Patents

Literature

30results about How to "Excellent toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method of vermicular cast iron piston ring

InactiveCN103451510AMeet performance needsHigh tensile strengthPiston ringsFoundry mouldsWear resistanceToughness

The invention discloses a manufacturing method of a vermicular cast iron piston ring. The material of the vermicular cast iron piston ring comprises the following chemical components in percentage by weight: 3.4-4.0% of C, 2.4-3.2% of Si, not more than 0.3% of Mn, 0.2-0.4% of Cr, 0.2-0.6% of Mo, 0.5-1.0% of Cu, 0.05-0.15% of Ti, not more than 0.1% of P, not more than 0.05% of S, 0.009-0.02% of Mg and the balance of Fe and inevitable impurities. The manufacturing method of the vermicular cast iron piston ring comprises the following technical steps of moulding, smelting, casting, shaking out, shot blasting, mechanical processing, surface treatment and the like. By adopting the manufacturing method disclosed by the invention, the thinning of the piston ring is achieved, the production process is relatively simple, and the manufactured vermicular cast iron piston ring is high in elasticity, strength, toughness and wear resistance.

Owner:SHIJIAZHUANG JINGANG KAIYUAN POWER SCI & TECH

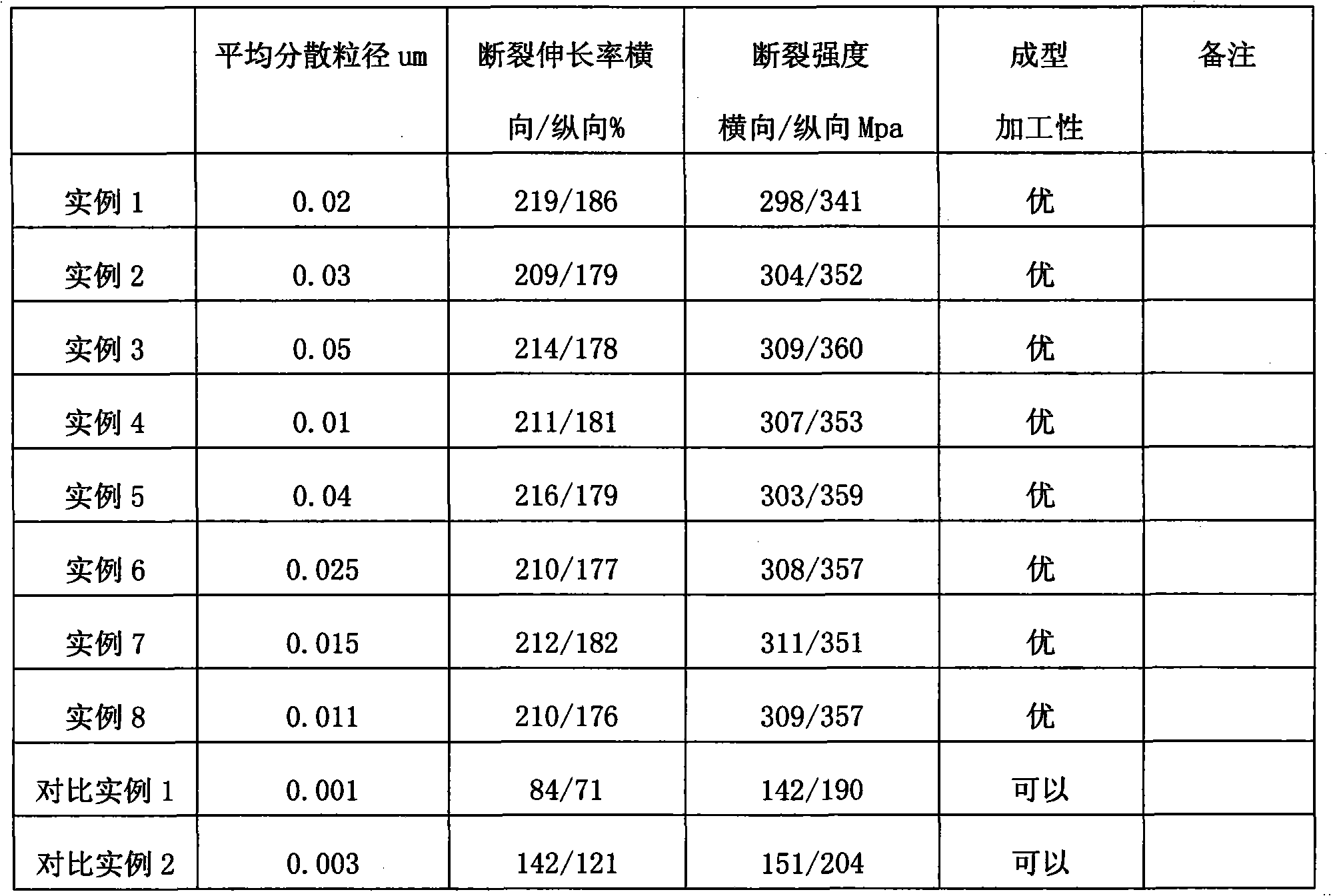

Polyphenylene sulfide compound film or fiber and manufacture method thereof

ActiveCN101921486AImprove structural strengthExcellent toughnessMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention relates to a polyphenylene sulfide compound film or fiber and a manufacture method thereof. The film or fiber comprises the following raw materials in percentage by weight: 60-90 percent of polyphenylene sulfide resin, 0-35 percent of polyphenylene sulfide resin containing aromatic heterocyclic rings, 0.5-0.7 percent of heat stabilizer, 0.4-0.8 percent of antioxidant, 3-5.8 percent of high polymer material, 0.2-0.6 percent of inorganic filler and 0.5-2.5 percent of organic filler. The manufacture method comprises the following steps of: pretreating the polyphenylene sulfide resin and the polyphenylene sulfide resin containing the aromatic heterocyclic rings, then adding the heat stabilizer and uniformly mixing for granulating and molding; drying obtained granules, adding the antioxidant, the high polymer material, the inorganic filler and the organic filler, and uniformly mixing; and finally, extruding the mixed material into films or fibers by using an extruder. The film or the fiber has the advantages of excellent insulating property and high self structural strength, and the toughness and the tensile breaking elongation of the film or the fiber are obviously superior to that of the film or the fiber manufactured in the prior art.

Owner:四川中科兴业高新材料有限公司

Bainite steel rail and preparation method thereof

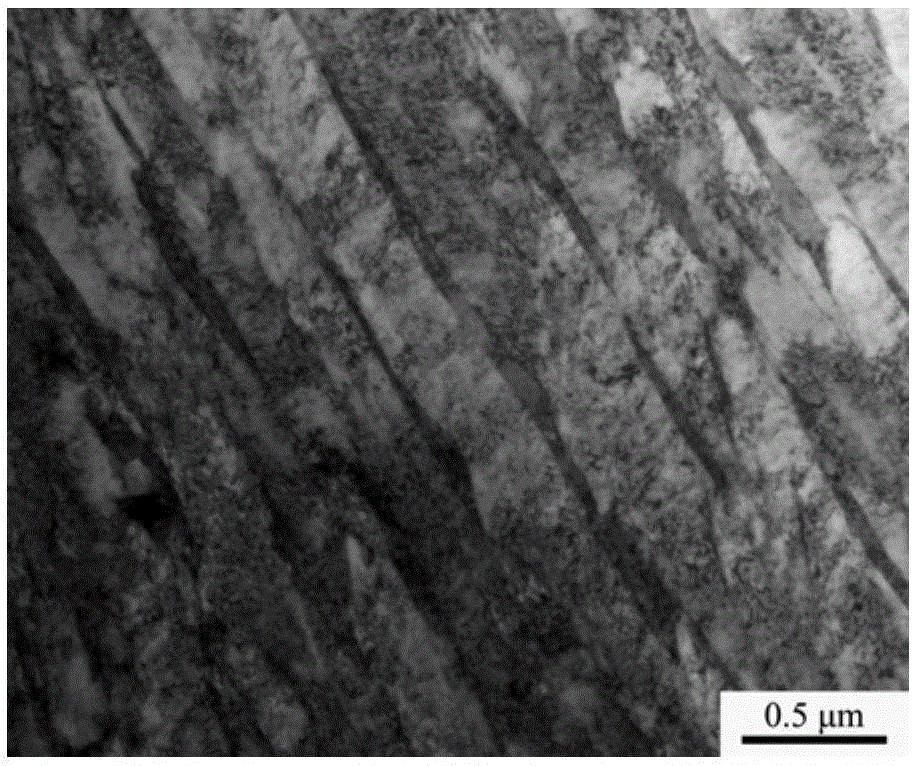

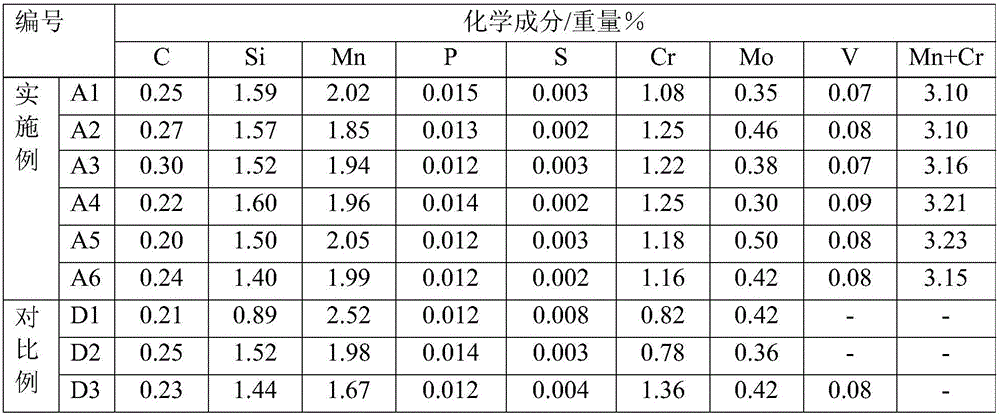

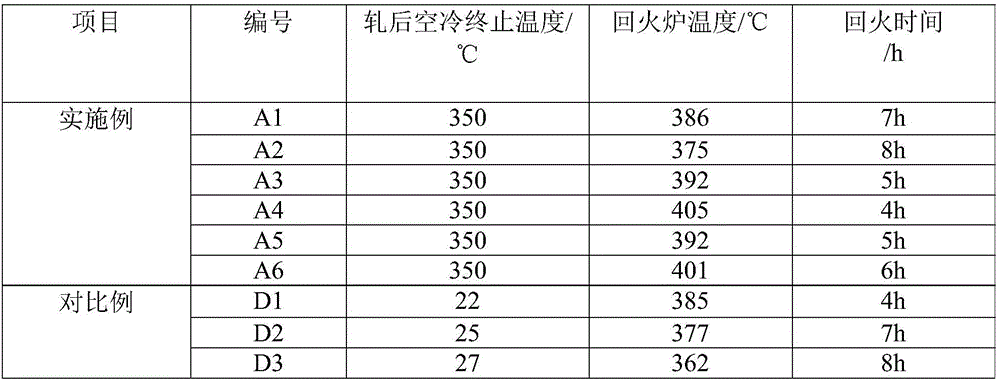

ActiveCN106435367AExcellent toughnessExcellent service safetyFurnace typesHeat treatment furnacesMetallurgyBainite

The invention relates to the field of steel rail materials and discloses a bainite steel rail and a preparation method thereof. On the basis of the weight of the bainite steel rail, the content of a bainite ferrite strip in a microscopic structure of a fillet part on a rail head of the bainite steel rail is more than or equal to 90wt% and the width of the bainite ferrite strip is 0.3-0.8 mu m; the content of a film-shaped retained austenite is less than or equal to 5wt% and the width of the film-shaped retained austenite is less than 0.1 mu m; the content of martensite is less than or equal to 5wt%; the chemical components of the billet steel of the acquired bainite steel rail meet the following conditions: on the basis of the weight of the bainite steel rail, the billet steel contains 0.20-0.30wt% of C, 1.40-1.60wt% of Si, 1.85-2.05wt% of Mn, 1.00-1.25wt% of Cr, 0.30-0.50wt% of Mo and 0.07-0.09wt% of V, wherein Mn+Cr is more than or equal to 3.1wt% but less than or equal to 3.3wt%. The bainite steel rail has excellent toughness performance and service safety.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Aluminum-steel composite plate and compositing process thereof

InactiveCN109248916AGuaranteed composite qualityGuaranteed Compounding EfficiencyMetal rolling arrangementsSheet steelComposite plate

The invention discloses an aluminum-steel composite plate. An aluminum alloy plate is combined to the upper surface of a steel plate base; another aluminum alloy plate is combined to the lower surfaceof the steel plate base. The invention also discloses a compositing process of the aluminum-steel composite plate. The compositing process includes the steps of heating a low-carbon steel plate and an aluminum alloy plate at 300-450 DEG C for 3-6 min, stacking the heated low-carbon steel plate and aluminum alloy plate according to an actually required shape, placing the stack on a horizontal bench top, placing a press roller on the upper surface of the stack, heating the aluminum-steel composite plate blank again at 200-300 DEG C, and performing trimming reshaping and surface treatment on thealuminum-steel composite plate blank. The plate layers herein can be softened and melted into a composite whole; the finished product is better than existing single-layer plates or composite plates made of other materials, in product strength, toughness and service life.

Owner:OKUMTEC TECH WENZHOU CO LTD

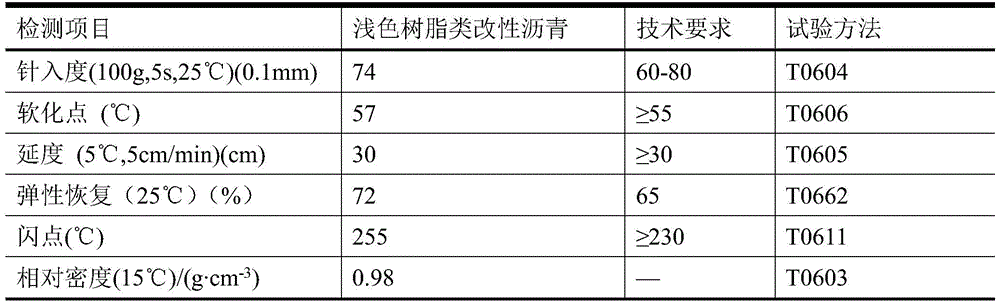

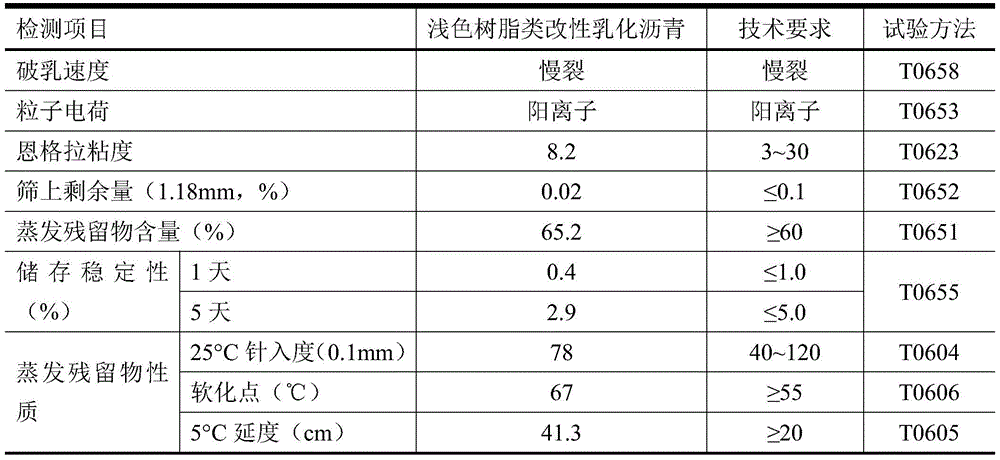

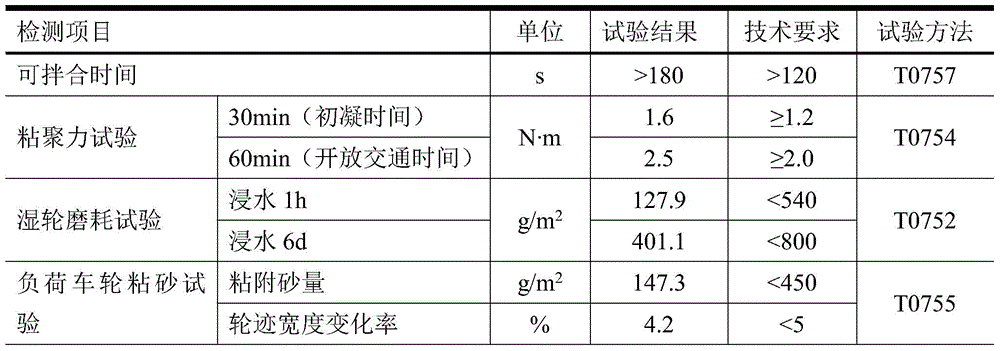

Method for preparing colored micro-surfacing based on resin modified emulsified asphalt

