assembly is used for clamping thestock bin conveyed through the material conveying layer, the material bin is driven by the driving assembly to be aligned with a material feeding position, and the material pushing mechanism is arranged opposite to the material lifting mechanism and is used for pushing materials in the material bin to the material feeding position. According to the full-automatic feeding device, the function of full-automatic feeding of the materials can be achieved, the manual feeding time is shortened, the feeding position is accurate, and the production efficiency is improved.

Owner:TZTEK TECH

Soybean washing and drying integrated device capable of automatically unloading materials

InactiveCN107836731AImprove drying efficiencyAchieve separationFood treatmentProcess engineeringEngineering

The present invention discloses a soybean washing and drying integrated device capable of automatically unloading materials. The soybean washing and drying integrated device comprises a bottom plate,a material storage cavity, a motor, a washing cavity, a lifting cavity, a conveyor belt and a collection tank; the washing cavity is arranged on an upper end of the bottom plate, the motor is arrangedon an upper end of the washing cavity, an output end of the motor is fixedly connected with a first rotating shaft, and a material control plate sleeves the first rotating shaft; a fixed board is rotatably connected to a lower end of the material control plate; the lifting cavity is arranged at a right side of the washing cavity; and the conveyor belt is arranged at a right side of the lifting cavity and heating tubes are arranged above the conveyor belt. The washing and drying integrated device can realize an automatic material unloading function, and is simple in structures and high in degree of automation. The lifting cavity is arranged to effectively realize separation of the soybeans and water, two methods of heating drying and hot air blow air-drying by the heating tubes are conducted at the same time, and the washing and drying integrated device increases a drying efficiency of the soybeans and is good in drying effects and high in work efficiency.

Owner:ANHUI YONSENT PHARMA

Stamping system with cleaning function for automobile part manufacturing

InactiveCN111531057AReduce the chance of exposureImprove securityShaping safety devicesCleaning using gasesMotor vehicle partPiston

The invention relates to a stamping system with a cleaning function for automobile part manufacturing. The stamping system involves a stamping device, a blanking mechanism and two dust removing mechanisms, wherein the stamping device comprises a workbench, a top die, a bottom die, a top plate, an air cylinder, a moving plate and two supporting plates, the blanking mechanism comprises a push plate,a connecting assembly, a transmission assembly and two blanking assemblies, each blanking assembly comprises a lead screw, a first gear and two first bearings, and each dust removing mechanism comprises a connecting box, an air inlet pipe, an air outlet pipe, an air cylinder, a piston and a driving assembly. According to the stamping system with the cleaning function for automobile part manufacturing, the automatic blanking function is achieved through the blanking mechanism, so that the probability that workers make contact with the equipment is reduced, the safety of the equipment is improved, the function of clearing dust and chippings is achieved through the dust removing mechanisms, the workers do not need to conduct clearing, and the clearing convenience and fastness are improved.

Owner:葛军

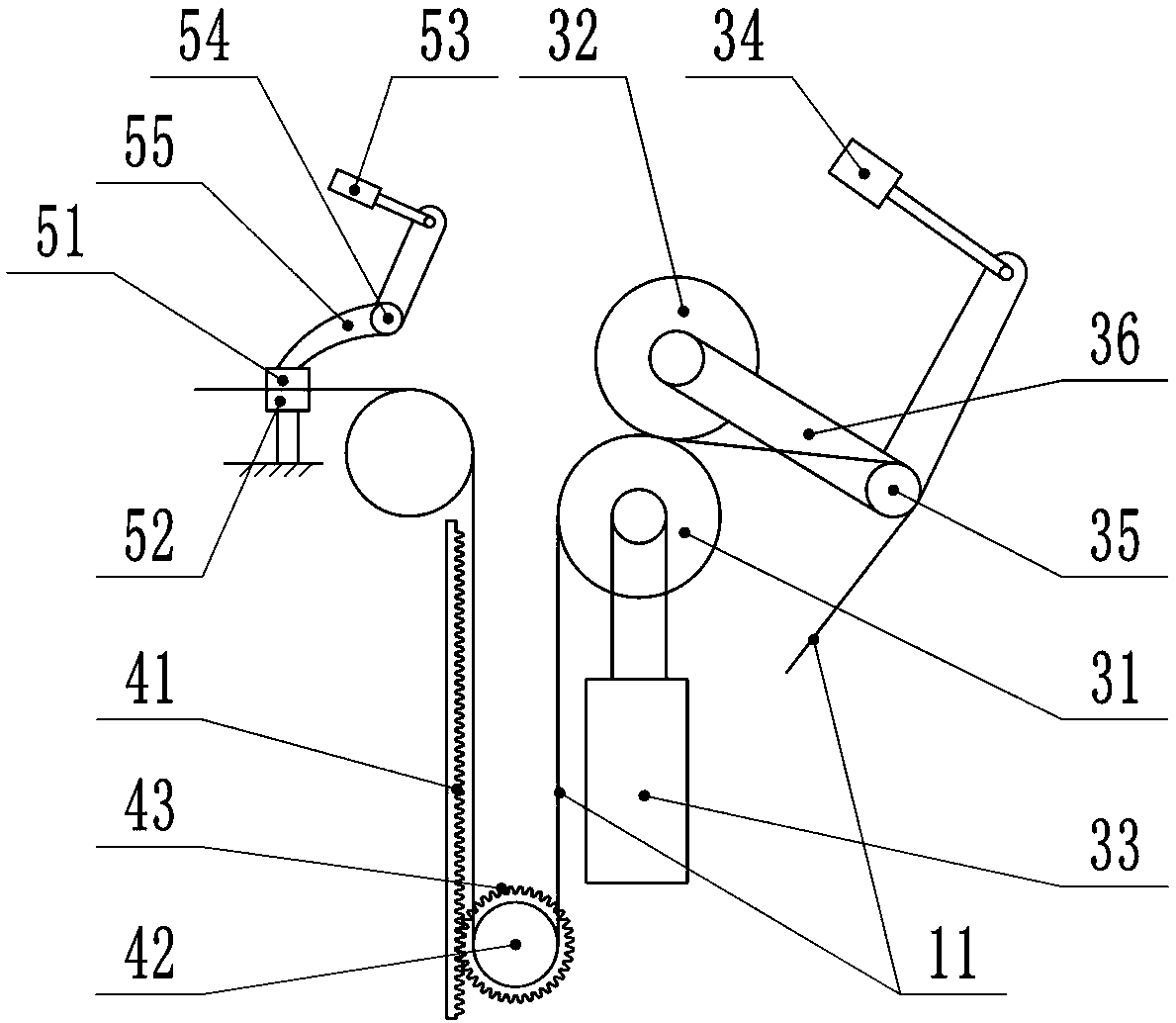

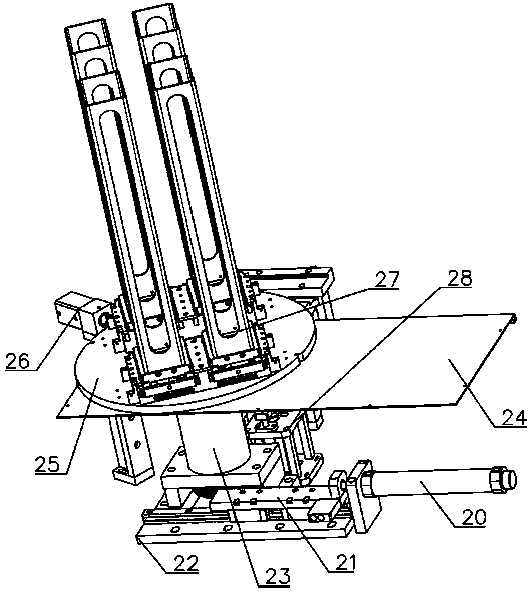

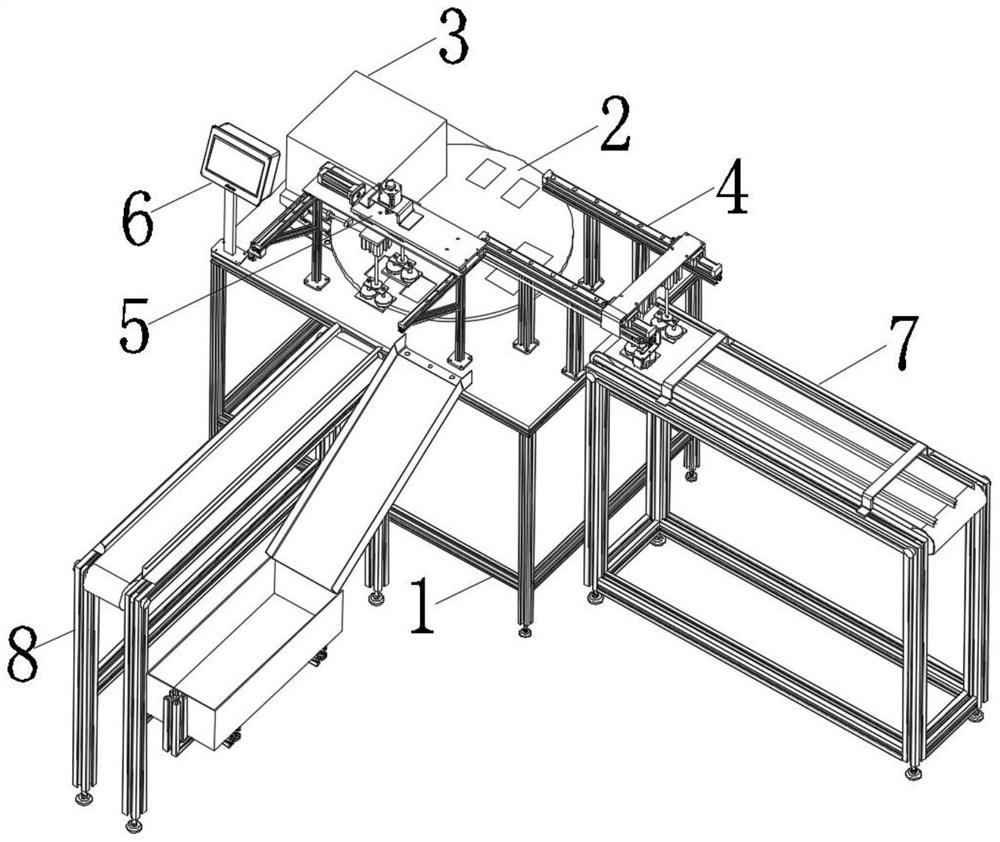

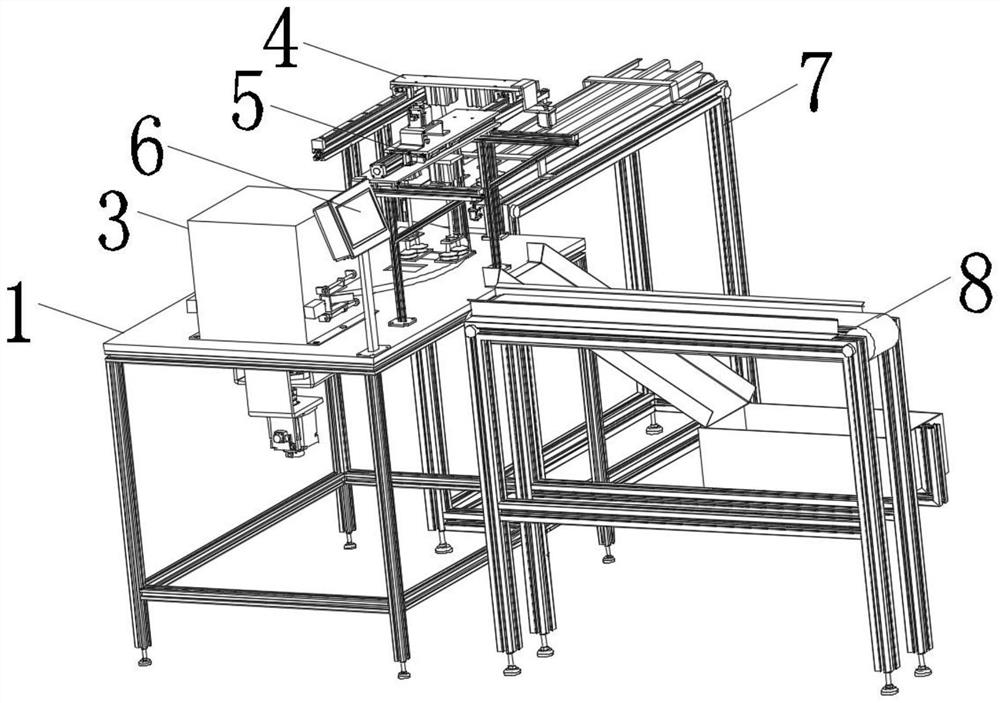

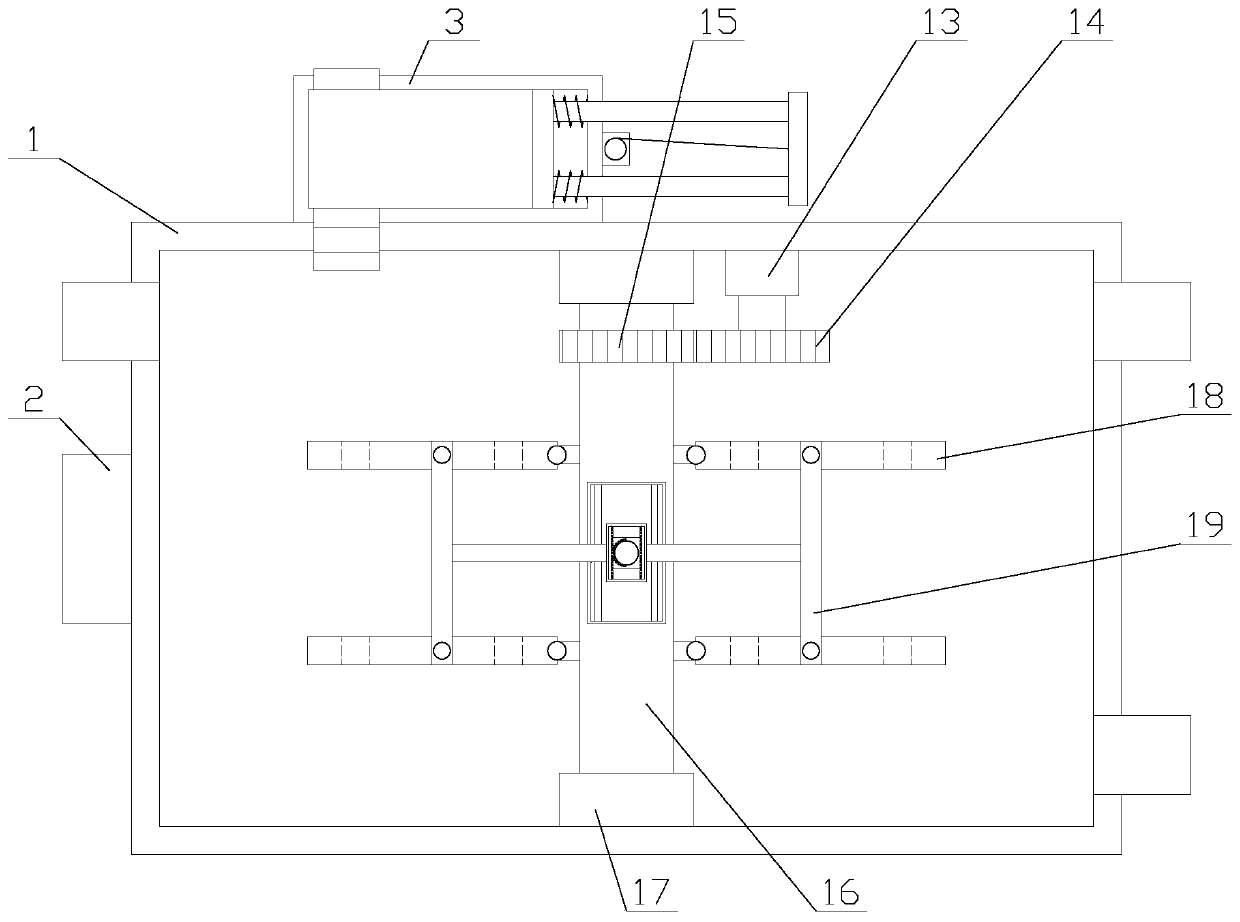

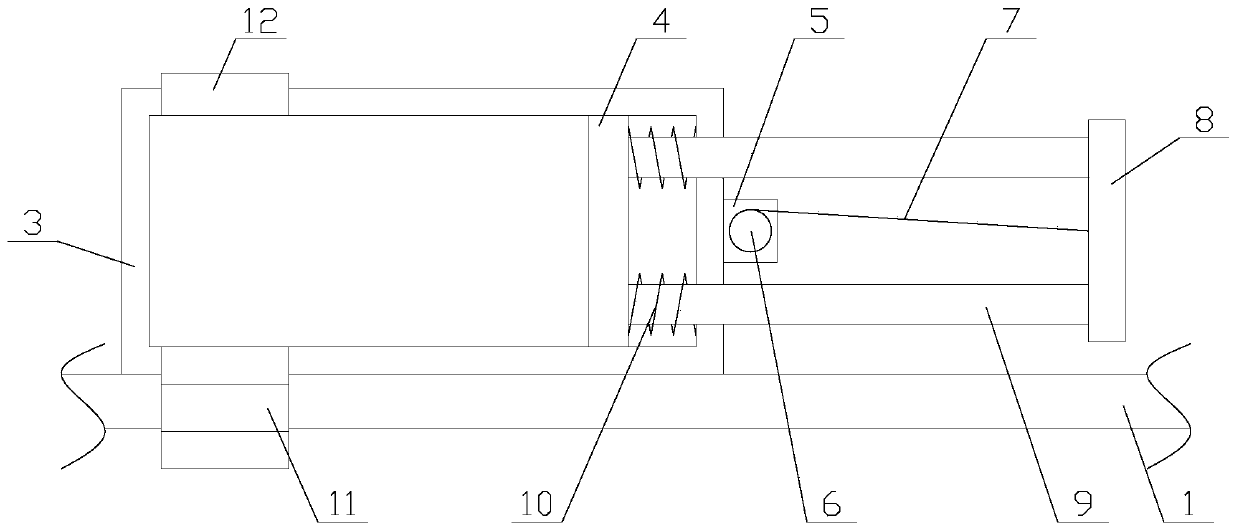

Chip hot melting and welding sealing machine

ActiveCN109256352ARealize the function of automatic feedingFully automatedWelding/cutting auxillary devicesSemiconductor/solid-state device manufacturingEngineeringHot melt

The invention discloses a chip hot melting and welding sealing machine, which is provided with a work table, and the upper surface of the work table is provided with a bearing and conveying mechanism.One side of the load-carrying conveying mechanism is sequentially provided with a load-carrying dispatching mechanism and a load-carrying receiving mechanism from right to left; A material dispense auxiliary device, a glue injecting device, a detection mechanism, a hot weld mechanism, a prepressing mechanism, a hot melt mechanism, a pressing mechanism and a material receiving auxiliary device aresequentially arranged on that other side of the load-carrying conveying mechanism according to the working procedure; The above mechanisms are arranged on the workbench; Through the cooperation of the loading and dispatching mechanism and the dispatching auxiliary device, the automatic cutting function of the product is realized. The combination structure is ingenious and the design is novel. Thechip peeling, adsorption, transfer, thermal bonding, placement and other steps are fully automated through the cooperation of the chip transfer device and the thermal bonding device.

