Patents

Literature

36results about How to "Wide range of grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

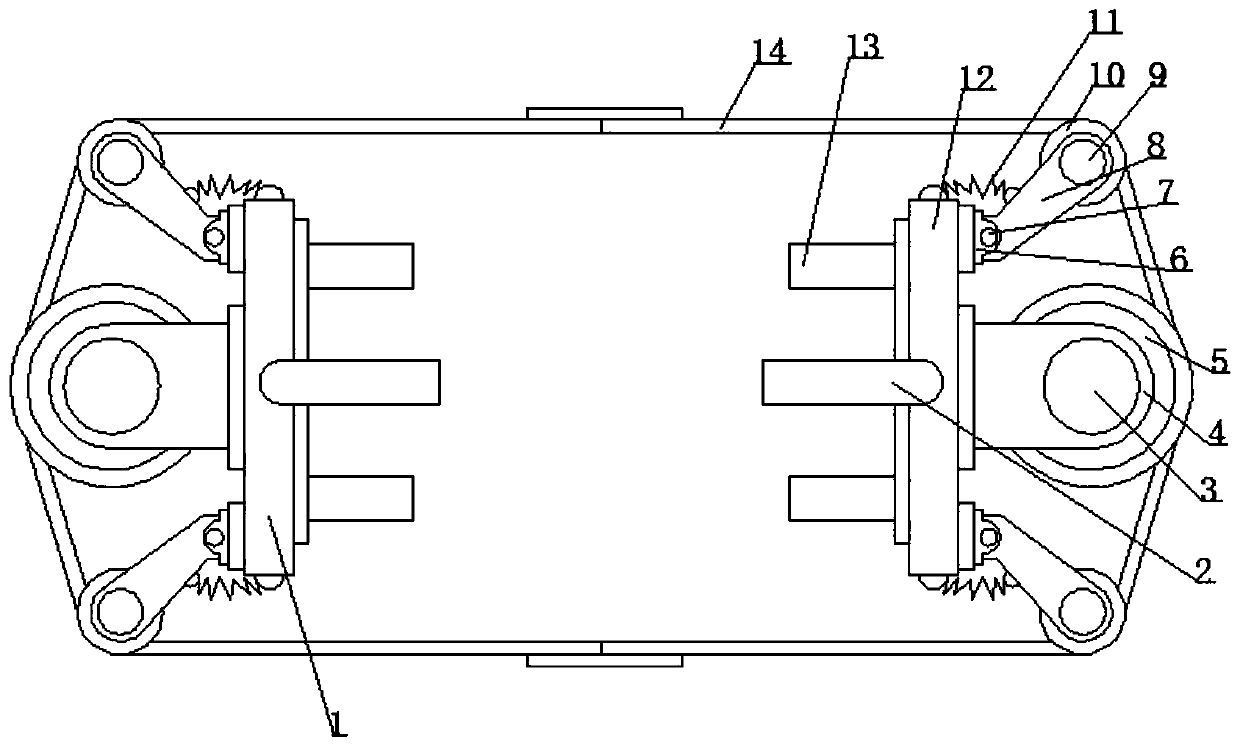

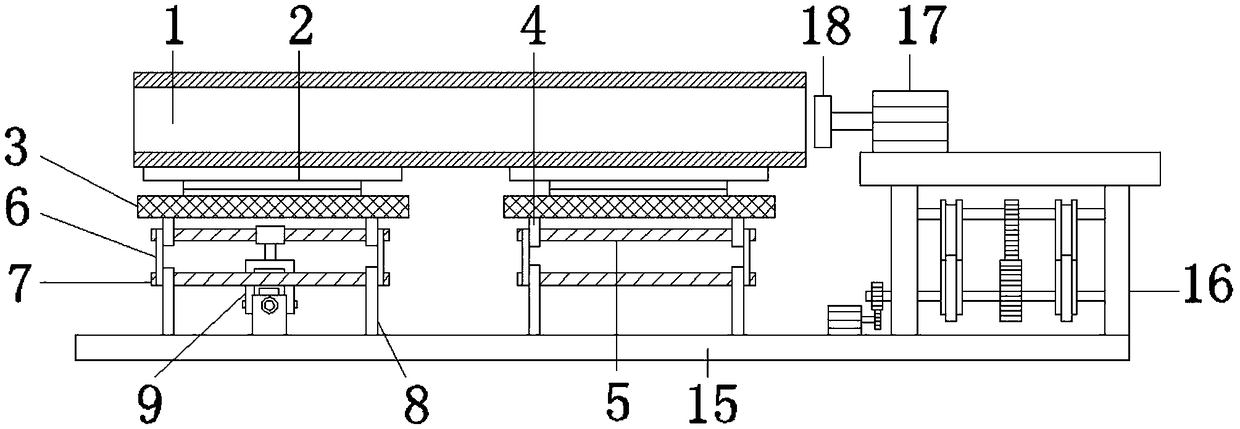

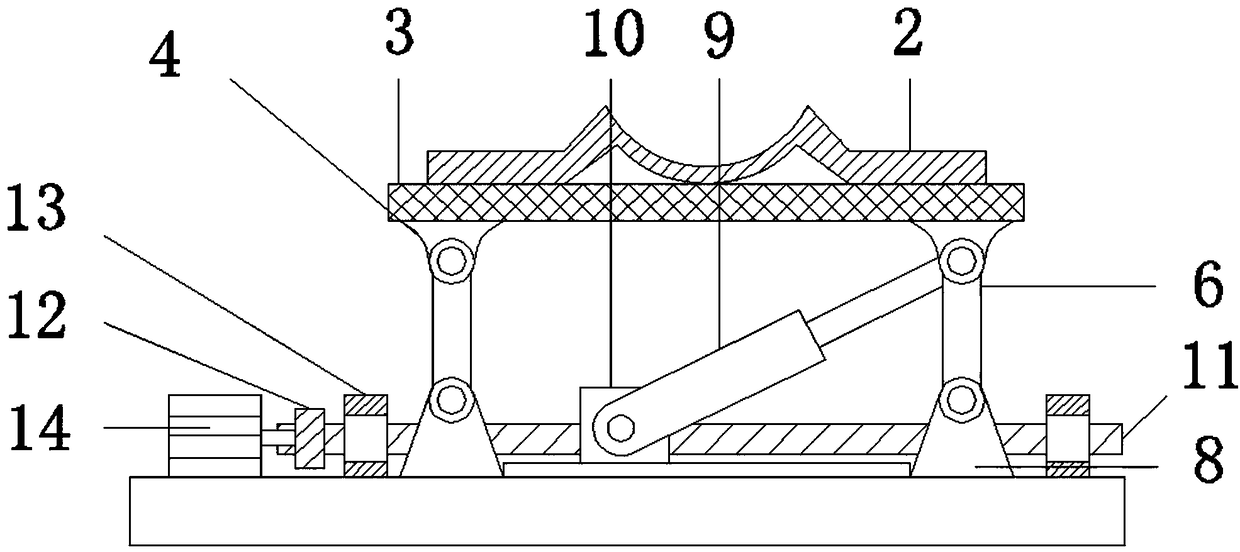

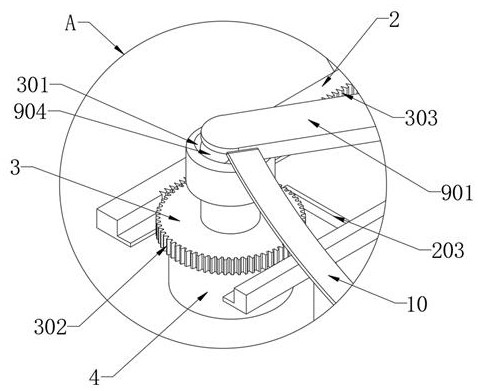

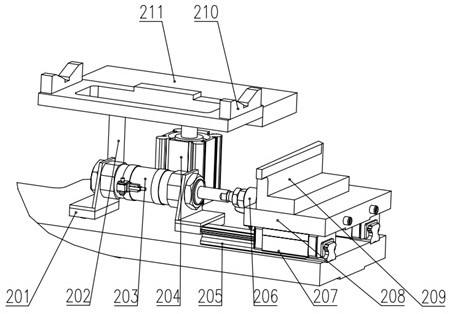

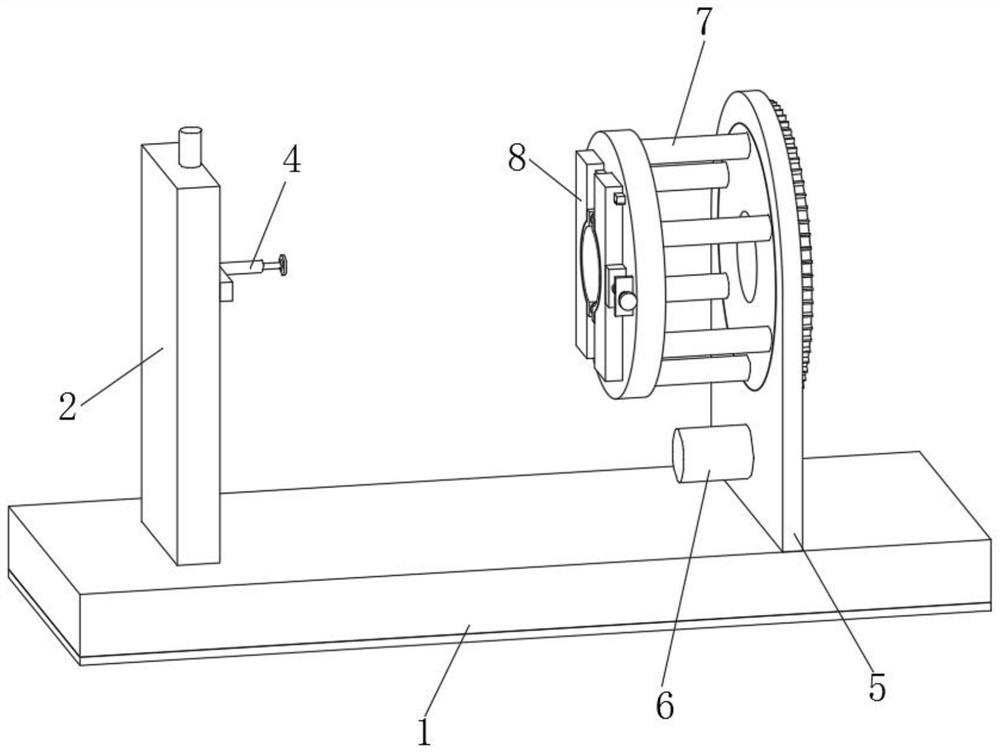

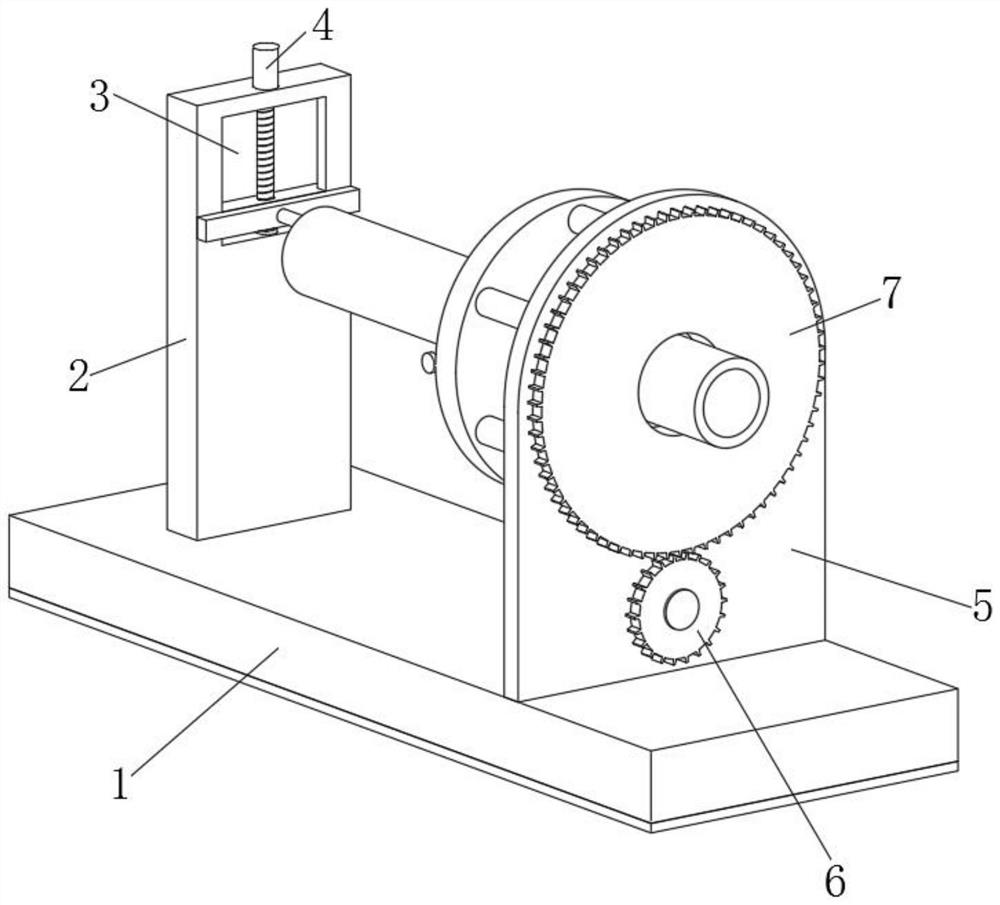

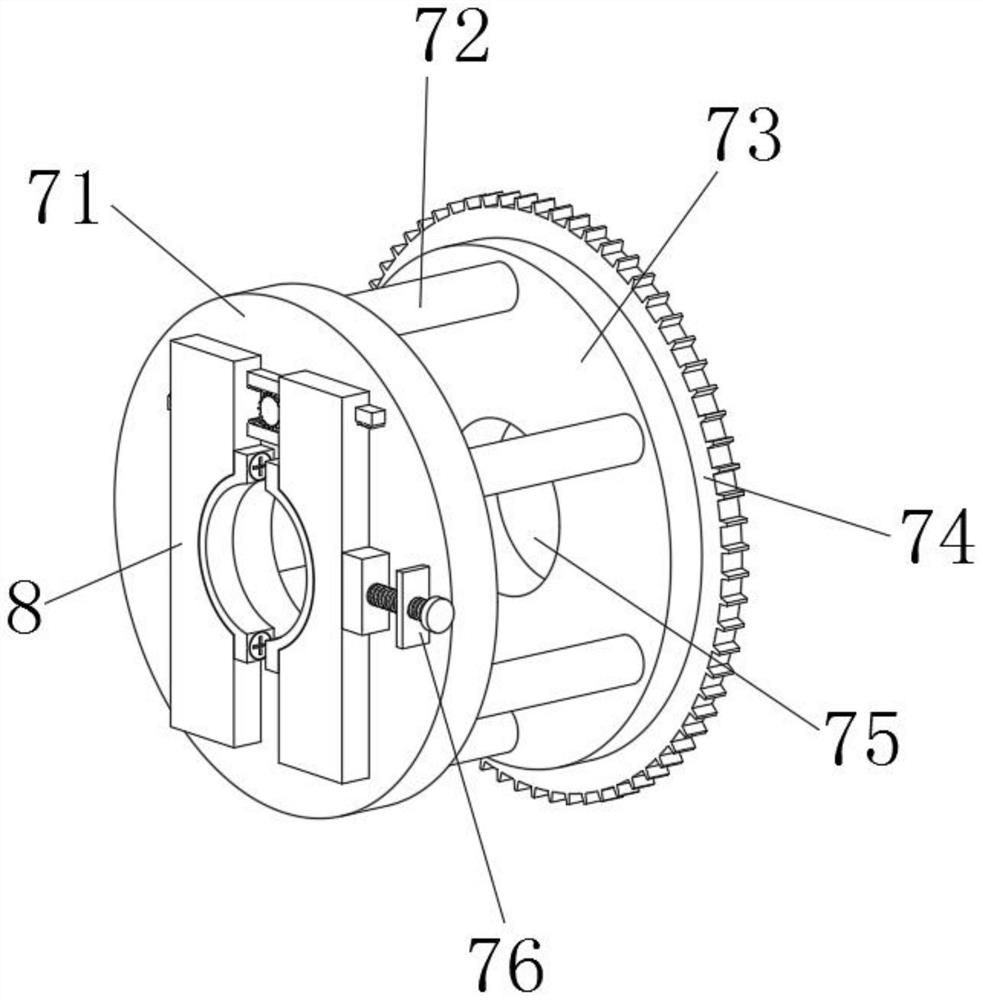

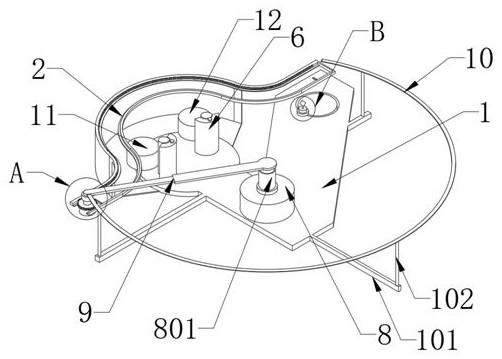

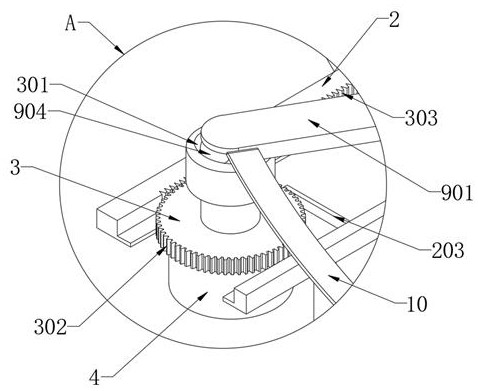

Flywheel polishing device with clamping function

InactiveCN109352463AAchieve clampingEasy clampingGrinding carriagesGrinding drivesEngineeringFlywheel

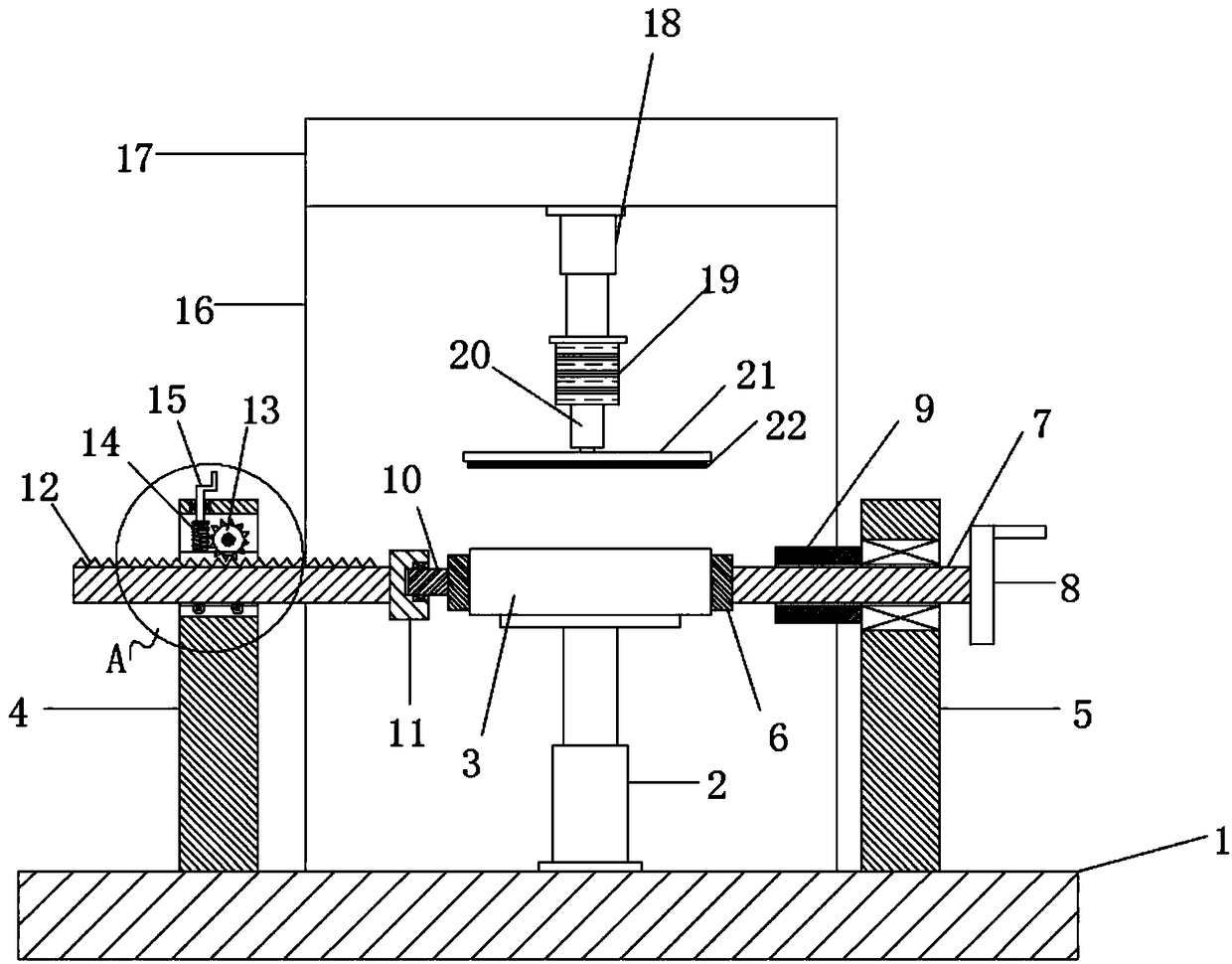

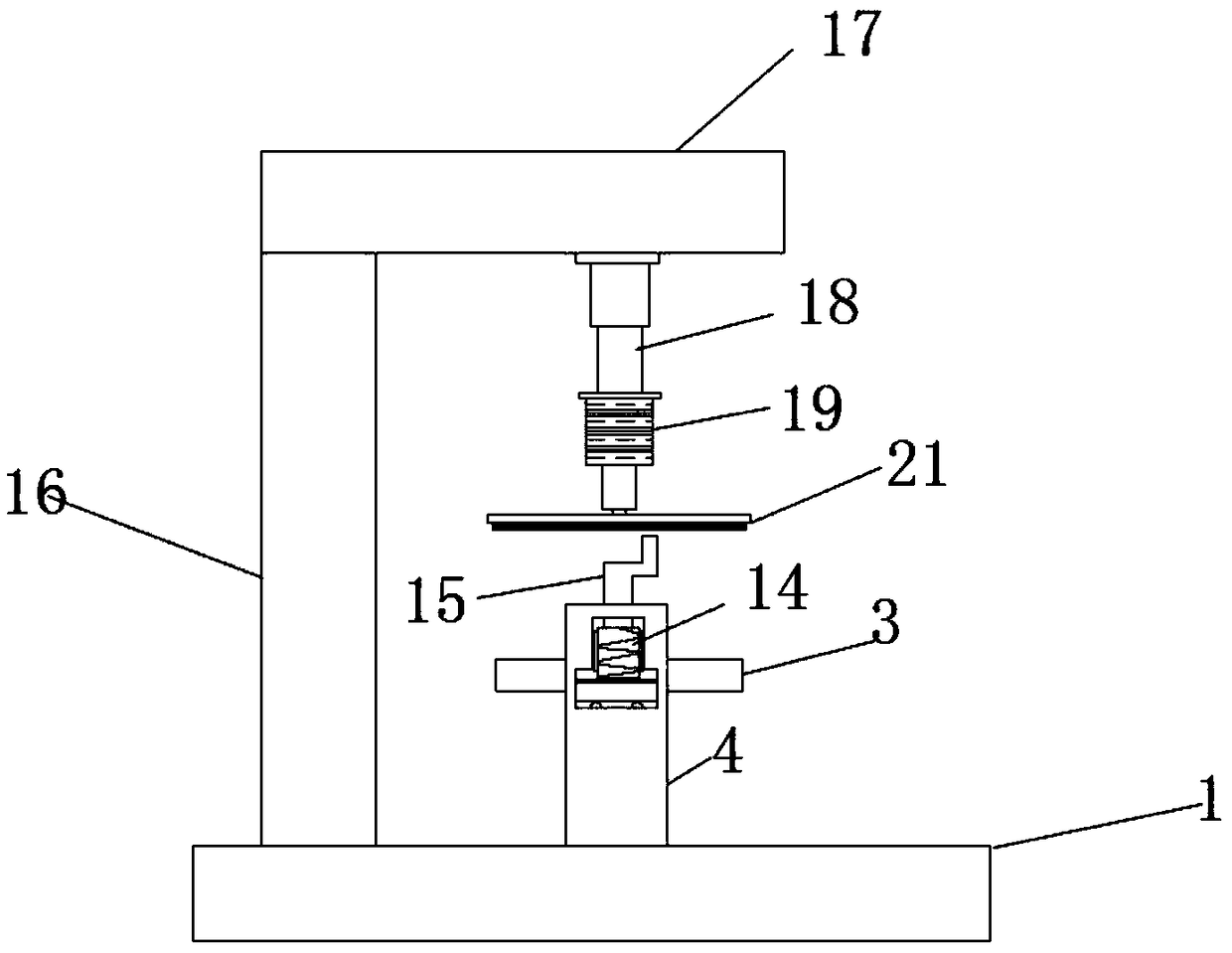

The invention discloses a flywheel polishing device with a clamping function, and belongs to the technical field of flywheel machining. The flywheel polishing device comprises a base, a telescopic supporting device is arranged in the middle of the top end of the base, a flywheel is placed at the top end of the telescopic supporting device, a first supporting base and a second supporting base are arranged on the left side and the right side of the telescopic supporting device correspondingly, and arc clamping blocks are symmetrically connected to the left side and the right side of the flywheel. By arranging a gear and rack structure, flywheels with different sizes can be clamped, flywheel overturning can be achieved by means of an arranged rotating shaft structure, the polishing device canpolish the two faces of the flywheel, flywheel secondary installation is not needed, installation time is saved, labor of users is saved, auxiliary supporting can be achieved for the flywheel by means of the arranged telescopic supporting device, installation and clamping are facilitated, the flywheel ground can be stably supported during polishing, the polishing effect is better, and polishing precision is improved.