The invention discloses a method for preparing colored micro-surfacing based on resin modified emulsified asphalt. The method comprises the steps: synthesizing light-colored resin modified asphalt: sequentially adding the raw materials in percentage by mass under the condition of heating: 55% to 60% of extract oil, 30.5% to 32.5% of rosin resin, 2% to 4% of viscosity reducer and 7% to 9% of SBS block copolymer, and carrying out uniform mixing; synthesizing light-colored resin modified emulsified asphalt: adding dodectoluenesulfonic acid into the light-colored resin modified asphalt at the temperature of 165 DEG C to 175 DEG C, and carrying out mixing; then, adding an emulsifier aqueous solution into the mixture, carrying out mixed-melted shearing, and carrying out cooling, so as to obtain the light-colored resin modified emulsified asphalt; and enabling the light-colored resin modified emulsified asphalt to be matched with colored mineral aggregates, thereby preparing the colored micro-surfacing based on the resin modified emulsified asphalt. According to the method, the resin modified emulsified asphalt can be used for remarkably improving the adhesivity and color durability of a colored micro-surfacing mixture, the colored micro-surfacing has good pavement performance and wear resistance, the production cost of the raw materials is greatly reduced, and the cost is reduced by 20% or more.

Owner:WUHAN UNIV OF TECH

Production process of thermoplastic elastomer rail pad

ActiveCN103753754AAmazing resilienceExcellent toughnessCoatingsThermoplastic elastomerProduction drawing

The invention provides a production process of a thermoplastic elastomer rail pad, and belongs to the technical field of railway fittings. The production process comprises the following steps: (1) drying raw materials, namely, adding rubber to a dryer to dry for at least two hours under drying temperature of 110 to 130 DEG C; (2) injection molding, namely, performing injection molding through an injection molding machine, adding the dried raw material to a material barrel of the injection molding machine for heating, and then closing a die, injecting, maintaining the pressure, cooling, and opening the die to finish injection molding; (3) cutting nozzles, namely, moving the product subjected to injection molding from a die cavity, and removing burr through a nozzle cutting machine so as to meet the requirements of a production drawing and product technology; and (4) examining and testing, namely, warehousing qualified thermoplastic elastomer rail pads. With the adoption of the production process, the produced thermoplastic elastomer rail pad is stable in structure, small in plastic change, and small in elastic deformation under heavy load, reaches 300 to 500kN / mm of static stiffness, has service life longer than that of a steel rail, realizes stable line and driving safety, and also enables the reduction of the cost of repair and maintenance.

Owner:浙江中元铁路配件有限公司

High-strength and high-toughness silicon carbide ceramic bearing plate, manufacturing method and application thereof

The invention discloses a high-strength and high-toughness silicon carbide ceramic bearing plate, a manufacturing method and application thereof. The silicon carbide ceramic bearing plate is preparedfrom the following materials in parts by mass: 70-95 parts of silicon carbide, 2-10 parts of silicon carbide whiskers, 1 to 15 parts of tungsten carbide, 0.5 to 5 parts of boron carbide, 1 to 10 partsof a binder and 0.5 to 10 parts of a lubricant. The manufacturing method comprises burdening, mixing, pulping, spray drying, isostatic pressing, sintering and finish machining. The silicon carbide ceramic bearing plate is applied to the assembly of chemical-mechanical polishing devices. According to the silicon carbide ceramic bearing plate made by the manufacturing method, the strength and toughness are greatly superior to a common corundum ceramic bearing plate at present; a ceramic bearing plate with the same size can be reduced by 1 / 3 in thickness; the ceramic bearing plate is applied tothe chemical-mechanical polishing devices, the stability in the polishing process is greatly improved, the reliability in the operation process is greatly increased, the service life of the ceramic bearing plate is greatly prolonged, and the process manufacturing cost is reduced.

Owner:NANTONG SANZER PRECISION CERAMICS CO LTD

Polyurethane acrylate prepolymer and preparation method thereof as well as paint prepared by same

ActiveCN103030768AExcellent toughnessExcellent cure ratePolyurea/polyurethane coatingsPrepolymerHydroquinone Compound

The invention discloses a polyurethane acrylate prepolymer and a preparation method thereof, as well as paint prepared by the polyurethane acrylate prepolymer. The prepolymer comprises the following components in part by mass: 900-1100 parts of hexamethylene diisocyanate, 2-5 parts of dibutyl tin laurate, 400-600 parts of polyethylene glycol, 1-3 parts of hydroquinone and 1000-1300 parts of hydroxyethyl acrylate. According to the invention, the paint prepared by the polyurethane acrylate prepolymer is high in curing rate, can effectively improve gloss, flexibility and adhesion level of floorboards, and is excellent in use effect.

Owner:JIUSHENG WOOD

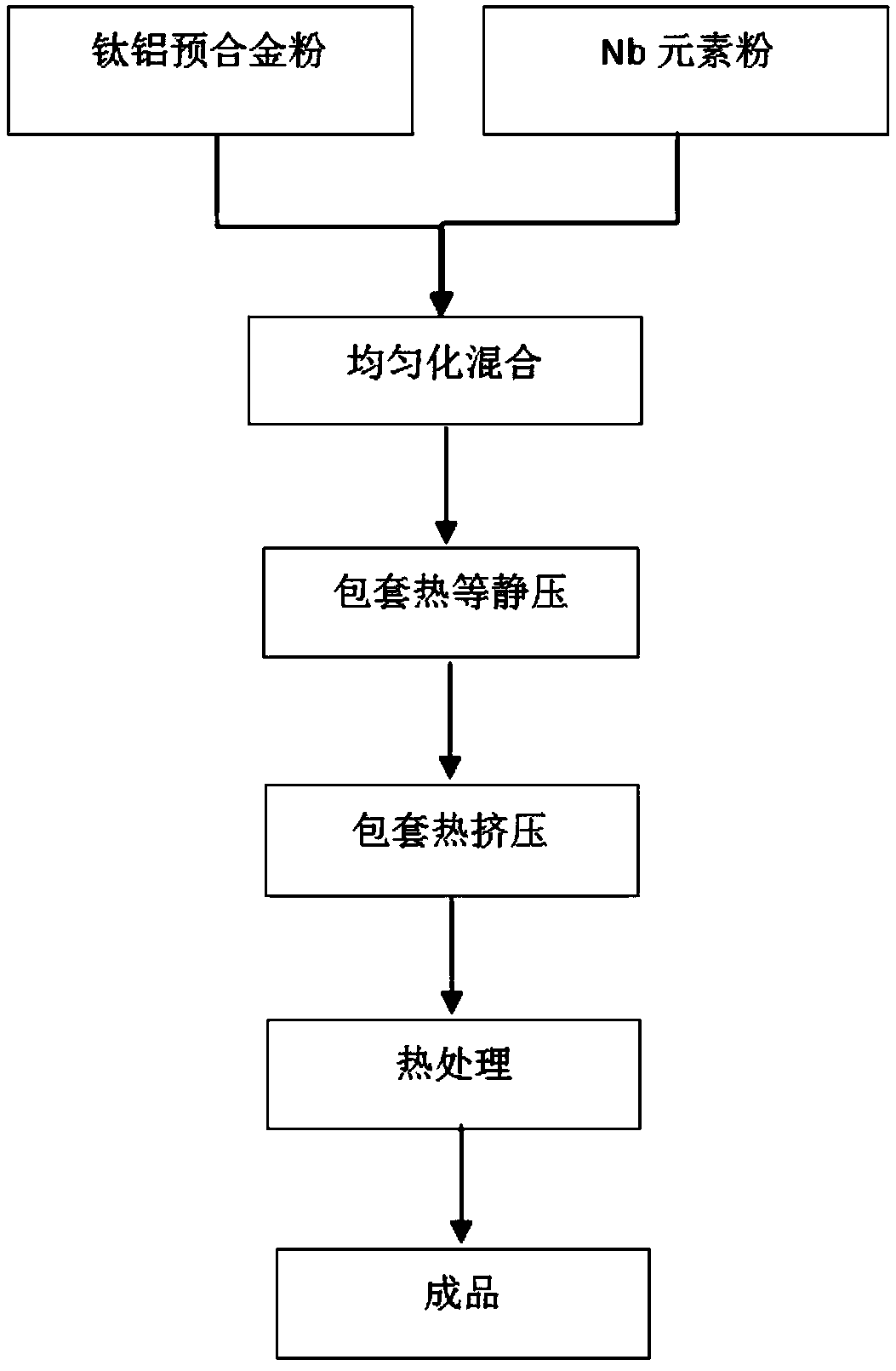

Preparation method of Nb roughening titanium aluminum base alloy composite material

The invention discloses a preparation method of a Nb roughening titanium aluminum base alloy composite material. The preparation method comprises the following steps: (1) titanium aluminum prealloyingpowder and Nb powder are uniformly mixed to form mixed powder, wherein the titanium aluminum prealloying powder comprises Ti, Al, Nb and W; (2) hot isostatic pressing is performed on the mixed powderobtained in the step (1) in vacuum to obtain a hot isostatic pressing blank; (3) high-temperature hot extrusion is performed on the hot isostatic pressing blank prepared in the step (2); and a rod blank is prepared after air cooling; and (4) the rod blank prepared in the step (3) is heated, and is cooled along with a furnace to obtain the Nb roughening titanium aluminum base alloy composite material. The preparation method is simple in process step, shorter in production period, simple and easy-obtained in raw material and low in cost; and prepared products are excellent in performance.

Owner:CENT SOUTH UNIV

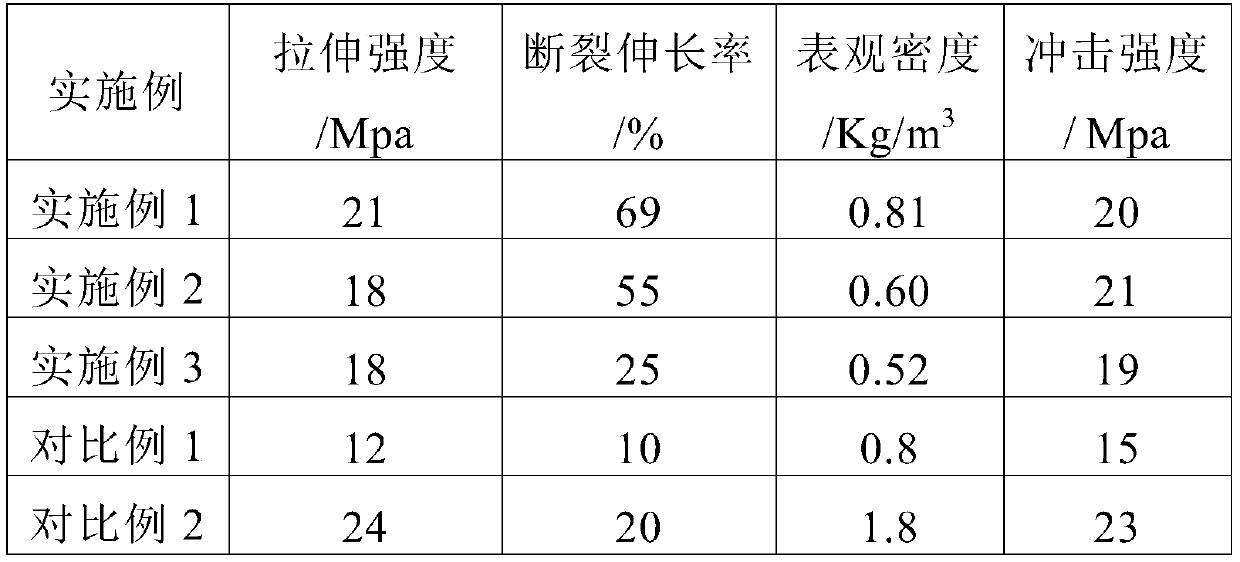

Micro-foaming full-biodegrade polymer sheet material and preparation method thereof

The invention provides a micro-foaming full-biodegrade polymer sheet material and a preparation method thereof. The micro-foaming full-biodegrade polymer sheet material comprises, by mass, 100 parts of a full-biodegrade polymer, 3-12 parts of microsphere foaming agent master batches, 10-50 parts of a biology-based filler and 3-8 parts of glycerinum. The microsphere foaming agent master batches areprepared from, by mass, 100 parts of a polymer capable of being processed through fusion at a low temperature, 50-100 parts of a microsphere foaming agent and 5-10 parts of a compatilizer. The full-biodegrade sheet material with good mechanical properties such as a high foaming rate, low destiny, good toughness and high impact resistance can be obtained and applied to manufacturing of fast-movingconsumer goods such as food containers and has high application value and good application prospects.

