Patents

Literature

1918results about "Film/foil adhesive release liners" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

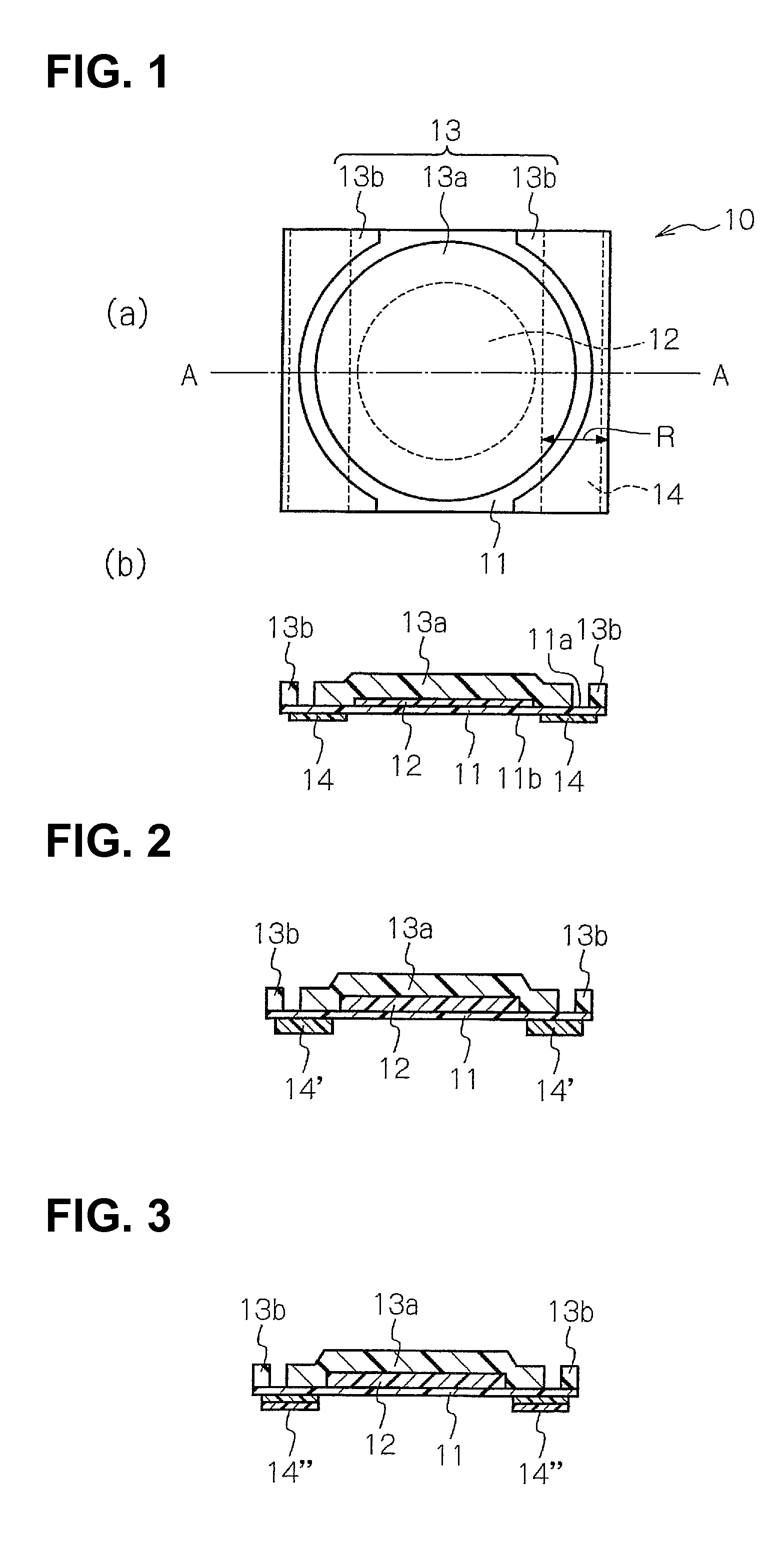

Marking method and sheet for both protective film forming and dicing

ActiveUS20060102987A1Improve accuracyWarpage suppressionSemiconductor/solid-state device detailsSolid-state devicesTectorial membraneEngineering

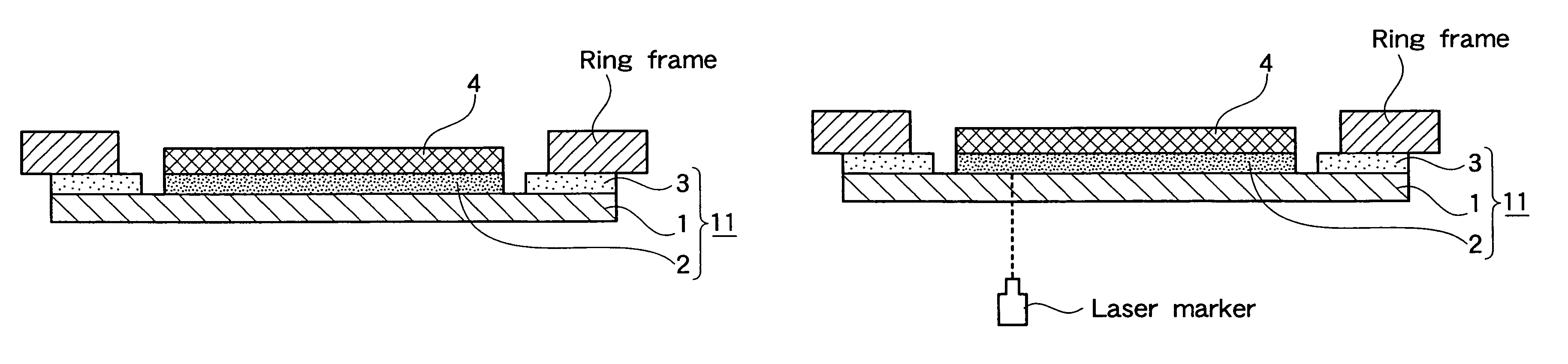

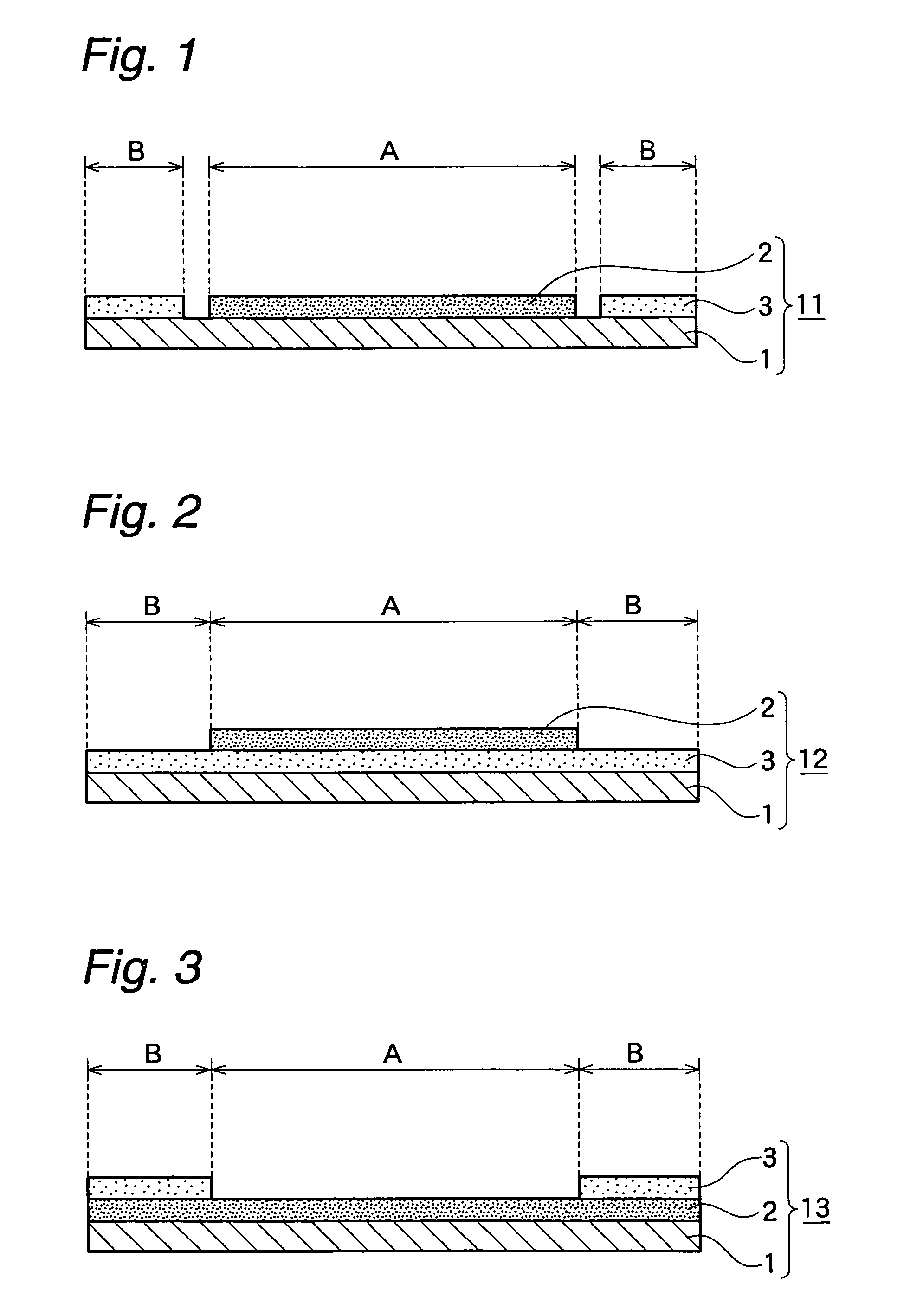

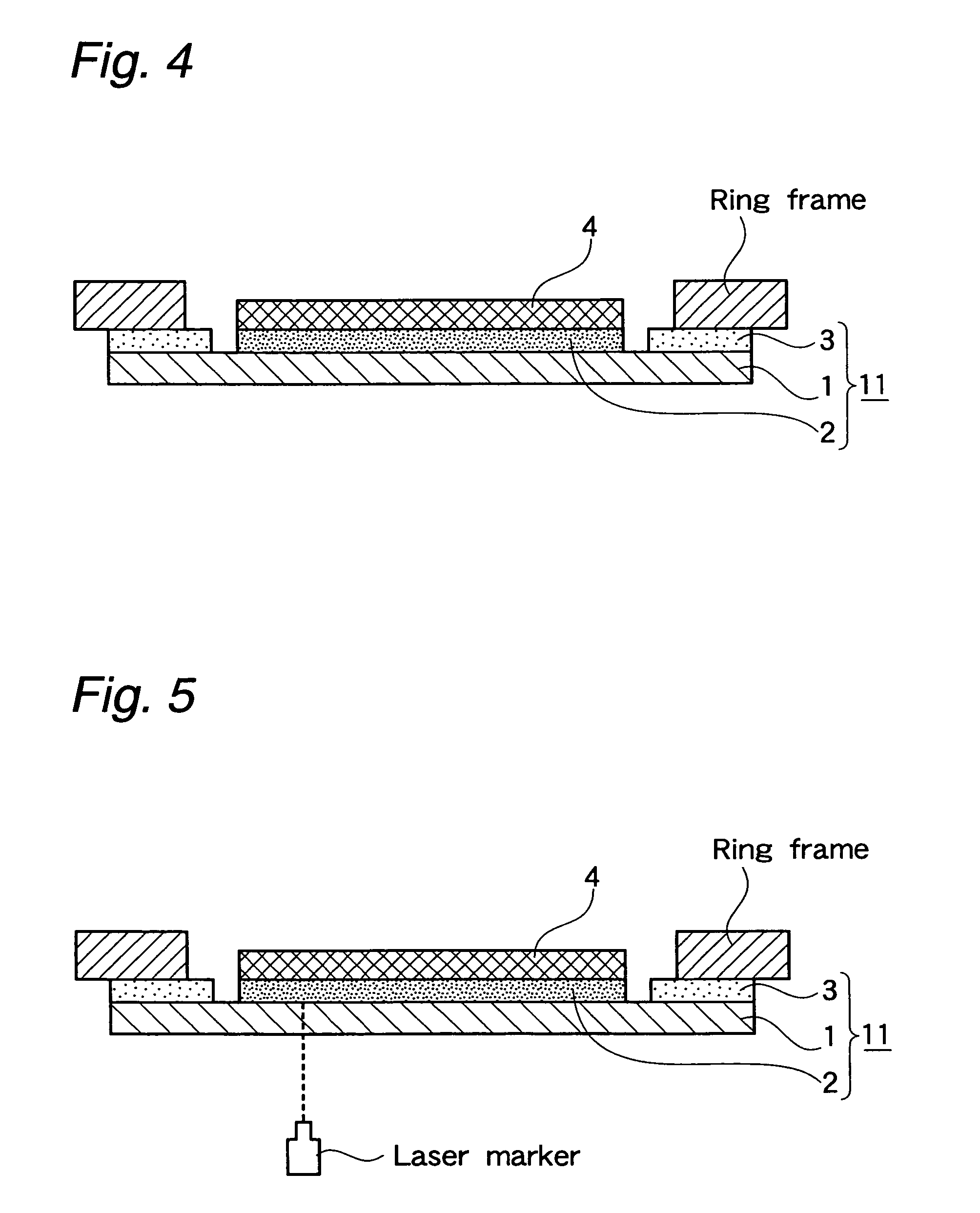

The invention provides a marking method in which marking is performed on a protective film formed on a work with a high accuracy while suppressing a warpage and, also, a sheet for both protective film forming and dicing which is advantageously used in the method. The marking method comprises irradiating laser light to a laminated structure comprising a support film tensely supported by a ring frame, a protective film releasably laminated on the support film and a work fixed to the protective film, wherein the protective film is irradiated laser light from a side of the support film, to thereby mark the protective film.

Owner:LINTEC CORP

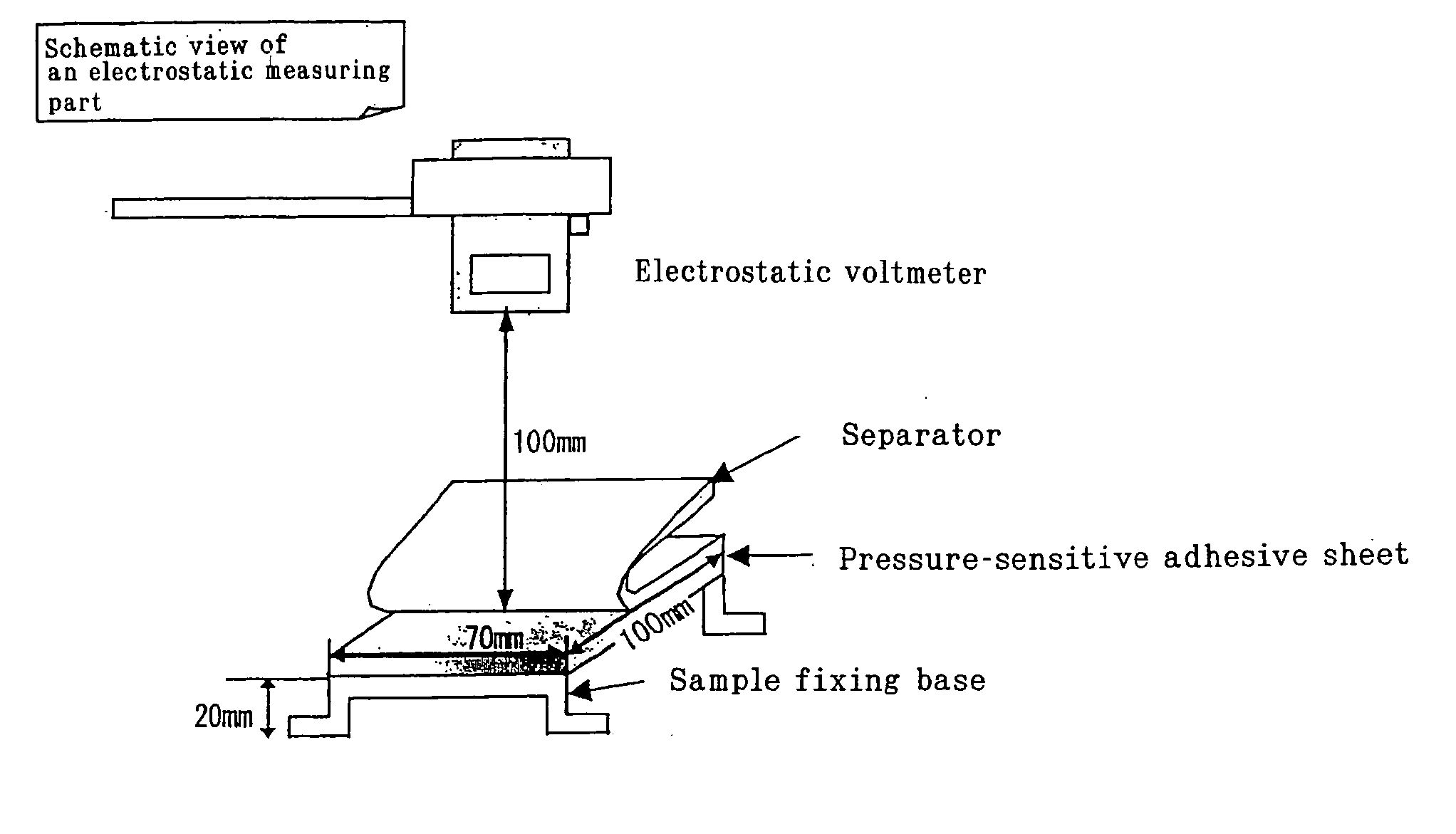

Pressure-sensitive adhesive composition, pressure-sensitive adhesive sheets and surface protecting film

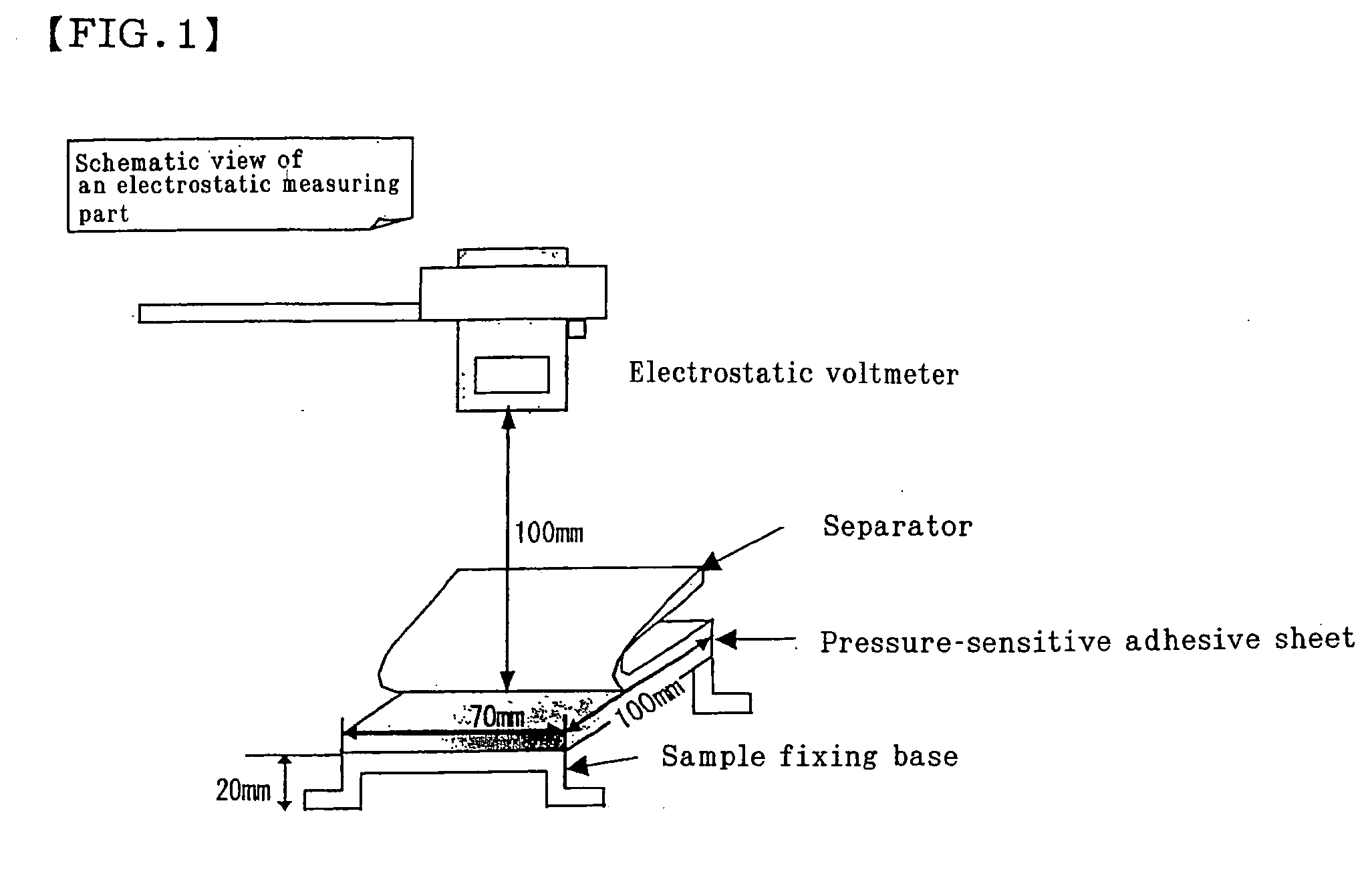

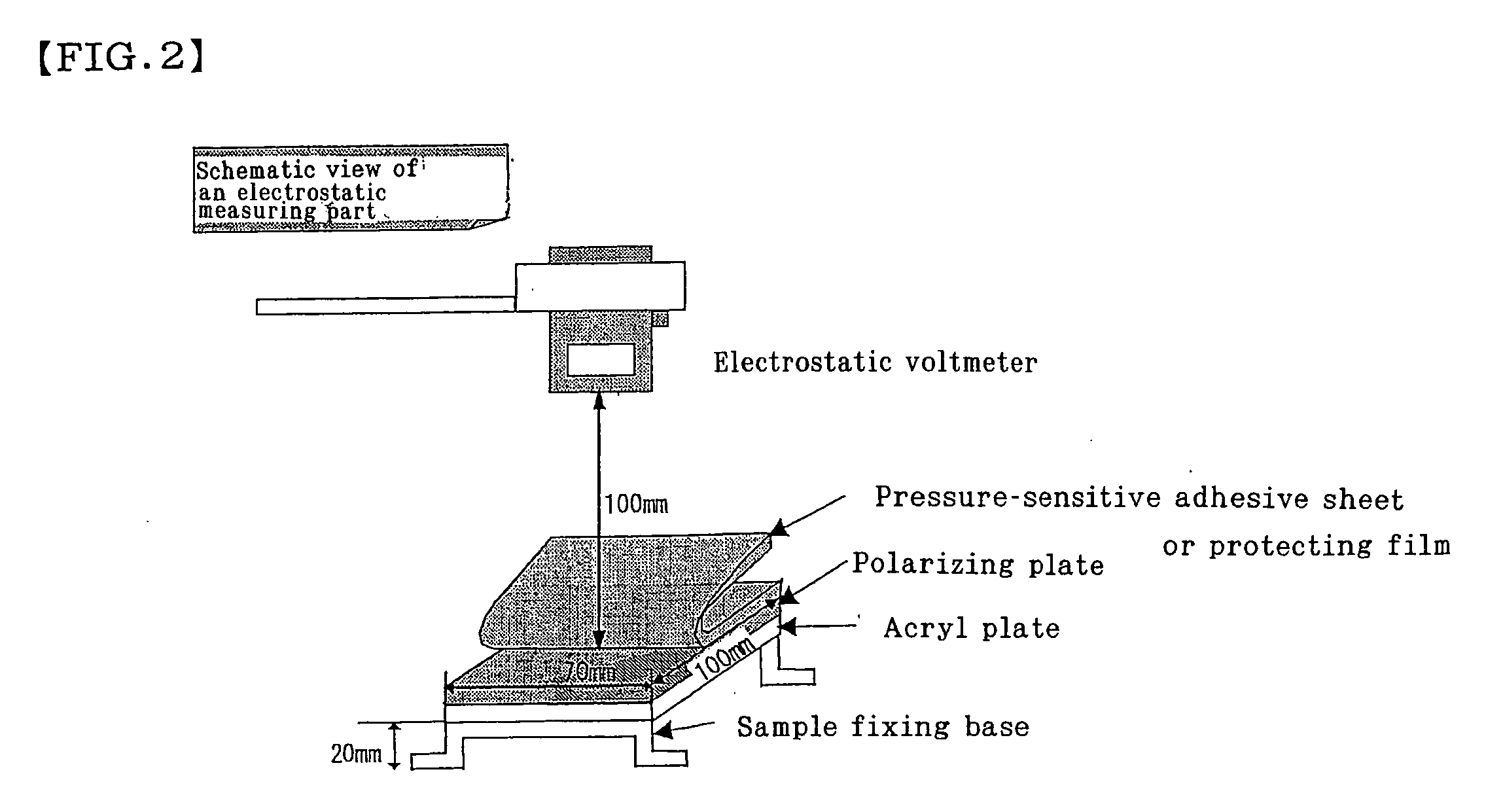

InactiveUS20050197450A1Reduce stainsAvoid electrificationNon-macromolecular adhesive additivesEster polymer adhesivesTectorial membraneGlass transition

An object of the present invention is to provide a pressure-sensitive adhesive composition in which electrification of a pressure-sensitive adhesive sheet can be prevented upon peeling, and staining property on an adherend can be reduced, and an antistatic pressure-sensitive sheet and surface protecting film using this. There is provided a pressure-sensitive composition comprising an ionic liquid and a polymer having a glass transition temperature Tg of 0° C. or lower as a base polymer.

