Patents

Literature

37 results about "Polish - product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transparent glaze and preparation method thereof

InactiveCN106007379ASolve pinholesSolve the defect of slight pollution suctionPolyvinyl alcoholSlurry

The invention discloses transparent glaze and a preparation method thereof. The transparent glaze is prepared from the following ingredients in parts by weight: 2 to 6 parts of calcined zinc oxide, 5 to 7 parts of barium carbonate, 14 to 17 parts of soda feldspar, 6 to 8 parts of aluminium oxide, 1 to 3 parts of calcined soapstone, 17 to 19 parts of quartz, 19 to 22 parts of dolomite, 14 to 17 parts of calcined aluminum powder, 9 to 12 parts of wollastonite, 11 to 14 parts of nepheline powder, 0.1 to 0.4 part of sodium carboxymethyl cellulose, 0.3 to 0.6 part of sodium tripolyphosphate and 0.1 to 0.4 part of polyvinyl alcohol. After the ingredients are mixed according to the corresponding mixture ratio, the mixture is fed into ball mill equipment to be subjected to ball milling to obtain slurry; then, spray drying is performed to form powder materials; the powder materials are put into a cabin for obsolescence; the powder materials are pressed for forming a glaze blank; then, drying is performed; the glaze blank is calcined and is then crushed into powder materials; the powder materials are put for use. The glaze material is used for manufacturing ceramic tiles; the transparent effect of full polish product is effectively improved.

Owner:GUANGDONG JIA MEI CERAMIC

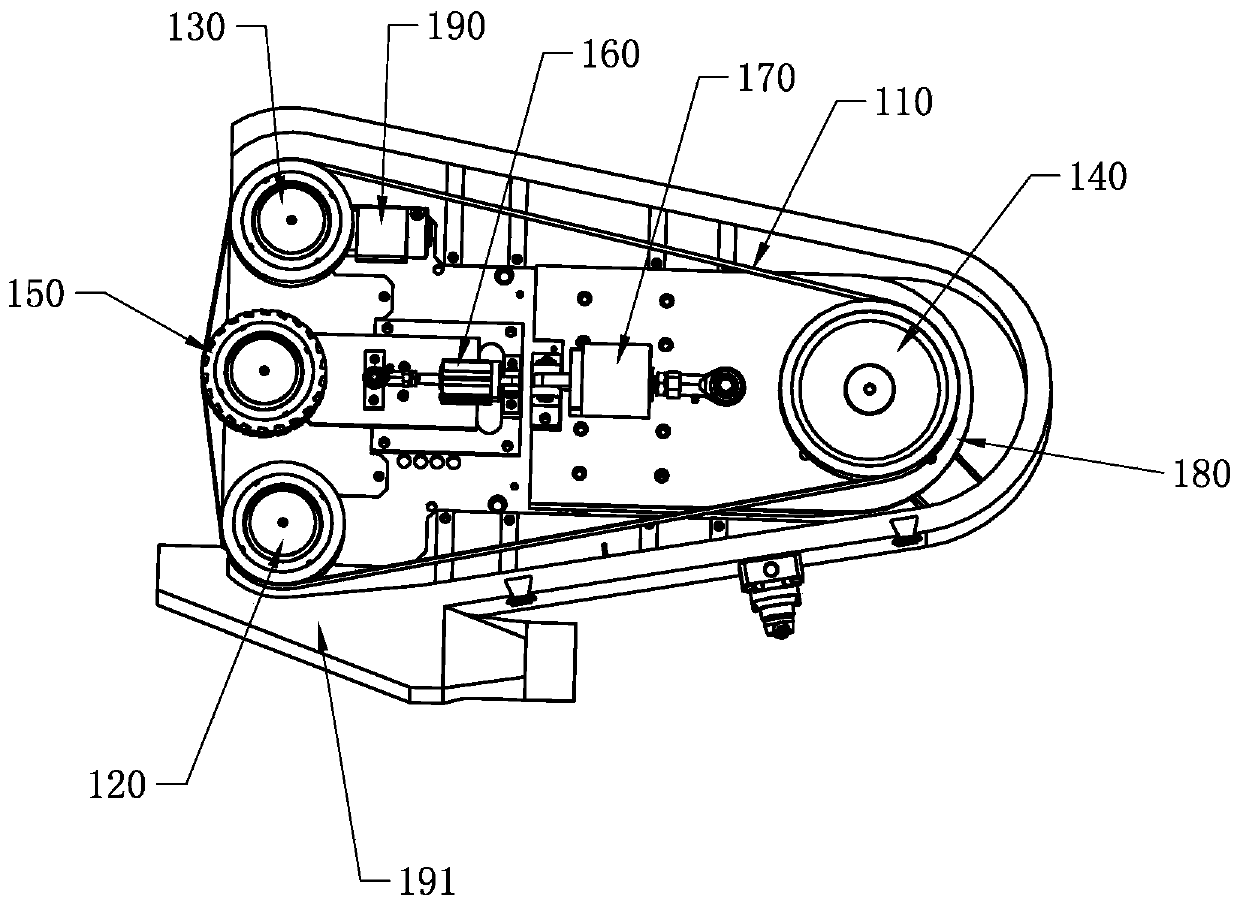

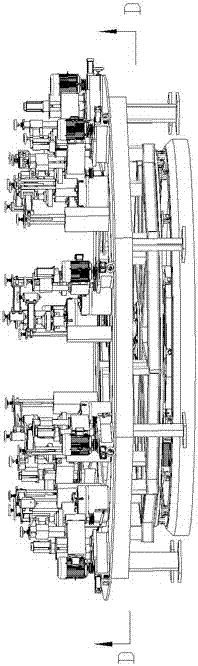

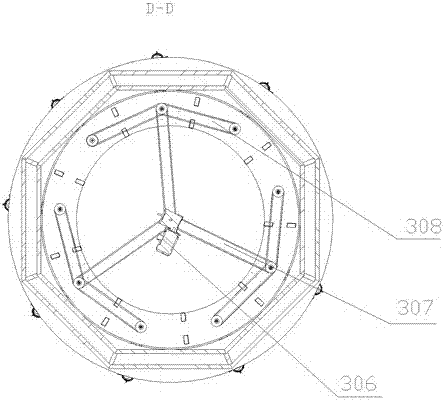

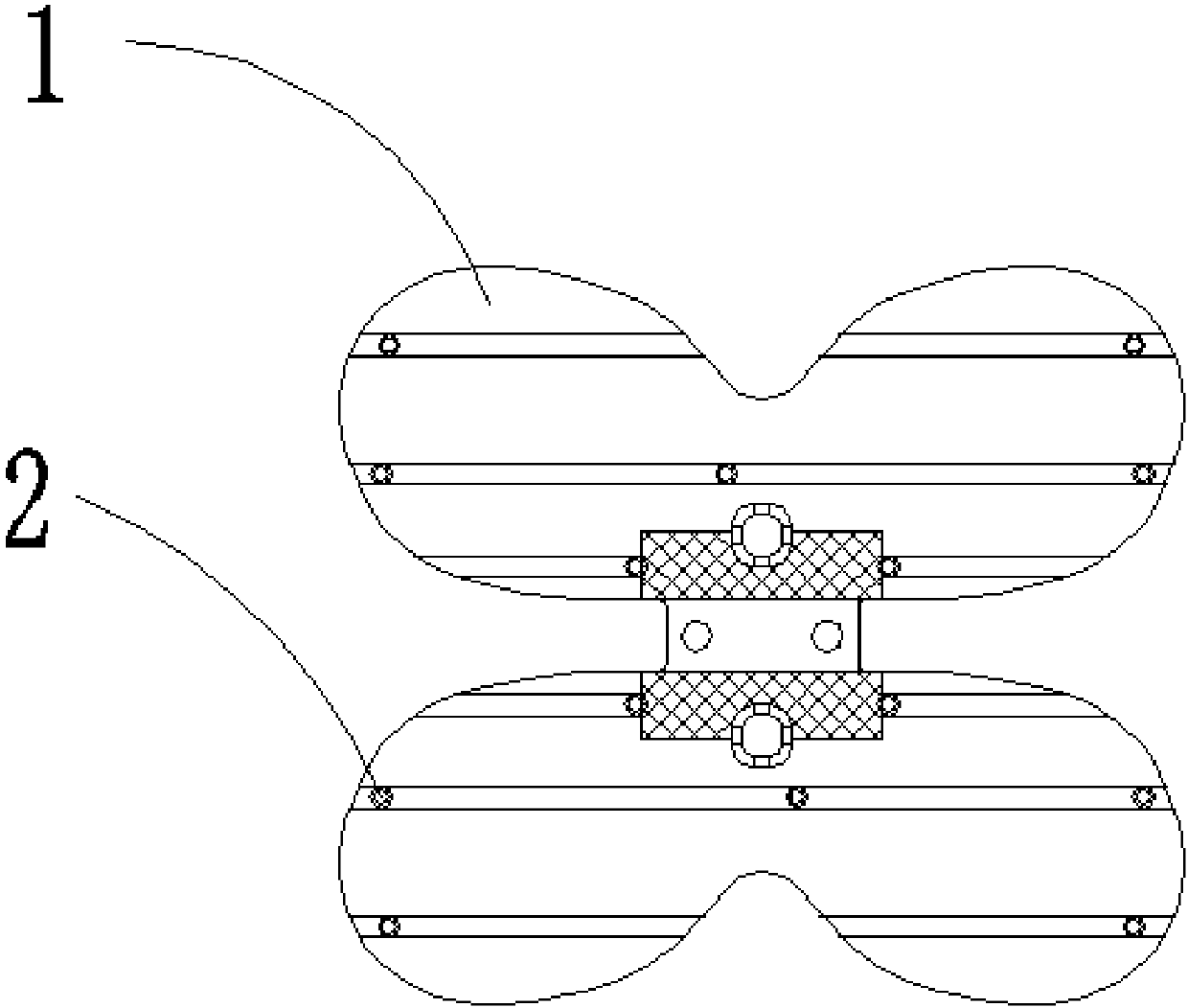

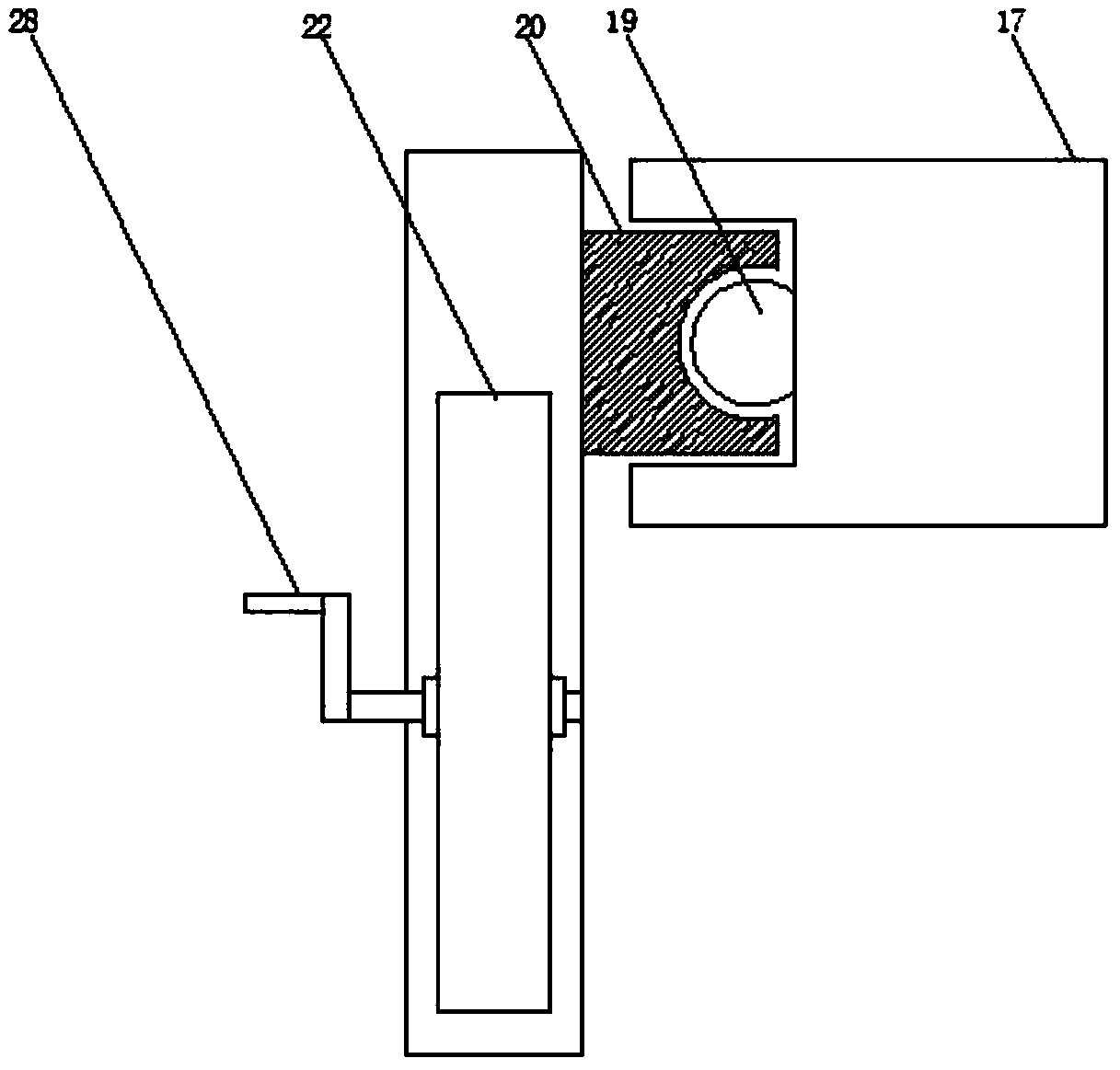

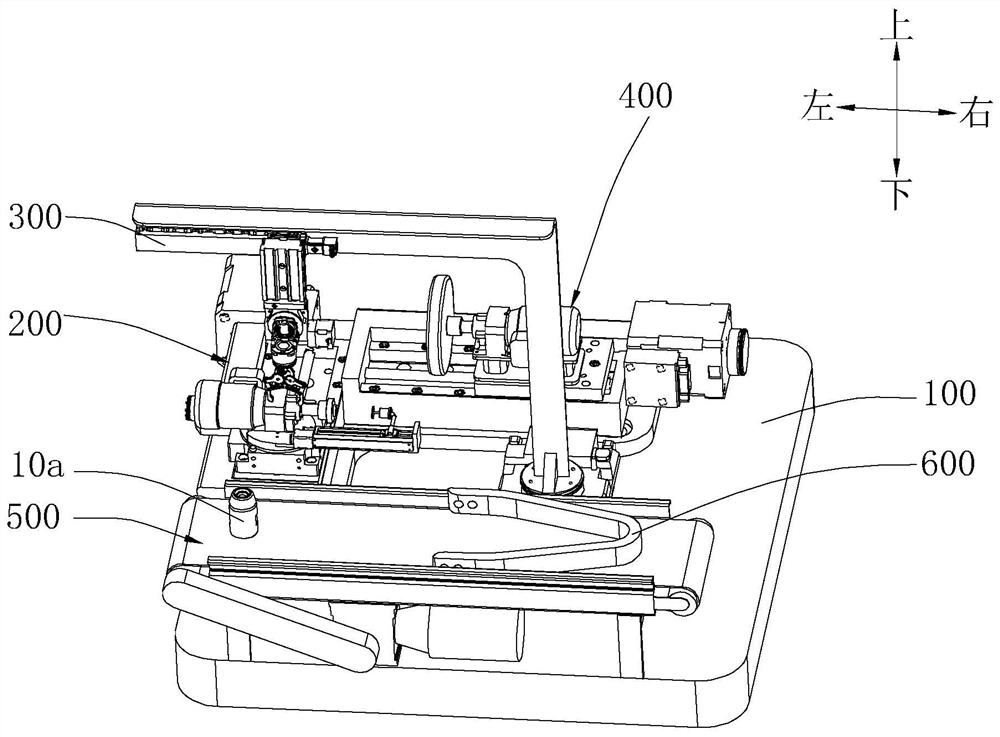

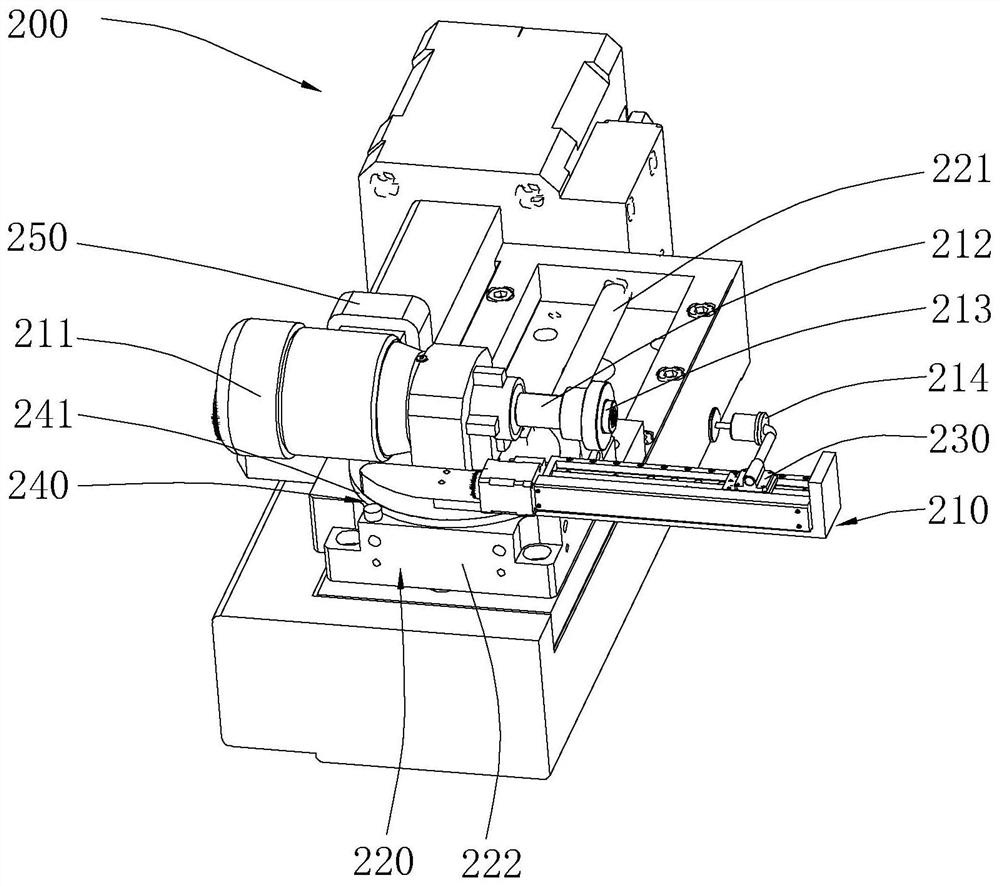

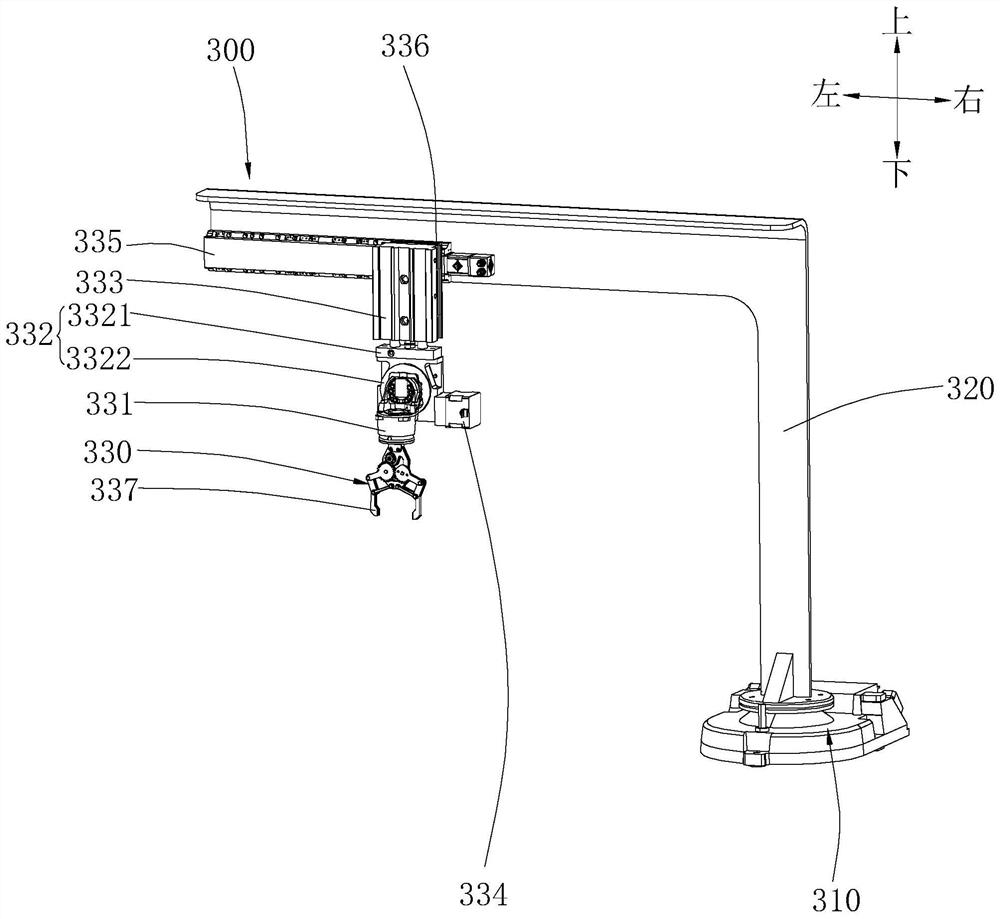

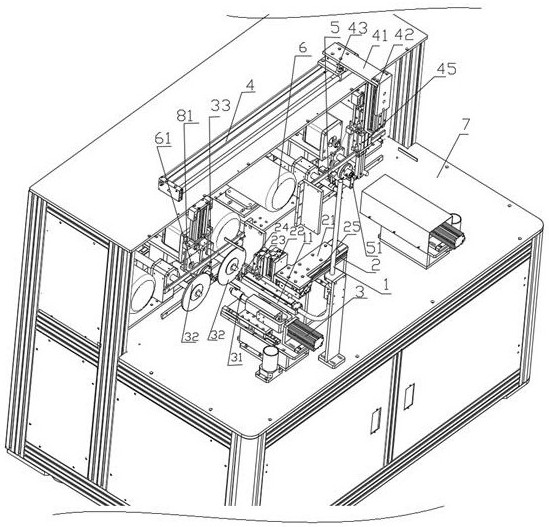

Polishing machine capable of rotationally polishing product

InactiveCN105856033AImprove labor productivityReduce labor costsPolishing machinesGrinding drivesTransmission beltEngineering

The invention discloses a polishing machine capable of rotationally polishing a product and belongs to the field of processing of automobile decorative parts. The polishing machine comprises a plurality of polishing components and a slide component used to move the polishing components and also comprises a conveying component used to convey a product and a plurality of turning mechanisms arranged on the conveying component, the turning component comprises a rotational positioning mechanism for mounting the product and a driving device, the rotational positioning mechanism comprises a support and a plurality of clamping mechanisms rotatably disposed on the support and used to mount the product, and the plurality of clamping mechanisms are connected with the driving device through a transmission belt to provide synchronous rotation. The rotational positioning mechanism is provided to simultaneously position and turn multiple sets of products to simultaneously three outer surfaces of each product, labor productivity is greatly improved, and labor cost is decreased.

