Oil-resistant silicone rubber composite and preparation method thereof

A silicone rubber composition and oil-resistant technology, applied in the field of silicone rubber, can solve the problems of high cost, poor oil resistance and poor stability of cream rubber, and achieve the effects of improving oil resistance, improving oil resistance and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

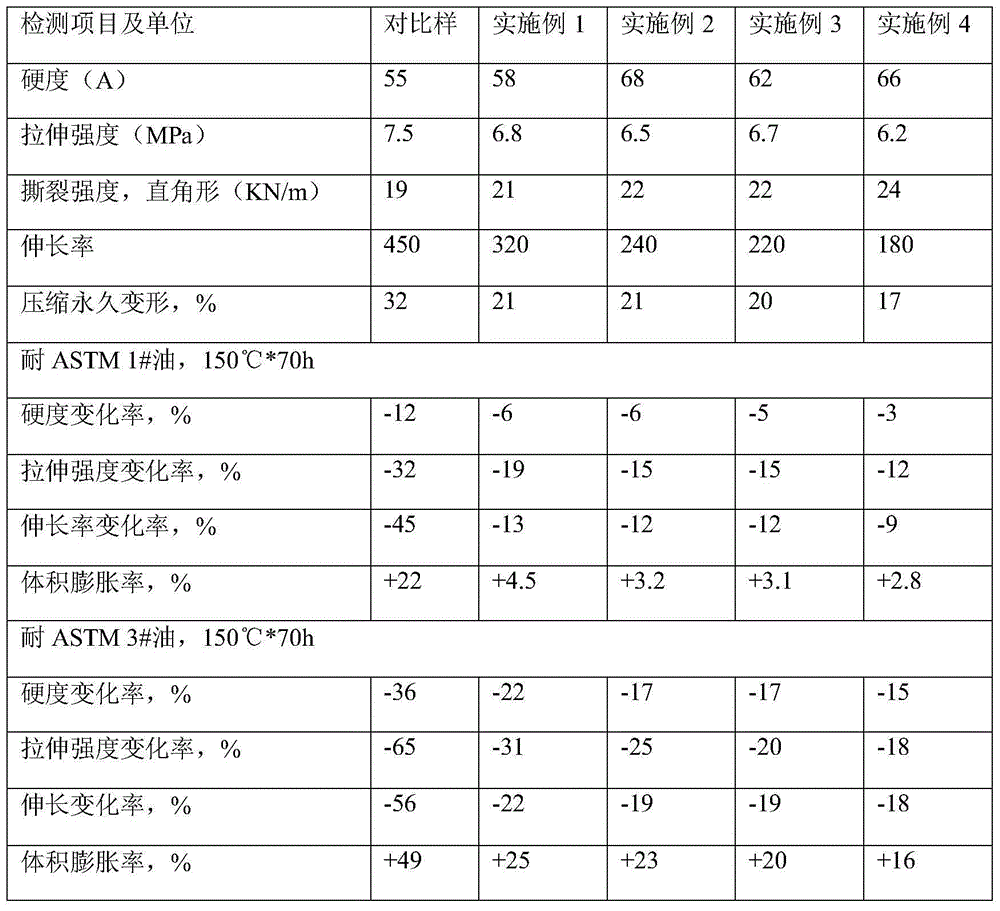

[0035] The oil-resistant silicone rubber composition, in parts by weight, consists of the following components:

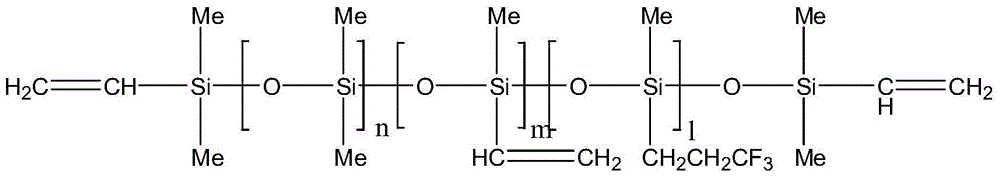

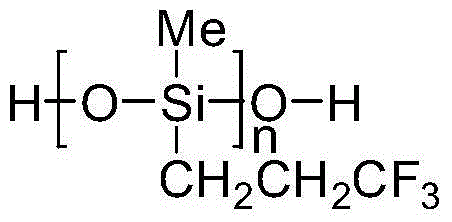

[0036] 100 parts of methyl trifluoropropyl-methyl vinyl-dimethyl copolyfluorosilicone raw rubber, wherein the molar fraction of trifluoropropyl chain link in the copolyfluorosilicone raw rubber is 10%, and the molar fraction of vinyl chain link 0.15%, the viscosity-average molecular weight of the raw rubber is 550,000; 40 parts of white carbon black; 3 parts of hydroxyfluorosilicone oil; 1.5 parts of hydrogen-containing silicone oil; 10 parts of 2500 mesh wollastonite; 2.5 parts of cerium oxide; ; 10 parts of 1250 mesh mica, 0.2 parts of internal release agent zinc stearate; 2 parts of vinyl triethoxysilane.

[0037] The preparation method of the above-mentioned oil-resistant silicone rubber composition comprises the following steps:

[0038] (1) Put methyltrifluoropropyl-methylvinyl-dimethyl copolyfluorosilicone raw rubber into the kneader, add cerium oxide at on...

Embodiment 2

[0045] The oil-resistant silicone rubber composition, in parts by weight, consists of the following components:

[0046] 100 parts of methyl trifluoropropyl-methyl vinyl-dimethyl copolyfluorosilicone raw rubber, wherein the molar fraction of trifluoropropyl chain link in the copolyfluorosilicone raw rubber is 15%, and the molar fraction of vinyl chain link 0.15%, the viscosity-average molecular weight of the raw rubber is 580,000; 35 parts of white carbon black; 5 parts of hydroxyl fluorosilicone oil; 1.4 parts of hydrogen-containing silicone oil; 5 parts of 1250 mesh mica; 0.3 parts of internal release agent zinc stearate; 2 parts of vinyl triethoxysilane.

[0047] The preparation method of the above-mentioned oil-resistant silicone rubber composition comprises the following steps:

[0048] (1) Put methyltrifluoropropyl-methylvinyl-dimethyl copolyfluorosilicone raw rubber into the kneader, add cerium oxide and zinc stearate at one time, add white carbon black in 5 batches, ...

Embodiment 3

[0052] The oil-resistant silicone rubber composition, in parts by weight, consists of the following components:

[0053] 100 parts of methyl trifluoropropyl-methyl vinyl-dimethyl copolyfluorosilicone raw rubber, wherein the molar fraction of trifluoropropyl chain link in the copolyfluorosilicone raw rubber is 20%, and the molar fraction of vinyl chain link 0.14%, the viscosity-average molecular weight of the raw rubber is 580,000; 40 parts of white carbon black; 3 parts of hydroxyl fluorosilicone oil; 1.4 parts of hydrogen-containing silicone oil; 15 parts of 1250 mesh mica; 0.5 parts of internal release agent zinc stearate; 2 parts of vinyl triethoxysilane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com