Patents

Literature

159 results about "Gilsonite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gilsonite, also known as "uintahite", "asphaltum" or asphaltite, is a naturally occurring soluble solid hydrocarbon, a form of asphalt (or bitumen) with a relatively high melting temperature. Its large-scale production occurs in the Uintah Basin of Utah and Colorado, United States. Although the substance has been historically mined in the Uintah Basin, resources are being discovered and mined more recently in other countries such as Colombia and Iran. Gilsonite is mined in underground shafts and resembles shiny black obsidian.

Pavement material

The present invention is a recipe and method for combining Gilsonite and other asphaltites with curative elastomers that are powder granular form and which are added to asphalt. Second recipe and method is disclosed to create a dry liquid concentrate comprised of cured elastomers in combination with tall oil or other fatty acids and may also include Gilsonite to be added to asphalt.

Owner:TEXAS ENCORE

High-temperature water-in-oil drilling fluid

InactiveCN102031095AOvercoming the problem of insufficient temperature resistanceMeet the requirements of temperature resistanceDrilling compositionMineral oilSODIUM DODECYL BENZENE SULFONATE

The invention relates to a high-temperature water-in-oil drilling fluid which is composed of the following components in parts by weight: 70-90 parts of base oil, 3-7 parts of organic bentonite, 2-5 parts of oxidized asphalt, 2-5 parts of sulfonated gilsonite, 20-60 parts of CaCl2 aqueous solution of which the mass concentration is 20%, 6-10 parts of calcium oxide, 1.5-5.5 parts of UZEMUL-S, 2-5 parts of ABS (acrylonitrile butadiene styrene) and barite, wherein the base oil is non-blooming mineral oil with low aromatic hydrocarbon; the UZEMUL-S is a main emulsifier, the HLB (hydrophile-lipophile balance) value is 2.5, and the UZEMUL-S is formed by synthetizing an organic acid and an organic acid amide; and the ABS auxiliary emulsifier is sodium dodecyl benzene sulfonate, and the HLB value is 10. The invention resists temperature of 240 DEG C, can overcome the difficulty of insufficient heat-resistant capability of the existing drilling fluid and is favourable for satisfying the requirement of drilling fluid heat-resistant capability for deep wells and ultra deep wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Direct-casting type anti-track agent and preparation method

ActiveCN102585522AImprove plasticityHigh modulus at room temperatureBuilding insulationsWaxPolyester

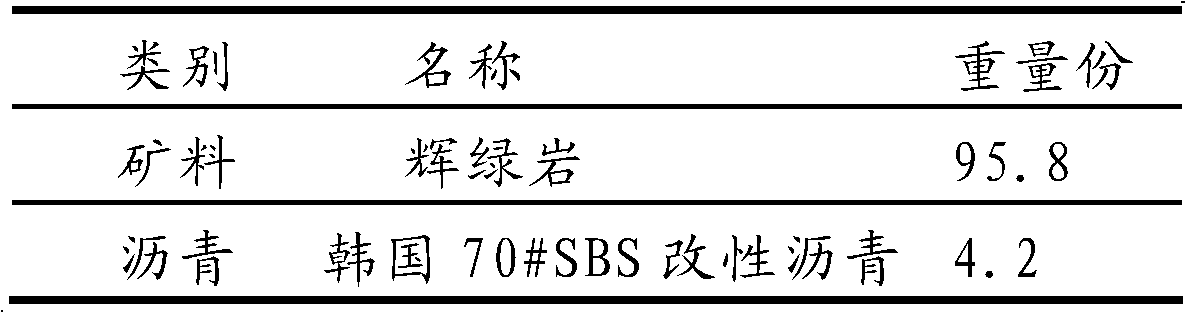

The invention discloses a direct-casting type anti-track agent, which is formed by the following components by weight in mixing mode: 20 to 40 parts of regenerative polyolefine plastic, 10 to 20 parts of regenerative polyester plastic, 2 to 10 parts of regenerative wax, 2 to 10 parts of organic powder body with small particle size and 5 to 10 parts of gilsonite. A preparation method of the direct-casting type anti-crack agent and a method for preparing asphalt mixture by adopting the direct-casting type anti-crack agent are further disclosed. Particles of the direct-casting type anti-crack agent can be directly cast in hot aggregate on construction sites to be mixed with the hot aggregate in drying mode, intermittent construction can be conducted, and the direct-casting type anti-track agent lowers or reduces probability of separation of modified asphalt in the cooling, transporting and storing processes, and break through limit and restraint brought by continuous production and construction.

Owner:SHANGHAI PUDONG ROAD & BRIDGE GRP CO LTD

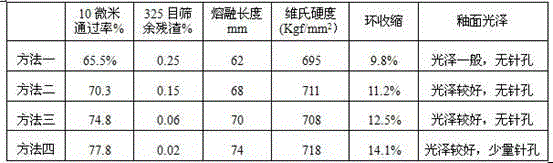

Production method of anti-bacterial external wall tiles

The invention provides a production method of anti-bacterial external wall tiles, wherein a glazing layer is applied on the tiles through the following steps: (A) spraying a ground glaze layer on a bottom green body, naturally air-drying the ground glaze layer to immobilize it; (B) spraying a layer of active water repellent to form a layer of hydrocarbon chains being hydrophobic; (C) spraying a cover glaze slurry, naturally air-drying the cover glaze slurry to form an antibacterial glaze slurry layer; and (D) spraying a protective glaze insulating layer. The cover glaze includes, by weight, 29% of quartz powder; 20% of potassium feldspar, 10% of wollastonite, 5.5% of calcite, 4% of dolomite, 2.5% of cordierite, 5% of zirconium phosphate, 6.5% of aluminum oxide, 2% of zinc oxide, 4.5% of a frit, 5% of zirconium silicate and 8% of titanium oxide. The anti-bacterial external wall tile is a novel functional ceramic product, has the anti-bacterial, mildew-proofing, decomposition and deodorization effects, can avoid invasion to human from various infections, can keep the external wall of buildings to be clean and can avoid mildew pollution.

Owner:FOSHAN SANSHUI NEW PEARL CONSTR CERAMICS IND +1

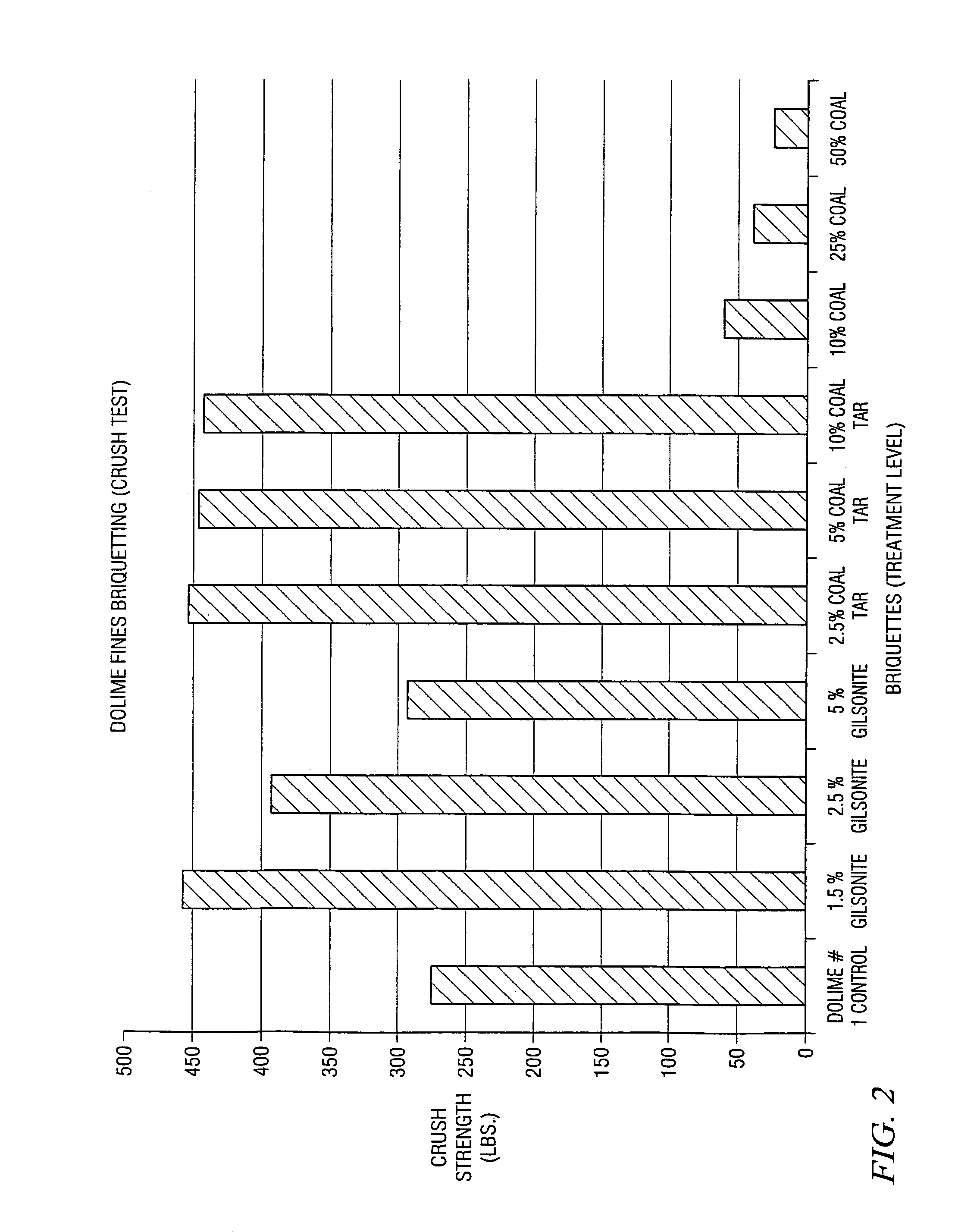

Briquetting of lime based products with carbon based additives

A method is shown for briquetting quicklime fines. A source of quicklime or dolomitic quicklime fines is combined with a binder in the form of a pseudo-plastic carbon containing material which will deform under briquetting conditions of elevated temperature and pressure and flow and which will also return to a solid phase and bind the quicklime fines upon cooling. An external force is applied to the mixture of fines and binder, as with a briquetting machine, sufficient to form the mixture into a briquette having requisite strength and durability characteristics. Suitable classes of carbon containing materials include Gilsonite®, a solid coal tar pitch and recycled plastics such as polyethylene and polypropylene.