Owner:IDEA ROBOT TECH KUNSHAN CO LTD

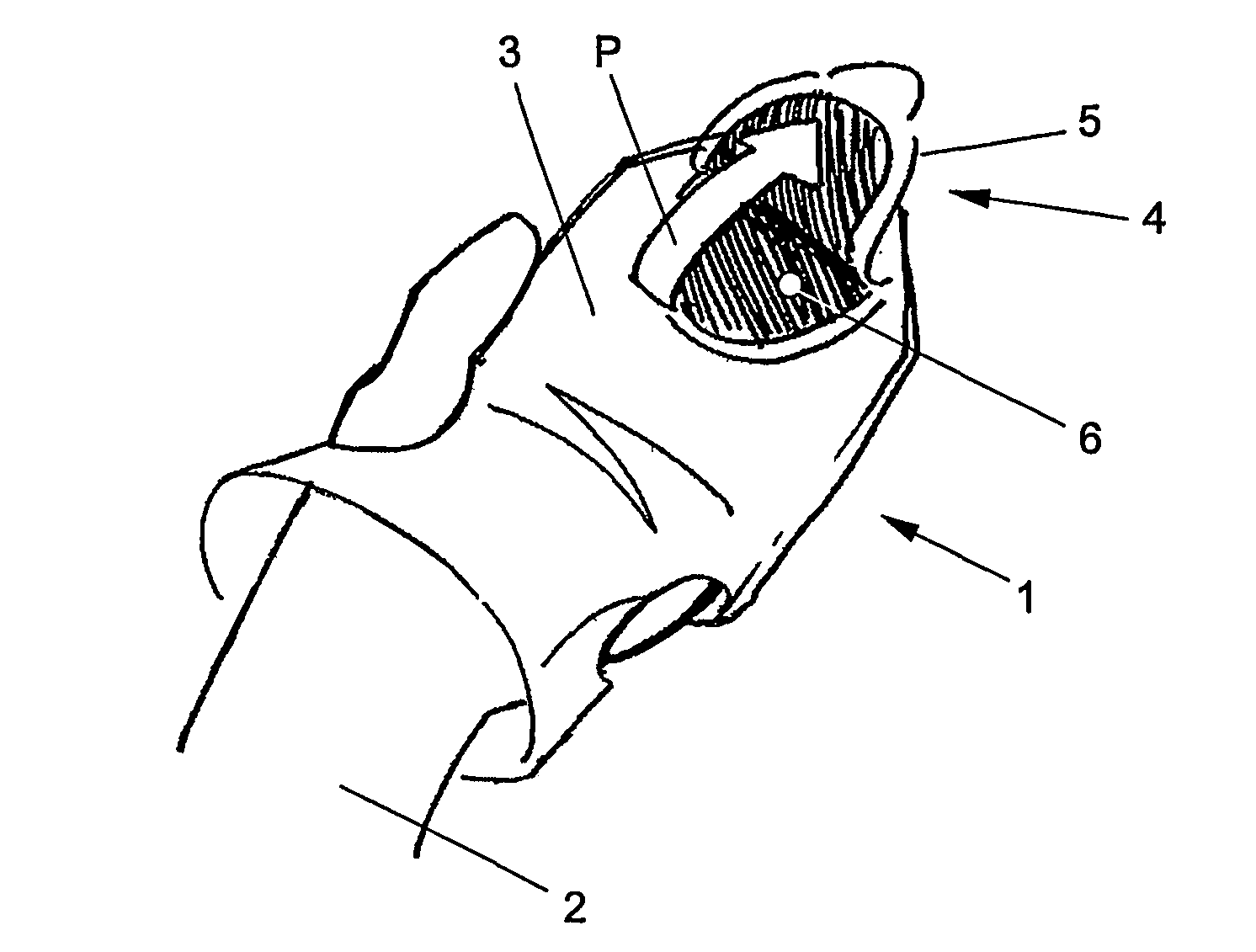

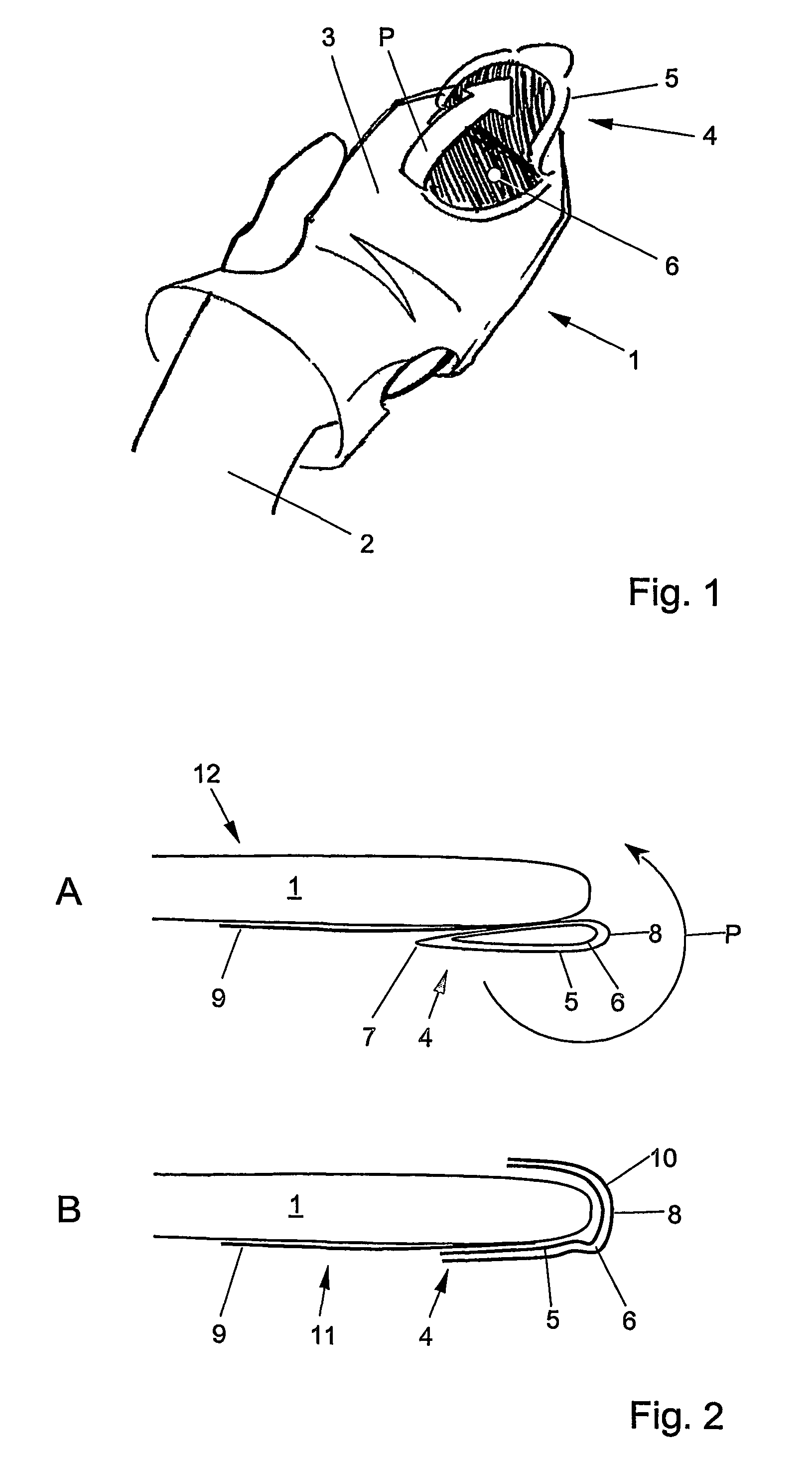

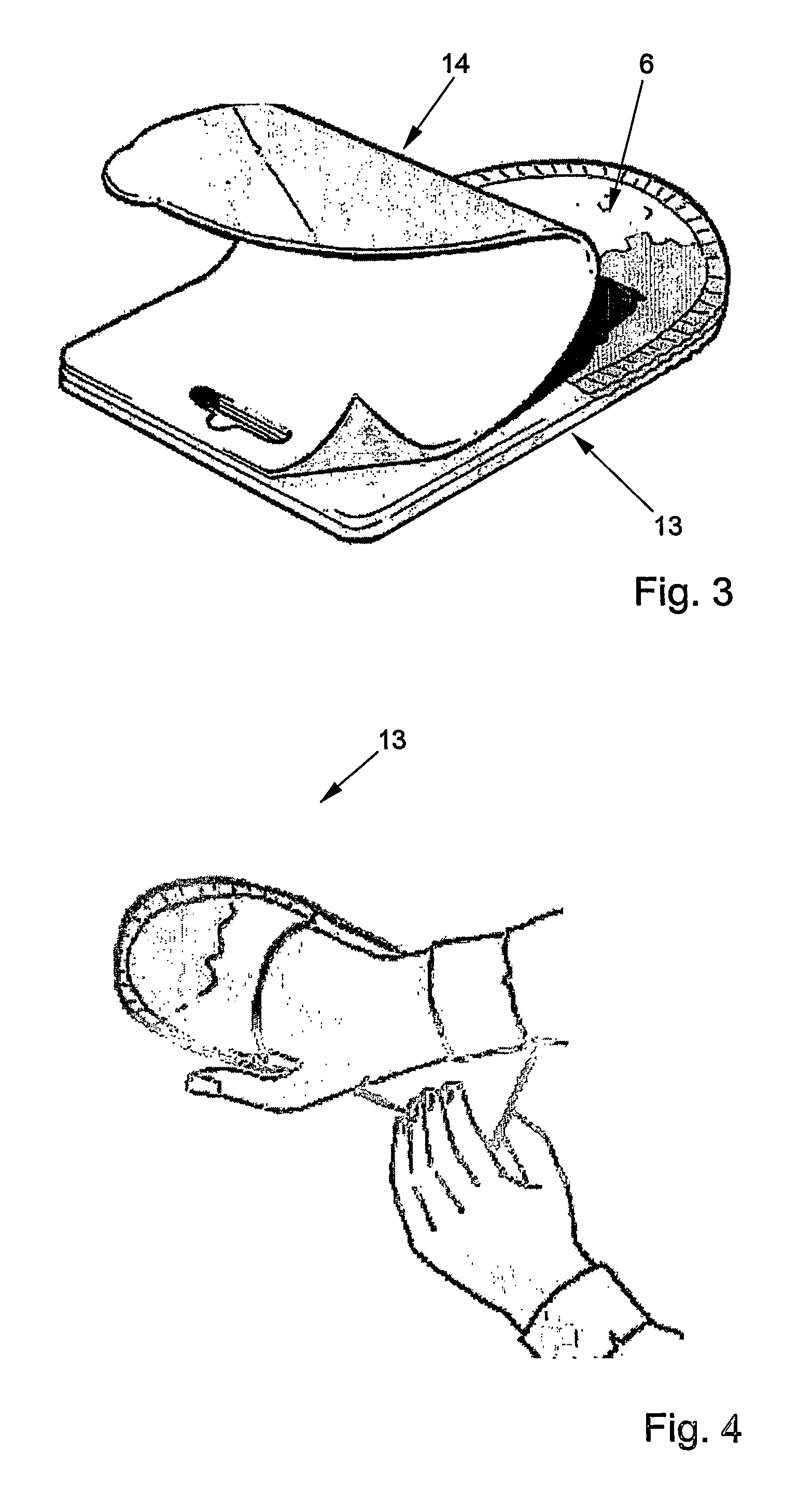

Polishing implement for polishing shoes

ActiveUS7636978B2Broaden applicationEasy to polishBoard cleaning devicesCarpet cleanersEngineeringPolish - product

A polishing implement for polishing a shoe or the like, including a structure to be handheld provided with an absorbing fiber layer for forming a first polishing layer; and a sachet provided on or to be provided on the structure for containing the polishing product. According to the invention, the sachet includes a fiber layer impregnated with polishing product and, in closed condition, screened off by a protective layer while in opened condition, the impregnated fiber layer forms a second polishing layer for applying the polishing product to the shoe.

Owner:SC JOHNSON & SON INC

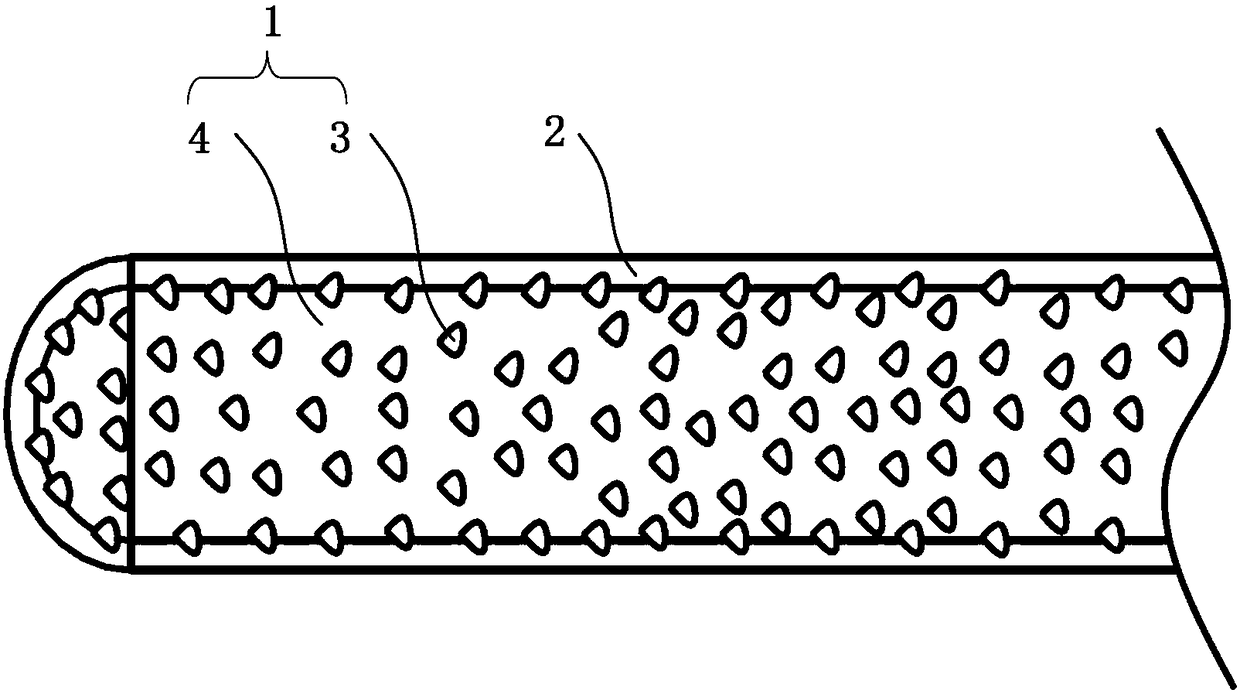

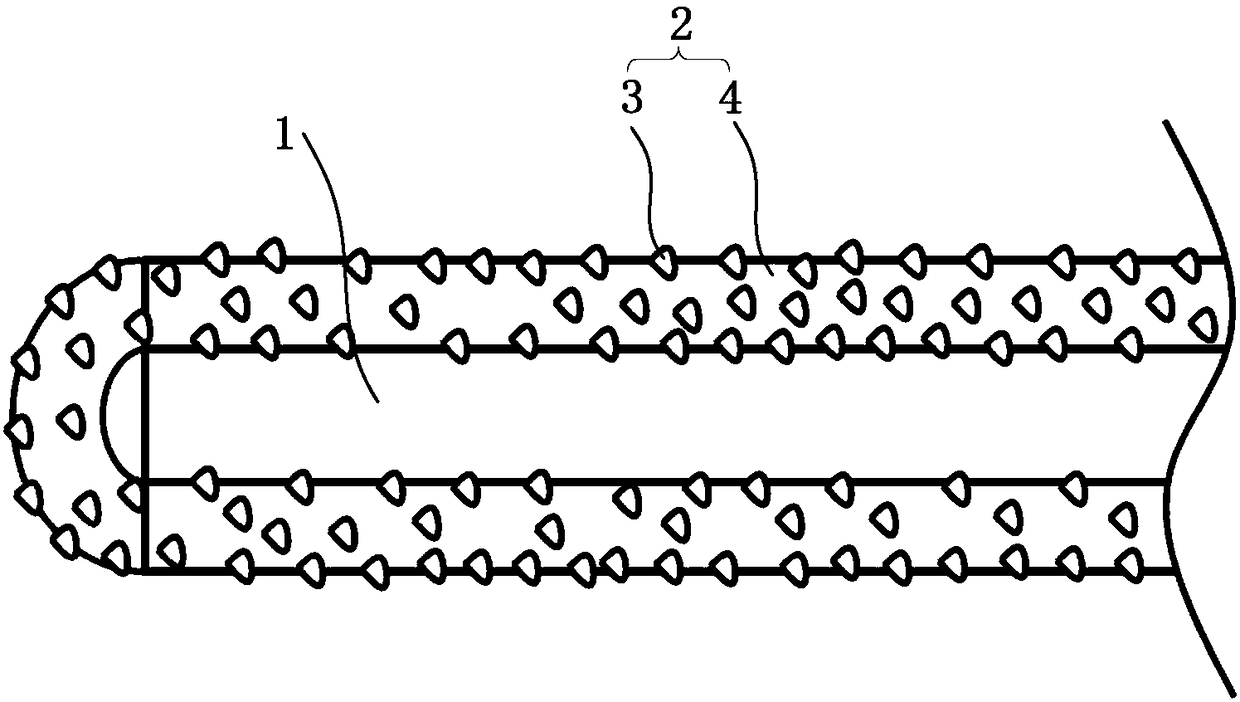

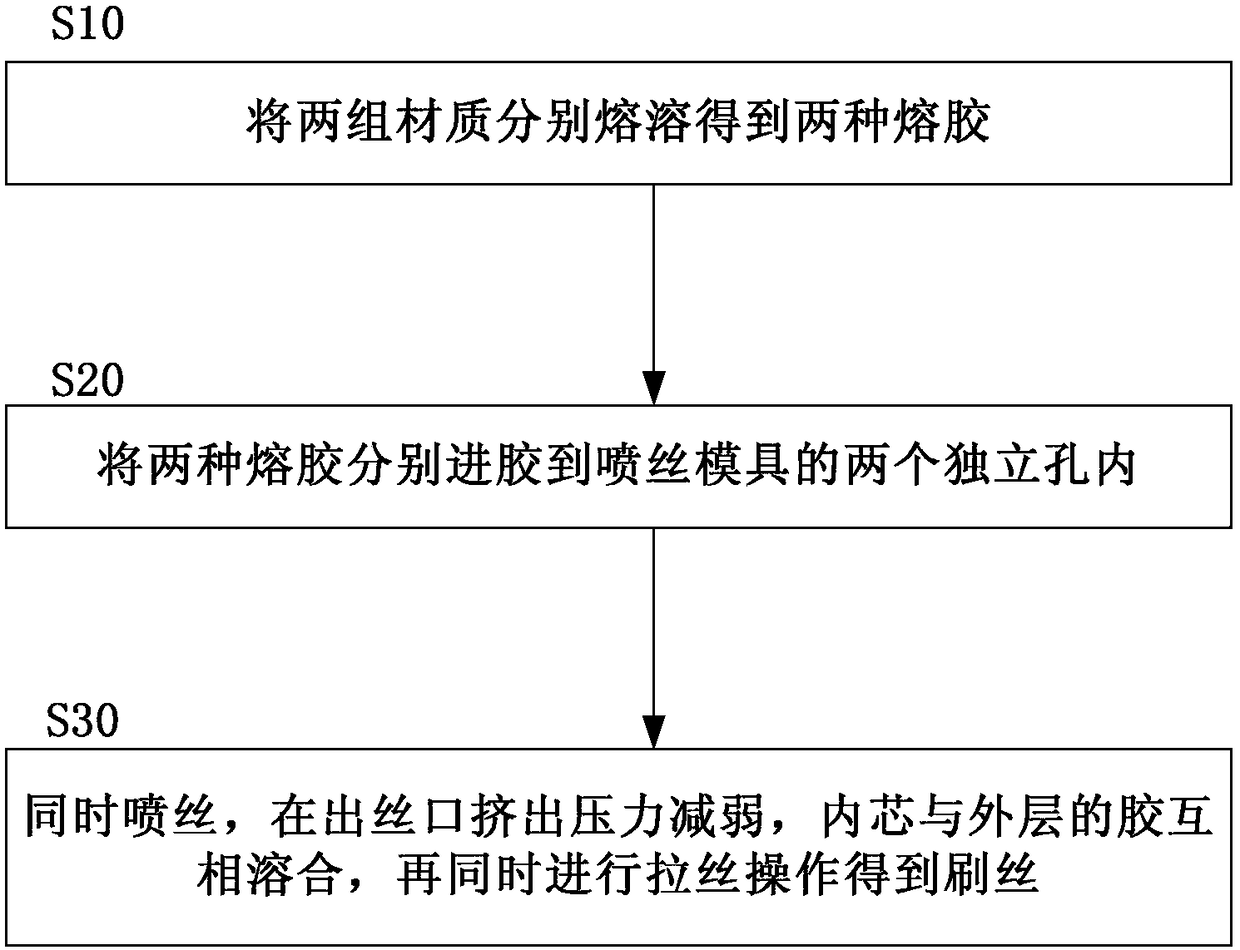

A coated grinding brush filament, a brush and a manufacturing method of the coated grinding brush filament

InactiveCN108972379ACompact structureAvoid wear and tearAbrasion apparatusBristleSurface cleaningEngineering

The invention discloses a coated grinding brush filament, a brush and a manufacturing method of the coated grinding brush filament, and relates to the field of grinding and polishing products and / orbrushes. The method is used for optimizing brush filament quality of conventional industrial grinding and polishing and household brush products. The coated grinding brush filament includes an inner core and an outer sheath. The inner core and the outer sheath are integrated into one body. The inner core and / or the outer sheath contain abrasive sand. In the brush filament provided by the technical scheme, at least one of the inner core and the outer sheath contains the abrasive sand, the inner core and the outer sheath are tightly integrated into one body, and so no glue failure happens, theinner layer and outer layer cannot be separated, and the grinding is uniform. The coated grinding brush filament provided by the technical scheme can be used for manufacturing cross-section grinding hairbrushes, cleaning and polishing hairbrushes, highly descaling and cleaning hairbrushes and other products, and is suitable for flat surface cleaning.

Owner:深圳市众力兴化纤科技有限公司

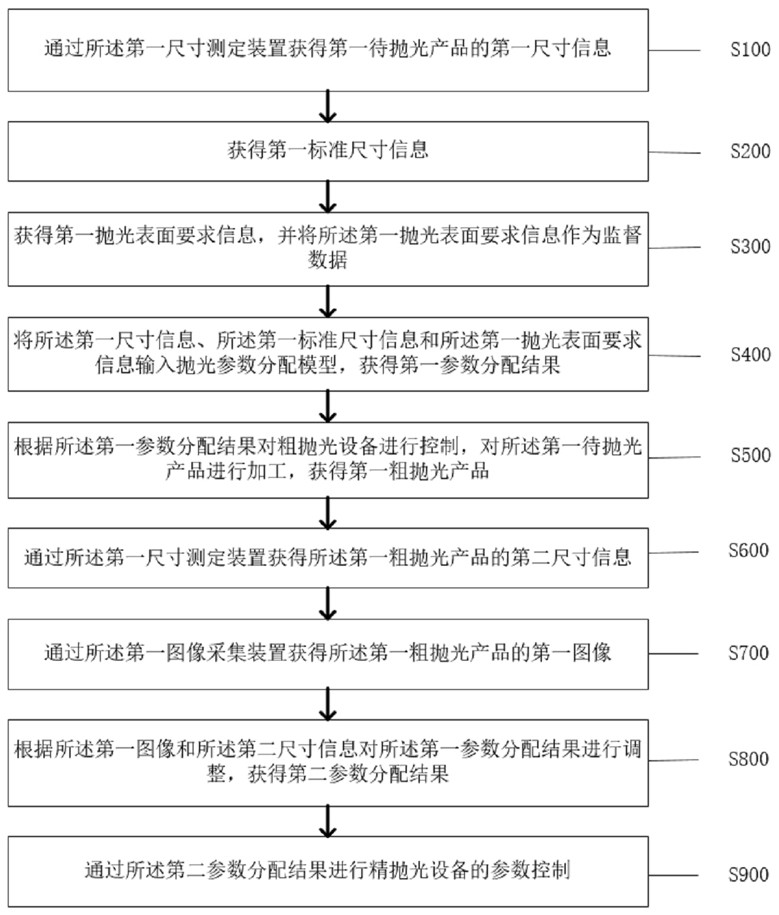

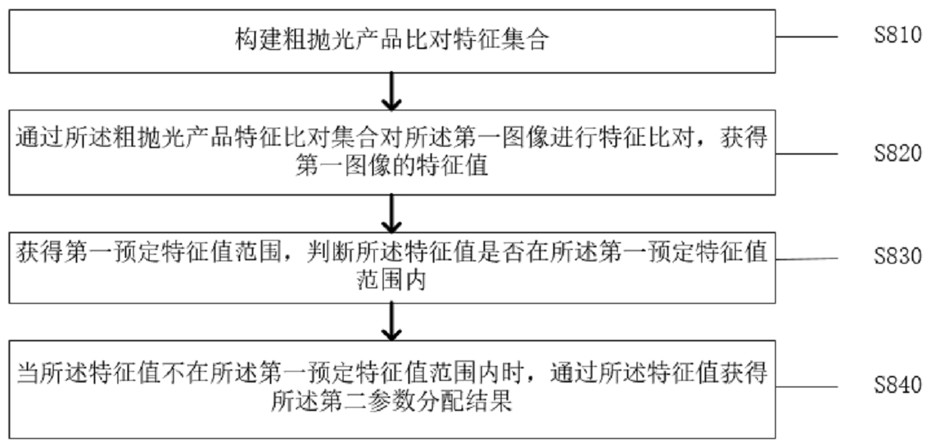

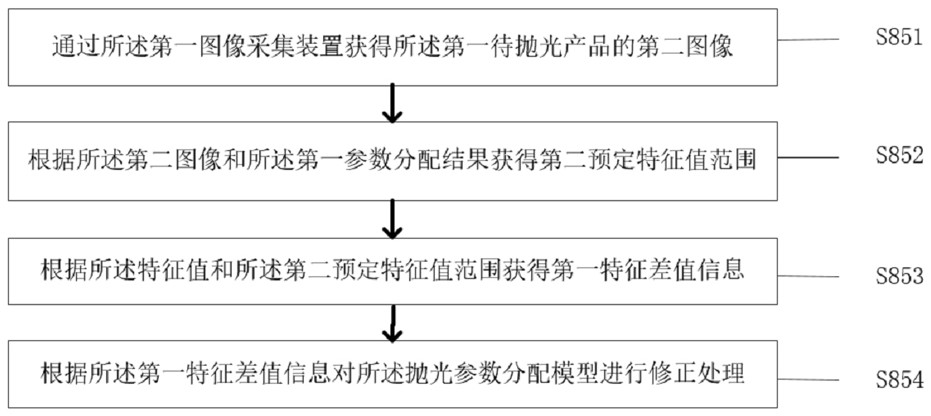

Intelligent control method and system for polishing equipment

ActiveCN113681469AImprove polishing yieldGrinding feed controlCharacter and pattern recognitionPolishingProcess engineering

