Patents

Literature

213results about How to "Good mechanical strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogel implant for sensing metabolites in body tissue

ActiveUS20100331634A1Good mechanical strengthHigh network densityMaterial analysis by observing effect on chemical indicatorCatheterMetaboliteBody fluid

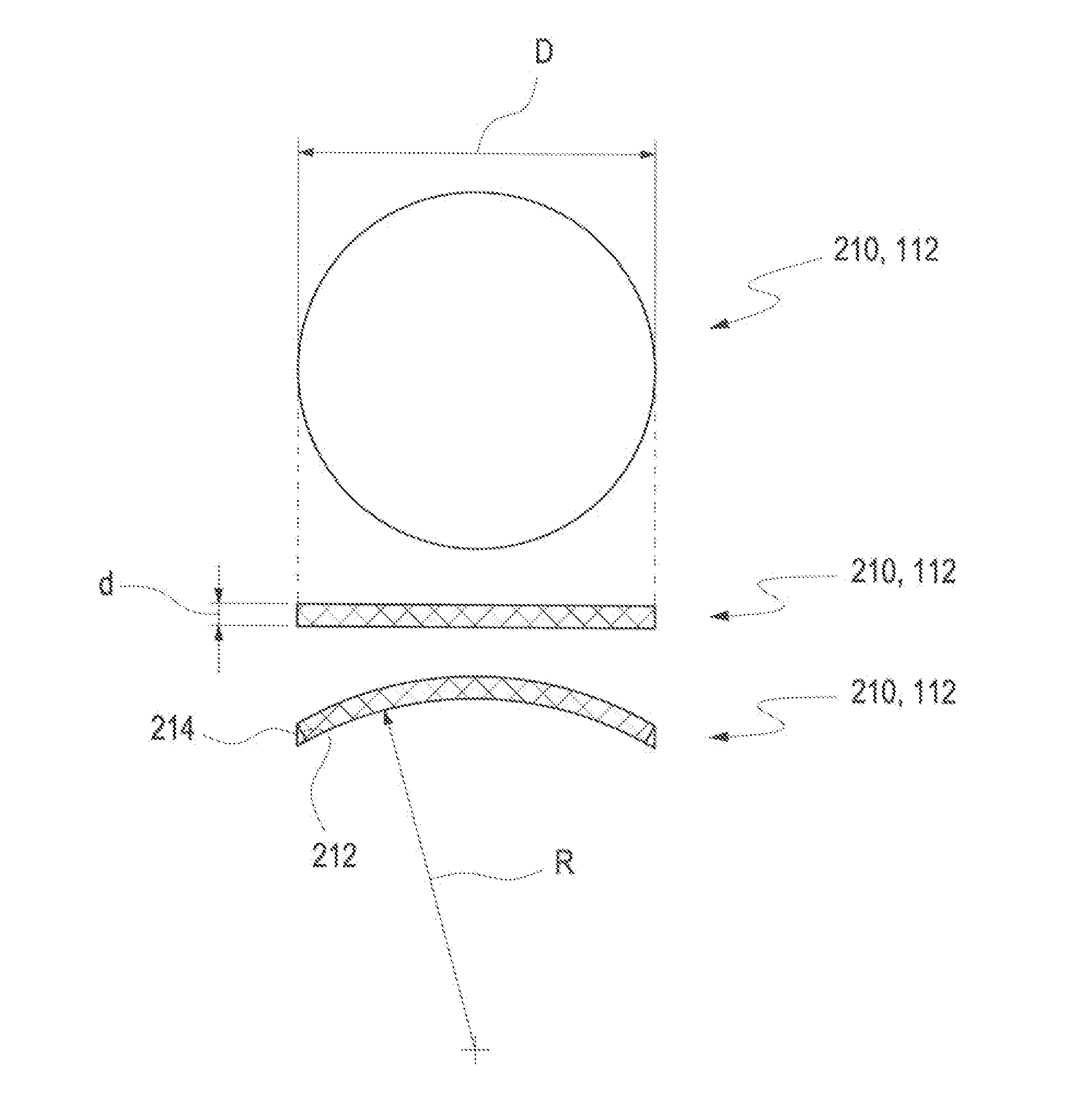

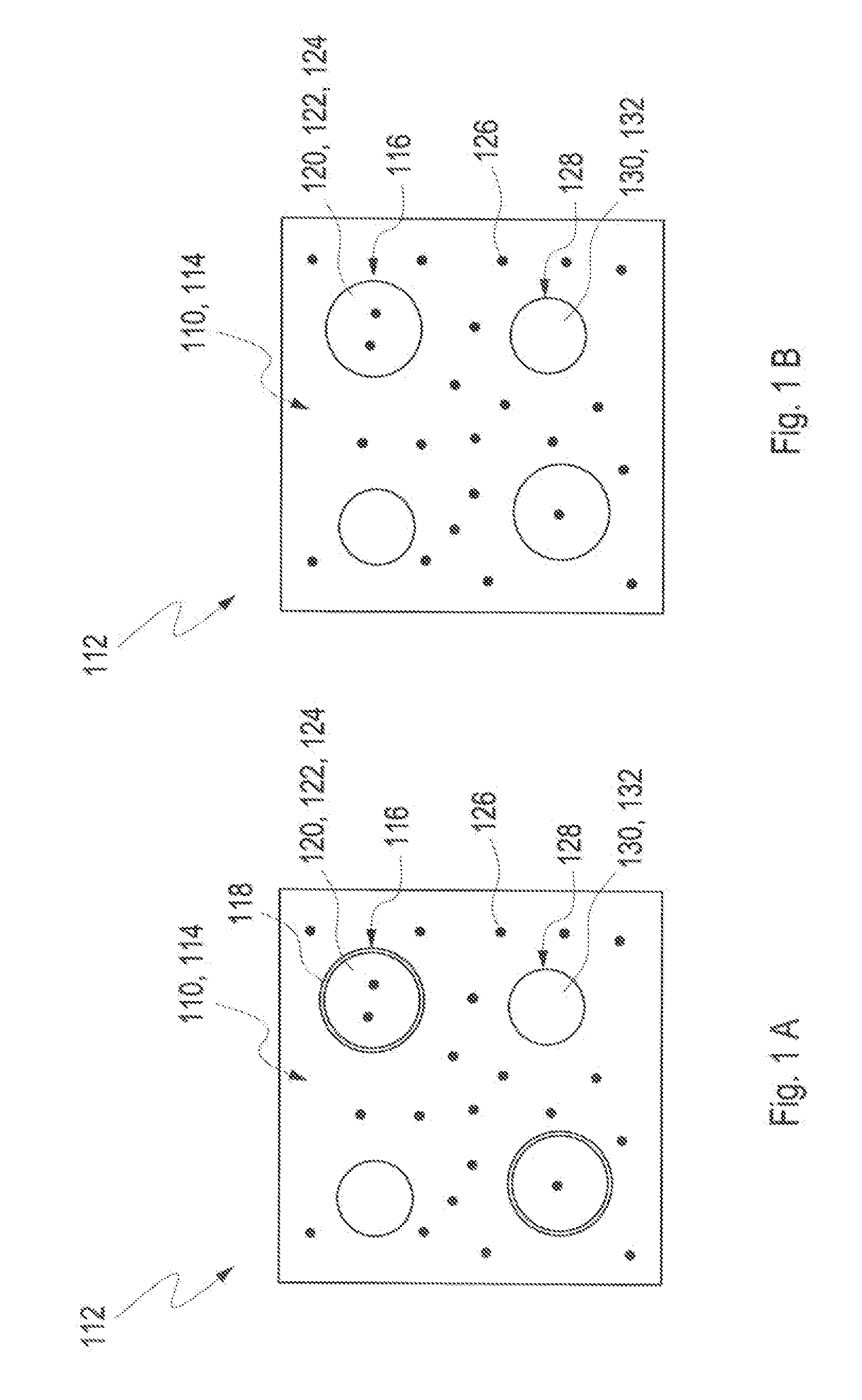

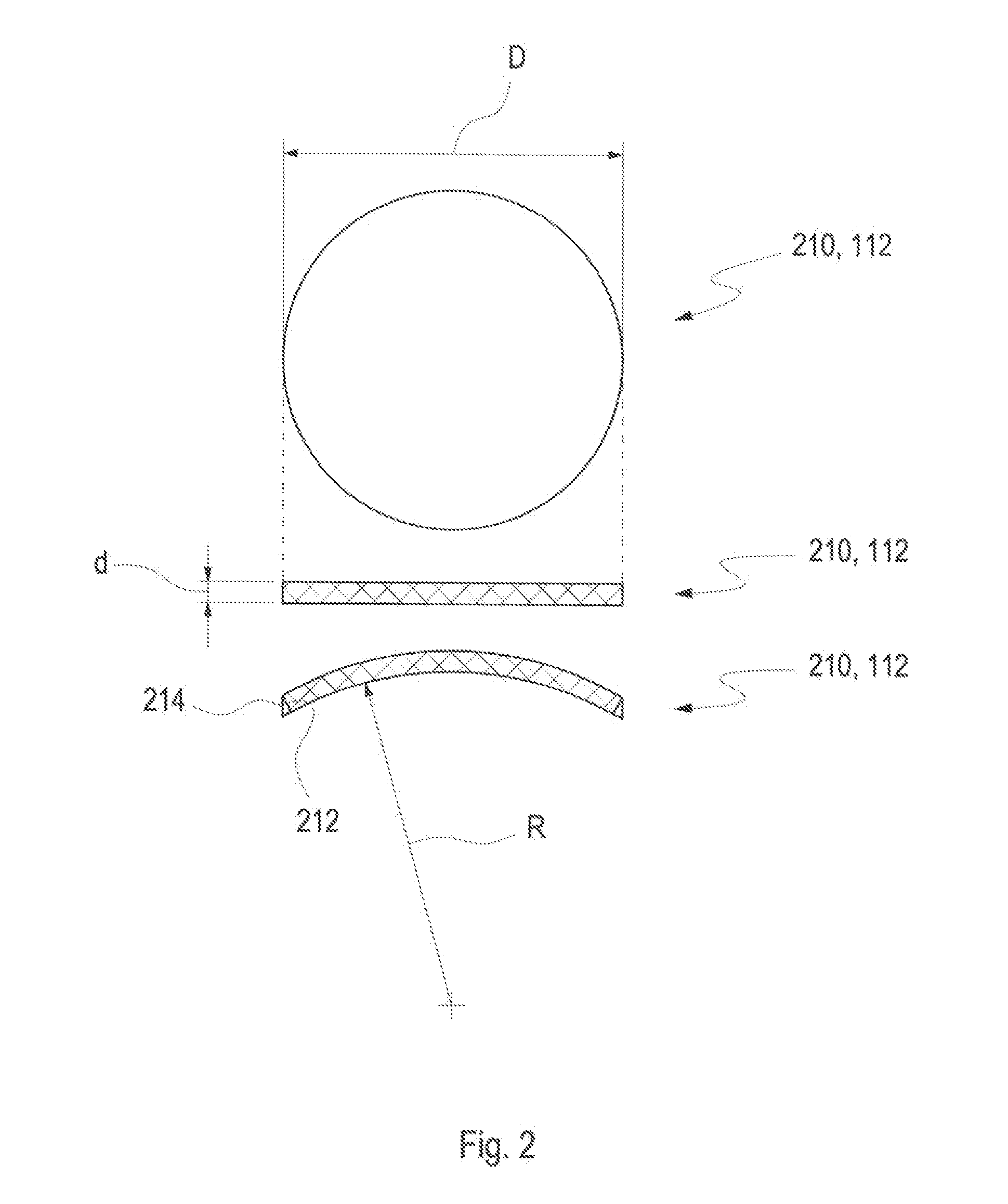

An implant (110) for detecting at least one analyte (126) in a body fluid, in particular an eye fluid, is proposed. The implant (110) is designed to be implanted in a tissue layer and / or a chamber of an eye of a patient, the implant (110) having a hydrogel matrix (110) with at least one hydrogel (114). The implant (110) also has sensor particles (116) dispersed in the hydrogel matrix (110), the sensor particles (116) having at least one sensor matrix (120) with a sensor matrix material (122) and at least one sensor material (124).

