Energy-saving and environment-friendly smelting furnace

An energy-saving, environmentally friendly, melting furnace technology, applied in furnaces, furnace components, stirring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

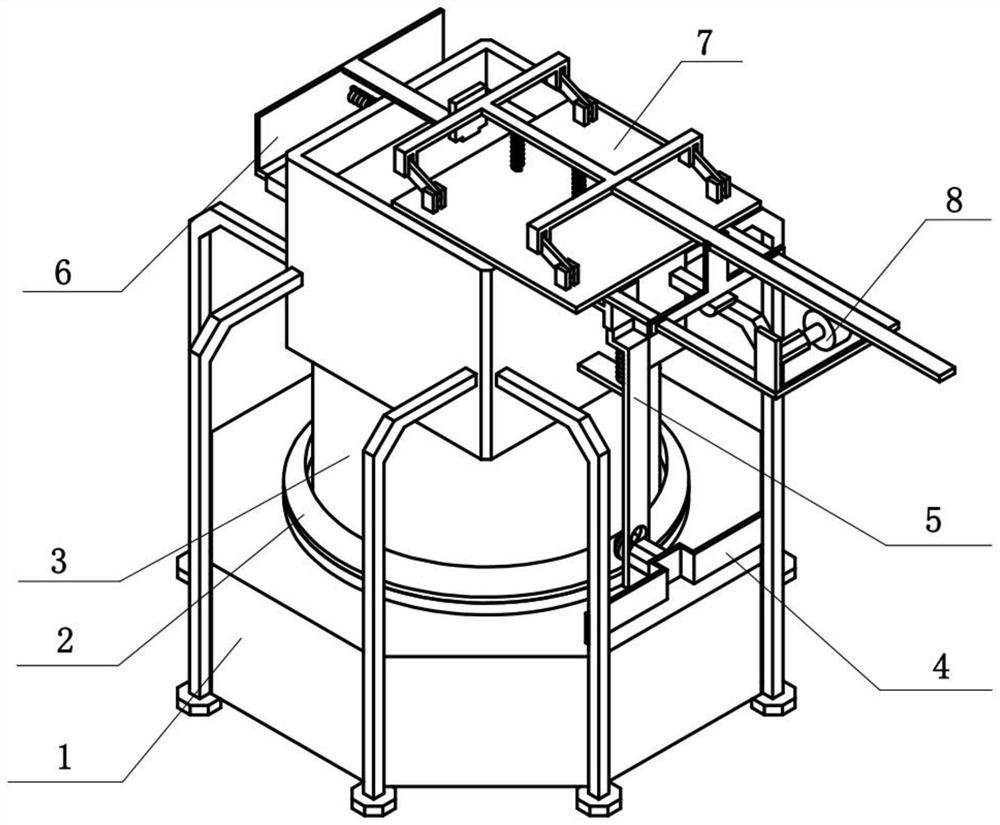

[0032] Combine below Figure 1-9 Describe this embodiment, an energy-saving and environment-friendly smelting furnace, including a supporting heating assembly 1, a material rotating and raising assembly 2, a stirring assembly 3, a driving assembly 4, an opening and closing assembly 5, a feeding assembly 6, a capping assembly 7 and a starting assembly 8 , the material rotating rising assembly 2 is rotatably connected to the supporting heating assembly 1, the stirring assembly 3 is fixedly connected to the material rotating rising assembly 2, the driving assembly 4 is fixedly connected to the right side of the supporting heating assembly 1, and the driving assembly 4 and the material rotating The lifting component 2 engages the transmission, the opening and closing component 5 is fixedly connected to the right side of the supporting heating component 1, the feeding component 6 is slidably connected to the left end of the upper part of the supporting heating component 1, and the c...