Owner:LHOIST NORTH AMERICA INC

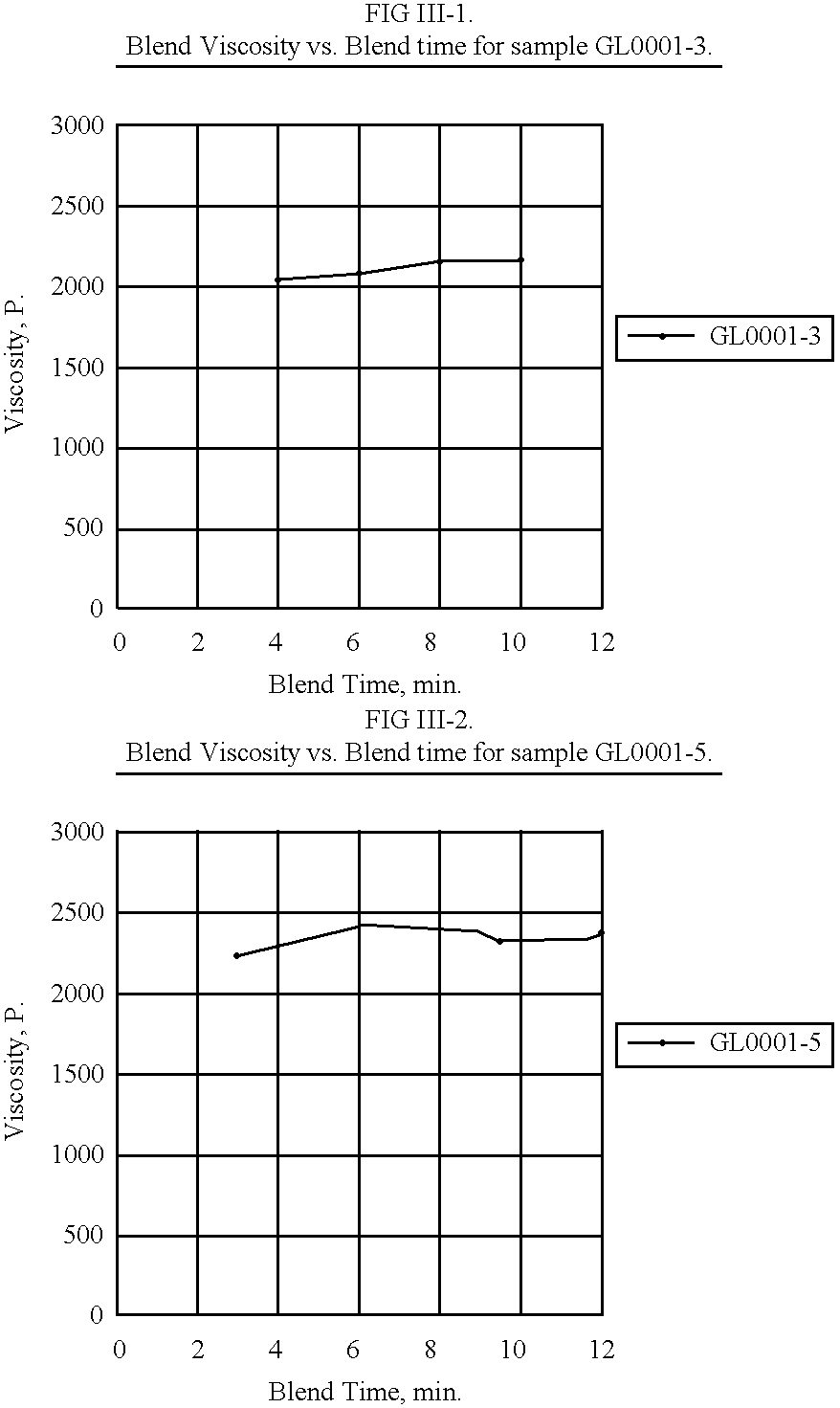

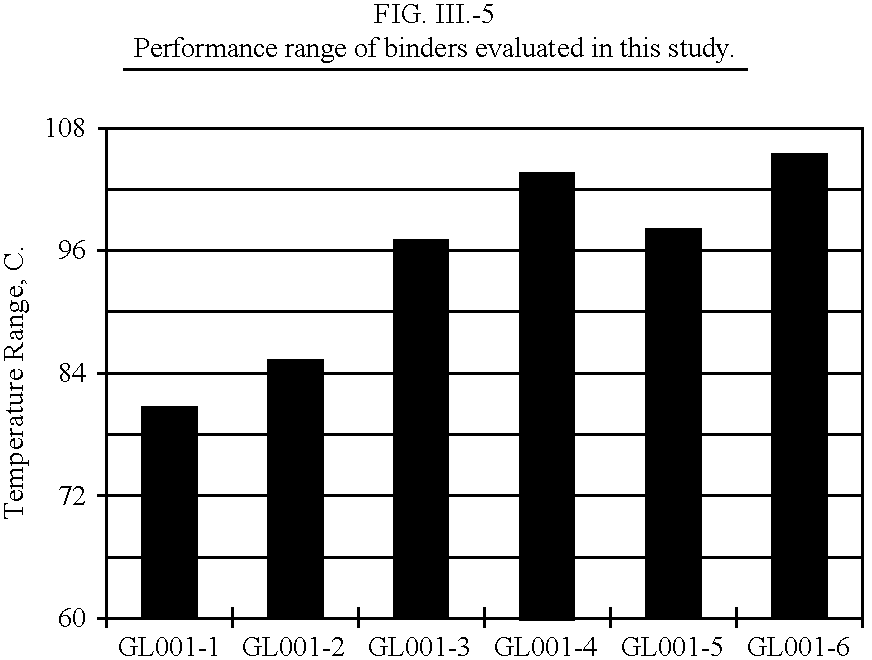

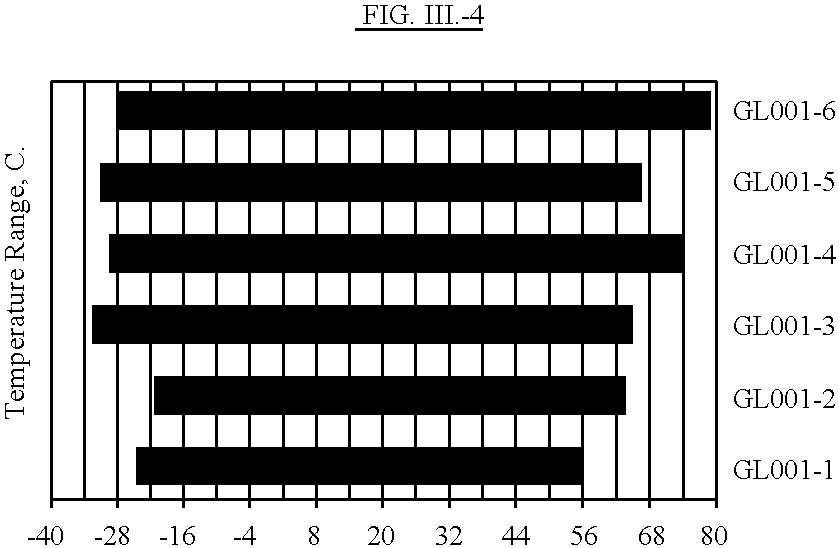

Incorporation of gilsonite into asphalt compositions

It has been discovered that a synthetic flux oil can contain and deliver asphaltites, such as gilsonite, more easily and readily to an asphalt to improve its properties. The synthetic flux oil includes the asphaltite and a carrier oil. Depending on the nature of the carrier oil, the synthetic flux oil may or may not need to be heated during mixing and incorporation into the asphalt.

