Patents

Literature

78 results about "Obsolescence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Obsolescence is the state of being which occurs when an object, service, or practice is no longer wanted even though it may still be in good working order. The international standard EN62402 Obsolescence Management - Application Guide defines obsolescence as being the "transition from availability of products by the original manufacturer or supplier to unavailability".

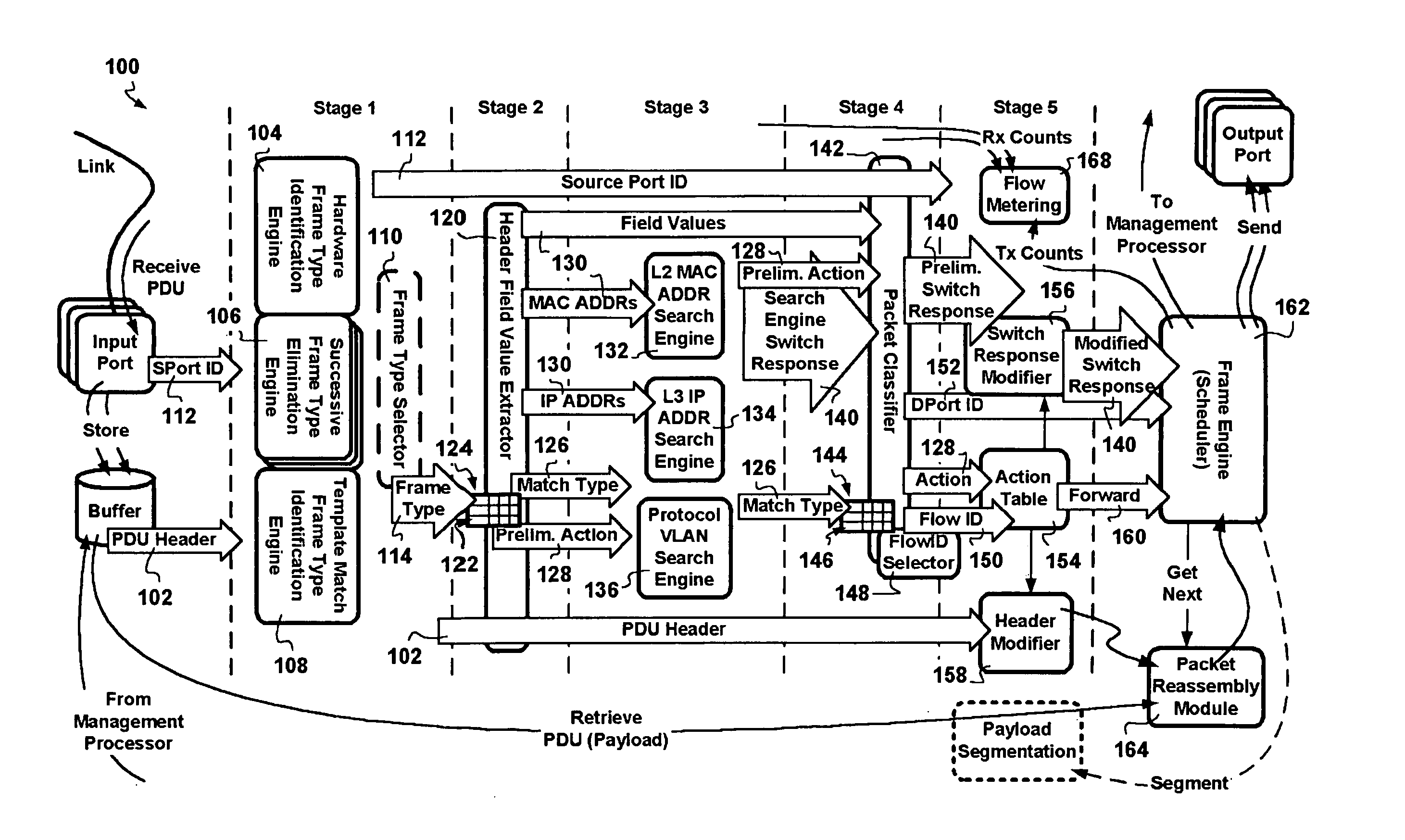

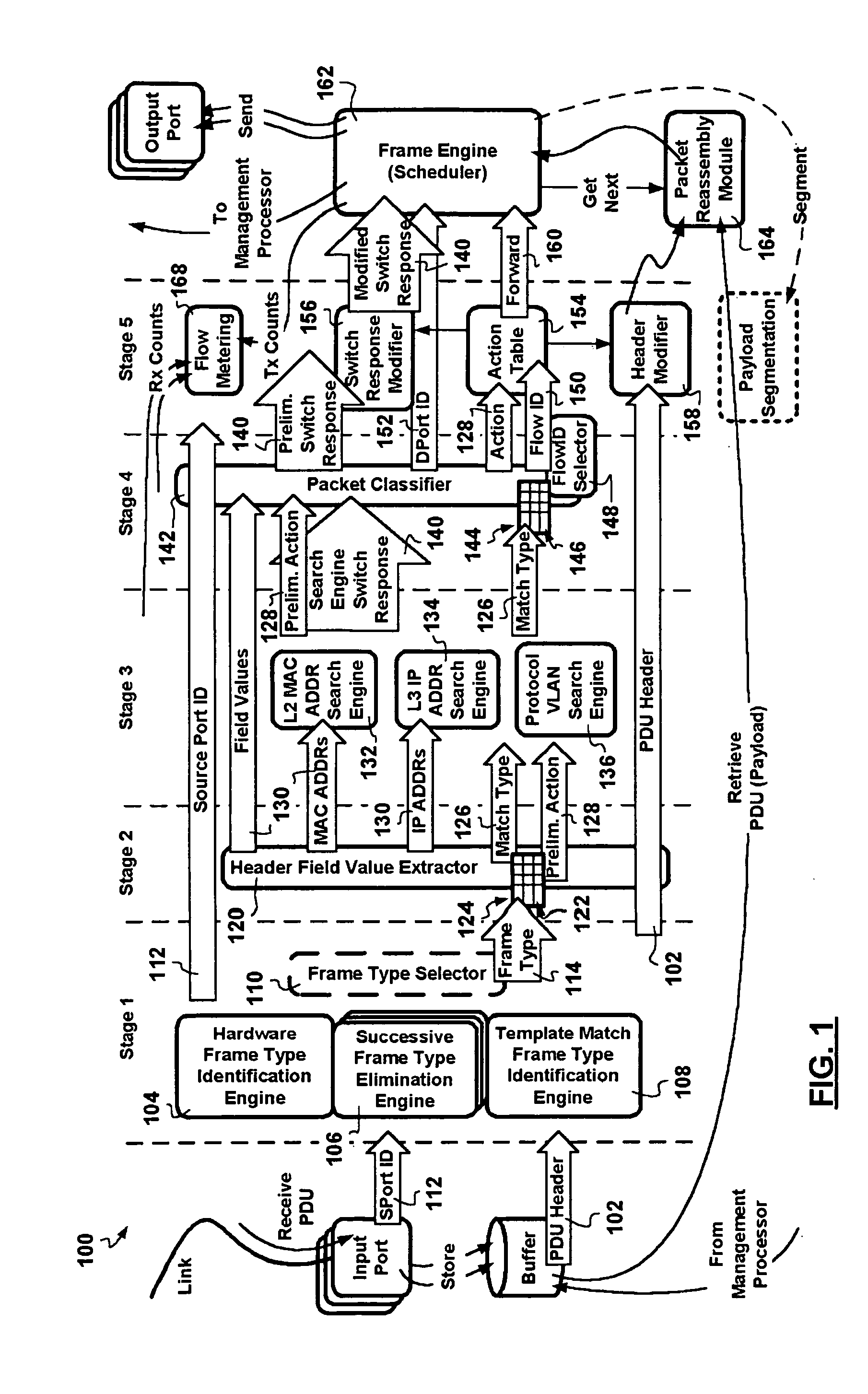

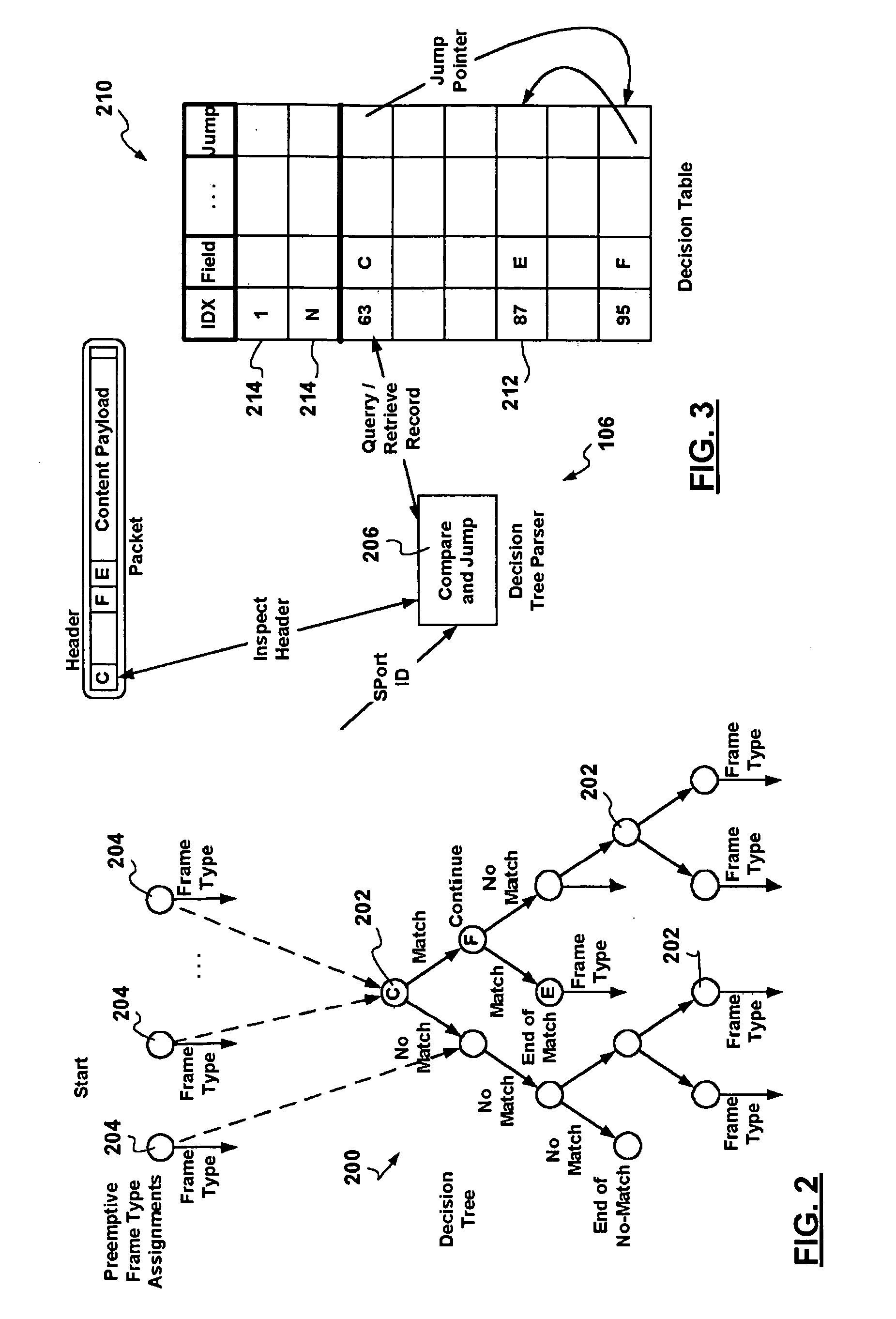

Combined pipelined classification and address search method and apparatus for switching environments

InactiveUS20060002386A1Network degradationReduce data transfer bandwidthTime-division multiplexData switching by path configurationNetwork addressingObsolescence

A packet switching node having a pipelined packet processing architecture processing packets received via an input port associated with the packet switching node is presented. The method performed by the apparatus includes: determining a packet frame type of the packet received; selectively extracting packet header field values specific to a packet frame type, the extracted packet header field value including packet addressing information; ascribing to the packet a preliminary action to be performed in respect of the packet; searching packet switching information tracked by the packet switching node based on extracted packet addressing information; formulating a preliminary switch response for the packet; classifying the packet into one of a plurality of packet flows; modifying the preliminary switch response in accordance with one of the preliminary action, the packet flow into which the packet was classified, and a default port action corresponding to the input port; modifying the packet header in accordance with one of the preliminary action, the packet flow, and the default port action; and processing the packet in accordance with the switch response. Advantages are derived from: pipelined processing of packets which enables short-cutting the rest of the processing for improper packets; a flexible frame type determination which is fast for well know frame types yet flexible in support of new frame types delaying obsolescence of a particular implementation; an early determination of a processing action which is successively refined by subsequent stages; a combined Layer-2 and Layer-3 network addressing search engine operating on short bit length indexed Layer-2 and Layer-3 network addresses reducing network address table storage requirements, requiring a reduced data transfer bandwidth for network address table access, a large external hashed primary network address table, and a small internal secondary network address table; an early determination of a switch response; and packet-classification-based switch response and packet header modification.

Owner:SYNAPTICS INC

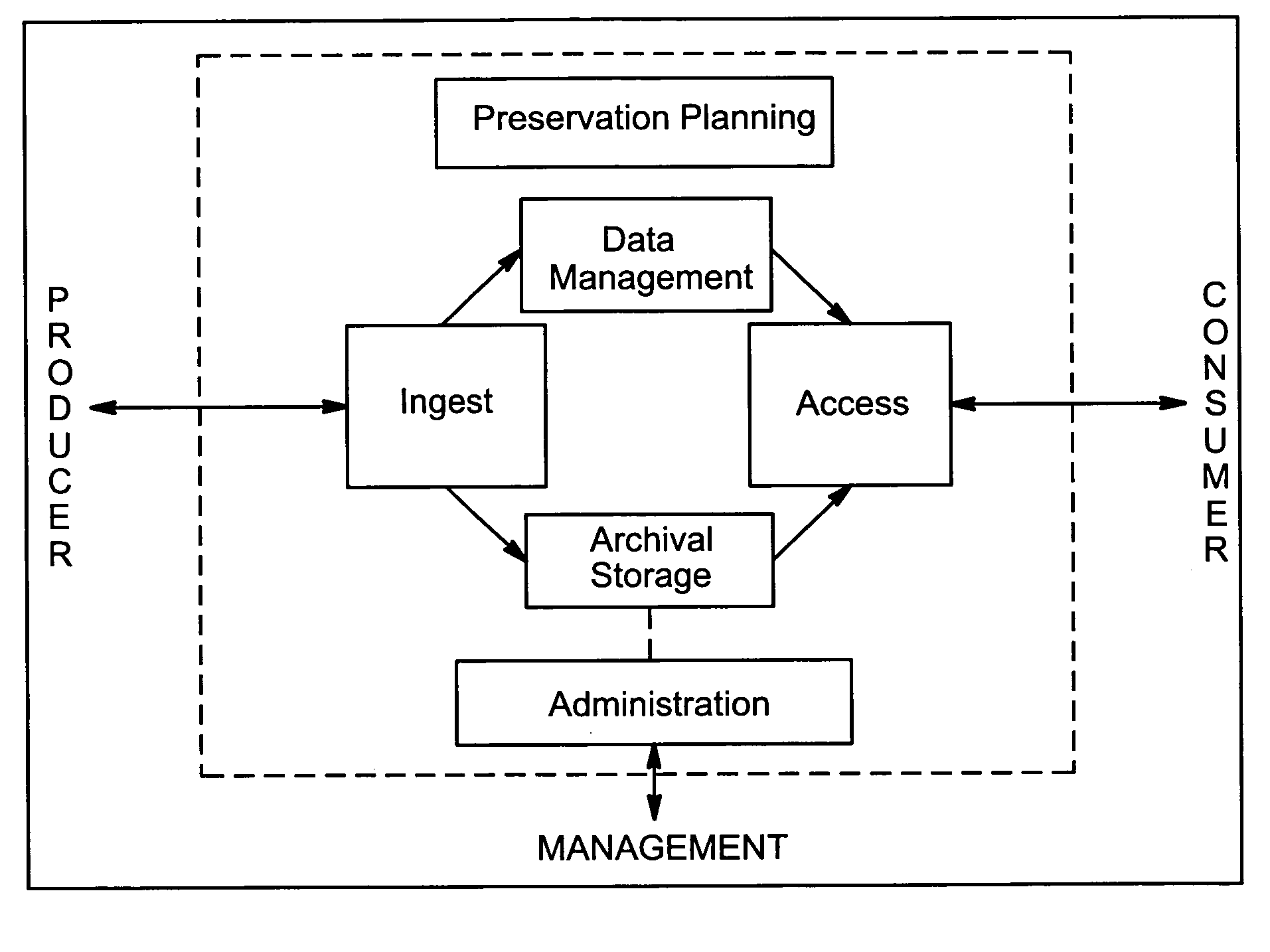

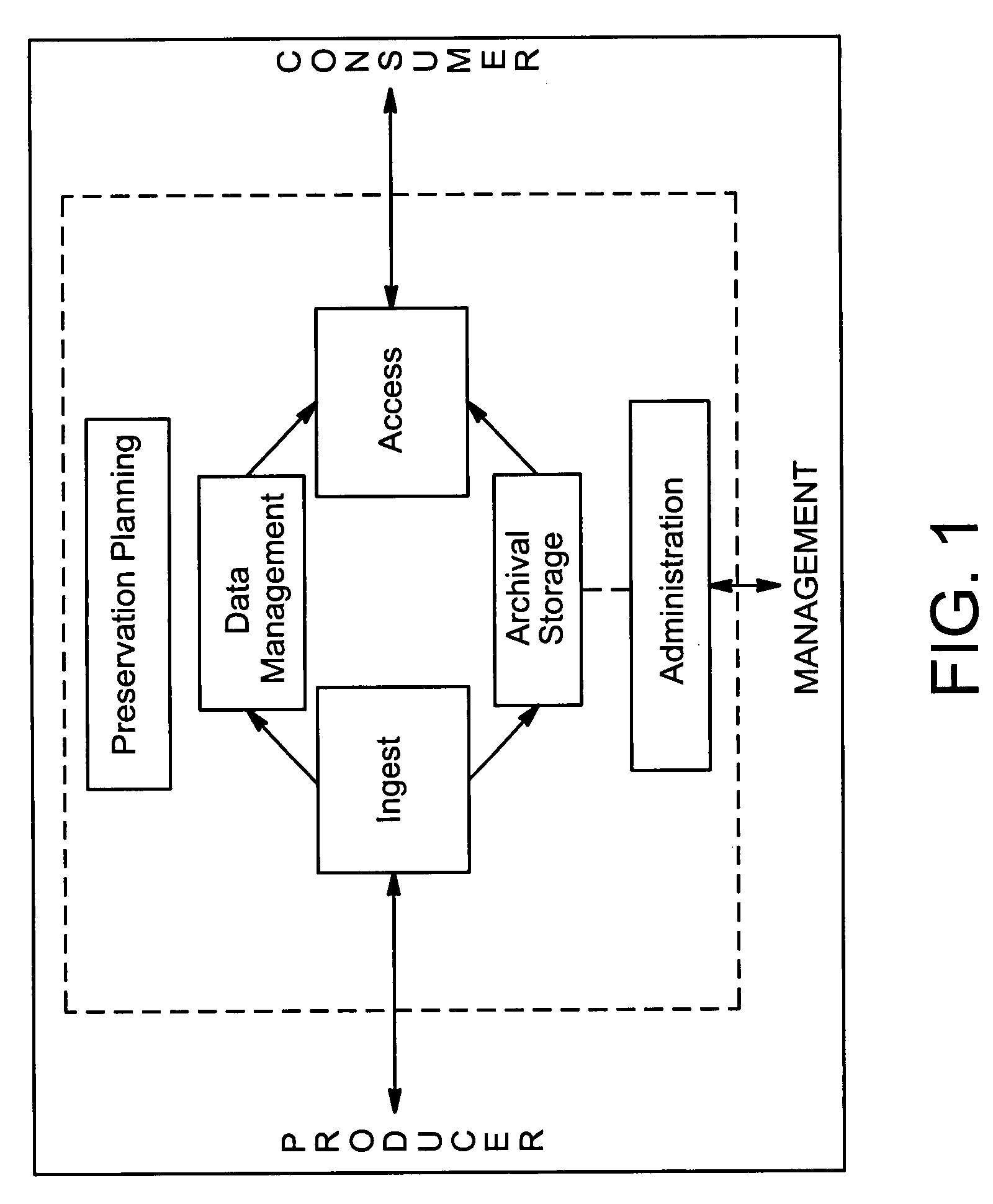

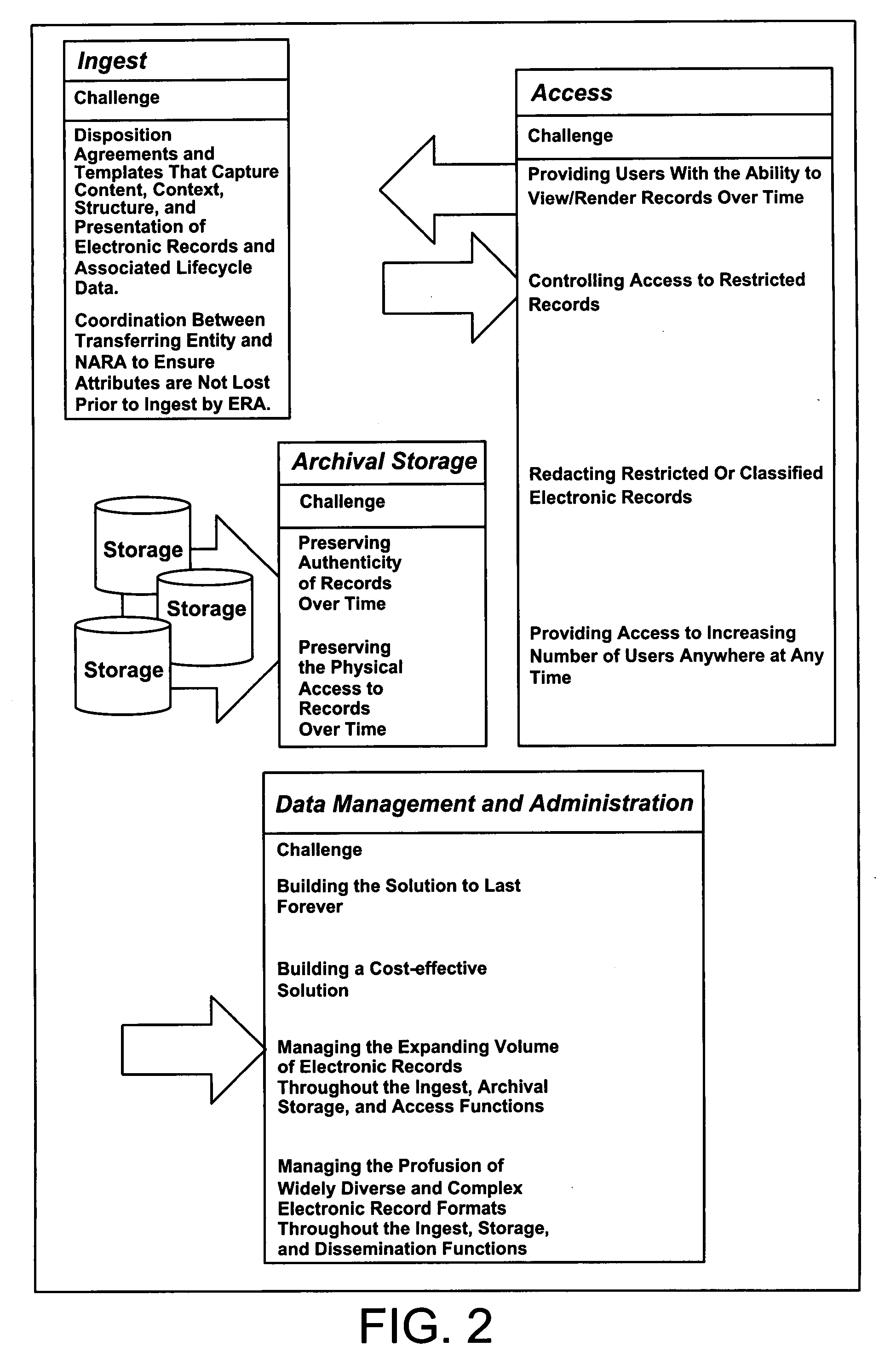

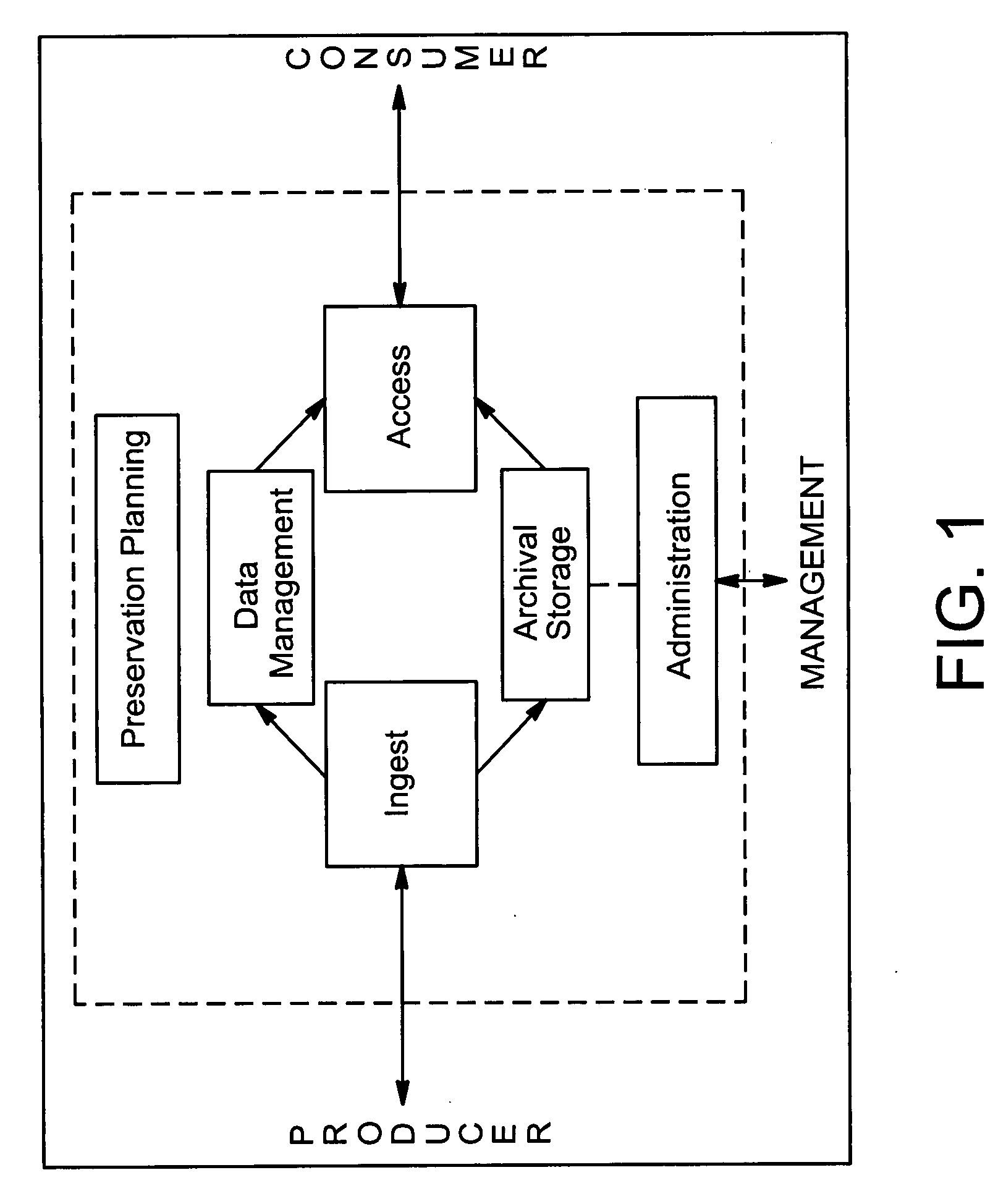

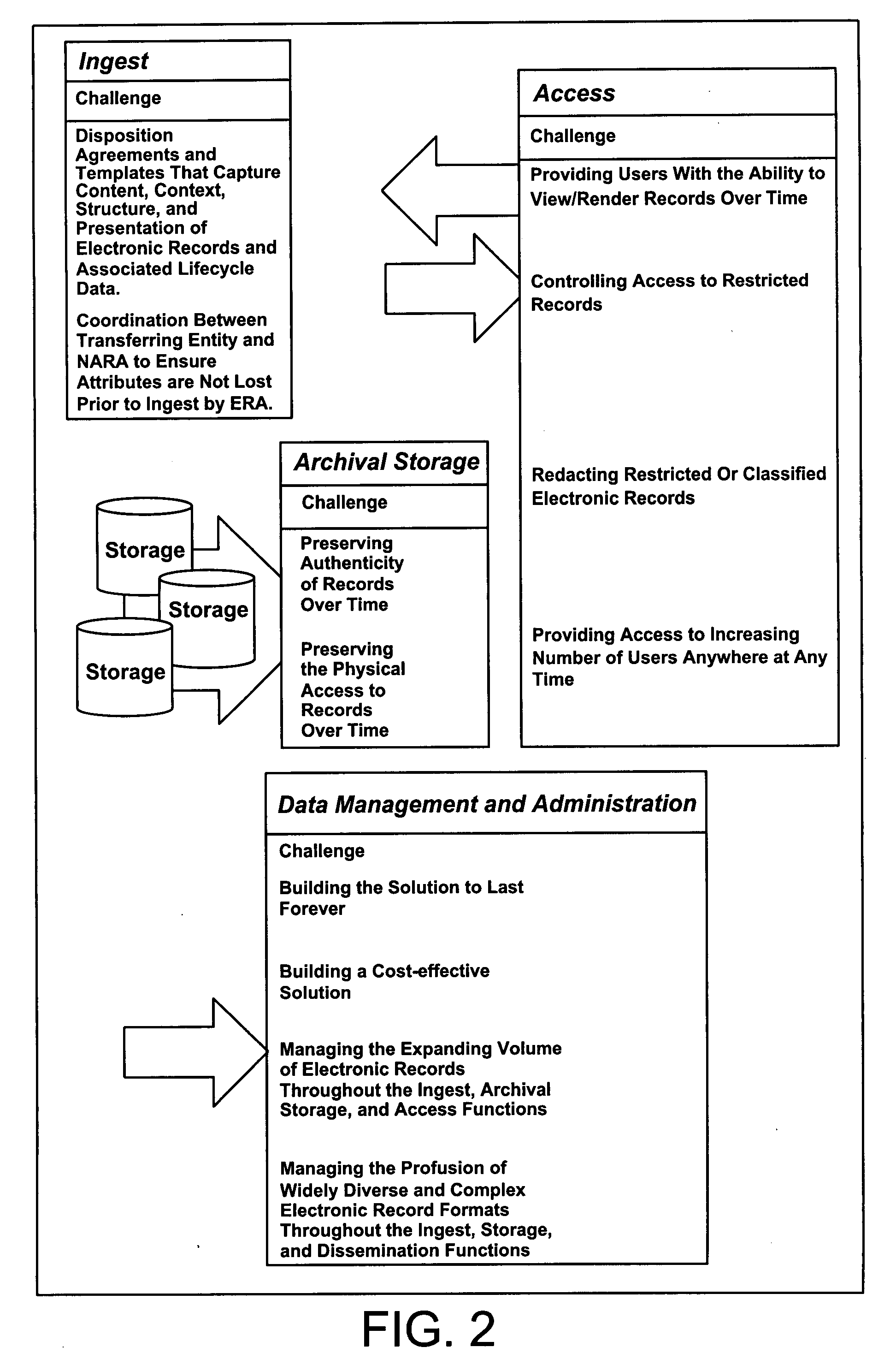

System and method for immutably cataloging electronic assets in a large-scale computer system

InactiveUS20070260476A1Data processing applicationsDigital data information retrievalSurvivabilityObsolescence

Systems and / or methods for storing and / or retrieving assets in connection with an extremely large scale computer storage system are provided. An asset catalog may comprise a plurality of asset catalog entries stored according to at least one schema and corresponding to a plurality of assets. A storage architecture may be capable of storing the plurality of assets, with the storage architecture comprising a storage locator and a federator. An item identification scheme may be capable of providing identifiers to reference, locate, and / or access said assets and / or said asset catalog entries stored in the asset catalog in the storage architecture. The computer storage system may be scalable essentially without limitation while maintaining asset storage and retrieval flexibility and substantially obsolescence-proof survivability of assets.

