Environment-friendly wall surface smoothing device for building construction and building construction method

A kind of construction and environmental protection technology, applied in the direction of grinding drive device, grinding/polishing safety device, machine tool suitable for grinding workpiece plane, etc., can solve the problems of poor grinding effect, inconvenient use, small range, etc., to achieve Uniform grinding thickness, easy to use, and strong application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

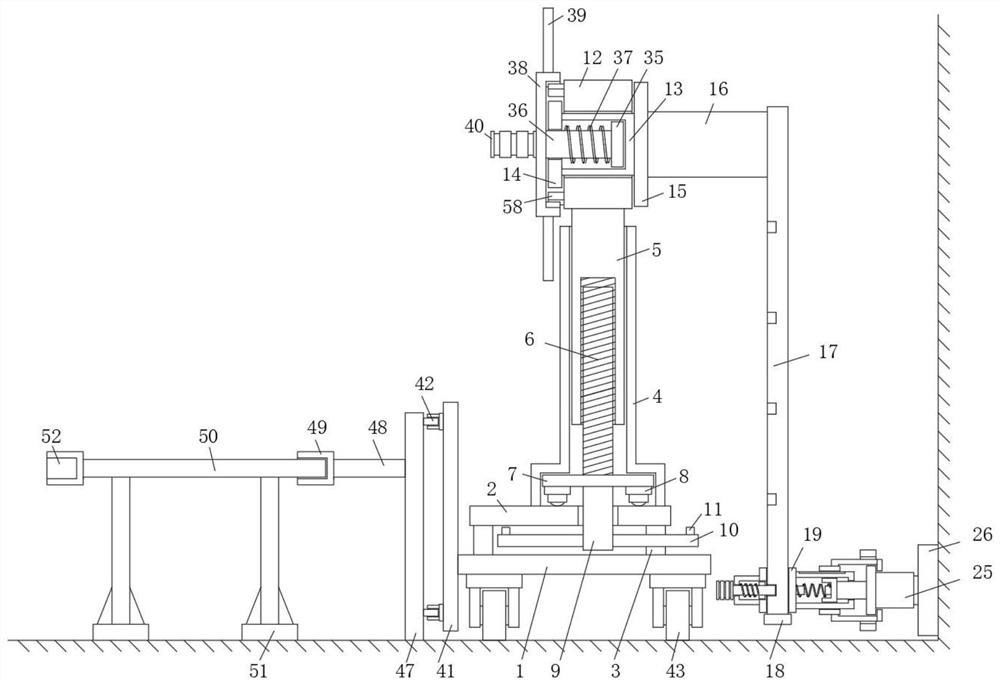

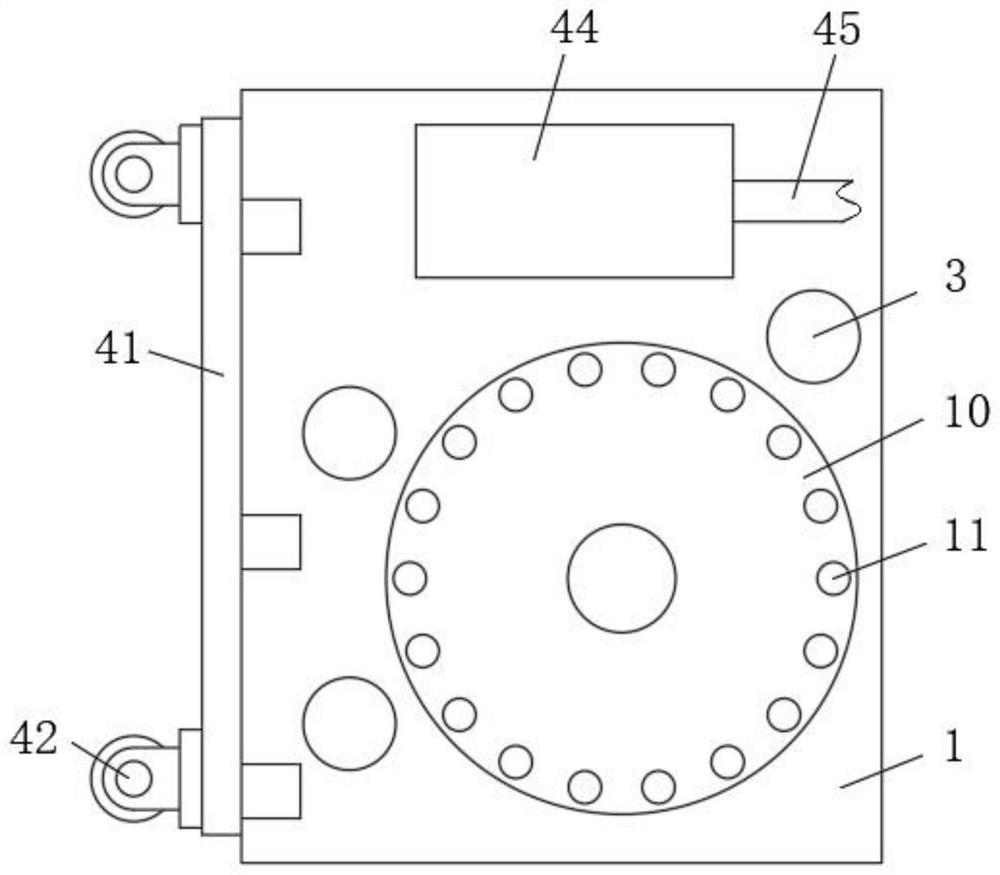

[0035] refer to Figure 1-5 , an environment-friendly building construction wall grinding device and building construction method, comprising a grinding trolley and a board assembly, the grinding trolley includes a vehicle plate 1, and the four corners of the bottom of the vehicle plate 1 are equipped with locking universal wheels 43 , the top of the vehicle plate 1 is provided with a platform 2, a foot 3 is provided between the bottom side of the platform 2 and the vehicle panel 1, and a track riser 4 is fixedly installed on the top side of the platform 2, and the track riser 4 is a rectangular pipe-shaped structure and A rectangular lifting column 5 is vertically slid inside, and the bottom of the rectangular lifting column 5 is provided with a threaded groove and threaded with a threaded column 6. The bottom end of the threaded column 6 is fixedly mounted with a rotating circular plate 7, and the bottom side of the rotating circular plate 7 Universal balls 8 and connecting ...

Embodiment 2