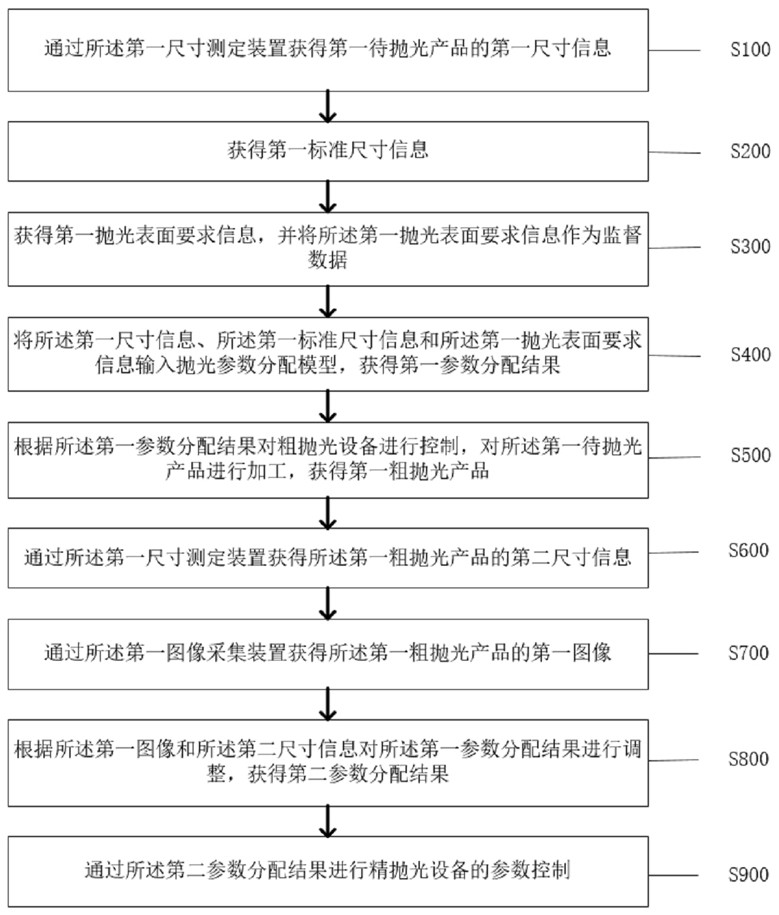

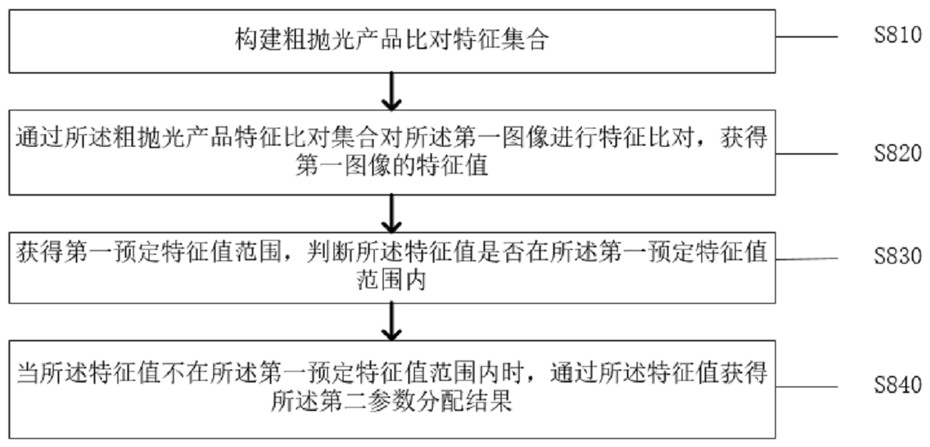

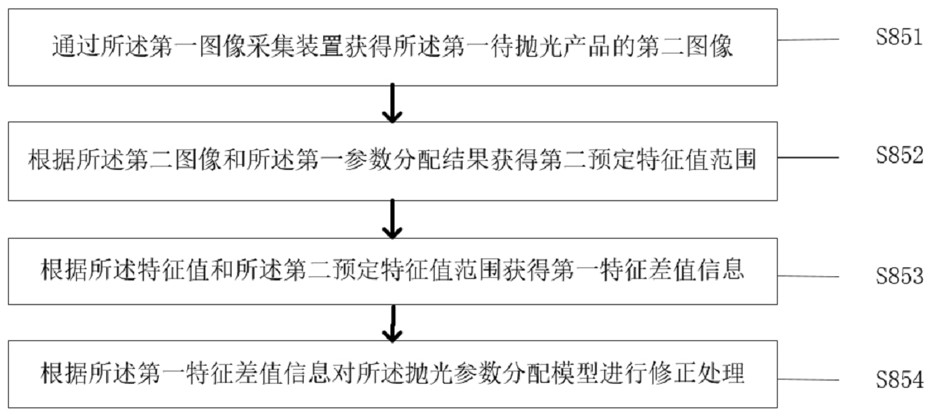

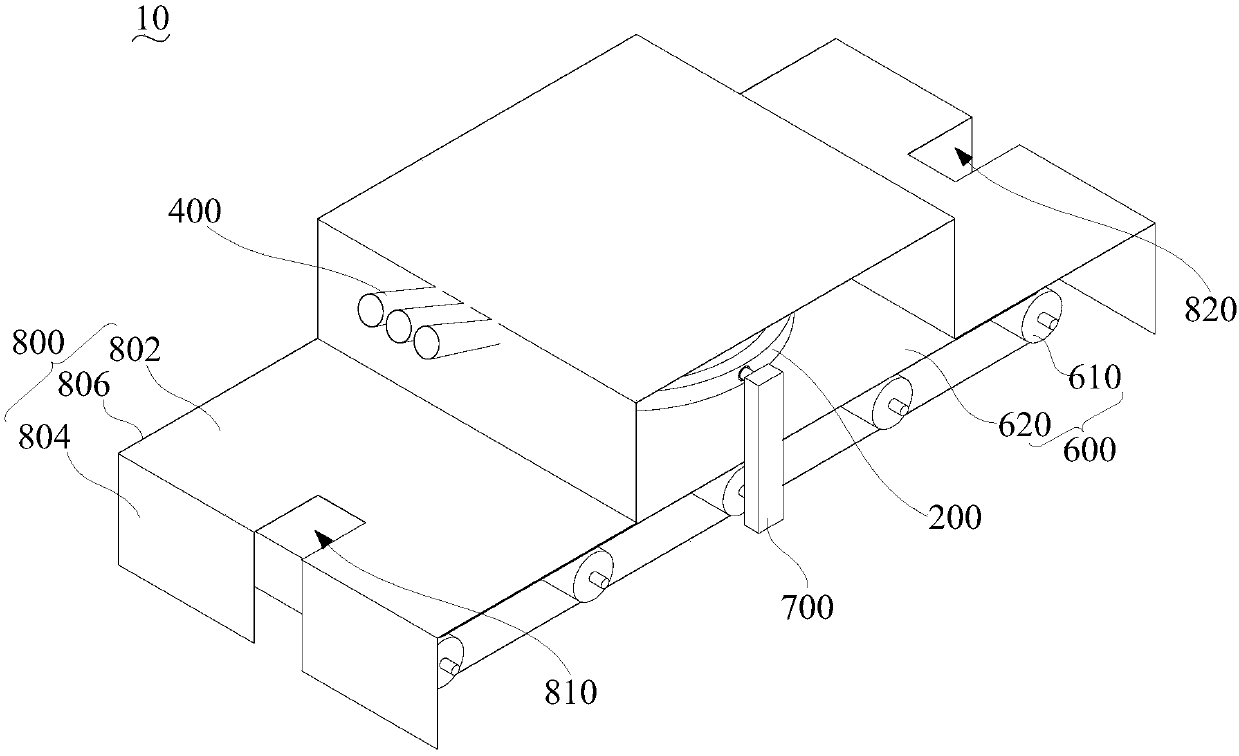

The invention discloses an intelligent control method and system for polishing equipment. The intelligent control method comprises the steps that first size information is obtained; first standard size information is obtained; first polishing surface requirement information is obtained, the first size information, the first standard size information and the first polishing surface requirement information are input into a polishing parameter distribution model, and a first parameter distribution result is obtained; rough polishing equipment is controlled according to the first parameter distribution result to obtain a first rough polishing product; second size information of the first rough polishing product is obtained; a first image of the first rough polishing product is obtained; the first parameter distribution result is adjusted according to the first image and the second size information to obtain a second parameter distribution result; and fine polishing equipment parameter control is carried out according to the second parameter distribution result. The technical problem that in the prior art, joint intelligent control over rough polishing and fine polishing parameters cannot be intelligently conducted according to specific parameter information and product demand information of products, and consequently the polishing reject ratio is increased is solved.

Owner:南通豪派金属制品有限公司

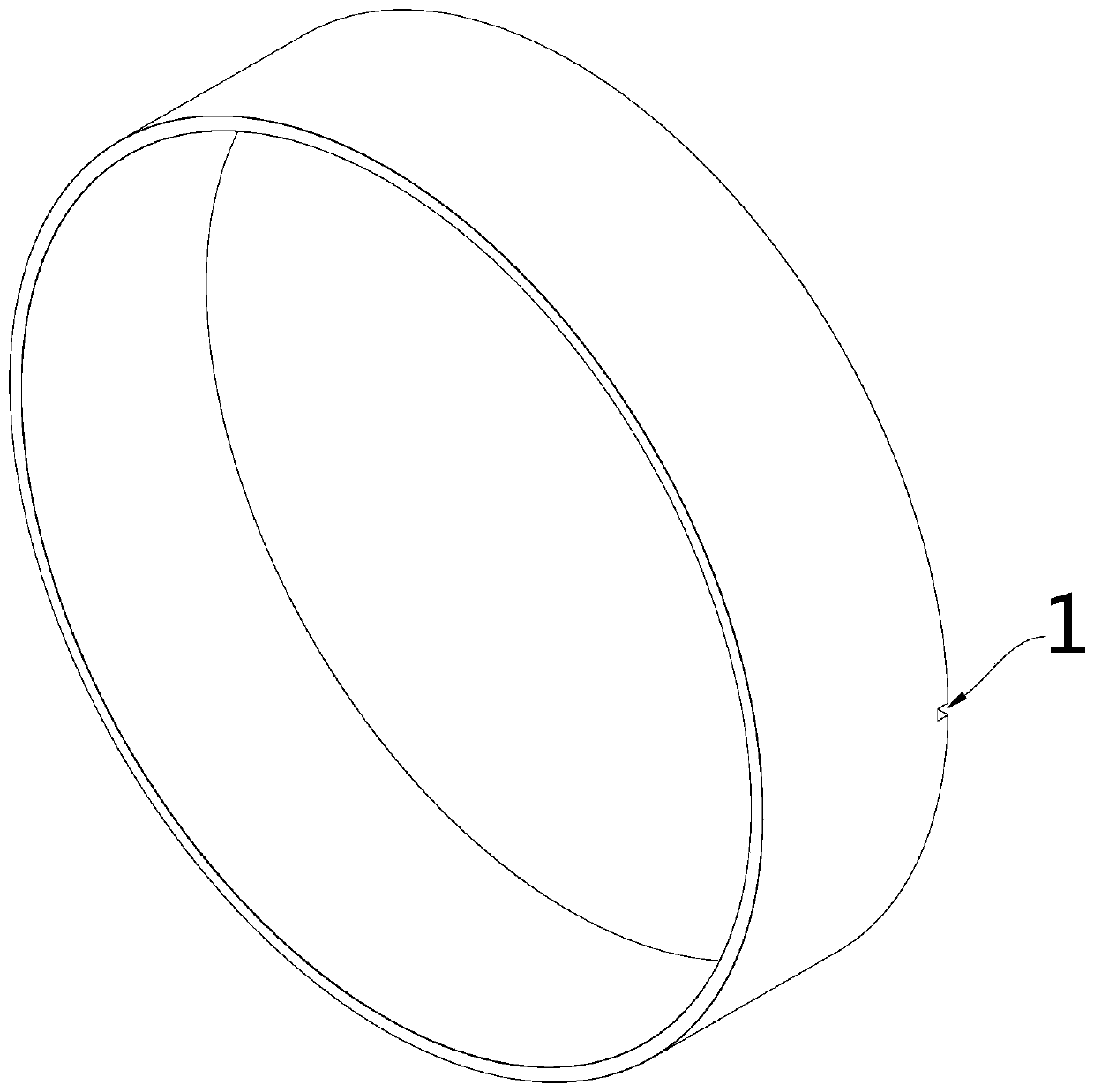

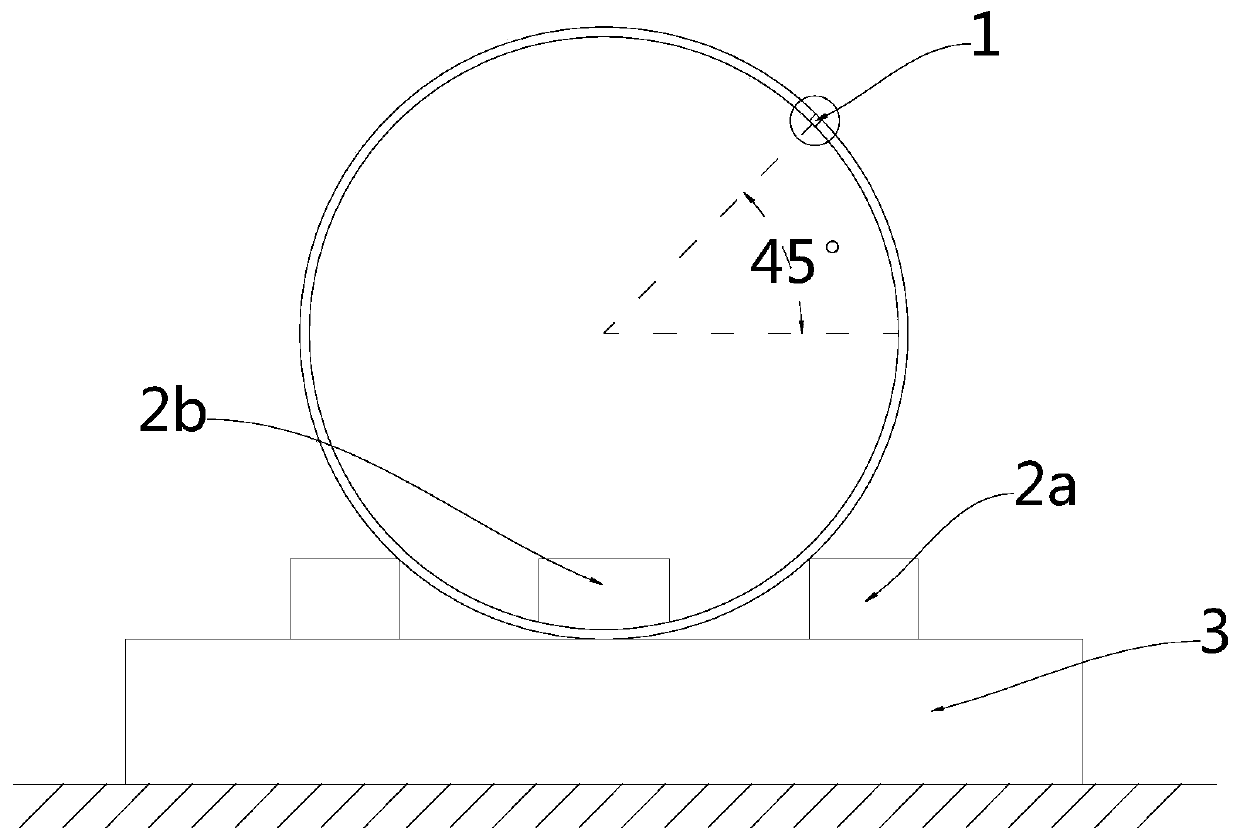

Polishing process for large quartz ring provided with notch

The invention discloses a polishing process for a large quartz ring provided with a notch. The polishing process comprises the following steps of: (A) polishing the outer diameter; (B) carrying out washing; (C) placing the large quartz ring on a worktable in a manner that the axis is kept to be horizontal so that the notch of the large quartz ring is positioned at the midpoint of 1 / 4 of the circular arc which takes the highest point of the large quartz ring as the end point; (D) slowly pushing the large quartz ring into an annealing furnace and heating the annealing furnace, stopping heating when the temperature of the annealing furnace is increased to 950 DEG C, and pulling out the large quartz ring; (E) carrying out high-temperature polishing on the half circumference of the upper part of the large quartz ring by means of flame jetting (F) pushing the large quartz ring into the annealing furnace for annealing; (G) checking the stress, rotating the large quartz ring by 180 degrees along the axis, and carrying out high-temperature polishing on the unpolished parts of the large quartz ring by means of flame jetting; (H) pushing the large quartz ring into the annealing furnace for annealing again; and (I) inspecting a finished product. The polishing process disclosed by the invention adopts an electrochemical technology for high-temperature polishing, achieves a good polishing effect and solves the problem about easy burst of high-temperature polished products.