Owner:LOCKHEED MARTIN CORP +1

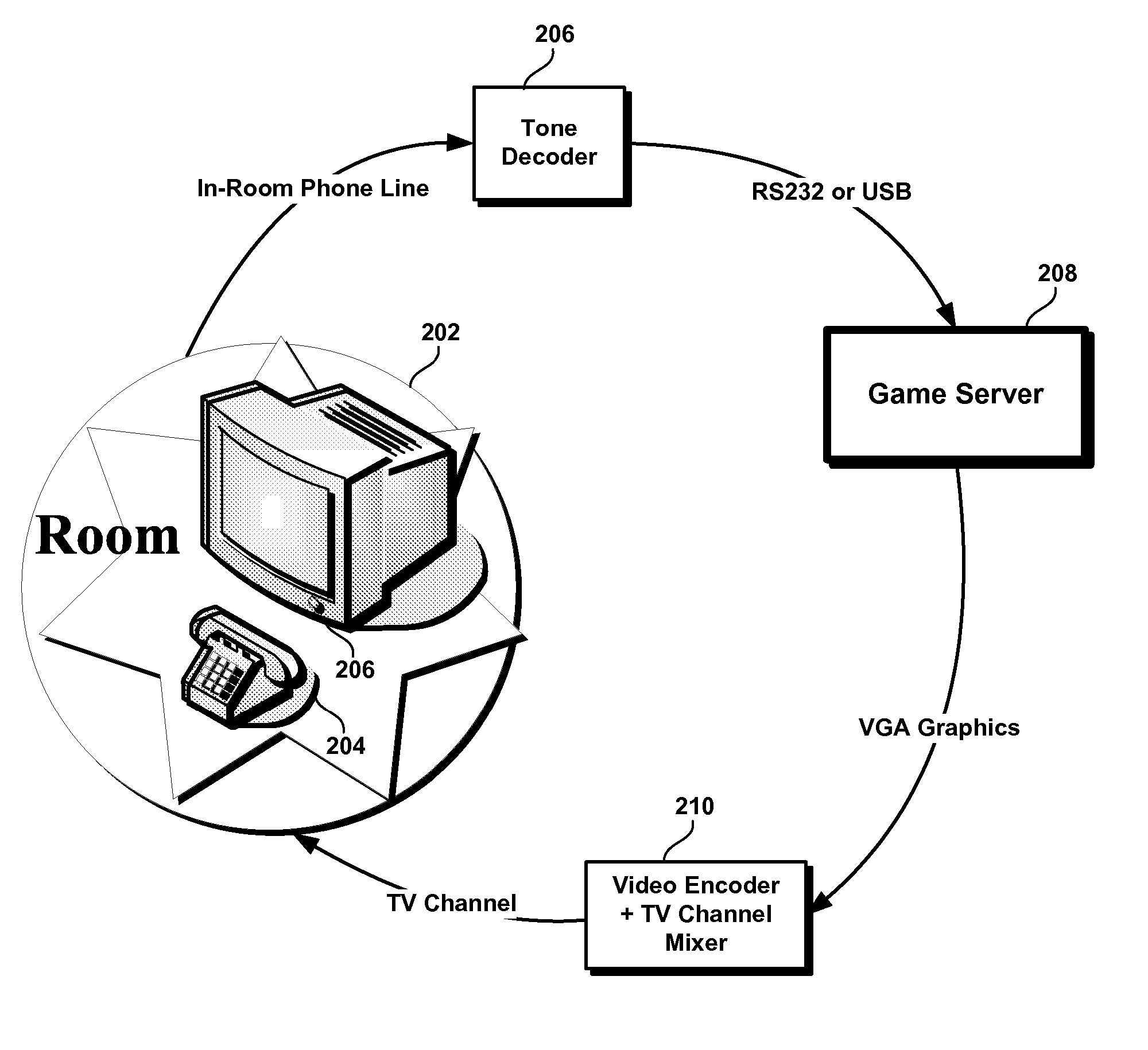

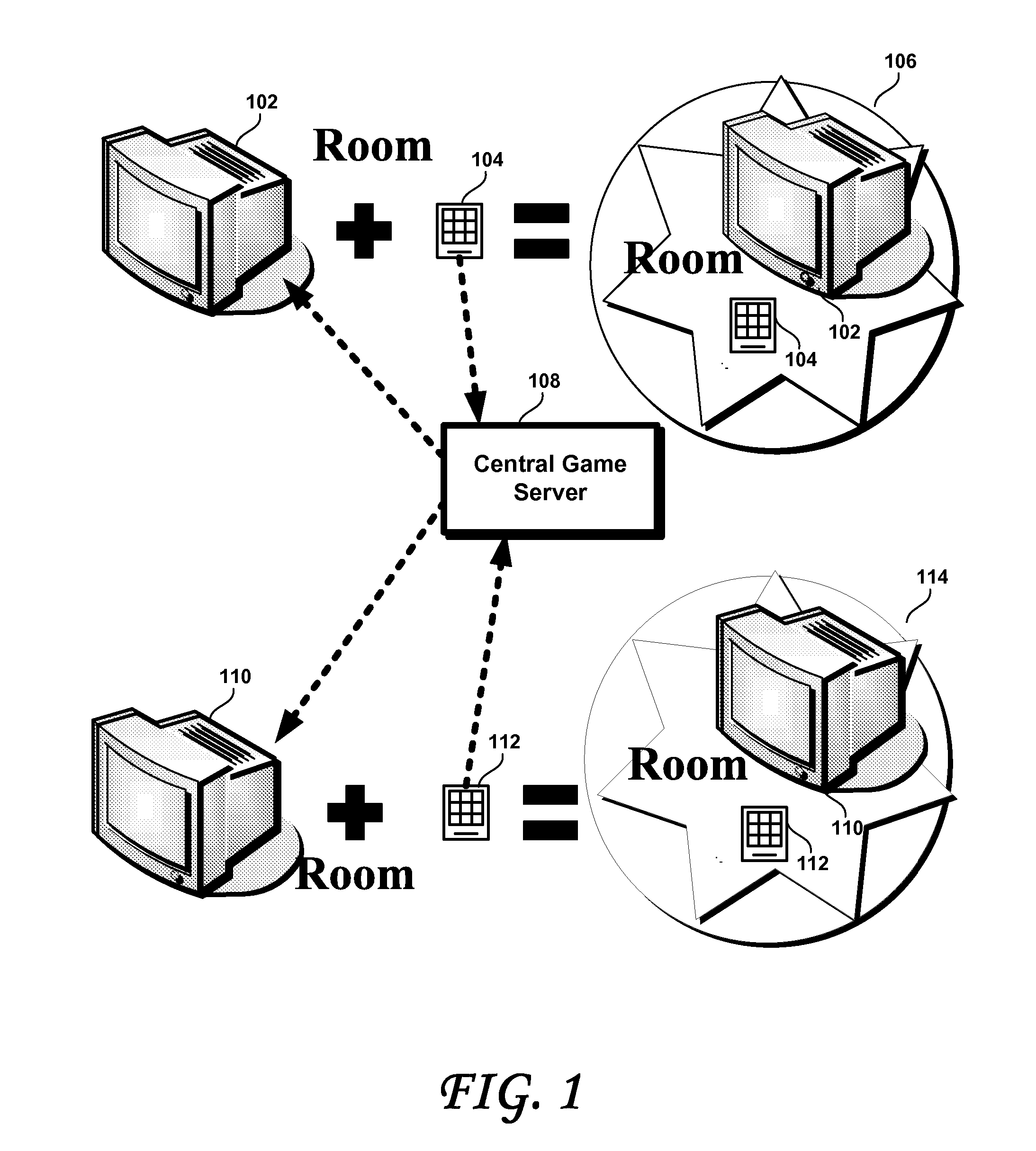

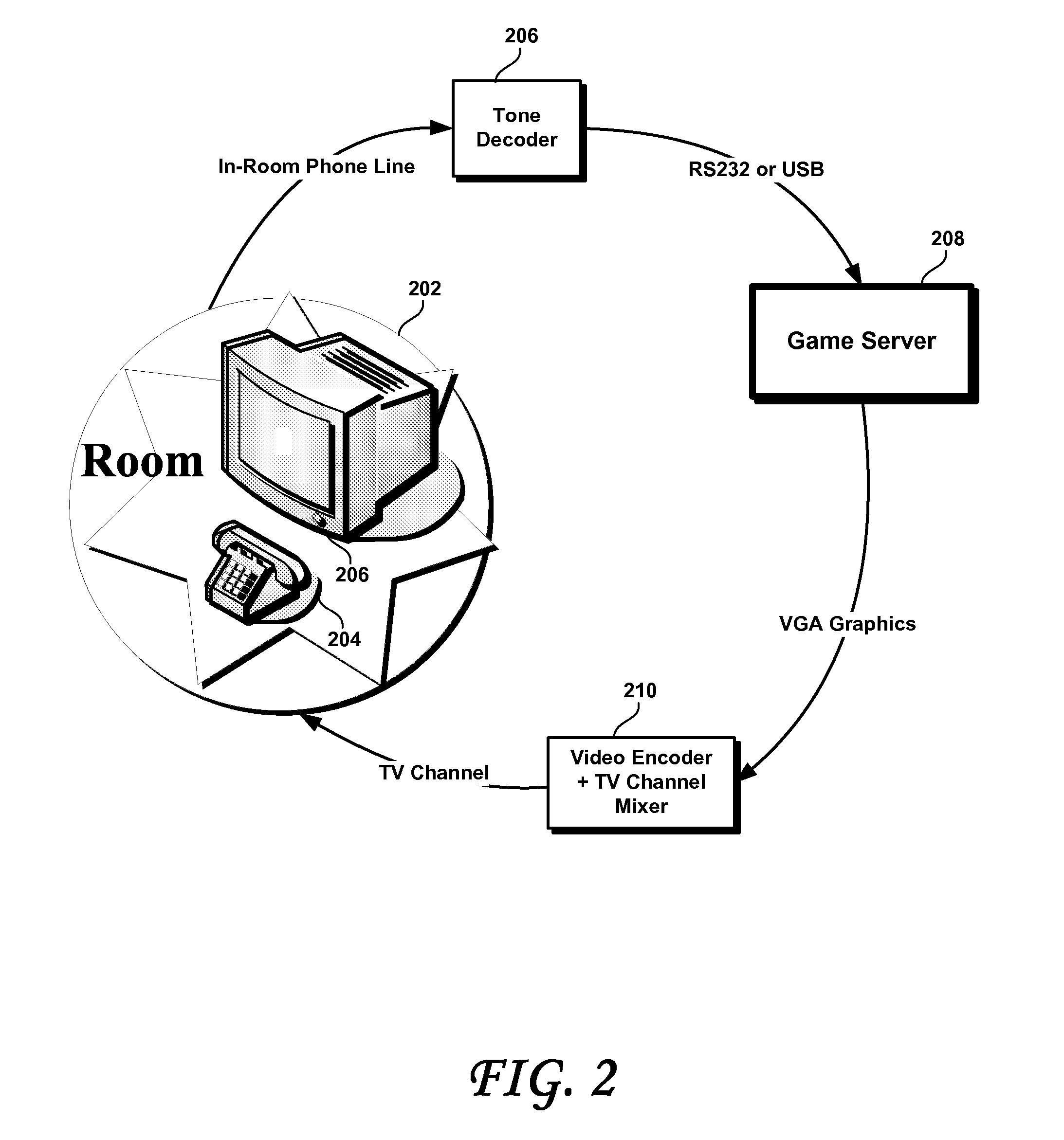

In-room gaming

InactiveUS20070155507A1Lower latencyLow bandwidthApparatus for meter-controlled dispensingVideo gamesCredit cardObsolescence

A method for in-room gaming suitable for cruise ships and remote hotels allows players to play electronic games of skill or chance on their room TV or on any other available TV. Players may interact with the games via an input device as simple as a standard telephone or as powerful as a palm-sized WiFi device fitted with a credit card reader. The method and system need not require any rewiring of the room and leverages on any data service already in place, such as an individual telephone line, a wired or Wifi local area network. The in-room gaming system may include a central gaming server that generates the game video rendering for each player, the video being streamed or otherwise provided to the associated TV via an individual TV channel, thereby enabling rich, powerful and secure gaming while reducing maintenance costs and preventing obsolescence. In-room players may enjoy the flexibility to wager from any available television and may use the in-room gaming system to build relationships and social networks with other players if they desire.

