Patents

Literature

48results about How to "Avoid excessive sanding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Area based steel rail grinding method

ActiveCN105386375AImprove calculation accuracyAvoid excessive sandingRailway track constructionMetallurgyEnergy consumption

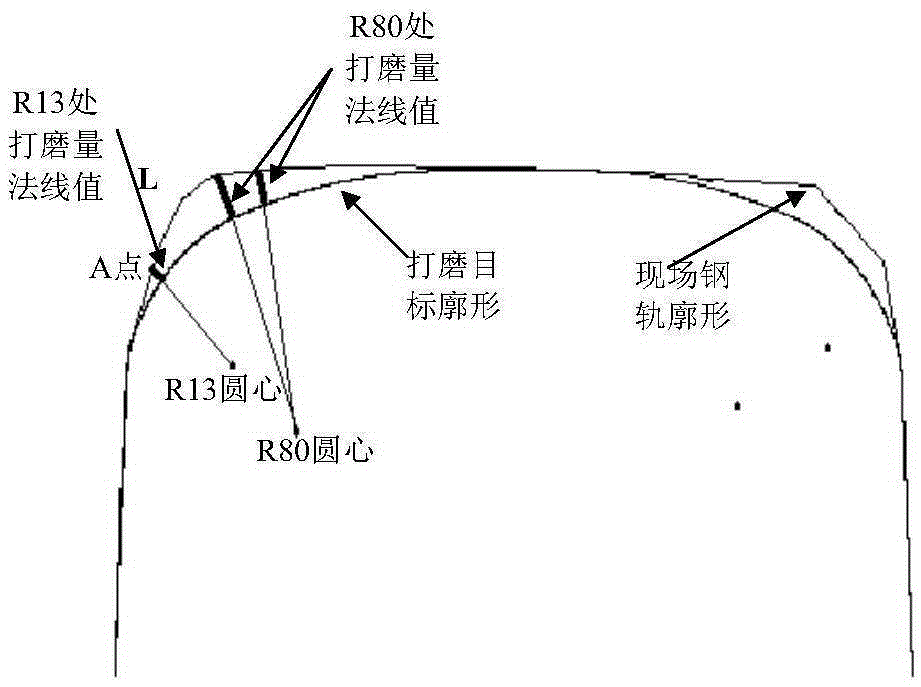

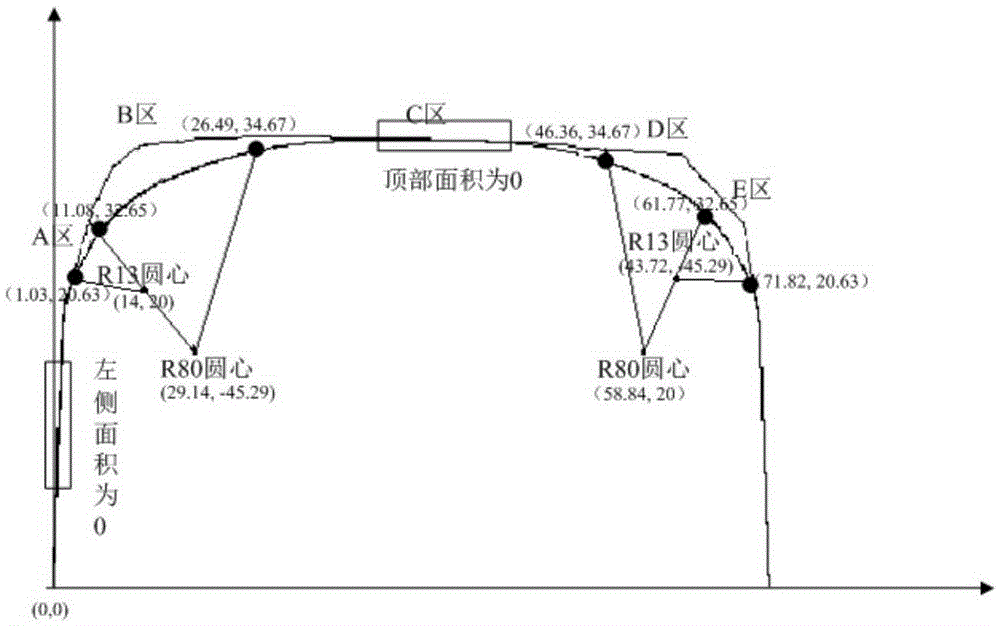

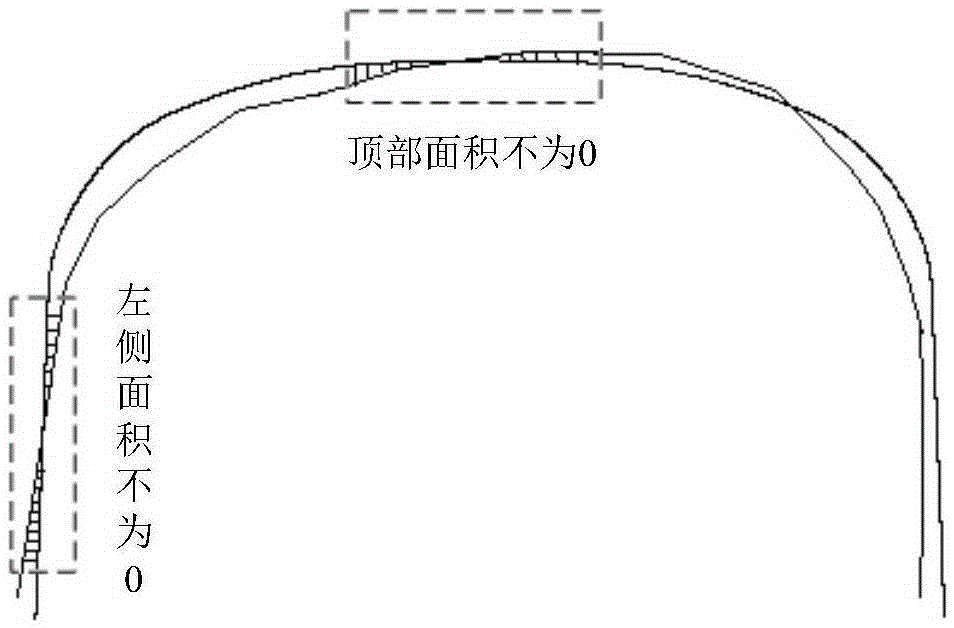

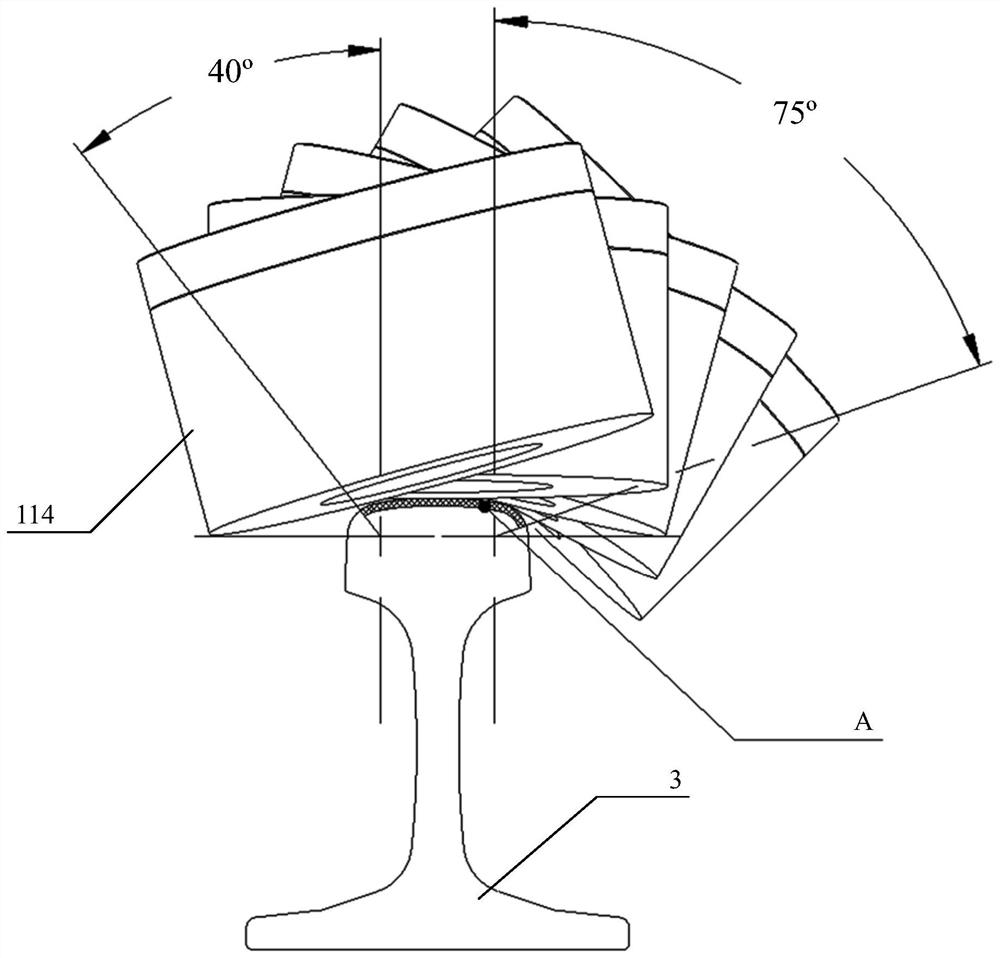

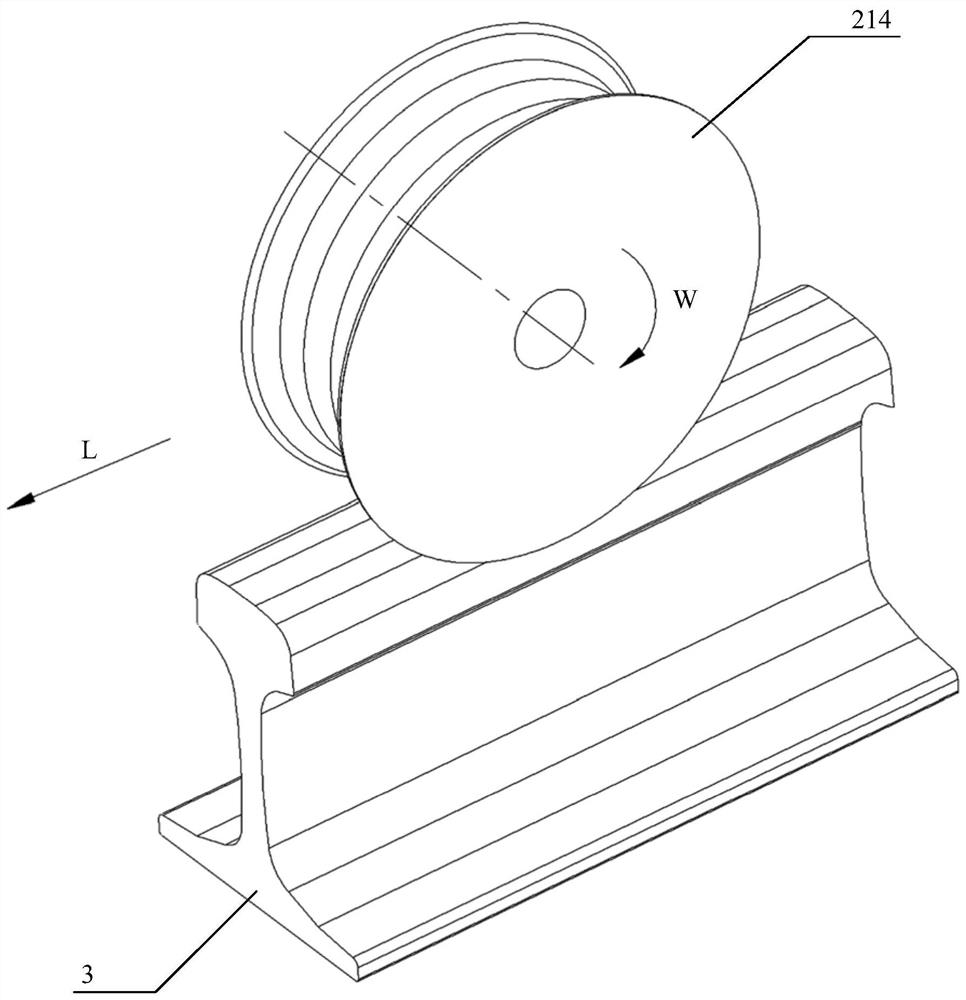

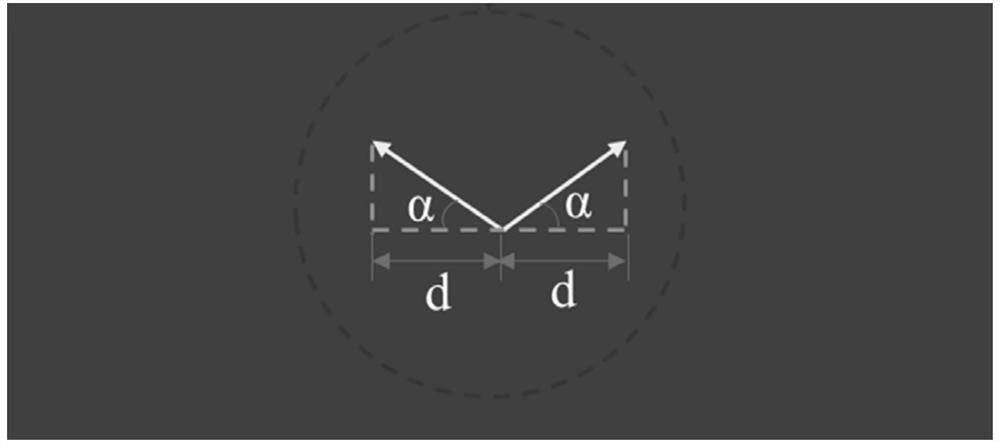

The invention discloses an area based steel rail grinding method. The method comprises the following steps: (1) dividing a section profile of a steel rail into a plurality of grinding regions; (2) aligning the measured section profile of the on-site steel rail to a polishing target section profile; (3) calculating a steel rail polishing area of each grinding region of the on-site steel rail after alignment; (4) calculating the number of grinding heads required by each grinding region of the on-site steel rail; and (5) equally dividing the steel rail grinding area of each grinding region of the on-site steel rail according to the number of the required grinding heads, namely dividing each grinding region into small blocks equal in area, wherein a center line angle of each small block is an angle of each steel rail grinding head. The area based steel rail grinding method greatly improves the accuracy of steel rail grinding, is capable of effectively reducing the energy consumption of a grinding train, reducing unnecessary steel rail grinding quantity and prolonging the service life of the steel rail, and thus has important theoretical and practical significances.

Owner:CHINA RAILWAYS CORPORATION +1

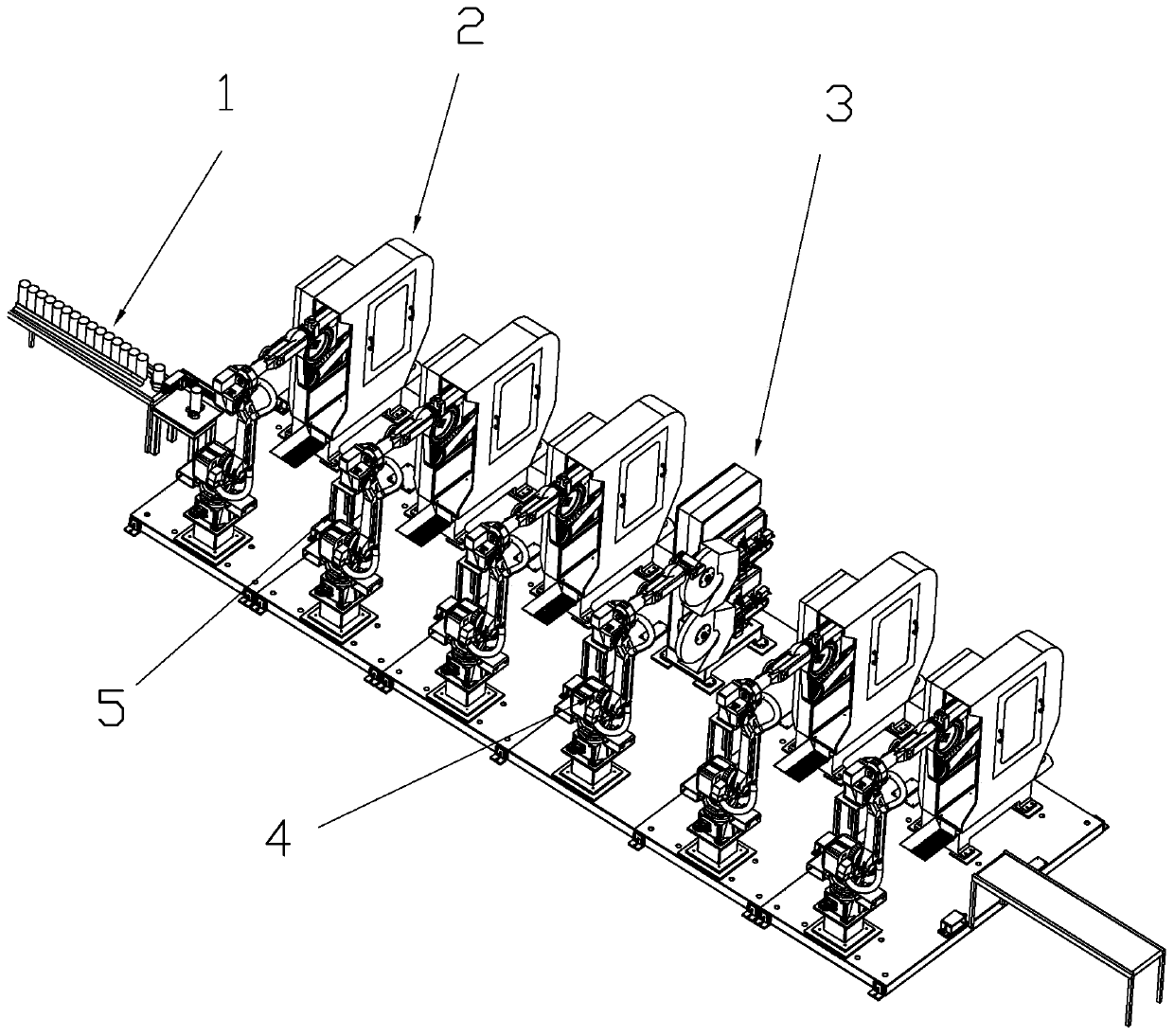

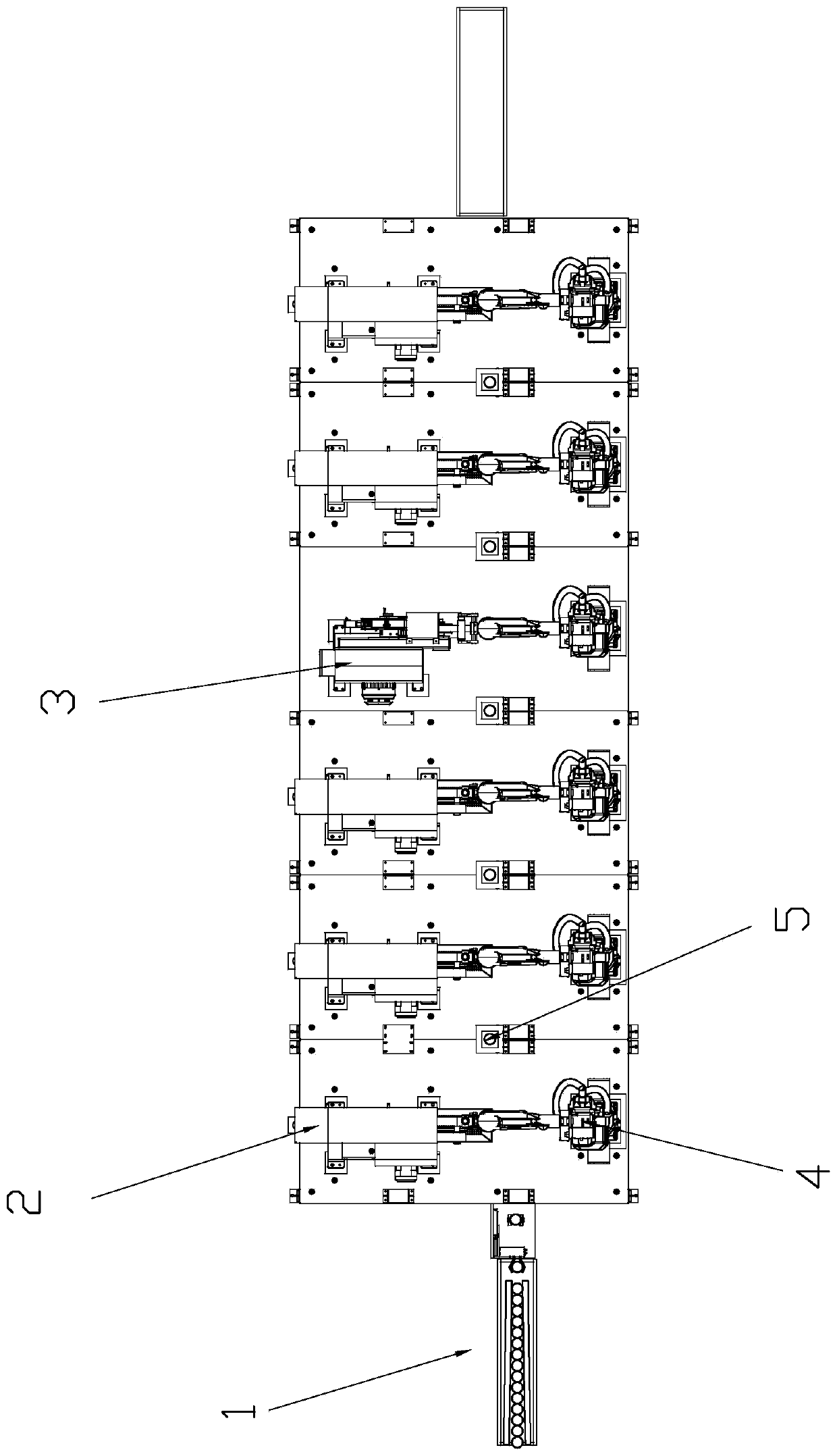

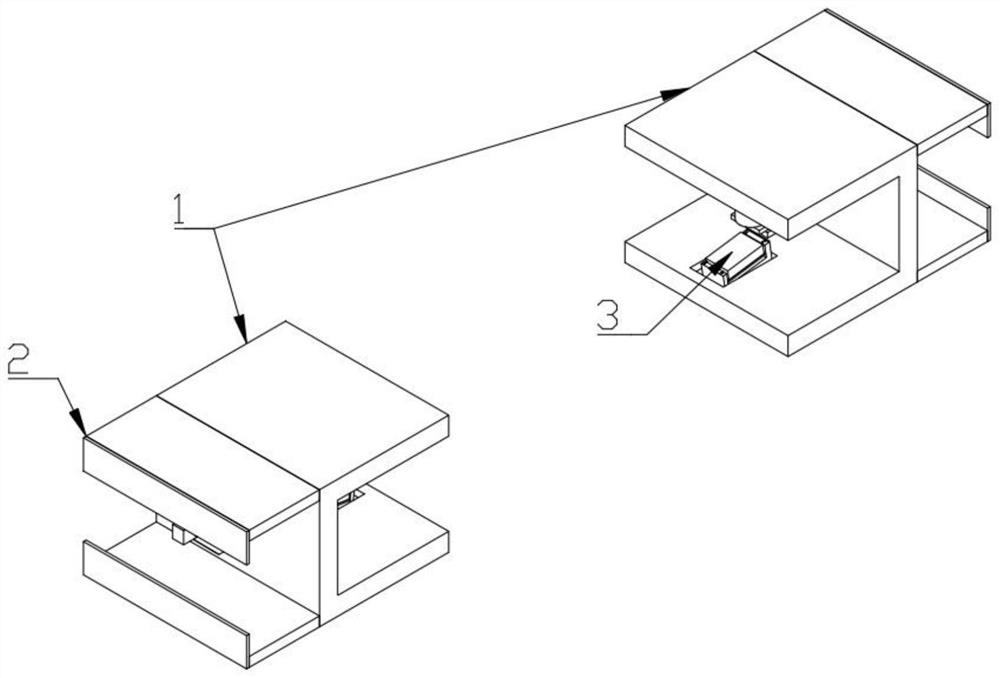

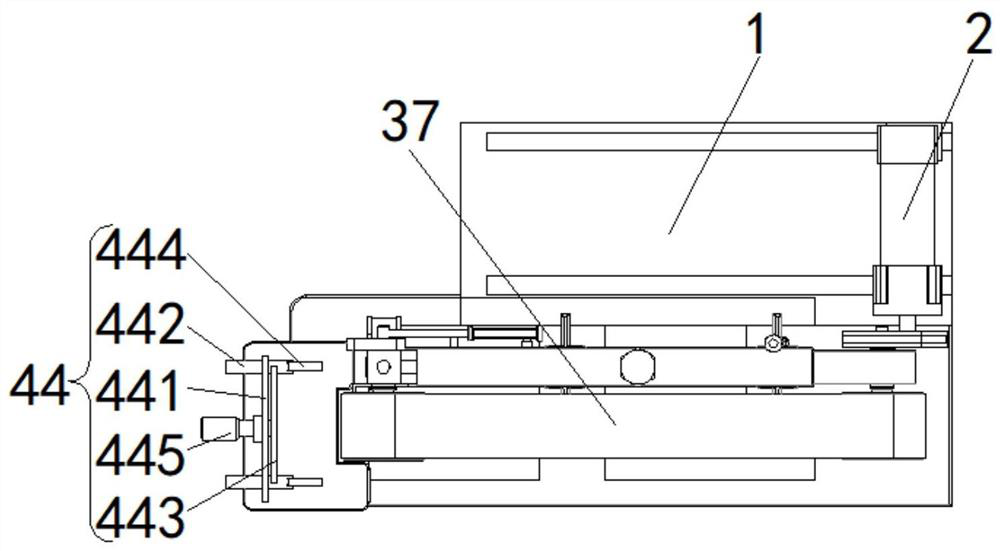

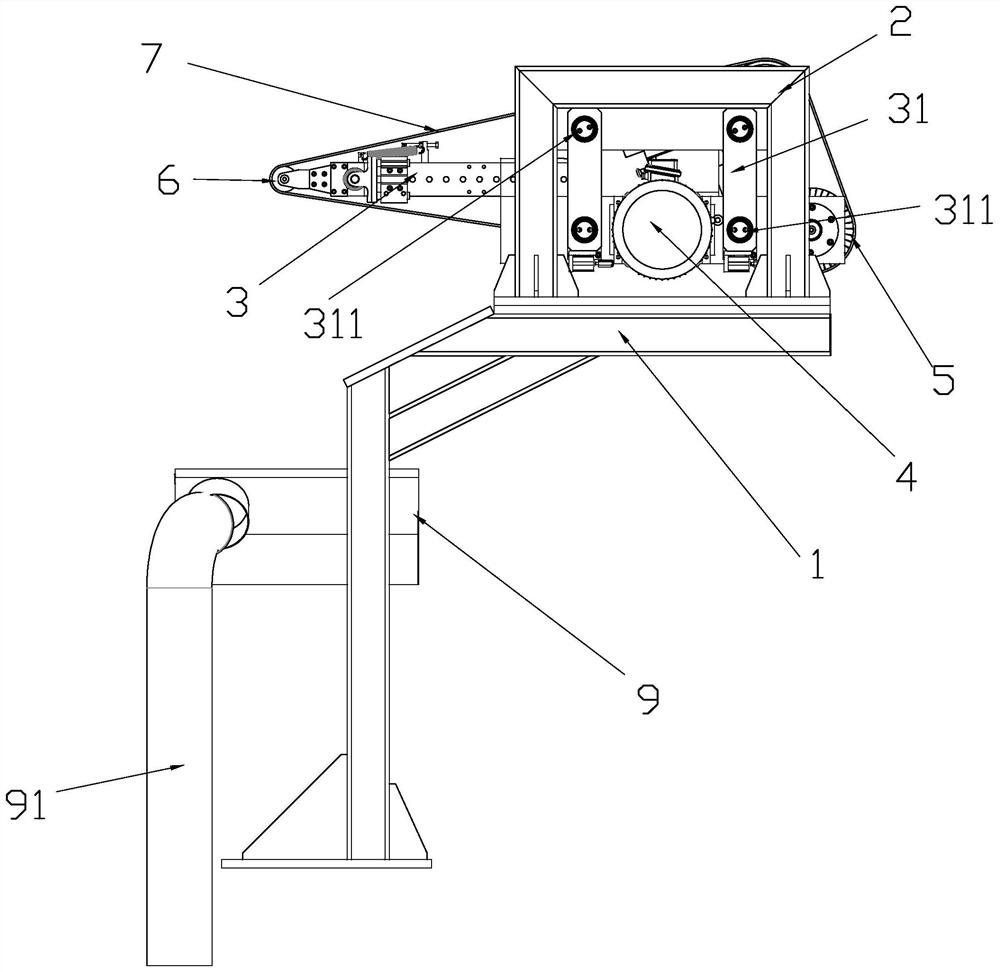

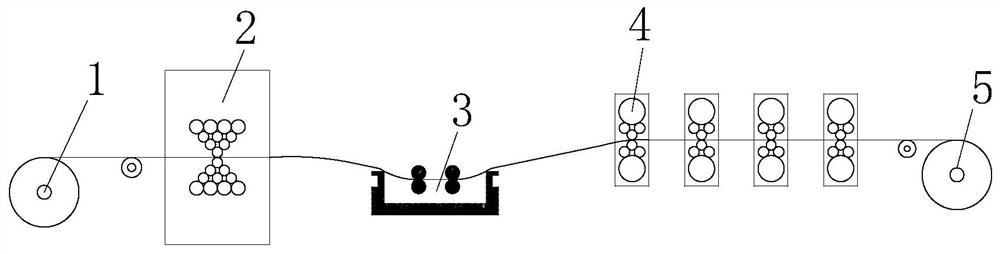

Vacuum cup grinding production line

PendingCN111390715AImprove the finishAvoid idlingBelt grinding machinesGrinding feedersElectric machineryGrinding

The invention relates to a vacuum cup grinding production line. The vacuum cup grinding production line comprises a feeding device, a plurality of grinding devices and a plurality of polishing deviceswhich are sequentially arranged and used for conveying vacuum cups one by one, and further comprises a plurality of industrial robots used for transferring the vacuum cups to the grinding devices orthe polishing devices to be ground or polished. The plurality of grinding devices and the plurality of polishing devices correspond to the plurality of industrial robots in a one-to-one mode; each grinding device comprises a belt sander rack, each belt sander rack is provided with an abrasive belt mechanism, each abrasive belt mechanism comprises an abrasive belt main beam, a driving motor, a driving wheel, a driven wheel and an abrasive belt, and each driven wheel is arranged on the corresponding abrasive belt main beam through a driven support; and a floating grinding assembly is arranged between each abrasive belt main beam and the corresponding belt sander rack, each floating grinding assembly comprises a floating arm, bearing columns are arranged at the two ends of each floating arm,and each floating arm is movably connected with the corresponding abrasive belt main beam and belt sander rack through the bearing columns and enables the abrasive belt main beam to swing left and right in the belt sander rack through the corresponding floating arm.