Owner:HUZHOU DONGKE ELECTRONICS QUARTZ

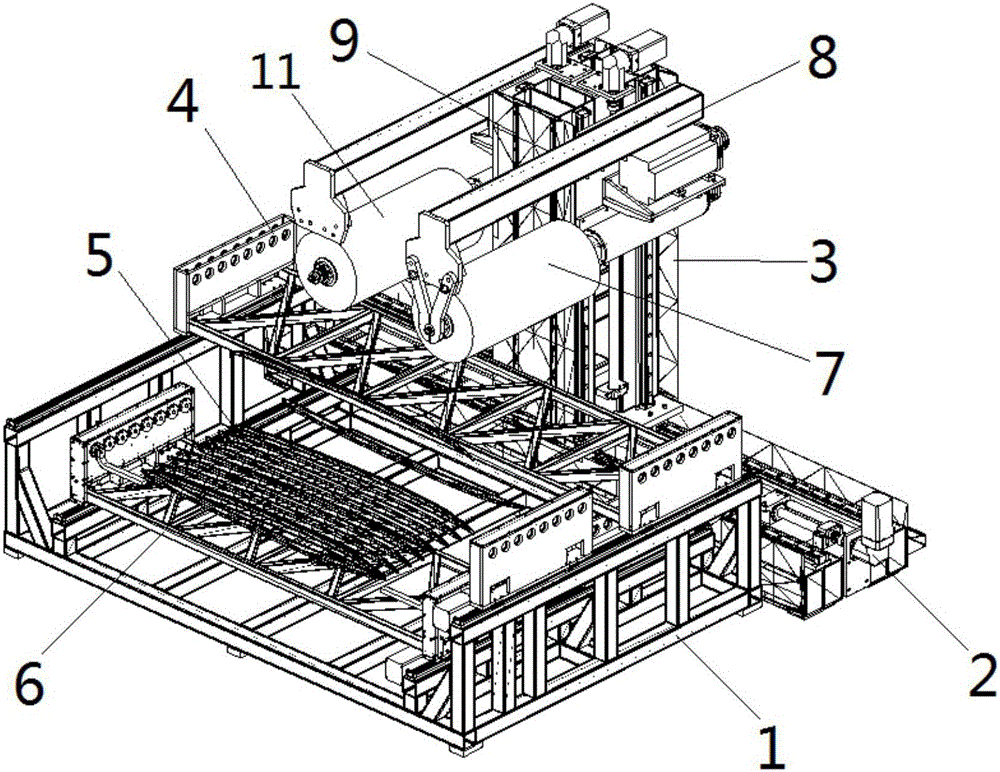

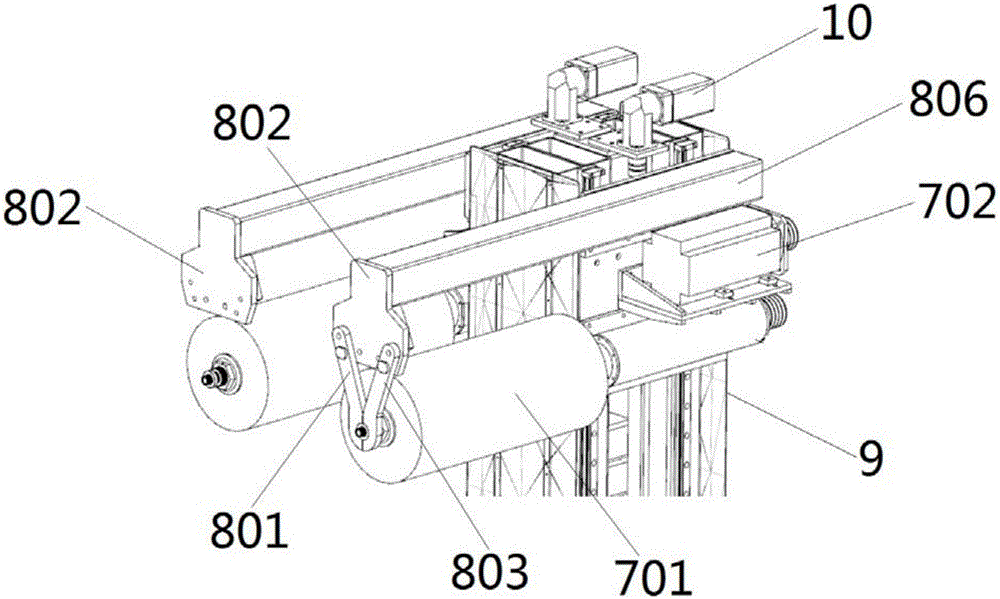

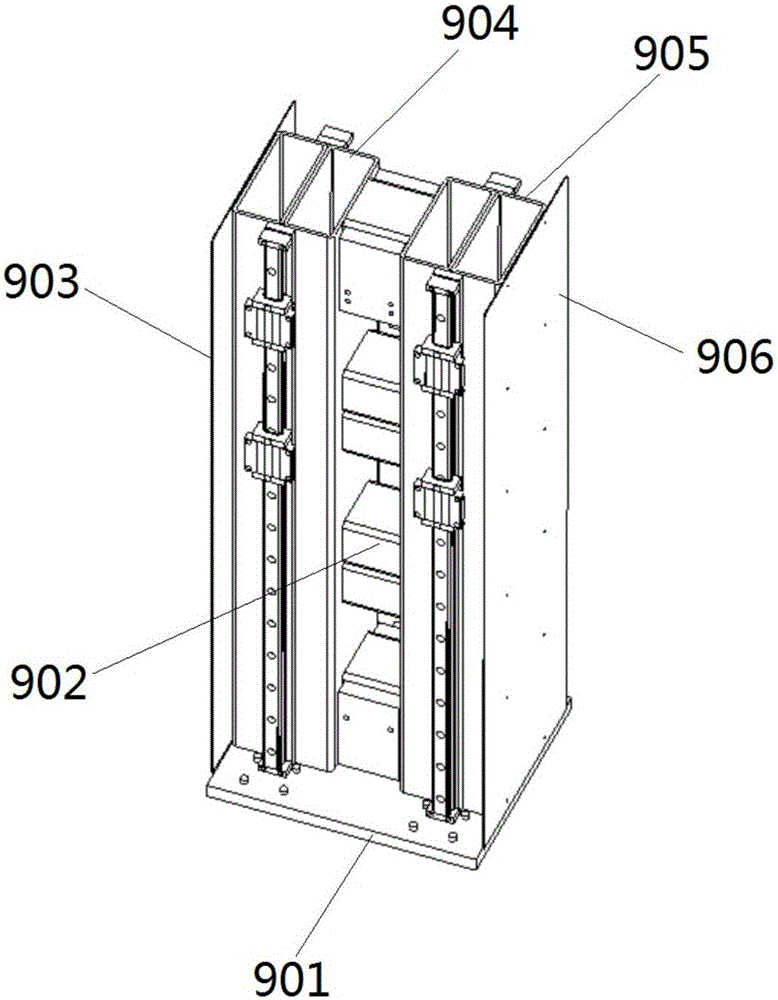

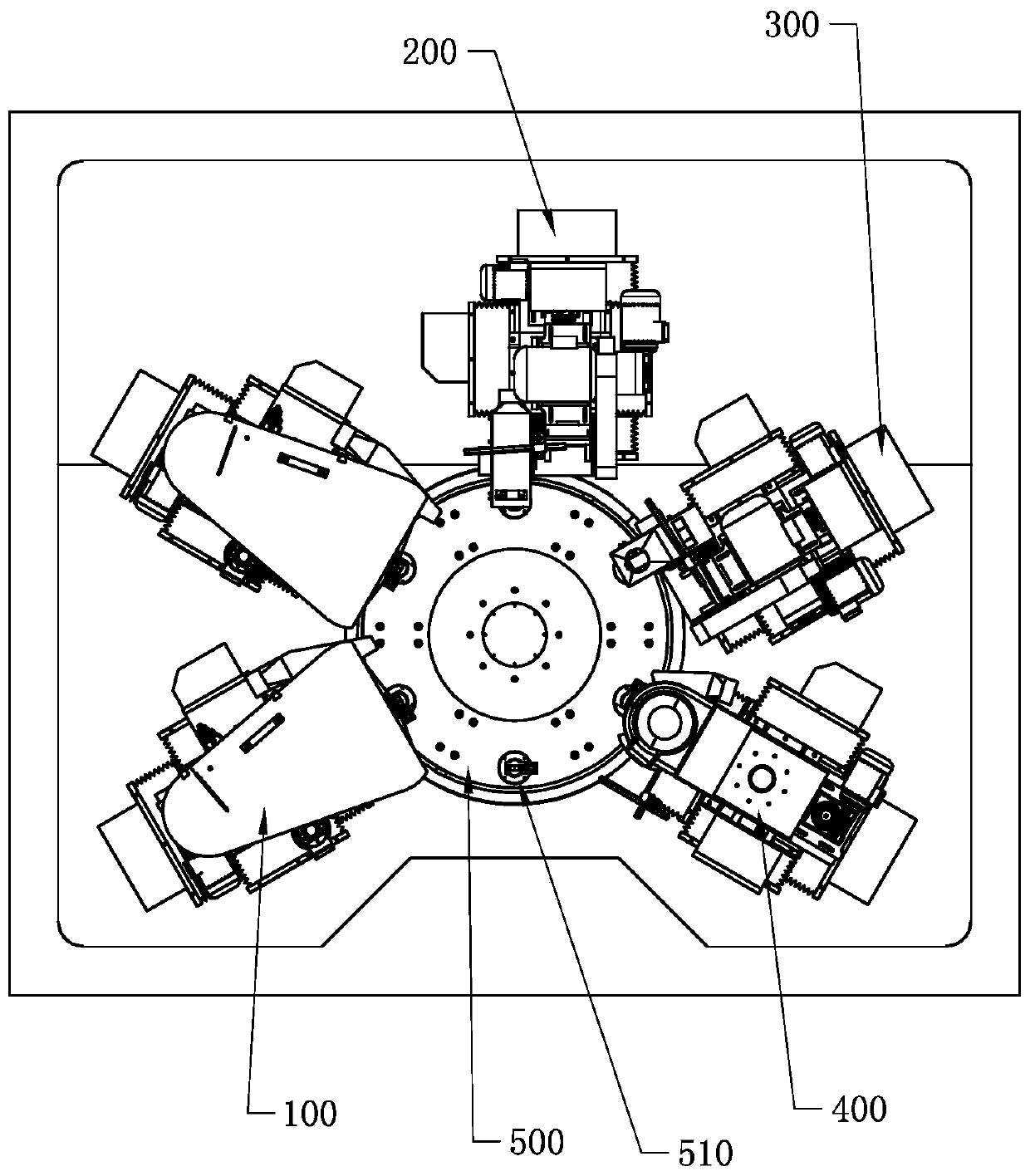

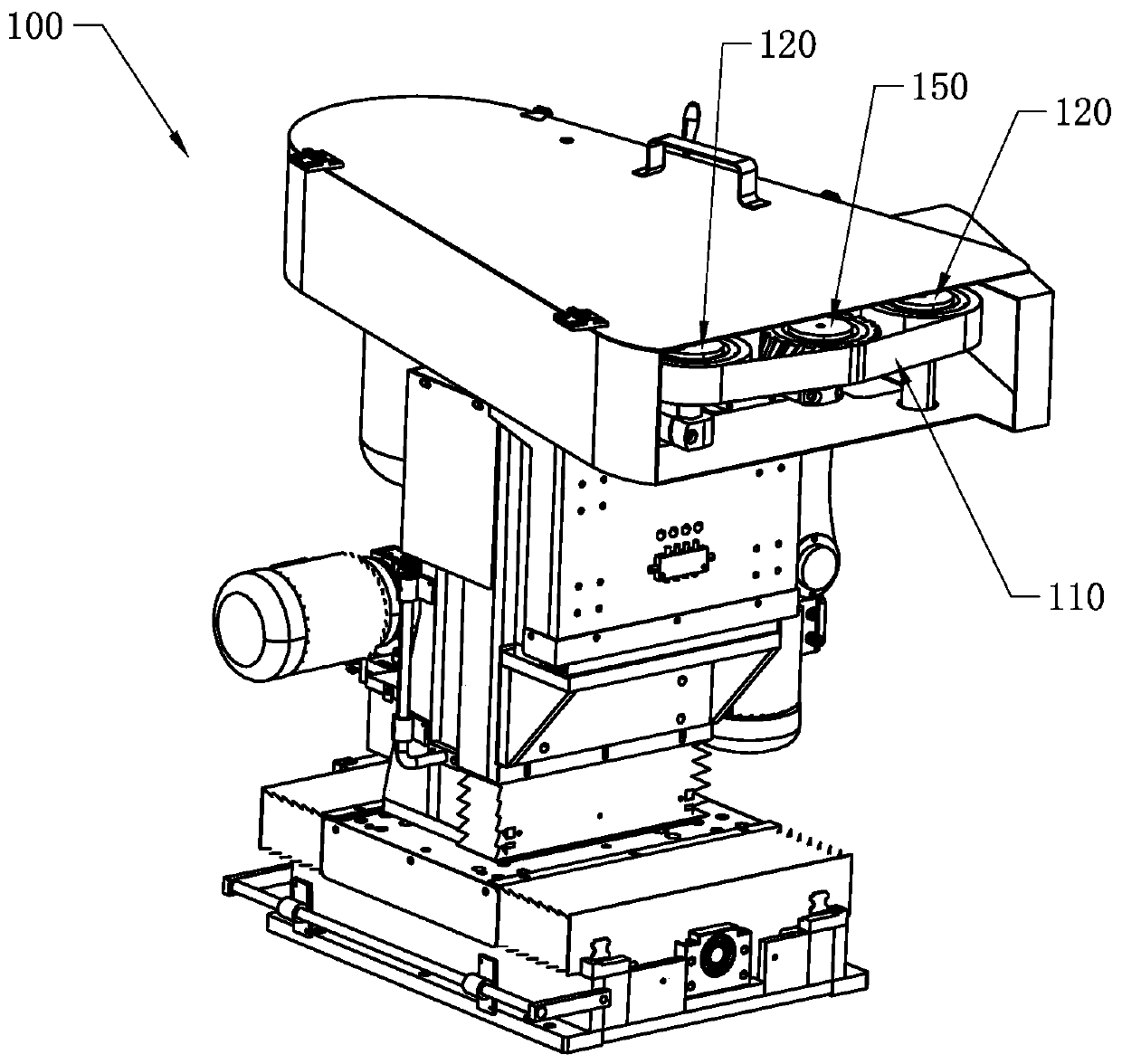

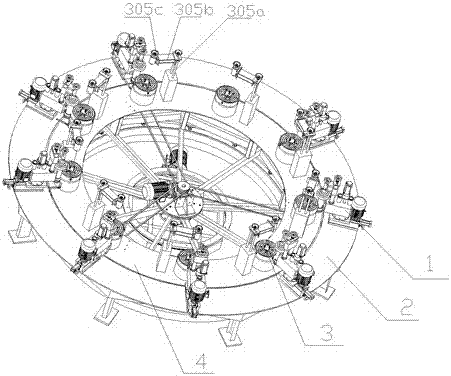

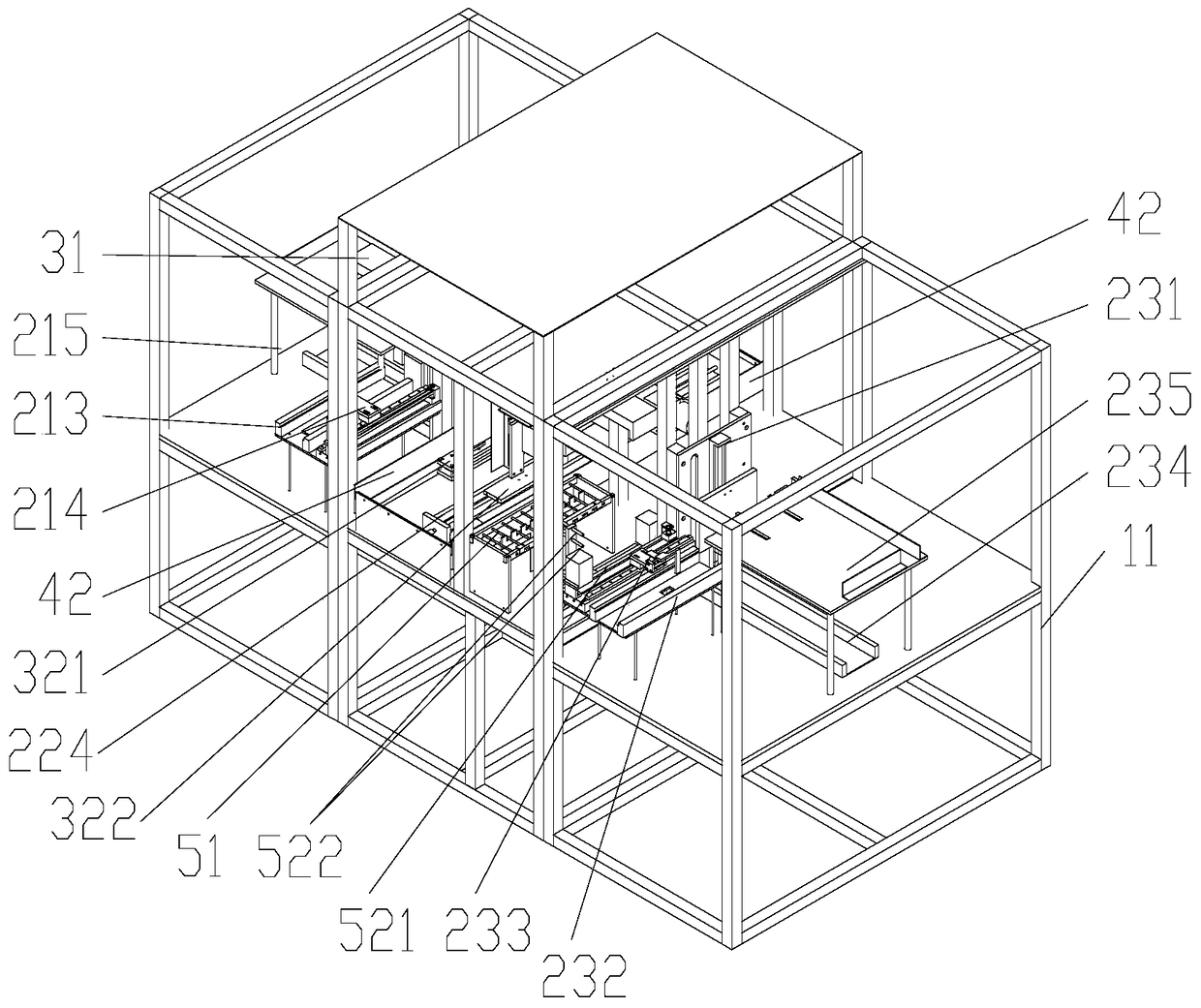

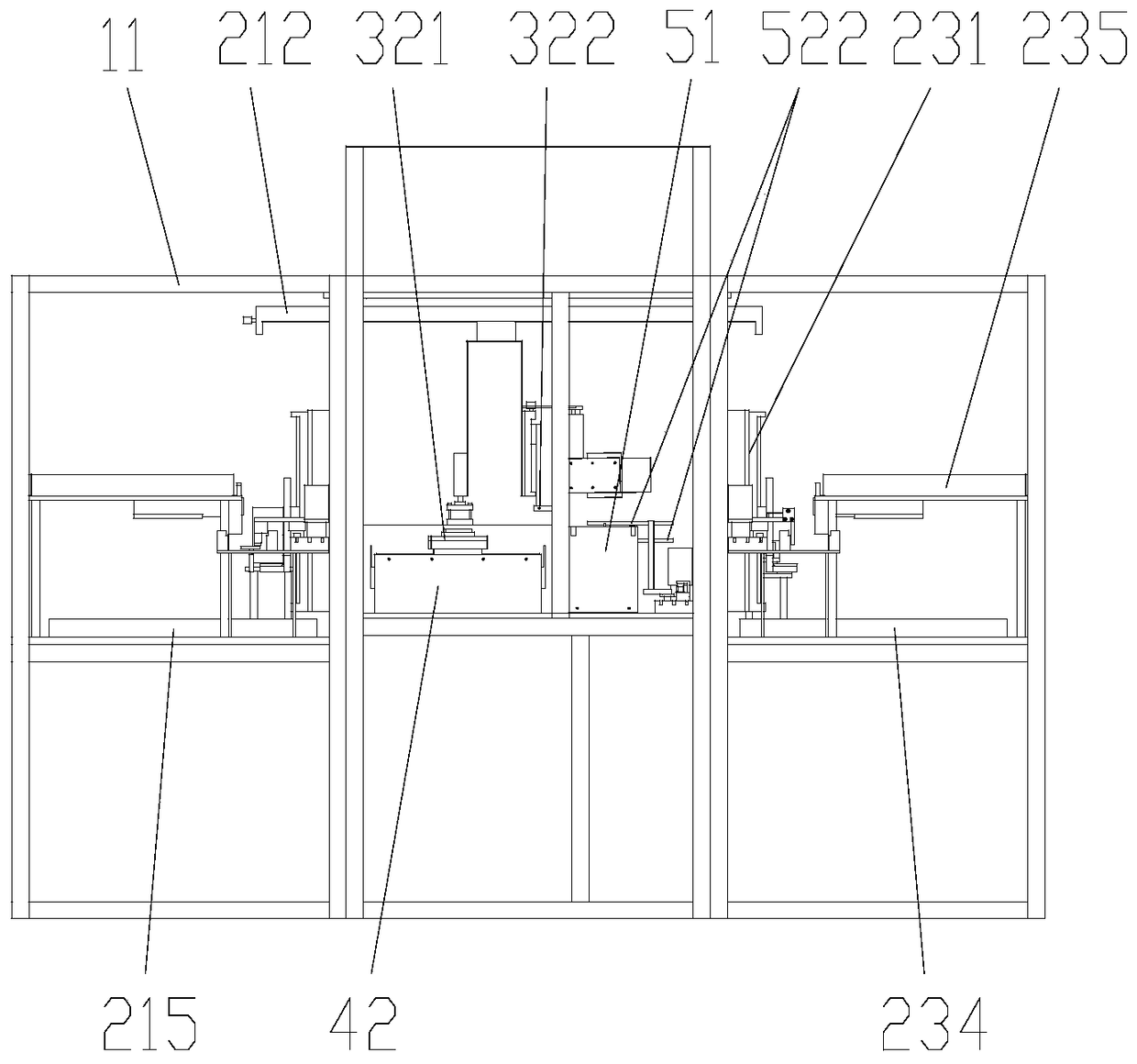

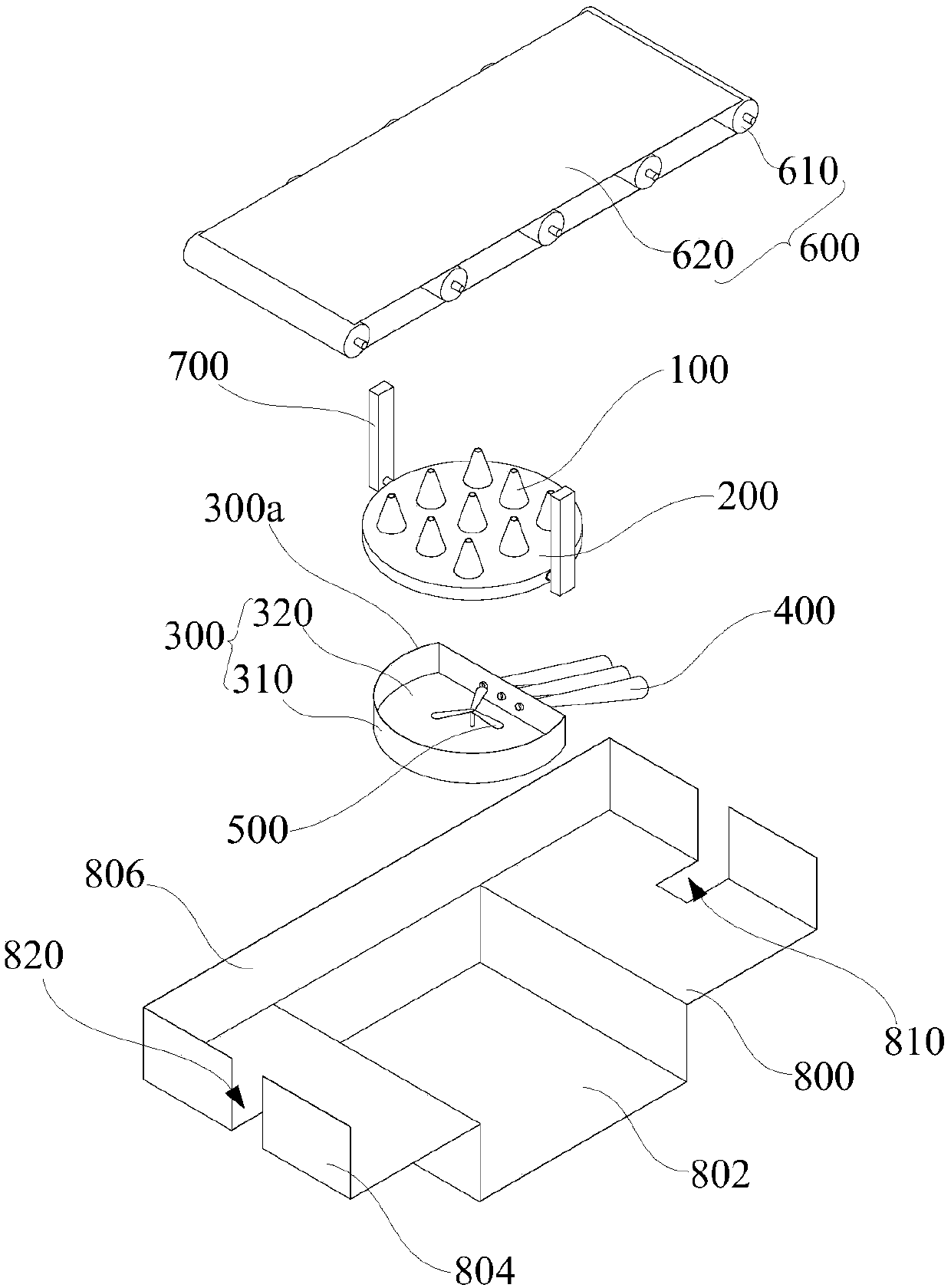

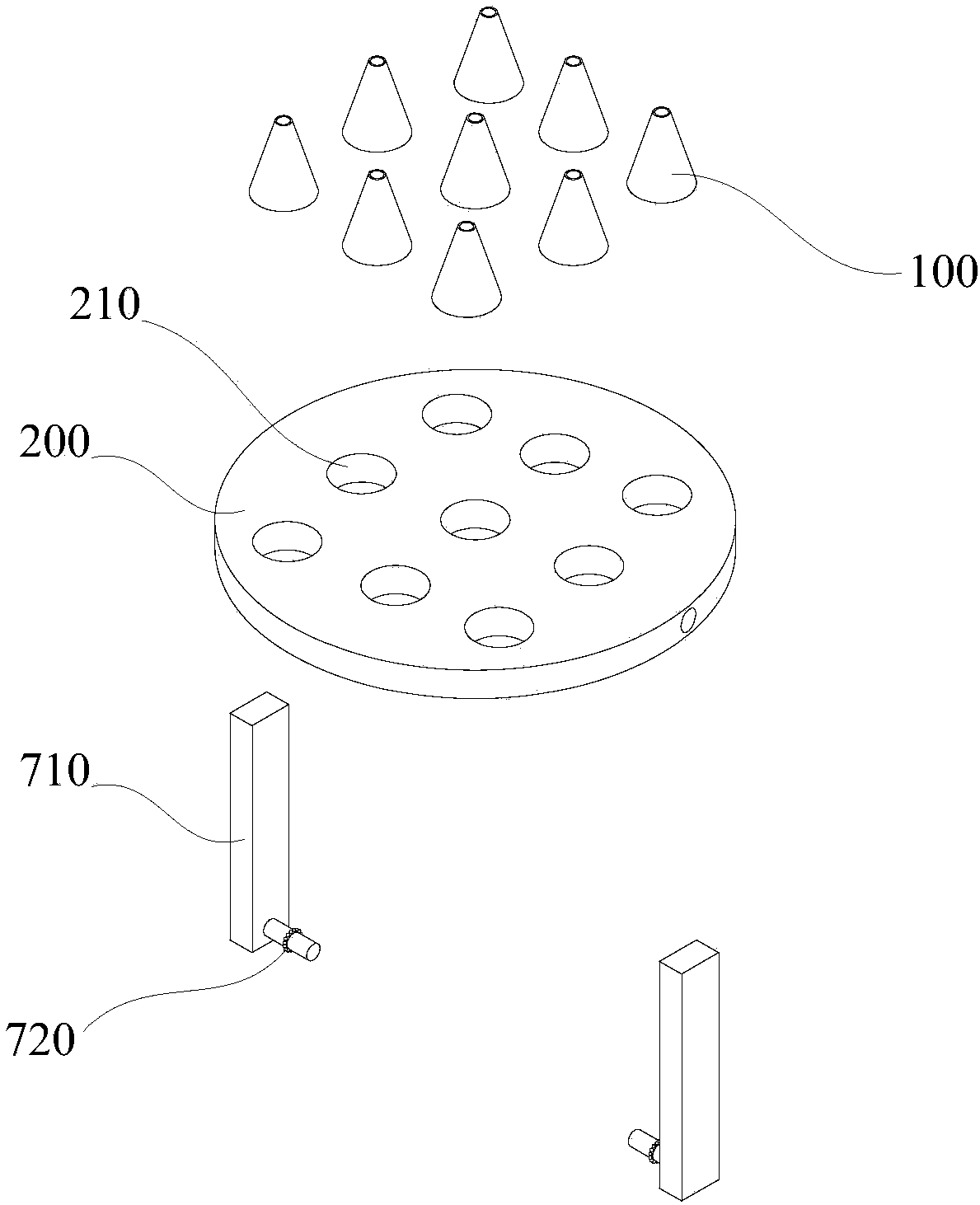

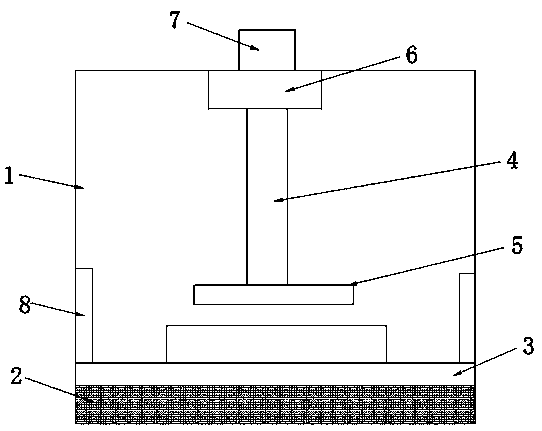

Full-automatic efficient polishing machine

PendingCN111300235AAchieve concentrationReduce disassembly workGrinding carriagesPolishing machinesMotor drivePolishing

The invention discloses a full-automatic efficient polishing machine. The full-automatic efficient polishing machine comprises a rotary disc capable of rotating in an indexing mode, a first side facerough polishing device, a second side face rough polishing device, a forward longitudinal polishing device, a reverse longitudinal polishing device and a transverse polishing device, wherein the firstside face rough polishing device, the second side face rough polishing device, the forward longitudinal polishing device, the reverse longitudinal polishing device and the transverse polishing deviceare arranged in the circumferential direction of the rotary disc, and a plurality of clamps evenly distributed and used for fixing products to be polished and a first motor driving one clamp to horizontally rotate are arranged in the circumferential direction of the rotary disc. According to the full-automatic efficient polishing machine, grid textures can be formed on the surface of a product, and the function of the polishing machine is expanded.