Owner:深圳成为控股有限公司

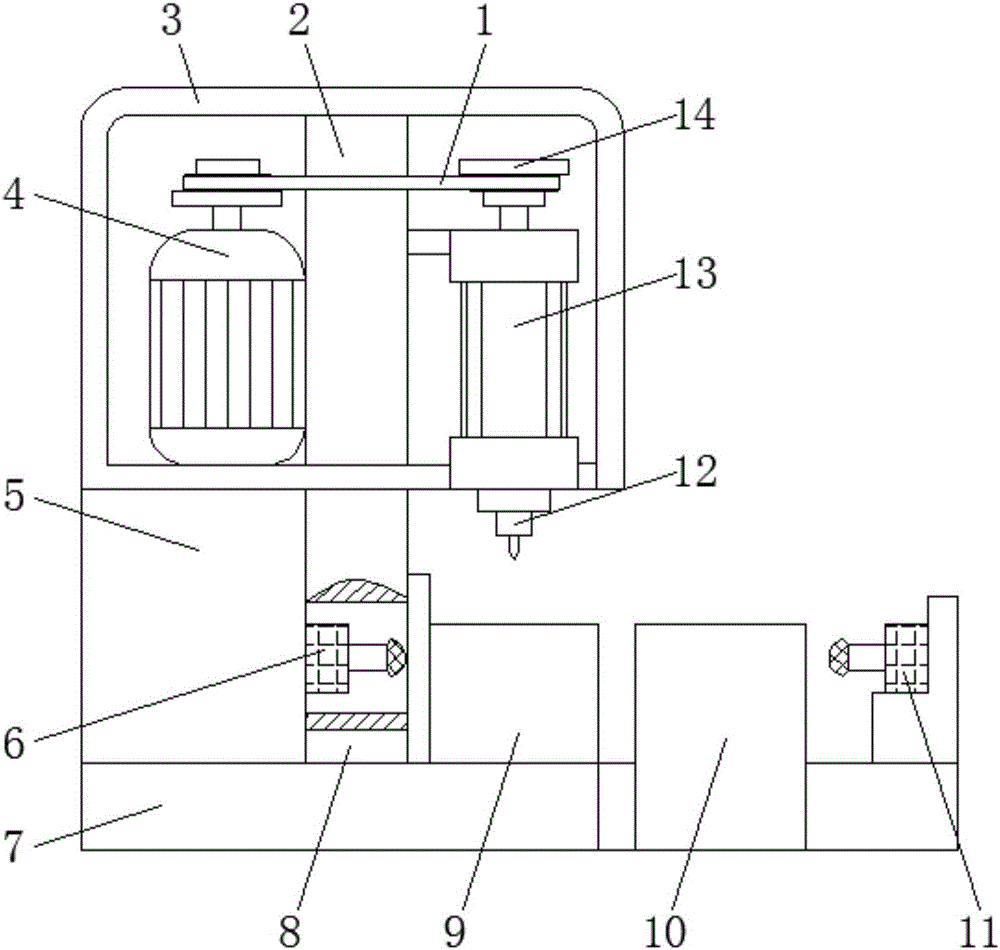

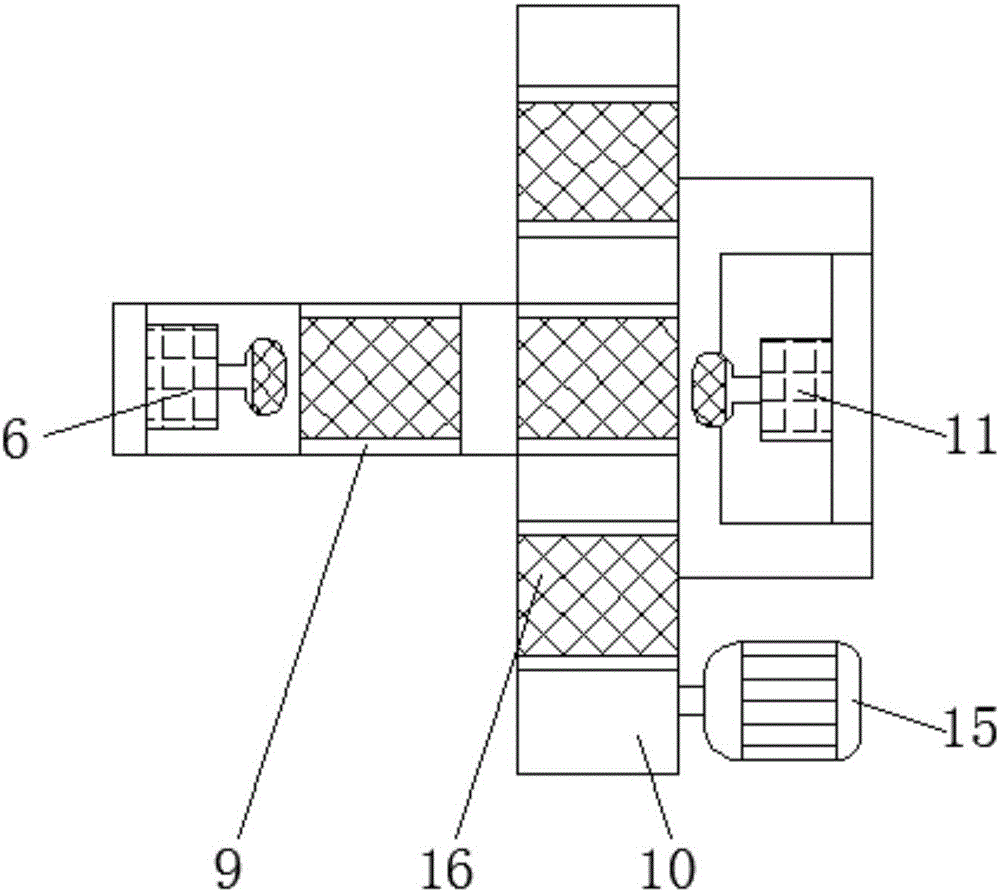

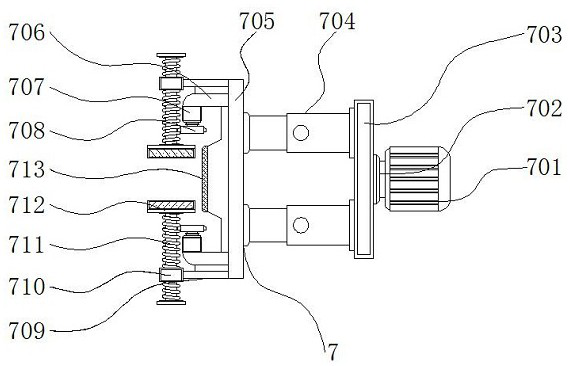

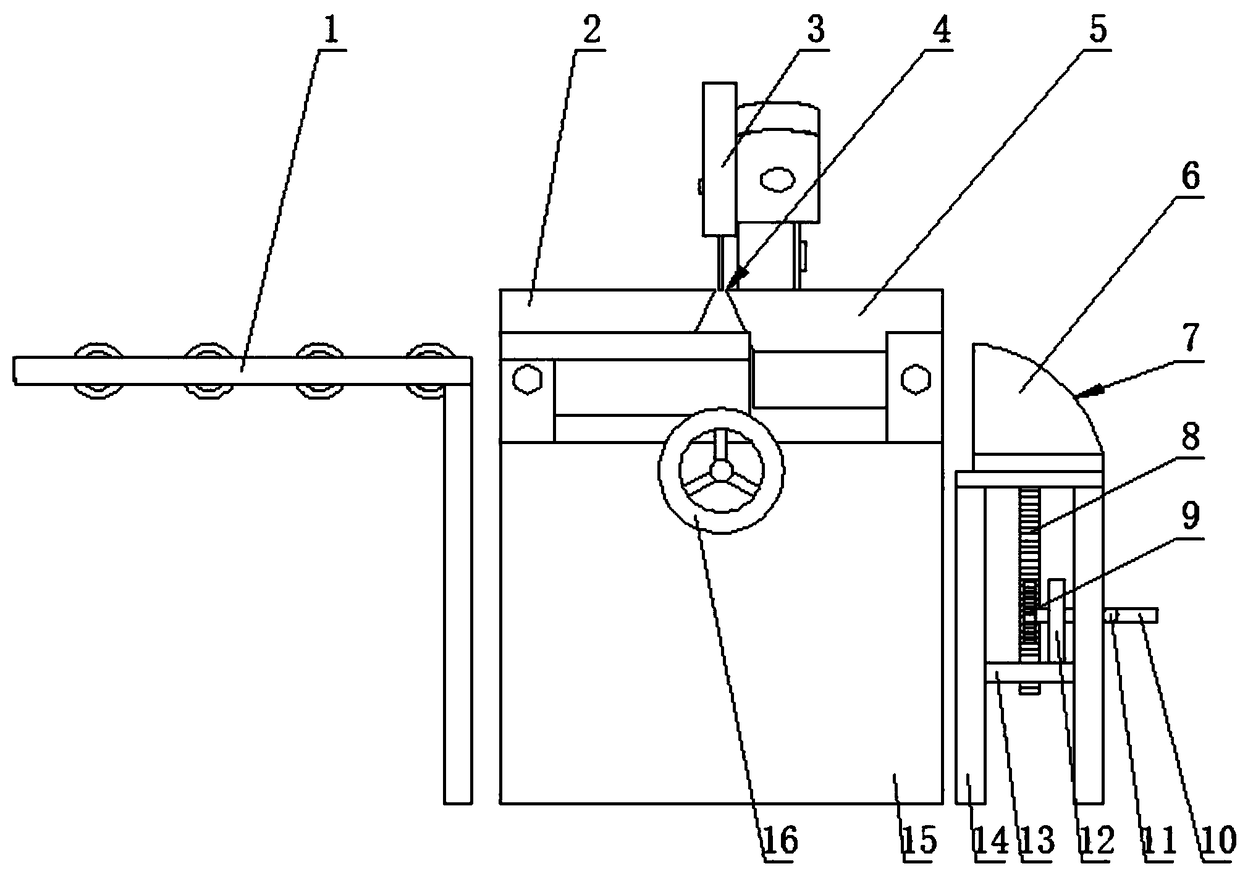

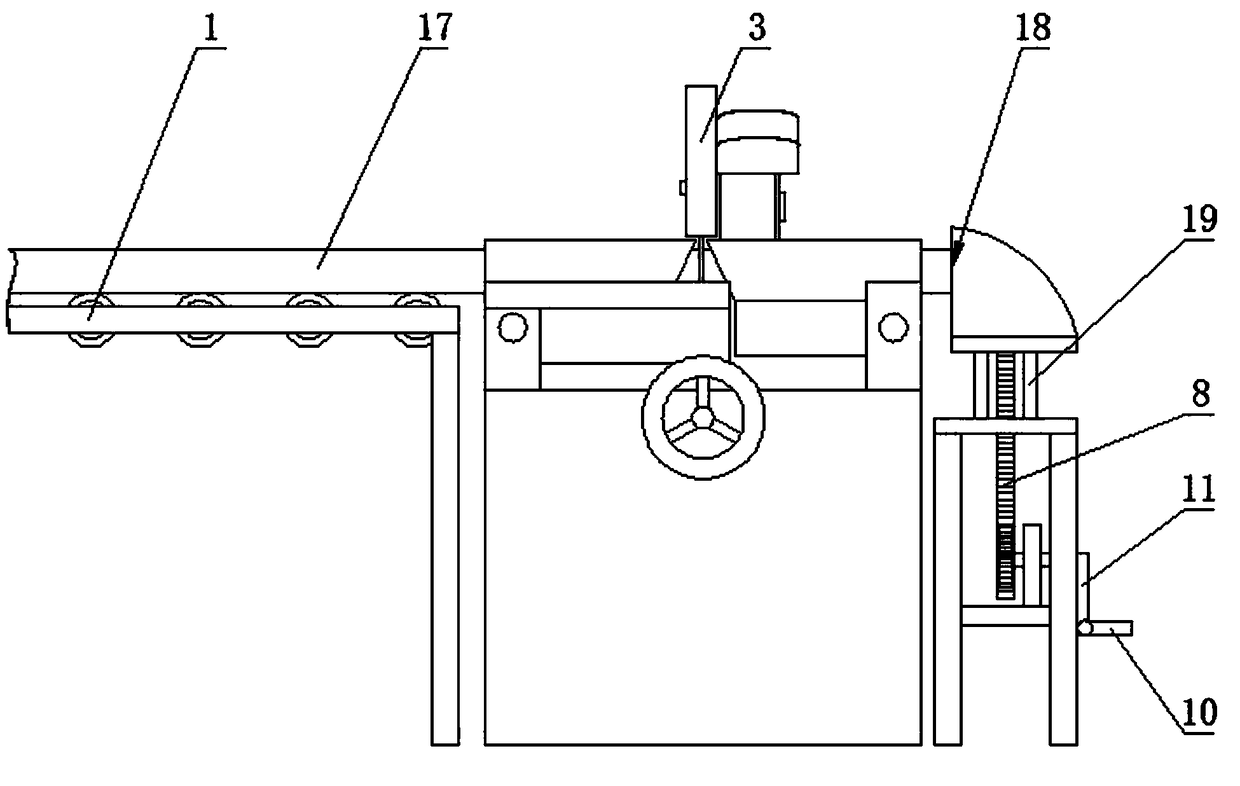

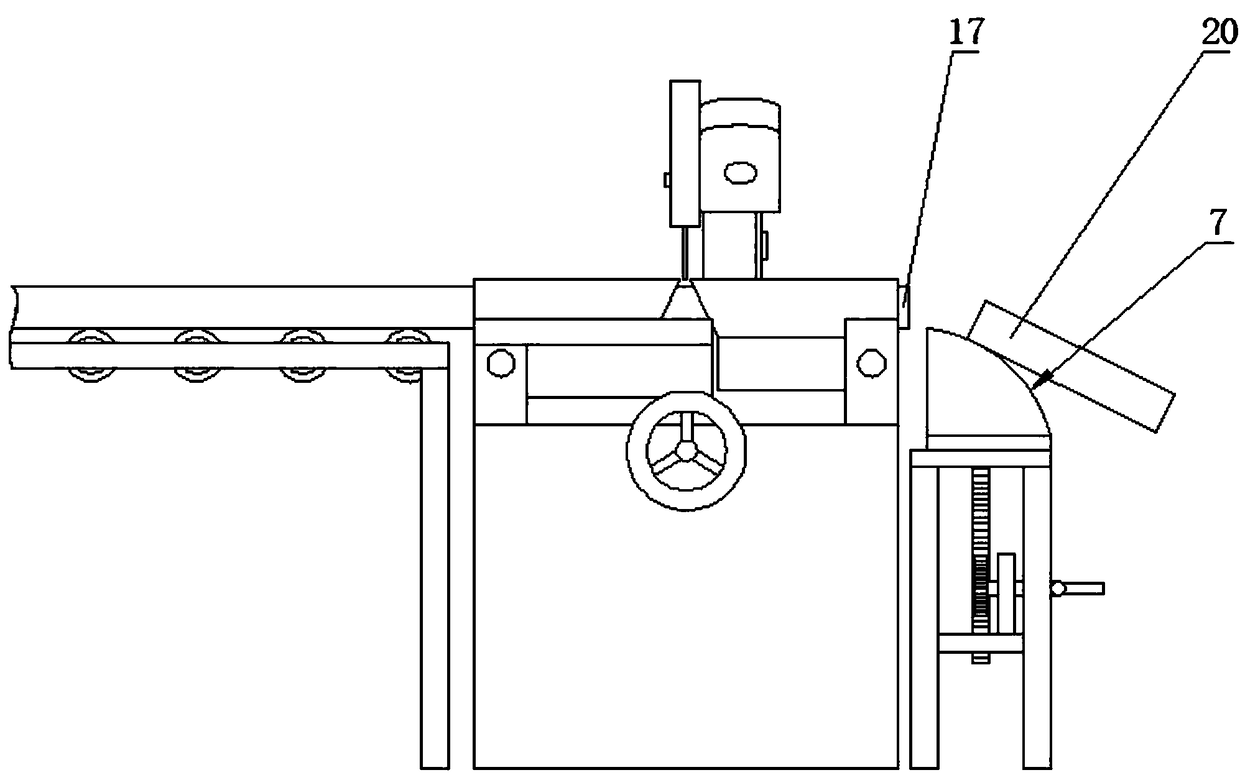

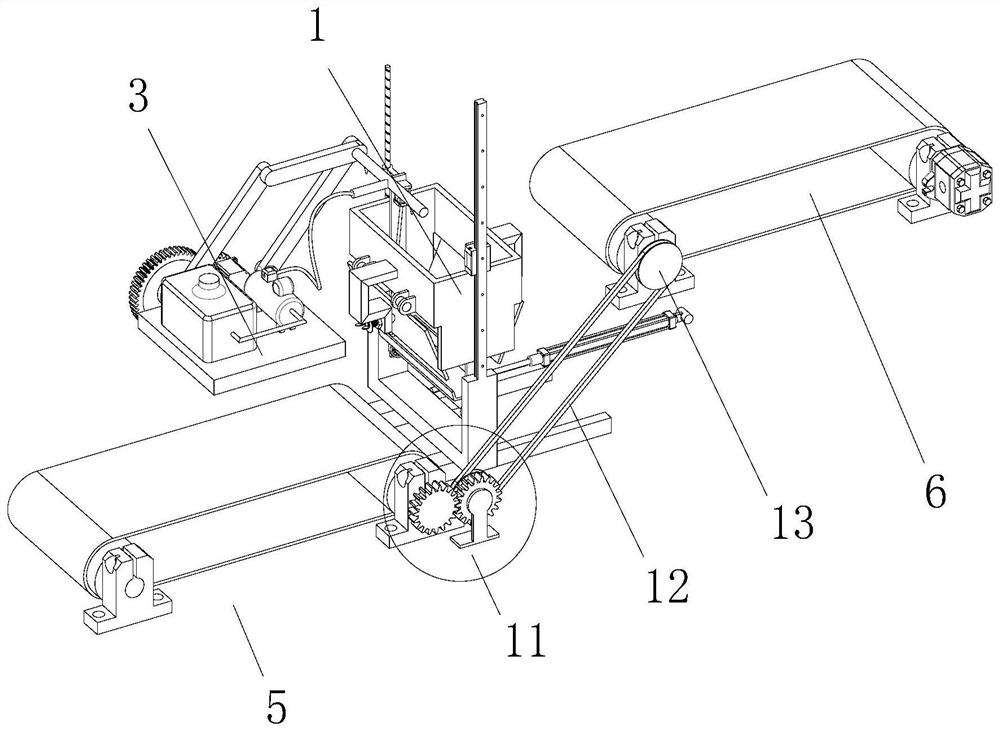

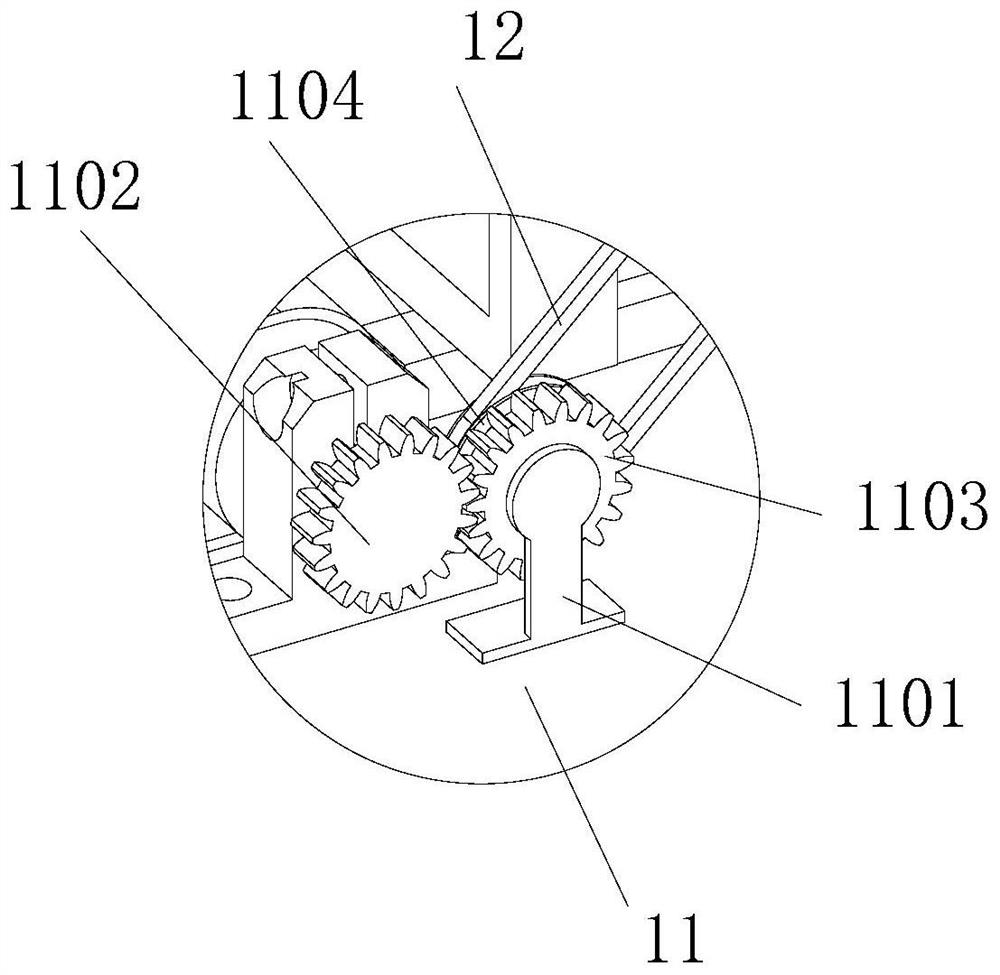

Intelligent hydraulic perforating rig device

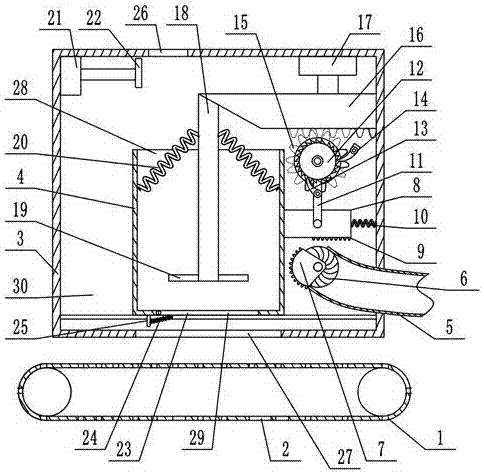

InactiveCN106424808ASolve randomnessRealize the function of automatic feedingMetal working apparatusMaintainance and safety accessoriesGear wheelEngineering

The invention discloses an intelligent hydraulic perforating rig device. The intelligent hydraulic perforating bur device comprises a rig body and a perforating worktable. A hydraulic telescoping cylinder is mounted on one side of the rig body and a first driving motor is mounted on the other side of the rig body; a multi-stage gear is mounted above the hydraulic telescoping cylinder and is in transmission connection to the first driving motor through a V-shaped belt; a drill is mounted at the bottom of the hydraulic telescoping cylinder; a first telescopic push rod is mounted in the drill body; a second telescopic push rod is mounted on one side of a material conveyor belt; and a bottom plate is mounted in the bottom of the rig body. According to the intelligent hydraulic perforating rig device disclosed by the invention, the material conveyor belt is driven through the motor on the right side of the perforating worktable and a material is pushed before and after perforating through the two telescopic push rods, so that an automatic material feeding function is achieved; a dust collecting cabin is mounted on the left side of the device, and when perforating work is performed, a dust absorbing hole absorbs chippings generated by perforating into the dust collecting cabin.