Owner:浙江珂斯顿机器人科技有限公司

Baseball bat machining and grinding integrated device

InactiveCN110052904AImprove processing efficiencyImprove cleanlinessRevolution surface grinding machinesGrinding/polishing safety devicesTransmission beltThreaded rod

The invention discloses a baseball bat machining and grinding integrated device. The baseball bat machining and grinding integrated device comprises a workbench, a machining and grinding device main body and a mounting plate, wherein a first rotary motor is arranged at the lower end of the interior of the machining and grinding device main body, first threaded rods are arranged on the two sides ofthe first rotary motor, transmission belt wheels are arranged on the surfaces of the first threaded rods, a plurality of nuts are arranged at the upper end of each transmission belt wheel, connectingrods are arranged on one sides of the nuts, the mounting plate is arranged on one sides of the connecting rods, a driving belt wheel is arranged on one side of the mounting plate, auxiliary belt wheels are arranged on the two sides of the lower end of the driving belt wheel, a grinding belt is arranged on one sides of the auxiliary belt wheels, and a plurality of second sliding rails are arrangedon the surface of the other side of the mounting plate. According to the baseball bat machining and grinding integrated device, a nicking tool and the grinding belt are arranged so that grinding canbe carried out through the grinding belt while plastic carving is carried out through the nicking knife, and the machining efficiency of a baseball bat is greatly improved.

Owner:黄飞云

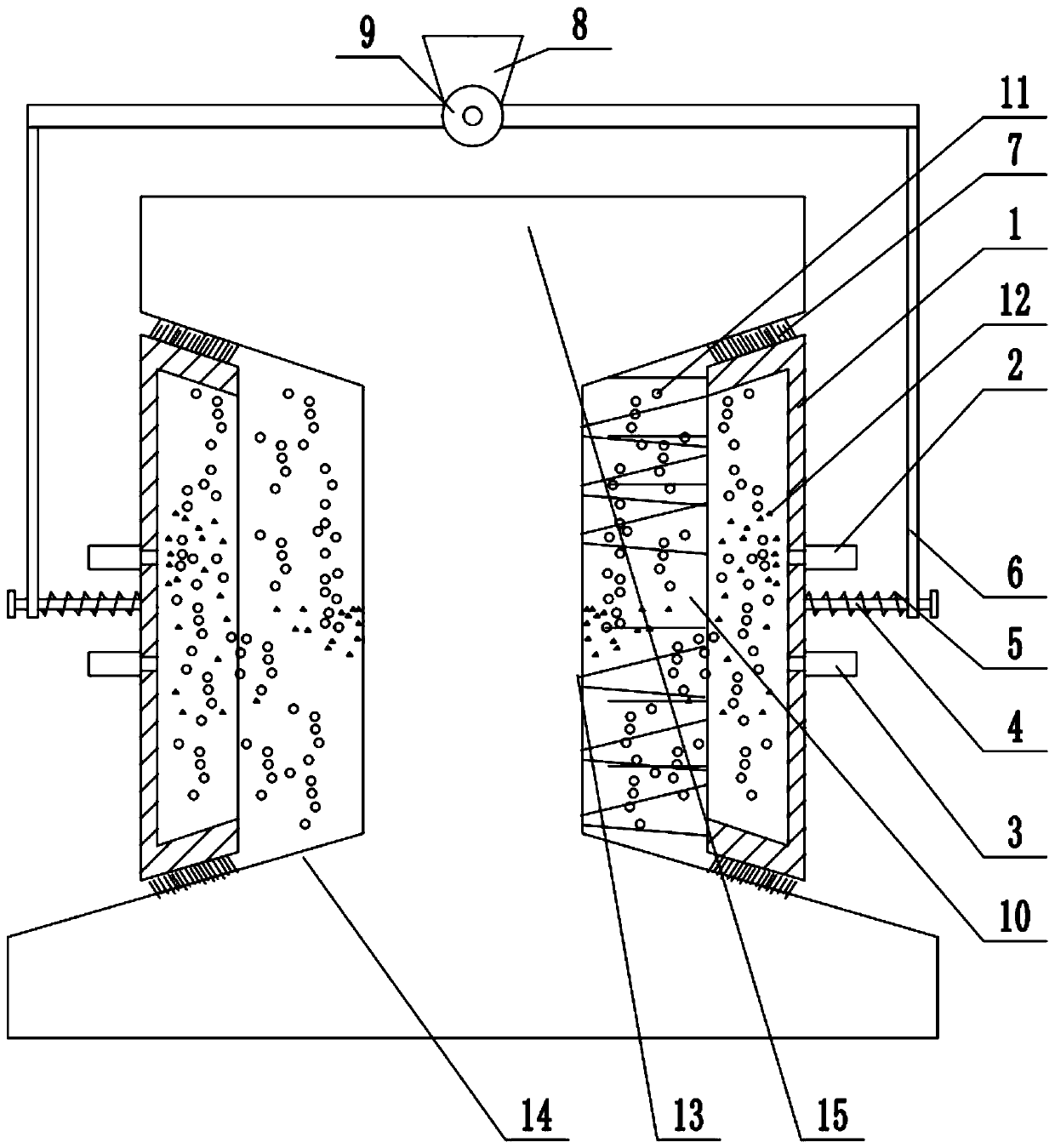

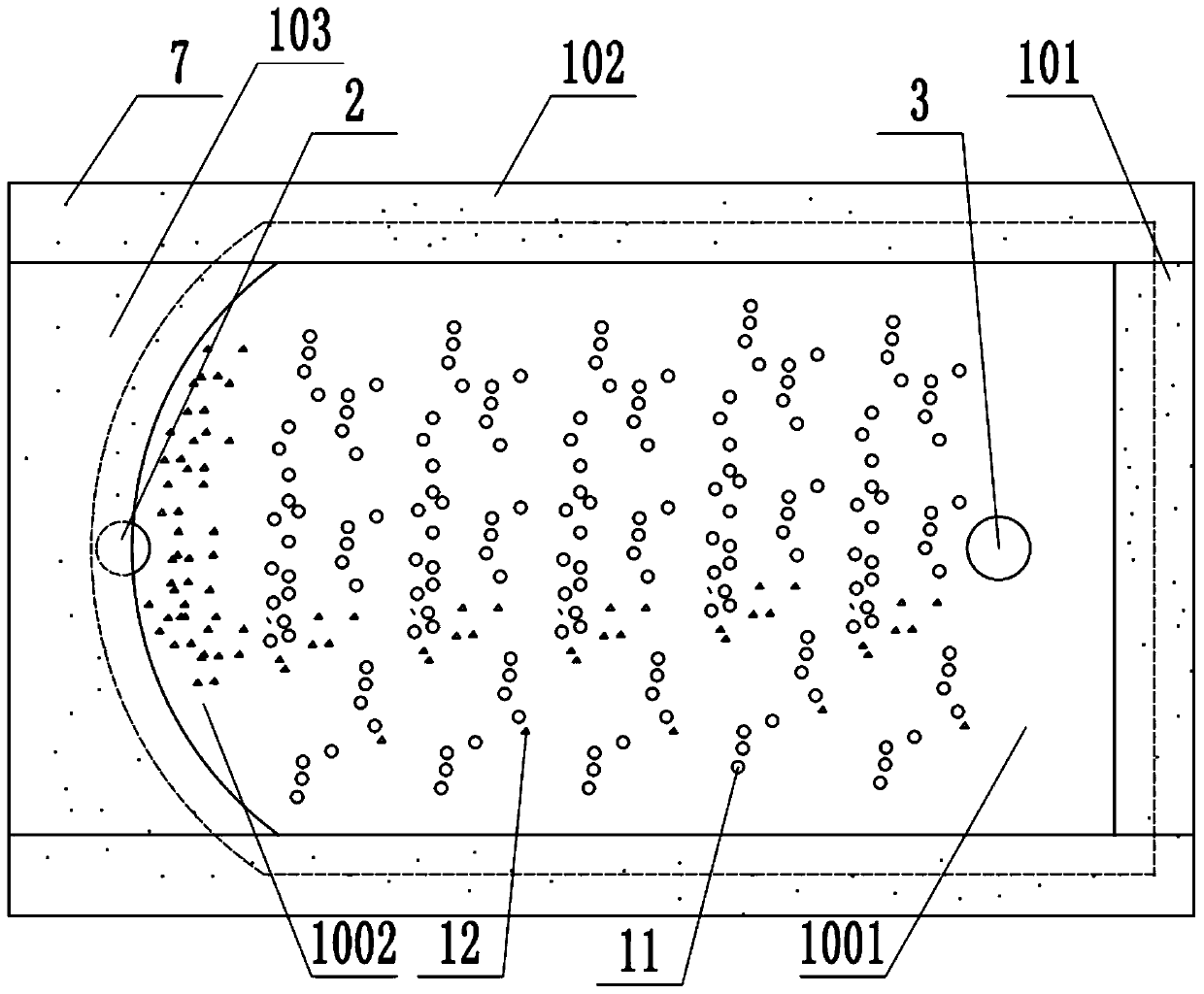

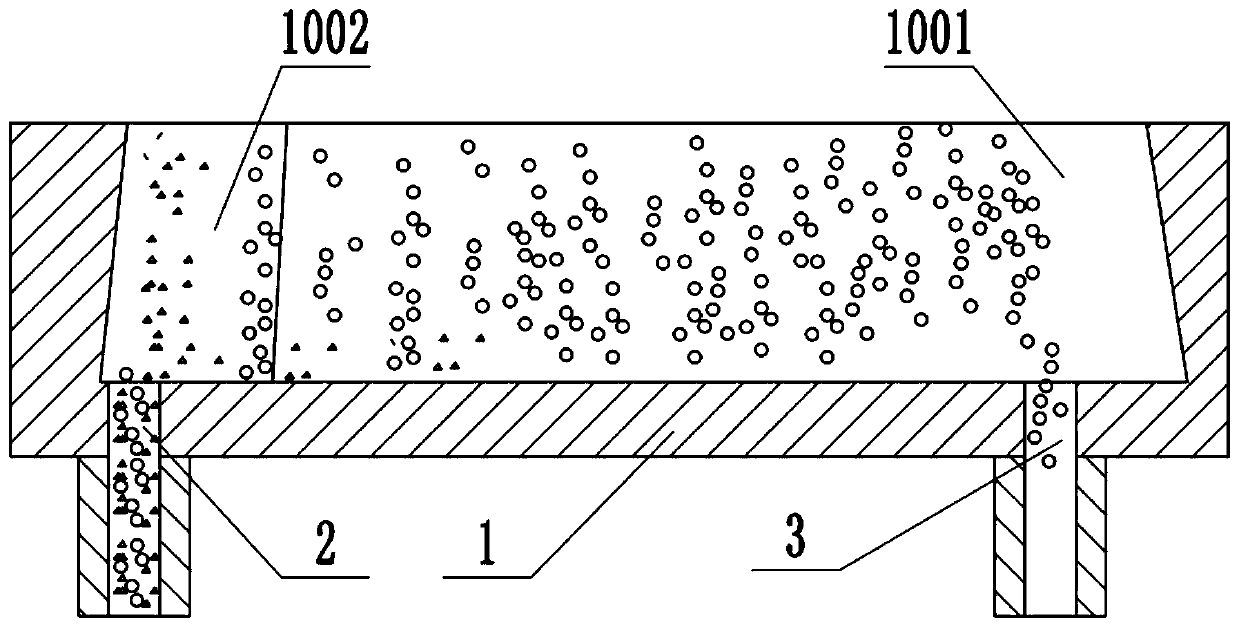

Railway track rust removal device and method

ActiveCN110900461AImprove smudge effectPrevent proliferationAbrasive machine appurtenancesAbrasive blasting machinesMining engineeringStructural engineering

The invention discloses a railway track rust removal device and method. The device comprises a mobile platform; a shot blasting structure, an exhaust fan and a collecting box are borne on the mobile platform; a box body with a cavity is connected below the mobile platform; an opening is formed in the side surface of the cavity; the opening is used for being matched with a rail to form a closed operation cavity; the box body is provided with a first interface and a second interface which are communicated with the cavity; the first interface is communicated with the shot blasting structure; theshot blasting structure is used for spraying airflow carrying a spraying material onto the rail web through the first interface; the second interface is sequentially communicated with the exhaust fanand the collecting box. The shot blasting structure is used for spraying materials to a rail web, attached dust falls off due to impact vibration, a rail web base body is exposed, the sprayed materials, the dust and air are extracted by the exhaust fan in cooperation with the collecting box to be separated from an operation box, rust dust attached to a rail is removed, and the problem that the efficiency of an antirust agent is affected by residual dust is solved.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

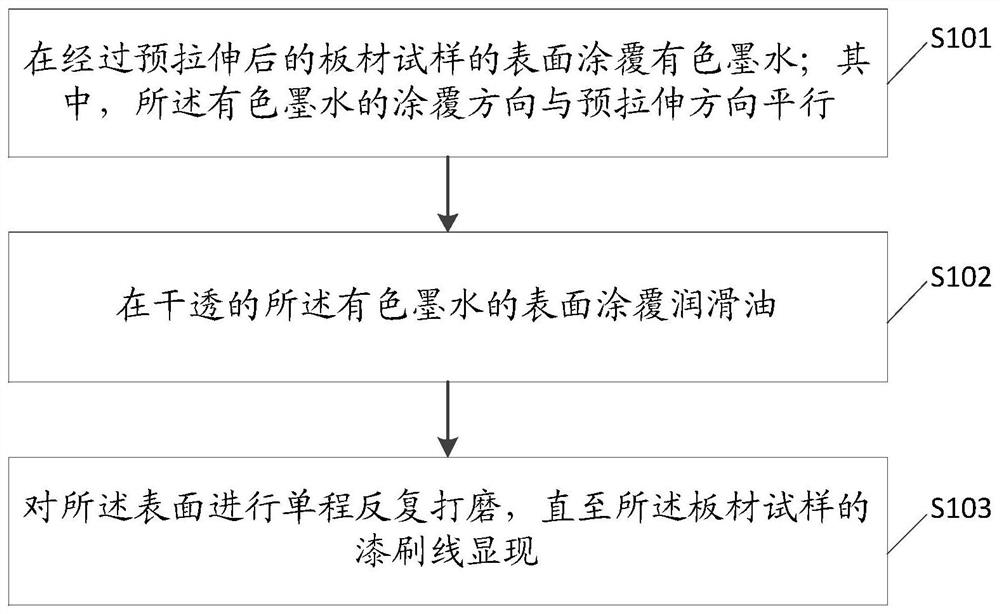

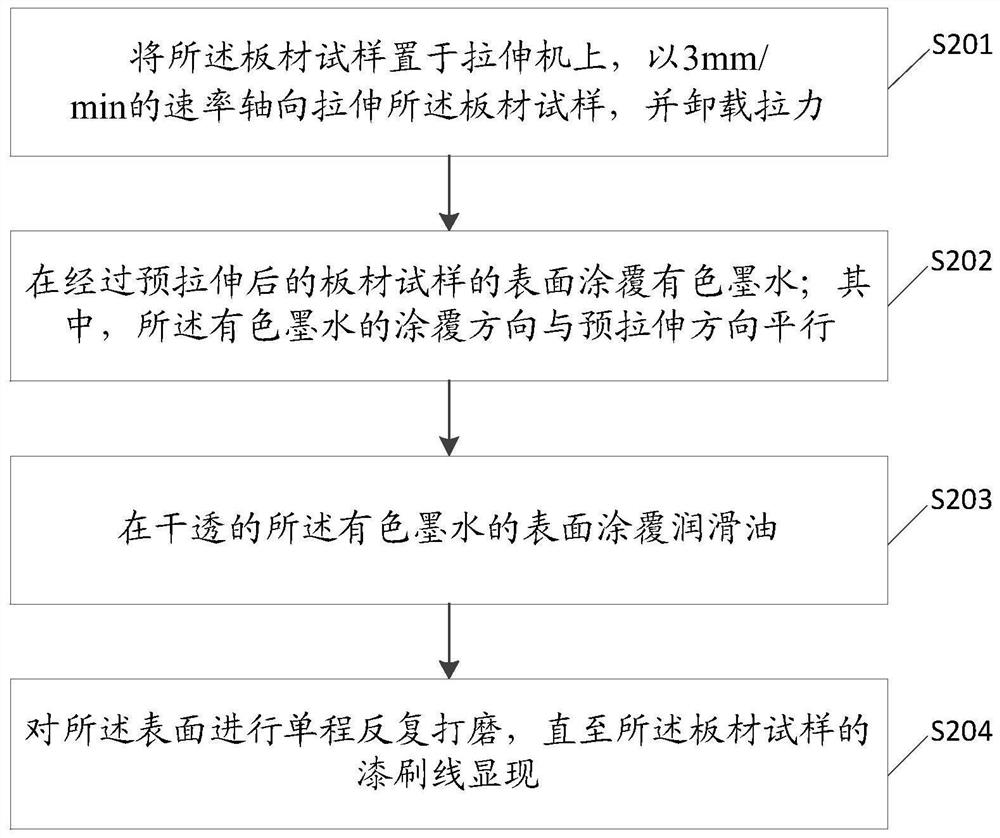

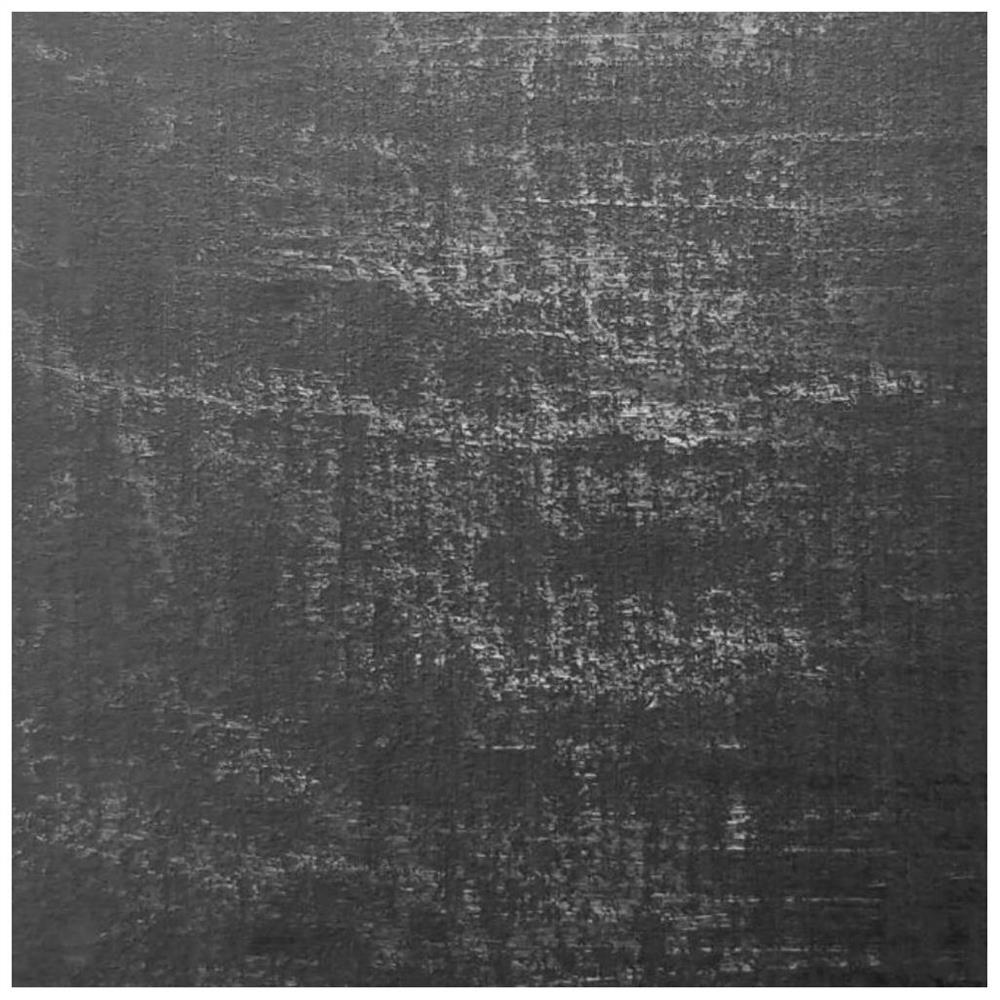

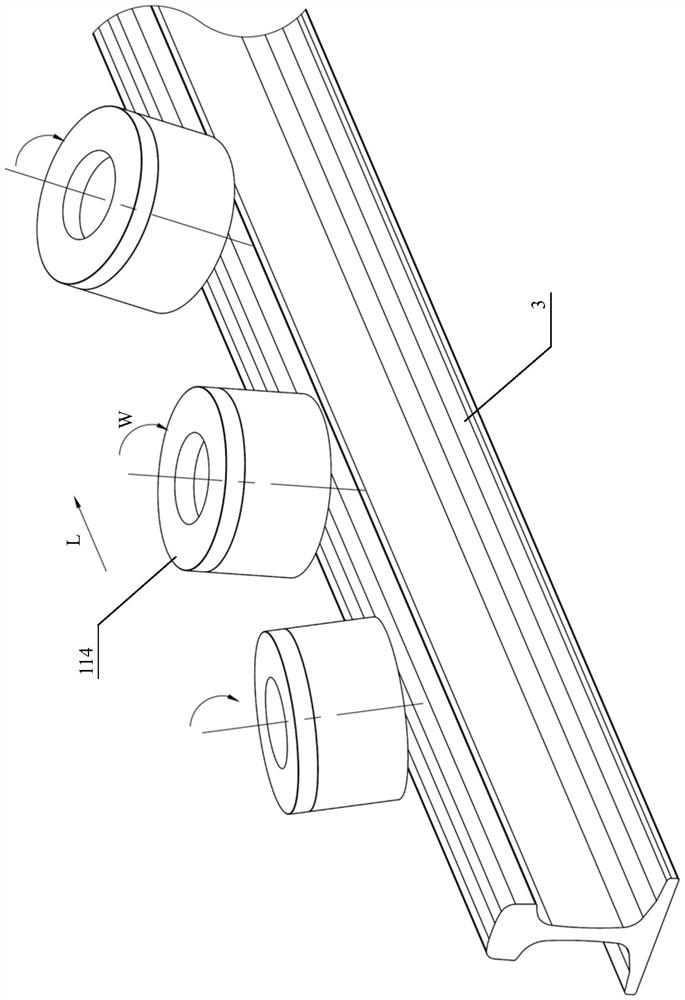

Paint brush line display method

PendingCN112461746AIncrease contrastImprove accuracyUsing mechanical meansMaterial analysisPolymer sciencePolishing

The invention discloses a paint brush line display method which comprises the steps: coating the surface of a pre-stretched plate sample with colored ink, wherein the coating direction of the coloredink is parallel to the pre-stretching direction; coating lubricating oil on the surface of the completely dried colored ink; and repeatedly polishing the surface in a single pass until the paint brushline of the plate sample appears. It can be seen that according to the paint brush line display method, the surface of the pre-stretched sample plate is coated with a layer of colored ink firstly, then the surface of the pre-stretched sample plate is coated with lubricating oil, then polishing is conducted, in the polishing process, the colored ink in the protruding area where the paint brush line is located is polished, the area is brightened, and the colored ink in the concave area is not polished away, and the area is still dark so that the concave-convex area contrast is obvious, the paint brush line contrast and the display accuracy are improved, and due to the existence of colored ink, the polishing degree is easy to judge, excessive polishing is avoided, and the polishing difficulty is reduced.

Owner:SOUTHWEST ALUMINUM GRP

Steel rail composite grinding wagon

PendingCN113136751AAchieve grindingImprove applicabilityRailway track constructionVehicle framePolishing

The invention discloses a steel rail composite grinding wagon. The steel rail composite grinding wagon comprises a wagon body; a frame, which is arranged at the lower part of the wagon body; and a steel rail composite polishing device, which is mounted on the frame, and comprises an envelope polishing unit and a profiling polishing unit which are arranged above a steel rail in the operation direction, wherein the enveloping and polishing unit is used for carrying out enveloping type polishing on the rail surface of the steel rail by using a cup-shaped grinding wheel, and the profiling grinding unit is used for conducting profiling grinding on the rail surface of the steel rail through a profiling grinding wheel. The technical problem that an existing steel rail grinding wagon cannot meet the requirements of large steel rail grinding amount, wide grinding angle range, high operation efficiency, good operation trafficability and the like at the same time can be solved.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD

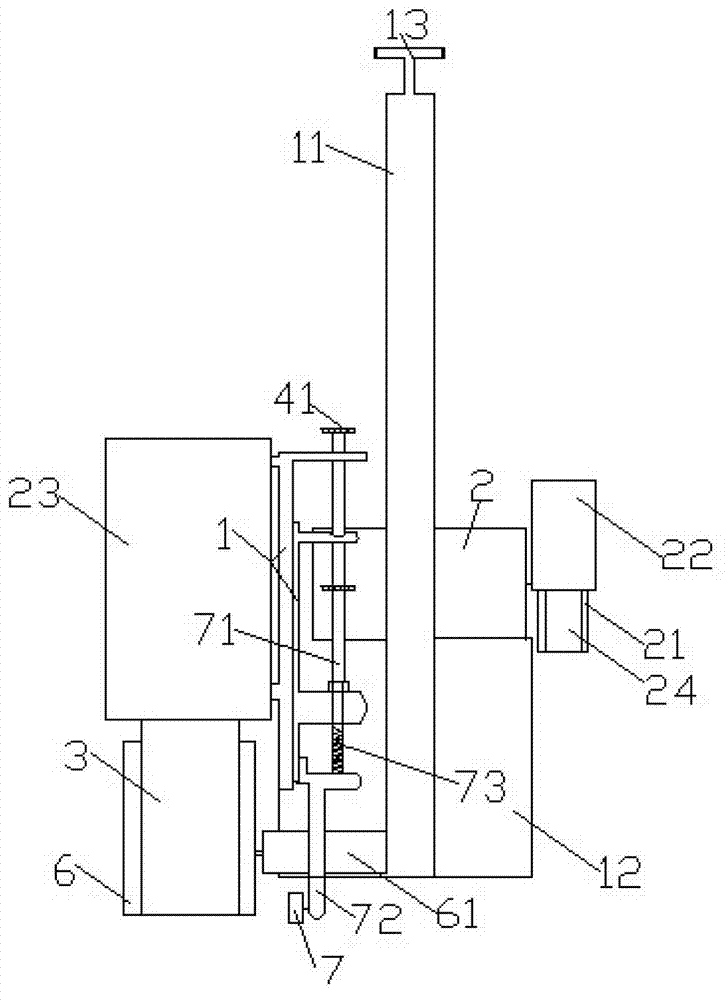

Opening closing and grinding structure for self-locking nut of aerospace vehicle

ActiveCN106625098AStrong vibration resistanceAchieve cleanupEdge grinding machinesAviationEngineering

The invention discloses an opening closing and grinding structure for a self-locking nut of an aerospace vehicle. The structure comprises a base and a stand column arranged on the base; a spacing hole which is matched with a self-locking nut is formed in the upper end surface of the stand column; the structure also comprises an annular opening closing plate arranged on the stand column in a sleeving manner; a plurality of straight holes are formed in the radial direction of the opening closing plate on a main body; after the end part of an ejecting block movably penetrates through the straight holes, the end of the ejecting block extends to the middle of the opening closing plate; and a grinding sheet which is matched with the opening closing part of the self-locking nut is arranged at the end part of the extended section of the ejecting block and the grinding sheet directly faces the upper end of the spacing hole. Aiming at the defects, the inventor develops a quick grinding and polishing device for the self-locking nut after completion of opening closing, removal of the burr or protrusion on the opening closing part of the self-locking nut is realized quickly, and besides, the follow-up treatment cost of numerous self-locking threads in the aerospace vehicle is reduced, so that the self-locking nut has good anti-vibration ability.