Owner:郭志斌

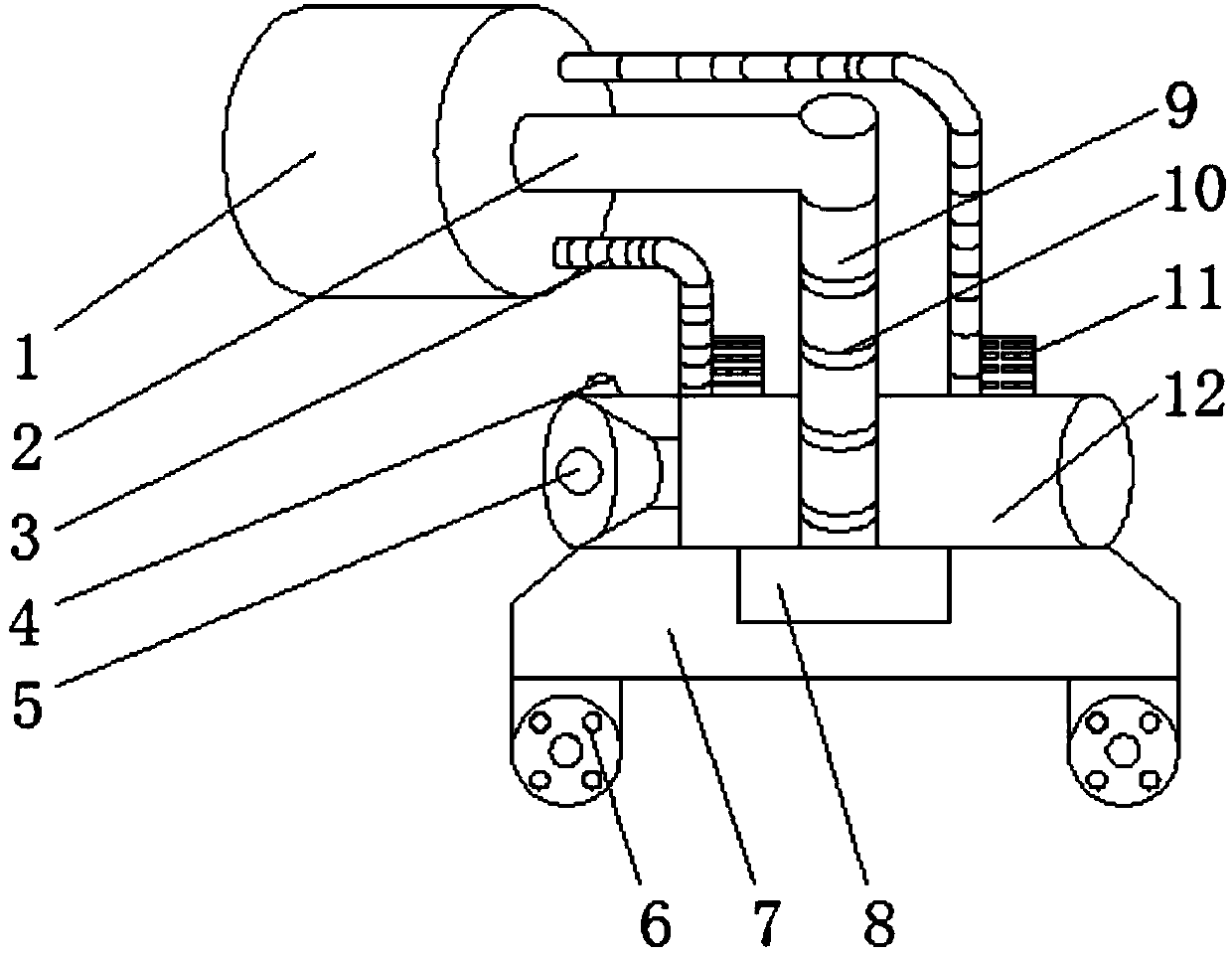

Building wall polishing device with dust collection function

InactiveCN107283240AEasy to polishImprove grinding efficiencyGrinding drivesPlane surface grinding machinesSanderMotor drive

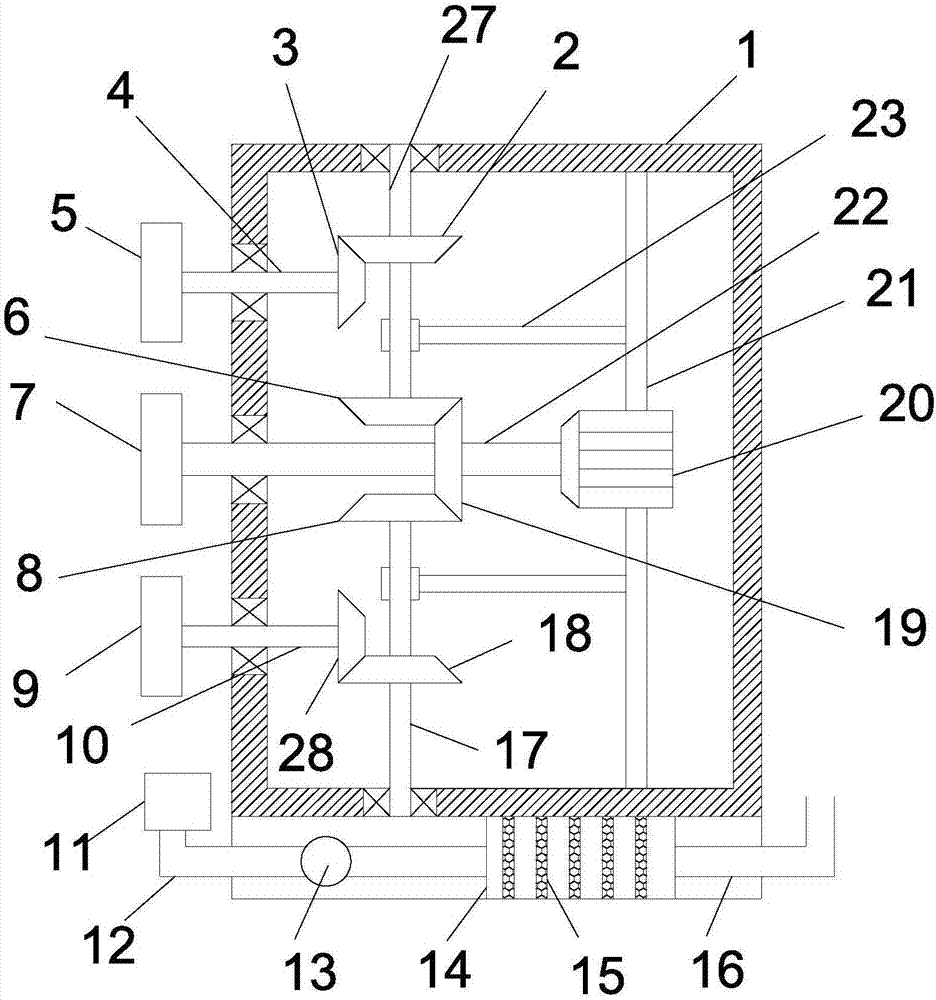

A building wall grinding device with a dust-absorbing function, comprising a main body, a main bracket is arranged in the main body, a driving motor is fixedly installed on the main bracket, the motor shaft of the driving motor is fixedly connected with the driving shaft through a coupling, and the main bracket is Two auxiliary brackets are welded and fixed on the bracket, and one end of the first transmission shaft is coaxially fixed with a first transmission bevel gear; the left side wall of the main body is rotatably provided with a first driven shaft and a second driven shaft; The front grinding disc is fixedly installed on the left end of the driven shaft, and the first secondary-stage driven bevel gear is fixedly installed on the right end of the first driven shaft. The first secondary-stage driven bevel gear is meshed with the first secondary-stage driving bevel gear. A conveying fan is installed on it, and an air outlet pipe is arranged on the side of the filter box away from the conveying pipe; in the present invention, the front grinding disc, the active grinding disc and the rear grinding disc rotate and grind the wall body, which makes the grinding range wider and effectively improves the Efficiency of wall grinding.

Owner:沈美珍

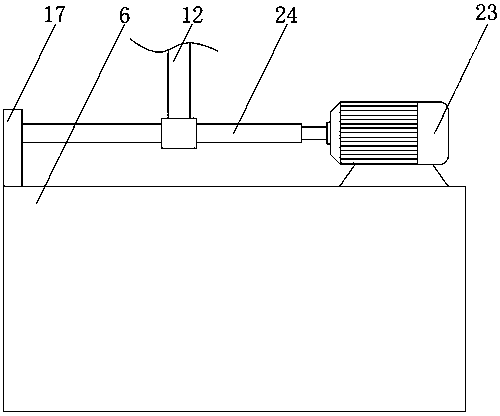

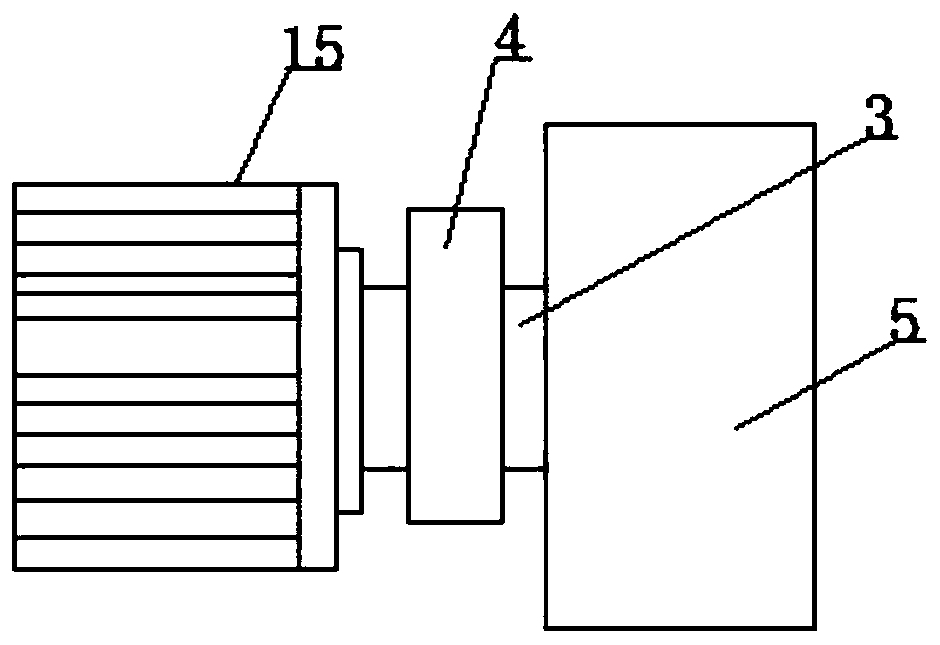

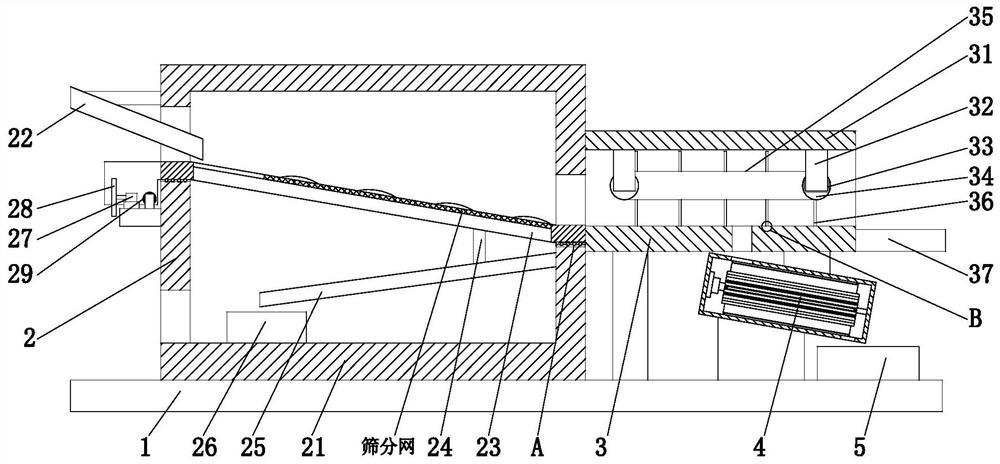

Refrigerator U shell metal plate forming line

InactiveCN109822415AAvoid offsetAvoid accidental damageEdge grinding machinesGrinding carriagesArchitectural engineeringDrive motor

The invention discloses a refrigerator U shell metal plate forming line comprising a workbench. The workbench is of a U-type structure; a mounting groove is formed in the bottom of the workbench; a horizontal threaded rod is arranged inside the mounting groove; one end of the threaded rod is fixed to the output end of a drive motor; the drive motor is vertically arranged at the bottom of the workbench; vertical hydraulic rods are installed at two ends of the threaded rod; vertical supporting boards are fixed to the tops of the two hydraulic rods; vertical concave limiting blocks are installedon one sides of the supporting boards; a horizontal refrigerator U shell plate is fixed in the middle of the two concave limiting blocks; a rotary shaft is installed on the side, close to the drive motor, of the concave limiting blocks; the rotary shaft extends out of the supporting boards and is fixedly provided with a handle; and a horizontal driver is installed on the inner top of the workbench. The refrigerator U shell metal plate forming line is ingenious in design, reasonable in structure, wide in polishing range, capable of fixing and polishing plates, high in practicability and suitable for being popularized,

