Method for preparing colored micro-surfacing based on resin modified emulsified asphalt

A technology for emulsified asphalt and modified asphalt, applied in the field of road engineering, can solve the problems of cost constraints on the popularization and application of color pavement, lack of theoretical and practical guidance, and no color micro-surface, and improve adhesion and color durability. , wide selectivity, beneficial to the effect of promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples further illustrate the beneficial effects of the present invention, but are not intended to limit the scope of the present invention.

[0020] Preparation of light color resin modified asphalt:

[0021] Extract oil 60%, rosin resin 30.5%, viscosity reducer 2.5%, SBS modifier 7%.

[0022] Heat the extracted oil to 130°C in the synthesis tank, keep it for 30min, then raise the heating temperature to 160°C, then add N2316 resin and keep stirring at a constant speed of 800r / min for 30min, raise the heating temperature to 170°C, and then Add 8017-type viscosity reducer and keep stirring for 15 minutes. Finally, add SBS modifier and keep stirring for 6 hours to obtain light-colored resin-modified asphalt. The performance is shown in Table 1.

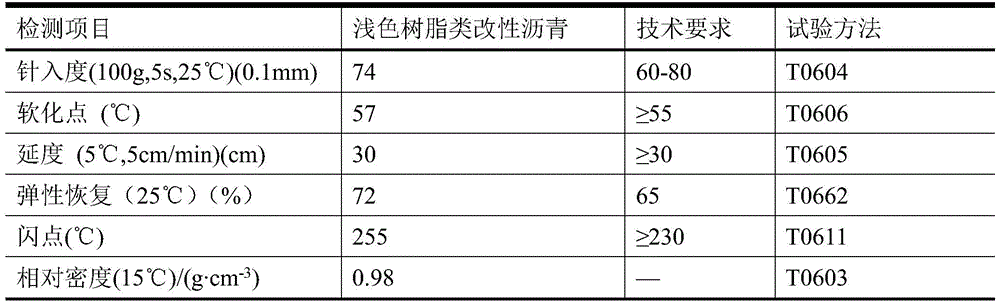

[0023] Table 1

[0024]

[0025] The light-colored resin-modified asphalt in the present invention has performance characteristics similar to ordinary petroleum asphalt, and its cohesiveness, elasticity and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com