Owner:CHENGDU ZHIRONG ZHICHUANG INTPROP MANAGEMENT CO LTD

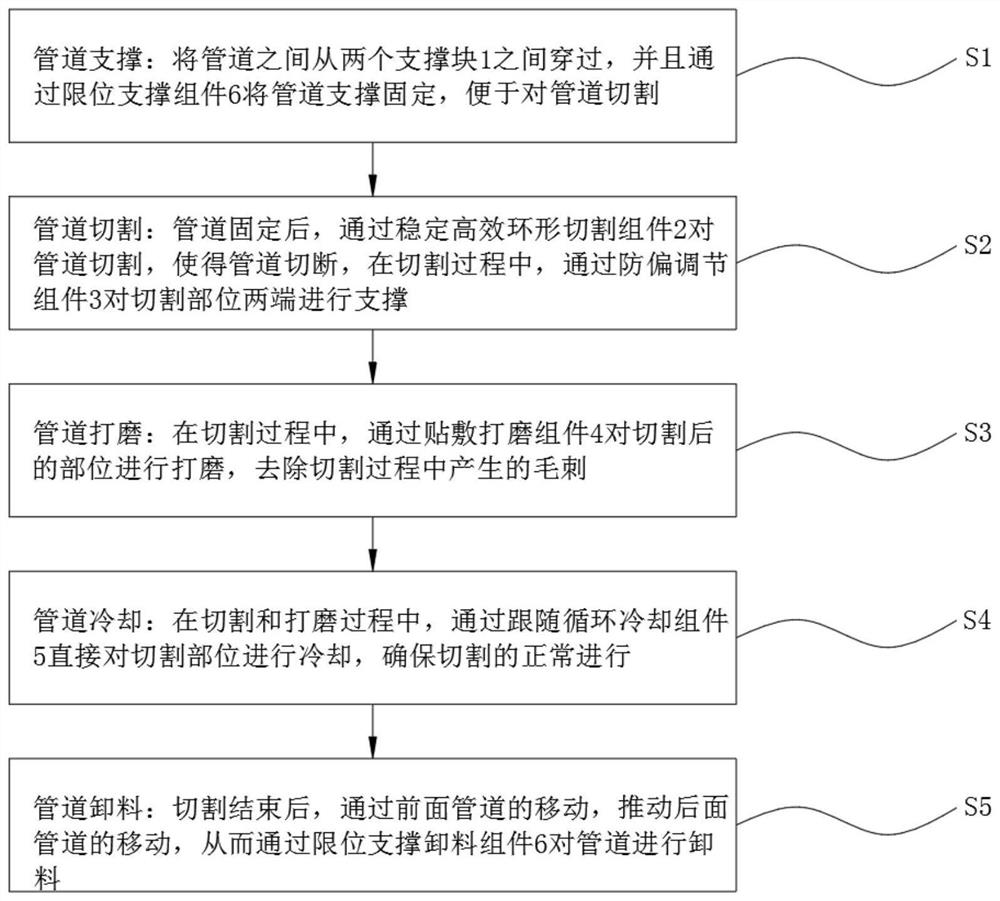

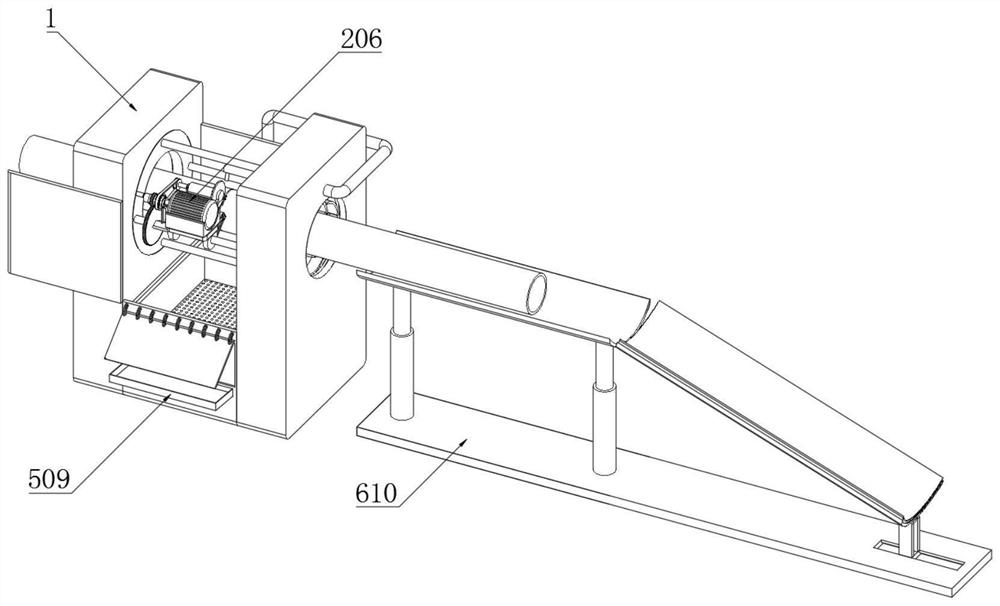

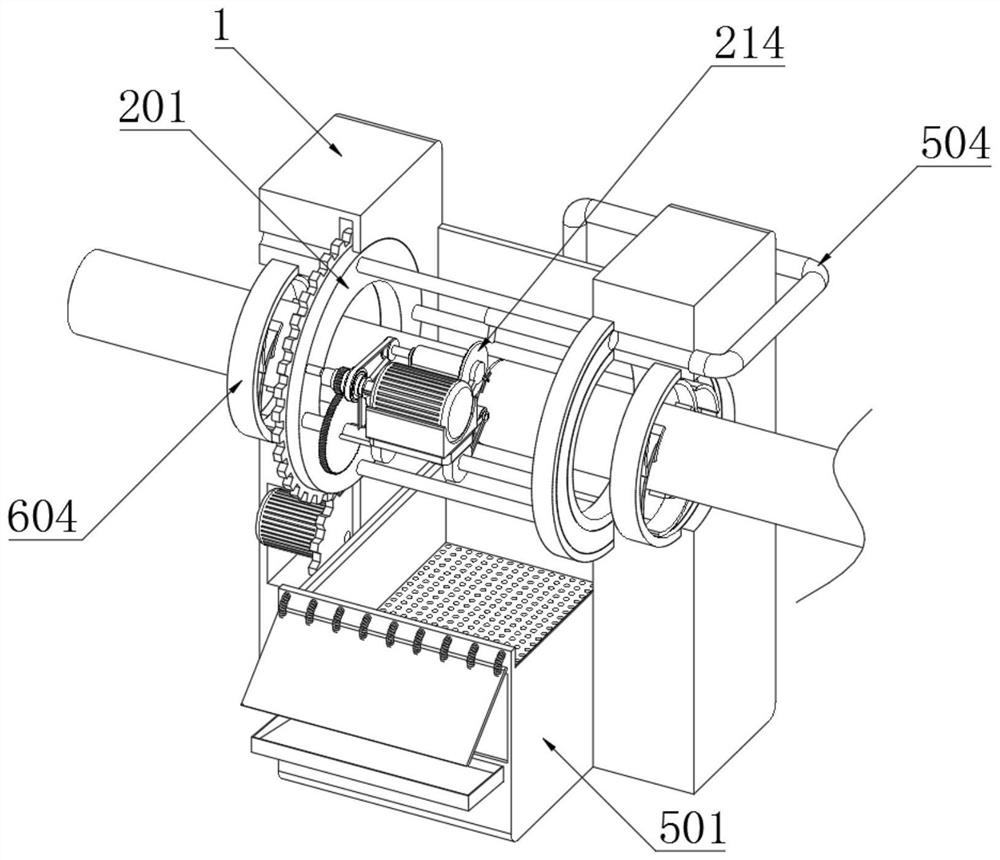

Efficient treatment method based on pipeline machining

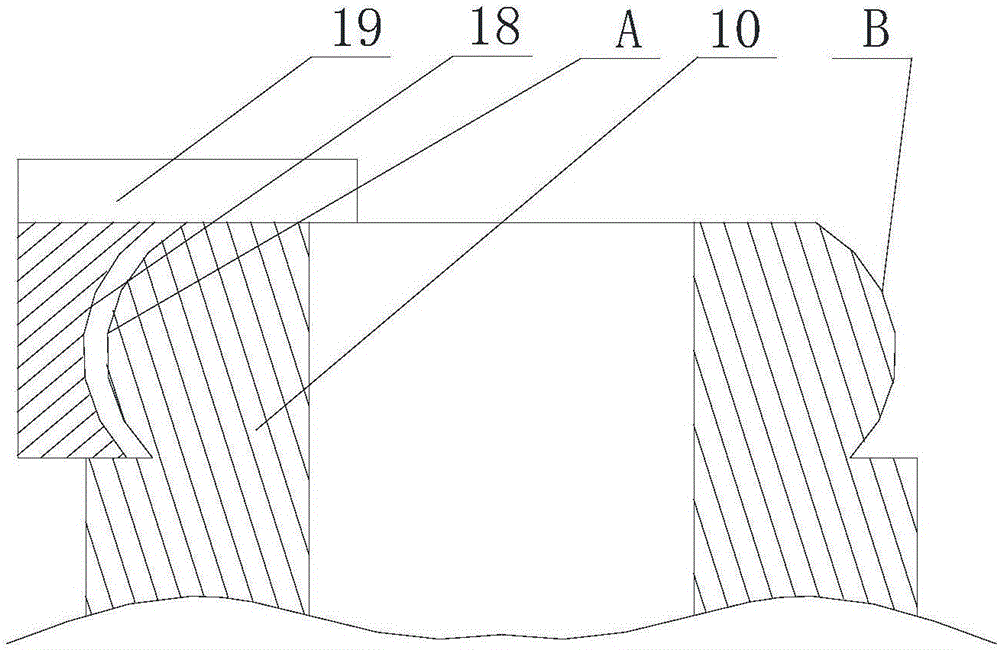

ActiveCN112045429AEven by forceAvoid wrinklesOther manufacturing equipments/toolsTube shearing machinesRotational axisElectric machine

The invention discloses an efficient treatment method based on pipeline machining. The method is characterized in that two rotating rings are arranged at the two ends of the bottom of a driving motorcorrespondingly, an output shaft of the driving motor is fixedly connected with a rotating shaft, the outer side of the rotating shaft is movably sleeved with a rotating cylinder, a movable electric push rod is arranged at one end of the rotating cylinder, one end of the movable electric push rod is arranged at one end of the rotating ring, one end of the rotating cylinder is movably connected toone end of a first belt driving mechanism in a sleeve mode, the other end of the first belt driving mechanism is connected to the outer side of the rotating shaft in a sleeving mode, the outer side ofone end of the rotating shaft is provided with a cutting blade through a screw, a fixing frame is movably arranged on the outer side of the rotating shaft, and one end of the fixing frame is arrangedon the one end of the driving motor. According to the method, the cutting blade can gradually go deep in the cutting process, so that cutting is easy, the cutting effect and efficiency are improved,the phenomena that the cutting blade is stuck and broken in the cutting process are effectively prevented, the safety coefficient in the cutting process is improved, the cutting quality and efficiencyare improved, and the service life of the cutting blade is effectively prolonged.

Owner:沧州市鑫宜达管道有限公司

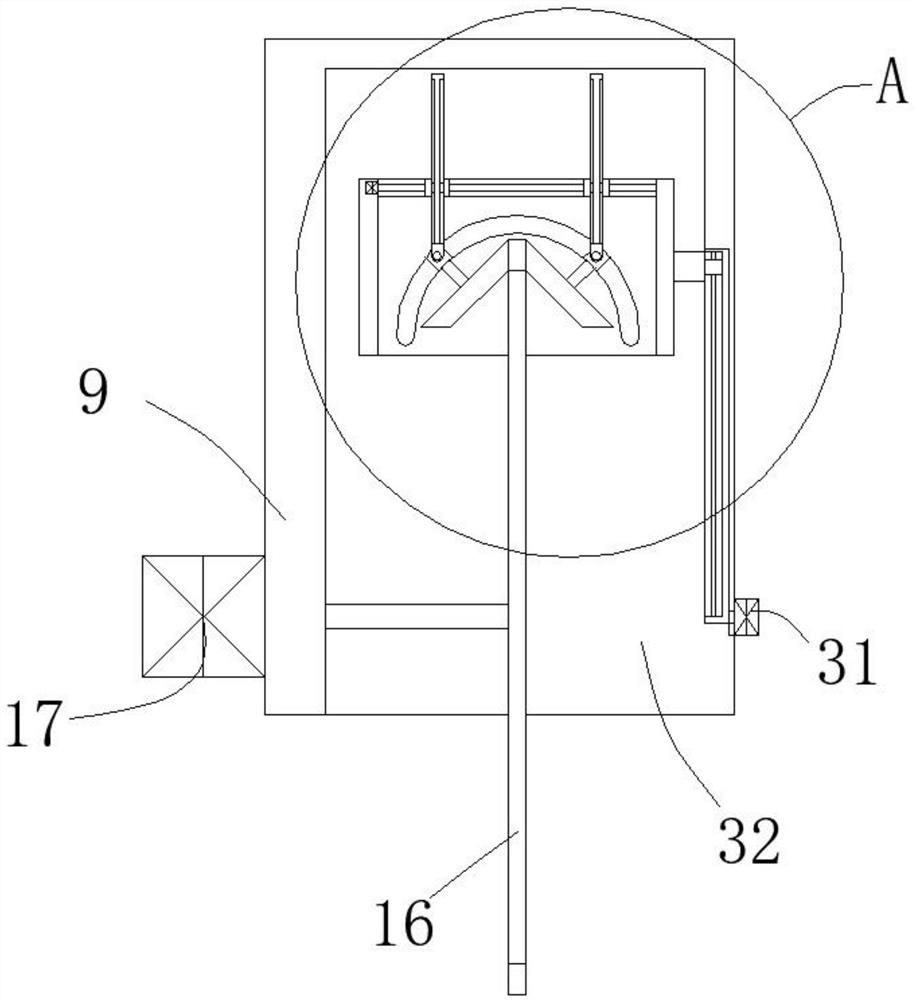

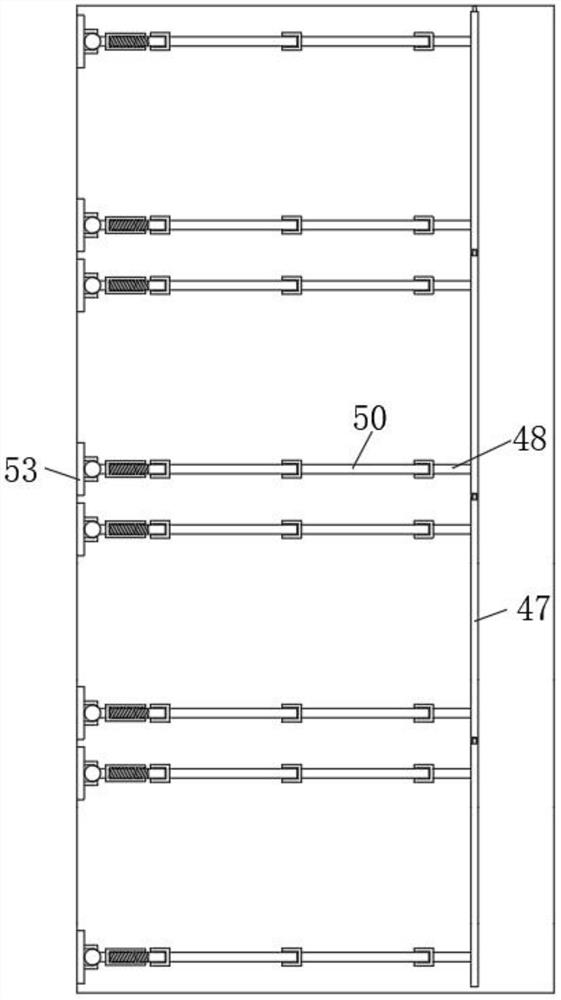

Machining device for removing burrs in steel transportation

InactiveCN112692673ASimple structurePracticalEdge grinding machinesGrinding carriagesPulleySteel plates

The invention discloses a machining device for removing burrs in steel transportation. The machining device comprises at least two fixed frames, wherein horizontal movable rods are mounted on the inner sides of the fixed frames, the horizontal movable rods penetrate through the side walls of the fixed frames, and fixed plates are mounted at the ends, located on the inner sides of the fixed frames, of the horizontal movable rods; a steel laminate abutting pulley is rotatably connected in the fixing plate, the steel laminate abutting pulley makes contact with the side wall of the steel in an abutting mode, a first expansion spring is mounted in front of the fixing plate and the inner wall of the fixing frame, and the horizontal movable rod is sleeved with the first expansion spring; by designing the device, the device is mounted on steel plate transportation equipment. When a steel plate passes, a steel laminate is extruded to abut against the pulley, so that a grinding block fixing piece rotates towards one side of the steel plate, burrs of the steel plate are ground and removed through a grinding block, and when the device is not used, the grinding block fixing piece can reset under the action of a tightening spring; The device is simple in structure and high in practicability.

Owner:上海钢度电子商务有限公司

Circular saw with grinding function

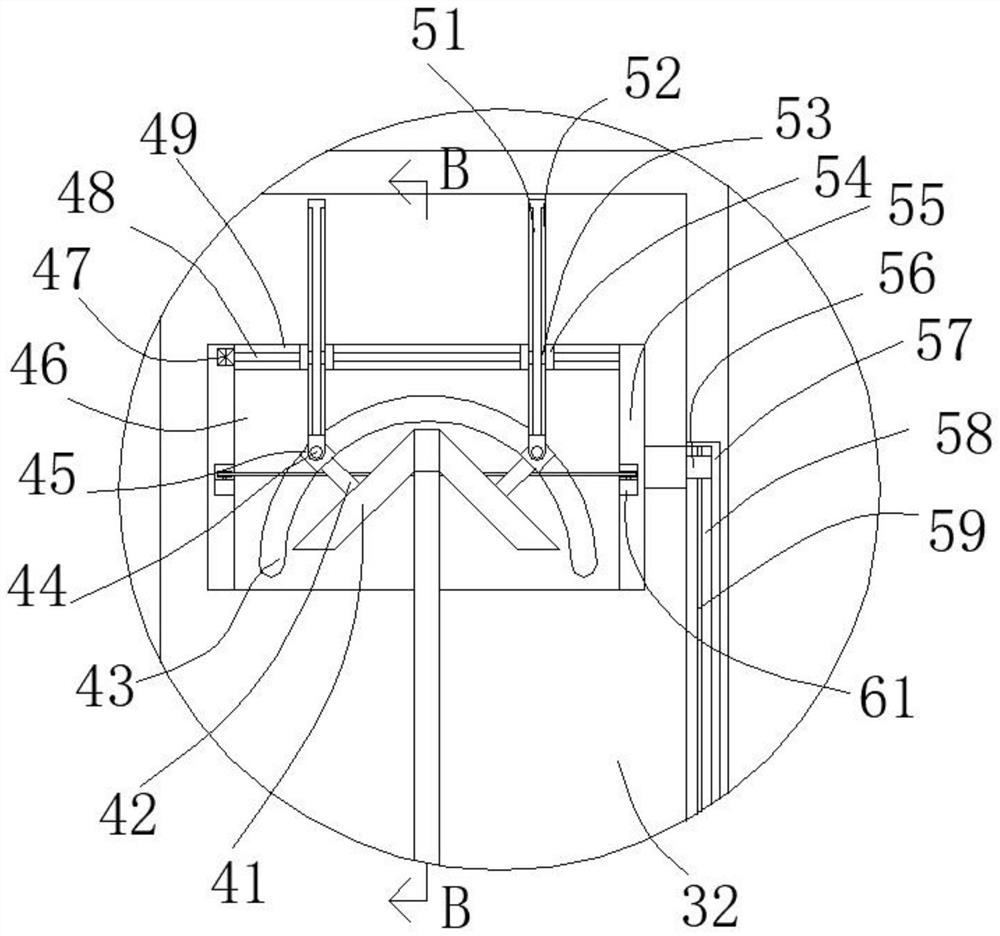

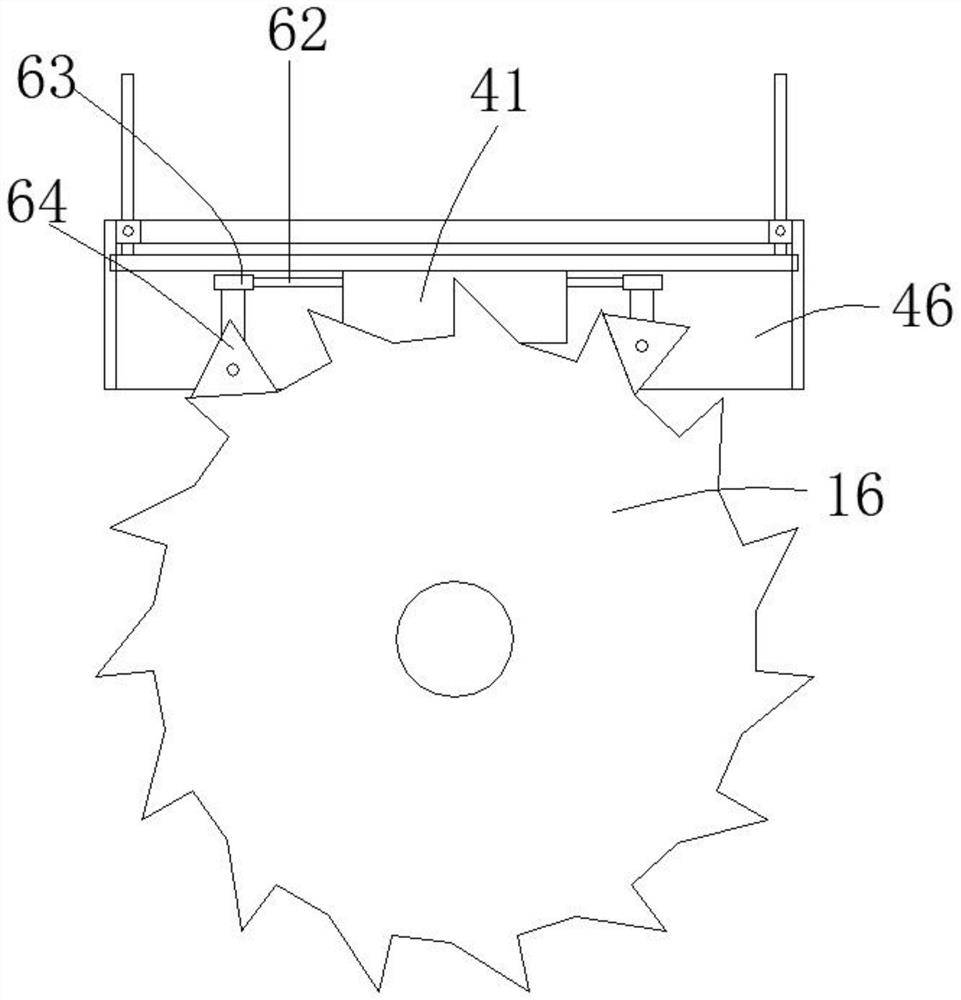

InactiveCN113665002AFull and efficient grindingImprove working conditionGrinding drivesFiling/rasping devicesCircular sawElectric machinery

The invention discloses a circular saw with a grinding function. The circular saw with the grinding function comprises an L-shaped connecting plate, one side of the lower end of the L-shaped connecting plate is connected with a cutting motor through a bolt, an output shaft of the cutting motor penetrates through one side of the L-shaped connecting plate, a cutting blade is arranged at the end of the output shaft of the cutting motor, a matched inner cavity is formed in the L-shaped connecting plate, the cutting blade is located in the matched inner cavity, a middle box body is arranged in the matched inner cavity, an inner cavity is formed in the middle box body, symmetrical surrounding grooves are formed in the end walls of the two sides of the inner cavity in a communicating mode, symmetrical sliding blocks are arranged in the surrounding grooves in a sliding mode, matching column bodies are arranged between the positions, located on the two sides of the inner cavity, of the sliding blocks, connecting rods are arranged on one sides of the matching column bodies, and grinding cone pulleys are rotationally arranged on one sides of the connecting rods. According to the equipment, and a saw blade of the circular saw can be fully and efficiently ground through a triangular file so that the circular saw can be kept in a good working state.

Owner:赵浩翔

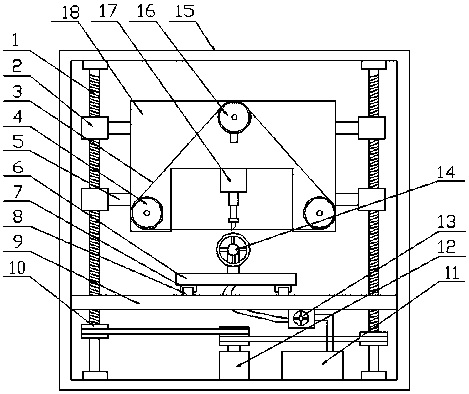

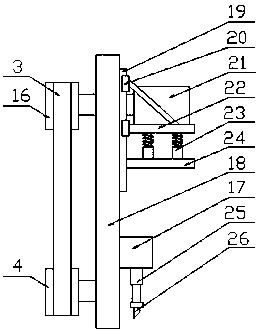

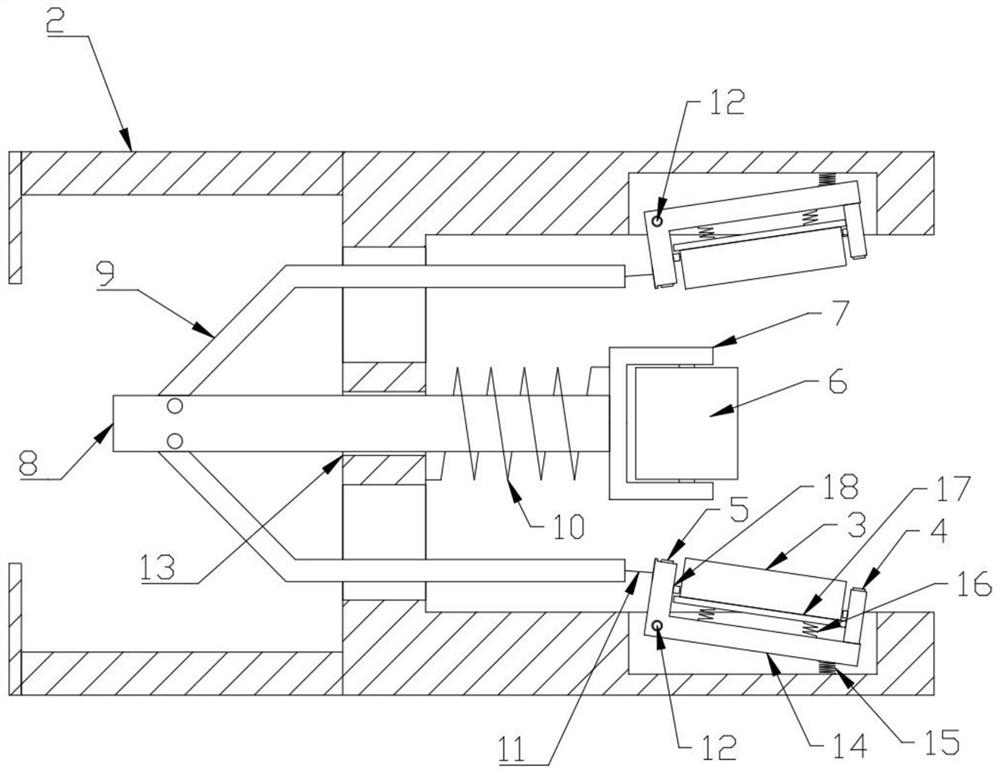

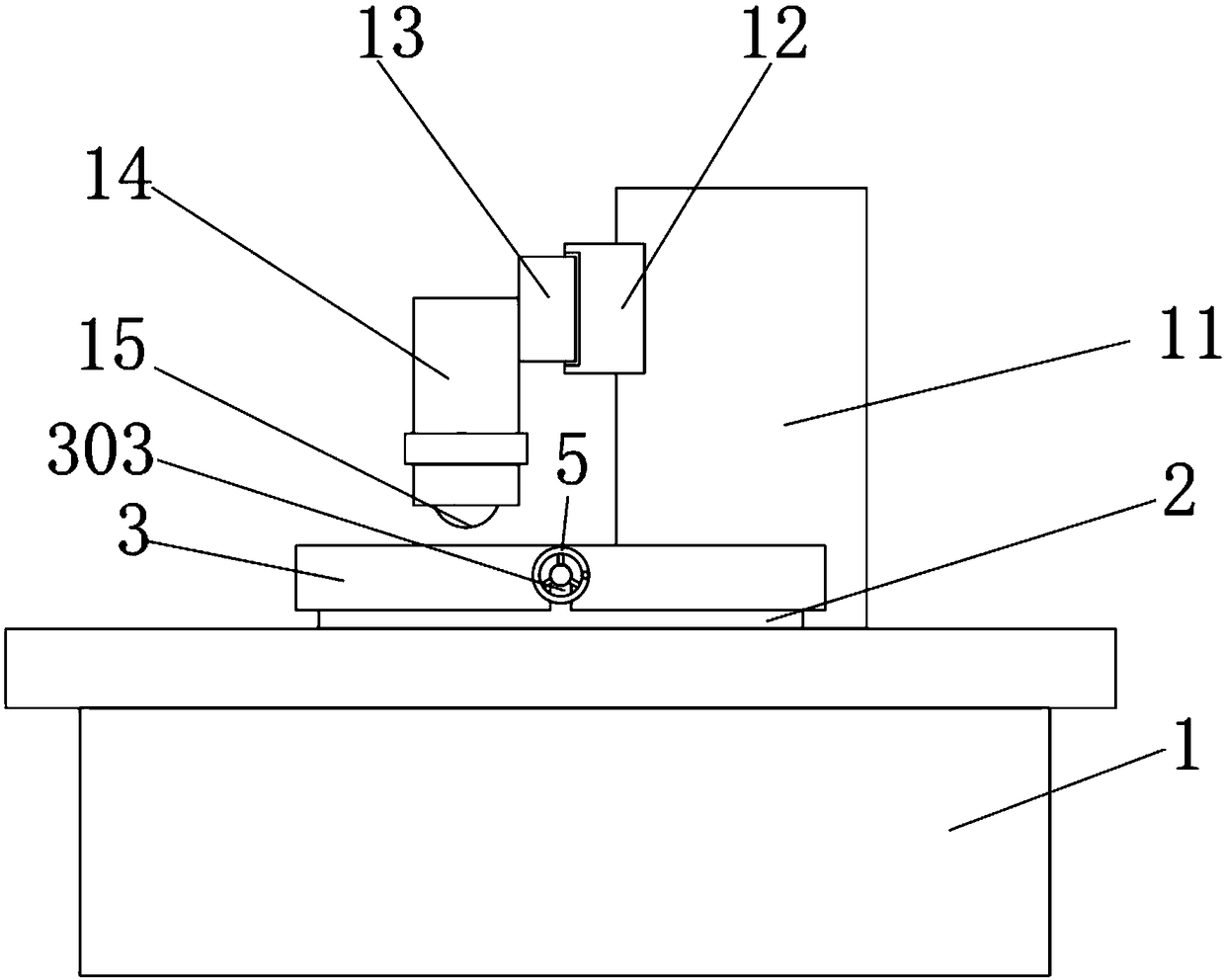

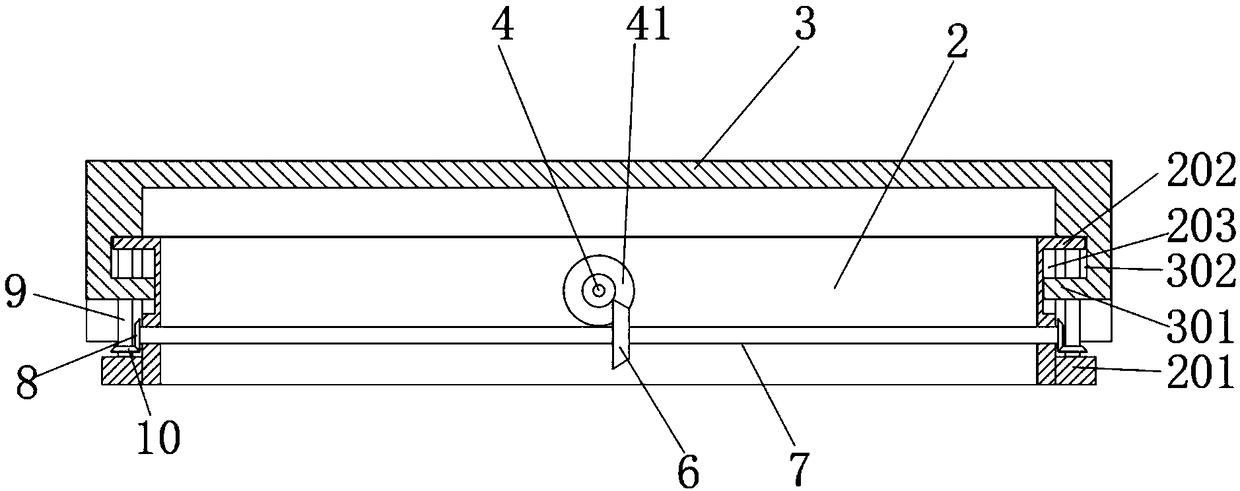

Surface grinder with lifting platform

InactiveCN108747811AAvoid collisionAvoid excessive sandingGrinding carriagesGrinding drivesEngineeringGrinding wheel