Owner:NITTO DENKO CORP

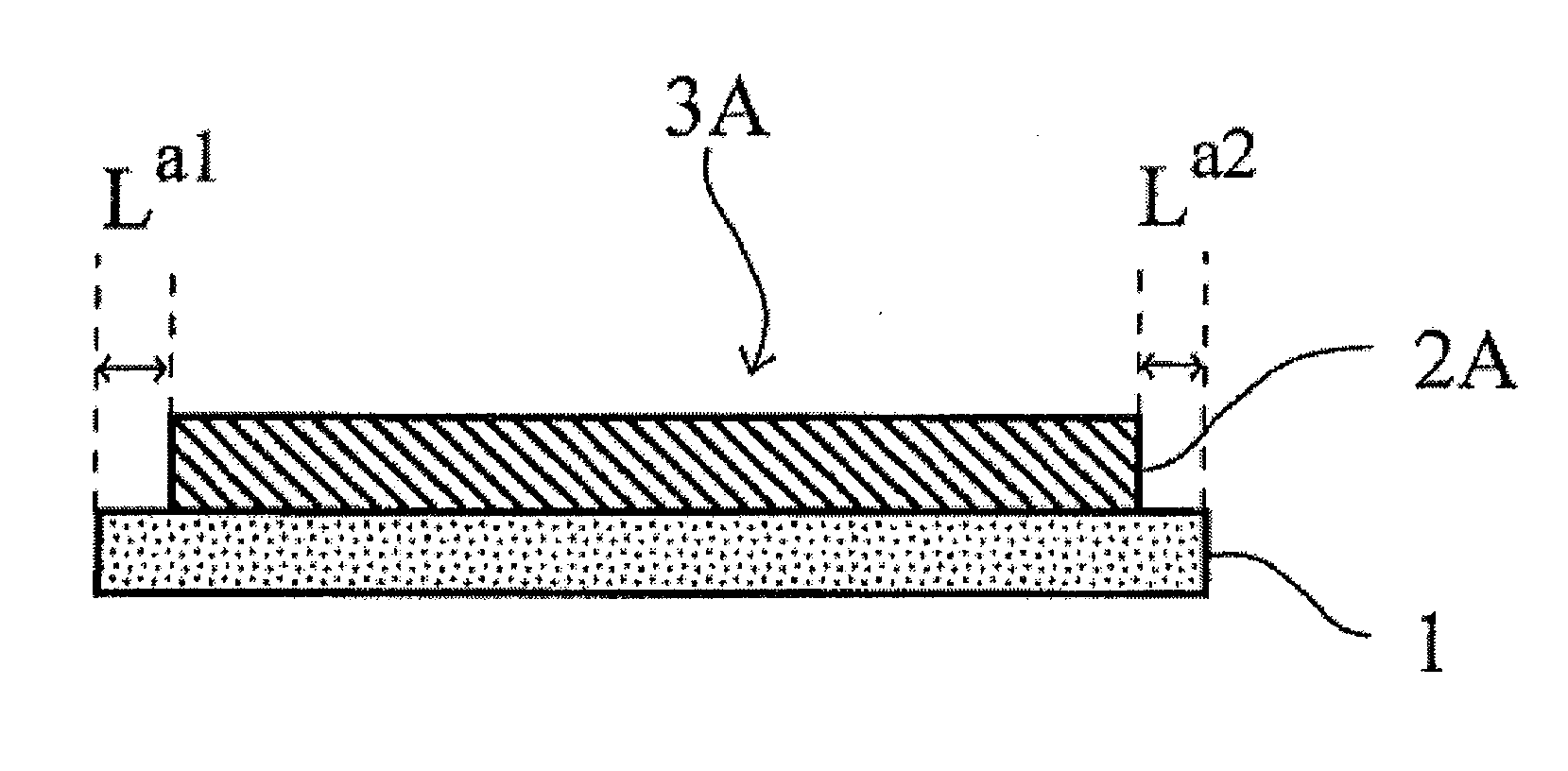

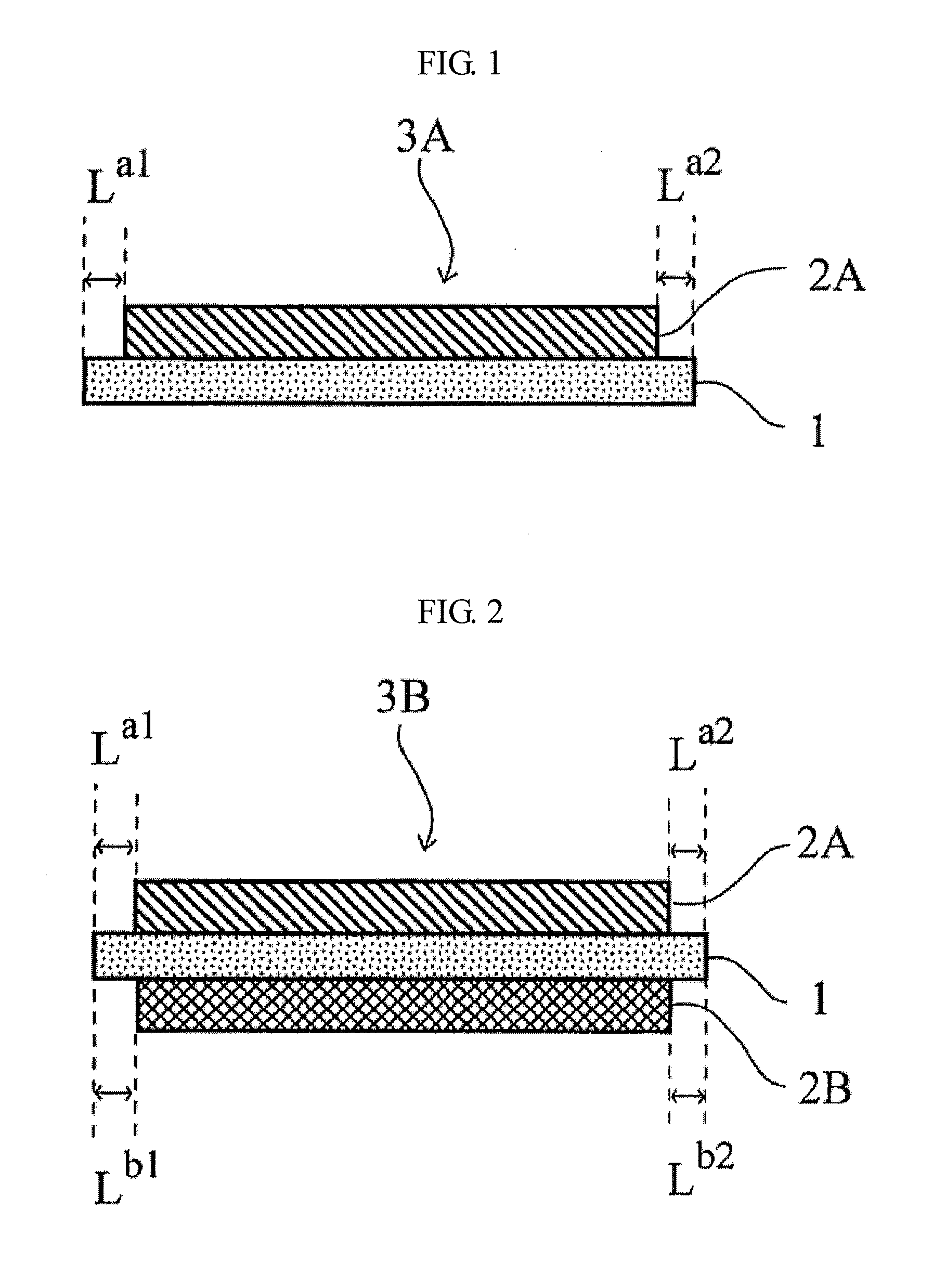

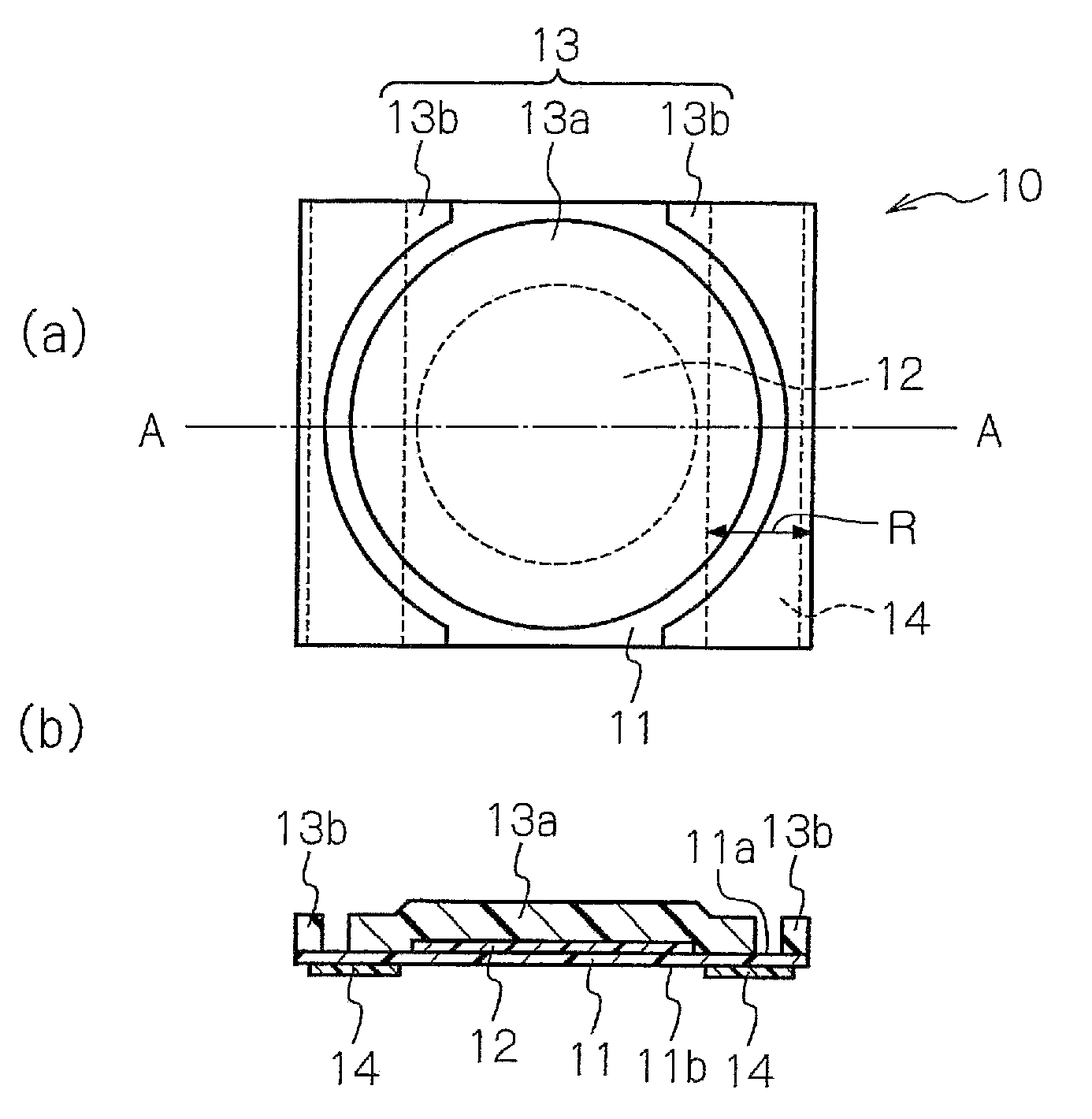

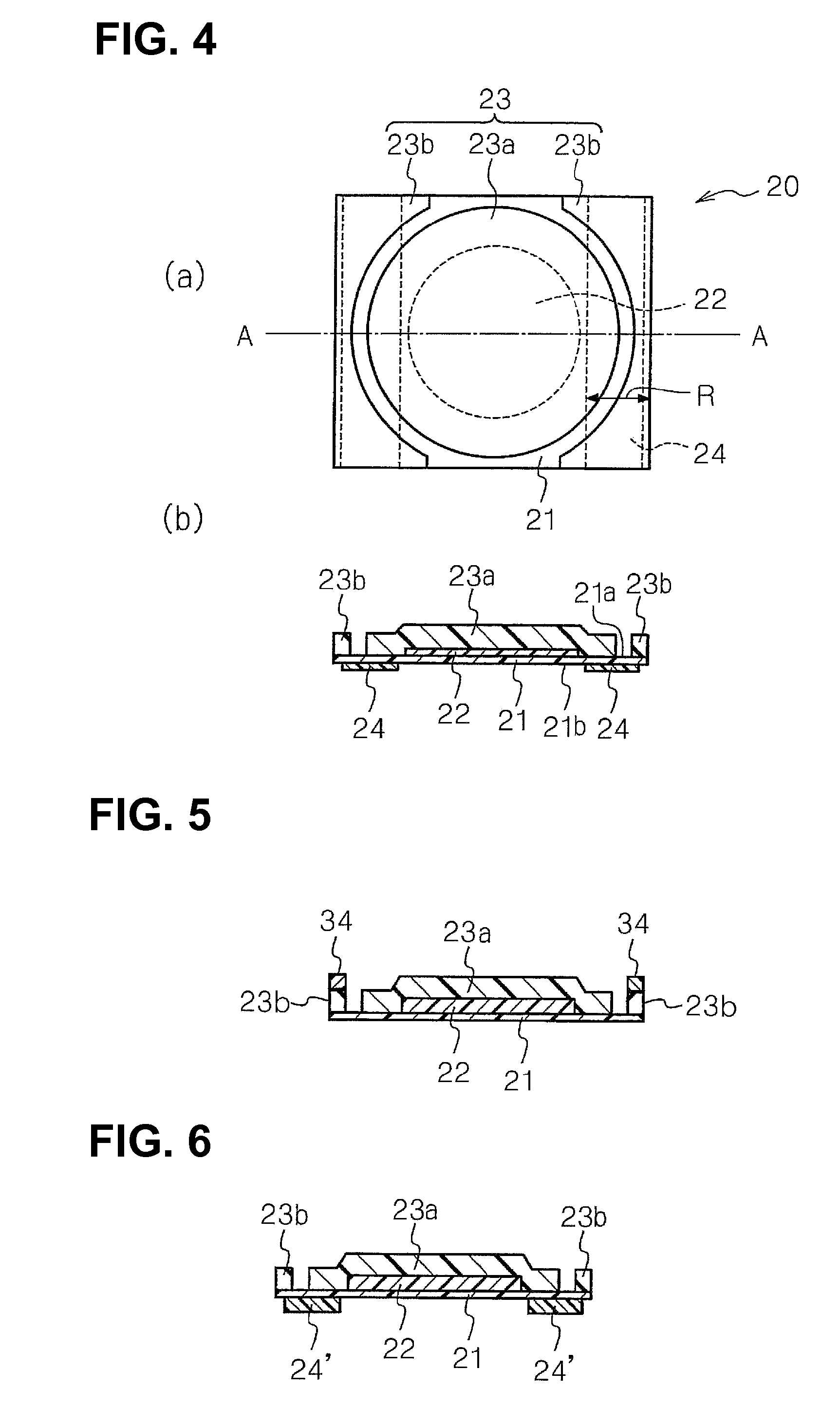

Dicing Sheet with Protective Film Forming Layer and Chip Fabrication Method

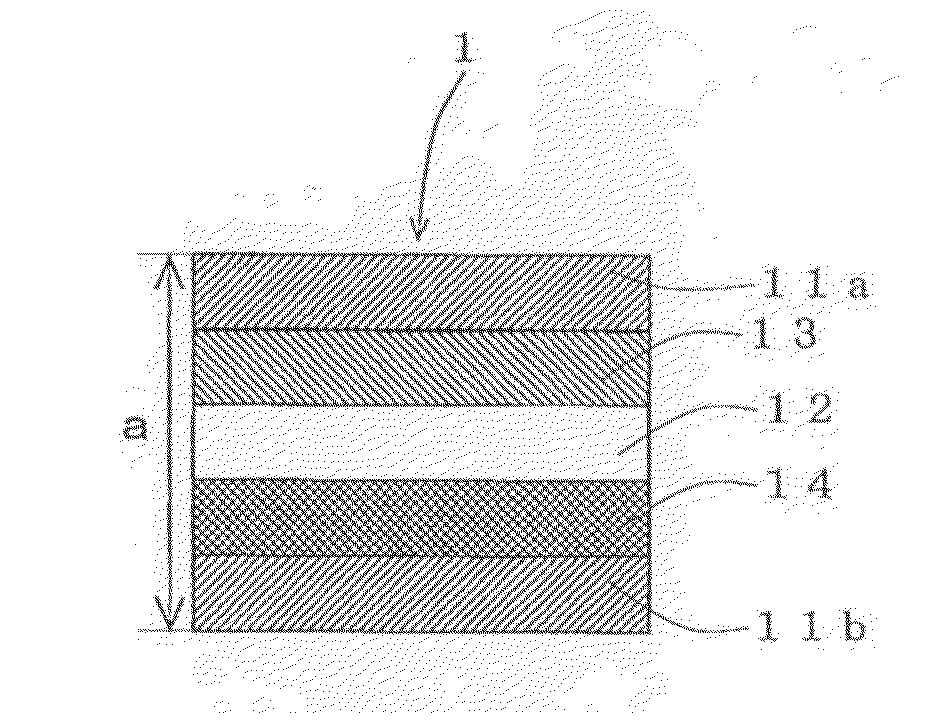

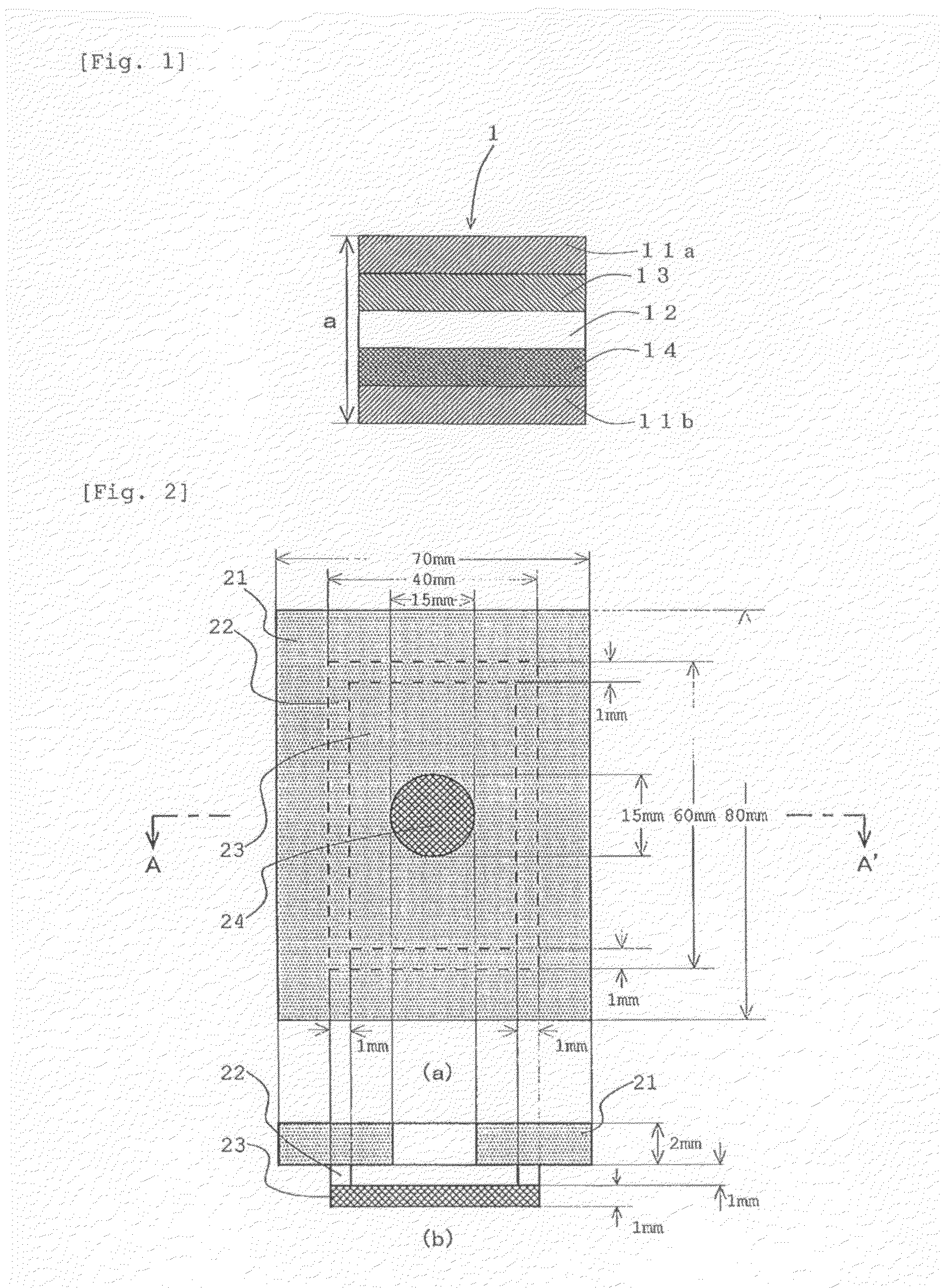

ActiveUS20140295646A1Improve printing accuracyWell formedLayered productsSemiconductor/solid-state device detailsTectorial membraneThermal contraction