Owner:FINA TECH

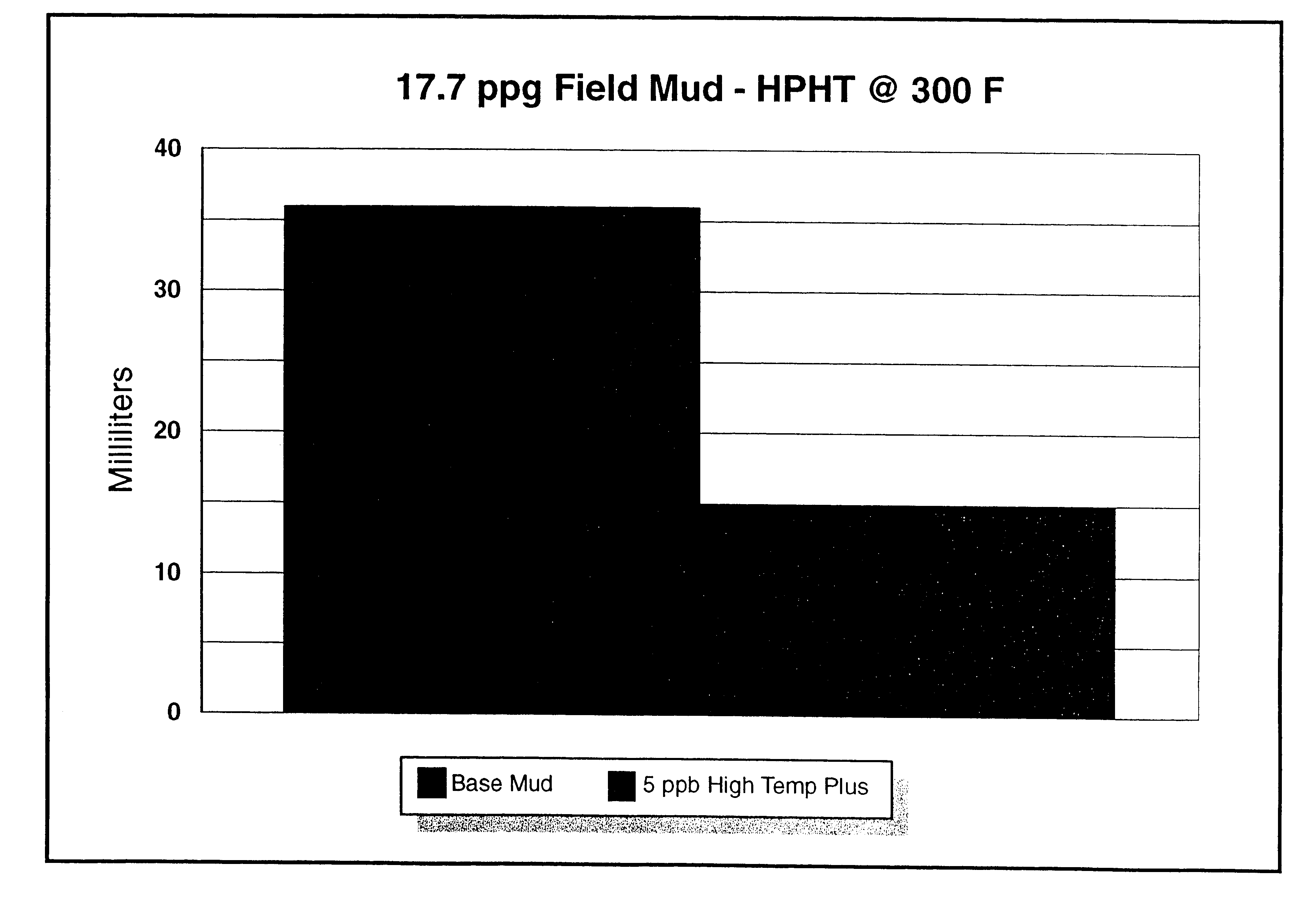

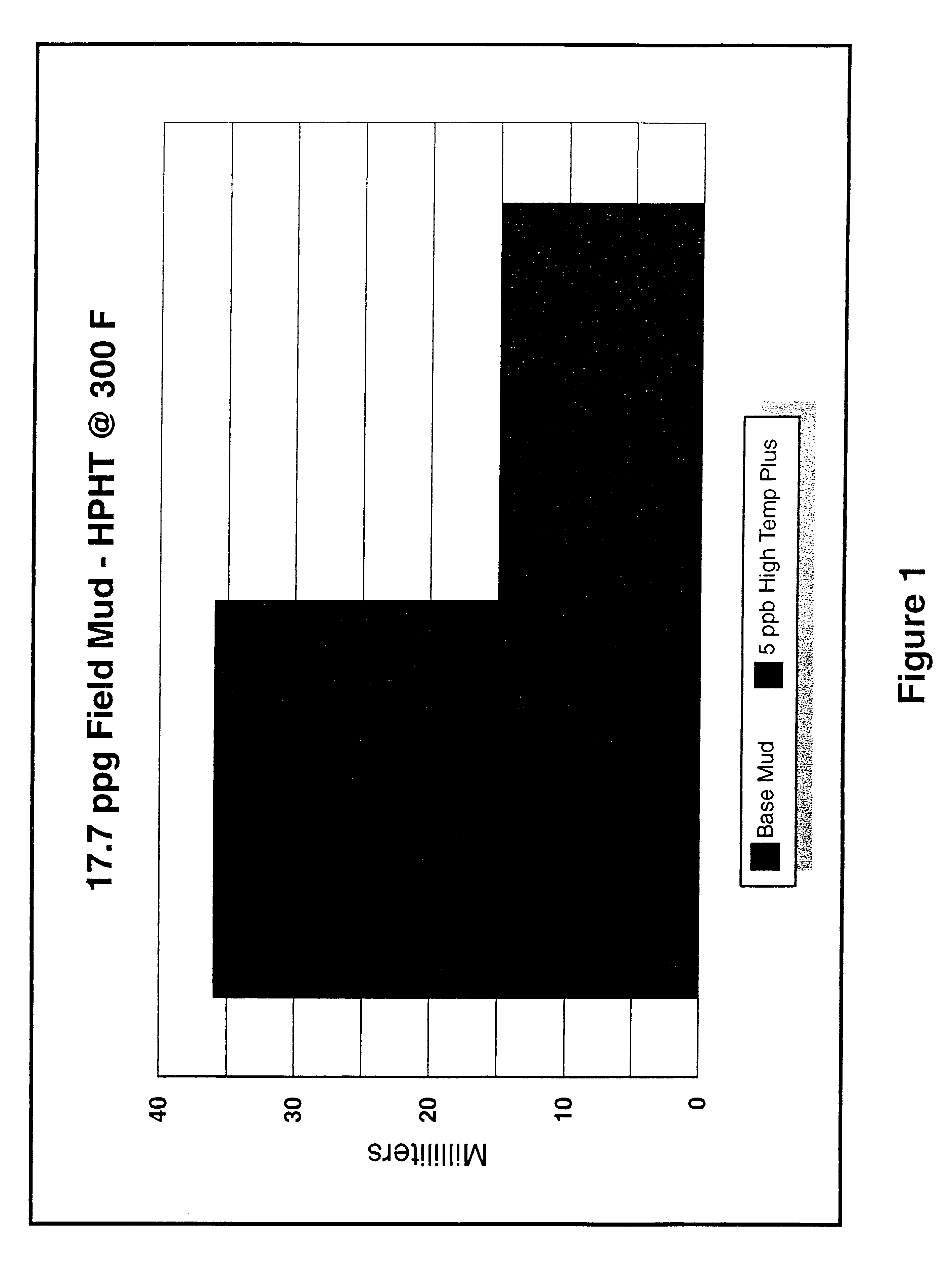

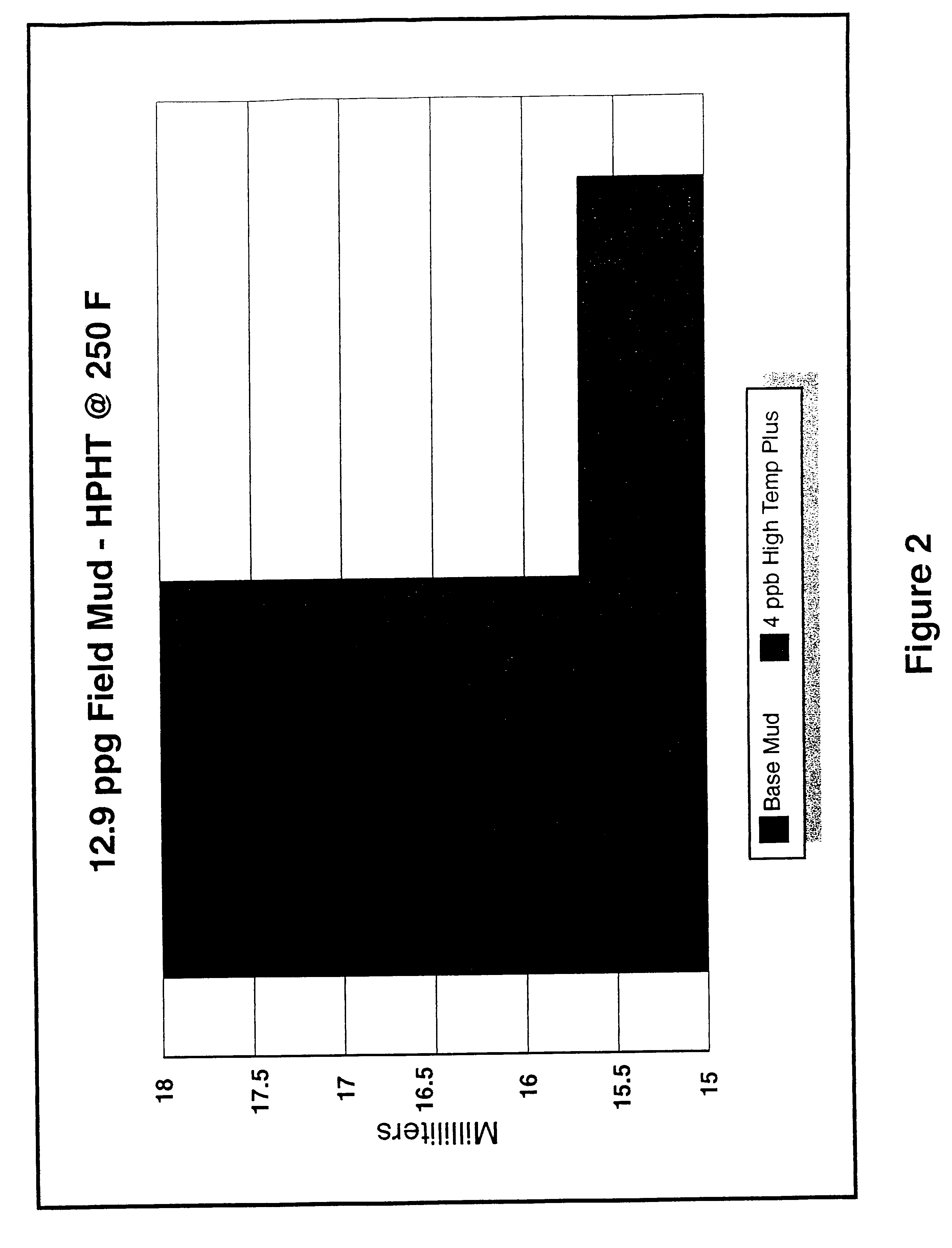

High pressure, high temperature (HPHT) fluid loss control aid for drilling fluids

InactiveUS6395686B2Excellent shale stabilizerReduces HPHT filtrate lossFlushingDrilling compositionEngineeringHigh pressure

The invention relates to a composition comprising an HPHT fluid loss control aid, stable at elevated temperatures and which also acts as an excellent shale stabilizer, bore hold lubricant, sealant for depleted sand, and wall cake conditioner. The HPHT fluid loss control aid broadly comprises a uintaite sold under the trade name Gilsonite(R), which also contains a surfactant such as a nonionic surfactant. The HPHT fluid loss control aid also contains a solubilized lignite such as causticized lignite and carbon black. The fluid loss control aid reduces HPHT filtrate loss, has good stability at elevated temperatures such as at 300° F., stabilizes troublesome shales and decreases bore hole erosion, helps seal depleted sands, reduces torque and drag, causes no adverse effects on the flow properties of the properly conditioned drilling fluid, and lowers total well costs.

Owner:SUN DRILLING PRODS

Agate-containing dark green glaze for ru-porcelain, processing method of glaze as well as ru-porcelain and firing method thereof

The invention relates to agate-containing dark green glaze for ru-porcelain, a processing method of the glaze as well as the ru-porcelain and a firing method thereof and relates to the technical field of silicate ceramics. The agate-containing dark green glaze for the ru-porcelain is prepared from components in parts by weight as follows: 6-20 parts of ru jade, 1-15 parts of agate, 10-70 parts of feldspar, 2-8 parts of calcite, 1-20 parts of wollastonite, 0-2 parts of talc, 0-15 parts of chest wood ash, 1-8 parts of ammolite and 1-20 parts of black bluestone. The enamel of the ru-porcelain fired with the adoption of the agate-containing dark green glaze for the ru-porcelain takes dark green as a base, can present the deep and full sky blue, azure, light greenish blue, bluish white, pale blue and bright green and can present bright and transparent pea green and onion green color. The ru-porcelain adopting the agate-containing dark green glaze for the ru-porcelain has good jade sense and opalescence effects and has a smoother glaze surface, higher mechanical strength, lower water absorption rate and high firing qualification rate.

Owner:郭秀贞

Wood-grain pottery glaze, wood-grain pottery product prepared by same, and process

ActiveCN104130031ASolve the problem of excessive dissolutionReduce processing costsPolymer sciencePotassium

The invention relates to the technical field of pottery, and particularly relates to a wood-grain pottery glaze, and a process for preparing a pottery product by using the same. The wood-grain pottery glaze comprises the following components by weight: a bottom glaze comprising 43%-47% of potassium feldspar, 4%-6% of No. 1 clinker, 19%-21% of barium carbonate, 4%-6% of limestone, 4%-6% of calcined talcum, 9%-11% of Longyan kaolin, 9%-11% of titanium oxide and 1%-3% of vanadium yellow; a top glaze comprising 28%-32% of potassium feldspar, 39.9%-43.7% of No.2 clinker, 11%-13% of wollastonite, 5%-6% of Longyan kaolin, 10%-12% of pigments and 0.1%-0.3% of carboxymethyl cellulose. The process can overcome the problem that dissolution quantity of lead and cadmium exceeds a standard, reduces steps and labor cost, greatly increases yield of products, and saves production cost.

Owner:FUJIAN DEHUA YOUSHENG CERAMICS

Nanoscale waterproof film and preparation method thereof

ActiveCN103756460AImprove hydrophobicityGood light transmissionPolyurea/polyurethane coatingsFiberPolymer science

The invention discloses a nanoscale waterproof film and a preparation method thereof. The waterproof film mainly comprises the following raw materials in percentage by weight: 30-60 percent of nano-fluorine polymer particles, 0.1-8 percent of polysiloxane, 5-15 percent of polyurethane, 40-70 percent of an odorless solvent, 1-10 percent of wollastonite fibers, 0.5-5 percent of nano-titanium dioxide, 1-8 percent of nano-zinc oxide and 0.2-1.5 percent of an additive, wherein the particle diameters of the nano-fluorine polymer particles are 50-100 nanometers. After a nanoscale liquid film is formed on an electronic product, liquid contacting with the film is condensed into water drops which fall off freely, so that the electronic product has completely the same function as normal use. By adopting the nanoscale film, objects can be prevented from being corroded by damp air, sweat, moisture and the like without influencing the appearances of electronic products or causing changes in the properties such as inherent properties, weights and optical performance of the electronic products.

Owner:深圳九合伟业科技有限公司

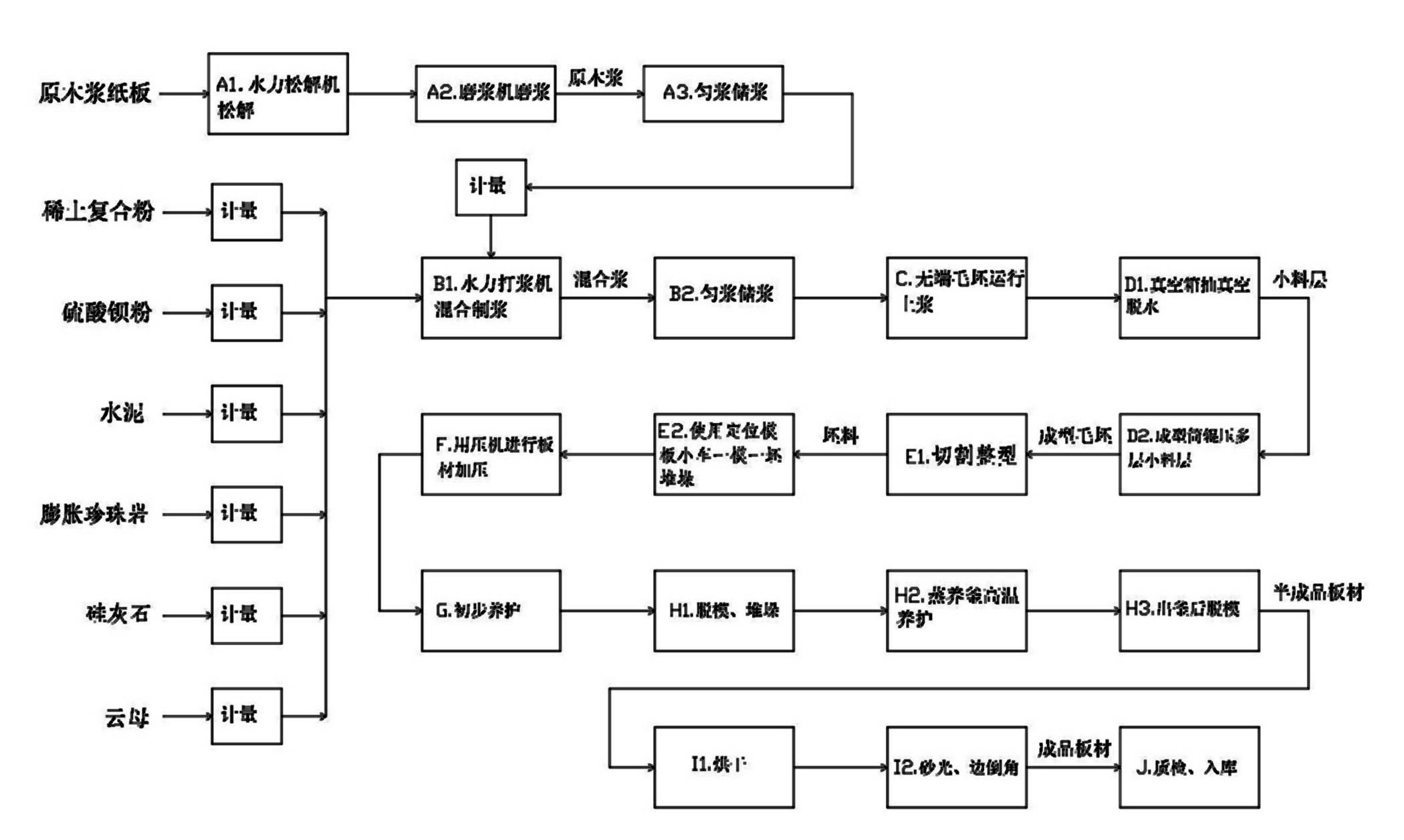

Method utilizing industrial waste to prepare non-asbestos calcium silicate board

The invention provides a method utilizing industrial waste to prepare a non-asbestos calcium silicate board. The method includes the following steps: (1) producing waste concrete paper bag sizing agent; (2) dosing: 6%-10% of the waste concrete paper bag sizing agent, 35%-45% of quartz tailing mineral powder, 2%-8% of calcium carbide slurry, 4%-10% of wollastonite powder, 1%-5% of mica powder, 15%-25% of concrete, 5%-10% of slaked lime powder, 5%-10% of sanding powder, and 0.05%-0.1% of poly-acetamide; (3) pulping; (4) after starching by a pulp flowing machine, producing by a board-making machine board, cutting by a cutting machine board, steaming by a still kettle, drying by a drying machine, grind edging by an edge grinding machine, and sanding by a sander, the non-asbestos calcium silicate board is obtained. Due to the fact that the waste concrete paper bags, the quartz tailing mineral powder, the calcium carbide slurry and the like are used for raw materials for preparing the non-asbestos calcium silicate board, the method utilizing industrial waste to prepare the non-asbestos calcium silicate board not only is beneficial for saving natural resources such as raw ore and wood, but also is beneficial for reducing pollution from the waste to environment. Besides, the prepared products are low in cost, safe, and environmental friendly.

