Flexible thermoelectric nanofiber thin film and preparation and application thereof

A nanofiber and film technology, applied in flexible thermoelectric nanofiber films and their preparation and application fields, can solve the problems of flexibility and poor mechanical properties of thermoelectric films, achieve excellent thermoelectric performance, increase phonon scattering, and increase electron transfer channels. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

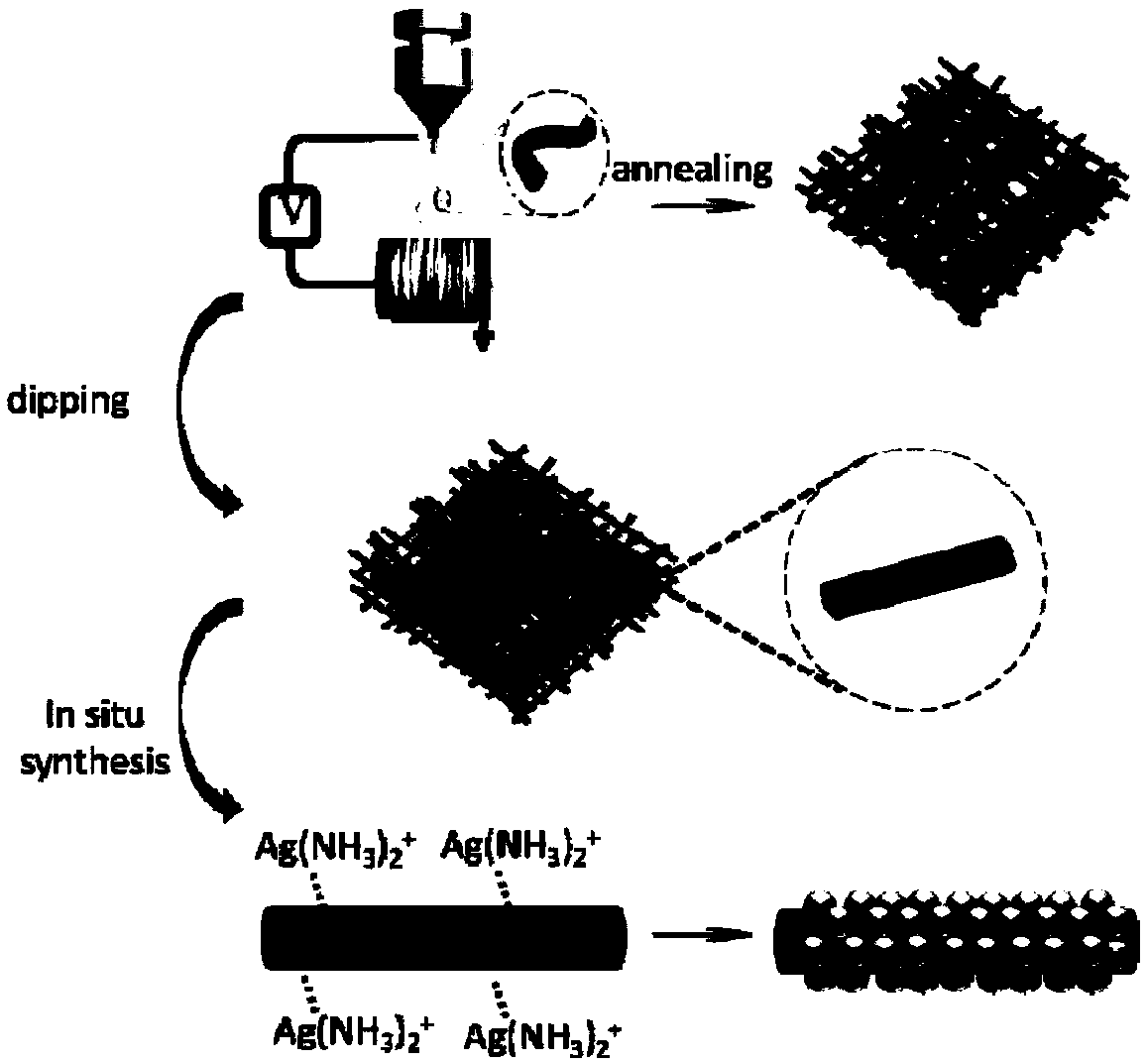

[0037] (1) Preparation of PEDOT:PSS-based nanofiber film: 1) Weigh 1g of PVA (polymerization degree: 2600 degree of alcoholysis: 97-98.8) and 18.05g of PEDOT:PSS solution and magnetically stir for 4h at 95°C , after cooling to room temperature, 0.95g DMSO was added for magnetic stirring for 2h, and finally 20g spinning solution was prepared. Wherein the mass ratio of PEDOT:PSS and DMSO is 95:5, and the PVA content in the spinning solution is 5wt%. The above PEDOT:PSS solution is an aqueous solution with a solid content of 1.3wt%, and the conductivity is 1S / cm.

[0038]2) Prepare the above-mentioned spinning solution by electrospinning into a PEDOT:PSS-based nanofiber film. The electrospinning conditions are as follows: the spinning voltage is 23kV, the spinning rate is 0.4mL / h, and the silicone oil-coated paper is used. The drum is received, the receiving distance is 90mm, and the drum speed is 100rpm.