Owner:IGT

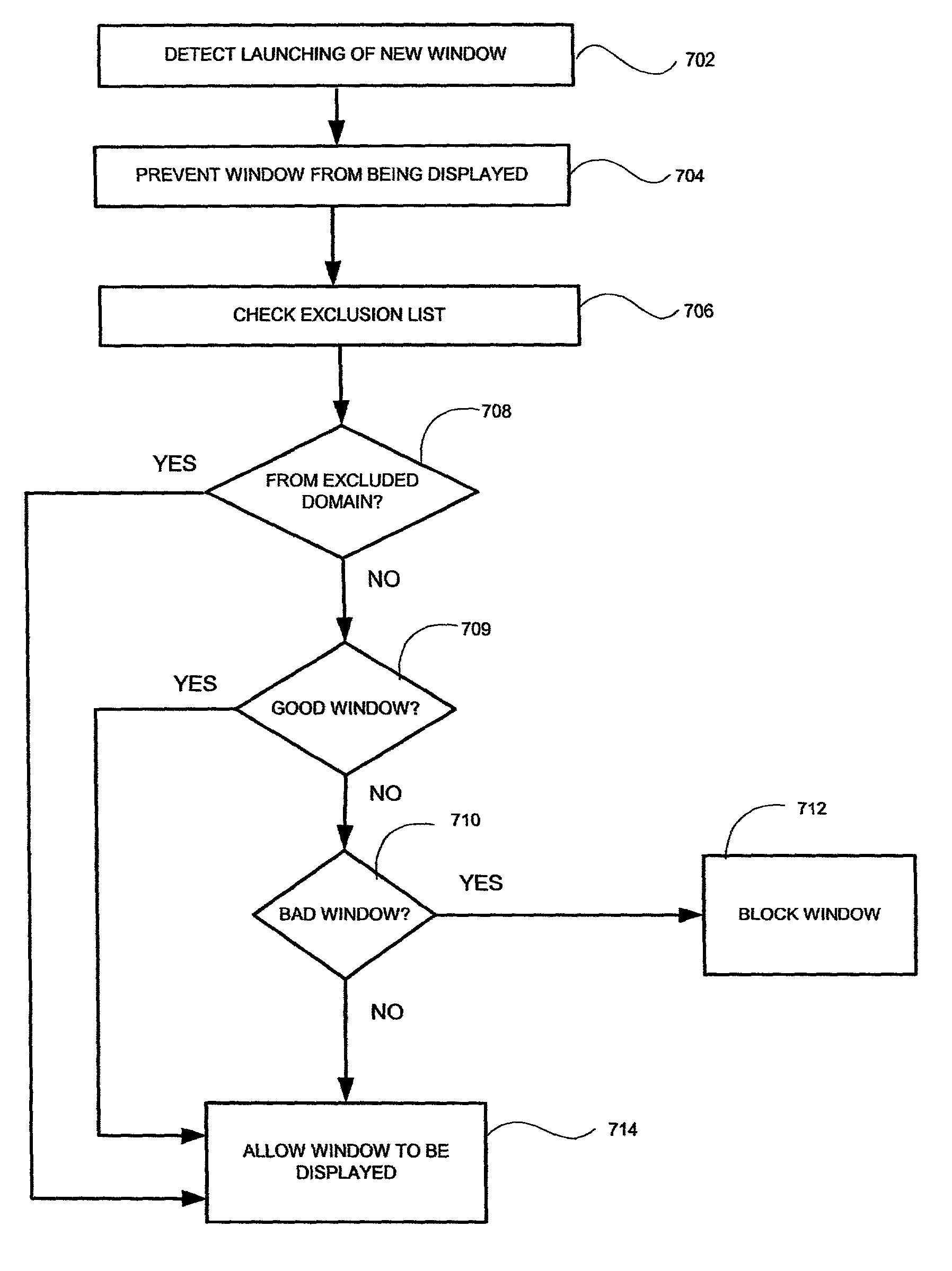

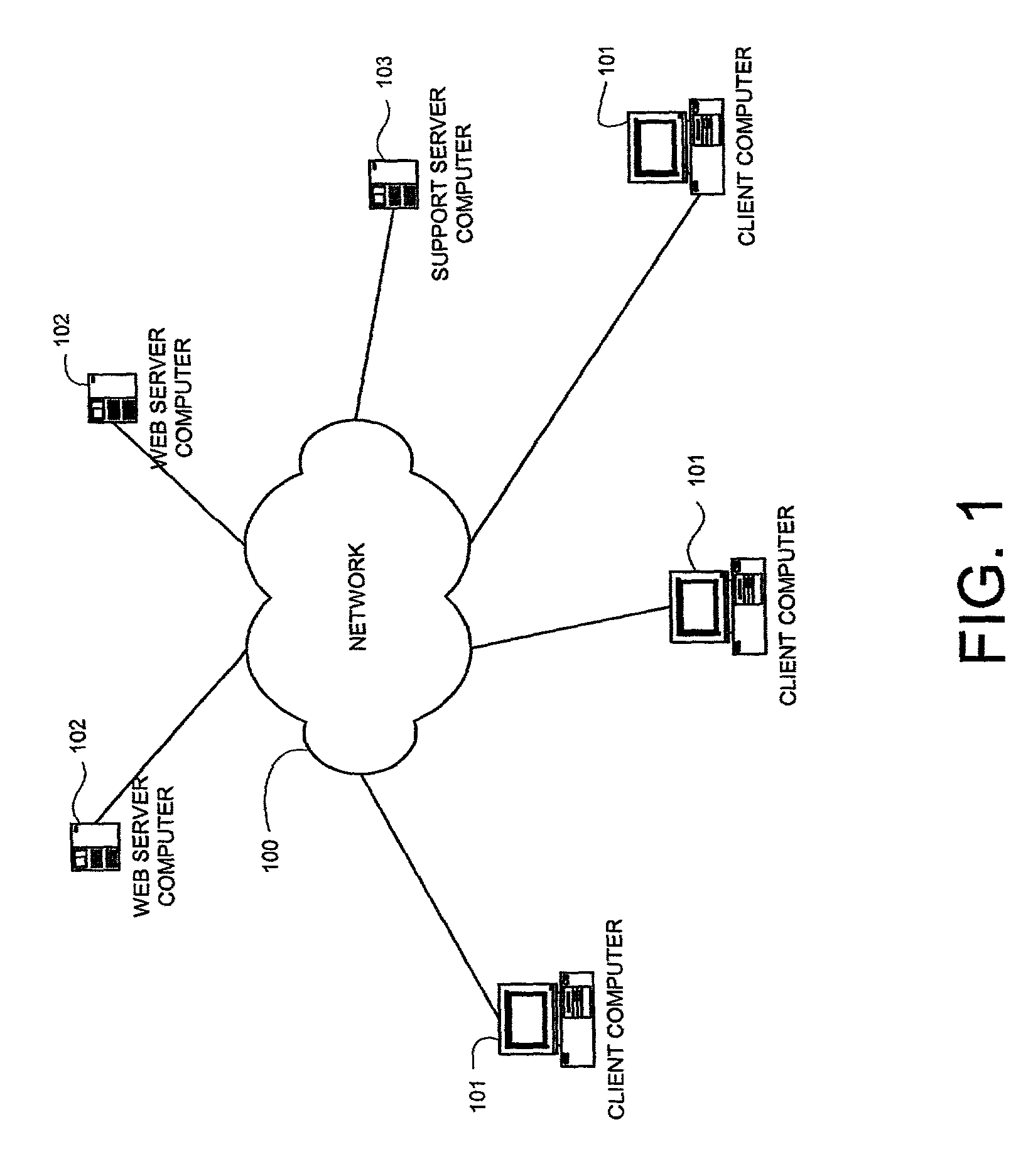

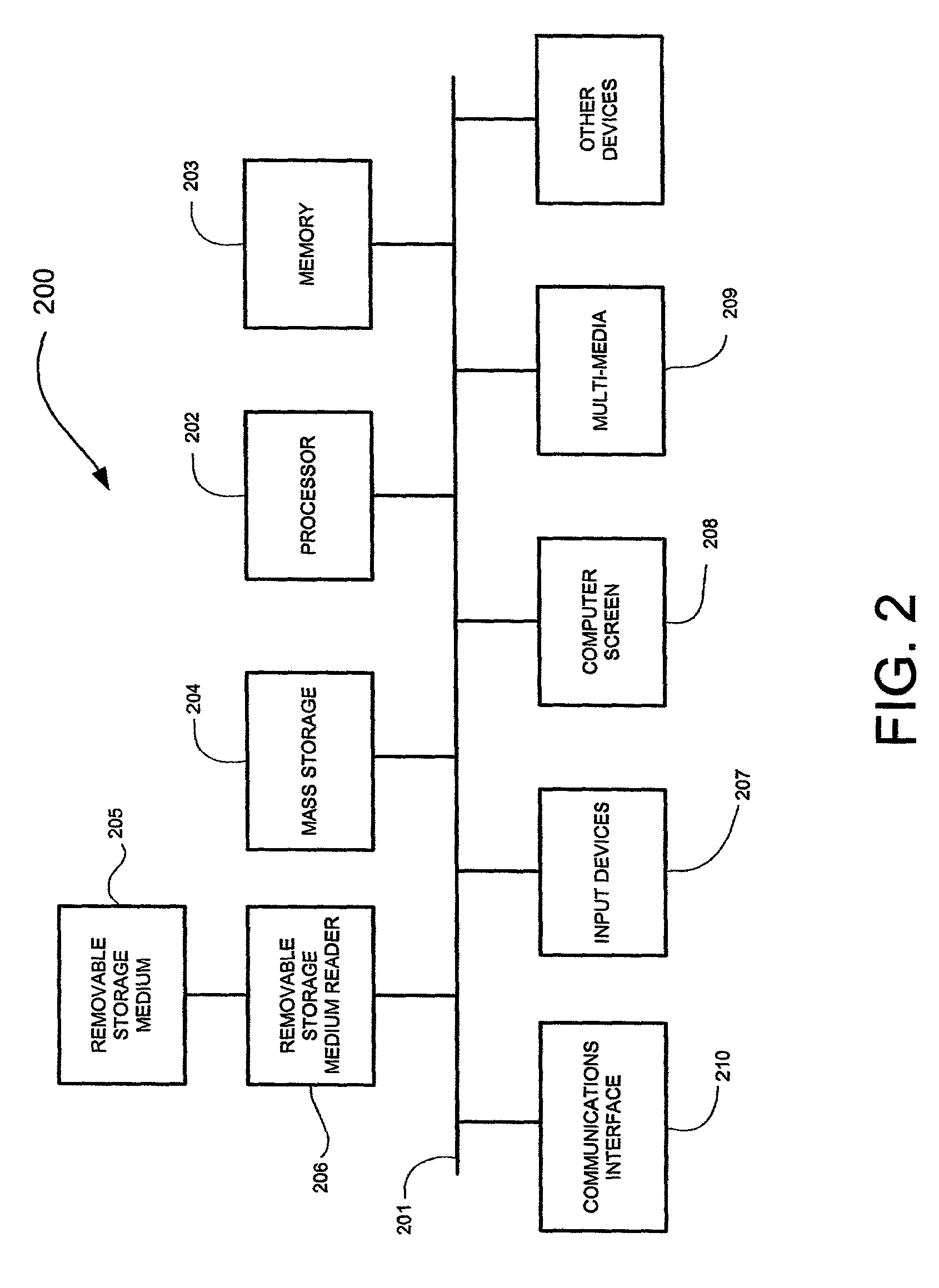

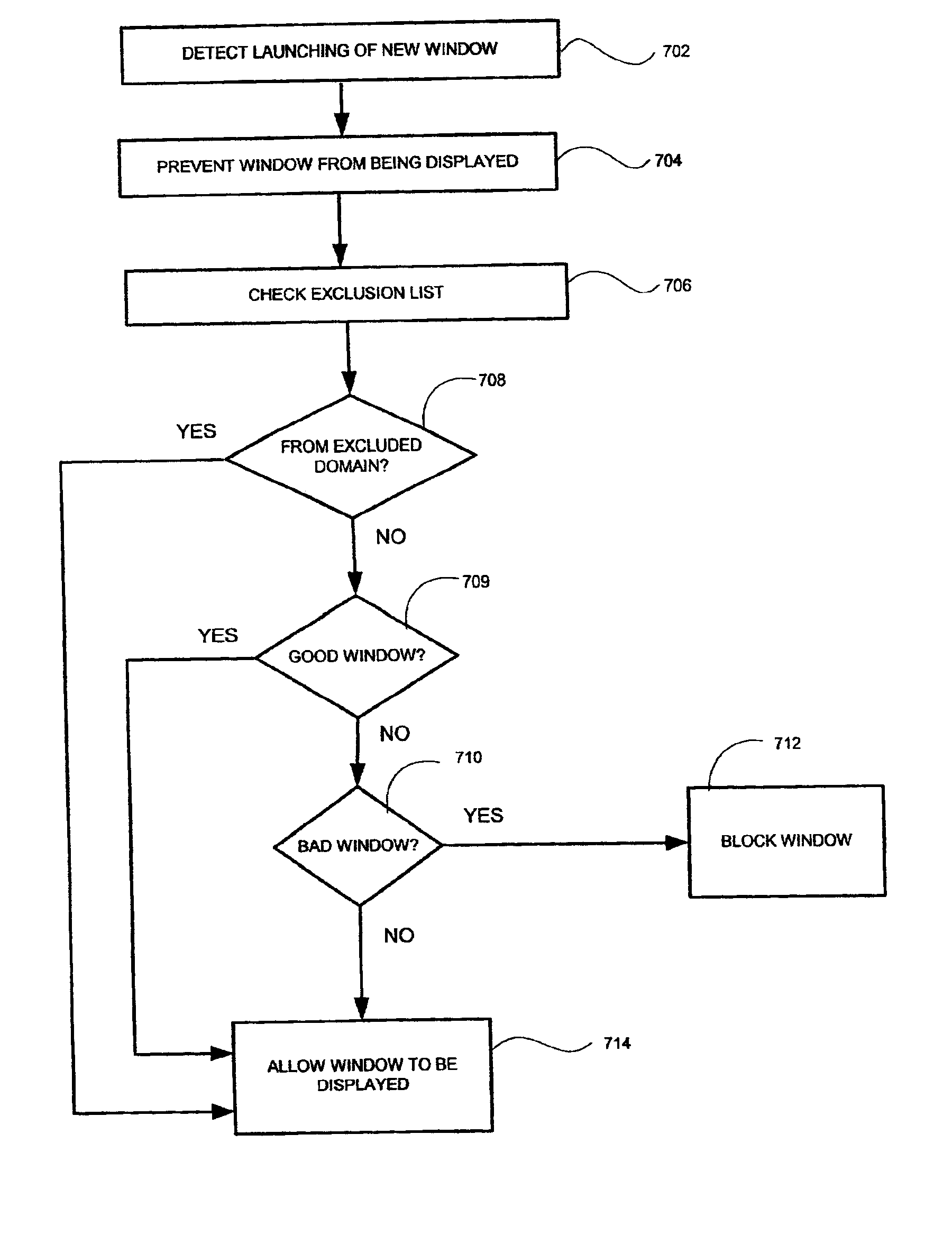

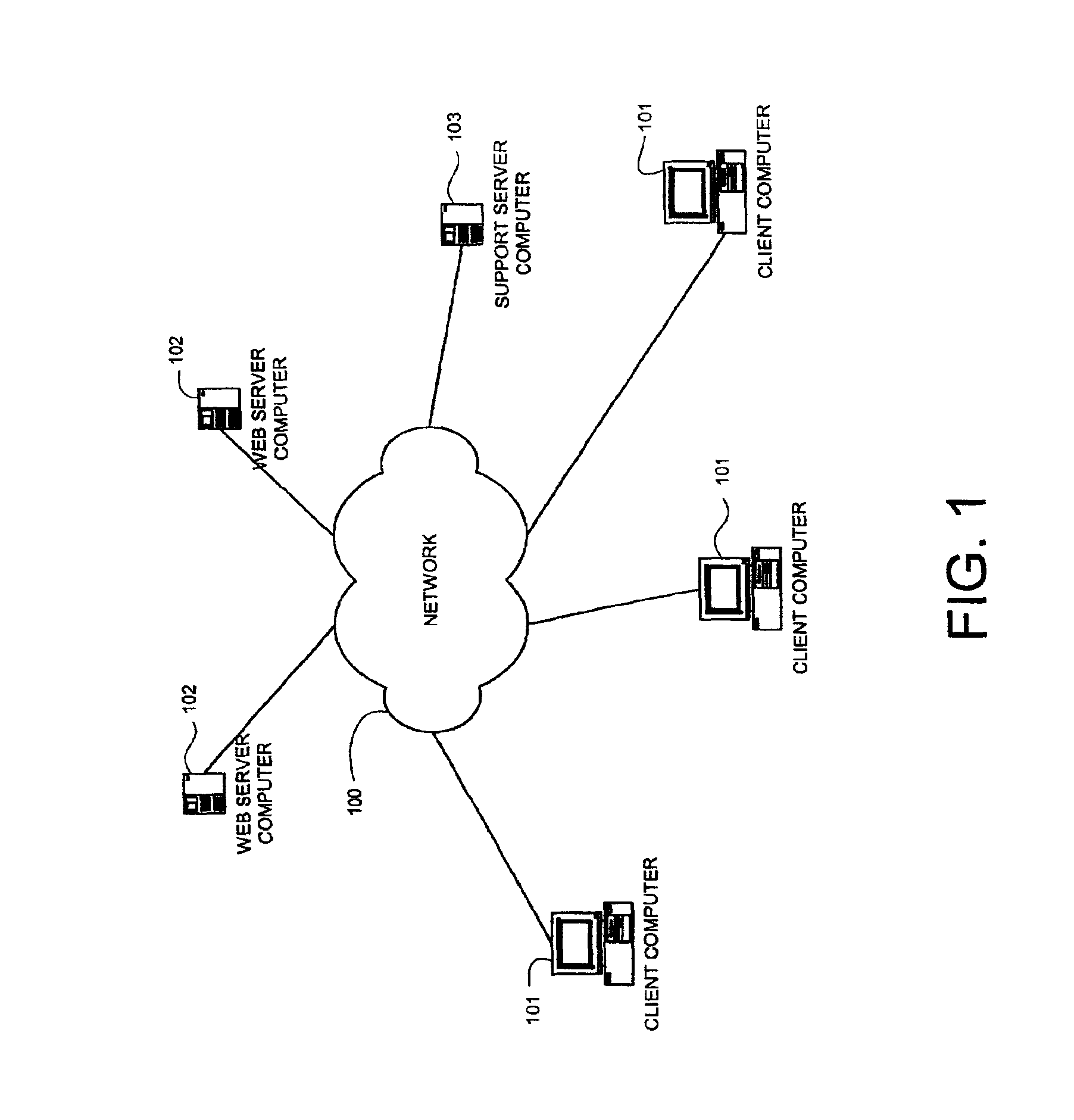

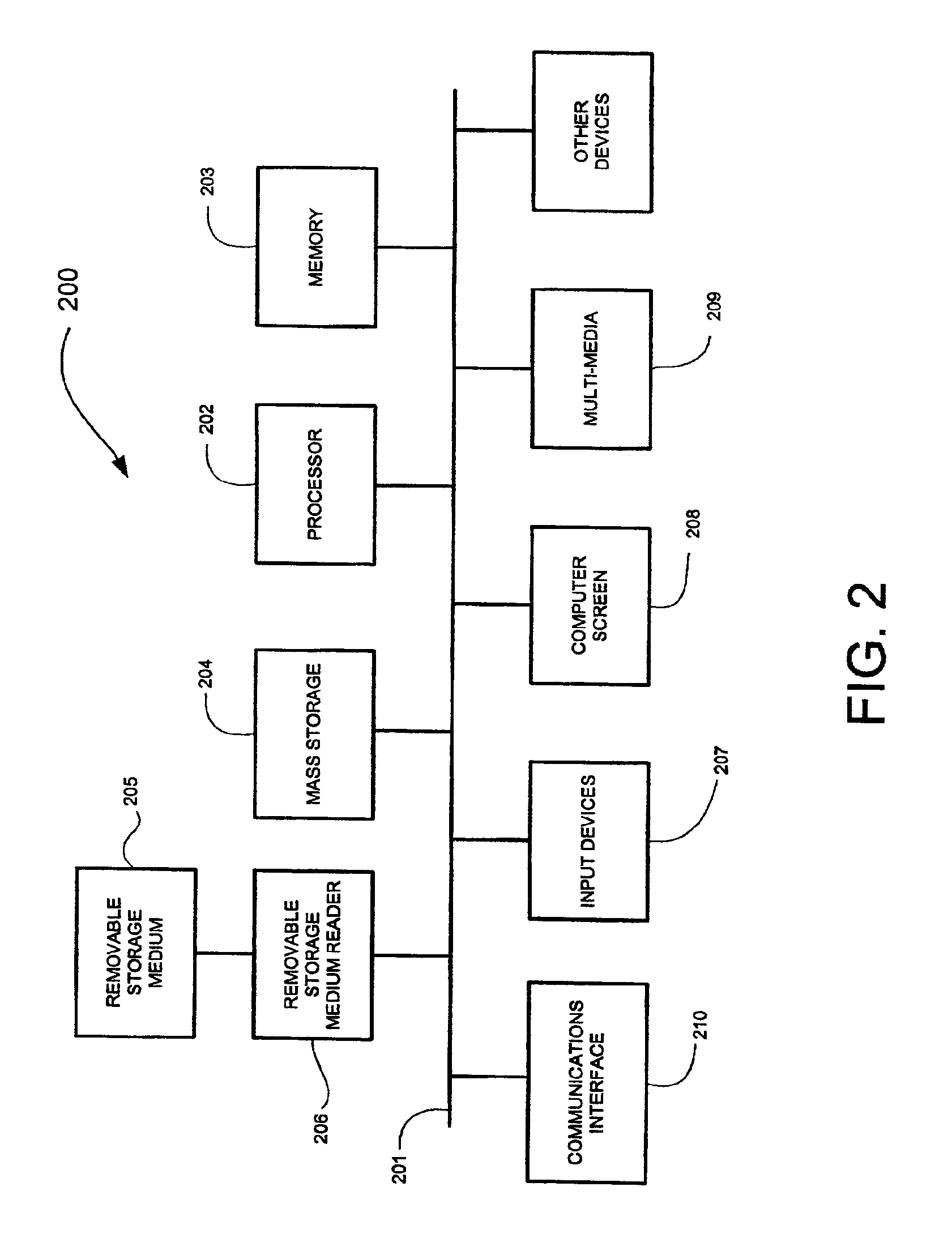

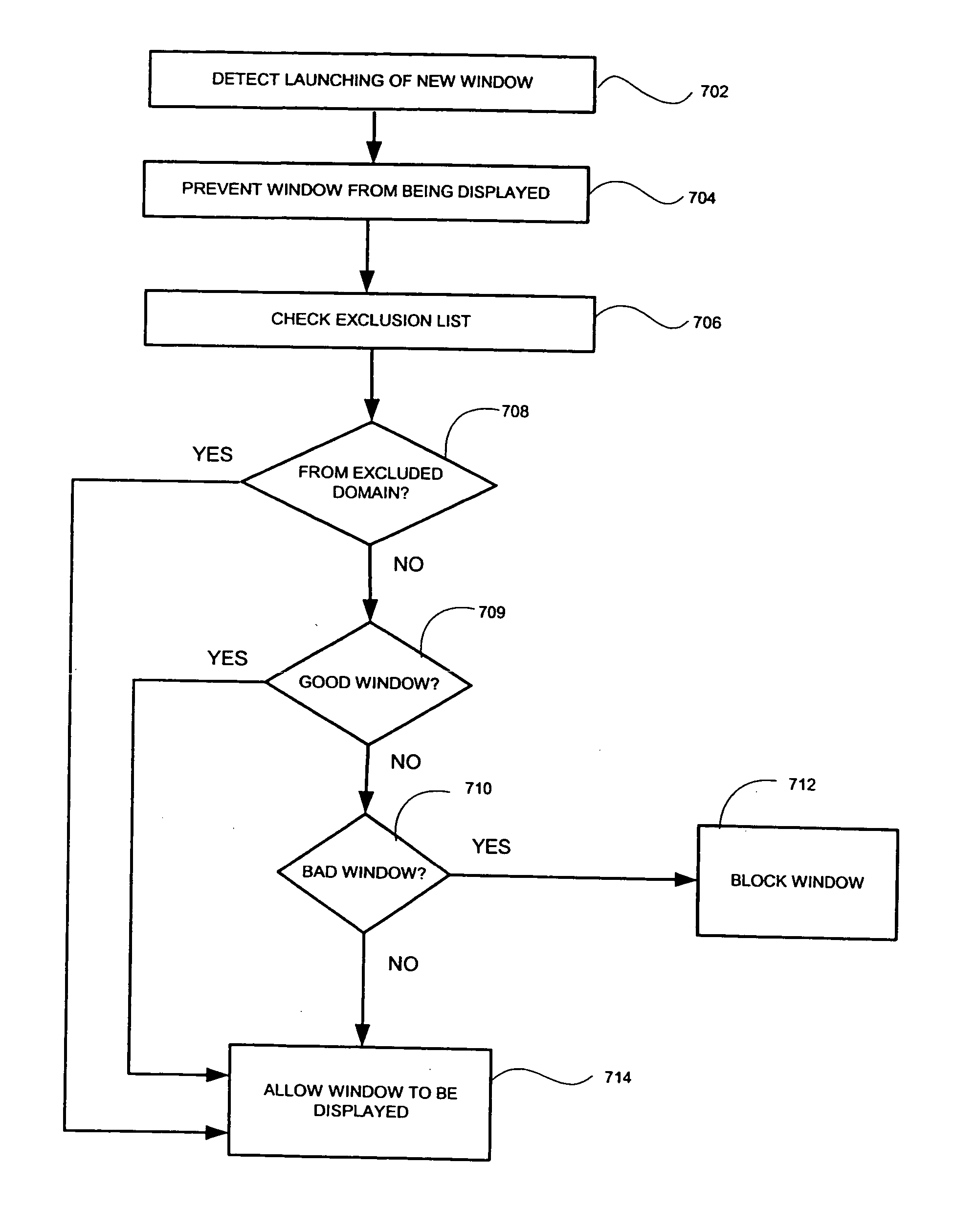

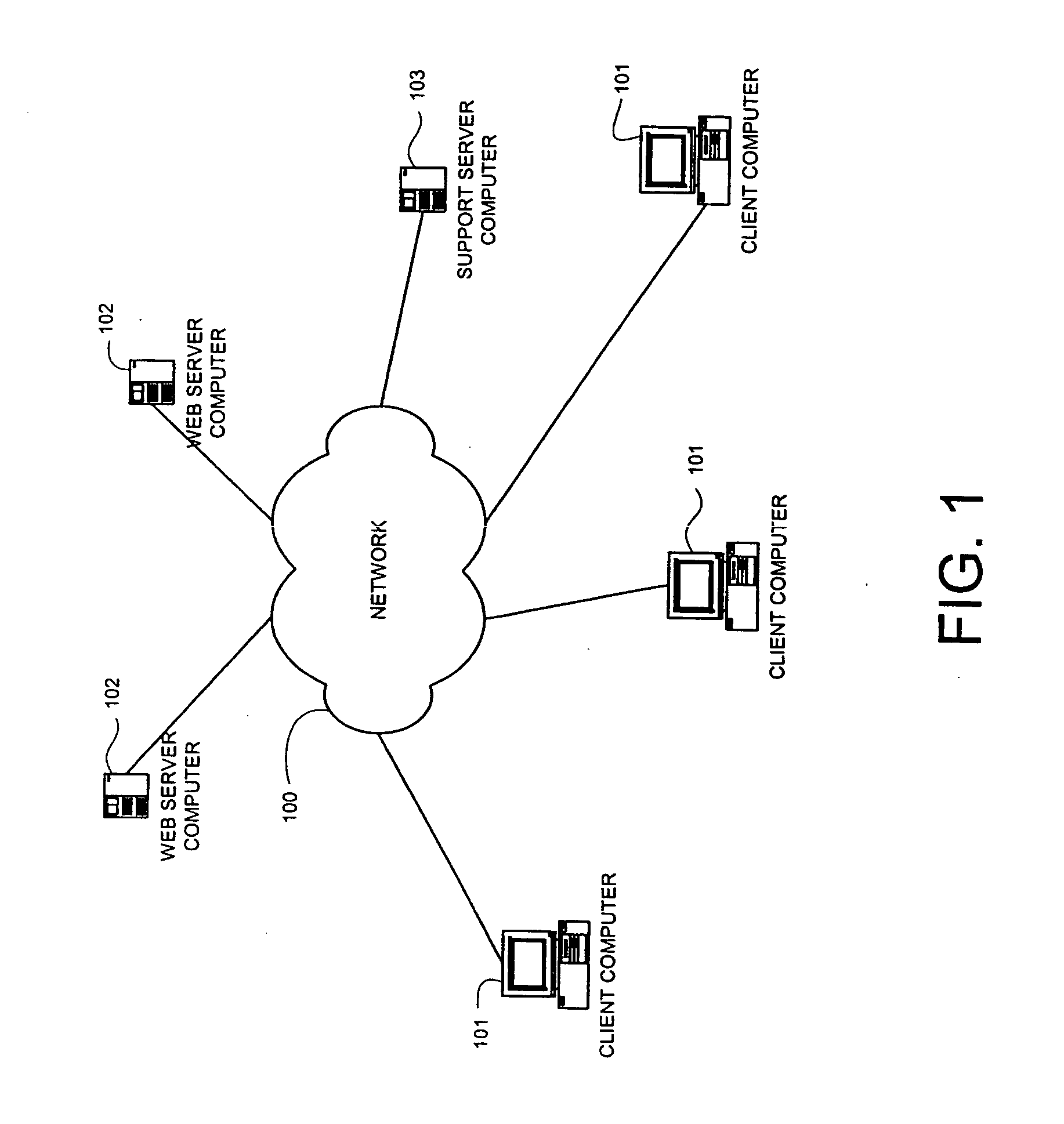

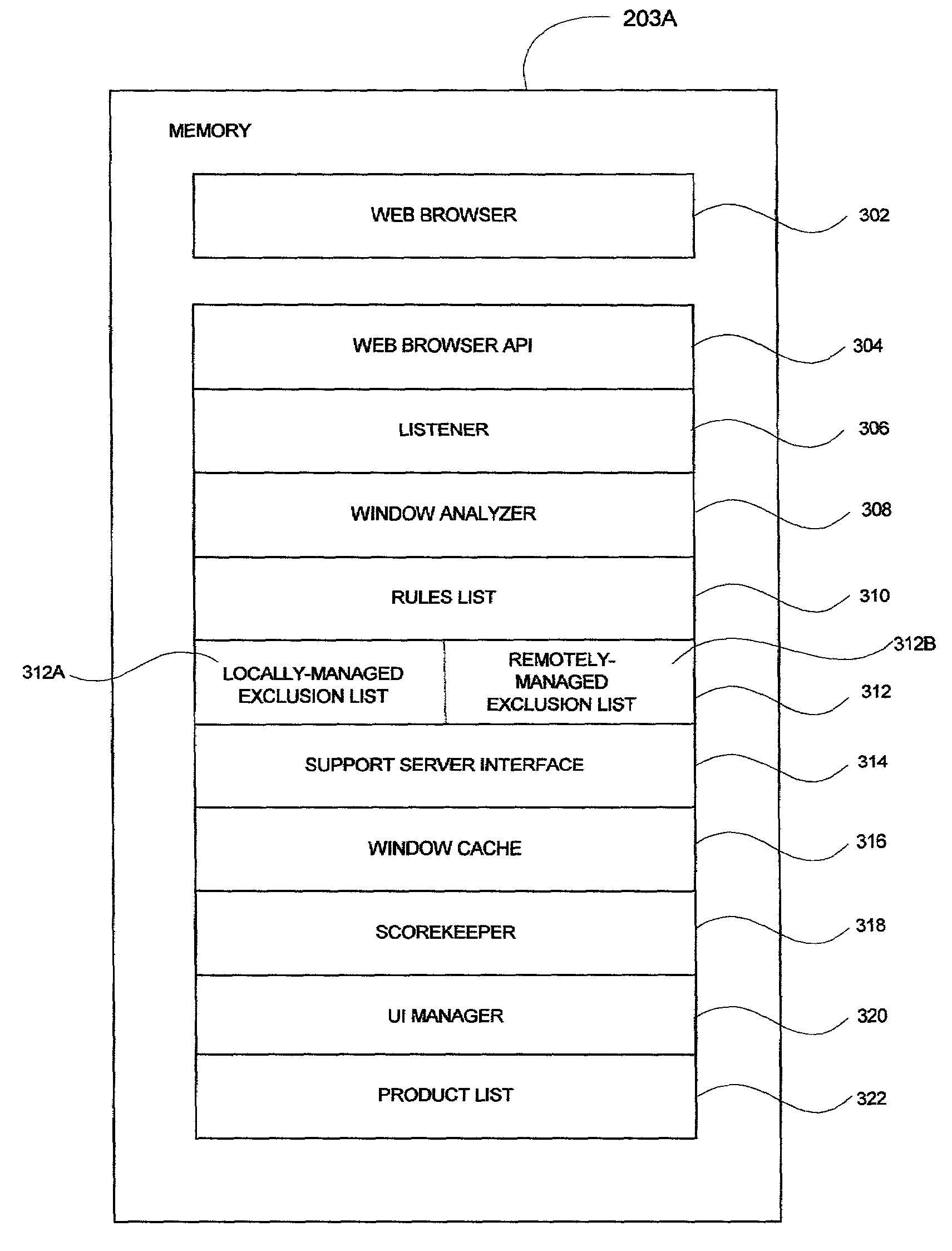

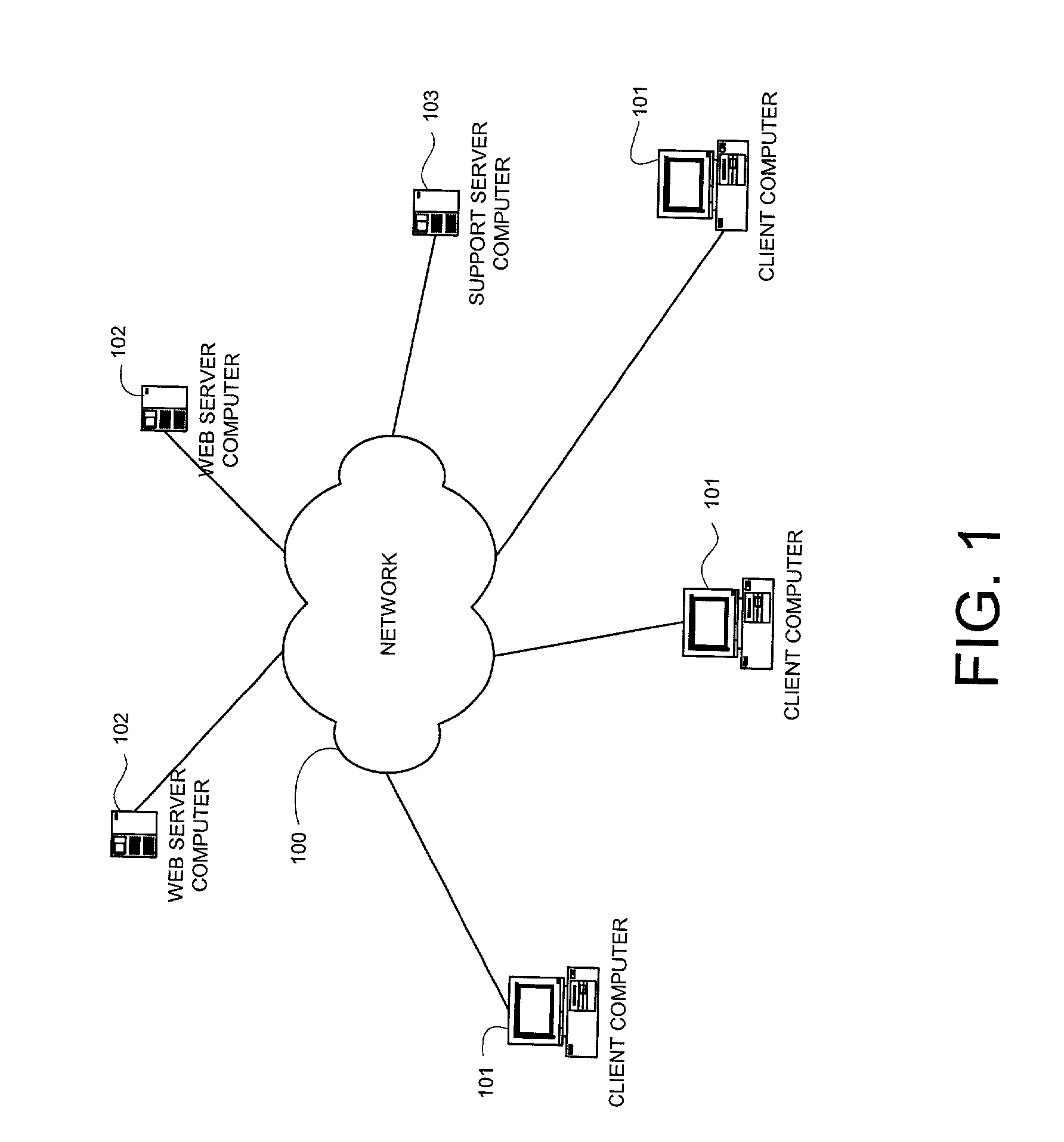

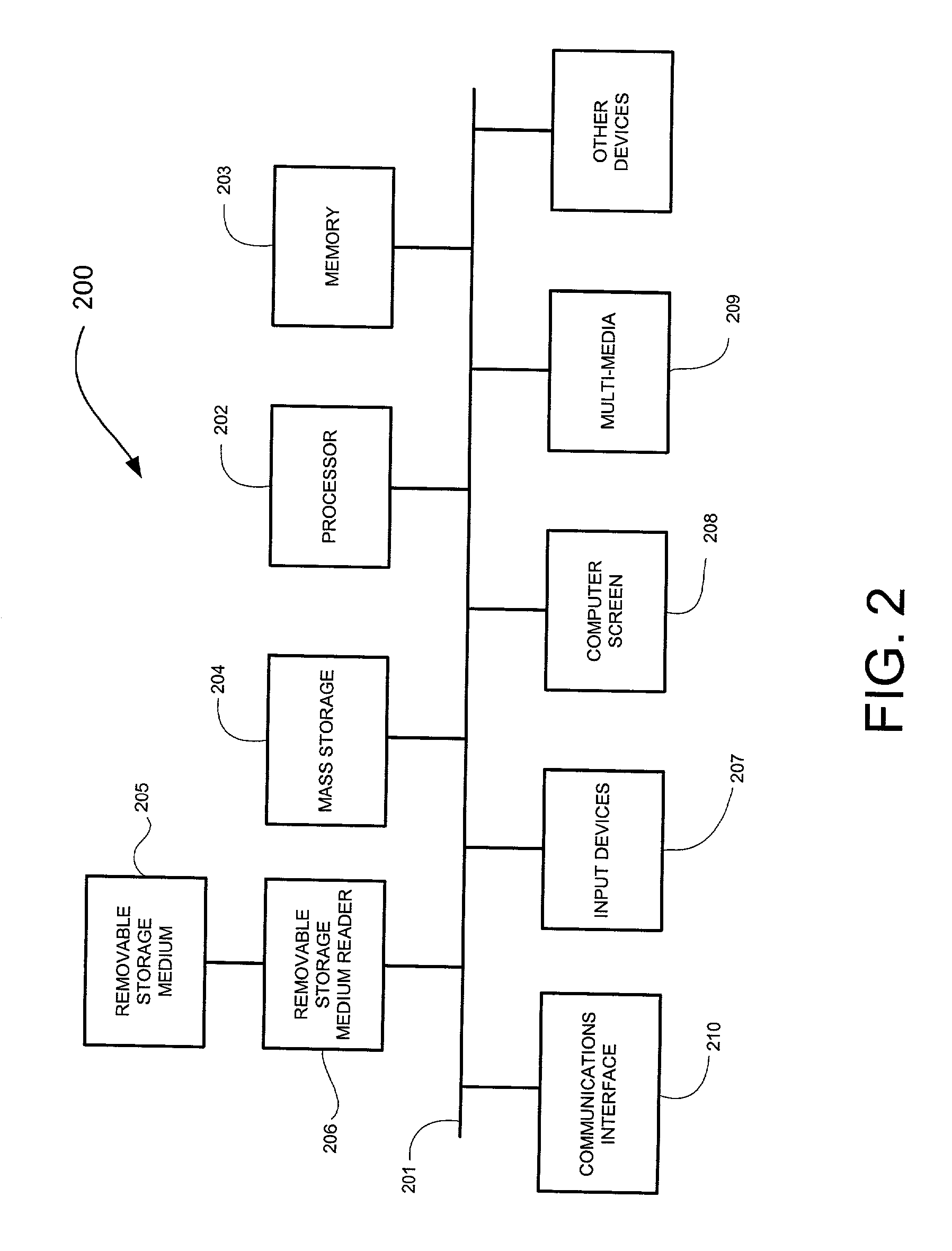

Method and apparatus for blocking unwanted windows

ActiveUS7162739B2Enhanced informationRaise the possibilityWeb data retrievalMemory loss protectionObsolescenceWorld Wide Web

In one embodiment, a computer program blocks windows categorized as bad windows, while allowing windows categorized as good windows to be displayed. The computer program may categorize a window by consulting one or more lists. In one embodiment, a list may be updated from time to time to optimize the computer program and prevent program-obsolescence. Techniques for defeating a window-blocking mechanism are also disclosed. In one embodiment, a computer program detects if a window is of a type that offers a product to a user. If so, the computer program provides a separate window containing information regarding the product. In one embodiment, a computer program detects if a user has a need for the computer program. If so, the user is informed of the efficacy of the computer program, which is then offered to the user.

Owner:GULA CONSULTING LLC

Method and apparatus for defeating a mechanism that blocks windows

InactiveUS6968507B2Raise the possibilityTelevision system detailsDigital data information retrievalObsolescenceWorld Wide Web

In one embodiment, a computer program blocks windows categorized as bad windows, while allowing windows categorized as good windows to be displayed. The computer program may categorize a window by consulting one or more lists. In one embodiment, a list may be updated from time to time to optimize the computer program and prevent program-obsolescence. Techniques for defeating a window-blocking mechanism are also disclosed. In one embodiment, a computer program detects if a window is of a type that offers a product to a user. If so, the computer program provides a separate window containing information regarding the product. In one embodiment, a computer program detects if a user has a need for the computer program. If so, the user is informed of the efficacy of the computer program, which is then offered to the user.

Owner:GULA CONSULTING LLC

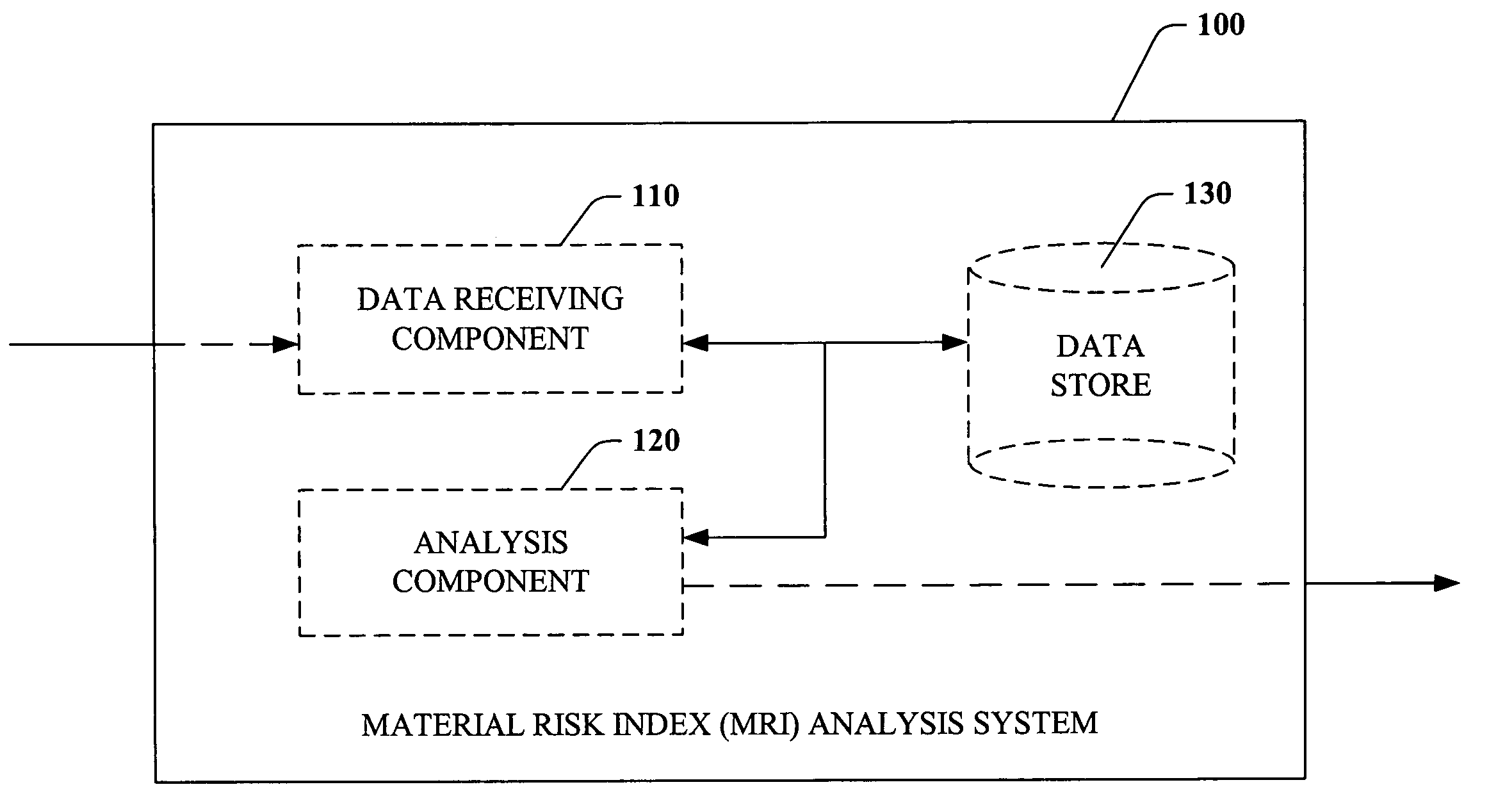

Systems and methods for automatically determining and/or inferring component end of life (EOL)

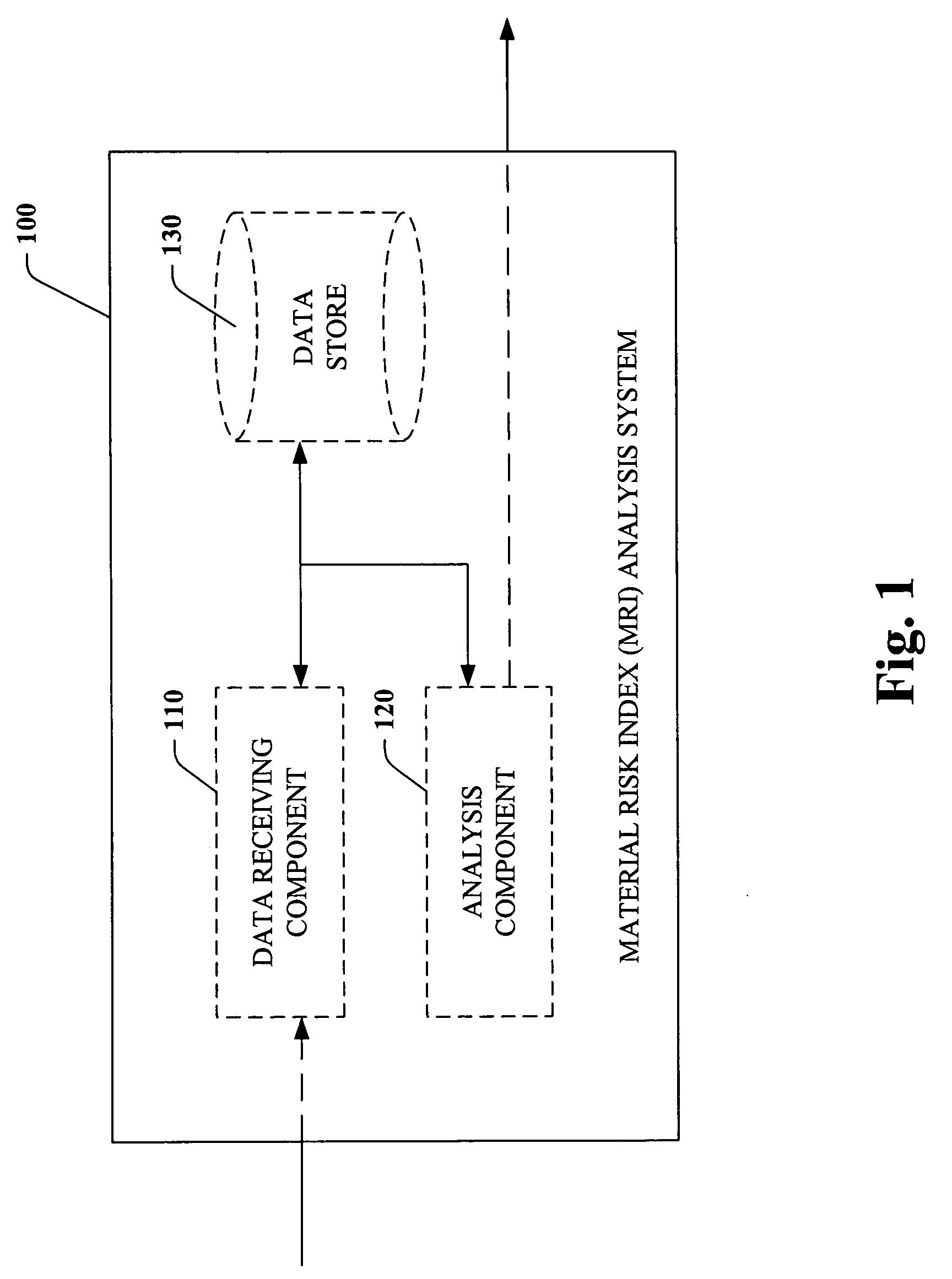

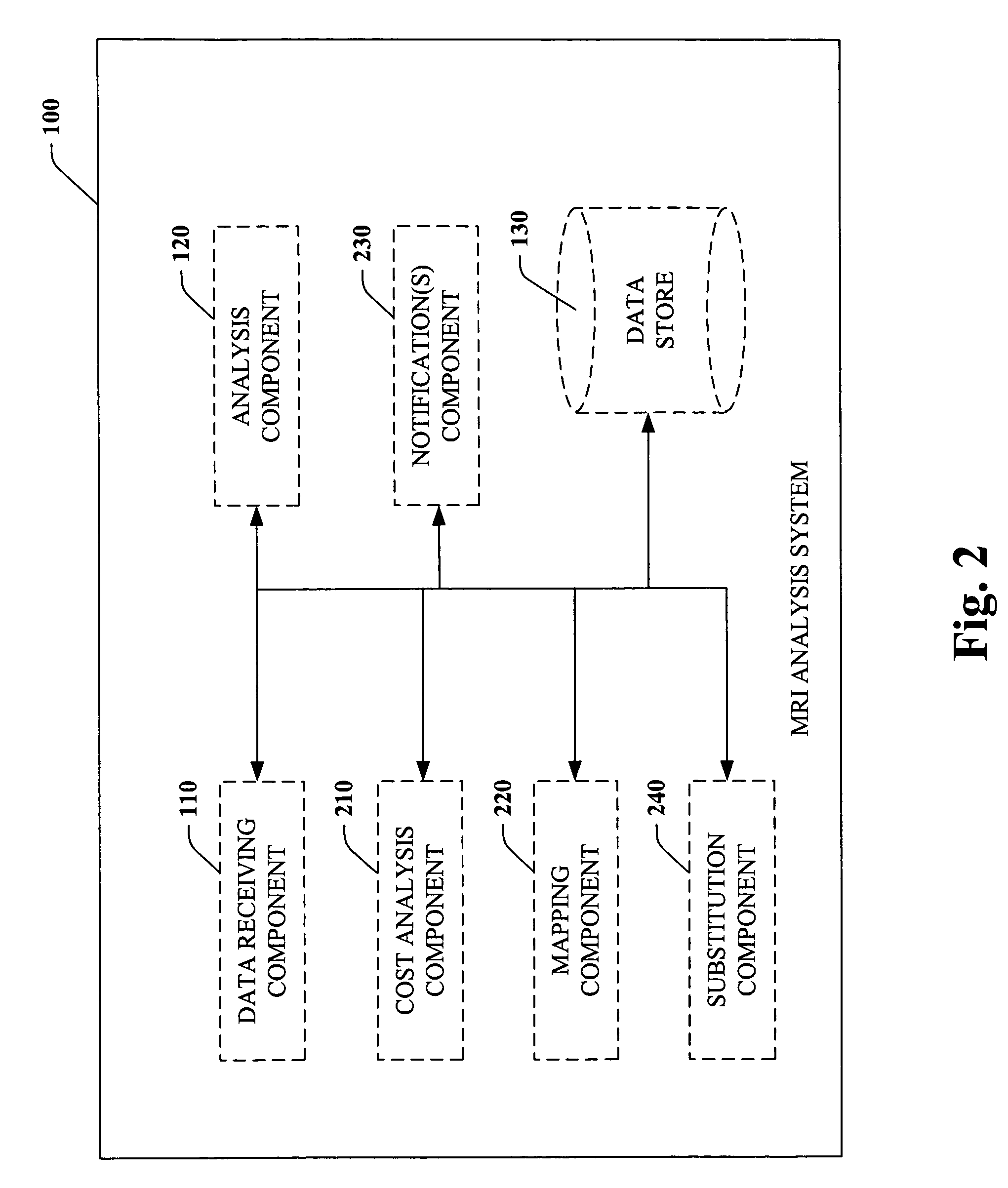

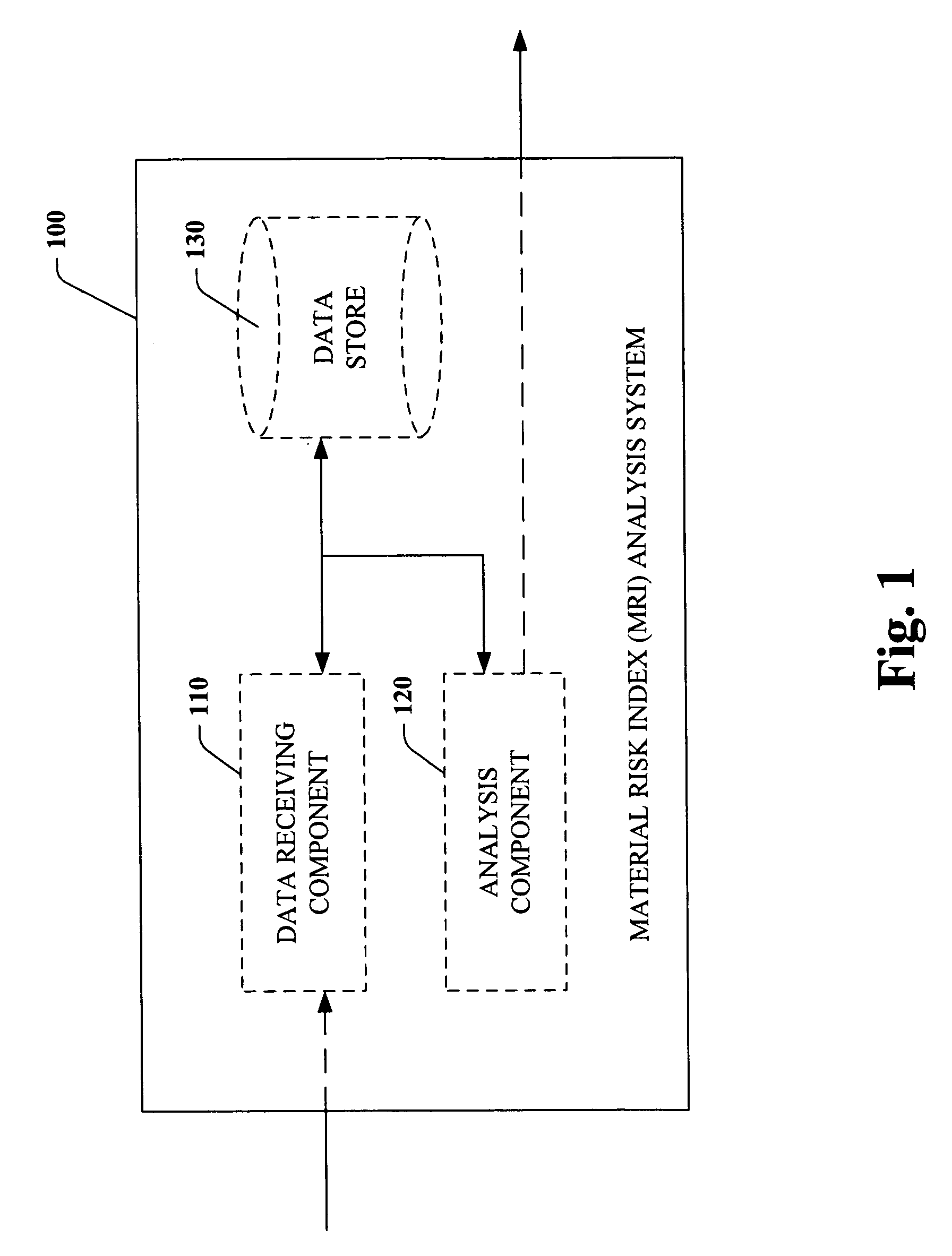

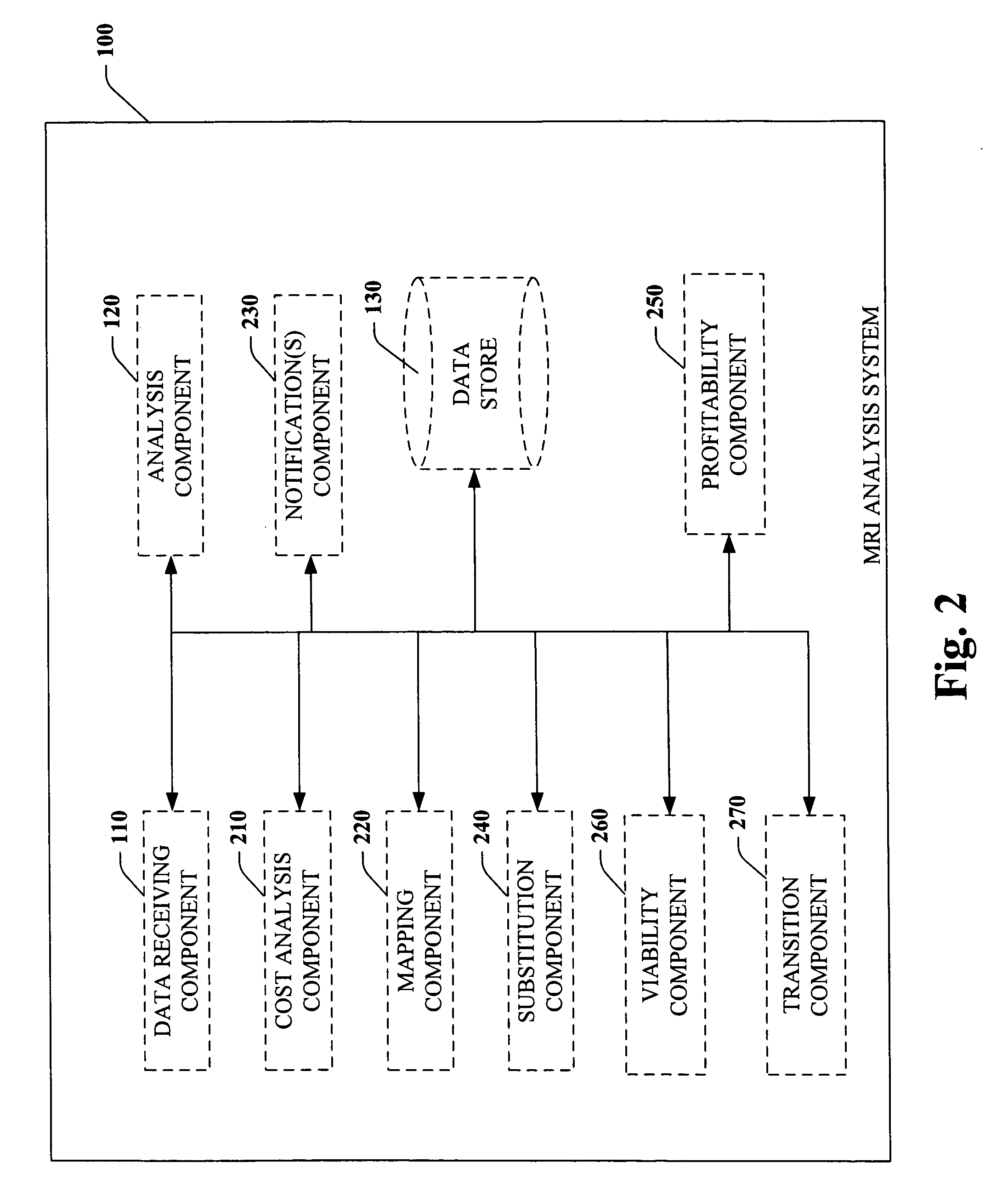

InactiveUS20050187744A1Facilitates proactively maintaining product life-cyclesFacilitates componentComputation using non-denominational number representationResourcesCost analysisObsolescence

The present invention relates to a system and methodology for facilitating managing product life cycle. A component that determines relevance of components to a product; an analyzing component that determines, infers or predicts obsolescence, level of risk to EOL of a subset of the components. A substitution component that identifies replacement components and suppliers for the subset of components. A cost analysis component that determines material / components cost savings, and redesign cost implementation and / or redesign cost avoidance.