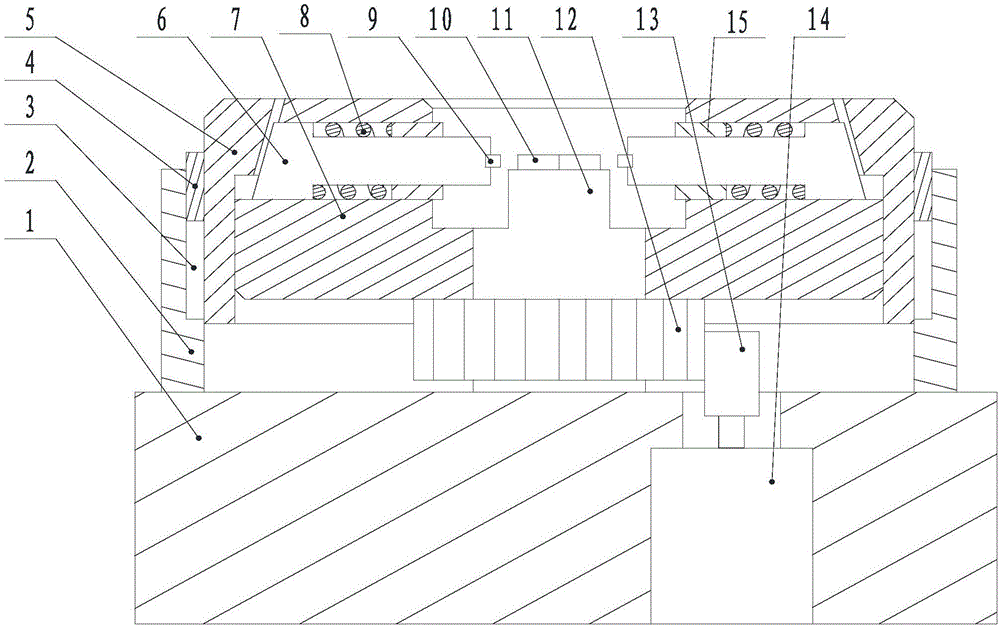

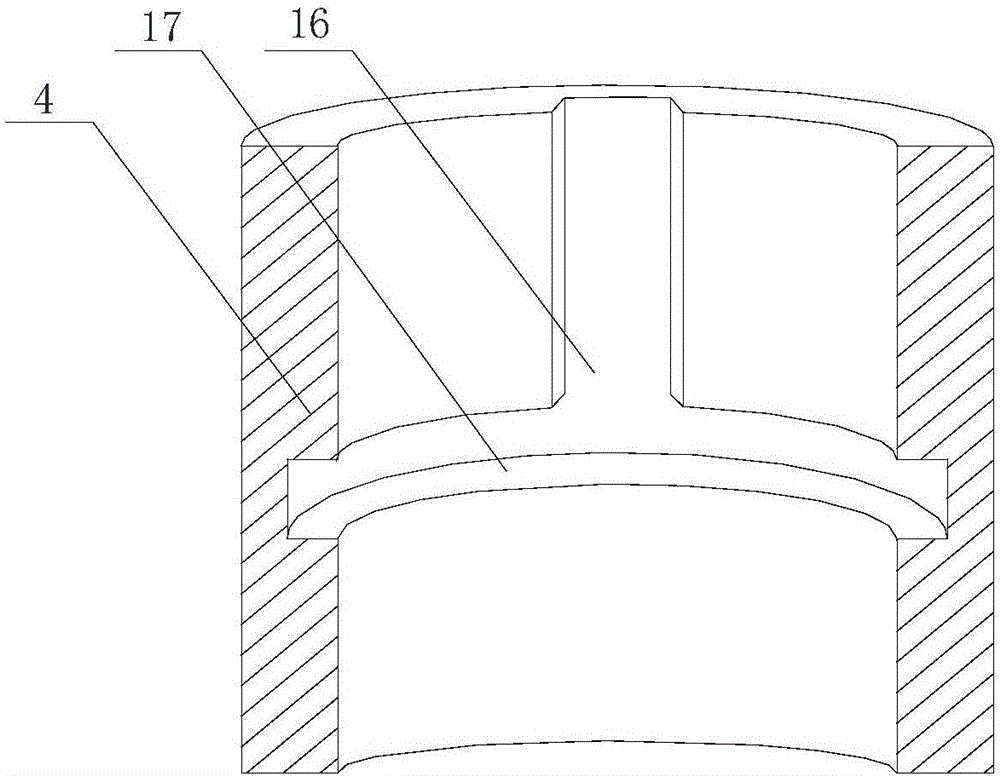

The invention discloses a surface grinder with a lifting platform, and belongs to the technical field of surface grinders. The surface grinder with the lifting platform comprises a lathe bed. A fixedseat is arranged at the top of the lathe bed, the lifting platform is arranged at the top of the fixed seat, fixed blocks are arranged on the outer sides of the bottom of the left and right sides of the fixed seat, and a rotating bevel gear is arranged at the bottom of the outer wall of a screw rod. The rotating bevel gear meshes with a driven bevel gear, lifting blocks are arranged on the inner sides of the bottom of the left and right sides of the lifting platform, the lifting blocks are screwed to a screw rod in a threaded mode, and a stand column is arranged at the rear end of the lathe bed. An upper and lower moving plate is arranged at the left end of the stand column. A front and rear moving plate is arranged at the left end of the upper and lower moving plate, and a grinding wheelframe is arranged at the left end of the front and rear moving plate. A grinding wheel is arranged at the bottom of the grinding wheel frame. The surface grinder with the lifting platform can adjust the lifting and lowering of a working platform slightly by manually rotating a rotating disc, and the requirement of accurate grinding is met.

Owner:高邮市金利达机械有限公司

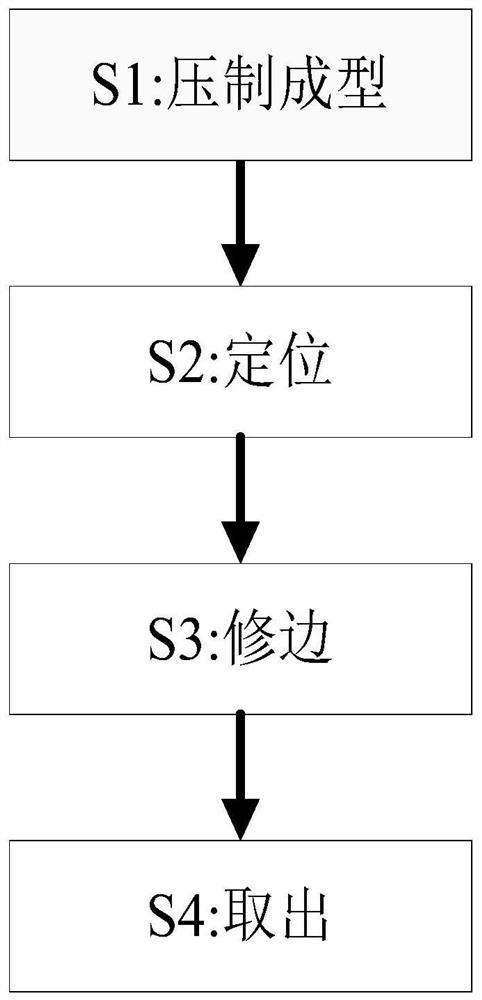

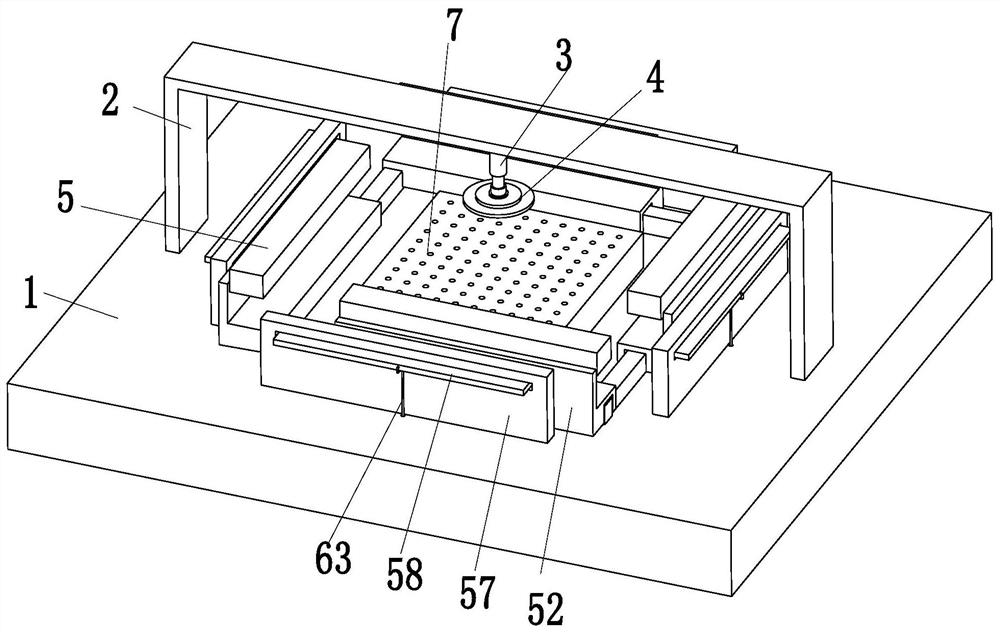

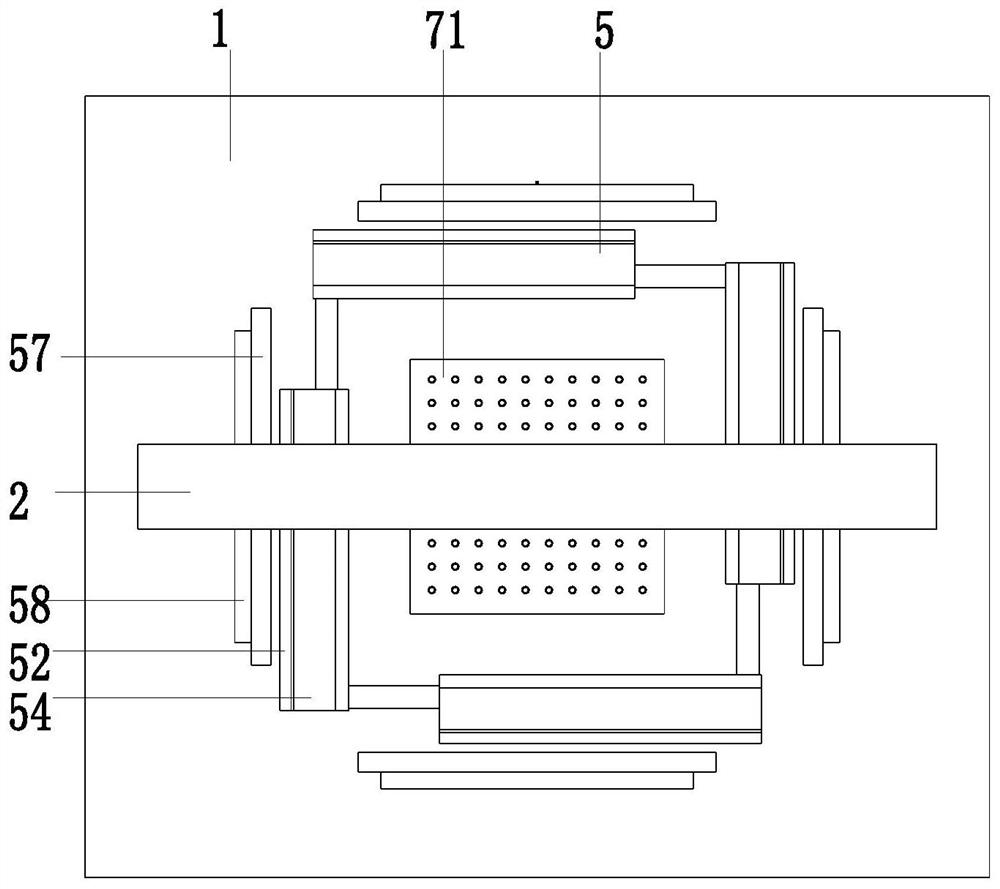

Manufacturing process of high-frequency copper clad plate

ActiveCN111958452ATimely collectionAvoid excessive sandingGrinding carriagesLaminationEdge surfacePolishing

The invention provides a manufacturing process of a high-frequency copper clad plate. The cooperation is completed through the cooperation of a base, a U-shaped frame, a downward pressure cylinder, apositioning block, a trimming unit, a driving unit and an air suction unit. The problems that the end surface of the copper clad plate is damaged due to the fact that sandpaper may come into contact with the upper and lower end surfaces of the copper clad plate when sanding due to small edge surface of the copper clad plate, excessive polishing often occurs due to difficult to control the strengthof manual polishing, and material chips produced by polishing are difficult to collect are solved.

Owner:聚创(江门)新材料科技有限公司

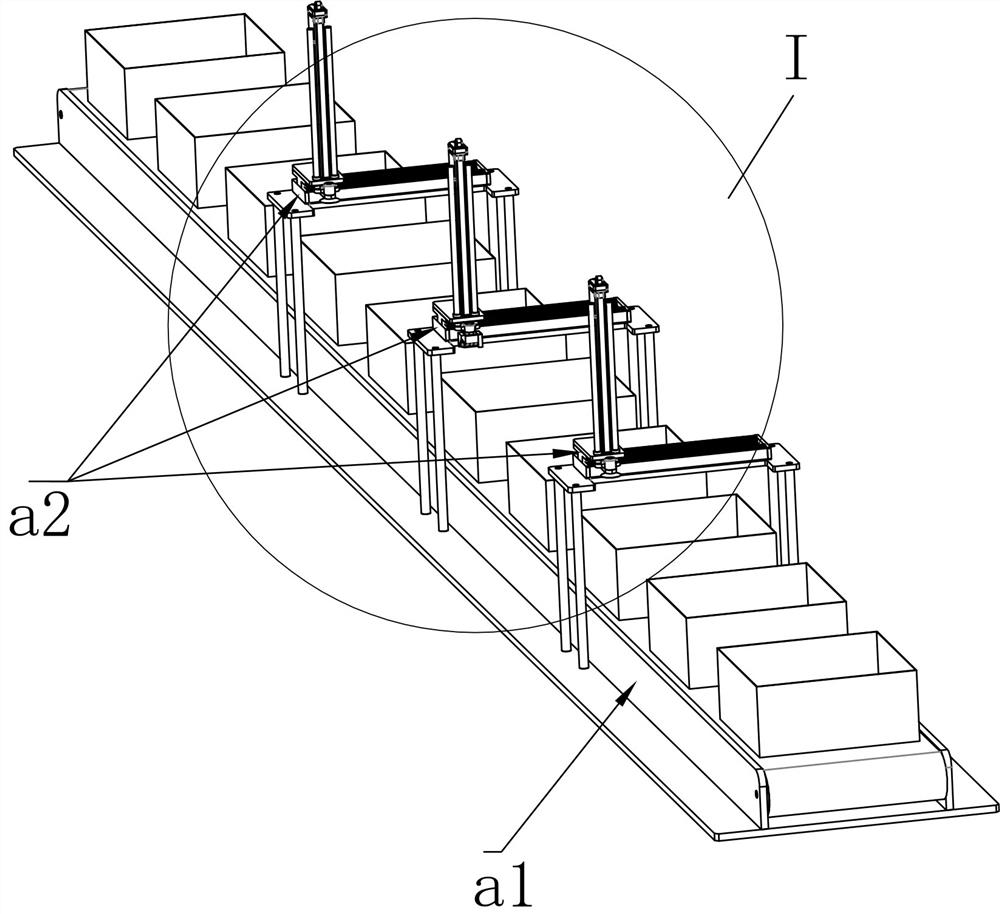

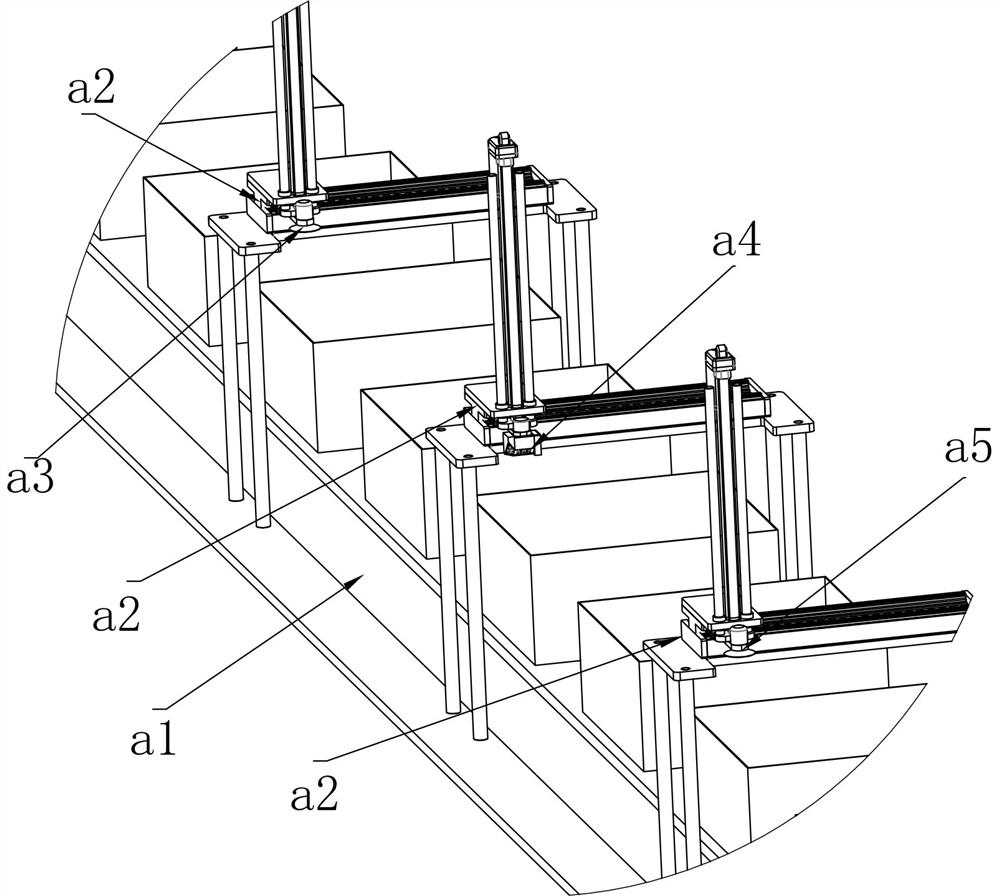

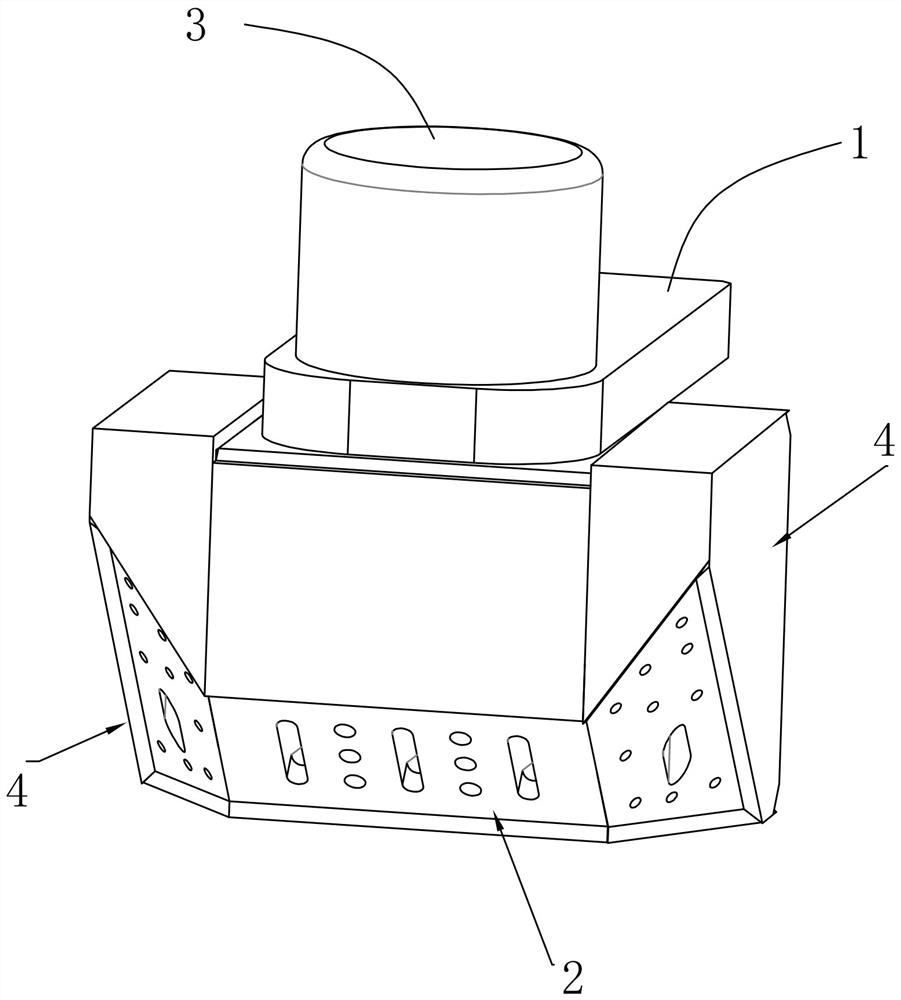

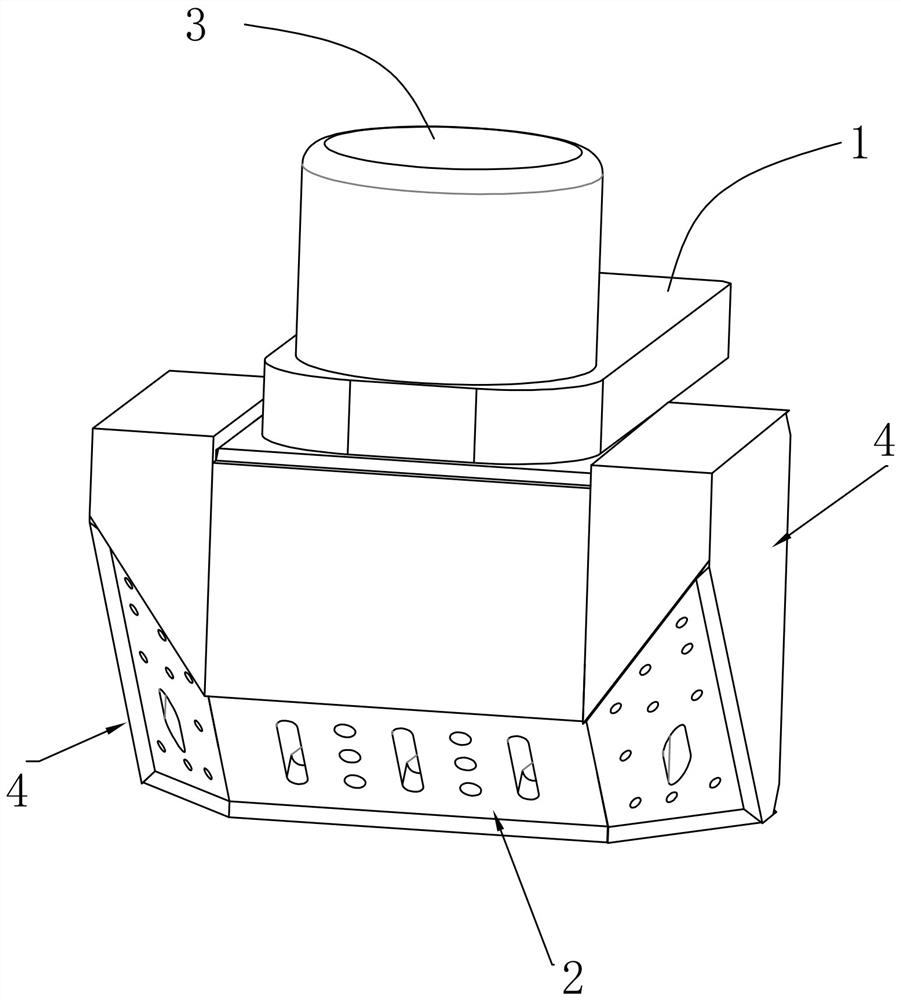

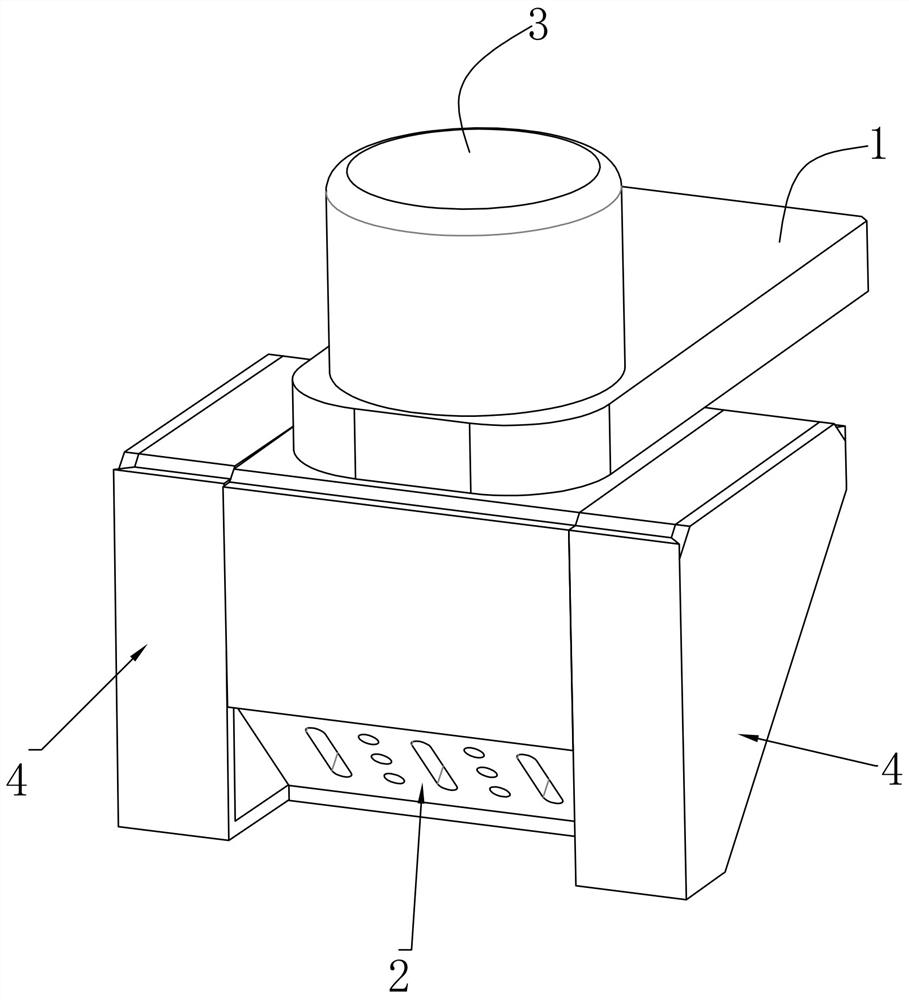

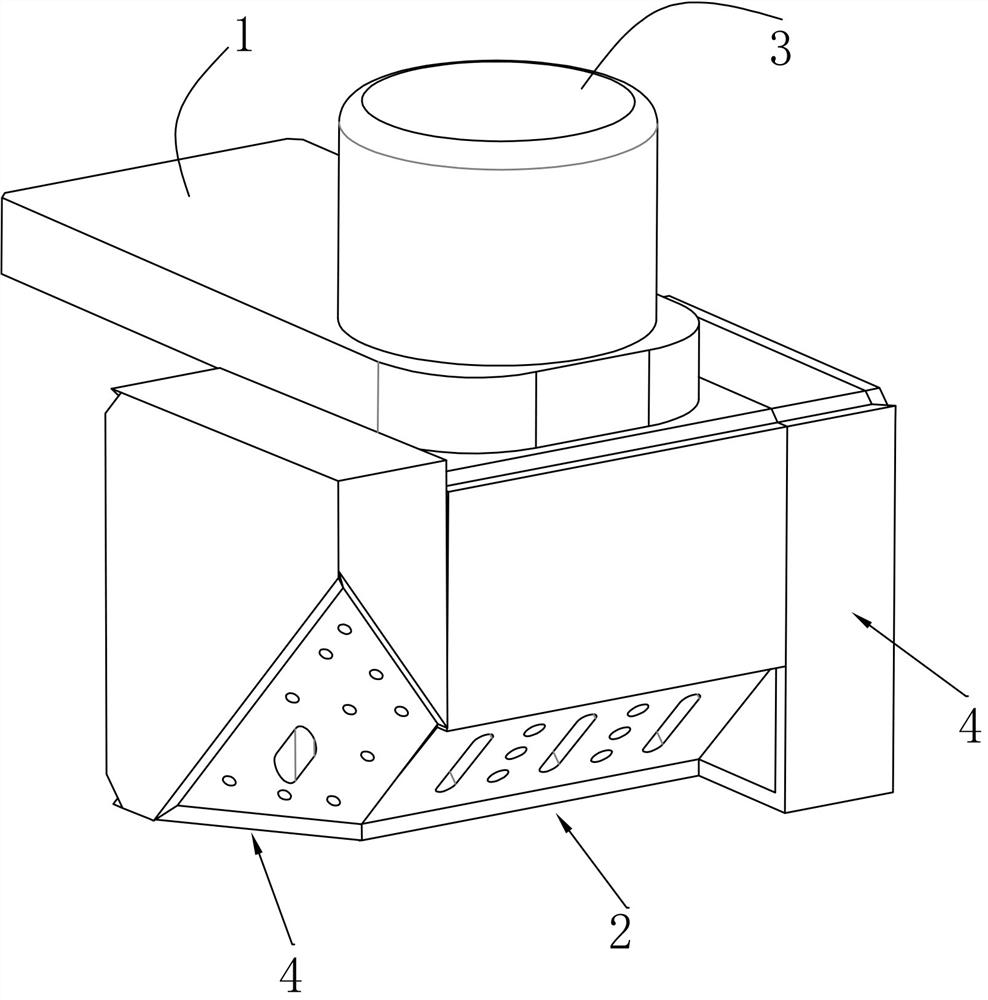

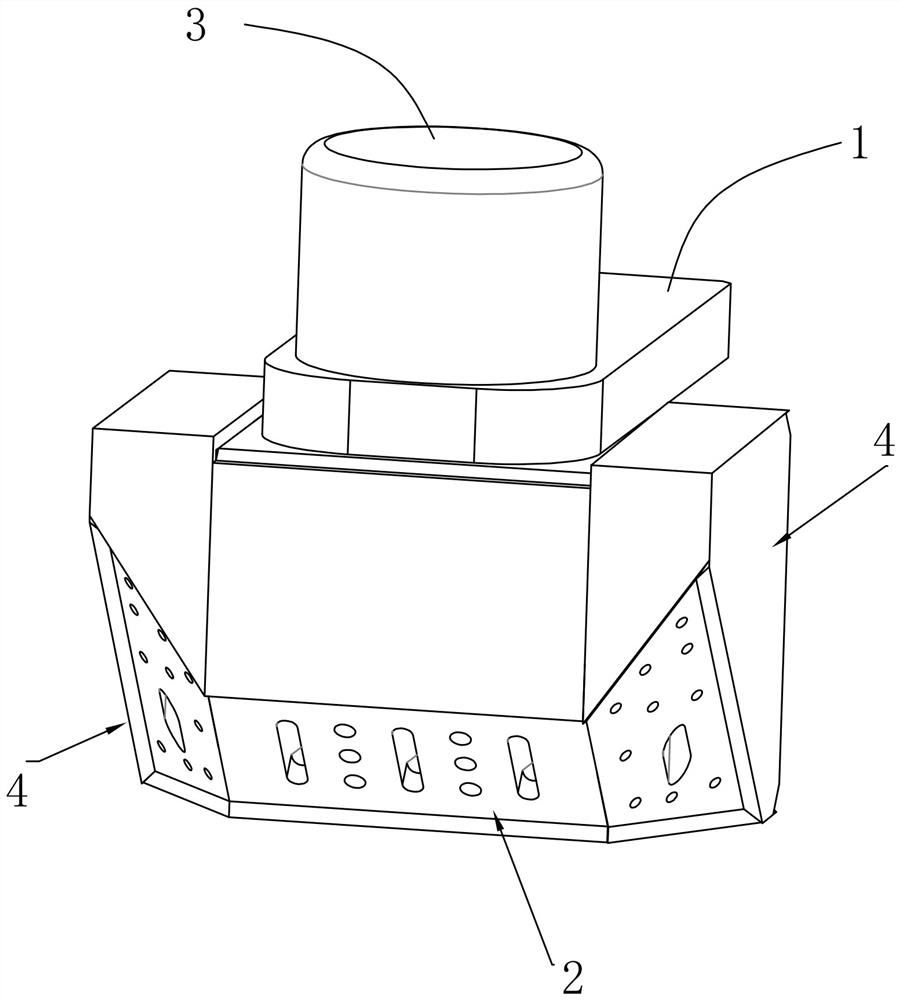

Robot production line for grinding and polishing corners of inner cavity of metal plate box