Owner:滁州精峰机电科技有限公司

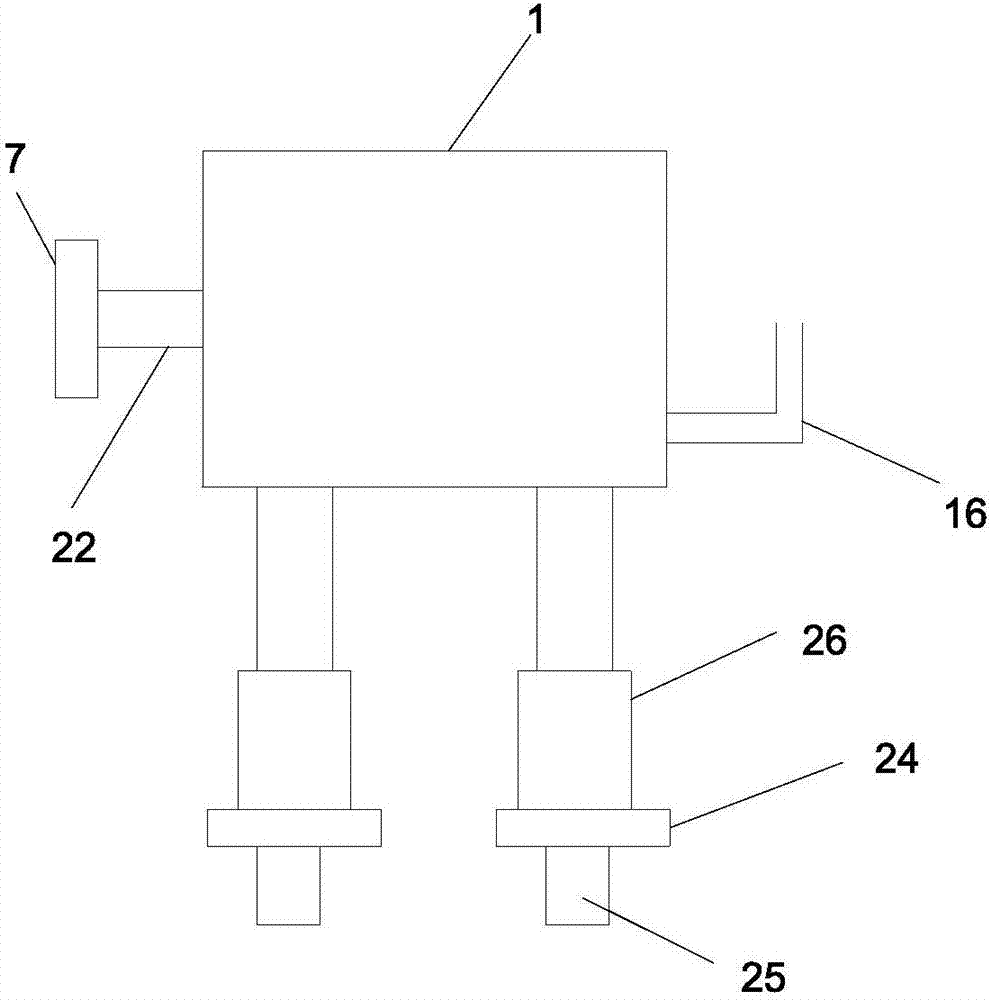

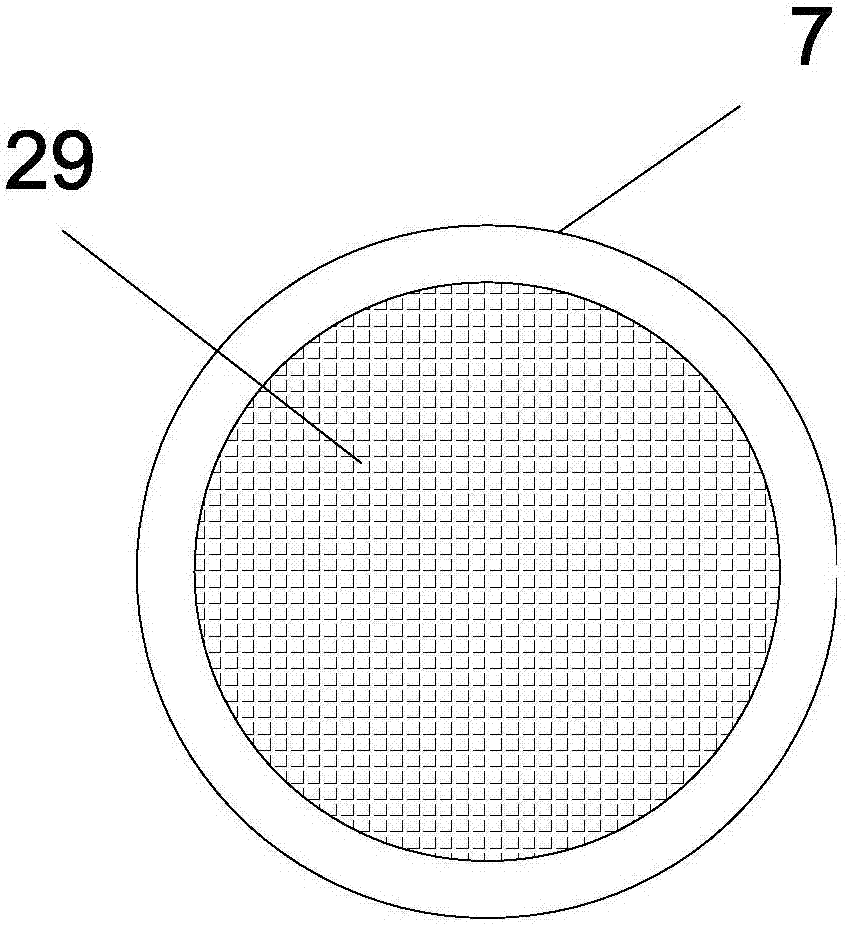

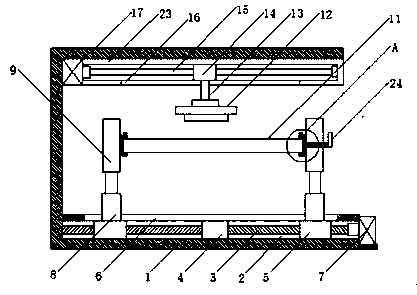

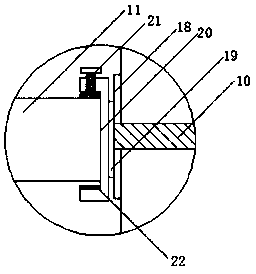

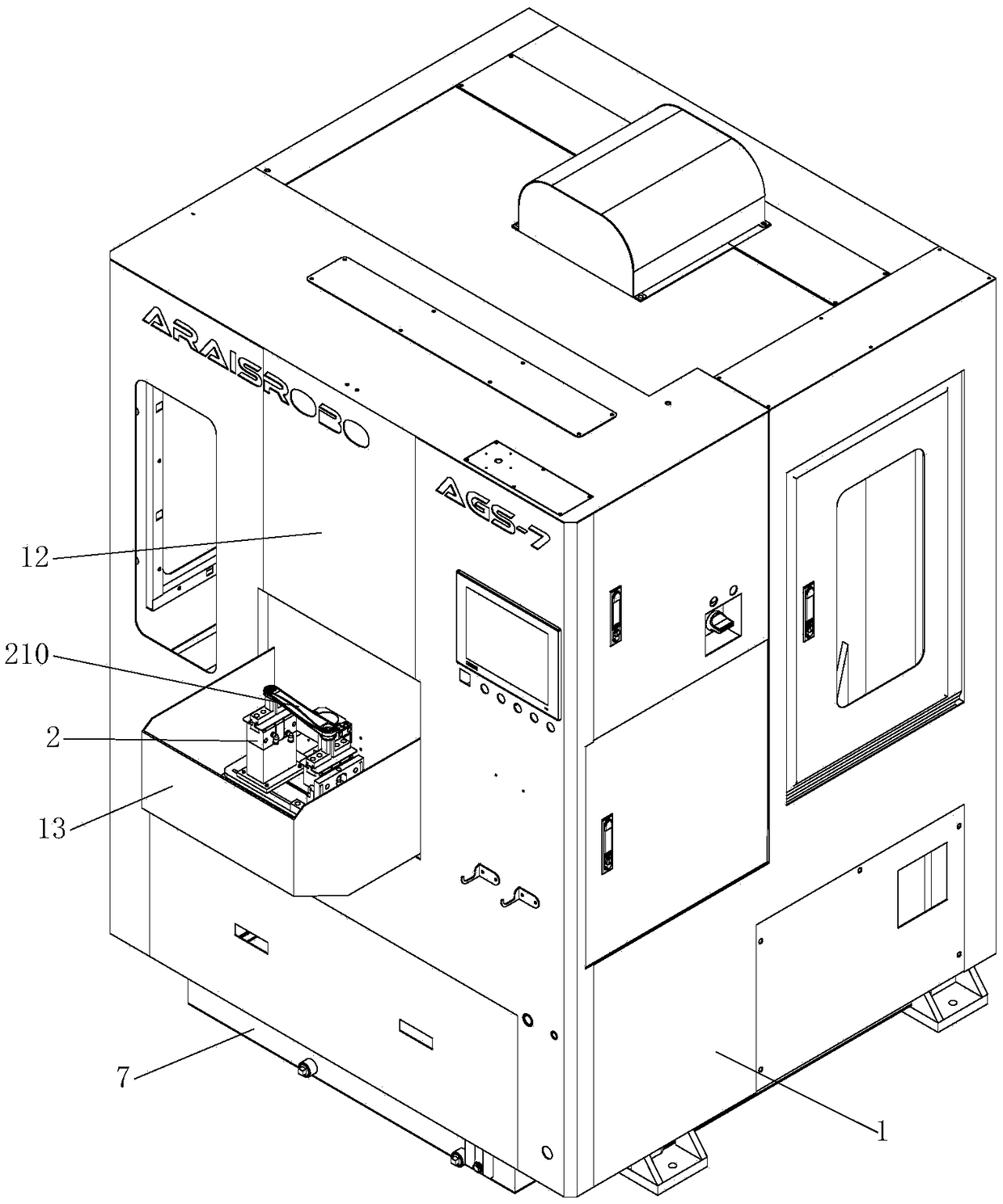

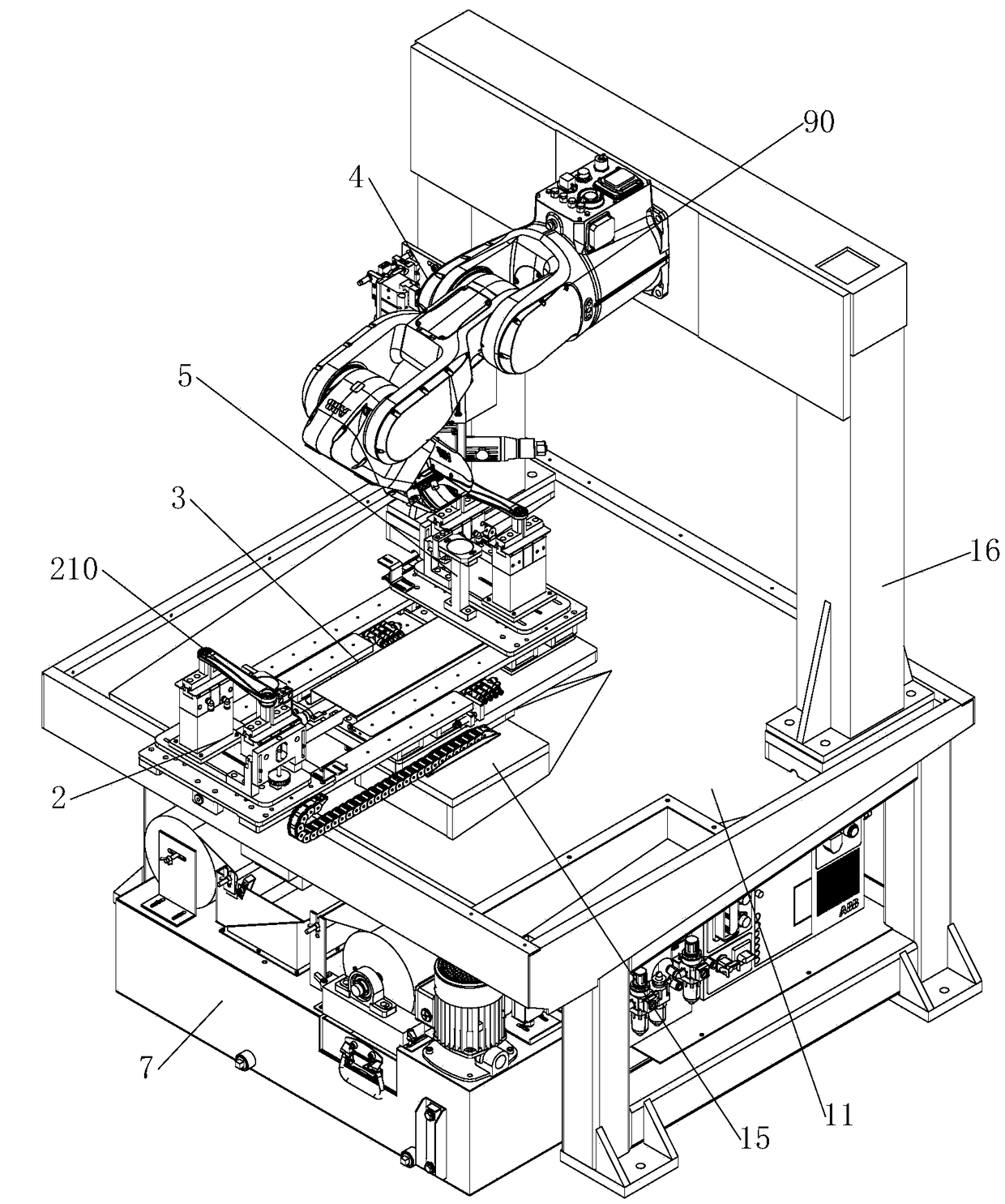

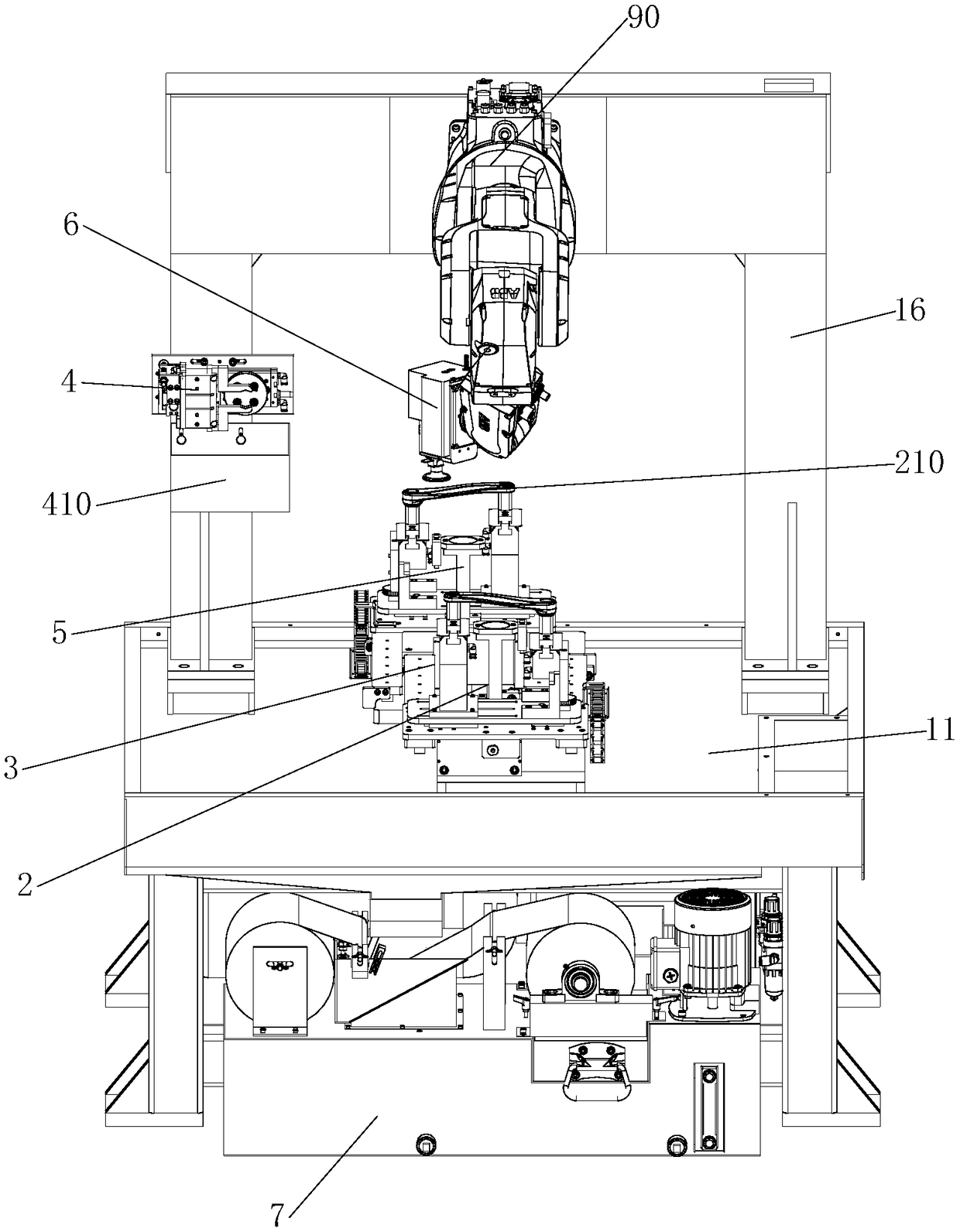

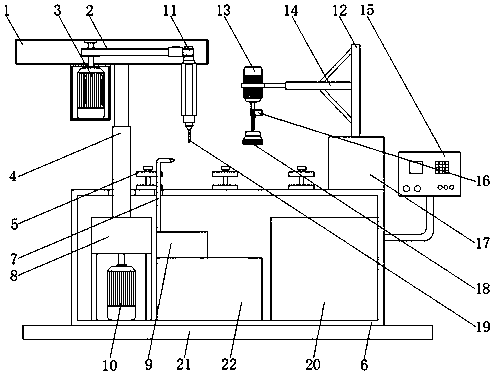

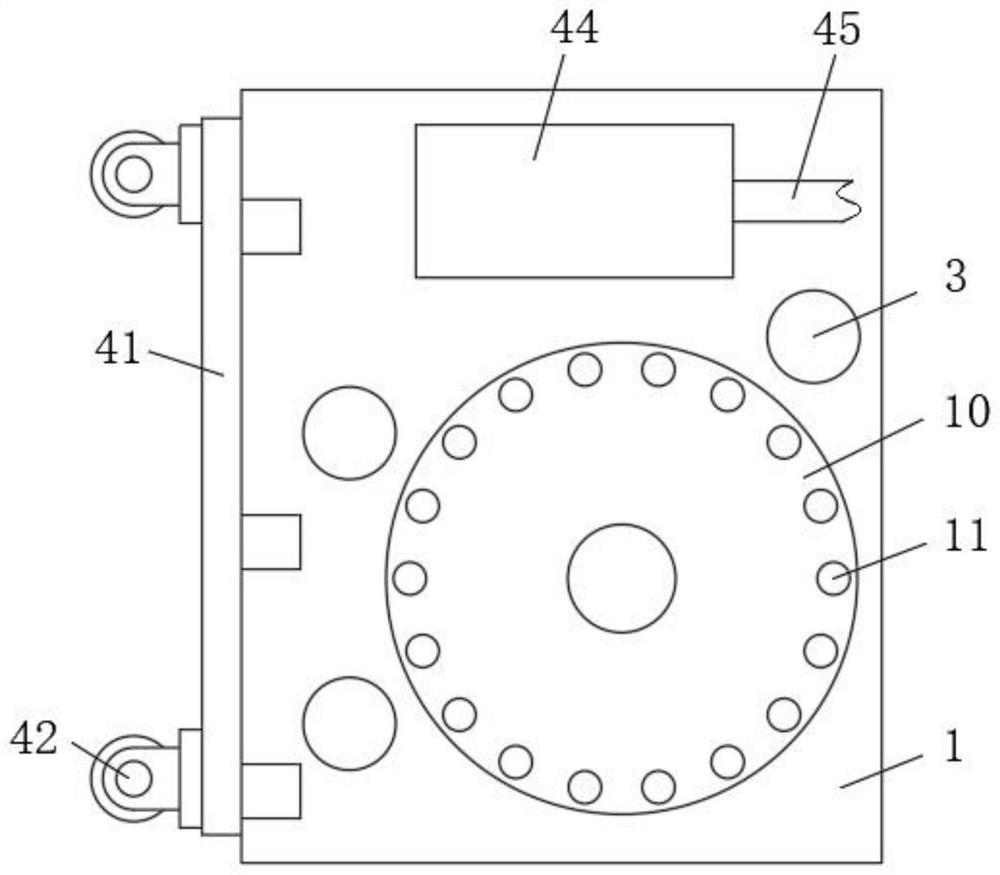

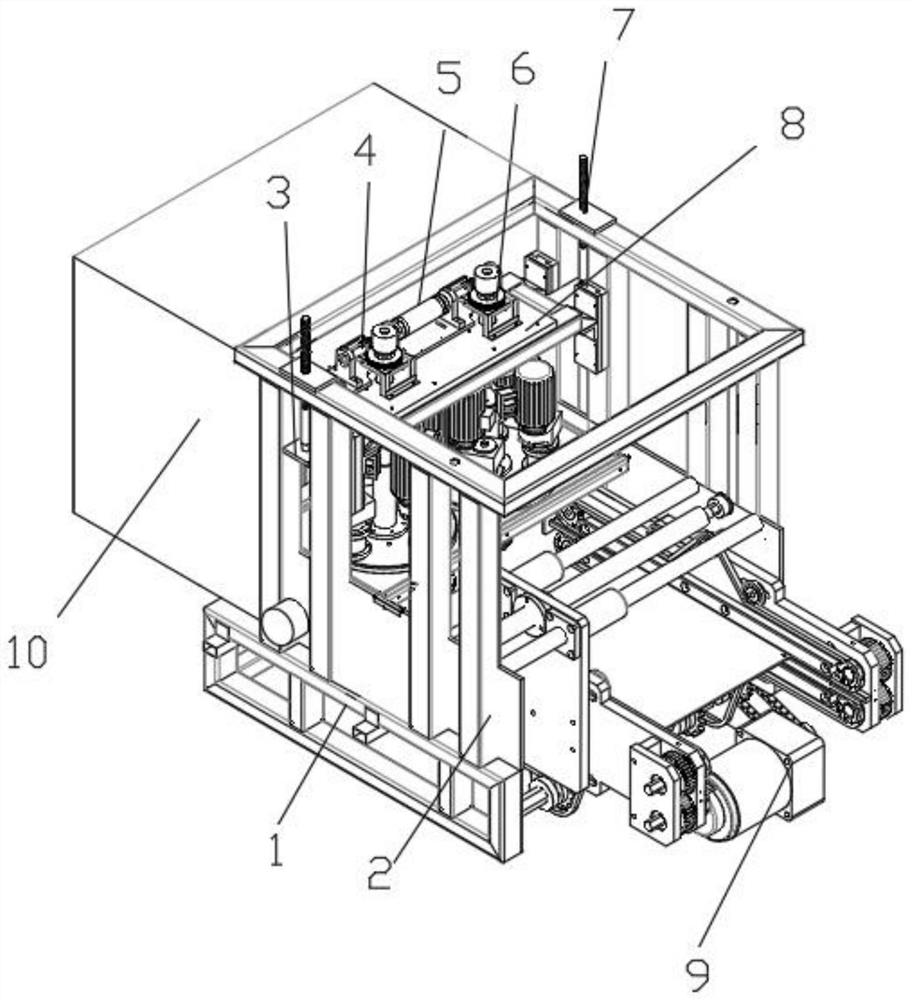

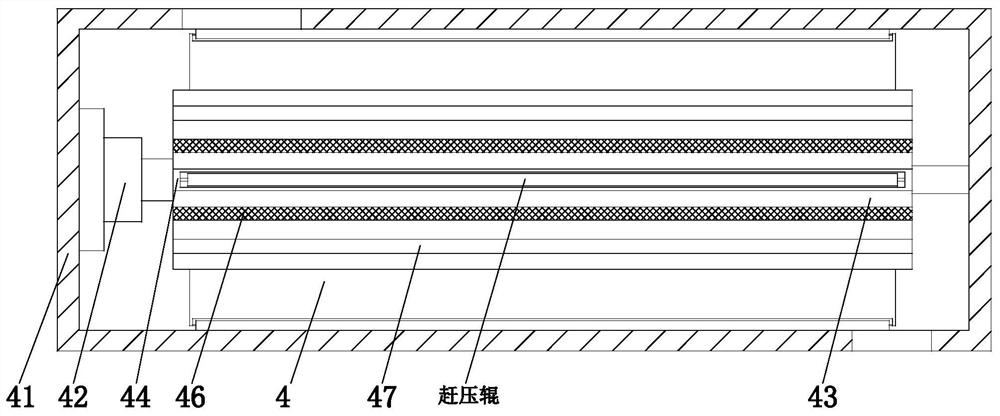

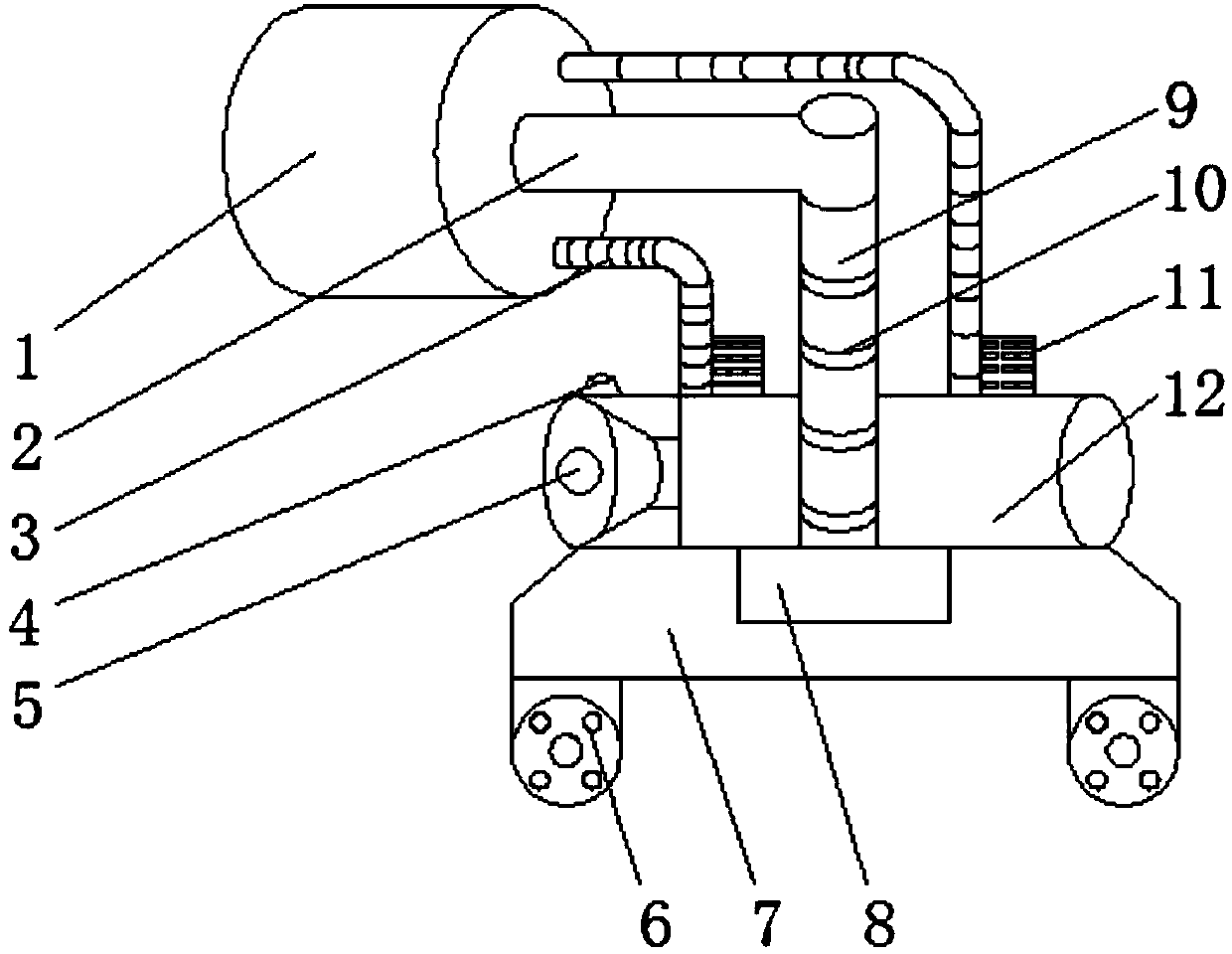

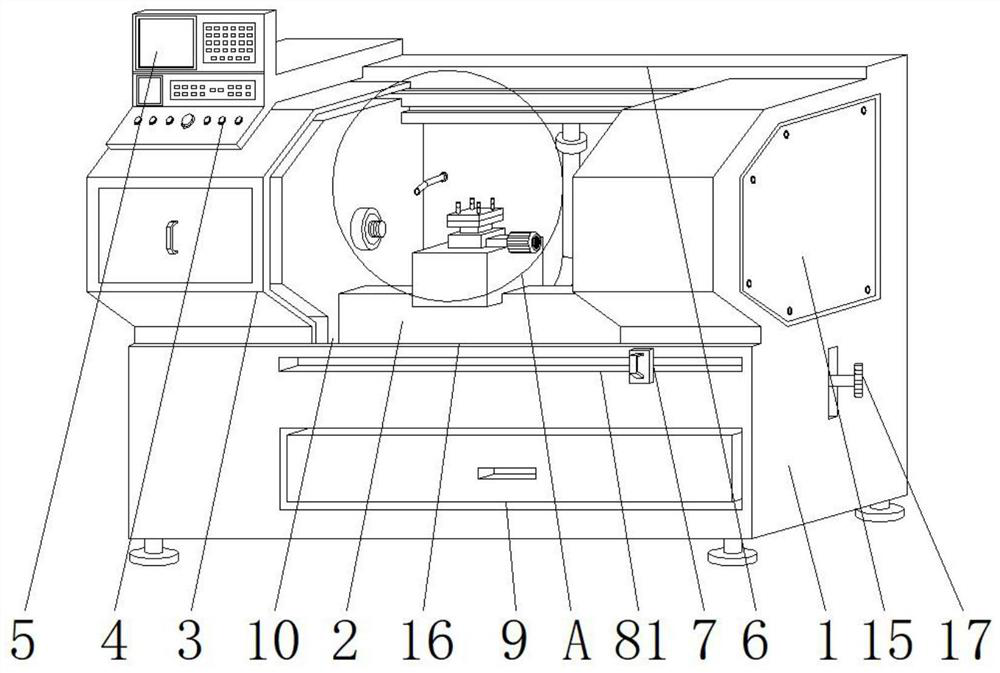

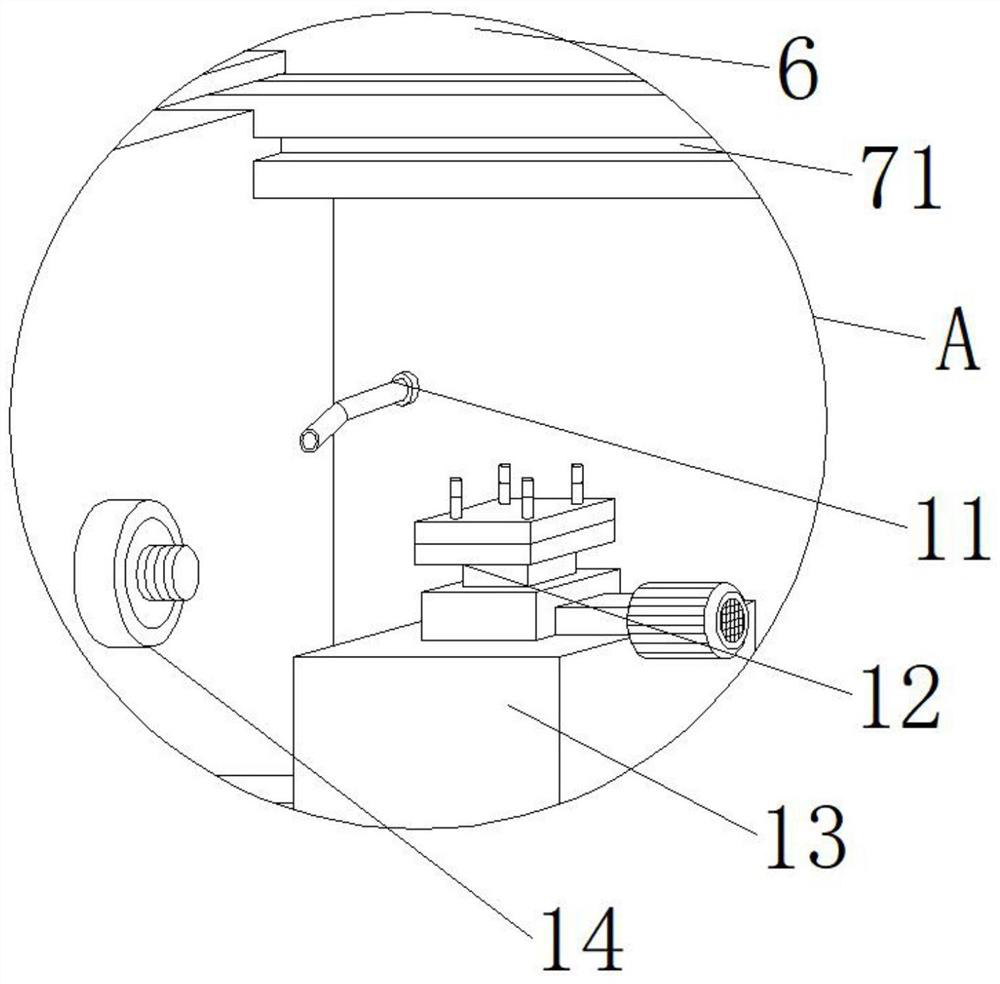

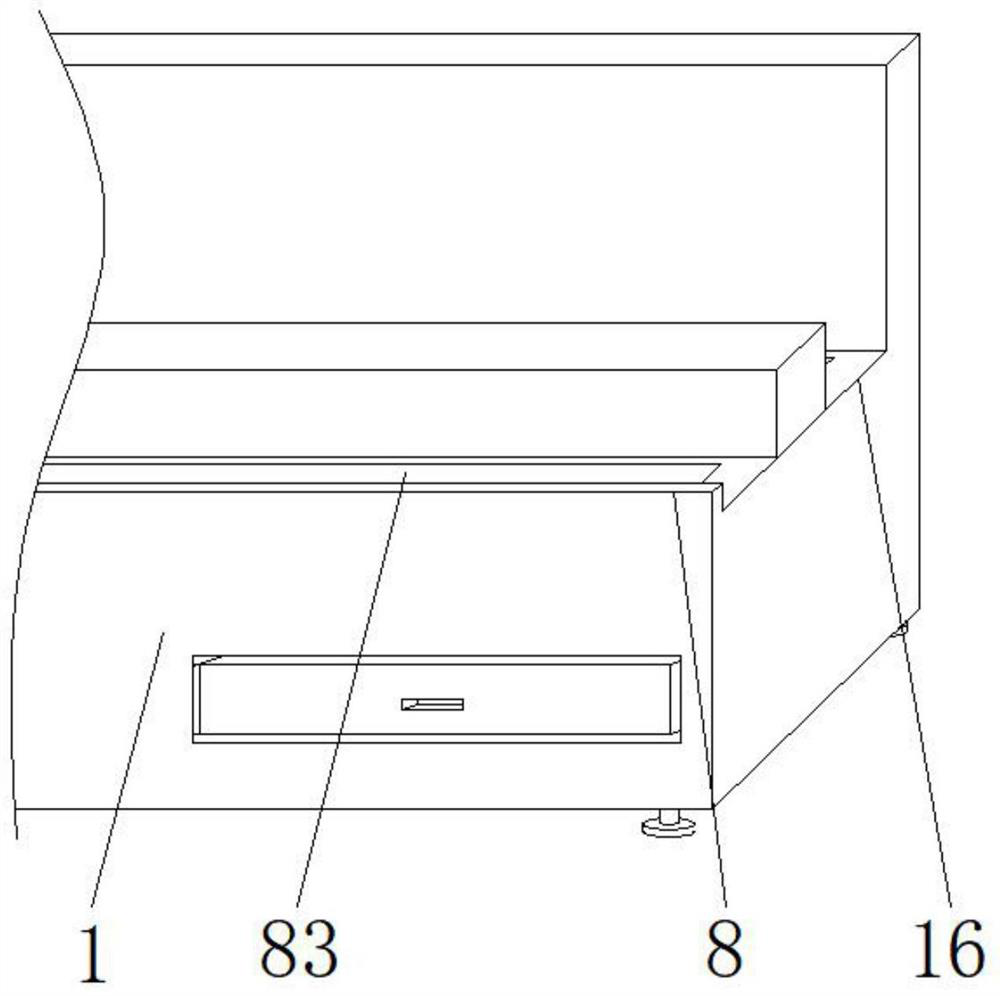

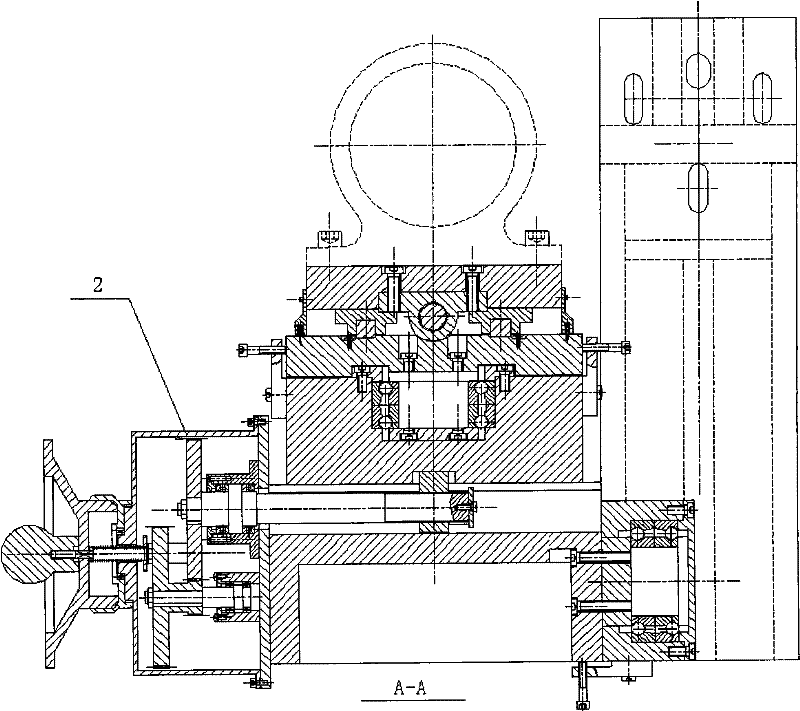

Wet automatic grinding and polishing machine

PendingCN108747715AImprove efficiencyLow costGrinding drivesGrinding feed controlFiltrationClosed loop

The invention relates to a wet automatic grinding and polishing machine. A grinding machine is installed on a moving device, the moving device is installed on a base, and the base, the moving device and the grinding machine are all located in a housing; the housing is a full-closed shell, and an automatic door is arranged on the housing; a workpiece fixing device and a sand disc assembling deviceare installed at the two ends of a double-station rotary exchange platform correspondingly, the double-station rotary exchange platform and a sand disc disassembling device are both fixed to the base,and a grinding control device is installed between the grinding machine and the moving device; and a circulating filtration device is installed under the base, a universal cooling pipe is installed on the housing, the base is further provided a water outlet, and the water outlet is connected with the circulating filtration device. The wet automatic grinding and polishing machine has the full-closed grinding machine body structure, adopts a wet grinding mode and is high in safety; and in addition, a full-closed loop force feedback grinding pressure control system is adopted, the grinding forceand the rotation speed can be precisely controlled, the smooth and even surface effect can be formed, the sand disc replacement speed is high, and the filter material using rate is high.