Owner:ROCKWELL AUTOMATION TECH

Systems and methods for automatically determining and/or inferring component end of life (EOL)

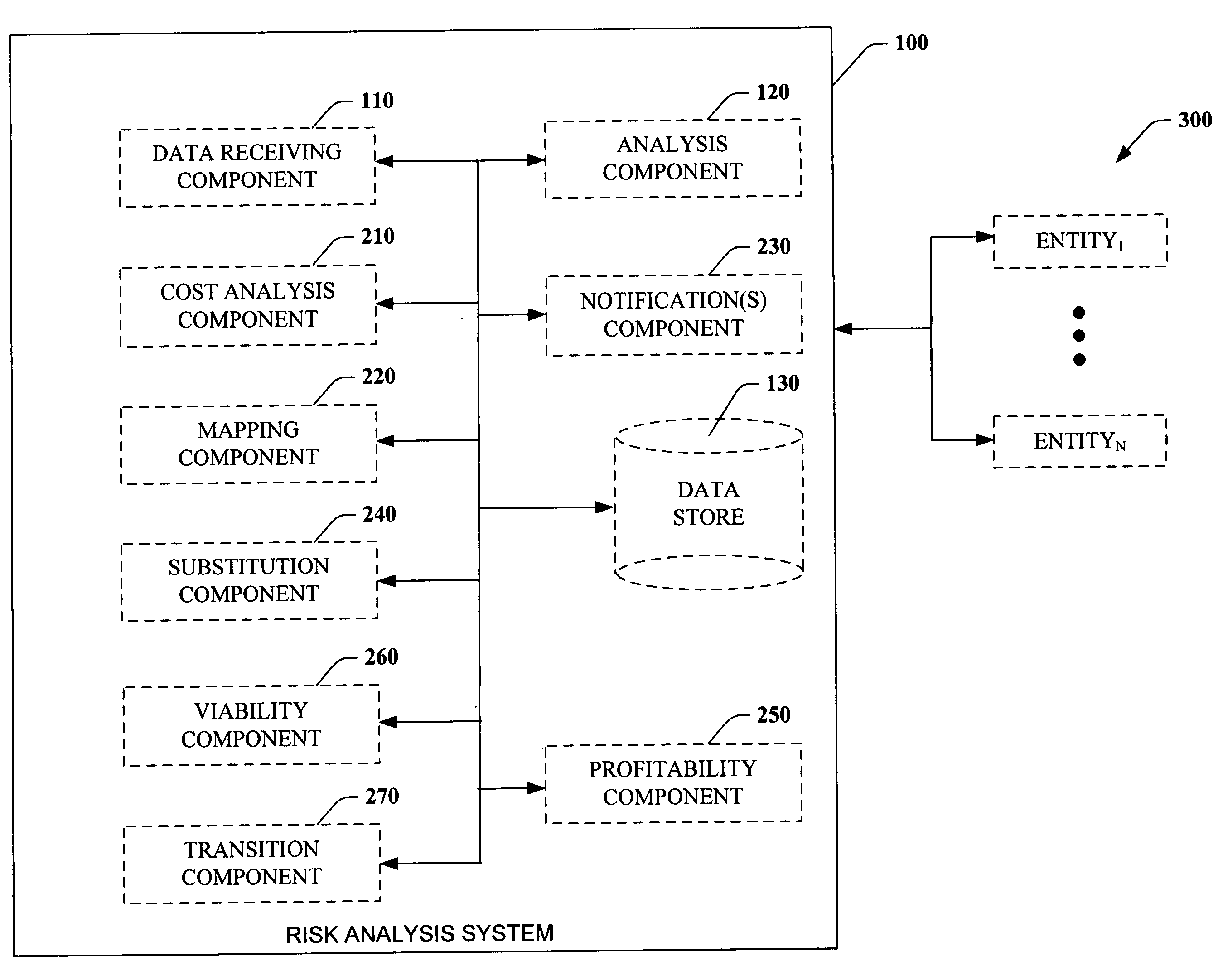

InactiveUS7672921B1Facilitates proactively maintaining product life-cyclesFacilitates componentDigital computer detailsResourcesCost analysisObsolescence

The invention relates to a system and methodology for facilitating managing product life cycle. A component that determines relevance of components to a product; an analyzing component that determines, infers or predicts obsolescence, level of risk to EOL of a subset of the components. A substitution component that identifies replacement components and suppliers for the subset of components. A cost analysis component that determines material / components cost savings, and redesign cost implementation and / or redesign cost avoidance. A viability component that measures reliability of a component. A transition component that identifies components that require updating or replacement. A profitability component that determines the expected revenue derived from a component over its projected remaining life.

Owner:ROCKWELL AUTOMATION TECH

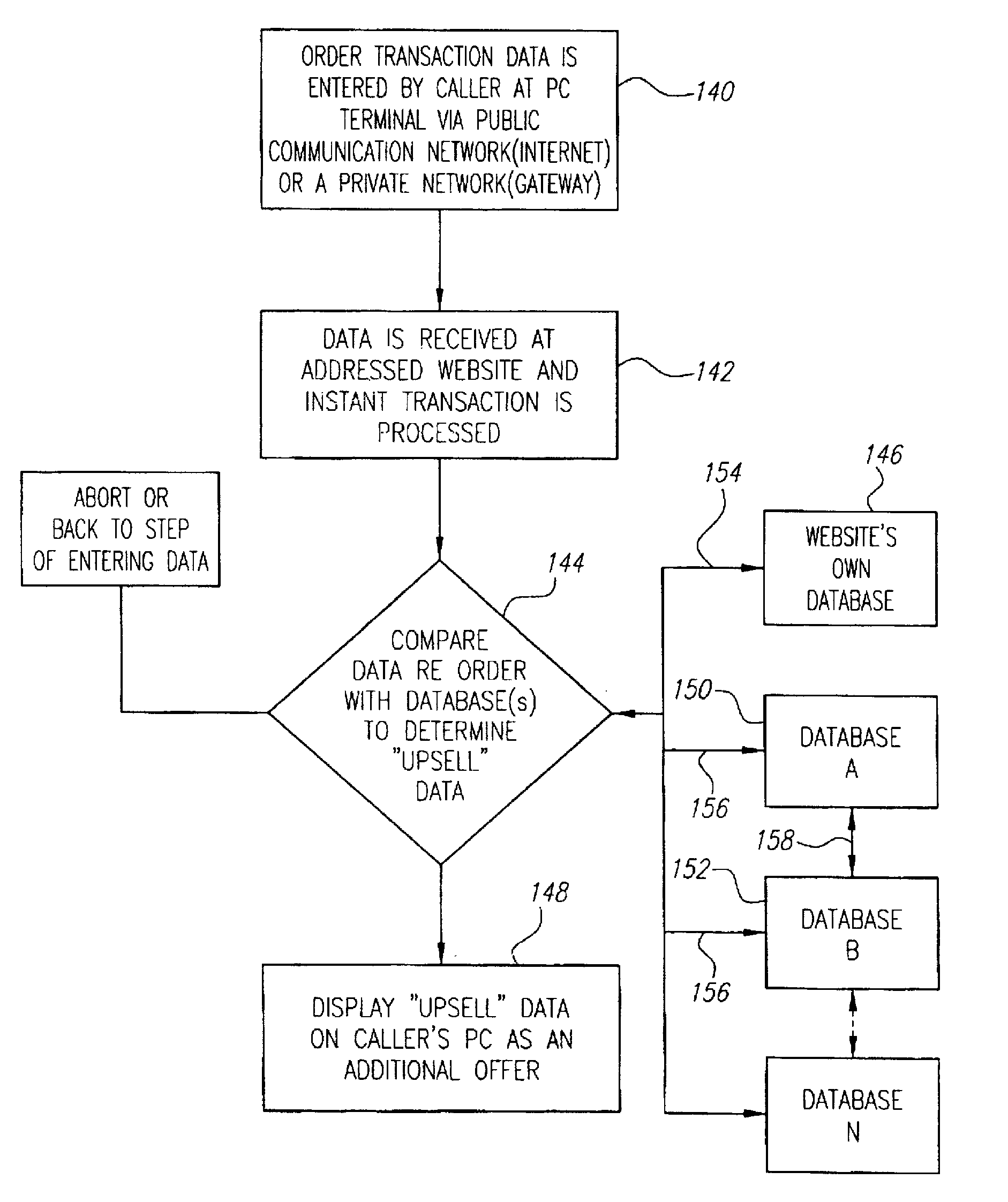

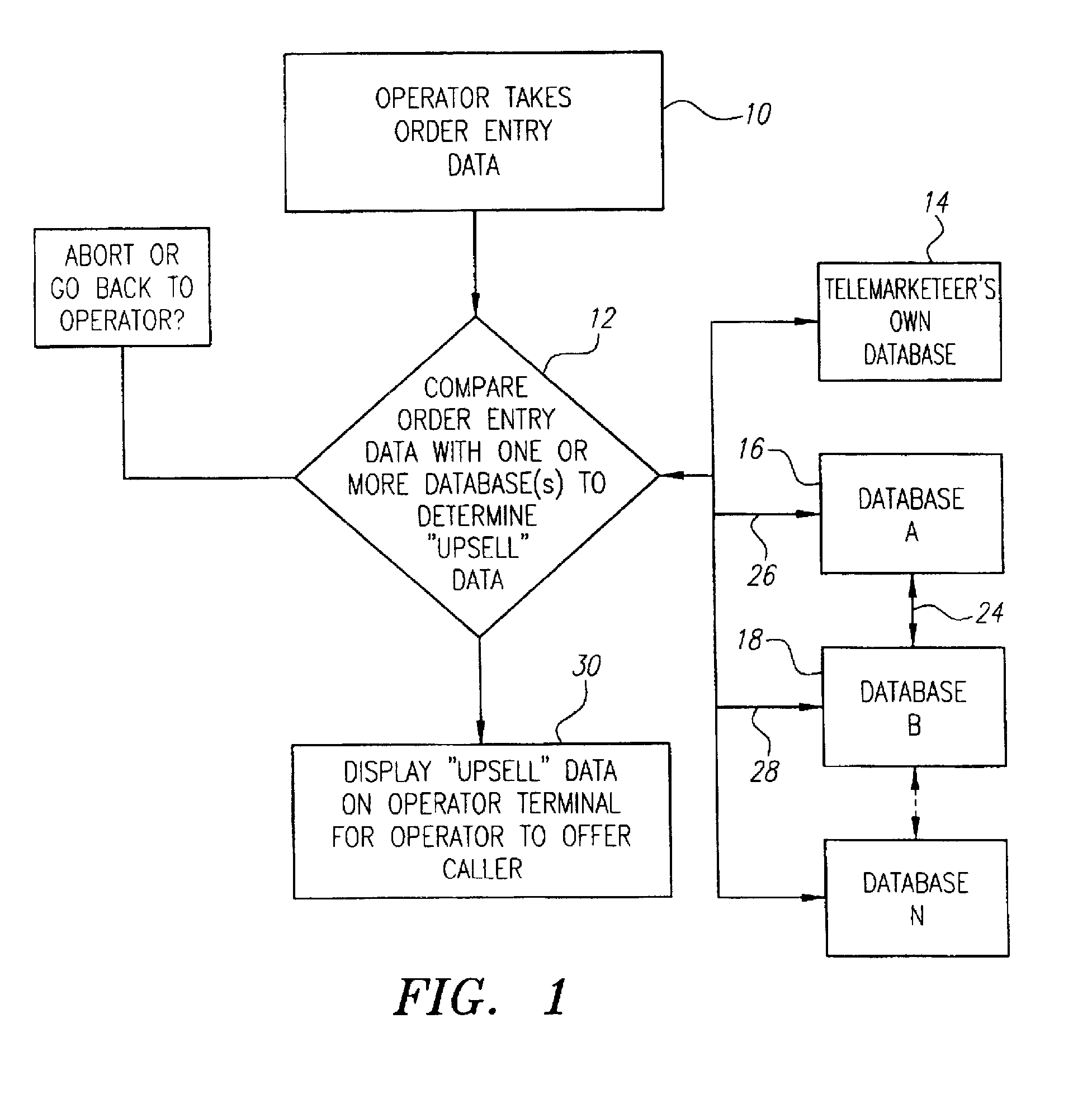

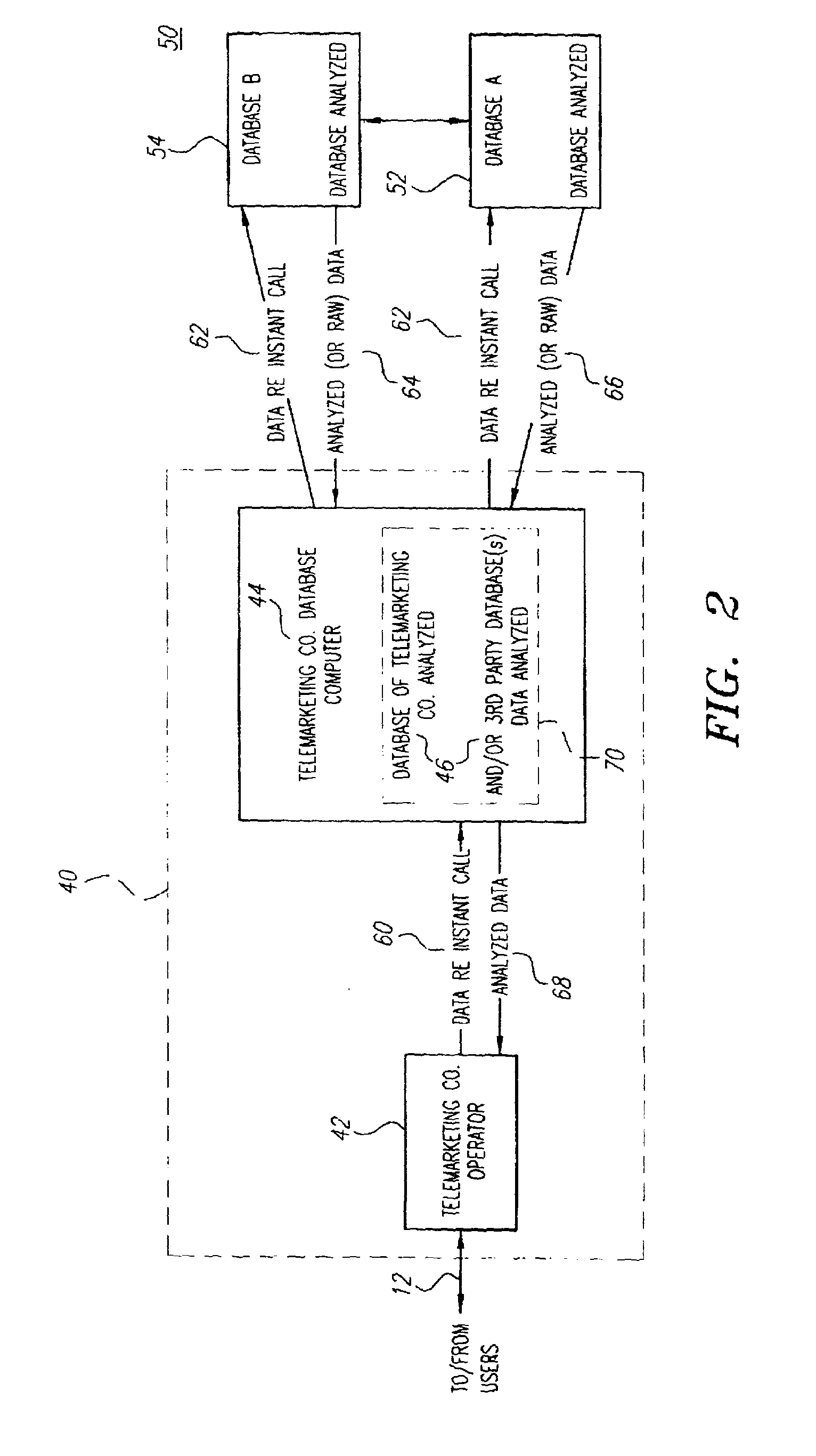

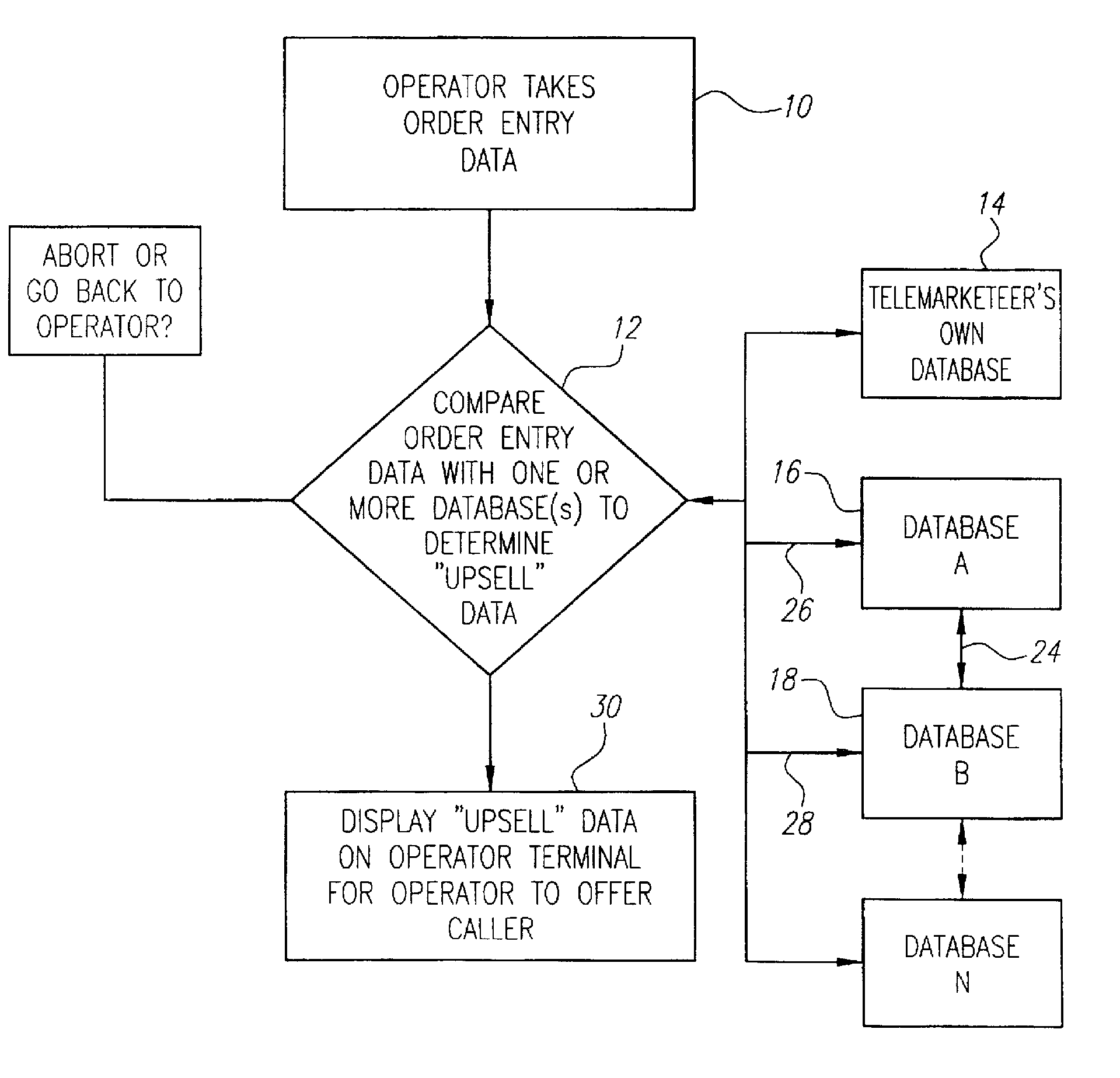

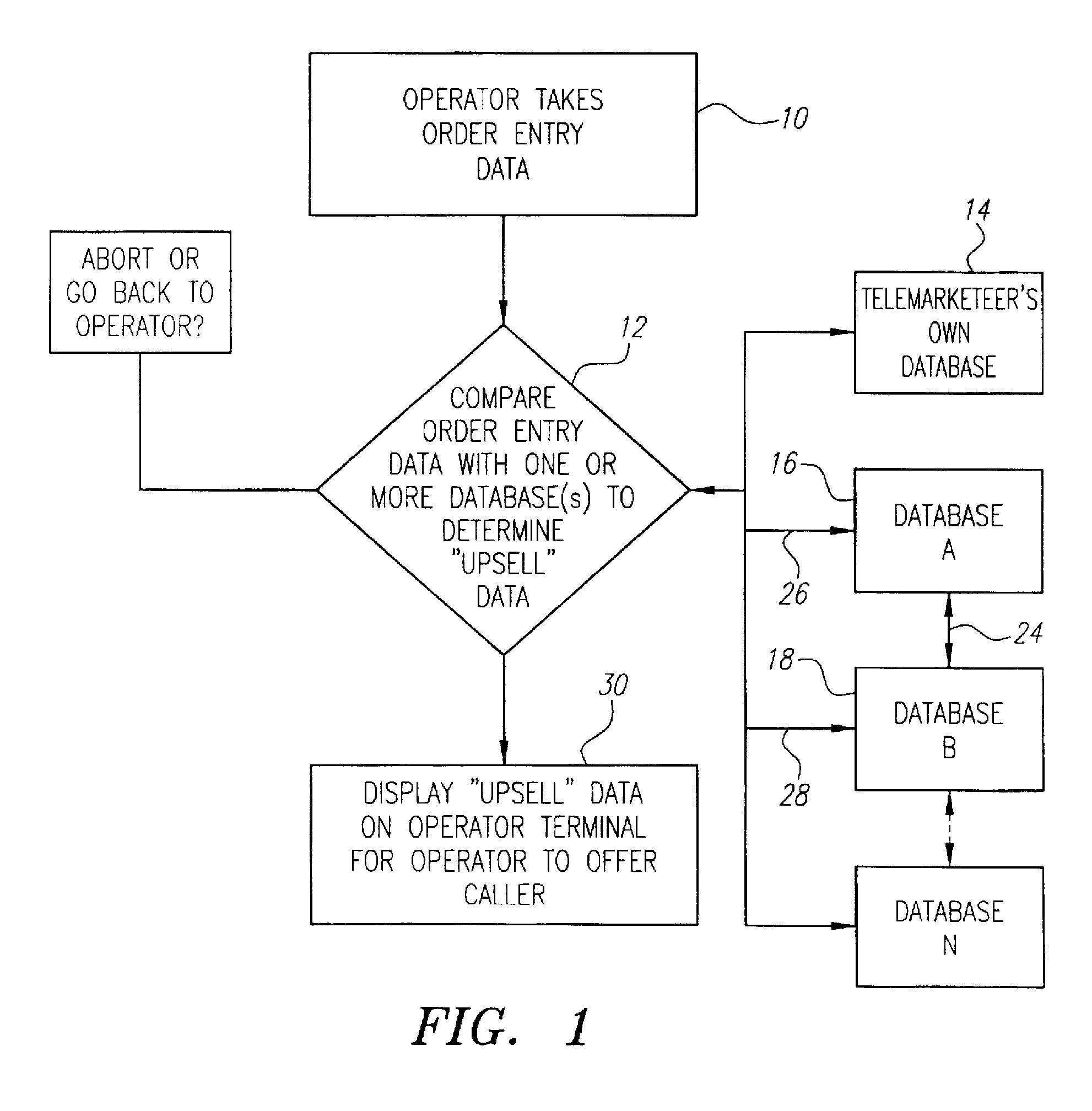

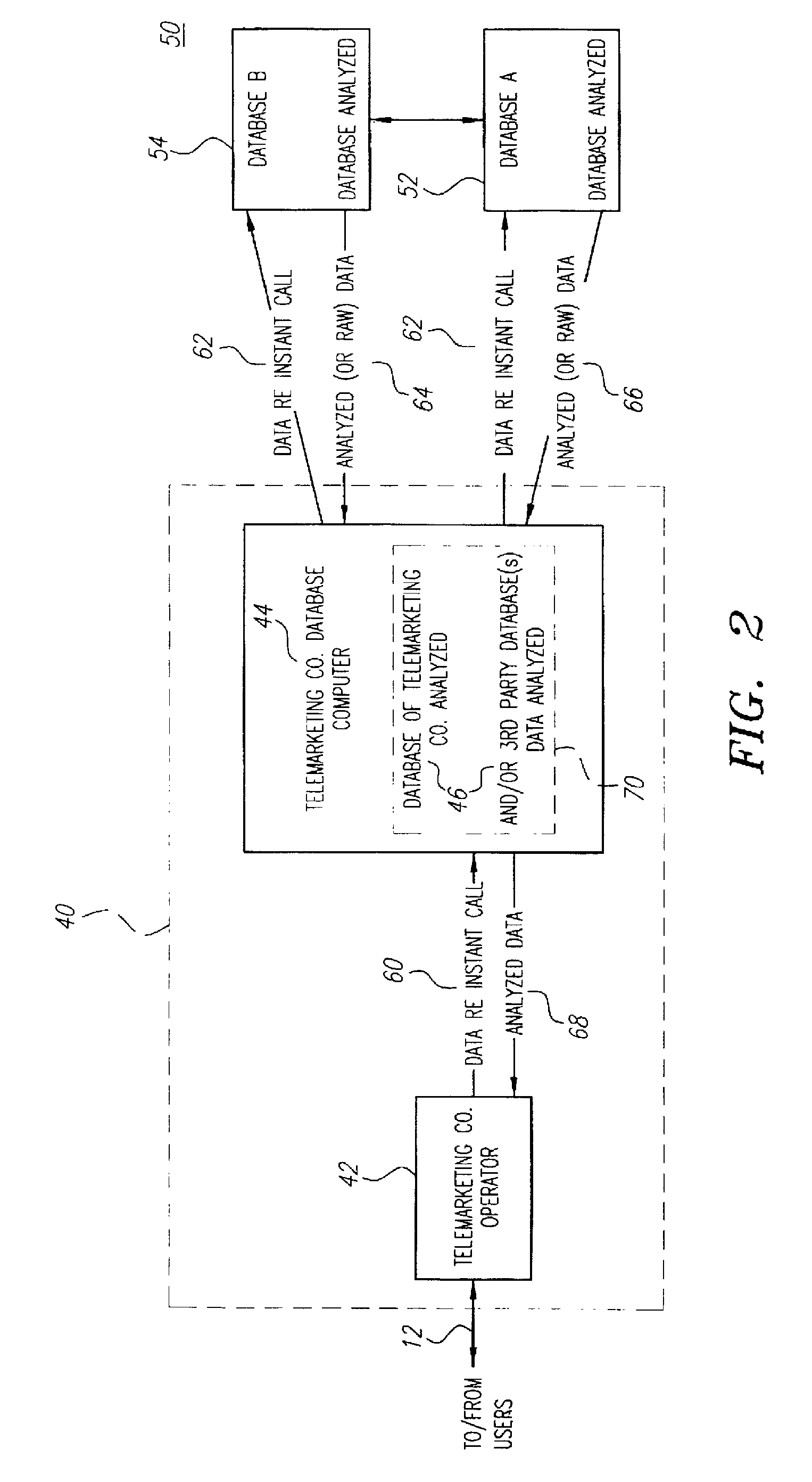

Method and system for providing real time offers to a user based on obsolescence of possessed items

InactiveUS7822647B1Increase probabilityIncrease profitabilityDigital data information retrievalDiscounts/incentivesWeb siteThird party

In a remote communication environment, a method for real-time presentation of information to one or more users accessing one or more websites using an electronic communications device. Various aspects of the method comprise at least the following. Communication is established via the electronic communications device between the user and the website to conduct one or more primary transactions. One or more electronic identifiers associated with the user are obtained. One or more further or additional data elements related to the user are obtained from a third party using the at least one electronic identifier. Based at least on the electronic identifier and the further data element, the information is selected for presentation to the user in real time with the primary transaction. The information is presented to the user in real time with the primary transaction.

Owner:WEST CORPORATION

System and method for an immutable identification scheme in a large-scale computer system

ActiveUS20070260621A1FlexibilityMaintenanceDigital data information retrievalData processing applicationsSurvivabilityObsolescence

Systems and / or methods for storing and / or retrieving assets in connection with an extremely large scale computer storage system are provided. An asset catalog may comprise a plurality of asset catalog entries stored according to at least one schema and corresponding to a plurality of assets. A storage architecture may be capable of storing the plurality of assets, with the storage architecture comprising a storage locator and a federator. An item identification scheme may be capable of providing identifiers to reference, locate, and / or access said assets and / or said asset catalog entries stored in the asset catalog in the storage architecture. The computer storage system may be scalable essentially without limitation while maintaining asset storage and retrieval flexibility and substantially obsolescence-proof survivability of assets.

Owner:LOCKHEED MARTIN CORP +1

System and method for immutably storing electronic assets in a large-scale computer system

InactiveUS20070260620A1Large scaleExtreme flexibilityData processing applicationsDigital data information retrievalSurvivabilityObsolescence

Systems and / or methods for storing and / or retrieving assets in connection with an extremely large scale computer storage system are provided. An asset catalog may comprise a plurality of asset catalog entries stored according to at least one schema and corresponding to a plurality of assets. A storage architecture may be capable of storing the plurality of assets, with the storage architecture comprising a storage locator and a federator. An item identification scheme may be capable of providing identifiers to reference, locate, and / or access said assets and / or said asset catalog entries stored in the asset catalog in the storage architecture. The computer storage system may be scalable essentially without limitation while maintaining asset storage and retrieval flexibility and substantially obsolescence-proof survivability of assets.

