Fixing device for grinding inner hole of gear

A fixing device and inner hole technology, applied in machine tools, grinding machines, grinding workpiece supports, etc. designed for grinding the rotating surface of workpieces, can solve the problems of inability to complete processing, easy generation of waste products, processing errors, etc., and reduce labor intensity. , improve work efficiency, improve the effect of safety

Active Publication Date: 2018-06-22

CHONGQING SHUNHUAI MACHINERY MFG CO LTD

View PDF5 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When clamping, the pressure plate and the base are fixed with bolts, and the distance between the pressure plate and the base is fixed. However, during the casting process of the gear, it is always inevitable that machining errors will occur, making the height of the gear high or low, resulting in The height of the gear is not fixed

If the gear is high, the gear cannot smoothly enter the working cavity between the pressure plate and the base, and the processing cannot be completed

If the height of the gear is low, there will be a gap between the gear and the tooling, which will affect the normal processing of the gear and easily produce waste products

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

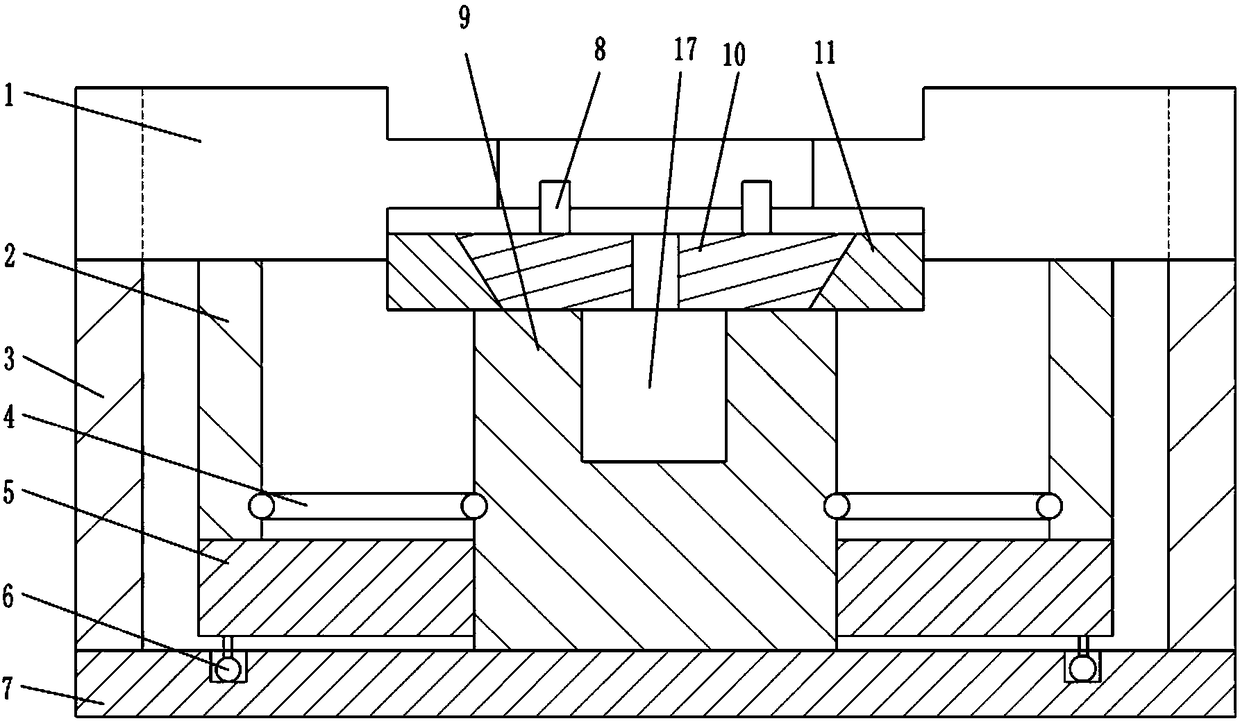

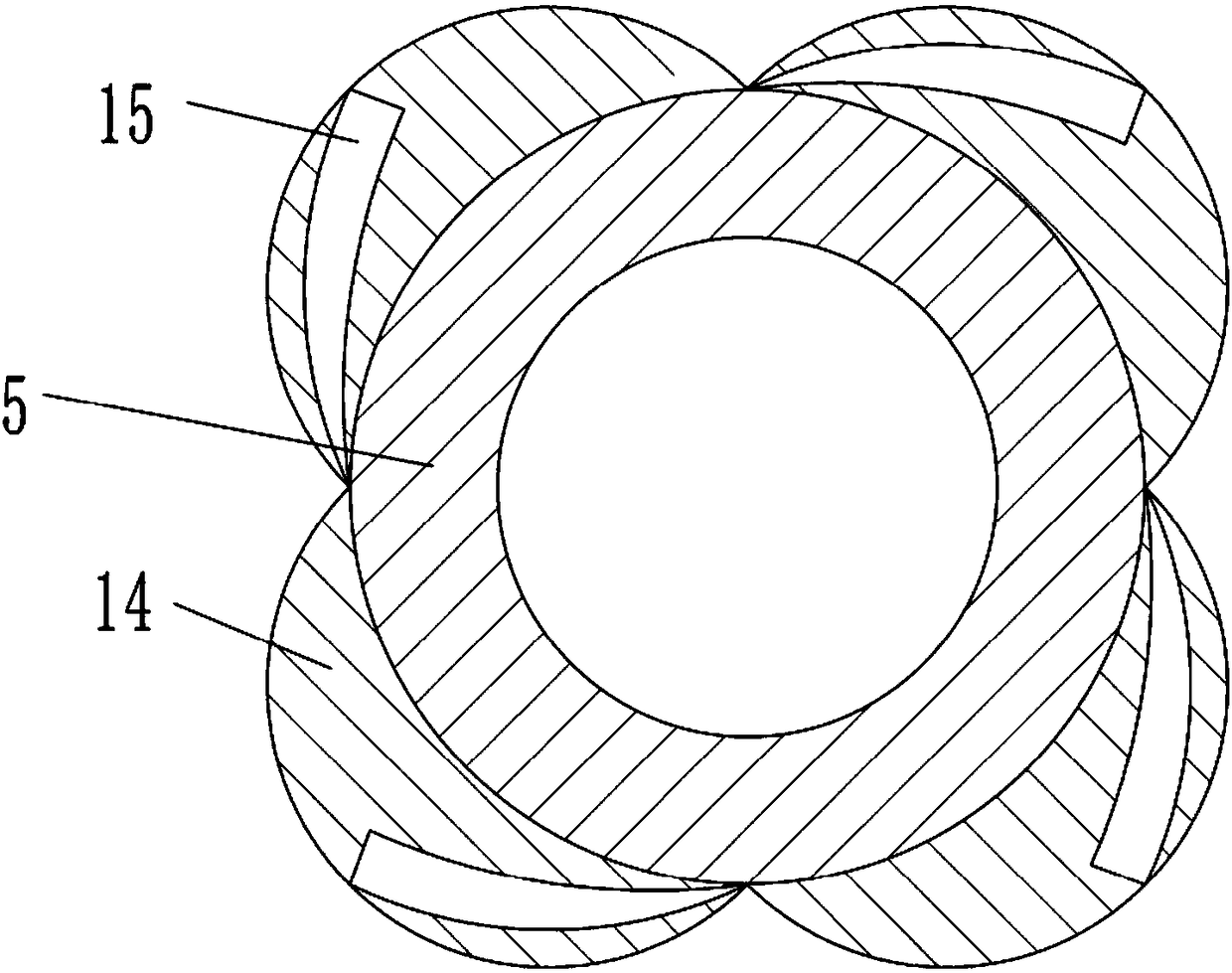