Owner:江西玉源环保科技有限公司

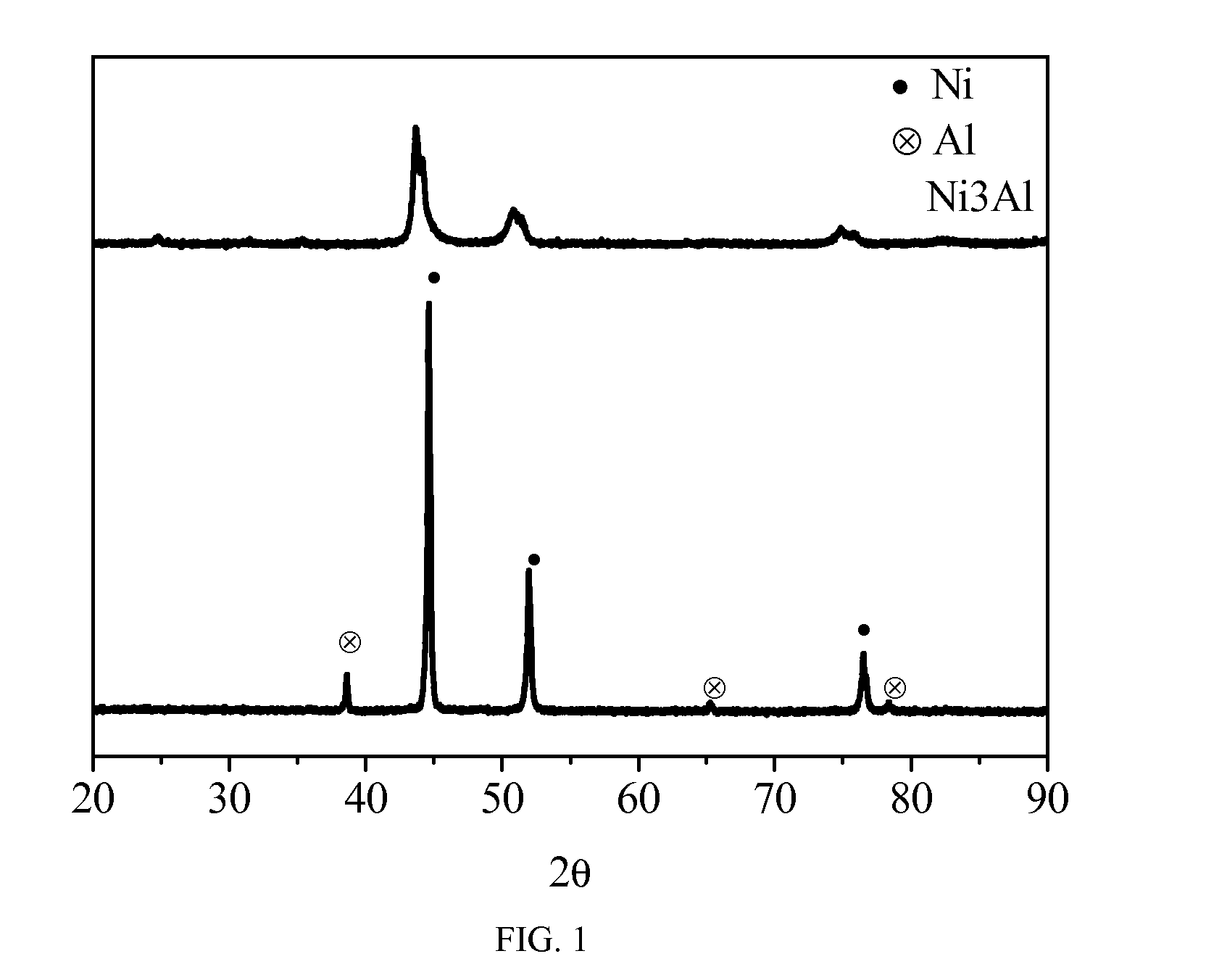

Ti(C,N)-BASED CERMET WITH Ni3Al AND Ni AS BINDER AND PREPARATION METHOD THEREOF

Provided are Ti(C,N)-based cermets with Ni3Al and Ni as binder and a preparation method thereof. The Ti(C,N)-based cermets are prepared by raw materials subjected to ball-mill mixing, die forming, vacuum degreasing and vacuum sintering, wherein weight percentage of each chemical component of the raw materials is as follows: TiC 34.2˜43%, TiN 8˜15%, Mo 10˜15%, WC 5˜10%, graphite 0.8˜1.0%, Ni 20˜24%, and Ni3Al powder containing B 6˜10%. Ni powder and Ni3Al powder containing B are used as binder. The Ti(C,N)-based cermets feature in excellent corrosion resistance, oxidation resistance and mechanical properties at high temperature, has a hardness of 89.0˜91.9 HRA, a room temperature bending strength of 1600 MPa or more, and a fracture toughness of 14 MPa·m1 / 2 or more, and is applicable for manufacturing high-speed cutting tools, dies and heat-resisting and corrosion-resisting components.

Owner:HUAZHONG UNIV OF SCI & TECH

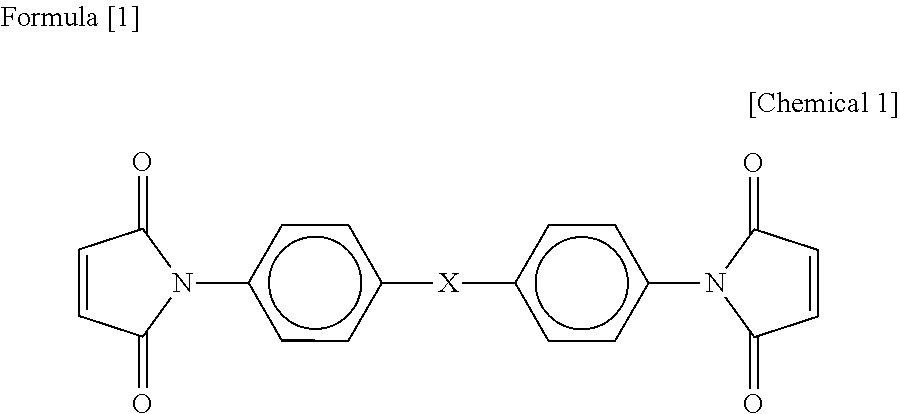

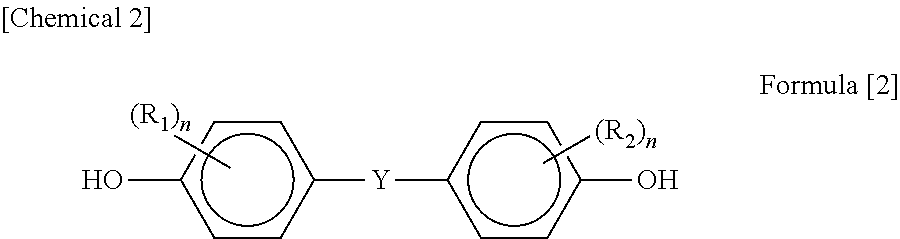

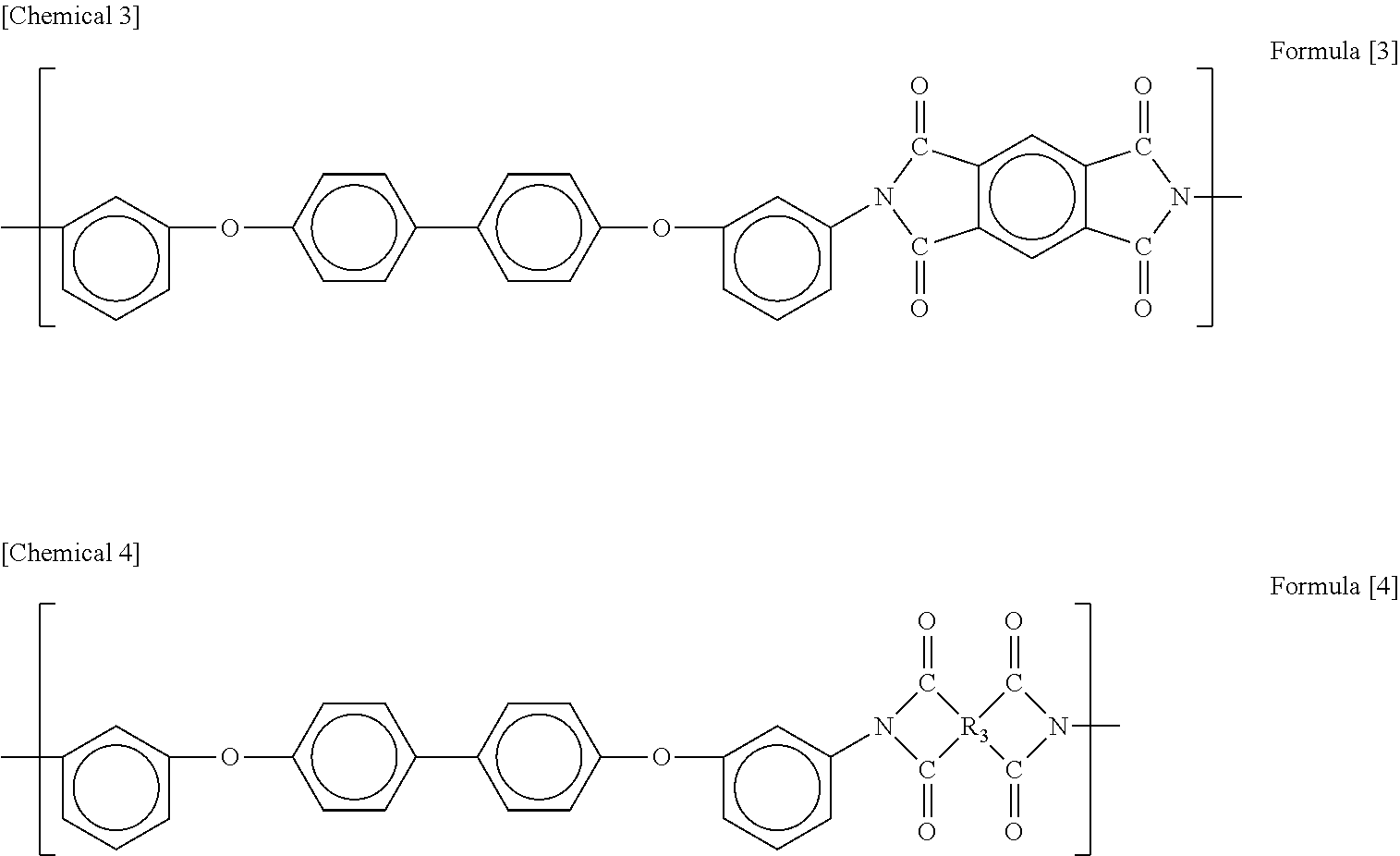

Fiber-reinforced prepreg and composite material obtained therefrom

InactiveUS20110130059A1Excellent toughnessExcellent thermal and mechanical characteristicSynthetic resin layered productsWoven fabricsChemistryPolyimide

There are provided a prepreg obtained by impregnating into a fiber reinforcement a resin composition including 40 to 70 parts by weight of an aromatic bismaleimide (A) expressed by a specific general formula, 60 to 30 parts by weight of an alkenylphenol (B) expressed by a specific general formula, 1 to 10% by weight of a polyetherimide (C) of a thermoplastic resin base on the total amount of components (A) and (B), and 15 to 50% by weight of an amorphous polyimide (D) having a glass transition temperature of 200° C. or higher, and a composite material obtained by heating and curing the prepreg. Also provided are the fiber-reinforced prepreg and the composite material without spoiling thermal resistance characteristic of the aromatic bismaleimide resin used as a main component of a resin and having excellent toughness imparted thereto.

Owner:TOHO TAYON CO LTD

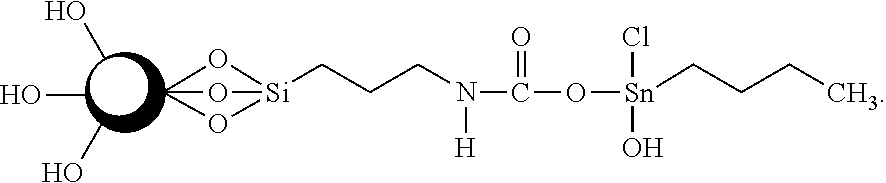

Poly (cyclic butylene terephthalate) / silicon dioxide nanocomposite

ActiveUS9631069B1Excellent dispersibilityExcellent toughnessOrganic-compounds/hydrides/coordination-complexes catalystsMetal/metal-oxides/metal-hydroxide catalystsNanometrePolymer composites

The present invention relates to the technical field of polymer composites, in particular to a poly (cyclic butylene terephthalate) / silicon dioxide nanocomposite, wherein the added silicon dioxide is catalyst-modified nanosilicon dioxide.