Owner:JIANGMEN SHUNZONG POLISHING EQUIP

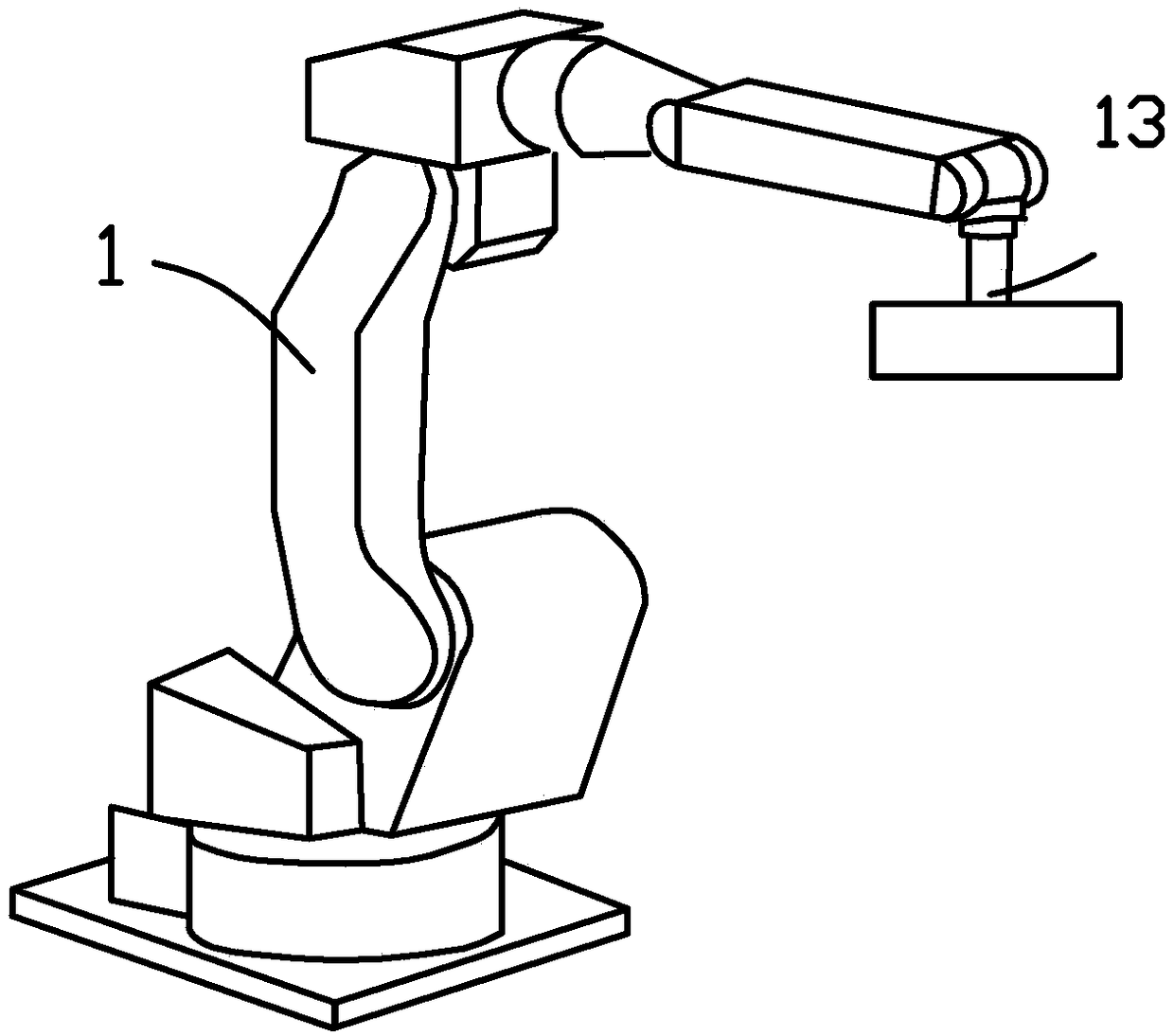

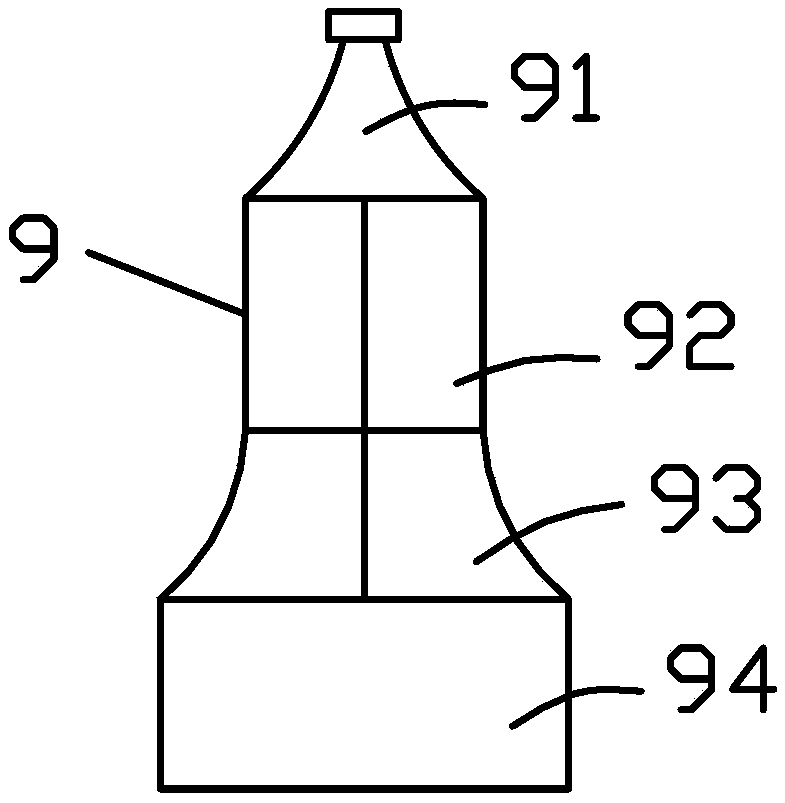

Industrial robot demonstration device based on six freedom degree

InactiveCN108665783ADoes not affect operationEasy to handleEducational modelsCleaning using gasesStress conditionsEngineering

The invention discloses an industrial robot demonstration device based on six freedom degree, and belongs to the technical field of industrial robot demonstration teaching. The system comprises a pushing device, a polishing electronic model and an air micro grinder electronic model, wherein the polishing electronic model is in a polishing product shape and successively comprises a rectangular part, a round ball part, an upright column part and a clamping part from top to bottom, thin film pressure sensors are uniformly laid on the outer-side surfaces of the round ball part, rectangular part and upright column part, the thin film pressure sensors are connected with a processing module arranged in the clamping part, and the processing module is further connected with a wireless module installed in the clamping part; the air micro grinder electronic model comprises a rotating head and an air leg body, the air leg body is connected with an external air supplying device and is arranged at the clamping end of a working arm, the rotating head can be driven by the air leg body to rotate, and the rotating head is made from elastic materials. The system can carry out demonstration teaching visually, simulate multiple polishing conditions, show the stress conditions in the polishing process, and make students conveniently know operating conditions.

Owner:HECHI UNIV

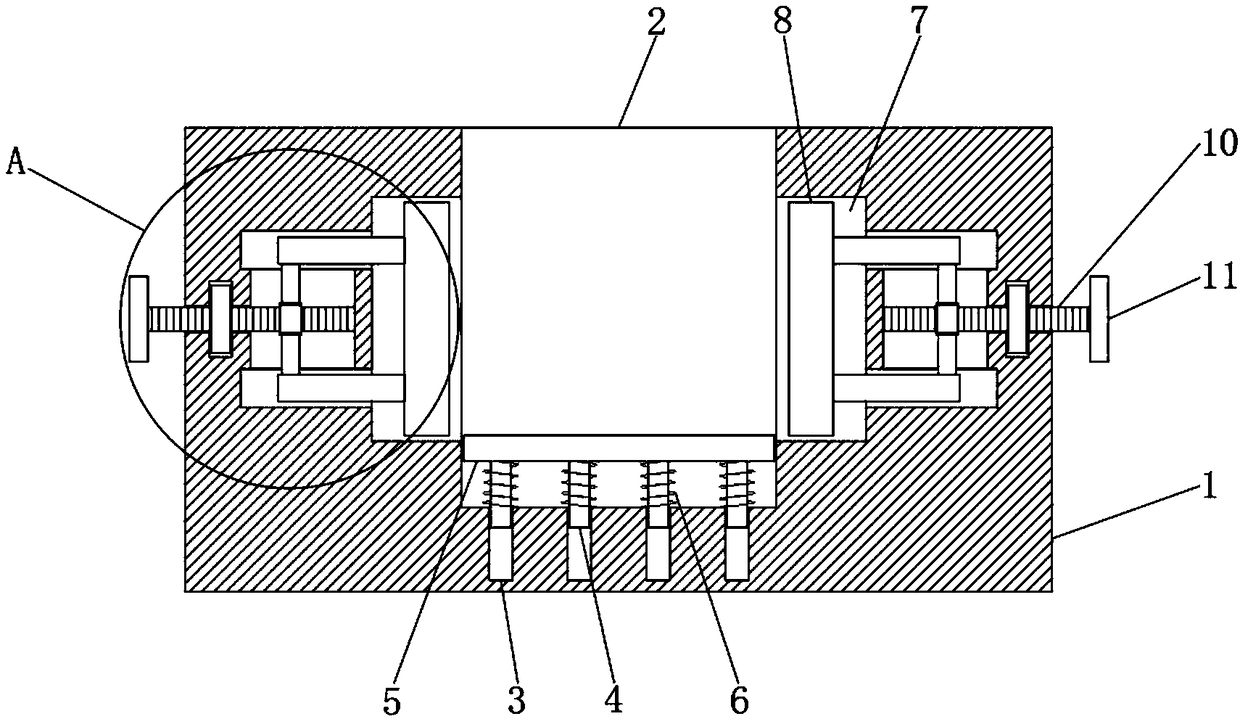

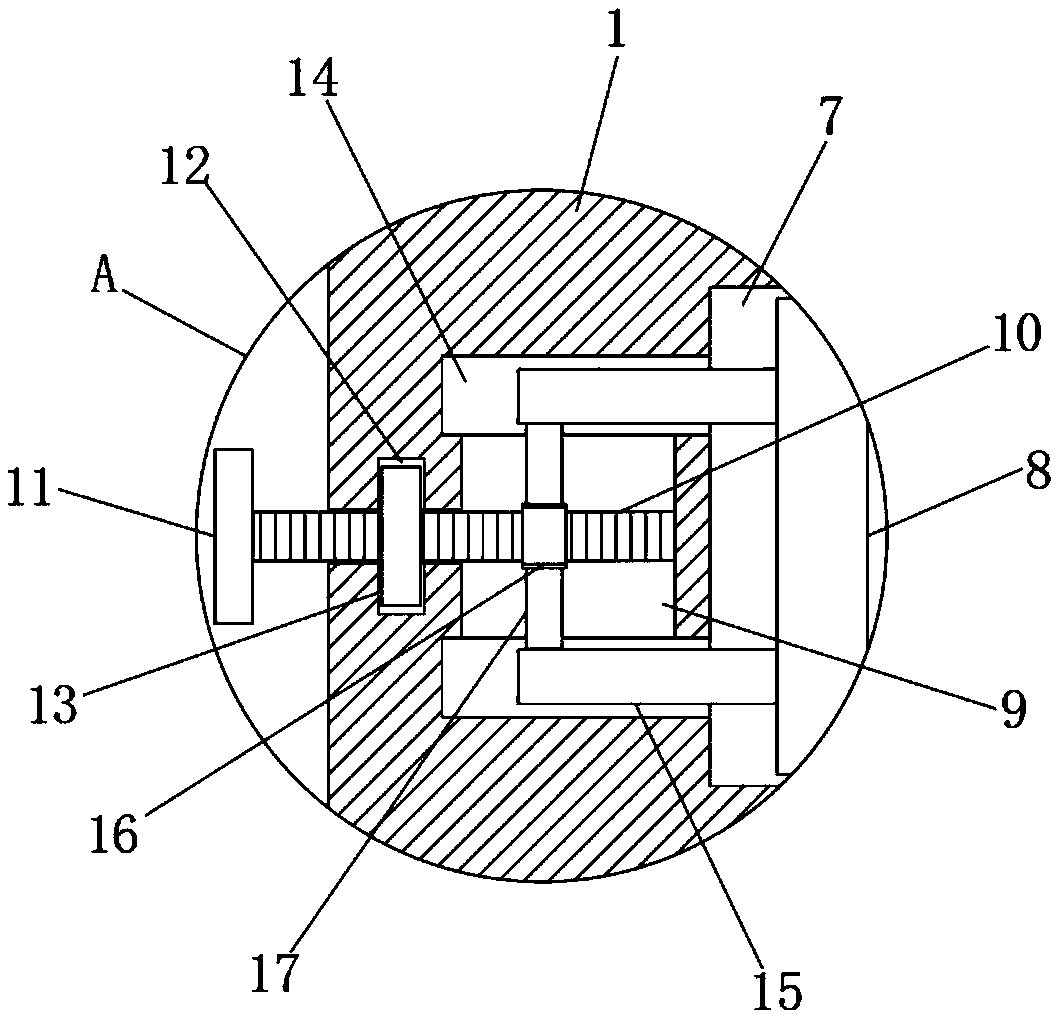

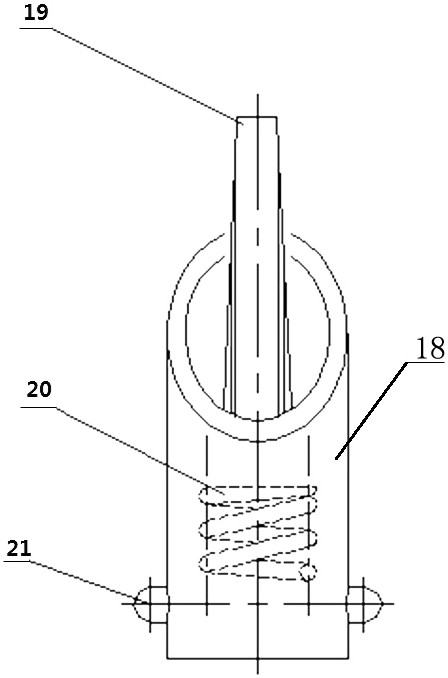

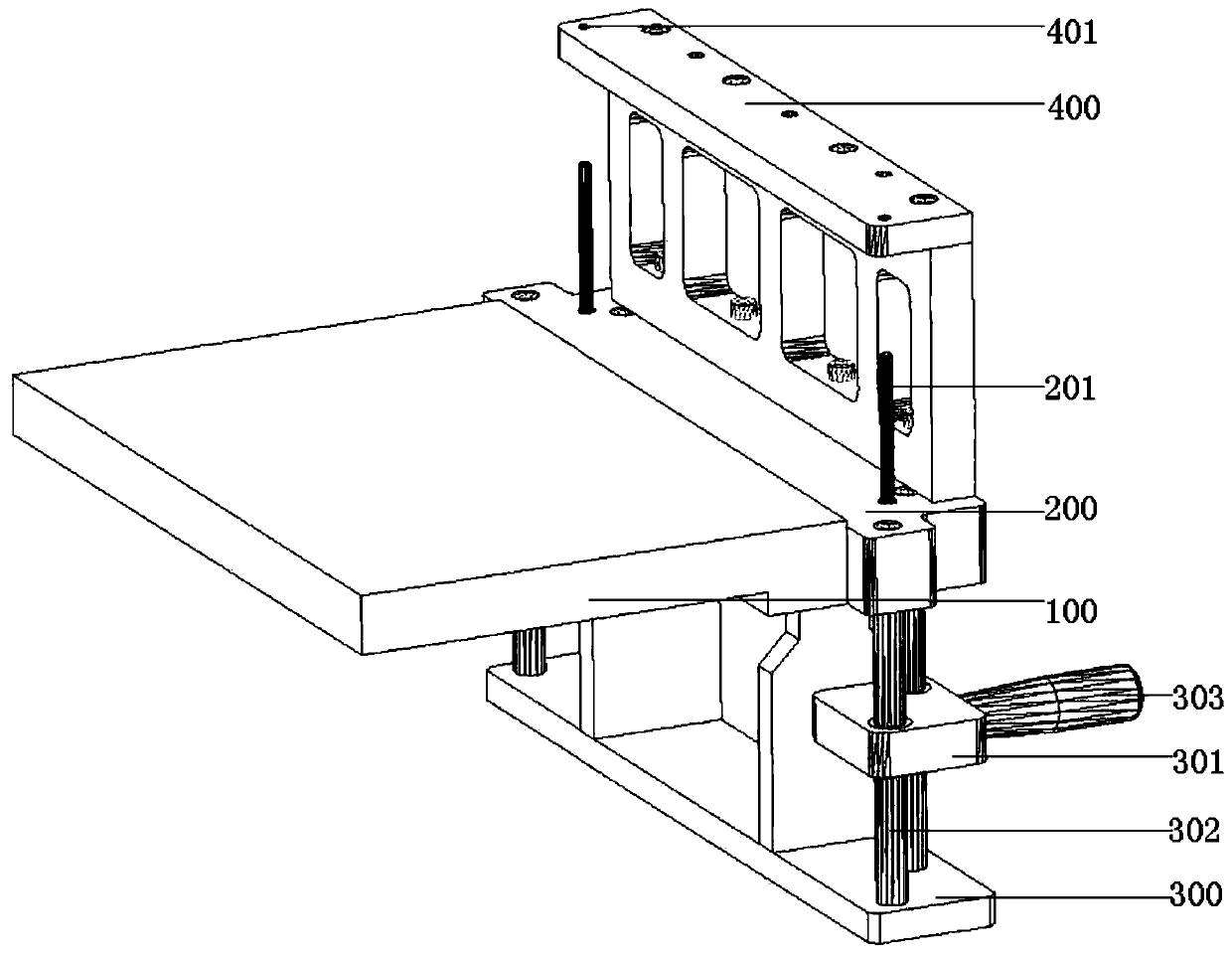

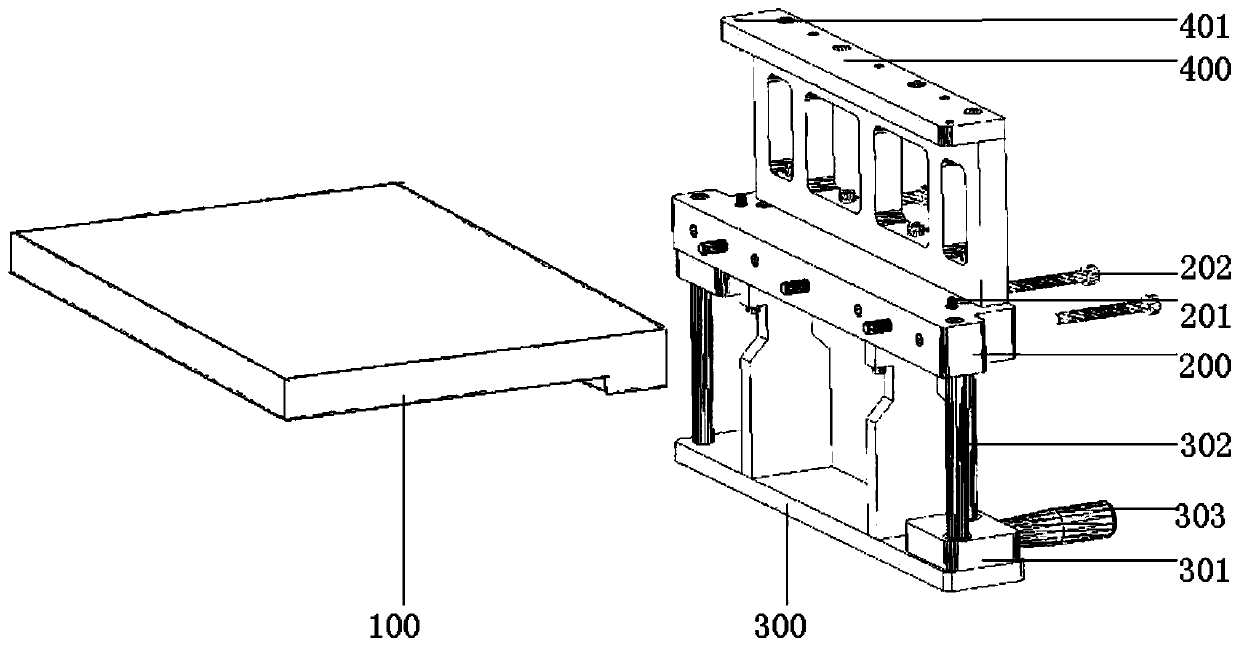

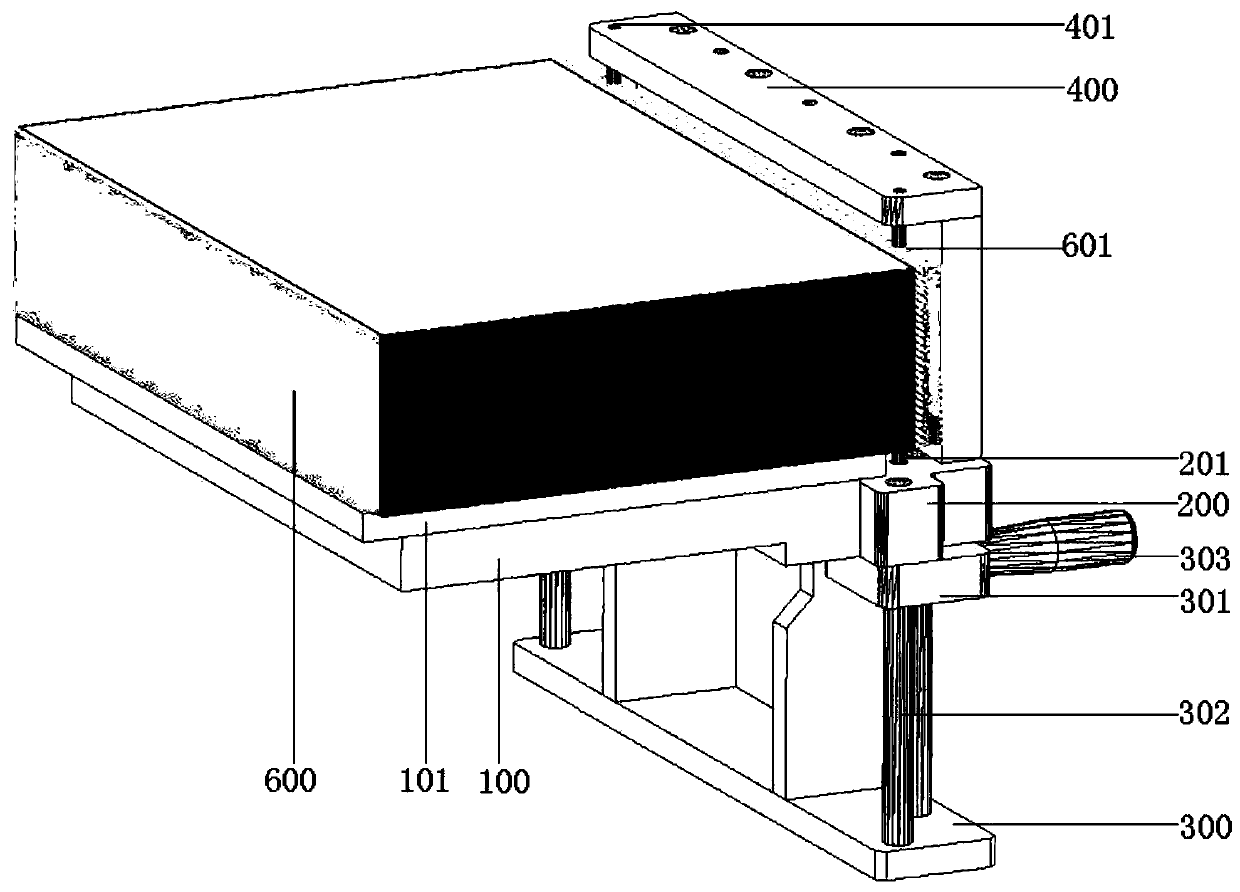

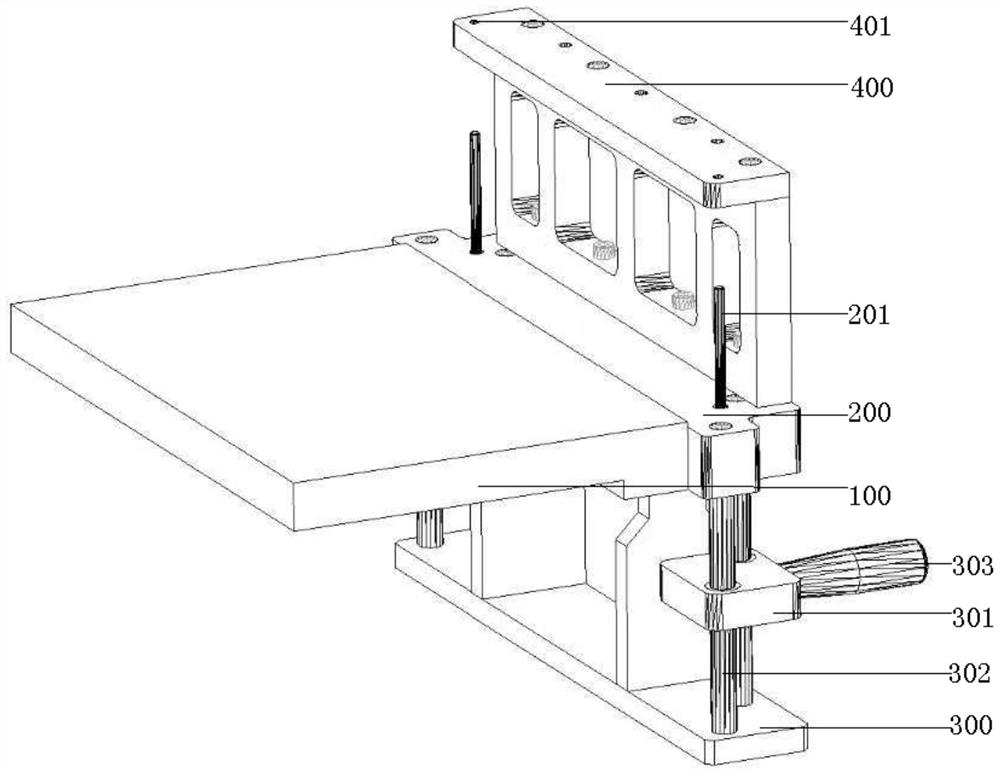

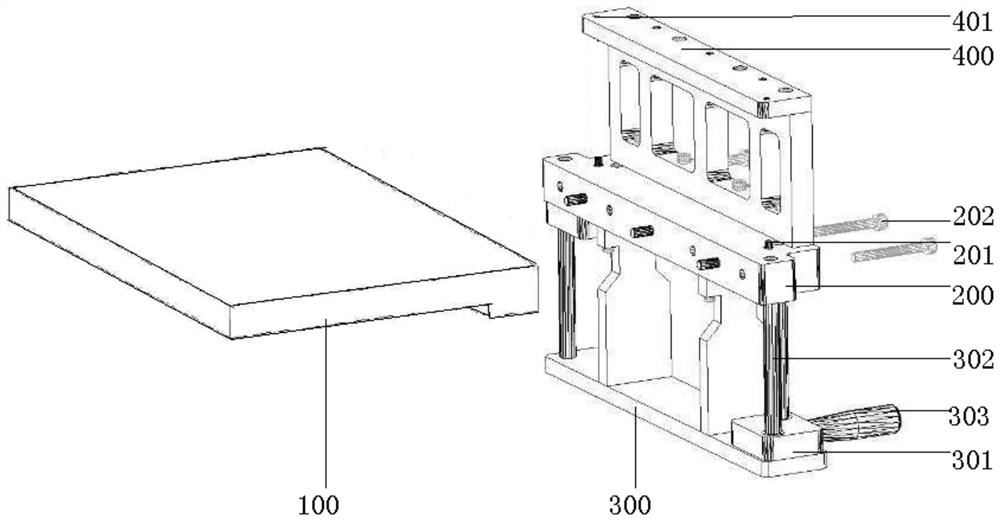

Adjustable insert type polishing clamp

InactiveCN109227384AFree balanceAvoid skiddingPolishing machinesGrinding work supportsEngineeringMechanical engineering

The invention discloses an adjustable insert type polishing clamp which comprises a clamp body. A placement groove with an upward opening is formed in the side wall of the clamp body. A plurality of slide grooves are formed in the inner wall of the bottom of the placement groove at equal intervals and each internally sliding connected with a slide rod. The side walls of the upper ends of the sliderods are all connected with a placement plate. The side walls of the slide rods are each sleeved with a spring. The opposite inner walls of the placement groove are each provided with a groove. Eachgroove is internally sliding connected with an insert. The adjustable insert type polishing clamp is simple in structure and easy and convenient to use; the overall balancing of a to-be-polished product can be freely adjusted, bidirectional clamping can be realized, clamping is stable and firm, slippery during polishing is avoided, polishing is convenient, the to-be-polished product occupies a correct position, the specified technology requirements can be met, product quality is improved, and work efficiency is improved.