Owner:三明市金宫硅酸钙板有限公司

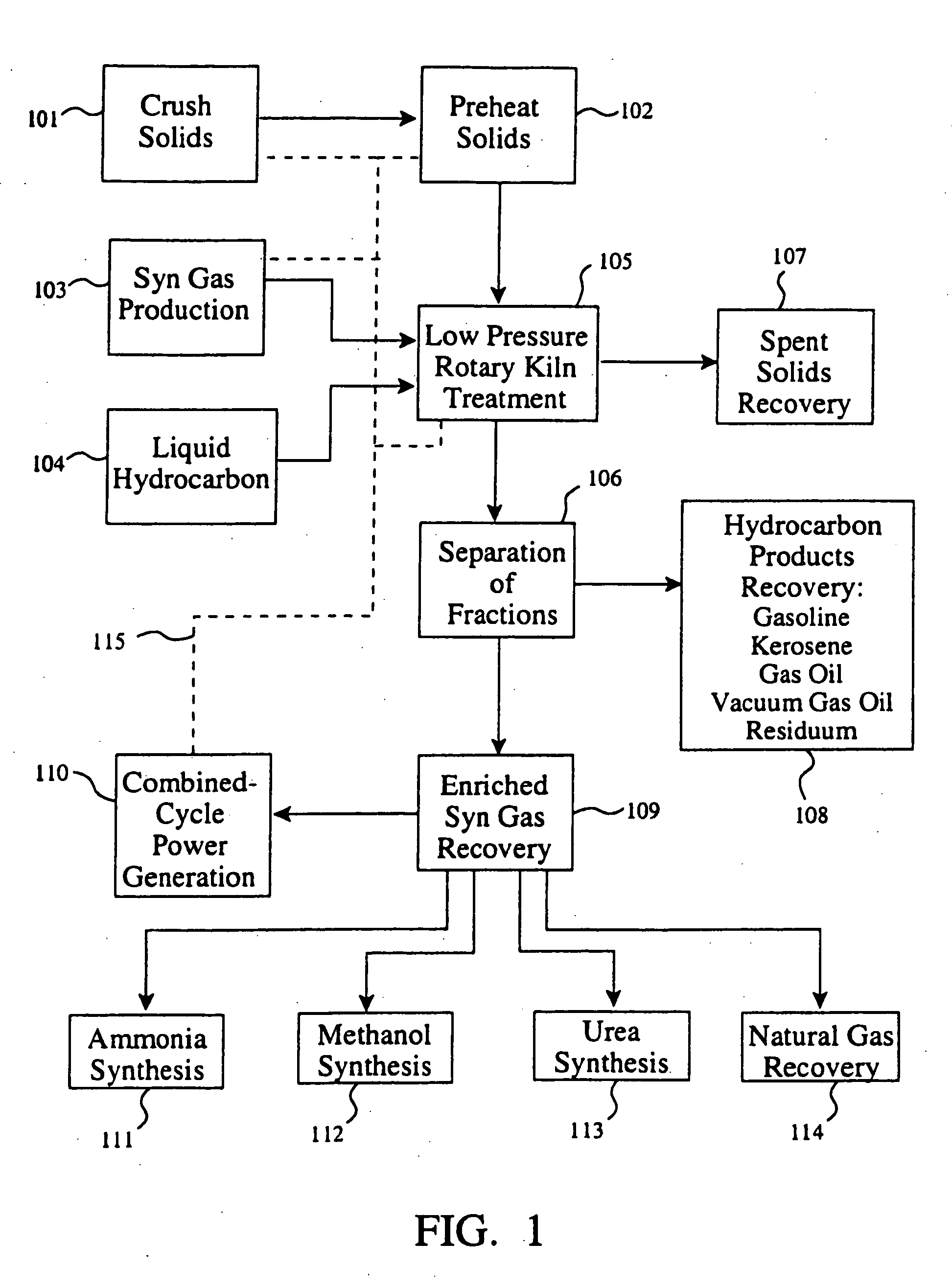

Process for the recovery of hydrocarbon fractions from hydrocarbonaceous solids

InactiveUS20060076275A1Increase productionMinimizes burningLiquid hydrocarbon mixture productionAtmospheric emissionsExternal energy

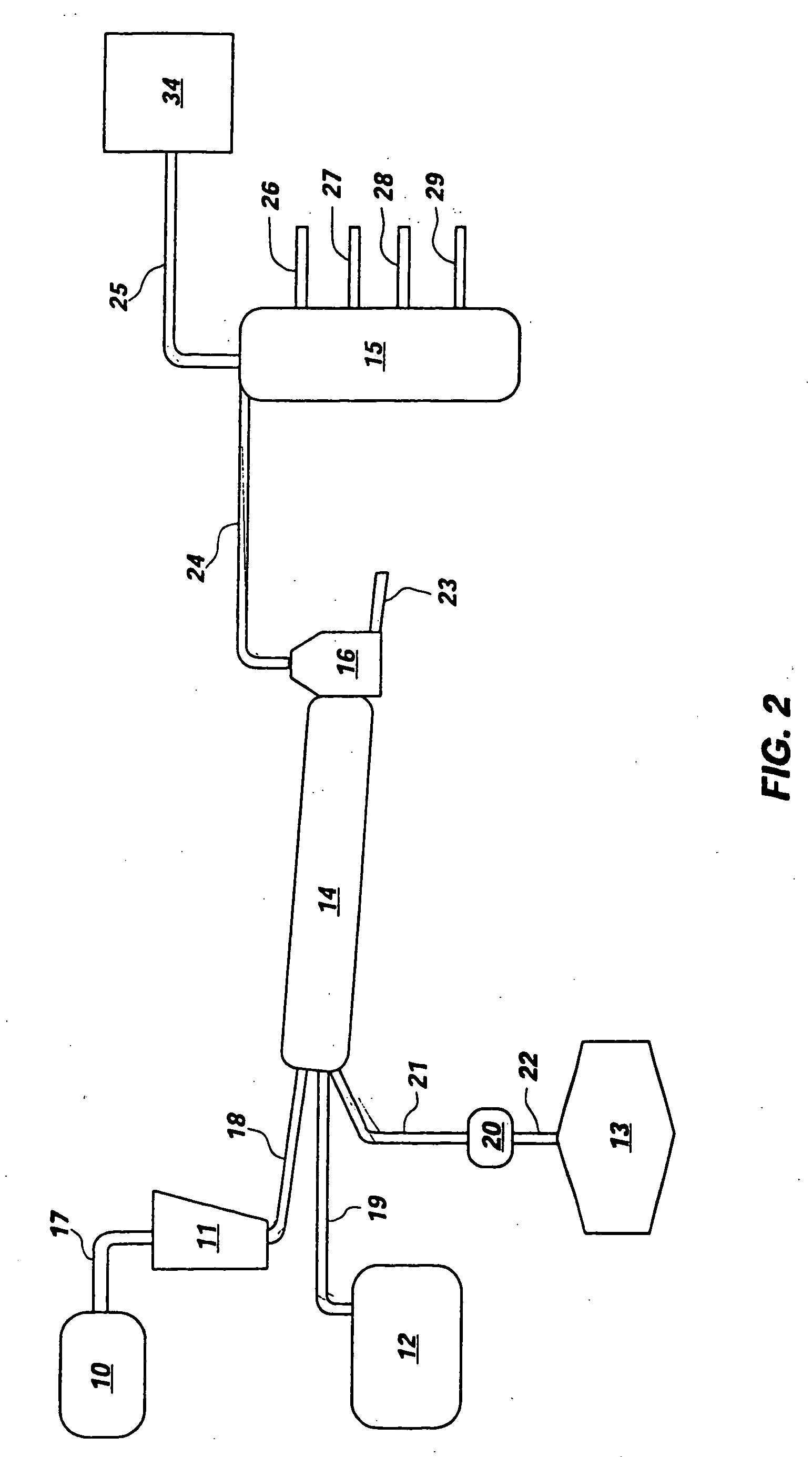

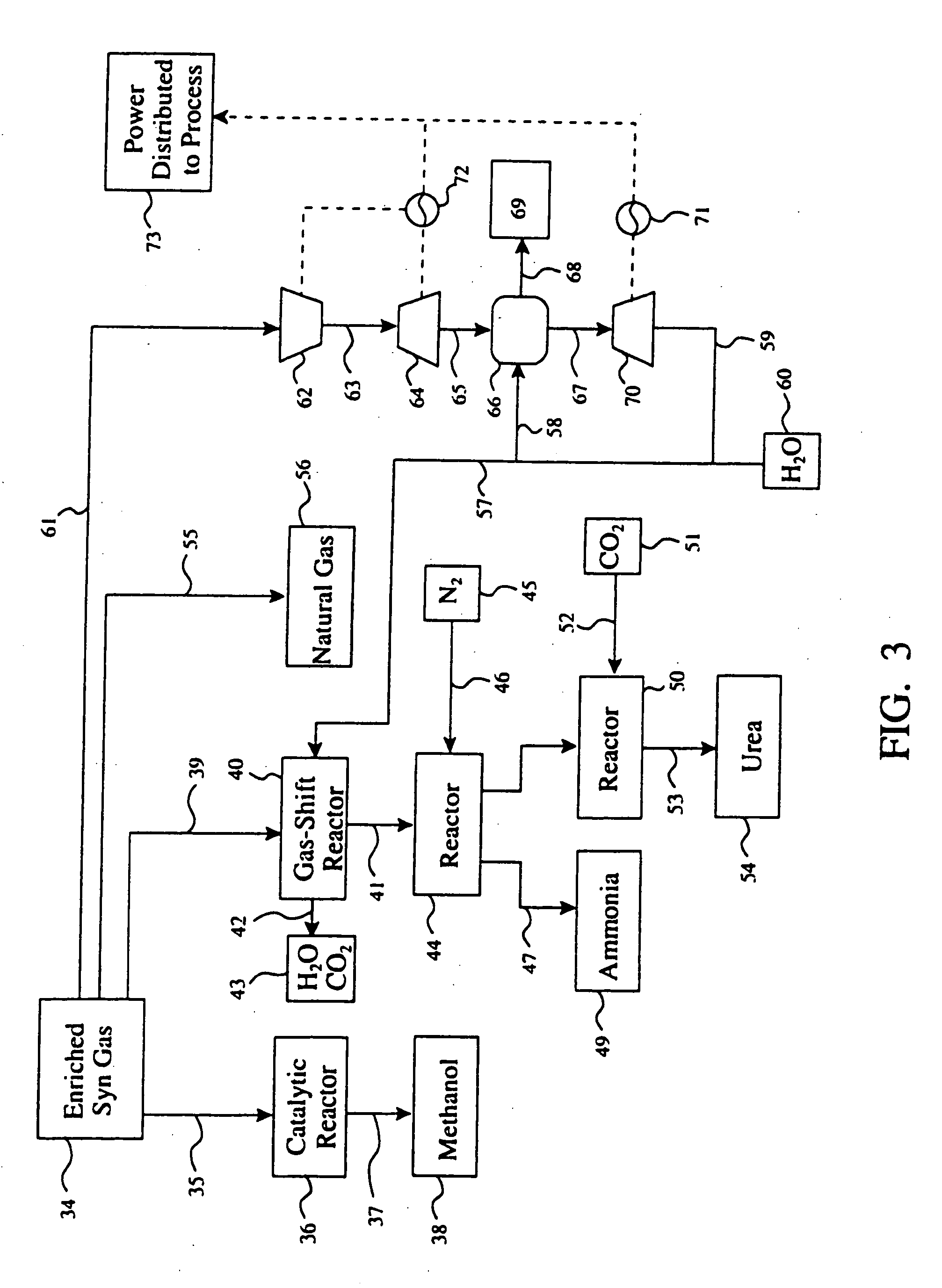

Process and apparatus for extraction of oil and hydrocarbons from crushed hydrocarbonaceous solids (101), such as oil shale, involving the pyrolyzing of the crushed solids (101) with liquid hydrocarbon (104) and hot gas such as syn gas (103) rich in hydrogen, carbon dioxide and carbon monoxide or a solid hydrocarbon such as gilsonite. Crushed hydrocarbonaceous solids are treated with a hydrocarbon and hot gas in a rotary kiln (105) where the crushed solids are cascaded into the hot gas for sufficient time to strip the volatile liquids and gases found in the solids, removing the vaporized liquids, enriched hot gas and spent crushed solids from the kiln, fractionating the vaporized liquids (106) and enriched syn gas into the desired fractions. Use of hot syn gas is particularly suited for use in conjunction with combined-cycle electricity generation (110) and in the preparation of various by-products. The process efficiently recycles heat and energy to reduce harmful atmospheric emissions and reliance on external energy sources.