Owner:CHENGDU KECHUANGGU TECH CO LTD

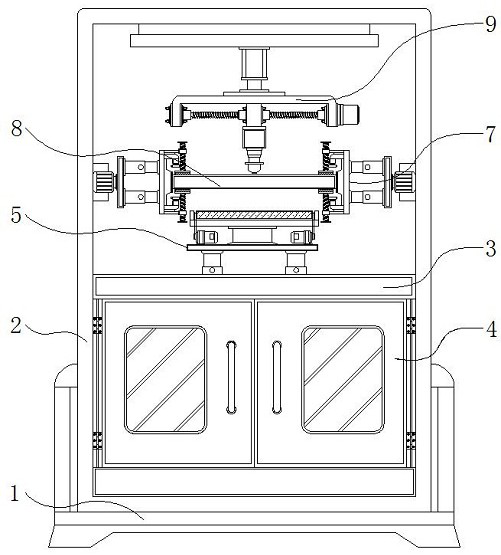

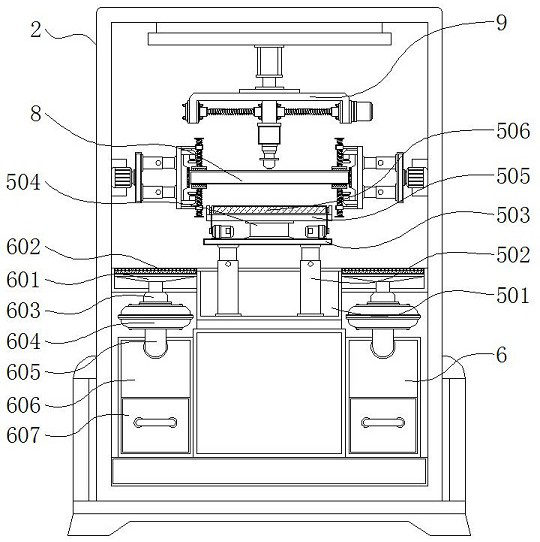

Forming equipment with positioning structure for computer graphics card backboard machining

InactiveCN113172370AEasy to adjustLoad stabilityWelding/cutting auxillary devicesDirt cleaningGear wheelElectric machinery

The invention discloses forming equipment with a positioning structure for computer graphics card backboard machining, and relates to the technical field of computer graphics card backboard machining. The forming equipment comprises an equipment outer frame, a positioning clamping mechanism and a welding forming mechanism, a base is arranged under the equipment outer frame, and a workbench is fixed in the middle of the interior of the equipment outer frame; and an opening and closing door is mounted on the outer side of the lower portion of the equipment outer frame and connected with the equipment outer frame through hinges, and a feeding mechanism is arranged on the upper portion of the middle of the workbench and comprises a mounting frame, hydraulic push rods, a supporting plate, a bearing column, a bearing plate and a conveying belt. The forming equipment has the beneficial effects that the positioning clamping mechanism of the forming equipment is provided with gears and threaded rods, the gears are conveniently driven to rotate through a micro motor, the gears and the threaded rods are of an engaged structure so that the rotating gears can drive the threaded rods to move up and down, the positions of positioning plates at one ends of the threaded rods can be conveniently adjusted, and attaching gaps of the positioning plates is reduced.

Owner:长沙市熊亮机电设备有限公司

Automatic-discharging type steel pipe cutting device

InactiveCN108067674AAvoid accumulationIncrease the bearing areaTube shearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention relates to the field of hardware machining device, in particular to an automatic-discharging type steel pipe cutting device. An automatic discharging device for a pipe cutter comprises abase; a guide sleeve and a locking sleeve are separately installed at the left and right sides of the upper end of the base in a spaced manner; the guide sleeve and the locking sleeve are separatelyinternally provided with accommodating passages for a steel pipe to pass through; the two accommodating passages of the guide sleeve and a positioning sleeve correspond to each other in position; a conveying device is installed at one side of a feeding end of the guide sleeve and is used for pushing the steel pipe into the accommodating passage formed in the guide sleeve; a frame is installed by the side of a discharging end of the positioning sleeve; an air cylinder is horizontally installed inside the upper end face of the frame; a limiting block is installed at a piston rod of the air cylinder; the horizontal position of the limiting block and the discharging end of the locking sleeve are positioned in the same horizontal plane; when the air cylinder is in an outwards-moving state, thelimiting block is positioned at a corresponding position at the front end of the locking sleeve; and when the air cylinder is in a returning state, the limiting block is positioned by the side of thelocking sleeve.

Owner:天津市宝利华峰五金制品有限公司

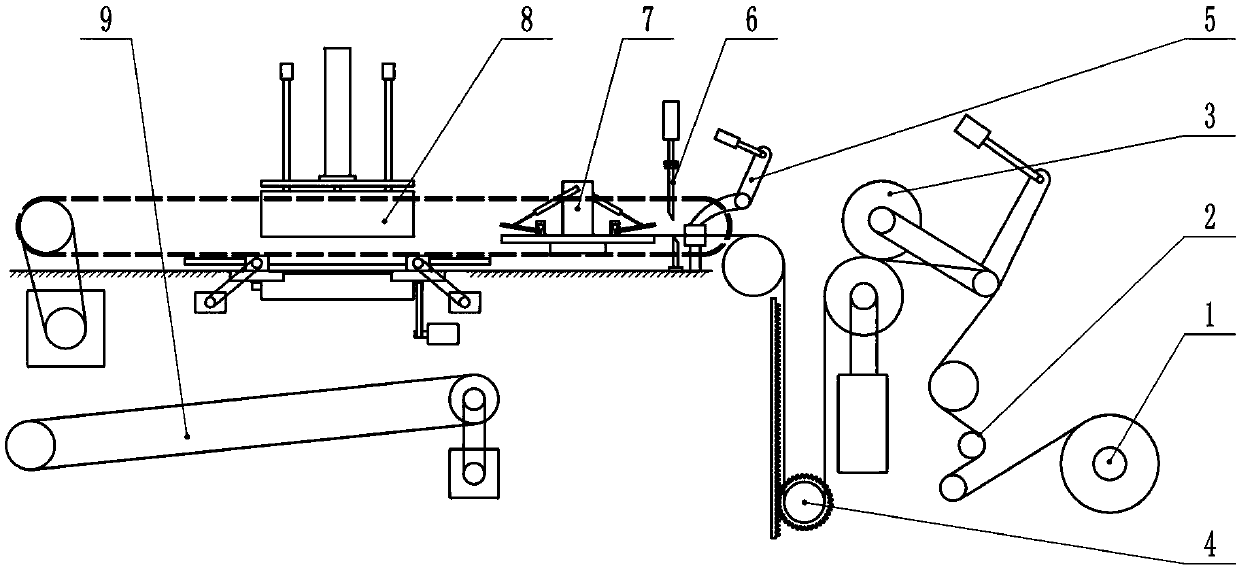

Bamboo pulp paper package production equipment

InactiveCN109719791ARealize the function of automatic feedingAvoid warpingBox making operationsPaper-makingMagnetDrive wheel

The invention relates to the technical field of paperboard processing and discloses bamboo pulp paper package production equipment. The bamboo pulp paper package production equipment comprises a cutting tank body. The cutting tank body is internally provided with a charging mechanism, a transmission mechanism, a cutting mechanism, a control unit and a collection tank. The transmission mechanism comprises driving wheels and a conveyor belt. The cutting mechanism comprises a cutter and a lead screw set for driving the cutter to do bidirectional motion. The charging mechanism comprises a chargingbox. The bottom of the charging box is provided with a slot capable of allowing a piece of paperboard to pass through in the paperboard conveying direction. A second permanent magnet is slidably connected between the charging box and the inner wall of the cutting tank body. The circular arc, close to the charging box, of the edge of the side face of each driving wheel of the charging box is provided with a first permanent magnet capable of being attracted with the second permanent magnet. Through intermittent attraction between the first permanent magnets and the second permanent magnet, thebamboo pulp paper package production equipment implements automatic charging, controls the cutter to cut the paperboard through the lead screw set and bidirectionally forms slots quickly in the paperboard.

Owner:CHONGQING SAN HAO PAPER IND

Automatic poultry feeding device

InactiveCN107711593ARealize the function of automatic feedingSimple preparation processAvicultureProgramme control in sequence/logic controllersData controlWater storage

The invention discloses an automatic feeding device for poultry, which comprises a supporting device and a feeding device; the storage tank is interspersed and arranged on the upper left side of the horizontal plate; uniform through holes are arranged on the upper side of the stirring plate; It is arranged at the lower end of the material storage barrel, and a first electromagnetic valve is arranged above the lower hopper; the water storage barrel is interspersed and arranged on the upper right side of the horizontal plate; the second electromagnetic valve is arranged above the water pipe; the feeding tank is fixed It is arranged on the bottom plate; the placement frame is arranged on the upper right end of the horizontal plate; the hook is fixed on the upper right side of the column; the device of the present invention detects the amount of feed in the feed tank through a pressure sensor, and inputs the data into the control device, The control device controls the opening of the first solenoid valve so that the feed falls, the water level detector detects the water volume in the water tank, and inputs the signal to the control device, the control device controls the opening of the second solenoid valve, and the water is introduced into the water tank, thereby realizing the automatic feeding of poultry Function.