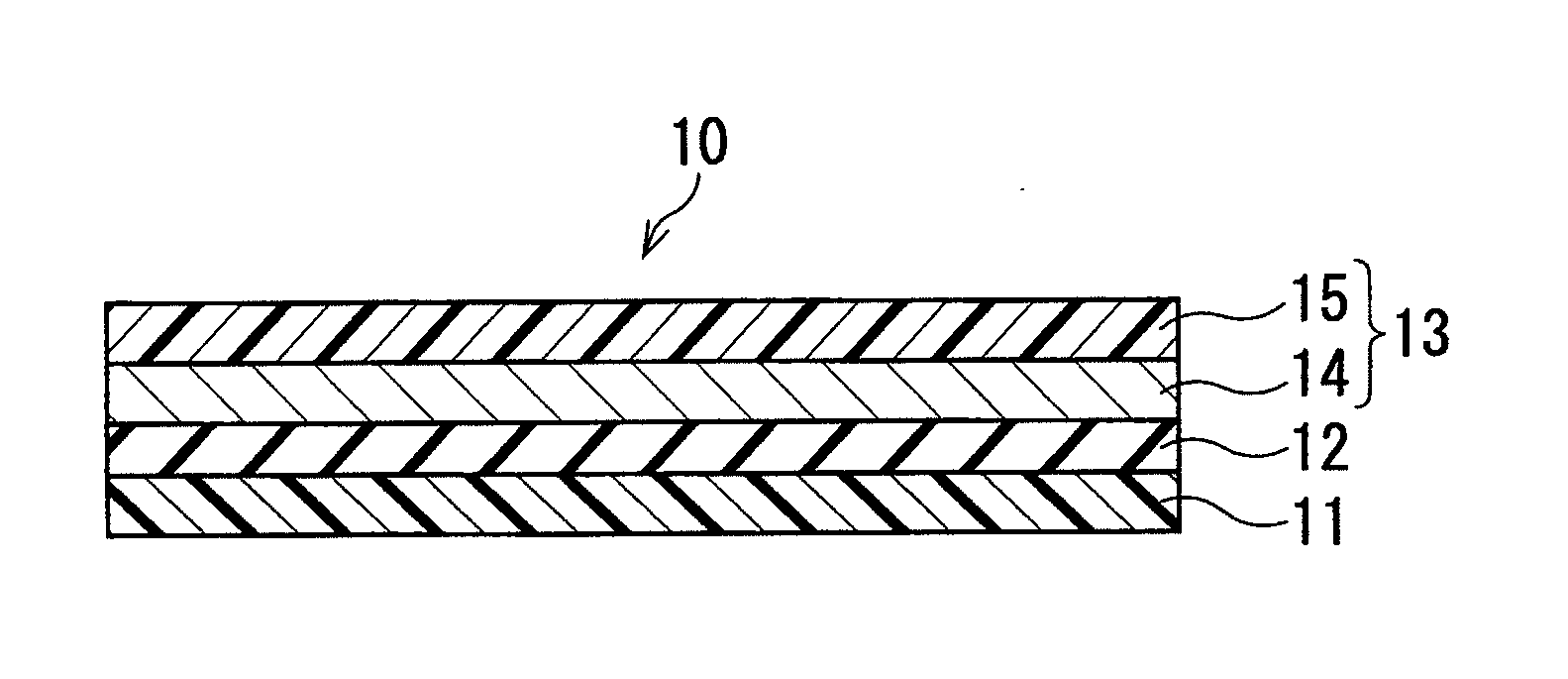

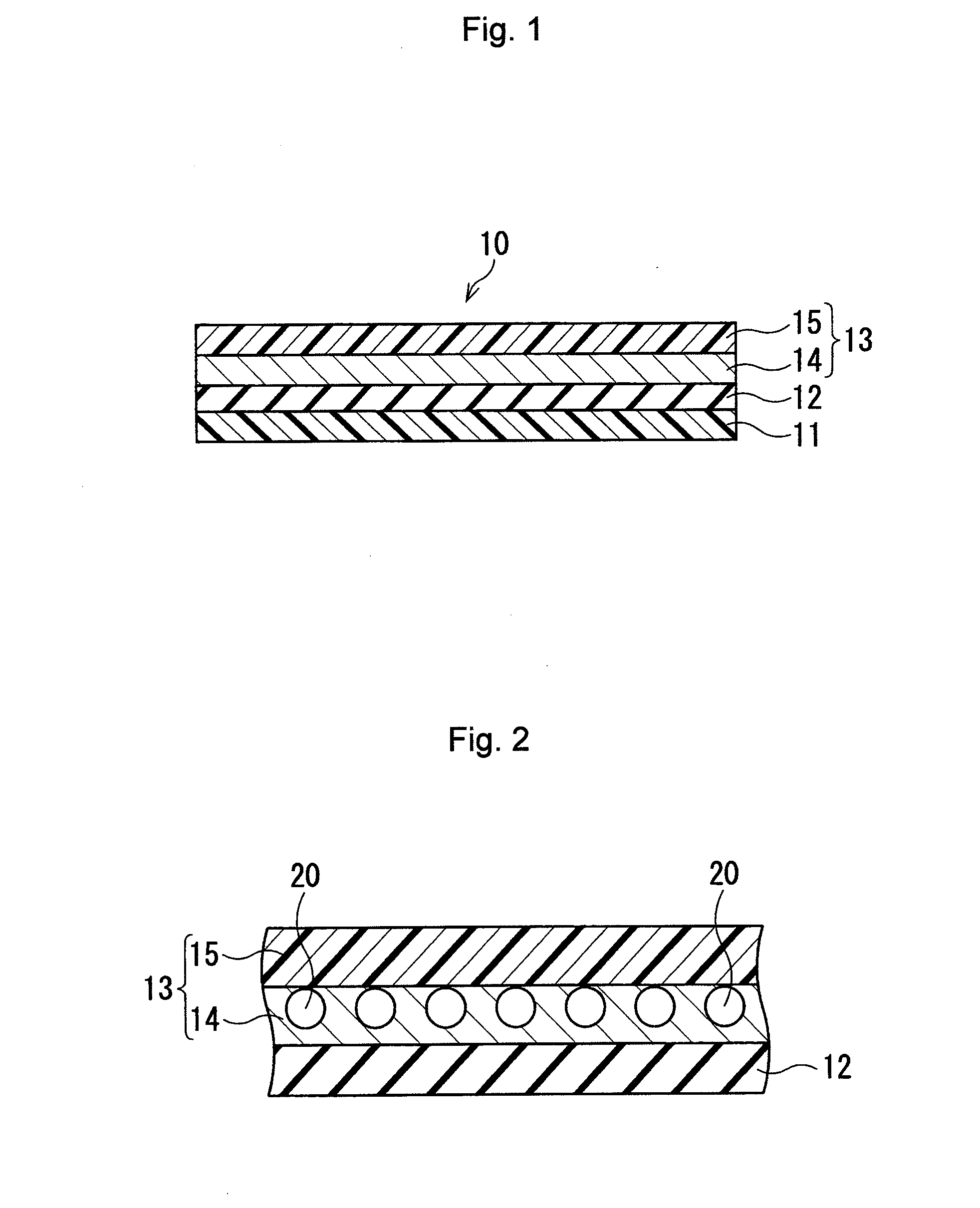

A dicing sheet with a protective film forming layer has a substrate film, an adhesive layer, and a protective film forming layer, and at a minimum, the adhesive layer is formed in an area surrounding the protective film forming layer in a planar view, and the substrate film has the following characteristics (a)-(c): (a) the melting point either exceeds 130° C. or the film has no melting point; (b) the thermal contraction rate under conditions of heating at 130° C. for two hours is from −5 to +5%, and (c) the degree of elongation-to-break in the MD direction and the CD direction is at least 100%, and the stress at 25% is no more than 100 MPa.

Owner:LINTEC CORP

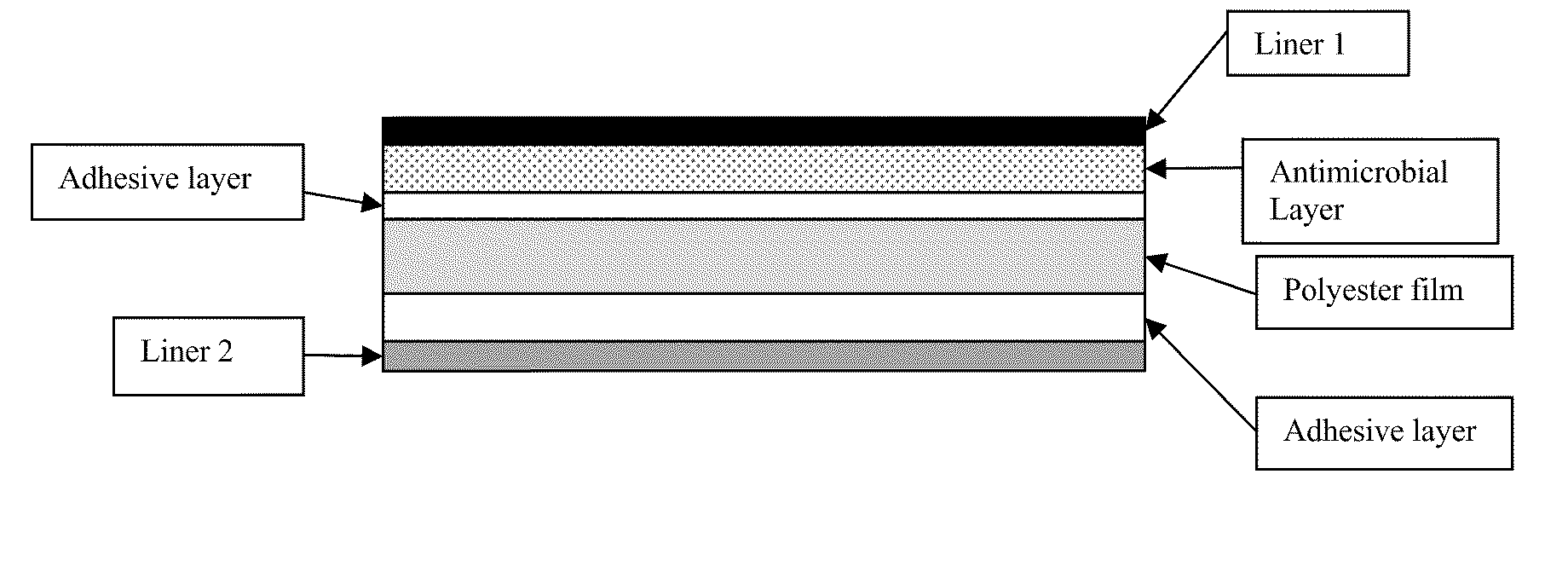

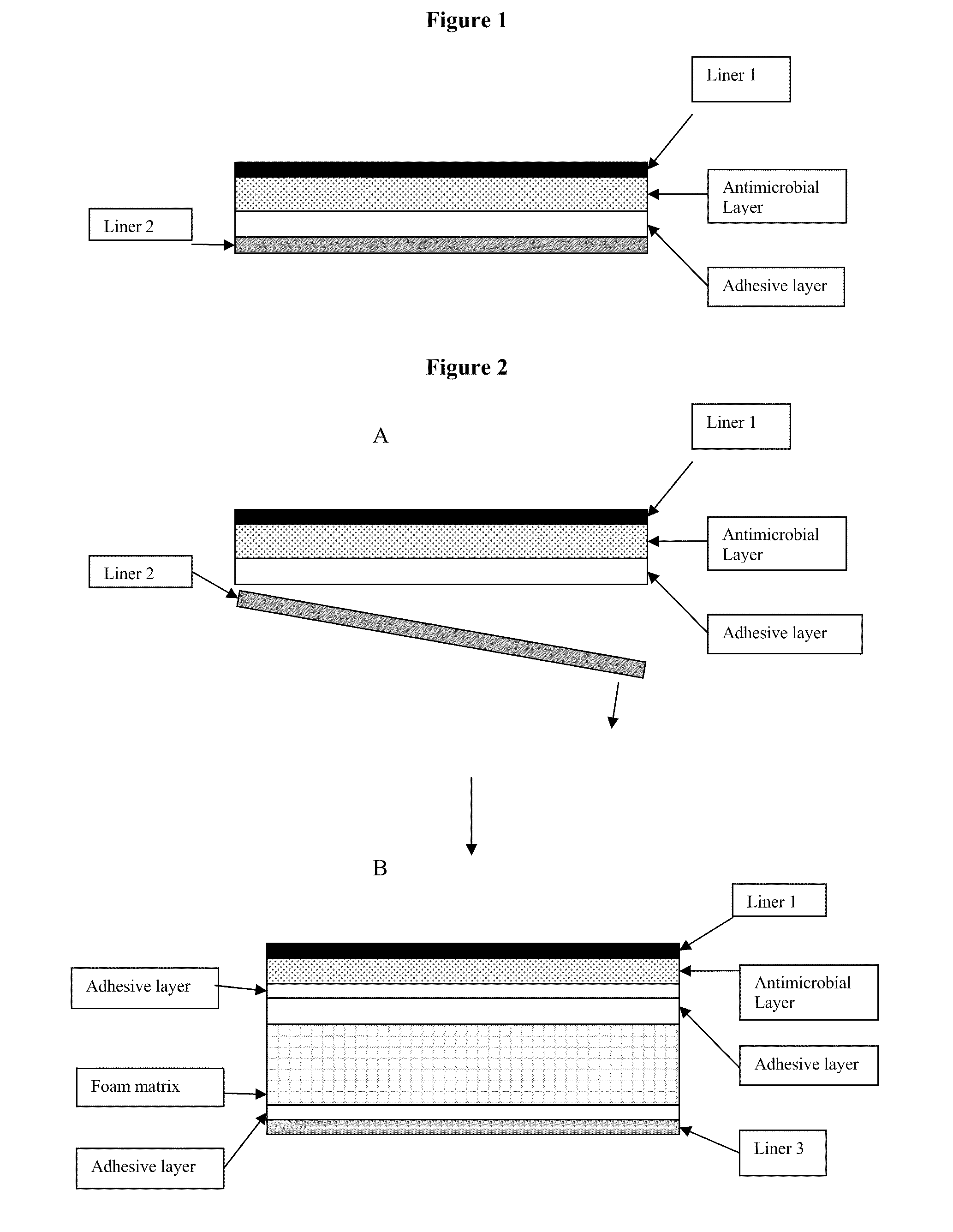

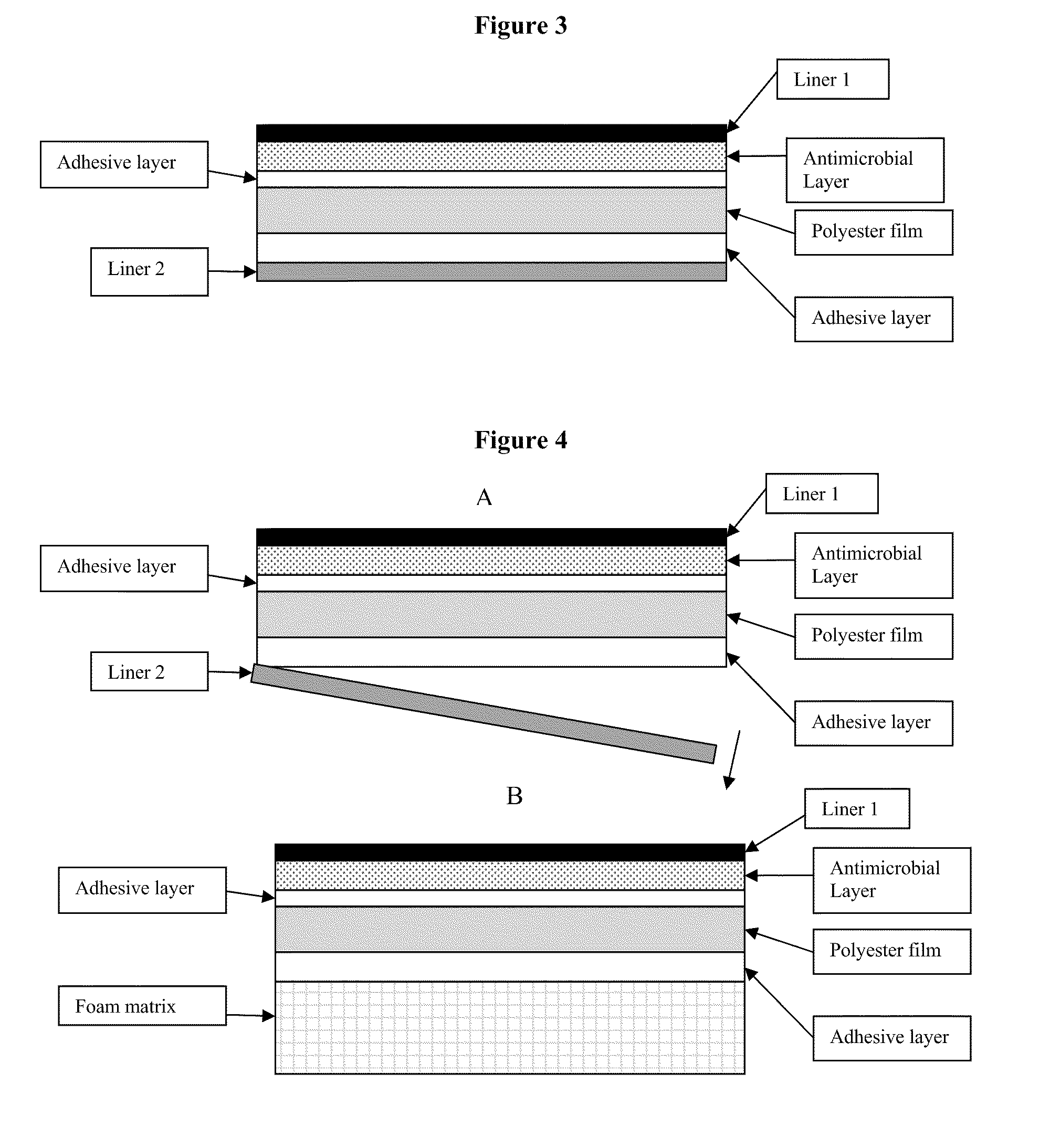

Antimicrobial laminate constructs

InactiveUS20100190004A1Change color quicklyPretreated surfacesAdhesive dressingsMedicineMedical device

The present invention comprises methods for making and using antimicrobial laminate constructs comprising an antimicrobial layer and optionally, an adhesive layer. The present invention comprises methods for making medical devices, surfaces that may be in contact with medical equipment, personnel or patients, or treatment areas antimicrobial comprising, for example, applying an antimicrobial laminate construct.

Owner:AVENT INC

Release liners for pressure sensitive adhesive labels

InactiveUS6110552AReduce thicknessEasy transferCoatings with pigmentsSynthetic resin layered productsEngineeringFacial tissue

A release liner for use with face stocks for pressure sensitive labels, tapes, decals and other products formed from sheet and roll stock. A filled polymer is laminated to one side of a paper web. An extrudate is laminated to the other side of the paper substrate to form a release liner. The filled polymer has paper-like properties and replaces paper tissue back liners.

Owner:FLEXCON

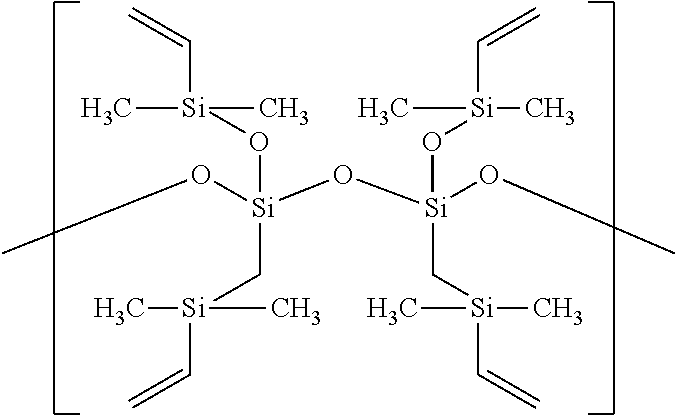

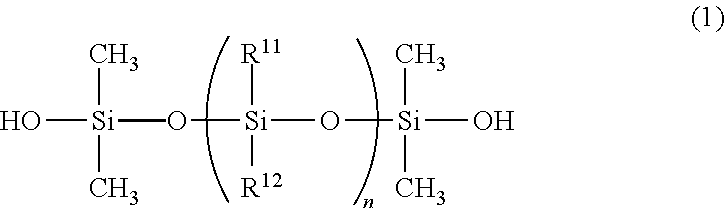

Solventless Cured Release Coating-Forming Organopolysiloxane Composition And Sheet-Form Substrate Having A Cured Release Coating

InactiveUS20110287267A1Good slipperinessGood release effectCoatingsThin material handlingPolymer sciencePtru catalyst

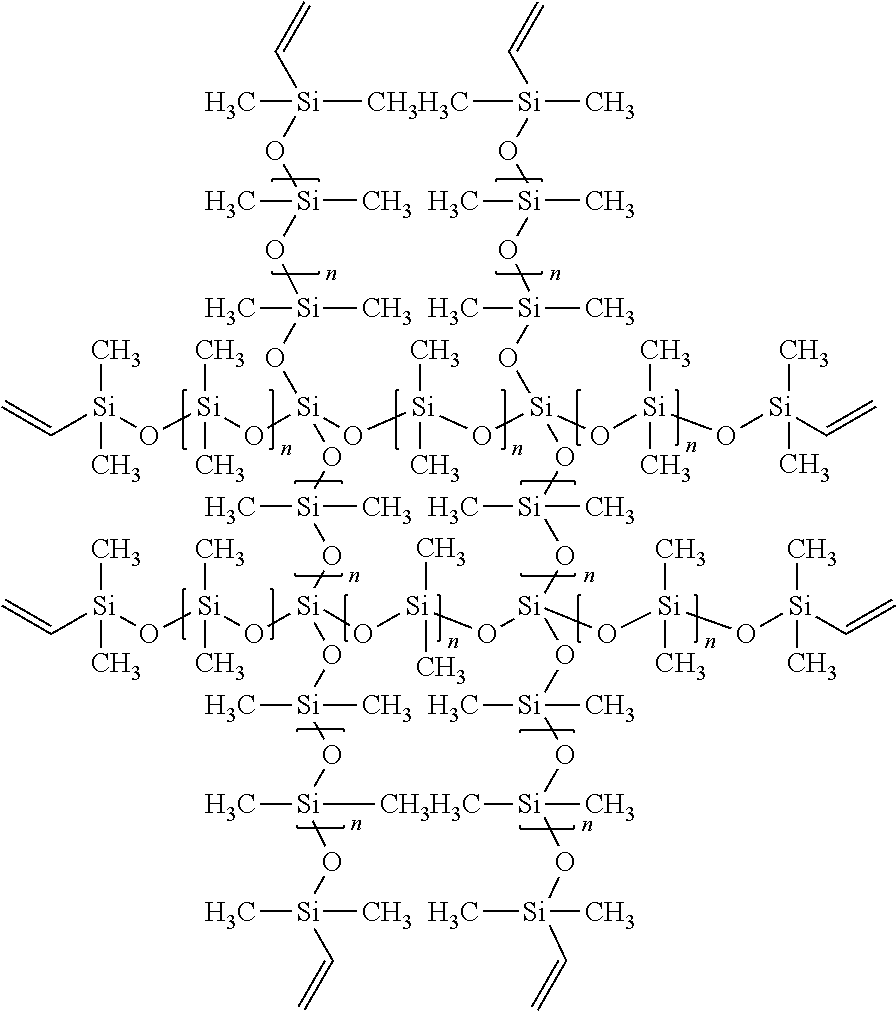

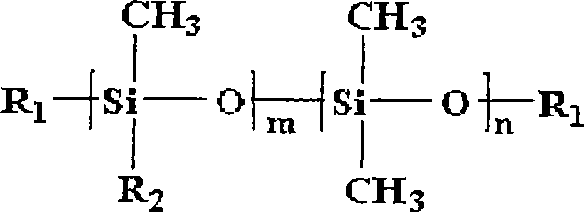

A solventless cured release coating-forming organopolysiloxane composition having a viscosity at 25° C. of 50 to 2,000 mPa·s comprising (A) 100 weight parts of an alkenyl-functional diorganopolysiloxane that has a viscosity of 25 to 1,000 mPa·s; (B) 0.5 to 15 weight parts of a diorganopolysiloxane that has a viscosity of at least 10,000 mPa·s and that has an aliphatically unsaturated group content of no more than 0.1 mole %; (C) 0.5 to 5 weight parts of a branched organopolysiloxane that has more than one SiO4 / 2 unit and that is a polymer product provided by an equilibration polymerization between a branched organosiloxane oligomer represented by the average siloxane unit formula (1) (SiO4 / 2)(RaRb2SiO1 / 2)x(1) and a diorganosiloxane oligomer; (D) a specific amount of an organohydrogenpolysiloxane that has a viscosity of 1 to 1,000 mPa·s; and (E) a hydrosilylation reaction catalyst in a catalytic quantity.

Owner:DOW CORNING TORAY CO LTD +1

Release liner for pressure sensitive adhesives

InactiveUS6982107B1Imparts thermal stabilityNot likely to significantly decompose and meltSynthetic resin layered productsWater-setting substance layered productPolymer chemistryRelease liner

A release liner for use with a pressure sensitive adhesive. The release liner includes a film of a thermoplastic elastomeric olefin.