Owner:SMITH ANTHON L

Nonvolatile ordinary temperature modified asphalt binder and nonvolatile ordinary temperature regenerated asphalt mixture using same

ActiveUS20200199024A1Improve mechanical propertiesMarshall stabilityIn situ pavingsDrilling compositionPolymer scienceIsoprene

A nonvolatile cold modified asphalt binder and a nonvolatile cold recycled asphalt mixture using the same are manufactured by optimally mixing a petroleum asphalt, a native asphalt, a polymer modifier, process oil, and an adhesive strength enhancer. The nonvolatile cold modified asphalt binder includes at least one petroleum asphalt selected from a straight asphalt or a blown asphalt; at least one native asphalt selected from gilsonite, glance pitch, and grahamite; a rubber-modified-compound (RMC) polymer modifier which is a vinyl aromatic hydrocarbon-conjugated diene block copolymer including at least one of a styrene-butadiene block copolymer (SBS), a styrene-isoprene block copolymer (SIS), and a styrene-ethylene-butylene block copolymer (SEBS); at least one process oil selected from paraffin oil, naphthenic oil, aromatic oil, natural oil, and mineral oil; and at least one adhesive strength enhancer selected from rosin esters, modified acryls, modified silicones, polyvinyl esters, and silicone resins.

Owner:HANSOO ROAD IND CO LTD

Flotation separation method for aedelforsite and quartz

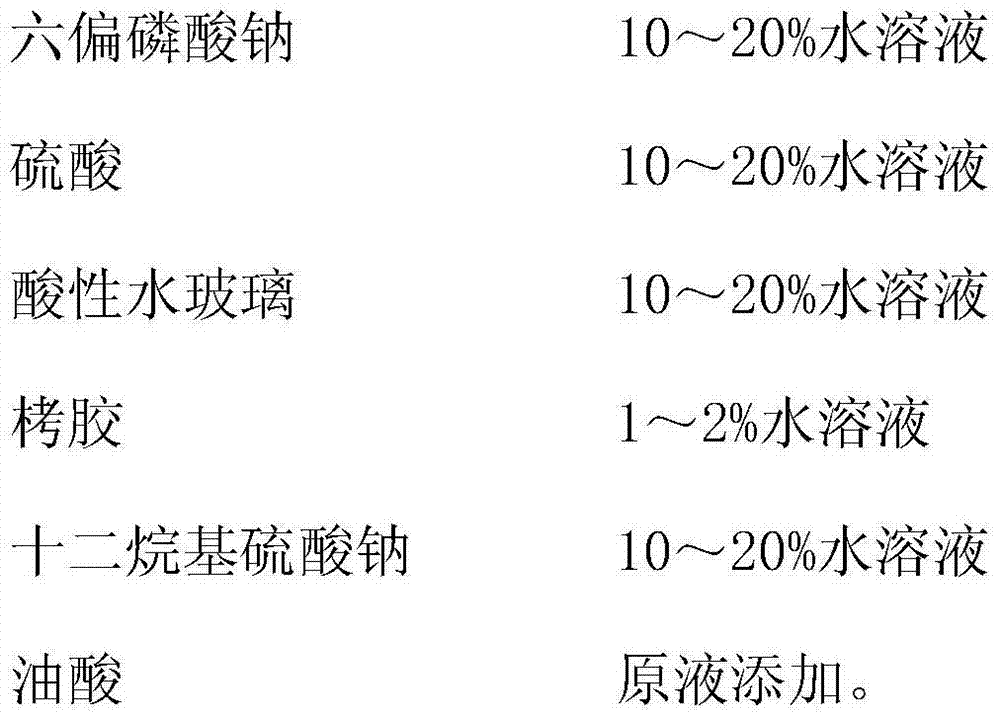

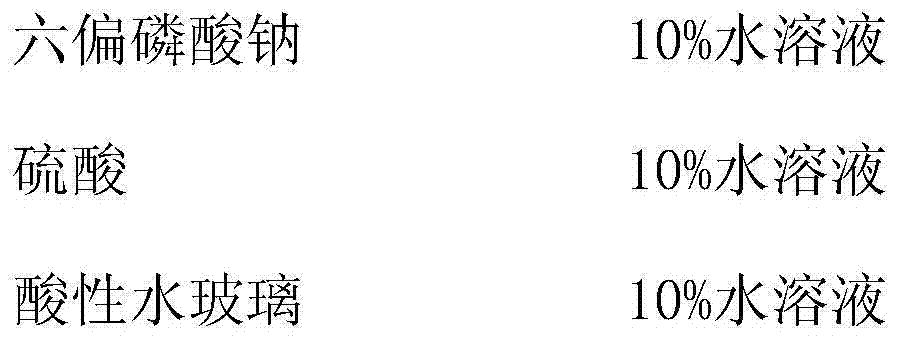

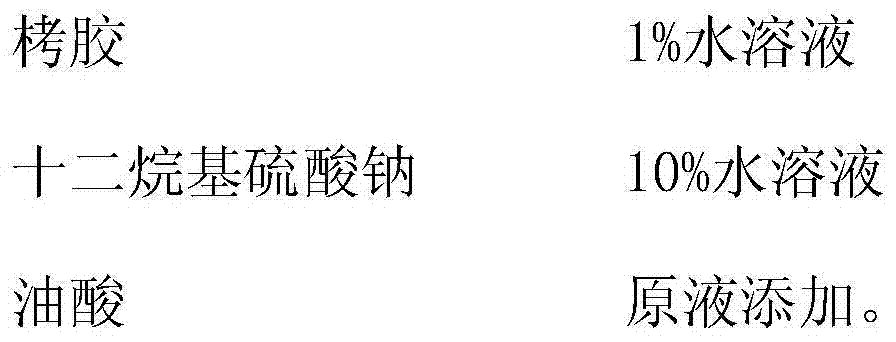

The invention discloses a flotation separation method for aedelforsite and quartz. According to the method, sodium hexametaphosphate is taken as a mineral dispersing agent, sulfuric acid is taken as a pH value adjusting agent, acid soluble glass and tannin extract are taken as quartz inhibitors, and oleic acid and lauryl sodium sulfate are taken as aedelforsite mineral collecting agents. According to the flotation separation method, flotation separation of aedelforsite minerals from quartz minerals can be realized, the flow structure is simple, the medicament dosage is less, and the aedelforsite minerals can be recovered effectively. After flotation separation is performed under the condition that the content of feeding aedelforsite is 47.85-53.90 percent, aedelforsite concentrate of which the aedelforsite content is 93.83-95.18 percent and the recovery rate is 85.74-89.62 percent is obtained.

Owner:GUANGXI UNIV

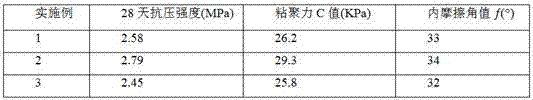

Sludge powder nano soft soil modifier and preparation method thereof

InactiveCN107324726APlay a compact roleHigh compressive strengthFixation/solidifcation sludge treatmentFiberSludge

The invention belongs to the field of sludge treatment and in particular relates to a sludge powder nano soft soil modifier and a preparation method thereof. The sludge powder nano soft soil modifier is prepared from the following raw materials in parts by weight: 1.8-2.0 parts of P.O 42.5R ordinary Portland cement, 2.1-2.3 parts of S95 granulated blast-furnace slag, 1.8-2.0 parts of CL90 quick lime, 0.5-0.6 part of F.II level pulverized fuel ash, 0.5-0.6 part of nano-scale silica powder, 0.5-0.6 part of a composite activator, 0.4-0.5 part of sepiolite fibers, 0.6-0.8 part of alkali-resistant glass fibers, 0.8-1.0 part of datolite fibers and 0.8-1.2 parts of paper-making white mud. The paper-making white mud, the sepiolite fibers, the alkali-resistant glass fibers, the datolite fibers, the S95 granulated blast-furnace slag, the P.O 42.5R ordinary Portland cement and the composite activator are mixed, so that flocculated solid gel and lots of fibriform hydration products are produced, the solidified body formed with sludge has stable performance, the compressive strength is high, and the shear force is high.

Owner:福建港湾岩土工程集团有限公司

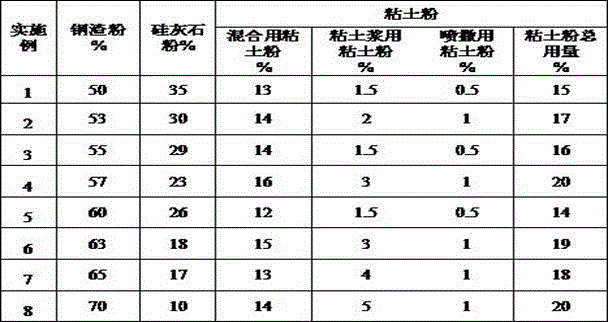

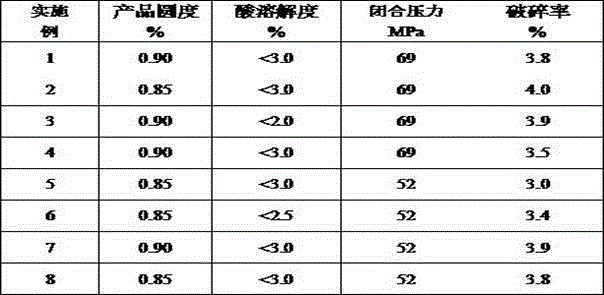

Fracturing ceramsite proppant produced by steel slag and preparation method thereof

The invention provides a fracturing ceramsite proppant produced by steel slag. The raw materials by weight percentage of the fracturing ceramsite proppant are as follows: 50-90% of steel slag with the granularity of less than 75 microns, 5-45% of wollastonite with the granularity of less than 75 microns, and 5-20% of clay with the granularity of less than 45 microns, wherein the clay with the total weight percentage of not greater than 5% is taken to mix with water to prepare clay slip, the clay with the total weight percentage of not greater than 25% is taken to spray in a ceramsite preparation process, and the rest of the clay is taken as a mixture; and an acid-resisting polymer is added. The fracturing ceramsite proppant produced by steel slag is prepared by the following steps: mixing the steel slag, the wollastonite and the rest of the clay, except the clay for preparing the clay slip and the clay for spraying to prepare the ceramsite; palletizing, drying, sintering, naturally cooling to room temperature, grinding rotationally heating, and standing for later use. According to the fracturing ceramsite proppant produced by steel slag and the preparation method thereof, the steel slag, the clay and the wollastonite are taken as the main raw materials; the produced fracturing ceramsite proppant has high mechanical strength, is smooth in surface and resists acid corrosion; the roundness of products is larger than 0.85, the acid solubility is smaller than 4%, the compressive strength is not lower than 52 MPa, and the pressing crushing efficiency is smaller than 3%.

