Wood veneer flaw visual identification and automatic polishing workstation

A visual recognition and workstation technology, applied in the direction of grinding workpiece supports, machine tools suitable for grinding workpiece planes, grinding machines, etc., can solve the problems of wood dust human health hazards, poor working environment, high labor intensity, etc. Strength, easy operation, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

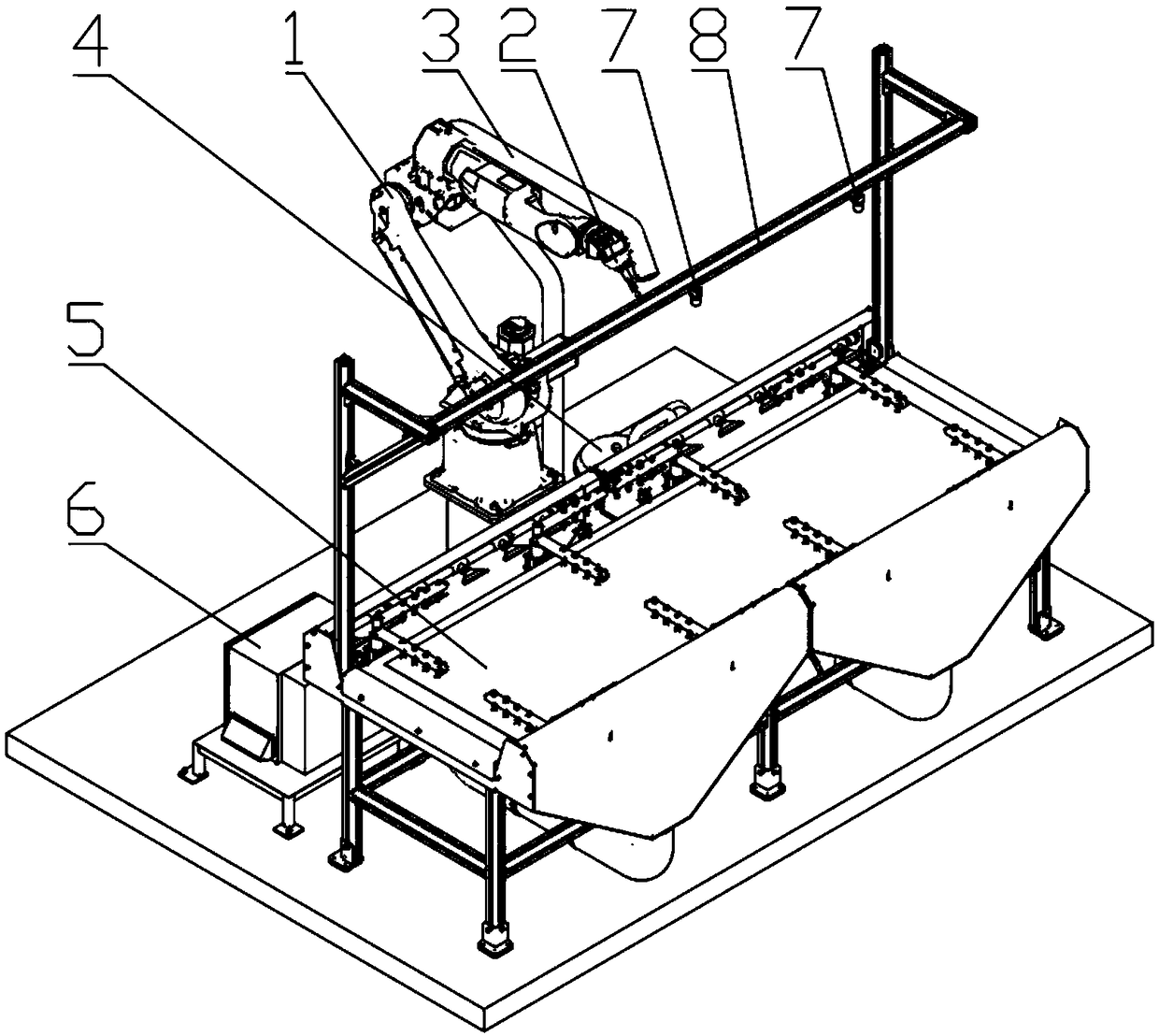

