Super-hydrophobic loofah sponge for separating oil and water and preparation method thereof

A technology of oil-water separation and loofah, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of complicated preparation process of super-hydrophobic sponge, and achieve good oil-water separation performance, easy availability of raw materials, and excellent mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

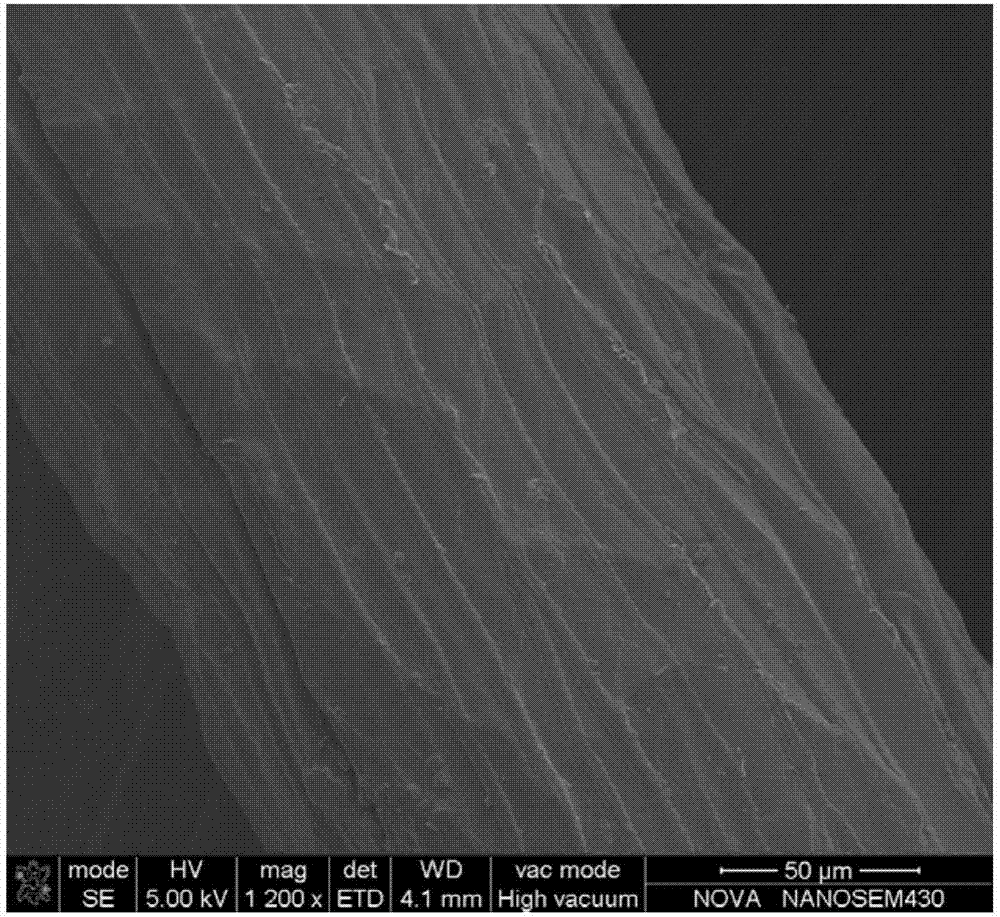

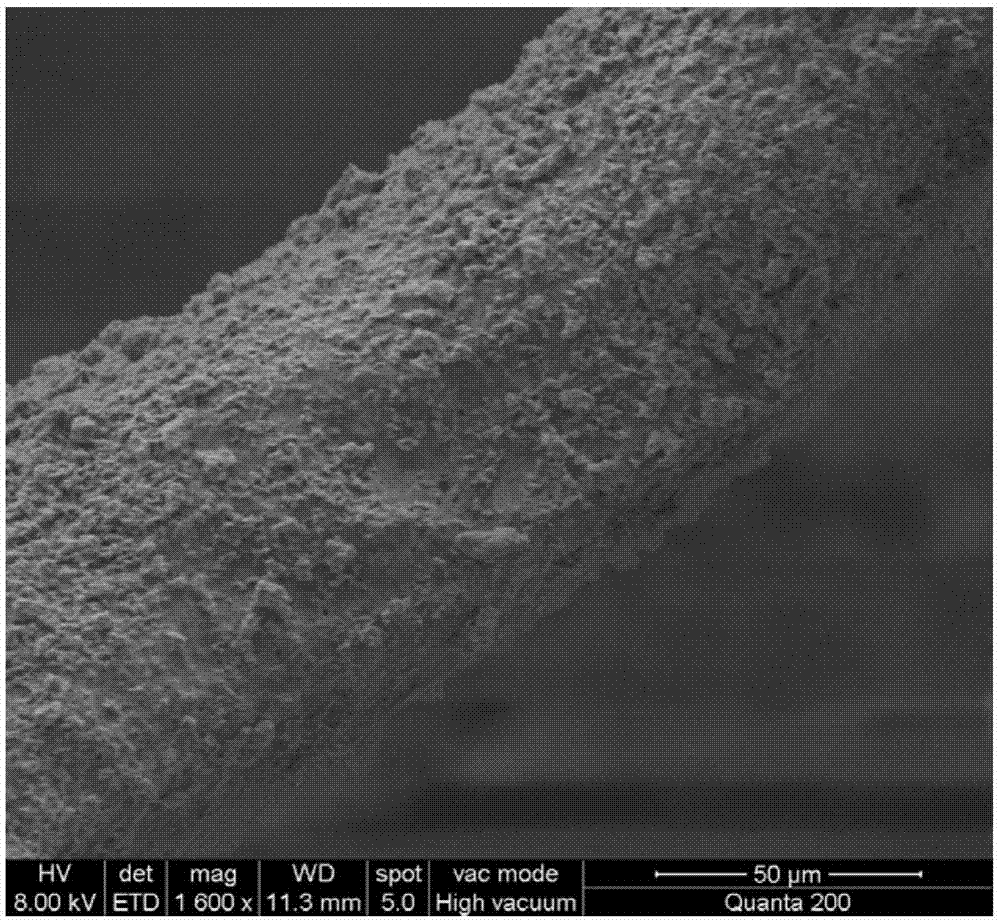

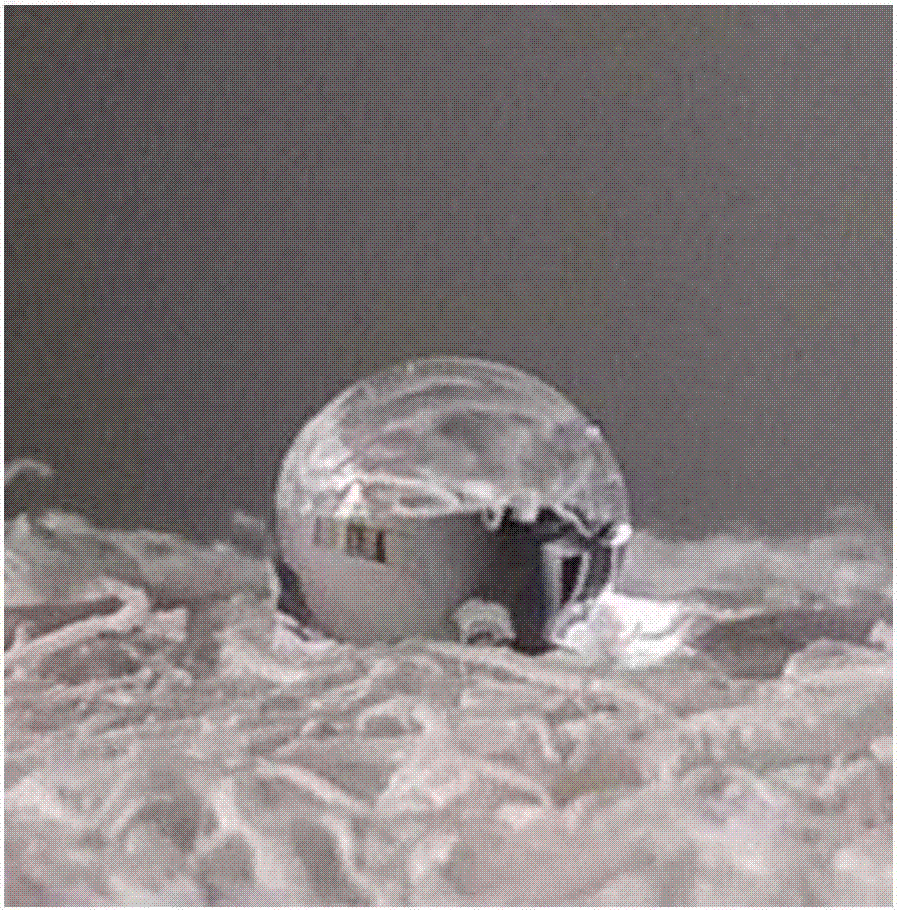

[0032] 1) Preparation of hydrophobically modified silica nanoparticles: in parts by mass, after mixing 5 parts of ammonia water and 25 parts of absolute ethanol evenly, add 5 parts of tetraethyl orthosilicate and 25 parts of anhydrous ethanol dropwise In the mixed solution of ethanol, heat to 30°C, stir and react for 5 hours; then, add 1 part of heptadecafluorodecyltrimethoxysilane to the reaction system, and continue the reaction for 10 hours; finally, wash the crude product at 80 Vacuum drying at ℃ for 4 hours to obtain hydrophobically modified silica nanoparticles;