Owner:盐城新时代智能检测设备制造厂

Cylindrical polishing machine

PendingCN107160277AImprove labor efficiencyImprove working environmentGrinding machinesGrinding feedersAssembly lineEngineering

The invention relates to the technical field of stone machines, in particular to a cylindrical polishing machine. The cylindrical polishing machine comprises a rotating clamping assembly and a plurality of polishing grinding head assemblies. The rotating clamping assembly comprises a rotating chassis and a plurality of rotating fixing assemblies, each rotating fixing assembly comprises a clutch, the clutches can single control rotation and stopping of the corresponding rotating fixing assemblies, and therefore replacement of workpieces is facilitated. According to the cylindrical polishing machine, manual operation is replaced with mechanical assembly line operation, the production efficiency is improved, and manpower and material resources are saved; meanwhile, a person does not need to get close to a to-be-polished product for a long time for polishing, so that the operation environment of the stone machining operation person is improved, and the condition that the body of the operator is unwell due to suction of dust is avoided.

Owner:王文胜

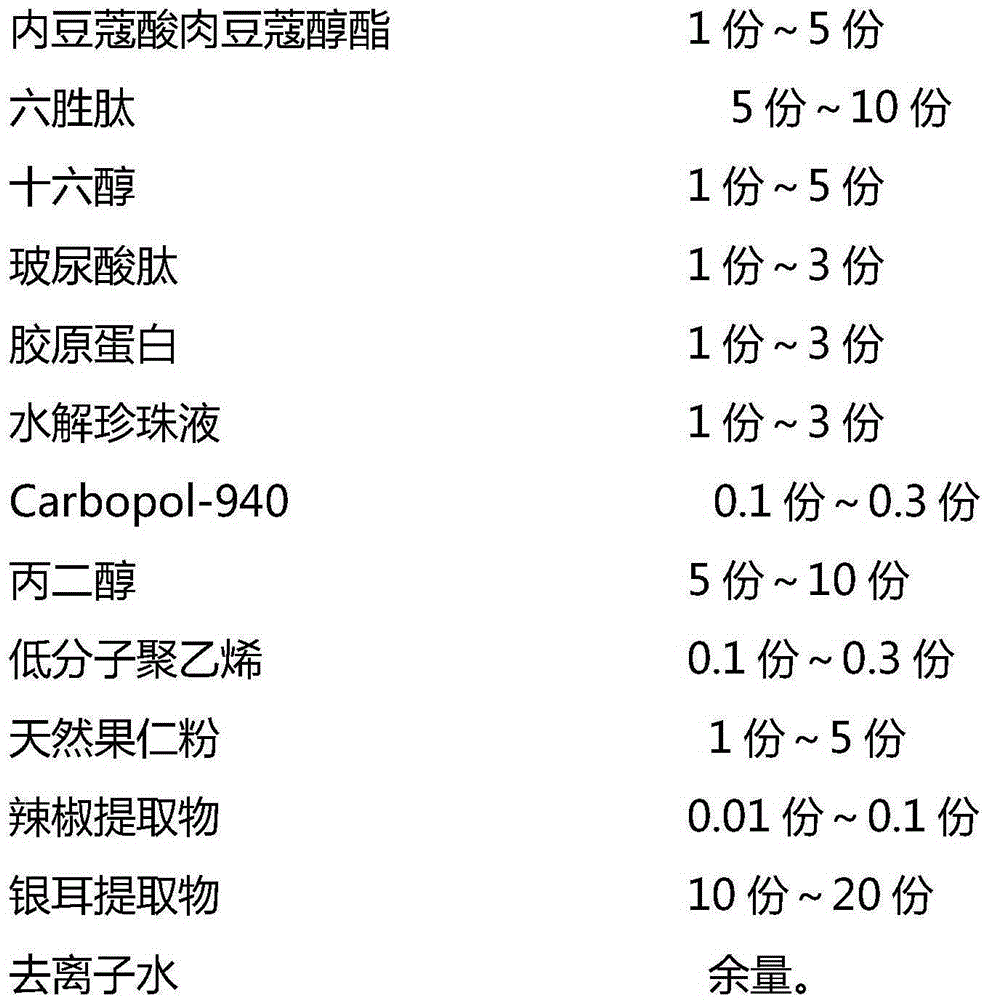

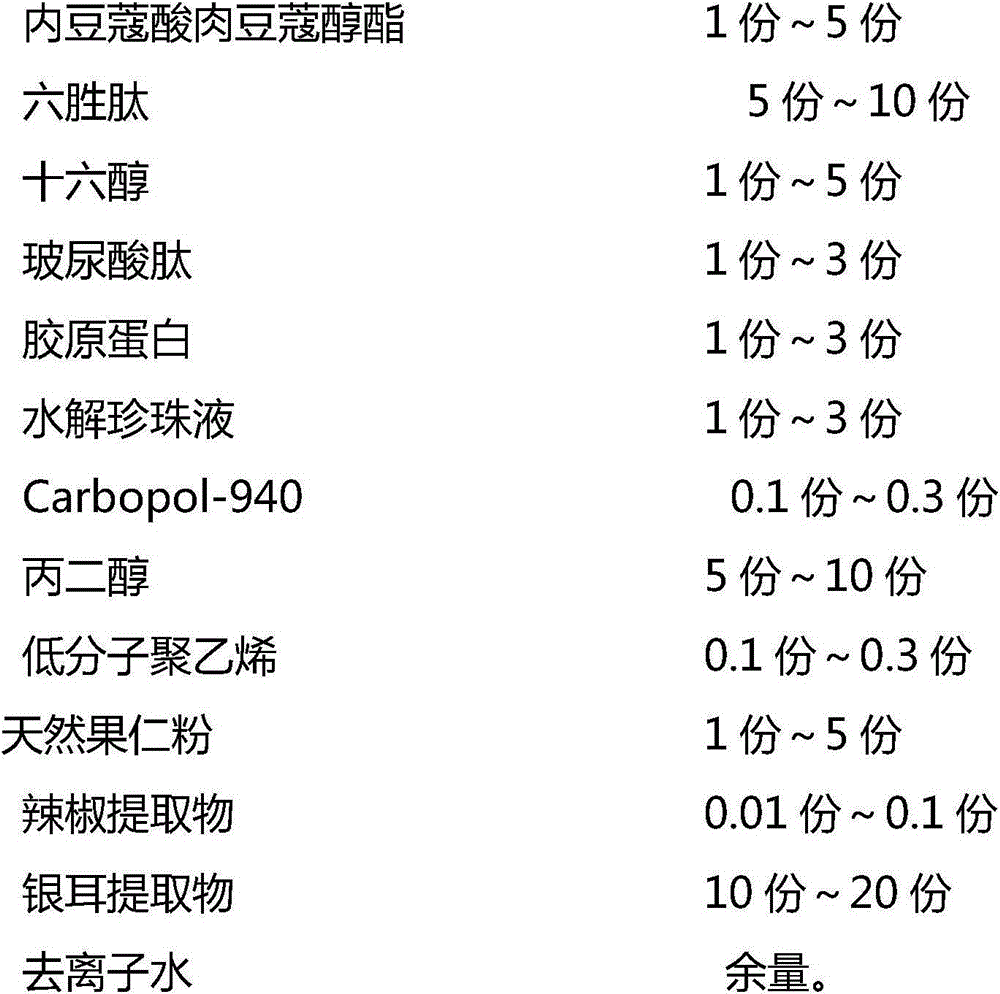

Fresh and cool hyaluronic acid face dull polish cream

The invention relates to the technical field of cosmetics, in particular to a fresh and cool hyaluronic acid face dull polish cream. The fresh and cool hyaluronic acid face dull polish cream is prepared from, by weight, myristyl myristate, hexapeptide, hexadecanol, hyaluronic acid peptide, collagen, hydrolyzed pearl liquid, Carbopol-940, propylene glycol, low-molecular polyethylene, natural nutlet powder, pepper extracts, tremella extracts and deionized water. While skin is cleaned, the fresh and cool hyaluronic acid face dull polish cream can effectively remove dirt on the skin and aged keratinocyte on the surface of the skin; particularly, it can be guaranteed that a dull polish agent is uniformly and stably dispersed in a system through exquisite design and experiments of the fresh and cool hyaluronic acid face dull polish cream according to the characteristics of face dull polish products, and uniform and stable skin milk is formed.

Owner:袁晓林

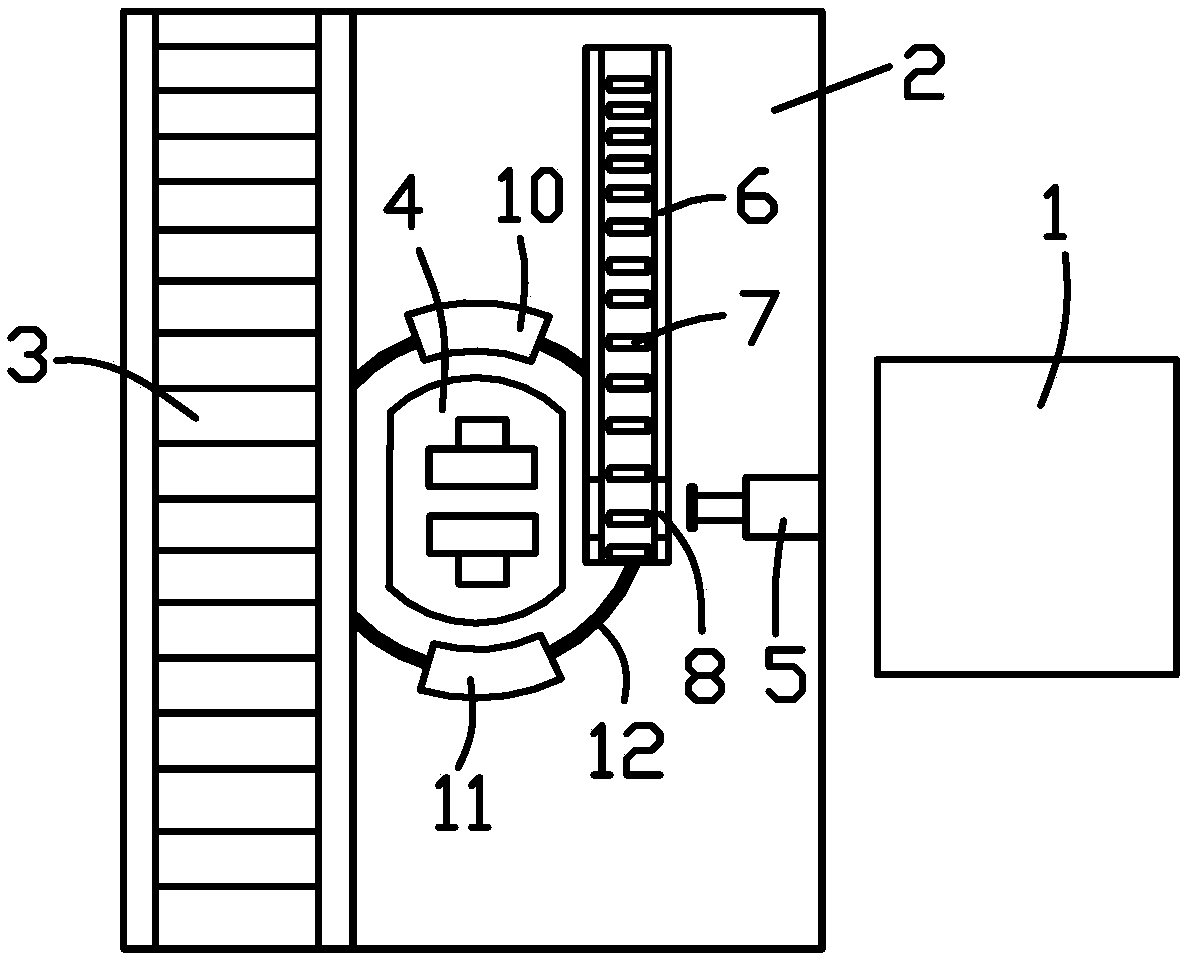

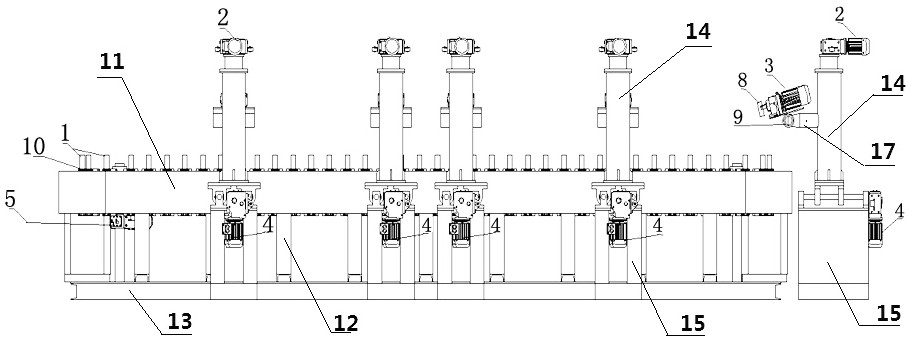

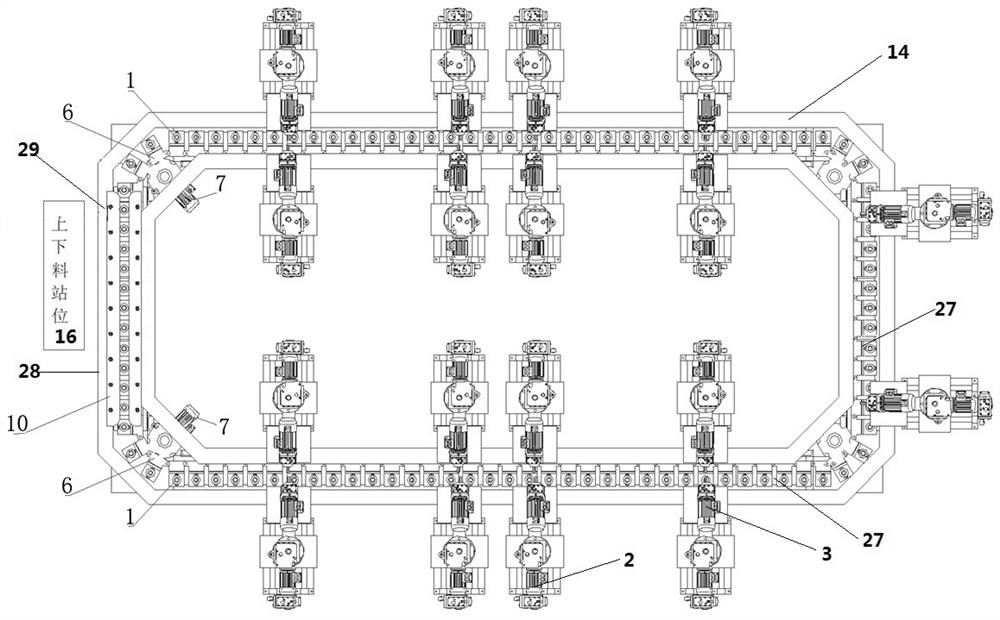

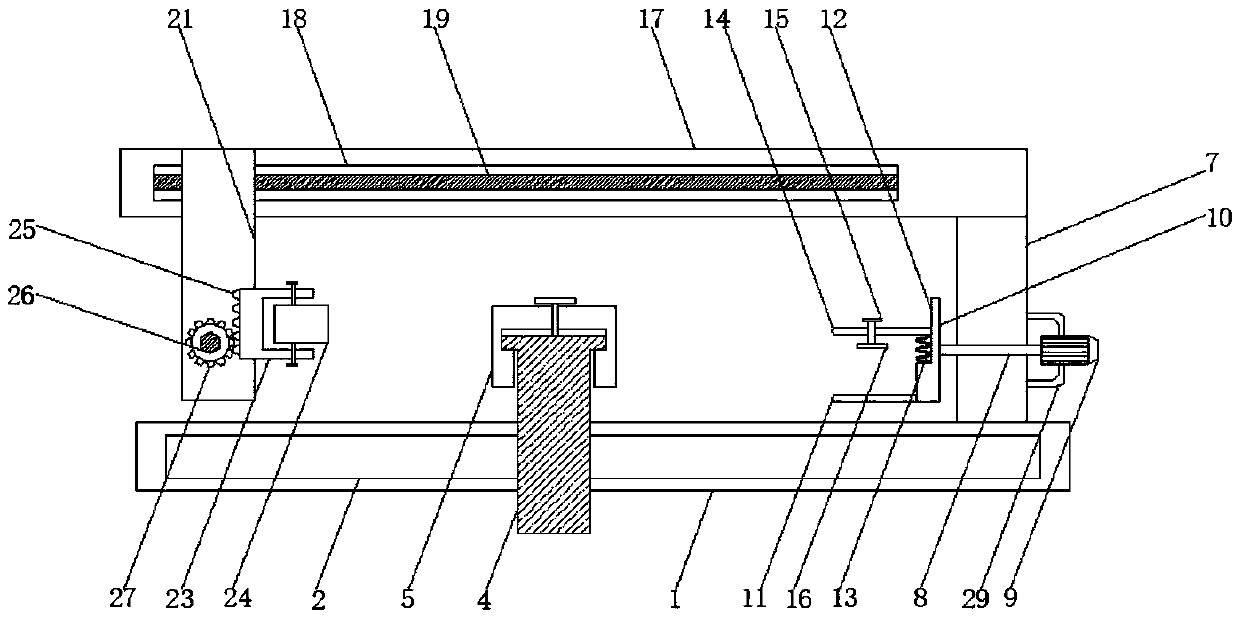

Steel shovel intelligent polishing device and process

InactiveCN112247809AGuarantee the quality of polished productsContinuous productionPolishing machinesGrinding drivesPolishingElectric machinery

The invention relates to a steel shovel intelligent polishing device and process, and belongs to the technical field of steel shovel surface treatment. According to the technical scheme, polishing wheels (8) are arranged on output shafts of polishing wheel driving motors (3), and the polishing wheels (8) are matched with clamps (1) on an annular transmission chain in position; the clamps (1) clampsteel shovels and move to polishing mechanisms on the annular transmission chain, and the positions of the polishing wheels (8) are adjusted through polishing wheel up-down adjusting mechanism and motors (2) and polishing wheel front-back advancing and retreating mechanism and motors (4) of the polishing mechanisms, so that the polishing wheels (8) are matched with the steel shovels on the clamps(1), and the polishing wheel driving motors (3) drive the polishing wheels (8) to rotate to complete steel shovel polishing. Each steel shovel is clamped for independent treatment, the quality of polished products is guaranteed, continuous production is achieved, automatic and intelligent production can be achieved conveniently, and efficiency is improved.

Owner:唐山先河智能机器有限公司 +1

Method for preparing wax polish

The invention discloses a method for preparing wax polish. The method produces a target product through sweating and blending by taking a P-F synthesized product as a raw material. The method comprises the following steps: based on a common sweating process, dissolving an oil soluble emulsifier and an oil soluble acid in the sweating raw material as an oil phase material; by taking an organic salt solution as a water phase material, emulsifying the water phase material to sweat; discharging air bubbles generated by reaction of the oil soluble acid and inorganic salt and a salt solution to form a micro space so as to form a channel for discharging liquid components, wherein the liquid component is quickly discharged, and meanwhile, carrying out the liquid component through a wax layer by means of an air flow in the sweating process to separate solid and liquid components in a forced manner so as to produce a base material which does not contain low-smelting-point components; and blending the base material with silicone oil, natural wax, a solvent and the like to obtain the wax polish product. The method disclosed by the invention has the advantages of being low in investment of production equipment, simple in production process, low in operating cost, safe, energy-saving and free of solvent pollution, and the wax polish product has good in high-temperature resistance and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Guitar polishing device

InactiveCN107738173AEasy to polishPolishing AdjustmentGrinding carriagesPolishing machinesProduct formationEngineering

The invention discloses a guitar polishing device. It includes a box body, fixed parts are arranged on both sides of the upper end of the box body, a chute is arranged in the fixed part, threaded rods are arranged in the chute, gears are connected to the opposite outer sides of the threaded rods on both sides, and the gears are connected to the first motor; The relative inner sides of the threaded rods on both sides are connected with a slide bar, the slide bar is provided with a slide block through the chute, the slide block is provided with a second motor, the lower end of the slide block is connected with a third motor, and a cleaning nozzle is provided below the third motor , the lower end of the third motor is connected with a polishing sheet; the two sides of the lower end of the box body are provided with air pressure lifting rods, the top of the air pressure lifting rods is connected with a lifting plate, and the top of the lifting plate is connected with a guitar fixing platform. The invention has the beneficial effects of using the invention for polishing to avoid harm to the human body, the polished product is smooth, the processing time is short, the polishing degree of the guitar surface is high, the guitar surface is not easy to be damaged, and the polishing automation degree is high.