Owner:3M INNOVATIVE PROPERTIES CO

Re-peelable pressure-sensitive adhesive sheet

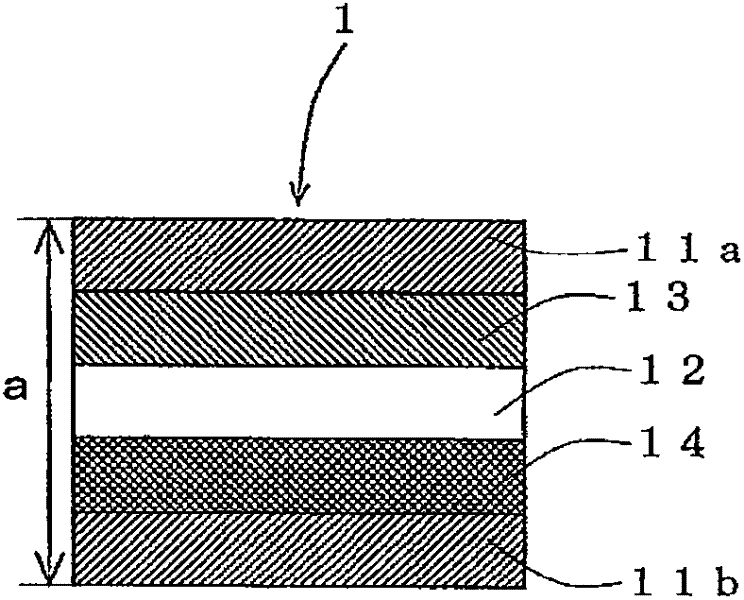

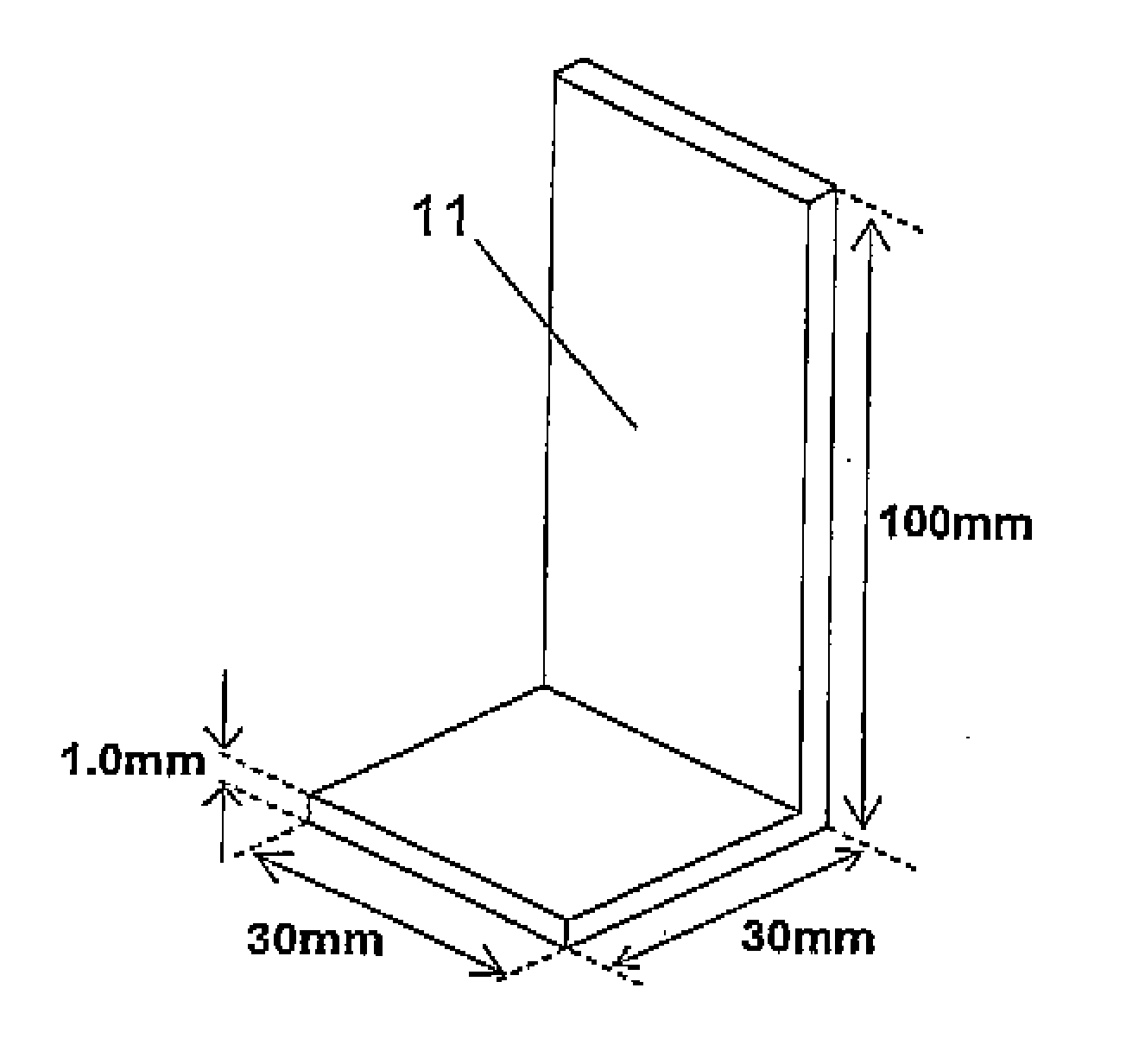

InactiveUS20050031861A1Lamination ancillary operationsSemiconductor/solid-state device manufacturingSemiconductorElastic modulus

The re-peelable pressure-sensitive adhesive sheet of the invention is a re-peelable pressure-sensitive adhesive sheet, which comprises an adhesive agent layer formed over a base film, and which further comprises at least one intermediate layer between the base film and the adhesive agent layer, the intermediate layer having a storage elastic modulus (G′) of 3.0×104 to 1.0×108 Pa at 23° C. and a storage elastic modulus (G′) of 1.0×103 to 8.0×104 Pa at 200° C. Even when this re-peelable pressure-sensitive adhesive sheet and a semiconductor wafer are adhered to each other and they are placed, as they are, in a heating environment, the wafer can be prevented from being warped.

Owner:NITTO DENKO CORP

Silicone-Based Releasable Adhesive Composition, Sheet-Form Substrate Having Releasable Adhesive Layer Formed By Curing This Composition, And Use Of Such A Protective Film Or Fixing Sheet

InactiveUS20120328863A1Easy to controlEasy to disassembleSynthetic resin layered productsOrganic non-macromolecular adhesivePolymer scienceAlkoxy group

Problem: To provide a silicone-based releasable adhesive composition that is capable of easily controlling peeling force of a releasable adhesive layer by the composition, and whereby the silicone-based releasable adhesive composition has excellent attachment characteristics and releasability characteristics. A further object is to provide a sheet-form substrate and a releasable adhesive sheet that have a releasable adhesive layer formed by curing this composition.Resolution Means: The silicone-based releasable adhesive composition includes an organopolysiloxane resin-organopolysiloxane condensation reaction product obtained by condensation reaction between (a1) 100 weight parts of an MQ type organopolysiloxane resin containing hydroxyl groups or alkoxy groups in a range of 0.3 to 2.0 weight % and having an M unit to Q unit molar ratio of 0.6 to 1.0, and (a2) 20 to 150 weight parts of a chain-like diorganopolysiloxane having an average degree of polymerization of 100 to 1,000 and having at least one hydroxyl group or alkoxy group, wherein the organopolysiloxane resin-organopolysiloxane condensation reaction product preferably includes a certain hydroxyl group content.

Owner:DOW CORNING TORAY CO LTD

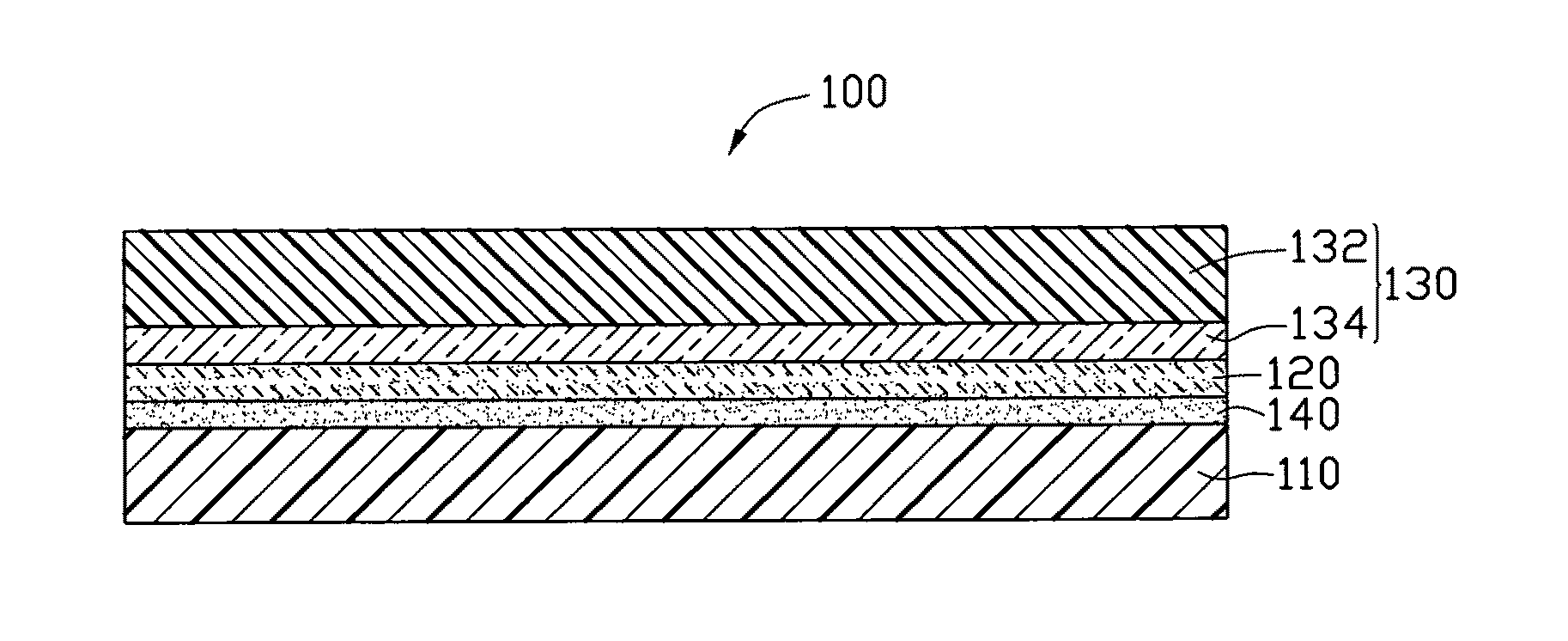

PRESSURE SENSITIVE ADHESIVE COMPOSITION (As Amended)

ActiveUS20120328800A1Improve wettabilityReduction in peel forceLiquid crystal compositionsEster polymer adhesivesPeel forcePressure sensitive

The present invention relates to a pressure sensitive adhesive composition. The present invention may effectively provide a pressure sensitive adhesive where peel forces for both sides are different and an modulus differs along the thickness direction. By applying the pressure sensitive adhesive as above, the present invention may provide, for example, an optical element, such as a polarizing plate, which can effectively inhibit light leakage and shows excellent durability, while being formed to have a thin thickness as well.