[0033] 2) Preparation of superhydrophobic loofah: in parts by mass, disperse the silicon dioxide nanoparticles prepared above in 30 parts of ethyl acetate by ultrasonic method, add 10 parts of loofah, 10 parts of 1,6‐6 Methylene diisocyanate and 0.1 part of dibutyltin dilaurate were reacted at 70°C for 5 hours; then, the loofah was taken out and washed 3 times with 40 parts of ethyl acetate; finally, the loofah...

Embodiment 2

[0040]1) Preparation of hydrophobically modified silica nanoparticles: in parts by mass, after mixing 0.5 parts of ammonia water and 10 parts of absolute ethanol evenly, add 2 parts of tetraethyl orthosilicate and 10 parts of anhydrous ethanol dropwise In the mixed solution of ethanol, heat to 60°C, stir and react for 0.5 hours; then, add 0.5 parts of heptadecafluorodecyltrimethoxysilane to the reaction system, and continue the reaction for 1 hour; finally, wash the crude product and Vacuum drying at ℃ for 24 hours to obtain hydrophobically modified silica nanoparticles;

[0041] 2) Preparation of superhydrophobic loofah: in parts by mass, disperse the silicon dioxide nanoparticles prepared above with 20 parts of ethyl acetate by ultrasonic method, add 10 parts of loofah, 5 parts of 1,6‐6 Methylene diisocyanate and 0.05 parts of dibutyltin dilaurate were reacted at 50°C for 12 hours; then, the loofah was taken out and washed 3 times with 30 parts of ethyl acetate; finally, the...

Embodiment 3

[0044] 1) Preparation of hydrophobically modified silica nanoparticles: in parts by mass, after mixing 4 parts of ammonia water and 25 parts of methanol evenly, add dropwise to a mixed solution of 4 parts of ethyl orthosilicate and 25 parts of methanol , heated to 50°C, stirred and reacted for 3 hours; then, 0.7 parts of tridecafluorooctyltrimethoxysilane was added to the reaction system, and the reaction was continued for 6 hours; finally, the crude product was washed and dried in vacuum at 50°C After 12 hours, hydrophobically modified silica nanoparticles were obtained;

[0045] 2) Preparation of superhydrophobic loofah: in parts by mass, disperse the silicon dioxide nanoparticles prepared above with 30 parts of butyl acetate by ultrasonic method, add 10 parts of loofah, 6 parts of diphenylmethane- 4,4′‐diisocyanate and 0.1 part of catalyst were reacted at 60°C for 7 hours; then, the loofah was taken out and washed twice with 30 parts of butyl acetate; finally, the loofah wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com