Owner:LEIDOS INNOVATIONS TECH INC +1

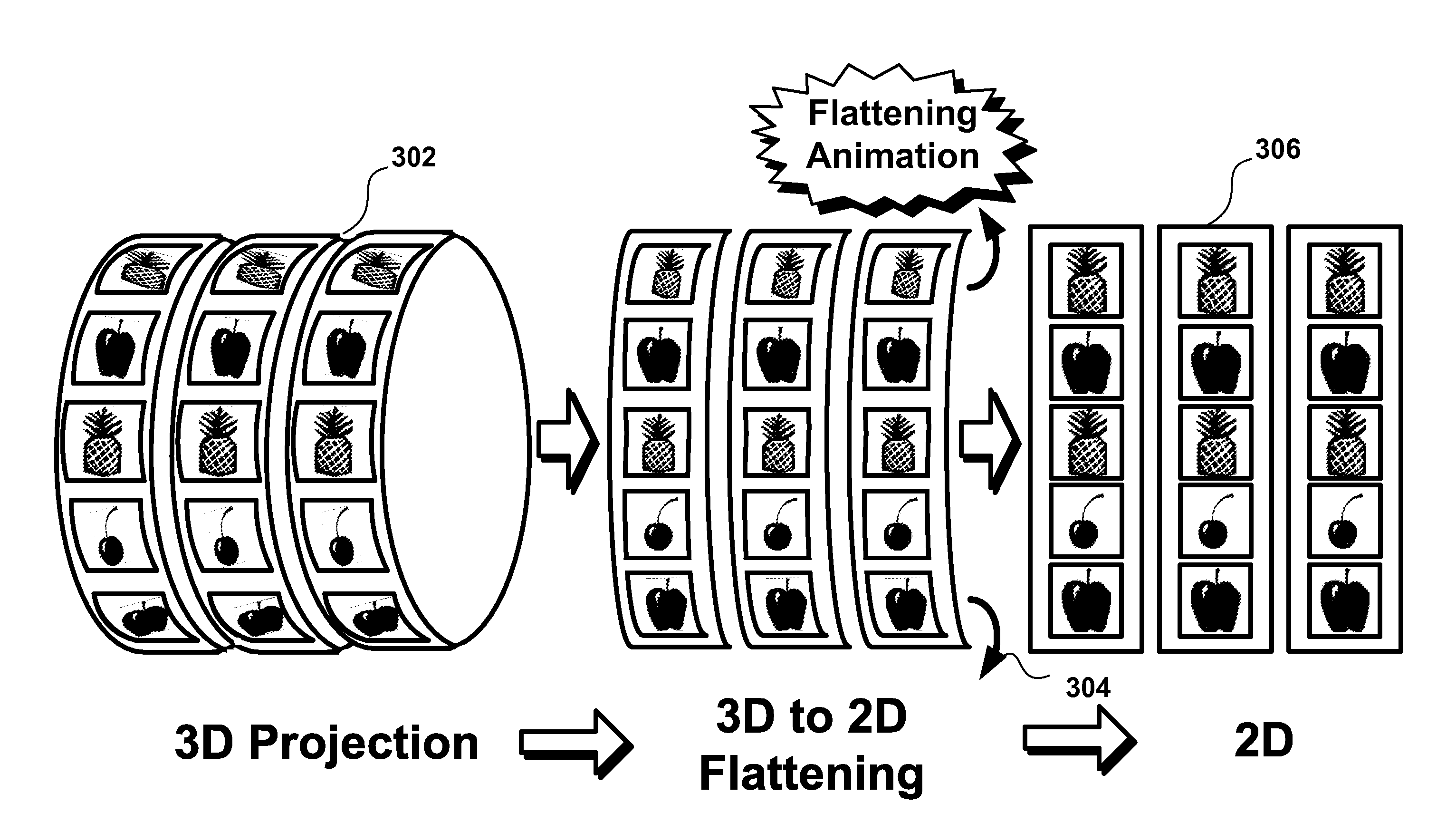

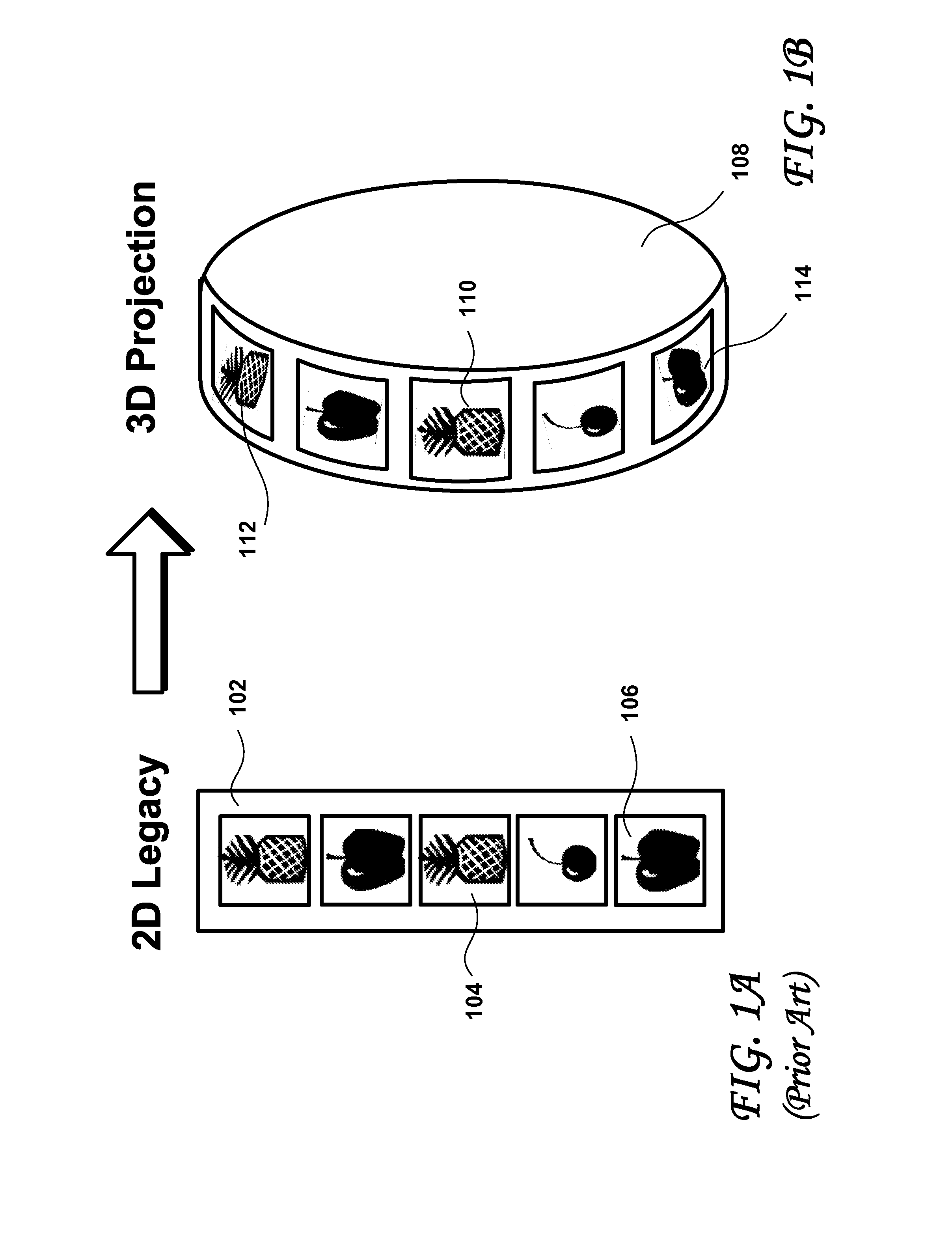

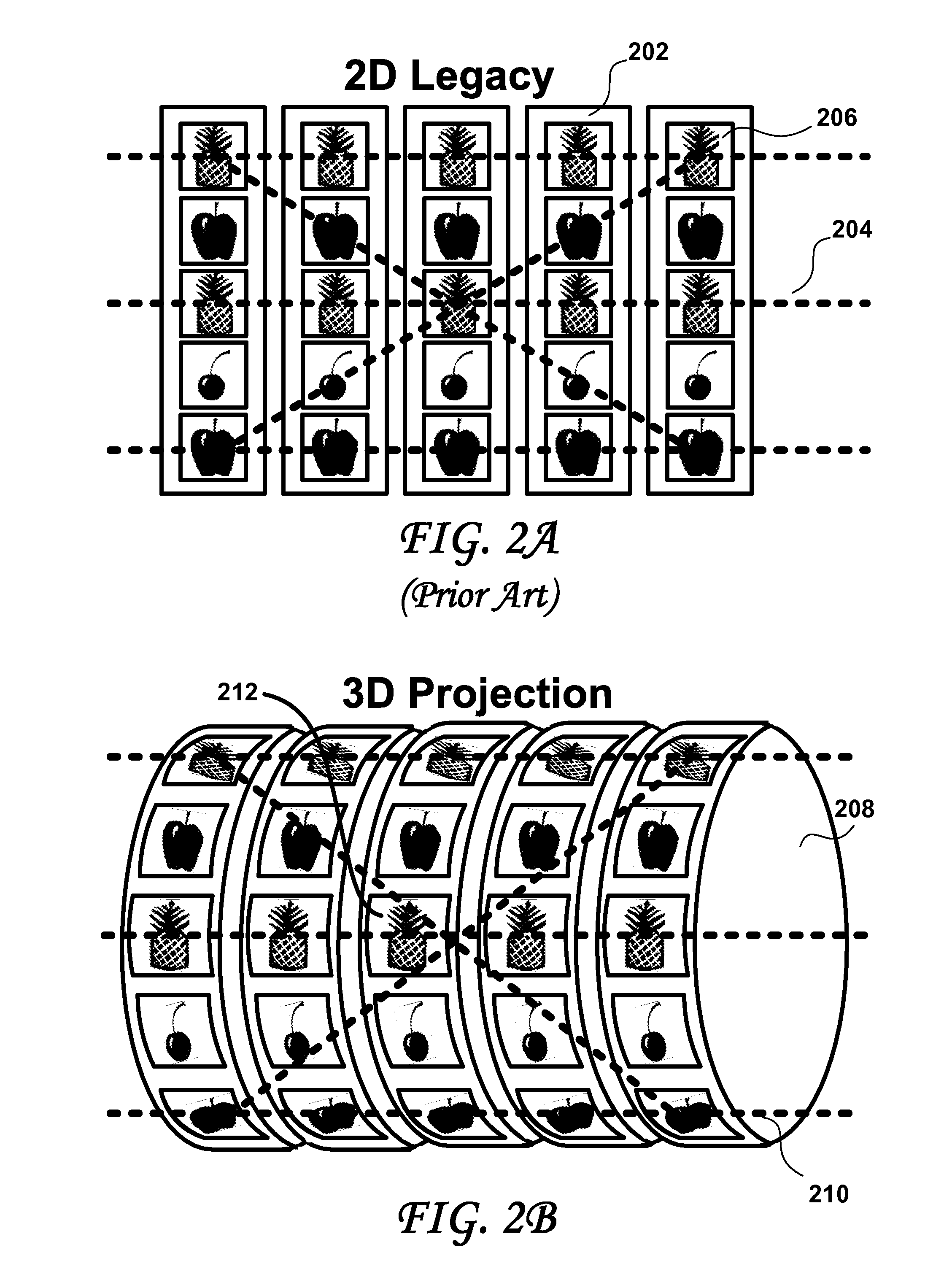

3D rendering of 2D legacy game assets

InactiveUS20080182647A1Selectable degree of opacitySelectable degree of transparencyApparatus for meter-controlled dispensingVideo gamesUpgradeObsolescence

The 3D Rendering of 2D Legacy Game Assets upgrade method of the present invention represents a means of un-retiring once popular video reel slot machine themes by projecting their 2D game symbols onto virtual reels mapped into a full 3D environment. Because this upgrade strategy makes use of original 2D legacy game artwork and does not require graphic artists to make modifications, it is both easy to implement and cost effective. The conversion process may be fully automated, allowing a mass upgrade of thousands of game titles on a relatively short timetable. Games created via the present 3D Rendering of 2D Legacy Game Assets upgrade method will allow players to enjoy the classic feel and realistic reel spinning action of mechanical reel games while not missing out on advanced features of video reel games like multi-line play and touch screen interactivity. In addition to combining never before possible feature groupings and rescuing a wealth of legacy games from obsolescence, these upgraded virtual reel games and their dynamic 3D assets represent a major technological advance in the slot machine industry as well as a means to rapidly increase the library of games available for download to slot machines.

Owner:IGT

Phase-transition self-temperature-regulating heat-preserving facing brick of external wall and manufacturing method thereof

InactiveCN101705741AHigh quality light weight, compressive strengthLight in massCovering/liningsSolid waste managementBrickSilicon oxide

The invention relates to a phase-transition self-temperature-regulating heat-preserving facing brick of an external wall, which is an integrated structure compacted by a phase-transition heat-preserving layer and an inorganic facing layer, wherein the phase-transition heat-preserving layer is mixed by proportion and compacted by hull-type expanded perlite heat-preserving aggregates, phase-transition temperature-regulating aggregates and cements; the inorganic facing layer is mixed by quartz sand, calcium carbonate, calcium oxide, cement and silicon oxide powders; and the phase-transition temperature-regulating aggregate is made of phase-transition cores and encapsulated hulls. The manufacturing method not only effectively solves the encapsulation problem of the phase-transition material, leads the prepared phase-transition self-temperature-regulating heat-preserving facing brick of the external wall to have excellent heat-preserving performance, waterproof performance and permanent anti-ageing performance, but also radically solves the obsolescence of thermo-physical property and the leakage problem of phase-transition material in the circulation process. The facing brick has the advantages of light weight, strong adhesion strength, large compressive strength, heat insulation, heat preservation, waterproof and moisture-proof performances, obvious energy-saving effect, and the like.

Owner:信阳天意节能技术股份有限公司

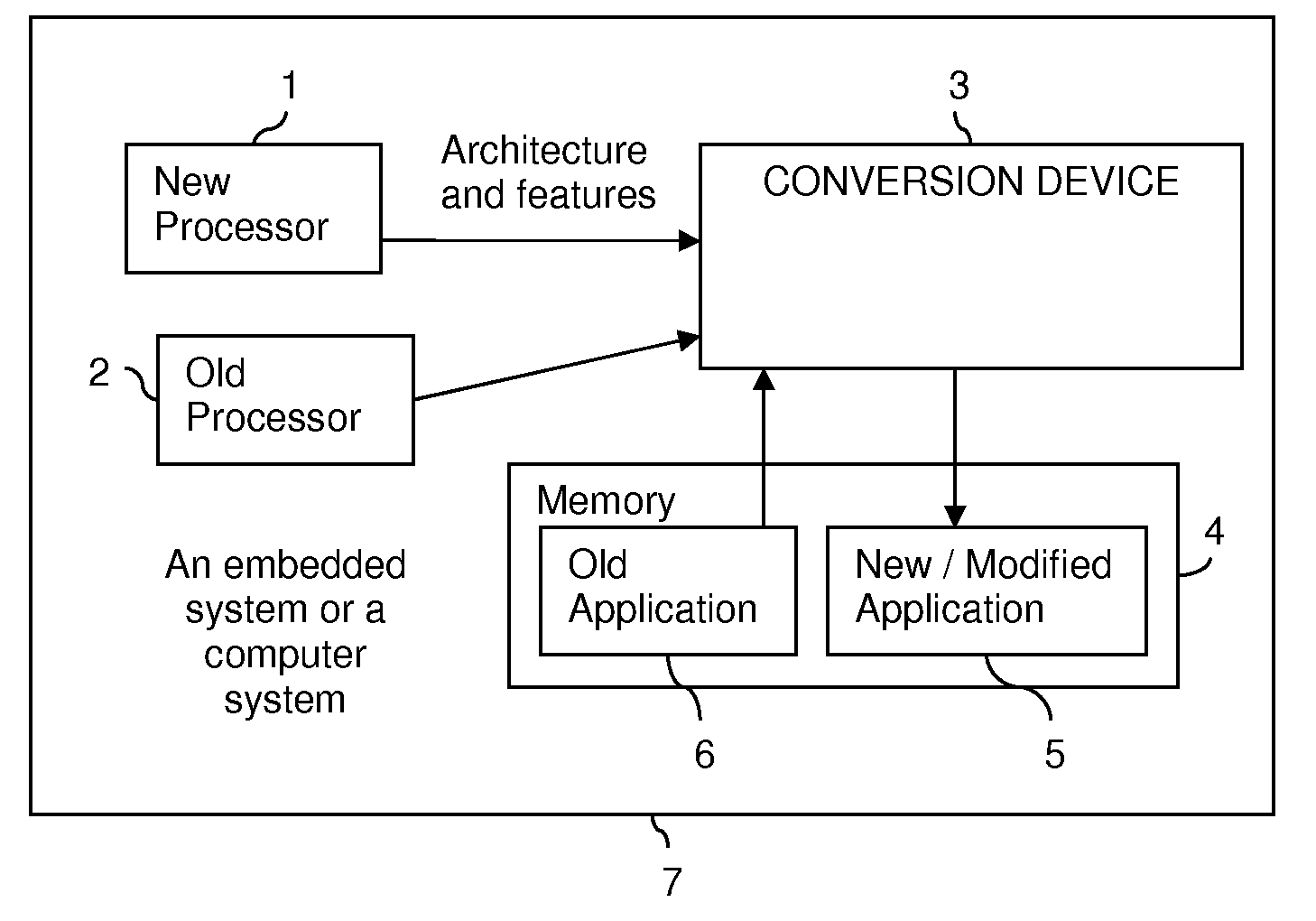

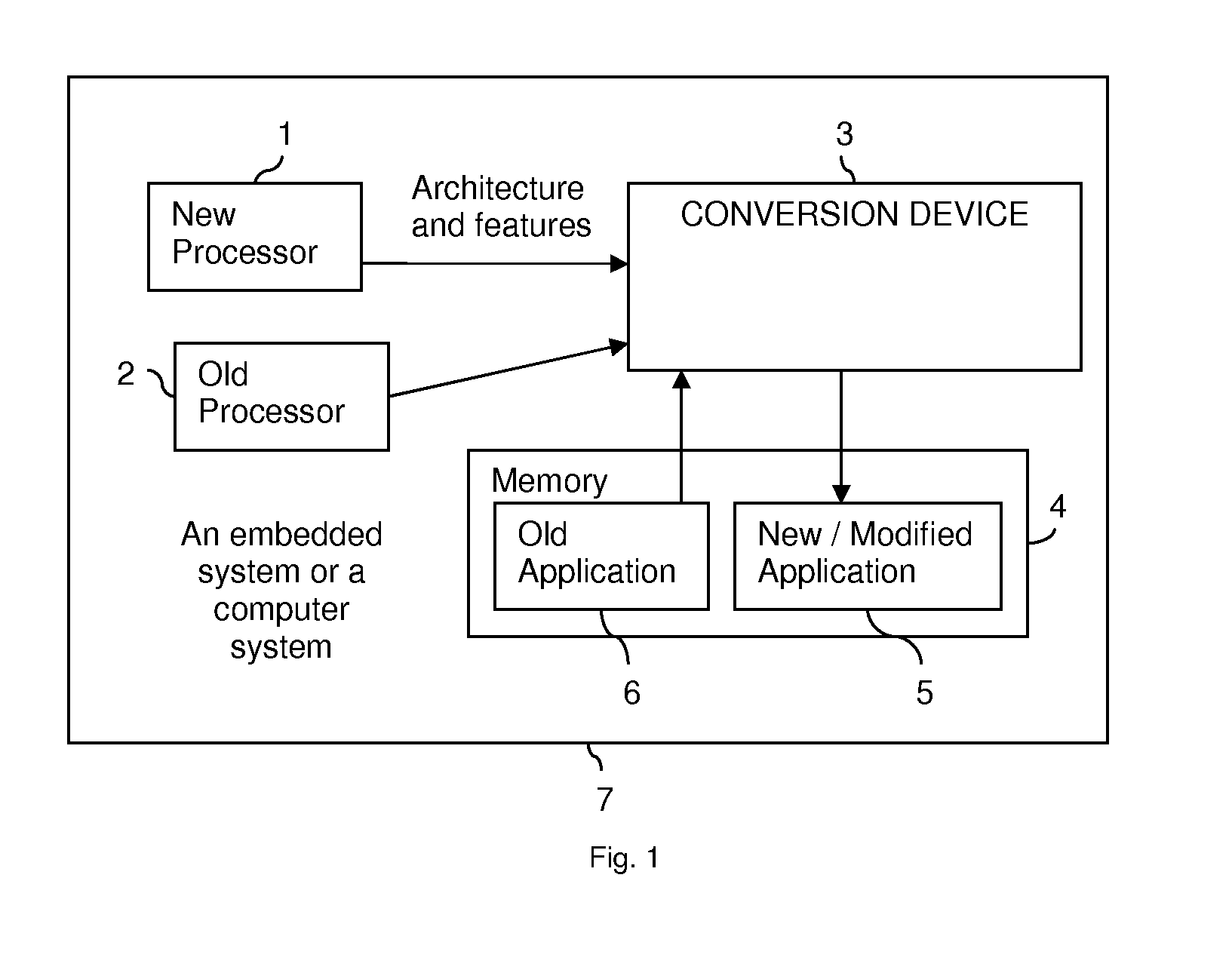

Mechanism to enable plug-and-play hardware components for semi-automatic software migration

A method and device for dealing with problem of software-incompatibility or obsolescence of hardware. The method includes copying of information regarding architecture and other features from hardware components, conversion of existing hardware-specific software to suit architecture of new hardware component and transmittal of adapted software to new hardware. The method and device provide for enabling semi automatic migration of hardware-specific software between hardware components such as computer processors. This process of software migration, in turn, provides for effective transfer of functionality from one hardware component to the other. This novel process can be used for migration of software from one processor to the other.

Owner:KPIT TECH LTD

Methods and system for providing real time offers to a user based on obsolescence of possessed items

InactiveUS8078503B1Increase probabilityIncrease profitabilityDigital data information retrievalDiscounts/incentivesThird partyElectronic identification

Owner:WEST CORPORATION

Method and apparatus for defeating a mechanism that blocks windows

InactiveUS20050198587A1Enhanced informationRaise the possibilityTelevision system detailsDigital data information retrievalObsolescenceWorld Wide Web

In one embodiment, a computer program blocks windows categorized as bad windows, while allowing windows categorized as good windows to be displayed. The computer program may categorize a window by consulting one or more lists. In one embodiment, a list may be updated from time to time to optimize the computer program and prevent program-obsolescence. Techniques for defeating a window-blocking mechanism are also disclosed. In one embodiment, a computer program detects if a window is of a type that offers a product to a user. If so, the computer program provides a separate window containing information regarding the product. In one embodiment, a computer program detects if a user has a need for the computer program. If so, the user is informed of the efficacy of the computer program, which is then offered to the user.

Owner:CARHAMM

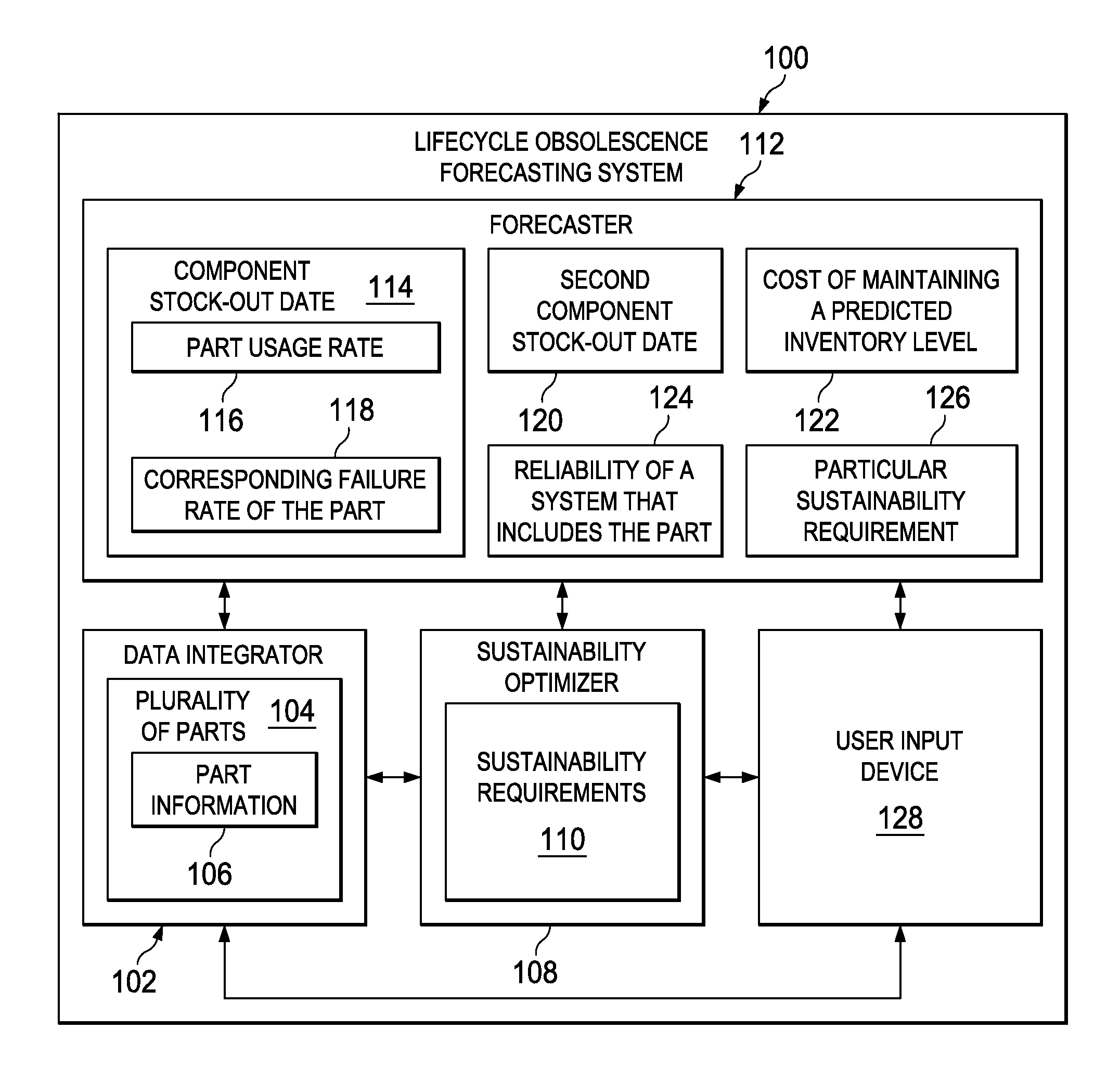

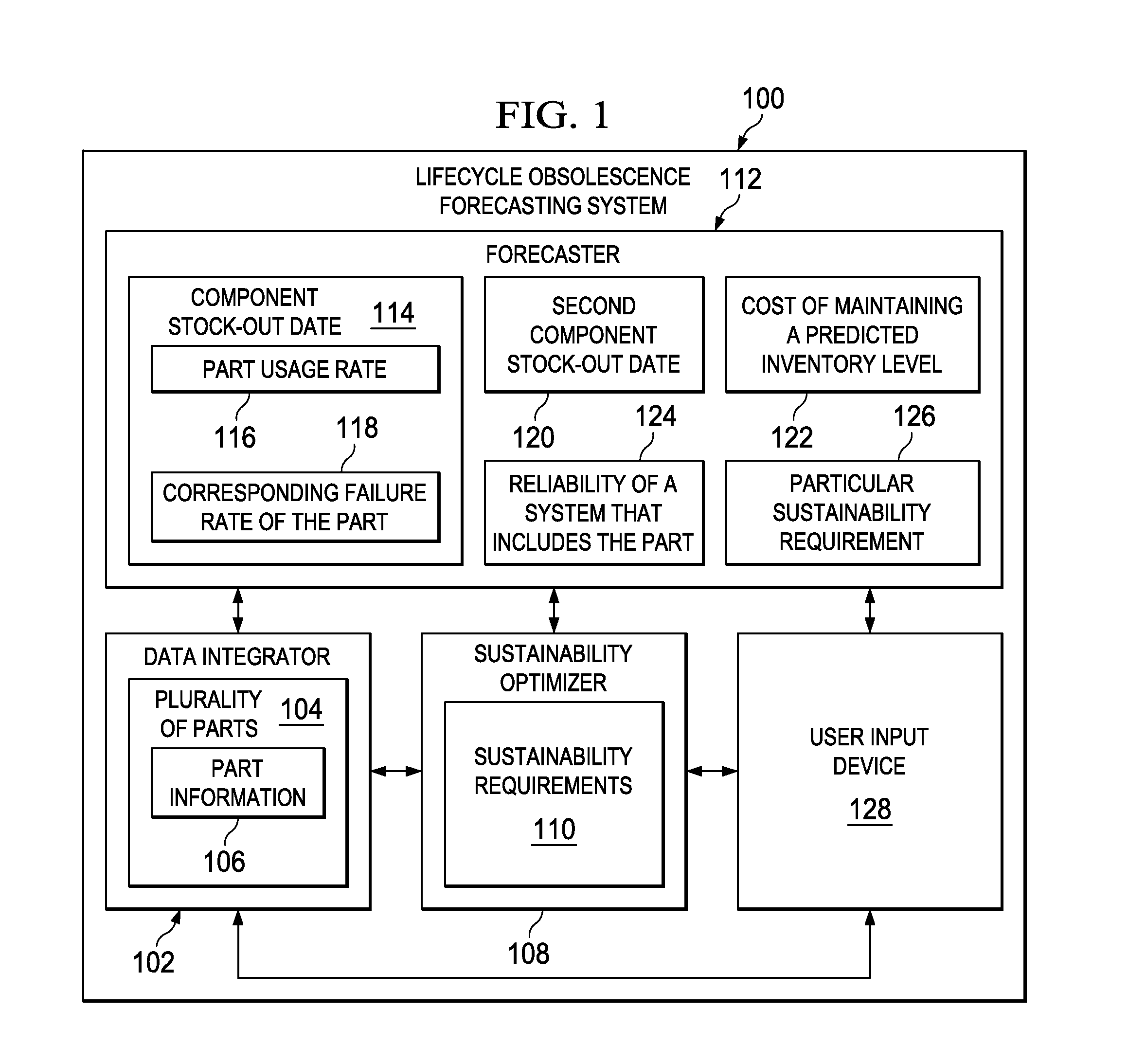

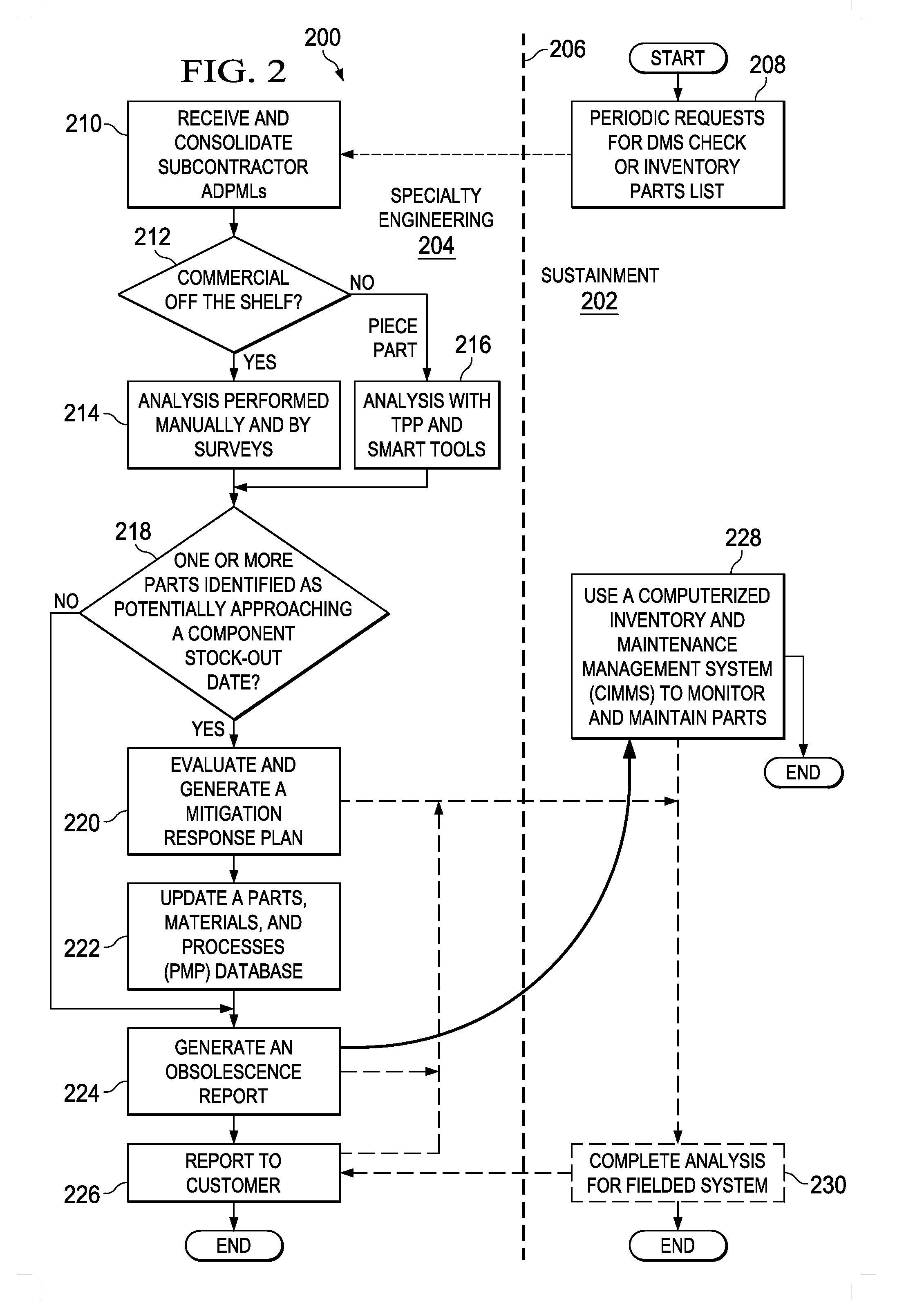

Lifecycle Obsolescence Forecasting Tool

A lifecycle obsolescence forecasting system. The system may include a data integrator configured to receive part information for a plurality of parts. The system may include a sustainability optimizer configured to receive one or more sustainability requirements for a part in the plurality of parts. The system may include a forecaster coupled to the data integrator and the sustainability optimizer, wherein the forecaster may be configured to analyze the part information and the one or more sustainability requirements to establish a component stock-out date for the part, wherein the component stock-out date may comprise a date when a last spare of the part is forecast to be removed from stock, and wherein the component stock-out date may be established as a function of at least the part usage rate and a corresponding failure rate of the part.