Owner:ZHEJIANG SCI-TECH UNIV

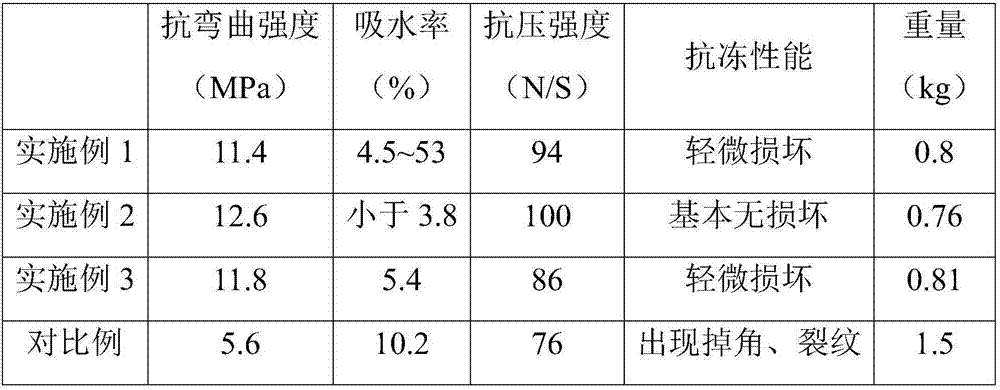

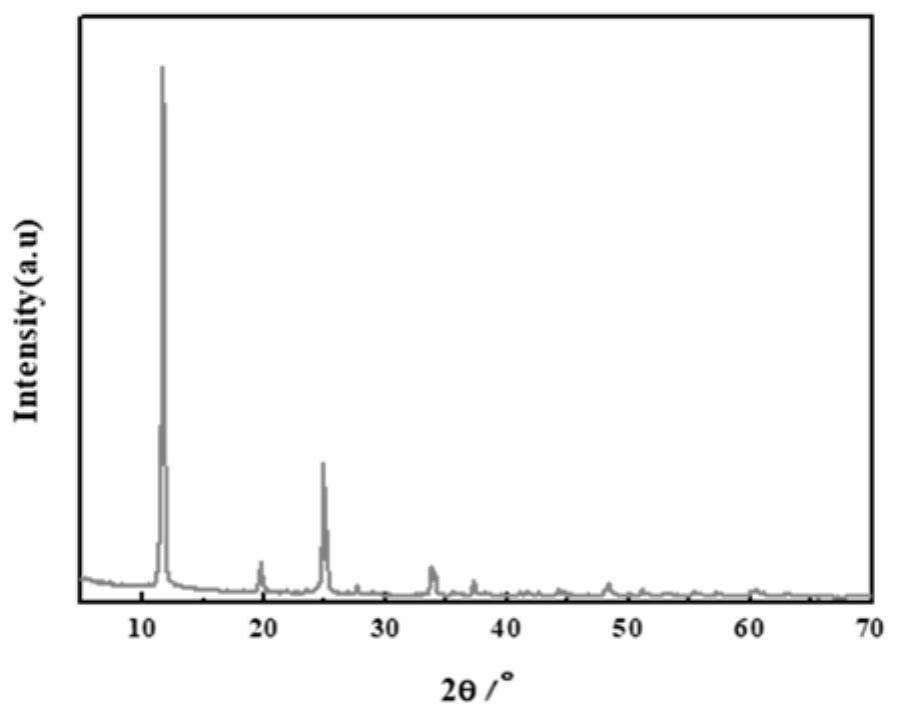

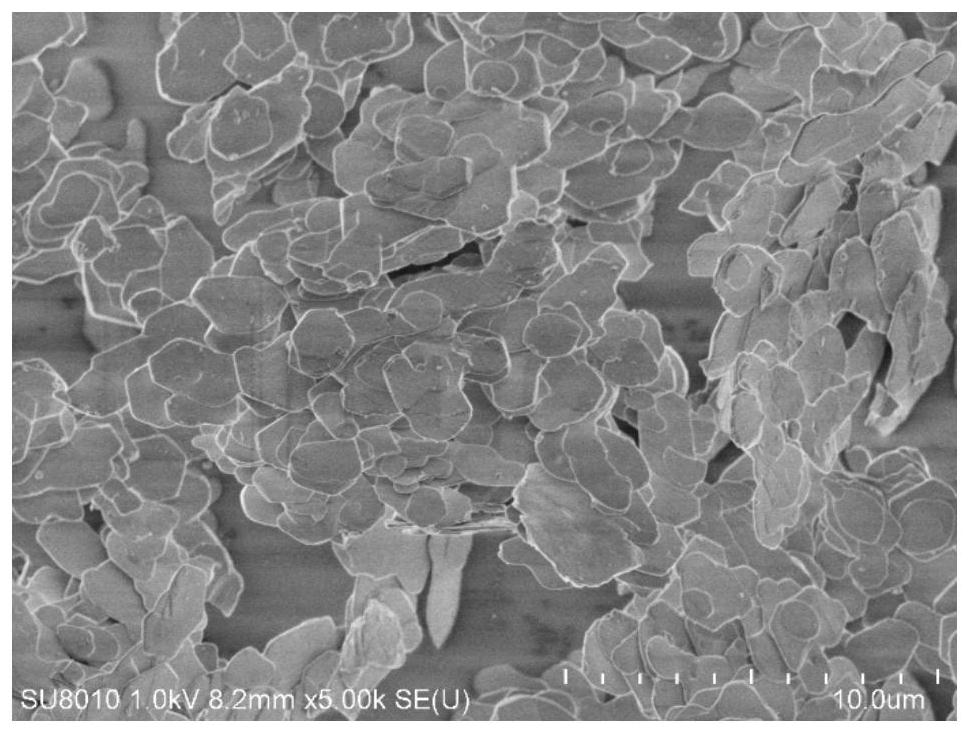

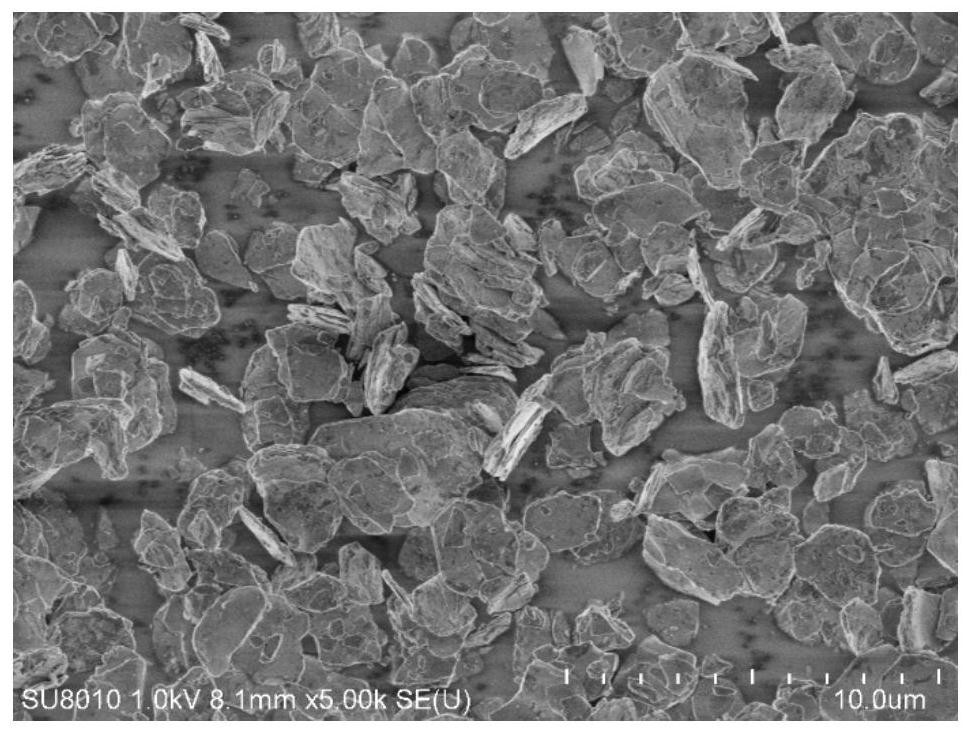

Unfired clay tile and production technology thereof

The invention discloses an unfired clay tile and a production technology thereof. The clay tile comprises, by weight, 10-15 parts of natural colored sands, 10-15 parts of natural colored quartz sands, 3-5 parts of polyester resin, 2-5 parts of a shrinkage agent, 5-8 parts of alkali-free glass fibers, 0.5-1 part of zinc stearate, 1-2 parts of a skeleton reinforced material, 2-5 parts of light magnesium oxide and 0.02-0.05 part of an antioxidant. The production technology comprises the following steps: (1) mixing the polyester resin, polystyrene resin and zinc stearate according to the above formula, stirring the mixed raw materials, adding the natural colored sands, continuous stirring the mixed raw materials and the natural colored sands, adding the alkali-free glass fibers, the light magnesium oxide, the antioxidant and the natural colored quartz sands, and stirring all above raw materials; and (2 ) placing a product obtained in step (1) in a molding chamber, adding the skeleton reinforced material, and molding the product and the skeleton reinforced material to obtain the unfired clay tile. The unfired clay tile produced through the method has the advantages of high strength, high flexural and compressive strength, good toughness and light weight and is suitable for various roofings.

Owner:四川尚典建材有限公司

Halogen-free flame-retardant scratch-resistant antibacterial polypropylene material as well as preparation method and application thereof

The invention discloses a halogen-free flame-retardant scratch-resistant antibacterial polypropylene material as well as a preparation method and application thereof. The halogen-free flame-retardantscratch-resistant antibacterial polypropylene material is prepared from the following raw materials in parts by weight: 76-89 parts of polypropylene; 4-10 parts of an intumescent flame retardant; 2-12parts of silver ammonium phosphomolybdate intercalation modified zirconium phosphonate; 1-5 parts of ceramic fiber powder; 0.5-4 parts of silicone master batch; 0.3-1 part of an antioxidant; and 0.2-1 part of white oil. The silver ammonium phosphomolybdate intercalation modified zirconium phosphonate, the ceramic fiber powder and the silicone master batch are added at the same time, so that the compatibility with polypropylene can be greatly improved, the flame retardant property of the material is improved, the addition amount of a flame retardant is greatly reduced, the scratch resistance of the material can be improved, the material has excellent antibacterial property, and the material has excellent comprehensive performance when applied to the field of intelligent toilet lids.

Owner:WANHUA CHEM GRP CO LTD +1

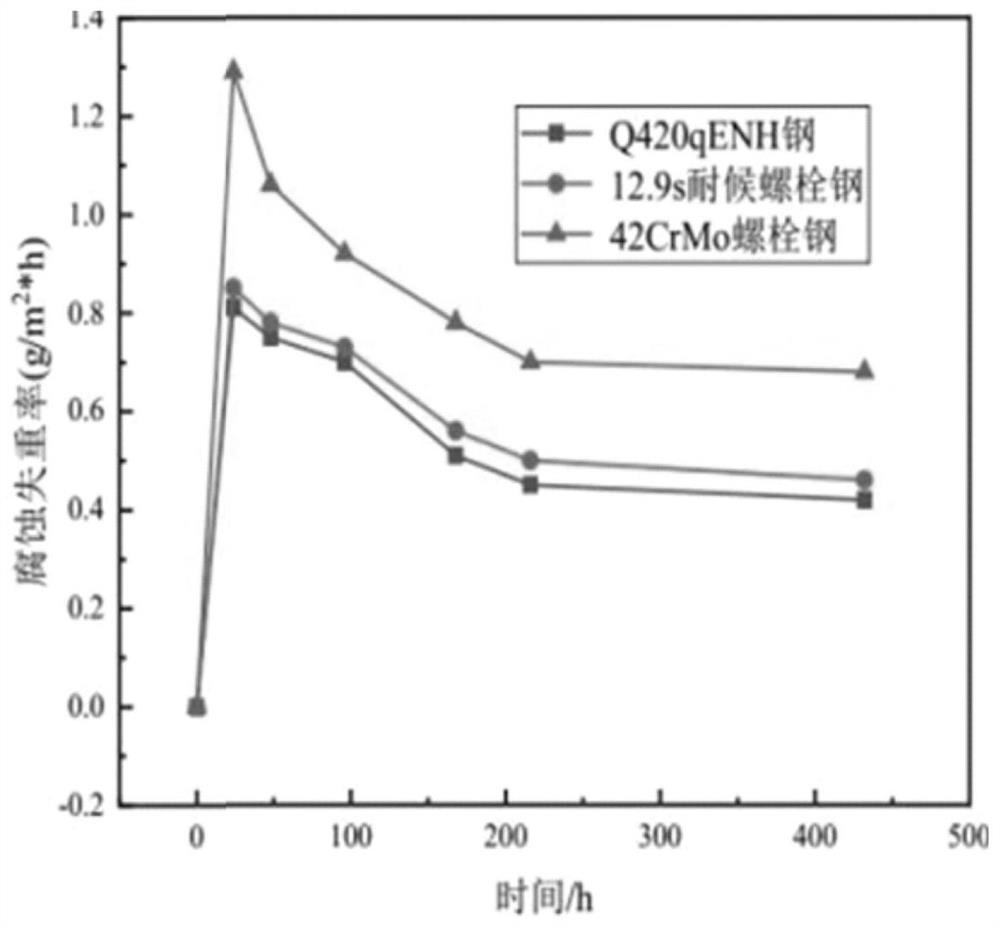

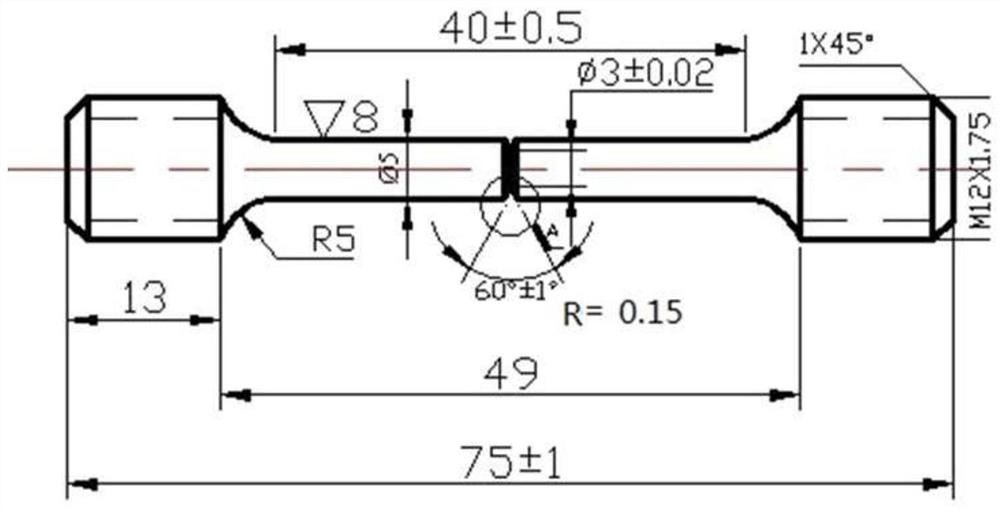

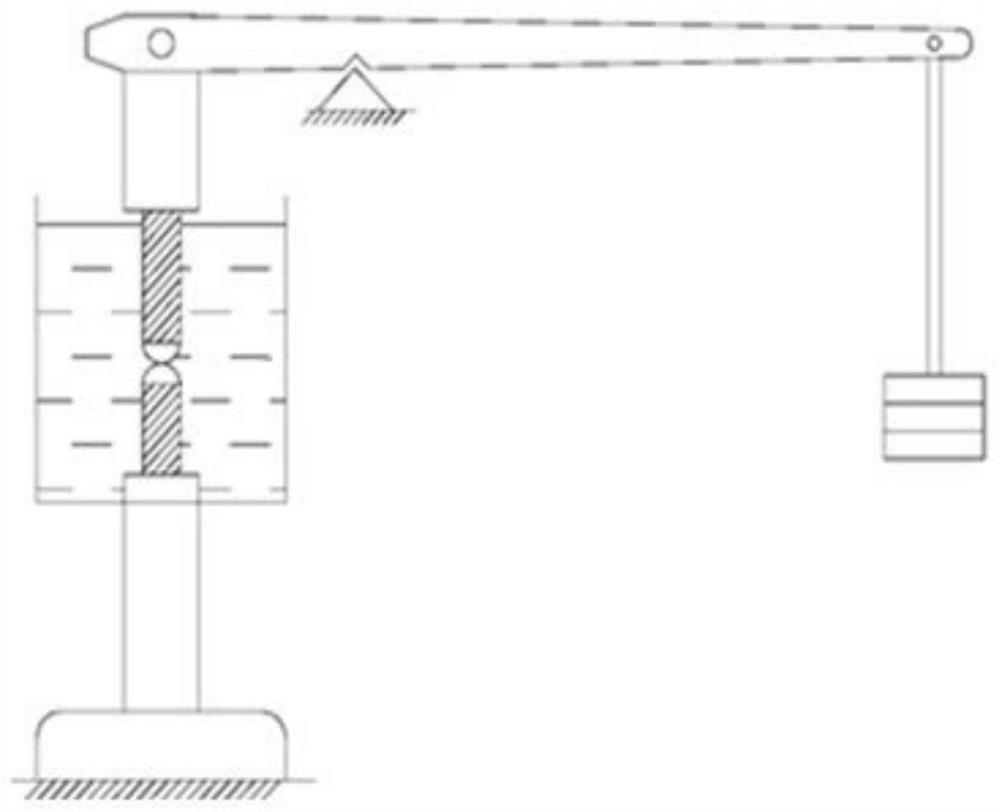

12.9-grade delayed-fracture-resistant weather-proof bolting steel and production method

InactiveCN112695241AExcellent toughnessGood low temperature resistanceFurnace typesHeat treatment furnacesAtmospheric corrosionDelayed fracture

The invention discloses 12.9-grade delayed-fracture-resistant weather-proof bolting steel and a production method. The steel comprises the following components according to the mass percentages: 0.35-0.45% of C, 0.10-0.40% of Si, 0.50-0.90% of Mn, less than or equal to 0.012% of P, less than or equal to 0.005% of S, 0.80-1.20% of Cr, 0.20-0.50% of Cu, 0.80-1.20% of Ni, 0.10-0.50% of V, Nb and Ti, 0.10-0.50% of Mo, 0.015-0.045% of Alt and the balance Fe and inevitable impurities. By designing the components and production technology parameters, the strength of the steel reaches a 12.9 grade, and meanwhile, the steel has excellent atmospheric corrosion resistance performance and delayed fracture resistance performance.

Owner:NANJING IRON & STEEL CO LTD

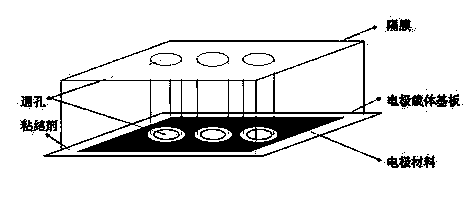

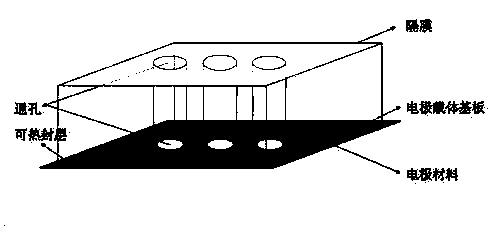

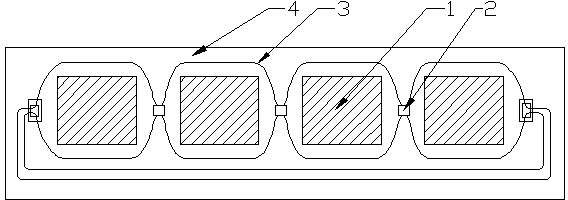

Thin film battery and preparation method thereof

ActiveCN110061281AThe overall thickness is thinExcellent toughnessFinal product manufactureSmall-sized flat cells/batteriesMarket needsEngineering

The invention provides a thin film battery and a preparation method thereof. The thin film battery prepared by the invention can be manufactured into various shapes and can be flexibly applied to various wearable devices to well satisfy such market need that the battery needs to be adapted in many forms, for example, some through holes (such as the through holes of the strap) may be needed. At thesame time, the thin film battery prepared by the invention can realize a thinner thickness, and superior mechanical flexibility as well as electrochemical performance of the thin film battery. The experimental results show that the thin film battery obtained by the invention can achieve a thinner thickness, such as 0.2mm to 0.9mm. In some embodiments of the invention, the thin film battery has athickness of 0.56mm or 0.73mm. In the condition of a bending radius of 3cm and a bending angle of 15 degrees of the thin film battery, the resistance reaches 110% to 120% of the original resistance and the capacity retention ratio exceeds 80% after bending for 3000 times.

