Grinding treatment device for metal pipeline

A technology for processing devices and metal pipes, which is applied in the direction of grinding drive devices, metal processing equipment, grinding machines, etc., can solve the problems of corrosion of metal blocks and the inability to realize automatic grinding, etc., and achieve the effect of facilitating automatic grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

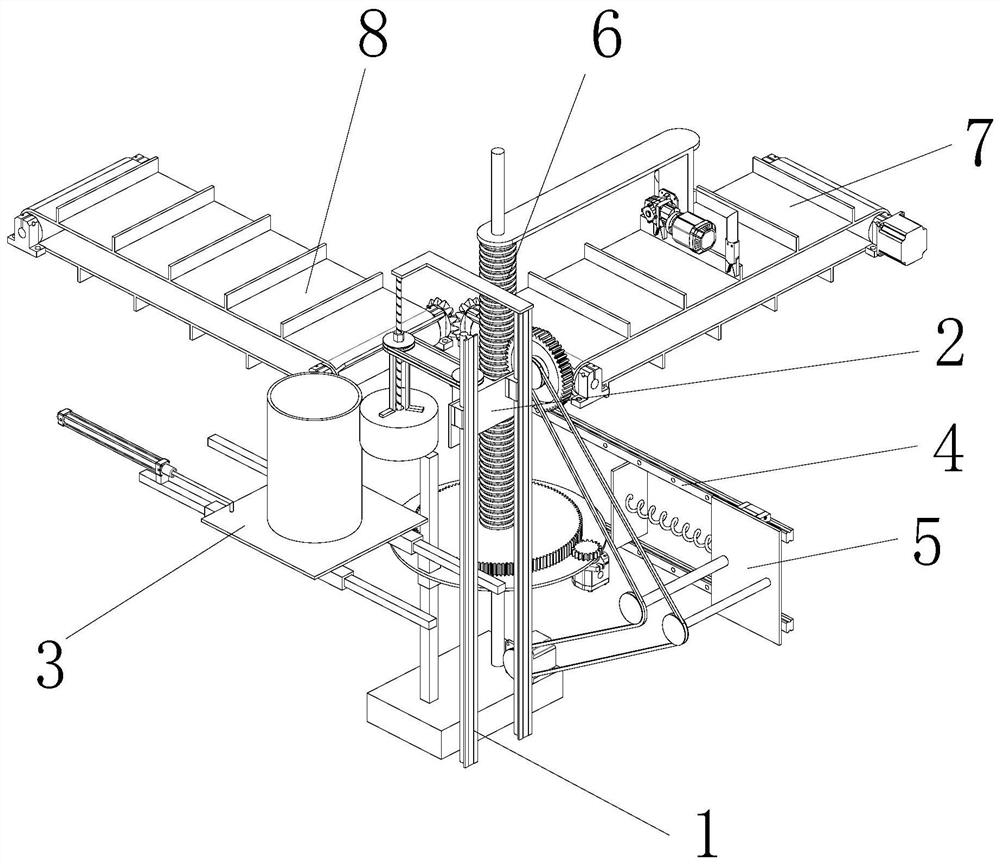

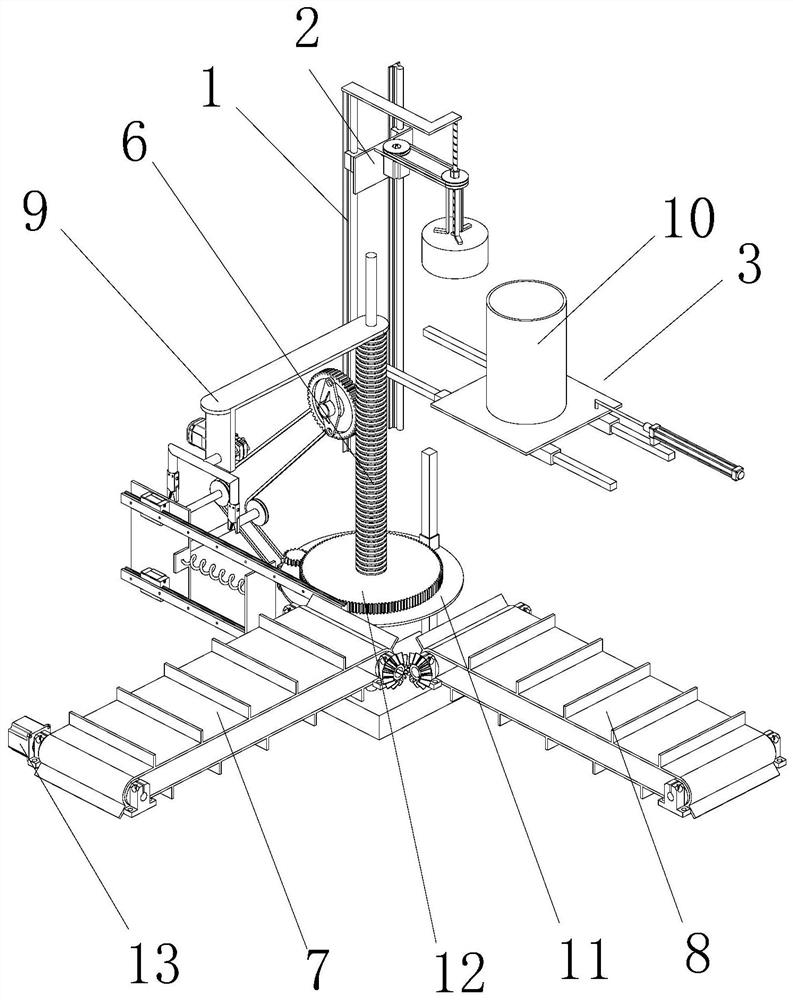

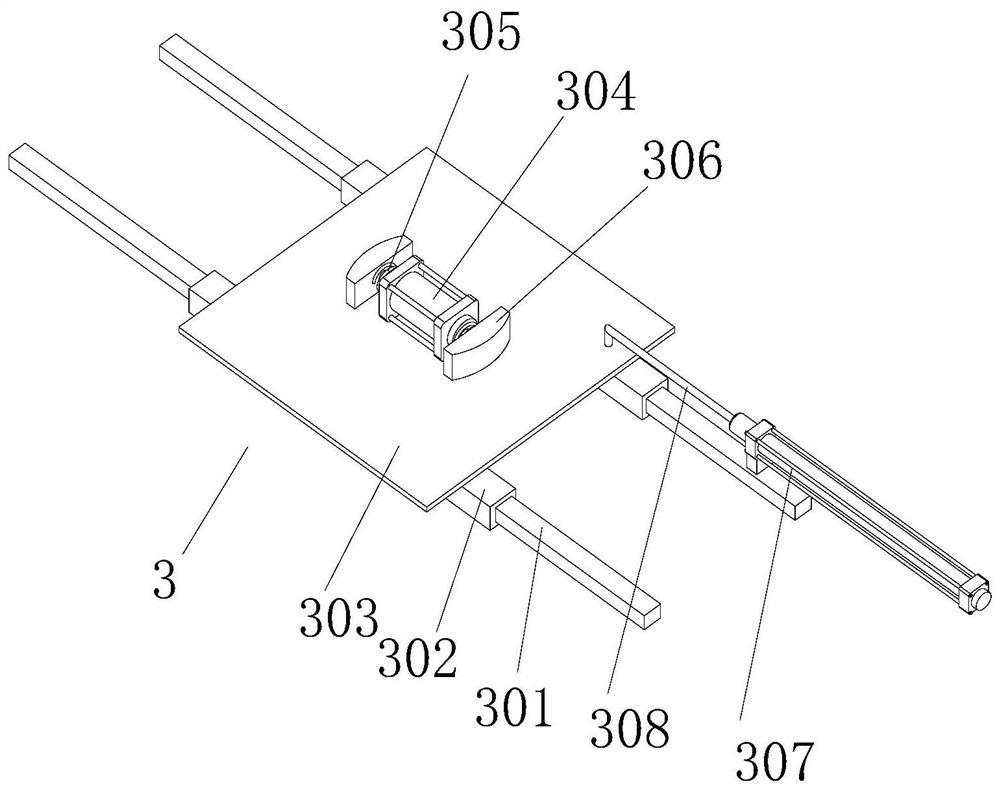

[0026] refer to Figures 1 to 8 The shown grinding treatment device for metal pipes includes vertical guide rails 1, two vertical guide rails 1 are provided in total, and the vertical guide rails 1 are fixedly installed, and each vertical guide rail 1 is equipped with a lifting slider 101, the lifting slider 101 is slidably connected to the vertical guide rail 1, and one side of the two lifting sliders 101 is jointly fixed with a lifting slide 2, and an extension plate 201 is vertically installed on the top of the lifting slide 2, and the extension plate 201 The bottom end is equipped with a grinding motor 202, and the end of the extension plate 201 adjacent to the lifting slide is equipped with a power roller 203, and the output end of the grinding motor 202 is connected through the extension plate 201 and the power roller 203, and the extension plate 201 is far away from the lifting slider 101 A grinding roller 205 is installed at one end of the grinding roller 205, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com