Owner:THE BOEING CO

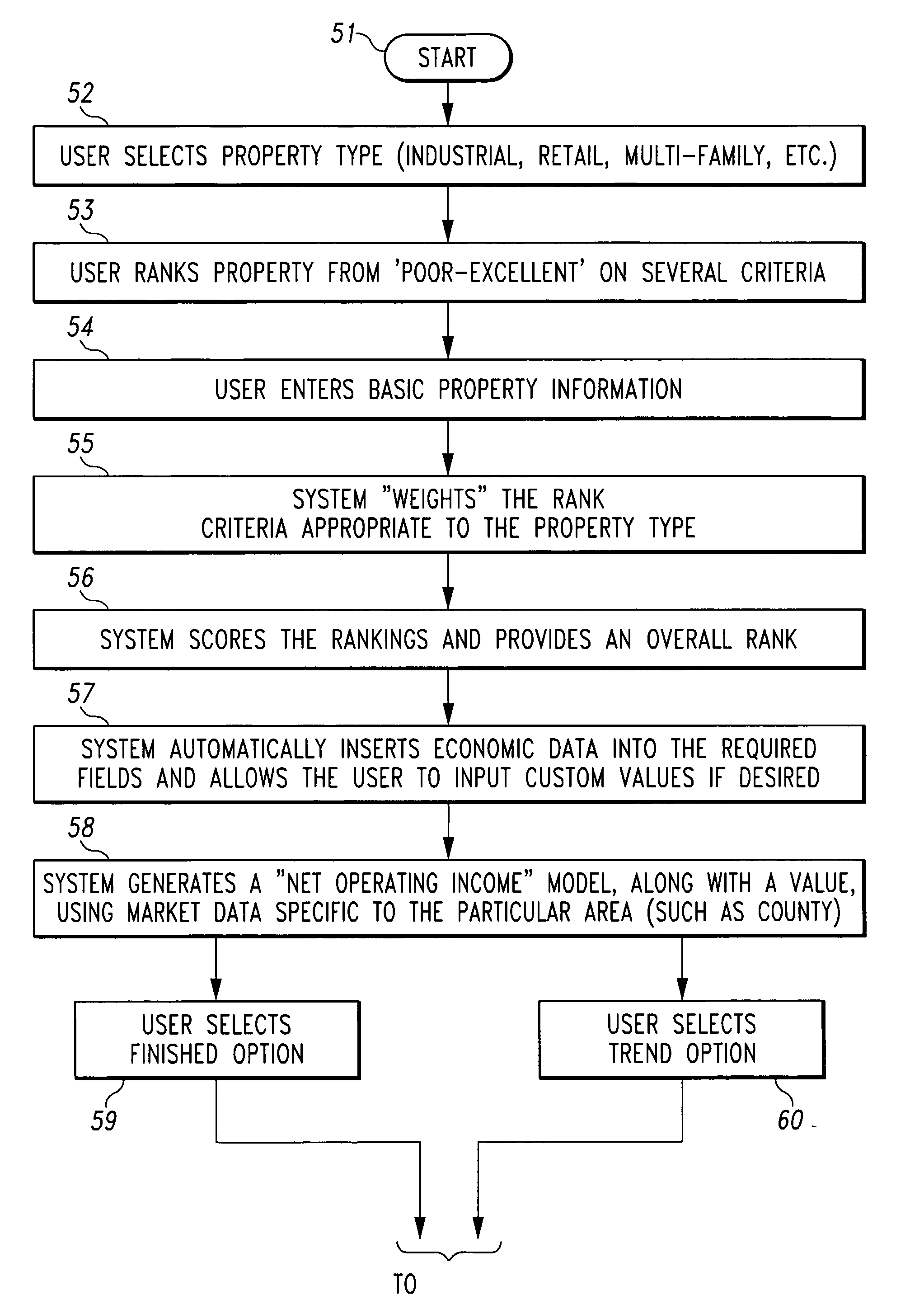

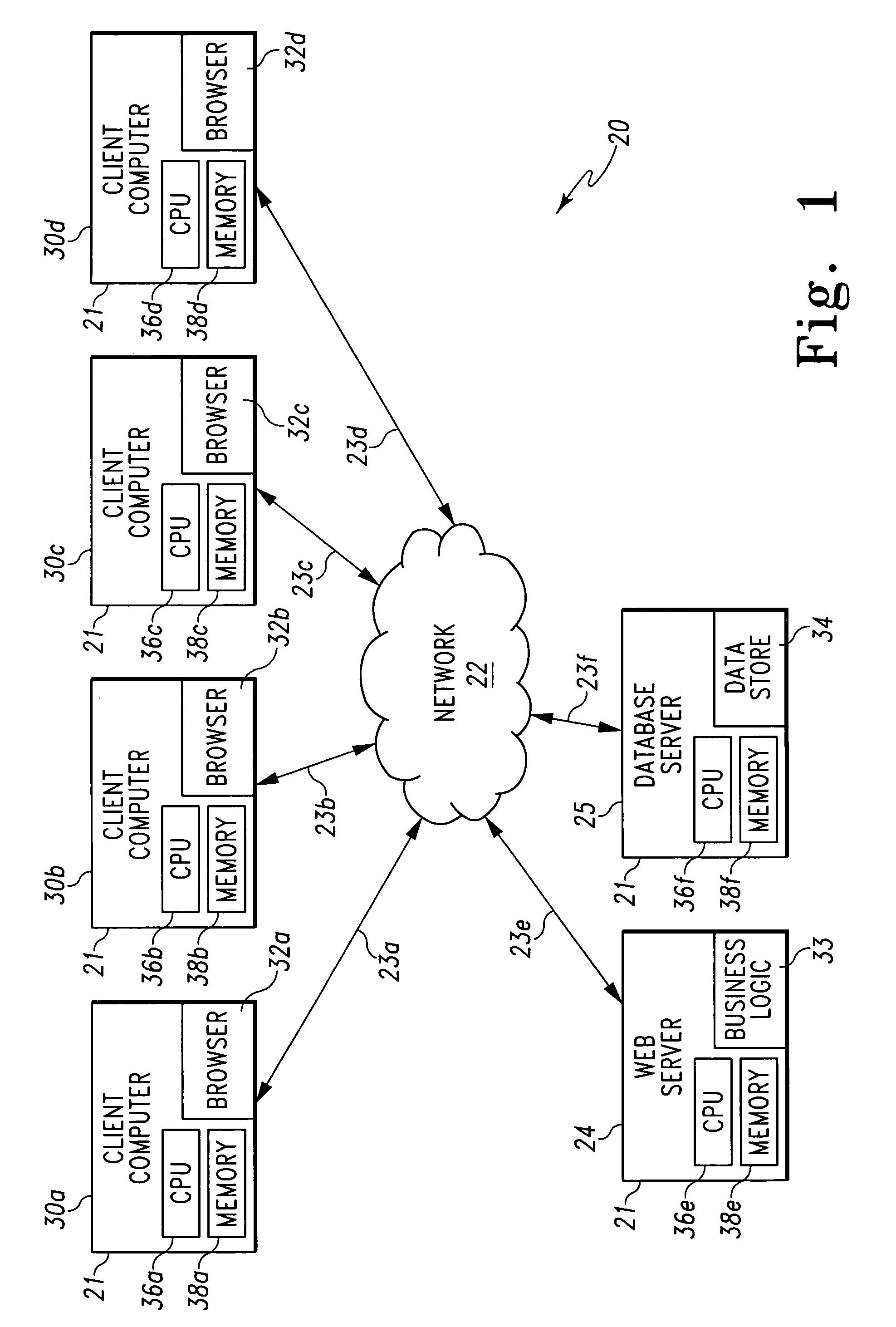

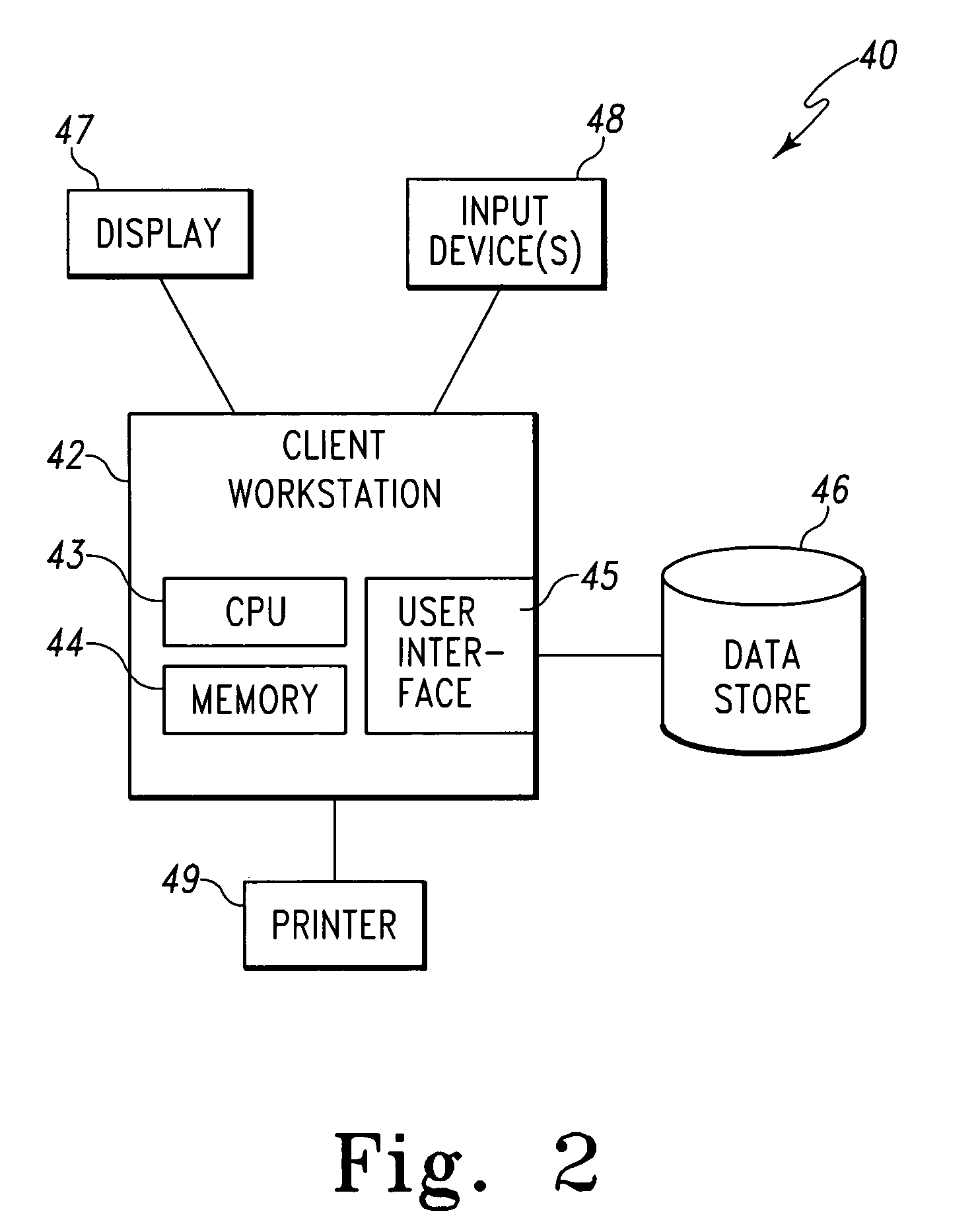

System and method for aiding commercial property assessment

A computer system and method is disclosed that aids assessors in valuing commercial real estate. To support their cost-based value, assessors use the system to generate an income-based value. The user inputs ranking criteria. The system has a database of rents, vacancy rates, expenses, and cap rates that are derived from the market and are specific for application to properties within the assessor's district. The system calculates an income value based on recommended or custom indicators. The system also aids assessors in accurately calculating obsolescence. After the user inputs requested data, the system brings up the trended income value, calculates a percent difference between the cost and income values, and offers an obsolescence analyzer test to determine if there is obsolescence. If there is obsolescence, the system instructs the user on the correct way to apply it, and if not, additional questions are offered to help identify the discrepancy.

Owner:ASSESSMENT ADVISORS LLC

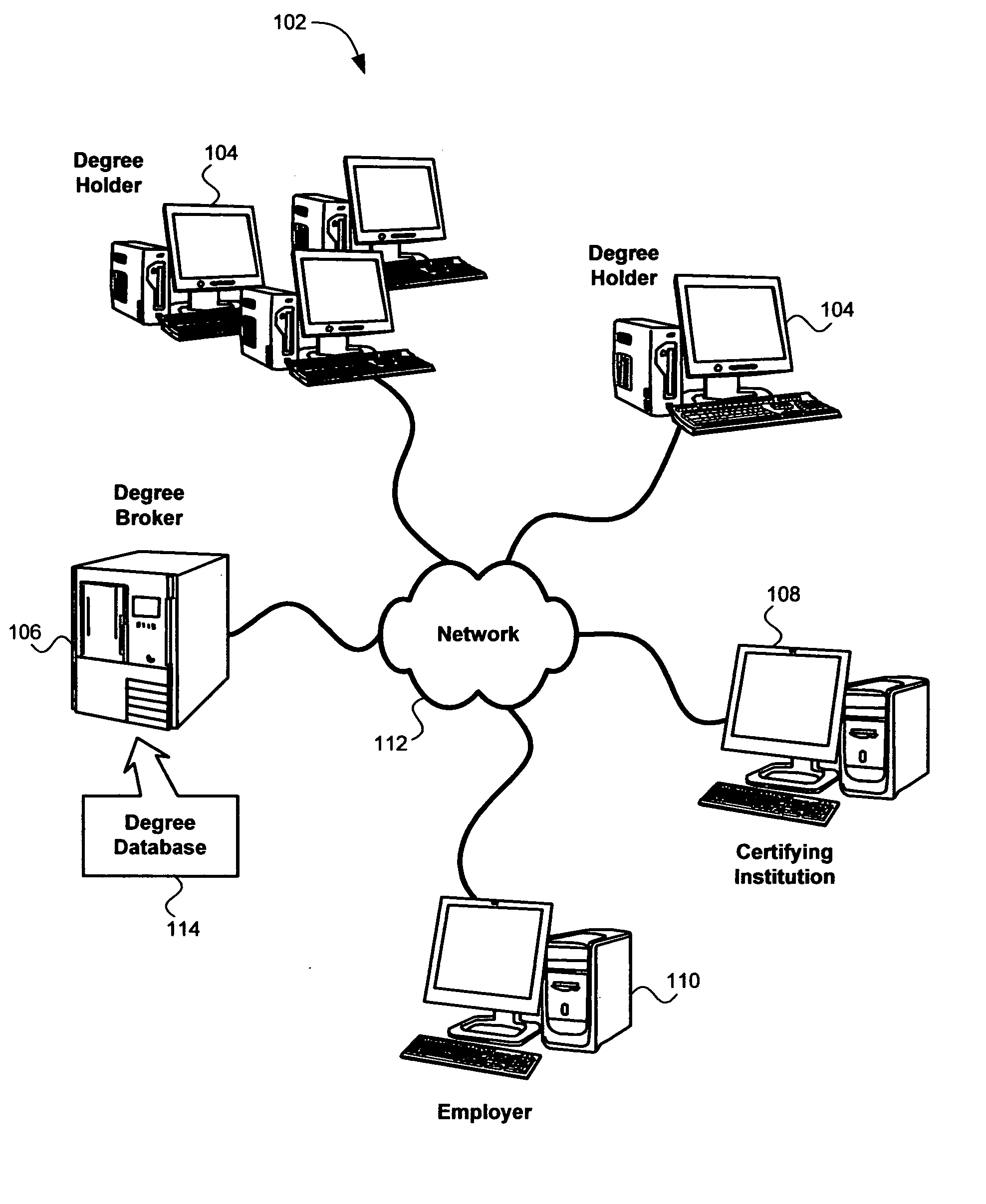

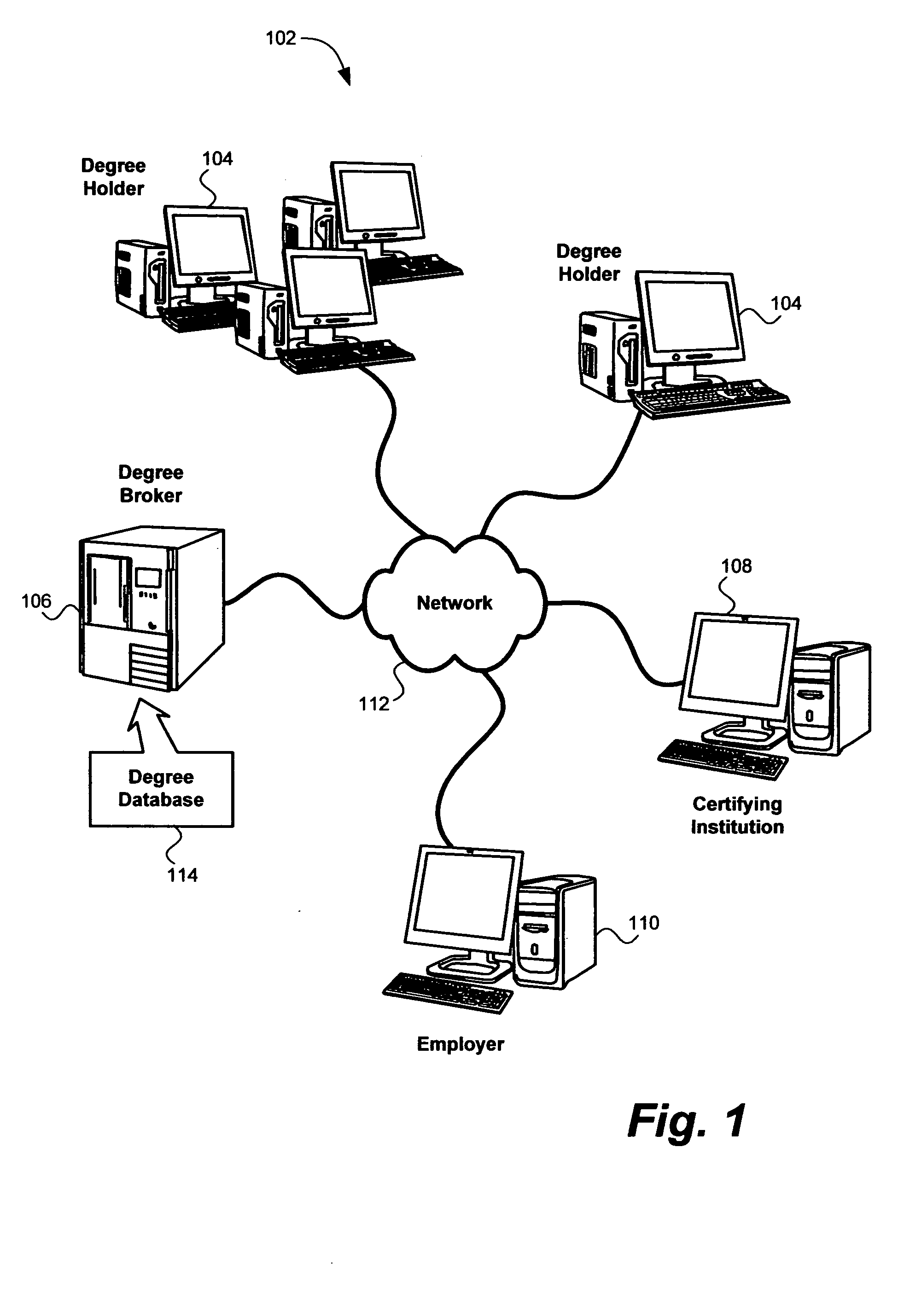

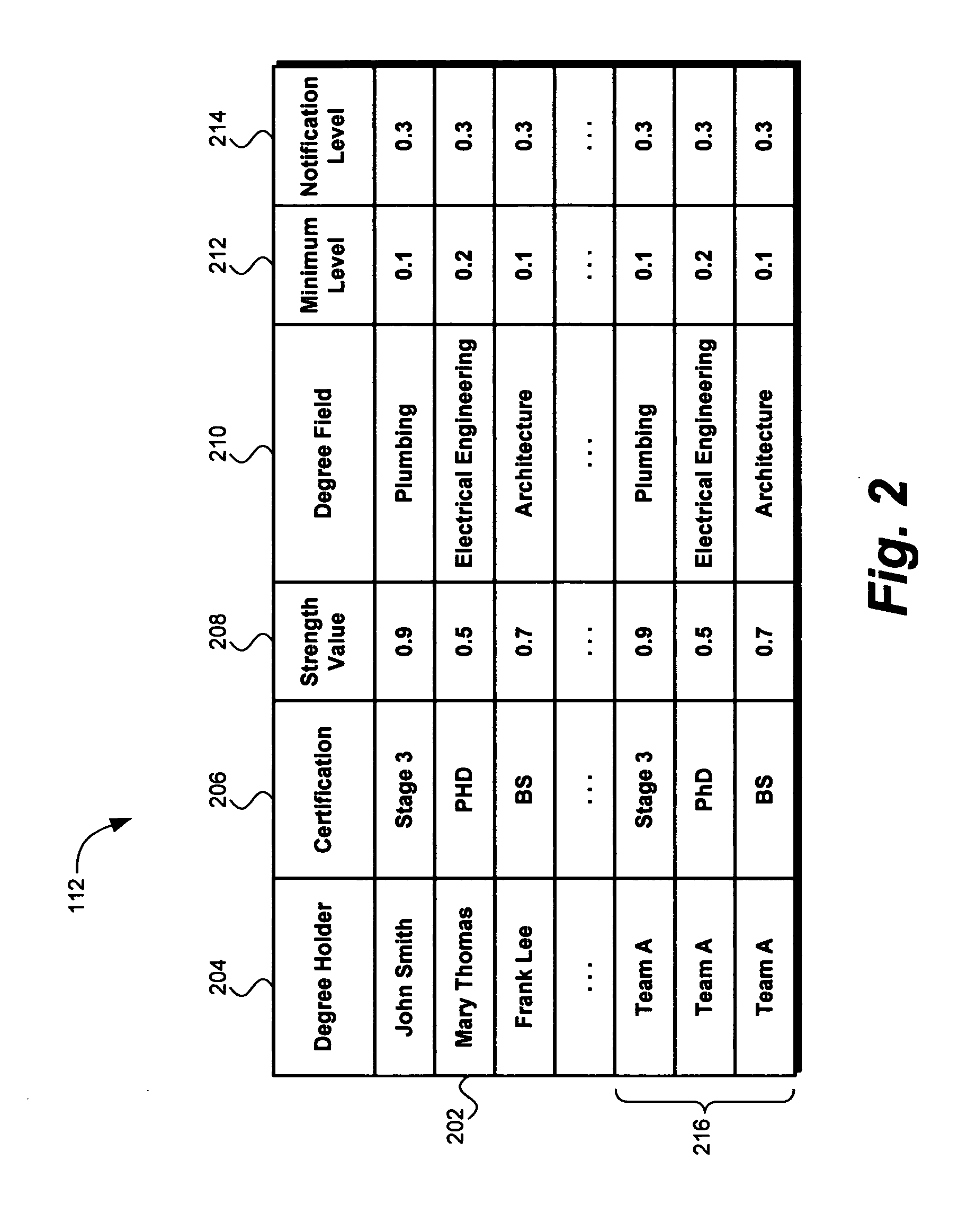

Automatic determination of E-learning obsolescence

InactiveUS20050130114A1Reduced strengthElectrical appliancesTeaching apparatusObsolescenceEngineering

A method, system, and computer program for managing proficiency information about a degree holder. An active degree in a degree field is issued to a degree holder. The active degree includes a certification that the degree holder has completed at least one degree process, a strength value associated with the certification indicating a proficiency in the degree field, and a strength evaluator configured to adjust the strength value such that the strength value reflects the degree holder's proficiency in the degree field over time.

Owner:IBM CORP

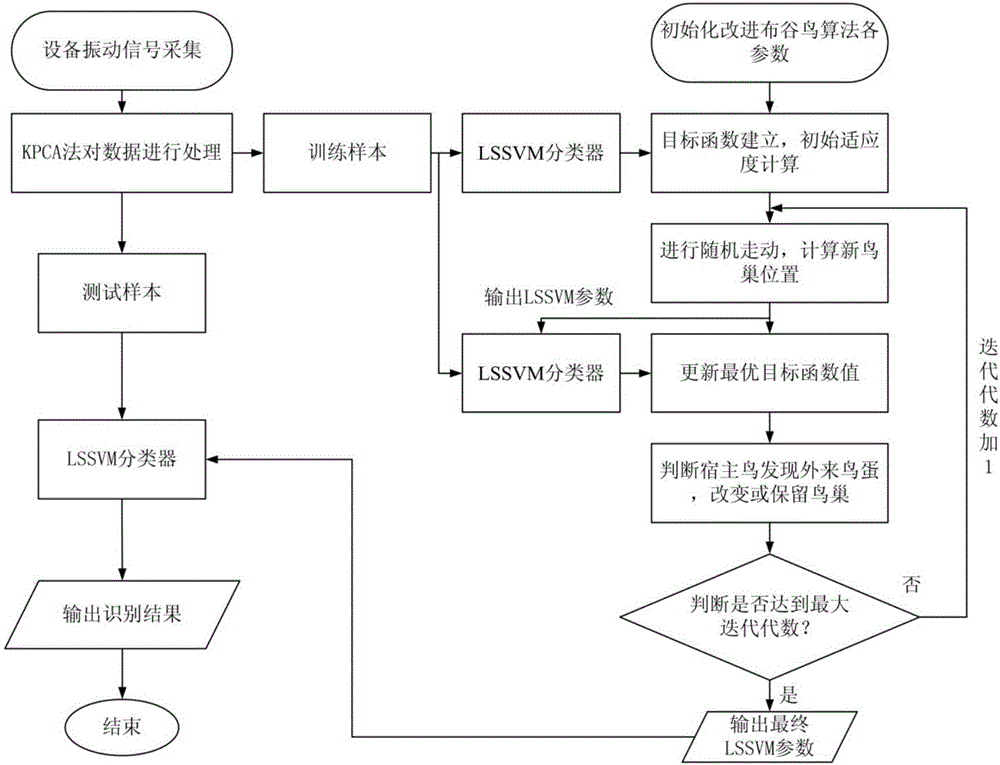

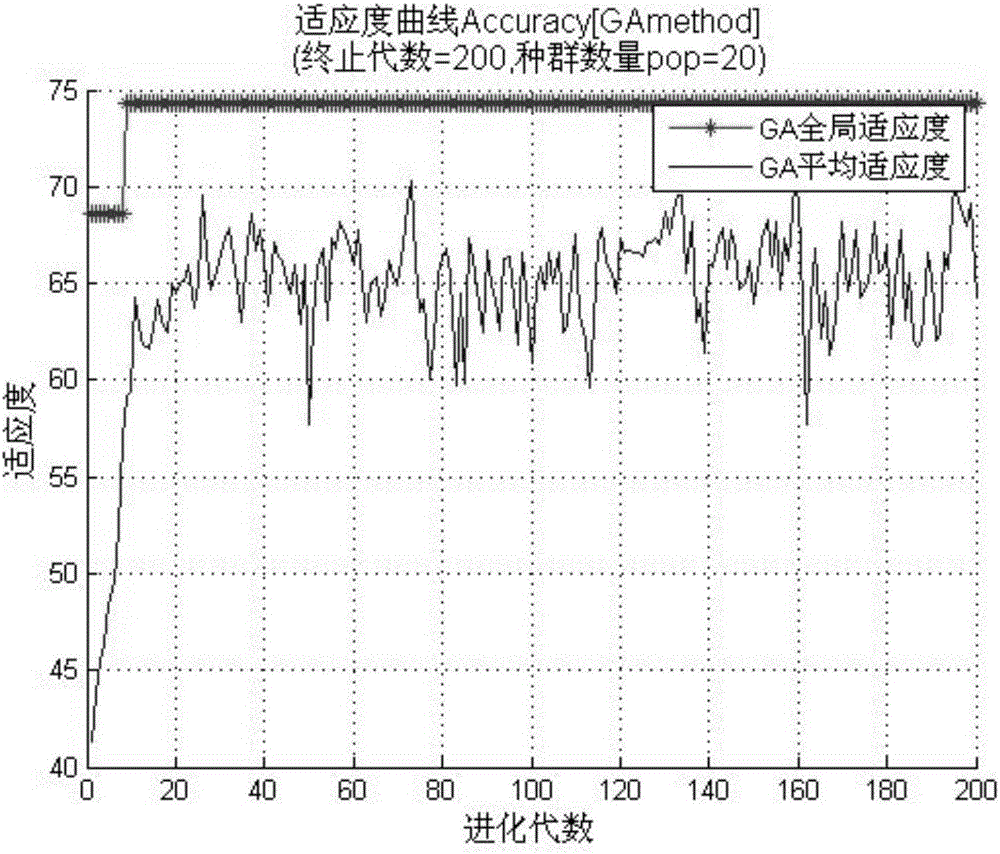

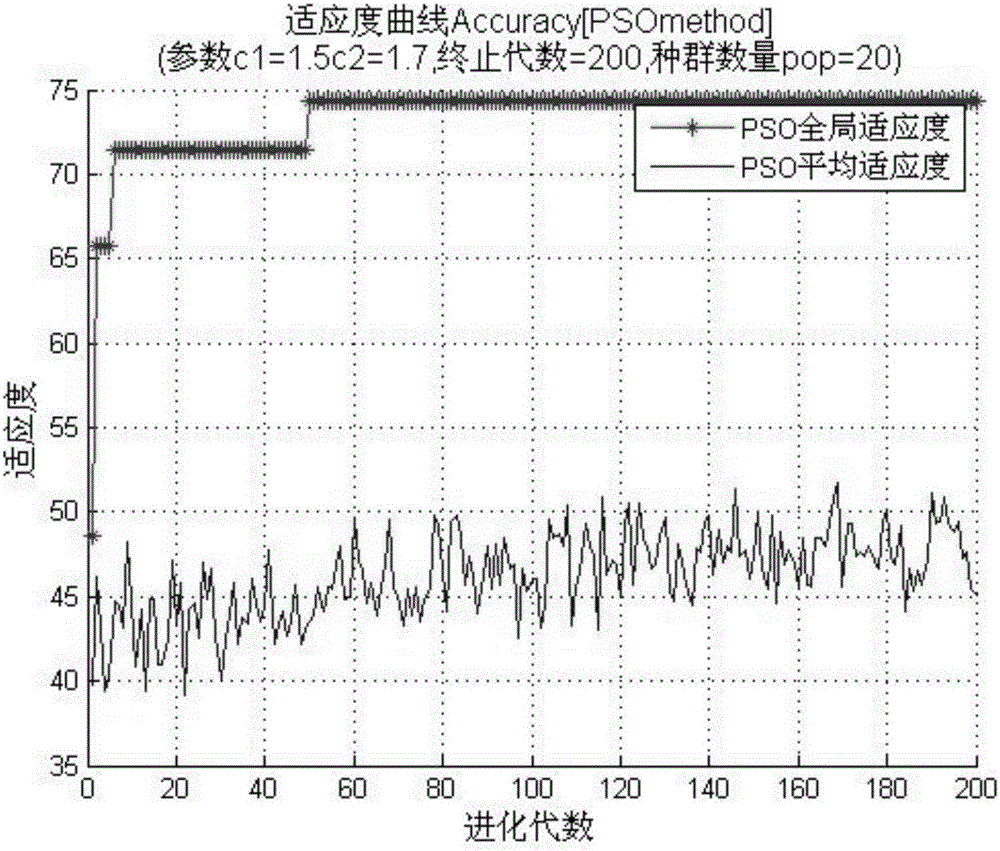

Device fault mode identification method based on improved CS-LSSVM

InactiveCN106384122AFast convergenceFit closelyCharacter and pattern recognitionArtificial lifeNormal conditionsDevice failure

The present invention discloses a device fault mode identification method based on an improved CS-LSSVM. The method comprises the following steps: 1, collecting the monitoring data in the normal condition and the abnormal condition, and performing preprocessing; 2, initializing the Cuckoo search algorithm parameters; 3, building an optimized objective function; 4, updating the bird's nest position through a Levee flight mode; 5, updating the optimized objective function; 6, updating the bird's nest position according to the obsolescence probability; 7, calculating the optimal bird's nest position of the iteration; 8, determining whether the optimal bird's nest position of the iteration reaches the maximum iteration algebra or not, if the iteration does not reach the maximum iteration algebra, returning back to the step 4, and if the iteration reaches the maximum iteration algebra, outputting the optimal bird's nest position; and 9, obtaining the LSSVM optimal penalty factors and the optimal kernel function parameters, and employing the LSSVM to perform fault mode identification of the test sample. The device fault mode identification method based on the improved CS-LSSVM is better in the rate of convergence and the precision of the LSSVM parameter optimization, can obtain globally optimal solution and can be better suitable for the identification of the LSSVM for the device fault mode.

Owner:JIANGSU UNIV OF SCI & TECH

Method and apparatus for providing information regarding computer programs

ActiveUS7480862B2Enhanced informationRaise the possibilityDigital data information retrievalMultiple digital computer combinationsObsolescenceWorld Wide Web

In one embodiment, a computer program blocks windows categorized as bad windows, while allowing windows categorized as good windows to be displayed. The computer program may categorize a window by consulting one or more lists. In one embodiment, a list may be updated from time to time to optimize the computer program and prevent program-obsolescence. Techniques for defeating a window-blocking mechanism are also disclosed. In one embodiment, a computer program detects if a window is of a type that offers a product to a user. If so, the computer program provides a separate window containing information regarding the product. In one embodiment, a computer program detects if a user has a need for the computer program. If so, the user is informed of the efficacy of the computer program, which is then offered to the user.

Owner:GULA CONSULTING LLC

Transparent glaze and preparation method thereof

InactiveCN106007379ASolve pinholesSolve the defect of slight pollution suctionPolyvinyl alcoholSlurry

The invention discloses transparent glaze and a preparation method thereof. The transparent glaze is prepared from the following ingredients in parts by weight: 2 to 6 parts of calcined zinc oxide, 5 to 7 parts of barium carbonate, 14 to 17 parts of soda feldspar, 6 to 8 parts of aluminium oxide, 1 to 3 parts of calcined soapstone, 17 to 19 parts of quartz, 19 to 22 parts of dolomite, 14 to 17 parts of calcined aluminum powder, 9 to 12 parts of wollastonite, 11 to 14 parts of nepheline powder, 0.1 to 0.4 part of sodium carboxymethyl cellulose, 0.3 to 0.6 part of sodium tripolyphosphate and 0.1 to 0.4 part of polyvinyl alcohol. After the ingredients are mixed according to the corresponding mixture ratio, the mixture is fed into ball mill equipment to be subjected to ball milling to obtain slurry; then, spray drying is performed to form powder materials; the powder materials are put into a cabin for obsolescence; the powder materials are pressed for forming a glaze blank; then, drying is performed; the glaze blank is calcined and is then crushed into powder materials; the powder materials are put for use. The glaze material is used for manufacturing ceramic tiles; the transparent effect of full polish product is effectively improved.

Owner:GUANGDONG JIA MEI CERAMIC

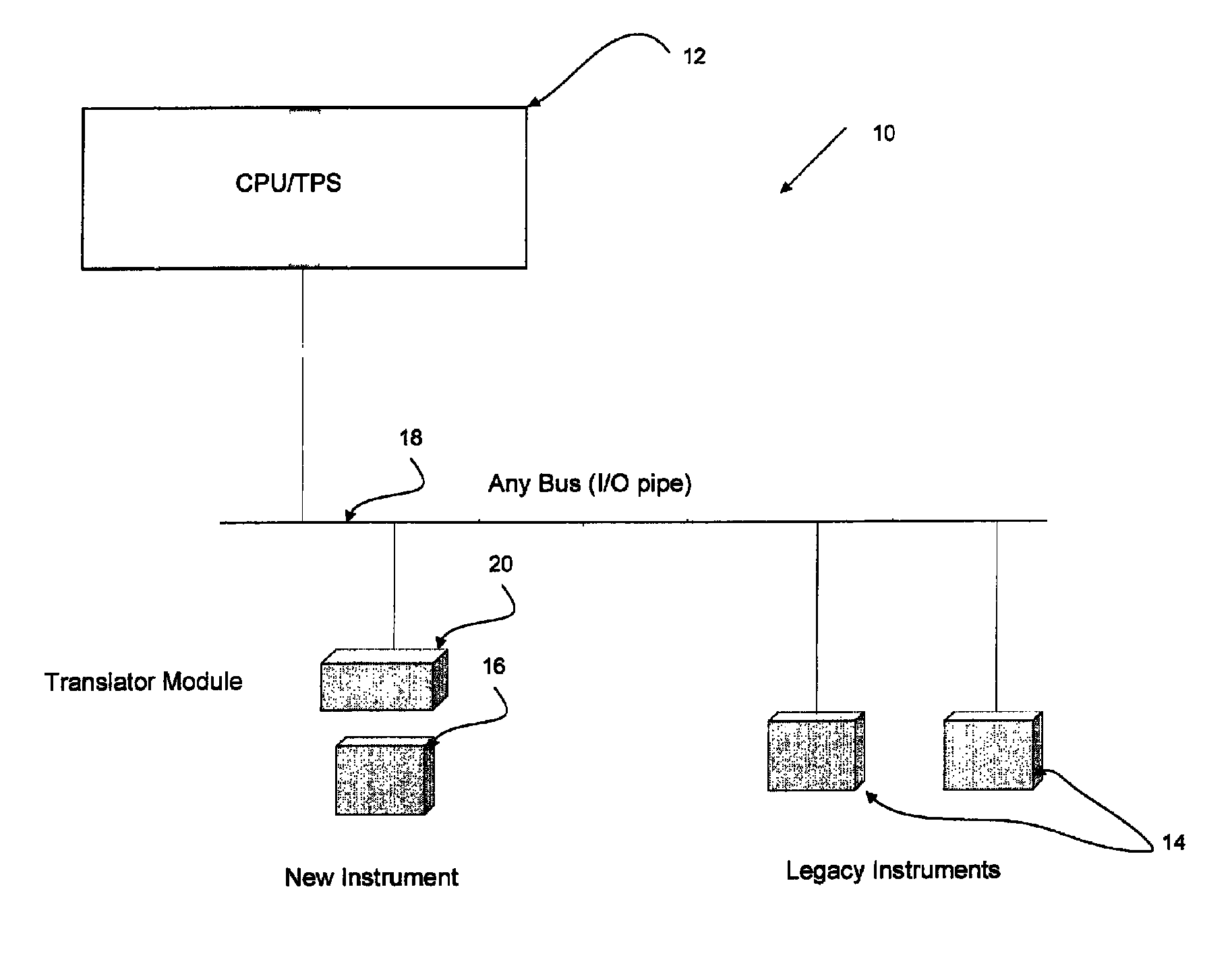

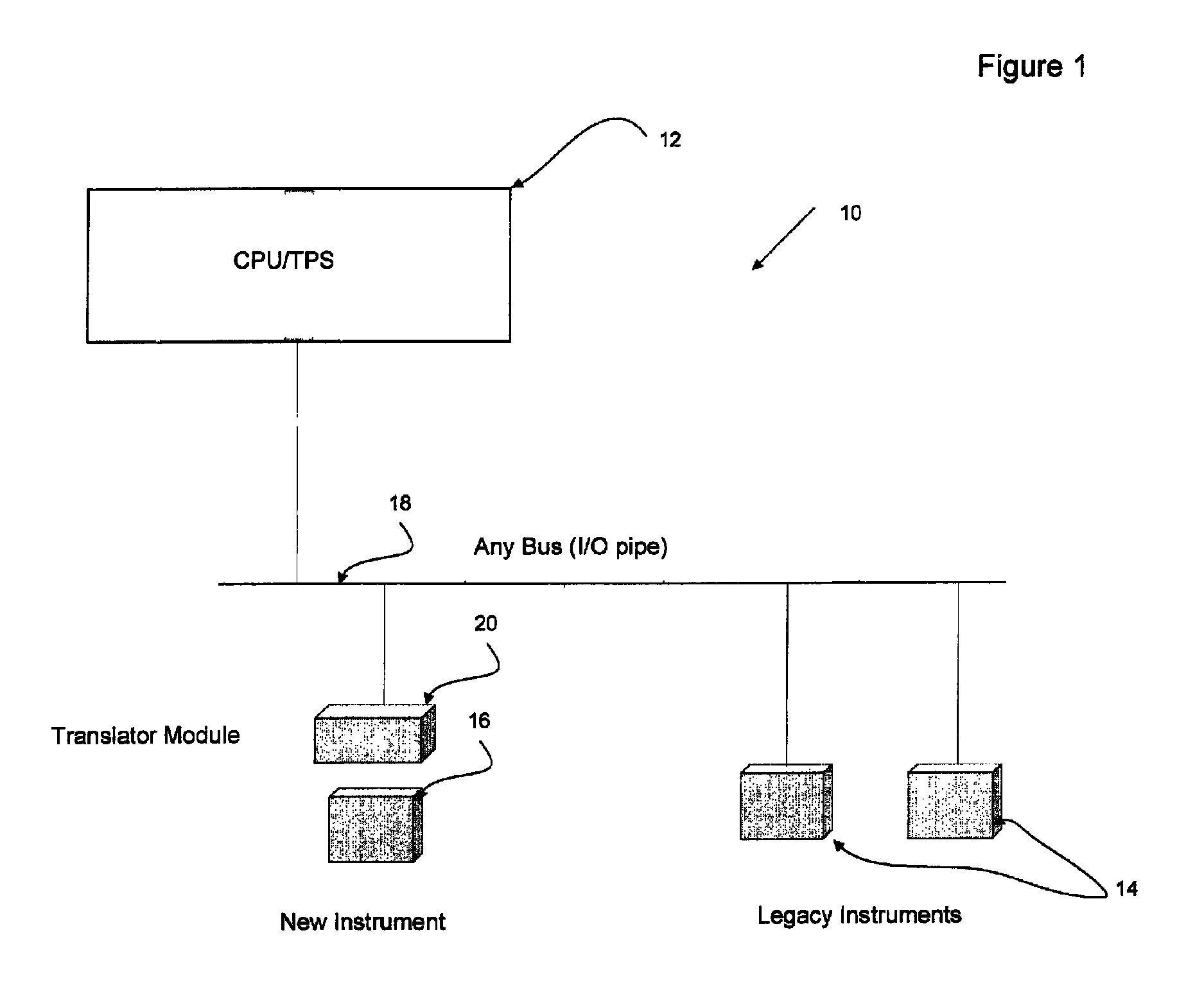

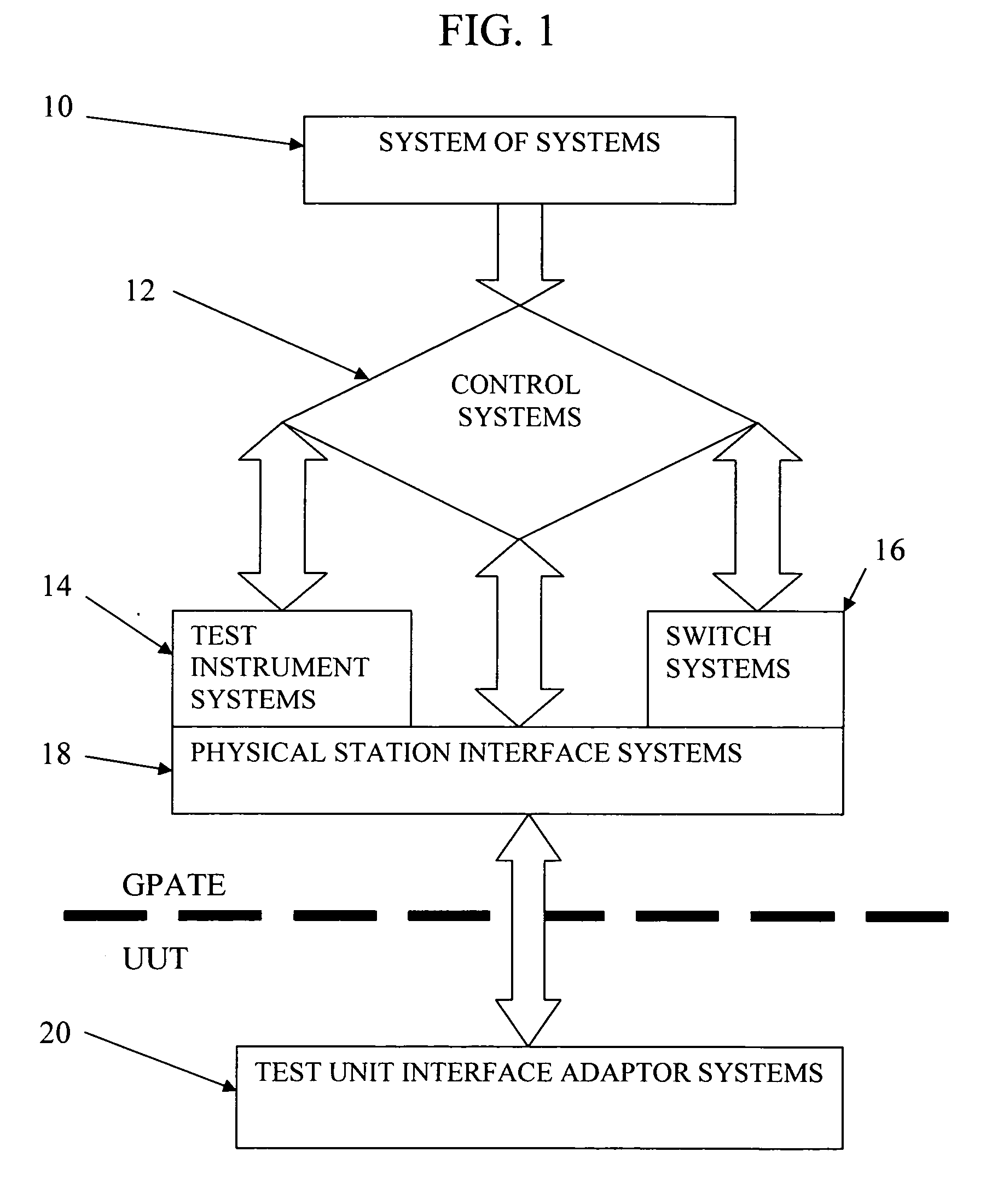

Instrumentation ATS/TPS mitigation utilizing I/O data stream

ActiveUS8359585B1Maintaining their functionalityGuaranteed to continue to useTransformation of program codeSpecific program execution arrangementsObsolescenceApplication software