Owner:WUXI AOTU AUTOMATION TECH CO LTD

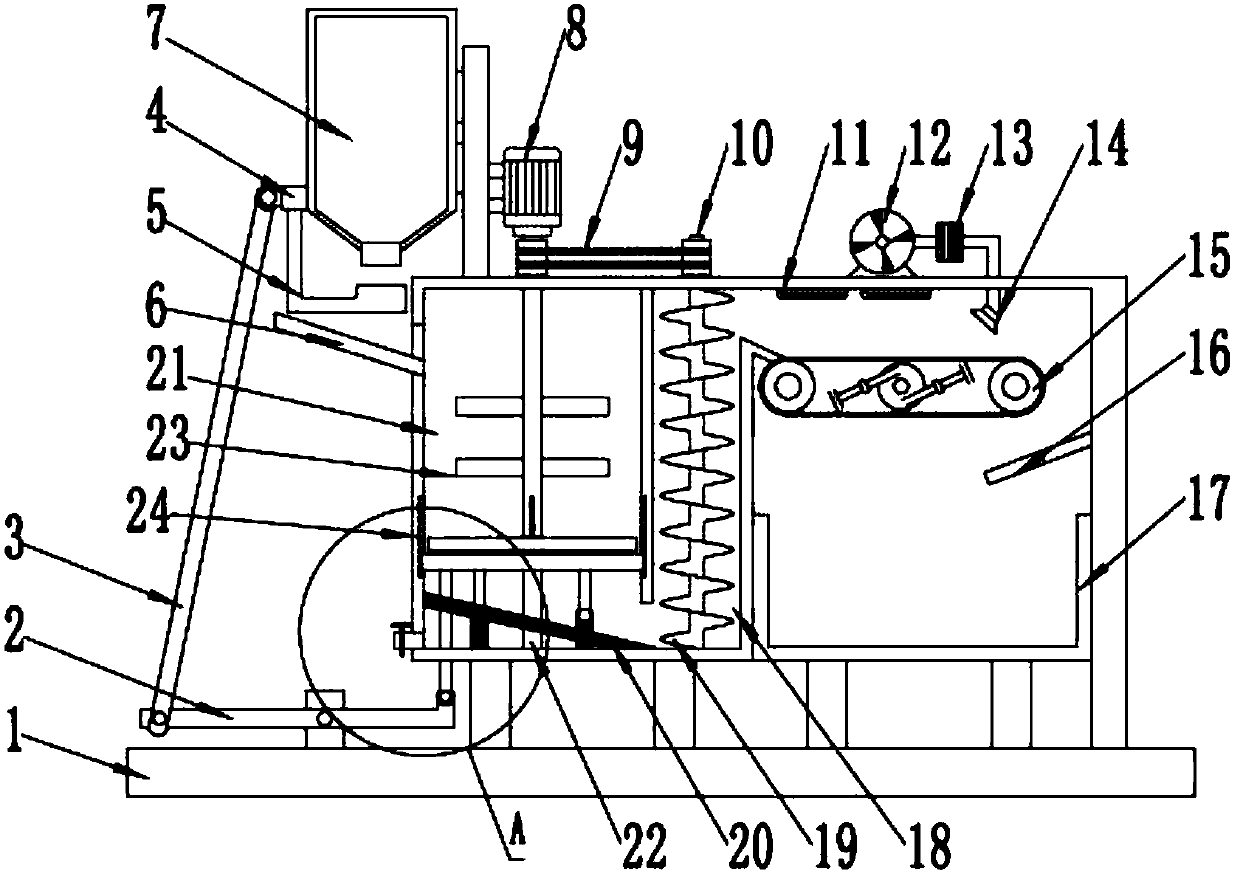

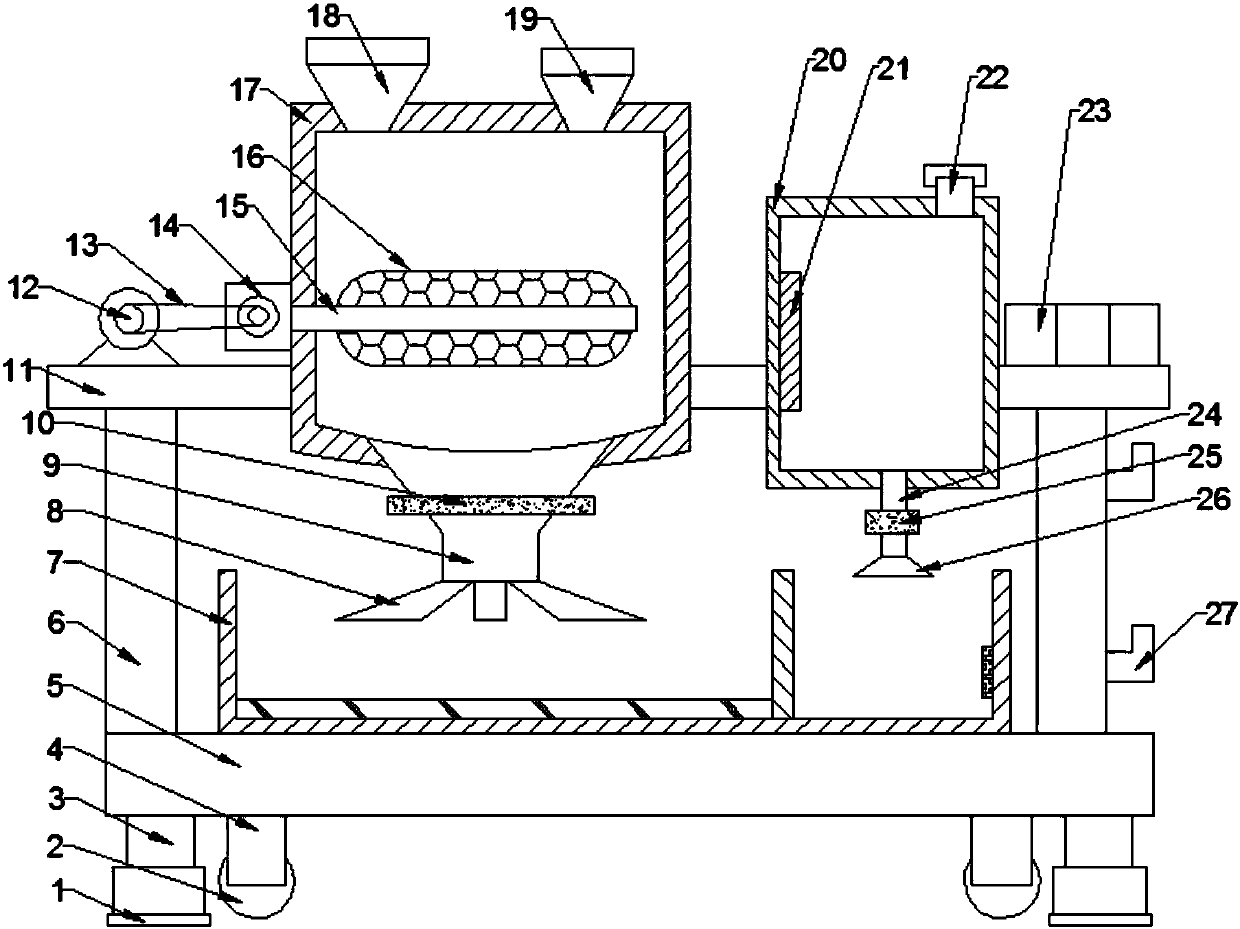

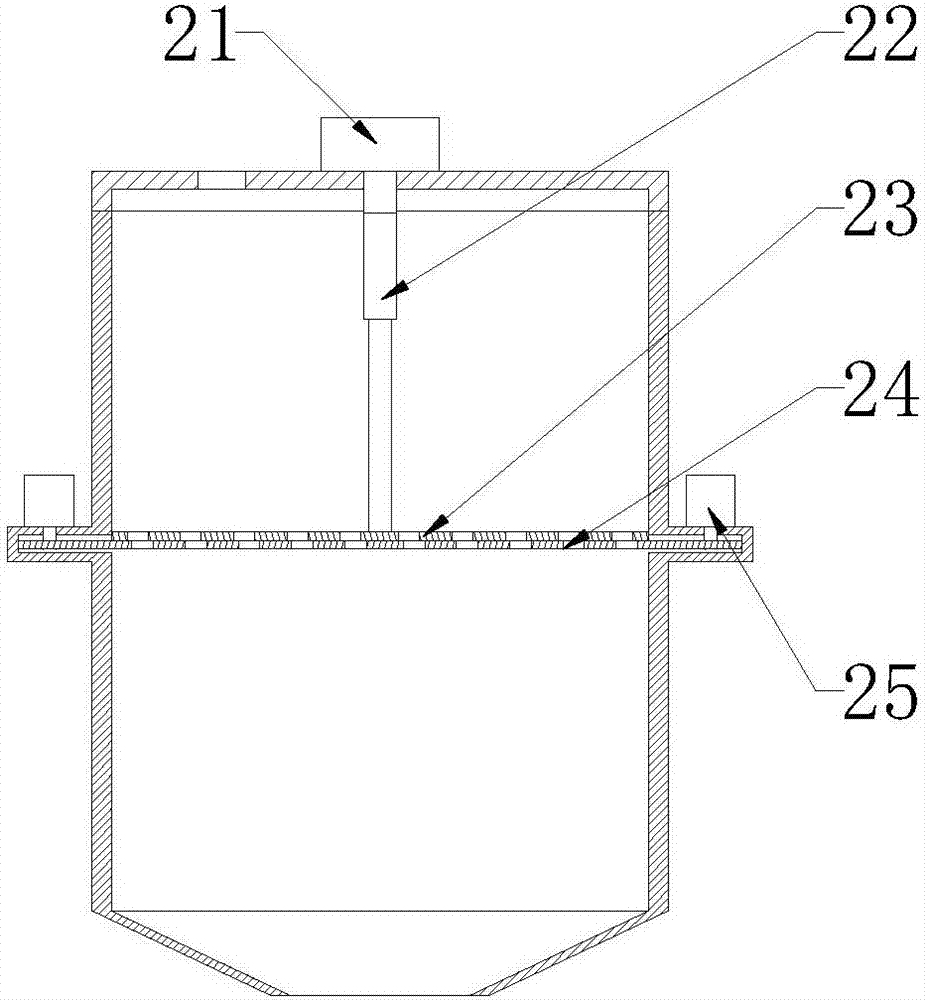

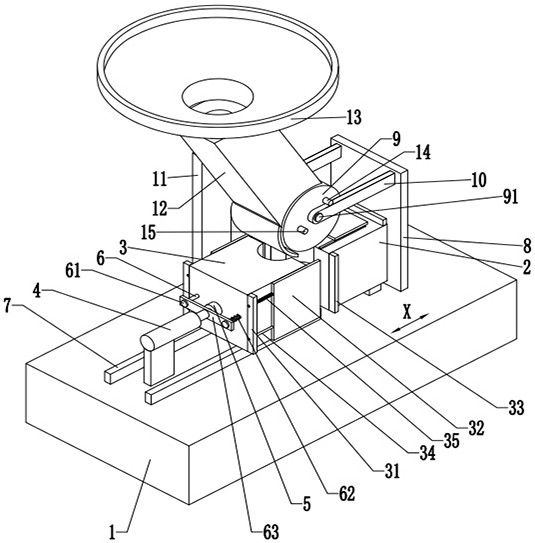

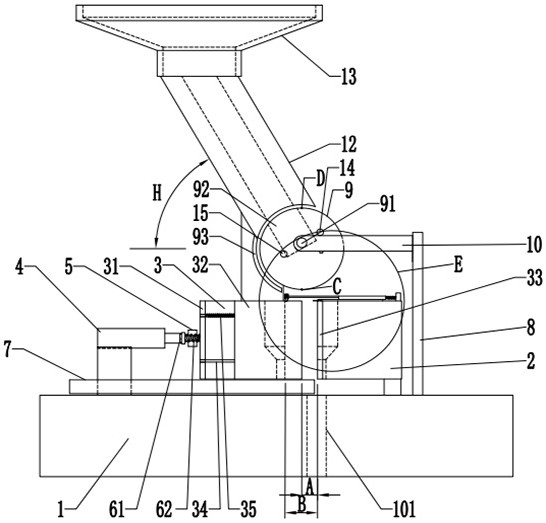

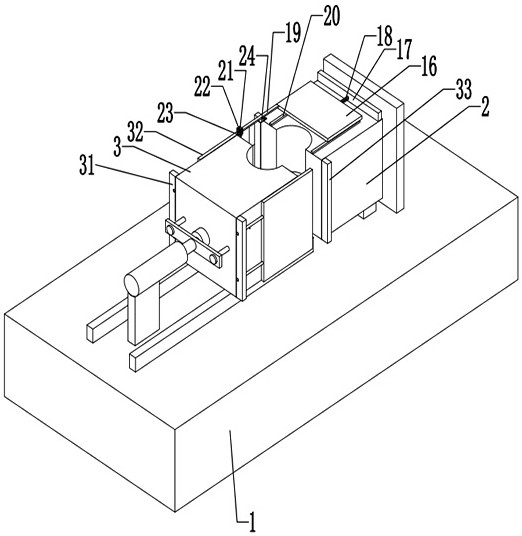

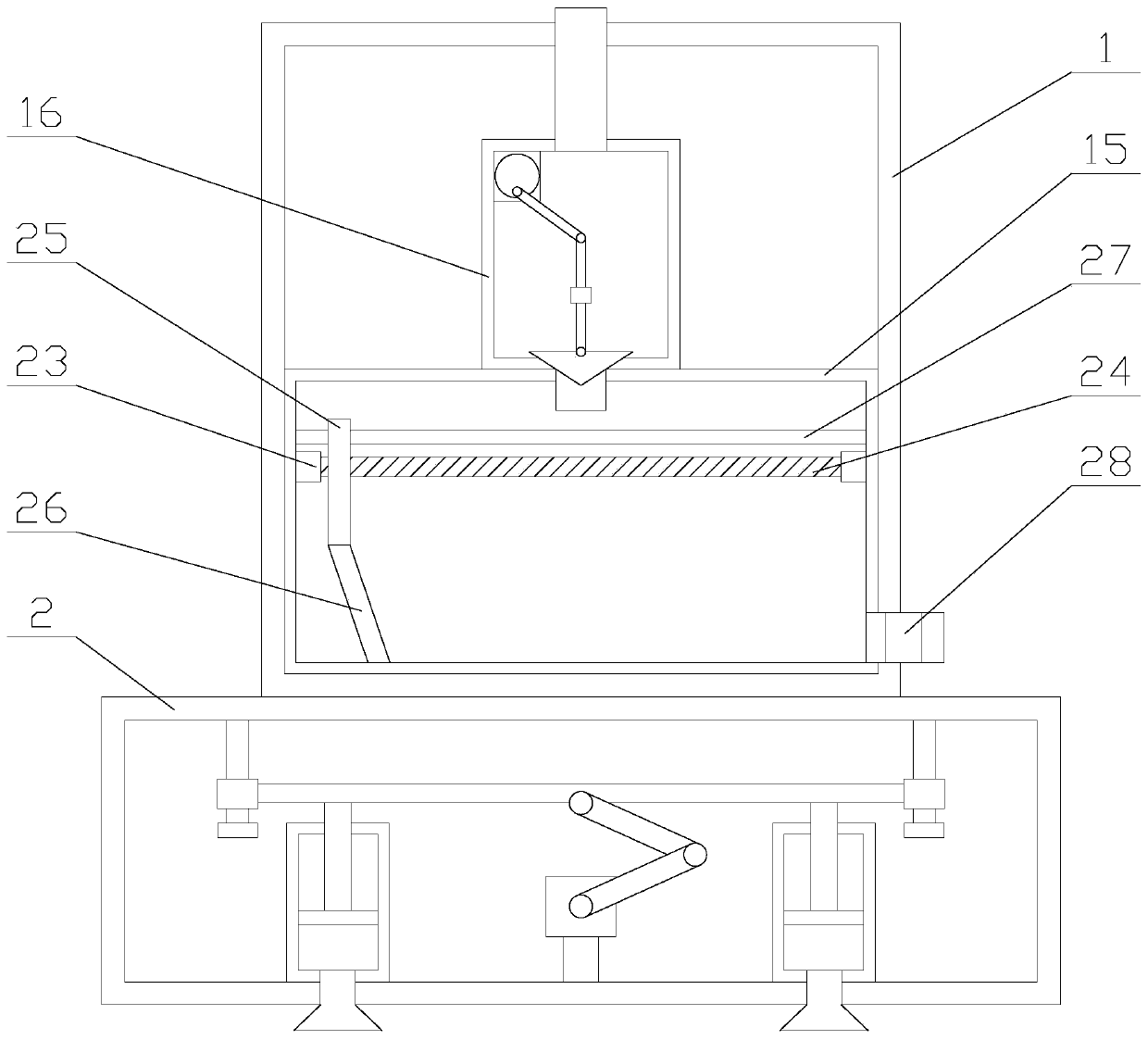

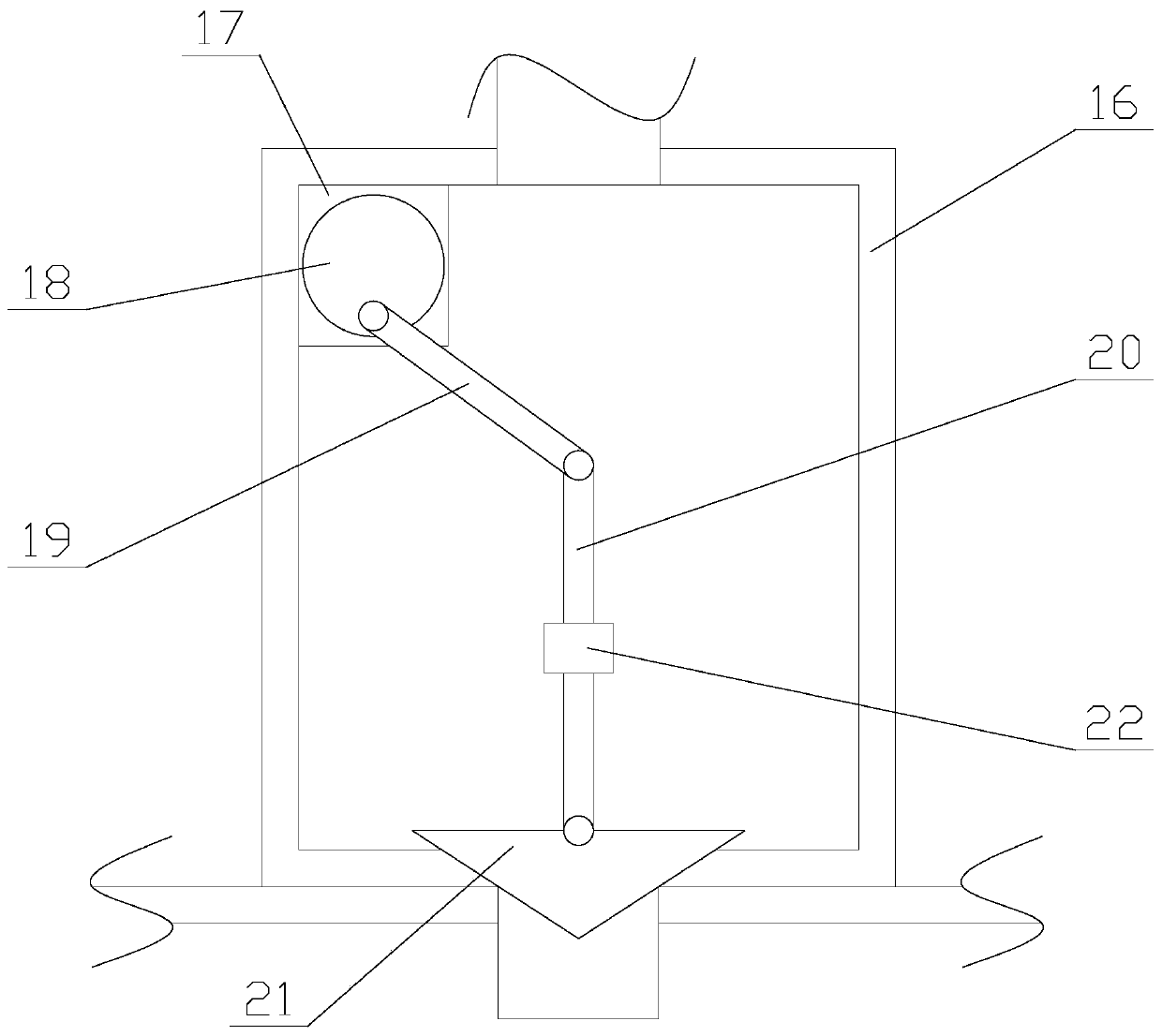

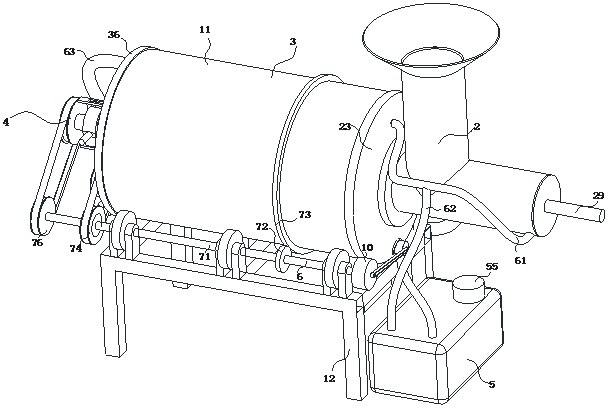

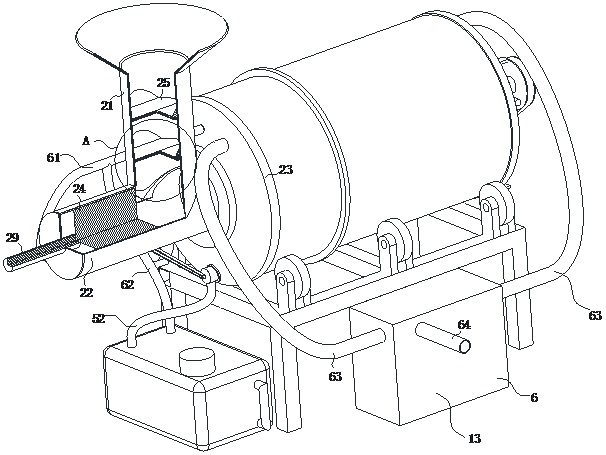

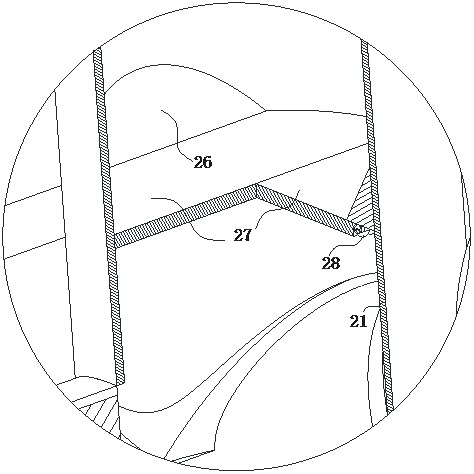

Method of using brewing equipment

The invention belongs to the field of brewing, and specifically discloses a method for using brewing equipment, including the following steps: (1) adding grain grains and water; (2) inputting heat preservation steam; , the inner box, and the top-opening mixing unit perform the initial oscillation and first stirring of the grain grains; (4) the stepping ejection unit and the top-opening stirring unit perform the second stirring on the grain grains; (5) the pushing unit, the inner box, the top Open the stirring unit to reset and complete the second oscillation of the grain grains; (6) Push the stirring unit to move along the direction of the inner outlet, and carry out the third stirring of the grain grains; (7) Push the stirring unit to move to the maximum value and Open the sealing unit, and the grain grains fall to the conveyor belt; (8) The reset unit restores the step ejection unit, the top stirring unit and the sealing unit to their original state. This scheme can perform two vibrations and three stirrings on the grain grains, which improves the effect of moistening grains, and can realize automatic feeding, which reduces labor costs.

Owner:遵义市永胜金属设备有限公司

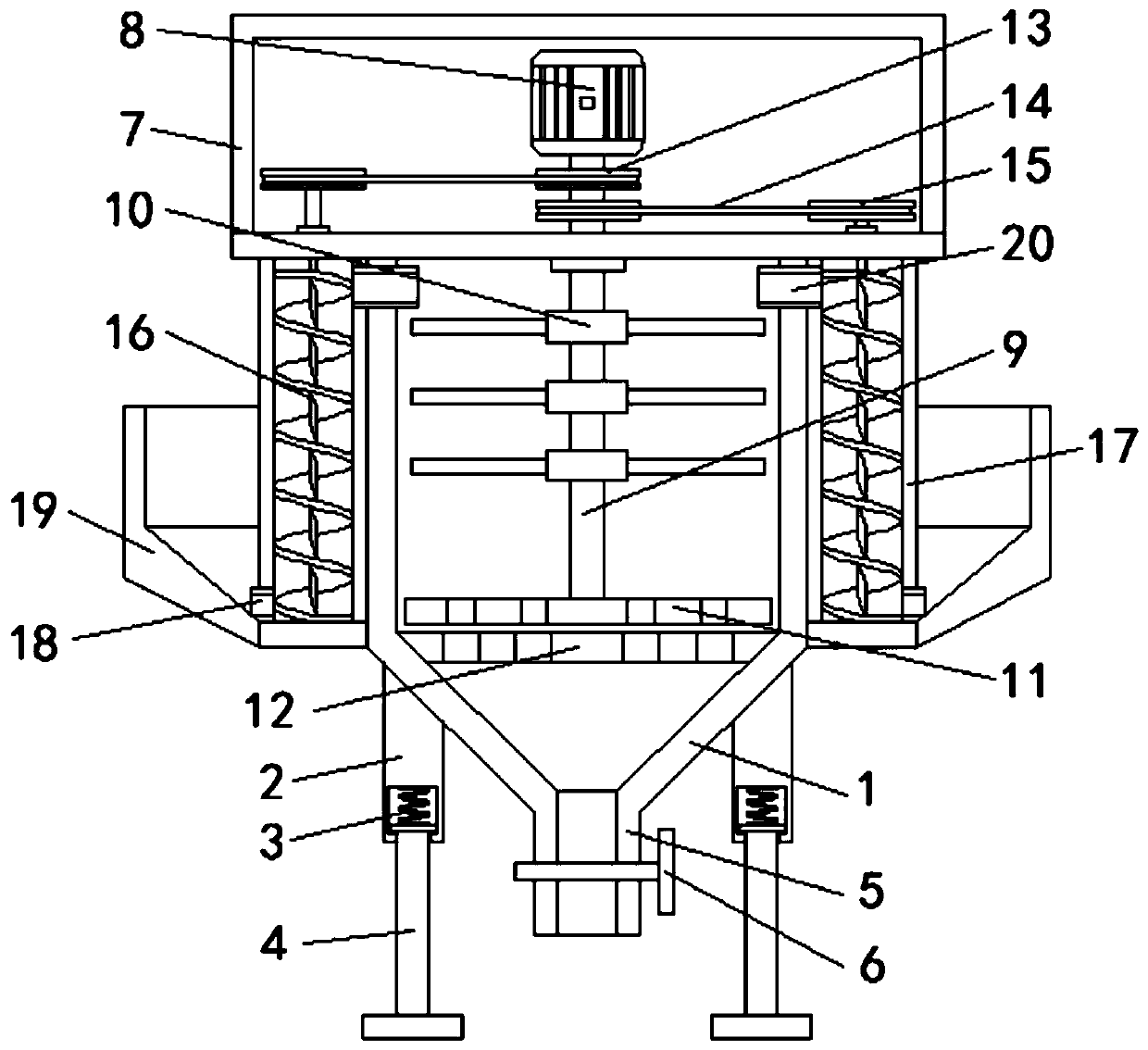

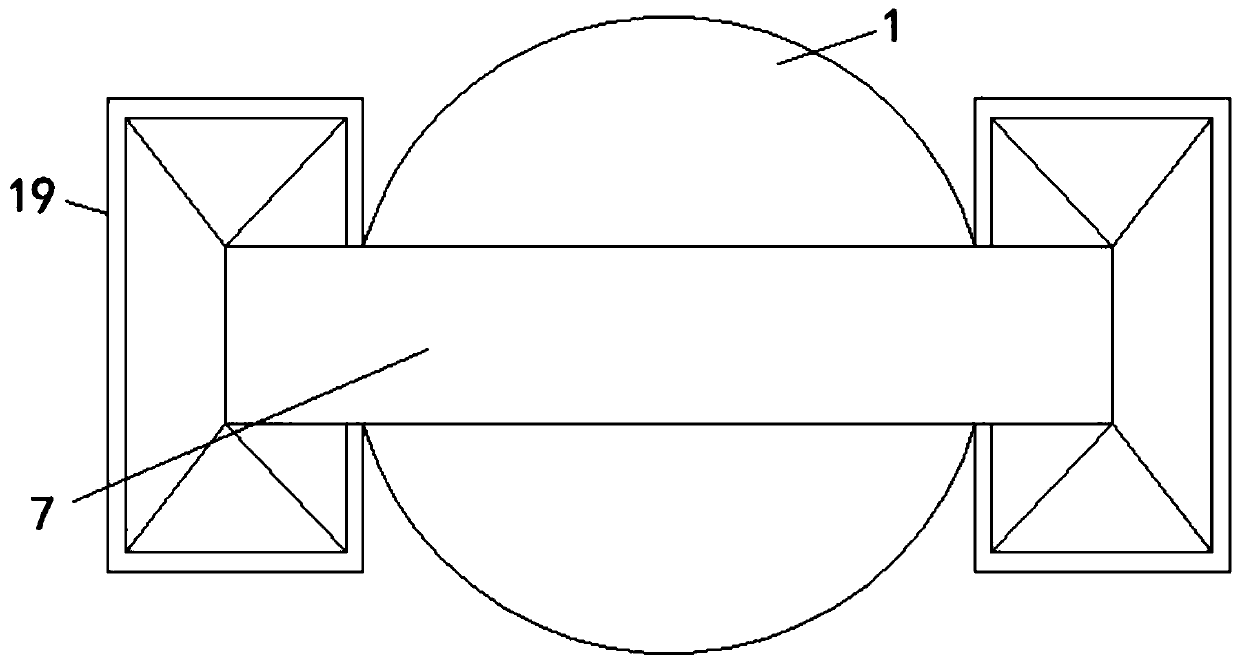

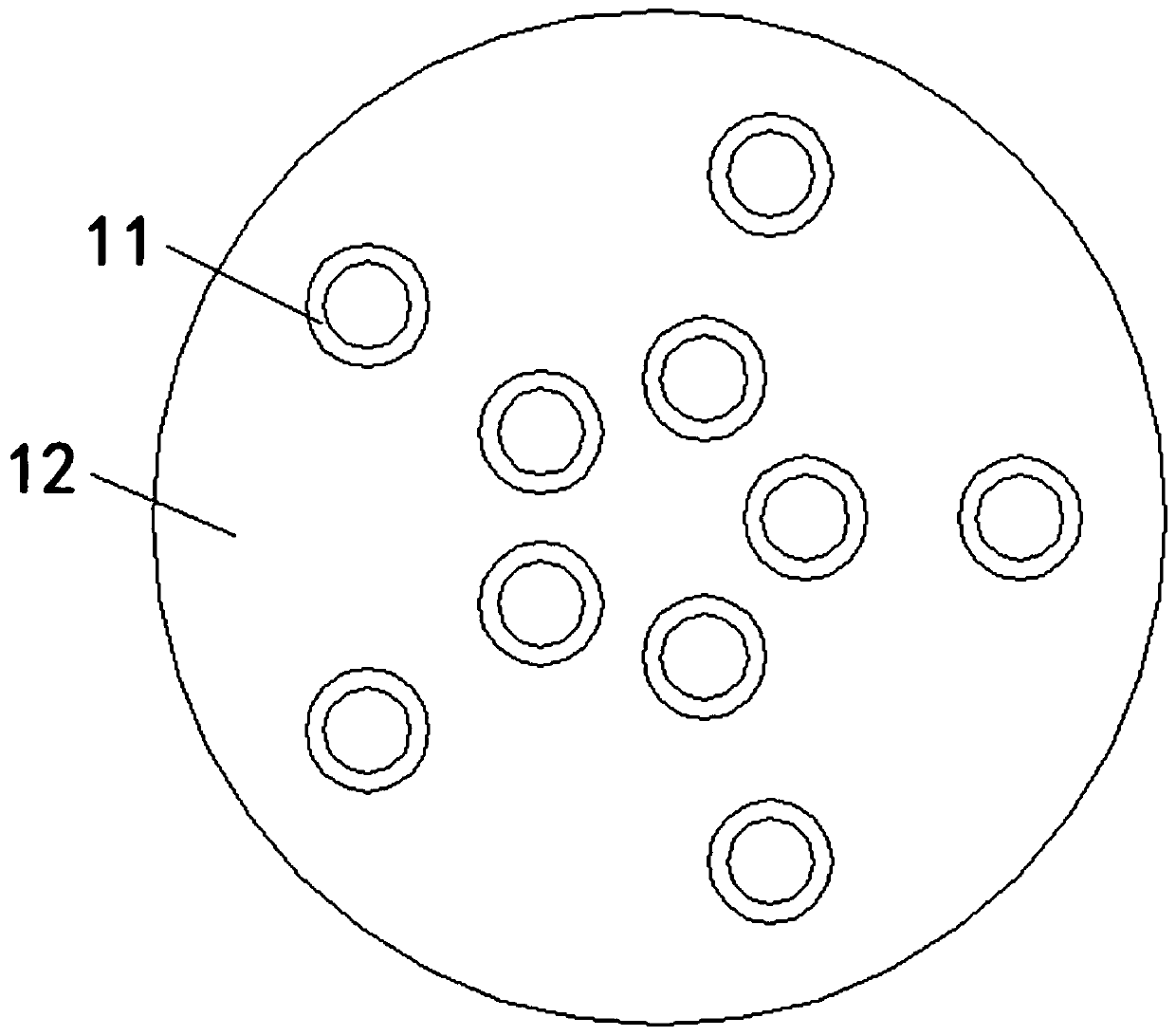

Mortar vibrating screen device for concrete wet screening

InactiveCN107051874AReduce labor intensityRealize the function of automatic feedingSievingScreeningEngineeringControl theory

The invention provides a concrete wet screen mortar vibrating screen device, which includes a concrete delivery pump, a box body, a connecting plate, a shock absorbing spring, a shock absorbing plate, a bottom plate, a normally closed switch, a return spring, a servo motor, a telescopic rod, an adjusting screen and Bottom sieve and concrete delivery pump are installed at the left end of the box, the outer end of the box is equipped with a connecting plate, the lower end of the connecting plate is equipped with a shock absorbing spring, the lower end of the shock absorbing spring is equipped with a shock absorbing plate, and the lower end of the shock absorbing plate is equipped with a return spring, reset The spring is installed on the top of the bottom plate, and a normally closed switch is set on the top of the bottom plate. This design realizes the function of automatic feeding. The servo motor is installed on the upper end of the box, the telescopic rod is set inside the box, and the lower end of the telescopic rod is equipped with an adjusting screen. Installed on the upper end of the bottom sieve, the design can adjust the size of the sieved material. The invention is easy to use, easy to operate, good in stability, high in reliability, and improves flexibility.

