Preliminary outer surface layer grinding treatment equipment for lens processing

A technology for lens processing and processing equipment, applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve problems such as damage to the lens, the water temperature cannot reach a constant temperature, and the quality of the lens is reduced, and achieves the effect of improving the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

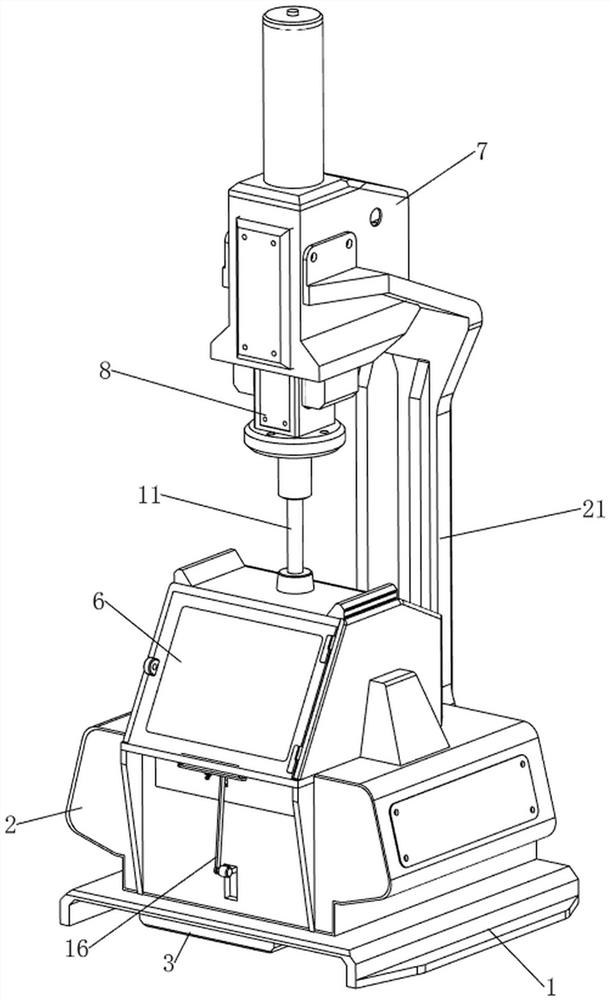

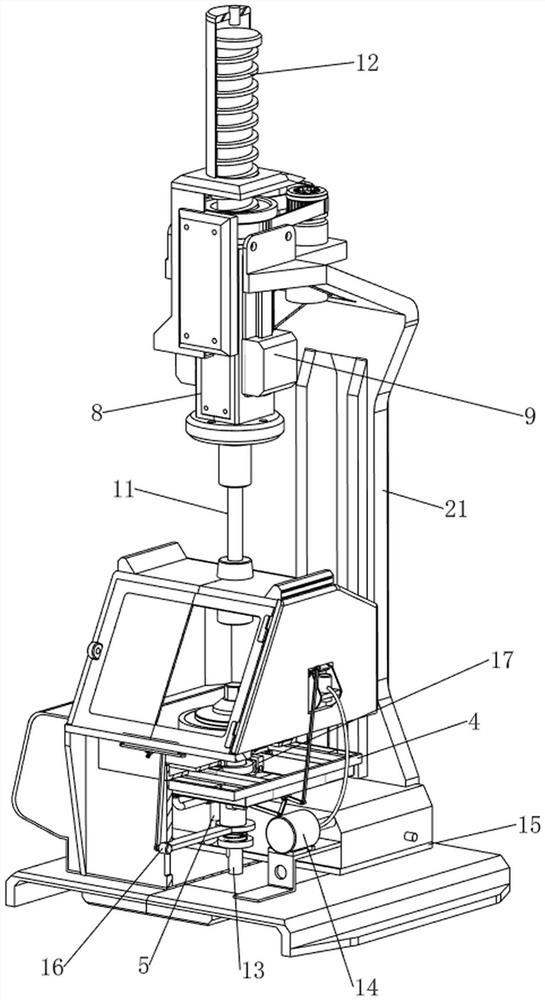

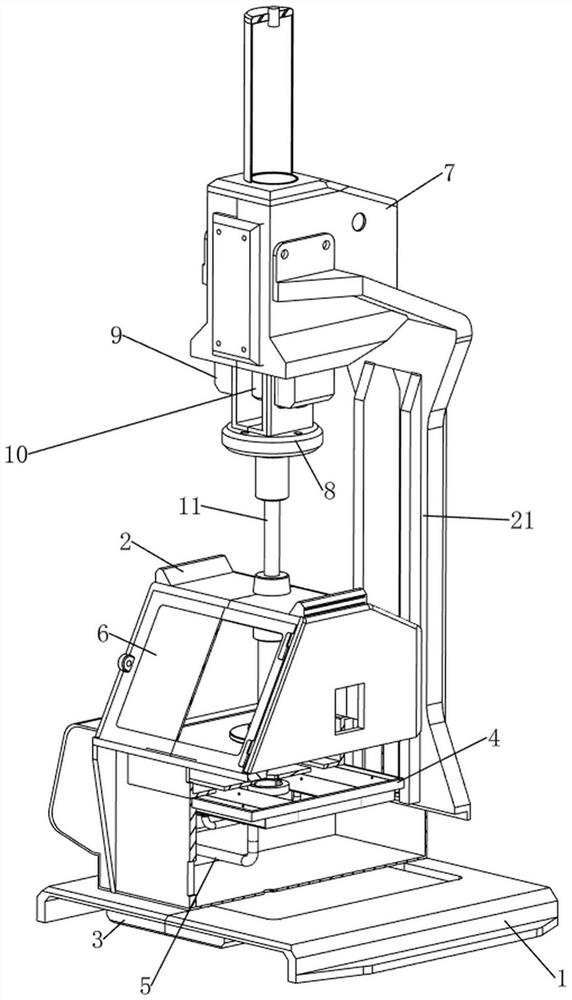

[0041] A kind of preliminary outer layer grinding treatment equipment for lens processing, such as Figure 1-13 As shown, it includes a base 1, a first shell 2, a first bracket 21, a fixed plate 4, a water pipe 5, a cover plate 6, a second shell 7, a sliding frame 8, a first slide rail 9, a driving motor 10, and a rotating shaft 11 , grinding mechanism 12, bearing mechanism 13, flushing mechanism 14 and constant temperature mechanism 15, the first casing 2 is arranged in the middle of the top of the base 1, the inside of the first casing 2 is provided with strip grooves on the front and rear sides, and on the front of the first casing 2 The side sliding type is connected with a cover plate 6, and the cover plate 6 is made of glass, which is convenient for people to observe the process of lens polishing. The rear side of the top of the base 1 is welded with a first bracket 21, and the upper part of the first bracket 21 is welded with a second shell 7. The left and right sides o...

Embodiment 2

[0048] On the basis of Example 1, such as figure 1 , figure 2 , Figure 14 , Figure 15 , Figure 16 and Figure 17 As shown, a clamping mechanism 16 is also included for clamping the cover plate 6. The clamping mechanism 16 includes a third connecting rod 161, a fourth connecting rod 162, a second rotating rod 163, and a fifth connecting rod 164. and the clamping block 165, the clamping block 165 is slidably connected in the middle of the front side of the first shell 2, and the clamping block 165 is used for clamping and limiting the cover plate 6, and the bottom of the clamping block 165 is connected with the fifth connecting rod 164 in a rotatable manner. The middle of the lower side of the front part of the housing 2 is rotationally connected with a second rotating rod 163, and the front side of the second rotating rod 163 is rotationally connected with the fifth connecting rod 164. A fourth connecting rod 162 is rotatably connected between the front side of the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com