Owner:ZINERGY SHENZHEN LTD

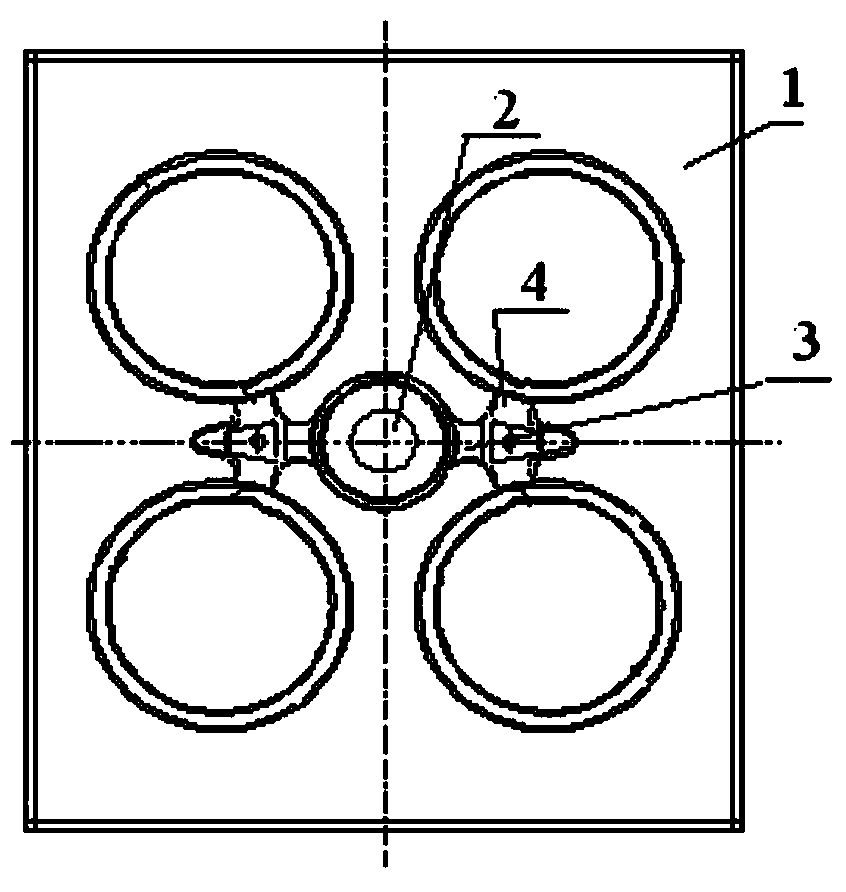

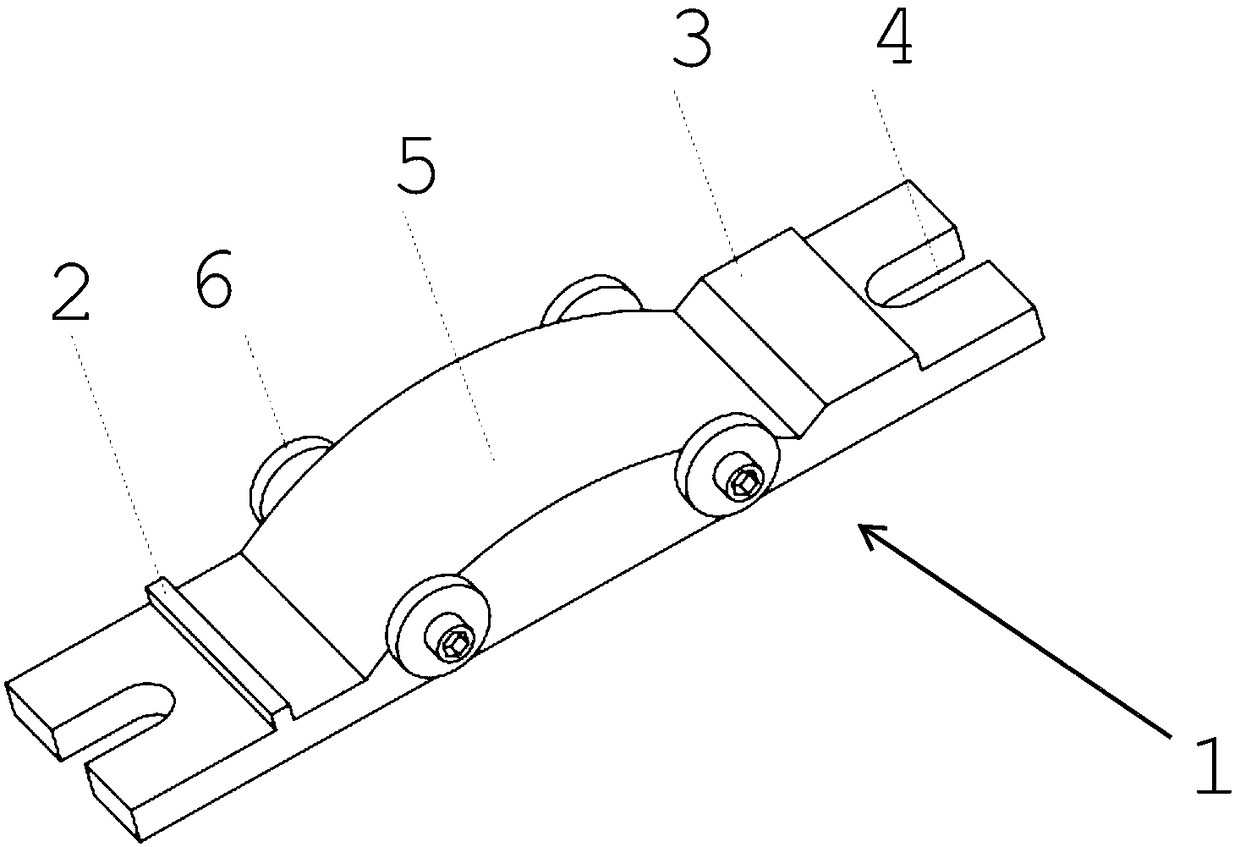

Rotary forging die clamp and surface processing method thereof

InactiveCN109226630AImprove clamping stabilityFit tightlyMolten spray coatingFurnace typesEngineeringMachining process

The invention relates to the field of forging die clamps, in particular to a rotary forging die clamp for clamping roller forging dies or other untraditional upright dies, and a surface processing method of the rotary forging die clamp. The problems that an existing clamp cannot effectively and stably clamp the untraditional upright dies, fixing and clamping are difficult, production efficiency isreduced, the dies bear uneven force, workpieces easily shake in the production and machining process, the machining dies deviate from the original requirements, the halving and leveling process is quite complicated for operators, and the quality cannot be ensured are solved. By means of the technical scheme, the rotary forging die clamp comprises a body and fixed clamping grooves. The fixed clamping grooves are formed in the two ends of the body in the length direction. An arch base is arranged on one bottom face of the body and provided with a curved surface. The curved surface is bent in the length direction of the body. At least two fastening devices are symmetrically arranged on the arch base. A positioning inclined surface is arranged at the end, extending in the length direction ofthe body, of the arch base, and a positioning block is oppositely arranged at the other end of the arch base.

Owner:ZHEJIANG YUEJIN MACHINERY

Novel high-tenacity PVC (Poly Vinyl Chloride) pipe formula

The invention discloses a novel high-tenacity PVC (Poly Vinyl Chloride) pipe formula which is composed of the following components in parts by weight: 40-60 parts of PVC resin, 5-15 parts of engineering plastics, 1-2 parts of soybean oil, 3-5 parts of rubber powder, 3-4 parts of stabilizer, 2-3 parts of titanium dioxide, 10-20 parts of light calcium carbonate, 1-5 parts of fire retardant and 1-2 parts of paraffin. The novel high-tenacity PVC pipe formula provided by the invention has the advantages of good flexibility, environmental friendliness, high strength, good fire retarding effect, good compression performance and tenacity, good processability and excellent overall performance.

Owner:QINGDAO SANLI XINYUAN ELECTRICAL APPLIANCES

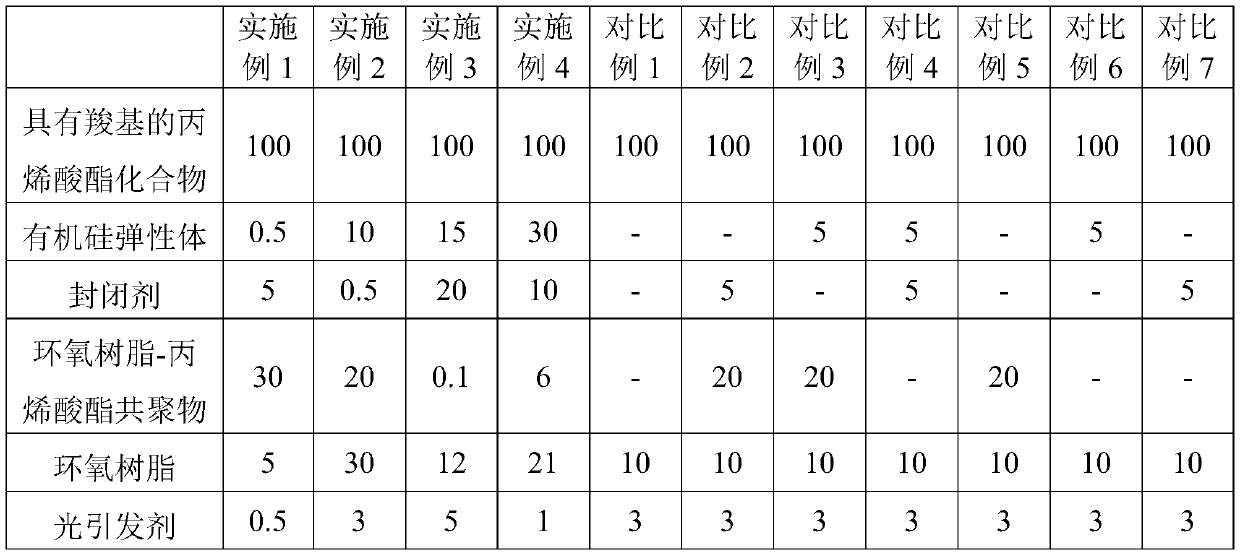

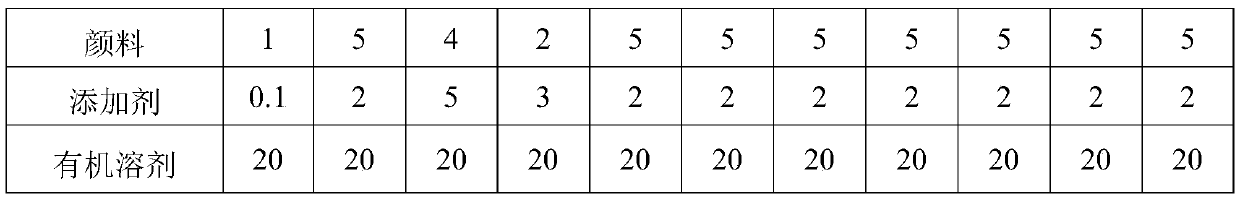

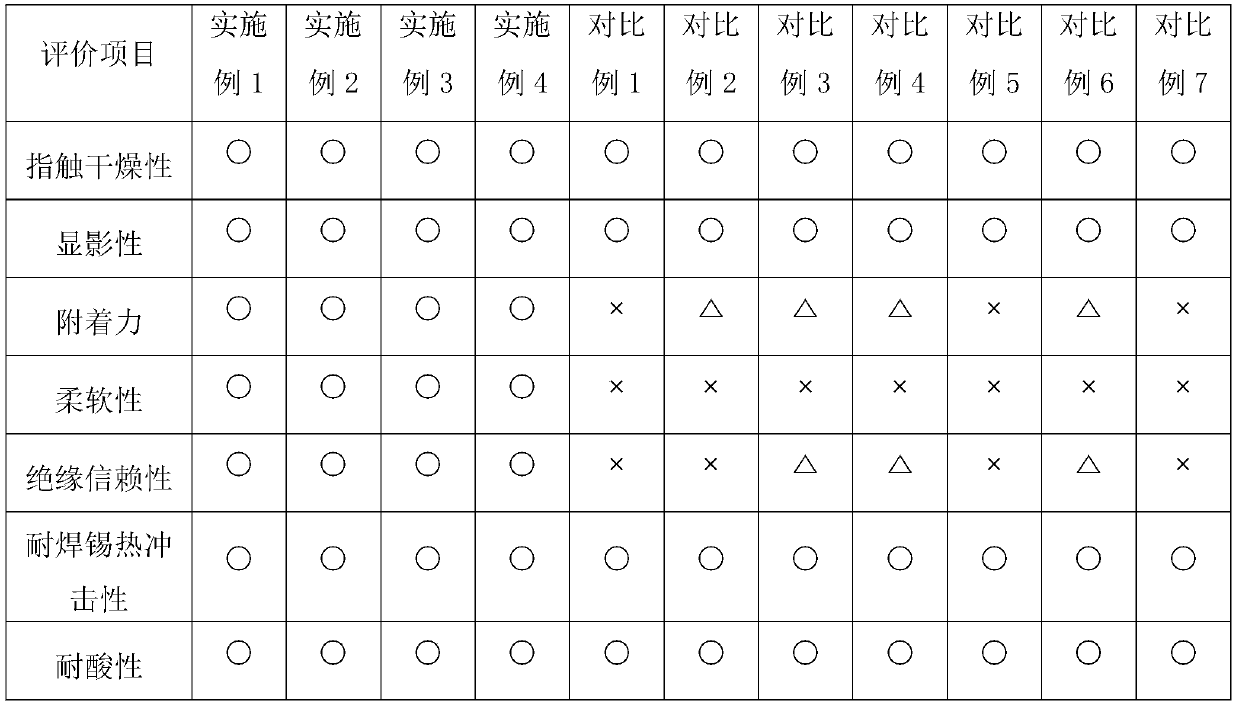

Photothermal dual-curing solder resist ink with high adhesion and use method thereof

InactiveCN109868005AStrong adhesionExcellent toughnessInksPhotosensitive materials for photomechanical apparatusResistChemistry

The invention belongs to the technical field of ink, and relates to a photothermal dual-curing solder resist ink with high adhesion and a use method thereof. A formula of the photothermal dual-curingsolder resist ink comprises 100 parts by mass of an acrylate compound with a carboxyl group, 0.5-30 parts by mass of organosilicon elastomer, 0.5-20 parts by mass of a sealant, 0.1-30 parts by mass ofan epoxy resin-acrylate copolymer, 5-30 parts by mass of epoxy resin, 0.5-5 parts by mass of a photoinitiator, 1-5 parts by mass of pigment, 0.1-5 parts by mass of an additive and an organic solventfor dissolving the above components. The use method comprises the steps of coating, exposure development and curing. The solder resist ink coating of the invention has good adhesion, excellent toughness, softness and insulation reliability, is especially used for a FPC roll-to-roll process, and can pass various FPC reliability tests.

