Re-dressing utilizing method for non-ferrous metal tailings

A technology for non-ferrous metals and tailings, applied in flotation, solid separation, etc., can solve the problems of unreasonable development and utilization of tailings, reasonable process flow, unqualified concentrate grade, narrow mining and selection range, etc., to reduce drug pollution and Hazards of slime, realization of recovery rate, effect of high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

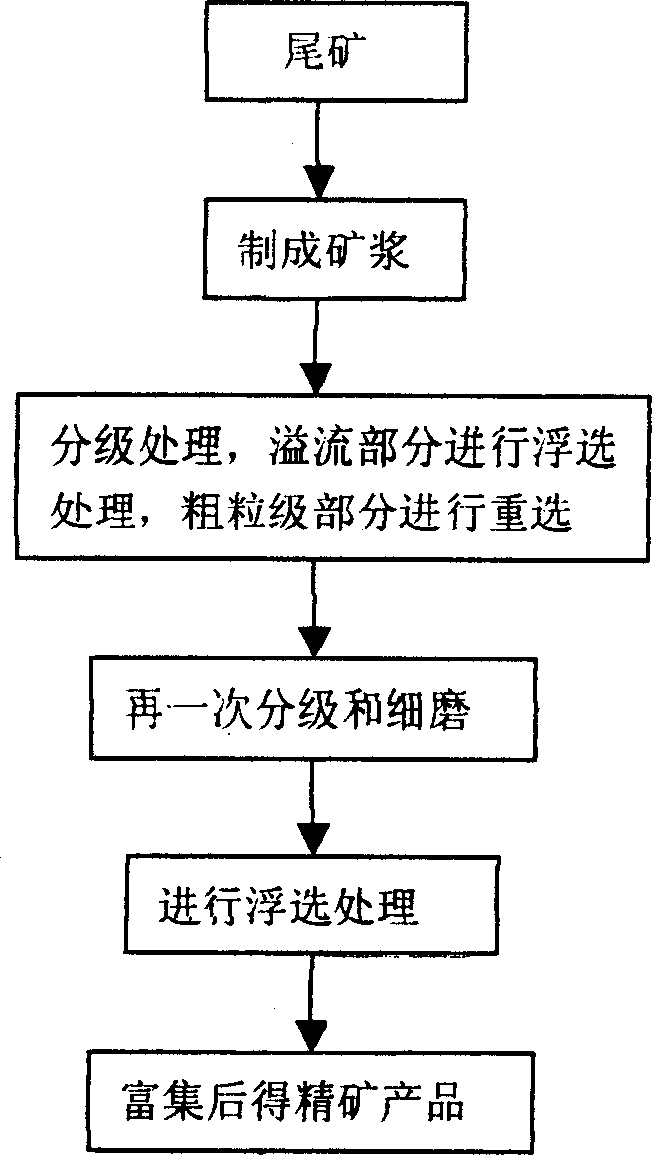

Image

Examples

Embodiment 1

[0011] For the treatment of Xinmiao tailings in Yingjing, Ya'an, Sichuan, the plant is about 40KM away from Yingjing County, with a daily processing capacity of 200T / day. The tailings dam is stacked along the Yinghe River with block stone cofferdams, with a storage capacity of 200,000M 3 , The tailings stacking time is from 1972 to the present, the average fineness of the tailings is 200 mesh, the muddy part accounts for 30%, and the deep muddy part accounts for 15%. When processing, first put the old tailings into the slurry tank, inject water and stir them into a slurry, and then put the slurry into a vertical flotation machine for classification and re-election through two-stage series scavenging to obtain a mixture of Pa, Zn, and S. Coarse concentrate, of which Zn25%, S38%, Pa19%, and the rest are impurities, and then through A-type machine-pressed sulfur flotation lead and zinc selection and fine grinding to obtain Pb, Zn mixed concentrate, of which Pb29%, Zn32%, bottom fl...

Embodiment 2

[0013] Put the old tailings into 10 pulping tanks for pulping treatment. The garbage and mud in the old tailings are screened out during the pulping process, and then prepared into a slurry with a concentration of 30%. After the spiral mixer stirs evenly, it enters the next processing procedure. After the slurry flows through the classifier, the suspended part of the overflow is processed by a vertical compound flotation machine. When the selected object reaches a certain grade, the coarse concentrate foam is discharged. Then the ore pulp is classified and re-selected, and the medium-coarse particles above 120 mesh in the ore pulp are extracted by a classifier, and the precipitated valuable components are extracted by shaking table re-selection, and a large amount of waste such as gangue is discarded, and then sent to a ball mill for grinding to obtain medium At the same time, the overflow part of the classifier is treated by the vertical compound high school flotation machine...

Embodiment 3

[0015] Take out the old tailings from the tailings dam, then pour water into the slurry mixing tank and stir to form a slurry with a concentration of 35%, while the garbage and mud in the old tailings are screened out during the slurry mixing process, and then After being evenly stirred by the spiral mixer, the ore pulp is classified, and the overflow part after classification is subjected to flotation treatment, and the medium and coarse ore particles larger than 120 mesh in the ore pulp are subsequently settled, and are transferred by the grading spiral blade and dehydrated to the slurry mixing Slurry in the barrel, and then the sorting object (that is, the middle ore) after the shaker treatment, and a large amount of waste rocks are removed, and then the coarse concentrate obtained after the classification is foamed and the middle ore obtained after re-selection is classified and refined again. Grinding to further dissociate the single crystal and intergrowth; the overflow p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com