Pipe fitting weld joint polishing equipment

A technology of equipment and pipe fittings, which is applied in the field of pipe fitting weld grinding equipment, can solve the problems of low grinding precision, position changes of grinding parts, and simultaneous grinding of convex and concave parts that cannot be welded, so as to achieve high grinding precision and avoid positioning deviation , a wide range of grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

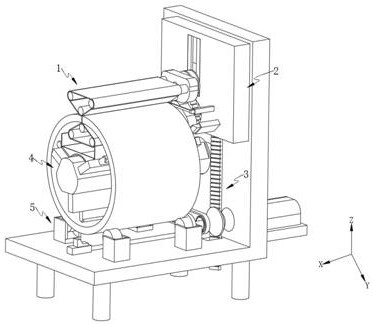

[0075] Such as Figure 1-2 Shown, a pipe fitting weld seam grinding equipment, including:

[0076] Grinding assembly 1, the grinding assembly 1 is distributed on the inner and outer ends of the grinding piece;

[0077] A detection unit 2, the detection unit 2 is arranged at the fixed end of the grinding assembly 1;

[0078] A fixing unit 4, the fixing unit 4 is arranged on the side of the detection unit 2;

[0079] After the grinding piece finds the position of the weld seam by the detection unit 2 during the rotation process, the position of the grinding piece is locked by the fixing unit 4, and a smooth grinding surface inside and outside is formed under the mode of grinding while the grinding assembly 1 is swinging.

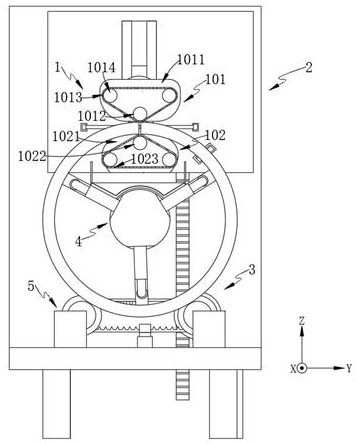

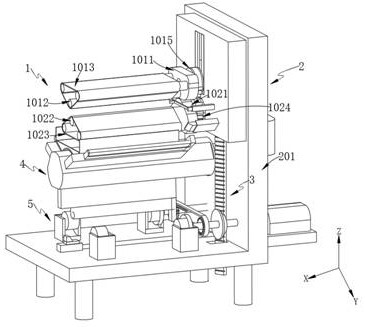

[0080] As an improvement, such as Figure 2-6 As shown, the grinding assembly 1 includes:

[0081] The first grinding roller 101;

[0082] The second grinding roller 102 is arranged at the lower part of the first grinding roller 101 .

[0083] Further, t...

Embodiment 2

[0139] Such as Figure 8 , Figure 11-12 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0140] By setting the air outlet 407 on the side of the inflation pipeline 402, after the grinding is finished, the driving motor 3011 drives the rack 2044 to move upward through the rotating roller 3012, and the rack 2044 drives the sleeve block 2042 to drive the lifting rod 2041 to move upward through the adjustment rod 2043. At this time, the first control valve 403 closes the inflation pipe 402, and at the same time the second control valve 404 opens the air outlet 407, so that the gas inside the gas storage tank 4061 and the limit assembly 501 flows back and is ejected at the air outlet 407, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com