Methods and systems for obsolescence mitigation of electronic systems including hardware and software components, in particular methods and systems for managing obsolete instrument hardware and application software used in legacy Automated Test Systems (ATS) or Automatic Test Equipment (ATE). When one or more components of a test program set (TPS) has been rendered obsolete, migration to one or more replacement instruments without any impact to the TPS or other remaining legacy instruments in the ATE or ATS is obtained by a translator module interposed between the new instrument and the system bus for translating instructions for the obsolete instrument or set of instruments into instructions or procedures for the new instrument whereby the new instrument thus functions in the same manner as the obsolete instrument or set of instruments.

Owner:ADVANCED TESTING TECH

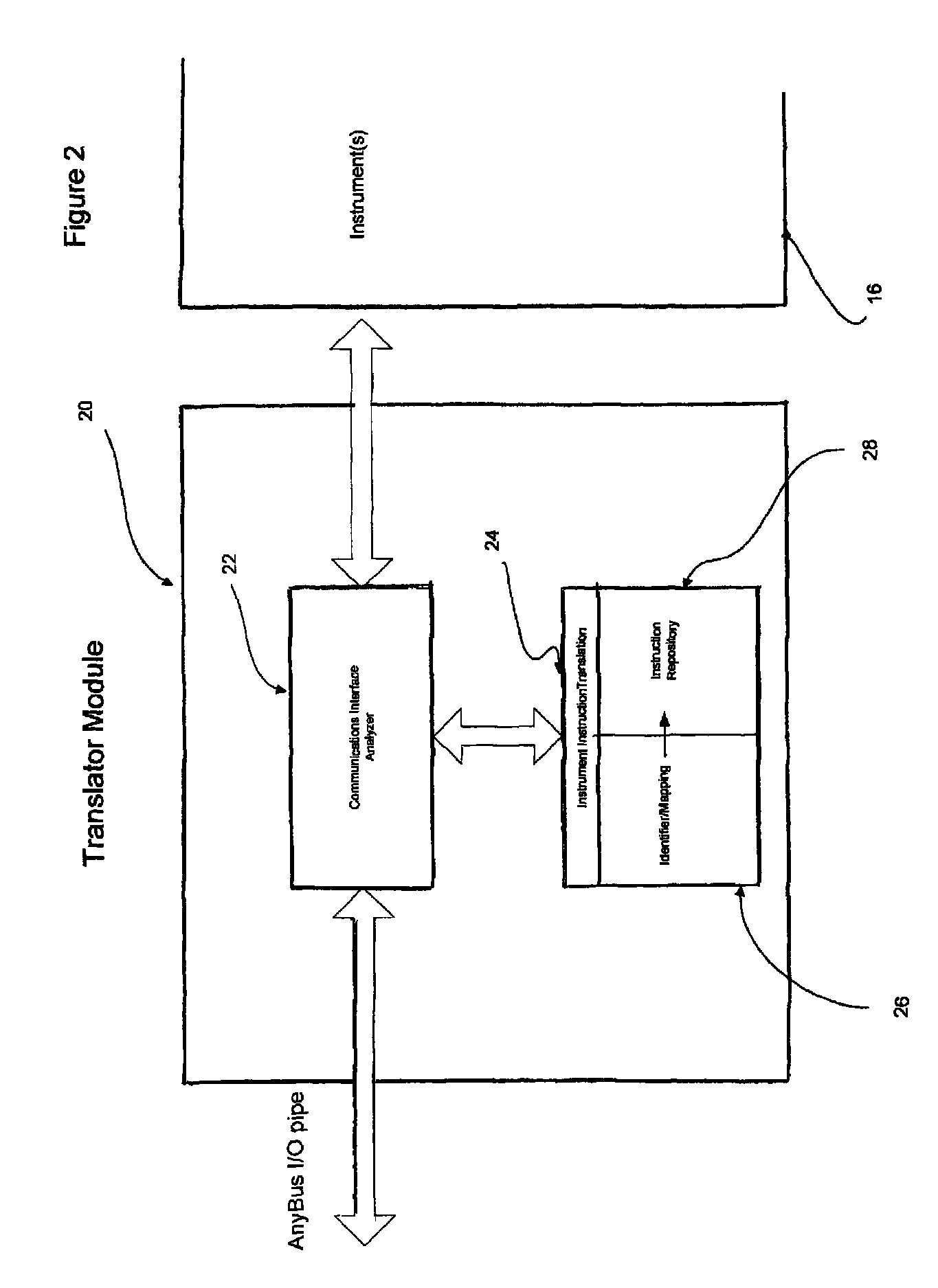

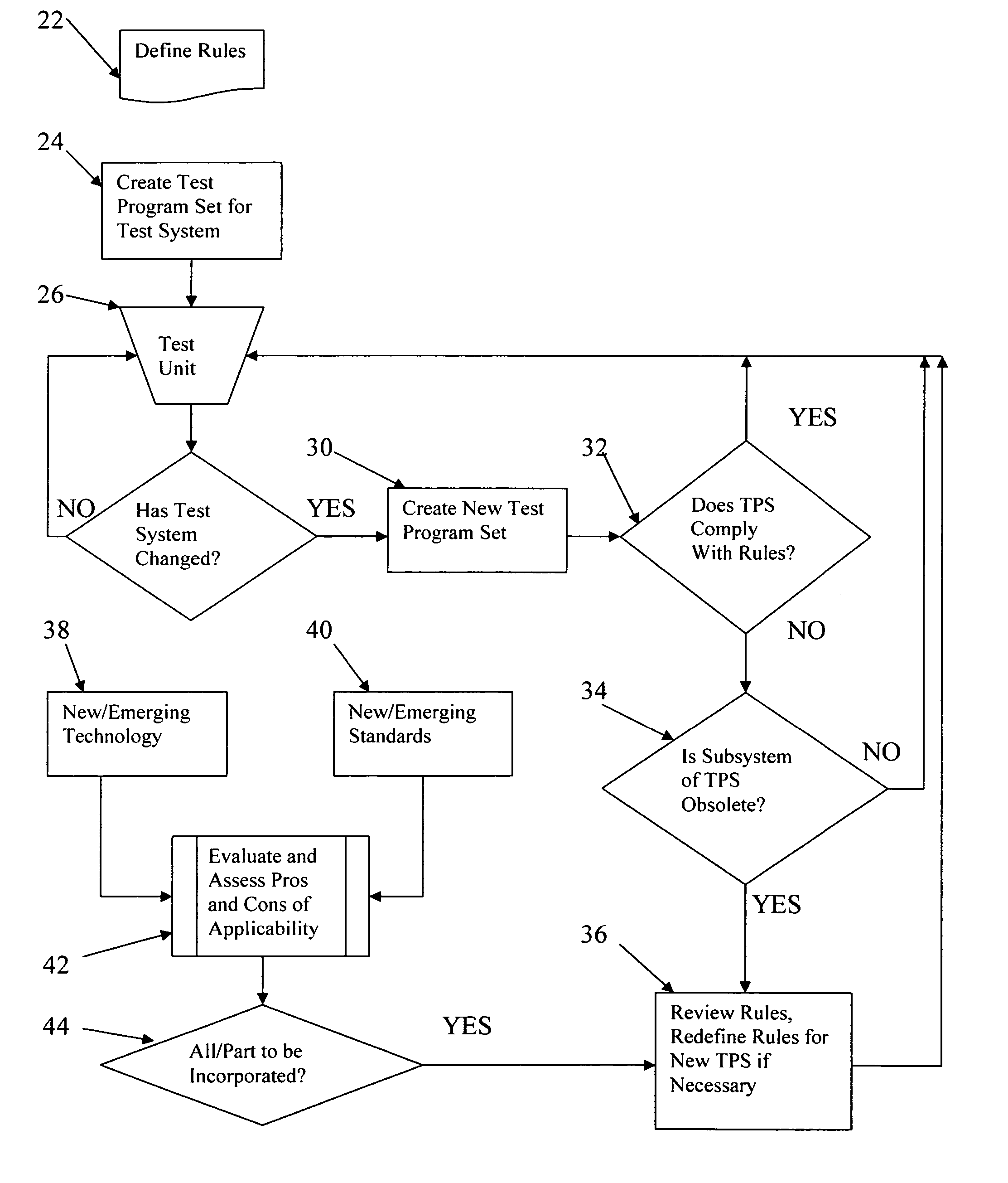

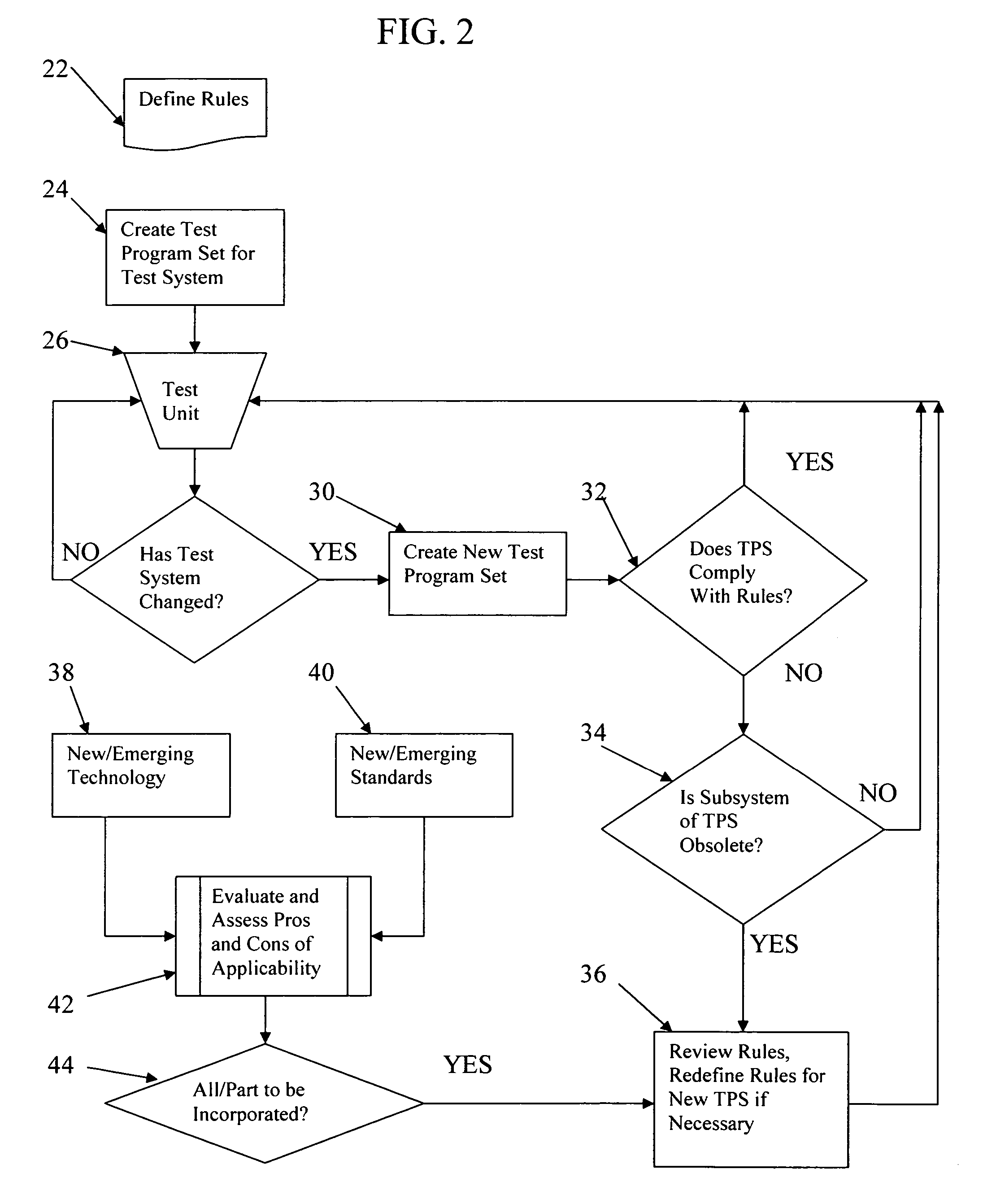

Test program set obsolescence mitigation through software and automatic test equipment system processes

ActiveUS20060156289A1Cost effectiveEliminate the transparent obsolescence mitigationError detection/correctionAutomated test systemsAutomatic test equipmentSoftware engineering

Electronic test system including hardware and software components and method of use of same which provide obsolescence mitigation. A set of governing rules for the system is defined and a test program test (TPS) is created to enable units to be tested. When a new component is introduced into the system, the change is detected and a new TPS is created. If the new TPS complies with the rules, testing using the new TPS is possible. If not, a determination is made as to whether any component of the TPS is obsolete and if not, the units can be tested using the new TPS without redefining the rules. When a component of the TPS is obsolete, the rules are reviewed to ascertain the effect of the removal of the component and optionally redefined to enable the new component to be used in combination with the remaining components.

Owner:ADVANCED TESTING TECH

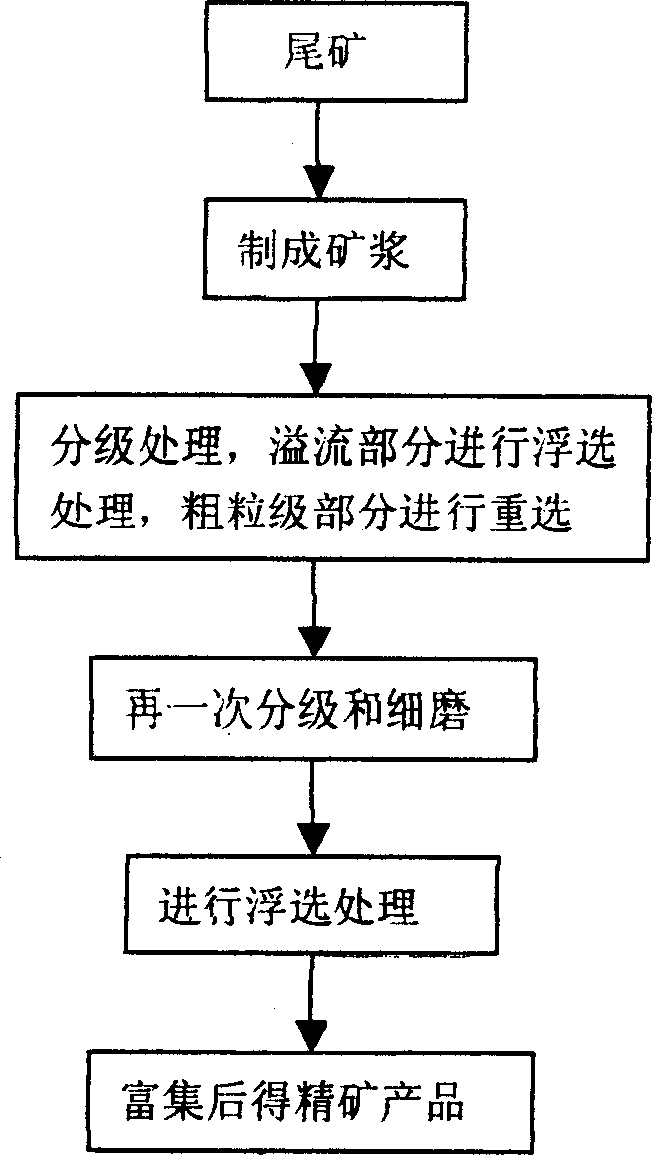

Re-dressing utilizing method for non-ferrous metal tailings

This invention relates to a recleaning using method of non-ferrous metal tailings, its feature is that the procedures of the method said are as following: a. obsolescence tailings are selected from tailings dam, then ore magma is agitated with water in conditioning pool. b. the magma is stage treated, then flotation treatment is done to overflow part, macrograin part is selected again. c. the ore foam and middlings got from reelecting after classification are done another calssificaiton and fine grinding. d. the overflow part from procedure c is flotation treated, then finished ore product is got after progressive enrichment. The waste water in tailings can be eliminated by using segregation processing, and damage of argillization matter and medicine pollution. Mineral grain120-300 items can be large treated in classification and reelection. Its accommodation limit is wide, then the monomer is liberated after again classification and fine grinding of the foam and middlings so the concentration ratio is heightened and high recovery is realized.

Owner:上海维莎宝矿产设备有限公司

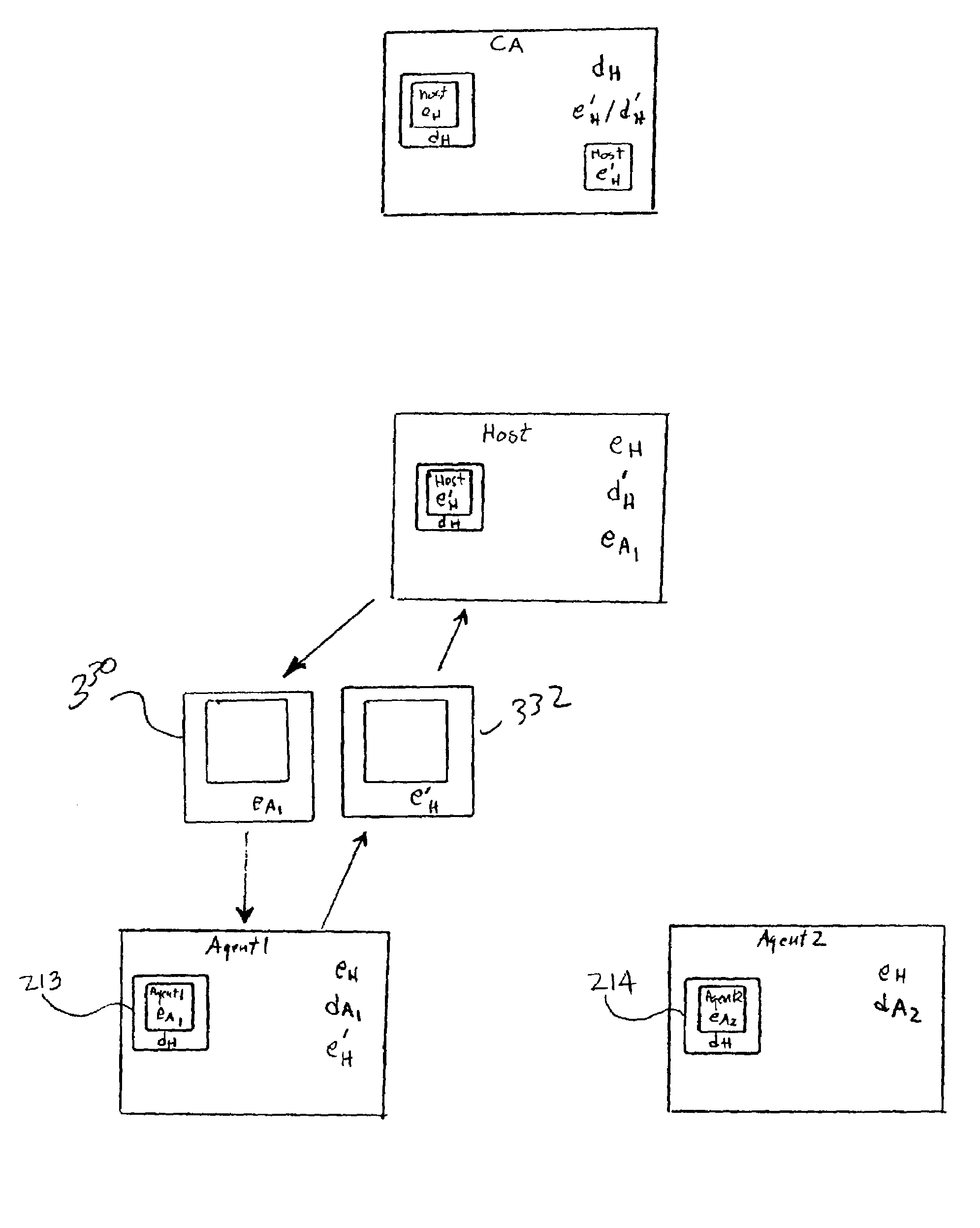

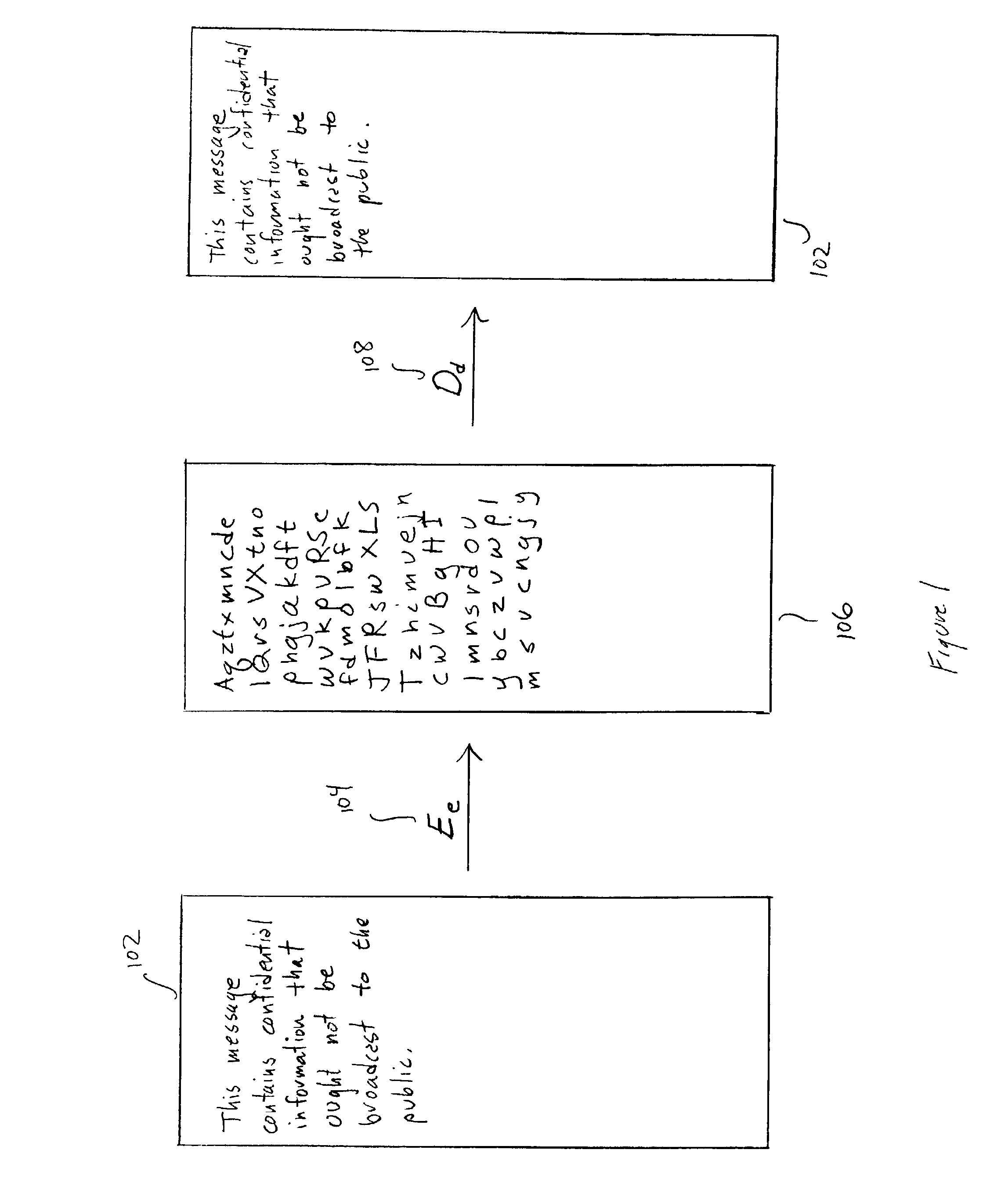

Method for upgrading a host/agent security system that includes digital certificate management and an upgradable backward compatible host/agent security system digital certificate infrastructure

A host / agent system and security-certificate-management infrastructure enhanced to provide backward compatibility, despite launching of new administrative host processes employing new software versions, to avoid regenerating and redistributing security certificates to existing agents. Certificate management is removed from the administrative host process and embedded within a new certification-authority entity. The new certification-authority entity generates new digitally signed security certificates using the previously generated host private decryption key, inherited as the new CA private decryption key by the CA. The administrative host software can be upgraded to a new version that includes security-certificate-management tools provided by a new vendor, without the need for generation of a new encryption / decryption key pair for verifying and digitally signing security certificates and concomitant obsolescence of the existing, already distributed security certificates.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

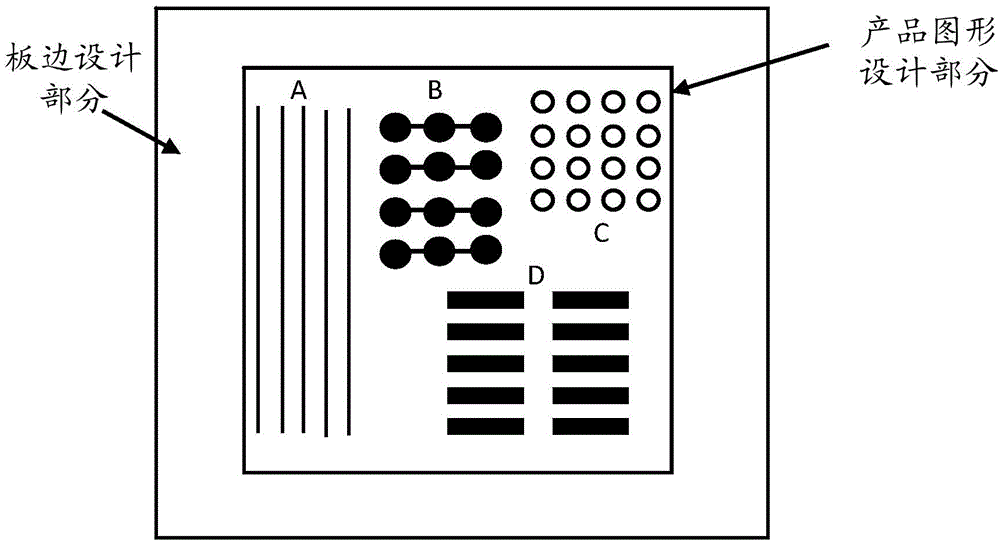

Electroplating quality detection module, printed circuit board motherboard and electroplating quality detection method

ActiveCN105722300AAccurate judgmentReduce quality riskPrinted circuit detailsOptically investigating flaws/contaminationComputer moduleObsolescence

The invention provides an electroplating quality detection module, a printed circuit board motherboard and an electroplating quality detection method, wherein the electroplating quality detection module is located on the edge of the printed circuit board motherboard, including : detection hole, metal plating is attached on the hole wall of the detection hole, and the aperture of the detection hole gradually decreases from top to bottom, so that the detection hole is in the shape of a circular platform with a large top and a small bottom, so that the detection hole can pass through the The metal coating on the hole wall is inspected for electroplating quality. Through this technical solution, the electroplating quality of the printed circuit board can be directly judged by detecting the detection hole, and whether there is no copper in the hole can be quickly and accurately judged, which reduces the quality risk of the product and improves the efficiency of electroplating quality inspection , to avoid product scrapping caused by destructive slice sampling, and to reduce production costs.