Owner:贵州华成乐器制造有限公司

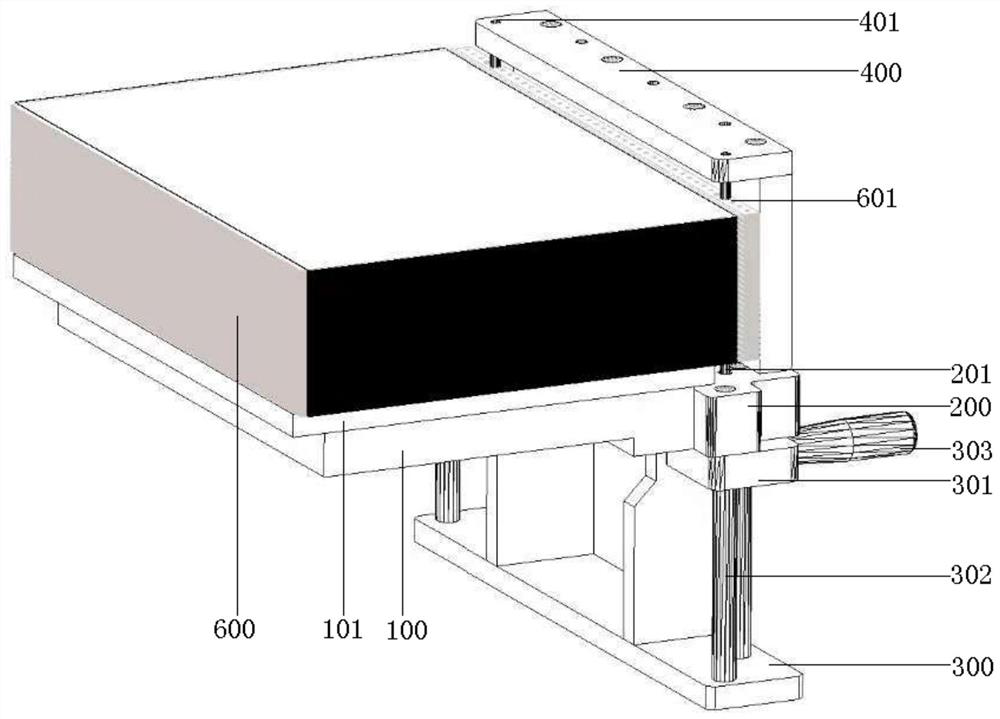

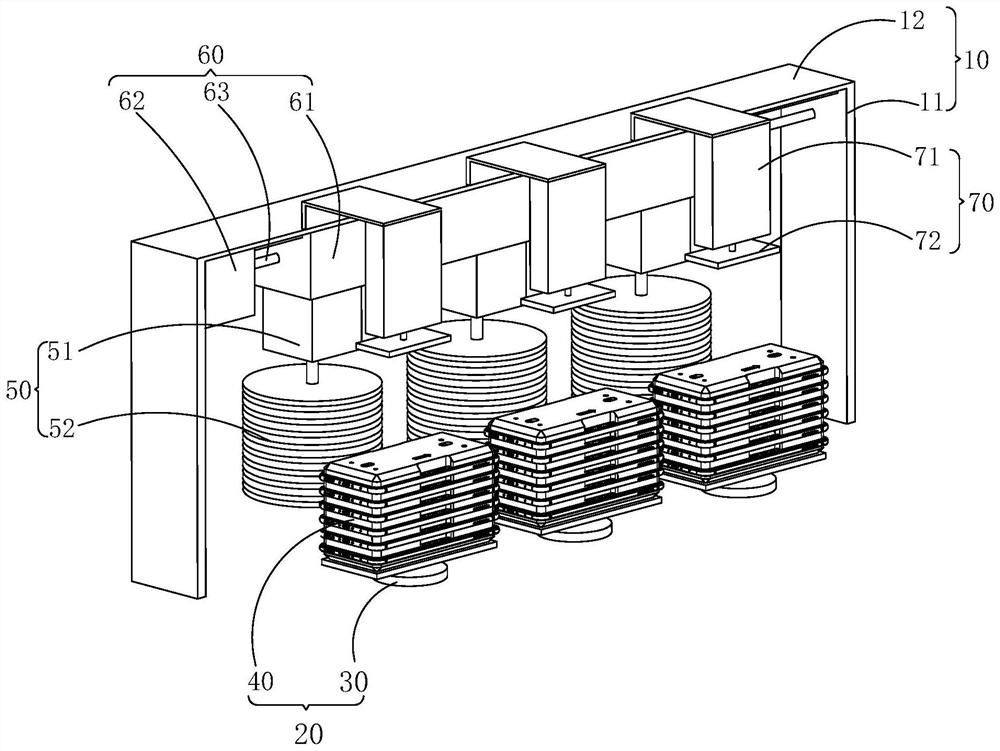

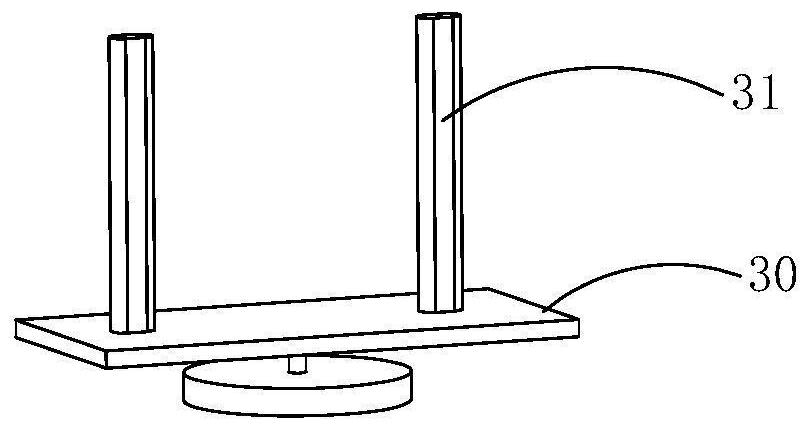

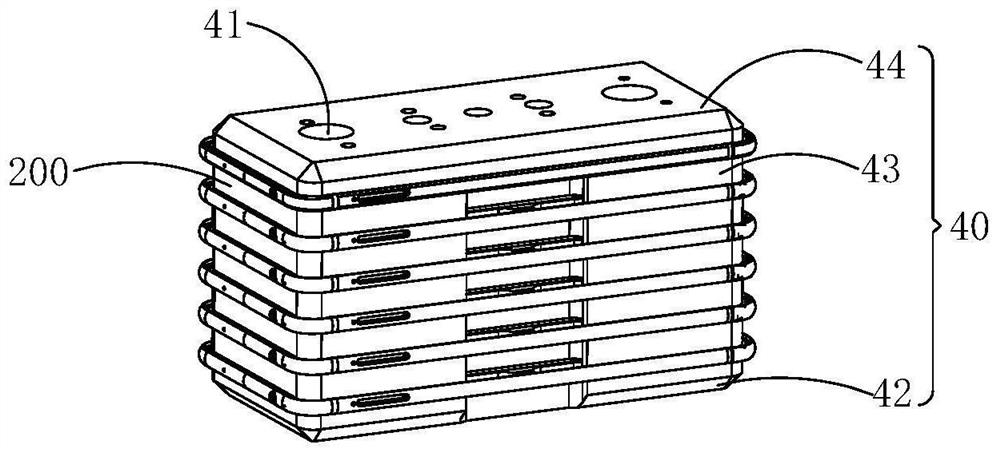

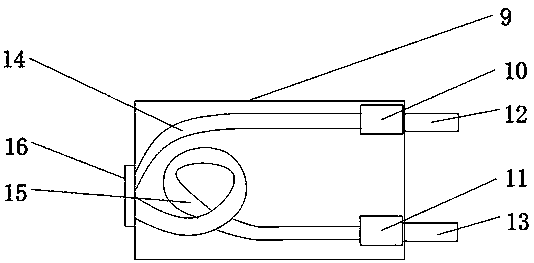

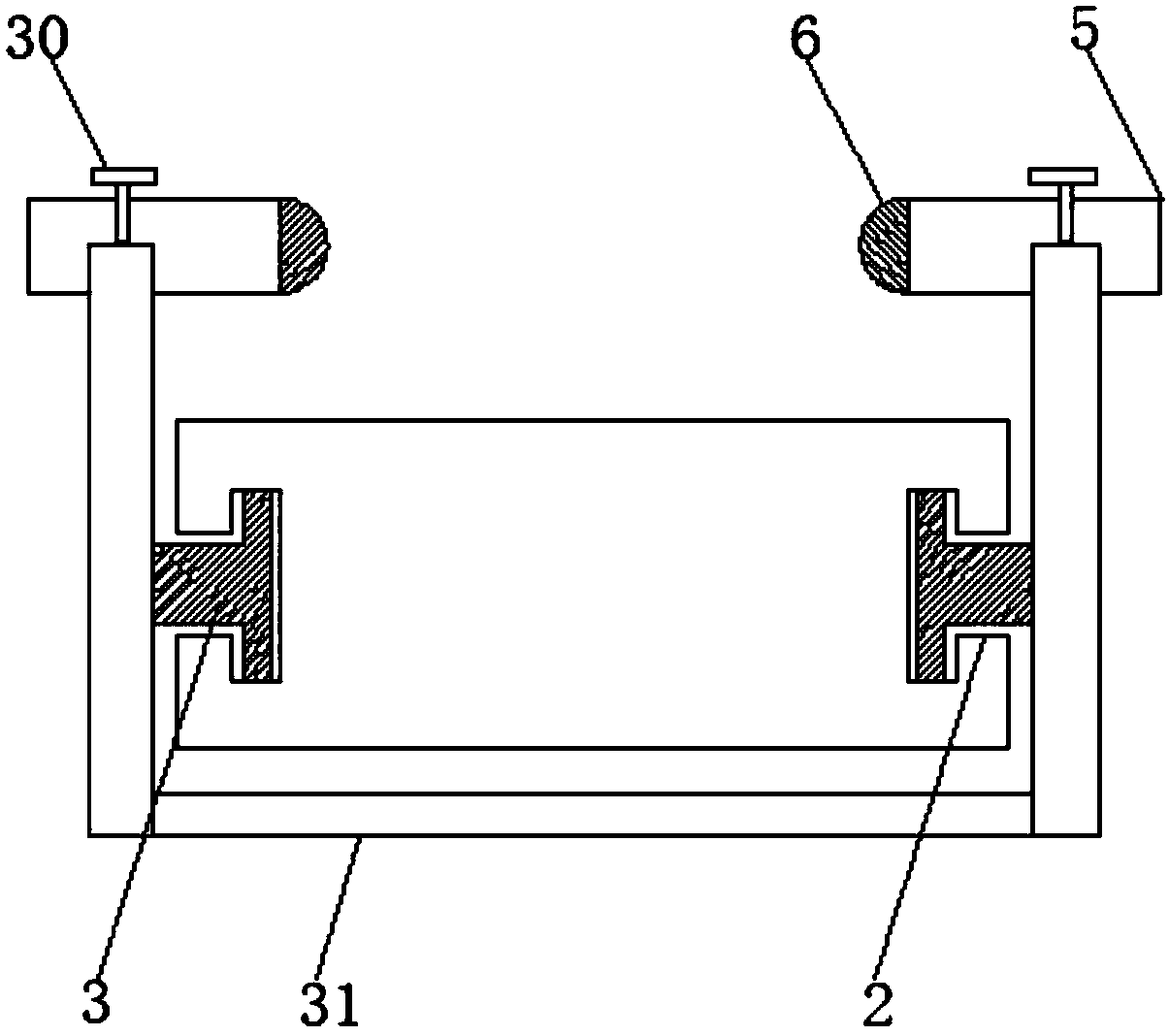

Polishing system and polishing method

ActiveCN111438626AEasy to polishImprove polishing efficiencyPolishing machinesGrinding work supportsPolishingRejection rate

The invention discloses a polishing system and a polishing method. The polishing system comprises a polishing fixing device and polishing equipment, and can polish to-be-polished sheet-like products which are stacked together, and positioning holes used for positioning are formed in each to-be-polished product. The invention aims to provide the polishing system and the polishing method. After hundreds of products are fixed by the polishing fixing device of the polishing system, hundreds of products can be polished at a time by the polishing equipment, the rejection rate of the polished products is substantially reduced while polishing efficiency is increased, and the rejection rate is as low as about 0.3%.

Owner:NICROTEK +1

A kind of polishing system and polishing method

ActiveCN111438626BEasy to polishImprove polishing efficiencyPolishing machinesGrinding work supportsPolishingMaterials science

Owner:NICROTEK +1

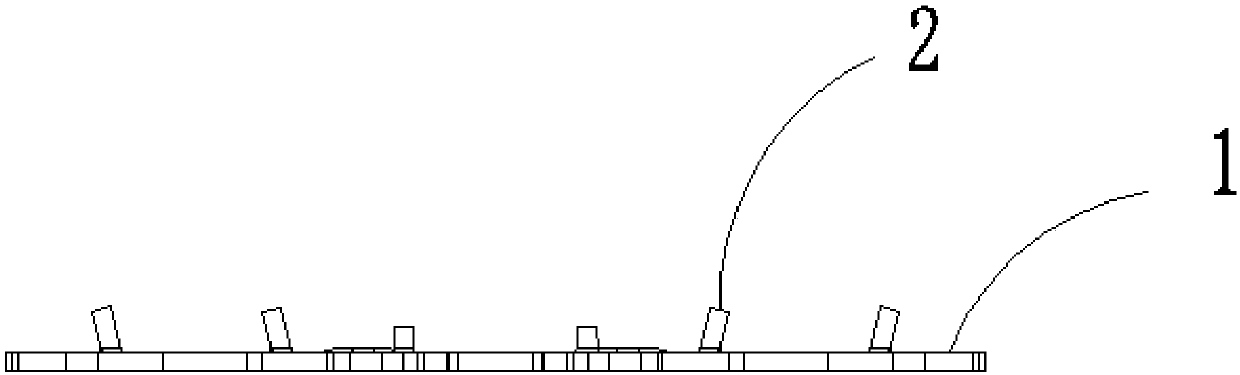

qfn product polishing machine

ActiveCN105150068BAvoid manual removalImprove polishing effectPolishing machinesGrinding machinesEngineeringMachining

The invention discloses a quad flat no lead (QFN) product polishing machine capable of realizing automatic polishing, and relates to the field of machining of electronic products. The QFN product polishing machine comprises a machine frame and a polishing mechanism used for polishing products on the machine frame. The polishing mechanism comprises a polishing wheel, a polishing wheel driving mechanism used for driving the polishing wheel to rotate and a product placement platform mechanism used for conveying the products to the position under the polishing wheel. The residual glue on the surfaces of the QFN products is removed in a polishing mode, the QFN products are automatically cleaned dried in a blowing mode after being polished, the polishing effect is good, and the efficiency is high. Automatic production is realized, labor is saved, and meanwhile production efficiency is improved.

Owner:苏州中搏成机电设备有限公司

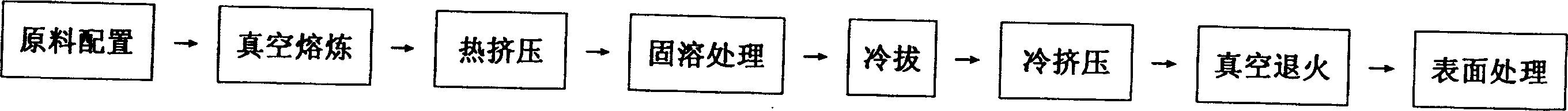

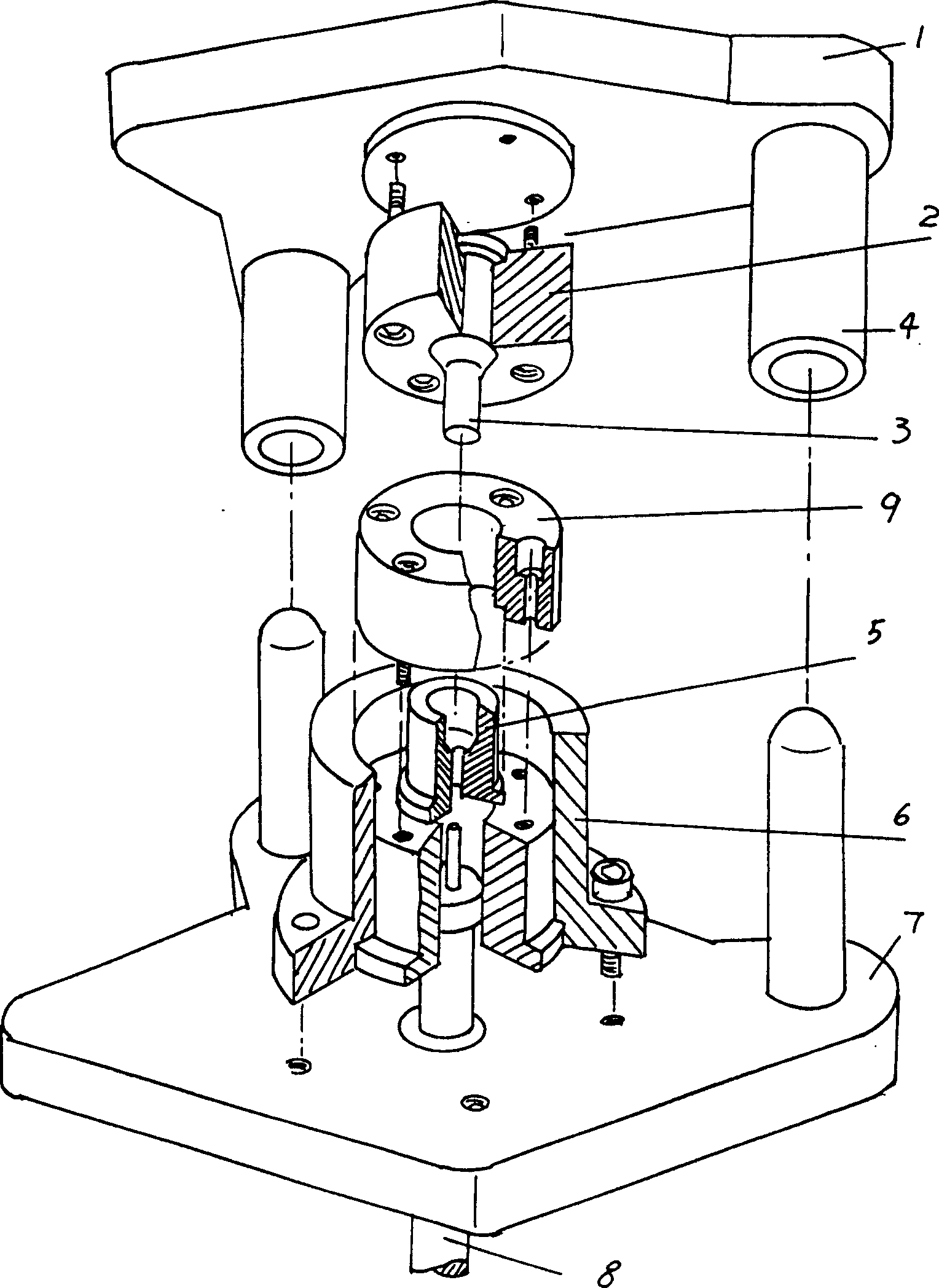

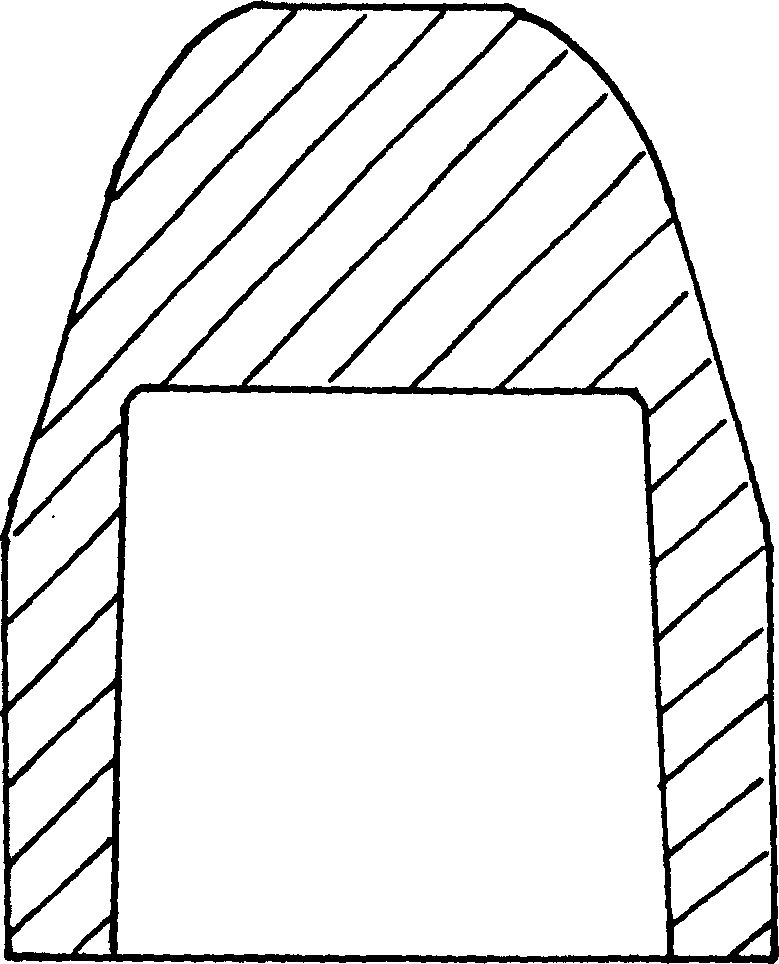

Manufacturing method of electrode cap used for welding automobile coated steel plate

InactiveCN1282517CAvoid alloying tendencyMeet the requirement of no sticking weldingWelding/cutting auxillary devicesElectrode featuresChromiumRaw material

The invention discloses a method for manufacturing an electrode cap used for welding coated steel plates of automobiles, belonging to the technical field of processing electrode materials for welding. It includes the following steps: (1) Raw material preparation, with cathode copper, chromium powder and zirconium powder as main raw materials, and magnesium as oxygen scavenger, wherein: the main raw materials are: 99% to 99.47% by weight of cathode copper, 0.4% ~0.8% chromium powder, 0.08%~0.20% zirconium powder, oxygen scavenger by weight percentage: 0.05%~0.1% magnesium; In the circular casting mold, the ingot billet is obtained; (3) the surface of the ingot billet is cleaned, and hot extruded into a bar; (4) solid solution treatment; (5) cold drawing and broaching; (6) blanking, And putting it into a cold extrusion mold for cold extrusion to form a hollow spherical green body; (7) vacuum annealing the hollow spherical green body after being released from the mold; (8) trimming and polishing to obtain an electrode cap product. The electrode cap made by the method has the advantages of anti-stick welding, high hardness, ideal electrical conductivity and good temperature resistance and softening property.

Owner:中外合资常熟明辉焊接器材有限公司

Intelligent control method and system for polishing equipment

ActiveCN113681469BImprove polishing yieldGrinding feed controlCharacter and pattern recognitionPolishingControl engineering

The invention discloses an intelligent control method and system for polishing equipment. The first size information is obtained; the first standard size information is obtained; the first polishing surface requirement information is obtained, and the first size information, the first standard size information and the second Input the polished surface requirement information into the polishing parameter distribution model to obtain the first parameter distribution result; control the rough polishing equipment according to the first parameter distribution result to obtain the first rough polished product; obtain the second size information of the first rough polished product; The first image of the first rough polished product is obtained; the first parameter distribution result is adjusted according to the first image and the second size information to obtain the second parameter distribution result; and the parameters of the fine polishing equipment are controlled by the second parameter distribution result. It solves the technical problem in the prior art that the combined intelligent control of the rough polishing and fine polishing parameters cannot be intelligently performed according to the specific parameter information of the product and the product demand information, resulting in an increase in the defective rate of polishing.

Owner:南通豪派金属制品有限公司

Polishing equipment

The invention relates to polishing equipment. The polishing equipment comprises a high-pressure spray gun, the high-pressure spray gun is used for being arranged spaced from a to-be-polished product,the high-pressure spray gun can spray an abrasive to the to-be-polished product so as to polish the to-be-polished product, and the high-pressure spray gun can rotate so that the high-pressure spray gun can be aligned with different areas of the to-be-polished product. In the polishing equipment, the high-pressure spray gun is used for being arranged spaced from the to-be-polished product, the high-pressure spray gun can spray the abrasive to the to-be-polished product so as to polish the to-be-polished product, so that when the polishing equipment polishes the product, non-heavy pressure andnon-contact polishing can be realized, then the probability of damaging the to-be-polished product is effectively reduced, and the finished product rate of the to-be-polished product is improved. Moreover, the high-pressure spray gun can rotate so that the high-pressure spray gun can be aligned with different areas of the to-be-polished product, thus the polishing equipment can polish the to-be-polished products with 3D and other special shapes, and the polishing equipment is not influenced by the size and shape of the to-be-polished product.

Owner:QINGYUAN CSG NEW ENERGY SAVING MATERIALS CO LTD +1

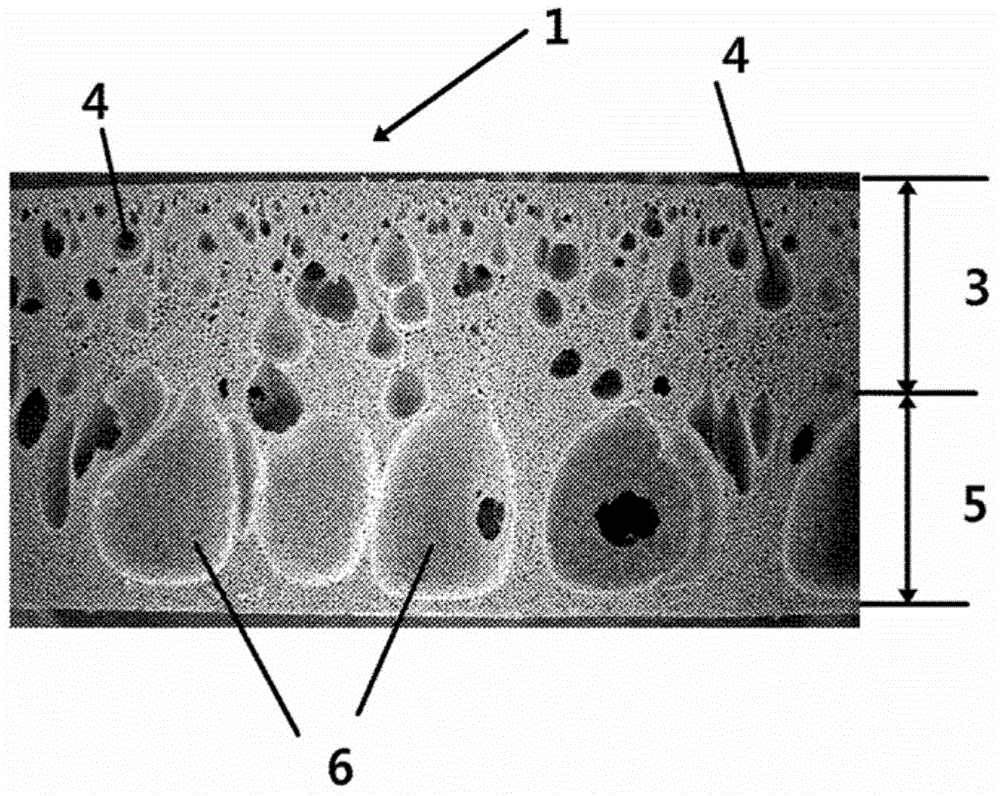

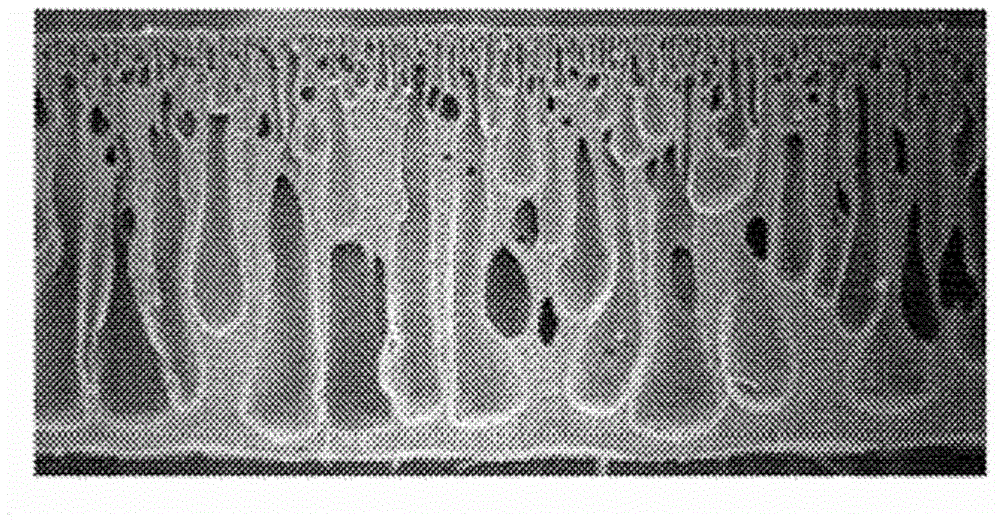

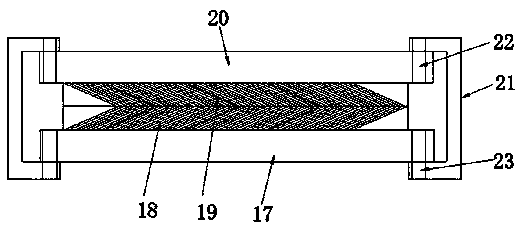

Maintaining pad having high-precision flatness

InactiveCN105269451AHigh strengthImprove wear resistanceSemiconductor/solid-state device manufacturingWork carriersCompressibilityElectrical and Electronics engineering

The present invention relates to a maintaining pad for supporting and fixing a polished product on a platform when the flat-plate polished product such as a glass substrate and a wafer is polished. The maintaining pad is characterized in that an upper supporting layer (3) in which small expanding foams (4) with small diameters are distributed is formed by crossing 50% area of a polyurethane pad, and a lower buffer layer (5) located at the area within the range from 60% to 90% of the thickness of the polyurethane pad has huge expanding foams (6) of which the diameters are relatively dozens of times larger than the diameters of the small expanding foams (4) of the upper supporting layer (3), thus the integral compressibility and compress recovery ratio can be improved, therefore, high-precision flatness is achieved.