Owner:CHANGSHA WUDAO IND DESIGN CO LTD

Guardrail assembling mechanism

InactiveCN112238338ARealize the function of automatic assemblySave human effortMetal working apparatusHydraulic cylinderElectric machinery

The invention discloses a guardrail assembling mechanism, and belongs to the field of guardrail processing. The guardrail assembling mechanism comprises two hoisting guide rails, the hoisting guide rails are fixedly mounted, hoisting slide blocks are mounted on the hoisting guide rails, the hoisting slide blocks are slidably connected with the hoisting guide rails, and clamping assemblies are fixedly mounted at the top ends of the hoisting slide blocks; and a lead screw is arranged below the clamping assemblies, the lead screw is mounted at the output end of a feeding motor, the feeding motoris fixedly mounted, each clamping assembly comprises an objective table, a nut block matched with the lead screw is arranged at the bottom end of each objective table, a vertical plate is arranged atthe top end of each objective table, one end of a spring is connected with a bending frame, the other end of the spring is connected with a clamping block, opening air cylinders are fixedly mounted onthe two sides of each vertical plate, ball heads are mounted at the output ends of the opening air cylinders and attached to the side face of the slope face, and a pushing hydraulic cylinder is arranged on the other side of each vertical plate. According to the guardrail assembling mechanism, automatic feeding and discharging can be achieved, and manpower is saved.

Owner:谷东虎

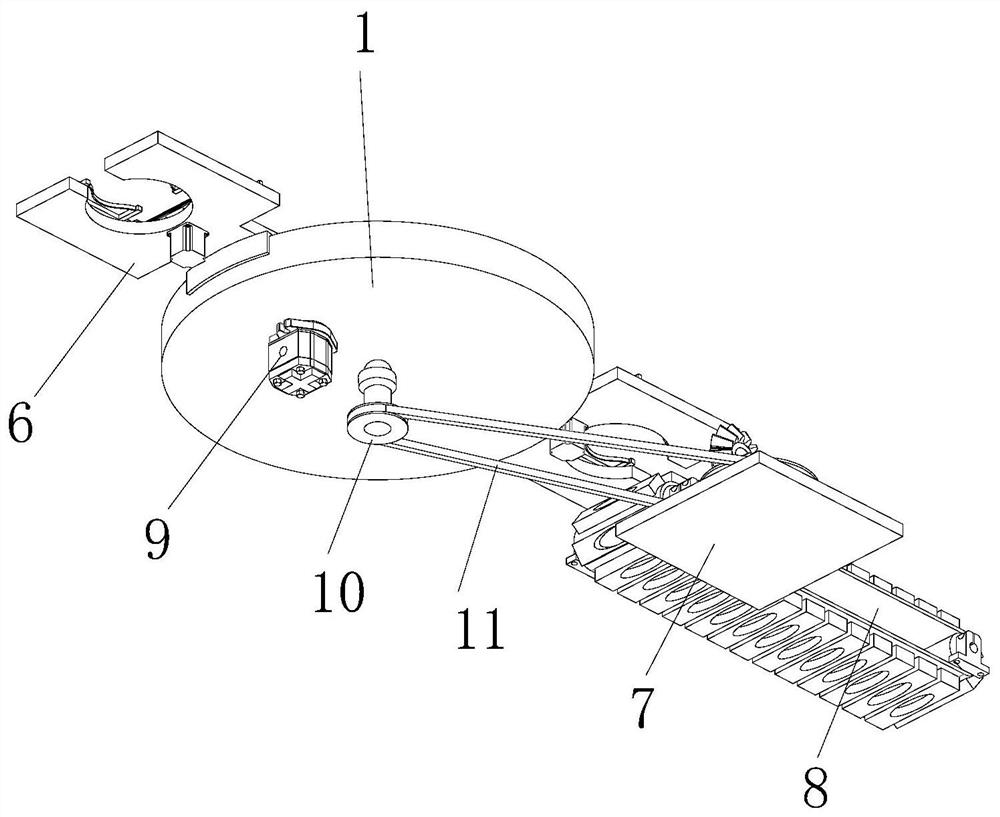

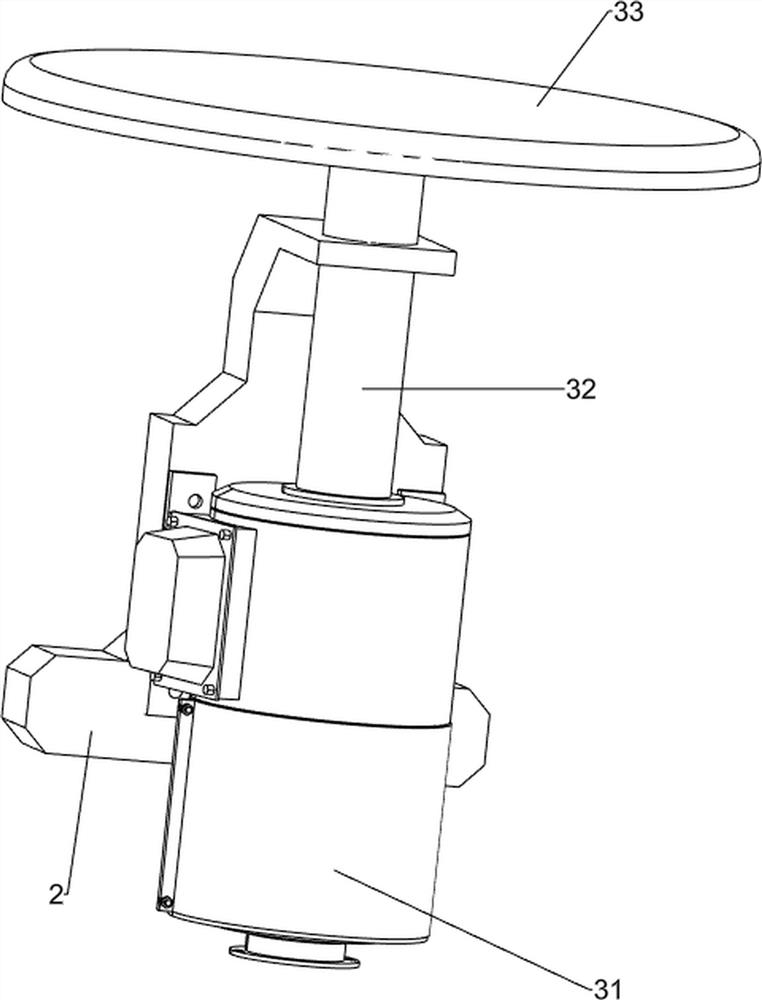

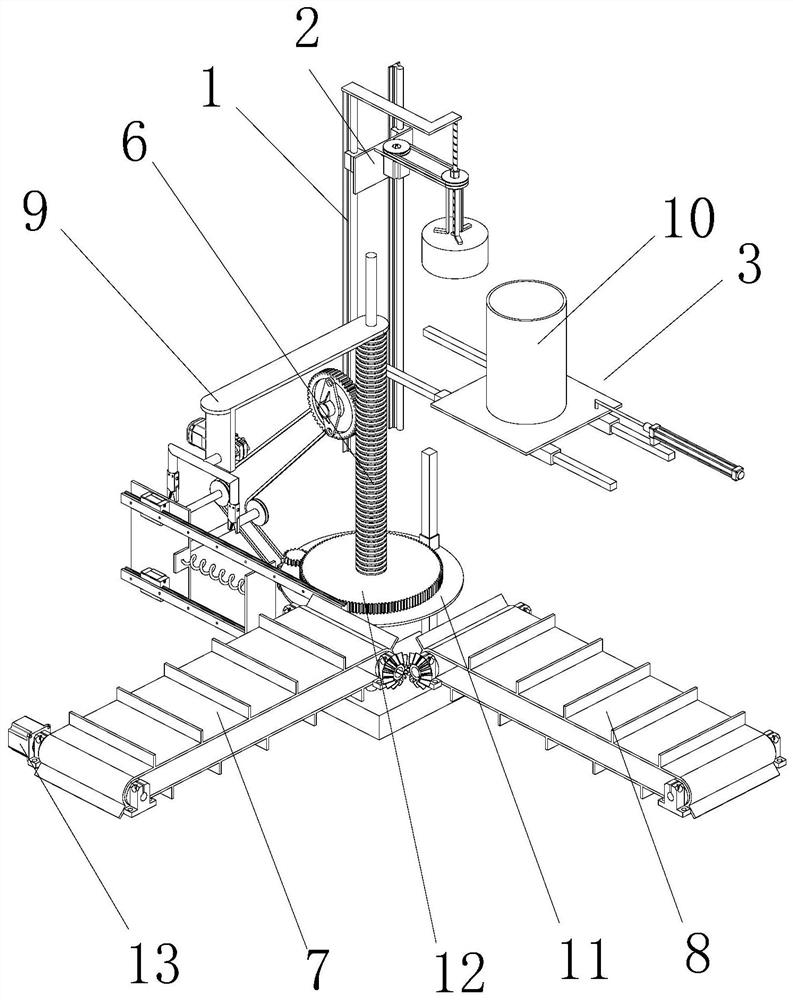

Cherry tree planting equipment

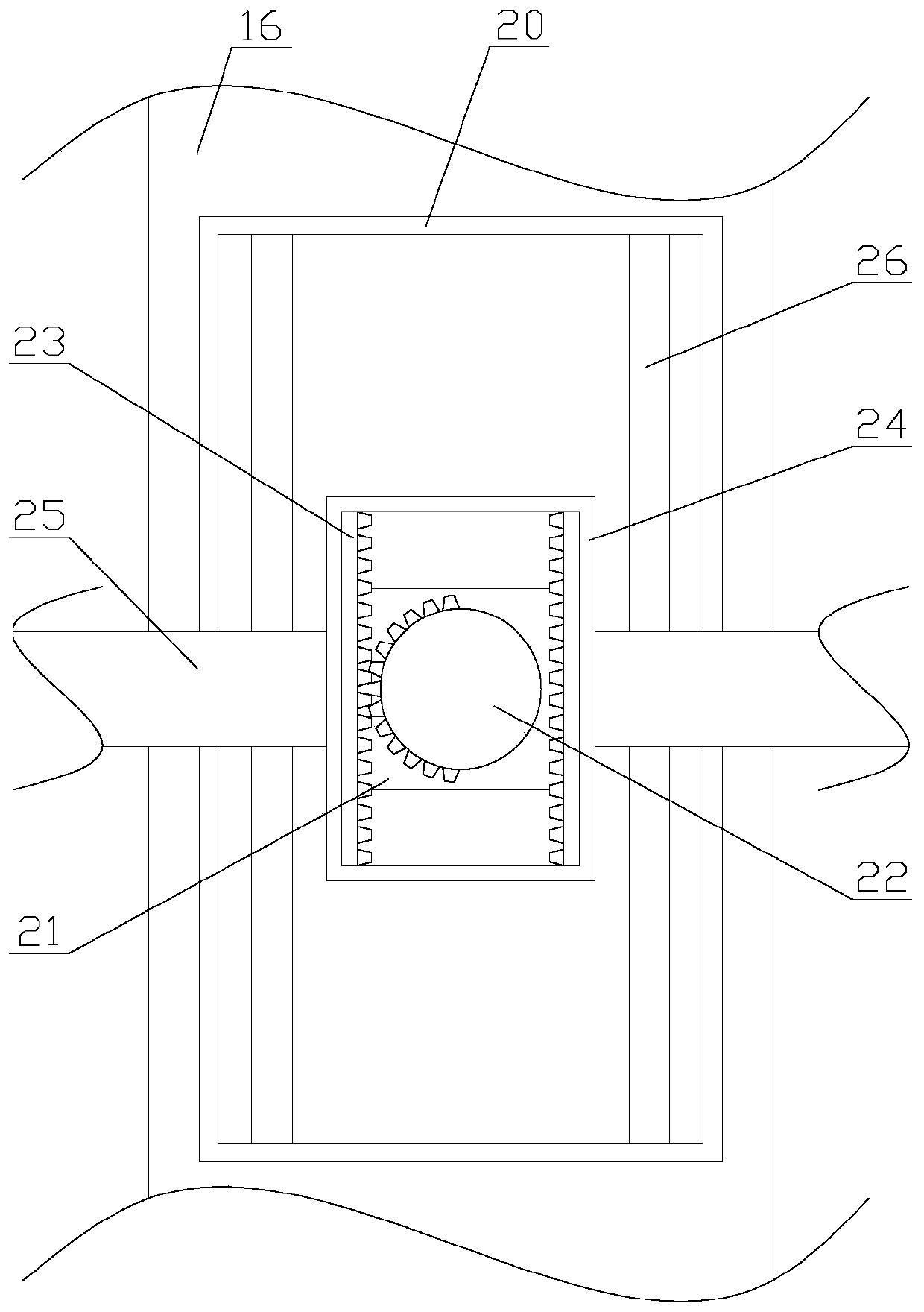

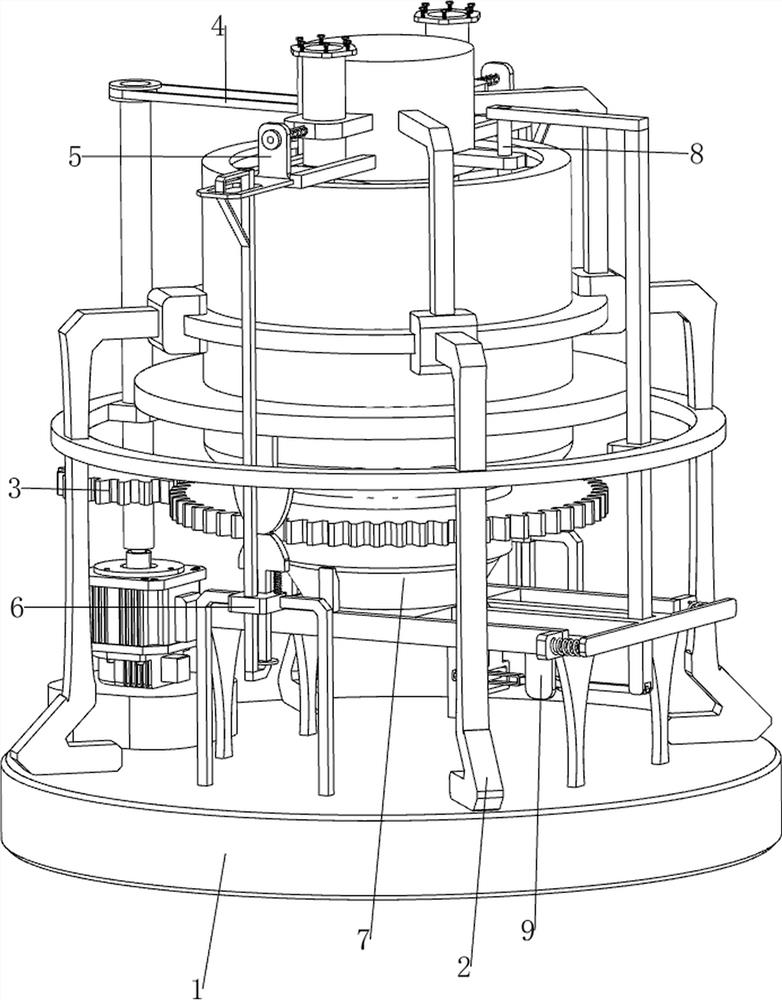

ActiveCN111742810ARealize the function of automatic feedingReduce working errorsForestryFixed bearingGear wheel

