Railway track rust removal device and method

A railway track and track technology, which is applied in the field of railway track derusting devices, can solve problems such as uneven application of antirust agents, irregular vibration and noise of trains, and excessive deformation of rail heads, so as to improve vibration removal efficiency and improve wall hanging Effects, effects that enhance the effect of smearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

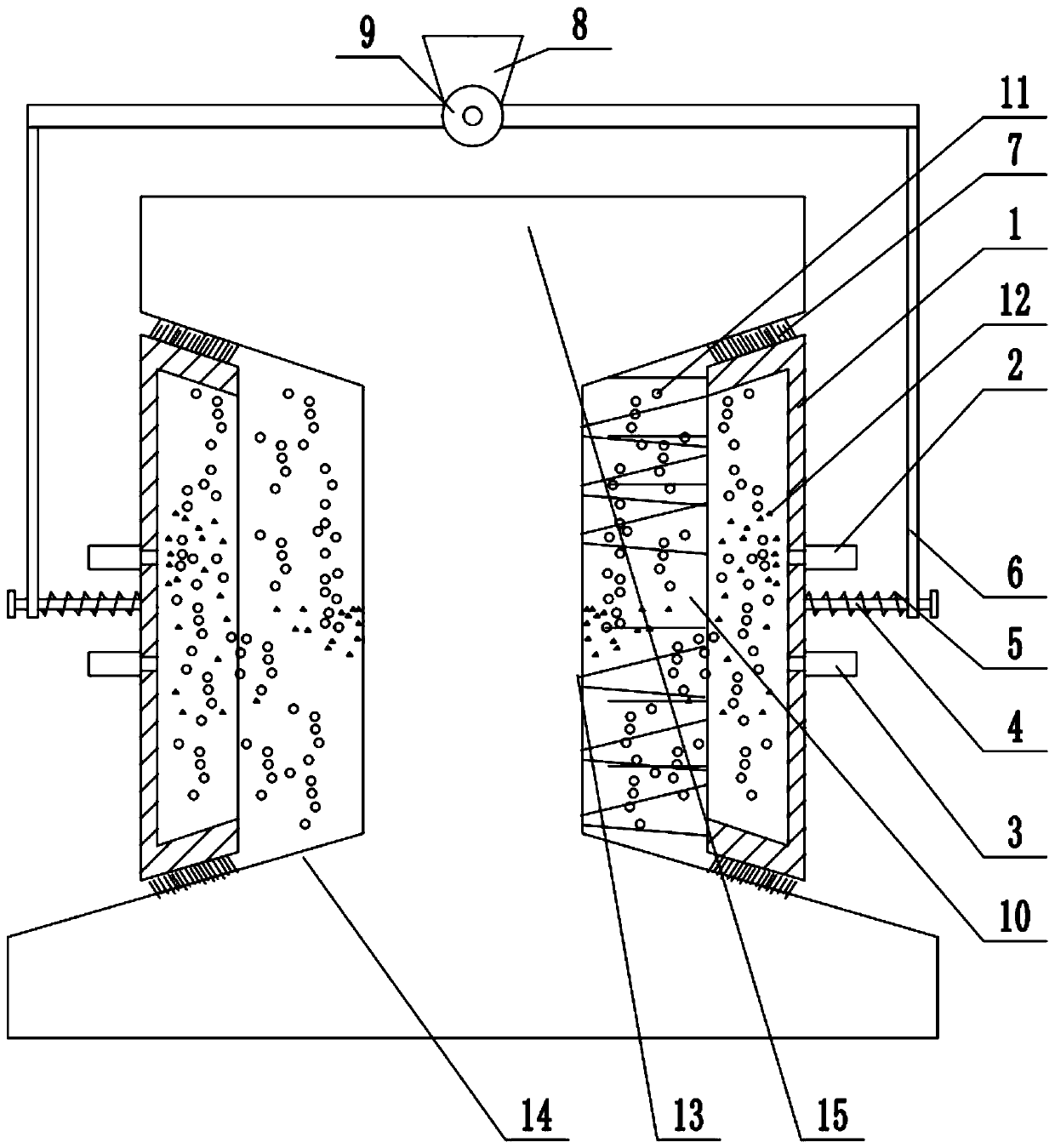

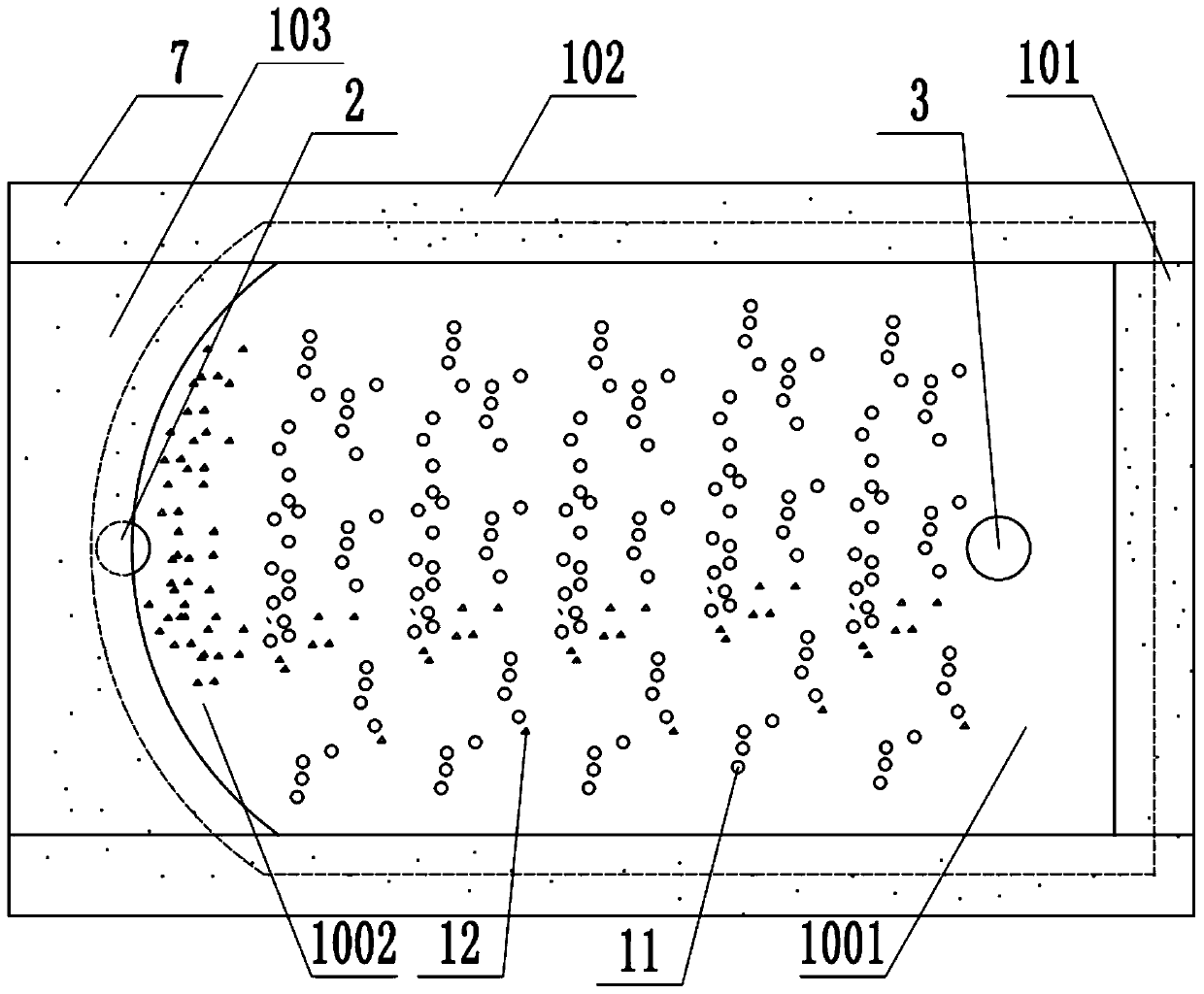

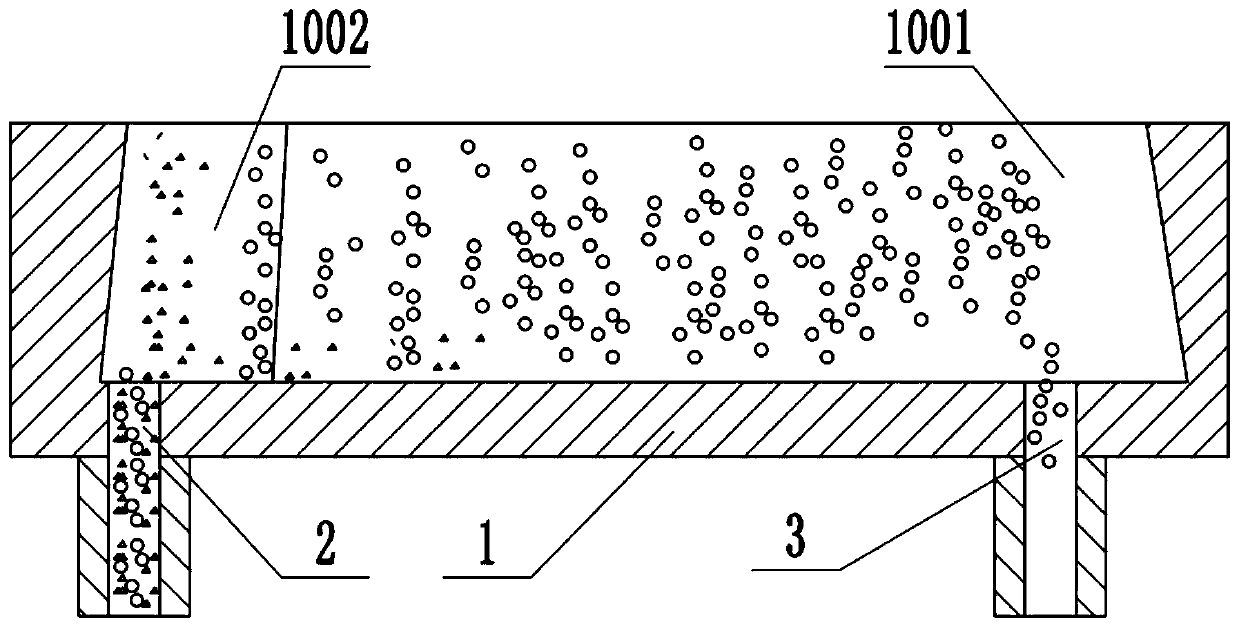

[0039] In a typical implementation of the present application, such as Figure 1-Figure 3 As shown, a railway track derusting device is proposed.

[0040] It includes a mobile platform, on which a shot blasting structure, an exhaust fan and a collection box are carried, and a box body 