Owner:武汉钢铁有限公司

Preparation method of electrolyte-resistant-type complex mineral gel

ActiveCN103638878APlay a supporting roleImprove stabilitySilicon compoundsColloidal chemistry detailsMagnesium aluminum hydroxideElectrolysis

The invention relates to a preparation method of electrolyte-resistant-type complex mineral gel. The method comprises the steps of firstly preparing bentonite minerals into ore pulp, separating and purifying, and preparing montmorillonite gel slurry, wherein the purity of the montmorillonite is 75%-95%, and the granularity of the montmorillonite is 0.01-2 microns. The method is characterized by also comprising the step of preparing modified columnar mineral slurry, namely, crushing columnar raw mineral materials including sepiolite, attapulgite, nemalite or wollastonite, adding water to prepare ore pulp, then adding polymer anionic compounds, sieving, grinding, peeling and centrifuging, adding dropwise magnesium hydroxide sol or magnesium aluminum hydroxide sol into the ore pulp, controlling the temperature to be at 50 DEG C-80 DEG C, and ageing for 1-3 days to obtain the modified columnar mineral slurry; and the step of preparing the complex mineral gel, namely mixing the montmorillonite gel slurry and the modified columnar mineral slurry to obtain the mixed slurry, ageing for 1-2 days, and spray-drying to obtain the electrolyte-resistant-type complex mineral gel, wherein the weight ratio of the montmorillonite to the modified columnar mineral is (3:1) to (1:1.5) on a dry basis. The electrolyte-resistant-type complex mineral gel prepared by the method has good electrolyte resistance.

Owner:苏州中材非金属矿工业设计研究院有限公司

Transparent glaze and preparation method thereof

InactiveCN106007379ASolve pinholesSolve the defect of slight pollution suctionPolyvinyl alcoholSlurry

The invention discloses transparent glaze and a preparation method thereof. The transparent glaze is prepared from the following ingredients in parts by weight: 2 to 6 parts of calcined zinc oxide, 5 to 7 parts of barium carbonate, 14 to 17 parts of soda feldspar, 6 to 8 parts of aluminium oxide, 1 to 3 parts of calcined soapstone, 17 to 19 parts of quartz, 19 to 22 parts of dolomite, 14 to 17 parts of calcined aluminum powder, 9 to 12 parts of wollastonite, 11 to 14 parts of nepheline powder, 0.1 to 0.4 part of sodium carboxymethyl cellulose, 0.3 to 0.6 part of sodium tripolyphosphate and 0.1 to 0.4 part of polyvinyl alcohol. After the ingredients are mixed according to the corresponding mixture ratio, the mixture is fed into ball mill equipment to be subjected to ball milling to obtain slurry; then, spray drying is performed to form powder materials; the powder materials are put into a cabin for obsolescence; the powder materials are pressed for forming a glaze blank; then, drying is performed; the glaze blank is calcined and is then crushed into powder materials; the powder materials are put for use. The glaze material is used for manufacturing ceramic tiles; the transparent effect of full polish product is effectively improved.

Owner:GUANGDONG JIA MEI CERAMIC

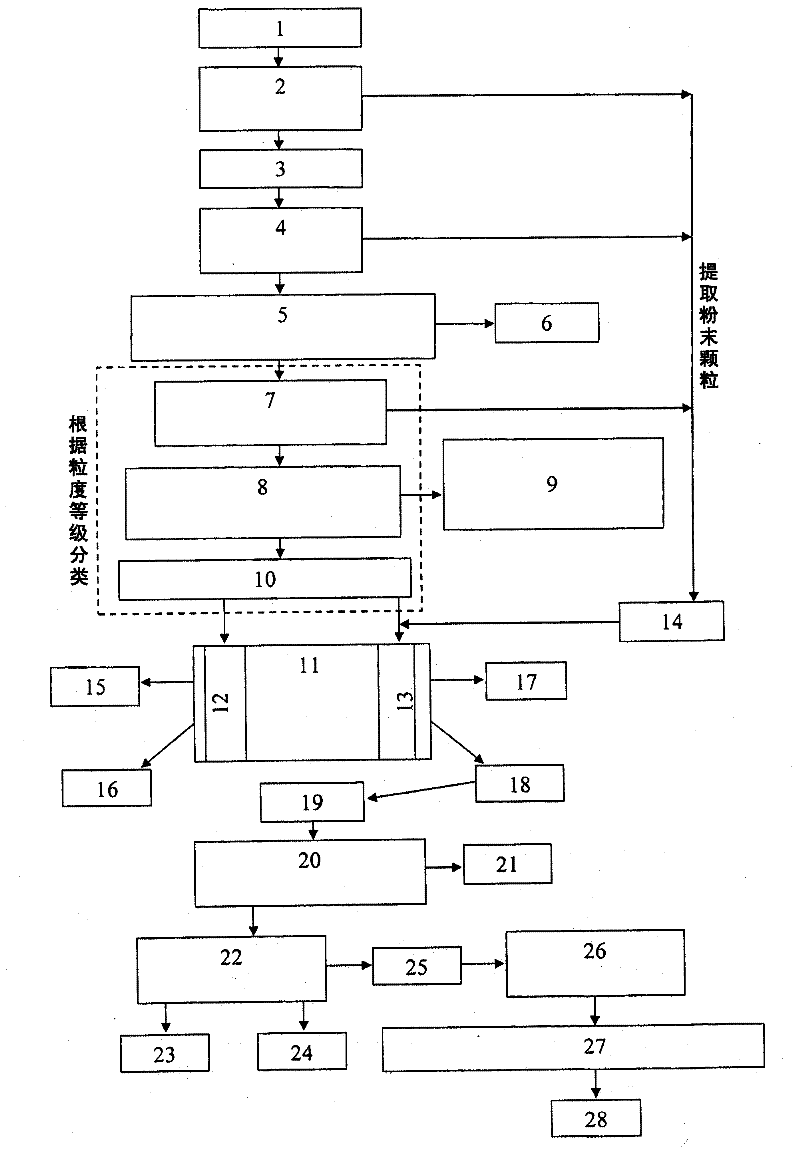

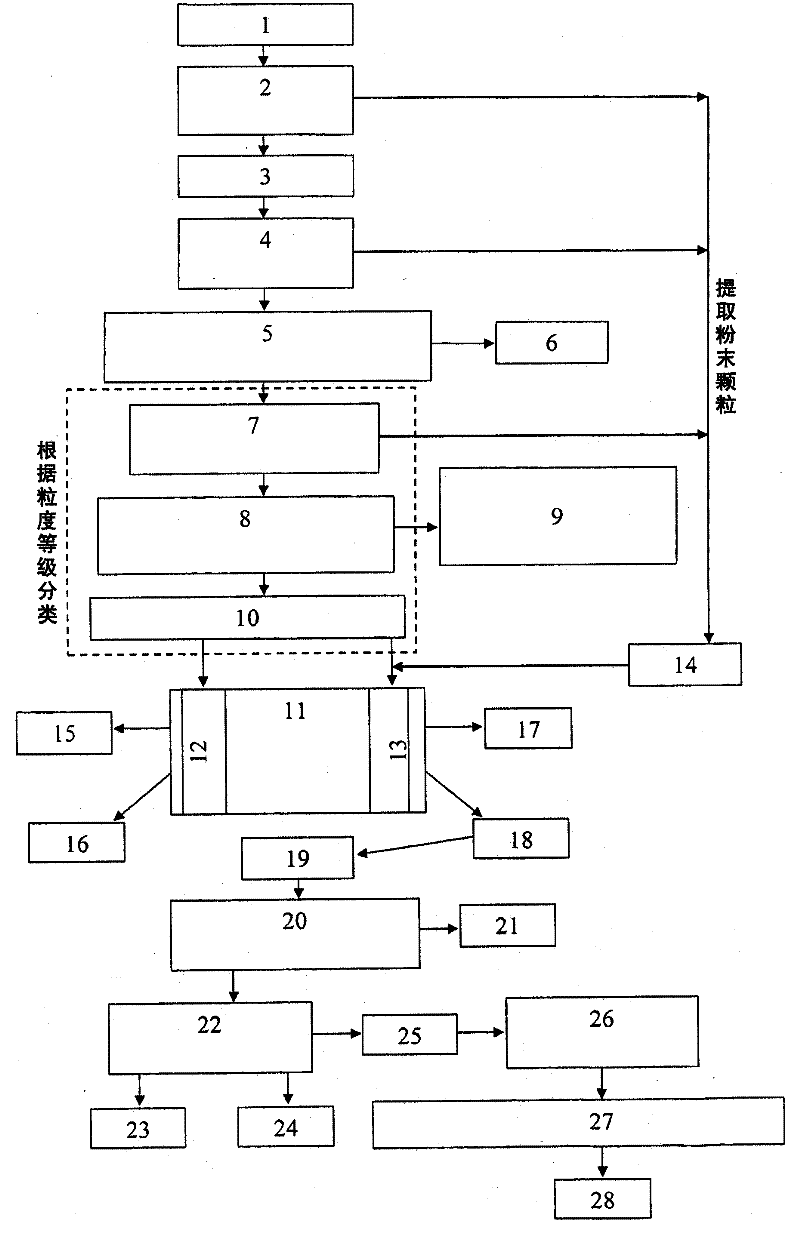

Method for the dry beneficiation of wollastonite ores

InactiveCN102239014AReduce wasteReduce lossesGas current separationMagnetic separationElectrostatic separationPrill

The invention relates to the beneficiation of mineral deposits and can be used for beneficiating wollastonite ores. The method for the dry beneficiation of a wollastonite ore involves the primary and secondary crushing of the ore, the material drying between said crushing stages, the X-ray fluorescent separation of the crushed material after the secondary crushing stage, the classification of the material according to grain-size categories immediately after the X-ray fluorescent separation by sequentially carrying out impact grinding, magnetic separation on a belt conveyor, and air sizing. Then, the method involves the magnetic separation on a roll-type separator for removing impurities from the different size wollastonite concentrate and the extraction of material flour particles at the primary and secondary crushing stages and during the impact grinding of the ore. All the extracted flour particles are delivered to one of the rolls of the roll-type separator, the wollastonite concentrate of one or more grain-sizes is dried and, then, the dried concentrate is exposed to electrostatic separation for removing impurities therefrom. Subsequently, the air sizing of the product received after electrostatic separation is carried out in order to divide said product into fractions having different grain-size. One or more product fractions are additionally crushed and electrostatic charge is removed. The proposed invention makes it possible to improve the product quality and to reduce wollastonite waste.

