Locking and separating structure for front face plate of drawer

A front panel and lock-away technology, applied in drawers, applications, home appliances, etc., can solve the problems of inconvenient daily use of drawer panels, inconvenient use by users, and unsatisfactory users, and reduce assembly steps. And the effect of manufacturing tolerance, quick disassembly and assembly, great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

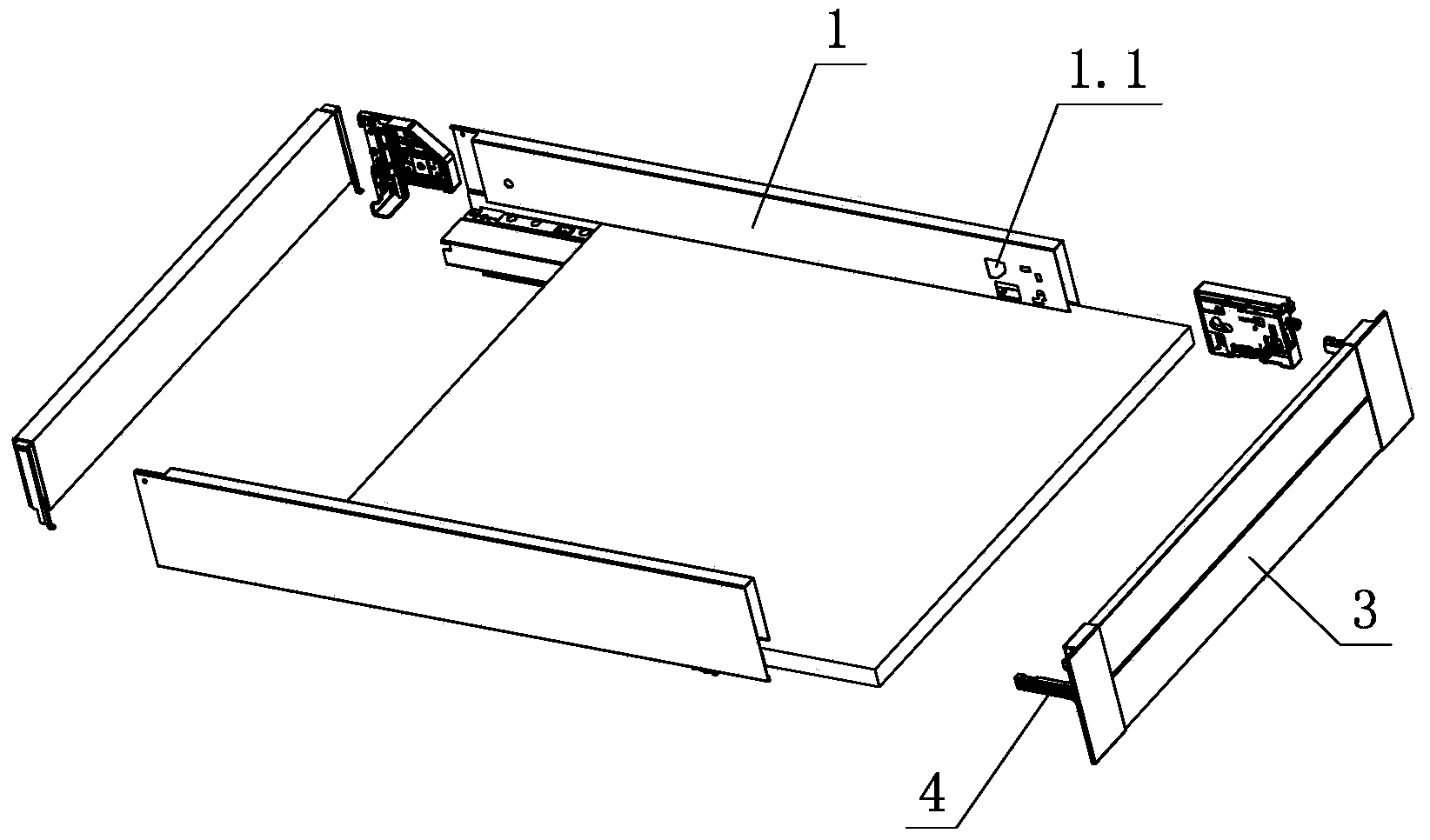

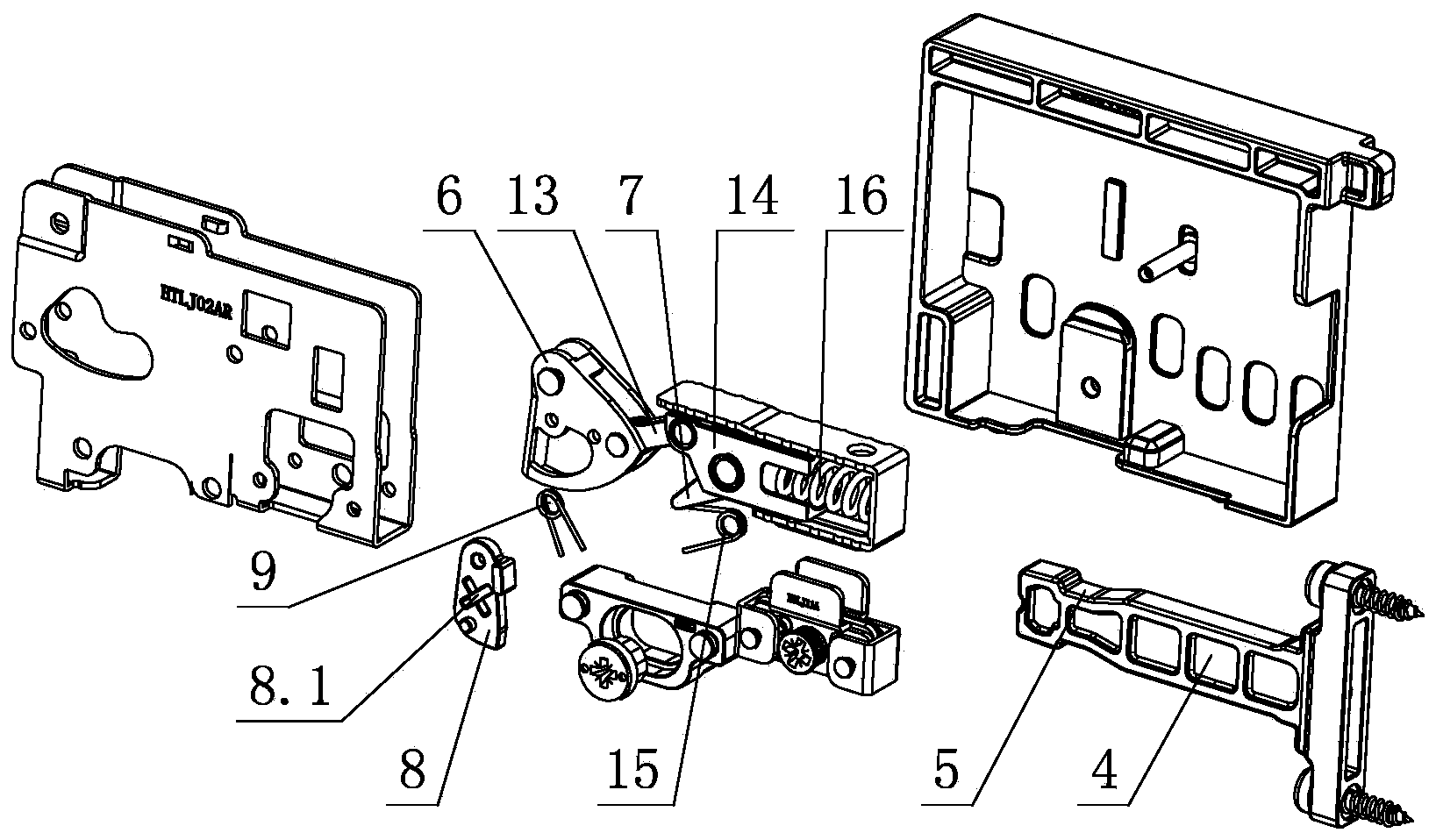

[0027] see Figure 1-Figure 8, which is used for the lock-off structure of the front panel of the drawer, including a fixing device arranged on the side panel 1, the front panel 3 is connected with the fixing device through a connecting element 4, and a set of locking and separating connections is provided on the fixing device The lock-off device of the element 4, the lock-off device includes a separation element 6, a finger-shaped element 7 and a holding element 8; wherein, when the connecting element 4 is installed, it is interlocked with the finger-shaped element 7 with force to realize automatic locking; When the connecting element 4 is disassembled, the tool 11 acts on the retaining element 8 with force, and drives the retaining element 8 to move, and then acts on the separating element 6 through the tool 11, and / or acts on the separating element 6 through the retaining element 8, finger-shaped The element 7 is separated from each other by the separation element 6 and the...