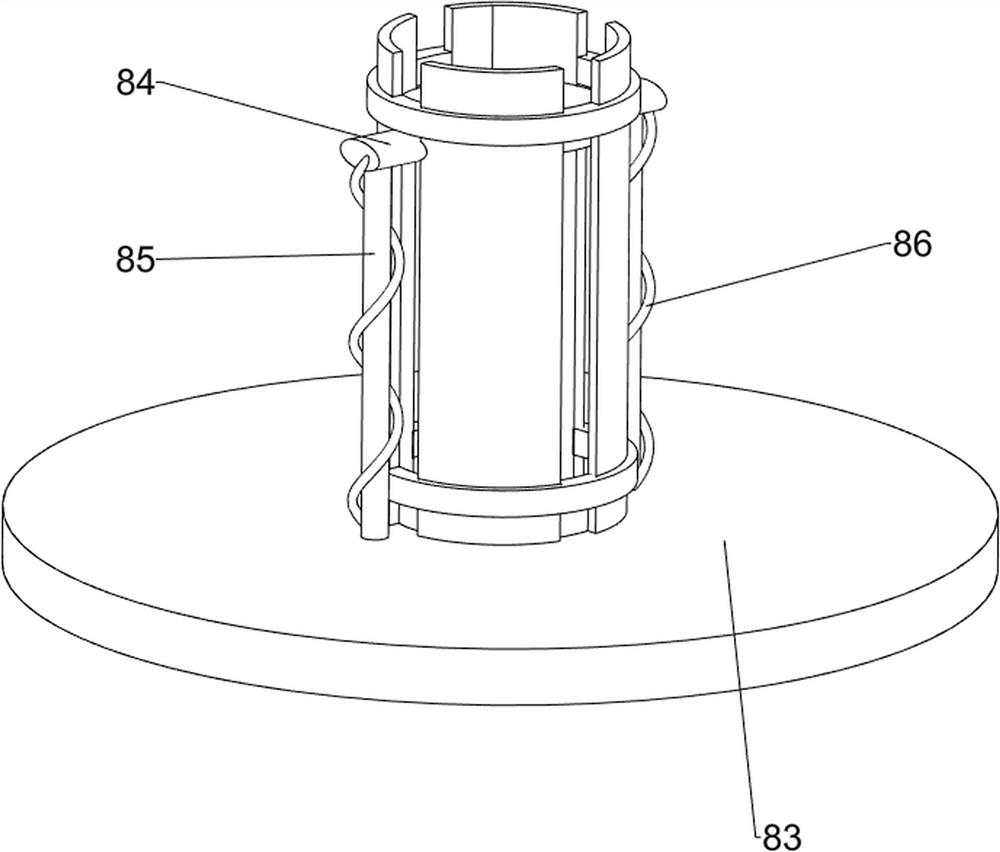

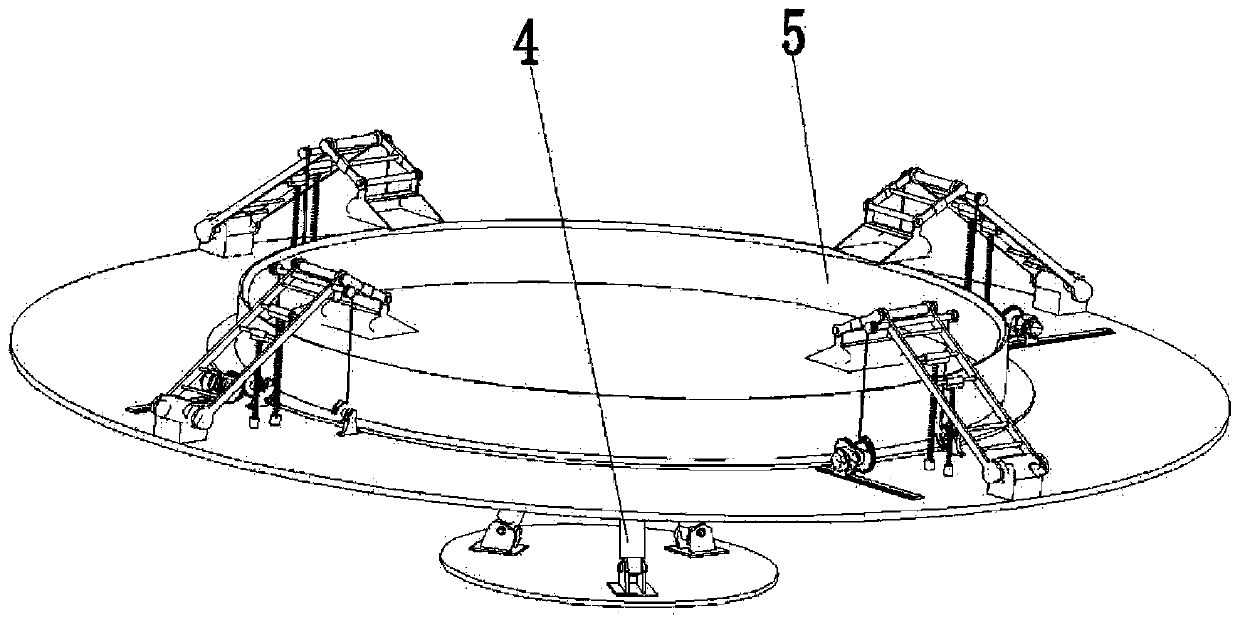

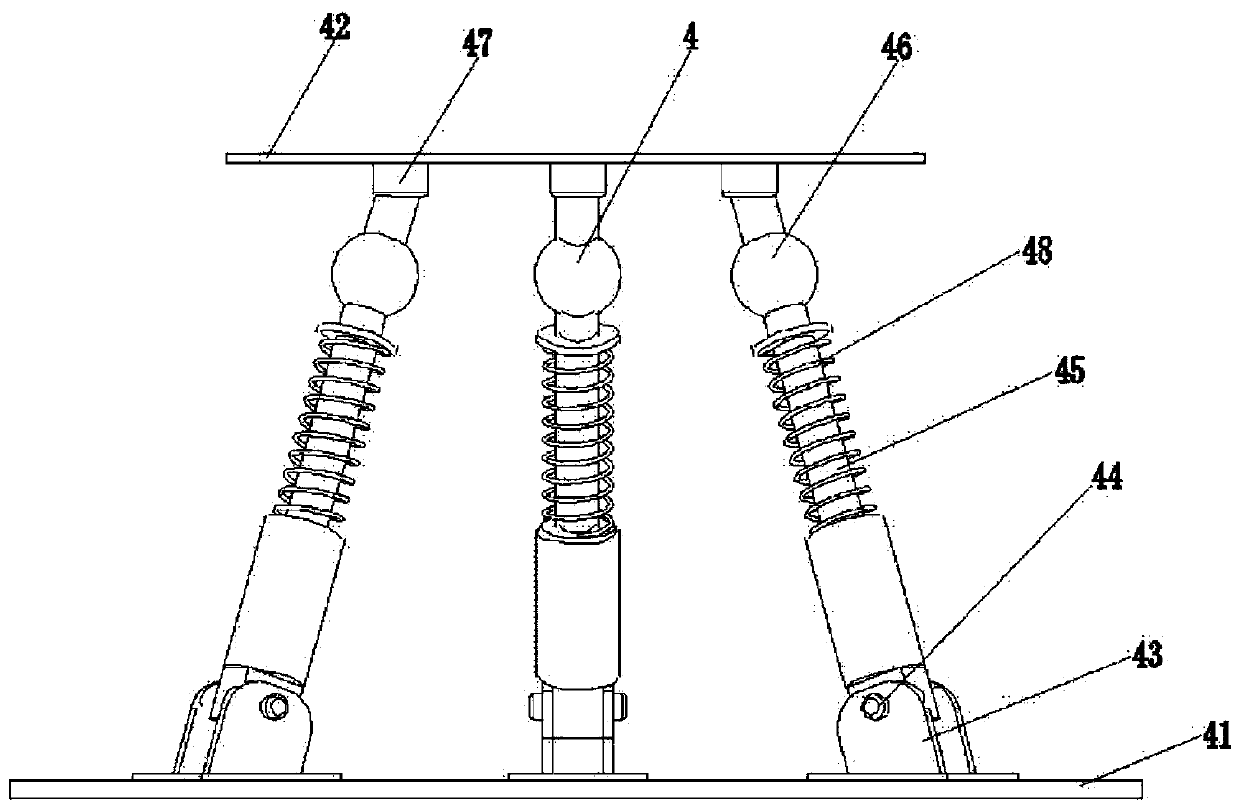

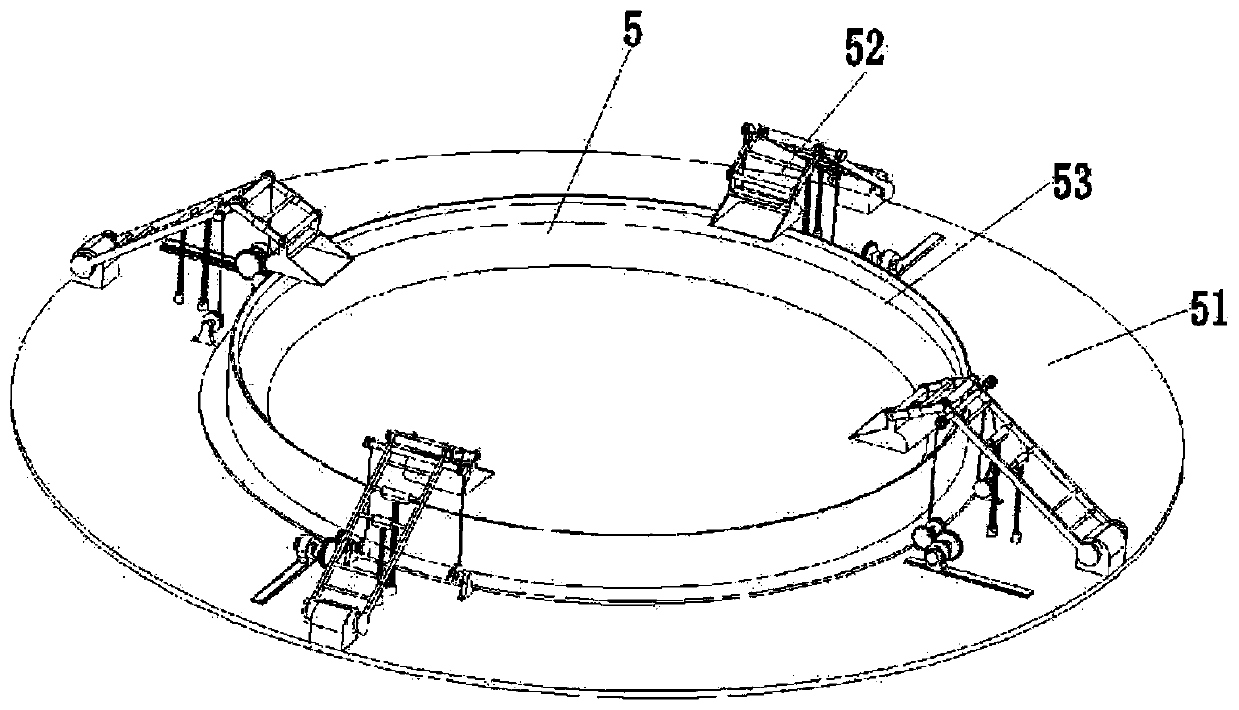

The invention relates to cherry tree planting equipment. The cherry tree planting equipment comprises a circular bottom plate, wherein an outer circular ring is mounted at the top end of the circularbottom plate; an inner circular ring is mounted on the circular bottom plate on the inner side of the outer circular ring; a gear disk is mounted at the middle part of the inner circular ring; a circular rod is arranged at the bottom end of the gear disk; a fixing bearing is mounted on the circular rod in a sleeving manner; an outer ring of the fixing bearing is fixedly connected with the circularbottom plate; an opening which is matched with the circular rod is formed in the middle part of the circular bottom plate; the circular rod penetrates through the upper side and the lower side of thecircular bottom plate; connecting blocks are arranged on two sides of the top end of the gear disk; a circular sleeve is mounted at one end of each connecting block; a second gear is mounted on the circular bottom plate on one side of the gear disk; the second gear and the gear disk are mutually meshed; the second gear is mounted at the output end of a stepping motor; the stepping motor is fixedto the bottom end of the circular bottom plate; and the inner circular sleeve and the inner circular ring are in sliding connection. Two clamping assemblies are arranged, so that seedlings can be clamped separately, and operation time is saved.

Owner:奉节县铭恒农业科技有限公司

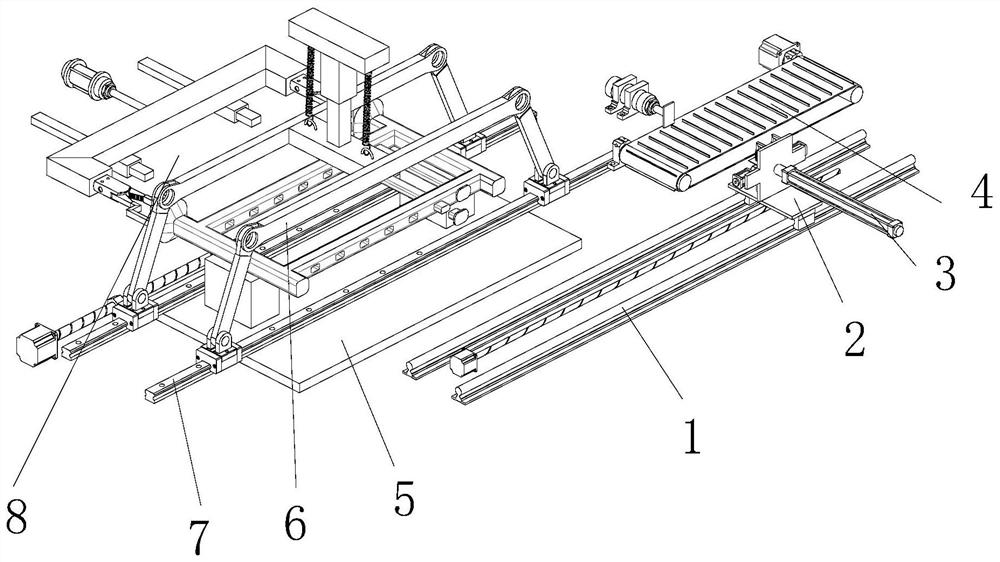

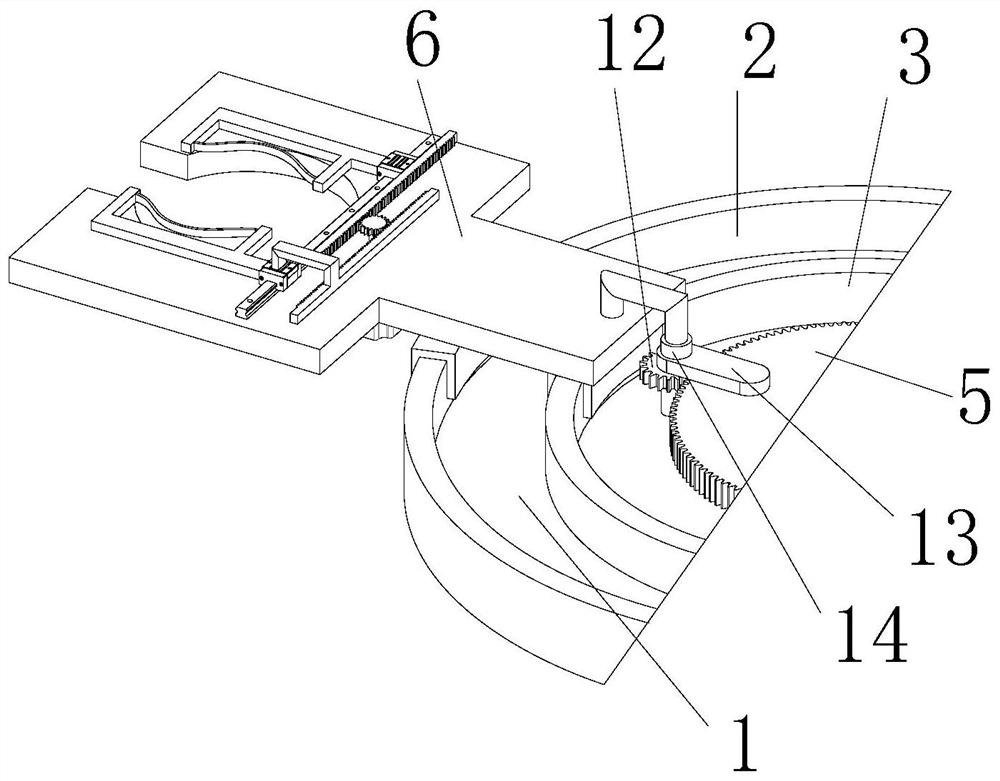

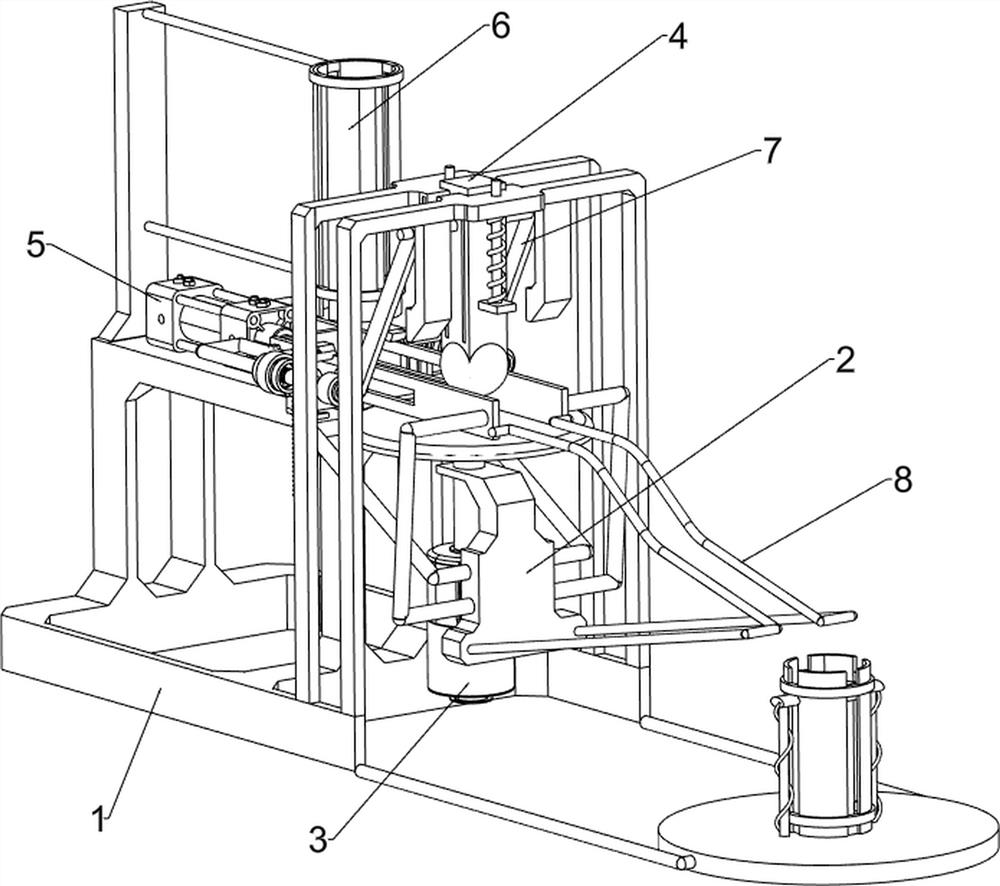

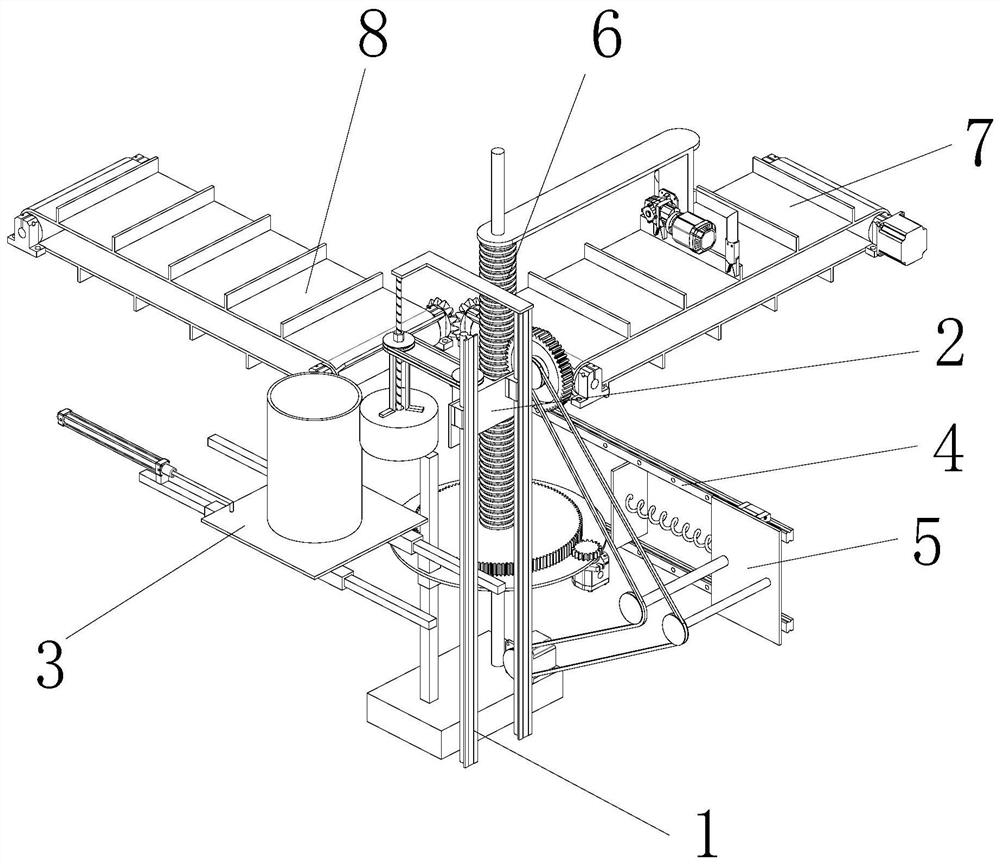

Plywood processing device

InactiveCN112060209ARealize the function of automatic feedingEasy to transfer automaticallyFeeding devicesGripping devicesHydraulic cylinderElectric machinery

The invention discloses a plywood processing device, and belongs to the field of plate processing. The plywood processing device comprises two fixing guide rails, wherein the two fixing guide rails are fixedly mounted, a feeding sliding block is mounted on each fixing guide rail, each feeding sliding block is slidably connected with the corresponding fixing guide rail, and a feeding assembly is fixedly mounted at the top ends of the feeding sliding blocks; the feeding assembly comprises a pushing plate, a sliding rod is fixedly installed in the middle of the feeding assembly, a sliding block is installed on the sliding rod, the sliding block is slidably connected with the sliding rod, a double-sided rack is fixedly installed at one side of the sliding block, and a hydraulic cylinder is fixedly arranged at the portion, at one side of the double-sided rack, of the pushing plate; and one end of the double-sided rack is fixedly connected with the output end of the hydraulic cylinder, a lead screw is arranged at the bottom end of the feeding assembly, a nut block is installed at the inner side of the lead screw, the nut block is installed at the output end of a feeding motor, and the feeding motor is fixedly installed. According to the plywood processing device, the lead screw drives the pushing plate to move in a reciprocating mode, so that materials can be conveniently and automatically pushed.

Owner:仇涛

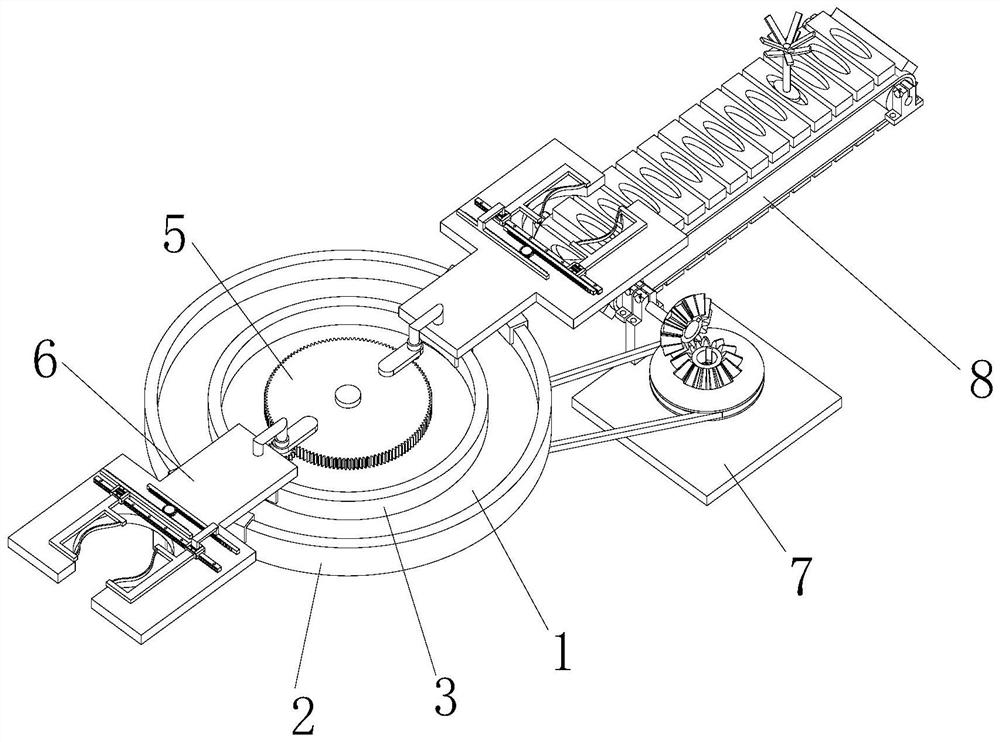

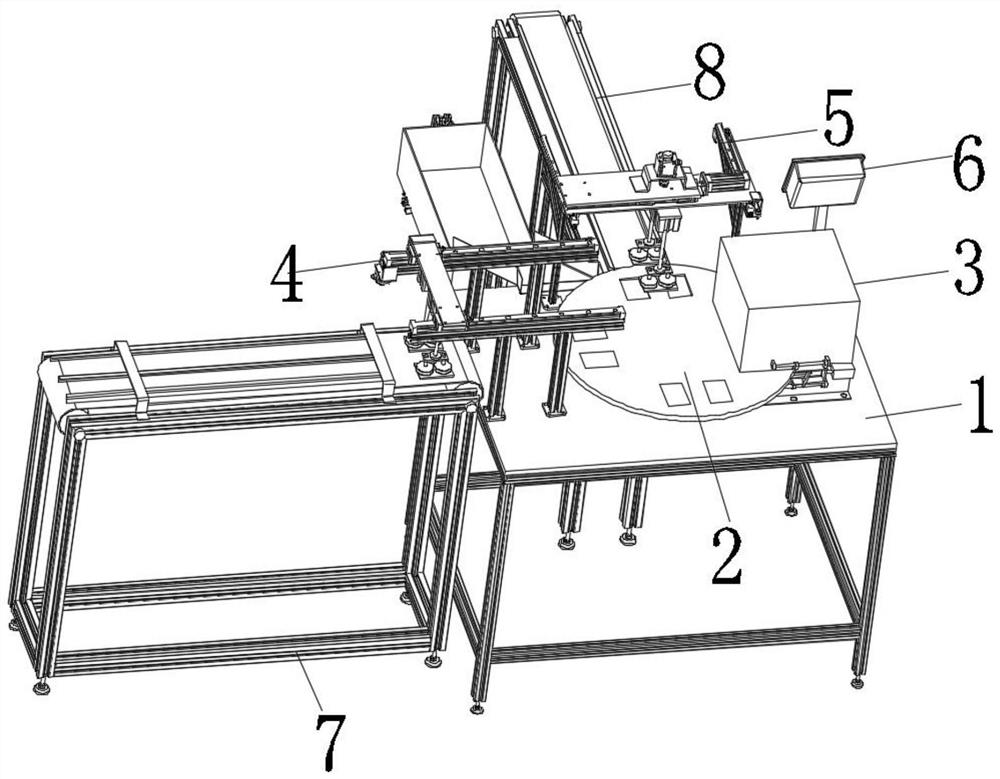

Detection equipment for liquid crystal panel production

InactiveCN112269279ARealize the function of automatic feedingReduce human resourcesNon-linear opticsBall bearingEngineering

The invention discloses detection equipment for liquid crystal panel production. The equipment comprises a workbench, a rotating disc mechanism is arranged in the center of the upper end surface of the workbench, a detection mechanism and a feeding mechanism are respectively arranged in the left side and the right side of the upper end surface of the workbench, an unloading mechanism is arranged on the front surface of the turntable mechanism, an operation screen is arranged on the left side of the discharging mechanism, a feeding conveying belt assembly is arranged on the right side of the feeding mechanism, a discharging conveying belt assembly is arranged on the front face of the discharging mechanism, the rotating disc mechanism comprises an installation base, a thrust ball bearing anda first rotating shaft, and the installation base is installed on a table panel of the workbench, and a counterbore is formed in the installation base. The functions of automatic feeding, transporting, detecting, discharging and detection result classifying are achieved, the overall automation degree of the device is high, the detection efficiency and the detection quality of a factory are effectively improved, more manpower resources are saved, and the use prospect is wide.