Owner:EYESENSE AG

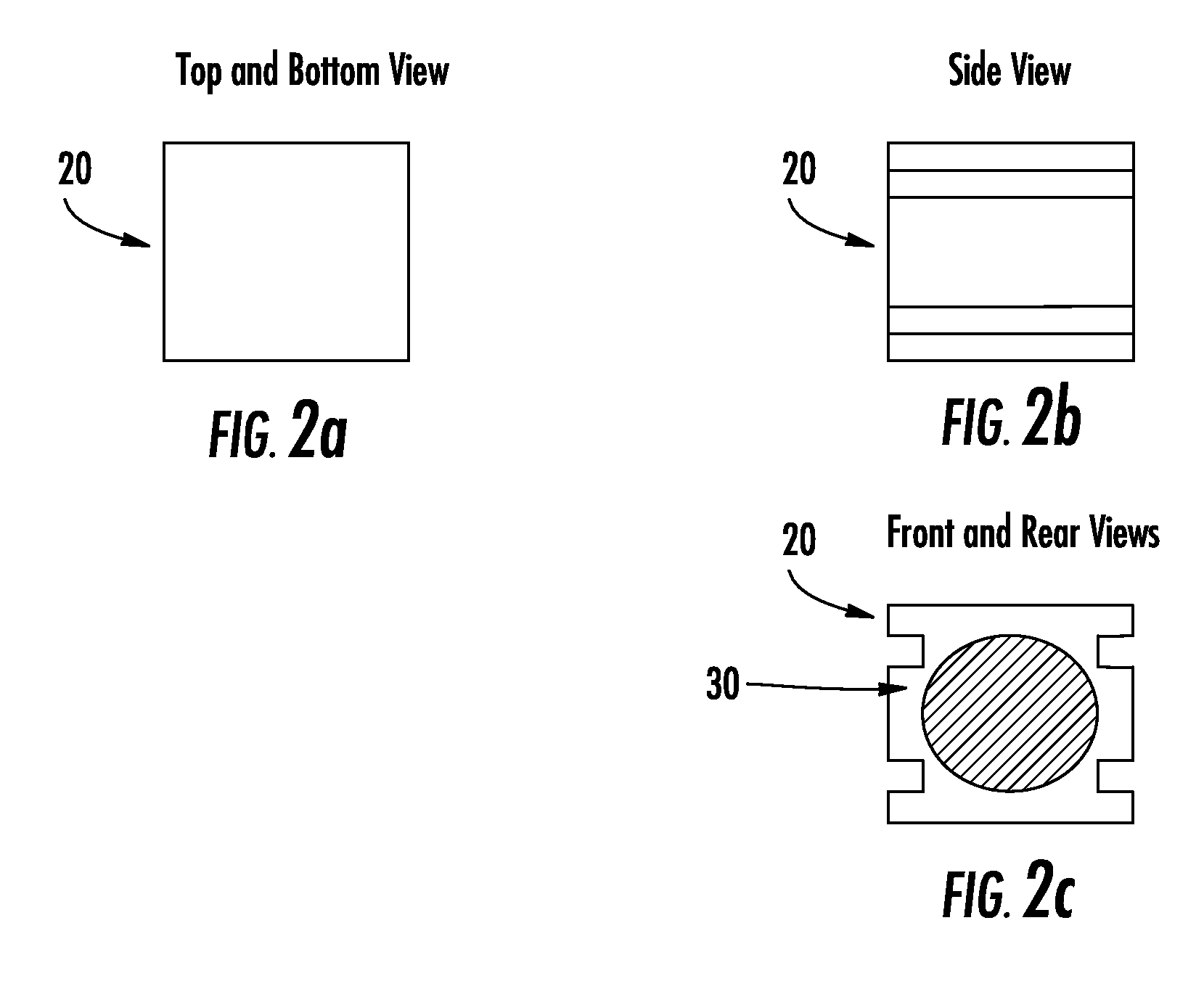

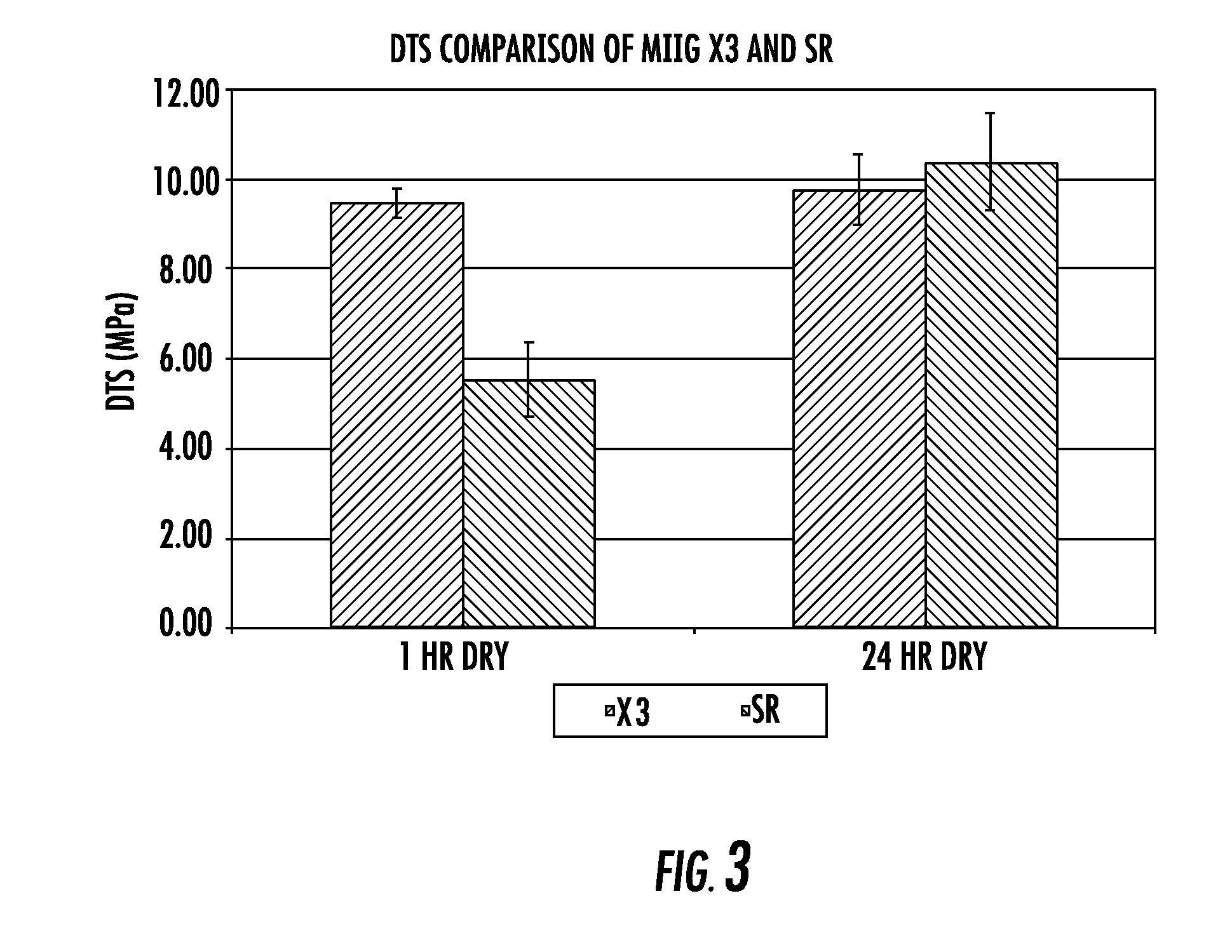

Composite bone graft substitute cement and articles produced therefrom

ActiveUS20070059281A1Good mechanical strengthFast resorption rateAntibacterial agentsPeptide/protein ingredientsChemistryCALCIUM DIHYDROGEN PHOSPHATE

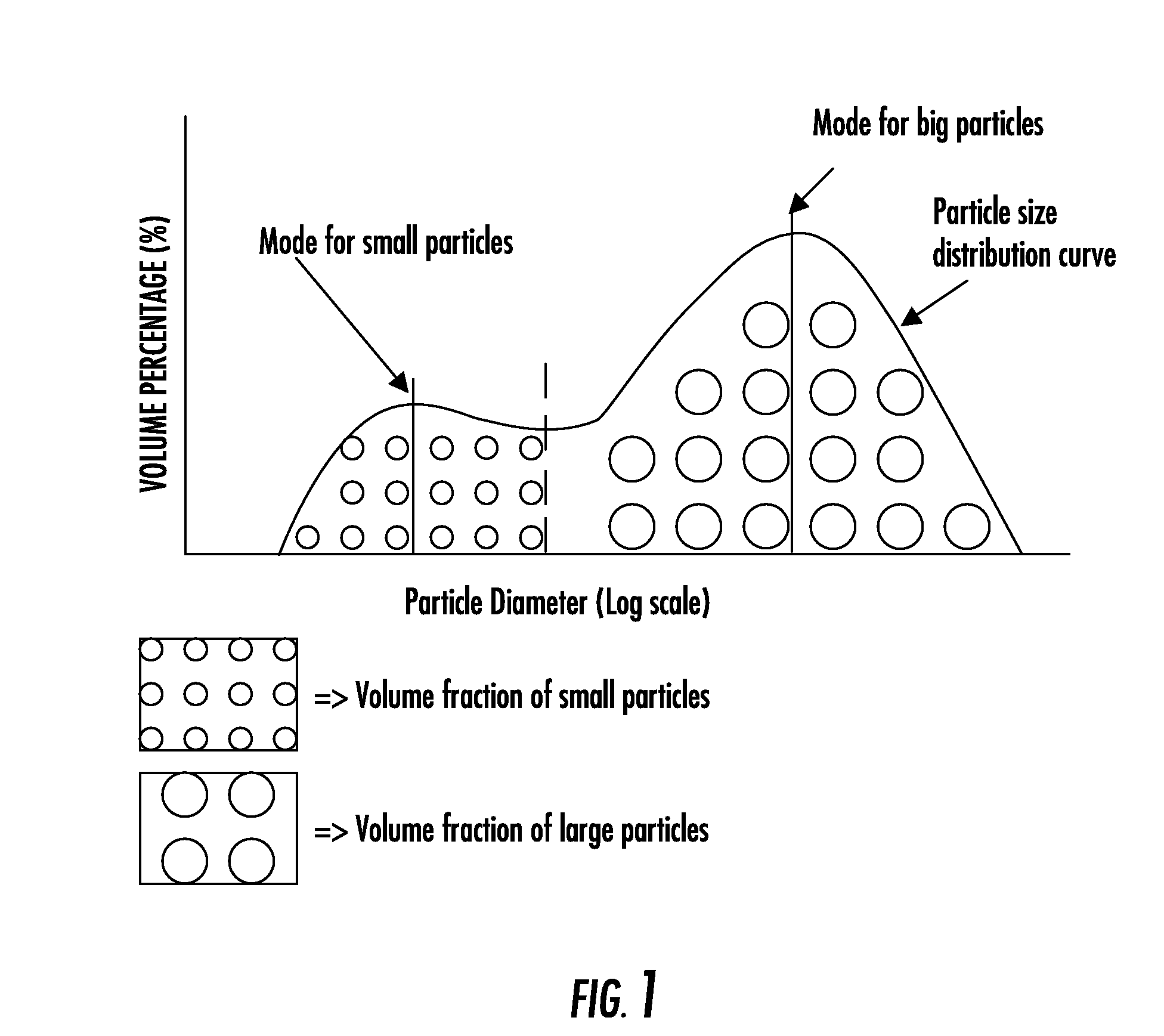

The invention provides a particulate composition adapted for forming a bone graft substitute cement upon mixing with an aqueous solution, including i) a calcium sulfate hemihydrate powder having a bimodal particle distribution and a median particle size of about 5 to about 20 microns, wherein the calcium sulfate hemihydrate is present at a concentration of at least about 70 weight percent based on the total weight of the particulate composition; ii) a monocalcium phosphate monohydrate powder; and iii) a β-tricalcium phosphate powder having a median particle size of less than about 20 microns. Bone graft substitute cements made therefrom, a bone graft substitute kit comprising the particulate composition, methods of making and using the particulate composition, and articles made from the bone graft substitute cement are also provided.

Owner:AGNOVOS HEALTHCARE

Process for preparing alumina carrier

ActiveCN101450327AGood mechanical strengthGood stabilityCatalyst carriersPelletizingMolecular dimensions

The invention belongs to the technical field of catalysis and relates to a method for preparing an alumina carrier. The carrier is prepared by mixing alumina (or pseudobochmite) with an adhesive and a pore-forming material and performing granulation, drying, tabletting and forming and roasting. The carrier prepared by the method has high mechanical strength, has the radial crushing resistant force reaching more than 300 N / cm, can be used as a carrier of a hydrogenation catalyst, and is particularly suitable to be used as a carrier of a hydrogenation catalyst containing compounds with larger molecular dimension such as benzene or compounds containing benzene rings.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD

TPU clad net

InactiveCN101225610AExcellent physical mechanism performanceGood mechanical strengthLaminationLamination apparatusCold tolerancePolyester

The invention provides a TPU mesh fabric, which is made by coating a special PU adhesive to a high-strength polyester fiber and then combining with a TPU film. The PU coating steps are: PU-coat arrow dry arrow cool the high-strength polyester fiber; the coating quantity is 180-200g / m2; the coating speed is 20-25m / min; the drying temperature is 110-130 DEG C; the two layers of TPU film (underlayer, face layer) are preheated and fused through the adjustment and change of the heating drum temperature, and then are rolled, cooled and formed with the high-strength polyester mesh fabric after middle-layer preheating through rubber roller and iron roll. The TPU mesh fabric has the advantages of environmental protection, innocuity, high strength, abrasion resistance, high cold tolerance, good color stability, good heat resistance and best PVC-replacing material.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

Preparation method of titanium-steel single-sided composite board

ActiveCN102773254AReasonable process designLow requirements for welding conditionsMetal rolling arrangementsLayer removalTechnical design

The invention discloses a preparation method of a titanium-steel single-sided composite board, comprising the following processing steps of: (1) respectively selecting two titanium plates with same size and two steel plates with same size and carrying out rust and oxide layer removal treatment on the surfaces of the plates; (2) assembling to form multiple layers of symmetrical combined blank sequentially including a steel plate, a transition layer, a titanium plate, a parting agent, a titanium plate, a transition layer and a steel plate, wherein a gap exists between the periphery of the titanium plate and a barrier strip in the combined blank; (3) compressing the combined blank and respectively welding the barrier strip with a first steel plate and a second steel plate to form a closed cavity among the first steel plate, the second steel plate and the barrier strip, drilling holes in the barrier strip and welding a steel tube in the holes, and communicating the steel tube and the closed cavity; (4) conveying the combined blank into a heating furnace to heat and vacuumizing; (5) sealing the outer end of the steel tube and then conveying the combined blank into a rolling mill; and (6) cutting the combined blank after rolling to obtain the titanium-steel single-sided composite board. The preparation method disclosed by the invention is rational in technical design and low in production cost.

Owner:河南盛荣金属复合新材料有限公司

Resin base adsorbent with high selectivity to heavy metal and preparing process thereof

ActiveCN1935356ALarge adsorption capacityGood mechanical strengthOther chemical processesWater/sewage treatment by sorptionIonChemistry

The present invention discloses a resin base adsorbing agent with high selectivity for heavy metal and its preparation method, belonging to the field of macroporous resin. The main structure composition of this adsorbing agent includes: (1), basic skeleton, it is a macroporous polystyrene skeleton; (2), functional group bond-linked on the skeleton is acid group or low-polar group; and (3), effective component of functional material fixedly-loaded on the inner surface of skeleton is Zr(HPO4)2. Said invention also provides its preparation method and concrete steps.

Owner:NANJING UNIV

High-strength corundum ceramics and preparation method thereof

The invention discloses a high-strength corundum ceramics and a preparation method thereof. A ceramic blank comprises the following components: 18-22 parts of aluminum oxide, 12-15 parts of quartz, 0.5-1.0 part of talc, 27-30 parts of feldspar, 25-29 parts of kaolin, 10-14 parts of chinastone and 0.5-1.5 parts of blank body plasticizing agent. In sintered porcelain, the aluminum oxide content is higher than 30 percent. The method comprises the following steps: ball-milling and pulverizing a blank; adding water and mixing to obtain blank slurry; deironing and press-filtering the blank slurry into a mud cake and roughly smelting the mud cake; mildewing the roughly smelted mud cake and refining the mildewed mud cake; rolling and moulding the refined mud in a die to obtain a blank body; drying, washing and glazing the blank body and sintering at 1,280-1,320 DEG C for 15-18 hours to obtain a finished product. The product has favorable mechanical strength, and the impact resistant capability of the product is more than four times that of common ceramics; and the product has favorable thermostability, no crack after thermal shock at 200 DEG C / 20 DEG C three times, the water absorption rate of lower than 0.1 percent, is more dense, firm and durable and is particularly suitable for an oven, a microwave oven and a dish-washing machine.