ActiveCN112428153AAvoid excessive sandingIncreased sanding area coverageAbrasive machine appurtenancesAbrasive blasting machinesProduction lineSand blasting

The invention discloses a robot production line for grinding and polishing corners of an inner cavity of a metal plate box. The robot production line comprises a conveying table, three cross-shaped sliding table devices, a rough polishing device, a corner grinding device and a fine polishing device, wherein the corner grinding device comprises a connecting plate, a forward sand blasting body, a rotary driving mechanism and two lateral sand blasting bodies; the forward sand blasting body is rotationally connected to the connecting plate and provided with a first chamfering part; the first chamfering part is provided with a plurality of first sand blasting through holes and a plurality of first chip removal through holes; the two lateral sand blasting bodies are symmetrically and rotationally arranged on the left side and the right side of the first chamfering part; and each lateral sand blasting body is provided with a second chamfering part, wherein the second chamfering part is obliquely arranged backwards and provided with a second chip removal through hole and a plurality of second sand blasting through holes. According to the robot production line, the grinding area range is enlarged, the grinding effect on the corners of the inner cavity of the metal plate box is improved, the problem that the grinding dead angle generated by corner grinding is large is solved, and excessive grinding on the vertical faces near the corners is avoided.

Owner:北斗长缨(北京)科技有限公司

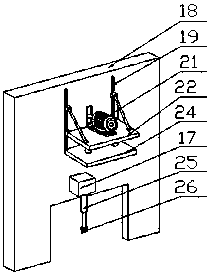

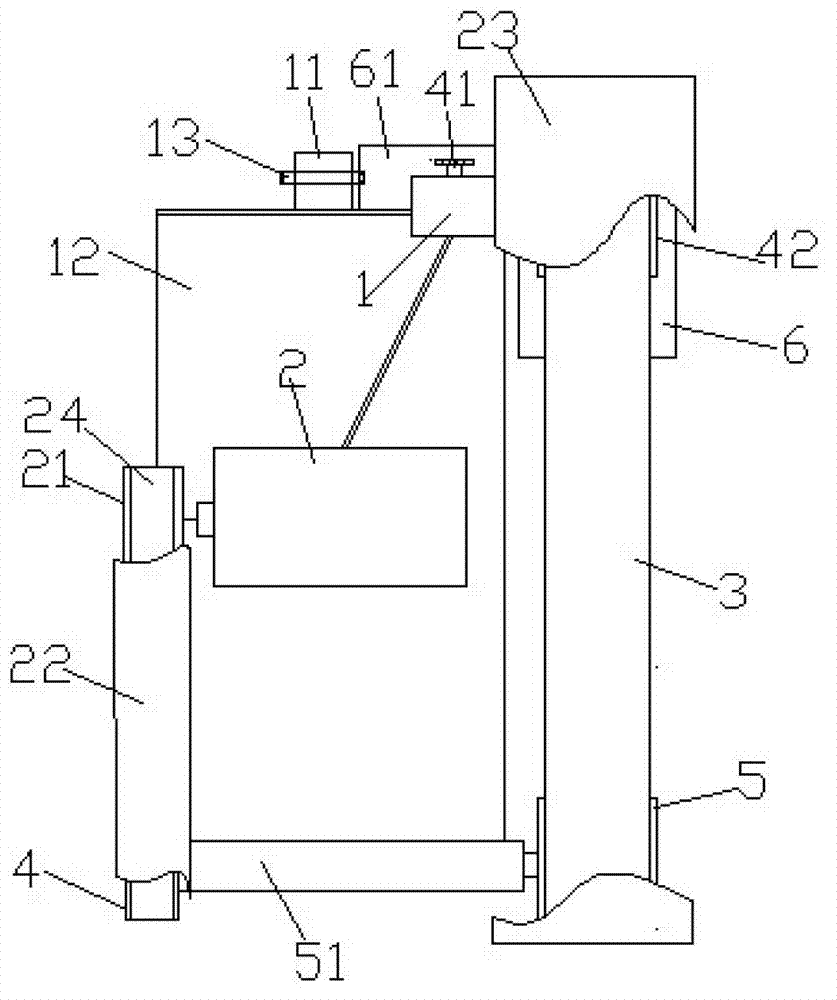

Environment-friendly wall surface smoothing device for building construction and building construction method

PendingCN113510549AAchieving Squeeze ContactSingle and stable force directionGrinding carriagesGrinding drivesArchitectural engineeringPlanishing

The invention discloses an environment-friendly wall surface smoothing device for building construction and a building construction method. The environment-friendly wall surface smoothing device comprises a smoothing trolley and an abutting plate assembly, the smoothing trolley comprises a trolley plate, and locking universal wheels are installed on the four corners of the bottom of the trolley plate; the environment-friendly wall surface smoothing device is characterized in that a stand is arranged at the top of the trolley plate, supporting legs are arranged between the bottom side of the stand and the trolley plate, a rail vertical pipe is fixedly mounted on the top side of the stand, the rail vertical pipe is of a rectangular pipeline-shaped structure, a rectangular lifting column is vertically and glidingly mounted in the rail vertical pipe, a threaded groove is formed in the bottom of the rectangular lifting column, a threaded column is connected in a threaded mode, a rotating circular plate is fixedly mounted at the bottom end of the threaded column, and a universal ball and a connecting rod are mounted on the bottom side of the rotating circular plate. According to the device, the wall surface smoothing effect is guaranteed, the polishing range is wide, using is more convenient and faster, labor is saved, the application range is wide, the design is reasonable, the structure is stable, and the using requirement of building workers for wall surface flatness treatment in the construction process is met.

Owner:葛泮忠

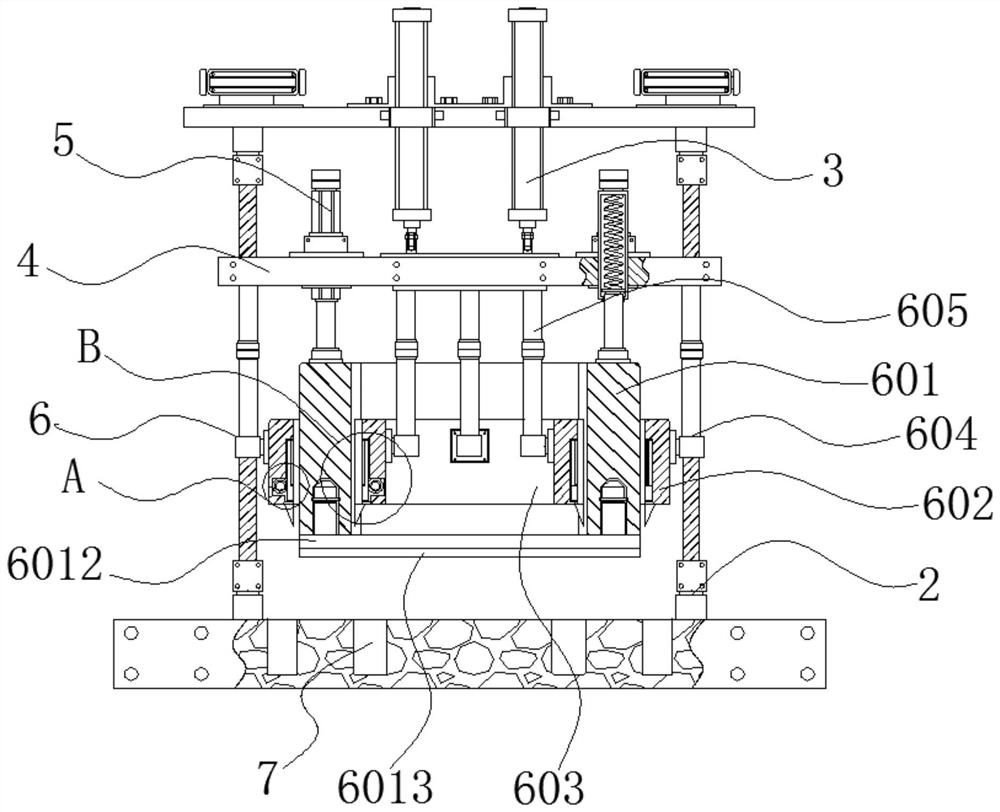

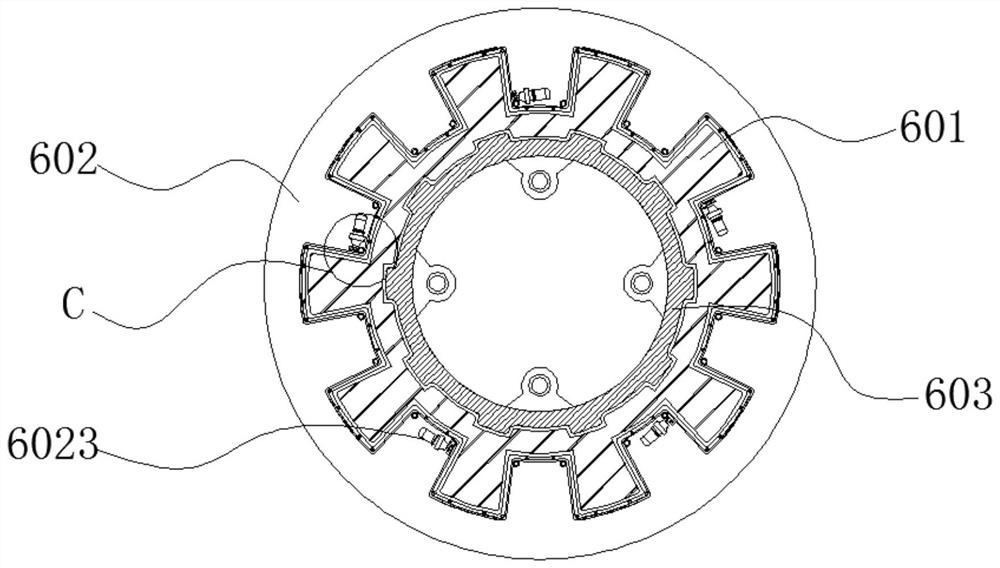

Stepping motor gear and one-time precision cutting die thereof

InactiveCN113102651AQuality improvementNo warpingBelt grinding machinesGear wheelsHydraulic cylinderGear wheel

The invention discloses a stepping motor gear and a one-time precision cutting die thereof, and relates to the technical field of stepping motor gear machining. The stepping motor gear comprises a stepping motor gear body and the one-time precision cutting die; the one-time precision cutting die comprises a machining support and a pressure plate, the machining support is used for placing a to-be-machined stainless steel plate material; the pressure plate is fixedly arranged at the bottom end of a hydraulic cylinder; a one-time precision cutting structure comprises a pre-pressing cylinder piece, a first supporting rod, and a second supporting rod, the bottom end of the second supporting rod is fixedly connected with an inner circle fine cutting piece through a bolt. According to the stepping motor gear and the one-time precision cutting die thereof, the flatness of the surface of a stainless steel plate can be detected before precision cutting, the uneven surface of the stainless steel plate is prevented from being machined, the surface of the stainless steel plate is pressed and clamped during precision cutting, and the condition that the finish-cut part on the surface of the stainless steel plate is tilted or the finish-cut surface is not flat is avoided, so that the quality of the machined stepping motor gear is improved.

Owner:苏州市鼎泰精密机械有限公司

Welding joint polishing machine for repair of composite boards

InactiveCN103111930AAvoid excessive sandingEnsure consistencyBelt grinding machinesEngineeringMechanical engineering

The invention relates to a welding joint polishing machine for repair of composite boards. The welding joint polishing machine comprises a grinding belt and a welding joint reinforcement verifying portion, wherein the grinding belt is driven by a motor and a belt, and the welding joint reinforcement verifying portion utilizes a top surface of a flat composite board beside a welding joint as datum. Height allowance is preset by utilizing the top surface of the flat composite board beside the welding joint according to the height of the welding joint. When the preset height allowance is polished, the welding joint reinforcement verifying portion can form hinderance for contact of the grinding belt and the welding joint, too much polishing of the welding joint is prevented, and uniformity of flatness after polishing of the welding joint is guaranteed.

Owner:山东龙祥金属复合材料有限公司

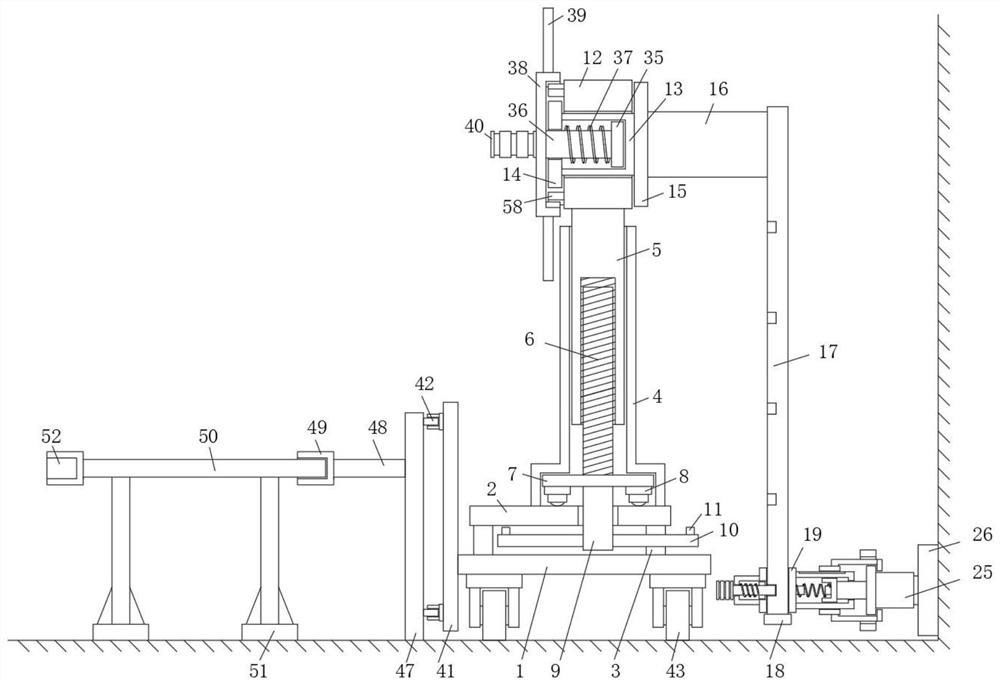

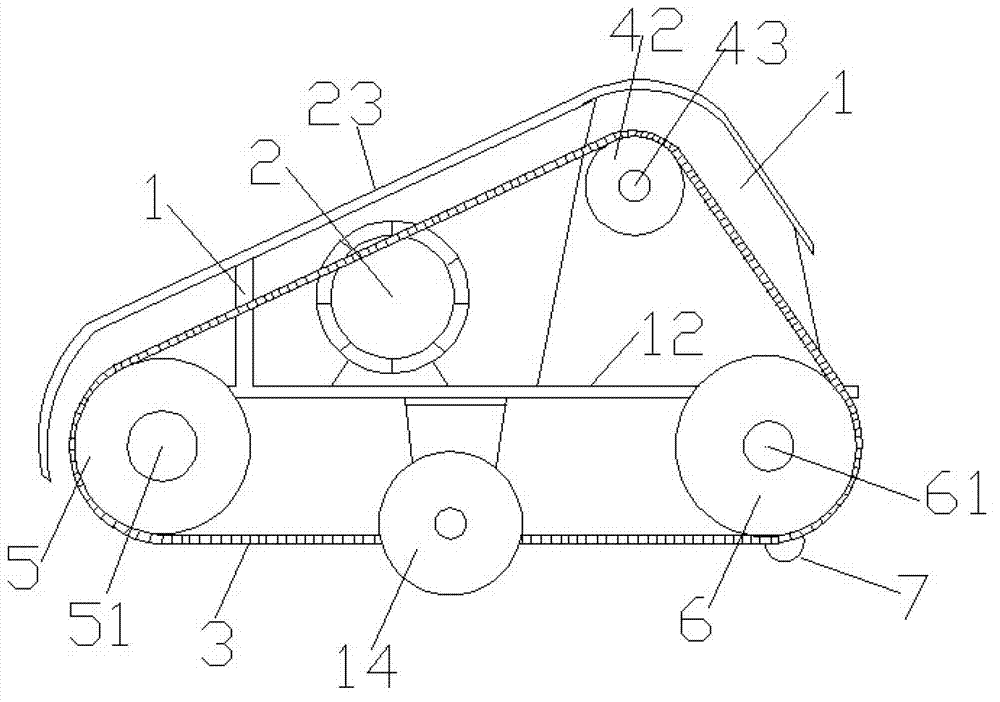

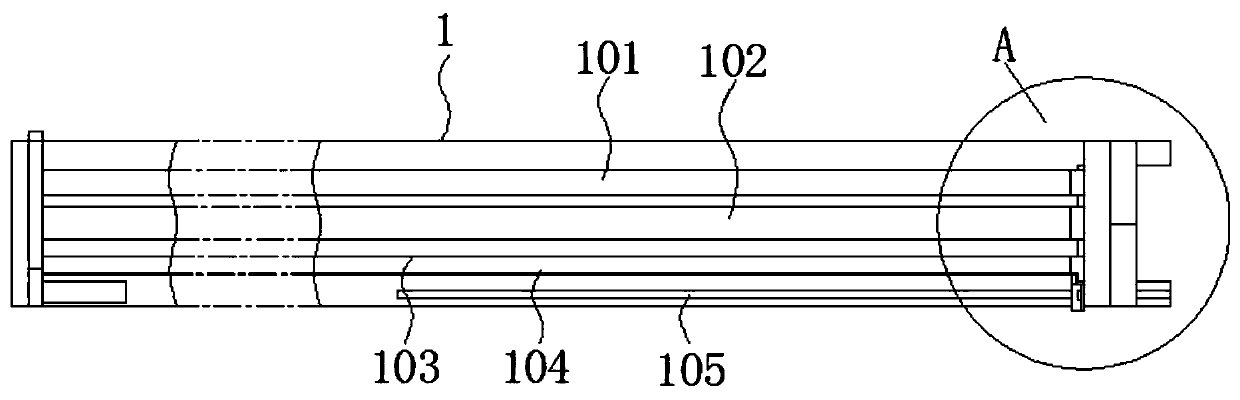

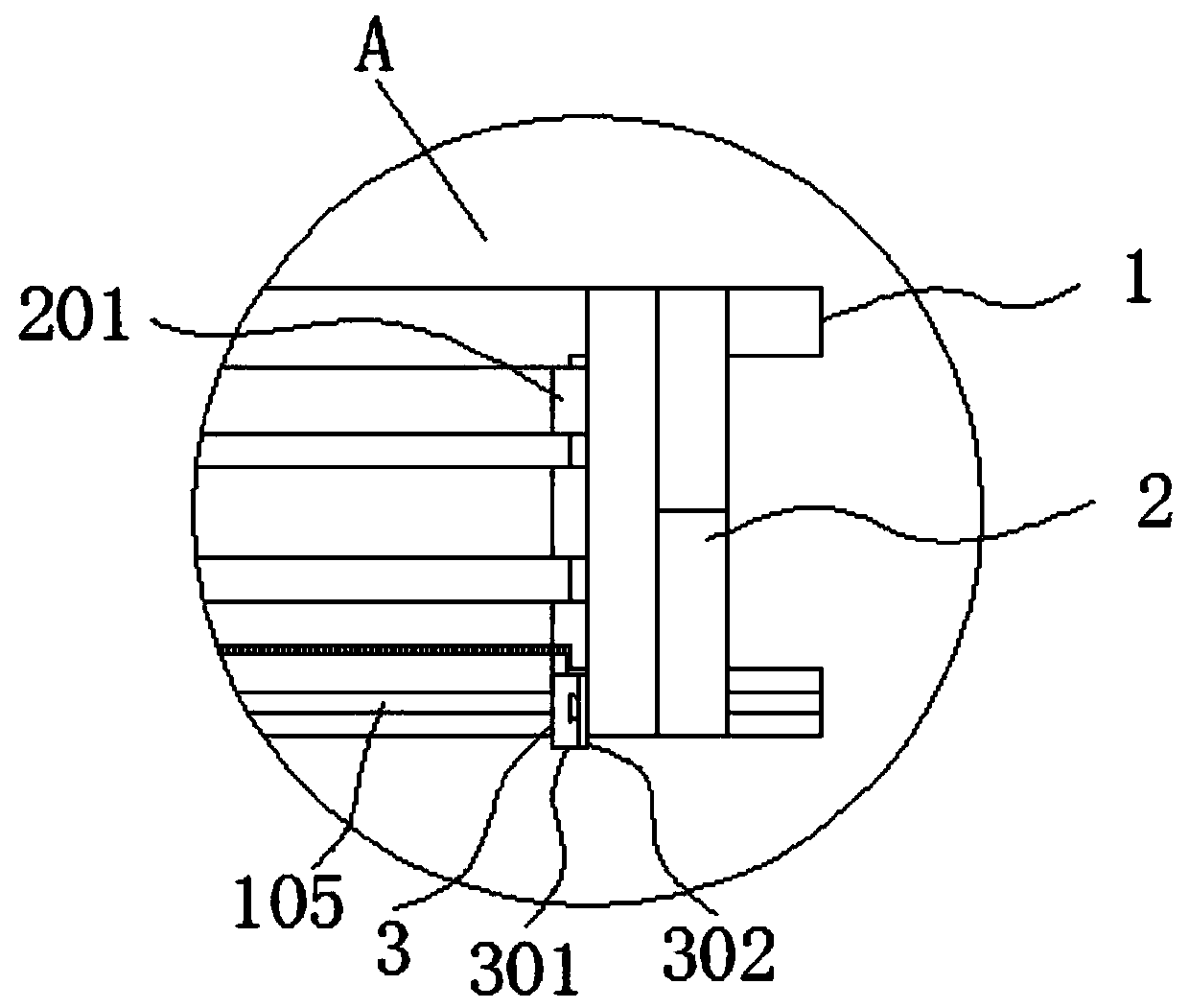

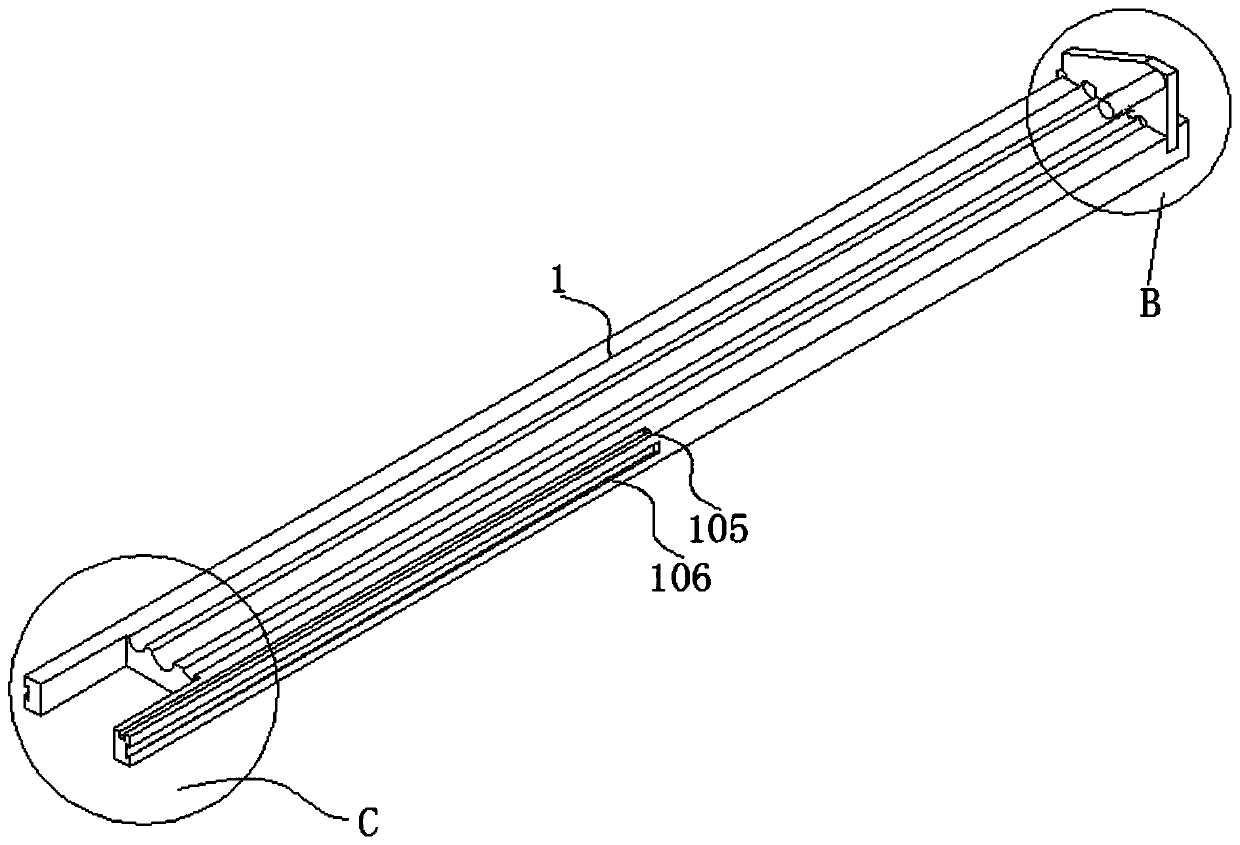

Belt type grinding device for shaft for electric power overhaul

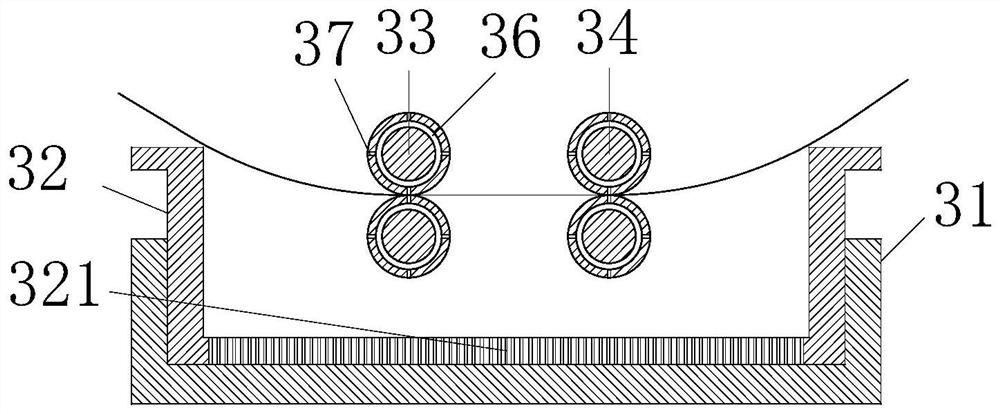

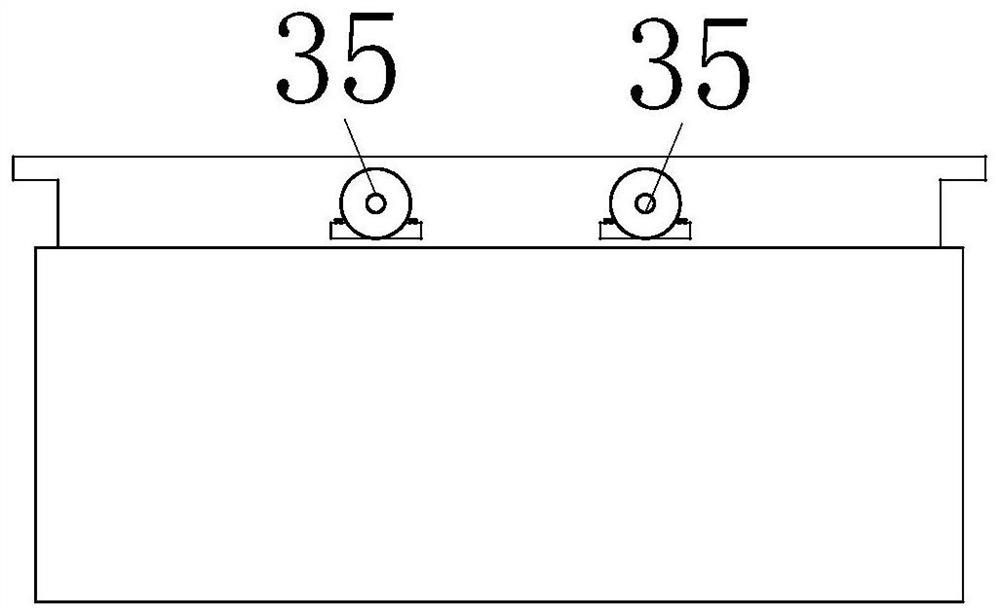

PendingCN112025496AAvoid excessive sandingReduce intensityGrinding carriagesGrinding drivesFastenerPolishing

The invention discloses a belt type grinding device for a shaft for electric power overhaul. The belt type grinding device comprises a mounting bottom plate, a transmission part, a bracket part and aclamping part; the bracket part comprises a first supporting frame and a second supporting frame; the first supporting frame and the second supporting frame are connected through a fastener; a first guide wheel is arranged on one side of the first supporting frame; a second guide wheel and a third guide wheel are arranged on the second supporting frame; and a guide wheel bracket part is arranged on the outer side face of the first supporting frame. According to the belt type grinding device, the clamping part is used for fixing and limiting, then a polishing abrasive belt is used for polishingthe welding position of a large shaft, excessive polishing is prevented, and the strength of the large shaft is prevented from being reduced; and meanwhile, the problem that assembly cannot be conducted due to the fact that polishing is insufficient can be solved, the polishing effect is guaranteed, the polishing efficiency is improved, and the use convenience is greatly improved.