no. 2 example

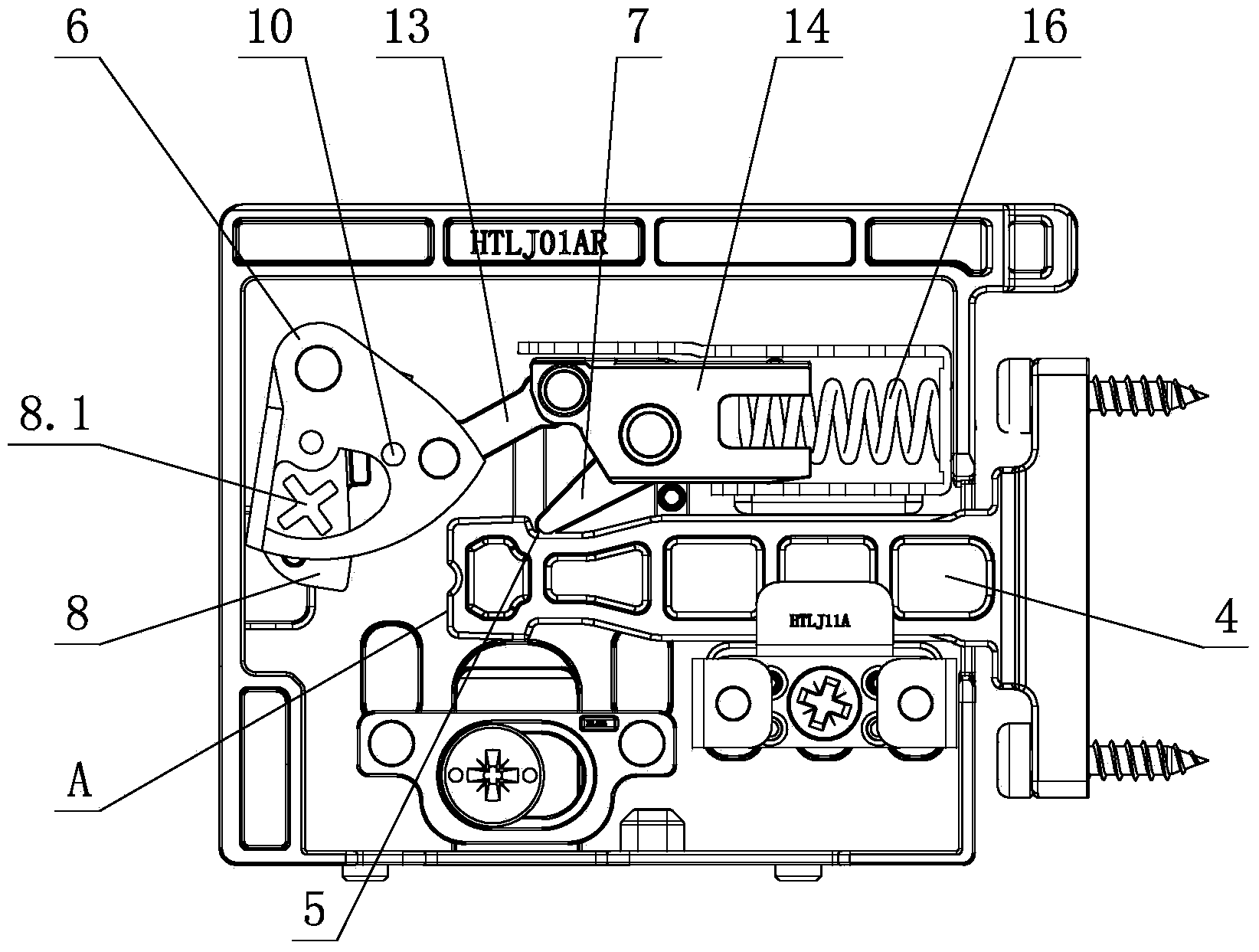

[0043] see Figure 9 , which is used for the lock-off structure of the front panel of the drawer, the separation element 6 is arranged on the fixing device through the swing of the pin shaft, and the holding element 8 is arranged on the separation element 6 through the swing of the pin shaft; the second elastic member 9 is a spring, and the spring is preferably It is a torsion spring, and one end acts on the holding element 8, and the other end acts on the separation element 6; the holding element 8 is driven to swing from the initial position by the tool 11 acting on the holding action part 8.1, and then acts on the separation element 6, And drive the separation element 6 to swing, the finger element 7 is engaged with and / or disengaged from the locking part 5 of the connection element 4 through the swing of the separation element 6, so as to realize the locking and / or separation of the locking device and the connection element 4.

[0044] Others are not described with the fir...

no. 3 example

[0046] see Figure 10 , Figure 11 , which is used for the lock-off structure of the front panel of the drawer. The separation element 6 is oscillated on the fixing device through a pin shaft, and the holding element 8 is a cam, which is rotated and positioned on the separation element 6; the second elastic member 9 is a spring, and the spring It is preferably a torsion spring, and one end acts on the holding element 8, and the other end acts on the separation element 6; the tool 11 acts on the holding part 8.1 and drives the holding element 8 to rotate from the initial position, and the holding element 8 rotates during the rotation process. , the transmission part 10 acts on the separation element 6, and drives the separation element 6 to swing, and the finger element 7 engages and / or disengages with the locking part 5 of the connection element 4 through the swing of the separation element 6, realizing the lock-out device and the connection Locking and / or disengagement of el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com