Owner:LG CHEM LTD

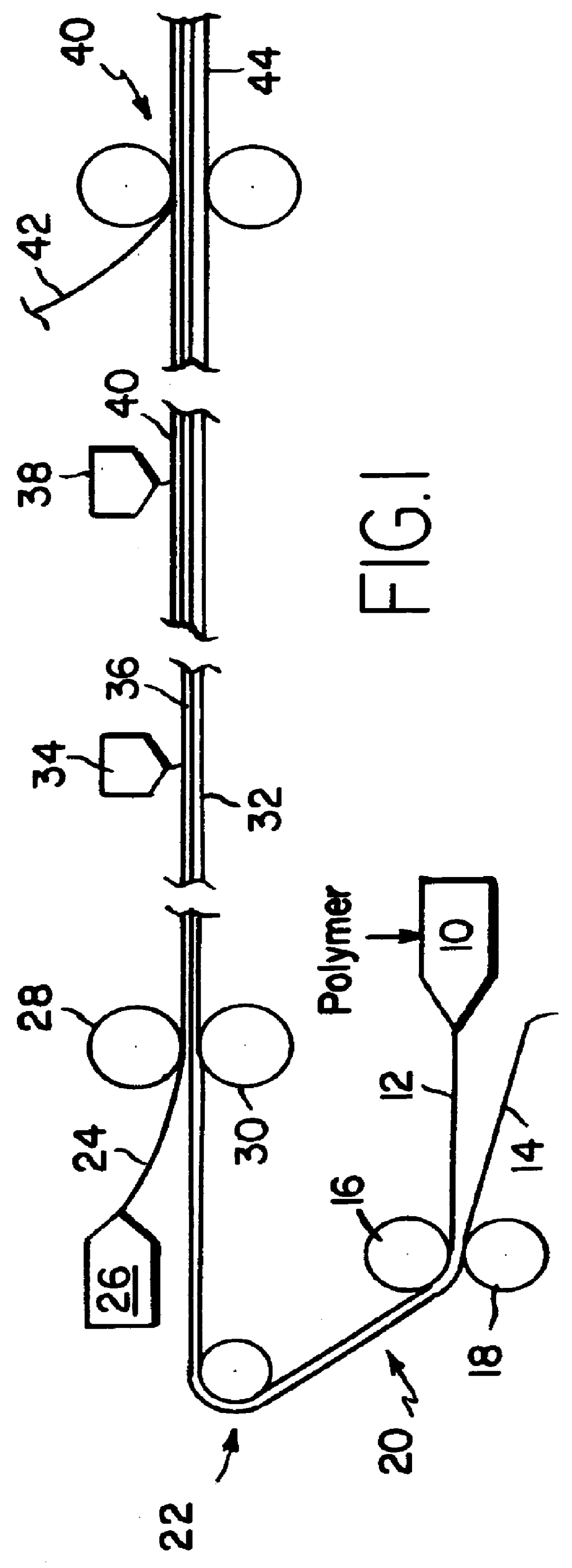

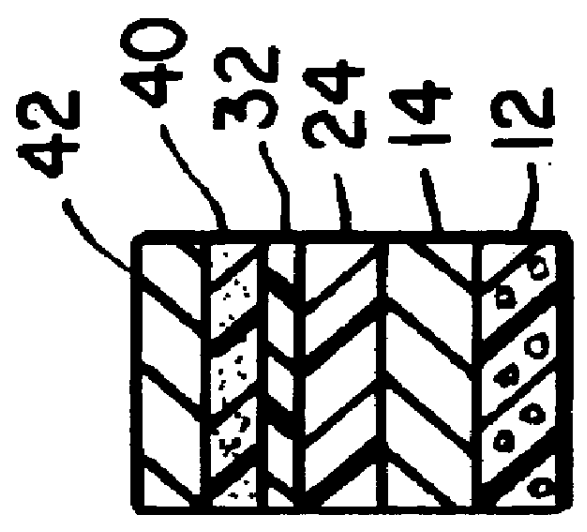

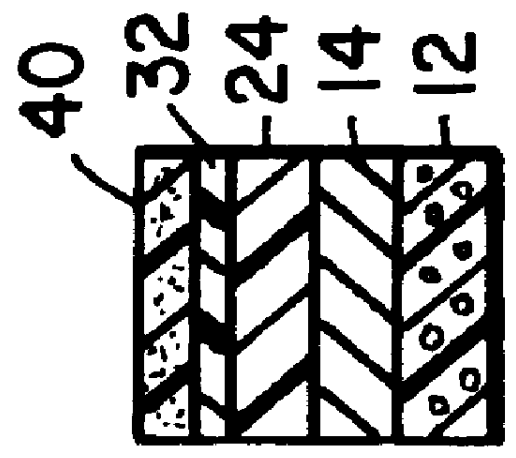

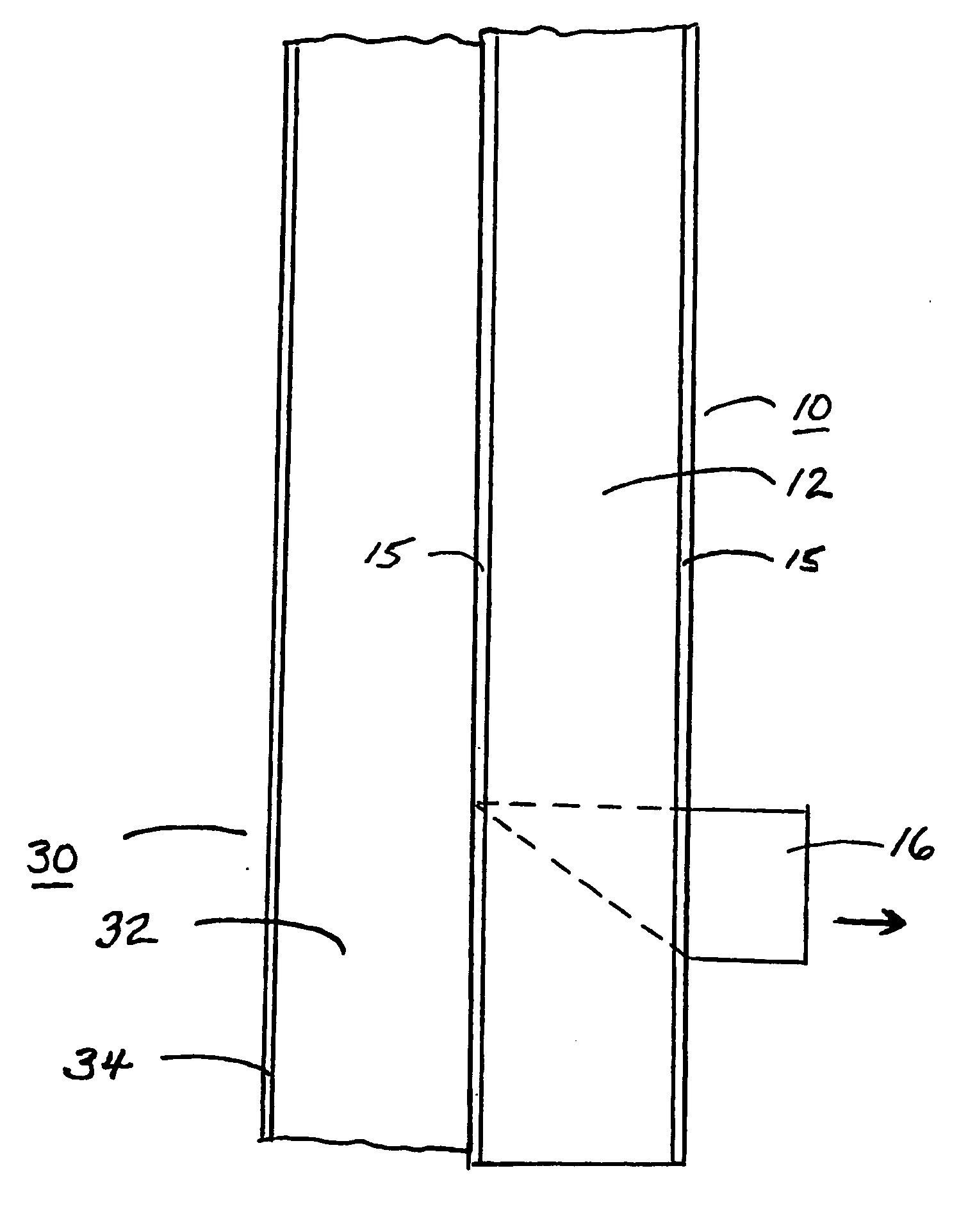

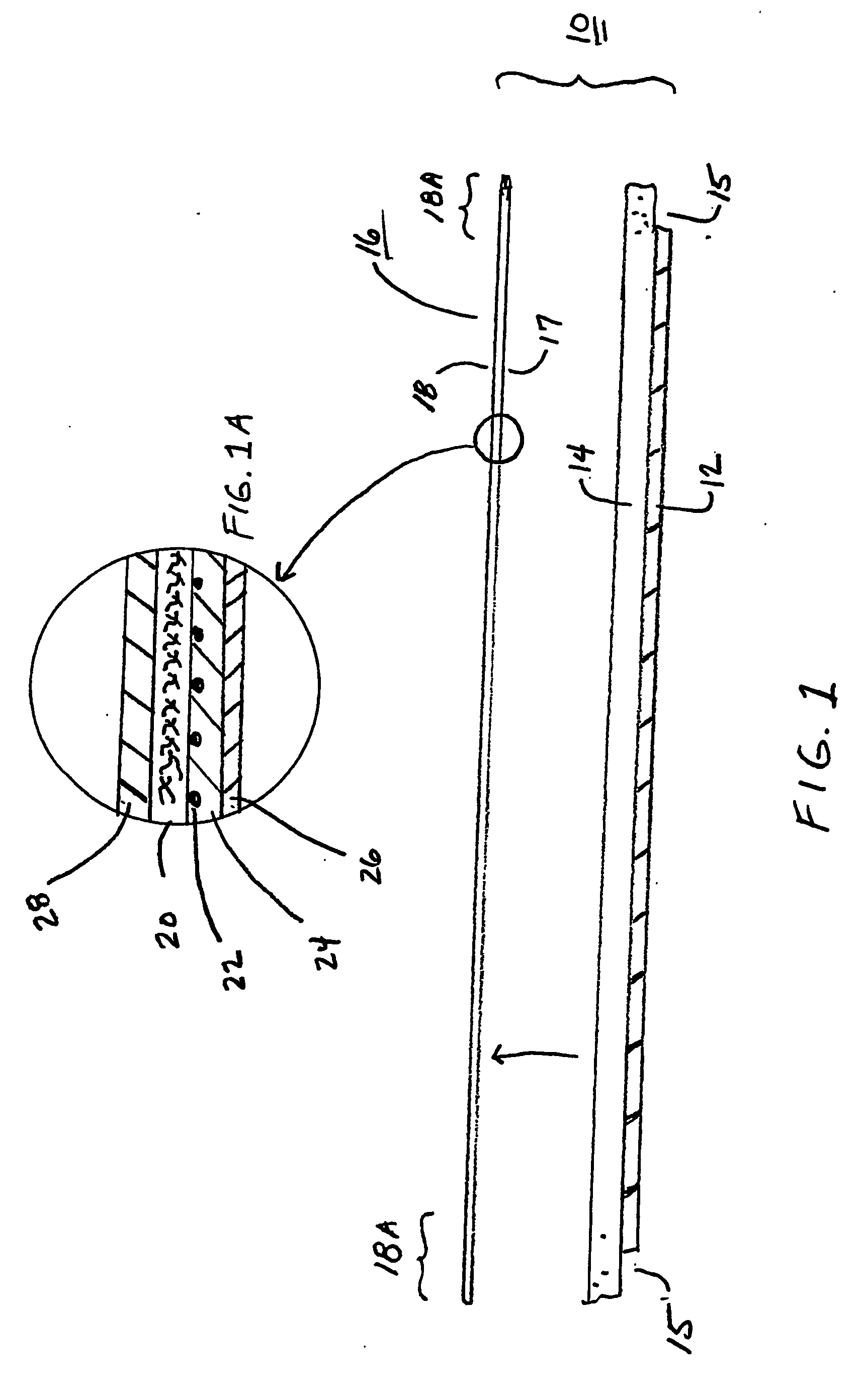

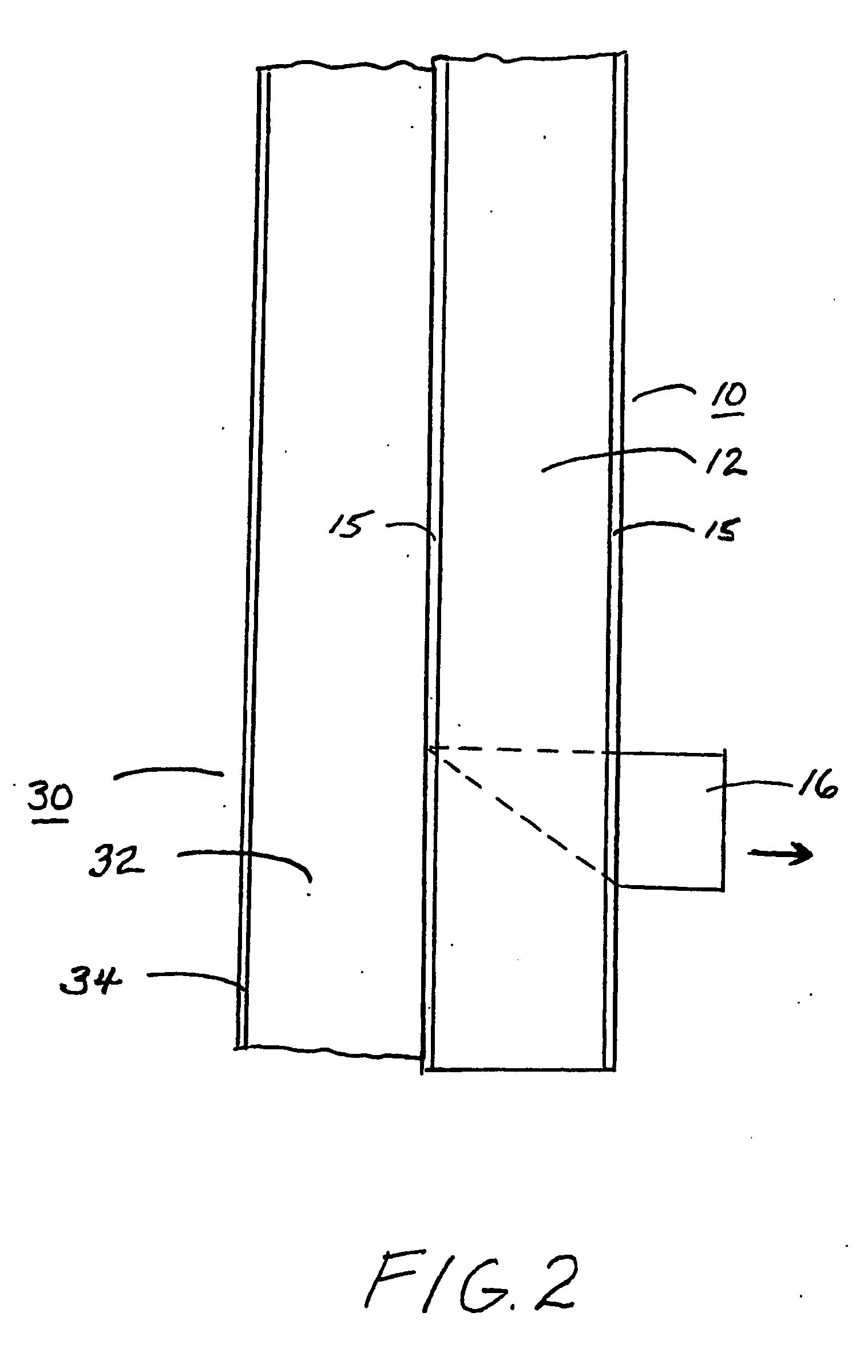

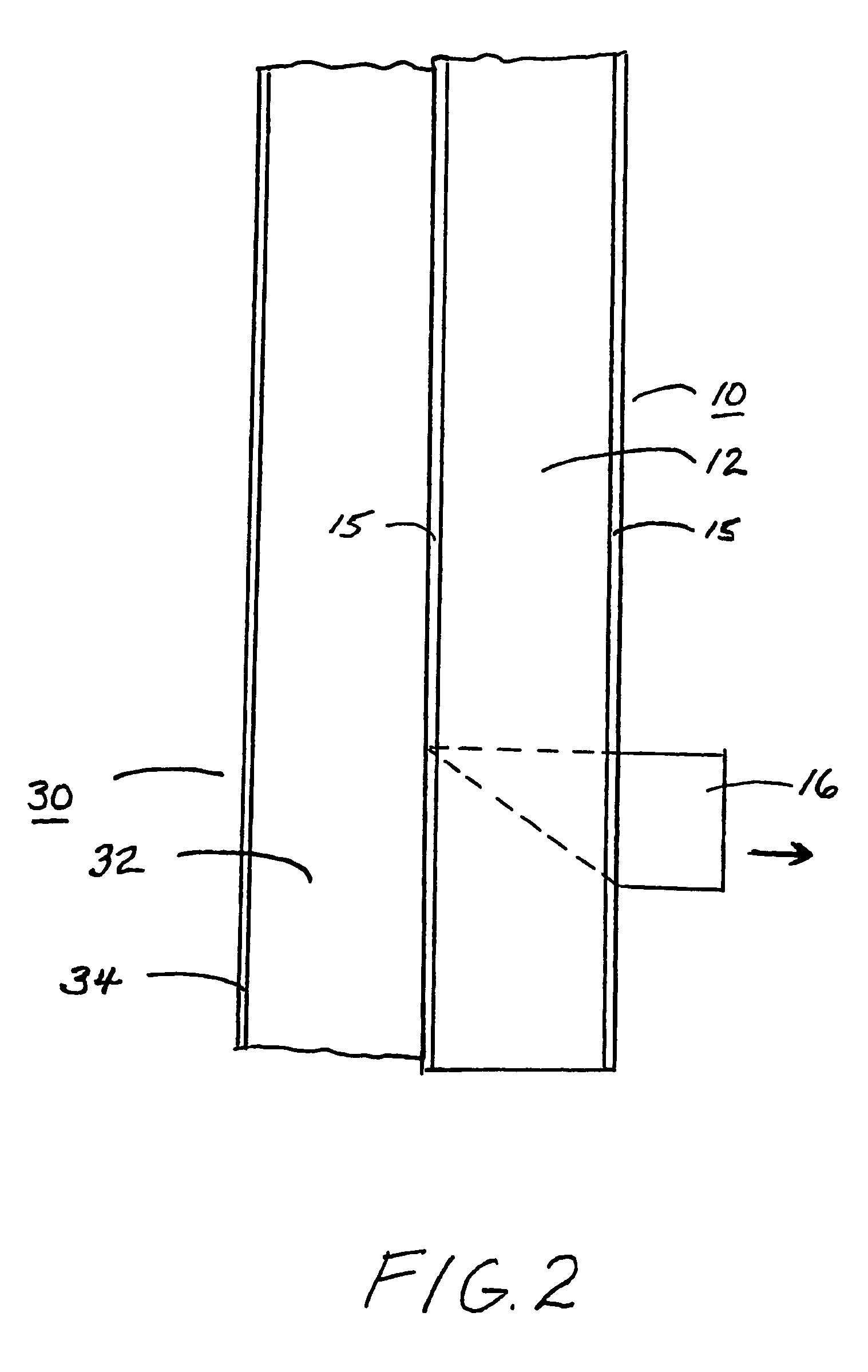

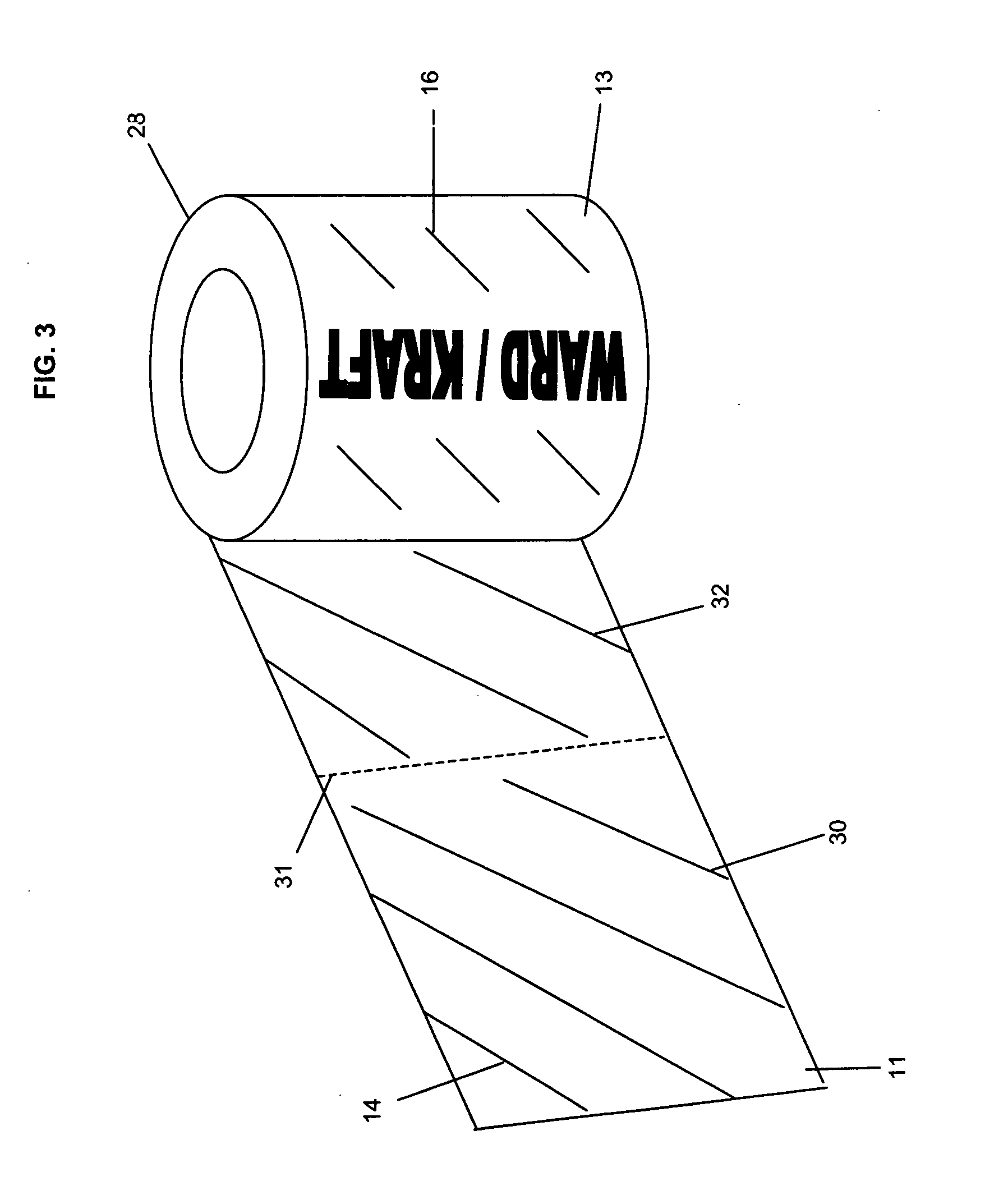

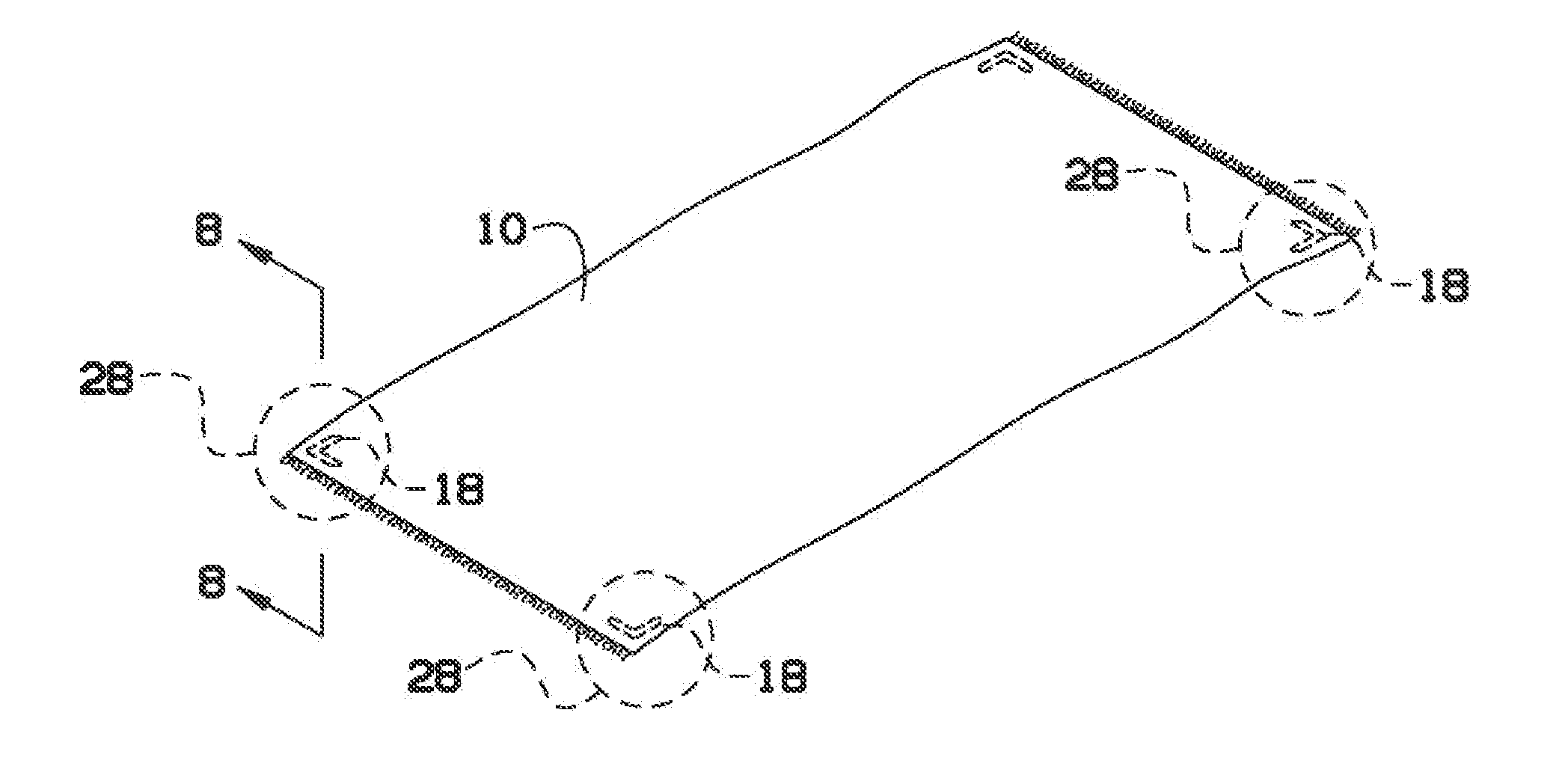

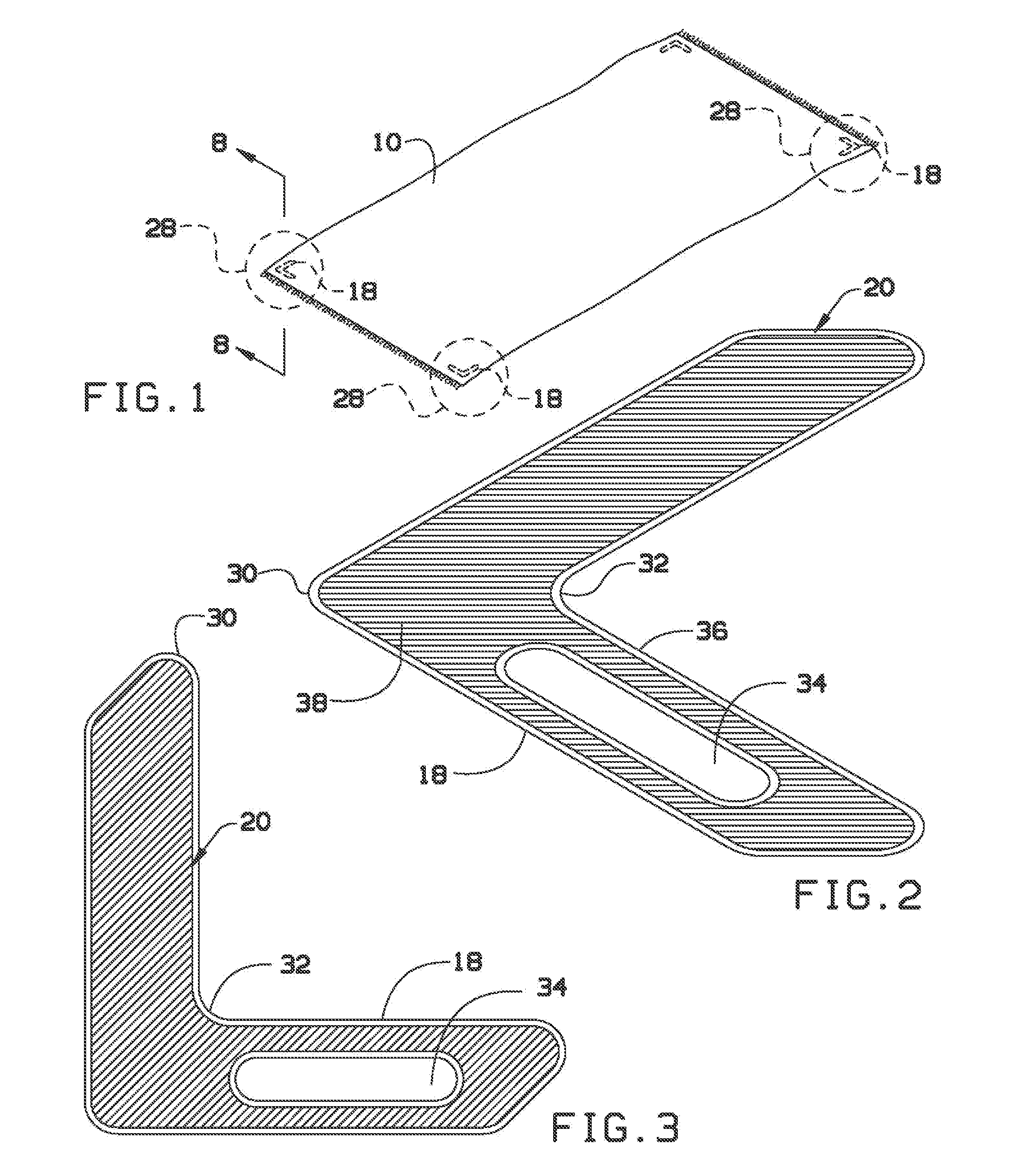

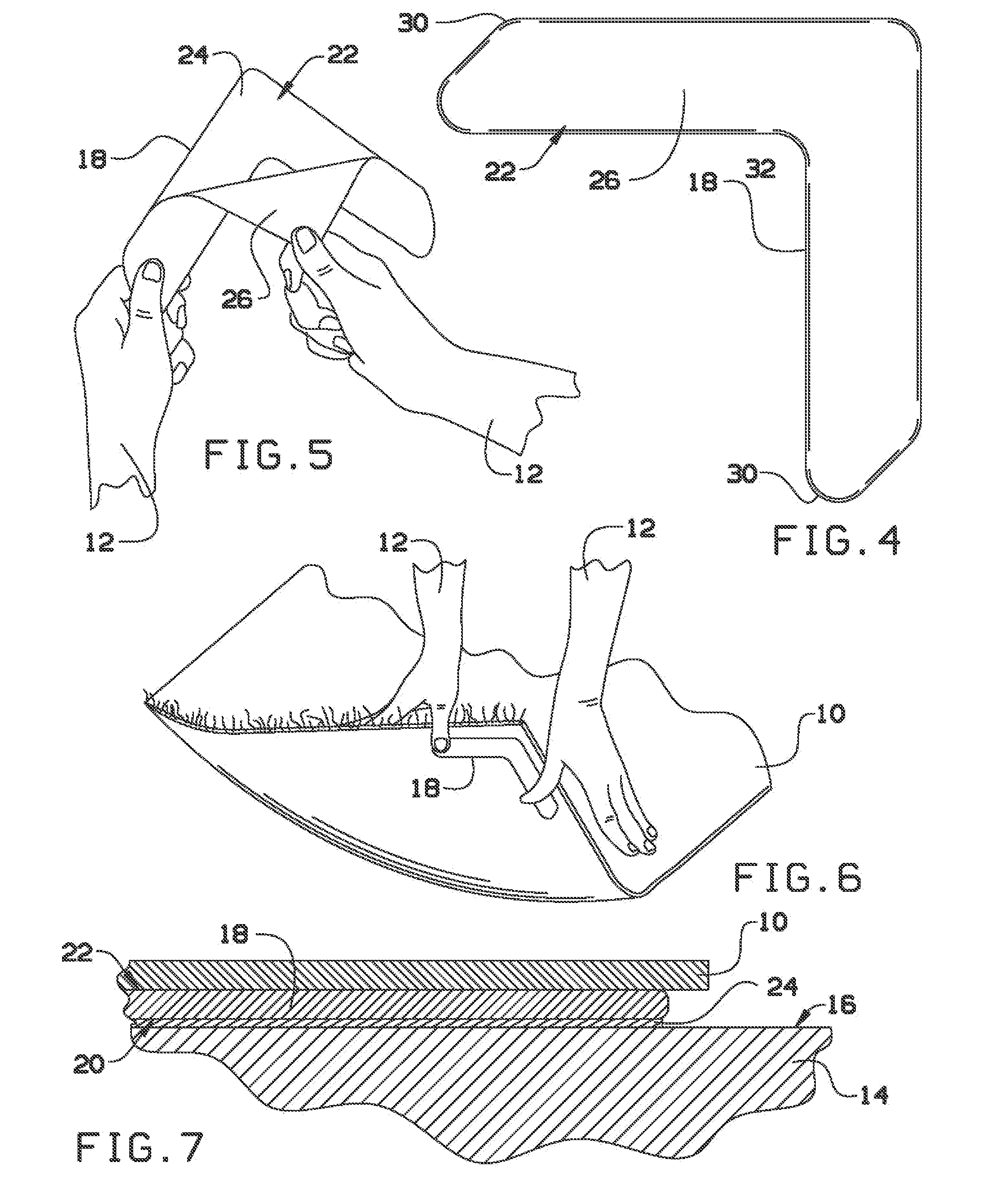

Moisture barrier membrane with tearable release liner composite

ActiveUS20060141191A1Improve economyGreat ecological advantageSynthetic resin layered productsLaminationWaxPolyolefin