Owner:阿莱克希・亚利桑德罗维奇・诺萨切夫

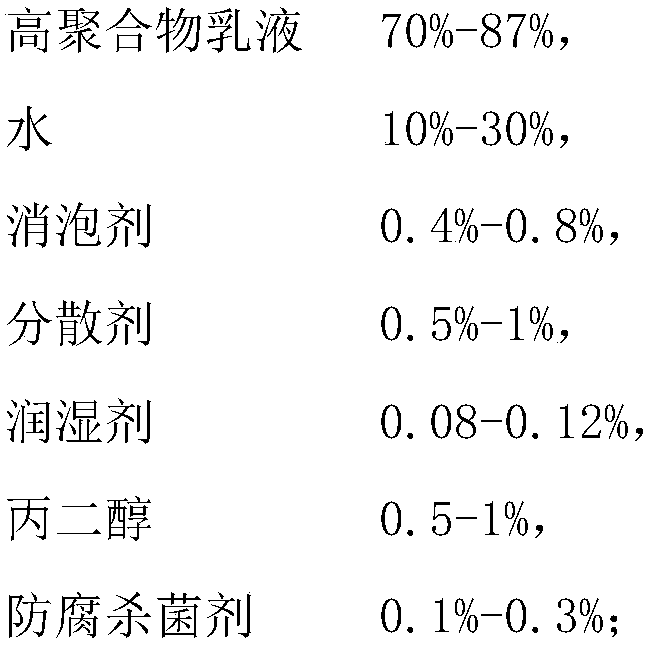

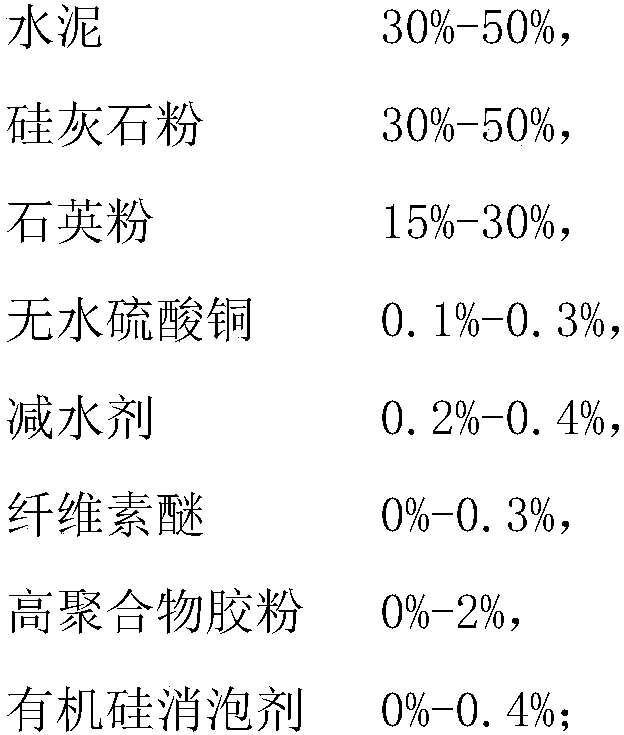

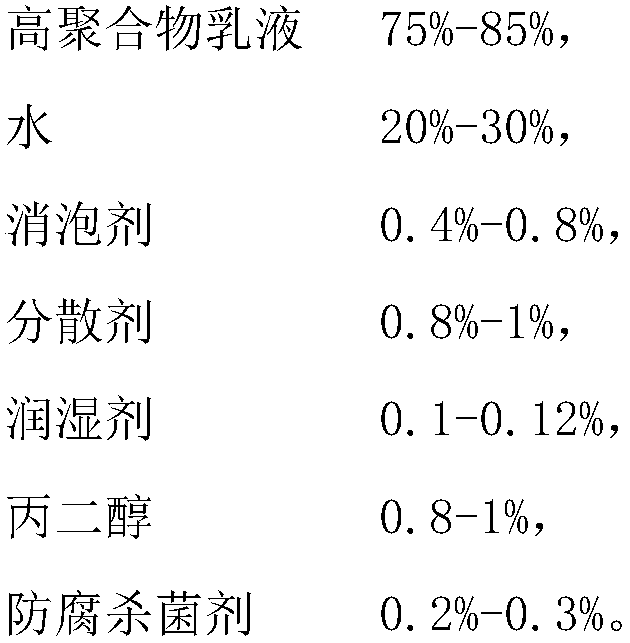

Polymer cement waterproof coating and preparation method thereof

The invention discloses polymer cement waterproof coating and a preparation method thereof and relates to the field of building materials. The waterproof coating comprises the following liquid materials: 70-87% of high polymer emulsion, 10-30% of water, 0.4-0.8% of a defoaming agent, 0.5-1% of a dispersing agent, 0.08-0.12% of a wetting agent, 0.5-1% of propylene glycol and 0.1-0.3% of an antiseptic fungicide; and the waterproof coating also comprises the following powder materials: 30-50% of cement, 30-50% of wollastonite in powder, 15-30% of quartz powder, 0.1-0.3% of anhydrous cupric sulfate, 0.2-0.4% of a water reducing agent, 0-0.3% of cellulose ether, 0-2% of high polymer latex powder and 0-0.4% of an organic silicon defoamer, wherein mesh granularities of the wollastonite in powderand quartz powder are 1200-1300 meshes respectively. The waterproof coating disclosed by the invention has basic properties and also has the advantage that a dried film changes color when encounteringwater, and a leakage location of a building can be rapidly, conveniently and accurately detected.

Owner:HUIZHOU ORIENTAL YUHONG BUILDING MATERIALS

High-strength registered embossing composite plastic sheet and preparation method thereof

The invention relates to the technical field of sheets, and particularly relates to a high-strength registered embossing composite plastic sheet and a preparation method thereof. The sheet comprises the following raw materials in parts by weight: 60-100 parts of PVC resin, 31-51 parts of a plasticizer, 1.6-2.8 parts of a heat stabilizer, 0.04-0.08 part of a slipping agent, 0.02-0.05 part of pigment powder and 0.1-0.2 part of a reinforcing agent, wherein the reinforcing agent is particles which adopt acicular wollastonite and a flat glass fiber as nuclear materials and are wrapped by a low-temperature acrylate emulsion as a shell on each surface. By adopting the raw materials and strictly controlling the weight ratios of the raw materials, the sheet disclosed by the invention is high in strength, heat-resistant, cold-resistant, acid-resistant, alkali-resistant, weight-resistant, ageing-resistant, anti-static, smooth in surface, free of a crack, free of bubbles, uniform in color and luster, high in third dimension, soft in texture, comfortable in hand feeling, healthy and environmental friendly.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

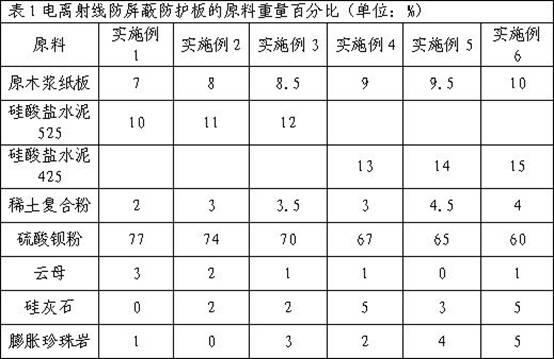

Ionizing ray shielding protective plate and manufacturing method thereof

The invention relates to a plate with an ionizing ray (X-ray or gamma-ray) radiation protecting function and provides an ionizing ray shielding protective plate. The protective plate comprises the following raw materials in percentage by weight: 7-10 percent of raw wood pulp material, 10-15 percent of cement, 2-5 percent of rare earth composite powder, 60-80 percent of barium sulfate powder and asmall amount of auxiliary materials (mica, aedelforsite and expanded perlite). A manufacturing method of the protective plate comprises the following steps of: preparing raw wood pulp; pulping by mixing; sizing; preparing a molded blank; reshaping and stacking; preparing a molded plate; initially curing; performing steam curing; drying the plate; performing post processing; and the like. The ionizing ray shielding protective plate has dual X-ray and gamma-ray protecting effects, high intensity and light weight, and can be used for replacing a lead plate. The raw materials used in the manufacturing method are sufficient, the foaming procedure in the production process is eliminated, the equipment and the process are simple, and the manufacturing cost is low.

Owner:GUANGZHOU CHUMAY BUILDING MATERIAL

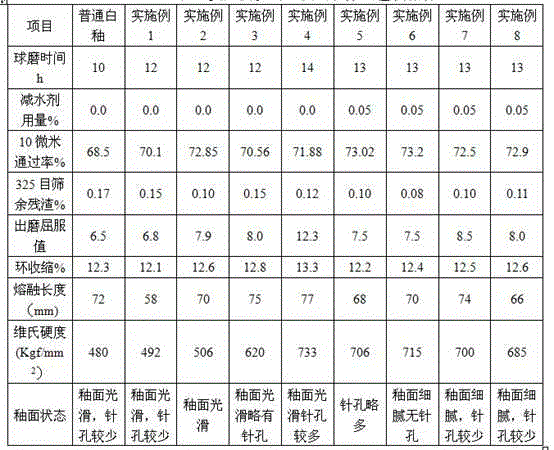

High-hardness wollastonite glaze slip and preparation method thereof

InactiveCN104692833AReduce the presence of air bubblesImprove the overall look and feelCalcitePotassium

The invention discloses a formula of wollastonite glaze slip for preparing a high-strength glaze surface of sanitary ceramics. The wollastonite glaze slip is prepared from the following raw materials in parts by mass: 28.0-33.0 parts of potash feldsphar, 24.0-27.0 parts of quartz, 7.0-8.0 parts of calcite, 12.0-15.0 parts of wollastonite, 3.0-5.0 parts of kaolin, 2.0-3.5 parts of calcinedtalc, 3.0-4.0 parts of zinc oxide, 8.0-10.5 parts of zirconium silicate, 1.0-2.0 parts of aluminum oxide and 1.0-2.0 parts of low-temperature frits. A great deal of wollastonite is introduced to the glaze slip, the calcinedtalc is pre-sintered, air bubbles in the glaze slip are reduced through reducing crystal water and carbonates in the raw materials, and aggregation is caused under the action of generating the frits through partial melting by virtue of disordered arrangement of acicular crystals of wollastonite to form an interwoven structure; and the average Vickers hardness of a glaze surface is higher than 700, so that the mechanical strength of the glaze surface is greatly improved.

Owner:ZHONGTAO SANITARY WARO MFG CO LTD OF TANGSHAN

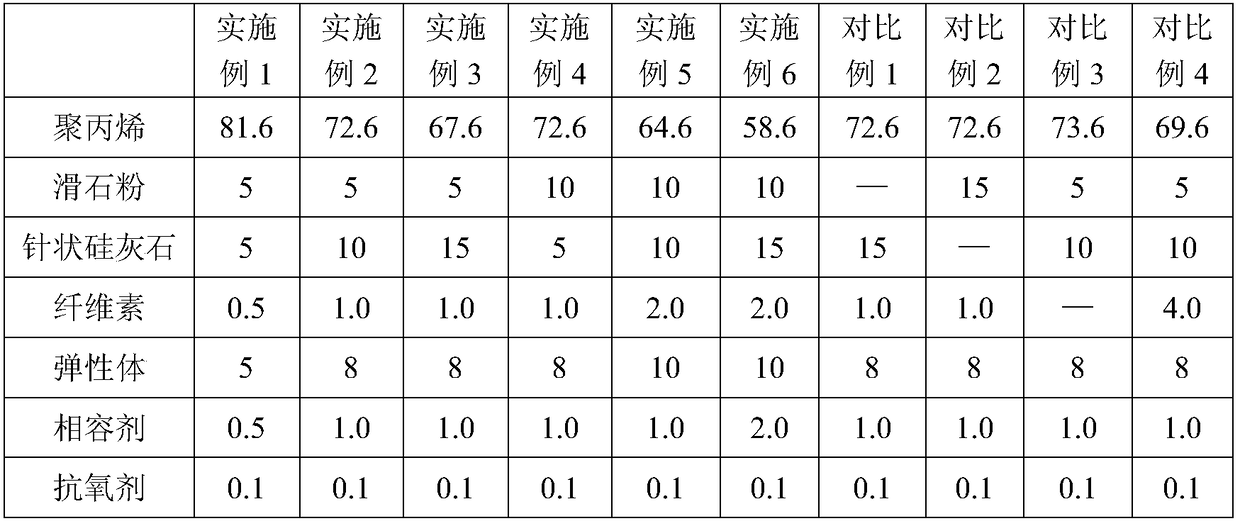

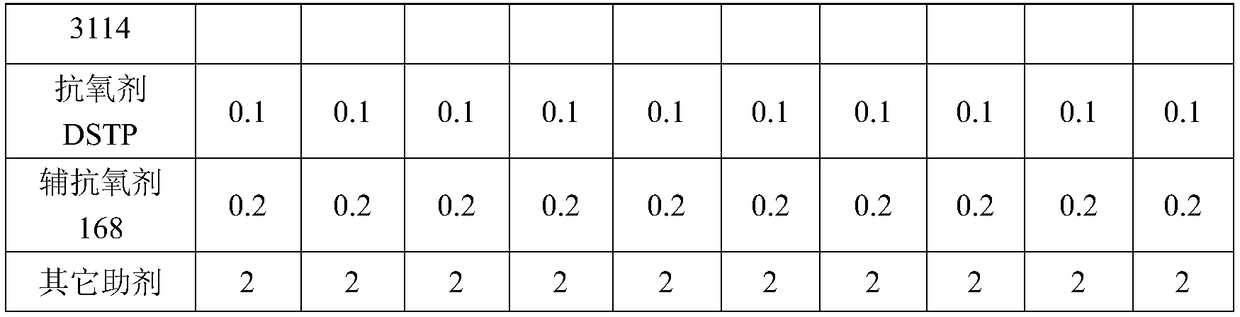

Low-linear thermal expansion coefficient, flocking effect polypropylene composite material and preparation method thereof

The invention discloses a low linear thermal expansion coefficient, a flocking effect polypropylene composite material and a preparation method thereof. The polypropylene composite material is prepared from the following raw materials in percentage by weight: 45 to 90 of polypropylene, 0 to 15 of talc powder, 5 to 15 of acicular wollastonite, 0.2 to 5 of cellulose, 1 to 15 of elastomer, 0.5 to 2 of compatilizer, 0.1 to 1 of antioxidant, 0 to 2 of other additives. According to the low linear thermal expansion coefficient, the flocking effect polypropylene composite material and the preparationmethod thereof, high aspect ratio acicular wollastonite and the cellulose are adopted to replace part or all of the talc powder for compounding and filling, and are added into an extruder through a side feeding method, so that the structures of the acicular wollastonite and the cellulose are maintained farthest, the post-shrinkage and linear thermal expansion coefficient of the composite materialare greatly reduced, a stronger plastic feel of the composite material is improved, and the material has a flocking effect, can be widely used in automotive interior trim parts such as automotive pillars, door panels, and instrument panels.