Owner:ALFAR SUZHOU AUTOMATION TECH

Hardware drilling device

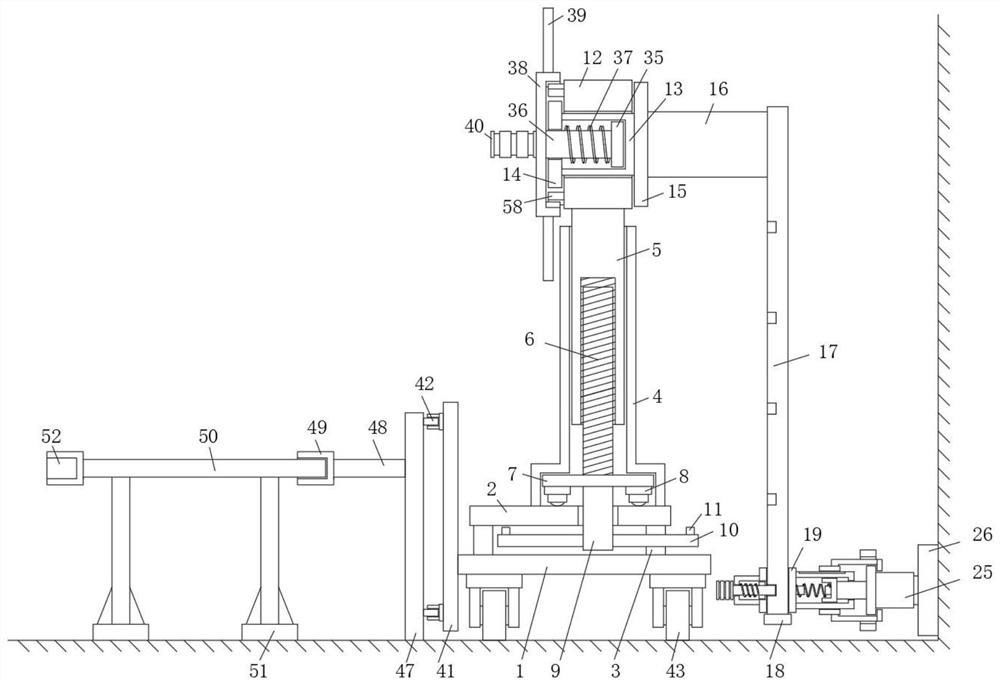

PendingCN109317977AEasy to adjustOptimize locationOther manufacturing equipments/toolsEngineeringMachining

The invention relates to the technical field of hardware machining, and discloses a hardware drilling device. The hardware drilling device comprises a transmission box, wherein a first motor is fixedly installed at the bottom of the transmission box, an output shaft of the first motor penetrates through and extends to the inner top wall of the transmission box, the outer side of the output shaft of the first motor is movably connected with a transmission belt wheel, and the other side of the transmission belt wheel is movably connected with a rotating shaft. According to the hardware drillingdevice, through the cooperation of a second motor and a reduction gear box, the first motor is enabled to work by controlling a control panel, after the first motor is started, the transmission belt wheel is driven to rotate, the transmission belt wheel drives a drill bit on the rotating shaft to rotate, meanwhile, the reduction gear box can reduce the rotating speed of an output shaft of the second motor, the drill bit can be conveniently adjusted to the required direction, drilling work is carried out by adjusting the height of a first hydraulic rod, manual operation by workers is avoided inthe using process, so that the purpose that the position of the drill bit is conveniently adjusted so as to realize convenient operation is achieved.

Owner:浙江亚普自动化装备科技股份有限公司

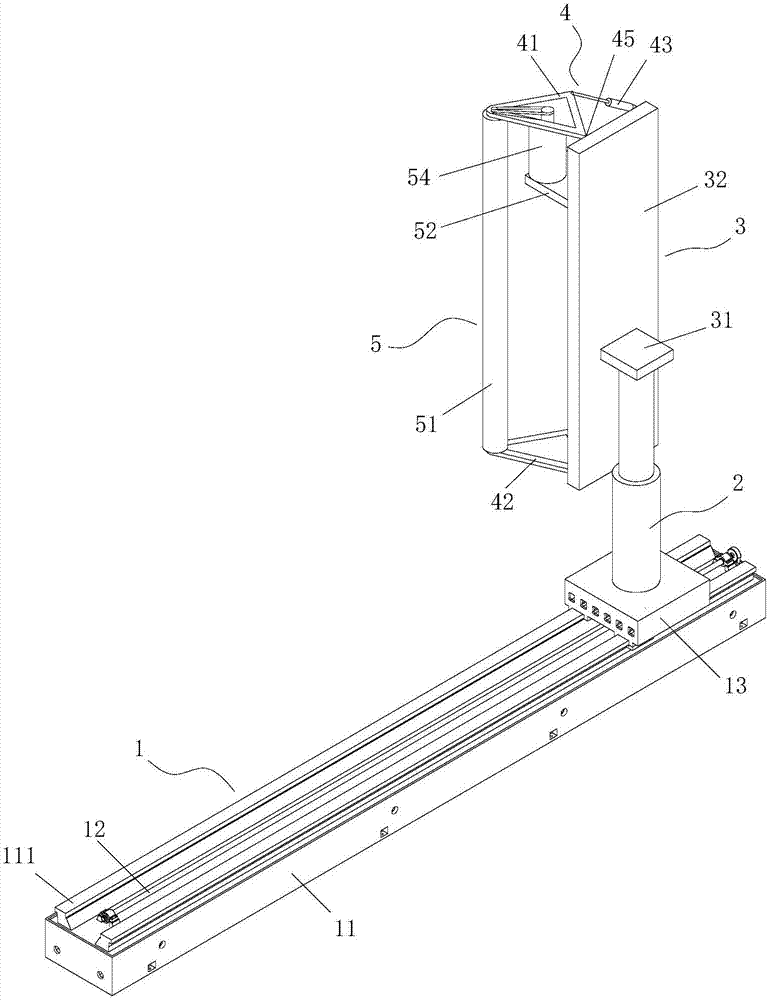

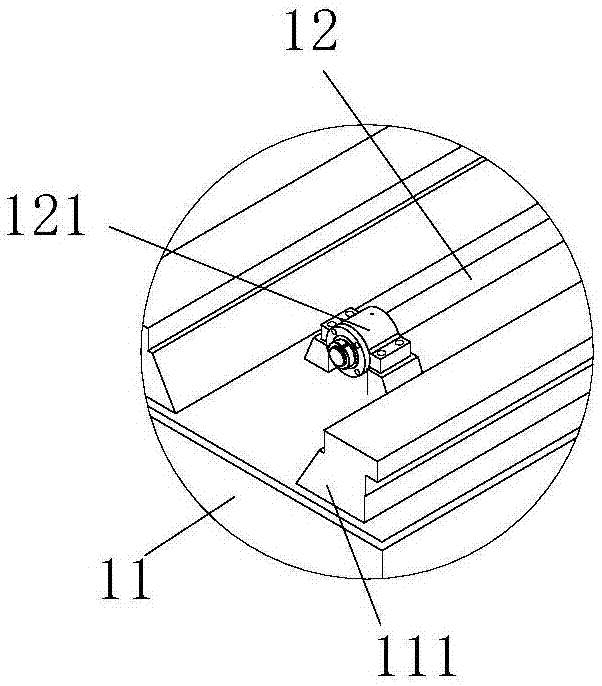

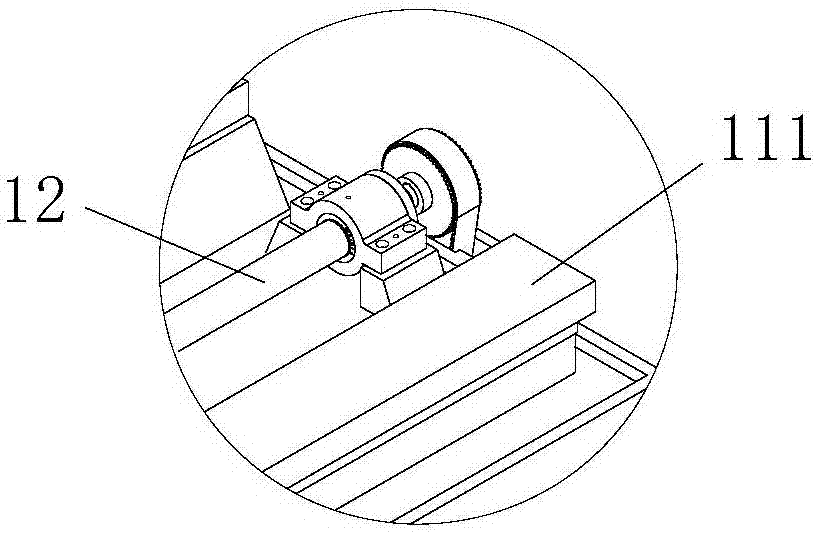

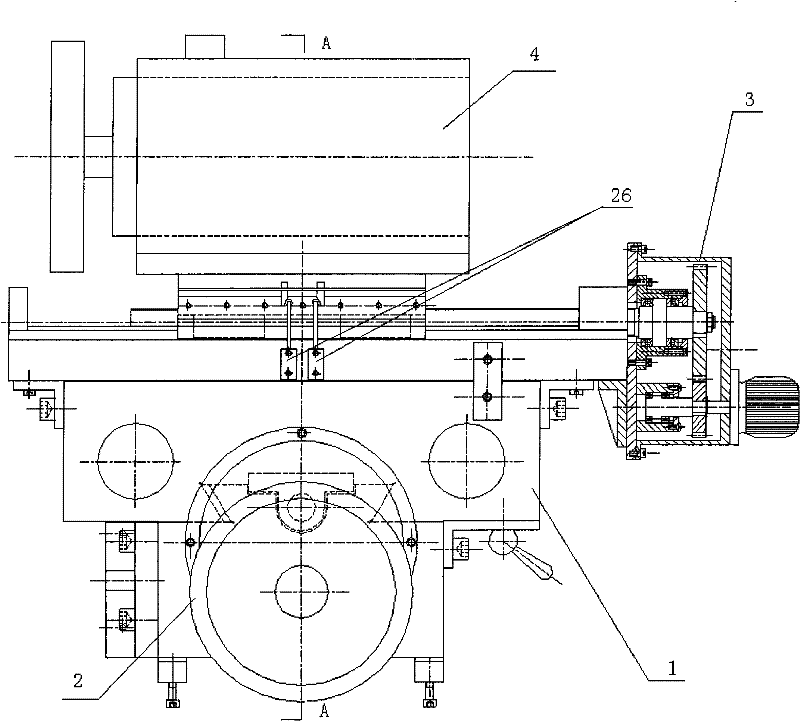

Automatic polishing pretreatment equipment for building wall surface

InactiveCN107263235AImprove efficiencyImprove grinding effectGrinding carriagesGrinding drivesEngineeringPre treatment

The invention discloses an automatic grinding pretreatment device for building walls. The automatic grinding pretreatment equipment for building walls includes a translation mechanism, a lifting mechanism, a frame, a tension adjustment mechanism, and a grinding mechanism. The lifting mechanism is installed on the translation mechanism. Above, the frame is fastened to the output end of the lifting mechanism, the tension adjustment mechanism is installed on the frame, and the grinding mechanism is installed on the tension adjustment mechanism, wherein: the translation mechanism includes a guide rail seat, Lead screw, slide table and lead screw drive motor, the lead screw is fastened on the guide rail seat, the slide table is connected to the lead screw through screw connection transmission, the lead screw drive motor is used to drive the lead screw to rotate, and then drive the slide table along the The guide rail seat makes translational movement along the length direction. The invention makes the grinding effect good through the adjustment effect of the tension adjustment mechanism. When the lifting drive device is lowered to the lowest position, the bottom of the second swing arm is flush with the bottom surface without affecting the movement of the second swing arm. The grinding range is wide and the efficiency is high. high.

Owner:罗厚镇

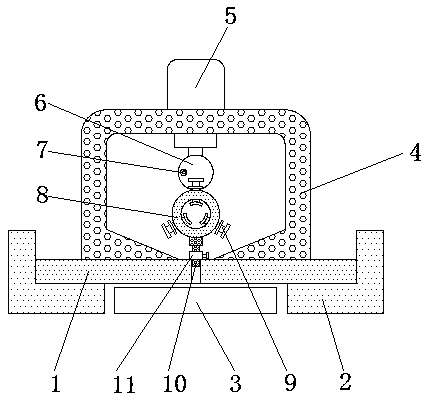

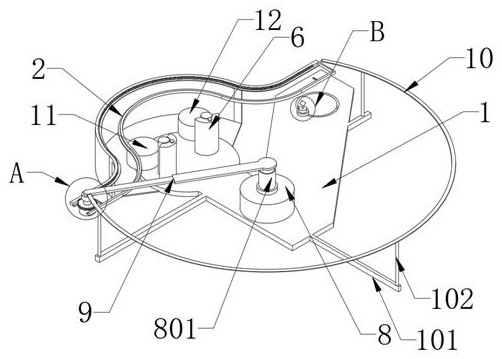

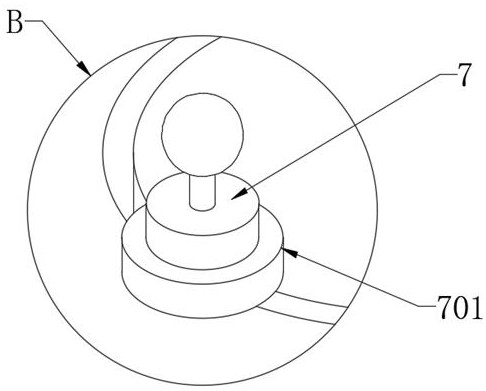

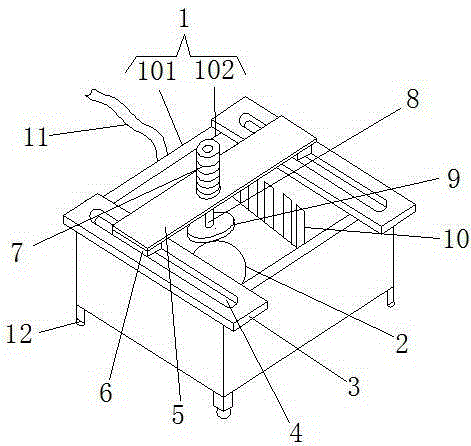

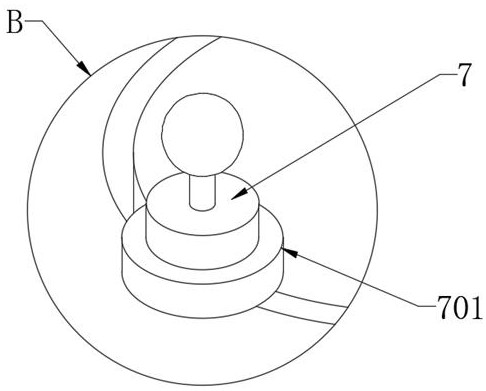

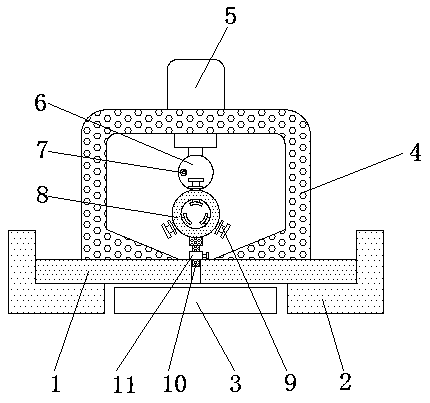

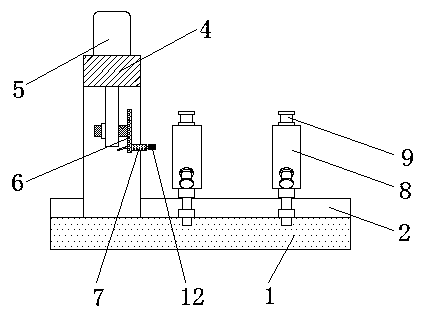

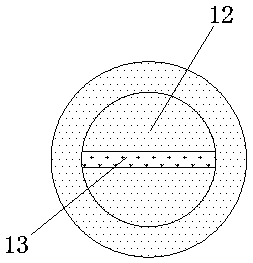

Polishing device for automobile accessory

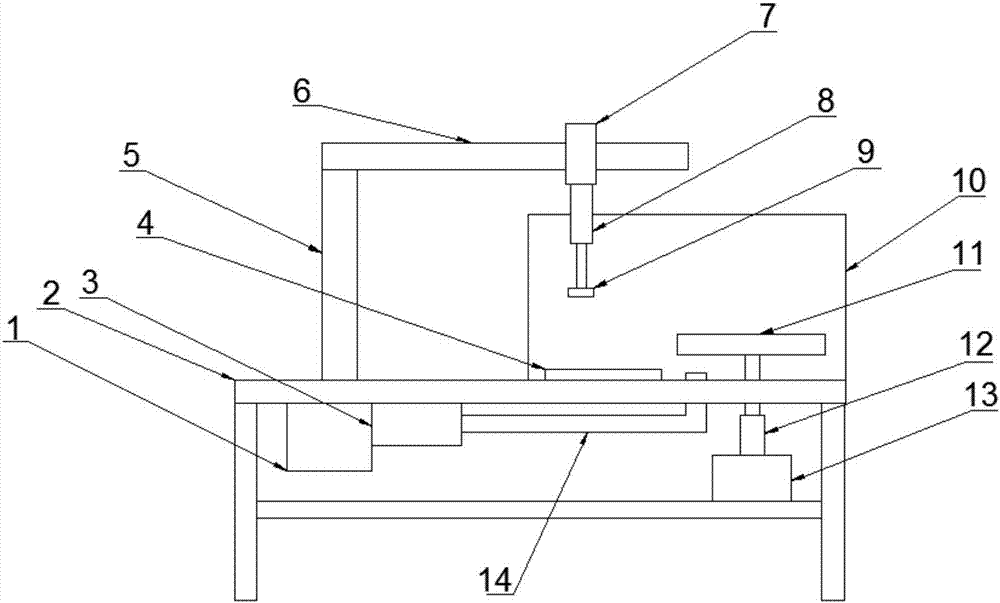

PendingCN106926078AEasy to polishWide range of grindingEdge grinding machinesGrinding carriagesPhysicsPolishing

The invention provides a polishing device for an automobile accessory. The polishing device comprises a worktable (2) which has two layers. The top of the upper layer of the worktable (2) is provided with a containing groove (4), a dustproof cover (10), a vertical rod (5) and a polishing wheel (11). A cross beam (6) is arranged on the top of the vertical rod (5), and an air cylinder (7) is arranged on the cross beam (6). A dust collecting bag (1) and an air blower (3) are arranged at the bottom of the upper layer of the worktable (2). The dust collecting bag (1) is directly connected with the air blower (3), and a rotating motor (13) is arranged on the lower layer of the worktable (2). The polishing device has the beneficial effects that a telescopic rod is connected with a workpiece through a sucker (9), existing rigid connection is avoided, and therefore the polishing wheel (11) has certain elasticity when making contact with the workpiece; a rotating shaft of a polishing motor is perpendicular to a polishing platform, the workpiece is fixed to the polishing platform, and polishing of the workpiece is facilitated; and chippings generated during polishing are discharged in time due to the design of the dustproof cover (10), pollution is prevented from being caused, and the polishing quality is also ensured.

Owner:四川瑞丰锻造有限公司

Pipe fitting weld joint polishing equipment

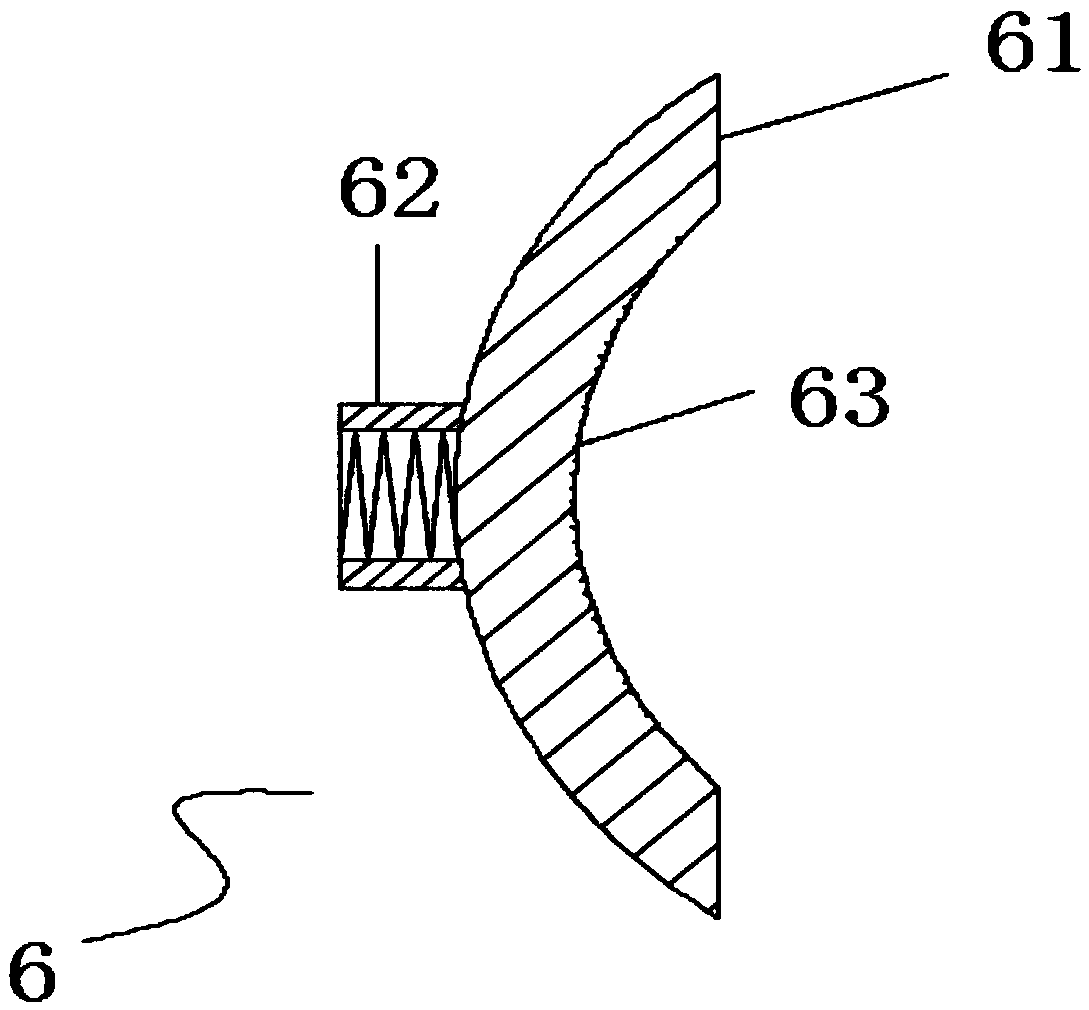

InactiveCN114161277AAutomatic detection of weld seam positionWide range of grindingGrinding carriagesBelt grinding machinesPipe fittingPolishing

The invention provides pipe fitting weld joint polishing equipment which is characterized by comprising polishing assemblies distributed at the inner end and the outer end of a polishing piece; the detection unit is arranged at the fixed end of the polishing assembly; the fixing unit is arranged at the side part of the detection unit; after the position of the welding seam is found by the detection unit in the rotating process of the grinding piece, the position of the grinding piece is locked through the fixing unit; the arc length between the first prediction assembly and the second prediction assembly is set to be equal to the effective length of the rack, and it is ensured that when the reverse wedge-shaped plate is inserted into the welding seam, the first grinding roller and the second grinding roller just make the upper end face and the lower end face of a grinding piece make contact; therefore, the welding seam position of the grinding piece can be automatically detected.