Owner:JIANGSU AISEN SEMICON MATERIAL CO LTD

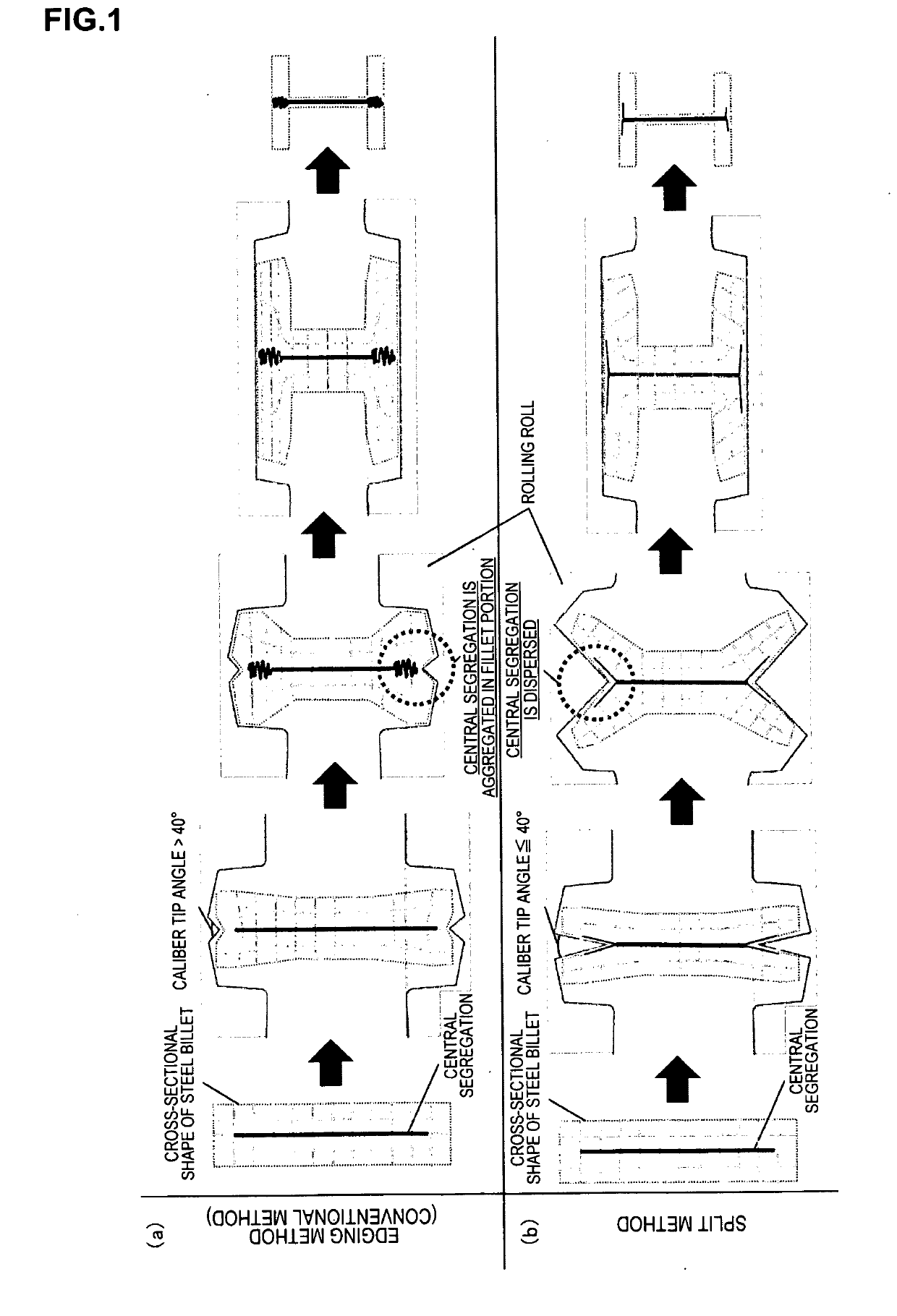

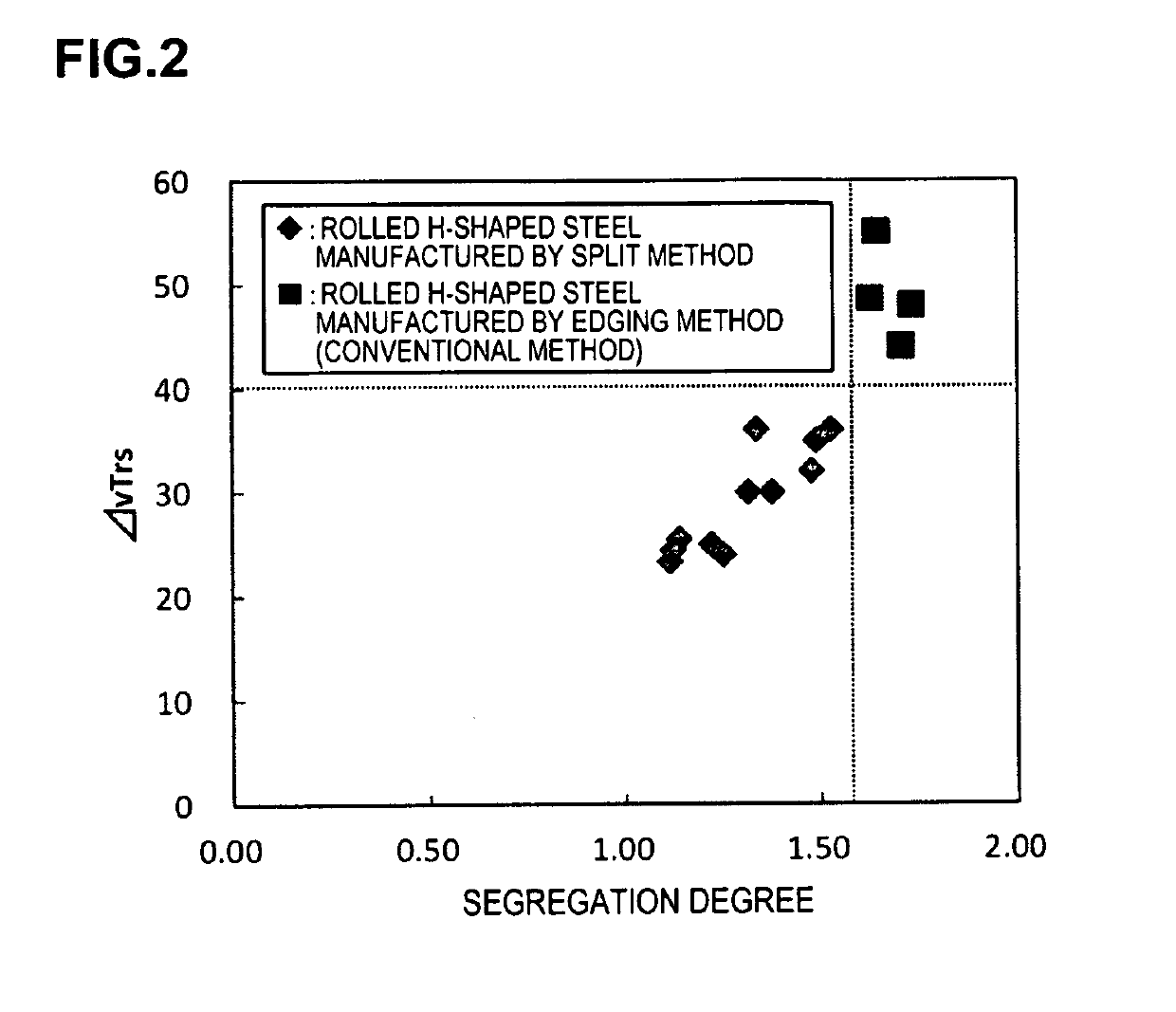

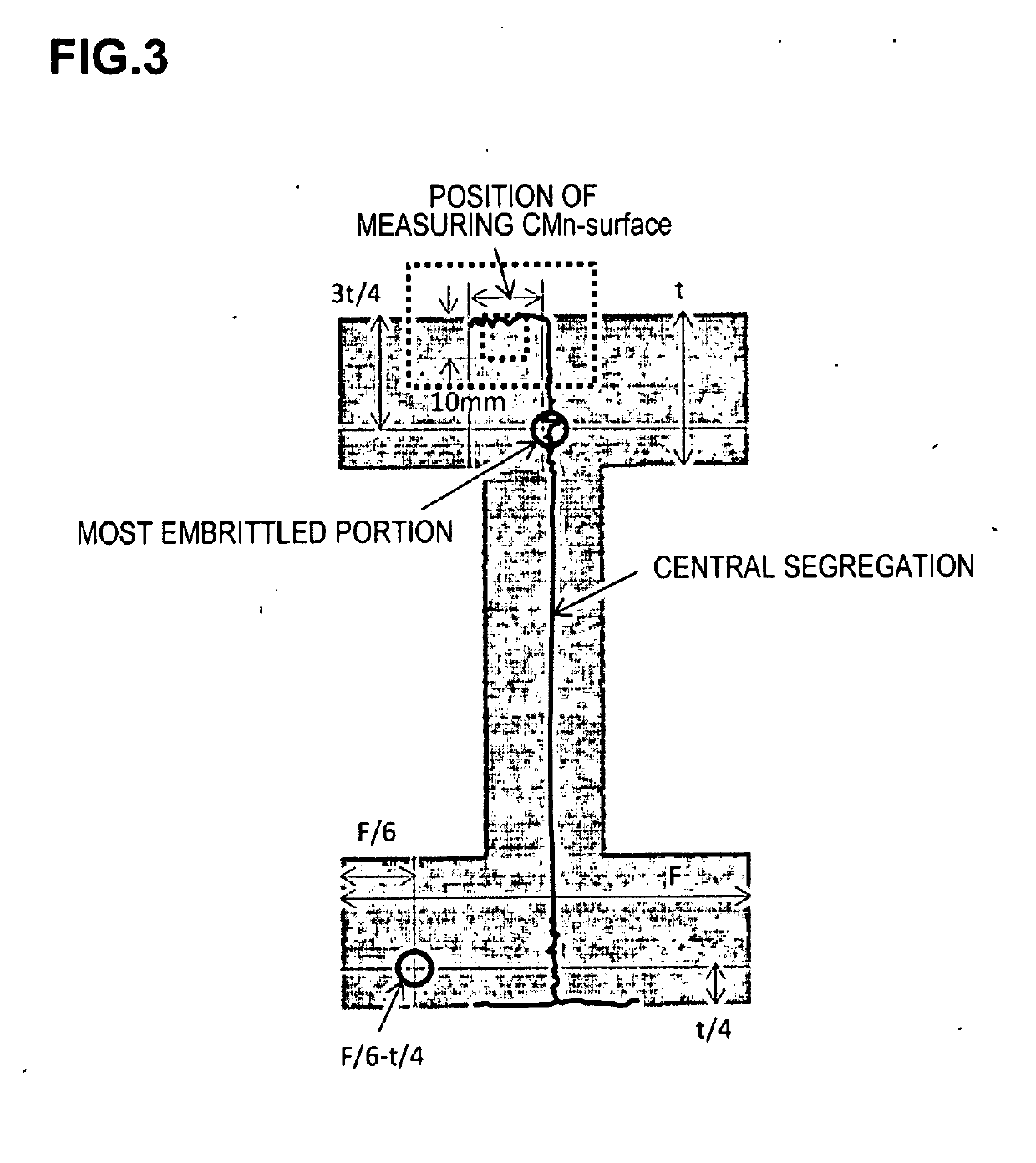

Rolled h-shaped steel and manufacturing method thereof

InactiveUS20190184436A1Improve reliabilityExcellent toughnessRollsMetal rolling arrangementsSurface layerFlange

Rolled H-shaped steel is characterized in that a top 5% average value of Mn concentrations in a most embrittled portion in a flange is 1.6 times or less an Mn concentration at a position of 1 / 6 in a flange width direction from an end face in the flange width direction and 1 / 4 in a flange thickness direction from a face of a flange positioned on a side opposite to that of a web, and a top 5% average value of Mn concentrations in a central segregation portion dispersed in a region 15 mm or more apart from a center of the flange width toward one end face or both end faces in the flange width direction and within 2 mm from a flange surface layer in the thickness direction is not less than 1.1 times nor more than 1.6 times the Mn concentration at the position of 1 / 6 in the flange width direction from the end face in the flange width direction and 1 / 4 in the flange thickness direction from the face of the flange positioned on the side opposite to that of the web.

Owner:NIPPON STEEL & SUMITOMO METAL CORP

Uoe steel pipe and a method for its manufacture

InactiveUS20100129680A1High strengthExcellent toughnessLayered productsBlade accessoriesBase metalWeld metal

UOE steel pipe which has a tensile strength of at least 900 MPa, which does not develop delayed hydrogen cracking of a weld or fracture of the weld during pipe expansion, and which has a weld and a heat affected zone having excellent toughness is provided. The tensile strength of a weld formed on a base metal having a tensile strength of at least 900 MPa is adjusted to be in the range of 95-110% of the tensile strength of the base metal, the oxygen content of the weld metal in the weld is made at most 0.035 mass %, and the weld is preheated to the range of 75-250° C. before carrying out welding from the outer side.

Owner:NIPPON STEEL & SUMITOMO METAL CORP

Duplex stainless steel plasma anode nitriding surface strengthening technology

ActiveCN108048789AInhibits the formation of brittle phasesExcellent toughnessSolid state diffusion coatingHardnessStable state

The invention discloses a duplex stainless steel plasma anode nitriding surface strengthening technology. The duplex stainless steel plasma anode nitriding surface strengthening technology comprises the following steps that (1) duplex stainless steel surface pretreatment is carried out; (2) plasma auxiliary anode nitriding is carried out, wherein a plasma auxiliary anode nitriding technology is adopted for conducting surface modification and strengthening processing on ultra-low carbon duplex stainless steel discs, and duplex stainless steel obtained after surface pretreatment is placed into an anode nitriding device for nitriding treatment; and (3) annealing is carried out. By means of the duplex stainless steel plasma anode nitriding surface strengthening technology, formation of a brittle phase can be effectively restrained, the discs have the excellent toughness matching from the surface layers to the center parts, workpiece secondary deformation caused by temperature gradient is reduced as many as possible on the basis of guaranteeing the excellent texture uniformity and mechanical property, coarsening damage caused by arc striking, edge effects and the like on treated surfaces can be avoided, meanwhile, formation of the white and bright semi-stable state compound S phase is better achieved, separation of brittle phases such as epsilon-Fe2-3N and gamma'-Fe4N is restrained,and the discs have the higher hardness, abrasion resistance and erosion resistance.

