A coated grinding brush filament, a brush and a manufacturing method of the coated grinding brush filament

A manufacturing method and a technology for grinding brushes, which are applied in the manufacture of brushes and coated grinding brush wires, and the field of coated grinding brush wires, can solve the problem that grinding brushes do not play any role, affect grinding and polishing ability and processing efficiency, and are inferior to grinding brushes. Silk and other problems, to achieve the effect of good elasticity, dense structure, and improved resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

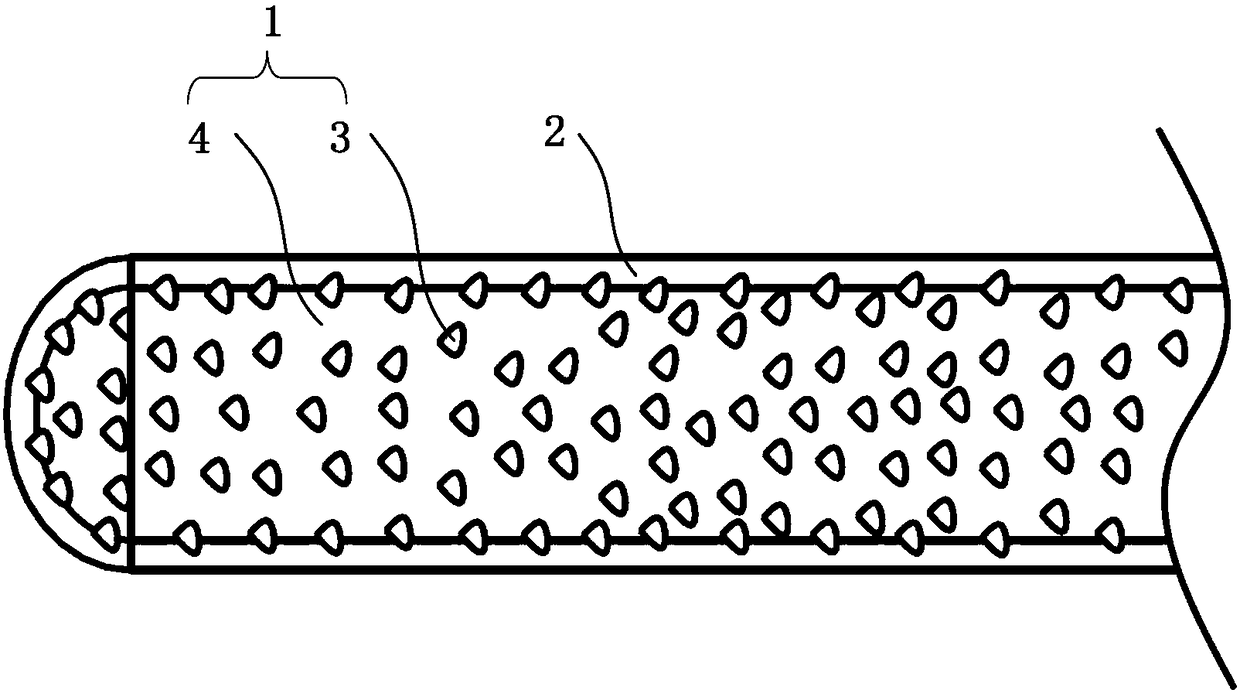

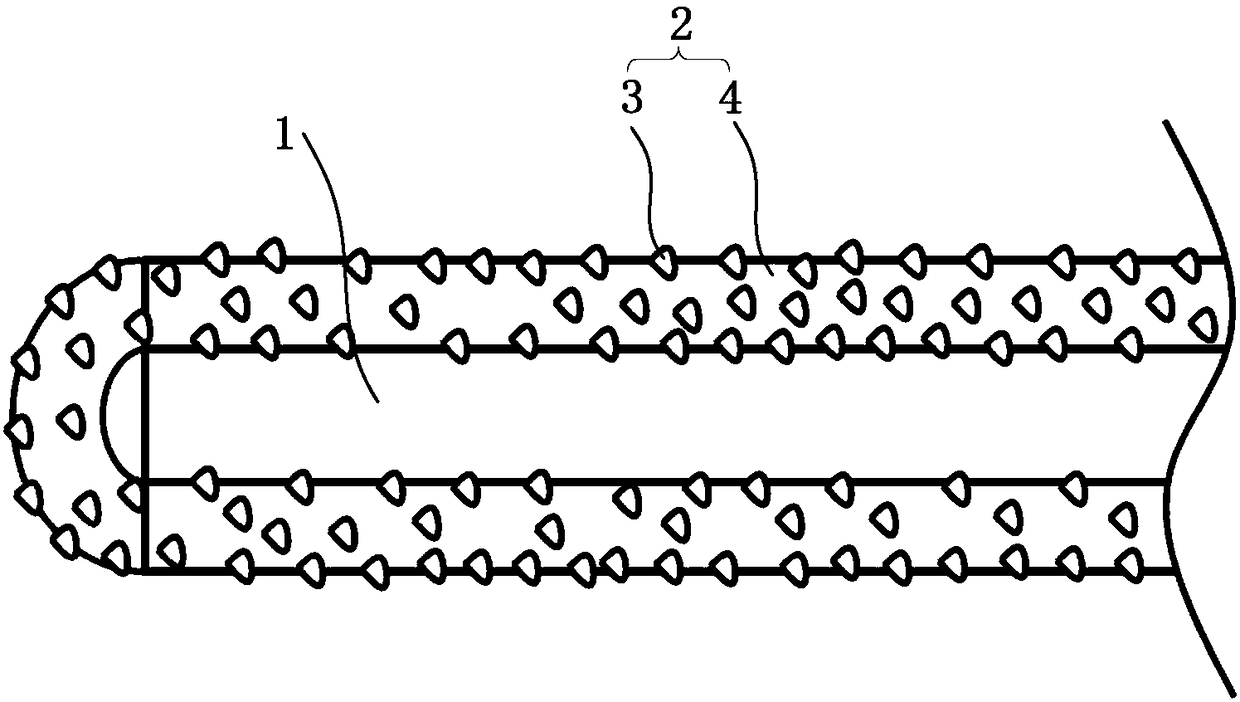

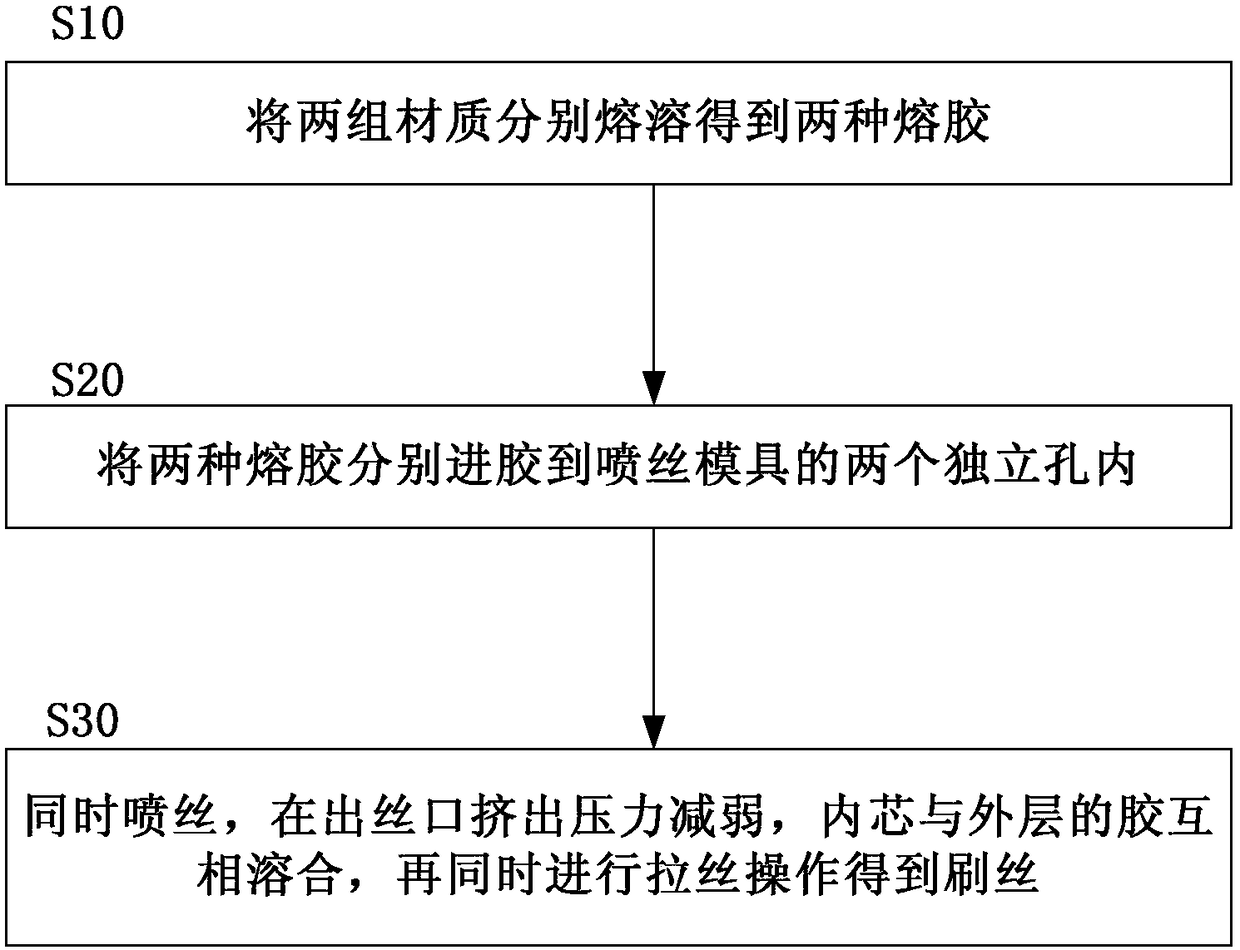

[0037] Combine below Figure 1 ~ Figure 3 The technical solution provided by the present invention is described in more detail.

[0038] see figure 1 and figure 2 , The embodiment of the present invention provides a coated abrasive brush filament, which includes an inner core 1 and an outer sheath 2 , the inner core 1 and the outer sheath 2 are integrated, and the inner core 1 and / or the outer sheath 2 contain abrasive sand 3 .

[0039] The inner core 1 is ground brush wire or pure plastic wire, and the inner core 1 and the outer skin 2 are integrated. The inner core 1 and the outer skin 2 are really completely integrated, melted into each other and stretched together in the melt state, and the abrasive sand is buckled into the pure nylon layer, which is completely integrated and will not fall off and separate, and thus produce differences. technical features and performance improvements.

[0040] The materials of the inner core 1 and the outer skin 2 are preferably the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com