specific Embodiment approach 2

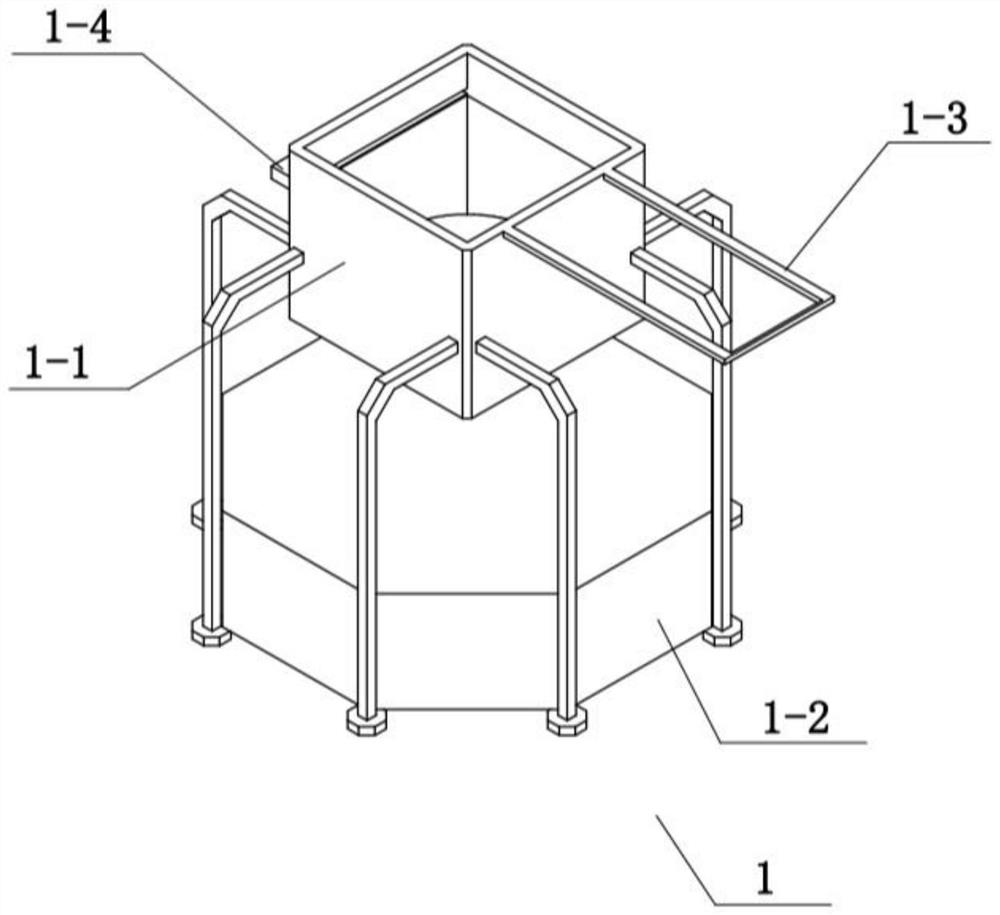

[0035] Combine below Figure 1-9 To illustrate this embodiment, the support heating assembly 1 includes an upper material box 1-1, a heater 1-2, a sliding rod 1-3 and a sliding frame 1-4, and the heater 1-2 is fixedly connected to the upper material box 1-2. 1, the sliding rod 1-3 is fixedly connected to the right side of the upper material box 1-1, and the sliding frame 1-4 is fixedly connected to the left side of the upper material box 1-1.

specific Embodiment approach 3

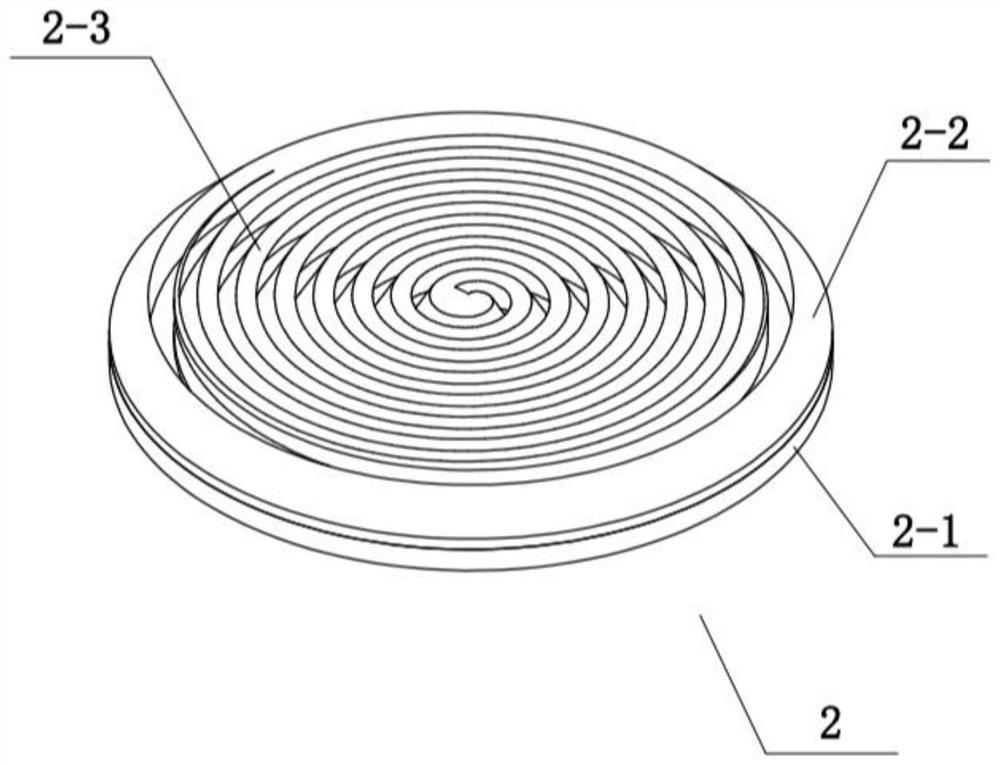

[0037]Combine below Figure 1-9 To illustrate this embodiment, the material rotating and rising assembly 2 includes a rotating disk 2-1, a rotating bevel tooth 2-2 and an inclined turbine plate 2-3, the rotating disk 2-1 is rotatably connected to the heater 1-2, and the rotating cone The teeth 2-2 are fixedly connected on the rotating disc 2-1, and the inclined turbine plate 2-3 is fixedly connected on the rotating disc 2-1.

[0038] The driving assembly 4 meshes to drive the rotating bevel gear 2-2 to rotate, and the rotating bevel gear 2-2 drives the rotating disc 2-1 to rotate, and the rotating disc 2-1 drives the inclined turbine plate 2-3 to rotate, and the inclined turbine plate 2-3 has a turbine shape It will make the melted material rotate and move centrifugally along the turbine groove, and the inclination angle of the turbine plate 2-3 will give the melted material an upward force, so that the melted material can be mixed up and down, which is more conducive to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com