Owner:安徽速彩电子科技有限公司

Convenient beneficiation flotation device with stirring function

InactiveCN110252519AImprove the mixing effectImprove practicalityFlotationArtificial materialsSlurry

The invention relates to a convenient beneficiation flotation device with a stirring function. The device comprises a main body, a material inlet tube, an ore discharging tube and a bubble discharging tube, and further comprises a stirring mechanism and a material feeding mechanism, wherein the material feeding mechanism comprises a material feeding box, a material feeding tube, a moving plate and a moving assembly, the stirring mechanism comprising a rotating assembly, a rotary shaft, a rotating shaft, a driving assembly, two bearings and two stirring assemblies, and each stirring assembly comprises a connecting rod, two support shafts and two stirring plates. The convenient beneficiation flotation device with the stirring function, the function of automatic material feeding is achieved through the material feeding mechanism, artificial material feeding is not needed, and convenience of material feeding is improved; and ore slurry can be stirred in the main body through the stirring mechanism, so that the ore slurry is in full contact with a flotation agent, and the flotation effect is improved.

Owner:深圳市大俊装饰工程有限公司

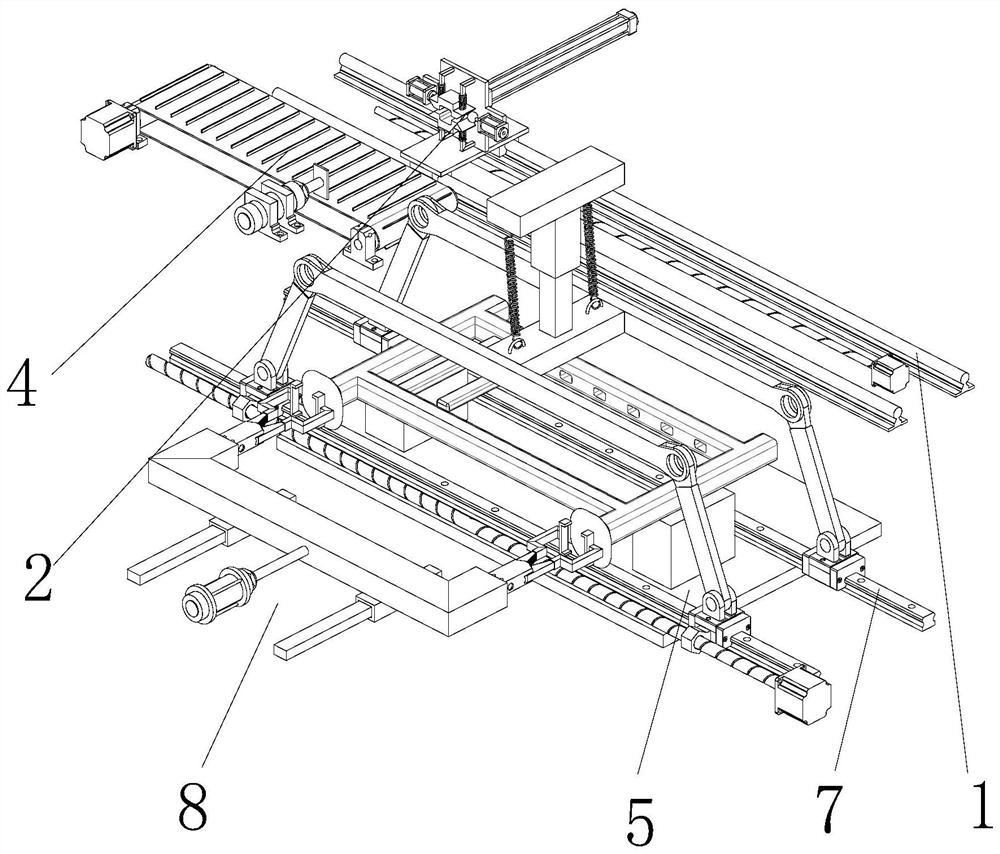

Excavator grab bucket machining device

ActiveCN112589461AImprove hole efficiencyPrevent rotationOther manufacturing equipments/toolsMetal working apparatusExcavatorIndustrial engineering

The invention discloses an excavator grab bucket machining device and belongs to the field of excavator grab buckets. The excavator grab bucket machining device comprises two fixed guide rails; the two fixed guide rails are respectively, independently and fixedly arranged; stepping slide blocks are arranged on the fixed guide rails; the stepping slide blocks are connected with the fixed guide rails in a sliding way; a bearing table is arranged at the top ends of the stepping slide blocks; and a slope table is arranged at the top end of the bearing table. According to the excavator grab bucketmachining device, the tapping efficiency of the grab bucket to be treated is high.

