Protection fixture and grinding method of electrostatic chuck

An electrostatic chuck and fixture technology, which is applied in the direction of circuits, electrical components, and electric solid devices, can solve the problems of decreased electrostatic adsorption capacity, decreased adsorption performance, and affecting device performance, so as to avoid excessive grinding and maintain adsorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the existing PVD sputtering process, due to process limitations, the edge of the electrostatic chuck will deposit metal. When maintaining the electrostatic chuck, it is easy to polish the non-edge position of the electrostatic chuck, resulting in excessive grinding of the electrostatic chuck.

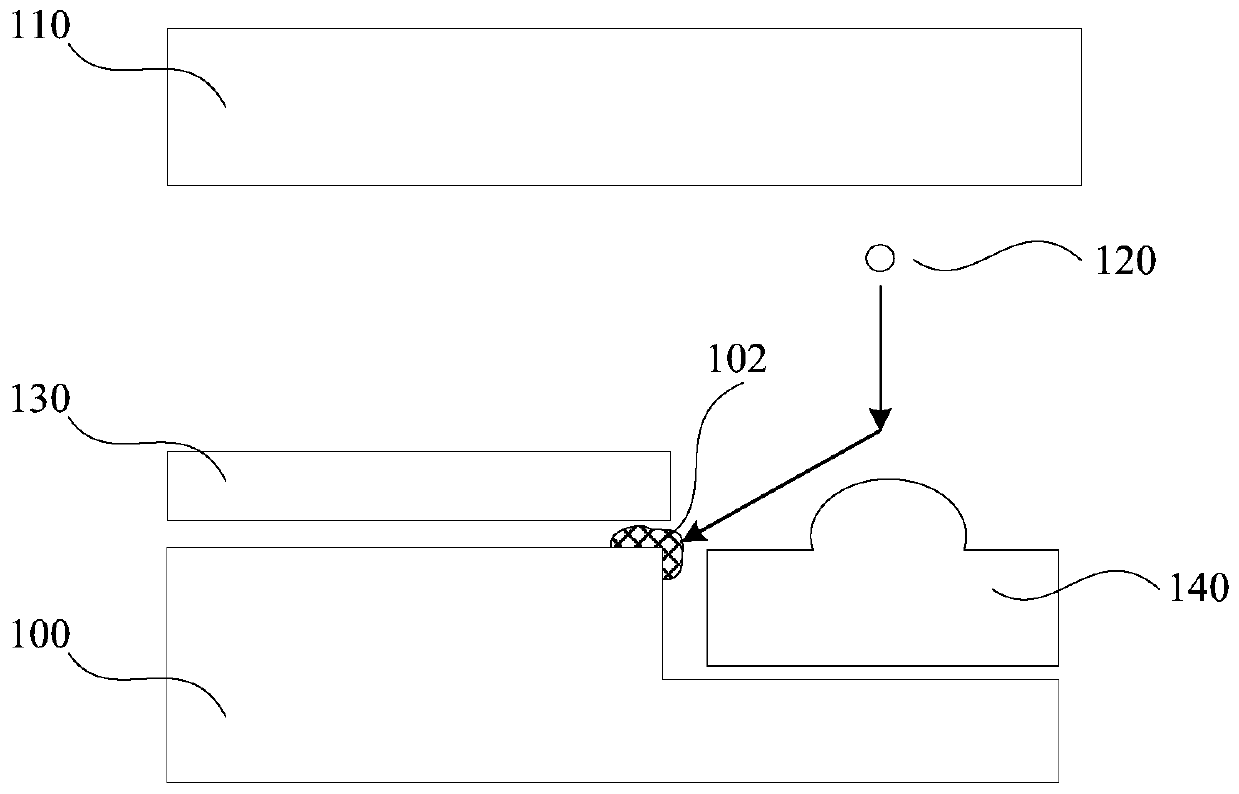

[0029] refer to figure 1 , figure 1 It is a scene diagram of a PVD sputtering process in the prior art.

[0030] In the existing PVD sputtering process, usually under vacuum conditions, low-voltage, high-current arc discharge technology is used, and gas discharge is used to make high-energy particles hit the target solid plate 110 with high purity. Metal particles 120 (for example, may include Cu, Al, Ta and Ti), and the knocked out metal particles 120 are deposited on the silicon wafer 130 . Wherein, the silicon wafer 130 is fixed by electrostatic attraction through an electrostatic chuck (Electro Static Chuck, ESC) 100 .

[0031] However, due to process limitations, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com