Owner:江门市凌志餐厨用品有限公司

Glass fiber air filter paper with high dust holding capacity and production process thereof

ActiveCN103541279AGood mechanical strengthStable chemical propertiesWater-repelling agents additionSynthetic cellulose/non-cellulose material pulp/paperCorrosionAdhesive

The invention discloses glass fiber air filter paper with high dust holding capacity, which is prepared from alkali-free glass fiber chopped strands and alkali-free glass fiber cotton in the diameter of 0.3-0.4 mu m, as well as an adhesive, wherein the glass fiber air filter paper comprises 3-8 parts by weight of the alkali-free glass fiber chopped strands and 92-97 parts by weight of the alkali-free glass fiber cotton, and the adhesive is a water repellent containing fluorocarbon. The invention further discloses a production process of the glass fiber air filter paper with the high dust holding capacity, and the production process comprises the following steps: firstly beating and dispersing raw material to obtain pulp, then performing wet process forming on the pulp to obtain wet paper, removing water in the wet paper, then performing two-sided sizing on the dehydrated wet paper, and finally drying to obtain a product, wherein the beating degree during beating is 52-56 degrees SR, suction dehydration is performed in three stages, and drying treatment is performed in four stages. The glass fiber air filter paper disclosed by the invention has the advantages of smooth and uniform surface, large specific surface area and dust holding capacity, high mechanical strength and resistance to acid and alkali corrosion.

Owner:CHONGQING ZAISHENG TECH CORP

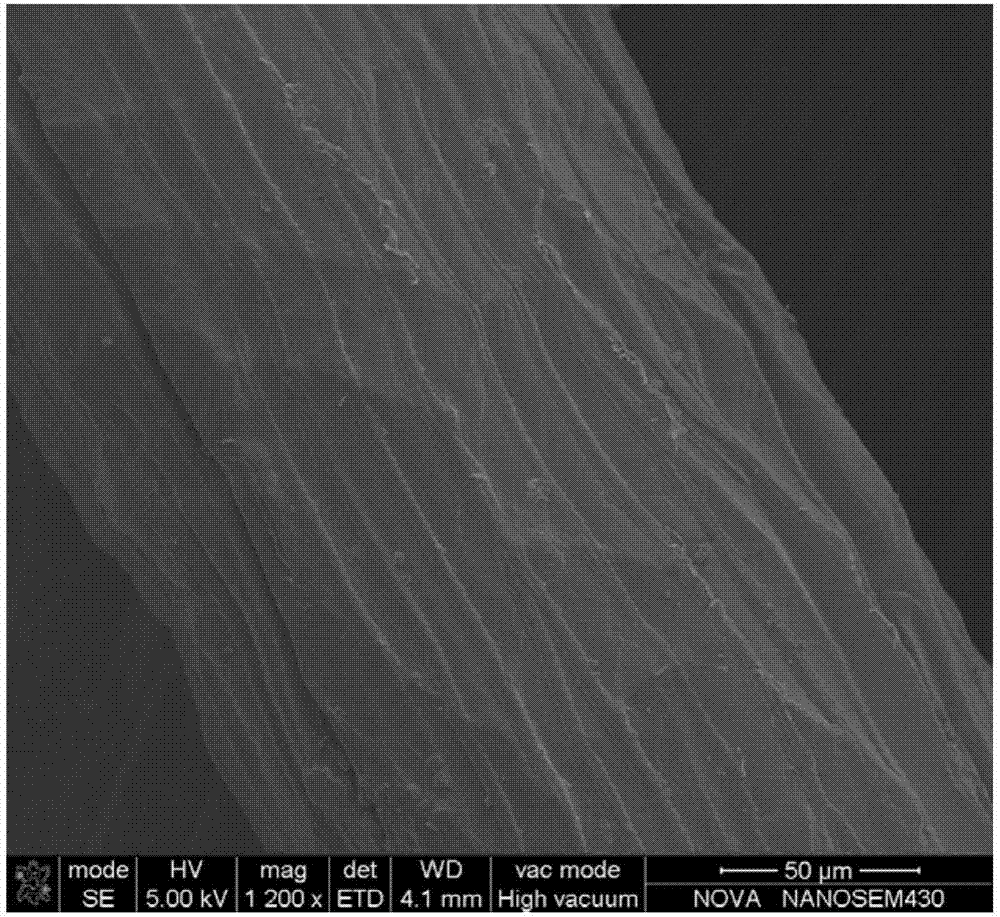

Method for preparing cellulose nanocrystals by combining biological enzymolysis and mechanical shearing

ActiveCN103103847AImprove operational safety and reliabilityGood mechanical strengthPaper material treatmentChemistryStrong acids

The invention relates to a method for preparing cellulose nanocrystals by combining biological enzymolysis and mechanical shearing. The method comprises the following steps of: preliminarily hydrolyzing or dismantling fiber or damaging 1,4-beta-D glucoside bonds in a cellulose amorphous region by using endoglucanase firstly, and then carrying out high-speed high-pressure mechanical shearing to obtain the cellulose nanocrystals. According to method disclosed by the invention, the operation safety and reliability are improved without the traditional strong acid hydrolysis; and meanwhile, the diameter and the length-diameter ratio of the cellulose nanocrystals can be adjusted by adjusting the enzymolysis and mechanical shearing degrees. The cellulose nanocrystals obtained by using the method are good in mechanical strength, good in crystallinity, moderate in length-diameter ratio and strong in light transmissivity, and; no acid radical ion is adsorbed onto the surfaces of the cellulose nanocrystals; and the cellulose nanocrystals are expected to be applied to the field of materials, such as polymerization enhancement, filtration, environmental friendliness and biomedical application instead of the traditional cellulose nanocrystals.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Polyacrylonitrile temperature-regulating fiber, and its manufacturing method

InactiveCN1851072AGood heat absorptionGood mechanical strengthMonocomponent synthetic polymer artificial filamentArtifical filament manufactureIonMelt spinning

The invention relates to the polyacrylonitrile and the producing process. The weight percent of the adjusting temperature is showed below: the acrylonitrile 30.0-92.5%; the second monomer 2.5-20.0%; the chain transferring reagent 0.03-0.3%; the solicitation reagent 0.05-0.4%; phase changing material tiny capsule 5.0-50.0%. the producing process adopts the said adjusting fiber material, the solicitation reagent is used to bring the second monomer and the existing possibly third monomer and the water phase deposit of the chain transferring reagent to converge in the phase changing material tiny capsule hanging chaotic liquid, the polymer produced form the action contains the said percentage of the phase changing material tiny capsule, the mixing hybrid of the acrylonitrile sharing material and the phase changing material tiny capsule is gained; the gained equal hybrid is cleaned by the secondary or thrice ion water and dried under the temperature of 45-95 degree, the filature is melted under the temperature of 10-40 degree above the melting point of the acrylonitrile gathering material in the screw extruding engine to produce the said adjusting temperature fiber. The said adjusting temperature fiber has many merits such as the good function of absorbing or releasing the heat energy, the high machine intension and the low cost.

Owner:TIANJIN POLYTECHNIC UNIV

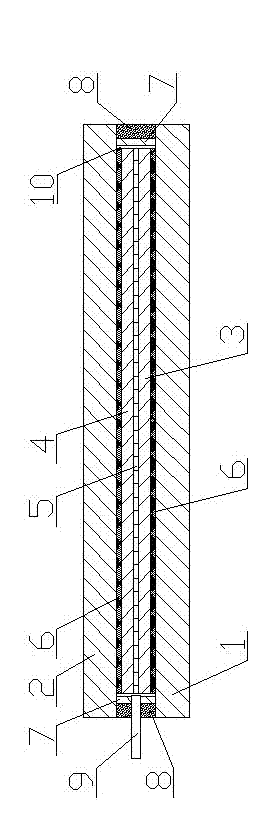

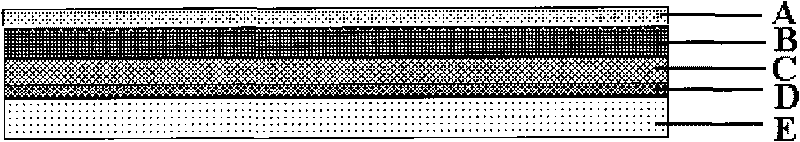

Back film for solar module

ActiveCN101764163AHigh gas barrierGood mechanical strengthSynthetic resin layered productsPhotovoltaic energy generationChemistryWater vapor

The invention discloses a back film for a solar module; the back film comprises an outer surface fluoride containing layer, a middle layer and an inner surface ethylene- vinyl acetate copolymer layer; the middle layer comprises a polyester layer, an ethylene-vinyl alcohol copolymer layer and a bonding layer; the middle layer is prepared by co-extruding the polyester material layer, the ethylene-vinyl alcohol copolymer layer and the bonding layer; the outer surface fluoride containing layer is a fluoride containing film compounded on the polyester layer of the middle layer or the fluoride containing coating coated on the polyester layer of the middle layer; and the inner surface ethylene- vinyl acetate copolymer layer is applied on the bonding layer of the middle layer by curtain coating. The back film of the solar module provided by the invention has the advantages of low water vapor transmission rate and high insulation performance, not only has excellent barrier and insulation performance, but also has the packaging performance.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

High-performance epoxy resin composition for sheet molding compound (SMC)

ActiveCN102337007AGood mechanical strengthImprove mechanical properties and water resistanceFlat articlesTemperature resistanceChemistry

The invention relates to a high-performance epoxy-based resin composition suitable for sheet molding compound (SMC) molding. The epoxy-based resin composition is prepared from the following components in parts by mass: 100 parts of mixed epoxy resin, 20-60 parts of curing agent, 10-40 parts of thickening agent, 0.5-5.0 parts of internal demolding agent and 50-120 parts of filler. The epoxy-based resin is separately selected from glycidyl ether epoxy resin and glycidyl amine epoxy resin or glycidyl ester epoxy resin, the epoxy resin composition has good wettability and bonding strength to fibers, the cured product has excellent heat resistance and mechanical strength, and the epoxy sheet molding compound prepared from the epoxy resin composition provided by the invention is suitable for the occasions with strict requirements on temperature resistance, corrosion resistance and insulation property.

Owner:北京蓝星清洗有限公司

Manufacturing method of titanium-steel-titanium two-sided composite plate

ActiveCN102773670AReasonable process designLow requirements for welding conditionsSheet steelTitanium

The invention discloses a manufacturing method of a titanium-steel-titanium two-sided composite plate. The manufacturing method comprises the following processing steps: (1) four titanium plates with the same dimension and three steel plates with the same dimension are selected respectively, and rust and oxide layer removal processing is performed on the surfaces of the titanium plates and the steel plates; (2) a multilayer combination blank with three layers of steel plates, four layers of titanium plates and four layers of transition layers is formed through assembly, and gaps are arranged between the peripheries of the titanium plates and barrier strips in the combination blank; (3) the combination blank is pressed tightly and enables the barrier strips to be welded to a first steel plate and a third steel plate so as to enable the first steel plate, the second steel plate and the inner portions of the barrier strips to form a closed cavity, holes are drilled on the barrier strips, steel tubes are welded in the holes, and the steel tubes are communicated with the closed cavity; (4) the combination blank is sent to a heating furnace to be heated and vacuumized; (5) the combination blank is sent to a rolling mill to be rolled after the outer ends of the steel tubes are sealed; and (6) one titanium-steel-titanium two-sided composite plate and two titanium-steel single-sided composite plates are obtained by slitting the combination blank after the combination blank is rolled. The manufacturing method of the titanium-steel-titanium two-sided composite plate is reasonable in design and low in production cost.

Owner:河南盛荣金属复合新材料有限公司

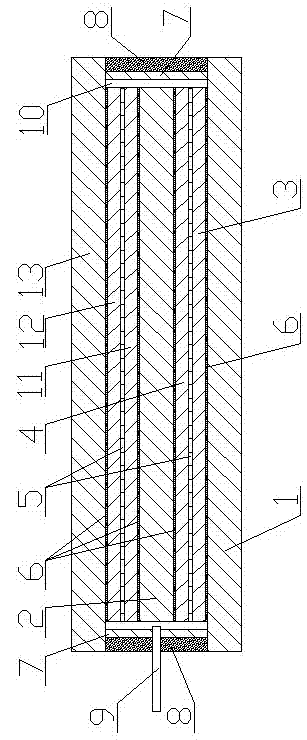

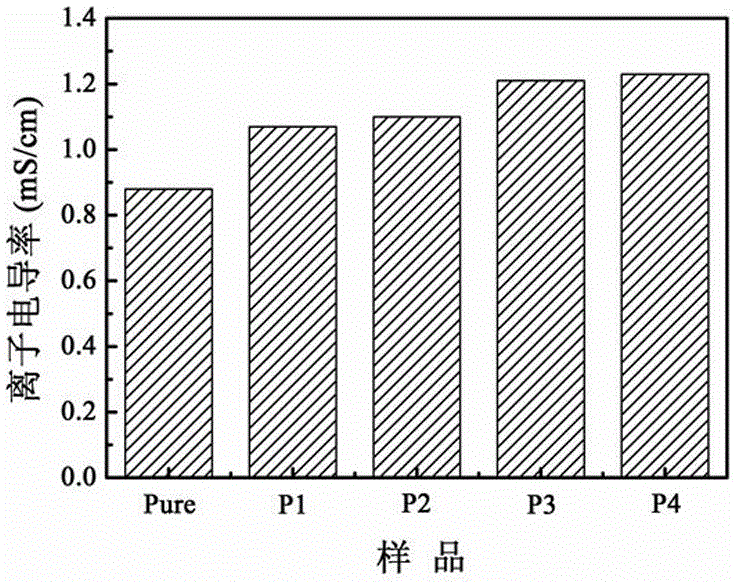

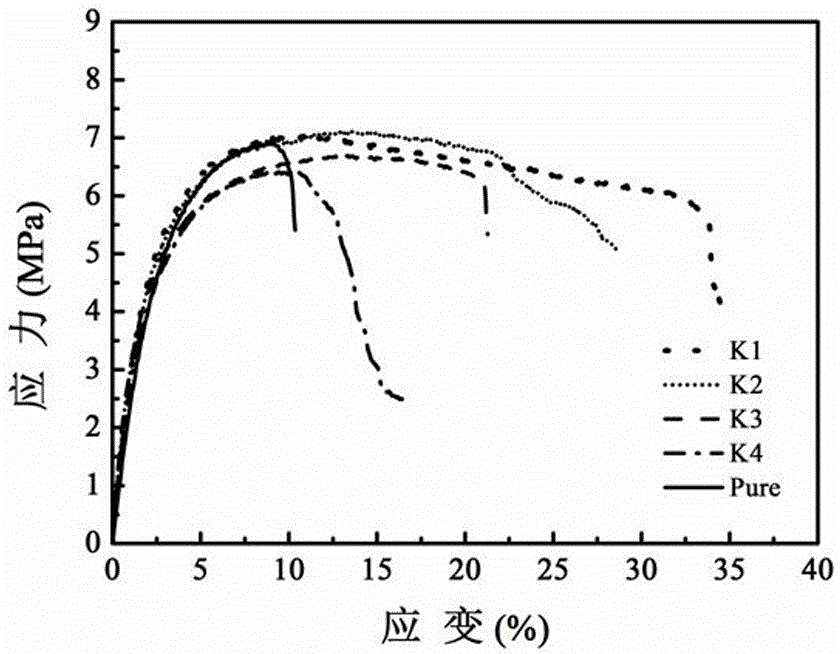

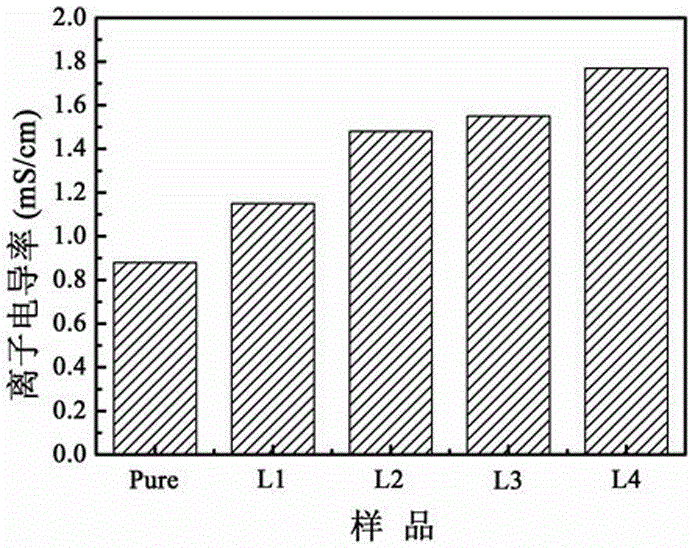

Porous lithium ion battery separator with interpenetrating polymer network structure, and preparation method and application for porous lithium ion battery separator