Owner:南通科翰机械工程有限公司

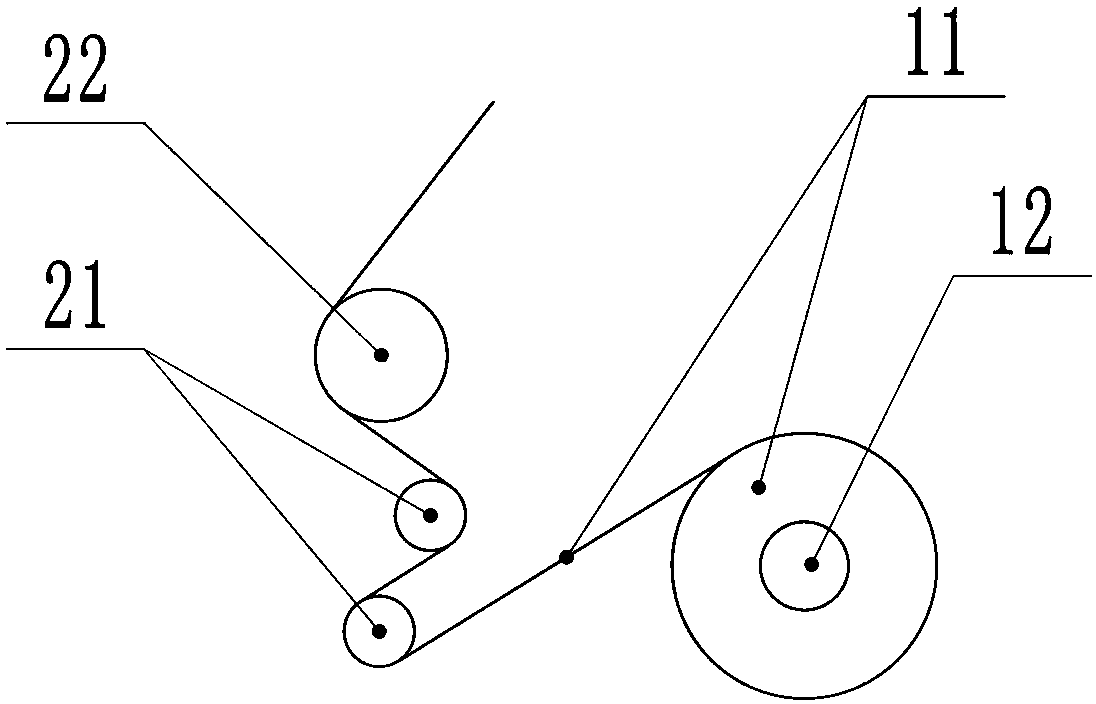

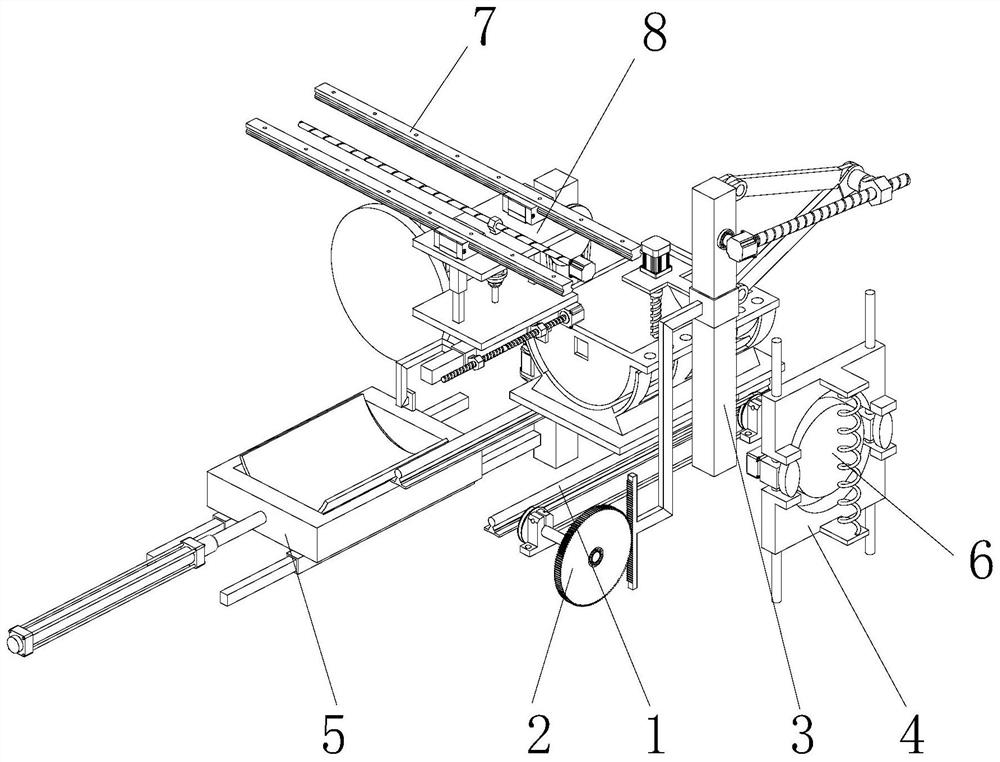

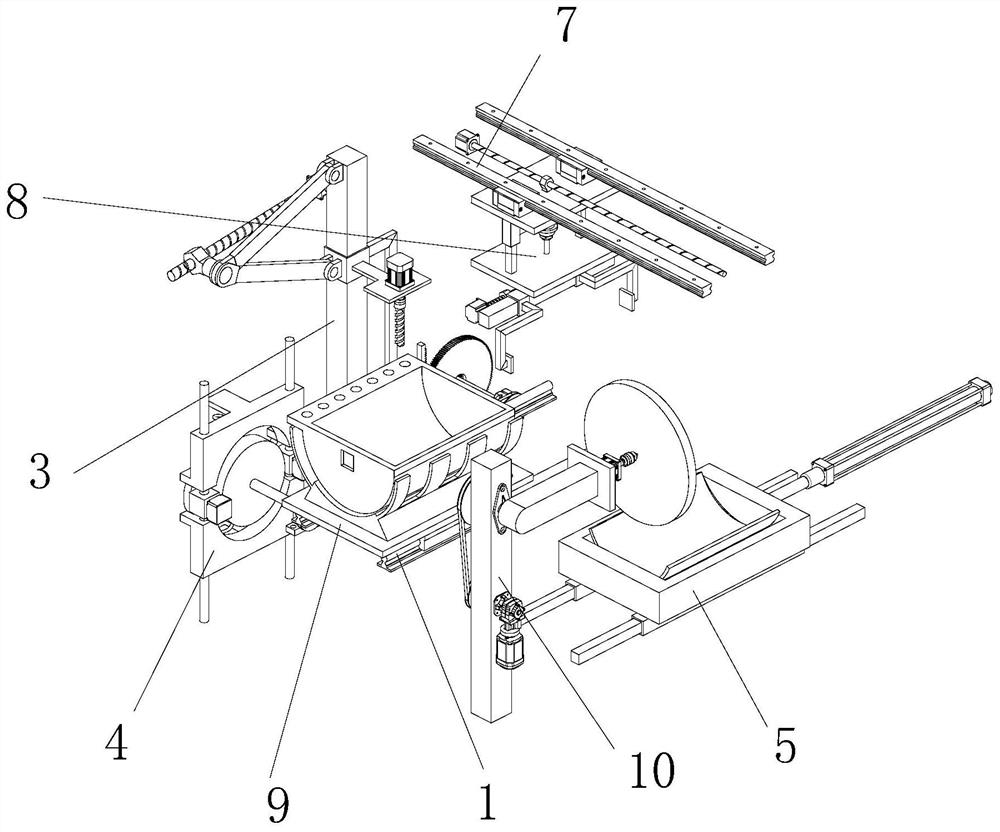

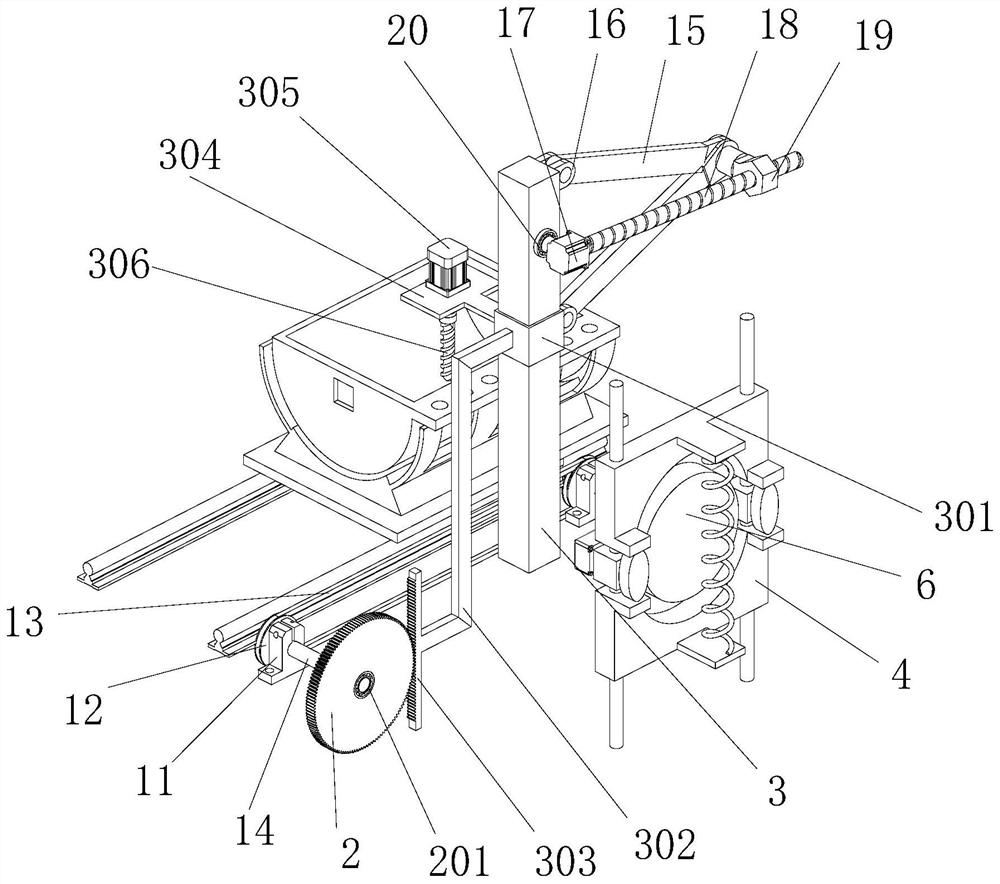

Wine-brewing equipment

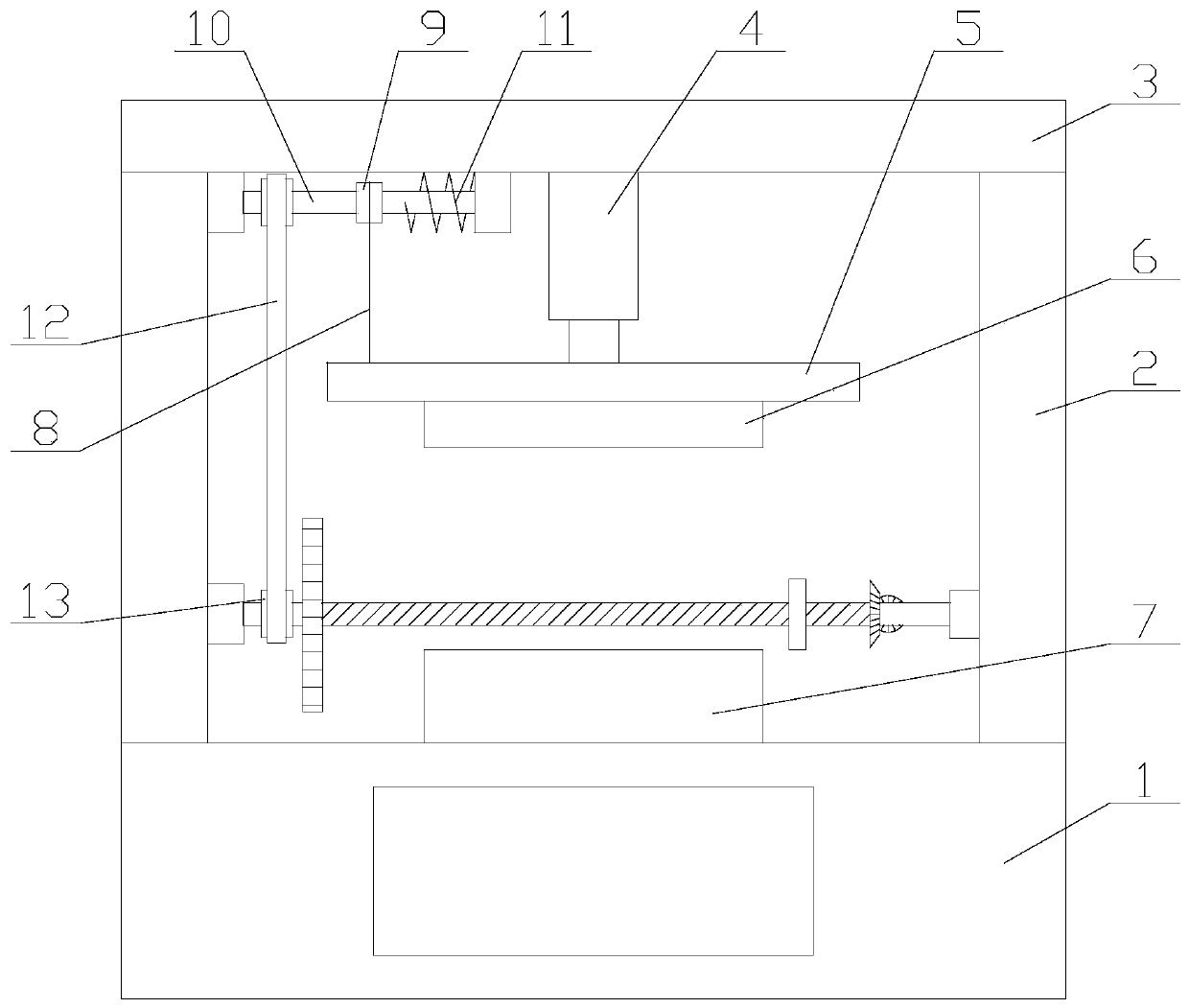

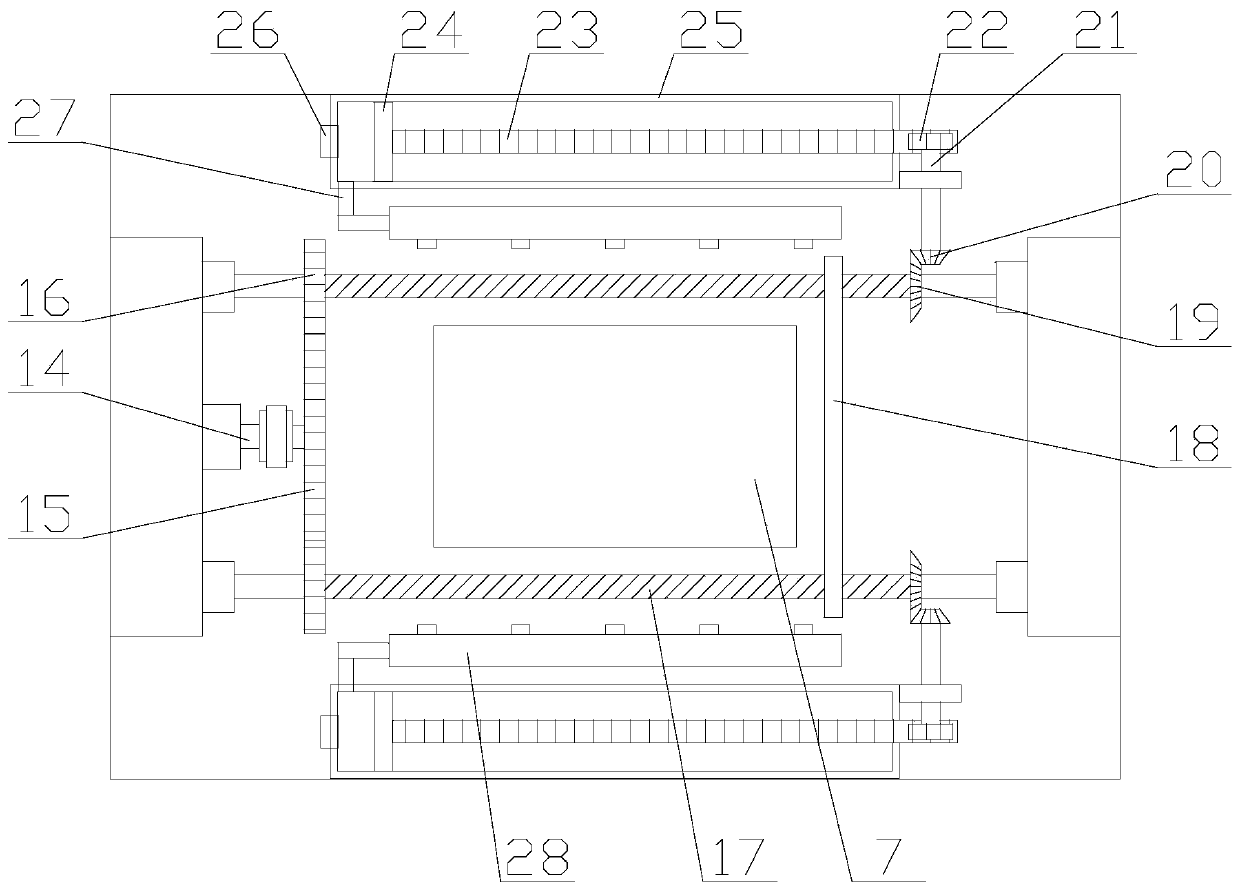

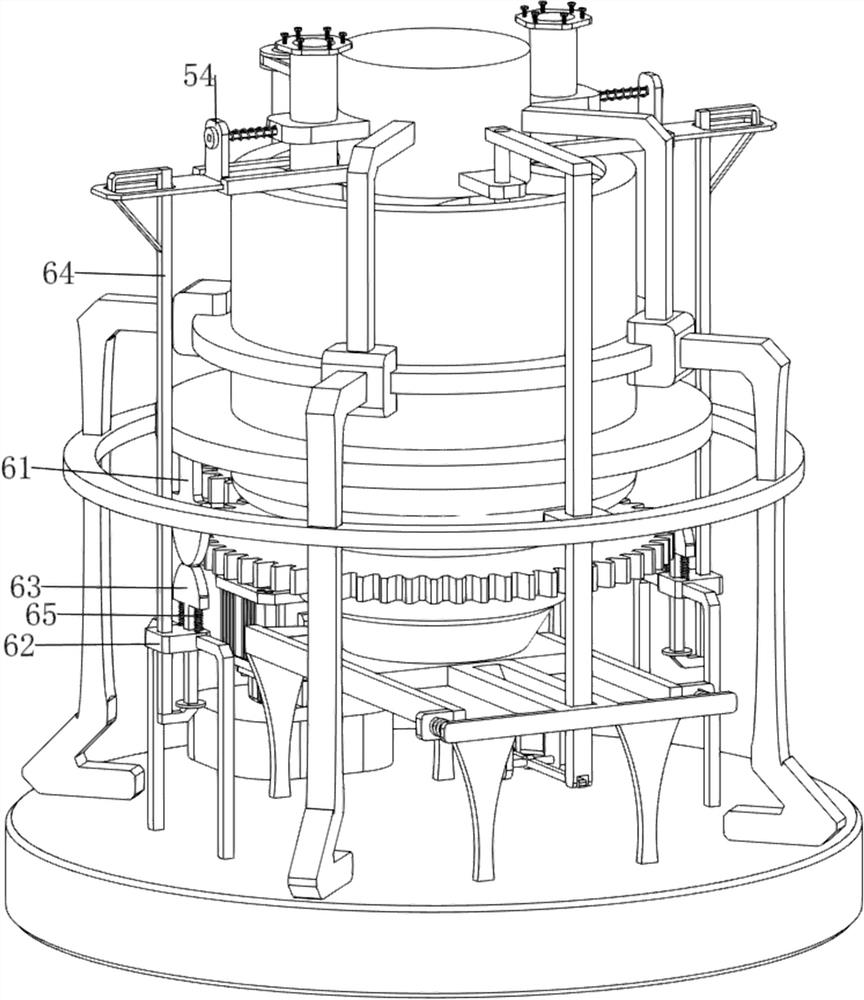

InactiveCN107299041AImprove the effect of moistening foodImprove the mixing effectAlcoholic beverage preparationEngineeringConveyor belt

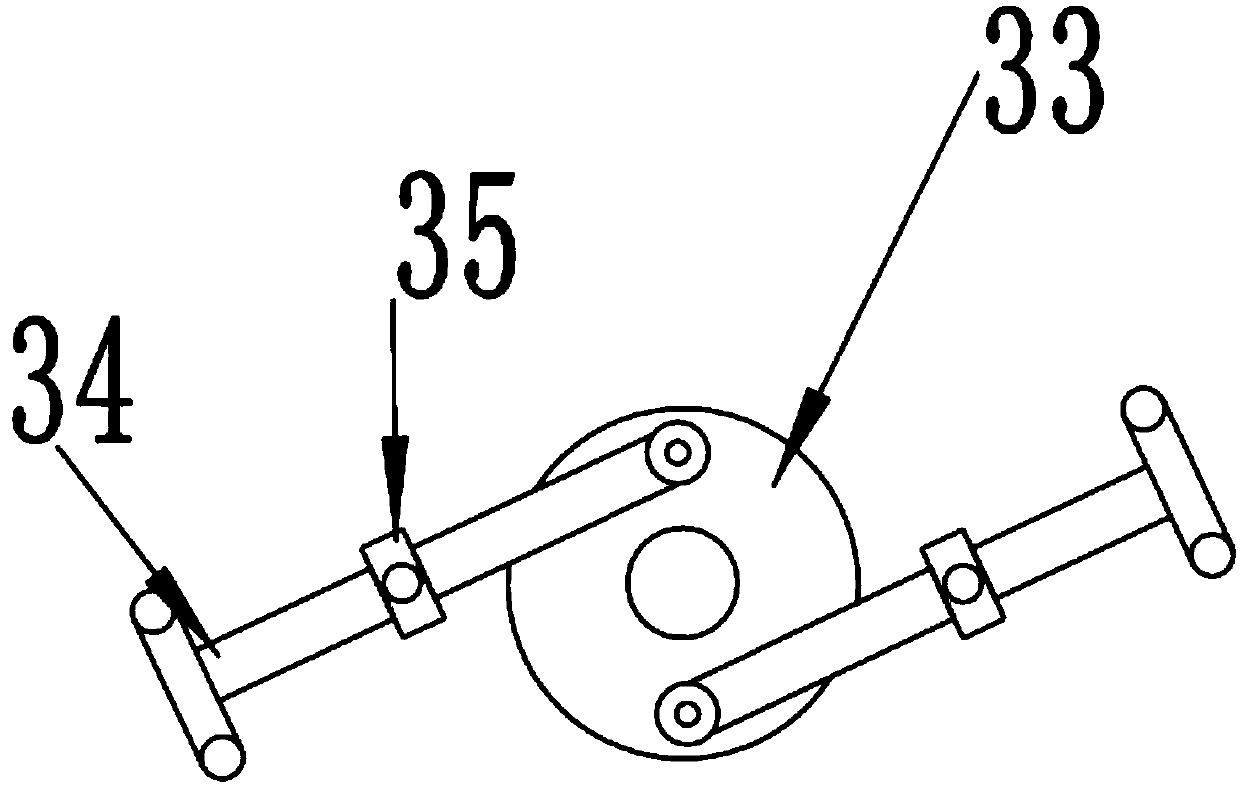

The invention belongs to wine-brewing field, specifically discloses a wine-brewing equipment, which comprises a grains moistening box and a conveyor belt. The grains moistening box includes an inner box and an outer shell, between which an insulation chamber is formed. The insulation chamber is connected with a stream pipe, a turbine is installed at the outlet of the stream pipe, and fan teeth are installed coaxially with the turbine, the fan teeth are meshed with a pushing unit. The inner box is provided with a top-open stirring unit. The outer shell is provided with a stepping ejection unit, which is used for making the top-open mixing unit move towards the direction of inner exit. The stepping ejection unit is connected with the pushing unit. The outer shell is provided with a reset unit, which helps the stepping ejection unit reset. The solution can keep the grains in a comparatively steady environment, shake the grains twice and stir the grains three times during the grains moistening process, which allows all parts of the grains to fully contact with the water to improve the result and efficiency of the grains moistening. In addition, the solution has the function of feeding the raw materials automatically, which dramatically lowers the labor cost.

Owner:遵义市永胜金属设备有限公司

Liquid medicine mixing preparation equipment for medicament department

PendingCN113181807AStir wellRealize the function of automatic feedingRotating receptacle mixersTransportation and packagingProcess engineeringBLENDER/MIXER

The invention relates to mixing preparation equipment, in particular to liquid medicine mixing preparation equipment for a medicament department. The liquid medicine mixing preparation equipment for the medicament department does not need manual operation and improves the working efficiency. The liquid medicine mixing preparation equipment for the medicament department comprises a plurality of racks arranged at the top of a bottom plate, a primary stirring mechanism arranged at the top of the bottom plate, and a secondary stirring mechanism arranged on the primary stirring mechanism. By means of the secondary stirring mechanism, liquid medicine is fully stirred, so that the liquid medicine is mixed; by means of an intermittent discharging mechanism, medical staff do not need to manually control a first spoiler, and the liquid medicine can intermittently flow into a stirring barrel; and by means of an automatic discharging mechanism, the medical staff do not need to manually control a T-shaped pull rod, and an automatic discharging effect is achieved.

Owner:苏翠洁

Molding sand strength detection device

ActiveCN113899627APrevent splashAvoid harmMaterial strength using tensile/compressive forcesCrushed stoneSlide plate

The invention is suitable for the technical field of material detection, and provides a molding sand strength detection device, which comprises a mold pressing assembly arranged on an equipment body, the mold pressing assembly comprises a fixed pressing die fixedly connected with one side of the equipment body and a movable pressing die slidably connected with the other side of the equipment body, a dustproof mechanism is arranged on the movable pressing die, the movable pressing die is slidably connected with a second connecting plate in the left-right direction, and a fourth elastic piece is arranged between the second connecting plate and the movable pressing die. The second connecting plate is fixedly connected with a sliding driving part for driving the second connecting plate to move, and a pressure sensor is arranged between the second connecting plate and the movable pressing die and movably contacts with the movable pressing die. By arranging the dustproof mechanism, the dustproof sliding plate is preferentially in a closed state when the mold pressing assembly is closed, and the problem that broken stones generated when the mold pressing assembly extrudes a molding sand test block are splashed out of the detection device, and consequently workers are injured is solved.

Owner:潍坊市凯隆机械有限公司

Highly safe and reliable refrigeration equipment with purification function

InactiveCN109855216AImprove safety and reliabilityImprove stabilityMechanical apparatusLighting and heating apparatusEngineeringRefrigeration

The invention relates to highly safe and reliable refrigeration equipment with a purification function. The highly safe and reliable refrigeration equipment comprises a main body, a water tank and a base, further comprises a stabilization mechanism and a purification mechanism, wherein the stabilization mechanism comprises a driving assembly, a movable plate and two stabilization assemblies; and each stabilization assembly comprises an air suction barrel, a piston, an air suction rod and a suction disc, the purification mechanism comprises a feeding assembly and a pushing assembly, the feedingassembly comprises a feeding box and a communicating pipe, and a first motor, a rotating disc, a rotating rod, a connecting rod and a blocking block are arranged in the feeding box. The highly safe and reliable refrigeration equipment with the purifying function is provided, the base can be adsorbed on the ground through the suction discs and a stabilization mechanism, the equipment is preventedfrom being knocked down, the damage probability of the equipment is reduced, and the safety of the equipment is improved; and water in the water tank can be purified through the purification mechanism, so that the water can be prevented from being stored in the water tank for a long time, and bacteria are bred.

Owner:刘艳伟

Bowl bottom polishing device for porcelain processing

InactiveCN112428099ASave human effortImprove work efficiencyGrinding carriagesGrinding drivesEngineeringMechanical engineering

The invention relates to a polishing device, in particular to a bowl bottom polishing device for porcelain processing. According to the technical problem to be solved, the bowl bottom polishing devicefor porcelain processing can realize automatic pressing and polishing of bowls. The bowl bottom polishing device for porcelain processing comprises a fixture, a supporting table, a polishing mechanism and a primary pressing mechanism, and the supporting table is connected to the right side of the fixture. The supporting table is connected with the polishing mechanism. The middle part of the fixture is connected with the primary pressing mechanism. Through cooperation of the polishing mechanism and the primary pressing mechanism, the bowl bottom can be automatically polished, manpower is saved, through cooperation of a pushing mechanism, a discharging mechanism and an automatic pressing mechanism, automatic feeding can be achieved, the bowl bottom is automatically conveyed rightwards, andthe effect of automatically pressing and fixing the bowls can be achieved while polishing is conducted; and the working efficiency of people can be improved.

Owner:宁正虎

Full-intelligent executing manipulator for integrated fish pond feeding machine

ActiveCN109699554ARealize the function of automatic feedingHigh degree of intelligenceClimate change adaptationPisciculture and aquariaEngineeringWorkload

Owner:江苏苋活生鲜食品有限公司

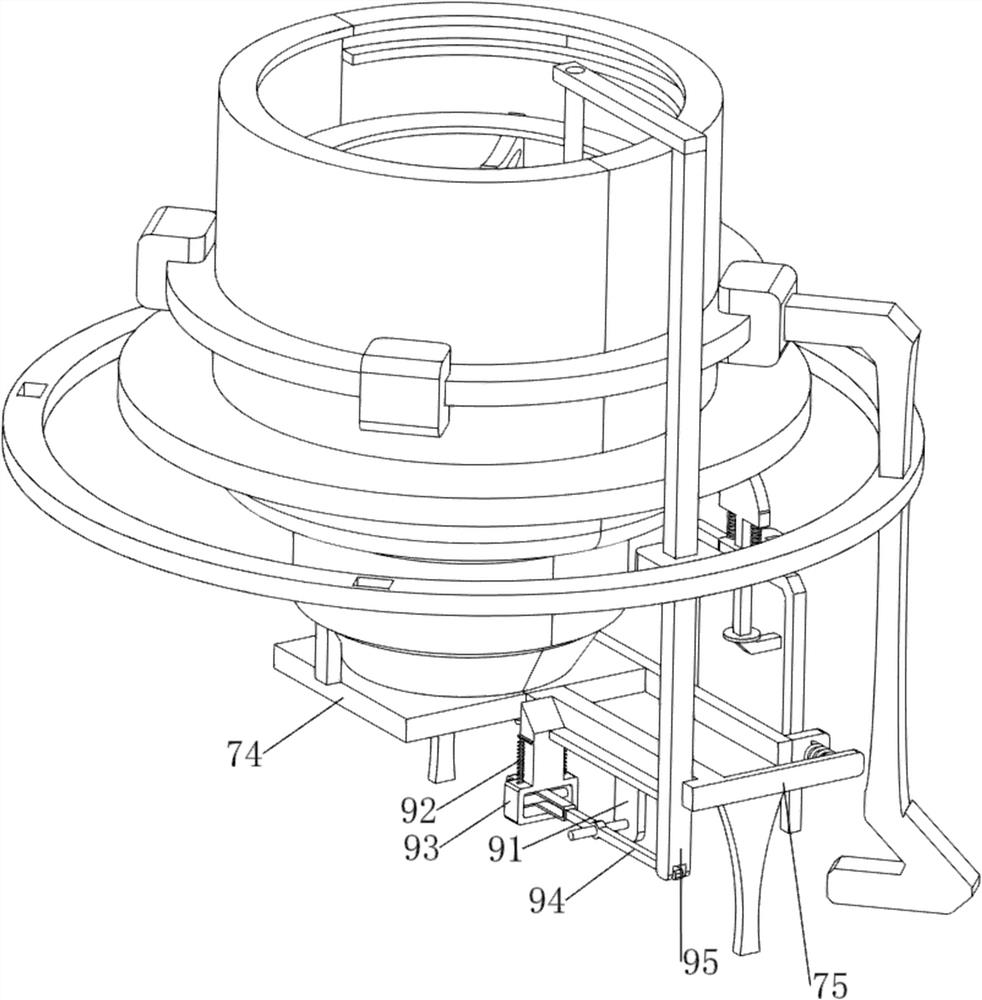

Microbial fermentation deodorization device applied to kitchen waste treatment

PendingCN112552085AEasy dischargeEliminate Pollution PotentialBioreactor/fermenter combinationsBiological substance pretreatmentsEnvironmental engineeringWaste treatment

The invention discloses a microbial fermentation deodorization device applied to kitchen waste treatment, which belongs to the technical field of kitchen waste treatment and comprises a low-speed motor, a fermentation kettle, supporting legs and a deodorization box, the motor is fixedly arranged on the supporting legs through a bracket, the deodorization box is fixedly arranged on the side edges of the supporting legs, and the fermentation kettle is fixedly arranged at the upper ends of the supporting legs, and comprises a feeding mechanism, a fermentation mechanism, a material returning mechanism, a water removal mechanism, a deodorization mechanism and a transmission mechanism, the feeding mechanism is fixedly arranged at the front end of the fermentation mechanism, the fermentation mechanism is rotatably connected to the upper ends of supporting legs through a plurality of rotating wheels, the supporting legs are fixedly arranged on the ground, and the water removal mechanism is fixedly arranged at the front ends of the supporting legs, the deodorization mechanism is fixedly arranged on the two ends of the fermentation kettle, the transmission mechanism is fixedly arranged on the edge of the upper end of the supporting leg, and the problems that an existing kitchen garbage disposal machine can emit foul irritant gas in the kitchen garbage disposal process, discharging is difficult, and feeding and cleaning cannot be continued are solved.

Owner:西安网浪互联网科技有限公司

Grinding treatment device for metal pipeline

InactiveCN112123152ARealize automatic grinding processEasy to grind automaticallyRevolution surface grinding machinesGrinding drivesMetal machiningElectric machinery

The invention discloses a grinding treatment device for a metal pipeline, and belongs to the field of metal processing. The grinding treatment device comprises two vertical guide rails, the two vertical guide rails are fixedly mounted; lifting sliding blocks are mounted on the vertical guide rails; the lifting sliding blocks are slidably connected with the vertical guide rails; lifting sliding plates are fixedly mounted on one sides of the lifting sliding blocks; extending plates are vertically installed at the top ends of the lifting sliding plates; grinding motors are installed at the bottomends of the extending plates; power rollers are installed at the ends, close to the lifting sliding plates, of the extending plates; output ends of the grinding motors penetrate through the extendingplates to be connected with the power rollers; and grinding rollers are installed at the ends, away from the lifting sliding blocks, of the extending plates. According to the grinding treatment device for metal pipeline provided by the invention, the grinding rollers can descend along a threaded rod when rotating, the inner wall of the pipeline can be automatically ground conveniently, and automatic grinding is achieved.

Owner:杨钧元

Vegetable sorting device for cold-chain logistics

InactiveCN112246644AImprove sorting efficiencyRealize the function of automatic feedingHollow article cleaningGradingCold chainLogistics management

The invention discloses a vegetable sorting device for cold-chain logistics, and belongs to the field of vegetable sorting equipment. The vegetable sorting device comprises a material distribution box; the material distribution box is fixedly mounted; opening and closing plates are arranged on the two sides of the material distribution box; fixed hinge blocks are mounted on the portions, at the top ends of the opening and closing plates, of the material distribution box; a fixing nut matched with a screw rod is arranged at the bottom end of a supporting frame; the screw rod is inserted into the inner side of the fixing nut in a penetrating mode; a wrench is installed at one end of the screw rod; a ball head is arranged at the other end of the screw rod and attached to the outer side face of each opening and closing plate; a lifting frame is installed on the inner side of the material distribution box; a bearing is installed at the bottom end of the lifting frame; an outer ring of the bearing is fixedly connected with the lifting frame; a torsion rod is installed in an inner ring of the bearing; a connecting piece is installed at the top end of the torsion rod; a material lifting plate is arranged at the top end of the connecting piece; and inclined panels are arranged on the two sides of the material lifting plate. The vegetable sorting device is high in vegetable sorting efficiency.

Owner:昌嘉控股集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com