Sheet metal box inner cavity corner grinding and polishing robot production line

A production line and robot technology, applied in the direction of abrasive jet machine tools, abrasives, metal processing equipment, etc., can solve the problems of inapplicable corner grinding, excessive grinding of facades, poor grinding effects, etc., to facilitate automated production and improve Work efficiency, improve the effect of grinding area range

Active Publication Date: 2022-05-31

北斗长缨(北京)科技有限公司

View PDF11 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Sheet metal cabinets often need to be polished before the surface is processed. Since the corners have elevations in three directions and the space is small, the existing disc grinder cannot be used for grinding the corners. However, due to the shielding effect of the facade of the sheet metal box in the overall sandblasting method, the grinding effect is not good, and it will also cause excessive grinding to the facade near the corners

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

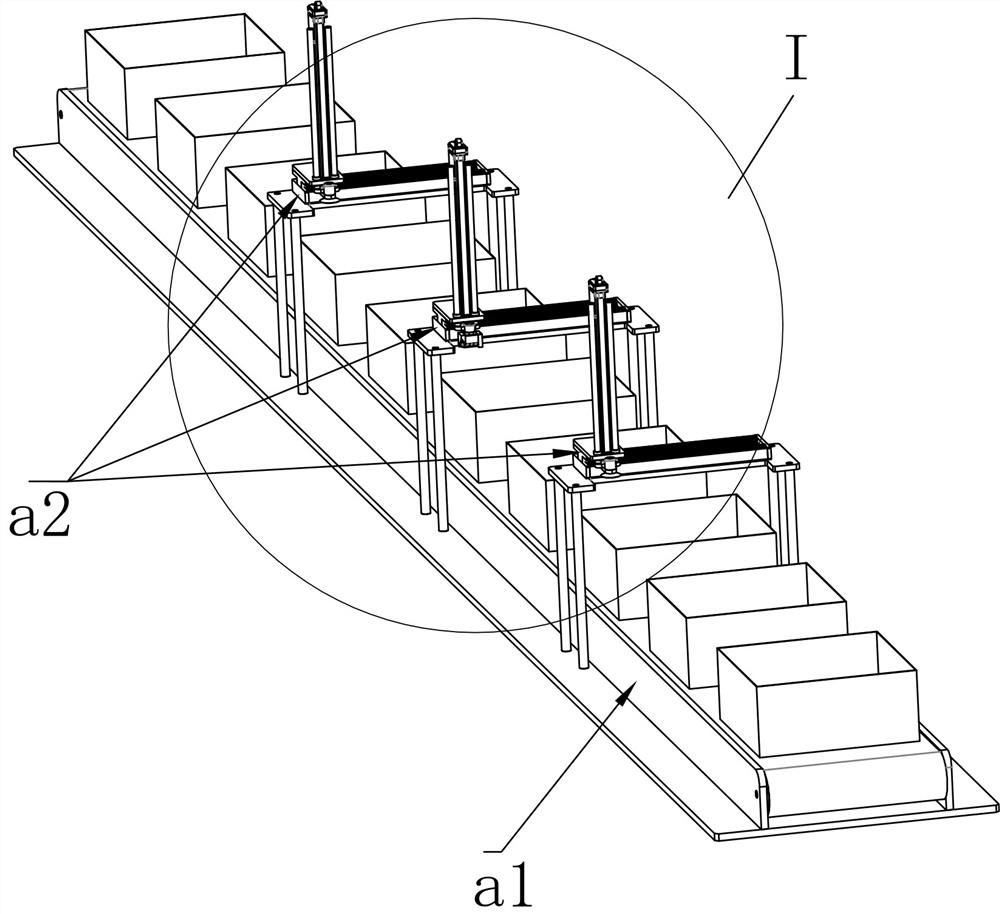

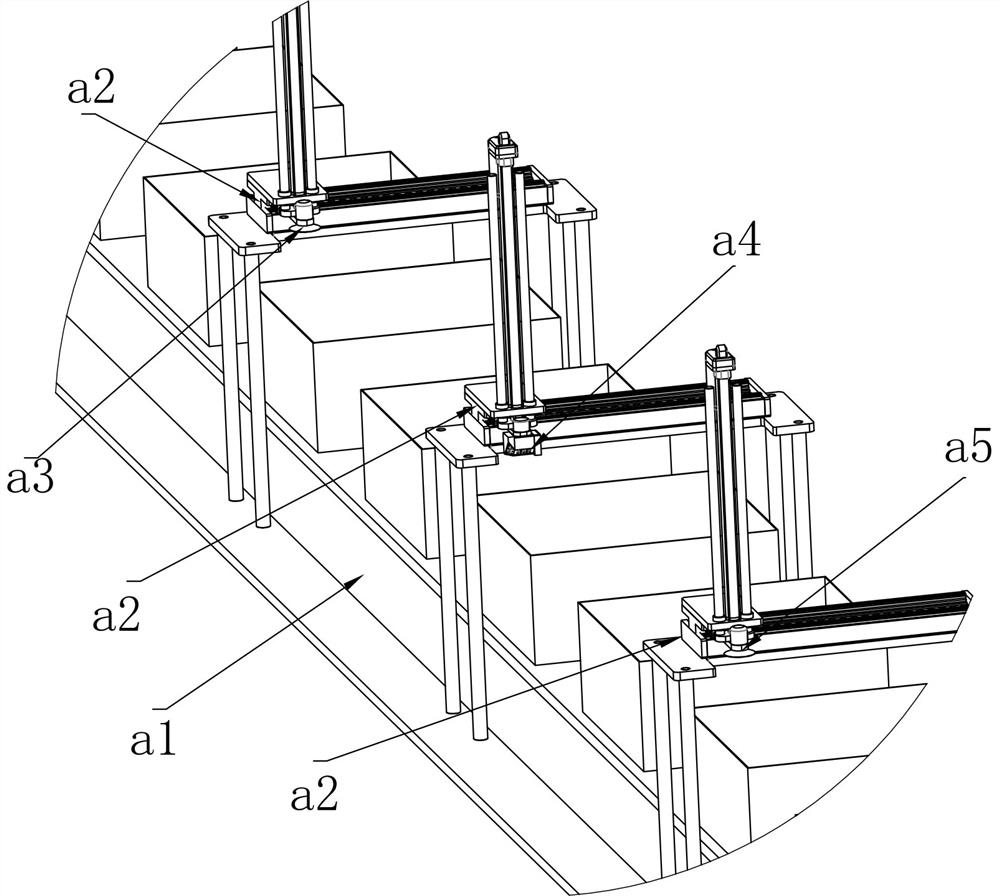

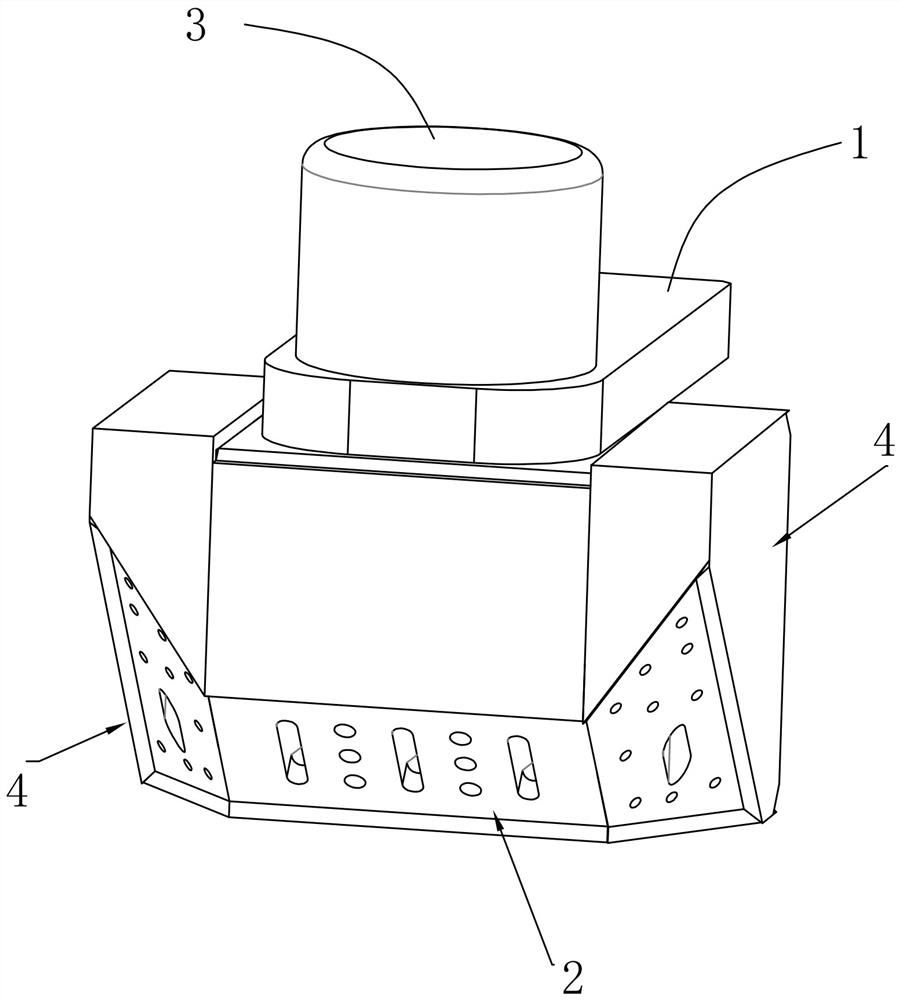

The invention discloses a production line of a robot for grinding and polishing the inner cavity of a sheet metal box, which includes a transfer table, three cross slide devices, a rough polishing device, a corner grinding device and a fine polishing device; The forward sandblasting body, the rotary drive mechanism and two side sandblasting bodies; the forward sandblasting body is rotatably connected to the connecting plate, the forward sandblasting body is provided with a first chamfer, and the first chamfer is provided with A plurality of first sandblasting through holes and a plurality of first chip