Owner:HUZHOU TEACHERS COLLEGE +1

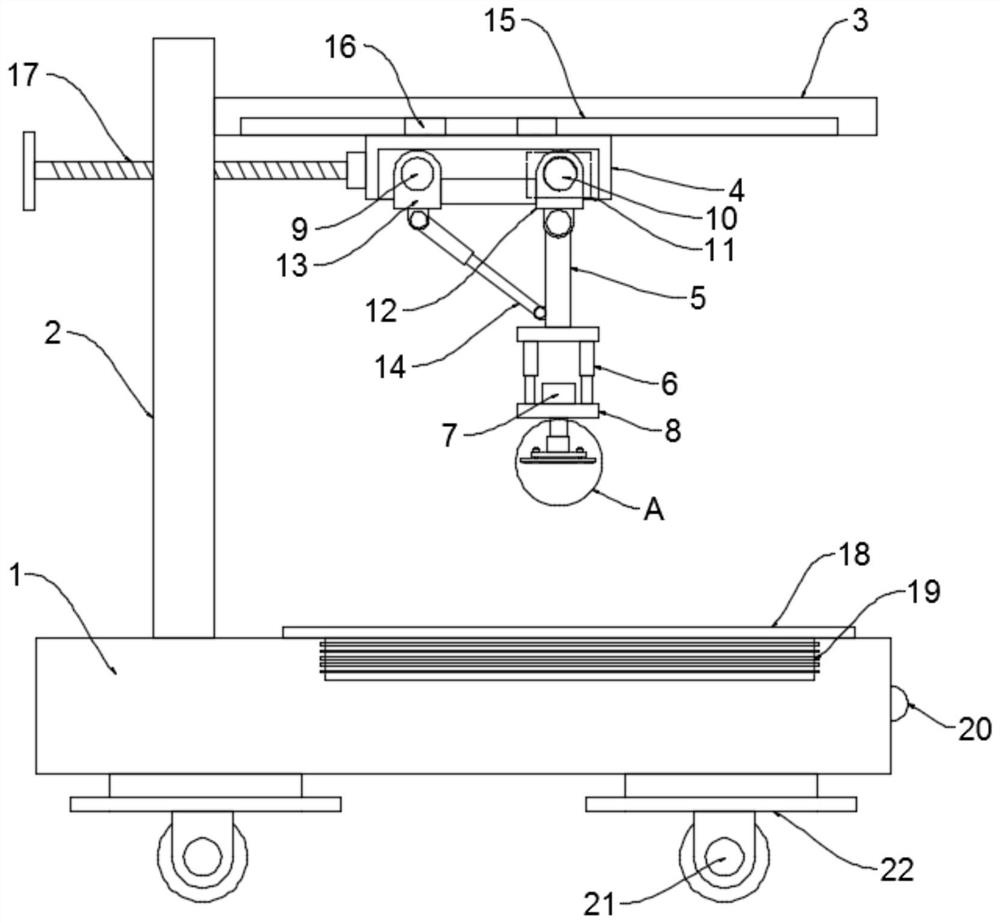

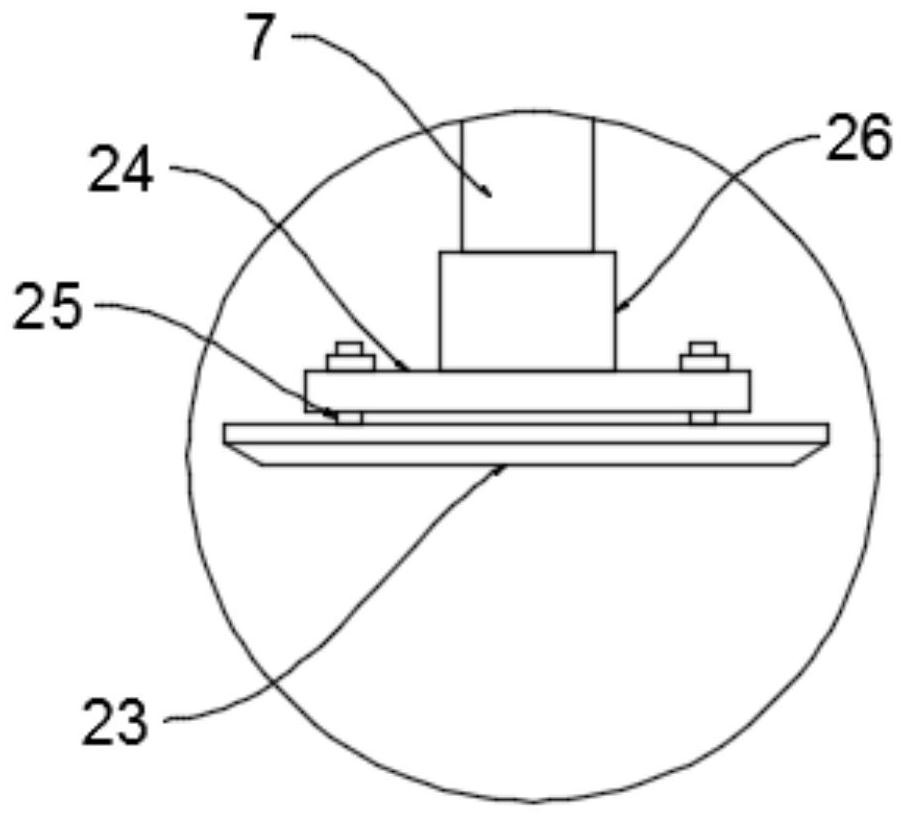

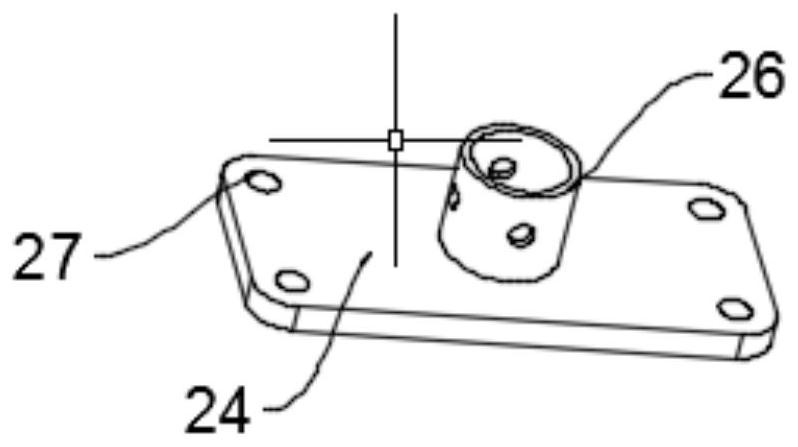

Flexible and adjustable automobile maintenance grinding wagon

InactiveCN111791131AEasy to useImprove grinding efficiencyGrinding carriagesGrinding machinesStructural engineeringMechanical engineering

The invention discloses a flexible and adjustable automobile maintenance grinding wagon, and relates to the technical field of grinding equipment. The automobile maintenance grinding wagon mainly aimsto solve the problem that the application range is narrow due to the fact that the grinding operation of a grinding wagon is inconvenient to adjust. The automobile maintenance grinding wagon comprises a grinding box body, a grinding mechanism and an adjusting assembly used for adjusting the orientation of the grinding mechanism, wherein a supporting vertical frame is fixed to the edge side of thetop of the grinding box body, a transverse frame is fixed to the top end of the supporting vertical frame, and the grinding mechanism is arranged on the transverse frame in a suspended mode and comprises a fixing hanging rod and a grinding sheet; and a limiting sliding rod is provided with a connecting sliding sleeve sliding on the limiting sliding rod, an adjusting lead screw is provided with afixing threaded sleeve spirally matched with the adjusting lead screw, the connecting sliding sleeve is fixedly connected with the end side of the fixing threaded sleeve, the lower end of the connecting sliding sleeve is hinged to an adjusting telescopic rod, and the other end of the adjusting telescopic rod is hinged to the rod wall of the fixing hanging rod. The flexible and adjustable automobile maintenance grinding wagon is simple in structure, large in grinding application range, high in efficiency, easy, convenient and flexible to operate and high in practicability.

Owner:辛东生

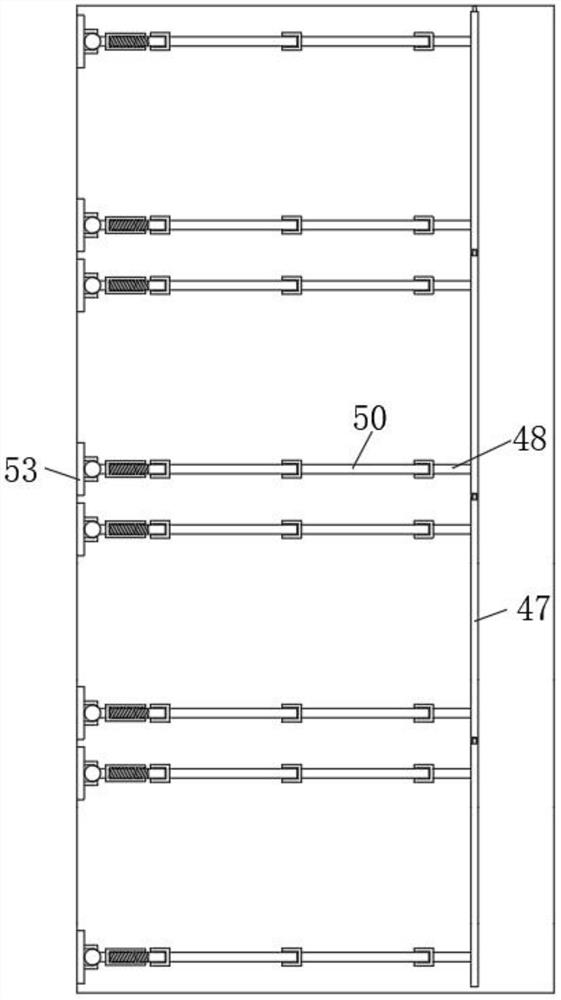

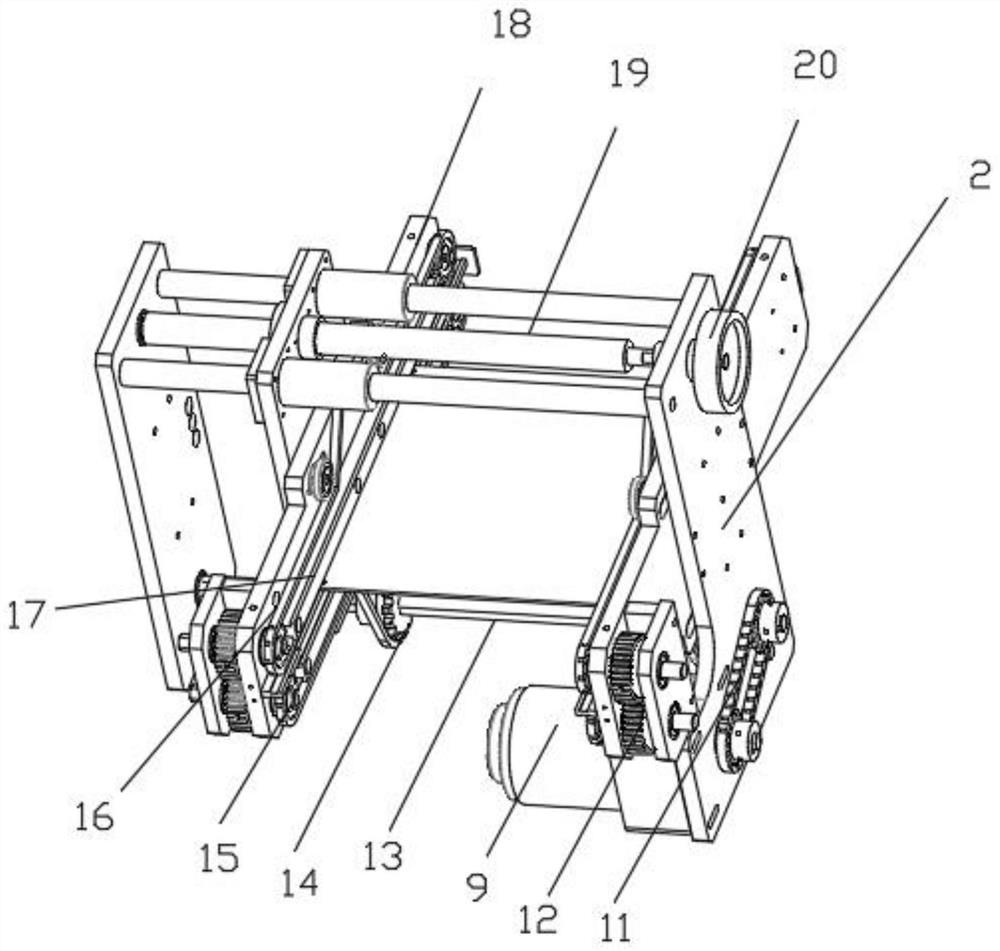

Sander for prefabricated slab laying

ActiveCN111571391ASmooth splicingFast full range sandingConstruction materialPortable grinding machinesSanderDrive wheel

The invention discloses a sander for prefabricated slab laying. The sander for prefabricated slab laying aims to solve the problem that in the prior art, the side faces of prefabricated slabs cannot be polished easily and rapidly. The sander for prefabricated slab laying comprises a first mounting plate and a second mounting plate. Inserting rods are evenly welded to the inner side face of the first mounting plate and the inner side face of the second mounting plate. Grips are fixedly mounted on the side faces of the first mounting plate and the second mounting plate, supporting rods are welded to the middles of the outer surfaces of the first mounting plate and the second mounting plate, driving wheels are mounted at the outer ends of the supporting rods, first rotating shafts are mountedbetween the driving wheels and the supporting rods, and motors are mounted at the outer ends of the first rotating shafts. Rotating blocks are welded to the two ends of the outer surface of the firstmounting plate and the two ends of the outer surface of the second mounting plate correspondingly, and rotating rods are sleeved with the rotating blocks. The motors are used for driving, a conveyingbelt is used for polishing the side faces of the prefabricated slabs, so that the prefabricated slabs are spliced more stably, the polishing area of the conveying belt is relatively large, the grinding efficiency is improved, and efficiency is relatively high.

Owner:广东南粤建筑工程有限公司

Silicon rod producing and machining polishing device with convenience in adjusting polishing directions

ActiveCN107639493AAdjust the grinding directionEasy to put inEdge grinding machinesGrinding carriagesEngineeringMechanical engineering

The invention discloses a silicon rod producing and machining polishing device with convenience in adjusting polishing directions. The silicon rod producing and machining polishing device comprises abottom plate, a turntable and a disc. Support tables are mounted on two lower sides of the bottom plate, an accommodating tank is arranged between the support tables, a support frame is arranged on the upper side of the bottom plate, a cylinder is mounted on the upper side of the support frame, a driving machine is fixed to the front side of the turntable, fixing screws are mounted on the side surfaces of the disc, a movable rod is arranged below the disc, a fixing device is arranged on the outer side of the movable rod, a polishing wheel is mounted on the front side of the driving machine, apolishing sheet is arranged on the front side of the polishing wheel, a rotary shaft is arranged between the polishing wheel and the driving machine, compressing sheets are arranged at ports of the fixing screws, and rubber layers are arranged on the compressing sheets. The silicon rod producing and machining polishing device with the convenience in adjusting the polishing directions has the advantages that the characteristics of fragility of silicon rods are taken into consideration, the silicon rods can be protected in silicon rod polishing procedures, and the polishing directions can be adjusted.

Owner:内蒙古和光新能源有限公司

Pipe bellmouth polishing device for nodular cast iron pipe

InactiveCN108620978AWide range of activitiesReasonable structural designEdge grinding machinesGrinding carriagesDrive motorUltimate tensile strength

The invention relates to the technical field of nodular cast iron pipes, in particular to a pipe bellmouth polishing device for a nodular cast iron pipe. The pipe bellmouth polishing device for the nodular cast iron pipe comprises the nodular cast iron pipe and is characterized in that supporting bases are symmetrically arranged on the left side and the right side of the bottom of the nodular castiron pipe, anti-vibration pads are arranged at the bottoms of the supporting bases, the left side and the right side of the bottom of each anti-vibration pad are symmetrically provided with movable supporting rods, the left side and the right side of each connection rod are symmetrically provided with supporting feet, the outer wall of the center of a movable rod on the left side is in sleeved connection with a movable support, a thread bushing is movably connected to the bottom of the movable support, a worm is in inserted connection with an inner cavity of the thread bushing, the outer walls of the left side and the right side of the worm are sleeved with supporting blocks correspondingly, the left side of the worm is provided with a driving motor, the bottoms of the supporting feet areprovided with a supporting plate, the right side of the top of the supporting plate is provided with a lifting mechanism, the right side of the top of the lifting mechanism is provided with a dull polishing motor, and the power output end of the dull polishing motor is connected with a dull polishing wheel. The problems that the angle cannot be adjusted when the nodular cast iron pipe is polished, the labor intensity is large, and stability of a lifting platform is not high are solved.

Owner:HANSHAN COUNTY XINGDA DUCTILE IRON FACTORY

Environment-friendly wall surface smoothing device for building construction and building construction method

PendingCN113510549AAchieving Squeeze ContactSingle and stable force directionGrinding carriagesGrinding drivesArchitectural engineeringPlanishing

The invention discloses an environment-friendly wall surface smoothing device for building construction and a building construction method. The environment-friendly wall surface smoothing device comprises a smoothing trolley and an abutting plate assembly, the smoothing trolley comprises a trolley plate, and locking universal wheels are installed on the four corners of the bottom of the trolley plate; the environment-friendly wall surface smoothing device is characterized in that a stand is arranged at the top of the trolley plate, supporting legs are arranged between the bottom side of the stand and the trolley plate, a rail vertical pipe is fixedly mounted on the top side of the stand, the rail vertical pipe is of a rectangular pipeline-shaped structure, a rectangular lifting column is vertically and glidingly mounted in the rail vertical pipe, a threaded groove is formed in the bottom of the rectangular lifting column, a threaded column is connected in a threaded mode, a rotating circular plate is fixedly mounted at the bottom end of the threaded column, and a universal ball and a connecting rod are mounted on the bottom side of the rotating circular plate. According to the device, the wall surface smoothing effect is guaranteed, the polishing range is wide, using is more convenient and faster, labor is saved, the application range is wide, the design is reasonable, the structure is stable, and the using requirement of building workers for wall surface flatness treatment in the construction process is met.

Owner:葛泮忠

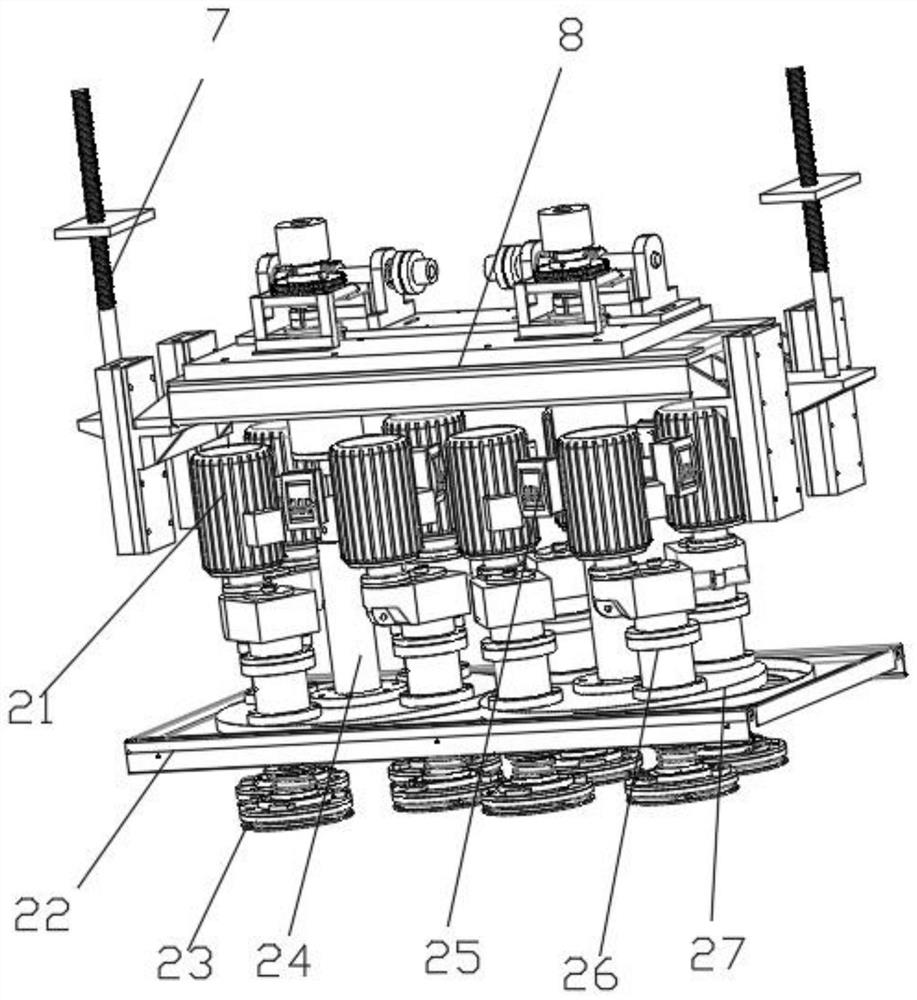

Multi-grinding-head multi-angle quick grinding device for grinding carbon-carbon crucible

ActiveCN114055311AImprove grinding efficiencyLarge grinding areaEdge grinding machinesGrinding carriagesElectric machineryEngineering

The invention discloses a multi-grinding-head multi-angle quick grinding device for grinding a carbon-carbon crucible, and relates to the technical field of grinding equipment. The multi-grinding-head multi-angle quick grinding device comprises a bearing table and a machining track, a clamping sleeve is arranged on the machining track, the bottom of the clamping sleeve is connected with a crucible in a clamping mode, and the machining track is arranged on the side edge of the bearing table; a first polisher, a second polisher and a third polisher are arranged on the bearing table, the edges of the first polisher and the second polisher are located on one side of the middle of the machining track, the third polisher is located below the tail of the machining track, a driving motor is fixedly connected into the bearing table, and a first output shaft is fixedly connected to the top of the driving motor; the bottom of the driving motor is fixedly connected with a second output shaft, the second output shaft is connected with a driving assembly in a sleeving mode, and the driving assembly is matched with the clamping sleeve. The carbon-carbon crucible can be ground in an industrial assembly line mode, and the grinding efficiency is high.

Owner:烟台奥森制动材料有限公司

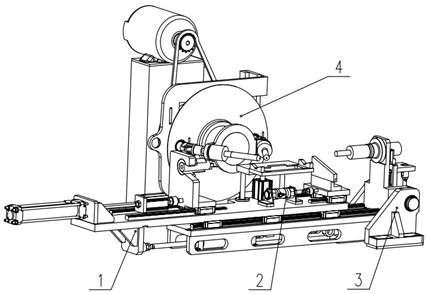

Stainless steel ingot grinding equipment

PendingCN112847026APrecise positioningHigh precisionGrinding drivesGrinding machinesGear wheelElectric machinery

The invention discloses stainless steel ingot grinding equipment which comprises a locating device, a workbench, a rotating device and a grinding device. The workbench is fixedly installed on the locating device, the rotating device is fixedly installed at the end of the workbench, and the grinding device is installed in the middle of the workbench. Air cylinders with three different mileages on the locating device are used for adjusting and location, and each steel ingot to be ground is fixed through a locating fixture. A V-shaped groove in the workbench is used for assisting in fixing the steel ingot in a large size, and the workbench is driven by a lifting electric cylinder to adjust the height. an end grinding rod is driven by a driver on the rotating device to grind the end of the steel ingot, and the angle is adjusted through the rotating shaft. A small belt wheel, a belt and a large belt wheel are driven by a motor on the grinding device, and therefore a large gear and a small gear are driven to transmit force; a transmission system is formed, and finally grinding heads which are symmetrically installed right and left are driven to grind the steel ingot.