ActiveCN105932203AGood mechanical strengthGuaranteed ionic conductivityCell seperators/membranes/diaphragms/spacersSecondary cellsSolventPolyvinylidene fluoride

The invention discloses a porous lithium ion battery separator with an interpenetrating polymer network structure, and a preparation method and an application for the porous lithium ion battery separator. The preparation method specifically comprises the steps of uniformly mixing polyvinylidene fluoride-hexafluoropropylene, (methyl) acrylate monomers, octavinyl octa-silsesquioxane cross-linking agent and pore-forming auxiliary in a proper solvent to form porous gel polymer film with the interpenetrating polymer network structure through free radical polymerization, wherein the ion conductivity of the polymer film at a temperature of 25 DEG C can reach 1.0*10<-3>S / cm, the tensile strength can reach 7MPa, and excellent dimensional stability is realized; and on the basis, carrying out post processing on the gel polymer film to obtain the porous separator. By adoption of the lithium ion battery separator provided by the invention, the ionic conductivity can be greatly improved, and the high rate charging-discharging performance can be also obviously enhanced as well, so that the porous lithium ion battery separator is high in application potential.

Owner:SUZHOU UNIV

Preparation method of cellulose fibres

InactiveCN102154720AIncrease productivityGood mechanical strengthMonocomponent cellulose artificial filamentMelt spinning methodsIonChemistry

The invention discloses a preparation method of cellulose fibres, which comprises the following steps: 1, smashing cellulose into fine particles, wherein the cellulose is selected from wood pulp, cotton pulp or bamboo pulp with polymerization degree of 400-1,000; 2, uniformly mixing the cellulose particles with a plasticizer, and then feeding the mixture into a double-screw extruder, and preparing a spinning melt, wherein the mass ratio of the cellulose to the plasticizer is 3-6:7-4, the plasticizer is imidazole-based ionic liquid, or the mixed liquid of imidazole-based ionic liquid and morpholine-based ionic liquid, and the mixed liquid contains the same anions; 3, melting spinning, wherein the spinning speed is 5-100m / min, extract liquid is ionic liquid water solution with the mass of 0 to 20%, the temperature is 20- 90 DEG C, the stretch ratio is 0.2 to 5 times, the stretch bath temperature is 40-90 DEG C, and the spinning air gap is 5-20cm; and 4, washing, bleaching, oiling and drying spinning fibres to obtain the cellulose fibres.

Owner:TIANJIN POLYTECHNIC UNIV

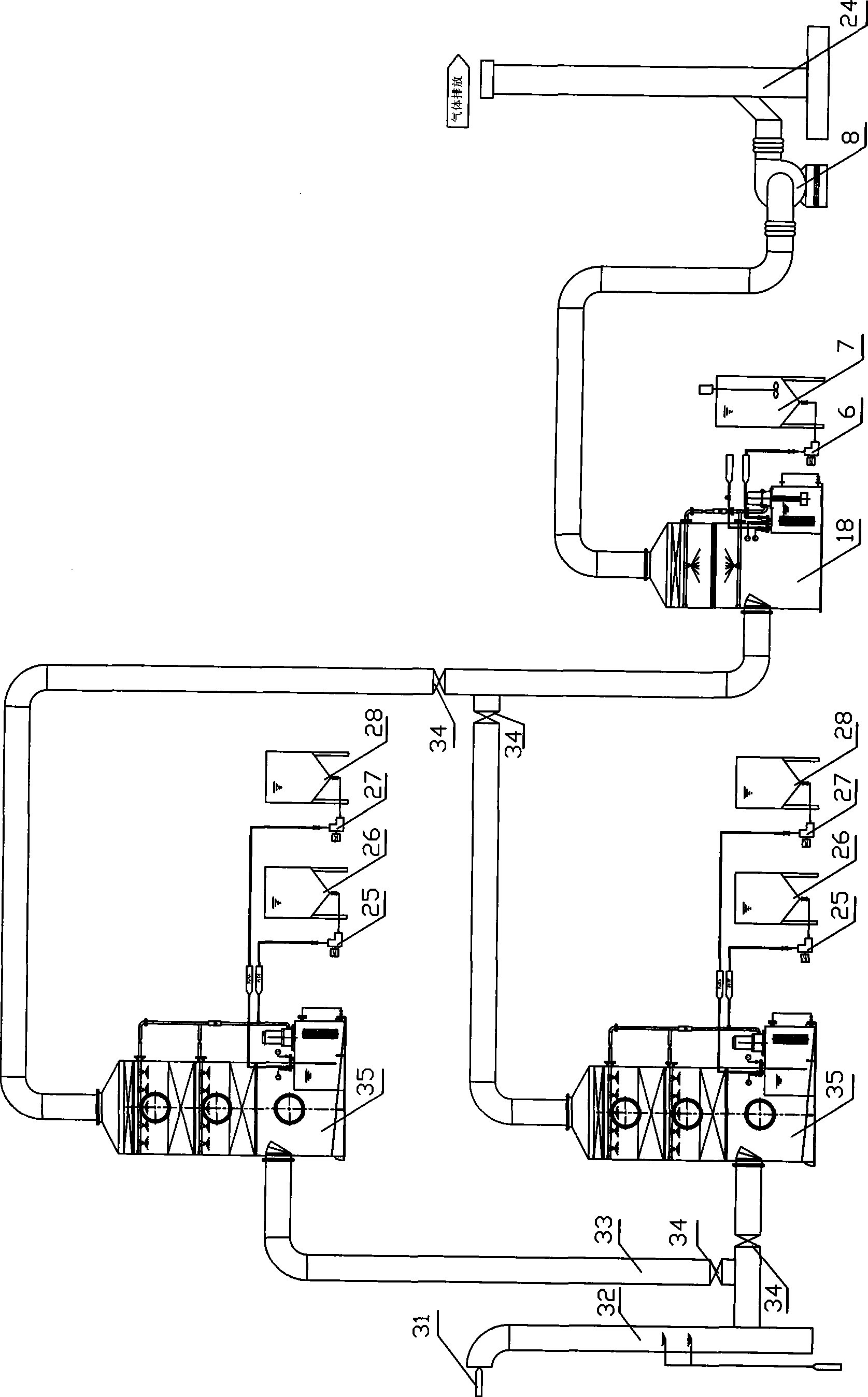

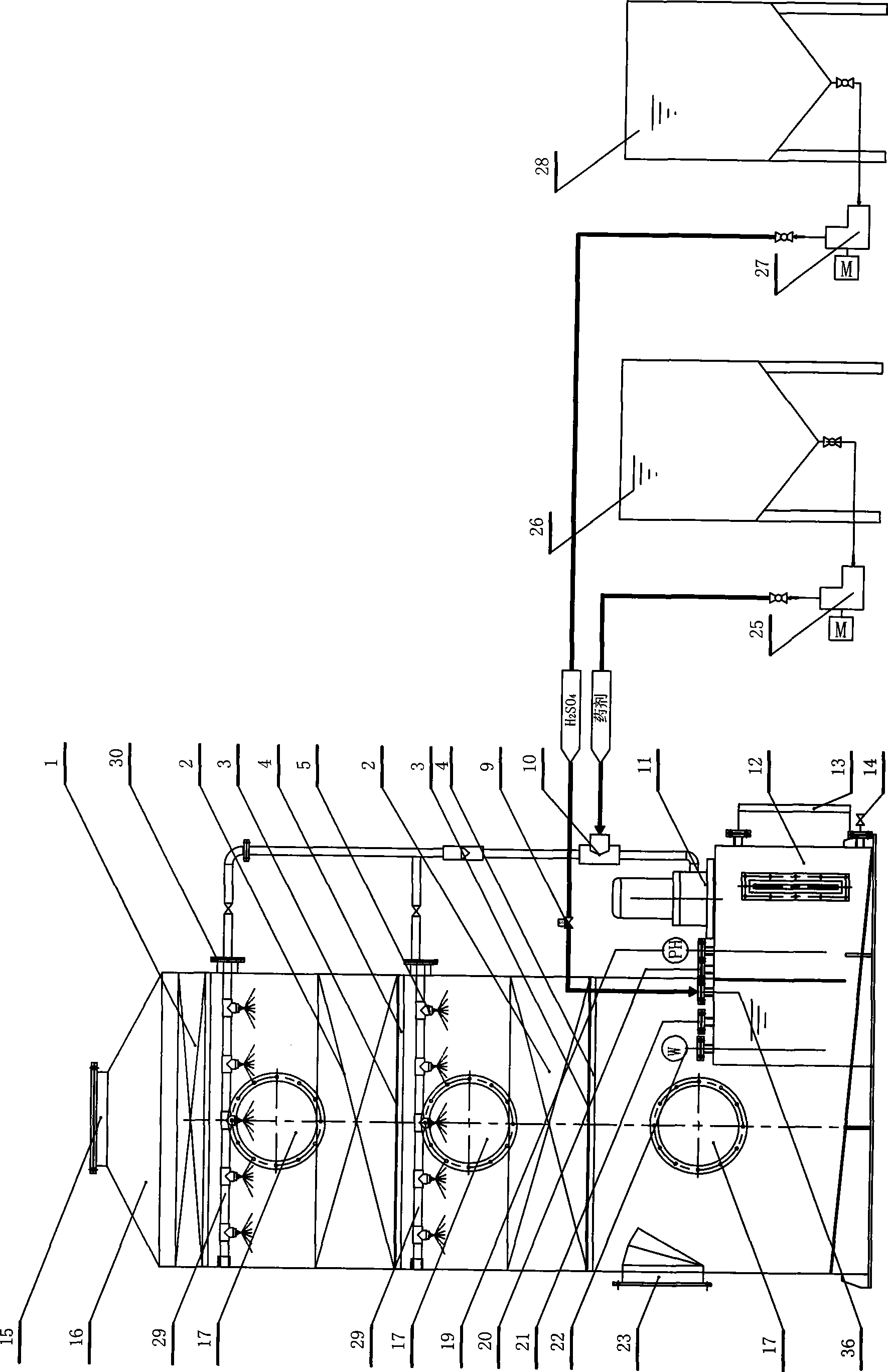

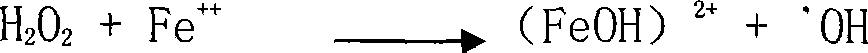

Method and device for processing malodorous gas by active bamboo charcoal-H2O2 complex phase catalytic oxidation

InactiveCN101496993AGood mechanical strengthSmall air resistanceCombination devicesOther chemical processesSpray towerAir volume

The invention relates to foul gas treatment technology and discloses a method and a device for treating foul gas through diphase catalytic oxidation of an activated bamboo charcoal-H2O2. The foul gas passes through a diphase bamboo charcoal catalyst and is adsorbed to remove foul substance molecules; an aqueous hydrogen peroxide solution is adopted to spray the diphase bamboo charcoal catalyst to decompose the adsorbed foul substance molecules so as to achieve cyclic utilization of the diphase bamboo charcoal catalyst; after water-gas separation by a demister, the gas is introduced to an alkali spraying tower; and an alkaline solution is sprayed to neutralize acidic substances of the gas; and the gas is discharged. The method for treating the foul gas has high treating efficiency and is in particular suitable for treating the foul gas with large wind volume.

Owner:SHANGHAI SHUITIAN ENVIRONMENTAL PROTECTION

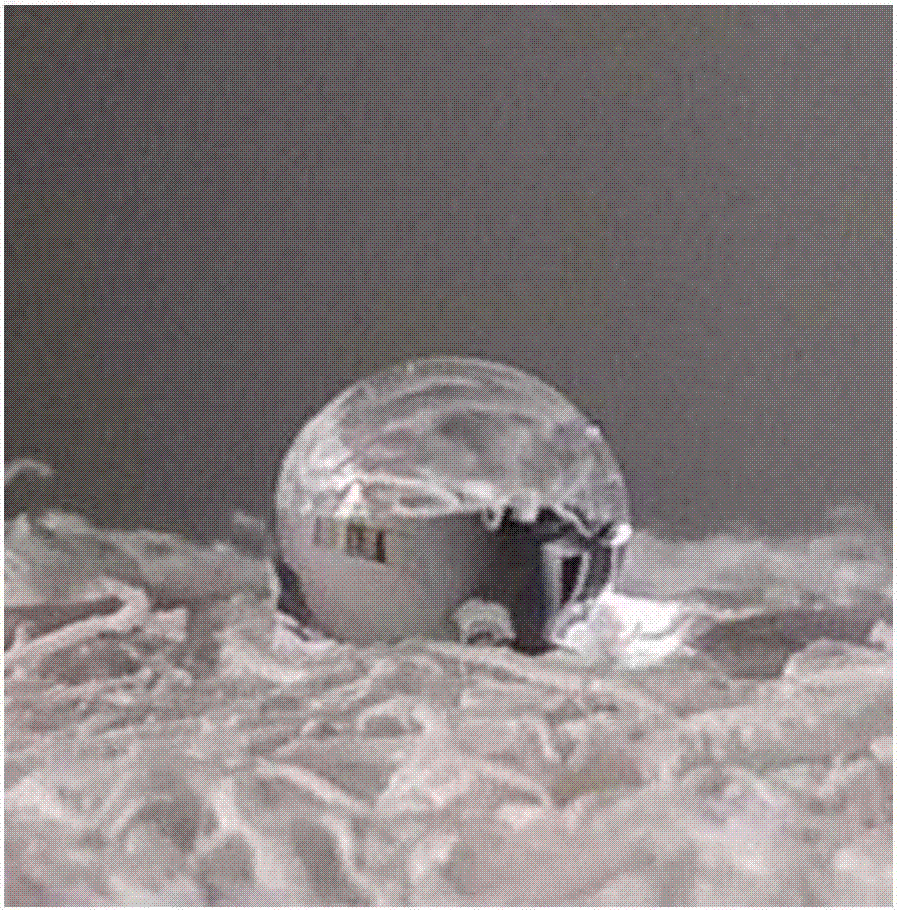

Super-hydrophobic loofah sponge for separating oil and water and preparation method thereof

ActiveCN106883588AUnique three-dimensional porous physical structureGood mechanical strengthNon-miscible liquid separationSolventChemistry

The invention discloses a super-hydrophobic loofah sponge for separating oil and water and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing ammonia water and a first solvent, adding an obtained mixture into a mixed solution of ethyl orthosilicate and the first solvent dropwise, reacting to obtain silicon dioxide nanoparticles, and adding a fluorine-containing silane coupling agent for performing surface hydrophobic modification to obtain hydrophobic silicon dioxide nanoparticles; then, fixing the silicon dioxide nanoparticles being subjected to hydrophobic modification to the surface of a loofah sponge with polyisocyanate to obtain the super-hydrophobic loofah sponge. The super-hydrophobic loofah sponge for separating oil and water has the advantages that a synthetic process is simple and feasible, the raw materials are readily-available, a contact angle with water is 156 degrees, high oil-water separating performance is realized, and the oil-water separating efficiency is 98 percent or above.