Owner:国网河南省电力公司洛宁县供电公司 +1

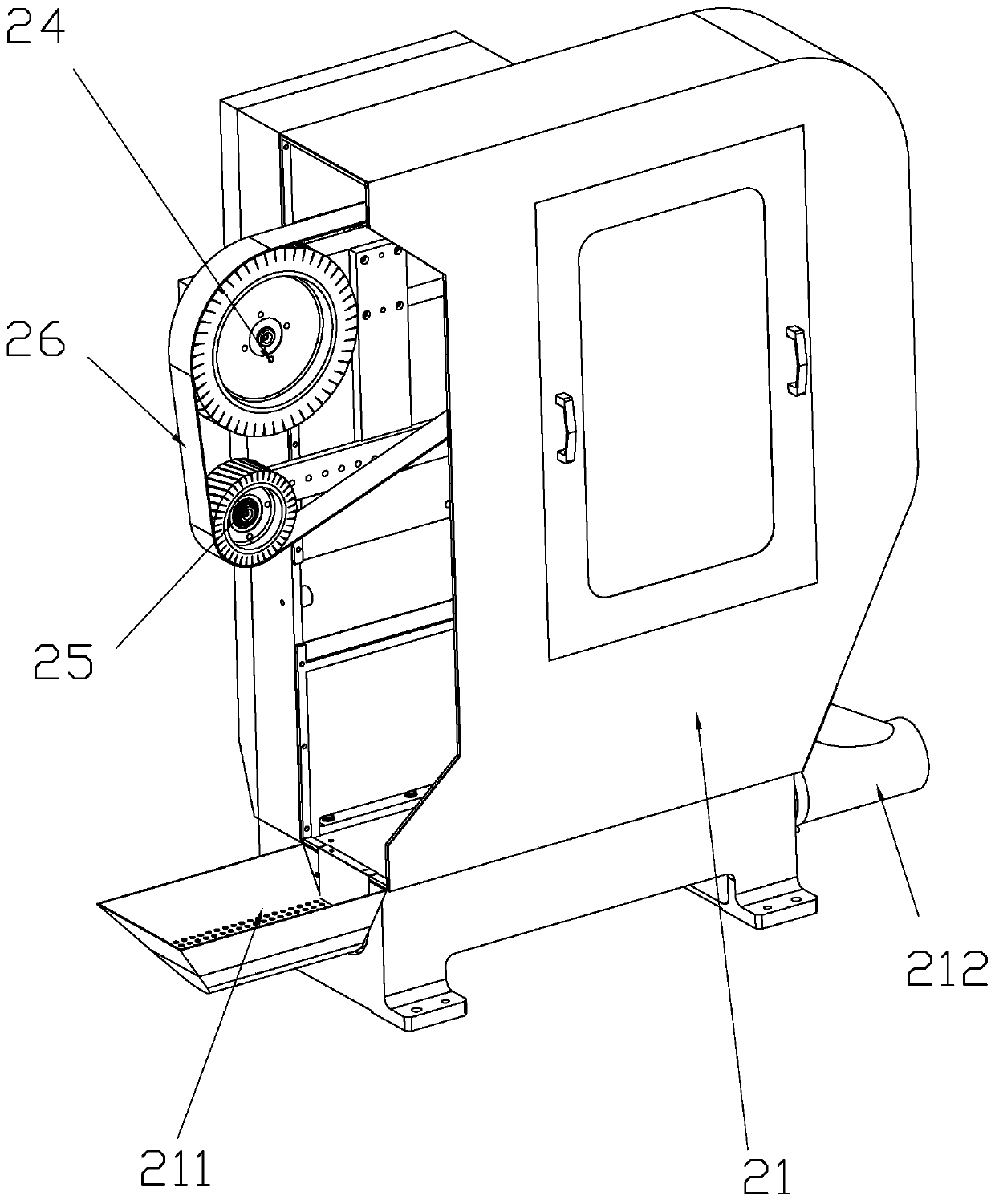

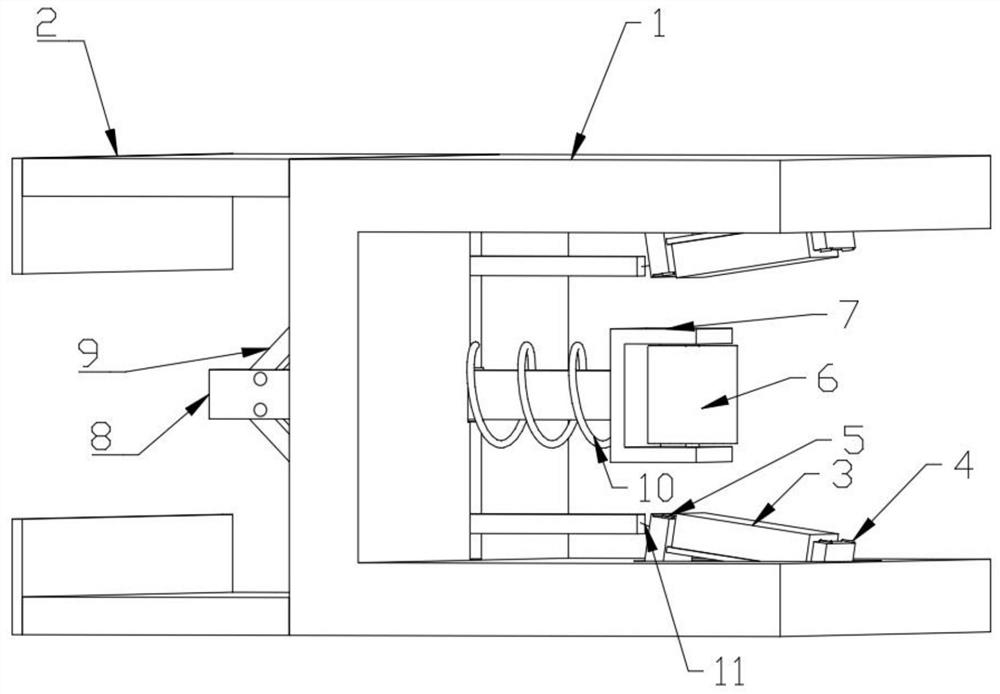

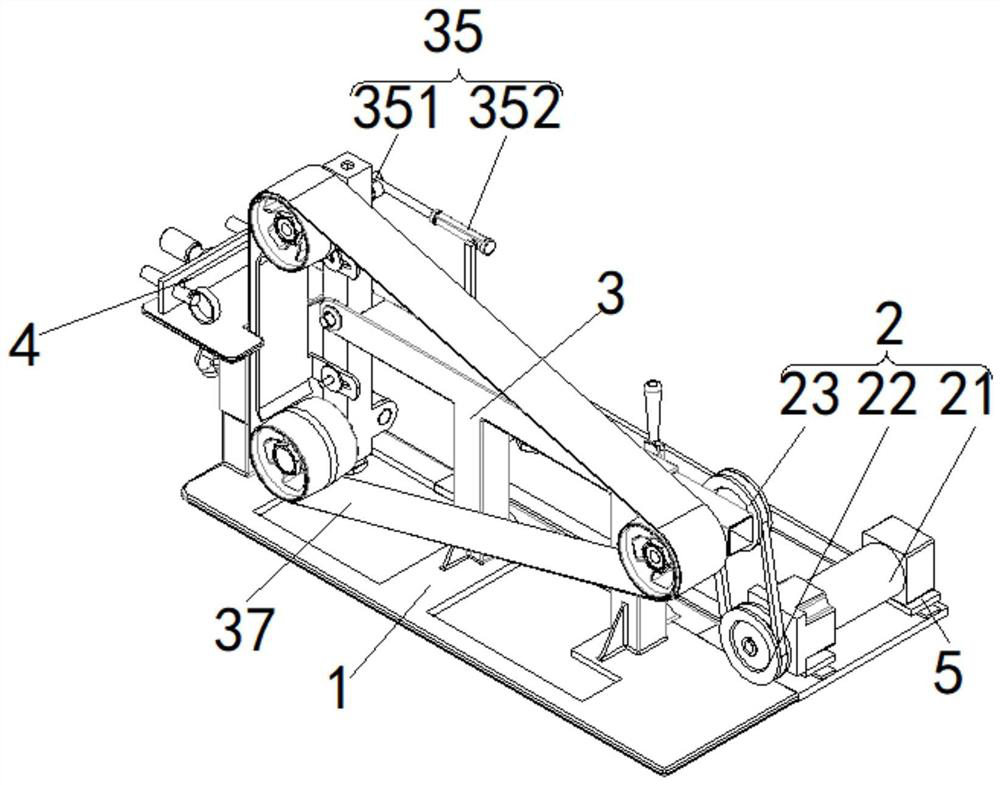

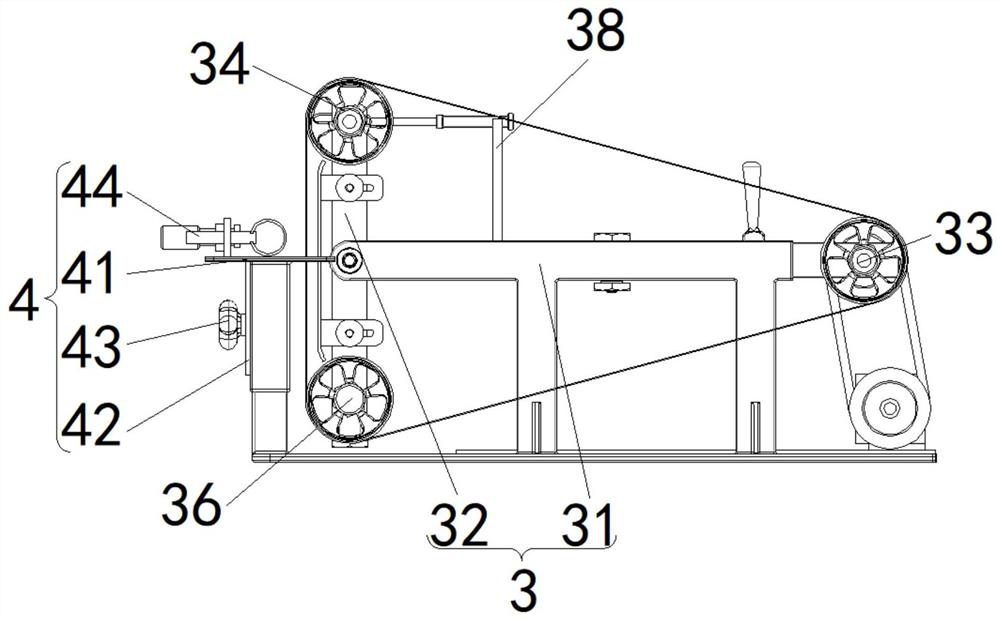

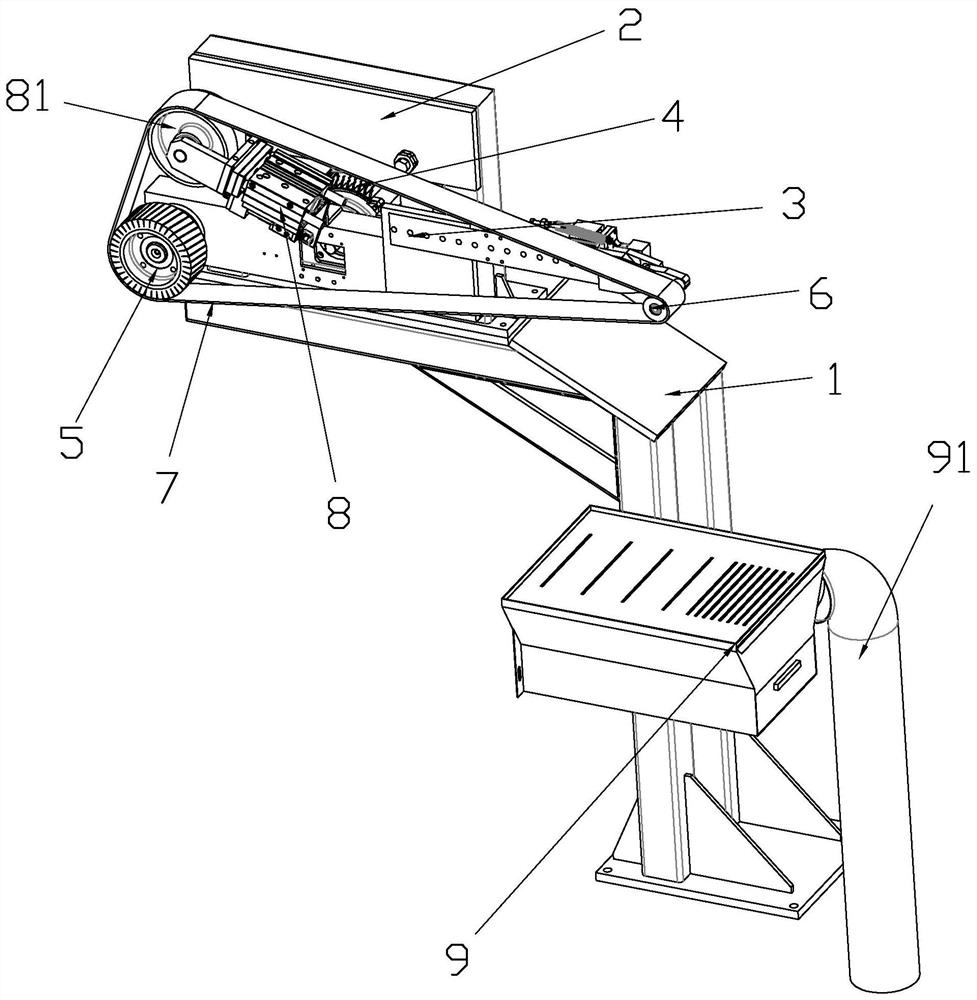

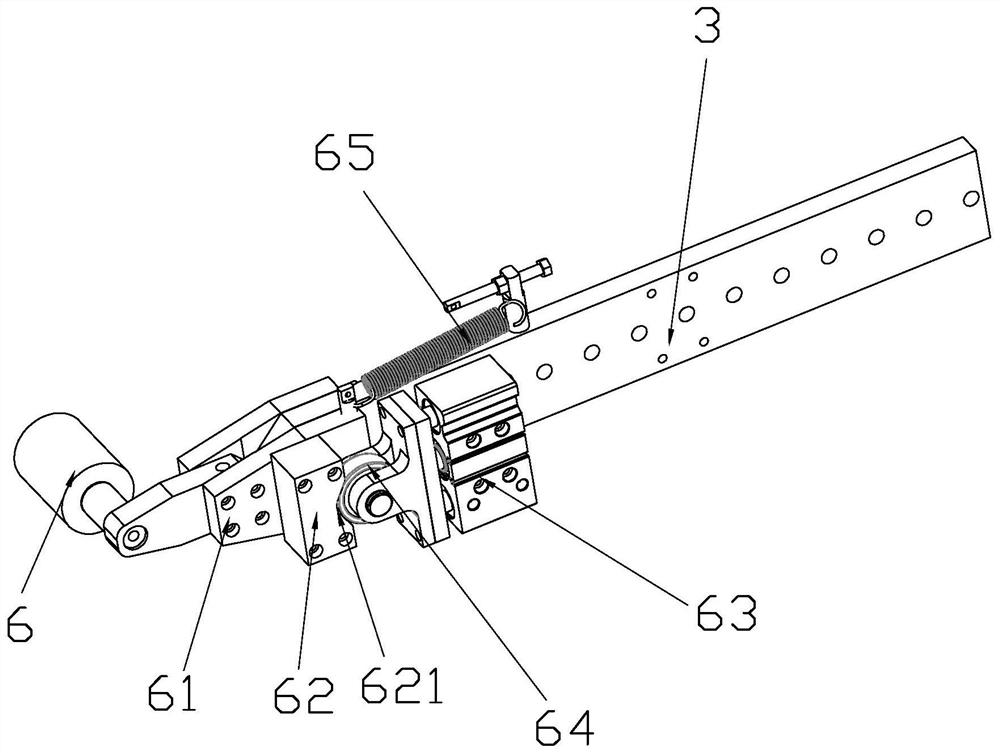

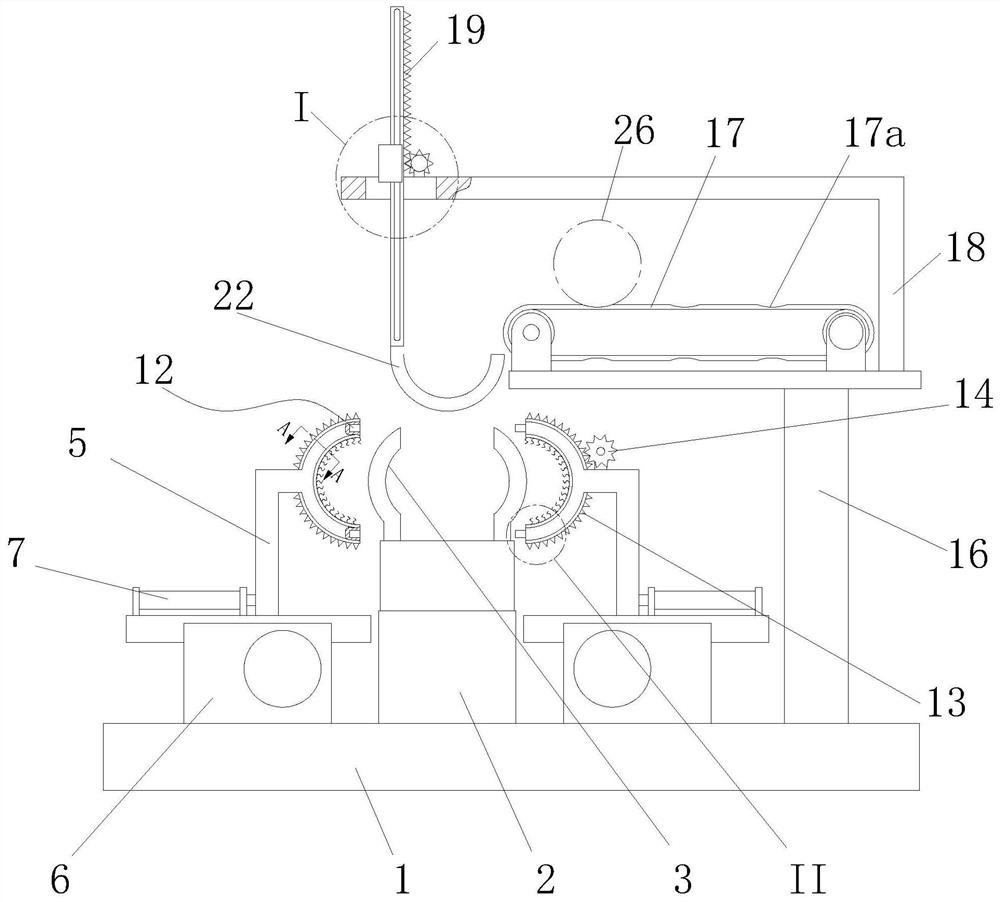

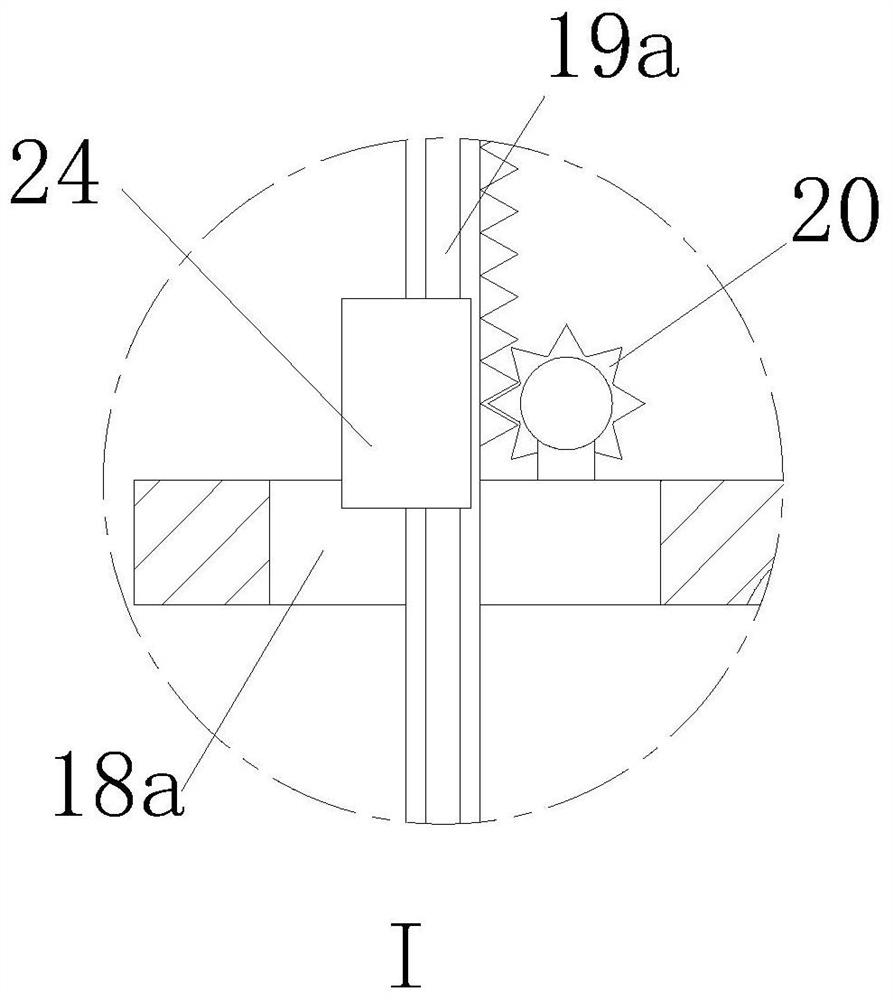

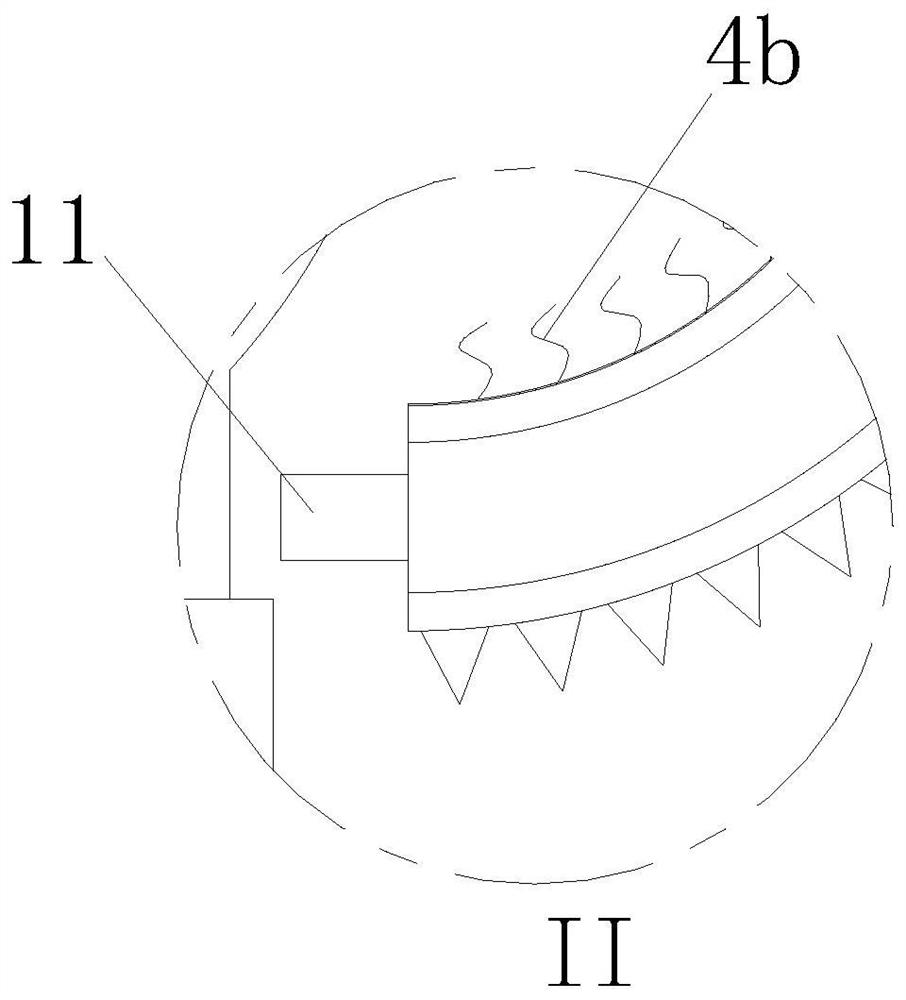

Abrasive belt grinding machine for casting head cutting and grinding assembly line of vehicle casting

PendingCN112355827AAvoid excessive sandingAffect healthBelt grinding machinesDrive wheelElectric machinery

The invention relates to an abrasive belt grinding machine for a casting head cutting and grinding assembly line of a vehicle casting. The abrasive belt grinding machine comprises a mounting frame andan abrasive belt grinding mechanism, and the abrasive belt grinding mechanism comprises an abrasive belt rack, an abrasive belt main beam, an abrasive belt driving motor, a driving wheel, a driven wheel and an abrasive belt. A flexible grinding assembly is arranged between the abrasive belt main beam and the abrasive belt rack, the flexible grinding assembly comprises a flexible swing arm, bearing columns are arranged at the two ends of the flexible swing arm, the flexible swing arm is movably connected with the abrasive belt main beam and the abrasive belt rack through the bearing columns, the abrasive belt main beam is made to swing left and right in the abrasive belt rack through the flexible swing arm, a floating grinding assembly is arranged between the driven wheel and the abrasivebelt main beam, the floating grinding assembly comprises a movable support, a swing base and a floating motor, the floating motor is provided with a buffer guide wheel, an arch-shaped groove is formedin the middle of the swing base, the buffer guide wheel is arranged in the arch-shaped groove, therefore, the driven wheel swings leftwards and rightwards through the movable support, the movable support is provided with a return tension spring, and the movable support returns after grinding through the return tension spring.