Owner:CHONGQNG PRET NEW MATERIAL +4

Incorporation of gilsonite into asphalt compositions

Owner:FINA TECH

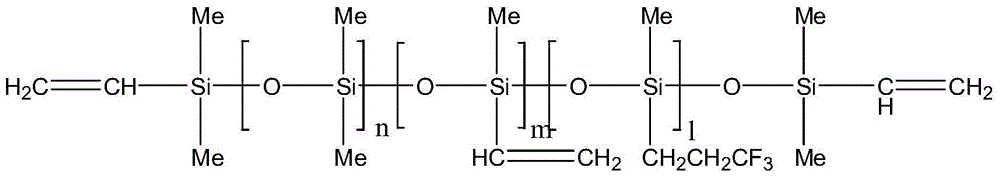

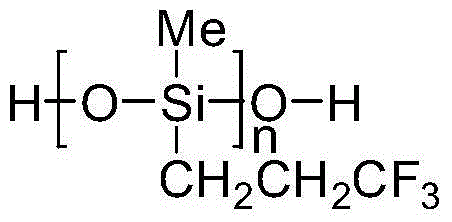

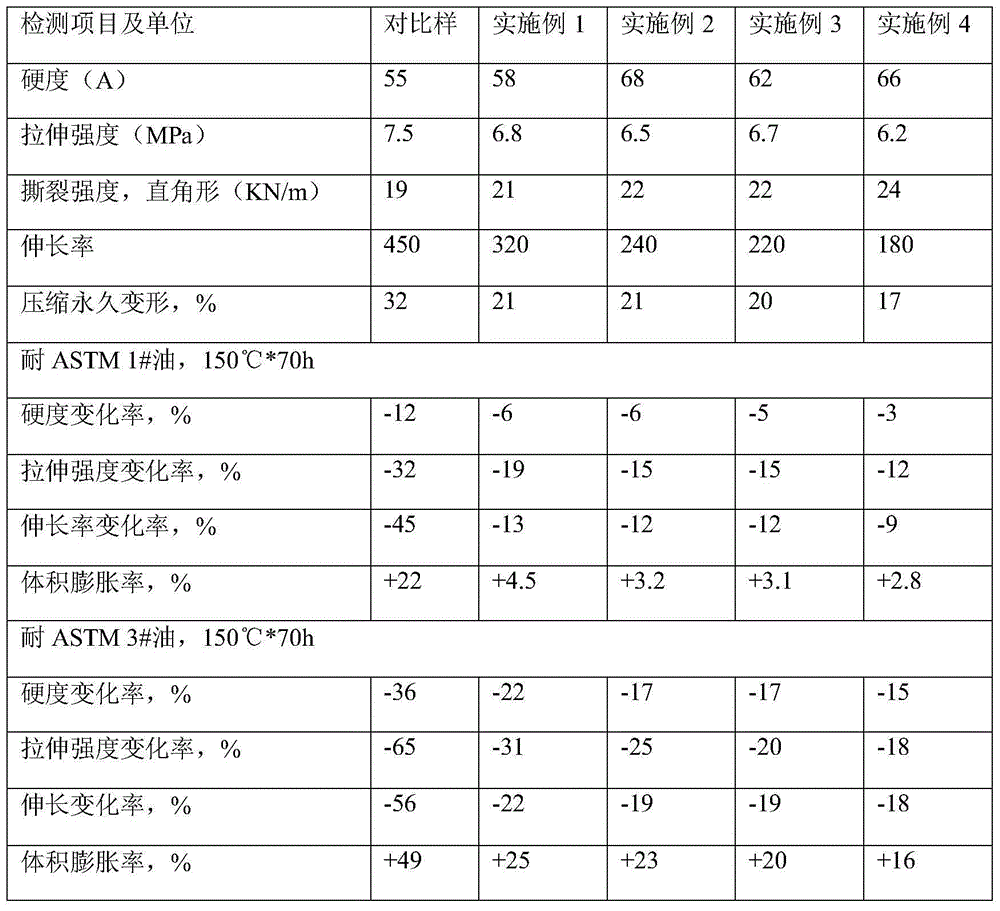

Oil-resistant silicone rubber composite and preparation method thereof

The invention discloses an oil-resistant silicone rubber composite. The components of the composite include fluorine-containing copolymer silicone rubber, hydroxy terminated fluorosilicone oil, simethicone, wollastonite and mica. Compared with the existing oil-resistant rubber, the composite has the advantages that the fluorine-containing copolymer silicone rubber and the hydroxy terminated fluorosilicone oil are adopted, the oil resistance is improved greatly, and the fine oil resistant effect is achieved; furthermore, the wollastonite and mica are adopted, the oil resistance is improved, the cost is lowered, and the market application value is provided. Compared with conventional oil-resistant rubber prepared through vinyl silicone rubber, the oil-resistant rubber prepared through fluorine-containing copolymer silicone rubber has the advantages of better oil resistance and physical properties and higher stability. The oil resistance is detected according to the GB / T1690-2006 standard, and the volume change rate is not greater than 25%.

Owner:DONGJUE SILICONE NANJING CO LTD

Method for comprehensively processing petroleum acid slag and alkaline residue

ActiveCN101323458AExtensive governanceReach the goal of treating waste with wasteSludge treatment by de-watering/drying/thickeningWorking-up pitch/asphalt/bitumen by chemical meansSlagFuel oil

The invention relates to a method for processing oil acid slag and alkali slag comprehensively; the method comprises the following steps of: adding the petroleum acid slag, the alkali slag and a demulsifying agent into a reaction kettle directly; adding an alkali solution into the reaction kettle and reacting when stirring completely till the PH value of the remaining slag is 7 to 9 after neutralization reaction; carrying out settlement and separation and refining an anti-rusting agent after the separated acid oil is processed by dry lime powder; decolorizing and filtering the separated water phase after settlement and separation by using activated clay; concentrating after the water phase enters a drying tower to be treated with spray drying so as to obtain the solid sodium sulfate of the finished product used for producing mirabilite; adding secondary-class demulsifying agent and acid solution into the remaining slag in the reaction kettle and carrying out stirring; carrying out settlement and separation further and separating out organic phase to be used as fuel oil; recycling the separated water phase after neutralization; adding the separated remaining slag into the alkali solution in hot to carry out neutralization reaction and obtaining paste sulfonated gilsonite.The method leads the acid slag and the alkali slag which are difficult to be processed to be processed comprehensively, achieves the object of using waste to treat the waste and can be widely used for the processing of the acid slag and the alkali in a refinery and a chemical plant.

Owner:常熟紫金知识产权服务有限公司

High-strength building composite ceramic material and preparation method thereof

The invention discloses a high-strength building composite ceramic material and a preparation method thereof. The high-strength building composite ceramic material is prepared from the following raw materials in parts by weight: 20-35 parts of red mud, 20-30 parts of zirconium n-butoxide, 15-30 parts of wollastonite, 10-20 parts of argil, 8-15 parts of industrial waste, 13-23 parts of reinforcing fiber, 20-35 parts of polybutadiene epoxy resin, 8-12 parts of flint clay, 9-15 parts of dibutyl phthalate, 3-7 parts of polyethyleneglycol, 10-16 parts of aluminum oxide, 5-10 parts of ceramic pigment, 10-12 parts of surfactant and 5-10 parts of non-toxicity plasticizer. By effectively proportioning the red mud, zirconium n-butoxide, wollastonite, argil, industrial waste, polybutadiene epoxy resin, flint clay and dibutyl phthalate, the reinforced ceramic has high strength and favorable compactness, has excellent comprehensive properties, has favorable oxidation resistance and corrosion resistance effects, and is favorable in use effect, environment-friendly, nontoxic and odorless. The product is low in production cost, can easily realize large-scale production and can be made into multiple shapes and textures; mineral resources are saved; and the product is low in price and simple in production process.

Owner:芜湖浩权建筑工程有限公司

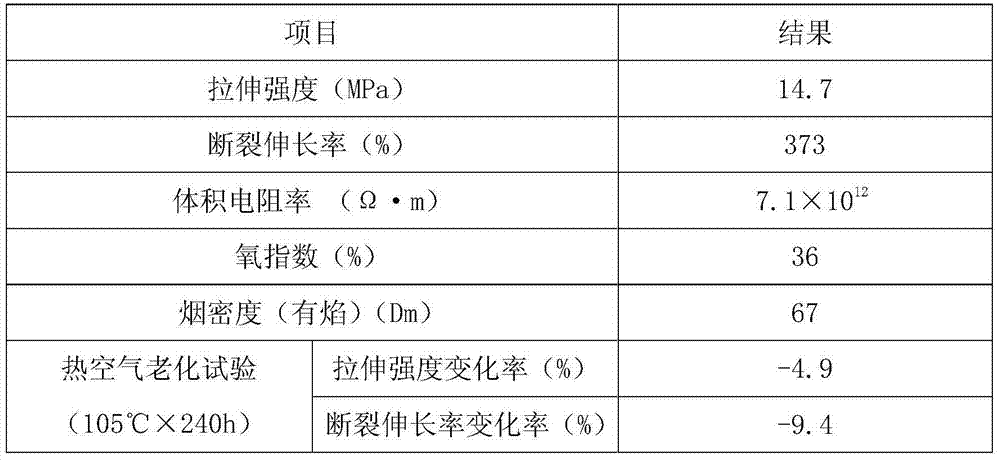

Tracking-resistant polyethylene sheath material for power wire and preparation method thereof

InactiveCN103540000AExcellent tracking resistanceGood physical and mechanical propertiesPlastic/resin/waxes insulatorsInsulated cablesGas releaseMechanical property

The invention discloses a tracking-resistant polyethylene sheath material for a power wire and a preparation method thereof. The tracking-resistant polyethylene sheath material for the power wire is prepared from the following substances in parts by weight: 50-70 parts of high-density polyethylene, 30-40 parts of linear low-density polyethylene, 15-25 parts of ethylene-propylene-diene monomer, 3-6 parts of polytrifluoropropyl methylsiloxane, 10-15 parts of nano wollastonite, 20-25 parts of sediment white carbon black, 5-10 parts of nano-montmorillonite, 4-6 parts of ferrocene, 10-15 parts of magnesium hydroxide, 8-12 parts of methyl phenyl silicone oil, 2-3 parts of dibutyltin dilaurate, 3-5 parts of phosphoguanidine and 5-10 parts of borax. The sheath material is excellent in tracking resistance, so that the electric erosion phenomenon on the surface of the power wire in extra-high voltage can be solved; meanwhile, the sheath material is good in physical and mechanical properties, electrical insulation property, environmental stress crack resistance, ageing resistance and heat resistance, durable in use, long-term in operation in outdoor severe environment without failure, good in flame retardant effect, low in smoke during combusting without harmful gas release, free of environmental pollution, safe and environment-friendly.

Owner:天长市富达电子科技股份有限公司

Confining liquid system beneficial for stability of barefoot well wall of high temperature and high pressure well

The invention discloses a confining liquid system beneficial for the stability of a barefoot well wall of a high temperature and high pressure well. The confining liquid system is prepared from the following components in parts by weight: 100 parts of fresh water, 10-20 parts of sodium bentonite, 2-4 parts of potassium chloride, 5-7 parts of caustic soda, 2-4 parts of low-viscosity polyanionic cellulose, 2-6 parts of a high temperature-resistant filtrate reducer, 10-20 parts of organic resin, 6-8 parts of a diluent, 7-9 parts of sulfonated lignite, 30-40 parts of sulfonated gilsonite, 2-4 parts of calcium oxide and 1-300 parts of barite. The confining liquid system is relatively good in rheological property, low in filter loss property and well in wall stability, and the problem that an electrical logging tool encounters resistance due to the situation that visual and thick mud cakes easily form on the well wall as the open hole section is exposed to well mud for a long time in the electrical logging operation period during the process of high temperature and high pressure well drilling can be solved; the confining liquid is applicable to the high temperature and high pressure well with the temperature of 150-220 DEG C, the long-term stability can reach 3 days, and the confining liquid has no special demand for well depth and is good in adaptability.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com