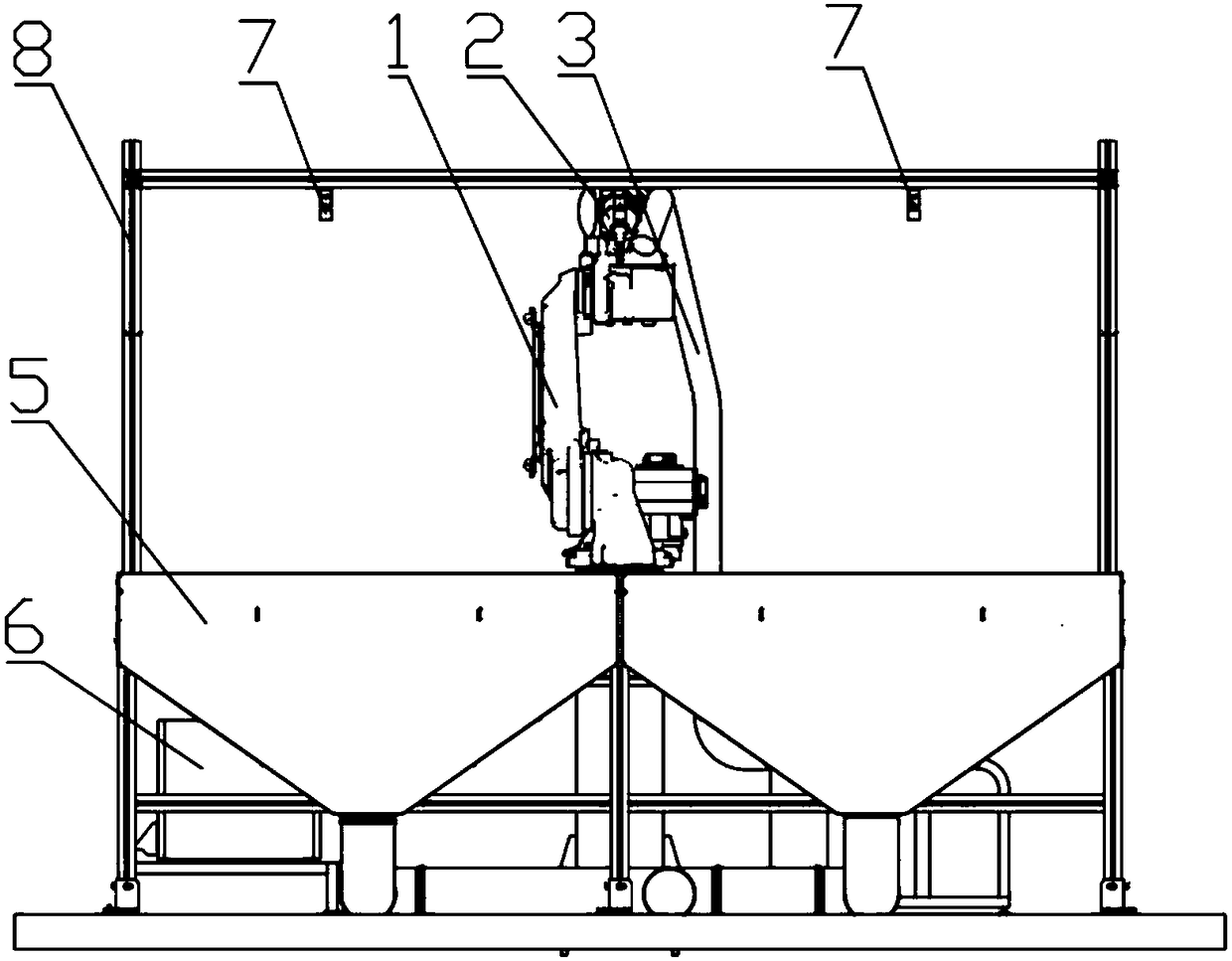

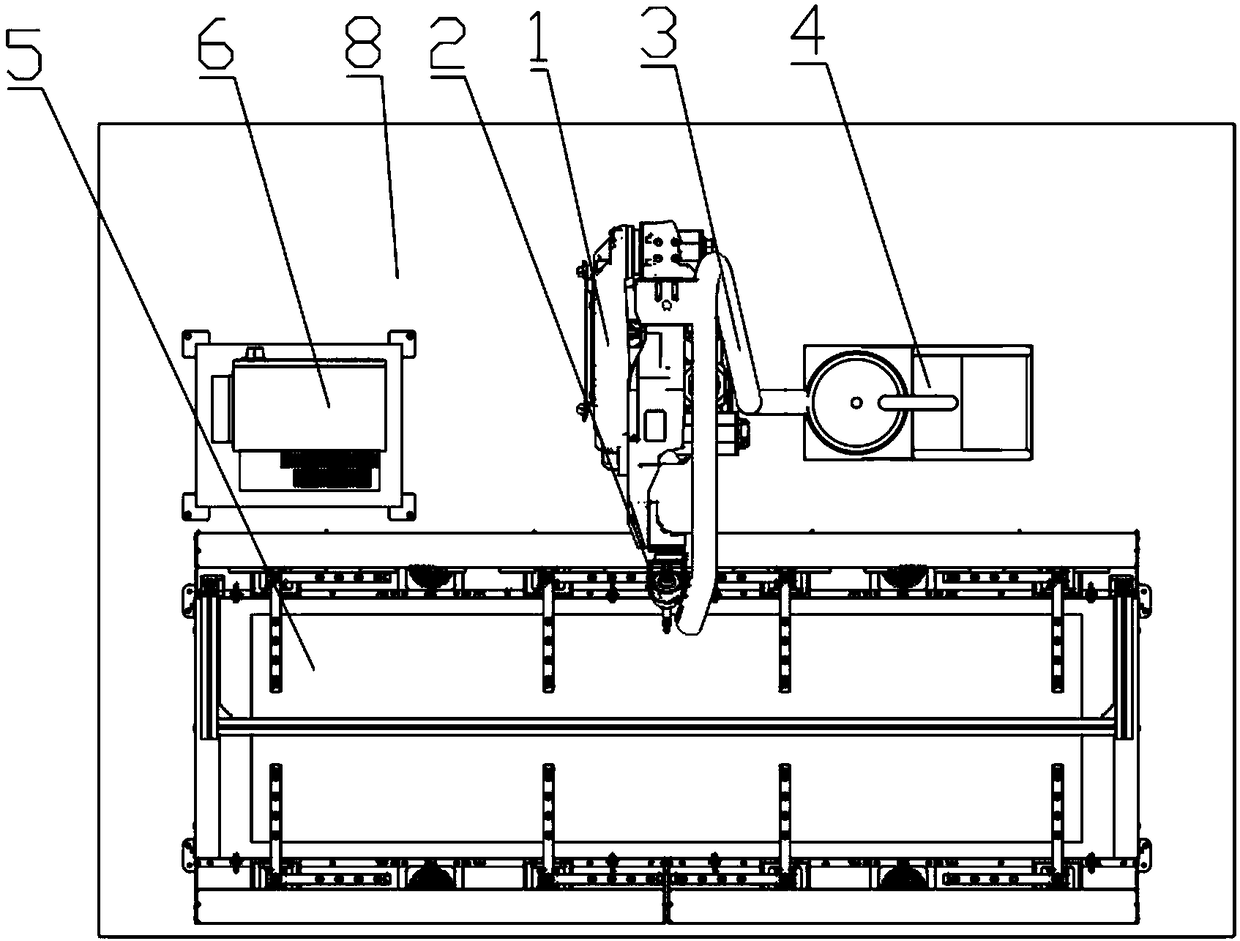

[0036] Such as Figure 1-Figure 4 As shown, a workstation for visual recognition and automatic polishing of veneer defects includes a control cabinet 6, a frame 9 and a manipulator 1 arranged on one side of the frame 9. The middle part of the frame 9 is fixedly provided with a polishing table 5 arranged along the horizontal direction. A dust removal shield 10 is fixedly arranged on the frame 9 on the front and rear sides of the 5, such as Figure 5-Figure 8 As shown, the front and rear sides of the grinding table 5 are also provided with a clamping device 15 for compressing the material on the grinding table 5 and an air blowing device 14 for blowing air to the grinding table 5, and the top of the grinding table 5 is provided with A plurality of visual cameras 7 arranged successively along the left and right directions, the visual cameras 7 are all fixedly installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com