Owner:NANJING INST OF TECH

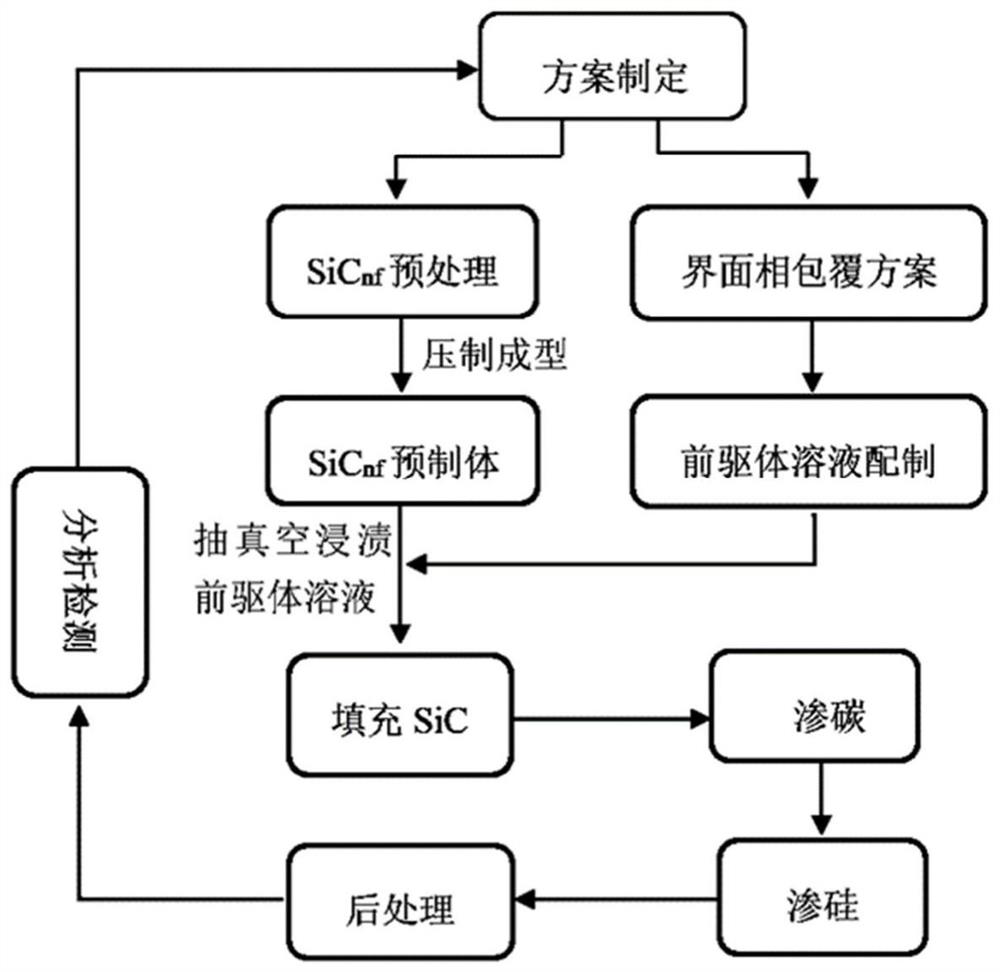

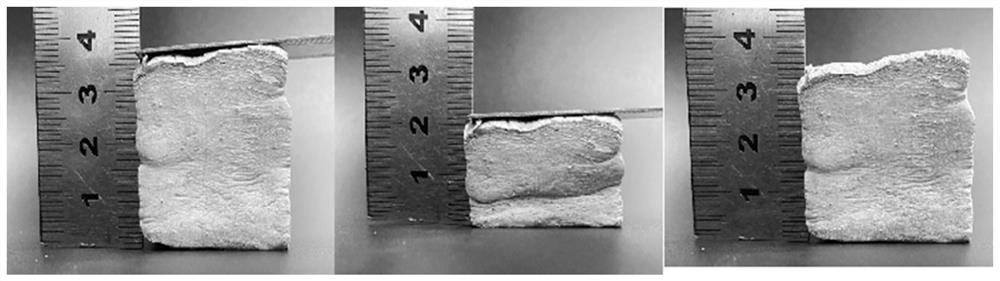

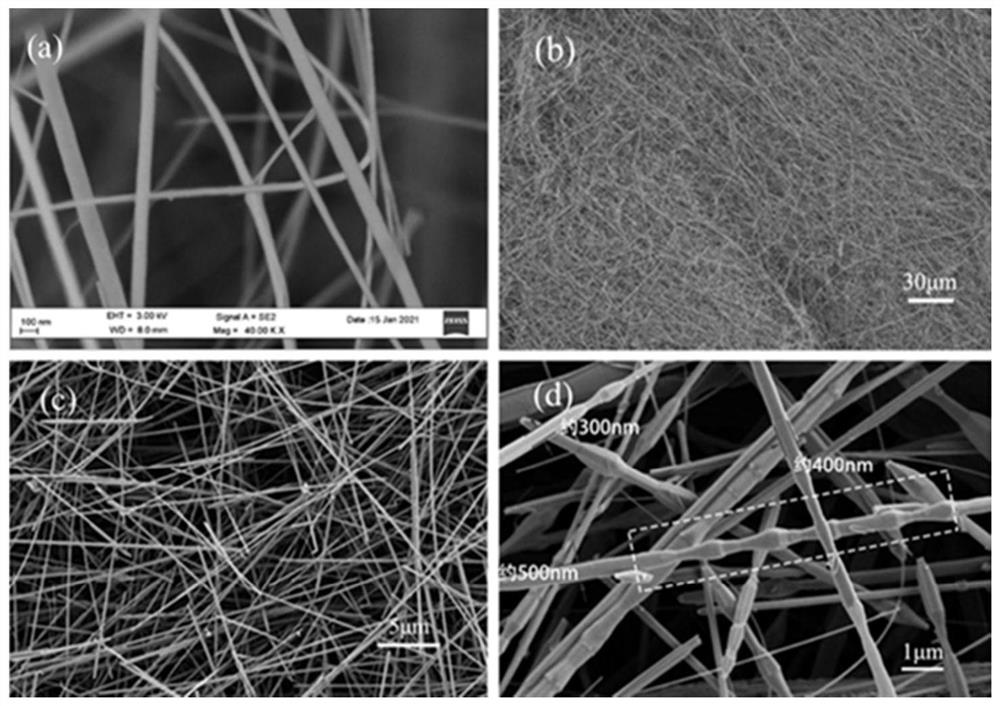

Method for preparing SiC ceramic-based composite material from spongy silicon carbide nanofiber preform

The invention discloses a method for preparing a SiC ceramic-based composite material from a spongy silicon carbide nanofiber preform. The method comprises: filling a glass tube with a spongy SiCnf material, and pre-compressing the spongy SiCnf material by external force to obtain a pre-compressed body; soaking the pre-compressed body in a low-concentration phenolic resin solution, taking out the pre-compressed body after soaking, drying the pre-compressed body to be half-dry, putting the pre-compressed body into a mold, carrying out pressing, drying, cracking, and repeating for multiple times; carrying out vacuum impregnation with a PCS solution, taking out the product, carrying out drying and cracking, and repeating for multiple times; after completely cooling, carrying out vacuum impregnation with a high-concentration phenolic resin solution, carrying out drying and cracking, and repeating for multiple times; and placing the above in a crucible, uniformly covering the surface with Si powder, and then firing. According to the invention, the characteristics of high strength, wear resistance, corrosion resistance and the like of SiC ceramic are retained, and the composite material also has the advantages of low density, high toughness and stable high-temperature performance, so that preparation of the SiCnf / SiC composite material with high volume fraction, high compact network structure, low porosity and low residual silicon is realized, and the composite material has excellent mechanical properties of a SiCnf reinforcement.

Owner:ZHEJIANG SCI-TECH UNIV

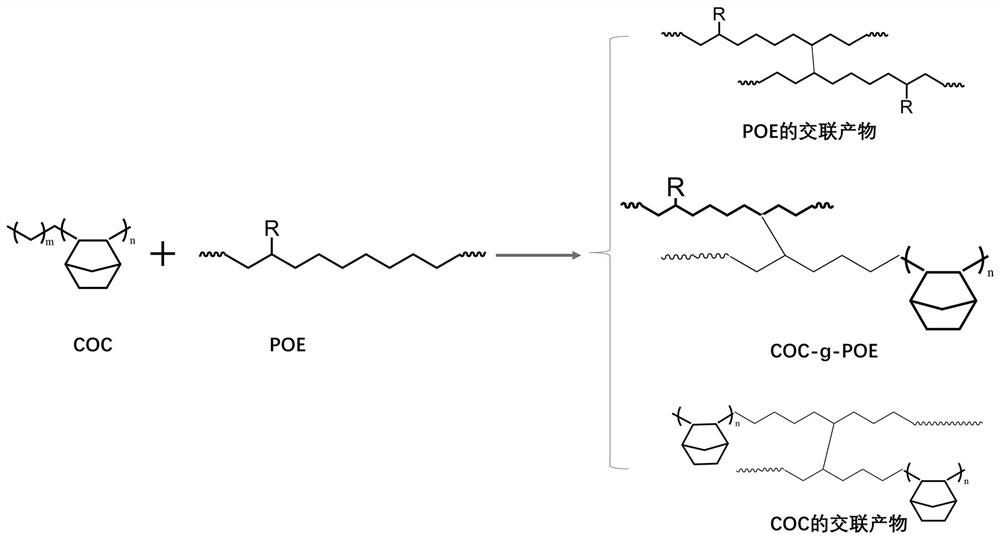

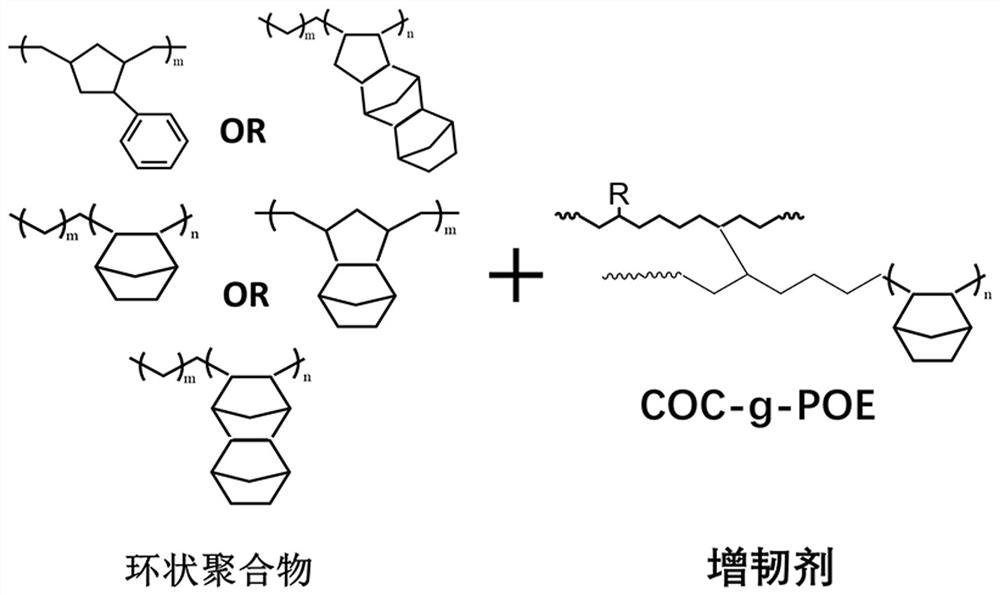

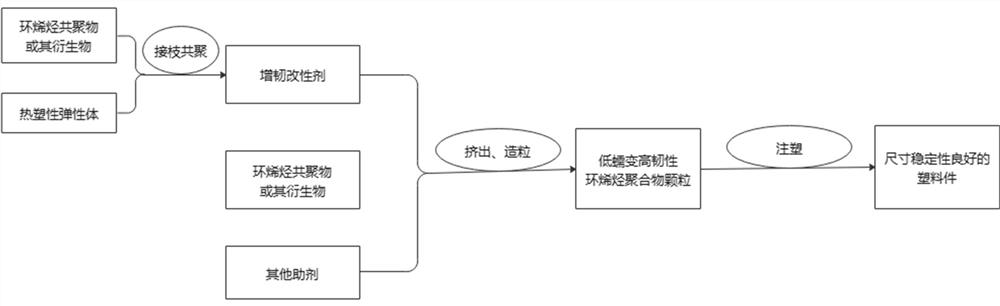

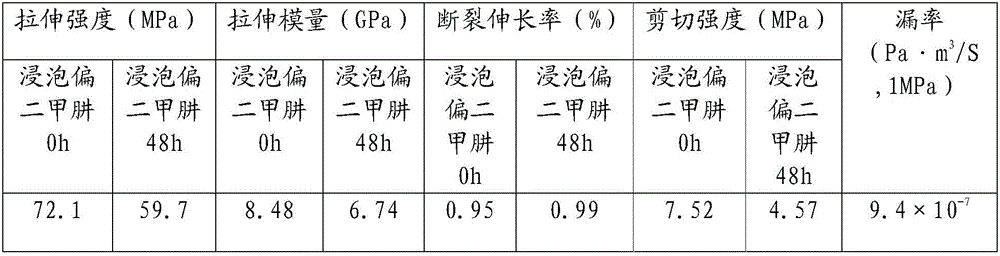

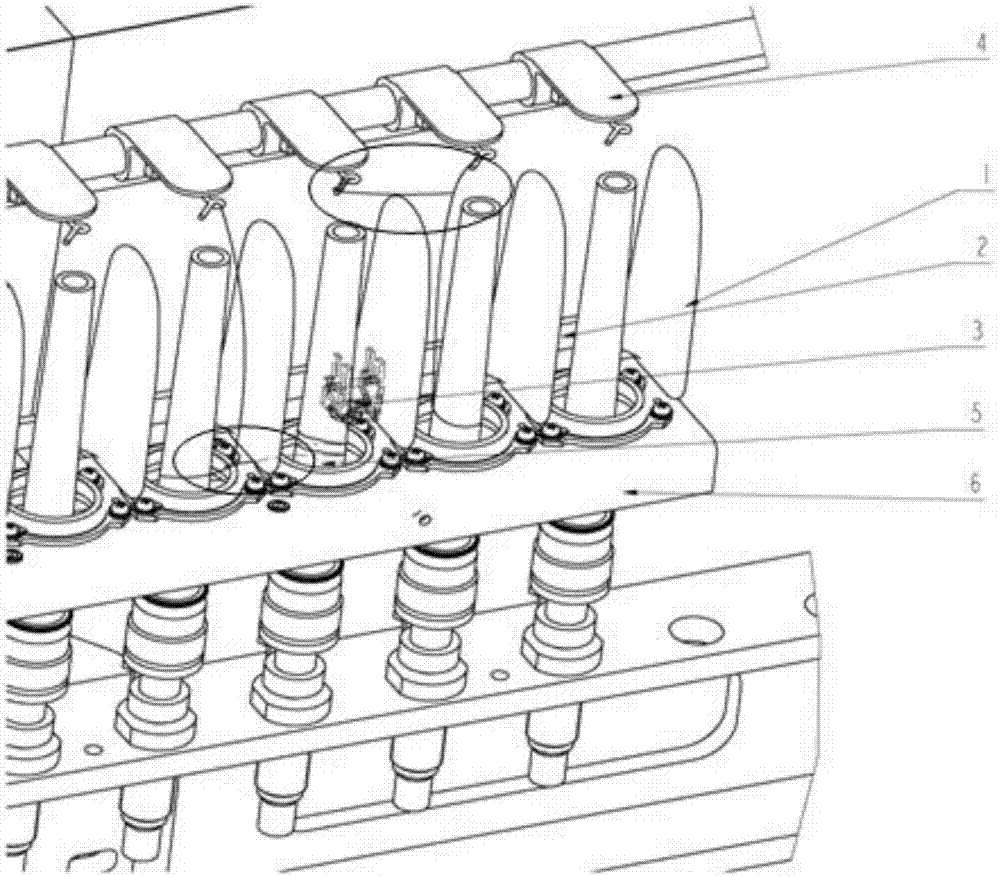

Low-creep high-toughness cycloolefin copolymer composite material and preparation method thereof

ActiveCN114479333AImprove creep resistanceGood dimensional stabilityPlastic recyclingCycloalkenePerylene derivatives

The invention discloses a low-creep high-toughness cycloolefin copolymer composite material which comprises the following components in parts by weight: 100 parts of cycloolefin copolymer resin or derivatives thereof, 5-30 parts of a toughening modifier and 0.1-3 parts of an anti-aging agent. The invention also provides a preparation method of the cycloolefin copolymer. The preparation method comprises the following steps: firstly, preparing the toughening modifier by using a melt grafting method, and then preparing the toughening modifier and cycloolefin copolymer resin or derivatives thereof into the low-creep high-toughness cycloolefin copolymer composite material by using a twin-screw extruder. The recycled cycloolefin copolymer can be used as a main raw material, so that the toughness of the recycled material is improved, the problem of resource shortage is solved, and the environmental problem is also solved.