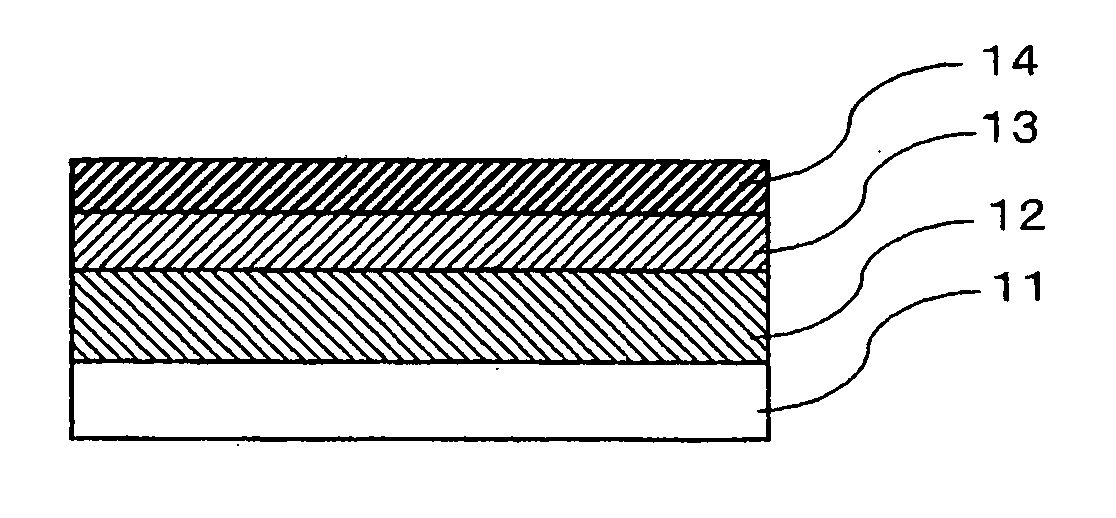

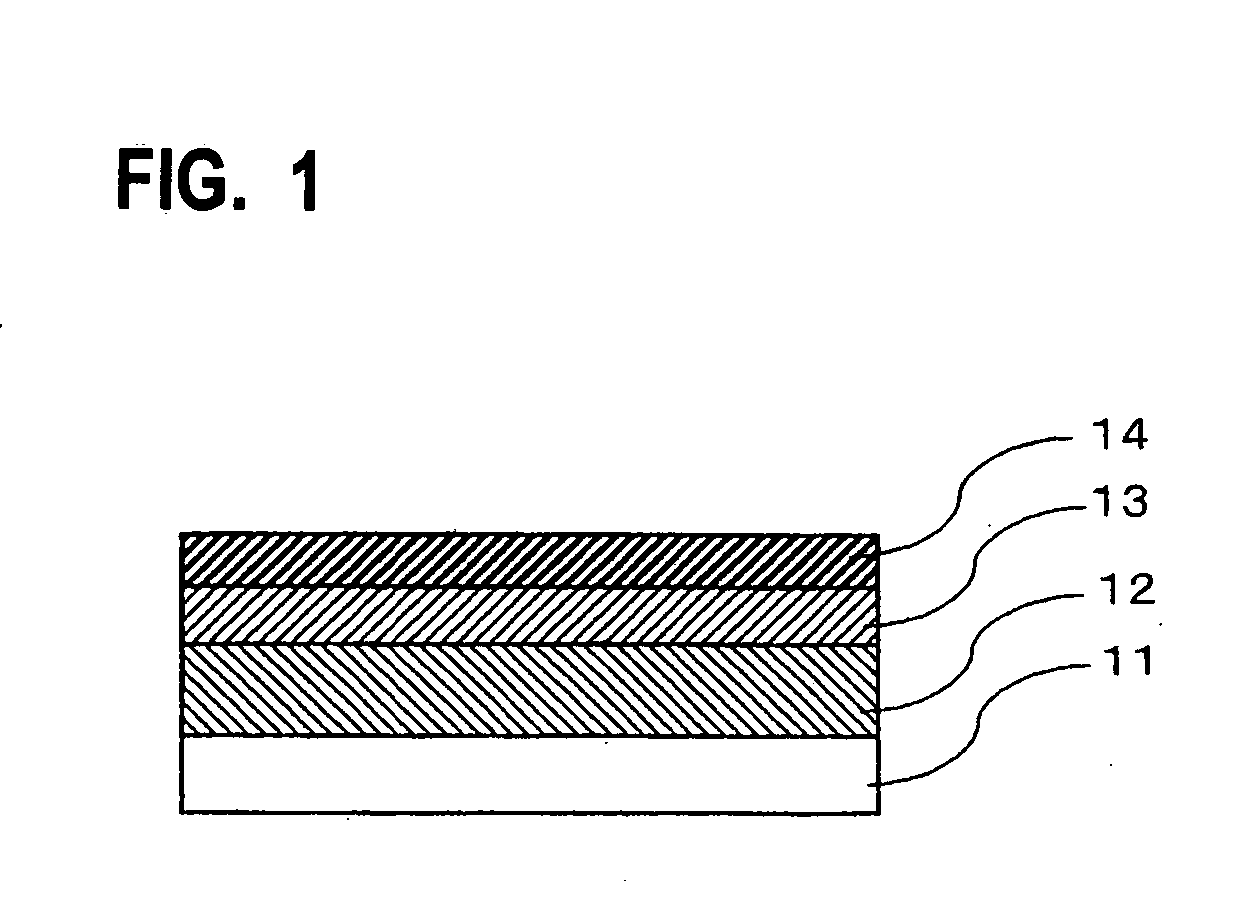

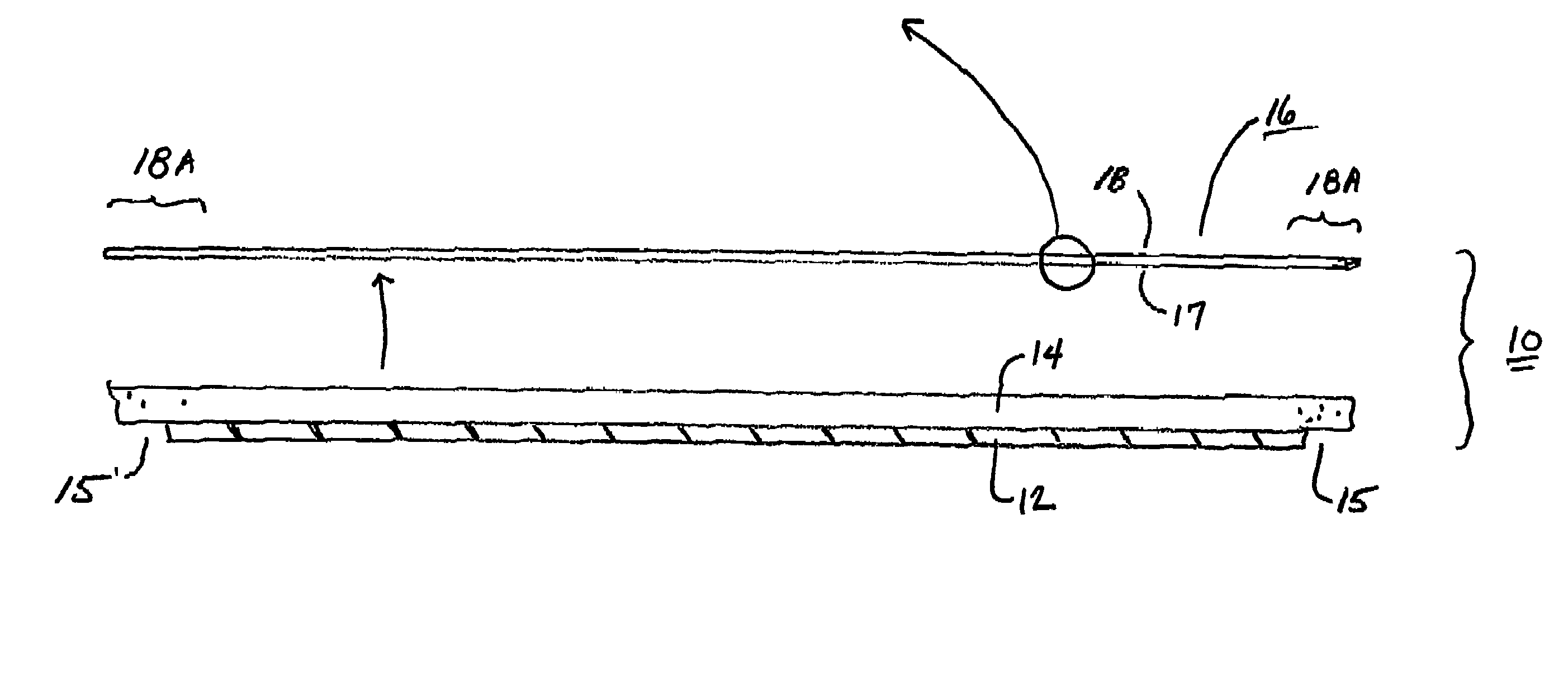

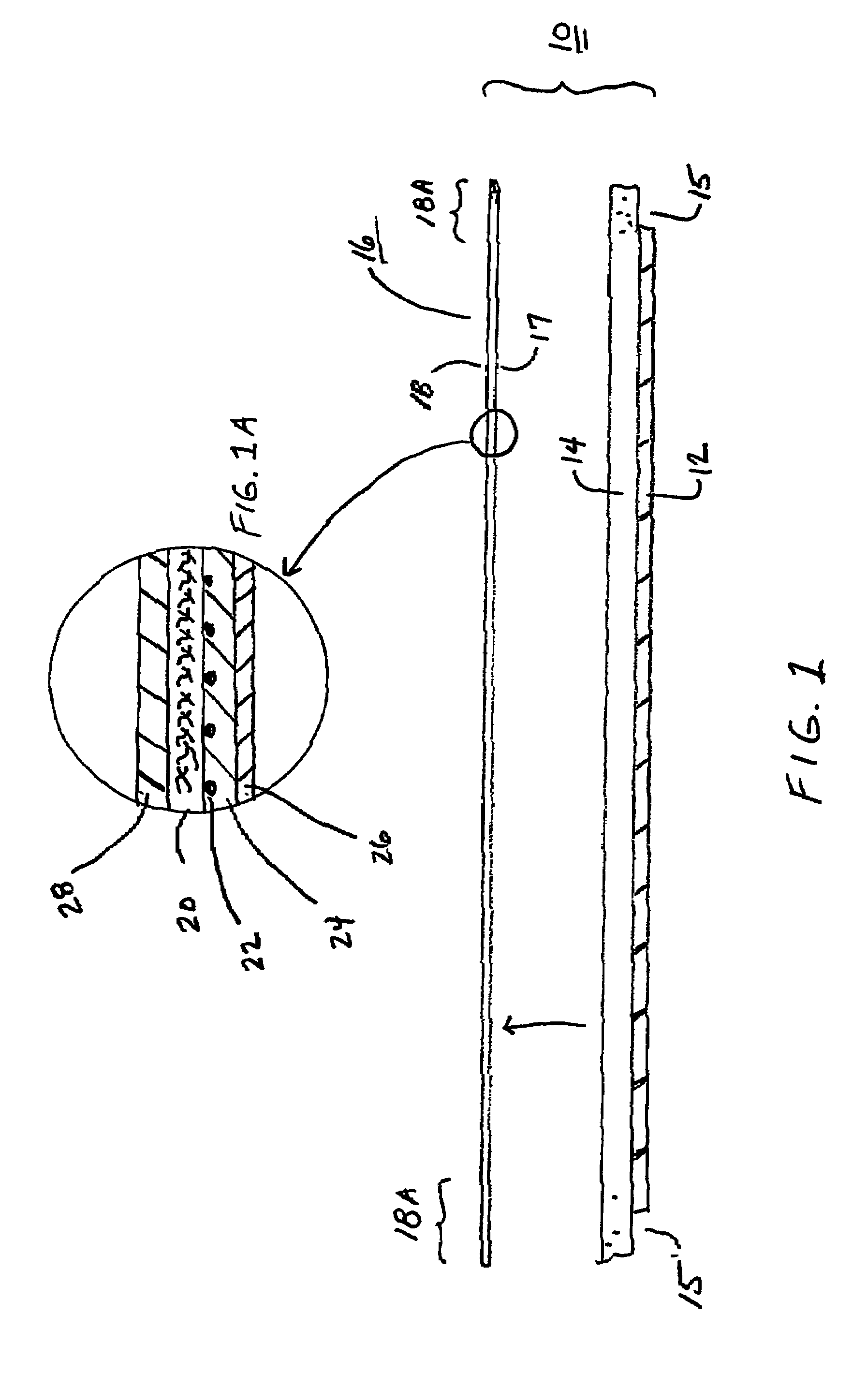

An exemplary moisture barrier membrane 10 comprises a waterproof adhesive layer, (14) a carrier support, (12) and a release liner (16) composite having a paper sheet, (20) cutting strings, (22) a polyolefin (24) coating or film for holding the strings against the paper and apart from the waterproof adhesive layer, and a release agent (26) such as silicone or wax over the polyolefin coating or film. This construction allows for relatively thin paper and strings to be used, such that tear resistance is conferred upon the release liner composite as a whole.

Owner:GCP APPL TECH INC

double sided adhesive tape

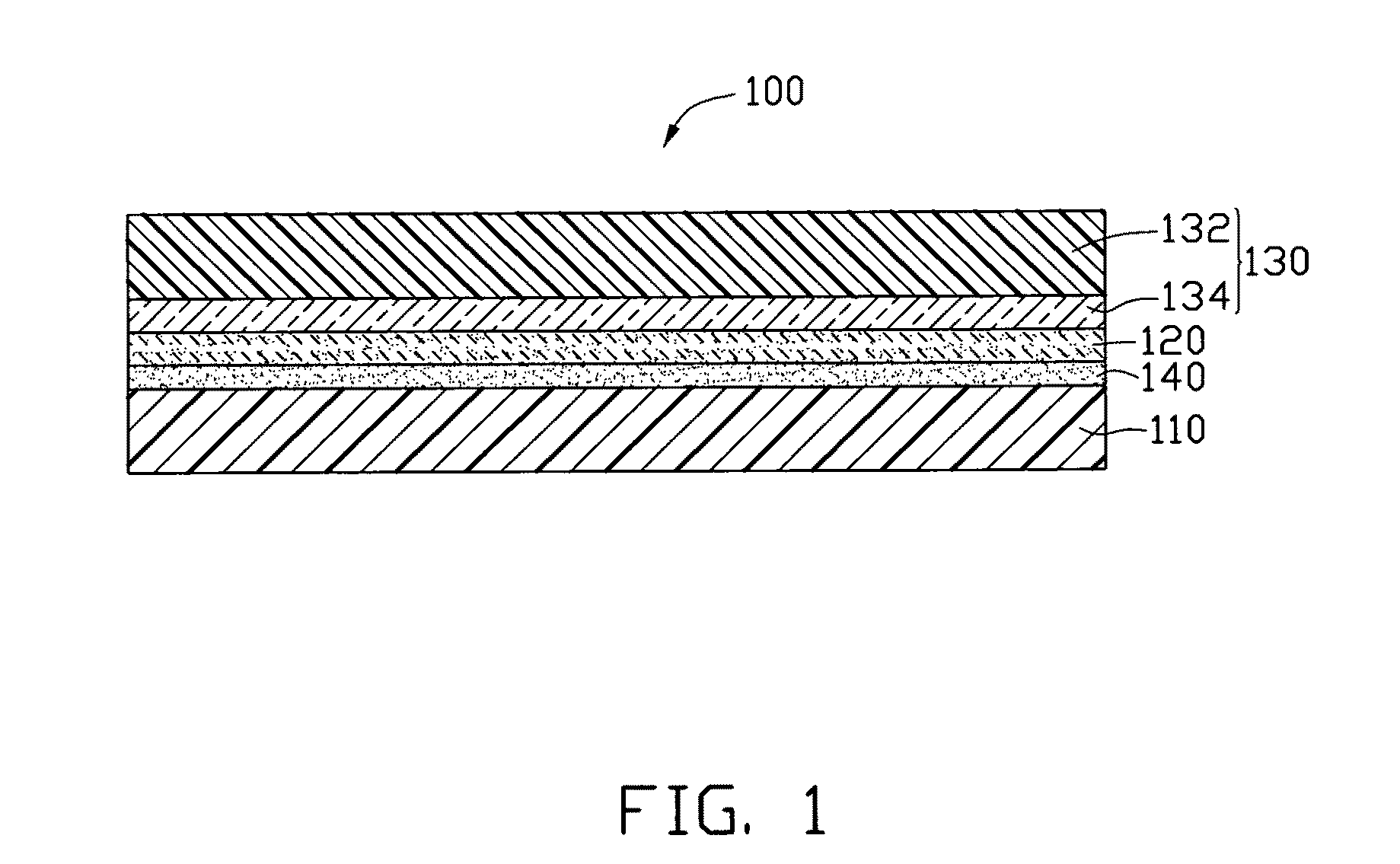

InactiveCN102268230AThe overall thickness is thinExcellent peelabilityEster polymer adhesivesFilm/foil adhesive release linersSurface layerAdhesive