removal through holes; two lateral sandblasting bodies are symmetrically rotated and arranged on the left and right sides of the first chamfered part, and the lateral sandblasting body has a second chamfered part , the second chamfering part is set inclined backward, and the second chamfering part is provided with a second chip removal through hole and a plurality of second sandblasting through holes; The grinding effect of the parts can solve the problem of relatively large grinding dead angles caused by corner grinding, and avoid excessive grinding of the facade near the corners.

Description

Sheet metal box cavity edge grinding and polishing robot production line technical field [0001] The present invention relates to a robotic production line for grinding and polishing the corners of a sheet metal box cavity. Background technique [0002] The sheet metal box type parts of the rectangular body structure are the most common type of sheet metal parts in sheet metal forming products. Widely used in machinery, electronics, electricity, transportation and other fields. [0003] The sheet metal box often needs to be polished before the surface is processed, because its three corners are There are elevations in all directions, and the space is small, which makes the existing disc grinder unsuitable for grinding the corners. Due to the shielding effect of the sheet metal box, the overall sandblasting method makes the grinding effect not good, and also affects the vertical surface near the corners. The surface causes excessive sanding. SUMMARY OF THE INVENTION ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B24C1/08B24C3/08B24C3/12B24C9/00

CPCB24C1/08B24C3/085B24C3/12B24C9/00B24C9/003Y02P70/10

Inventor 石蔚

Owner 北斗长缨(北京)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com