Owner:SOUTH CHINA UNIV OF TECH

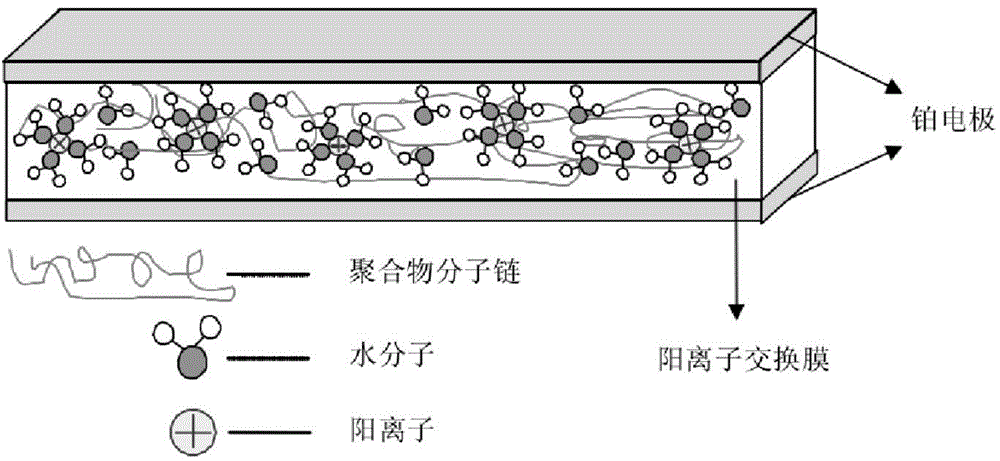

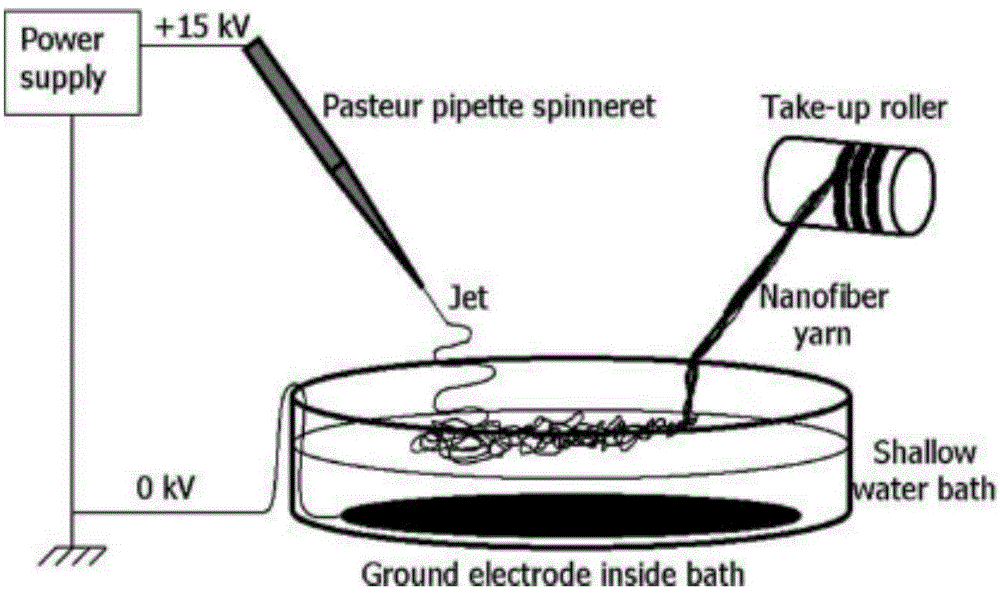

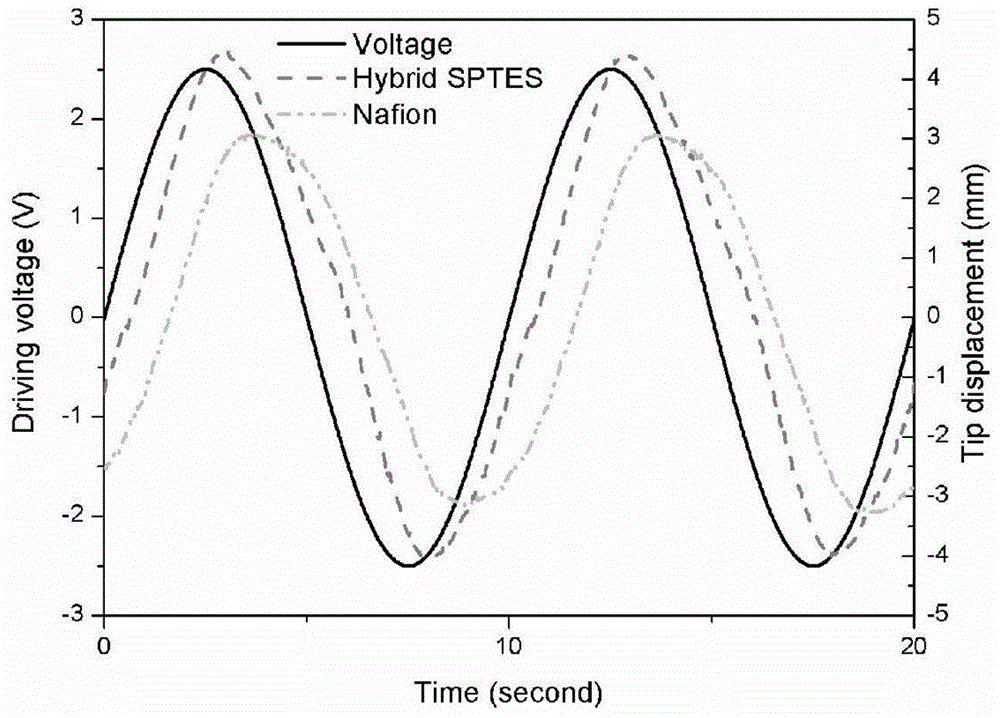

Biomimetic structure type polymer actuator and preparation method thereof

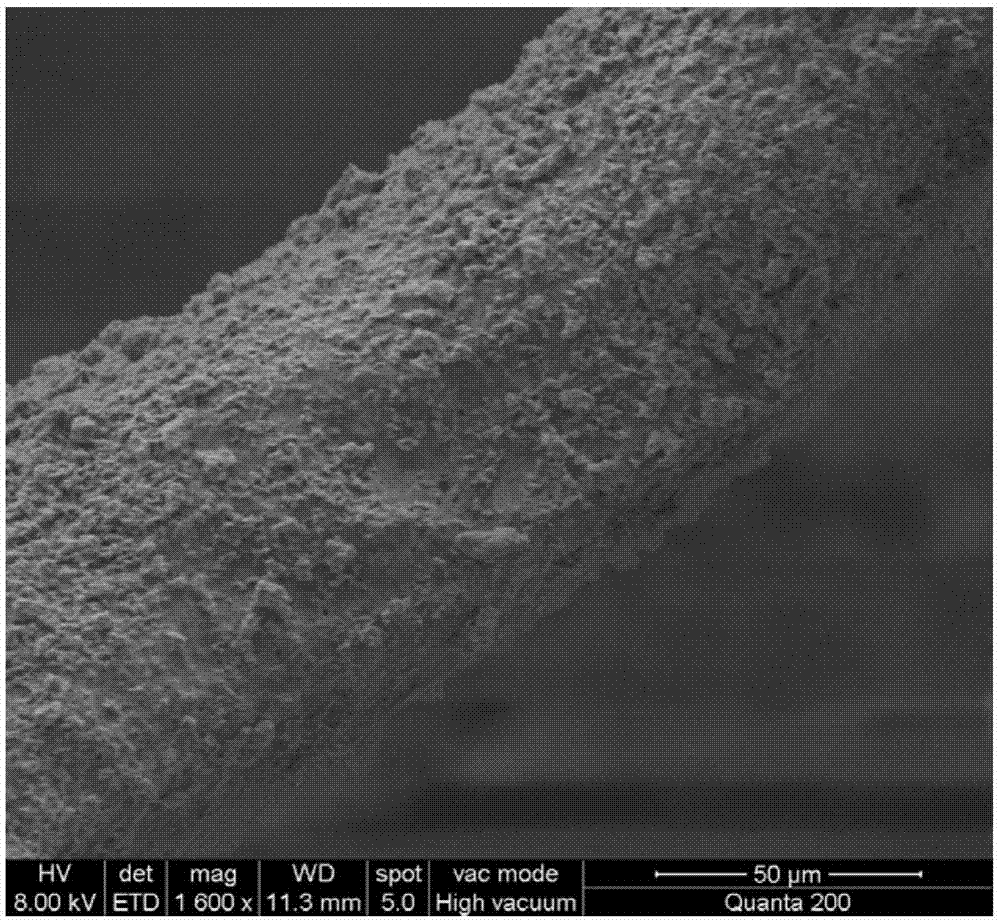

InactiveCN104389173AGood mechanical strengthGood thermal stabilityFibre typesLiquid/solution decomposition chemical coatingElectrospinningIon exchange

The invention relates to a biomimetic structure type polymer actuator. The biomimetic structure type polymer actuator is composed of a layer of polymer film and metal electrodes covering two sides of the polymer film, wherein the polymer film is a sulfonated block copolymer-Nafion hybrid film; the sulfonated block copolymer-Nafion hybrid film is prepared through the following steps: firstly synthesizing a sulfonated block copolymer, preparing a nanometer fiber film by statically spinning a sulfonated block copolymer solution, compounding the film with a Nafion solution, casting, standing and drying. The invention further provides a preparation method of the biomimetic structure type polymer actuator, the sulfonated block copolymer-Nafion hybrid film is subjected to earlier stage processing, ion exchange reaction, main chemical plating reaction, lithium ion substitution and clipping so as to obtain the actuator. The structure biomimetic polymer actuator disclosed by the invention has the advantages of being low in cost, stable in performance and biomimetic in structure.

Owner:CHONGQING UNIV OF TECH

Preparation method and application of citric acid modified palm tree bark adsorbing agent

InactiveCN103212378AGood physical and chemical stabilityGood mechanical strengthOther chemical processesWaste water treatment from textile industryChemistryHydroxycitric acid

The invention discloses a preparation method and an application technology of a citric acid modified palm tree bark adsorbing agent. The preparation method is characterized by comprising the following steps of: washing palm tree bark by water to remove mud and impurities, drying and crushing the washed palm tree bark, mixing the crushed palm tree bark with a 8%-20% citric acid solution according to the proportion of 1g: 5ml-15ml after the palm tree bark is dried by a NaOH aqueous solution, reacting the mixture for 35-60 minutes at room temperature, heating the reacted mixture to 50-60 DEG C, reacting the heated mixture for 24-36 hours, heating the reacted mixture to 120-130 DEG C, reacting the heated mixture for 1-2 hours, cooling the reacted mixture, washing the cooled mixture with distilled water until no citric acid exists in washing liquid, mixing the washing liquid with a 10%-20% magnesium chloride solution according to the proportion of 1g: 5ml-12ml, reacting the mixture at room temperature, performing suction filtration on the reacted mixture, washing the filtered mixture with a 5%-10% magnesium chloride solution, and finally, baking washing liquid to obtain the citric acid modified palm tree bark adsorbing agent. The adsorbing agent has high adsorption capacity to basic dye, good physical and chemical properties, high mechanical stability and strong regeneration capacity, and is recyclable, low in cost and environment-friendly.