[0042] Such as Figure 1-5 As shown, this embodiment is basically the same as Embodiment 1. Preferably, one side of the sliding sleeve 19 is fixedly connected with a side cylinder 30, the rod body of the insertion rod 31 passes through the sliding sleeve 19, and the outside of the rod body of the insertion rod 31 is fixedly connected There is a ring stopper 32, the ring stopper 32 is slidably connected in the side cylinder 30, and the side of the ring stopper 32 and the side away from the sliding sleeve 19 is provided with a spring 2 33, and one end of the insertion rod 31 extends to the outside of the side cylinder 30 and is fixedly connected with a handle one 34 .

[0043] In this embodiment, by moving the sliding sleeve 19 outside the swing rail 17, the grinding position of the grinding disc 26 is changed rapidly, and the grinding area of the wall surface is also greatly increased.

Embodiment 3

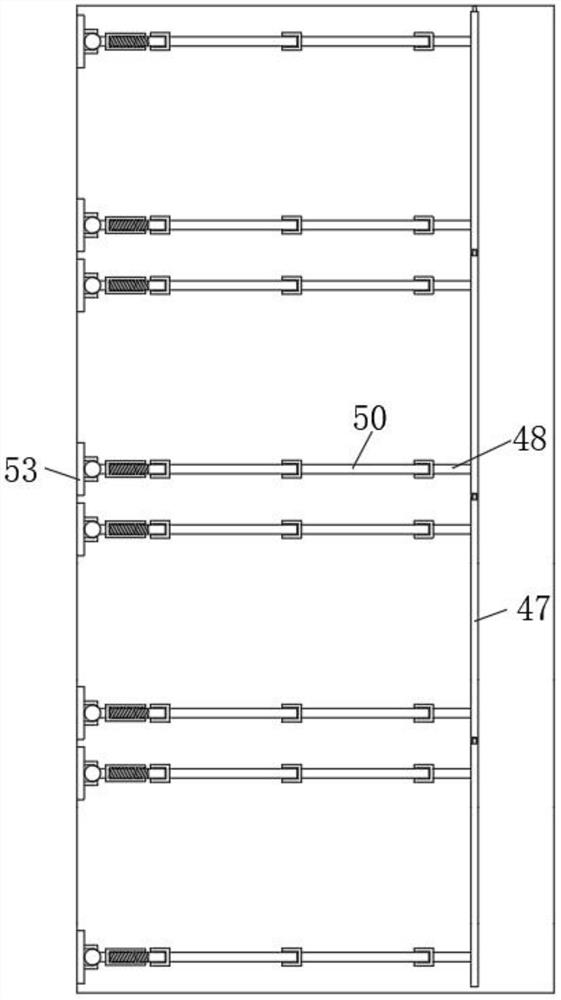

[0045] Such as Figure 1-5 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the abutment plate assembly includes an anti-displacement plate 47, an extension rod 50 and an abutment wall plate 53, and one side of the anti-displacement plate 47 is horizontally fixed with a horizontal bar- 48, one end of the cross bar 48 and the extension bar 50 are fixedly connected with ferrule 49 and ferrule two 52 respectively, the bottom side of the extension bar 50 is provided with a supporting foot 51, and one side of the wall board 53 is fixedly connected with a ball seat 54 One side of the ball seat 54 is provided with a spherical turning groove and a rotating ball 55 is installed for rotation. One side of the rotating ball 55 extends to the outside of the ball seat 54 and is fixedly connected to the threaded pipe 2 56. One end of the threaded pipe 2 56 is provided with a screw thread The cavity is threadedly connected with a threaded rod 57.

[0046] In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com