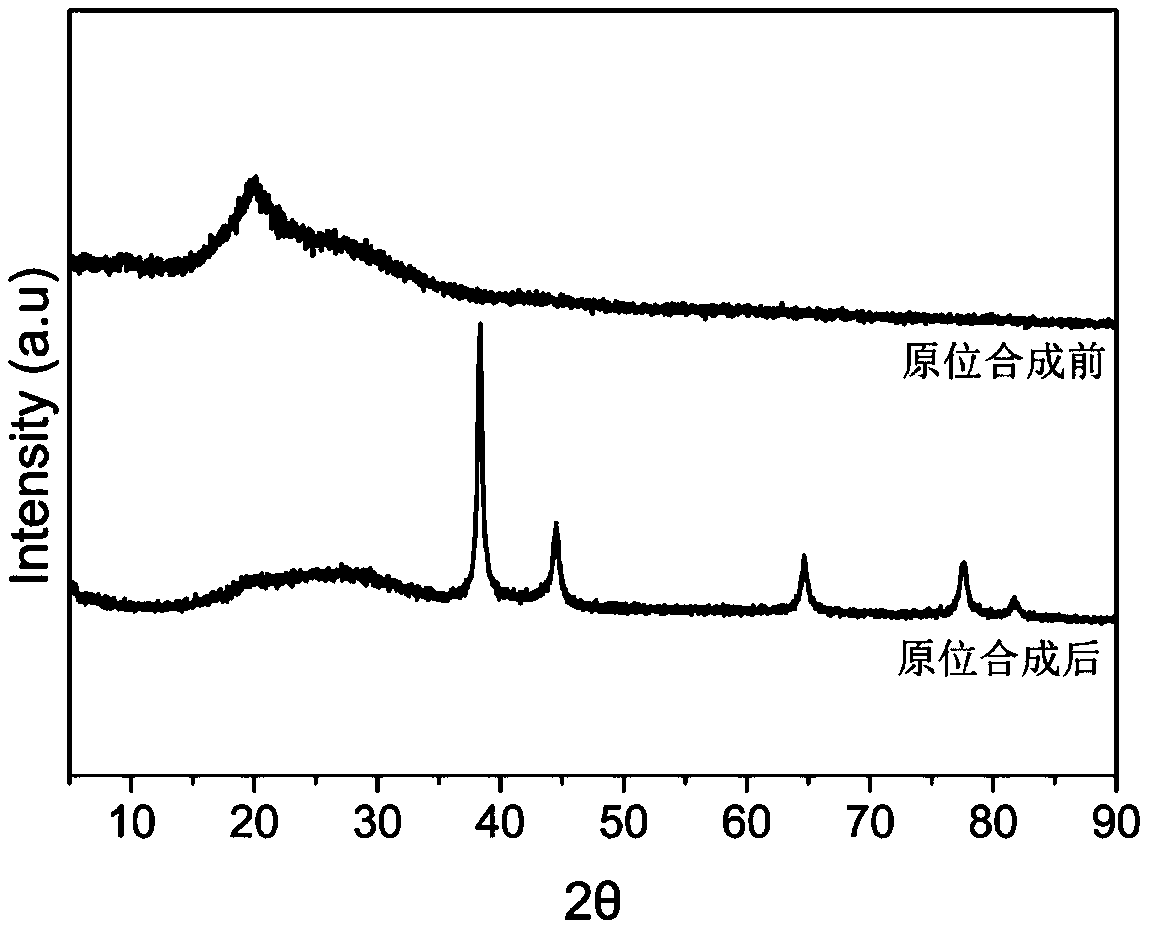

[0039] (2.) The nanofiber film obtained above was first annealed at 160...

Embodiment 2

[0043] (1) Preparation of PEDOT:PSS-based nanofiber film: 1) Weigh 1g of PVA (polymerization degree: 2600 degree of alcoholysis: 97-98.8) and 18.05g of PEDOT:PSS solution and magnetically stir for 4h at 95°C , after cooling to room temperature, 0.95g DMSO was added for magnetic stirring for 2h, and finally 20g spinning solution was prepared. Wherein the mass ratio of PEDOT:PSS and DMSO is 95:5, and the PVA content in the spinning solution is 5wt%. The above-mentioned PEDOT:PSS solution is an aqueous solution with a solid content of 1.3wt%, and the conductivity is 1S / cm.

[0044] 2) Prepare the above-mentioned spinning solution by electrospinning into a PEDOT:PSS-based nanofiber film. The electrospinning conditions are as follows: the spinning voltage is 23kV, the spinning rate is 0.4mL / h, and the silicone oil-coated paper is used. The drum is received, the receiving distance is 90mm, and the drum speed is 100rpm.

[0045] (2.) The nanofiber film obtained above was first anne...

Embodiment 3

[0049] (1) Preparation of PEDOT:PSS-based nanofiber film: 1) Weigh 1g of PVA (polymerization degree: 2600 degree of alcoholysis: 97-98.8) and 18.05g of PEDOT:PSS solution and magnetically stir for 4h at 95°C , after cooling to room temperature, 0.95g DMSO was added for magnetic stirring for 2h, and finally 20g spinning solution was prepared. Wherein the mass ratio of PEDOT:PSS and DMSO is 95:5, and the PVA content in the spinning solution is 5wt%. The above-mentioned PEDOT:PSS solution is an aqueous solution with a solid content of 1.3wt%, and the conductivity is 1S / cm.

[0050] 2) Prepare the above-mentioned spinning solution by electrospinning into a PEDOT:PSS-based nanofiber film. The electrospinning conditions are as follows: the spinning voltage is 23kV, the spinning rate is 0.4mL / h, and the silicone oil-coated paper is used. The drum is received, the receiving distance is 90mm, and the drum speed is 100rpm.

[0051] (2.) The nanofiber film obtained above was first anne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com