Owner:大元化成株式会社

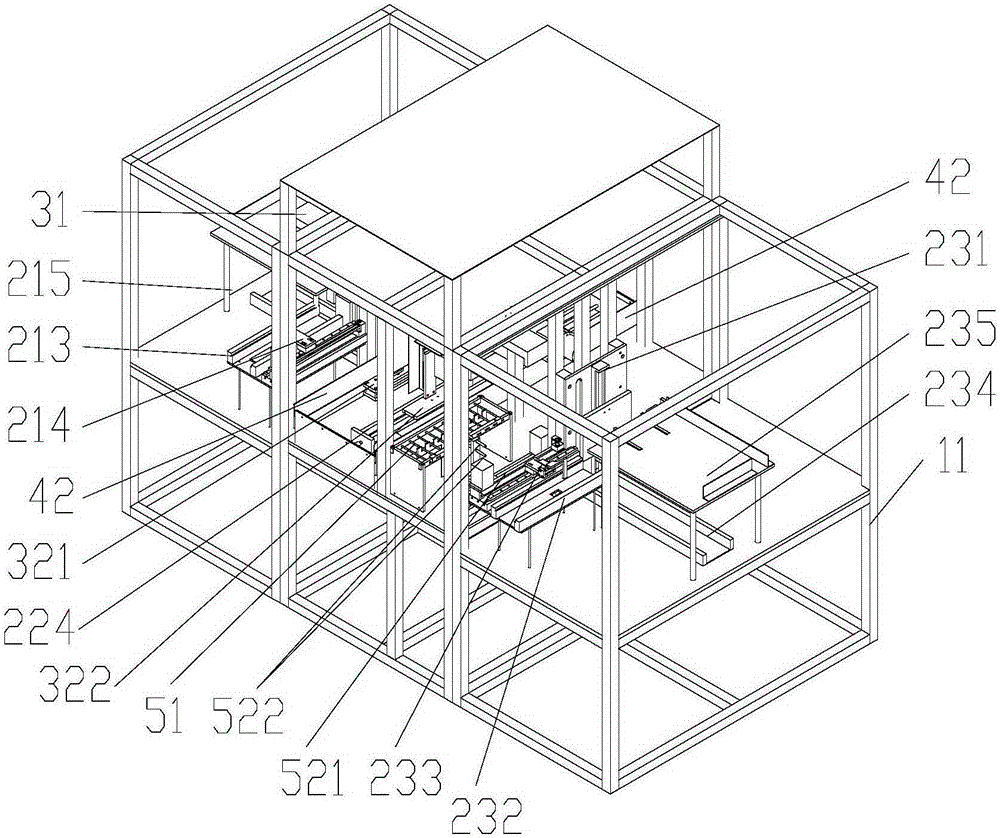

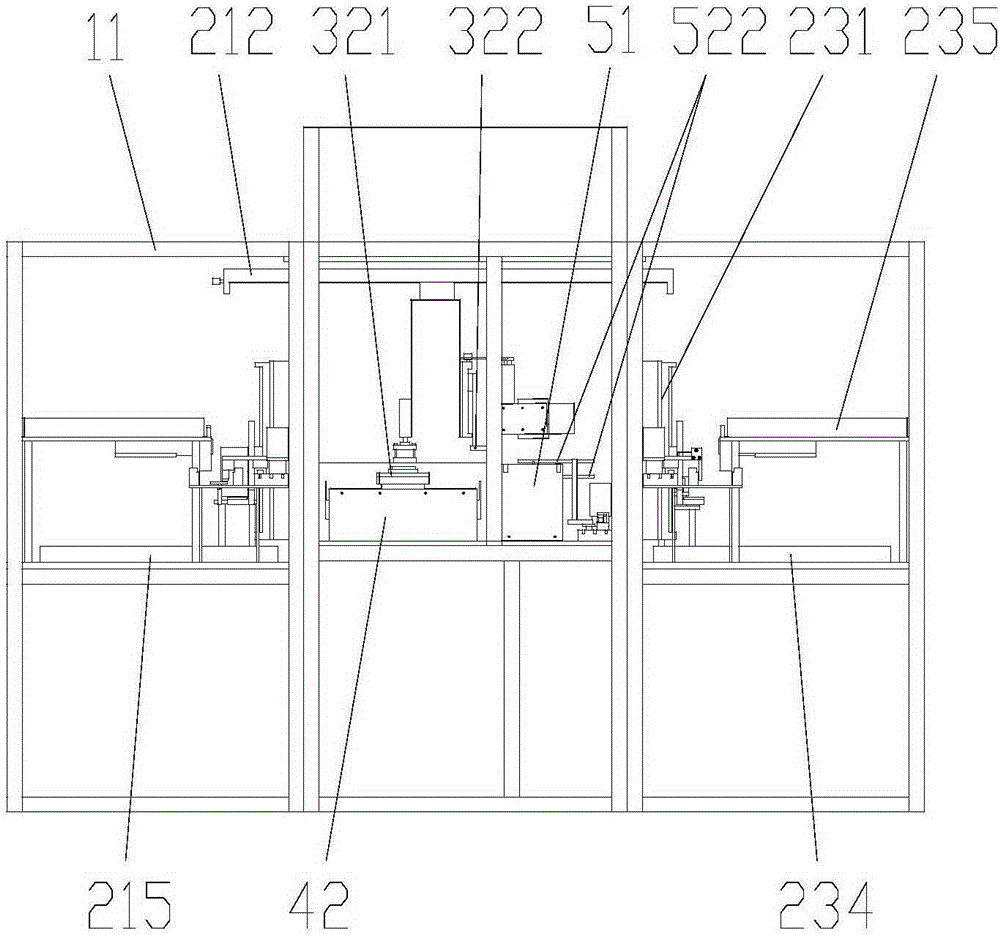

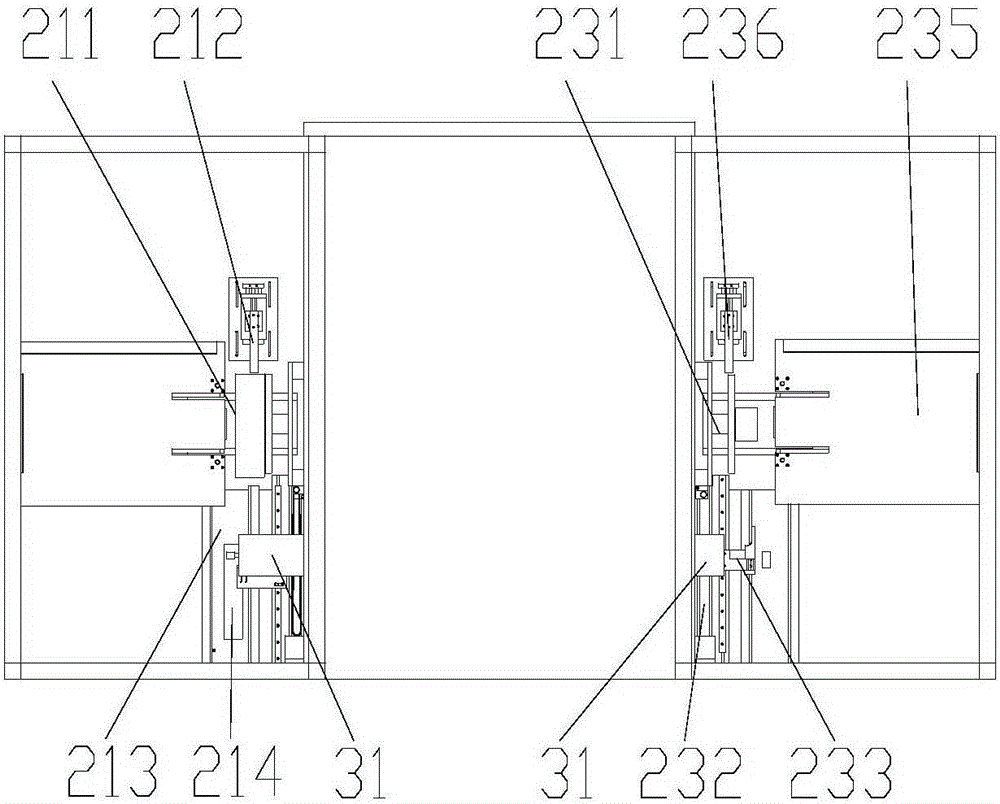

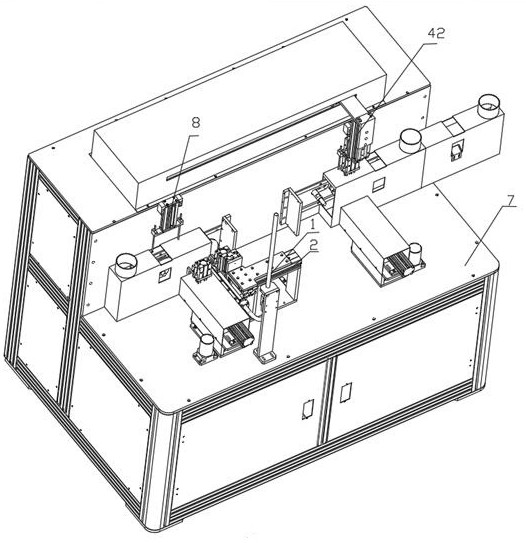

Quad flat no lead (QFN) product polishing machine

ActiveCN105150068AAvoid manual removalImprove polishing effectPolishing machinesGrinding machinesEngineeringProduct processing

The invention discloses a quad flat no lead (QFN) product polishing machine capable of realizing automatic polishing, and relates to the field of machining of electronic products. The QFN product polishing machine comprises a machine frame and a polishing mechanism used for polishing products on the machine frame. The polishing mechanism comprises a polishing wheel, a polishing wheel driving mechanism used for driving the polishing wheel to rotate and a product placement platform mechanism used for conveying the products to the position under the polishing wheel. The residual glue on the surfaces of the QFN products is removed in a polishing mode, the QFN products are automatically cleaned dried in a blowing mode after being polished, the polishing effect is good, and the efficiency is high. Automatic production is realized, labor is saved, and meanwhile production efficiency is improved.

Owner:苏州中搏成机电设备有限公司

polishing equipment

The invention discloses a polishing device, comprising: at least one product fixing device, the product fixing device is used to fix a plurality of products arranged at intervals along a first direction; at least one polishing device, the polishing device and the product fixing device are arranged in one-to-one correspondence, And located on one side of the product fixing device, it is used to simultaneously polish the end faces of all products fixed by the product fixing device; the polishing device includes a driving wheel rotating power mechanism and a polishing wheel connected to the driving wheel rotating power mechanism, and the axis of the polishing wheel is parallel to the first One direction, and located on one side of the product fixing device, the polishing wheel includes a wheel main body and polishing consumables attached to the outer circumferential surface of the wheel main body; the translational driving device is connected to the polishing device, and is used to drive the polishing device along the first The second direction of the direction moves back and forth. The polishing consumables attached to the wheel main body can simultaneously polish the end faces of multiple products fixed by the product fixing device at one time, which greatly improves the polishing efficiency.

Owner:GUANGDONG EVERWIN PRECISION TECH

Freeze-thaw stable water-in-oil emulsion cleaner and/or polish compositions

PendingUS20190144712A1Low costAvoid breakingOther chemical processesTransportation and packagingSucroseFreezing thawing

Water-in-oil (W / O) emulsion compositions having freeze-thaw stability are provided which include water, at least one hydrocarbon solvent, at least one nonionic emulsifier, and at least one freeze-thaw stabilizer which either prevents breaking of the emulsion after a freeze-thaw cycle or enables the emulsion to be re-formed following breaking after a freeze-thaw cycle by simple shaking of the emulsion composition. Preferred freeze-thaw stabilizers are polyols (e.g., glycerin), sugars (e.g., sucrose), polar aprotic solvents (e.g., dimethyl sulfoxide) and amphoteric compounds (e.g., lauryl dimethyl amine oxide). The freeze-thaw stabilizers are particularly useful in furniture care, shoe care and auto care cleaning and / or polishing products including therein water, hydrocarbon solvent(s), nonionic emulsifier(s) and additives, such as film former(s), surfactant(s), fragrance component(s) and preservative(s).

Owner:SC JOHNSON & SON INC

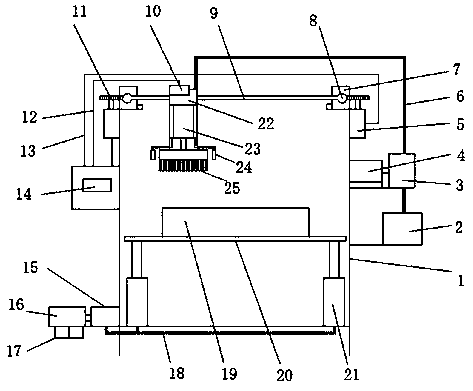

Novel polishing machine and application method

InactiveCN108637875AQuick Polishing and GrindingNo pollutionGrinding carriagesPolishing machinesABSORPTION BASEPulp and paper industry

The invention discloses a novel polishing machine and an application method. The polishing machine comprises a frame body. A shock absorption base is mounted at the bottom of the frame body. A to-be-polished product containing platform is arranged at the bottom of an inner cavity of the frame body. A polishing mechanism is arranged above the to-be-polished product containing platform and comprisesa telescopic sand column, a polishing head, a rotary head ad a motor, the lower end of the telescopic sand column is connected with the polishing head, the upper end of the telescopic sand column isconnected with the rotary head, and the rotary head is connected and mounted to a motor at the top of the frame body. Dust suction mechanisms are mounted on the two sides of the frame body correspondingly. The novel polishing machine is simple in structural principle and convenient to use, and marble products can be fast polished and ground; and in addition, no dust pollution is generated in the polishing process.

Owner:MAANSHAN SONGHAK INFORMATION TECH CO LTD

Process method for producing glass bodies of glasses

InactiveCN107797301ASimple processing technologyImprove work efficiencyNon-optical partsNumerical controlMaterials processing

The invention discloses a process method for producing glass bodies of glasses. The method comprises the following steps of processing materials into base materials of the two glass bodies of the glasses; performing CNC (computer numerical control) processing on the base materials to form a plurality of legs; bending the legs on the base materials, and enabling the legs to cooperate with working positions; cutting off the two glass bodies of the glasses, dipping in oil, forging for a first time, forging the glass bodies of the glasses into shapes which can cooperate with a mold, trimming coarsely and rinsing; dipping in the oil continuously, and forging and rinsing for a second time; dipping in the oil continuously, forging for a third time, trimming meticulously and rinsing; dipping in the oil continuously, and forging for a fourth time; polishing products, dipping in the oil and sizing; putting the products in an aging oven, and performing hardening treatment on the products. By adopting the design, the processing technology is simple, and the work efficiency is high.

Owner:深圳市懿臻实业有限公司

Teflon rod grinding device

InactiveCN107717643ASolve the problem of poor adaptabilitySolve the purpose that is not thorough enoughGrinding carriagesRevolution surface grinding machinesEngineeringThreaded rod

The invention discloses a teflon rod grinding device. The teflon rod grinding device comprises a base. A stand column is fixedly connected with the right side of the top of the base, the bottom of theright side of the stand column is connected with a rotary shaft in a penetrating mode, a baffle is fixedly connected with the left side of the rotary shaft, and a bottom plate is fixedly connected with the bottom of the left side of the baffle; a fixing groove is formed in the top of the left side of the baffle, a spring is fixedly connected with the bottom of the inner side of the fixing groove,and a top plate is fixedly connected with the top of the spring; and a groove is formed in the right side of a sliding rod, a fixing block is movably connected with the inner side of the groove in aclamped mode, and a bearing is connected with the right side of the fixing block in a penetrating mode. According to the teflon rod grinding device, through using of the baffle, the bottom plate, thefixing groove, the spring, the top plate, a threaded rod, an extrusion sheet and the bearing, the problem that the suitability of a polishing device is poor is solved, and through using of the base, aclamping groove, a clamping block, a supporting column, a polishing rod and a grinding block, the problem that the polishing equipment cannot thoroughly and exquisitely polish products is solved.

Owner:扬中市盛新氟塑制品有限公司

Polishing device

InactiveCN112008583AAvoid harmNo manual operationGrinding carriagesPolishing machinesEngineeringTower

The invention provides a polishing device. The polishing device comprises a clamping mechanism, wherein the clamping mechanism comprises a clamping device and a first sliding device, the first slidingdevice is installed on a rack, and the clamping device is installed on the first sliding device in a sliding mode; a tower mechanism which comprises a first driving device, a tower turntable, a towerand a grabbing part, wherein the tower is mounted on the tower turntable, the grabbing part is movably mounted on the tower, and the grabbing part is used for grabbing a to-be-polished product; a grinding mechanism which comprises a polishing device body and a second sliding device, wherein the second sliding device is installed on the rack, the polishing device body is installed on the second sliding device in a sliding mode and used for polishing the to-be-polished product, the first sliding device and the second sliding device are used for adjusting the positions of the clamping mechanismand the grinding mechanism; and a control device electrically connected with the tower mechanism, the clamping mechanism and the grinding mechanism. In the whole polishing process, the tower mechanism, the clamping mechanism and the grinding mechanism are controlled by the control device to complete polishing, manual operation is not needed, the automation degree is high, and the polishing efficiency is improved.

Owner:WUYI UNIV

A kind of preparation method of glazing wax

ActiveCN107523222BEasy dischargeEasy to separatePolishing compositionsPetroleum wax recoverySolid componentWax

The invention discloses a method for preparing wax polish. According to the method, an F-T synthetic product is adopted as a raw material, and a target product is prepared through sweating and emulsification. On the basis of a common sweating process, a liquid component is carried out through a wax layer by virtue of air flow in the sweating process, then a solid component is compulsively separated from the liquid component, meanwhile preferably a sweating raw material forms stable micro bubbles in the wax layer under the action of a bubble stabilizer, a constant-temperature process is added in the crystallization process, then the liquid component can be rapidly discharged out, and thus a basic material without low-melting point components is produced; and the basic material is further emulsified with components such as silicon oil, natural wax and oil-soluble aids, and then a wax polish product is prepared. The method disclosed by the invention has the advantages of being low in production equipment investment, simple in production process, low in operation cost, safe and energy-saving, free of solvent pollution, good in wax polish product high temperature resistance, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

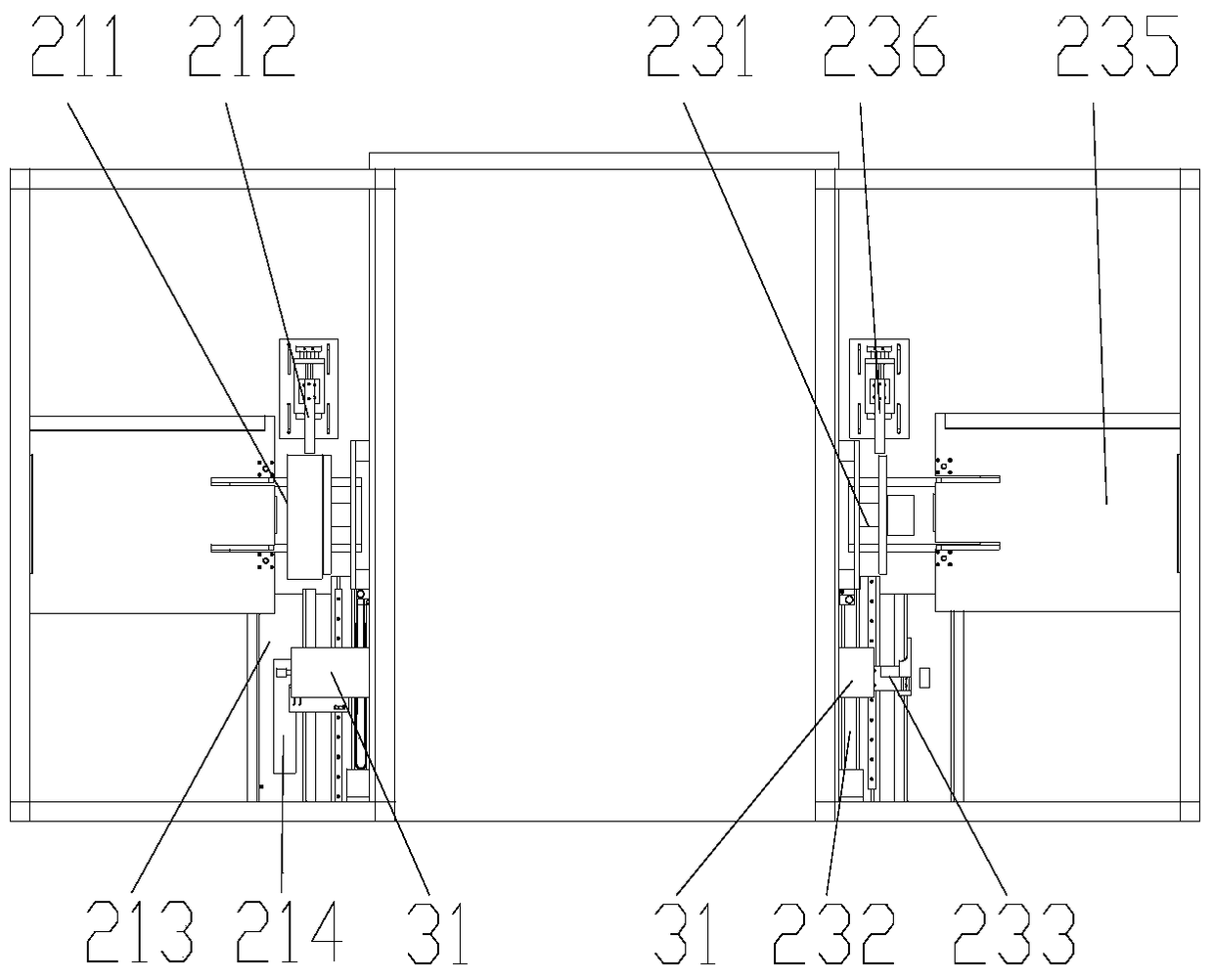

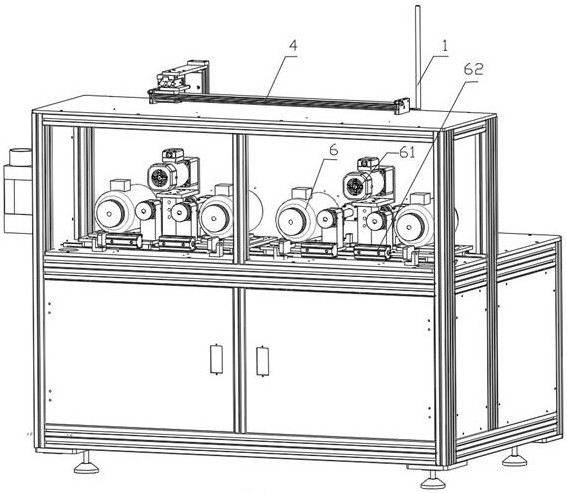

Double-station polishing machine for ceramic wire guide and polishing method of double-station polishing machine

PendingCN113927456AImprove continuityAvoid operabilityPolishing machinesGrinding drivesPolishingEngineering

The invention provides a double-station polishing machine for a ceramic wire guide and a polishing method of the double-station polishing machine. The double-station polishing machine for the ceramic wire guide comprises a feeding mechanism arranged on an operation table top and polishing assemblies arranged on one side of the feeding mechanism, wherein each polishing assembly comprises a polishing mechanism and a jacking mechanism arranged on the opposite face of the polishing mechanism; the polishing assemblies comprise the first polishing assembly and the second polishing assembly arranged on one side of the first polishing assembly; a material moving mechanism is arranged between the two polishing assemblies; and a to-be-polished product is fed by the feeding mechanism, one jacking mechanism jacks the product for first-time polishing, and the product subjected to the first-time polishing is moved to the second polishing assembly through the material moving mechanism to complete second-time polishing. The double-station polishing machine for the ceramic wire guide and the polishing method of the double-station polishing machine provided by the invention have the beneficial effects that continuity between two times of polishing is achieved, manual carrying operation and switching are avoided, time and labor are saved, and the polishing efficiency is greatly improved.

Owner:苏州赛琅泰克高技术陶瓷有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com