Owner:UNIV OF JINAN

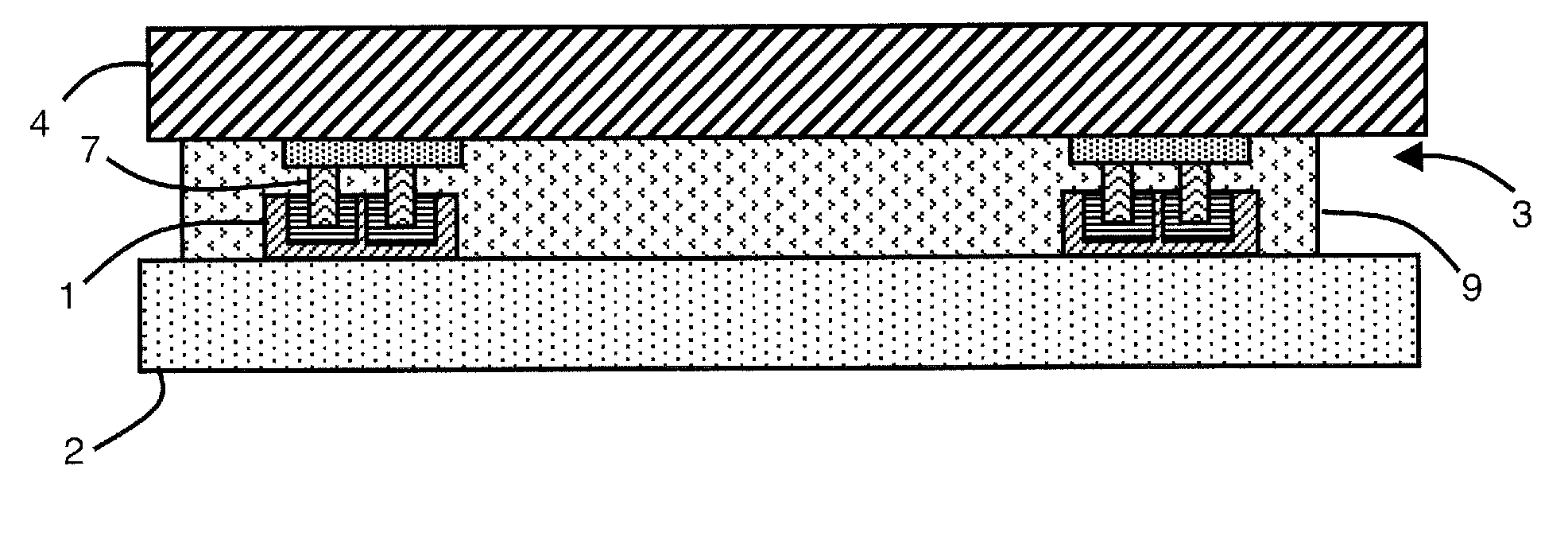

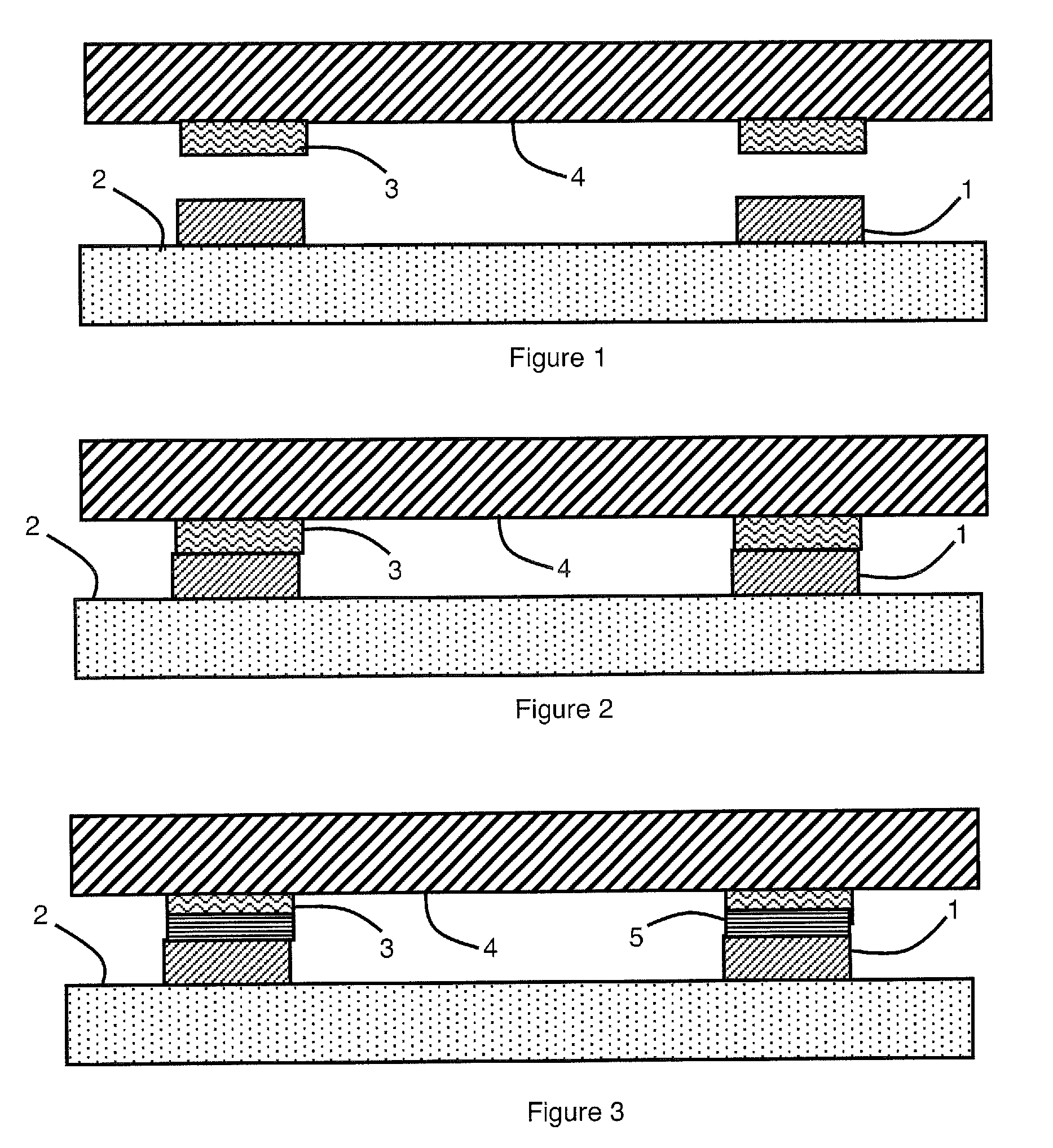

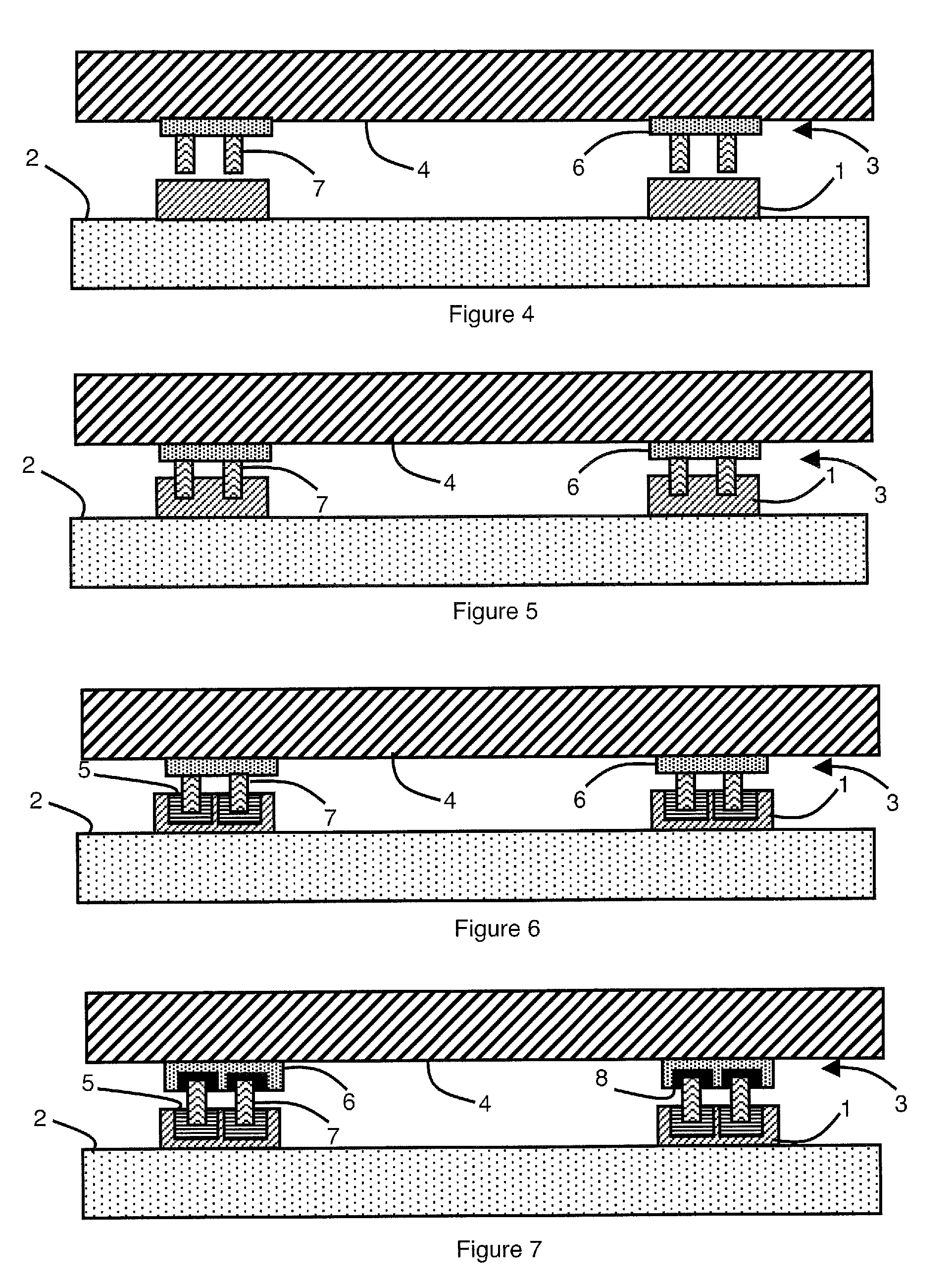

Method for fabricating two substrates connected by at least one mechanical and electrically conductive connection and structure obtained

InactiveUS20130313704A1Good mechanical strengthEasy to implementSemiconductor/solid-state device detailsSolid-state devicesElectrically conductiveMetallic materials

A first substrate provided with a receiving area made from a first metallic material is supplied. A second substrate provided with an insertion area comprising a base surface and at least two bumps made from a second metallic material is arranged facing the first substrate. The bumps are salient from the base surface. A pressure is applied between the first substrate and the second substrate so as to make the bumps penetrate into the receiving area. The first metallic material reacts with the second metallic material so as to form a continuous layer of an intermetallic compound having a base formed by the first and second metallic materials along the interface between the bumps and the receiving area.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Preparation of dimethyl diallyl ammonium chloride modified towel gourd vegetable sponge adsorbent

InactiveCN104289187AGood physical and chemical stabilityGood mechanical strengthFatty/oily/floating substances removal devicesOther chemical processesAmmonium sulfateChemistry

The invention discloses a preparation method and an application technology of a dimethyl diallyl ammonium chloride modified towel gourd vegetable sponge adsorbent, and is characterized in that the preparation method comprises the steps: peeling and denucleating mature fruits of towel gourd, washing with water to remove soil and impurities, drying, crushing, and carrying out chemical treatment drying to obtain acylating-chlorination towel gourd vegetable sponge; adding, by the mass percentage, 56-71% of dimethyl diallyl ammonium chloride, 10-20% of the acylating-chlorination towel gourd vegetable sponge, 12-26% of water and 0.5-2.0% of ammonium persulfate into a reactor, wherein the sum of the percentages of all the components is 100%; under the nitrogen protection and at a constant temperature of 45-55 DEG C, stirring and carrying out a reflux reaction for 4-5 h; and after cooling, washing with deionized water, carrying out suction filtration until a filtrate is neutral, drying in a vacuum drying oven, and thus obtaining the dimethyl diallyl ammonium chloride modified towel gourd vegetable sponge adsorbent. The adsorbent has the advantages of quite high adsorption capacity on grease, excellent physicochemical and mechanical properties, strong regeneration capacity, capacity of being repeatedly used many times, low cost, greenness and environmental protection.

Owner:UNIV OF JINAN

Preparation of pyromellitic dianhydride modified banana peel adsorbent

InactiveCN104289188AGood physical and chemical stabilityGood mechanical strengthOther chemical processesWater contaminantsDimethyl formamideIon

The invention discloses a preparation method and an application of a pyromellitic dianhydride modified banana peel adsorbent, and is characterized in that the preparation method comprises the steps: washing cleanly banana peels, drying, then smashing, and thus obtaining preprocessed banana peels; then, according to the mass percentage concentration, adding 78-92% of N,N-dimethylformamide and 1.0-5% of pyromellitic dianhydride into a reactor, completely dissolving, and then adding 5-18% of the alkalized banana peels, wherein the sum of the percentages of the components is 100%; and at the constant temperature of 70+ / -3 DEG C, carrying out a reflux reaction for 3-6 h, carrying out suction filtration, washing to be neutral, drying, and thus obtaining the pyromellitic dianhydride modified banana peel adsorbent. The adsorbent can directly adsorb lead ions in a water body, is high in adsorption efficiency, has good physicochemical and mechanical stability, can be used in a relatively wide pH range, and can be renewable and be used repeatedly; the banana peels are natural biomacromolecules, are biodegradable, belong to agricultural waste reuse, and is easy to obtain and cheap; and the adsorbent is a natural green adsorbent.