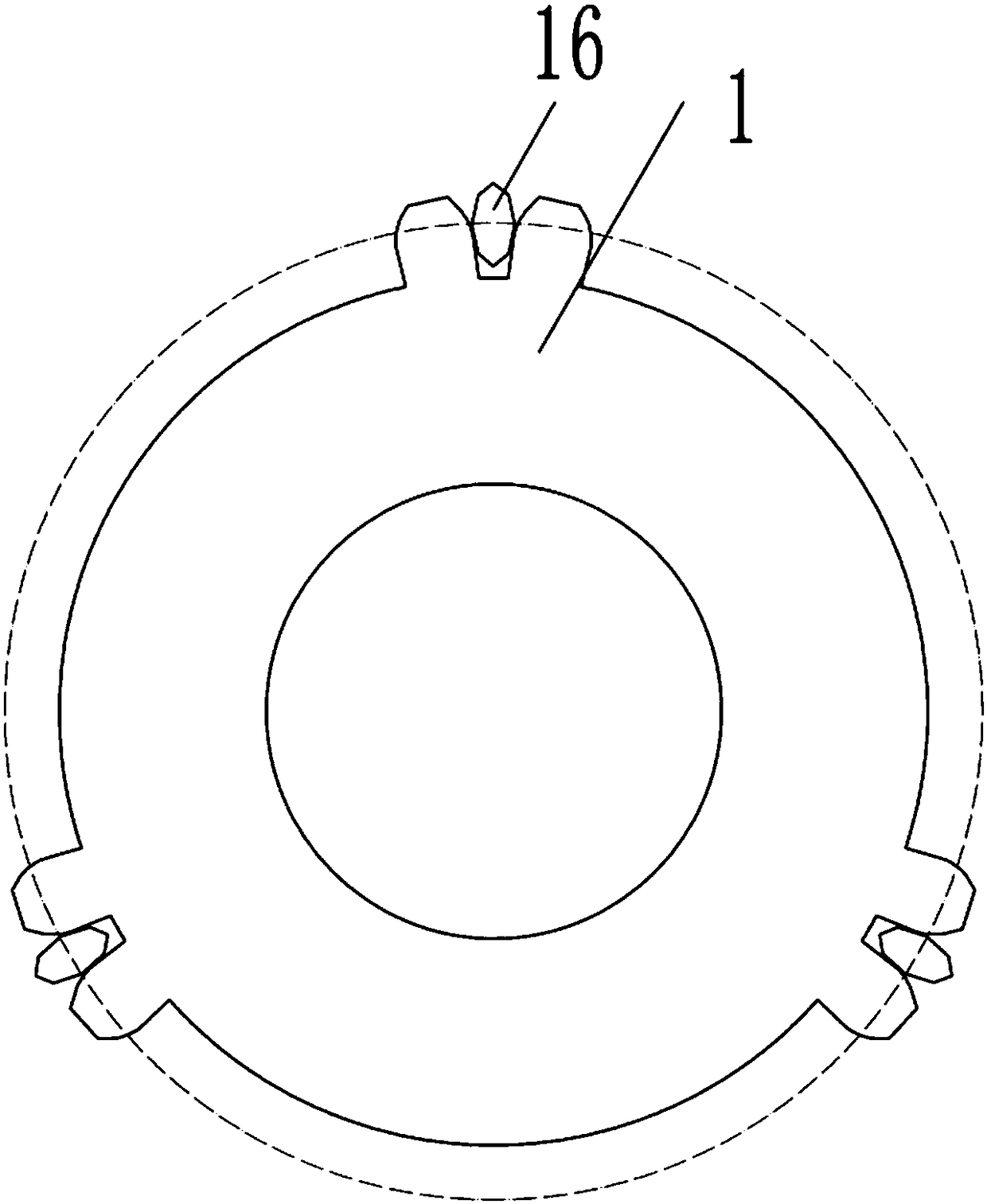

The invention belongs to the technical field of gear machining equipment, and particularly discloses a fixing device for grinding an inner hole of a gear. The fixing device comprises a round base, andeccentric locking cams are evenly distributed in the circumferential direction of the base. An annular round disc and a supporting column are arranged on the base, the annular round disc is rotatablyconnected to the base, arc-shaped sliding grooves are formed in the annular round disc, movable rods are slidably connected to the interiors of the arc-shaped sliding grooves, telescopic rods are connected to the lower portions of the movable rods, and the telescopic rods are fixedly connected to the supporting column. A motor is arranged in the supporting column, an output shaft of the motor islocated on the upper end face of the supporting column, four fan-shaped fixing blocks are slidably connected to the upper end face of the supporting column, and the inner rings of the fan-shaped fixing blocks are in wedge shapes. A gear disc with a planetary gear structure internally arranged are arranged on the fan-shaped fixing blocks in an erected mode, and positioning blocks are arranged on planetary gears. The side face of the gear disc is a wedge-shaped face capable of being matched with the inner rings of the wedge-shaped blocks of the fan-shaped fixing blocks. According to the scheme,the fixing device can achieve fixing of the gear when the inner hole of the gear is ground.

Description

technical field [0001] The invention belongs to the technical field of gear processing equipment, and in particular relates to a fixing device for grinding gear inner holes. Background technique [0002] A gear is a mechanical element with teeth on the rim that can continuously mesh to transmit motion and power. Gears are widely used in various modern machine transmissions. Its transmission is relatively accurate, high in efficiency, compact in structure, reliable in operation and long in life. During the processing of gears, all indicators must have high precision. Gear tooth profile processing is generally completed by milling, hobbing or shaping. For the finishing of the inner hole of the gear, a honing machine is used. [0003] When honing the inner hole of the gear, it is necessary to fix the gear with a honing tool. The previous gear honing tooling includes pressure plate, base and bolts. When clamping, the pressure plate and the base are fixed with bolts, and the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B24B41/06B24B5/48B24B27/00

CPCB24B5/48B24B27/0076B24B41/06

Inventor 刘险峰

Owner CHONGQING SHUNHUAI MACHINERY MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com