Owner:XIAMEN MAKE LOCKS MFGR CO LTD +1

Production method of chewing-resistant baby molar rod

PendingCN110692684AEasy extractionHigh hydraulic modificationDough treatmentBakery productsDietary fiberProcess engineering

The invention relates to a production method of a chewing-resistant baby molar rod. The production method includes the steps of firstly, subjecting wheat bran to steam explosion; secondly, ball-milling; thirdly, performing secondary steam explosion; fourthly, performing enzymolysis to prepare dietary fibers; fifthly, producing modified bran dietary fibers; sixthly, producing dough and performing proofing; seventhly, shaping and coating; eighthly, baking. The production method has the advantages that the hardness and toughness of the chewing-resistant baby molar rod produced by the method are better than those of common molar rods, and the chewing-resistant molar rod is less prone to breaking when a baby chews the molar rod.

Owner:HEFEI UNIV OF TECH

Unsymmetric dimethylhydrazine resistant plugging and sealing material as well as preparation method and application

ActiveCN105820515ATo overcome the lack of low toughnessGood dispersionOther chemical processesDimethylhydrazineGlass fiber

The invention provides an unsymmetric dimethylhydrazine resistant plugging and sealing material as well as a preparation method and application. The plugging and sealing material has the beneficial effects that the deficiency that epoxy sealing materials generally have low toughness is overcome; chopped glass fibers are adopted as toughening and anti-solvent fillers; meanwhile, alkyl silazane is adopted as a dispersing agent to promote dispersion of the chopped glass fibers, thus increasing the addition of the chopped glass fibers, improving the solvent resistance of the epoxy plugging and sealing material, reducing the viscosity of the material before curing and facilitating smearing; the pasty material is convenient for vertical surface and bottom surface construction; the plugging and sealing material can be conveniently used as an adhesive or a joint mixture before curing and can be also used as a pressurized plugging and sealing material formed in place.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

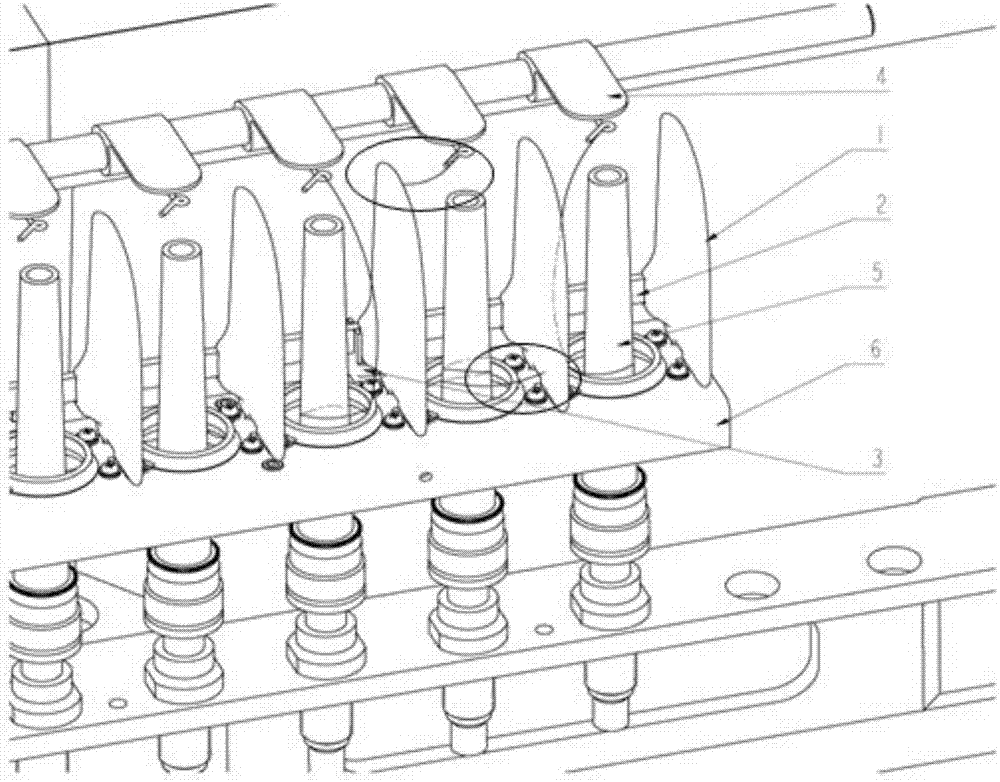

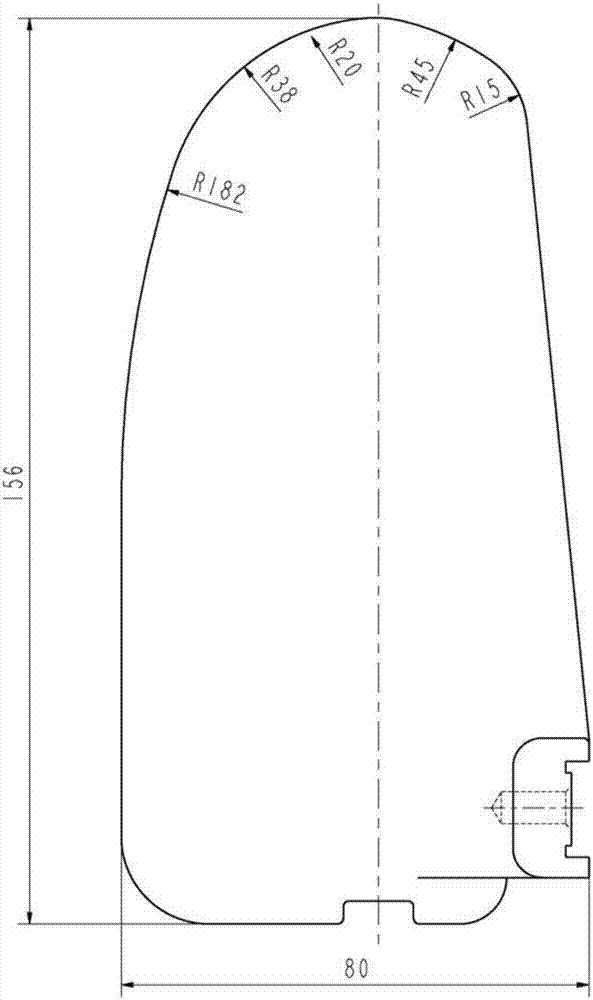

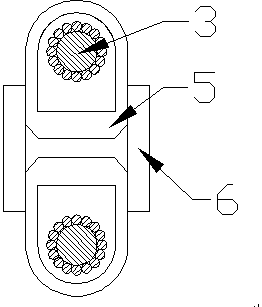

Textile yarn separators and applied high-speed ring spinning frame thereof

PendingCN107287706AIncrease heightIncrease widthContinuous wound-up machinesPolymer scienceTextile yarn

The invention relates to textile yarn separators, and the textile yarn separators are suitable for a ring spinning frame. The yarn separators are evenly distributed on a yarn guide flat steel, the yarn guide flat steel is fixed to flat iron bases of the yarn separators, and the upper portions of the yarn separators are arc segments; the arc segments are formed by several small arcs in a transition mode, the lower portions of the yarn separators are wider than the upper portions of the yarn separators, the width of the lower portions of the yarn separators is 80 mm, and the whole height of the yarn separators is 156mm. The height and width of the yarn separators are increased, so that the protection area is increased, adjacent yarn cannot interfere with each other on a broken end portion, the incidence of broken ends is effectively reduced, the labor intensity of spun yarn textile workers is lowered at the same time, the use efficiency of raw materials is improved, and the economic benefits are increased; the material quality of the yarn separators is further improved, zinc-aluminium alloys are adopted for novel yarn separators, and the intensity and tenacity of the novel yarn separators are better than those of original yarn separators; the surfaces of the yarn separators are sprayed and coated with anti-static flat powder, so that the anti-static effect is greatly improved, and the adherence of the surfaces of the yarn separators for flying flowers is avoided.

Owner:JINGWEI TEXTILE MASCH CO LTD

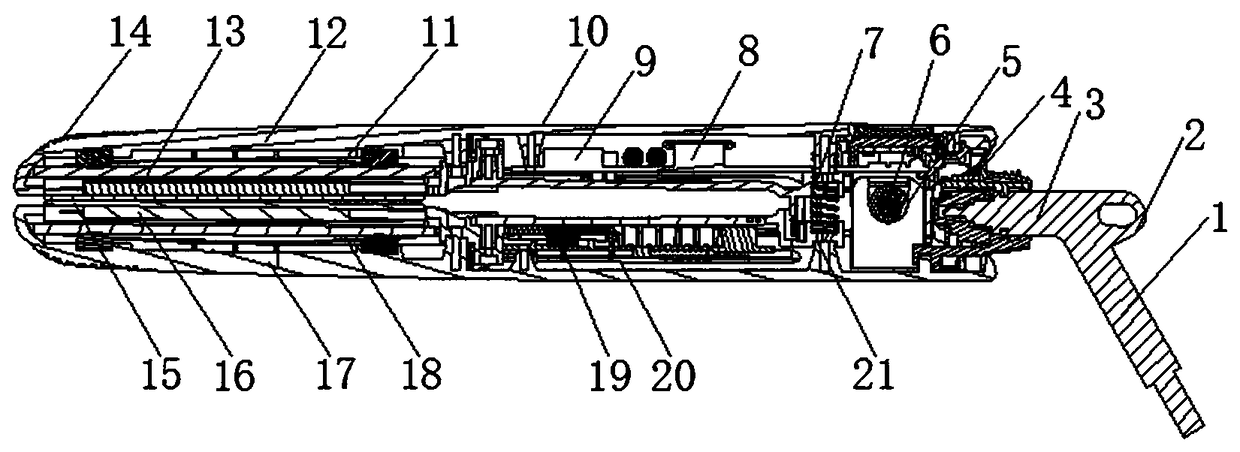

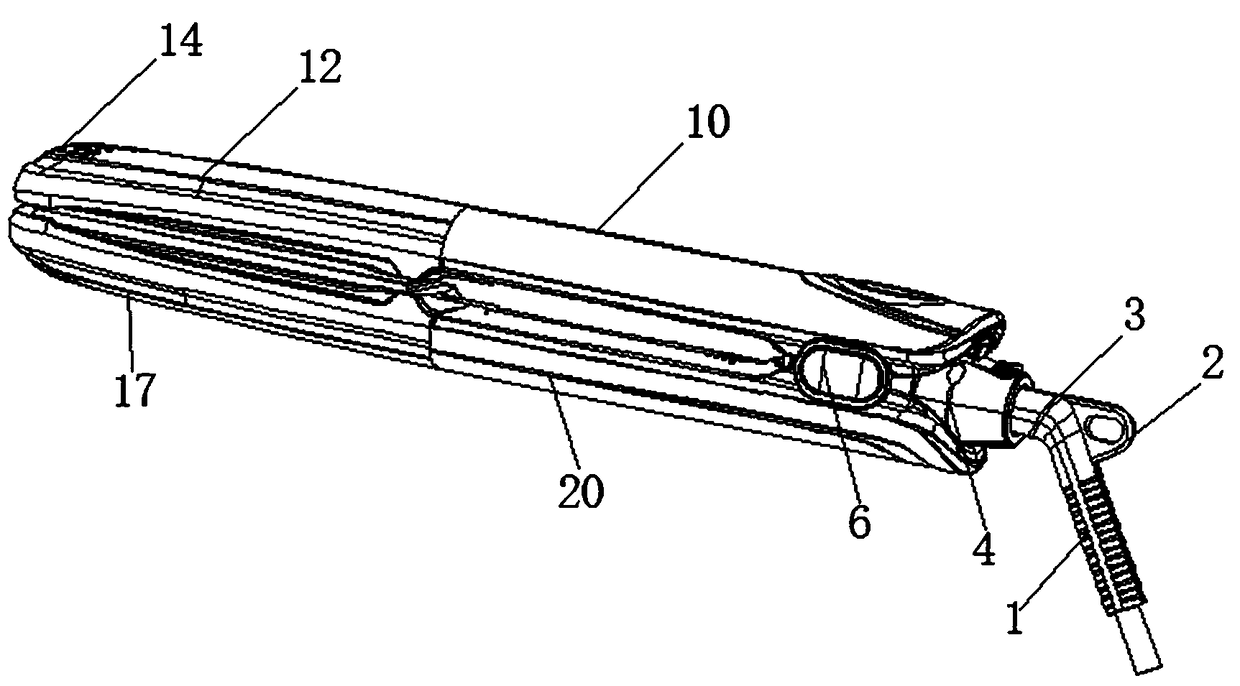

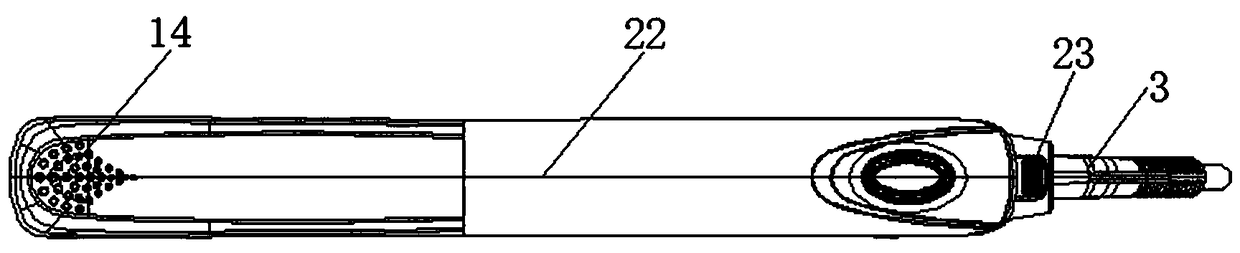

Electric hair drier

InactiveCN108209118AExtended service lifeReduce power consumptionHair dryingLiquid-crystal displayLight-emitting diode

The invention discloses an electric hair drier which comprises a connecting layer, a rotating mechanism, an upper handle, a lower handle and a fixed mechanism. A hanging part is arranged on the connecting layer, a wire leading hole is formed in the connecting layer, a clamp is arranged on the rotating mechanism, the connecting layer is fixedly connected with the rotating mechanism through the clamp, through holes are formed in the tail ends of the upper handle and the lower handle, a connecting rod penetrates the through holes, so that the upper handle is fixedly connected with the lower handle, and the upper handle and the lower handle are movably connected with the rotating mechanism. The electric hair drier is provided with an intelligent display screen, a new technology is applied to design of a hairdressing tool, temperature can be adjusted when the electric hair drier is conveniently operated, the intelligent display screen is an LED (light-emitting diode) backlight liquid crystal display screen, so that the display screen is long in service life, low in power consumption, high in brightness and uniform in color, a screen protection film is arranged on the surface of the intelligent display screen, and screen protection film cannot be scratched when being used for a long time.

Owner:吴少洁

Bridge plate

InactiveCN103726438AReduced likelihood of transverse fracturesImprove bearing capacityBridge structural detailsReinforced concreteEngineering

The invention discloses a bridge plate which comprises a plurality of girders and a tensioning mechanism. The plurality of the girders in array are transversely disposed on a cross beam between bridge piers to form a bridge body and fixed through the tensioning mechanism. Compared with a conventional beam and slab structure in a pure reinforced concrete structure, since steel cables are superior to rebars in toughness and tensile strength, the bridge plate in the structure can bear higher shearing force brought by bridge load bearing, possibility of cross fracture of the bridge plate is greatly reduced, and bridge bearing capacity is improved.

Owner:WUJIANG JUNCHENG PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com