Owner:南京轩田网络科技有限公司

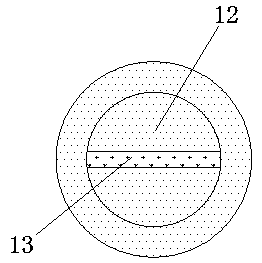

Quartz crystal forming polisher

InactiveCN105345625AEasy to moveWide range of grindingGrinding carriagesGrinding machinesEngineeringMechanical engineering

The invention discloses a quartz crystal forming polisher which comprises a polisher body. The polisher body comprises an outer polisher shell and an inner polisher shell. The inner polisher shell is arranged in the outer polisher shell. A cavity is formed between the outer polisher shell and the inner polisher shell. A containing table is arranged in the inner polisher shell. Sliding ways are fixedly arranged at the two ends of the top of the polisher body respectively. Sliding grooves are formed in the surfaces of the sliding ways. A connection frame is arranged above the sliding ways. Sliding blocks are arranged at the bottoms of the two ends of the connection frame respectively and arranged in the corresponding sliding grooves in a sliding manner. A motor is arranged on the connection frame. An output shaft of the motor is connected with one end of a connection rod through a coupler, wherein the connection rod is arranged on the connection frame in a penetrating manner. According to the quartz crystal forming polisher, the sliding ways and the sliding blocks are arranged so that polishing wheels can move to polish quartz, suction openings and a dust suction pipe are arranged so that a small amount of chippings generated in the polishing process can be guided out of the polisher, and damage to the polisher due to accumulated chippings is avoided.

Owner:张玮

Building environment-friendly thermal insulation material

PendingCN111675526AHigh strengthGood elasticityGrinding carriagesGrinding drivesBuilt environmentThermal insulation

The invention discloses a building environment-friendly thermal insulation material. The thermal insulation material is prepared from the following raw materials in parts by weight: 2-5 parts of fly ash, 1-4 parts of sericite powder, 0.5-2 parts of wood fiber powder, 5-8 parts of polypropylene fibers, 10-15 parts of quick lime, 60-80 parts of a cementing material and 10-15 parts of perlite. A cutsection bar is conveyed to the lower part of a hairbrush through a conveying belt; a second rotating shaft is driven to rotate to drive the hairbrush to rotate, the hairbrush conveys dust into a collecting and drawing groove through an arc-shaped plate, finally, a finished product is conveyed out of a cutting box, through the arrangement of the arc-shaped plate and an inclined plate, dust can be conveniently collected, polished and cut chippings can be conveniently recycled, and environmental pollution caused by the chippings is avoided.

Owner:XIANNING VOCATIONAL TECHN COLLEGE

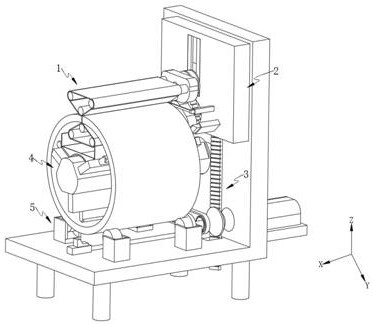

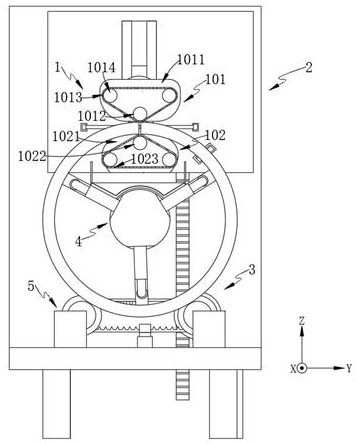

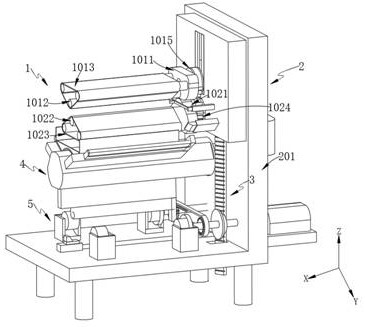

Production process and production equipment of stainless steel seamless steel pipe for ship

PendingCN114559217AQuality improvementImprove surface qualityRevolution surface grinding machinesGrinding drivesPolishingStructural engineering

The production technology comprises a base, a first side supporting plate is fixedly mounted on the left side of the upper end of the base, a movable groove is formed in the upper portion of the right end of the first side supporting plate, and a grinding mechanism is slidably connected into the movable groove; a second side supporting plate is fixedly installed on the right side of the upper end of the base, the left end of the driving mechanism is connected with the driving mechanism and a rotating mechanism in a penetrating mode, the driving mechanism and the rotating mechanism are movably installed on the second side supporting plate through bearings, the driving mechanism and the rotating mechanism are in transmission connection, and a clamping mechanism is arranged at the left end of the rotating mechanism. According to the production technology of the stainless steel seamless steel pipe for the ship, through multiple times of surface polishing treatment and deoiling and degreasing, the pipe is good in surface quality, free of burrs and accurate in size, the surface of the pipe is polished through multiple times of production equipment of the stainless steel seamless steel pipe for the ship, the labor intensity is low, the grinding efficiency is high, stress is uniform, and the grinding quality is high.

Owner:浙江永上特材有限公司

Pipe socket grinding device for ductile iron pipe

InactiveCN108620978BWide range of activitiesReasonable structural designEdge grinding machinesGrinding carriagesDrive motorUltimate tensile strength

The invention relates to the technical field of nodular cast iron pipes, in particular to a pipe bellmouth polishing device for a nodular cast iron pipe. The pipe bellmouth polishing device for the nodular cast iron pipe comprises the nodular cast iron pipe and is characterized in that supporting bases are symmetrically arranged on the left side and the right side of the bottom of the nodular castiron pipe, anti-vibration pads are arranged at the bottoms of the supporting bases, the left side and the right side of the bottom of each anti-vibration pad are symmetrically provided with movable supporting rods, the left side and the right side of each connection rod are symmetrically provided with supporting feet, the outer wall of the center of a movable rod on the left side is in sleeved connection with a movable support, a thread bushing is movably connected to the bottom of the movable support, a worm is in inserted connection with an inner cavity of the thread bushing, the outer walls of the left side and the right side of the worm are sleeved with supporting blocks correspondingly, the left side of the worm is provided with a driving motor, the bottoms of the supporting feet areprovided with a supporting plate, the right side of the top of the supporting plate is provided with a lifting mechanism, the right side of the top of the lifting mechanism is provided with a dull polishing motor, and the power output end of the dull polishing motor is connected with a dull polishing wheel. The problems that the angle cannot be adjusted when the nodular cast iron pipe is polished, the labor intensity is large, and stability of a lifting platform is not high are solved.

Owner:HANSHAN COUNTY XINGDA DUCTILE IRON FACTORY

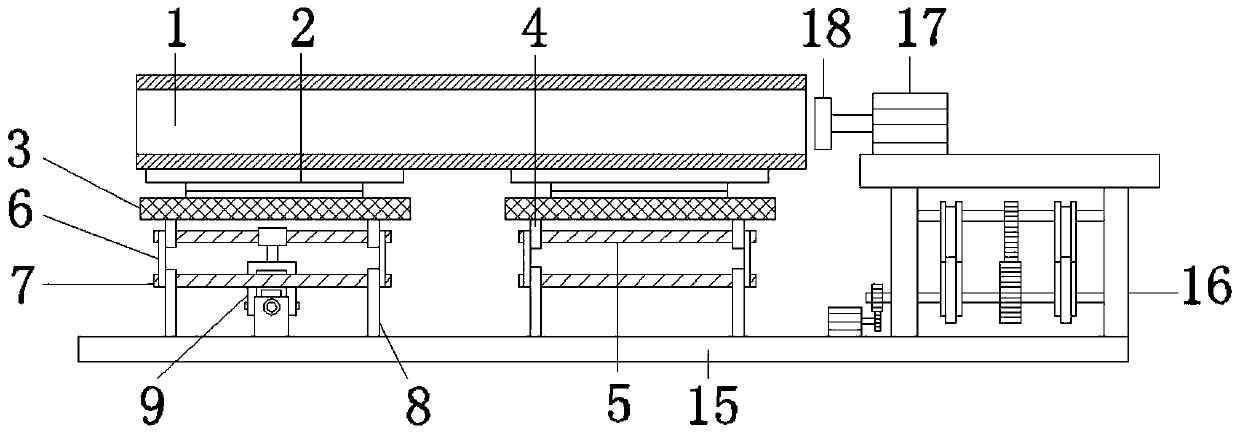

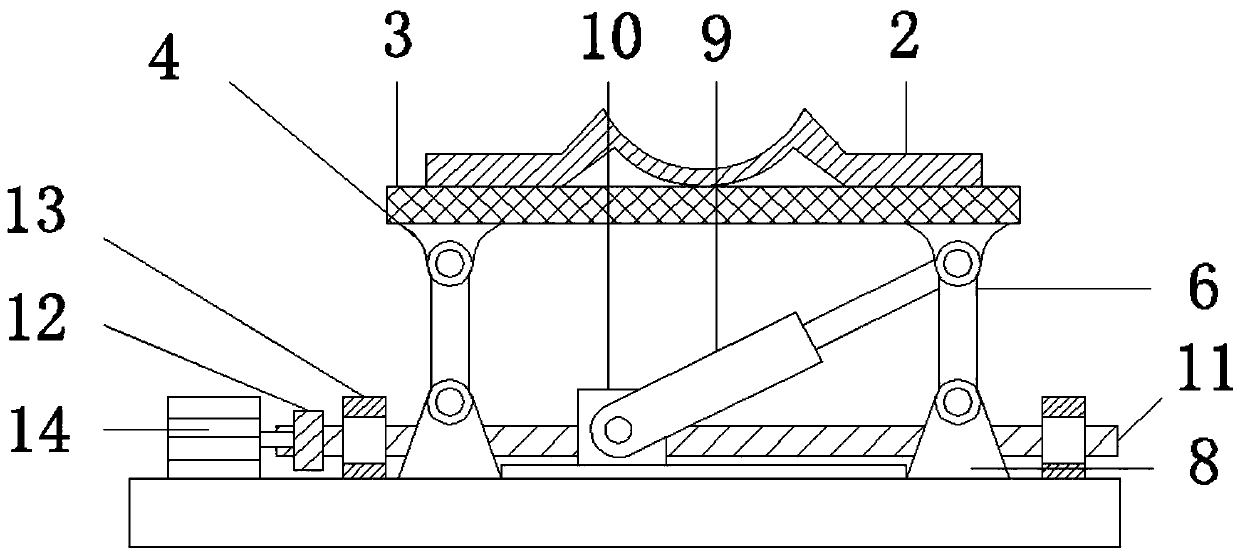

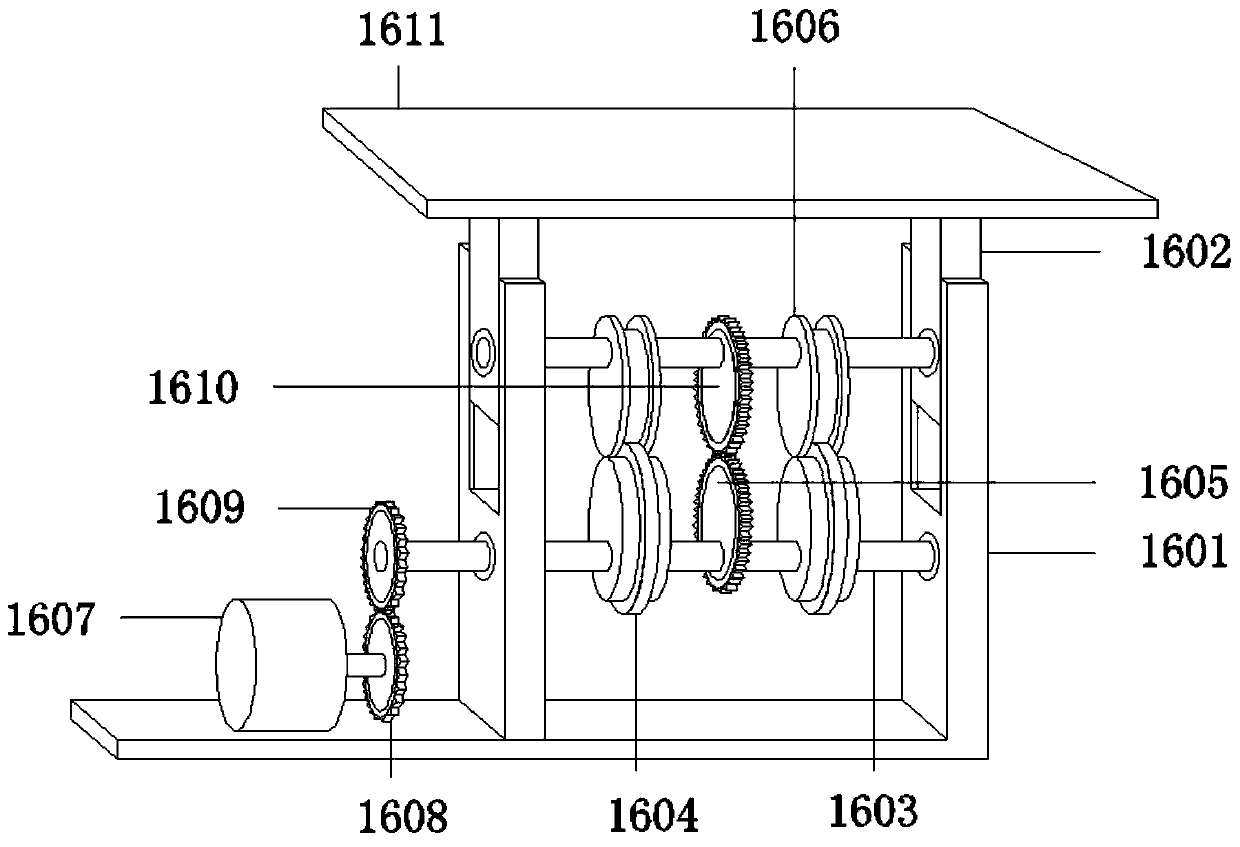

A kind of lime powder preparation method

The present invention relates to a lime powder preparation method, which adopts a lime powder preparation device. The lime powder preparation device includes a bottom frame, a screening mechanism, a conveying mechanism, a pulverizing and drying mechanism and a collection basket, which can solve the following problems: a After the lime powder is crushed, ground and calcined, during the storage process, due to the strong water absorption of the lime powder, the lime powder may absorb water and cause a hardening phenomenon, which will affect the subsequent mixing of the lime powder and other building materials. The use effect of powder, b In the traditional limestone preparation device, during the secondary grinding process of lime powder, the distance between the crushing frame and the cylinder wall cannot be adjusted, and it cannot be adjusted for the agglomeration of lime powder plates of different specifications. The pulverization treatment has low applicability, and during the grinding process, the surface of the cylinder wall is easy to adhere to the lime powder.

Owner:本溪市富佳矿业有限公司

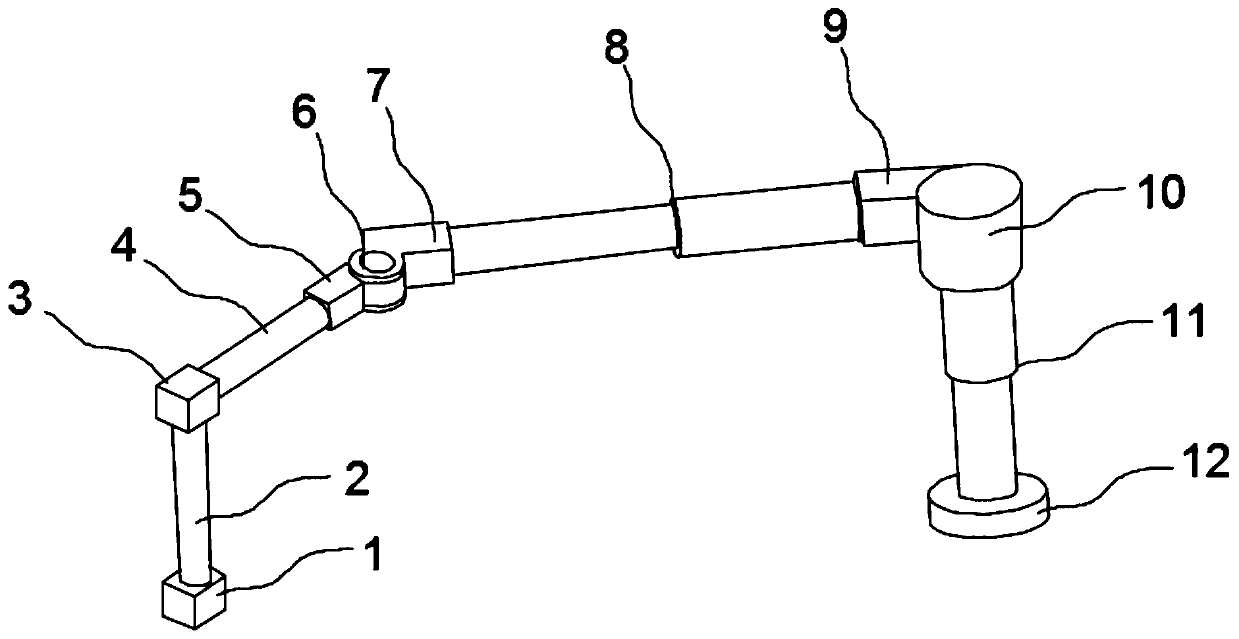

Multi-gradient machining equipment for local flatness treatment of building material

InactiveCN111546180ARealization of multi-latitude position adjustmentWide range of grindingGrinding carriagesGrinding drivesControl systemStructural engineering

The invention belongs to the field of building materials, and particularly relates to multi-gradient machining equipment for local flatness treatment of a building material. The multi-gradient machining equipment comprises a regulation and control system, and the regulation and control system comprises an X-axis arm structure, a Y-axis angle regulating structure and a Z-axis arm structure. The Y-axis angle regulating structure is additionally mounted on the X-axis arm structure, and can carry out 360-degree angle regulation on the X-axis arm structure. The X-axis arm structure is additionallymounted on the Z-axis arm structure and can carry out Z-axis length regulation through the Z-axis arm structure. The equipment further comprises a grinding head, and the grinding head is mounted on the X-axis arm structure and can carry out X-axis length regulation through the X-axis arm structure. The grinding head is rotationally connected with a disc-shaped grinding strip, and the disc-shaped grinding strip can rotate through a rotating structure additionally mounted on the grinding head. The grinding head is rotationally connected with the disc-shaped grinding strip, the disc-shaped grinding strip can carry out layered multi-gradient efficient grinding through the clearance of itself, and the grinding quality is high.

Owner:隋美青

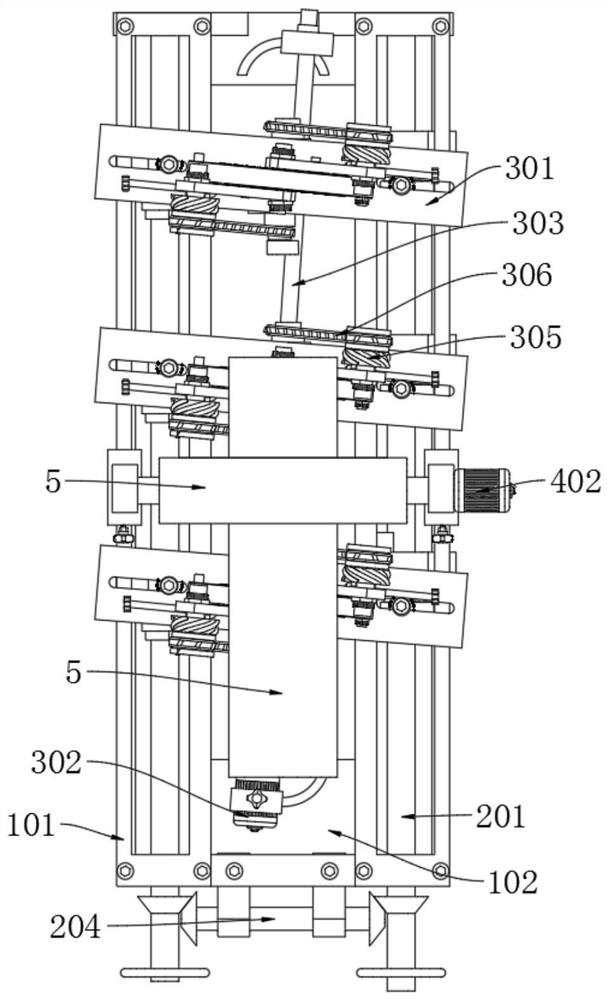

A special-shaped valve plate grinding equipment

ActiveCN112207675BImprove grinding effectImprove efficiencyGrinding drivesGrinding machinesChain linkOperating table

The invention discloses a special-shaped valve plate grinding equipment, which includes an operation table, on which a track simulation mechanism and a grinding mechanism are arranged; the track simulation mechanism includes a first rotating table, and the first rotating table is provided with The first fixed base, the first rotating shaft is rotatably connected with a first support frame, and the first support frame is slidingly connected with the operating table through a first guide rod, and the end of the first guide rod close to the operating table is sleeved with a second A support spring; the grinding mechanism includes a second turntable, the second turntable is rotatably connected to the first turntable through a chain, and the second support frame is connected to the first support frame through a connecting frame; the second turntable of the present invention A rotating shaft moves along the outer contour of the valve mold, and the first grinding rod moves and grinds along the outer contour of the valve to be polished. The corresponding grinding mold can be replaced according to different valves, and the valves of different shapes can be polished. wide.