1 with a cavity is connected under the platform of a bottle, and an opening is provided on the side of the cavity, and the box body 1 The opening cooperates with the track to form a closed working chamber 10. The top and bottom surfaces of the box body are inclined surfaces 102, which respectively fit the upper and lower wings of the rail. The box body is provided with a first connecting cavity. An interface 3 and a second interface 2, the first interface is connected with a shot blasting mechanism, and the shot blasting mechanism is used to spray the airflow entrained with the spray material 11 on the rail waist through the first interface, and use the spray material to spray the rail waist. Th...

Embodiment 2

[0060] In another embodiment of the present application, there is provided a rust removal method utilizing the above rust removal device, comprising the following steps:

[0061] The derusting car is used as a mobile platform, and the boxes are installed on the derusting car in pairs, and they are matched with the track to be derusted, so that the top and bottom sloping surfaces of the box are respectively in contact with the upper and lower wings of the track. wing plate;

[0062] Connect the first interface to the sandblasting structure, and connect the second interface to the exhaust fan and the collection box in turn;

[0063] Start the derusting car and drive along the track. The derusting shovel on the derusting car first cooperates with the rail waist to shovel the rusted part;

[0064] The corresponding opening of the box faces the rusted part treated by the derusting shovel, and the sandblasting structure outputs the spray material and airflow sprayed to the rusted p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com