Owner:UNIV OF JINAN

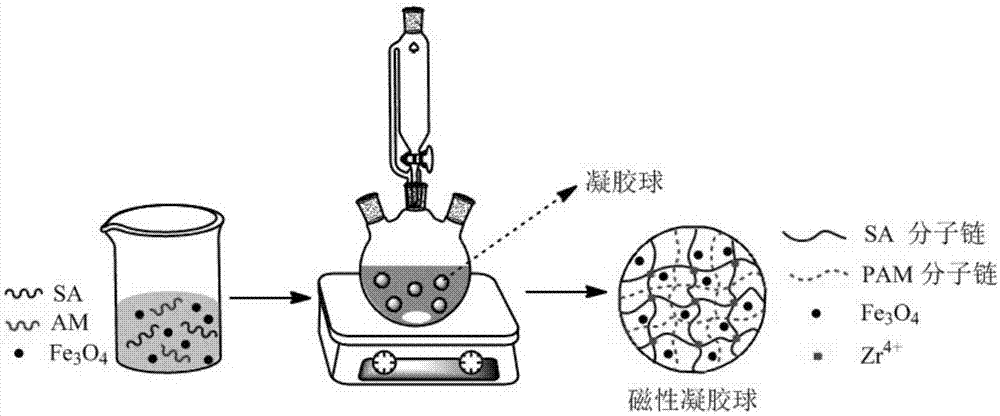

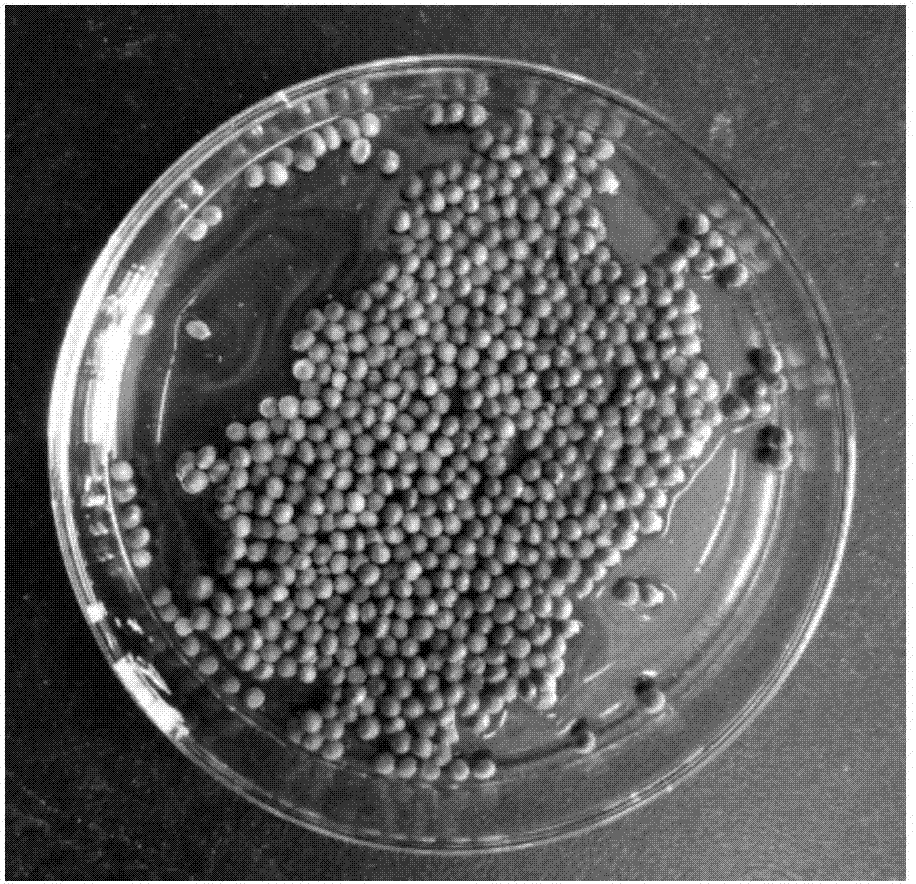

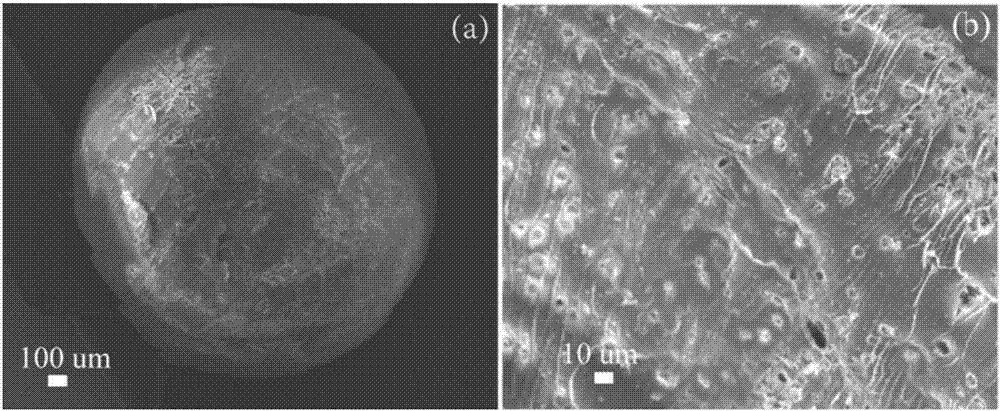

Magnetic polyacrylamide/zirconium alginate gel beads as well as preparation method and application thereof

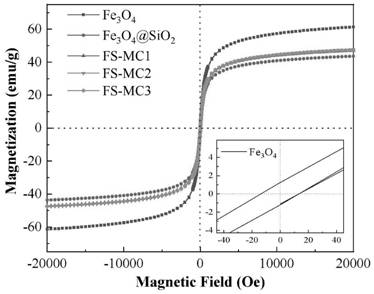

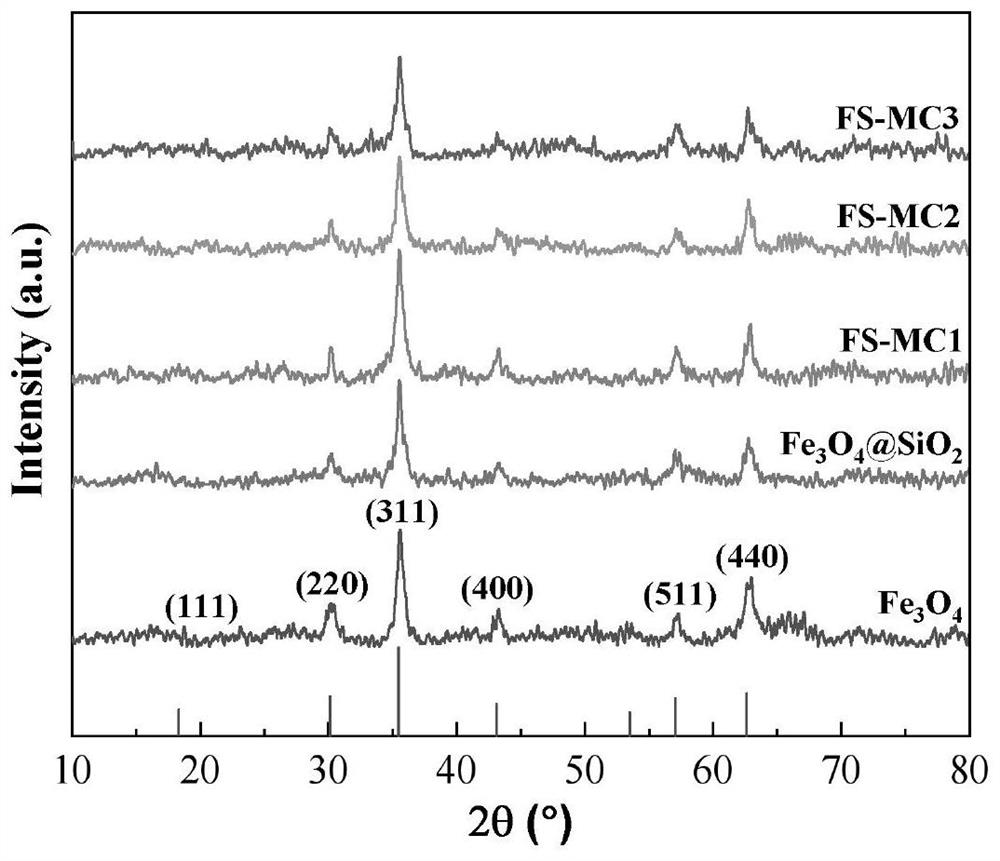

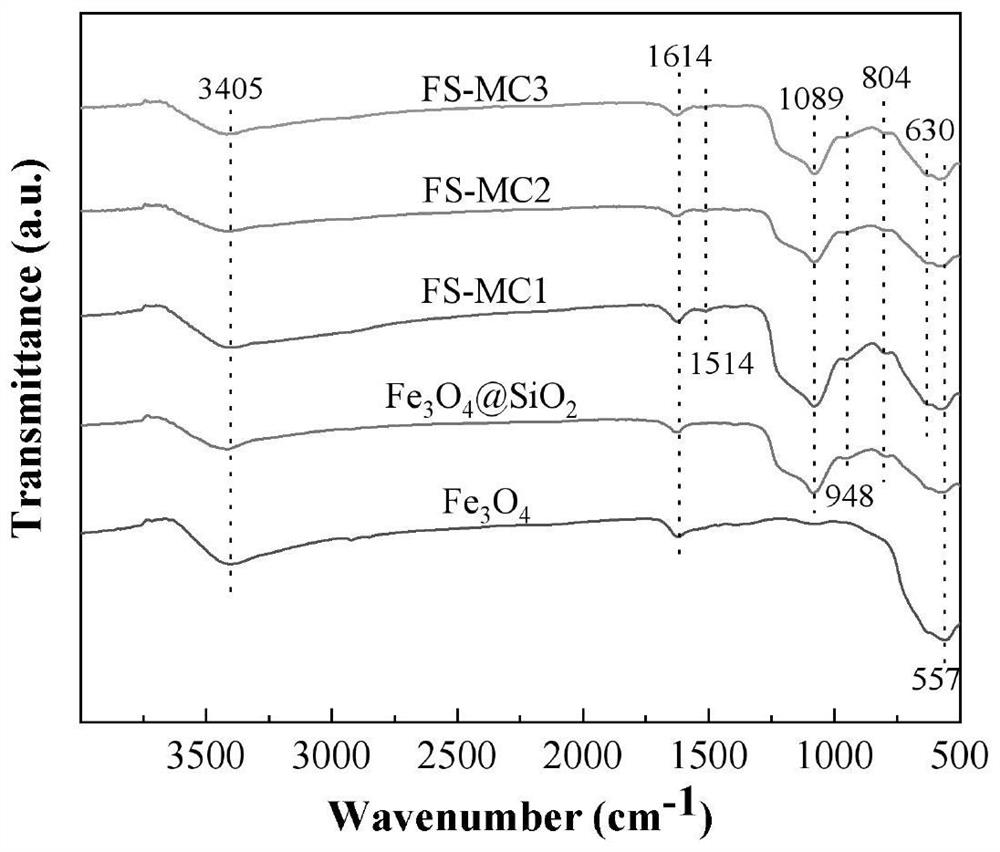

ActiveCN107442082AImprove adsorption performanceGood mechanical strengthOther chemical processesWater/sewage treatment by magnetic/electric fieldsChemistryPolyacrylamide

The invention relates to a method for preparing magnetic polyacrylamide / zirconium alginate gel beads. The method comprises the following steps: preparing a hydrophilic Fe3O4 nano-magnetic fluid by using a co-precipitation method; adding sodium alginate into the hydrophilic Fe3O4 nano-magnetic fluid, and preparing into a precursor solution of magnetic composite gel with multiple organic solvents; preparing a mixed solution of zirconium oxychloride and ammonium persulfate; and uniformly dropping the obtained gel precursor solution into the mixed solution, and carrying out a chemical cross-linking reaction, thereby obtaining the magnetic polyacrylamide / zirconium alginate gel beads. The adsorption capacity of the material on phosphate in water reaches 42.21mg-P / g, even if the material is recycled for 5 times, the adsorption capacity is basically maintained invariable, and the material has excellent stability and recycling characteristics. The method is simple in preparation process, easily controllable in conditions and suitable for large-scale production. Particularly, due to magnetic responsiveness, the magnetic polyacrylamide / zirconium alginate gel beads can be rapidly separated and recycled in an applied magnetic field and have the characteristics of being high in efficiency, energy-saving and environment-friendly.

Owner:GUANGZHOU UNIVERSITY

Method of preparing modified hydrotalcite for removing trace mercury and cadmium ion in water

InactiveCN101033095AGood mechanical strengthFast adsorptionWater/sewage treatment by sorptionThermal crystallizationCadmium ion

This invention discloses a method for preparing modified water-talcum for eliminating minim Hg and Cd ions, which takes amino acid as the main modified source to modify water-talcum and utilizes water-phase deposition thermal crystallization method to prepare it and realize optimization on structure by controlling the way of drying. Advantages: apart from having good mechanical strength and uniform grains, the Hg and Cd sorbent can adsorb marks, minim Hg and Cd ions in water and plant extracted materials quickly at large volume.

Owner:TIANJIN UNIV +1

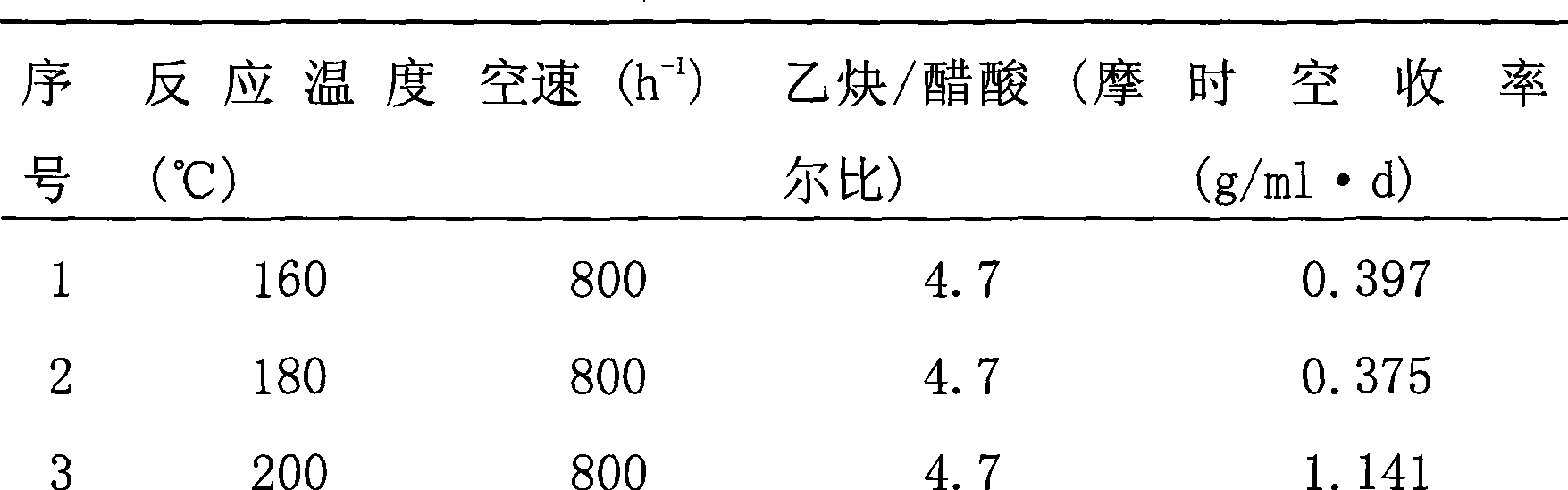

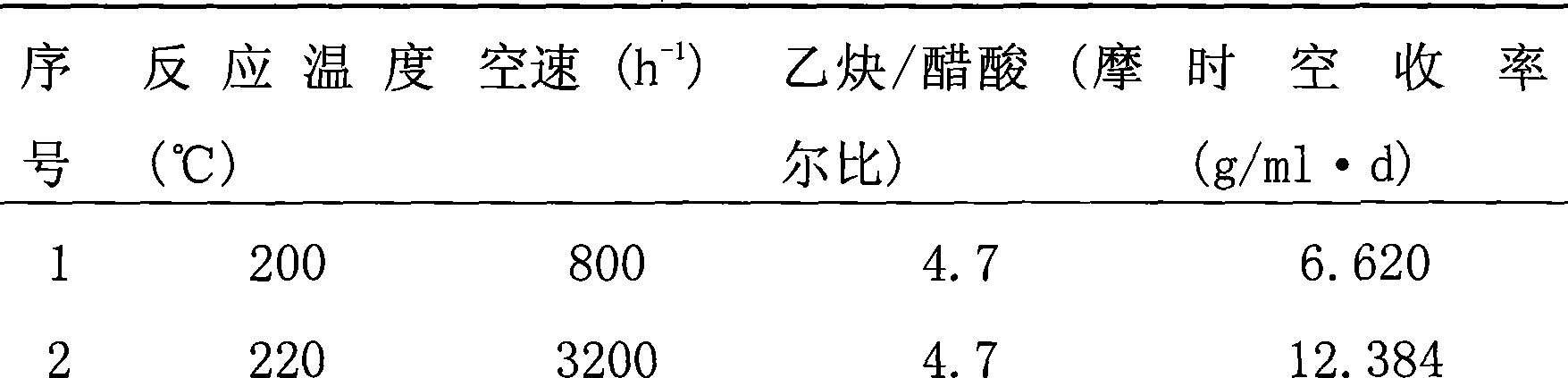

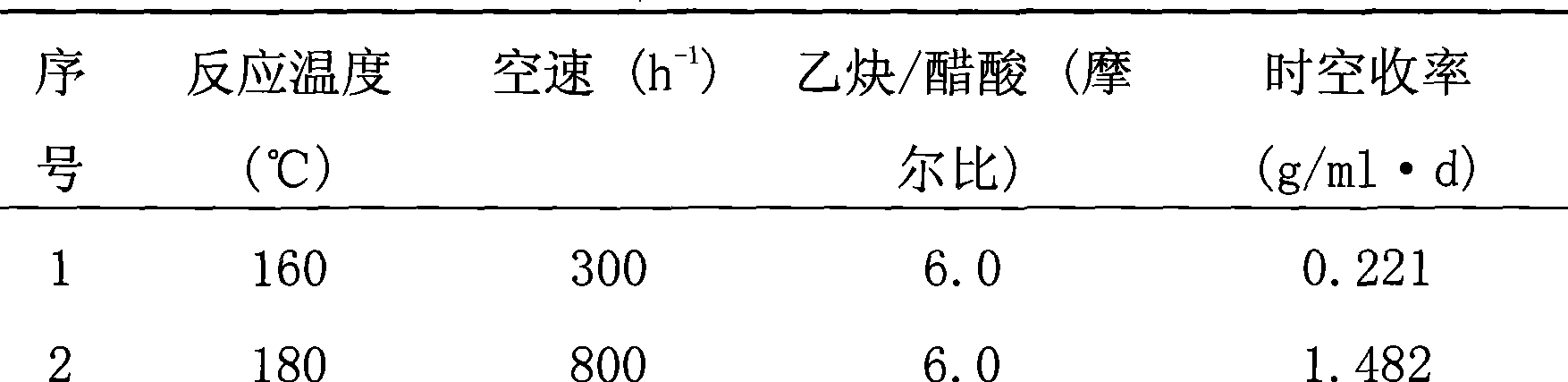

Catalyst for producing vinyl acetate by acetylene method and preparation method and use thereof