Owner:NITTO DENKO CORP

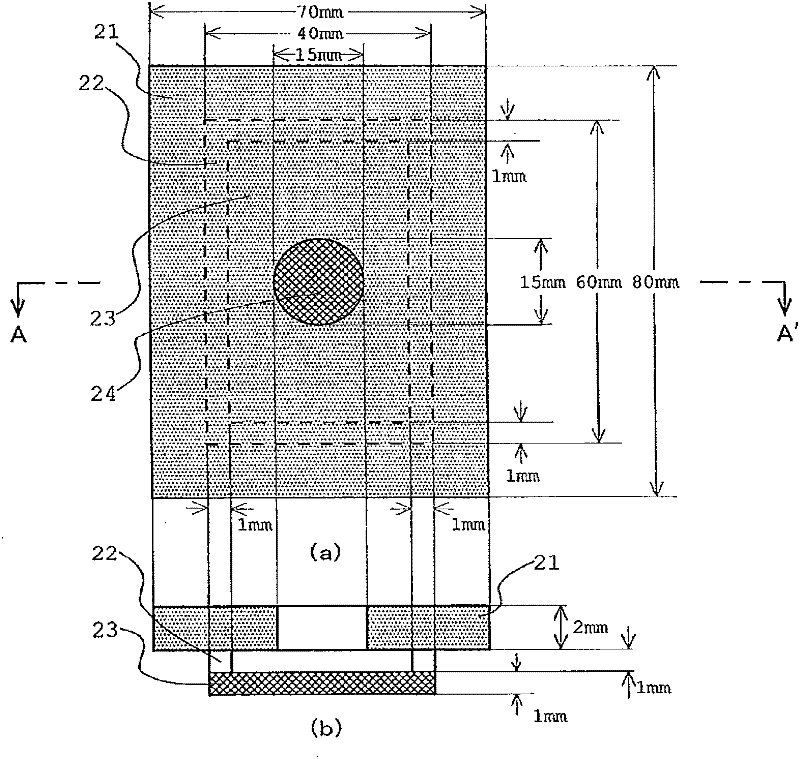

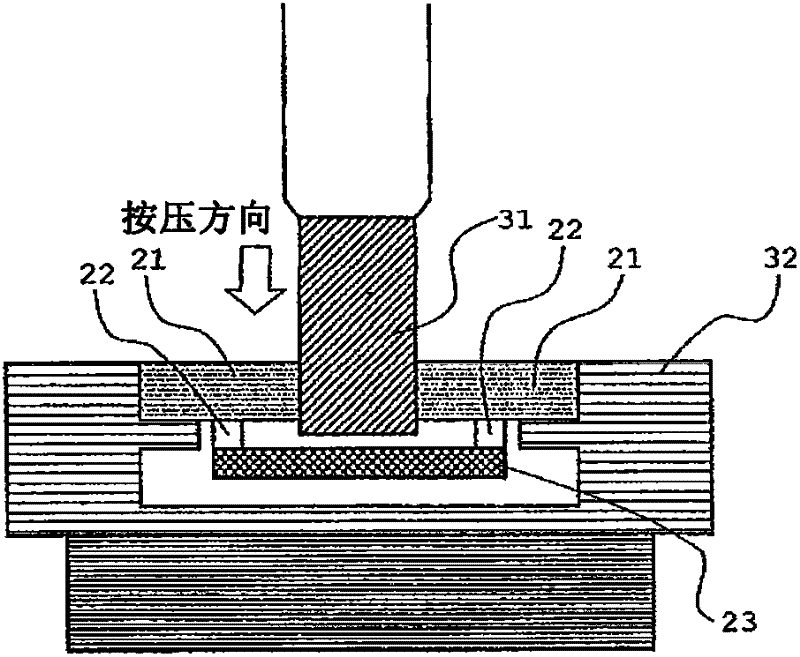

Optical-use pressure-sensitive adhesive sheet

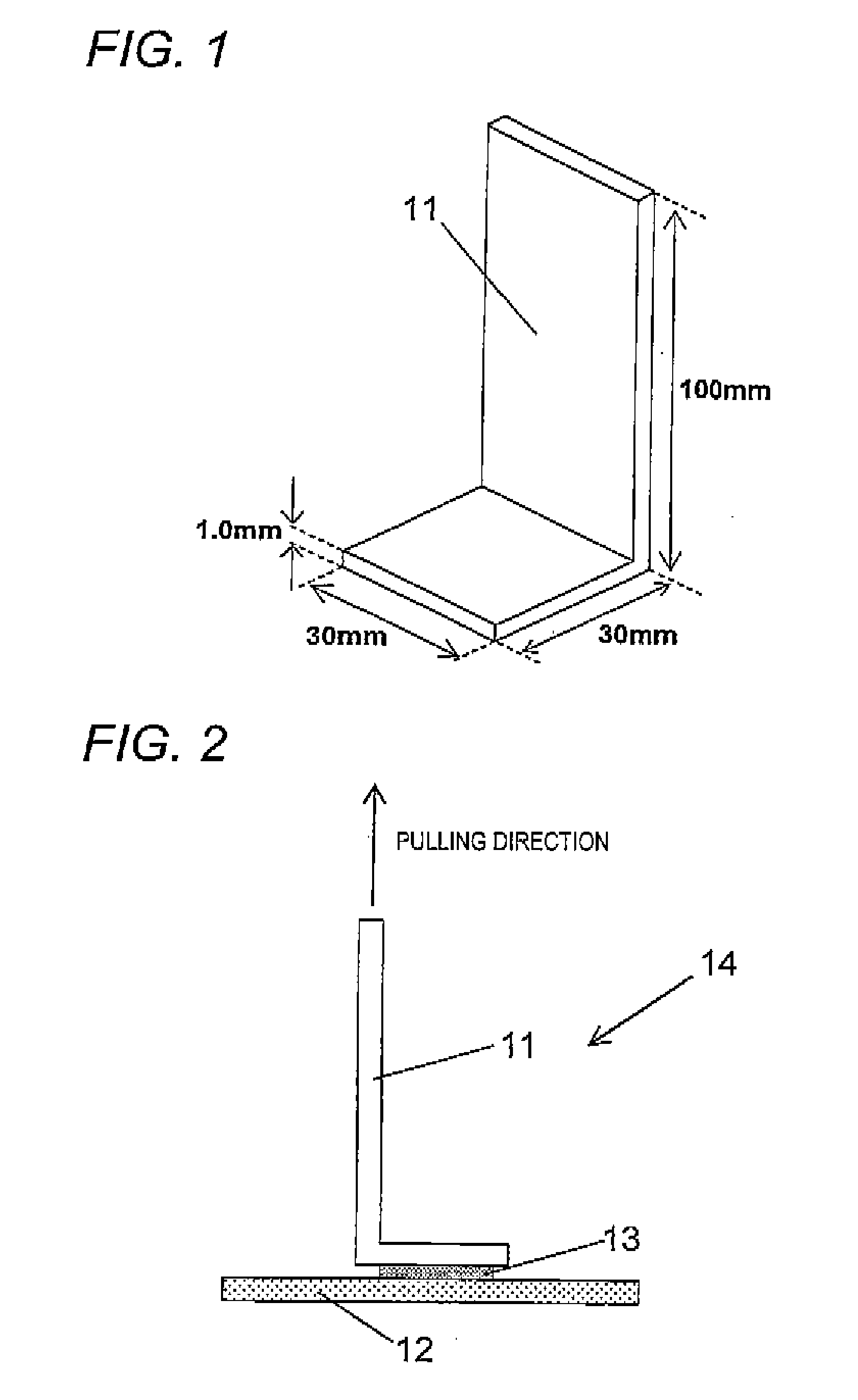

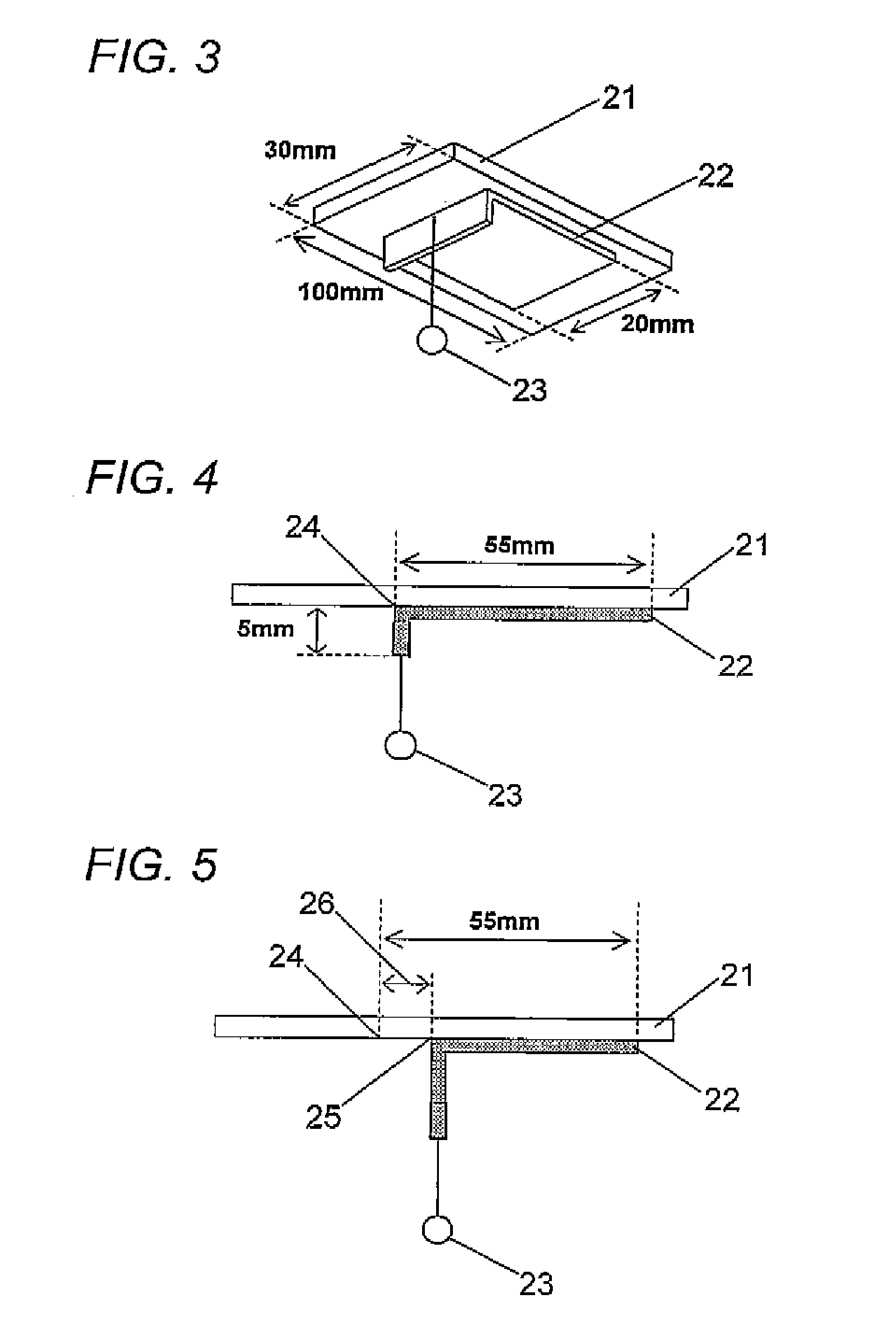

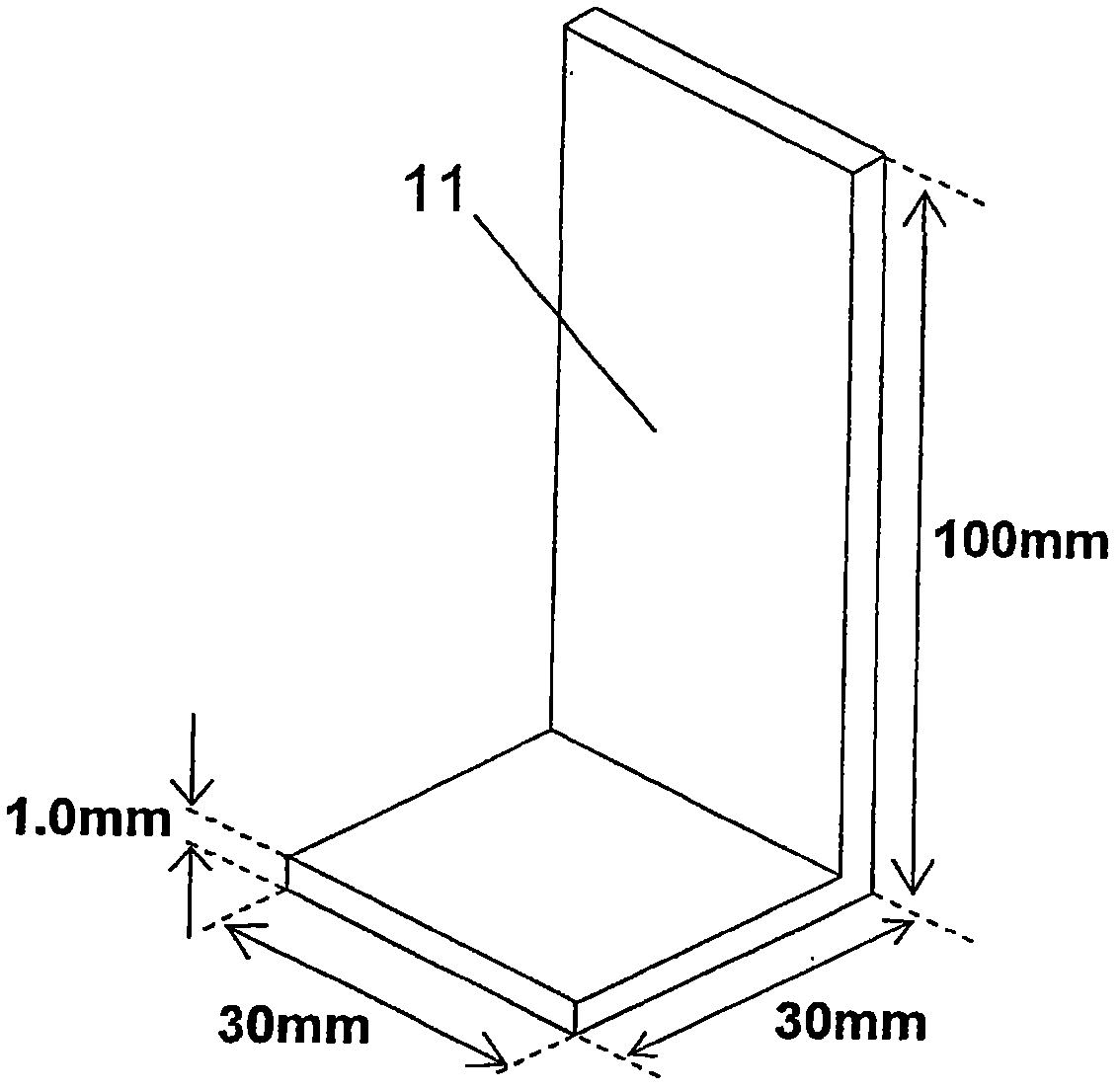

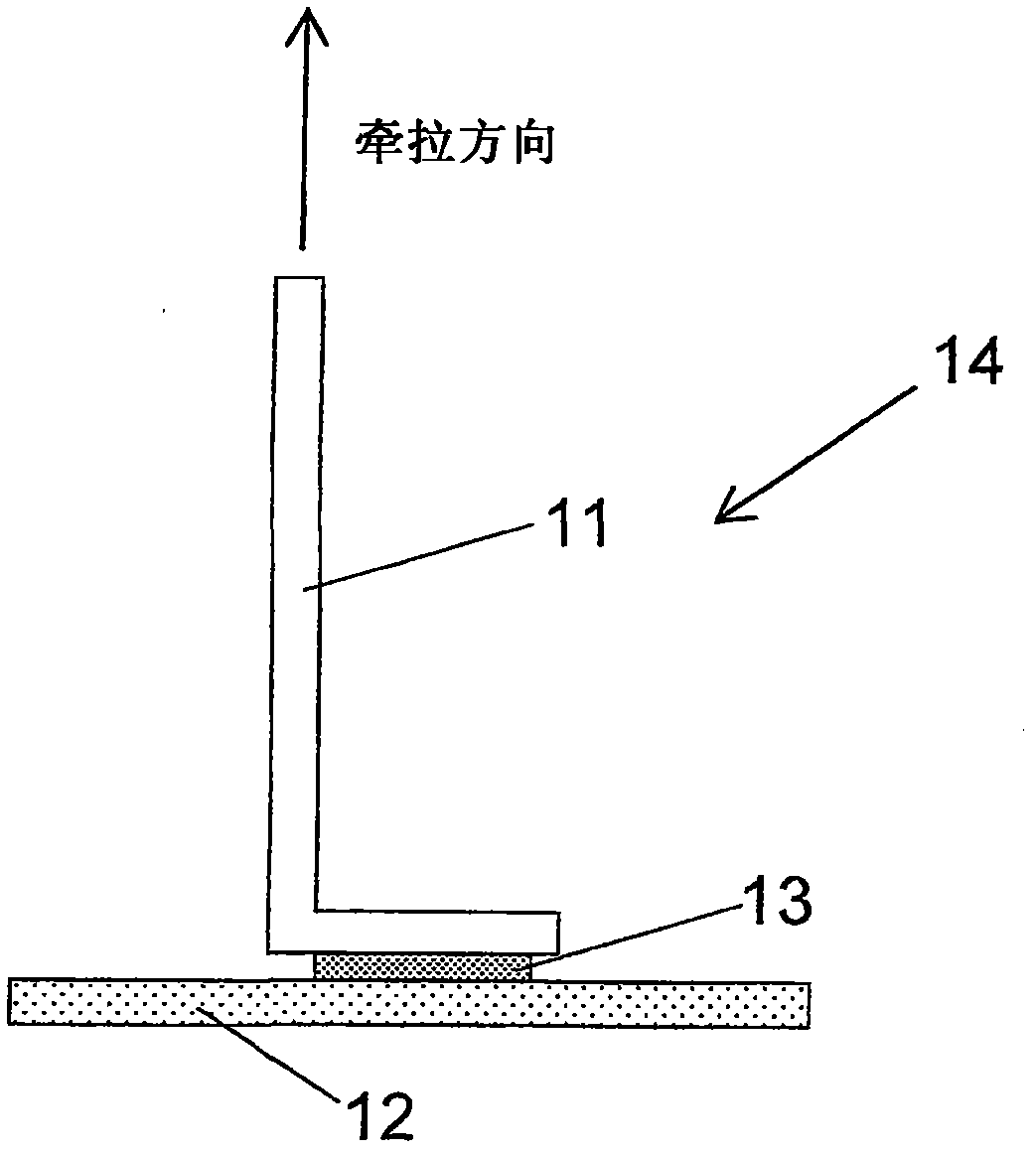

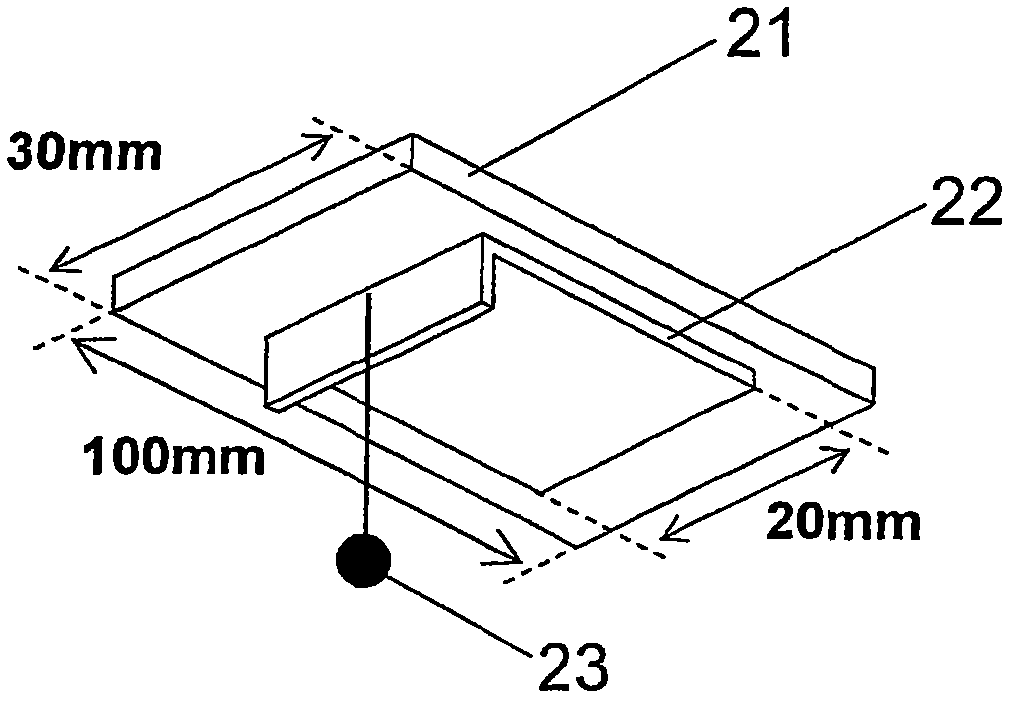

InactiveUS20110111220A1Improve adhesionExcellent in twist-proof adhesivenessMonocarboxylic acid ester polymer adhesivesOpticsConstant loadDynamic viscoelasticity

The present invention provides an optical-use pressure-sensitive adhesive sheet including a pressure-sensitive adhesive layer having, as measured through dynamic viscoelastometry, a storage elastic modulus at 80° C. of at least 2.0×104 Pa and a loss elastic modulus at 80° C. of at least 1.0×104 Pa, in which the pressure-sensitive adhesive sheet has a peel force, as measured in the L-shape peel test, of at least 0.16 MPa, and has a peel distance, as measured in the constant-load peel test (under a load of 100 gf for 3 hours), of at most 50 mm.

Owner:NITTO DENKO CORP

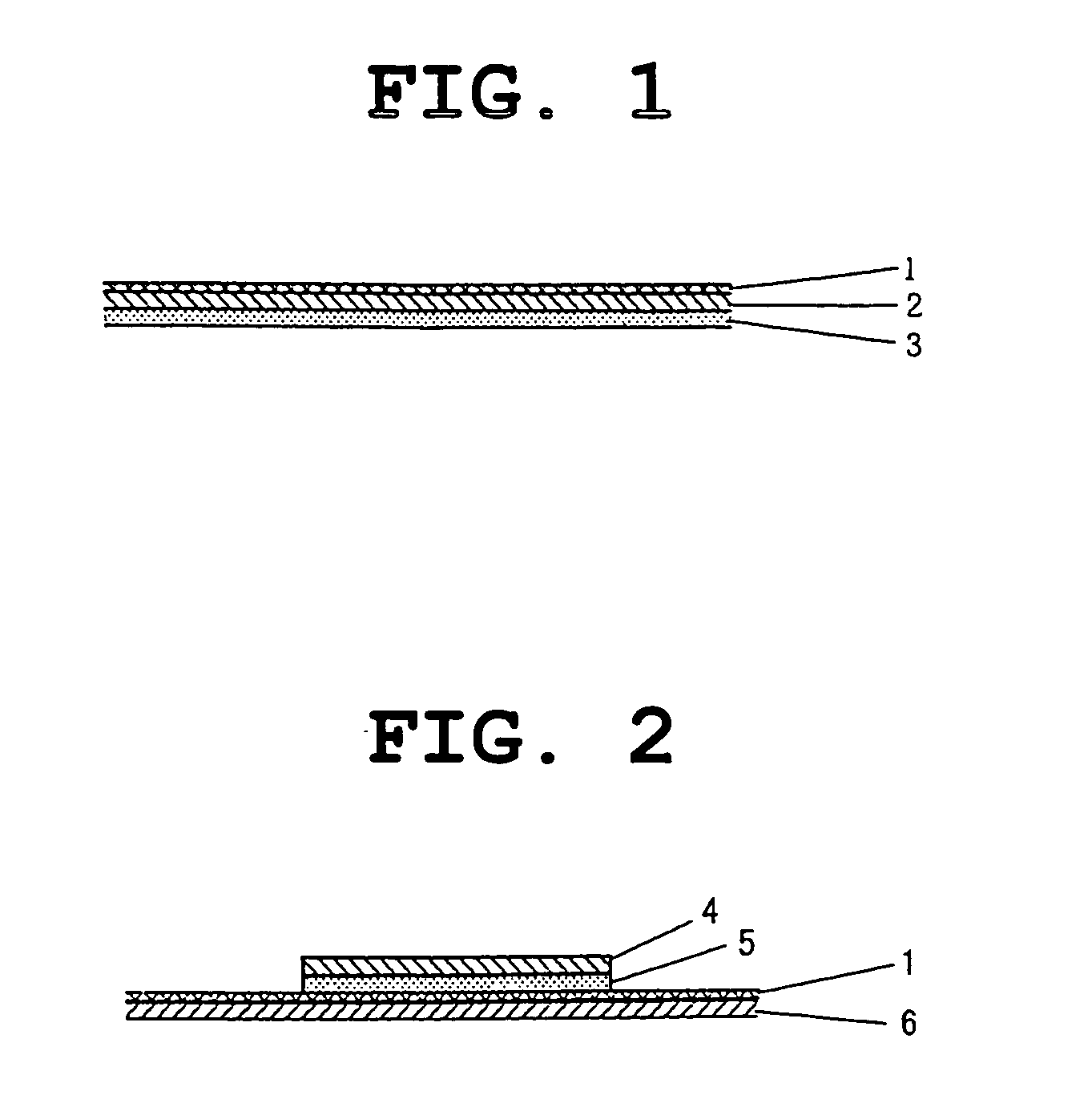

Double-coated pressure-sensitive adhesive tape

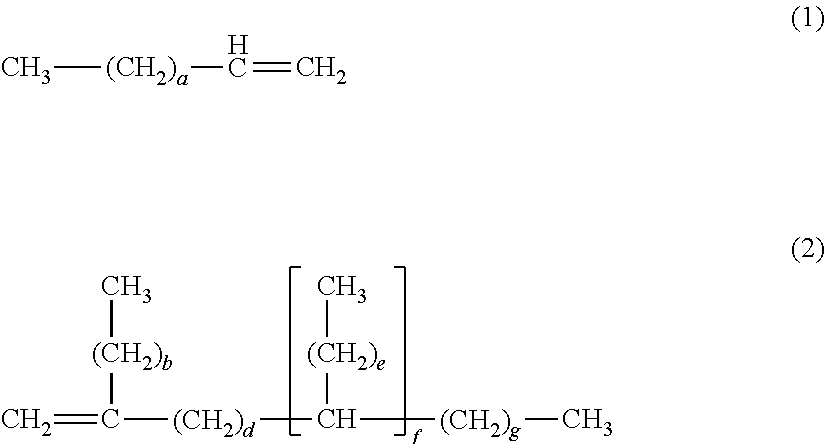

InactiveUS20110300361A1Small thicknessExcel in removabilitySynthetic resin layered productsEster polymer adhesivesSurface pressureTotal thickness

Disclosed is a double-coated pressure-sensitive adhesive tape which has a small total thickness, includes a foam layer, and excels in removability. The double-coated pressure-sensitive adhesive tape has a total thickness of 500 μm or less and includes a foam layer; a reinforcing layer; and two surface pressure-sensitive adhesive layers, in which at least one of the two surface pressure-sensitive adhesive layers is formed from a pressure-sensitive adhesive composition containing an acrylic polymer, a tackifier resin, and a crosslinking agent, the acrylic polymer including, as an essential monomer component, an alkyl(meth)acrylate whose alkyl moiety being a linear or branched-chain alkyl group having 4 to 9 carbon atoms.

Owner:NITTO DENKO CORP

Adhesive combination and surface protective film

ActiveCN102746811AAvoid residueImprove antistatic performancePolyureas/polyurethane adhesivesEster polymer adhesivesLow speedAdhesive

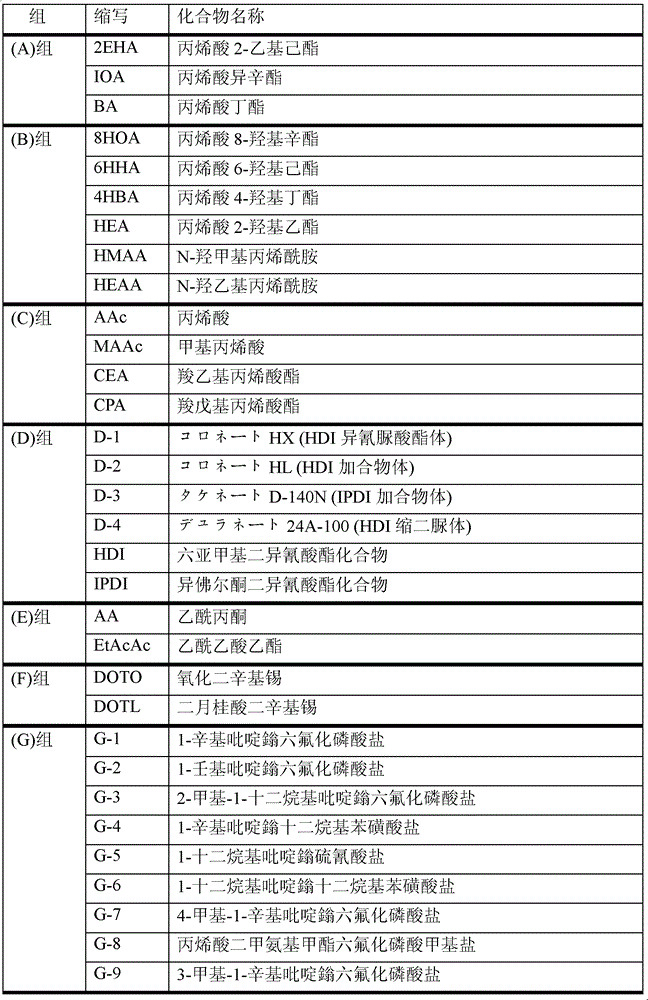

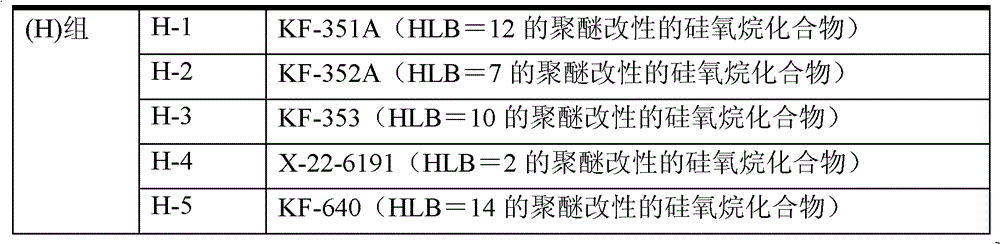

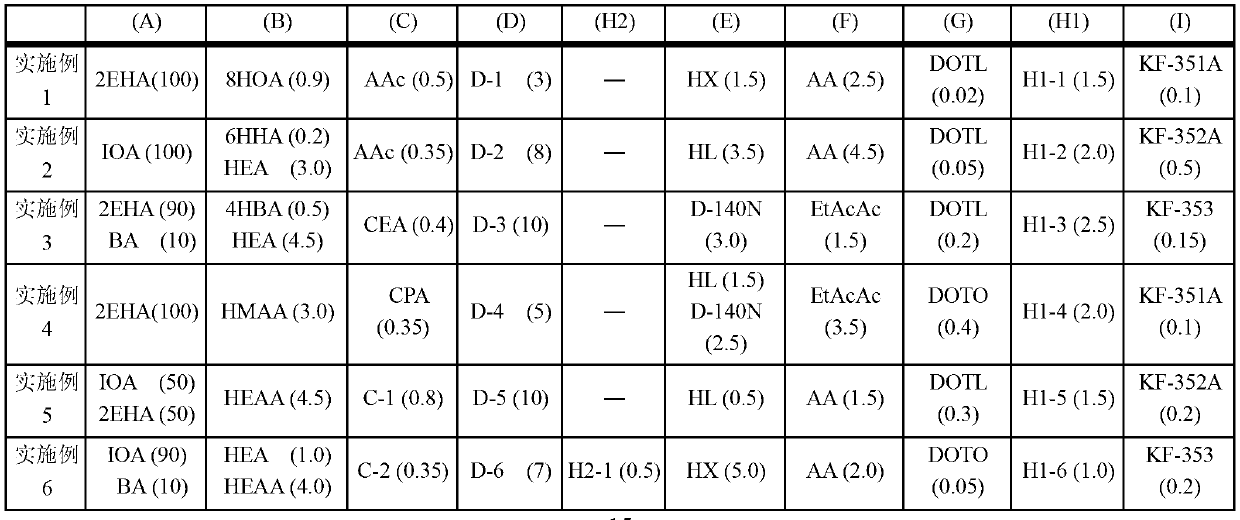

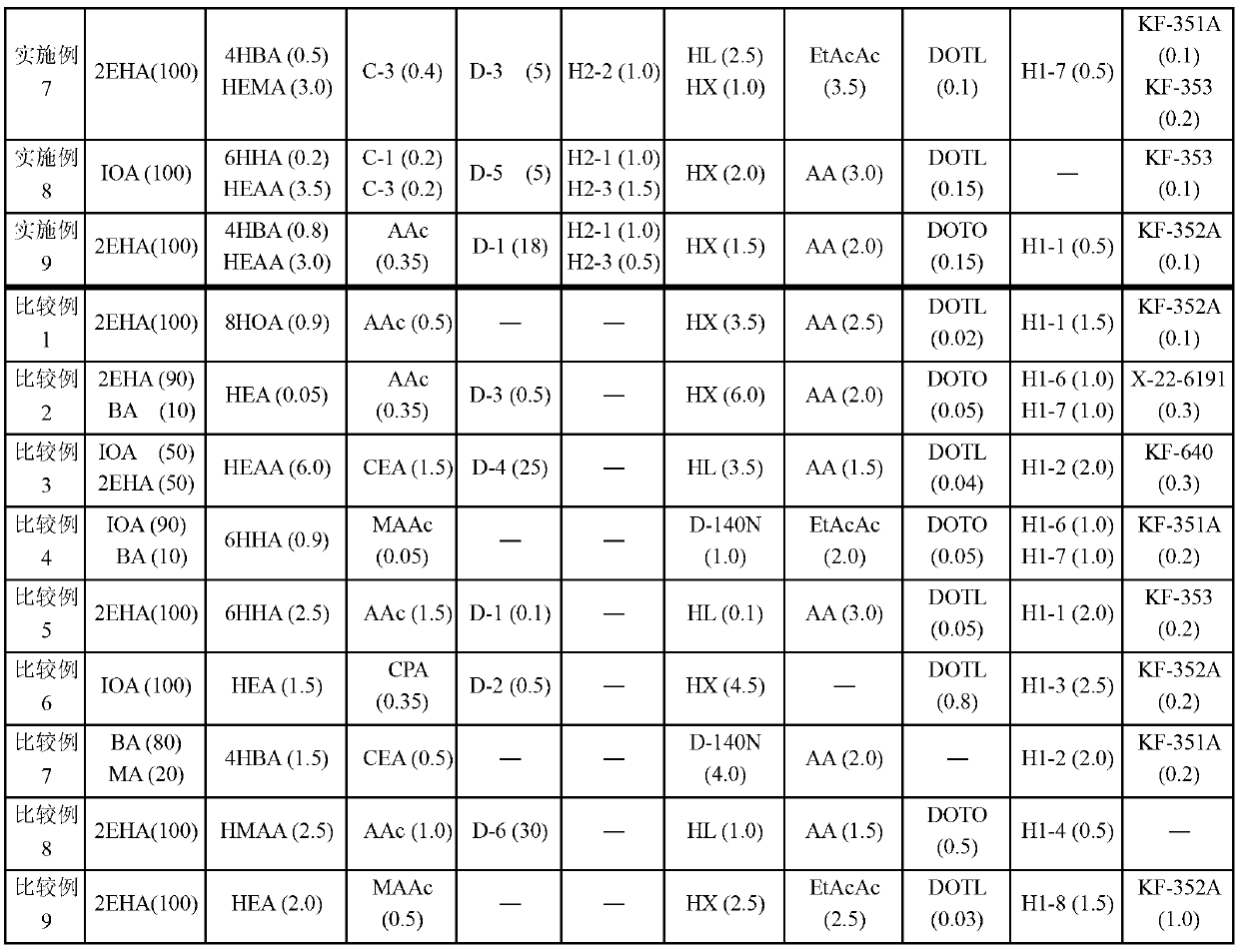

The present invention provides an adhesive combination and a surface protective film. The adhesive combination and the surface protective film can simultaneously satisfy the all required performances about: (1) obtaining balance of adhesive forces in a low-speed peeling field and a high-speed peeling field; (2) preventing occurrence of remaining of the adhesive; (3) having an excellent antistatic performance; and (4) having a reworkable property. The present invention provides an adhesive combination consisting of a copolymer containing (A) a (methyl)acrylate monomer having alkyl carbon atom number from C4 to C10, (B) a copolymerizable monomer containing hydroxyl, and (C) a copolymerizable monomer containing carboxyl, in addition, the adhesive combination further contains (D) an isocyanate compound having more than three functional groups, (E) a crosslinking inhibitor, (F) a crosslinking catalyst, (G) an antistatic agent, and (H) a polyether modified siloxane compound.

Owner:FUJIMORI KOGYO CO LTD

Antistatic silicone release coating films

ActiveCN101421104AReduce pollutionImprove adhesionSynthetic resin layered productsThin material handlingAdhesiveDisplay device

The invention relates to an antistatic silicone release film having a layer coated with an antistatic silicone release composition, and, used for semiconductors, electronics and display devices while addressing problems of static electricity generated when a general release film is separated from adhesive or an adhesive layer, and of contamination by such static electricity that causes critical product defects. The invention also relates to an antistatic silicon release film that can reduce product contamination caused by static electricity in peeling the film from adhesive or an adhesive layer, and achieves close adhesion between a substrate and a coated layer because of no interruption in curing a release layer, and also thereby has a stable release property.

