Thin film battery and preparation method thereof

A thin-film battery and electrode technology, applied in the field of thin-film battery and its preparation, can solve the problems of electrolyte leakage, high cost, and inability to obtain thinner thickness, etc., and achieve the effect of excellent mechanical flexibility and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

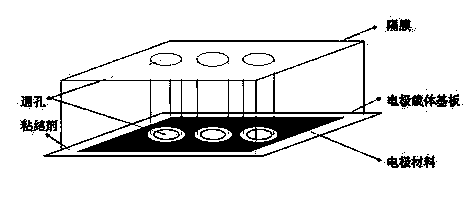

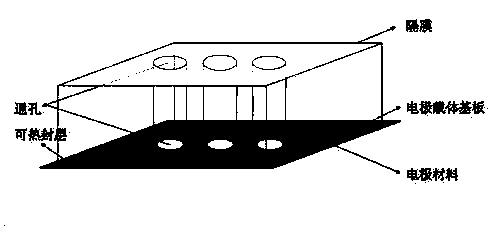

[0029] The invention provides a method for preparing a thin film battery, comprising the following steps:

[0030] A) Print the electrode material at the position away from the edge on the electrode carrier substrate, and leave the pattern of the through hole in the printed electrode pattern to obtain the electrode plate; die-cut at the pattern of the through hole of the electrode plate, so that The electrode plate produces a through hole, and the aperture of the through hole of the electrode plate is smaller than the aperture of the through hole of the electrode pattern; the electrode plate includes a positive electrode plate and a negative electrode plate;

[0031] Die-cutting the diaphragm so that the diaphragm produces a through hole, the aperture of the through hole of the diaphragm is smaller than the aperture of the through hole of the electrode pattern; the aperture of the through hole of the diaphragm is larger than the aperture of the through hole of the electrode pla...

Embodiment 1

[0084] The positive carrier substrate includes:

[0085] Aluminum foil layer with a thickness of 0.02mm;

[0086] A polyethylene terephthalate film with a thickness of 0.03mm is bonded to the front and back of the aluminum foil layer;

[0087] The adhesive used for the bonding is polyacrylic resin adhesive.

[0088] The negative carrier substrate includes:

[0089] Aluminum foil layer with a thickness of 0.05mm;

[0090] A polyethylene terephthalate film with a thickness of 0.03mm is bonded to the front and back of the aluminum foil layer;

[0091] The adhesive used for the bonding is polyacrylic resin adhesive.

[0092] The positive electrode current collector material carbon powder is screen printed on the positive electrode carrier substrate at a position away from the edge, the printing thickness is 0.08mm, and the pattern of a circular through hole with a diameter of 2cm is left in the printed positive electrode current collector pattern, at 120 After baking at 120°C...

Embodiment 2

[0100] The positive carrier substrate includes:

[0101] Polyethylene naphthalate film with a thickness of 0.05mm;

[0102] An aluminum foil layer with a thickness of 0.06 mm bonded to the polyethylene naphthalate film;

[0103] A polypropylene film with a thickness of 0.07 mm bonded to the aluminum foil layer;

[0104] printing the positive electrode material on the polypropylene film of the positive electrode carrier substrate;

[0105] The adhesive used for bonding is epoxy resin adhesive.

[0106] The negative carrier substrate includes:

[0107] Polyethylene naphthalate film with a thickness of 0.05mm;

[0108] An aluminum foil layer with a thickness of 0.06 mm bonded to the polyethylene naphthalate film;

[0109] A polypropylene film with a thickness of 0.07 mm bonded to the aluminum foil layer;

[0110] printing an anode material on the polypropylene film of the anode carrier substrate;

[0111] The adhesive used for bonding is epoxy resin adhesive.

[0112] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com