InactiveCN101385984AGood mechanical strengthRegular structureOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsZinc Acetate DihydrateVinyl acetate

Owner:JIANGSU SOPO GRP +1

High-strength antimicrobial dialdehyde starch crosslinked chitosan membane and preparation method and use thereof

InactiveCN1434072AGood mechanical strengthGood flexibilityPharmaceutical containersMedical packagingPliabilityChemistry

The present invention relates to a high-strength antimirobial dialdehyde starch cross-linked chitosan film, its production method and application. It is made up by using 1-3 wt% of chitosan acetic acid aqueos solution and 2-7 wt% of dialdehyde starch and adopting the processes of fully stirring, mixing, centrifugal defoaming, film-making, washing with acid, washing with water, drying by airing toobtain the invented product dried film. Said chitosan cross-linked film has excellent mechanical strength, flexibility and good antibacterial function, and has no toxic side effect for human body. Said chitosan cross-linked film has good bacteria-inhibiting action, can be used as clinical medical material for reducing infection of wound.

Owner:WUHAN UNIV

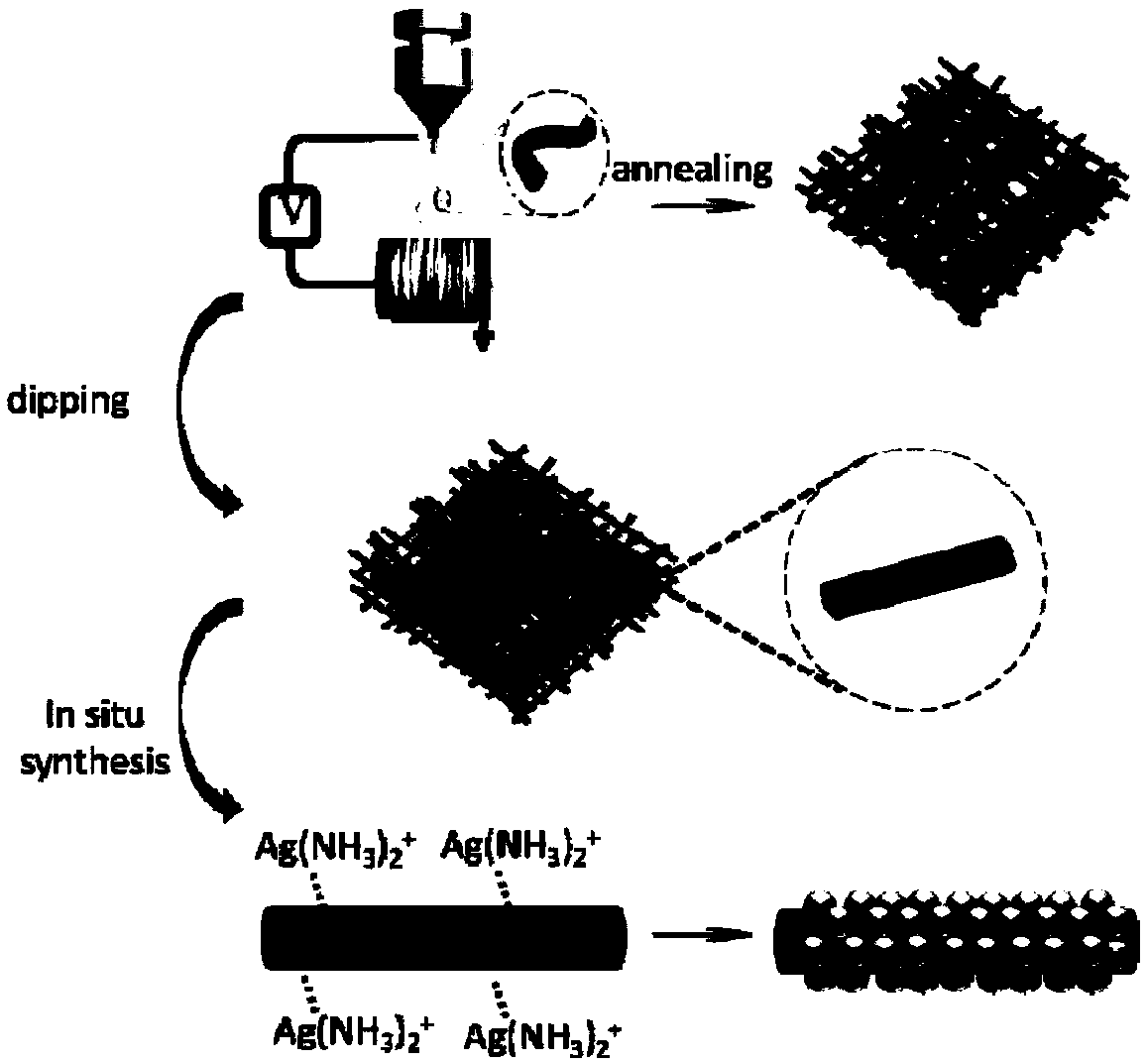

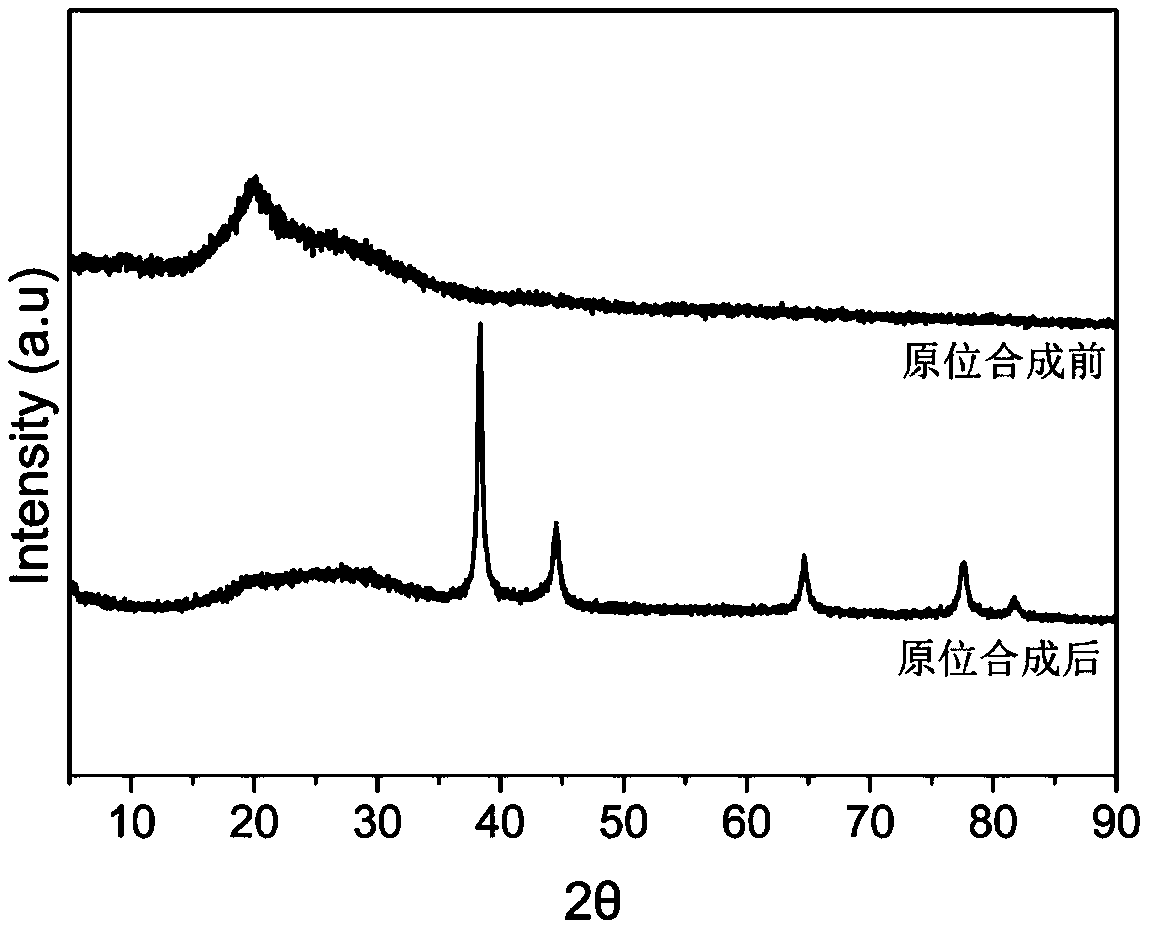

Flexible thermoelectric nanofiber thin film and preparation and application thereof

ActiveCN109295707AExcellent flexibilityGood mechanical strengthFibre typesMonocomponent synthetic polymer artificial filamentElectrospinningNanometre

The invention relates to a flexible thermoelectric nanofiber thin film and preparation and an application thereof, wherein the flexible thermoelectric nanofiber thin film is a PEDOT:PSS-based nanofiber thin film having the surface coated with silver nanoparticles. The preparation includes the steps: the PEDOT:PSS-based nanofiber thin film is obtained by an electrostatic spinning technology; the nanofiber thin film is annealed and then impregnated in a PEDOT:PSS solution, the excess solution on the surface is washed away, and then drying is performed; and the surface of the nanofibers is coatedwith silver nanoparticles by in situ synthesis. The thin film not only has good thermoelectric properties, but also has good mechanical properties and flexibility, and is easily processed into flexible thermoelectric devices. The method provides a new way for preparing the flexible thermoelectric thin film, and has important significance for development of the flexible thermoelectric devices.

Owner:DONGHUA UNIV

Magnetic covalent bond type chitosan-based modified flocculant and preparation method and application thereof

ActiveCN113121840AGood chemical stabilityGood mechanical strengthWater/sewage treatment by flocculation/precipitationLipophilicitySuperparamagnetism

The invention belongs to the field of water treatment, and particularly relates to a magnetic covalent bond type chitosan-based modified flocculant and a preparation method and application thereof. According to the invention, a cationic monomer and a hydrophobic monomer are introduced into chitosan molecules through a graft copolymerization reaction, so that the flocculant is ensured to have good stability, the electricity neutralization capability and the demulsification capability on oil droplets of the flocculant in a flocculation process are improved, the solubility of the flocculant is increased, the pH application range of the flocculant is widened, the dosage is reduced, meanwhile, the nano Fe3O4 has superparamagnetism, the settling performance of floc can be remarkably improved under the action of an external magnetic field when the nano Fe3O4 is introduced into the flocculating agent, and the settling time is shortened. Results of the embodiment show that the flocculant provided by the invention is good in lipophilicity and excellent in flocculation performance, and has efficient oil-water separation capacity, wider pH application range and excellent recoverability.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Graphene coating agent and preparation method for producing super lead-acid storage battery negative electrode plate from graphene coating agent

ActiveCN104979561AGood electrical propertiesGood mechanical strengthLead-acid accumulator electrodesGraphene coatingGram

The present invention discloses a graphene coating agent and a preparation method for producing a super lead-acid storage battery negative electrode plate from the graphene coating agent. The preparation method comprises: adding 20-120 parts by weight of graphene, 1-6 parts by weight of sodium ligninsulfonate (SLS), 5-10 parts by weight of a hydrogen evolution inhibitor, and 1000 parts by weight of water to a stirring tank, carrying out high speed and uniform stirring, adding 10-30 parts by weight of a binder and 500 parts by weight of water to another stirring tank, uniformly stirring, mixing the two mixtures, adding 300-1000 parts by weight of water, and carrying out high speed and uniform stirring to prepare the graphene coating agent; uniformly coating the graphene coating agent on both sides of a storage battery negative electrode generating plate, wherein the weight of the graphene coating agent is 0.25-2.5% of the gram weight of the negative electrode plate generating sheet; and closely wrapping with plate coating paper, flattening, pressing, laminating, compacting, carrying out cutting stacking, and drying for 2-4 h at a temperature of 60-100 DEG C. According to the present invention, the graphene coating agent is uniformly adhered on both sides of the lead-acid storage battery raw electrode plate, the adhesion reliability is high, the graphene coating agent is not easily shed, the battery charging time is reduced, and the specific energy, the cycle life, the high-current charge-discharge performance and the high power capacity of the battery are improved.

Owner:SINO INNOV SEMICON (PKU) CO LTD

Method for producing propylene, ethene by using catalytic cracking olefin through fluid bed

ActiveCN1915925AHigh reactivity and propylene selectivityGood mechanical strengthHydrocarbon by hydrocarbon crackingMolecular sieveActive component

This invention relates to a method for manufacturing propylene and ethylene by alkenes catalytic cracking in fluid bed reactor. The method comprises contacting alkenes with catalyst in a fluid bed reactor, and catalytically cracking to obtain propylene and ethylene. The catalyst uses ZSM molecular sieve 20-80 wt.% as the carrier, and rare earth oxides 0.01-6 wt.%, phosphorus oxides 0.01-6 wt.%, and binder 10-70 wt.% as the active components. The method solves the problems of quick coking inactivation and poor hydrothermal stability of the catalyst, low yield of propylene, etc., and can be used in propylene and ethylene manufacture by alkenes catalytic cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com