Owner:浙江珂斯顿机器人科技有限公司

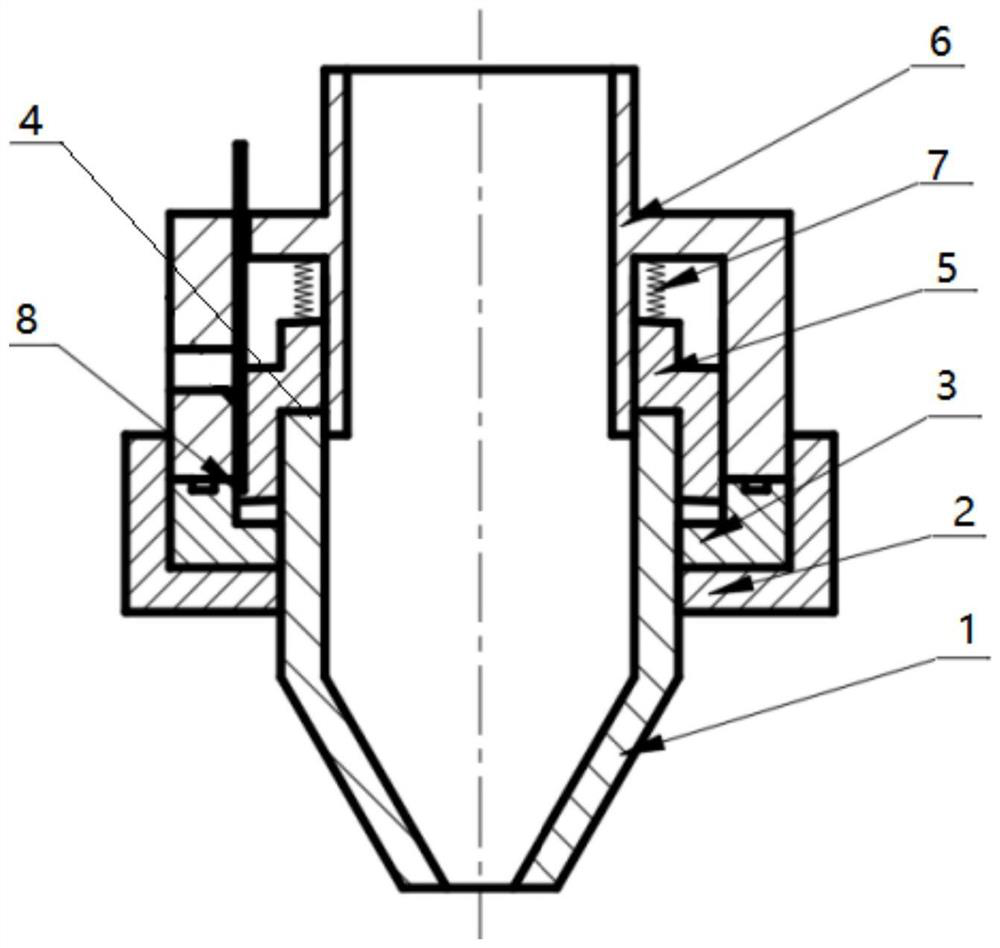

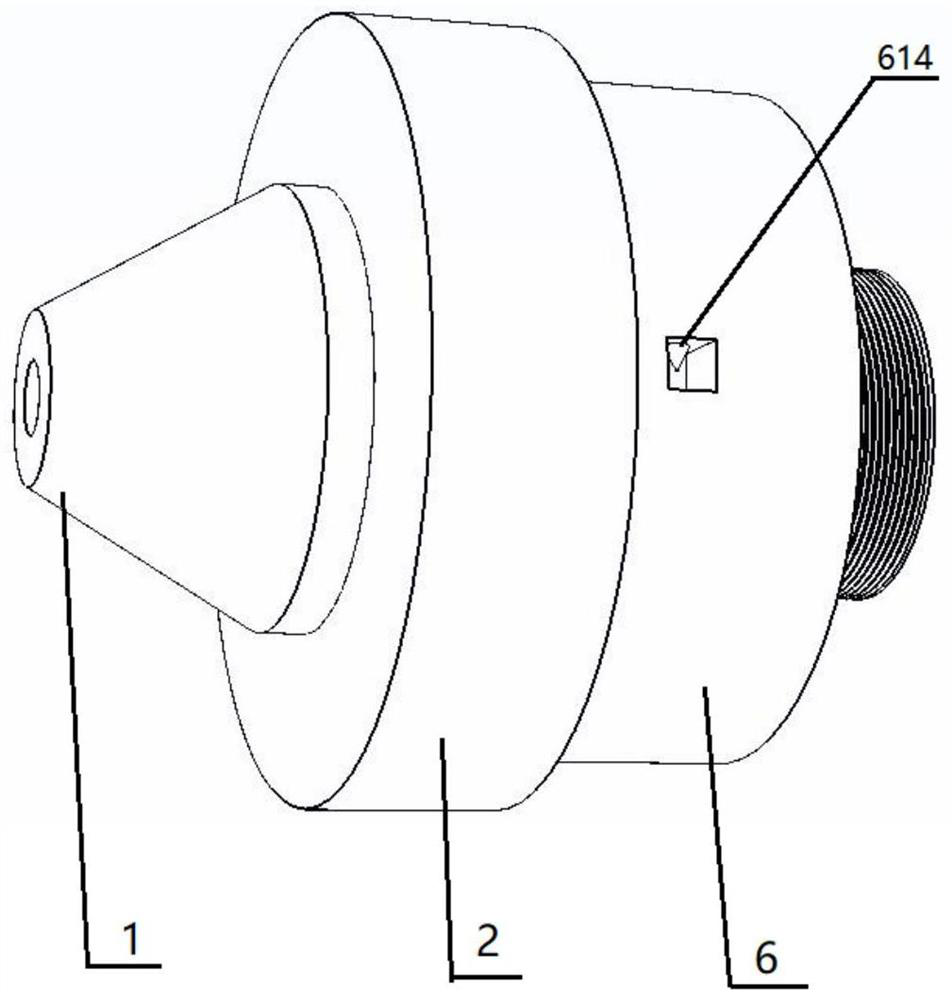

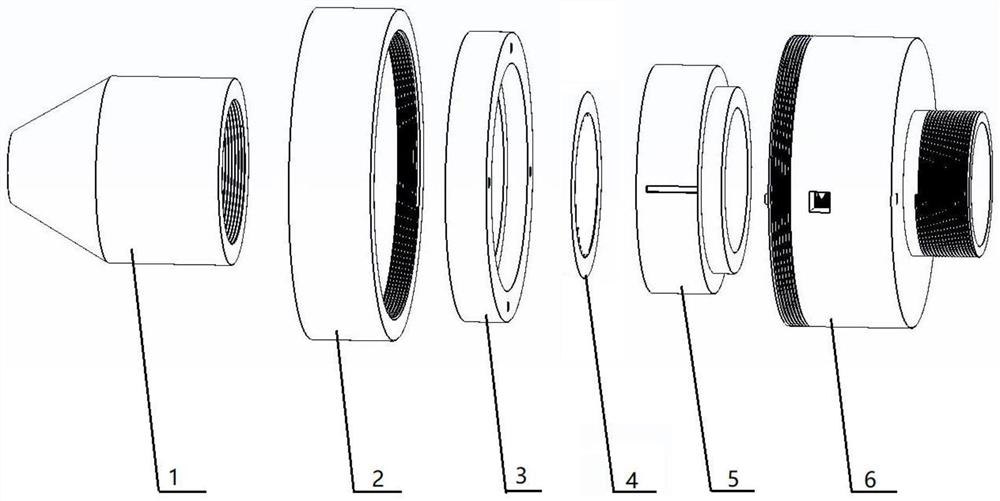

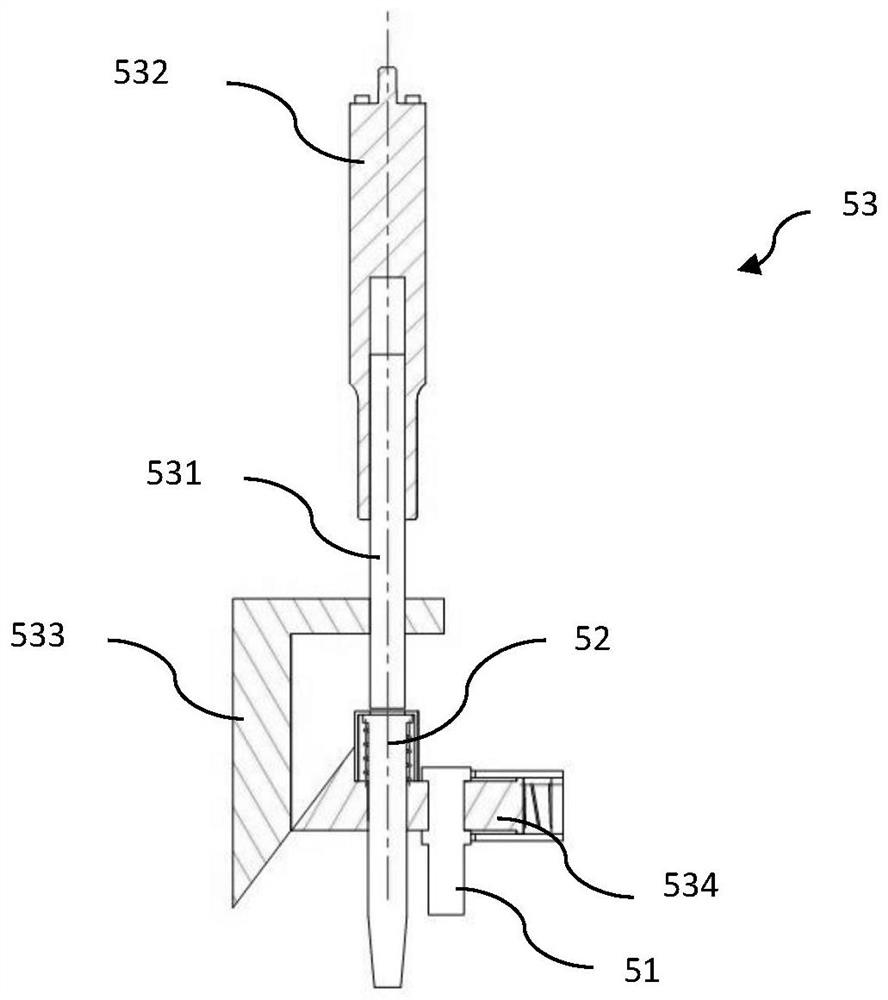

Target-distance-adjustable nozzle and method suitable for abrasive water jet steel rail polishing

ActiveCN114393519AGuaranteed grinding qualityAdjustable relative distanceBlast gunsAbrasive machine appurtenancesEngineeringAbrasive water jet

The invention discloses an adjustable-target-distance nozzle and method suitable for abrasive water jet steel rail polishing, the adjustable-target-distance nozzle comprises a nozzle main body, an outer cover, a lower baffle, a support frame and an upper baffle which are arranged on the same central axis, the nozzle main body is connected with the upper baffle through threads, and the nozzle target distance can be adjusted by screwing the displacement of the nozzle main body; the outer cover, the lower baffle and the support frame sleeve the nozzle main body to limit the radial displacement of the nozzle main body; a pressure sensor is arranged between the nozzle body and the supporting frame, a spring is arranged between the supporting frame and the upper baffle, the elastic coefficient of the spring is measured through the calibration gauge and the read pressure value, the upper computer generates a pressure-displacement curve comparison table according to the elastic coefficient, and after the adjustment distance needed by the optimal target distance to be adjusted of the nozzle is measured, the pressure-displacement curve comparison table is adjusted. The upper computer gives a pressure threshold value, the nozzle body is screwed to enable the pressure borne by the spring to reach the threshold value, and then the adjustment work of the optimal target distance can be completed. The nozzle can be independently adjusted, the target distance precision of other nozzles is not affected, the operation method is simple, and the target distance adjusting precision is high.

Owner:WUHAN UNIV +2

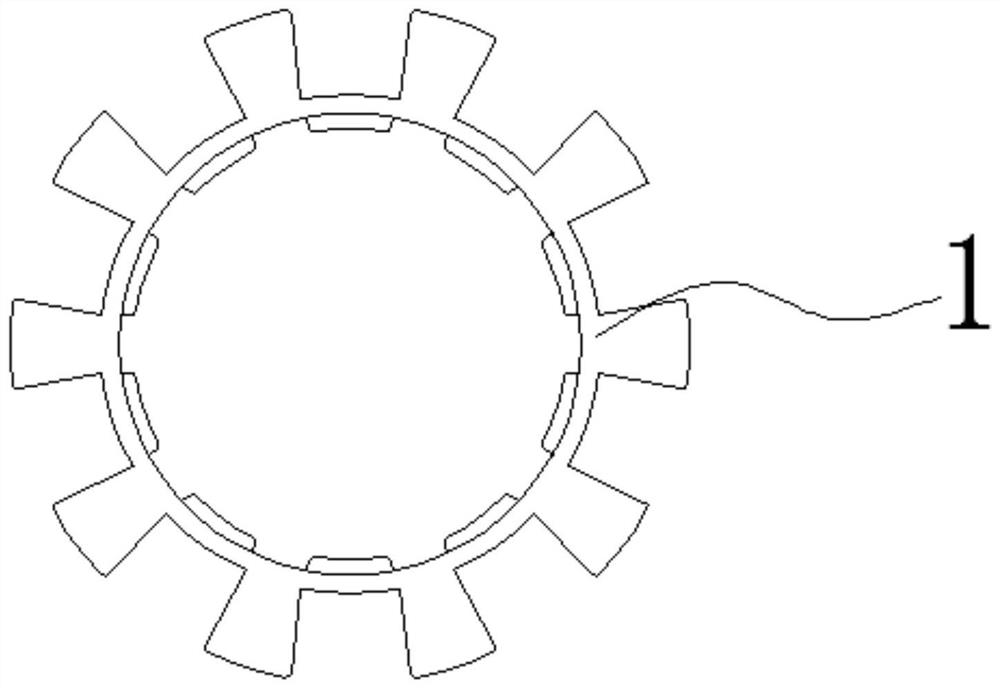

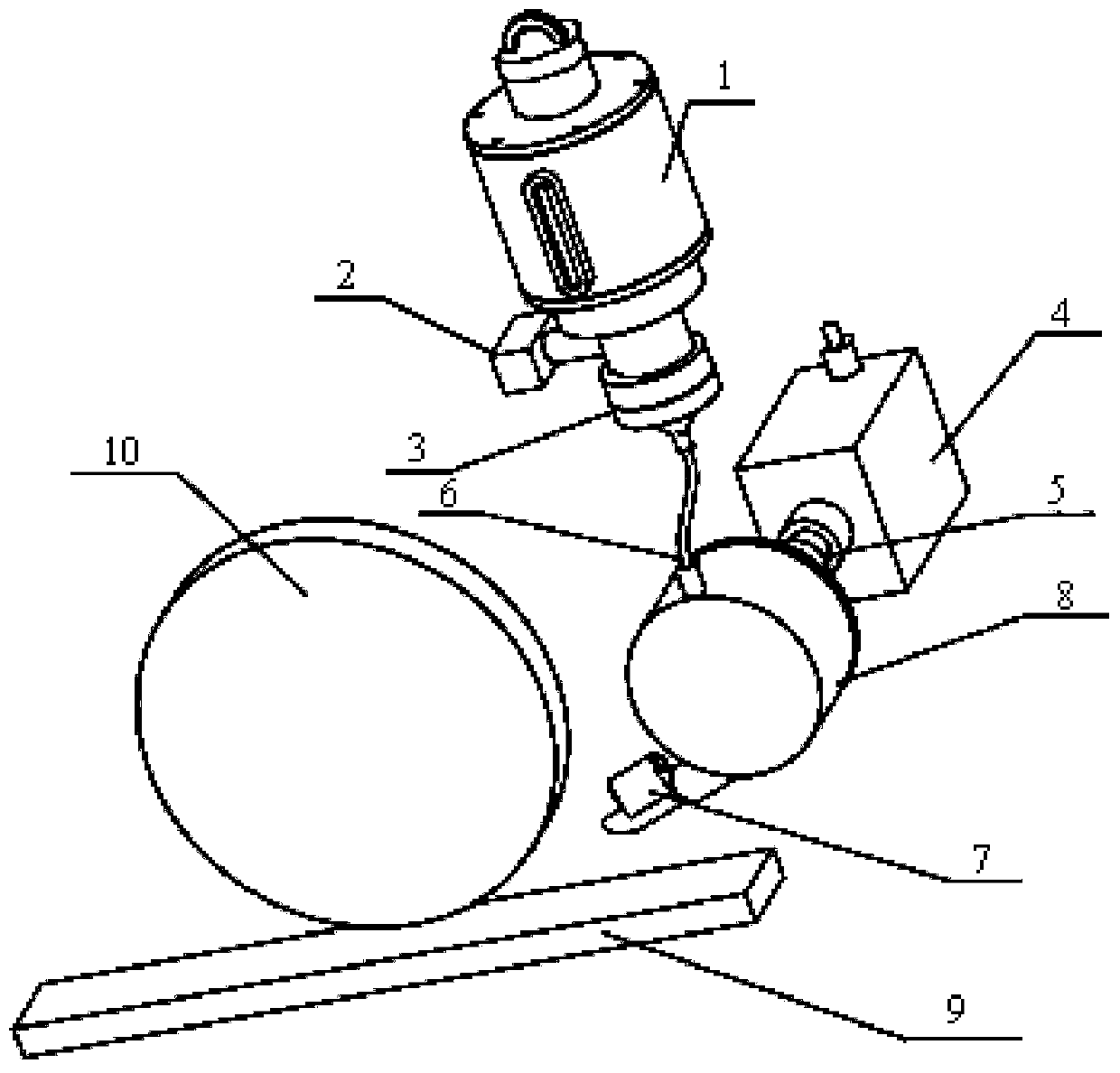

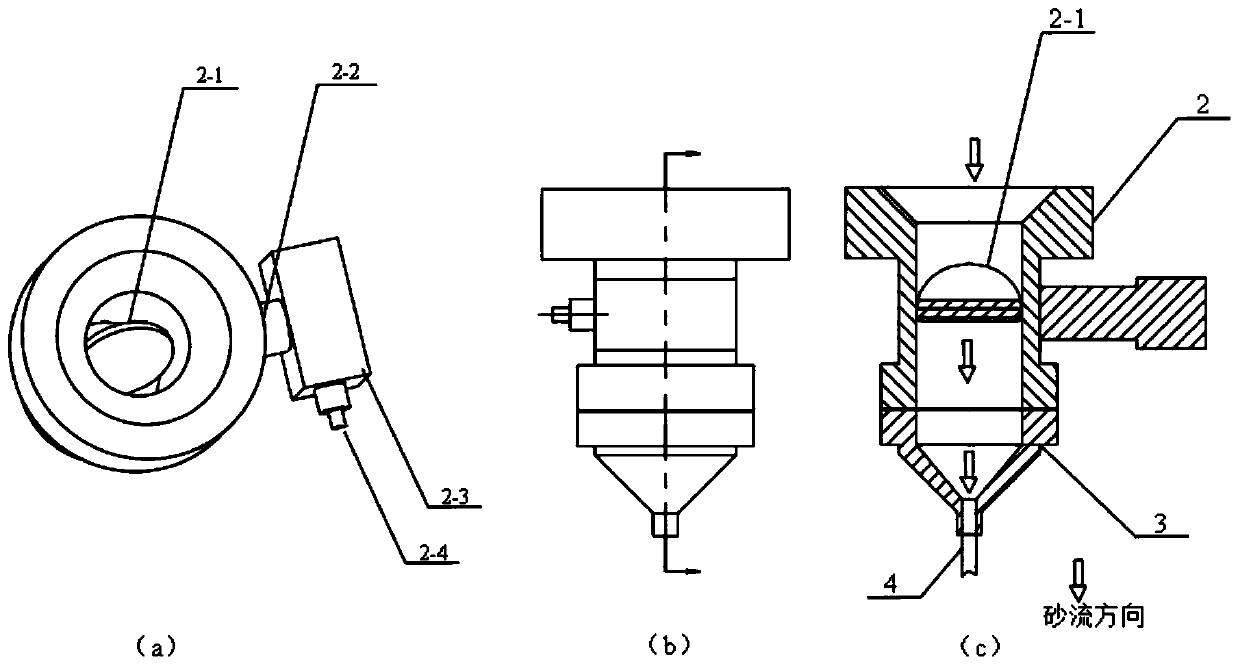

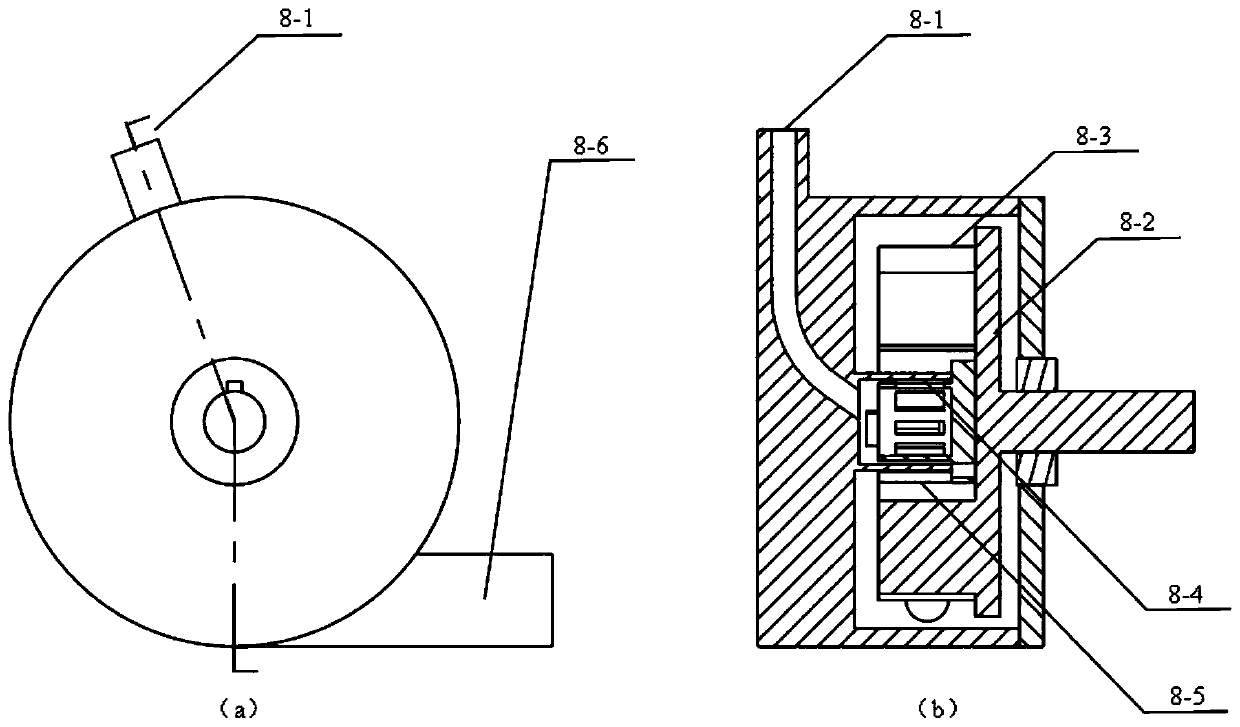

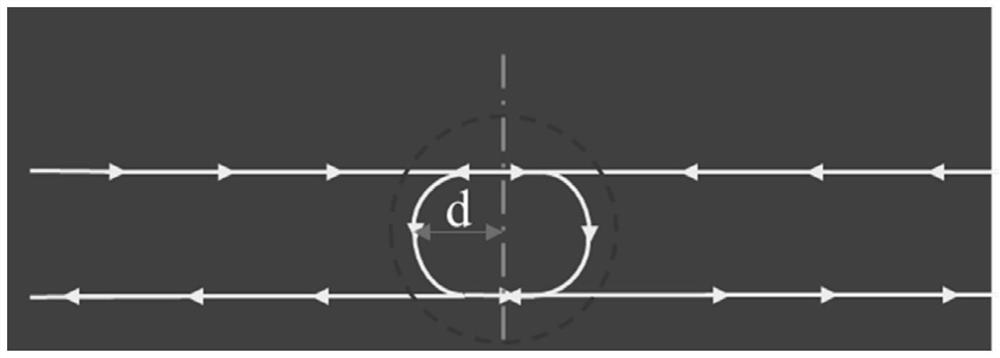

Mechanical acceleration type locomotive tackifying and sanding device

The invention discloses a mechanical acceleration type locomotive tackifying and sanding device. The device comprises a sand box, and a flow control valve is arranged at the joint of the lower end ofthe sand box and a funnel; the device further comprises an accelerator used for accelerating sand particles; the lower end of the funnel is connected to a sand inlet of the accelerator through a hose;the accelerator comprises an impeller and a branch grinding wheel arranged in the center of the impeller; a directional sleeve is arranged outside the branch grinding wheel; the accelerator further comprises a plurality of blade positioning sleeves which are uniformly arranged on the impeller, a plurality of through holes are formed in the blade positioning sleeves, and the through holes correspond to the positions between every two adjacent blades; a sand outlet is formed in the lower end of the accelerator and is connected with a nozzle; and the device further comprises a first motor used for driving the impeller to rotate. Viscous particles are sprayed out in an accelerated mode through the high-speed rotating impeller, so compared with a pressure type sanding device and a gravity typesanding device, the device of the invention achieves a higher sanding speed, can effectively avoid airflow interference in the high-speed running process of a locomotive, and improves the particle spraying efficiency.

Owner:SOUTHWEST JIAOTONG UNIV

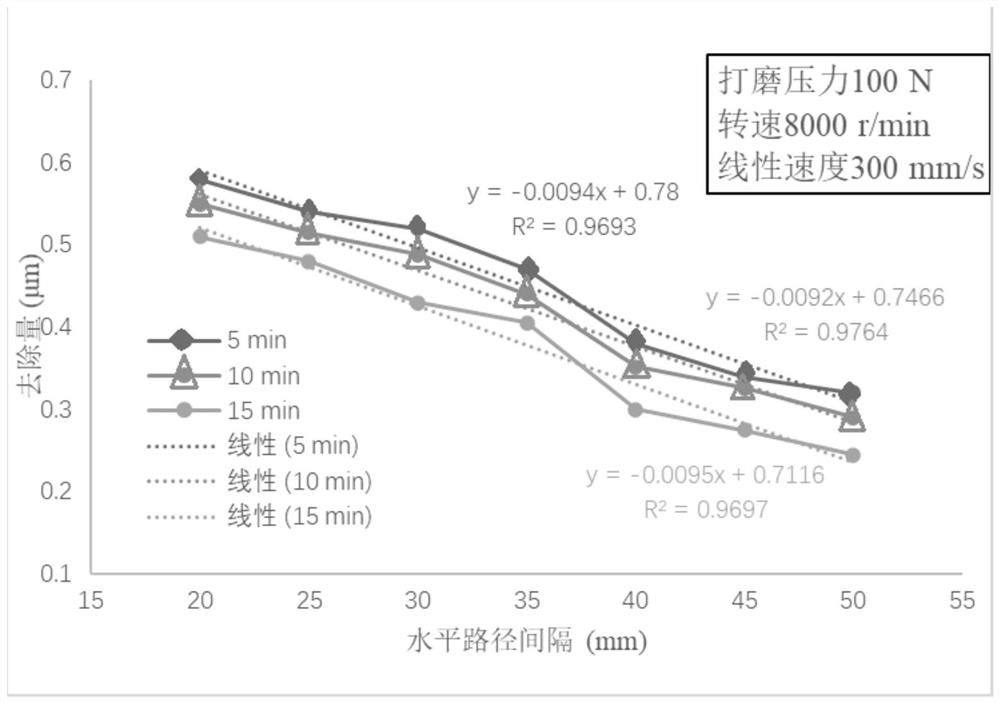

Method for establishing plane putty robot polishing database

PendingCN113836110AEfficient and repetitive grindingEasy to set upSpecial data processing applicationsDatabase design/maintainanceProgram testingMechanical engineering

The invention provides a method for establishing a plane putty robot polishing database. The method comprises the following steps: programming a program of a robot plane polishing track; testing the influence of the polishing parameters of the plane putty robot on the quality of the polished surface, and measuring the removal amount of the experimental polished surface by using a measuring tool; and, through comprehensive consideration of two data of the surface removal amount and the polishing time, determining the time-varying relation between polishing parameters and polishing results, and establishing a polishing database. According to the method, provided in the invention, for establishing the plane putty robot polishing database, the relation between the polishing parameters and the polishing quality is determined, and repeated plane polishing work can be efficiently carried out on the premise that the polishing quality is met.