Owner:六安中达信息科技有限公司

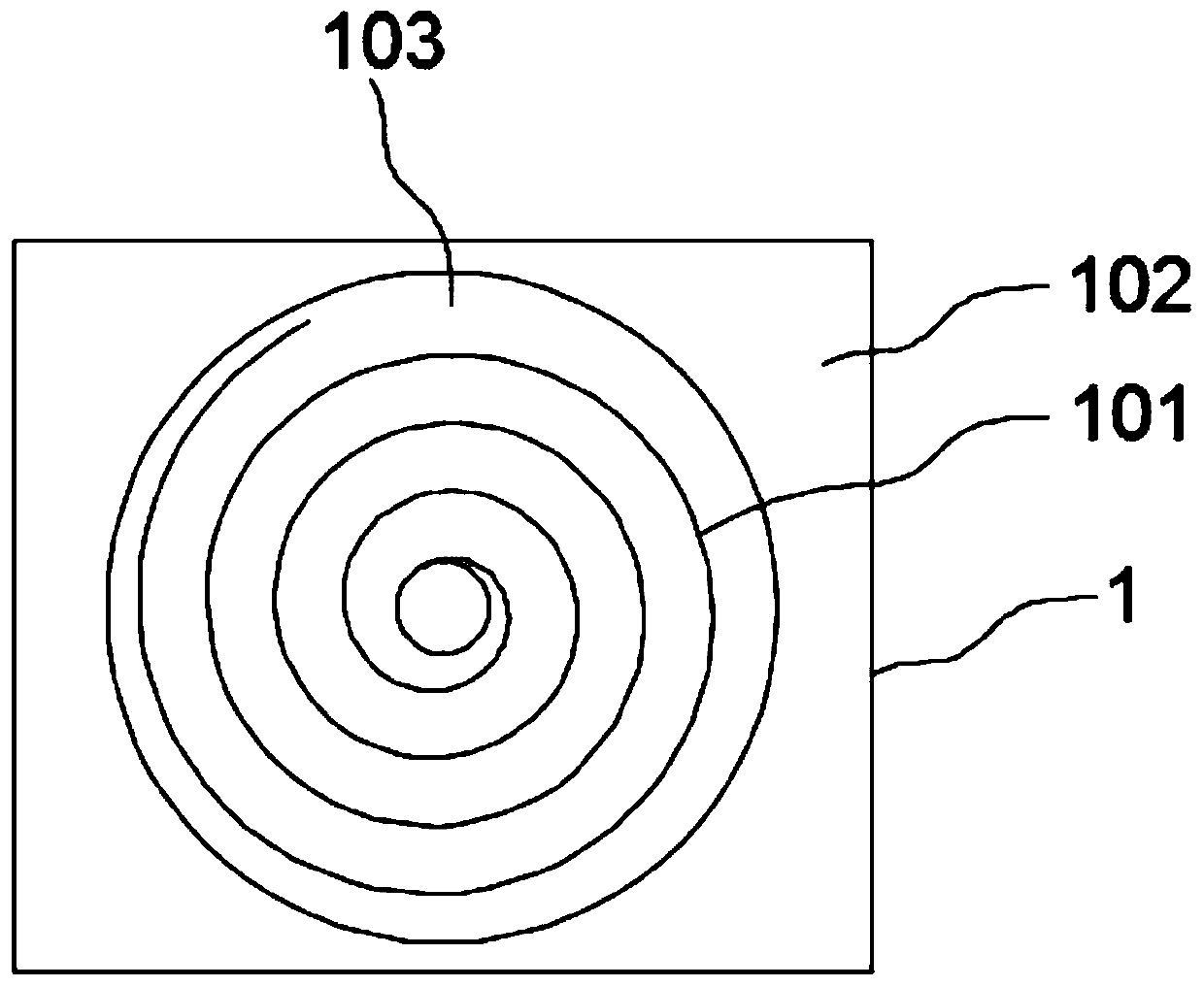

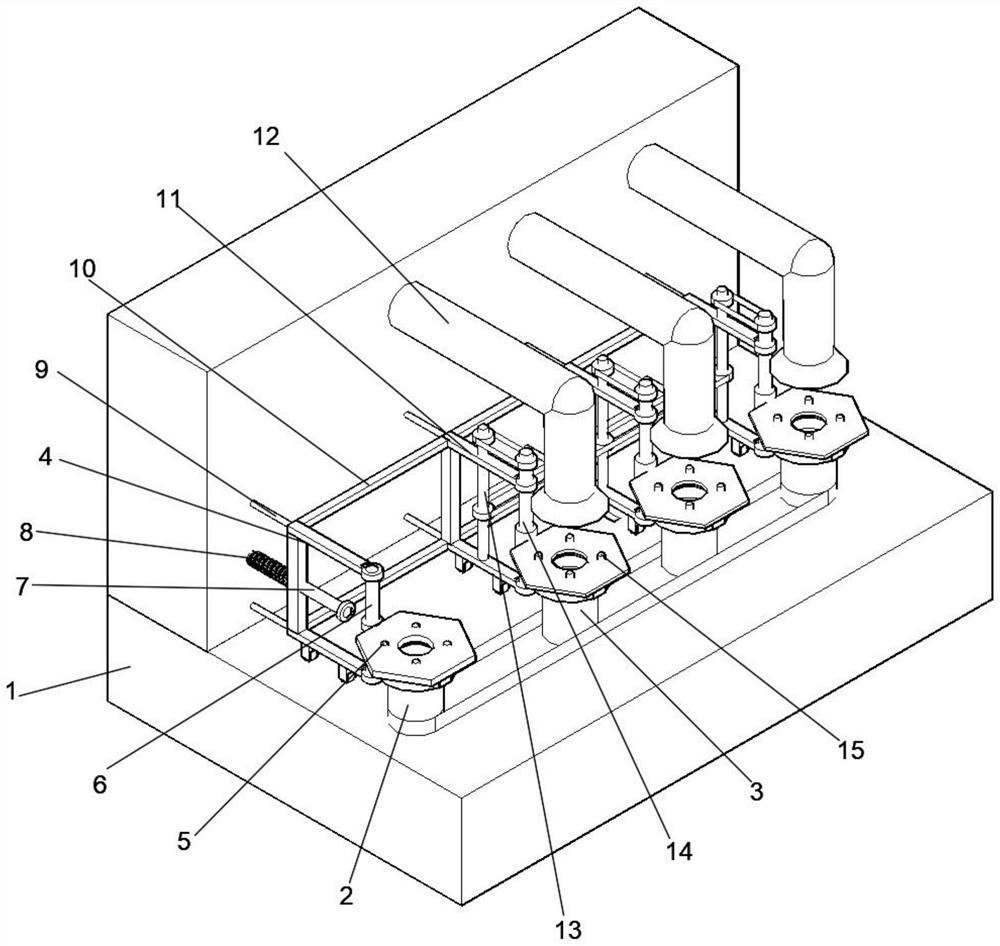

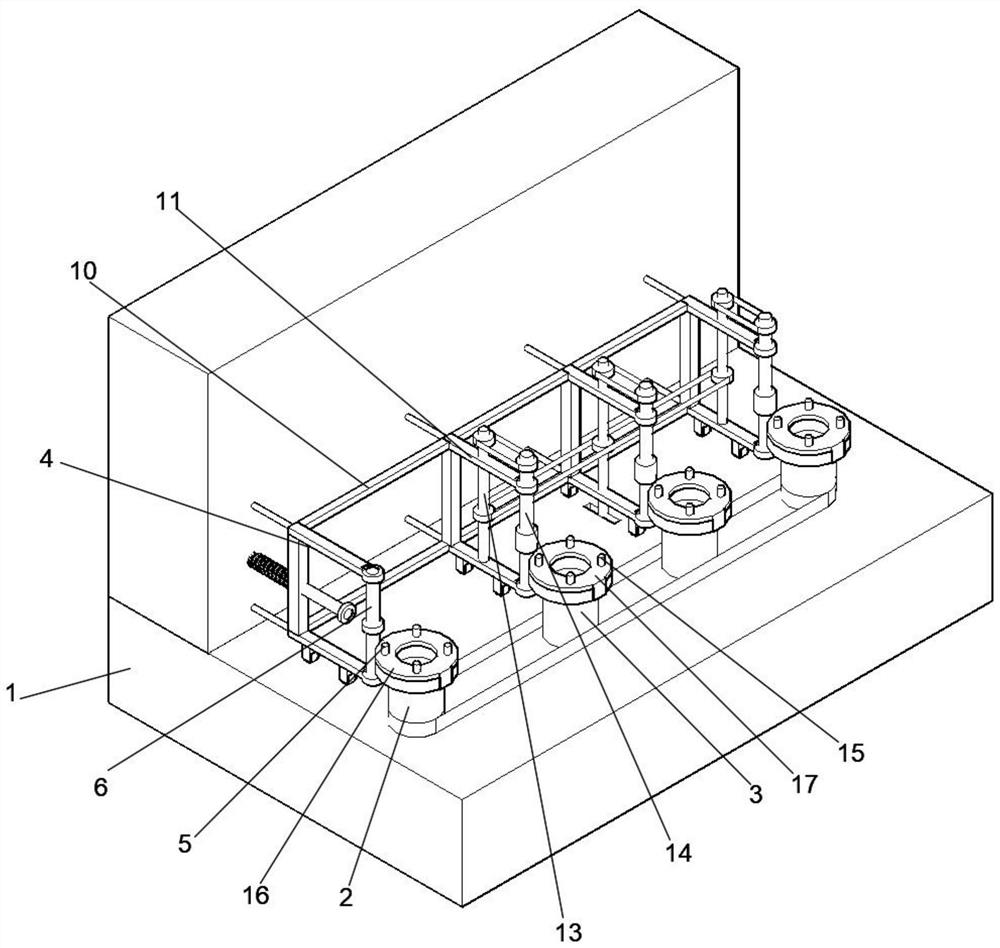

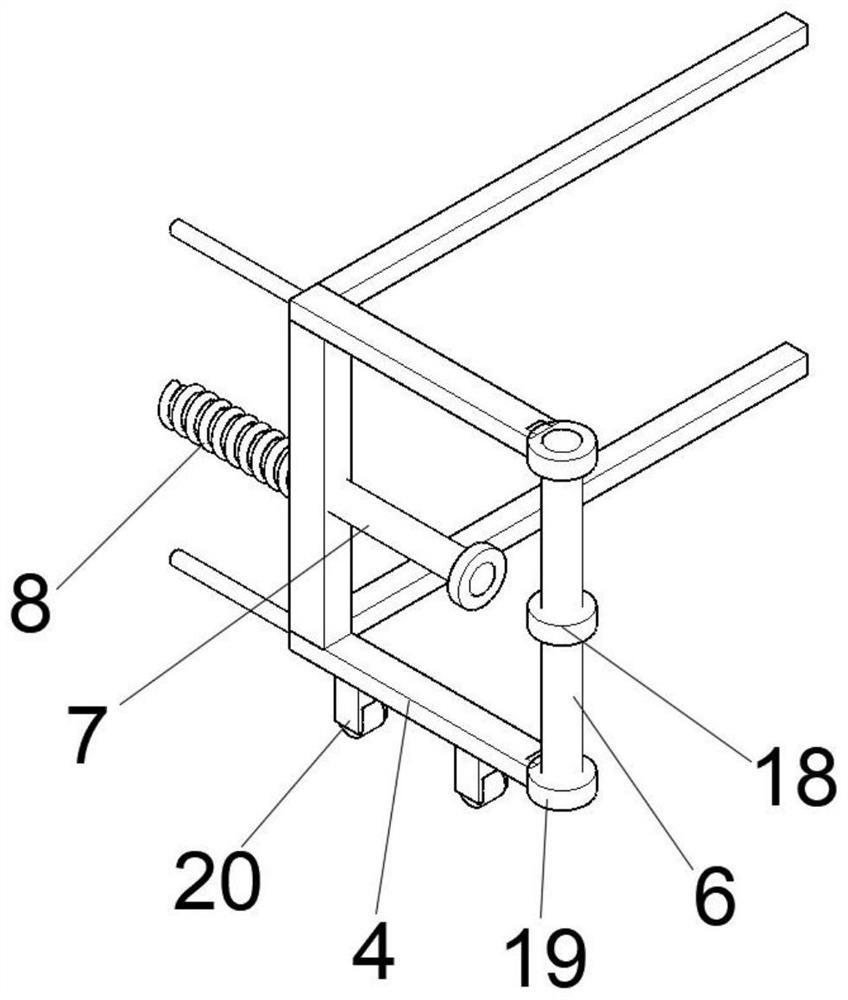

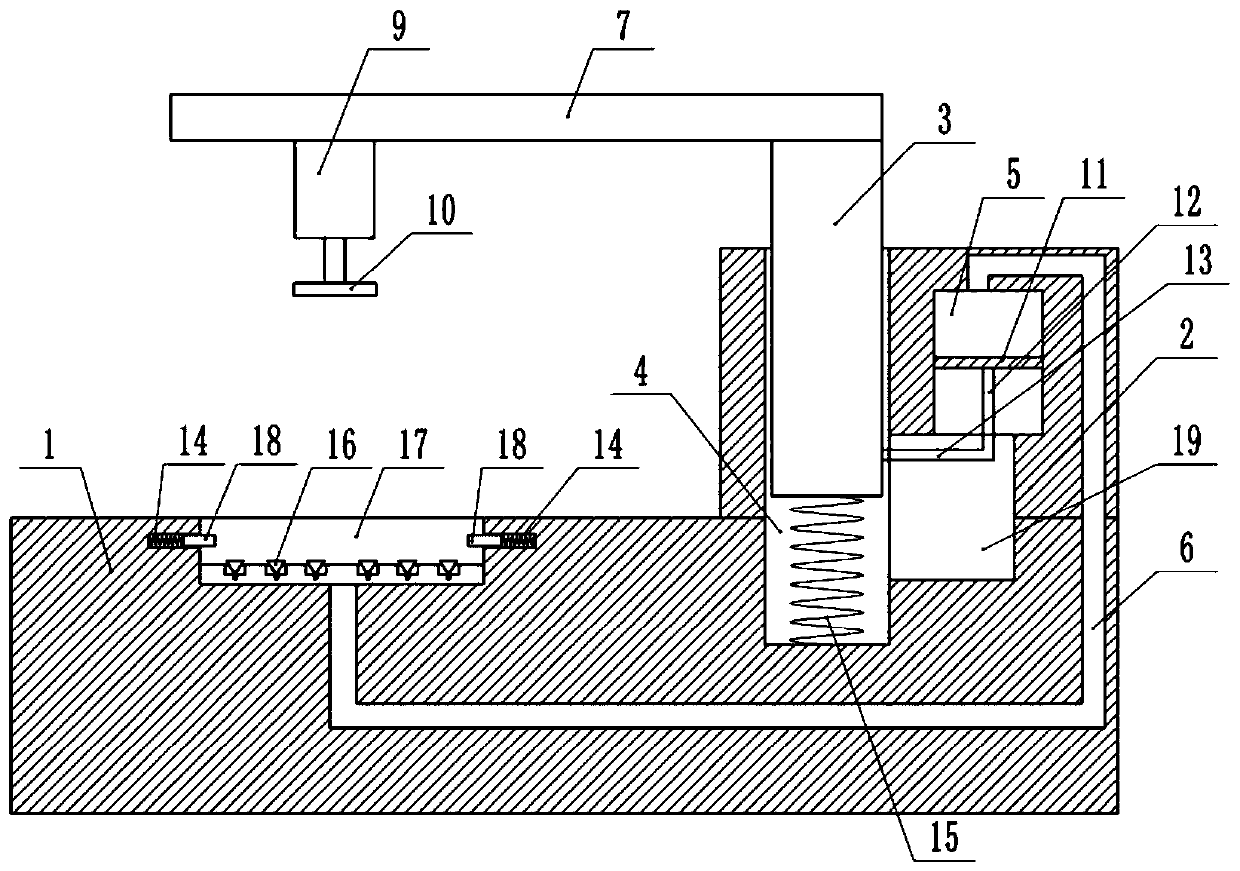

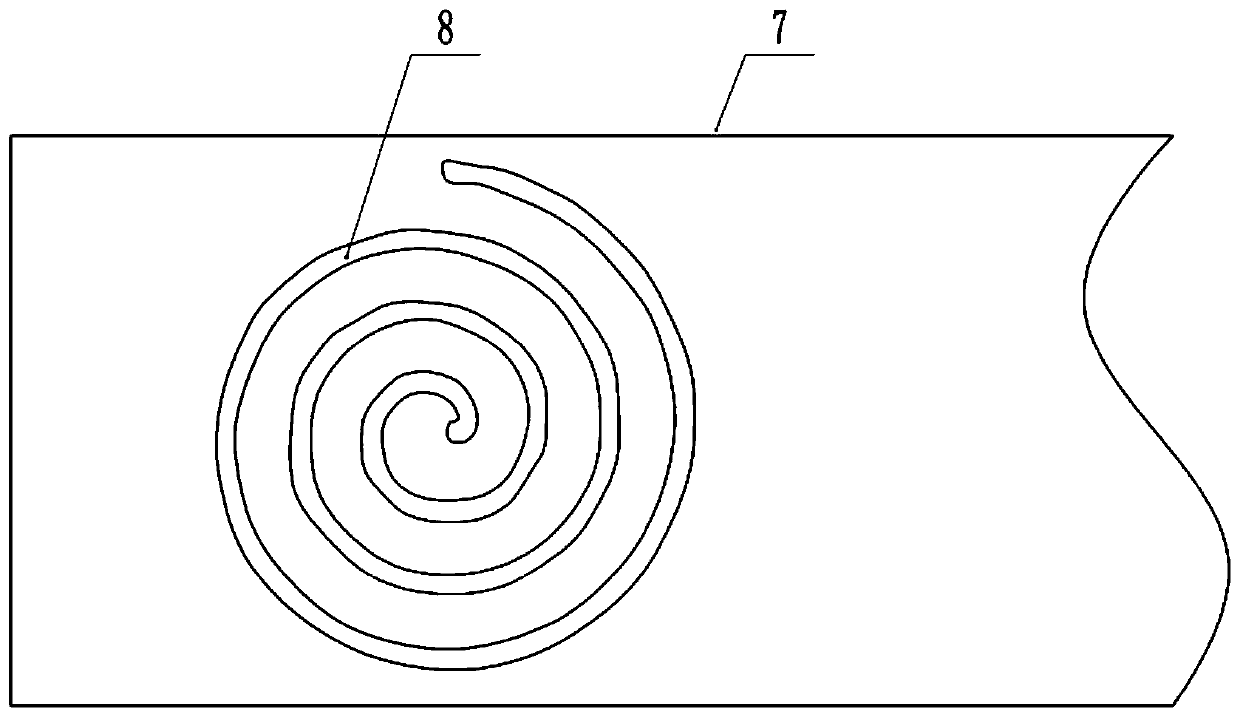

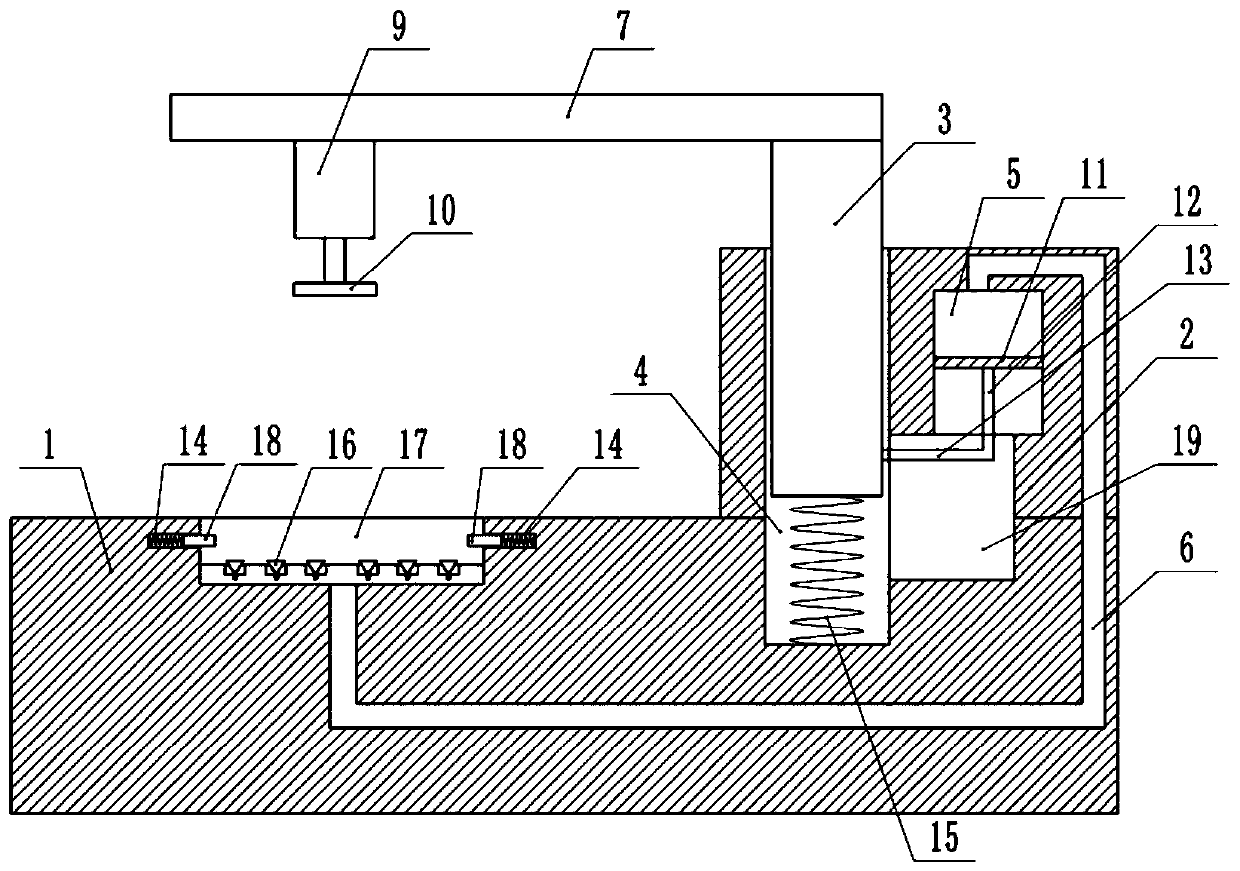

Parts Grinding Device

ActiveCN108274330BWide range of grindingImprove grinding efficiencyEdge grinding machinesGrinding carriagesTransverse planeEngineering

The invention relates to the technical field of polishing devices and specifically discloses a part polishing device. The part polishing device comprises a base and an air pump, wherein an upright column is arranged on the base; a first cavity structure, a second cavity structure and a third cavity structure are arranged on the upright column; a support column is arranged in the first cavity structure; a transverse plate is arranged at an upper end of the support column; a spiral track is arranged on the transverse plate; a sliding frame is arranged in the spiral track; a motor is arranged onthe sliding frame; a polishing disc is arranged at a shaft end of an output shaft of the motor; a piston is arranged in the second cavity structure; a piston rod is arranged on the piston; a transverse rod is connected between the piston rod and the support column; a plurality of adsorption holes is formed in the base; a suction disc is arranged in the adsorption hole; an air suction inlet is formed in the suction disc; and the third cavity structure is in communication with the air suction inlet and the second cavity structure. The part polishing device provided by the invention is mainly used for polishing parts and solves the problem of small polishing area during part polishing.

Owner:CHONGQING JIANAN IND & TRADE

Simple rough body eliminating instrument

InactiveCN109877663AReduce vibrationImprove work performanceGrinding machine componentsPlane surface grinding machinesSurface mountingDust emission

The invention discloses a simple rough body eliminating instrument. The simple rough body eliminating instrument comprises a dust isolation plate, a fixed pipe, a supporting disc, a connecting pipe, blowers, blowing openings and a power center, wherein a rotating part is mounted below the supporting disc, a length controller is mounted in the supporting disc, and the length controller is connectedwith the fixed pipe through an elastic device; the dust isolation plate is mounted on the left side of the fixed pipe, the power center is mounted below the blowing openings, a rotating device is mounted in the power center, and an air exhaust fan is mounted above the rotating device; an error alarm is mounted on the surface of the power center, the power center is connected with a grinding partthrough a transmission rod, and a grinding device is mounted on the left side of the grinding part; and an air exhaust pipeline is mounted below the fixed pipe, the corresponding blower is mounted onthe right side of the air exhaust pipeline, and a material bin is mounted below the blower. According to the simple rough body eliminating instrument, through the action of the grinding device in an isolation plate and the blowers, the grinding performance is improved while the dust emission is reduced, and an environment-friendly function is further provided during using.

Owner:孙红艳

Multi-head multi-angle fast grinding device for carbon-carbon crucible grinding

ActiveCN114055311BImprove grinding efficiencyLarge grinding areaEdge grinding machinesGrinding carriagesElectric machineryDrive motor

The invention discloses a multi-grinding-head and multi-angle quick-grinding device for grinding a carbon-carbon crucible, which relates to the technical field of grinding equipment, and includes a bearing table and a processing track. The track is arranged on the side of the bearing platform, and the first grinding machine, the second grinding machine and the third grinding machine are arranged on the bearing platform, the edges of the first grinding machine and the second grinding machine are on the side of the middle part of the processing track, and the third The grinder is located below the tail of the processing track, the drive motor is fixedly connected to the bearing table, the top of the drive motor is fixedly connected to the first output shaft, the bottom of the drive motor is fixedly connected to the second output shaft, and the second output shaft is socketed and connected to the drive assembly , the driving assembly cooperates with the ferrule, and the present invention can perform industrial assembly-line grinding on the carbon-carbon crucible, and the grinding efficiency is high.

Owner:烟台奥森制动材料有限公司

A grinding device for silicon rod production and processing that is convenient for adjusting the grinding direction

ActiveCN107639493BAdjust the grinding directionEasy to put inEdge grinding machinesGrinding carriagesCircular discEngineering

The invention discloses a silicon rod producing and machining polishing device with convenience in adjusting polishing directions. The silicon rod producing and machining polishing device comprises abottom plate, a turntable and a disc. Support tables are mounted on two lower sides of the bottom plate, an accommodating tank is arranged between the support tables, a support frame is arranged on the upper side of the bottom plate, a cylinder is mounted on the upper side of the support frame, a driving machine is fixed to the front side of the turntable, fixing screws are mounted on the side surfaces of the disc, a movable rod is arranged below the disc, a fixing device is arranged on the outer side of the movable rod, a polishing wheel is mounted on the front side of the driving machine, apolishing sheet is arranged on the front side of the polishing wheel, a rotary shaft is arranged between the polishing wheel and the driving machine, compressing sheets are arranged at ports of the fixing screws, and rubber layers are arranged on the compressing sheets. The silicon rod producing and machining polishing device with the convenience in adjusting the polishing directions has the advantages that the characteristics of fragility of silicon rods are taken into consideration, the silicon rods can be protected in silicon rod polishing procedures, and the polishing directions can be adjusted.

Owner:内蒙古和光新能源有限公司

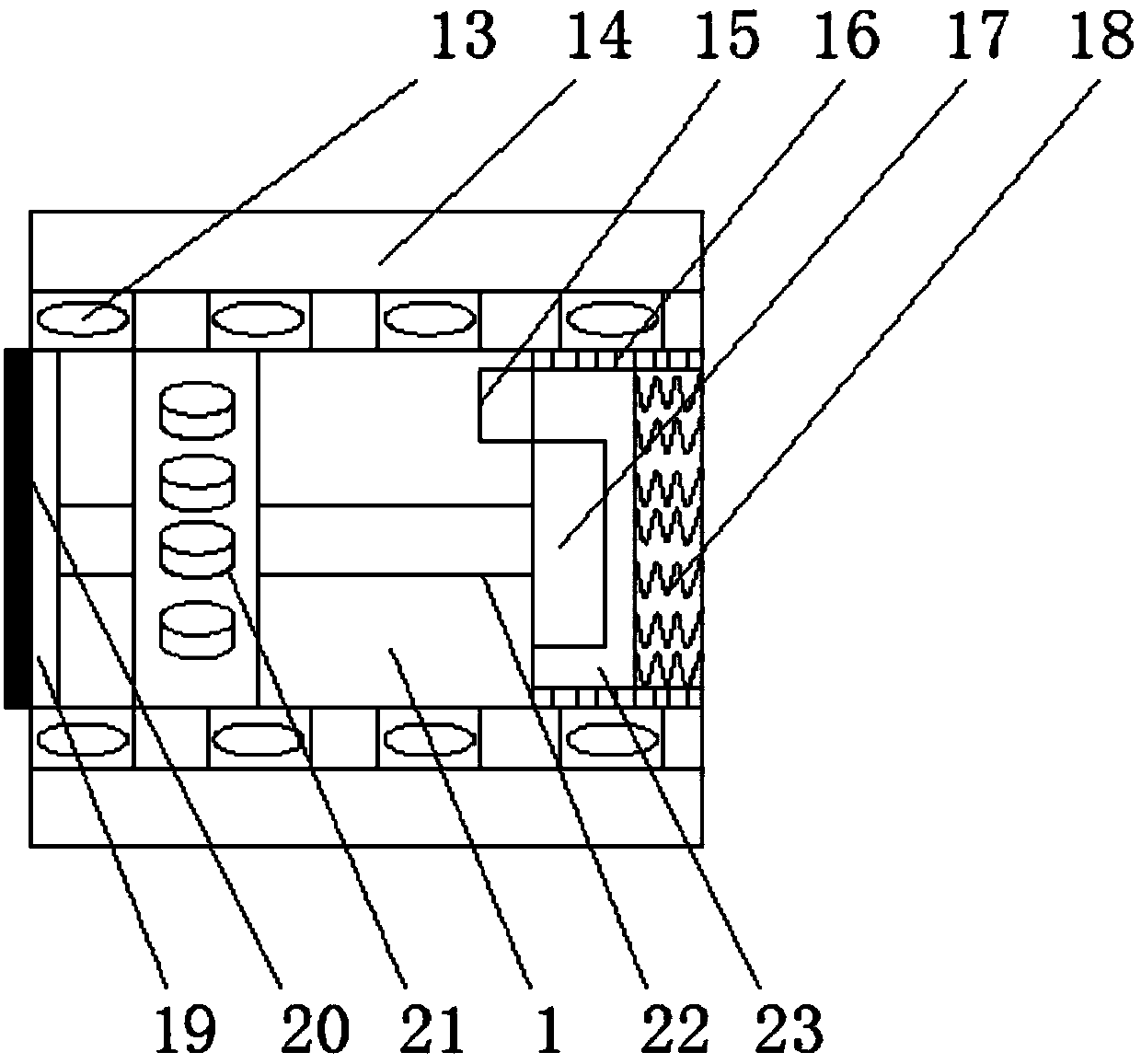

High-performance numerical control machine tool

PendingCN113601327AExtended service lifeExpand the scope of useGrinding carriagesGrinding drivesProcess engineeringMachine tool

The invention discloses a high-performance numerical control machine tool, and belongs to the technical field of numerical control machine tools. The high-performance numerical control machine tool comprises an outer shell, an operating floor is fixedly mounted at the upper end of the outer shell, a vertical plate is fixedly mounted at the rear end of the upper surface of the operating floor, and an integration box is fixedly mounted at the left end of the upper surface of the operating floor. By arranging a cleaning assembly, an air blowing assembly and a collecting assembly, a machining bin of the numerical control machine tool can be cleaned in all directions after polishing machining of the numerical control machine tool is completed, the cleaning assembly can flush chippings generated by polishing machining through water spraying, the collecting assembly can classify and collect waste water and chippings generated after flushing is completed through a filter screen and a collecting box, and the resource recycling rate is increased; and in addition, the air blowing assembly can blow and sweep the chippings generated during polishing machining, the interior of the machining bin can be dried after flushing is completed, and in addition, an adjusting assembly can widen the use range of the machine tool and reduce the production cost of enterprises.