Owner:NEW FOUNDER HLDG DEV LLC +1

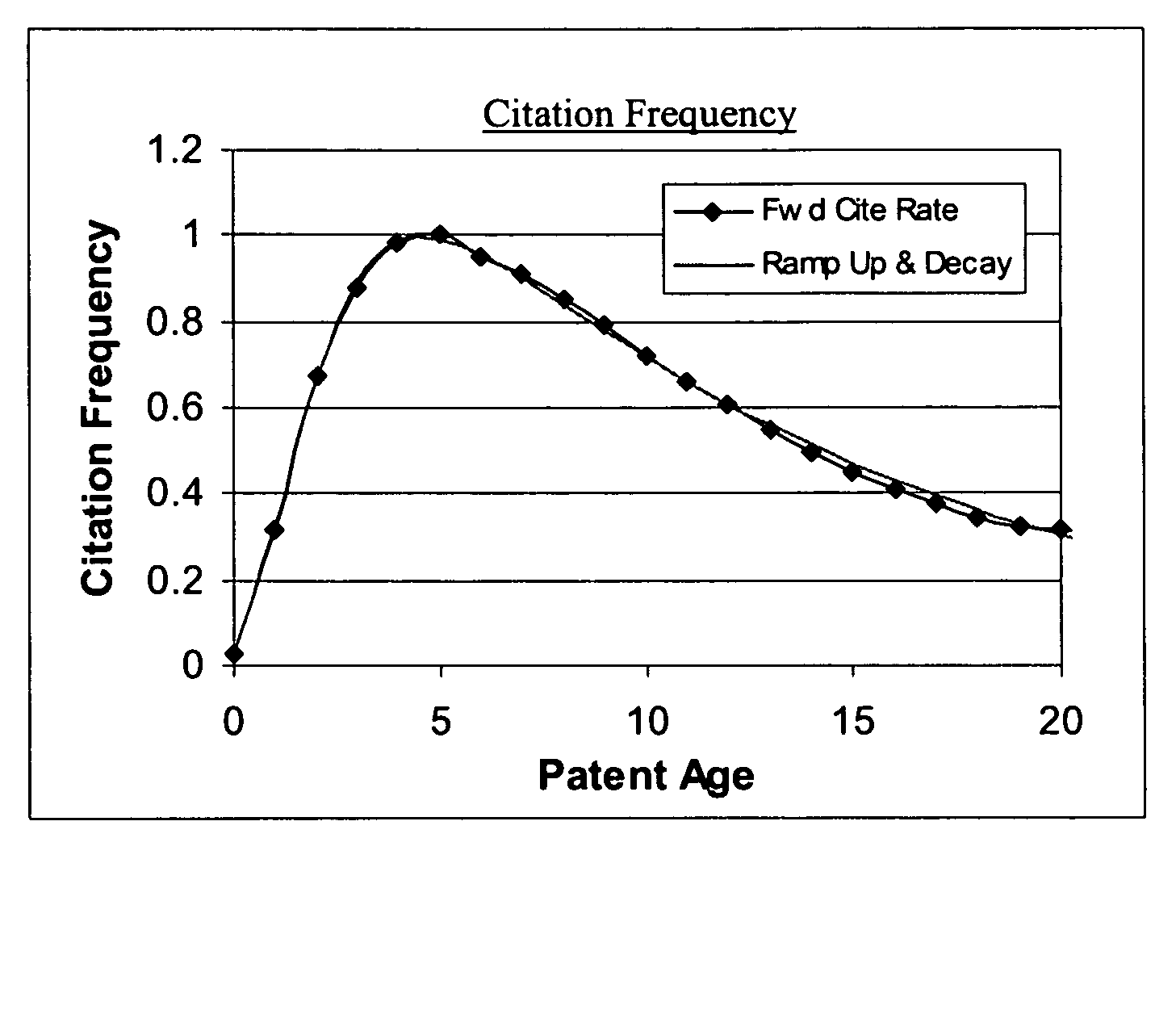

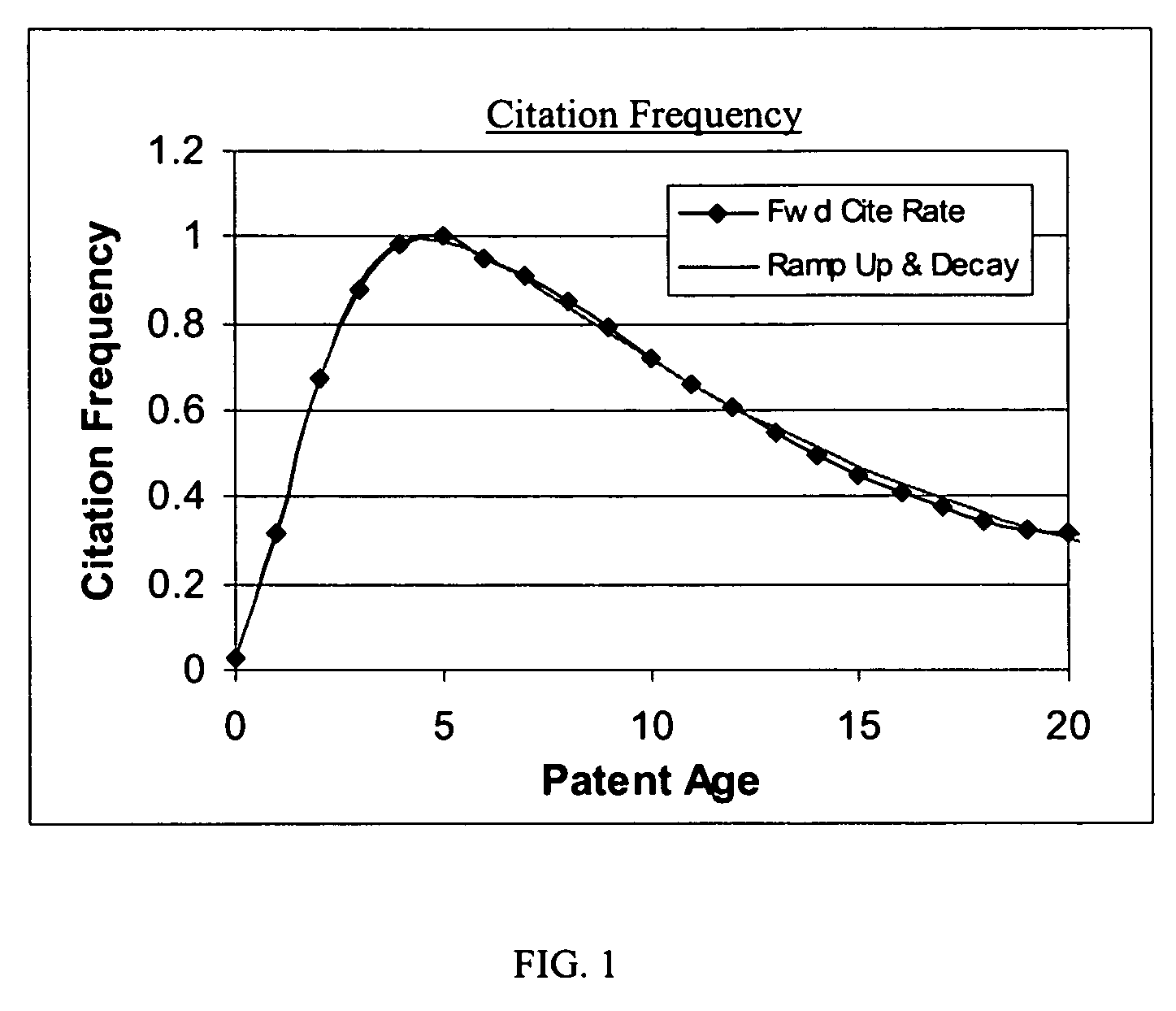

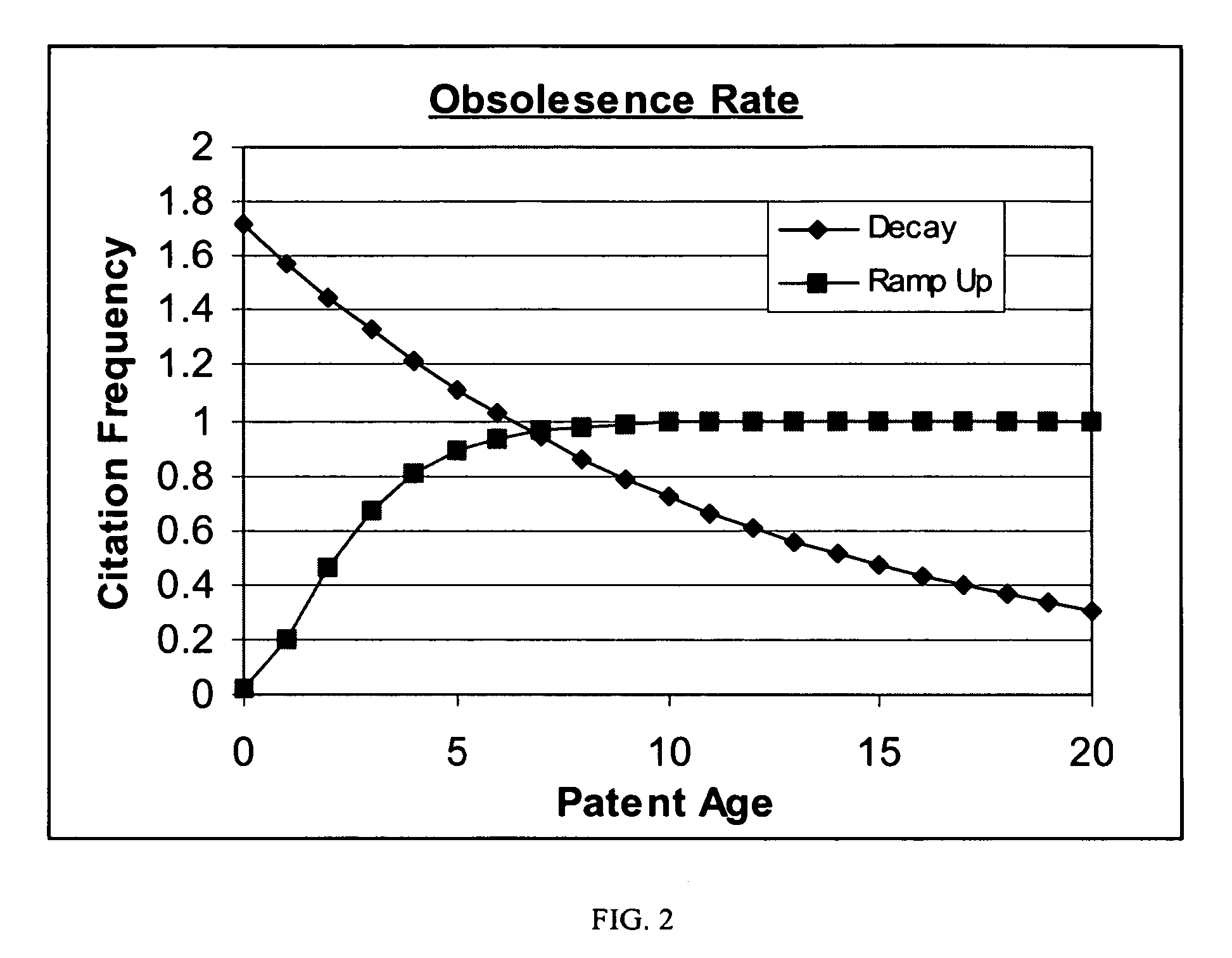

Method of determining an obsolescence rate of a technology

Owner:PATENTRATINGS

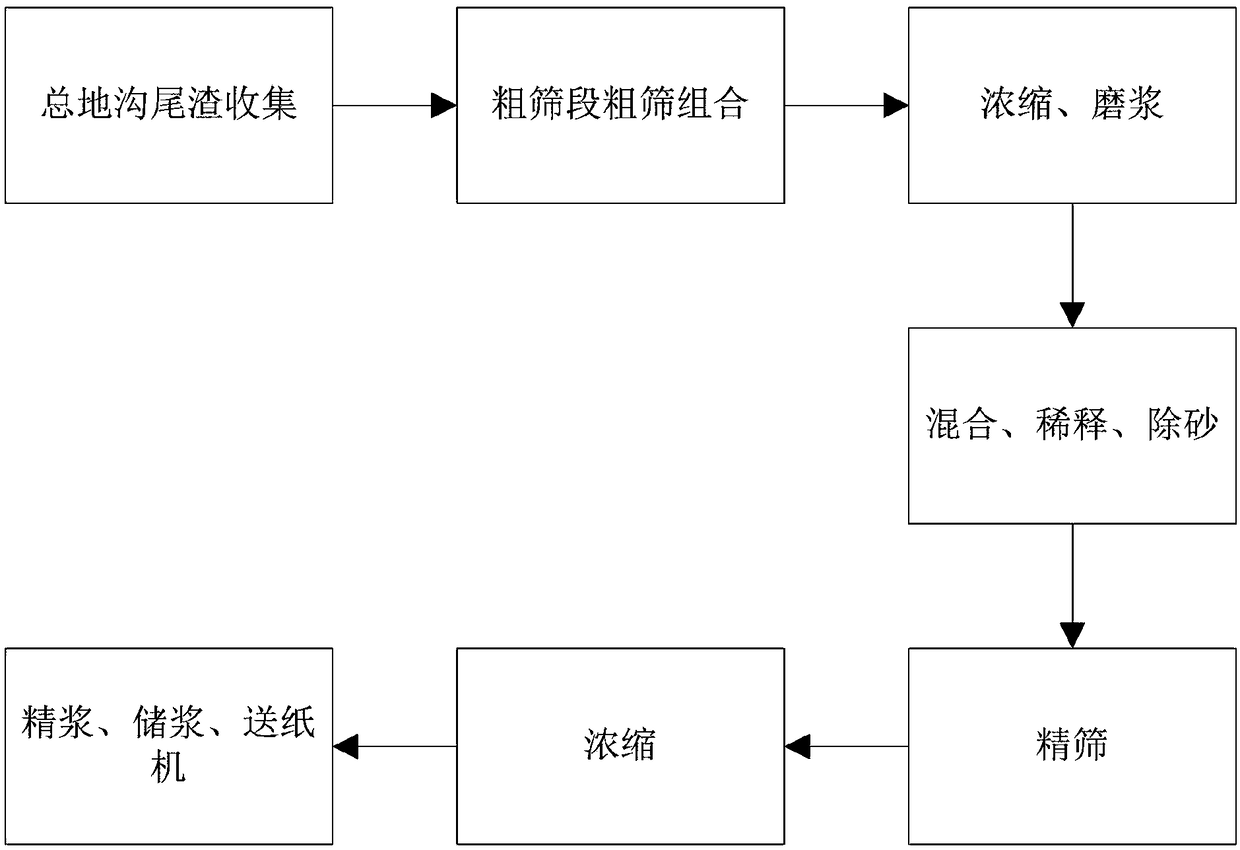

Efficient recycling production process of obsolescence corrugated cardboard (OCC) residue pulp

The invention relates to an efficient recycling production process of obsolescence corrugated cardboard (OCC) residue pulp, and belongs to the technical field of pulping and papermaking production. The production process comprises the steps of collecting total gutter tailing, combining coarse screens in a coarse screening section, carrying out concentration, carrying out grinding, carrying out mixing, carrying out dilution, removing sand, carrying out fine screening, carrying out concentration, refining pulp, storing the pulp and conveying the pulp to a paper machine. Through the addition of the combination of the coarse screens with re-crushing and screening functions in the screening section, sundries such as plastic, foam, gravels and the like are effectively prevented from blocking ordamaging disc mills, low-concentration sand removal devices, fine screening devices and the like used in the follow-up treatment process, and meanwhile, a high-power pulping machine is additionally arranged, so that fibers in the tailings are sufficiently defibered, ground and preliminarily separated and fibrillated. The daily tailing treatment amount is 500 t / d, the recovery pulp yield is 400 t / d, and the recovery rate reaches 80% which is greatly improved compared with the recovery rate of 60% in a conventional recovery process. Therefore, OCC residue pulp is efficiently recovered by adopting the production process provided by the technical scheme, and important economic and environmental benefits are achieved.

Owner:LIANSHENG PAPER IND LONGHAI

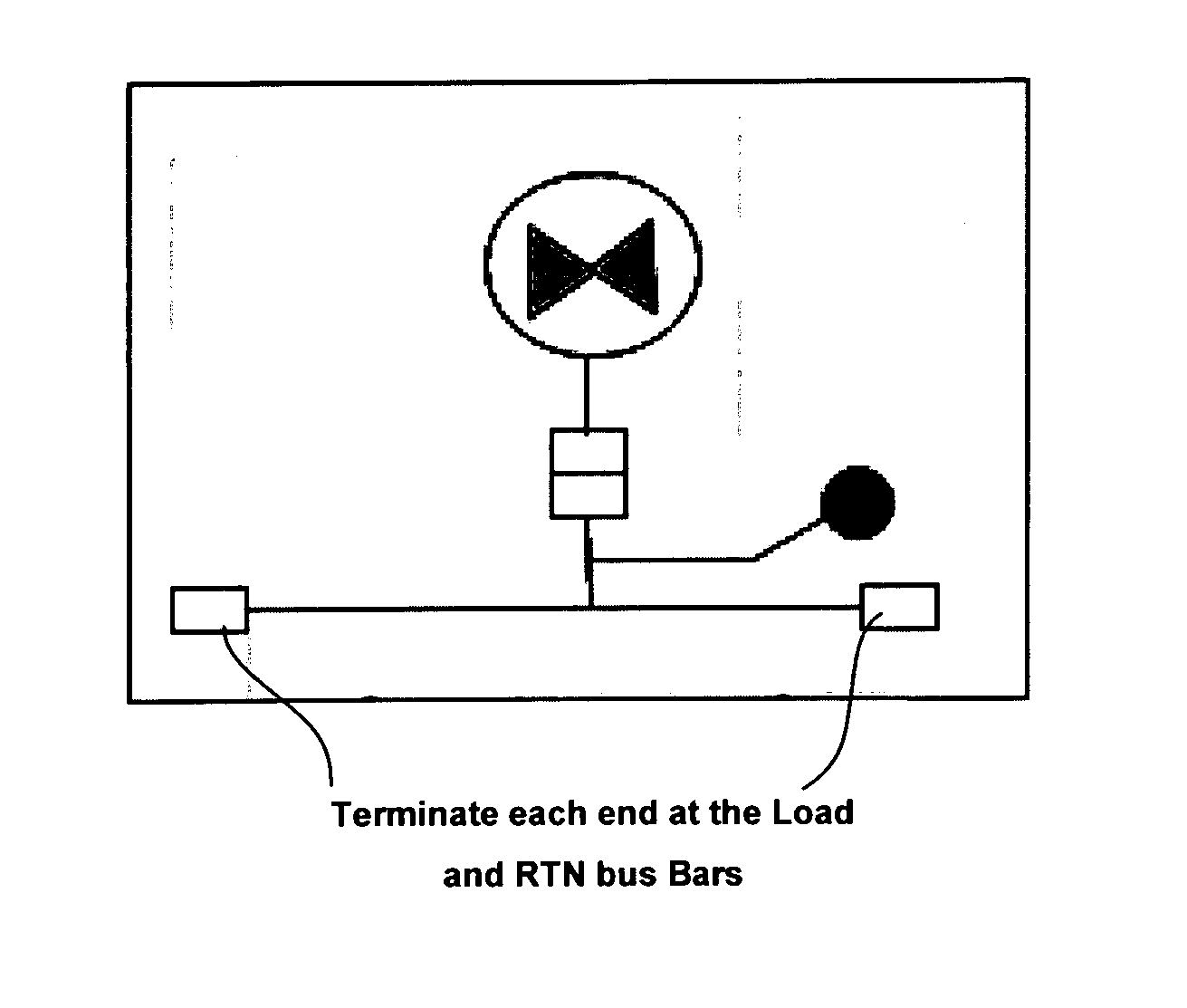

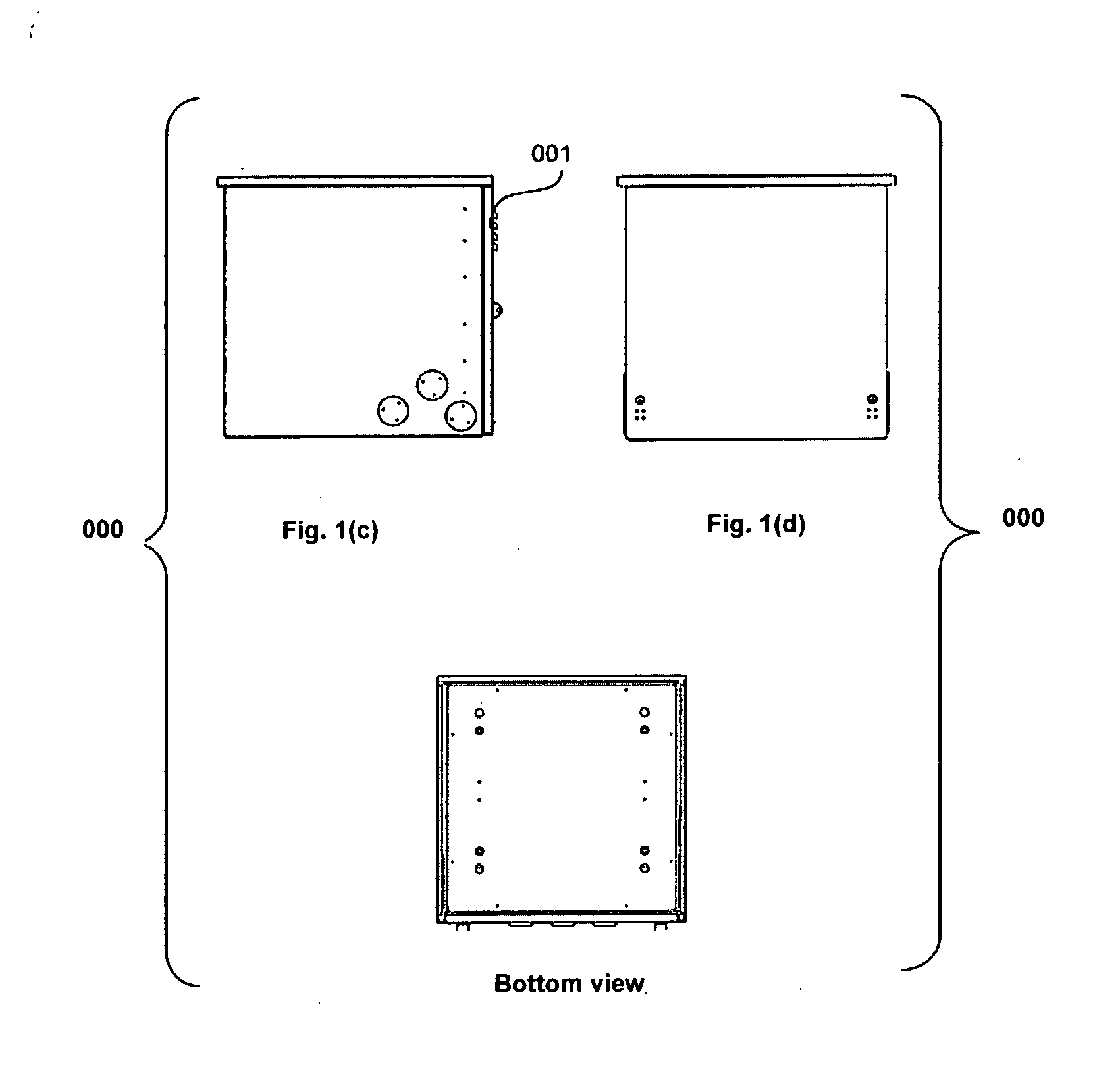

Electronic device and battery enclosure

InactiveUS20150382496A1Low costReduce skillsCells structural combinationFurniture partsObsolescenceComputer module

The present invention provides for a low cost, light weight, high strength earthquake certified power and equipment enclosure module which provides for an effective housing of DC batteries allowing for simultaneous dual voltage functionality with intelligent evacuation of thermal and toxic residuals. Stacking and interlocking the modules provides an environment for housing diverse electrical components making the invention enclosure invulnerable to obsolescence. Intuitive disassembly and reassembly allows the cabinet modules to be moved easily too hard-to-reach locations eliminating the need for costly cranes, lifts or excessive man-power. The design delivers the smallest footprint with the highest power density, embedded alarming and thermal management ensures safety in operation.

Owner:BURANT JR RICHARD

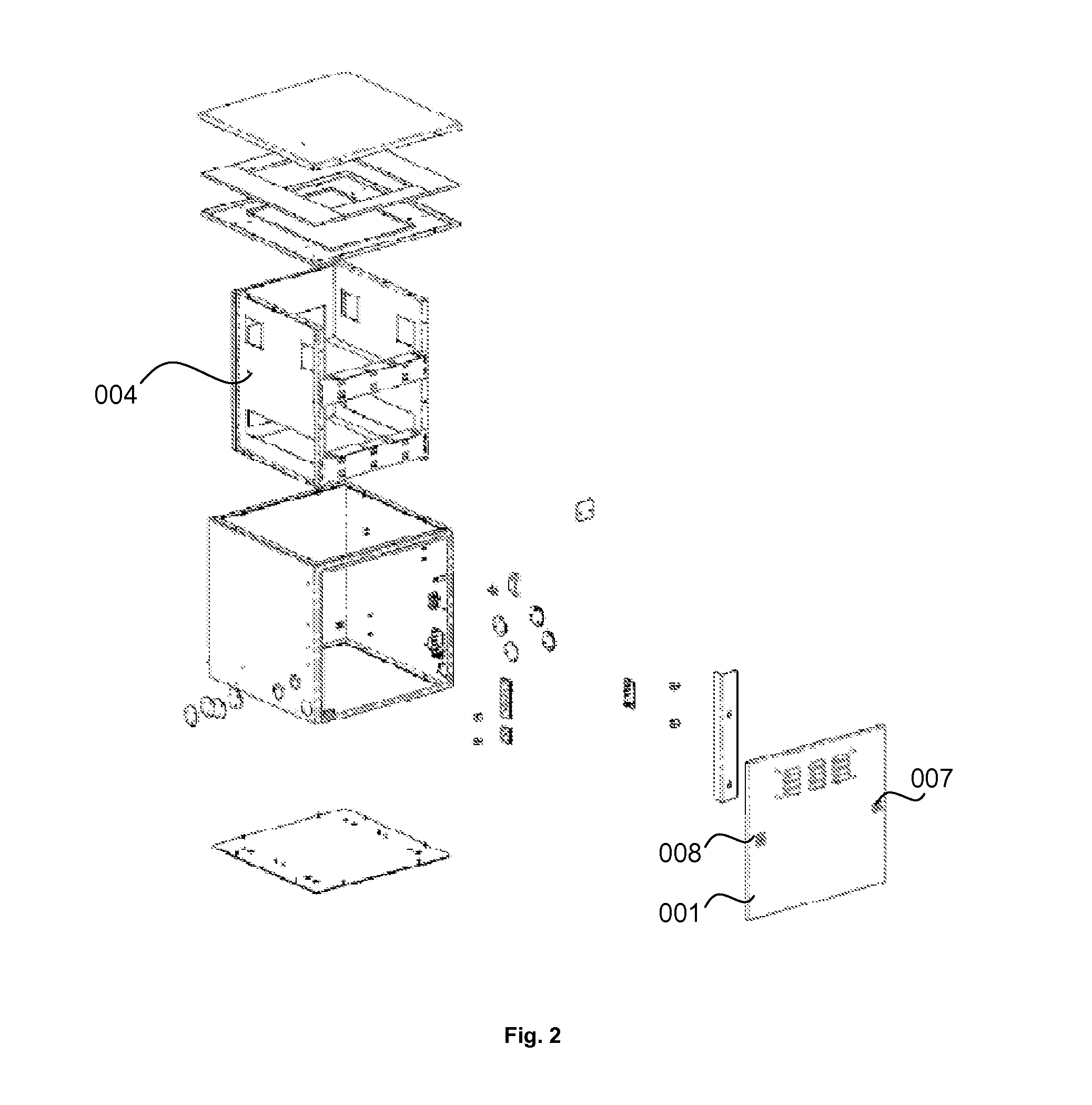

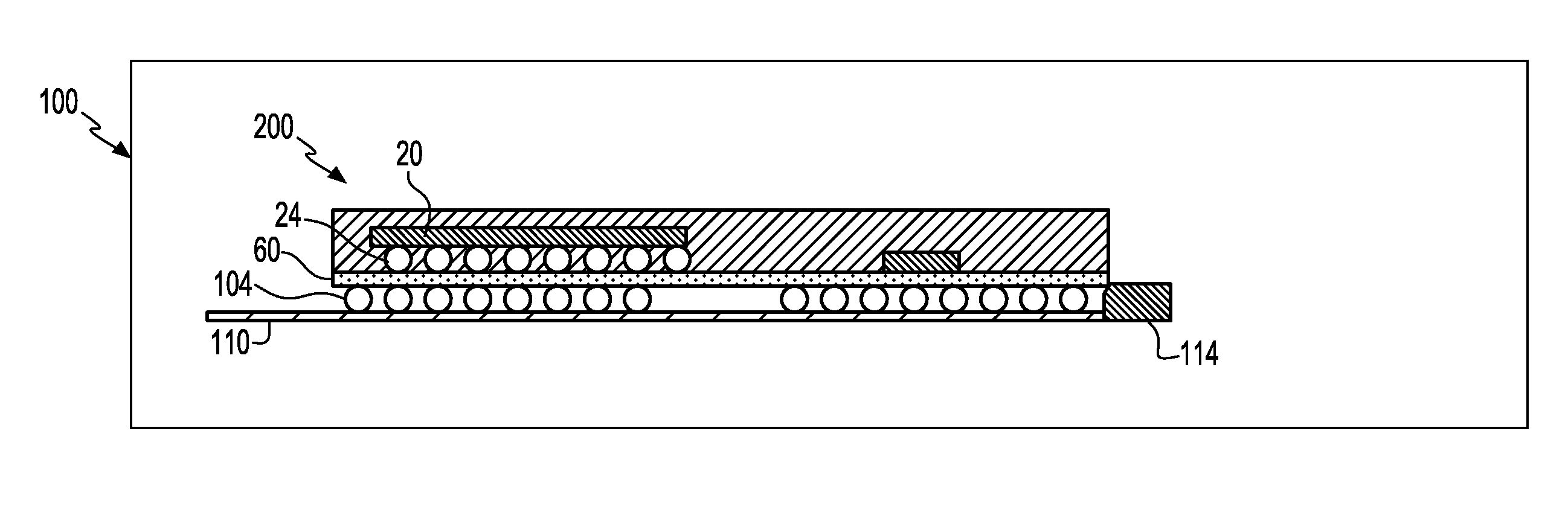

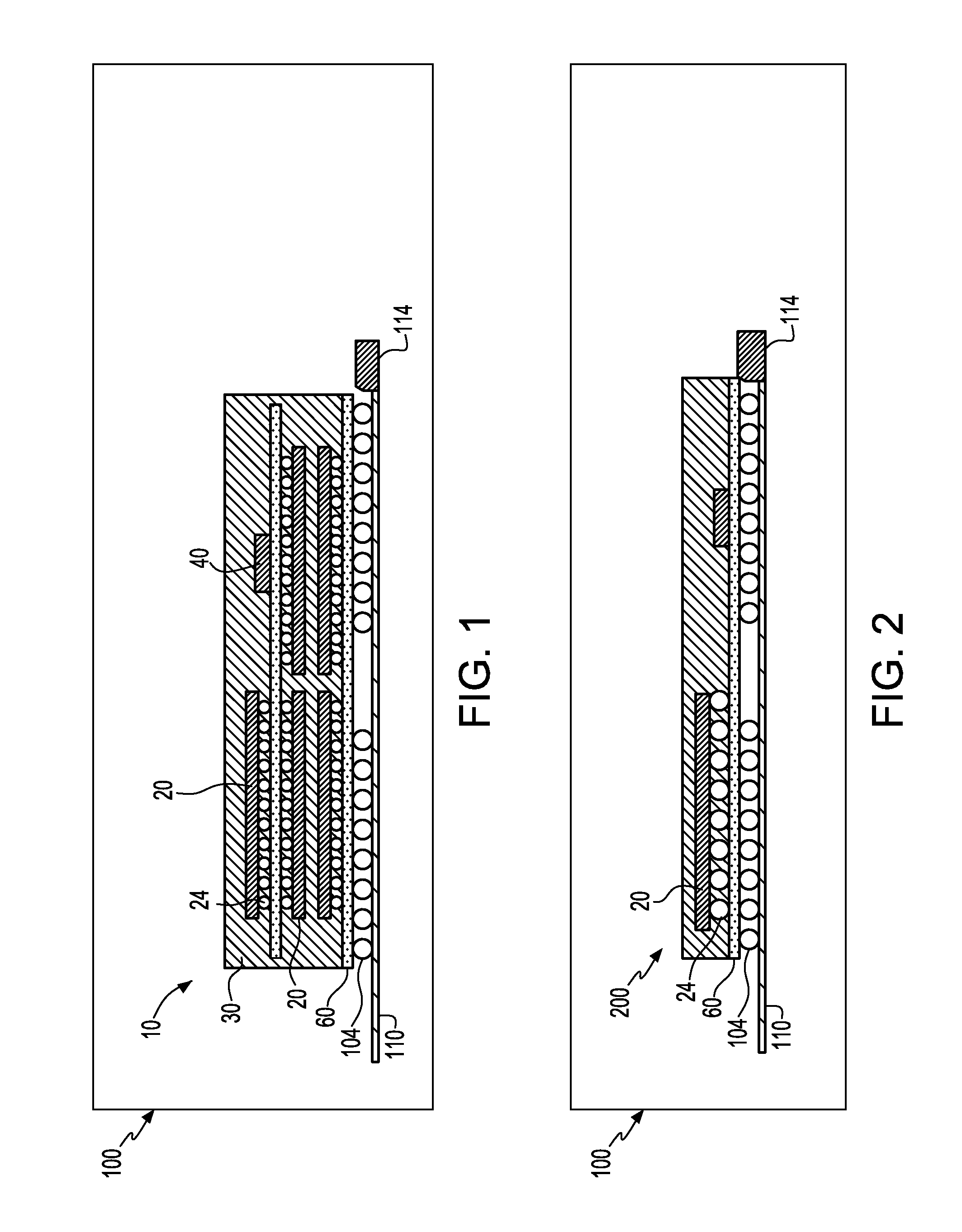

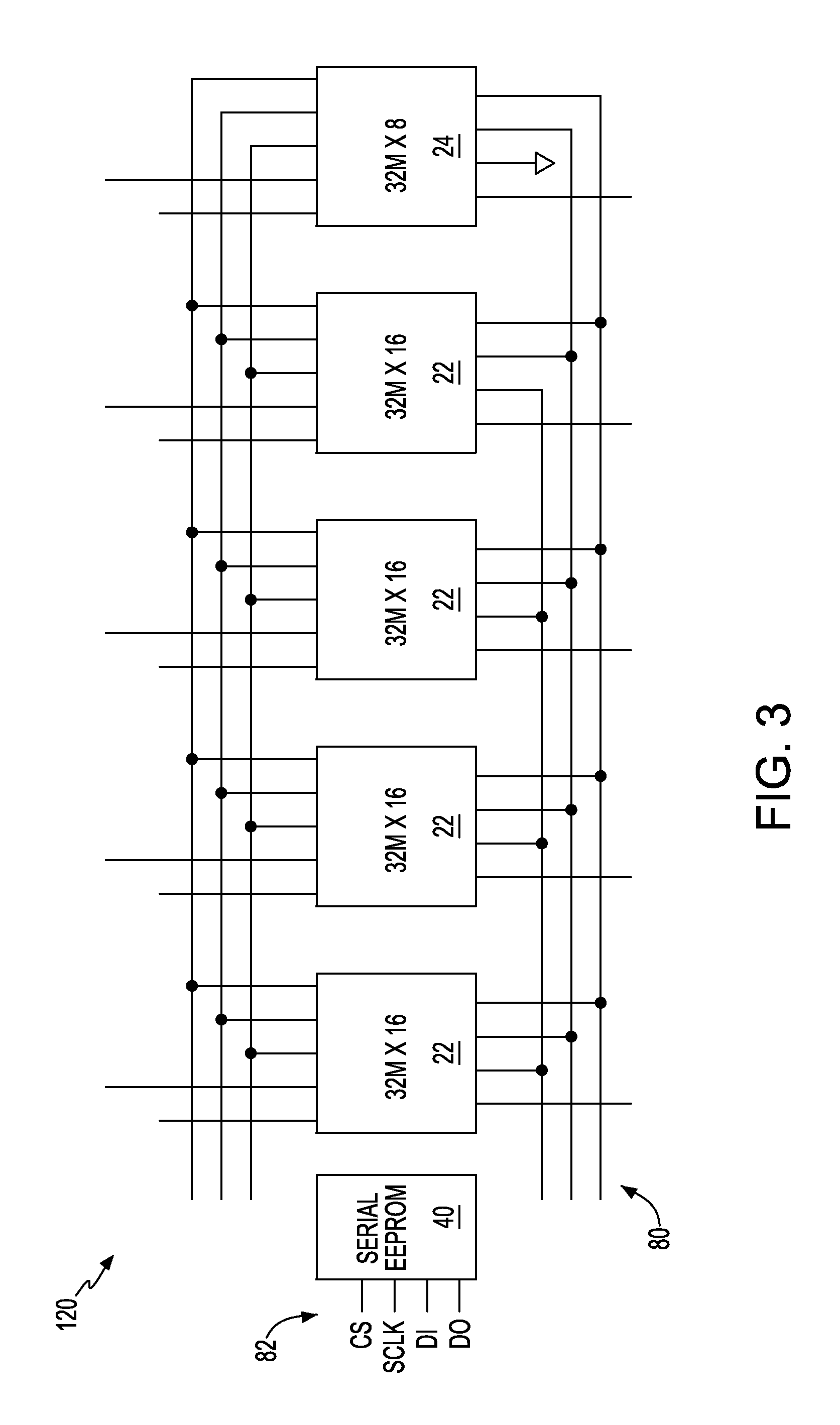

Obsolescence tolerant flash memory architecture and physical building block (PBB) implementation

ActiveUS20120320517A1Digital data processing detailsSolid-state devicesMemory interfaceElectrical connection

An electronic module and method for updating an electronic device wherein the electronic module is connected to a circuit board having one or more memory interfaces which may be embodied as processors in the electronic device. One or more semiconductor devices electrically communicate with an electrical circuit within the module. A programmable memory device including non-volatile memory electrically communicates with the electrical circuit of the electronic module. The programmable memory device includes a program having code saved therein. The code defines a multiplicity of functions for the electronic module for communication between the electronic module and a memory interface or processor of the electronic device. Electrical connection elements are attached to a substrate on a bottom side of the electronic module for electrically connecting the electrical circuit of the electronic module to the circuit board for communication between the programmable memory device and the memory interface or processor.

Owner:BAE SYSTEMS CONTROLS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com