Owner:CRRC QINGDAO SIFANG CO LTD

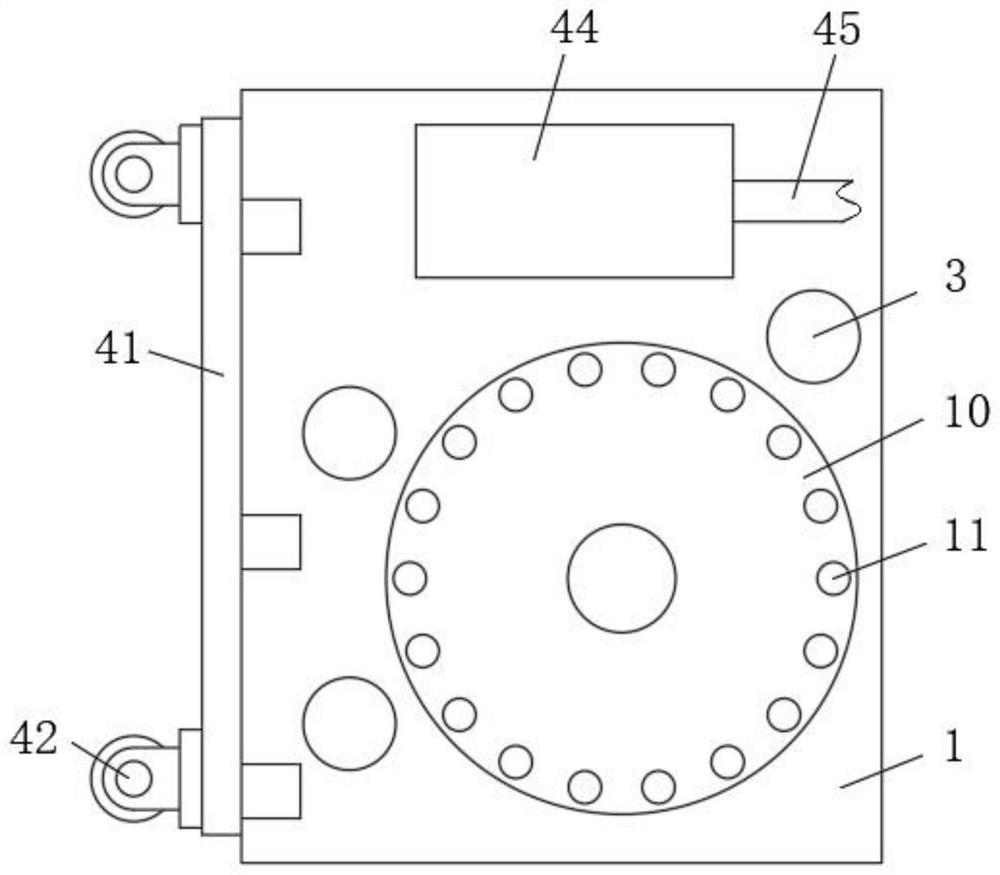

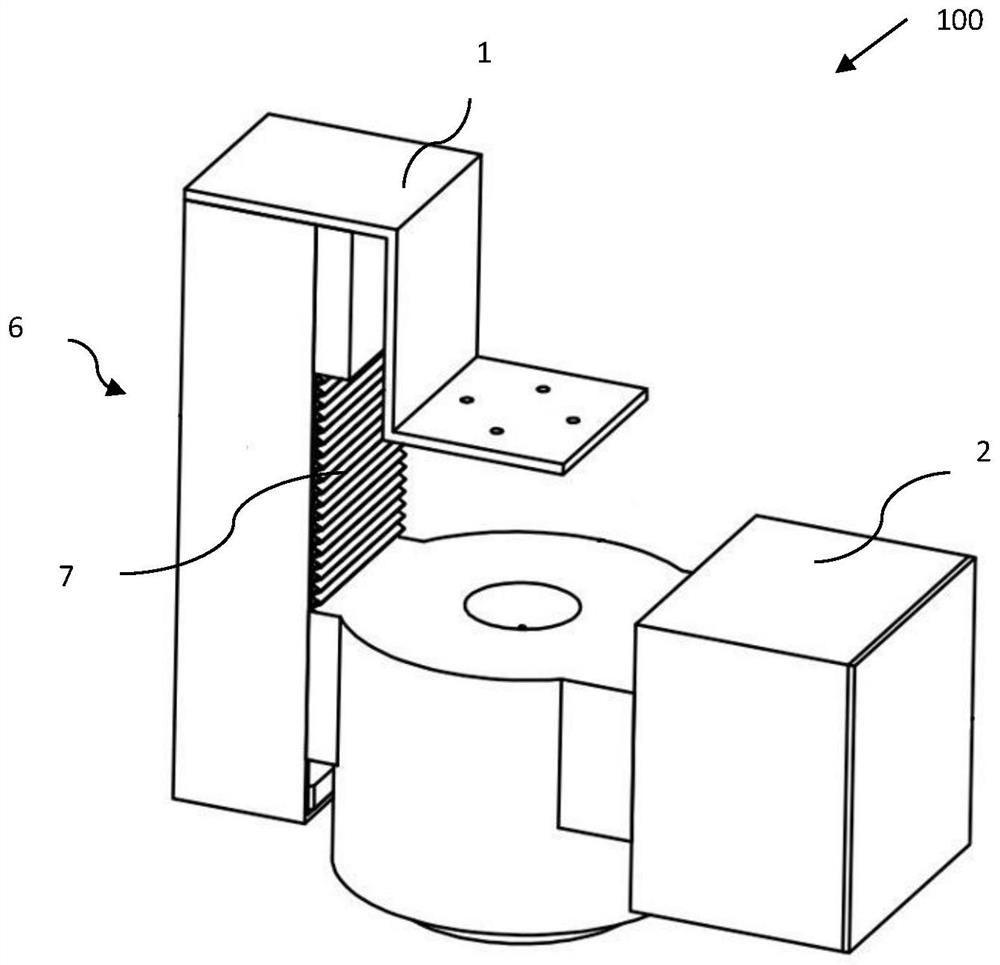

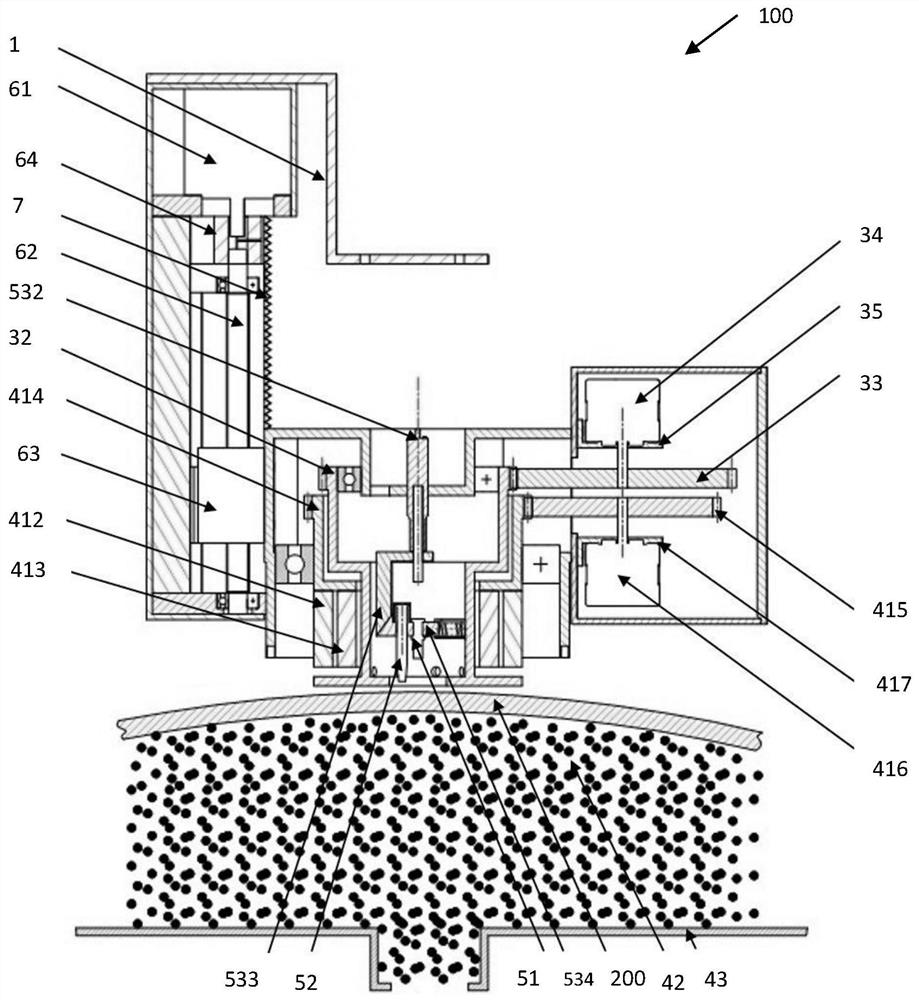

Manipulator composite grinding tool for thin-wall part

ActiveCN113561017ANormal pressure reductionReduce vibrationEdge grinding machinesPolishing machinesEngineeringManipulator

The invention provides a manipulator composite grinding tool for a thin-walled part, and belongs to the field of grinding and polishing. The manipulator composite grinding tool is characterized by comprising a bracket, a base, a grinding device, a magnetic grinding device and a control device; the bracket is used for being connected with a manipulator, the base is mounted on the bracket in a lifting manner; the grinding device is arranged on the base and is provided with a grinding part for polishing the thin-wall part from one side of the thin-wall part; the magnetic grinding device is arranged on the base and provided with a rotatable magnet assembly arranged on one side of the thin-wall part and magnetic abrasive particles arranged on the other side of the thin-wall part, and the magnetic abrasive particles are matched with the rotating magnet assembly to be used for grinding the other side of the thin-wall part; and the control device is used for controlling double-sided grinding of the grinding device and the magnetic grinding device. According to the grinding tool, the normal pressure on the thin-wall part is reduced, the stress deformation in the grinding process is reduced, the design difficulty and the manufacturing cost of a thin-wall part clamp are reduced, and the process efficiency is improved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Sandblasted sheet metal box cavity edge grinding robot arm

ActiveCN112454184BAvoid excessive sandingIncreased sanding area coverageBlast gunsAbrasive blasting machinesSand blastingStructural engineering

The invention discloses a sandblasting type sheet metal box inner cavity edge grinding mechanical arm, which comprises a connecting plate, a positive sandblasting body, a rotary drive mechanism and two side sandblasting bodies; the positive sandblasting body is rotatably connected to the On the connecting plate, the positive sandblasting body is provided with a first chamfering portion at the junction of its front surface and the bottom surface, and the first chamfering portion is provided with a plurality of first sandblasting through holes and a plurality of first chip evacuation through holes. A first sand blasting through hole and a plurality of first chip evacuation through holes are arranged at intervals; two lateral sand blasting bodies are symmetrically arranged on the left and right sides of the first chamfering part, and the lateral sand blasting body has a second chamfering body. The corner portion, the second chamfered portion is inclined backward, the second chamfered portion is provided with a second chip evacuation through hole and a plurality of second sand blasting through holes, and the plurality of second sand blasting through holes are dispersedly arranged; the invention improves the The scope of the grinding area and the grinding effect of the corners of the inner cavity of the sheet metal box can be improved to solve the problem of large dead corners caused by corner grinding, and avoid excessive grinding of the elevation near the corners.

Owner:佛山市聚旺五金制品有限公司

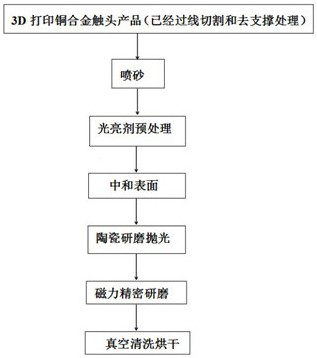

Surface post-treatment method for 3D printing copper alloy contact material

ActiveCN113369498AImprove surface qualityReduce roughnessAdditive manufacturing apparatusIncreasing energy efficiencySand blastingLiquid storage tank

The invention relates to the technical field of metal powder processing, and discloses a surface post-treatment method for a 3D printing copper alloy contact material. The surface post-treatment method comprises the following steps that S1, sand blasting grinding materials are sprayed out by sand blasting equipment to conduct sand blasting grinding on the surface of a copper alloy contact; S2, the copper alloy contact obtained after sand blasting and a cleaning tool are put into a PP liquid storage tank to be cleaned; S3, the surface is neutralized by using a degradable environment-friendly solvent; S4, rough polishing is conducted for 20-30 min at first, and then fine polishing is conducted three times through an Al2O3 and SiO2 ceramic abrasive material; S5, magnetic precision grinding is carried out, the frequency ranges from 20 Hz to 60 Hz, the time ranges from 60 min to 180 min, and the magnetic field exchange time ranges from 1 min to 3 min; and S6, vacuum cleaning and drying are conducted. The surface post-treatment method for the copper alloy contact can meet the requirements of the market on the appearance quality of the copper alloy contact, and has the advantages of low cost and high efficiency.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

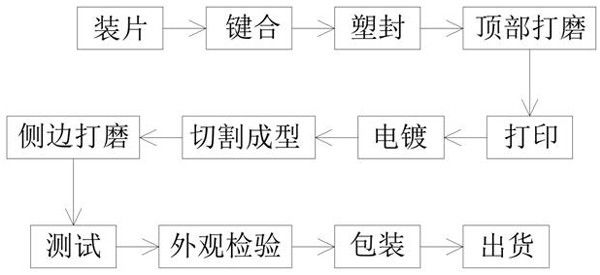

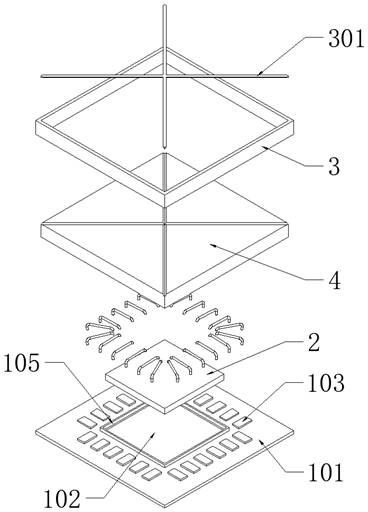

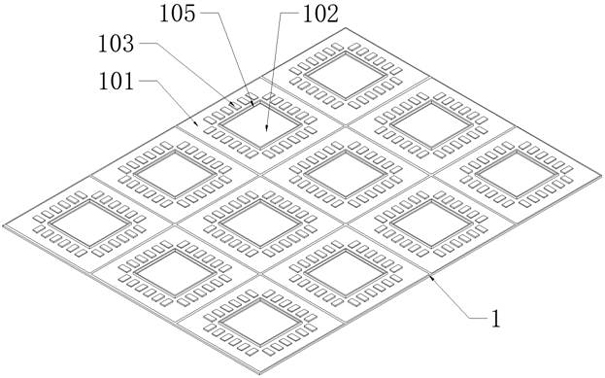

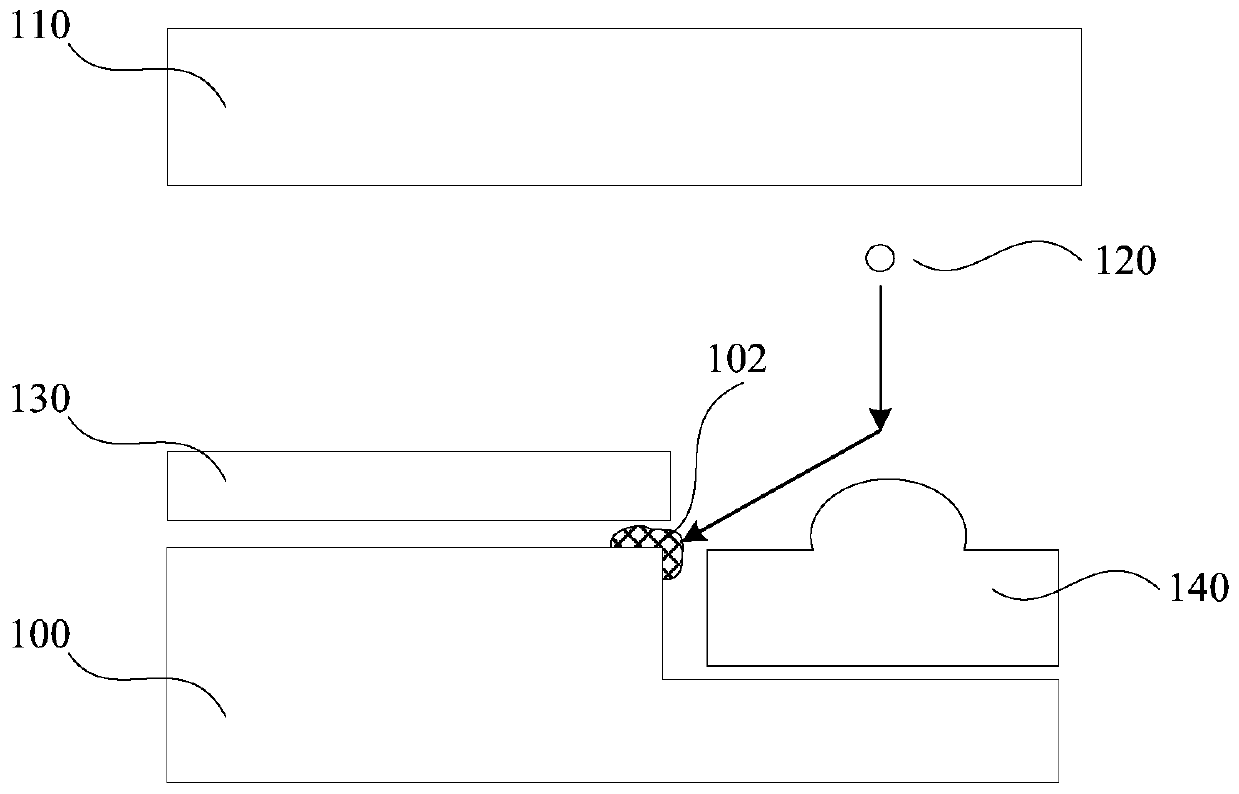

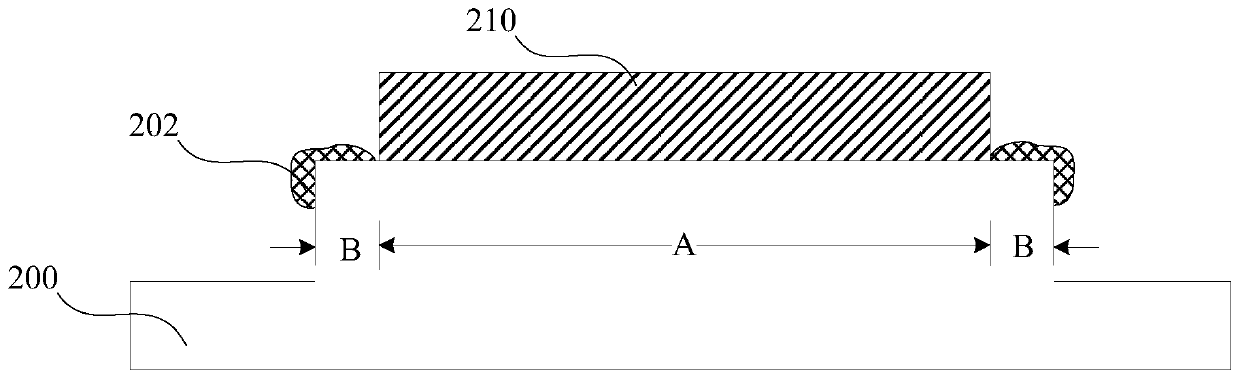

Low-power-consumption high-precision protocol integrated circuit module packaging process

ActiveCN114188235AReduced probability of being affected by epoxy resin flowImprove structural strengthSemiconductor/solid-state device detailsSolid-state devicesEpoxyHemt circuits

The invention discloses a low-power-consumption and high-precision protocol integrated circuit module packaging process, which can reduce the probability of chip offset, fly wire breakage or parallel connection among fly wires in the packaging process of a circuit module, and is characterized in that a metal frame is fixedly arranged above a circuit substrate in a sleeving manner when the circuit module is bonded; the metal frame is arranged on the top of the circuit substrate, the reinforcing ribs are fixedly arranged on the top of the metal frame, the probability that chips and fly wires are affected by flowing of epoxy resin during injection molding packaging can be effectively reduced, the production stability can be improved, meanwhile, the metal frame is arranged on the top of the circuit substrate, the probability that products are stressed and broken during later cutting can be reduced, and the product quality is improved. The structural strength of the circuit module small blocks produced by the process is improved, and the product quality is improved to a certain extent.

Owner:江苏高格芯微电子有限公司

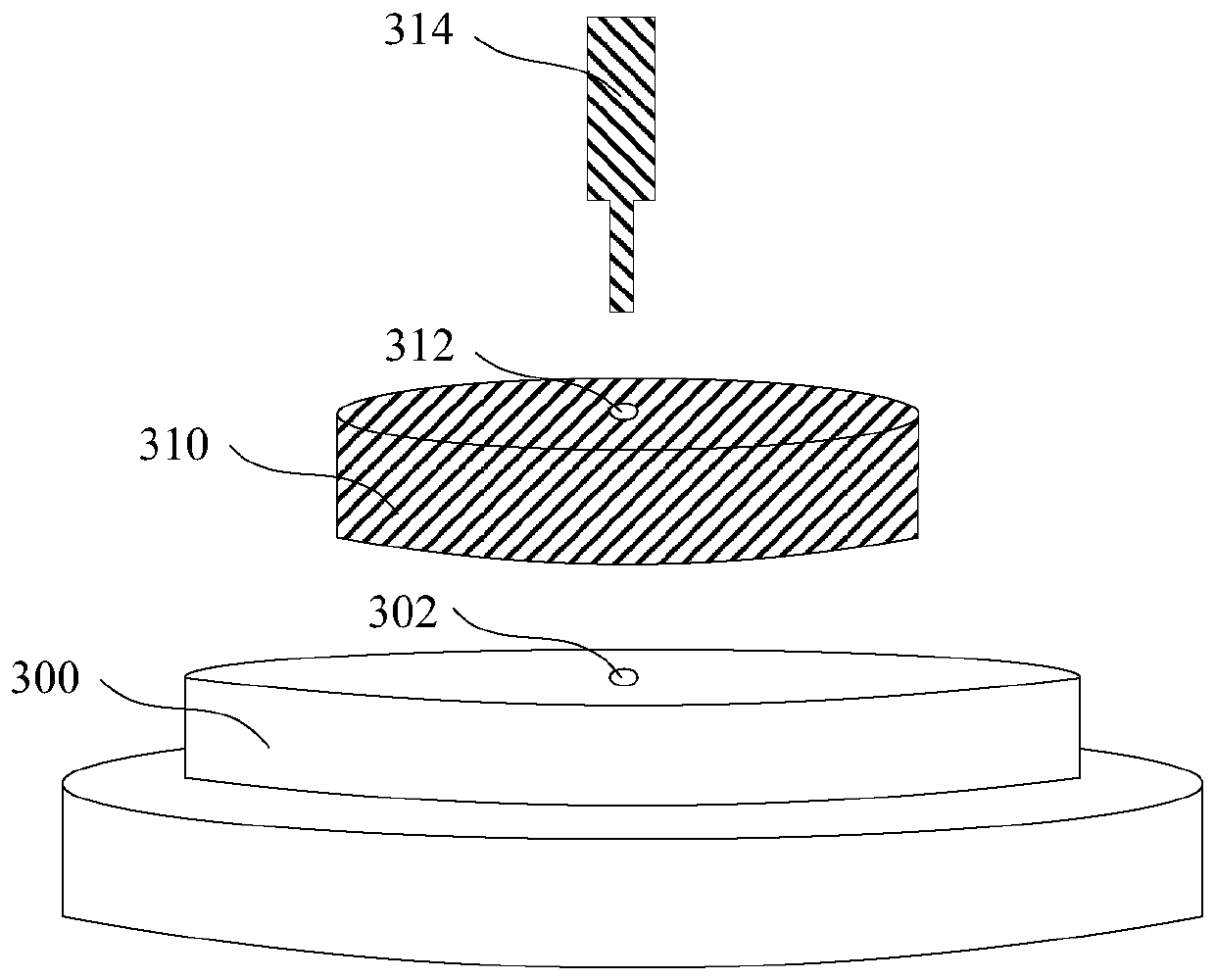

Protection fixture and grinding method of electrostatic chuck

ActiveCN107799456BAvoid excessive sandingGuaranteed adsorption effectSolid-state devicesSemiconductor/solid-state device manufacturingEngineering

The invention discloses a protection jig for an electrostatic chuck and a grinding method. The protection jig for the electrostatic chuck comprises a jig main body and a fixing part, wherein the jig main body covers a central area of the electrostatic chuck and a marginal area of the electrostatic chuck is exposed; the marginal area surrounds the central area; and the fixing part is suitable for fixing the jig main body on the electrostatic chuck. According to the protection jig, the electrostatic chuck can be prevented from being excessively ground, and the protection jig is conducive to keeping the absorption capability of the electrostatic chuck.

Owner:淮安西德工业设计有限公司

A copper tube end grinding device

ActiveCN108857683BEasy to polishUse Length GuaranteeEdge grinding machinesMaterials scienceGrinding process

The invention discloses a copper tube end grinding device, and belongs to the technical field of copper tube machining. The device comprises a base plate and a correction block, one surface of the base plate is provided with a first channel, a second channel, a third channel and a wire channel, one surface of the base plate is provided with a scale marking, and a baffle is hinged to one end of thebase plate and comprises a trapezoidal plate and a handle; the trapezoidal plate is provided with blind holes corresponding to the first channel, the second channel and the third channel separately,and the handle is hinged to one surface of the trapezoidal plate; the two opposite sides of the base plate are provided with guiding channels respectively; the correction block comprises a first blocking piece and a second blocking piece, one end of the first blocking piece is provided with a marking block, the first blocking piece is an L-shaped plate, and the correction block is installed at oneside edge of the base plate. According to the copper tube end grinding device, when the end of a copper tube is ground, the correction block limits the grinding process of the grinding device, excessive grinding is avoided accordingly, and the use length of the copper tube is ensured.

Owner:四川翰邦能源技术有限公司

A self-feeding automatic grinding machine for round rods

ActiveCN108381354BGrinding evenlyGuaranteed accuracyGrinding carriagesGrinding machinesGear wheelElectric machinery

Owner:WUHU LANREN INTELLIGENT TECH

Ferritic stainless steel cold-rolled strip steel production device

PendingCN114043366AAvoid damageQuality improvementGrinding drivesGrinding machinesElectric machineryStrip steel

The invention belongs to the technical field of strip steel production and processing, and particularly relates to a ferritic stainless steel cold-rolled strip steel production device, which comprises an uncoiler, a straightening machine, a pickling machine, a rolling mill and a coiler, and the pickling machine comprises a pickling tank, an inner tank, first grinding rollers, second grinding rollers and a motor; the pickling tank is fixedly connected to the ground; the inner tank is arranged in the pickling tank and slides on the inner wall of the pickling tank; first grinding rollers and second grinding rollers are arranged in the inner tank, the first grinding rollers and the second grinding rollers are rotationally connected with the inner tank, the number of the first grinding rollers is two, and the number of the second grinding rollers is two; the first grinding rollers and the second grinding rollers are vertically arranged in the inner tank; the motor is fixedly connected to the outer side of the inner tank; a pickling solution in the tank is used for pickling the polished strip steel, and the two modes of polishing and pickling are combined, so that the pickling quality and efficiency are improved, the strip steel is protected, the strip steel is prevented from being damaged due to excessive polishing, and the production and processing quality of the strip steel is improved.

Owner:孟祥平

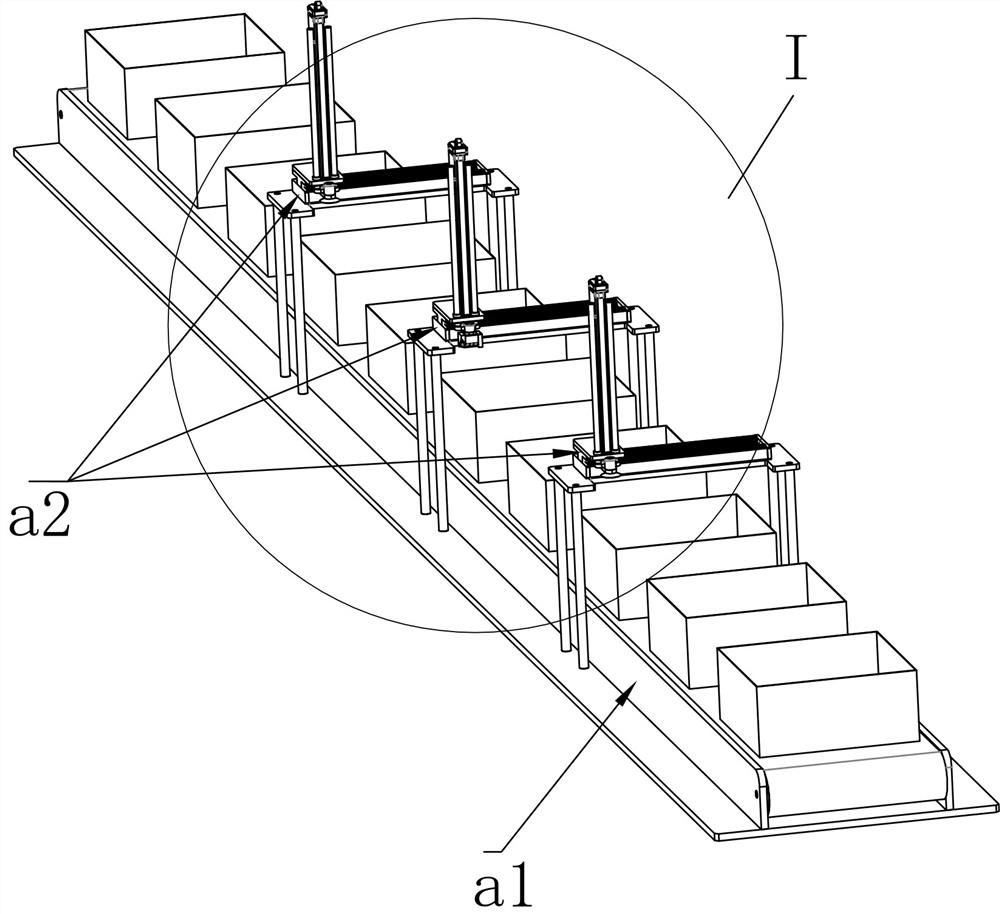

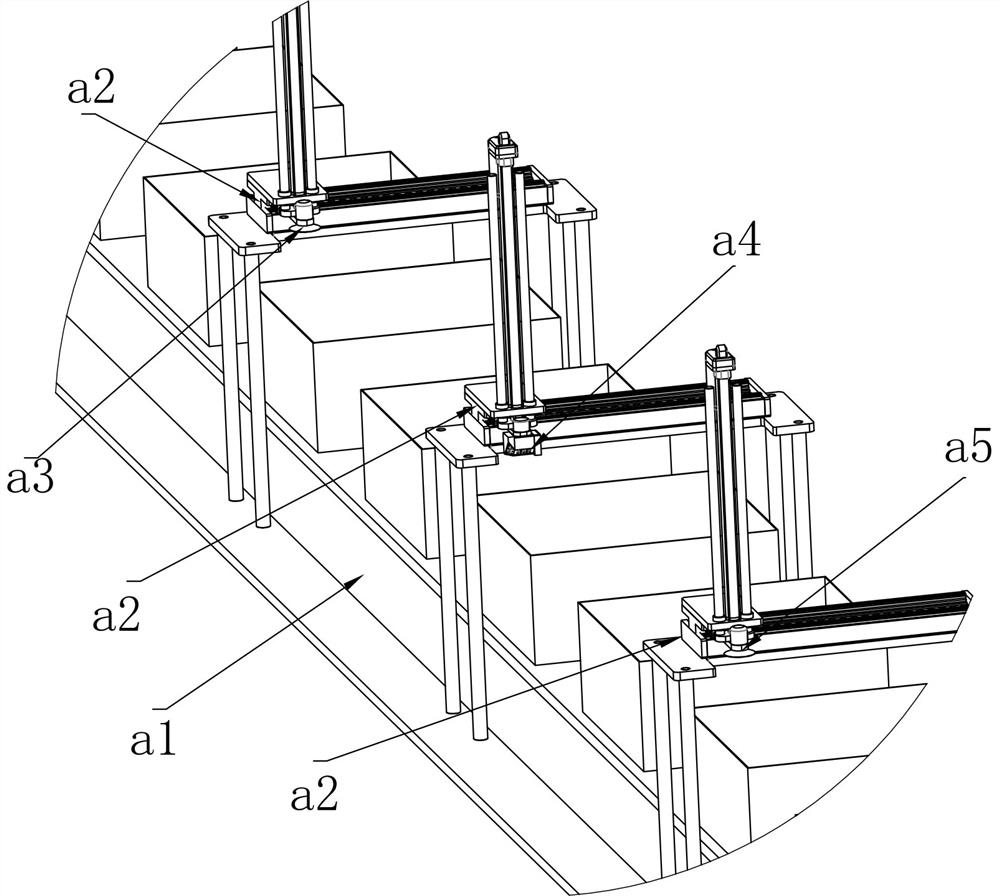

Sheet metal box inner cavity corner grinding and polishing robot production line

ActiveCN112428153BAvoid excessive sandingIncreased sanding area coverageAbrasive machine appurtenancesAbrasive blasting machinesProduction lineSand blasting

The invention discloses a production line of a robot for grinding and polishing the inner cavity of a sheet metal box, which includes a transfer table, three cross slide devices, a rough polishing device, a corner grinding device and a fine polishing device; The forward sandblasting body, the rotary drive mechanism and two side sandblasting bodies; the forward sandblasting body is rotatably connected to the connecting plate, the forward sandblasting body is provided with a first chamfer, and the first chamfer is provided with A plurality of first sandblasting through holes and a plurality of first chip removal through holes; two lateral sandblasting bodies are symmetrically rotated and arranged on the left and right sides of the first chamfered part, and the lateral sandblasting body has a second chamfered part , the second chamfering part is set inclined backward, and the second chamfering part is provided with a second chip removal through hole and a plurality of second sandblasting through holes; The grinding effect of the parts can solve the problem of relatively large grinding dead angles caused by corner grinding, and avoid excessive grinding of the facade near the corners.

Owner:北斗长缨(北京)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com