Owner:薛志鹏

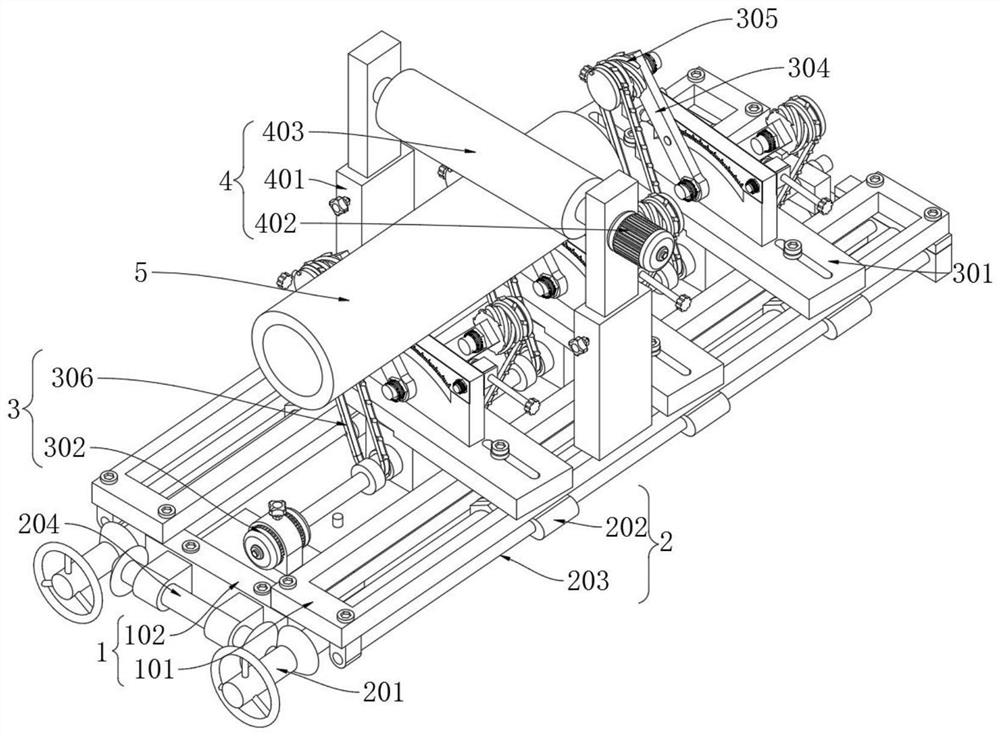

Feeding platform for new material processing and feeding that can be matched with pipe processing equipment

ActiveCN111604730BImprove the conveying structureWide range of grindingGrinding carriagesRevolution surface grinding machinesStructural engineeringMaterials processing

The invention provides a feeding platform for processing and feeding new materials that can be matched with pipe processing equipment, belongs to the technical field of pipe processing, and solves the existing problem of surface treatment after pipe processing, including a fixing mechanism; the fixing mechanism is connected with the processing equipment through bolts connected with each other, and the fixing mechanism is fixed and supported by bolts with an adjusting mechanism, and a rotating handle is installed on the adjusting mechanism; a conveying mechanism is fixed on the adjusting mechanism through bolts. There is a nut placement seat capable of translation on the lead screw, and the nut placement seat is limited in a balanced state by a limit rod. A round hole is provided on the T-shaped connecting seat, and the T-shaped connecting seat is connected to the nut through the round waist hole. The placement bases are connected, and when the lead screw is turned, the two lead screws will rotate in opposite directions, so that the nut placement base will translate in the opposite direction, and then the nut placement base will drive the T-shaped connection base to rotate to adjust the support angle. When adjusting multiple T It is more convenient when the angle of the connecting seat is shaped.

Owner:新疆华烨盛新管业有限公司

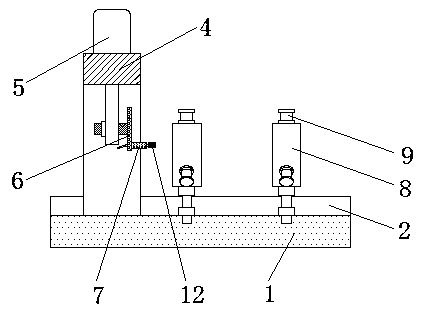

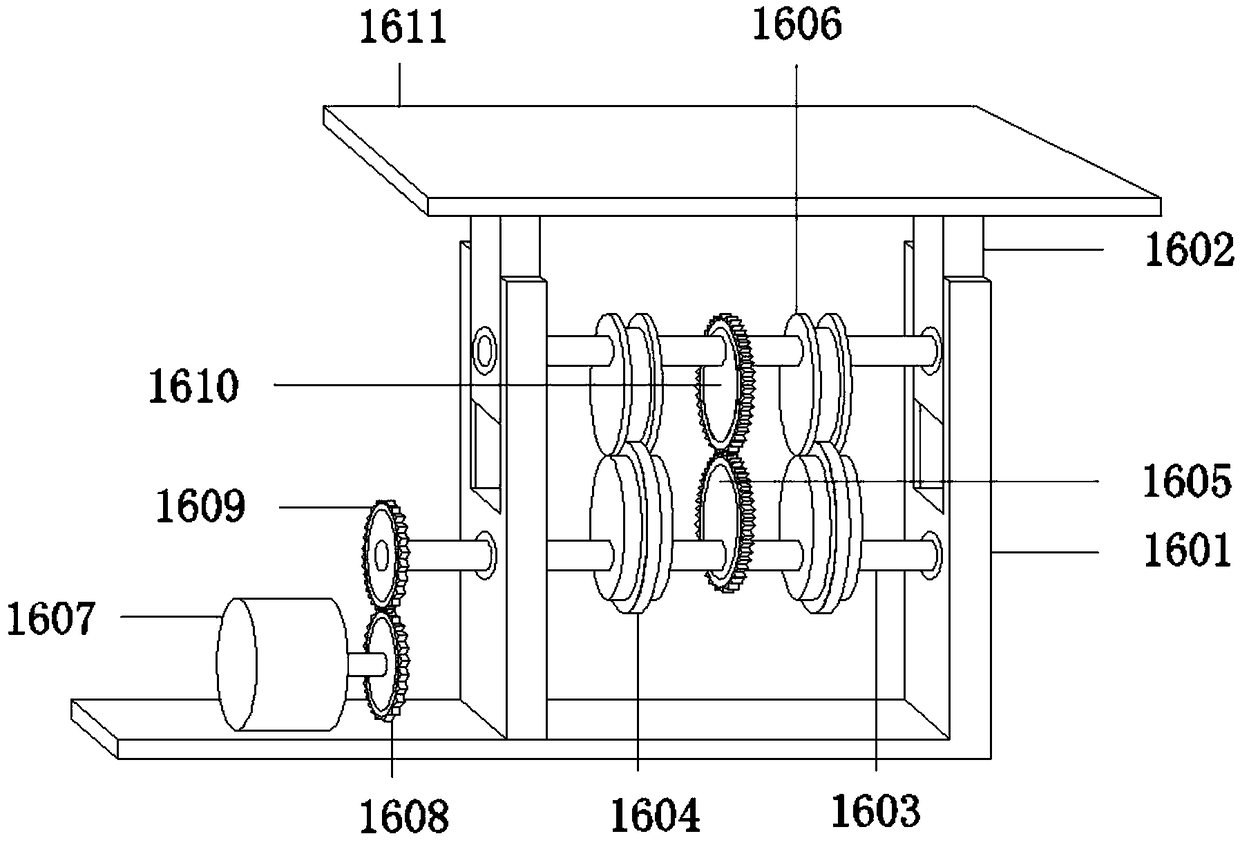

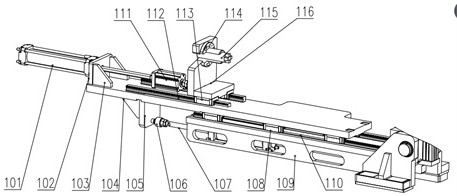

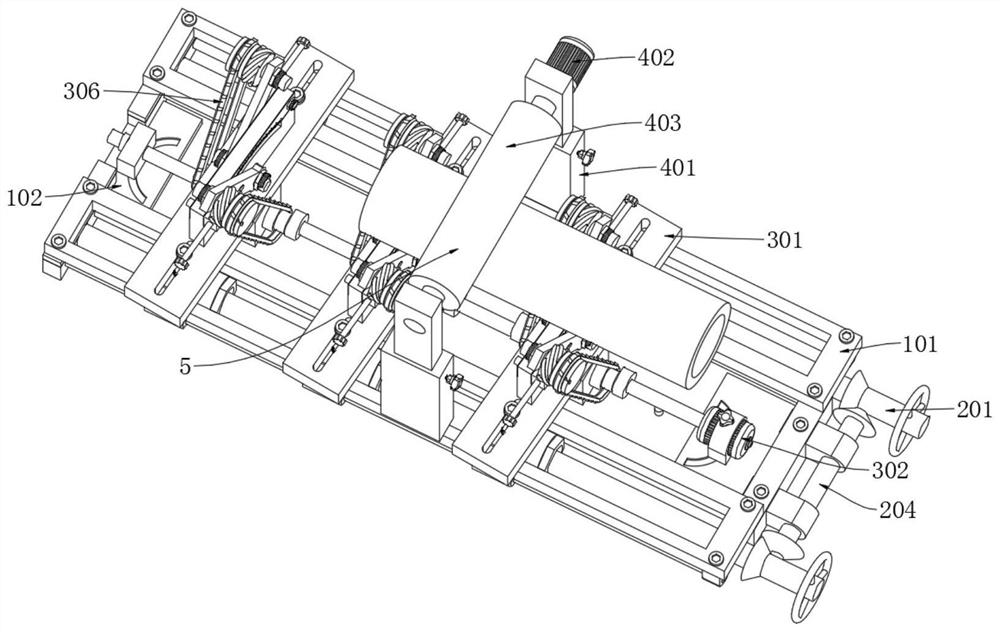

Micro-motion stepless speed regulation grinding device for common big vertical lathe

InactiveCN101804599BEasy loading and unloadingFlexible loading and unloadingGrinding carriagesGrinding drivesElectricityEngineering

The invention relates to a micro-motion stepless speed regulation grinding device for a common big vertical lathe, which comprises a two-dimensional regulation mechanism, a hand feeding mechanism, a lifting mechanism of a grinding head and a grinding head of an electric main shaft. The two-dimensional regulation mechanism connects a support body, a first connector, a second connector and a mounting plate of a guide rail sequentially by two pairs of swivel bearing pairs and one pair of dovetail pairs and realizes the two-dimensional regulation of the entire device; the hand feeding mechanism realizes microfeed by the transmission of the two pairs of gear pairs; the lifting mechanism of the grinding head drives one pair of gear pairs by a motor, and then the gear pairs push a lead screw thread pair with a linear guide rail, thereby realizing the up-and-down lifting of the mounting plate of the electric main shaft; and the grinding head of the electric main shaft is formed by sequentially connecting an electric main shaft seat, the electric main shaft, an Morse taper shank and a grinding wheel. The invention realizes that a grinding function is realized on the common big vertical lathe, the grinding range is 0 to 10000rpm, and the minimum feed amount of the hand feeding mechanism is 0.0005mm.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

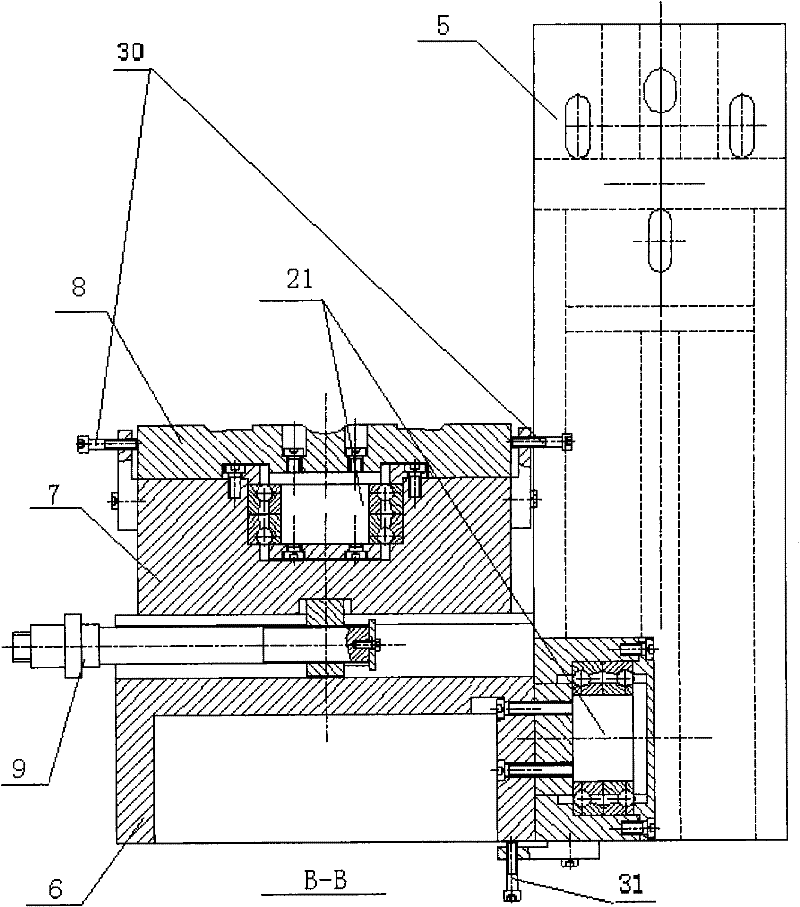

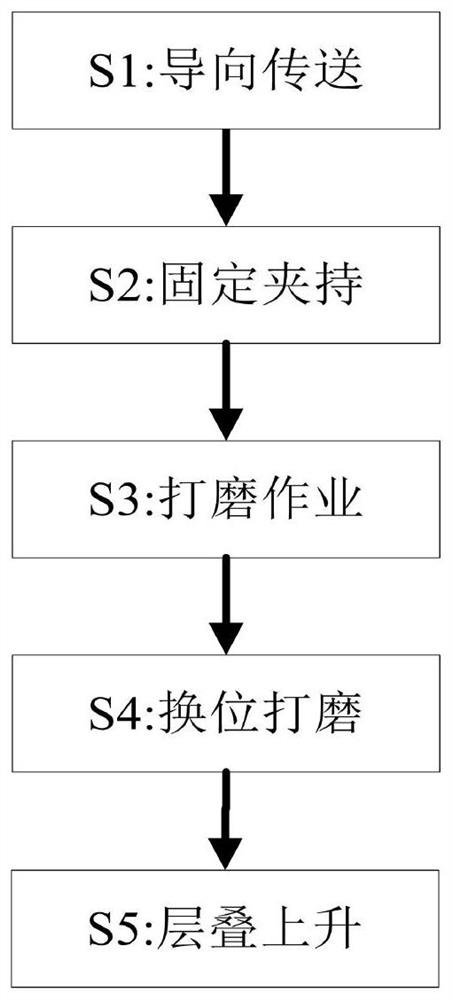

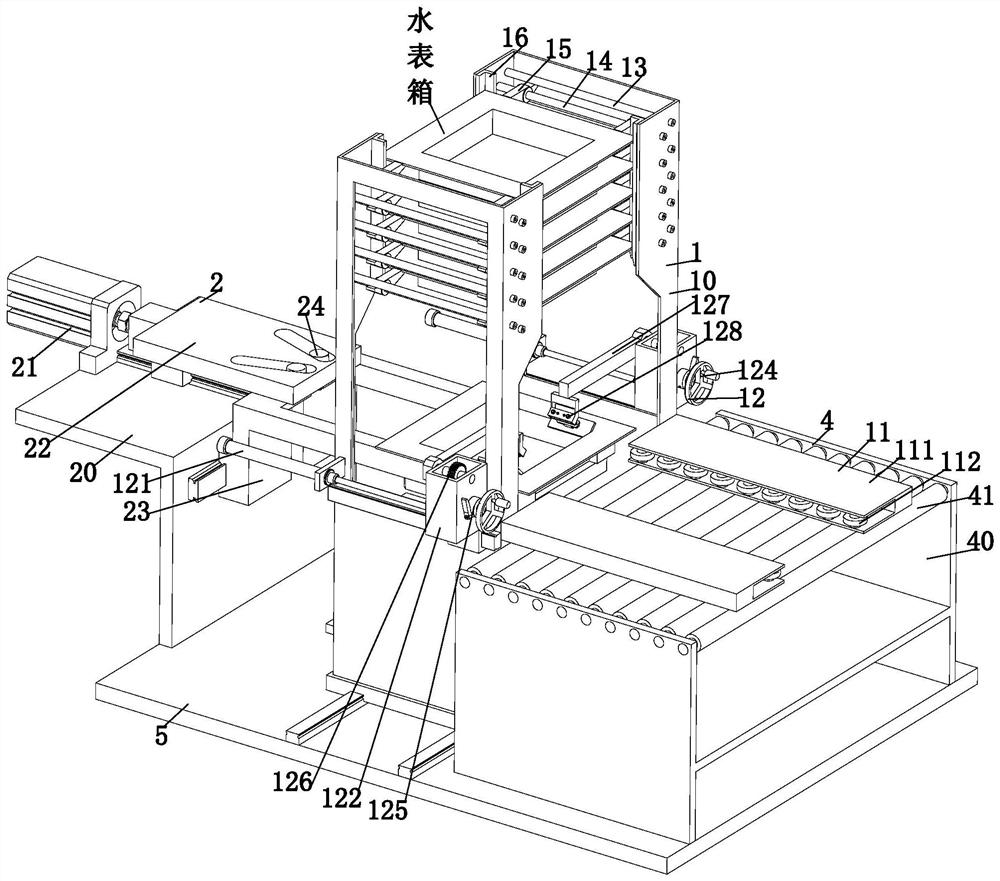

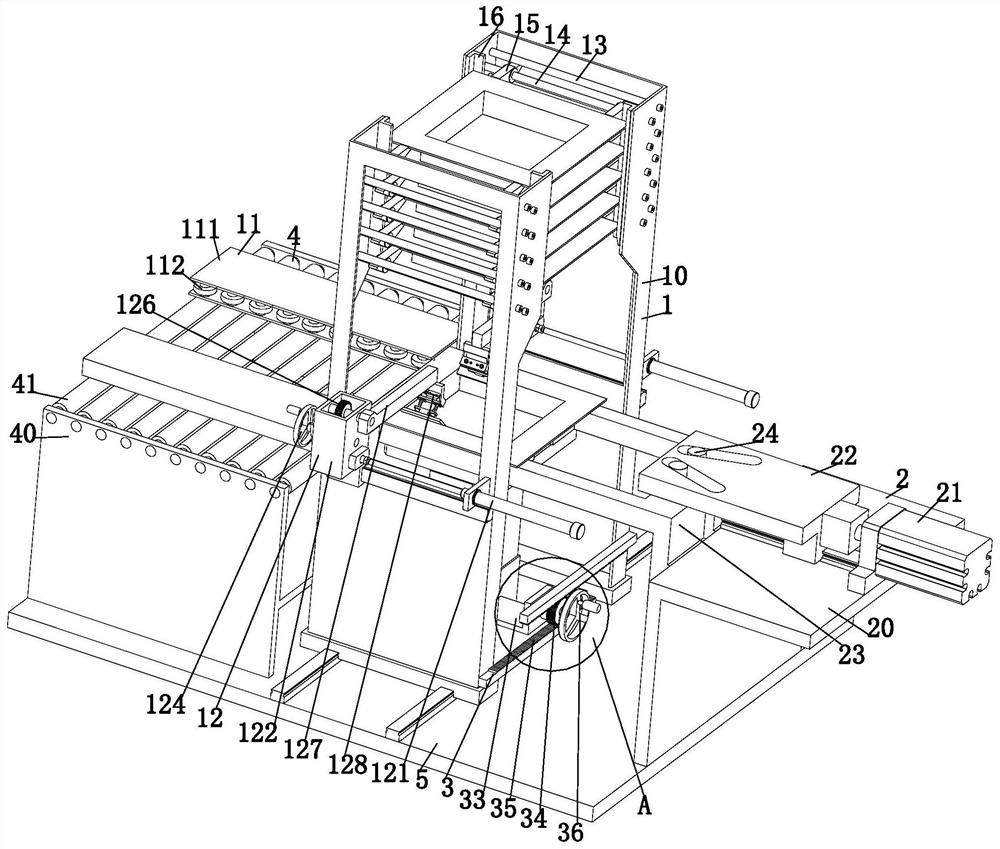

Composite water meter box forming treatment process

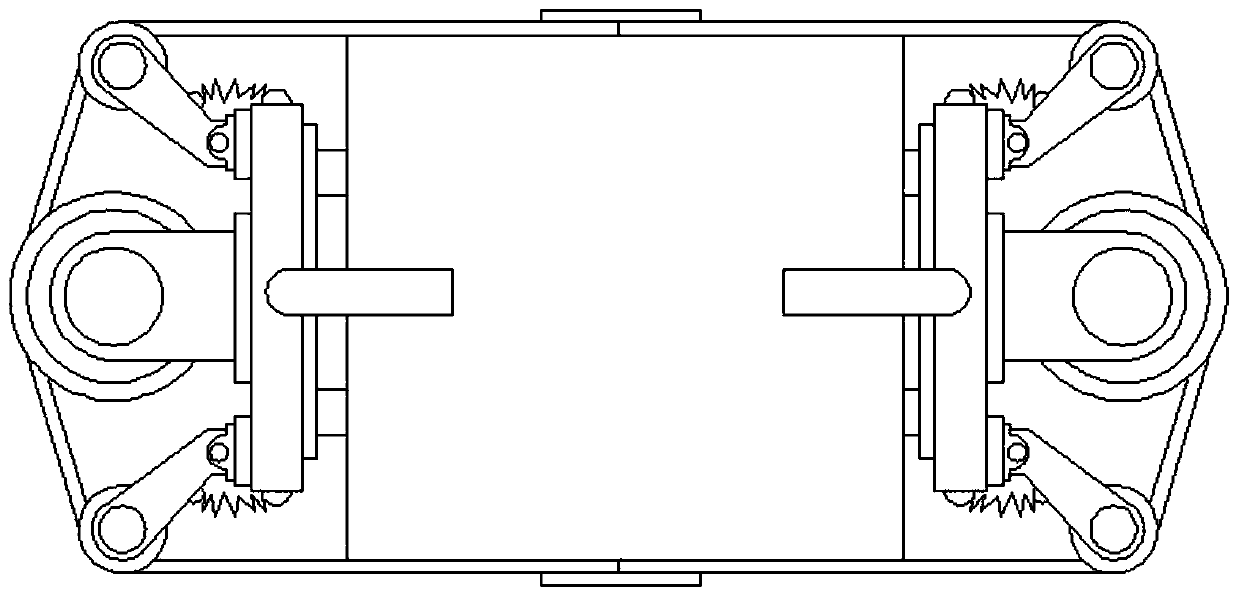

InactiveCN112454015AConvenient manual collectionDoes not interfere with sanding operationsEdge grinding machinesGrinding carriagesStructural engineeringMechanical engineering

The invention provides a composite water meter box forming treatment process which comprises executing mechanisms, a clamping mechanism, a platform mechanism, a conveying mechanism and a bottom plate,wherein the conveying mechanism is installed on the right end surface of the bottom plate, the clamping mechanism is installed on the left end surface of the bottom plate, the executing mechanisms are arranged between the conveying mechanism and the clamping mechanism, the executing mechanisms are symmetrically installed on the bottom plate in a sliding fit mode, the platform mechanism is arranged between the two executing mechanisms, the platform mechanism is installed on the bottom plate, and the platform mechanism and the executing mechanisms are connected with each other. The problems that at present, water meter boxes are mostly polished manually, the water meter boxes cannot be horizontally clamped and fixed, the polishing uniformity and quality of edges and corners of the water meter boxes cannot be guaranteed, the installation tightness of the water meter boxes and a foundation is affected, the installation state is directly affected, in addition, the polished water meter boxes need to be stacked and arranged manually, and the labor intensity of workers is thus increased are solved.

Owner:南京丰豪智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com