Owner:TORAY ADVANCED MATERIALS KOREA

Marking method and sheet for both protective film forming and dicing

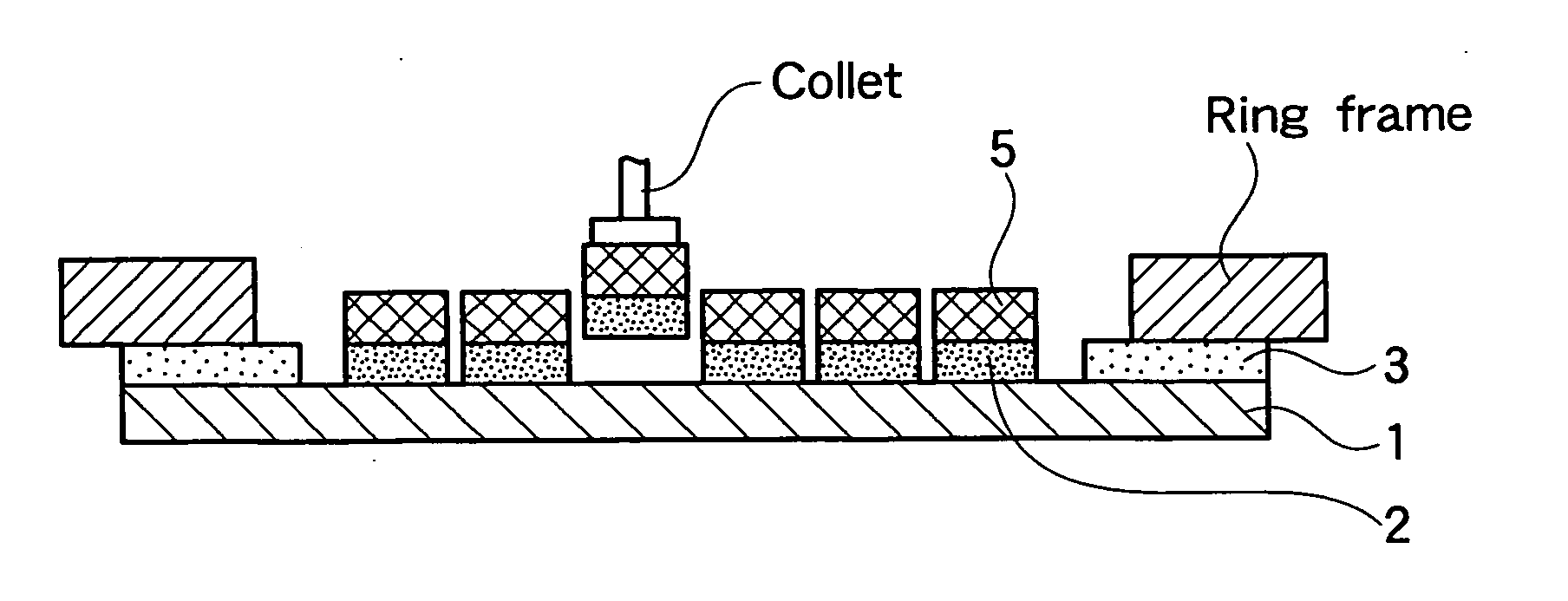

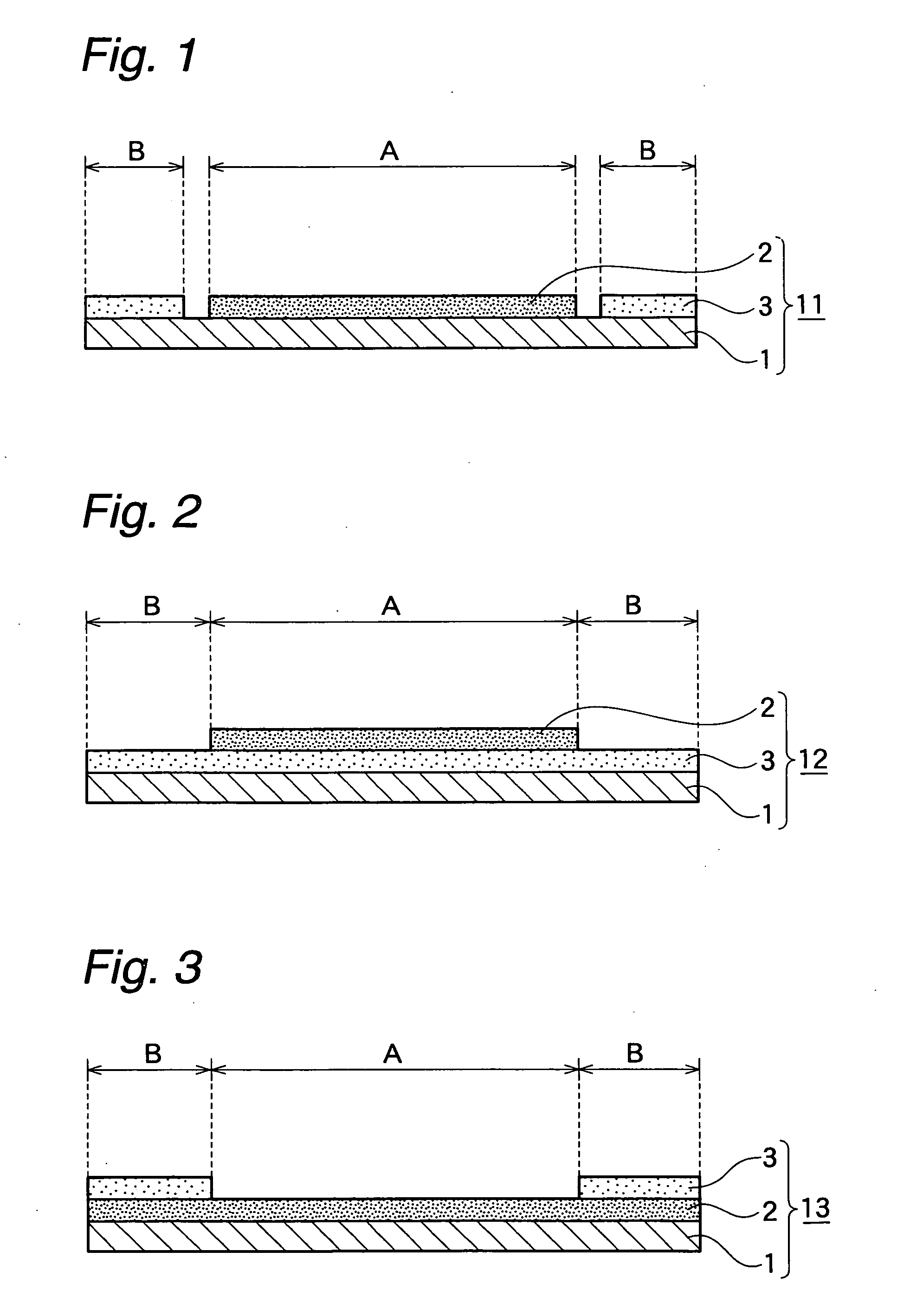

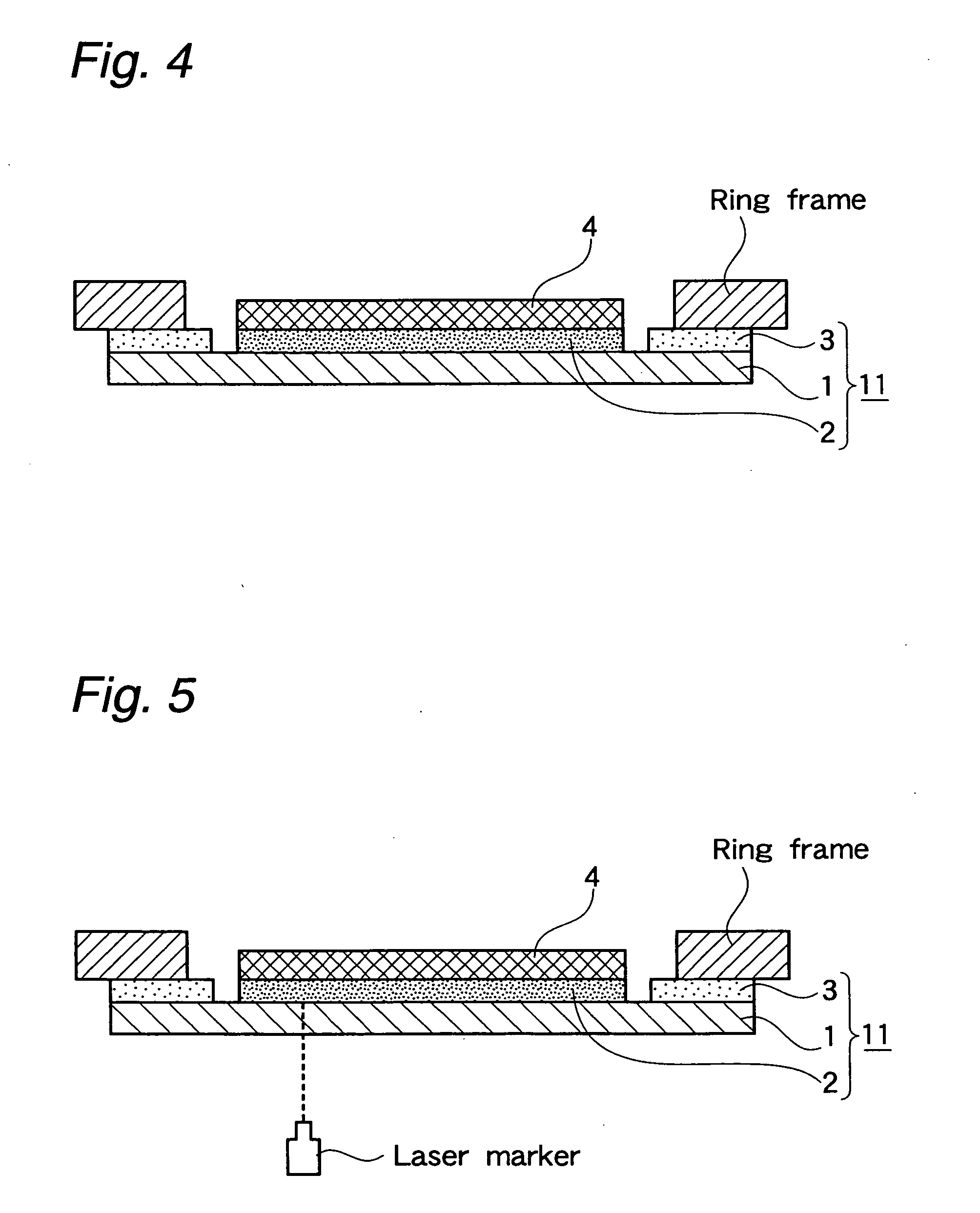

ActiveUS7935574B2Warpage suppressionImprove accuracySemiconductor/solid-state device detailsSolid-state devicesTectorial membraneEngineering

The invention provides a marking method in which marking is performed on a protective film formed on a work with a high accuracy while suppressing a warpage and, also, a sheet for both protective film forming and dicing which is advantageously used in the method. The marking method comprises irradiating laser light to a laminated structure comprising a support film tensely supported by a ring frame, a protective film releasably laminated on the support film and a work fixed to the protective film, wherein the protective film is irradiated laser light from a side of the support film, to thereby mark the protective film.

Owner:LINTEC CORP

Moisture barrier membrane with tearable release liner composite

An exemplary moisture barrier membrane 10 comprises a waterproof adhesive layer, (14) a carrier support, (12) and a release liner (16) composite having a paper sheet, (20) cutting strings, (22) a polyolefin (24) coating or film for holding the strings against the paper and apart from the waterproof adhesive layer, and a release agent (26) such as silicone or wax over the polyolefin coating or film. This construction allows for relatively thin paper and strings to be used, such that tear resistance is conferred upon the release liner composite as a whole.

Owner:GCP APPL TECH INC

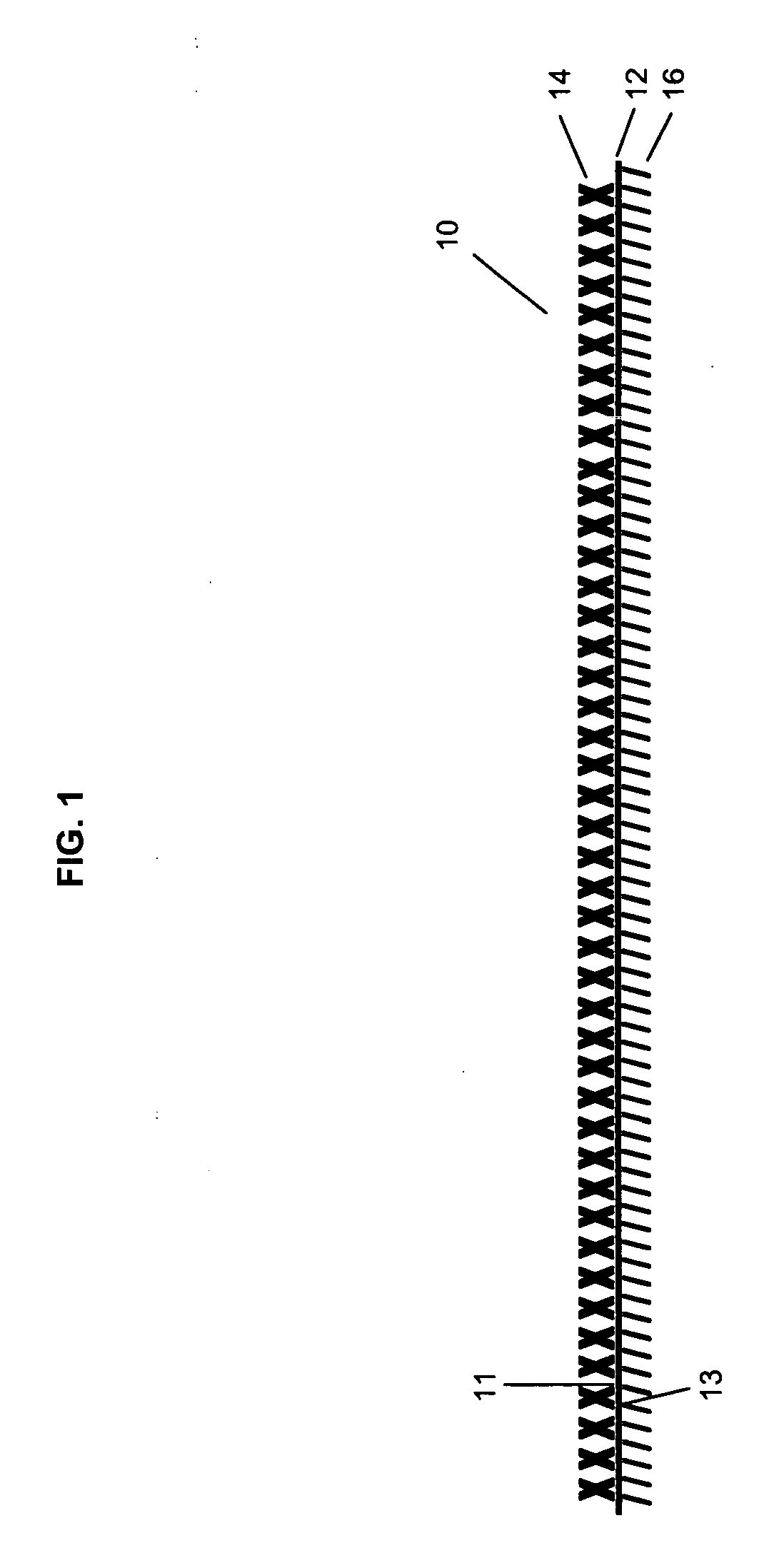

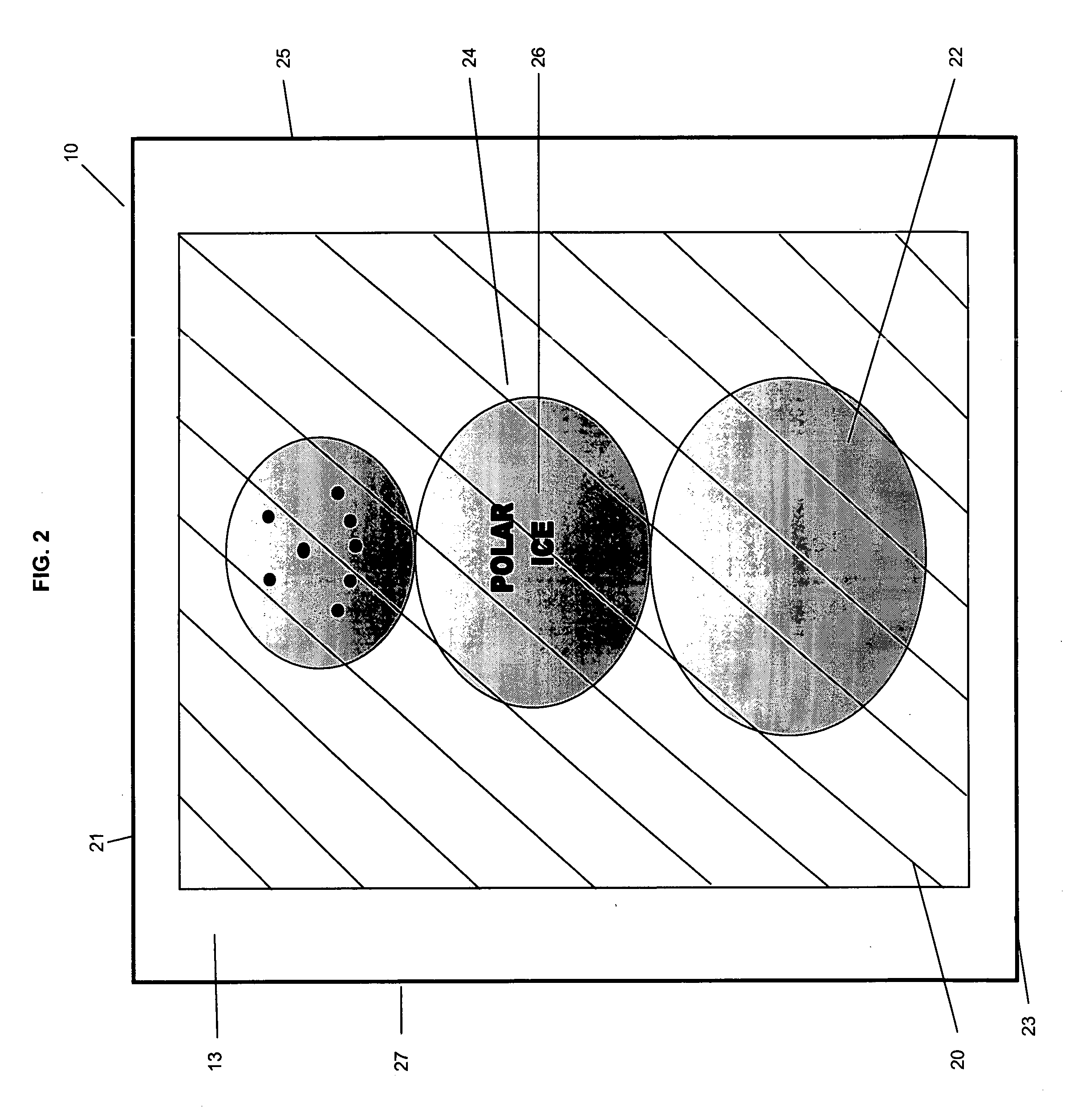

Linerless label with starch based release coating and method of creating

InactiveUS20050255298A1Easily unwoundEasy to removeStampsDecorative surface effectsCombinatorial chemistryCoating

The present invention is directed to a linerless label that utilizes a starch or starch ester based coating as a release coating. The release coating of the linerless label can be used to provide textural or aesthetic characteristics to the label in various patterns or arrangements as may be selected by the end user or manufacturer of the product.

Owner:WARDKRAFT

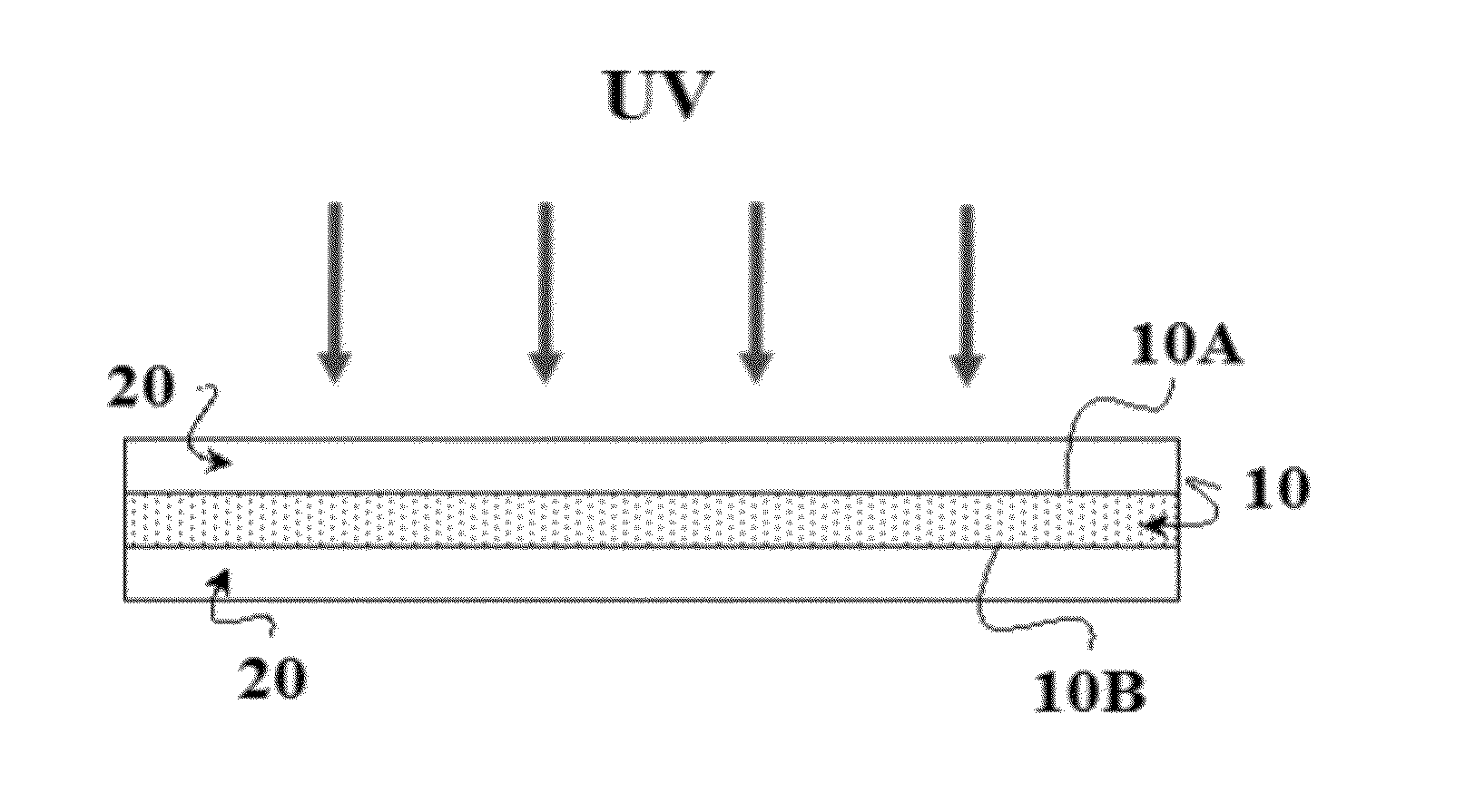

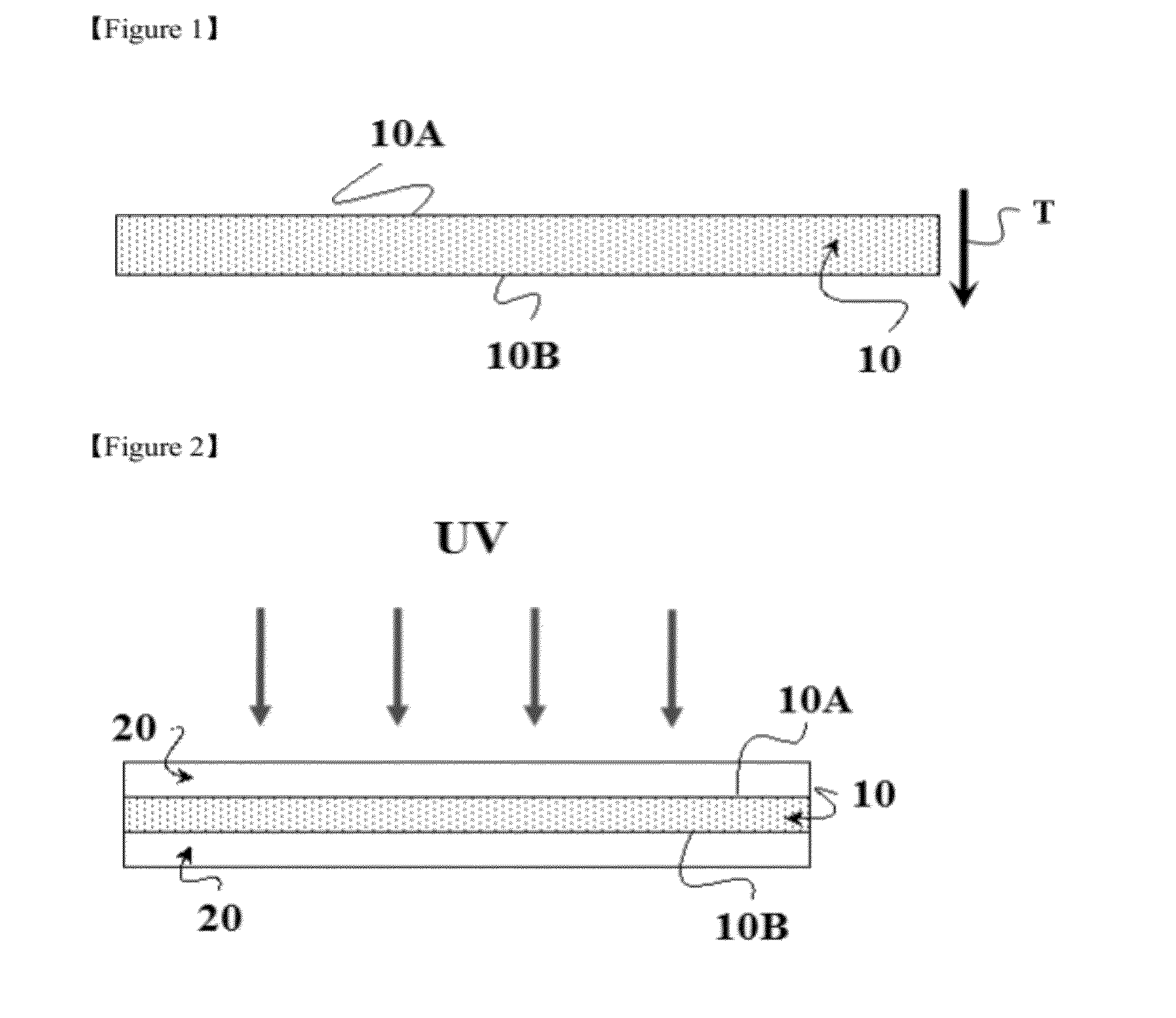

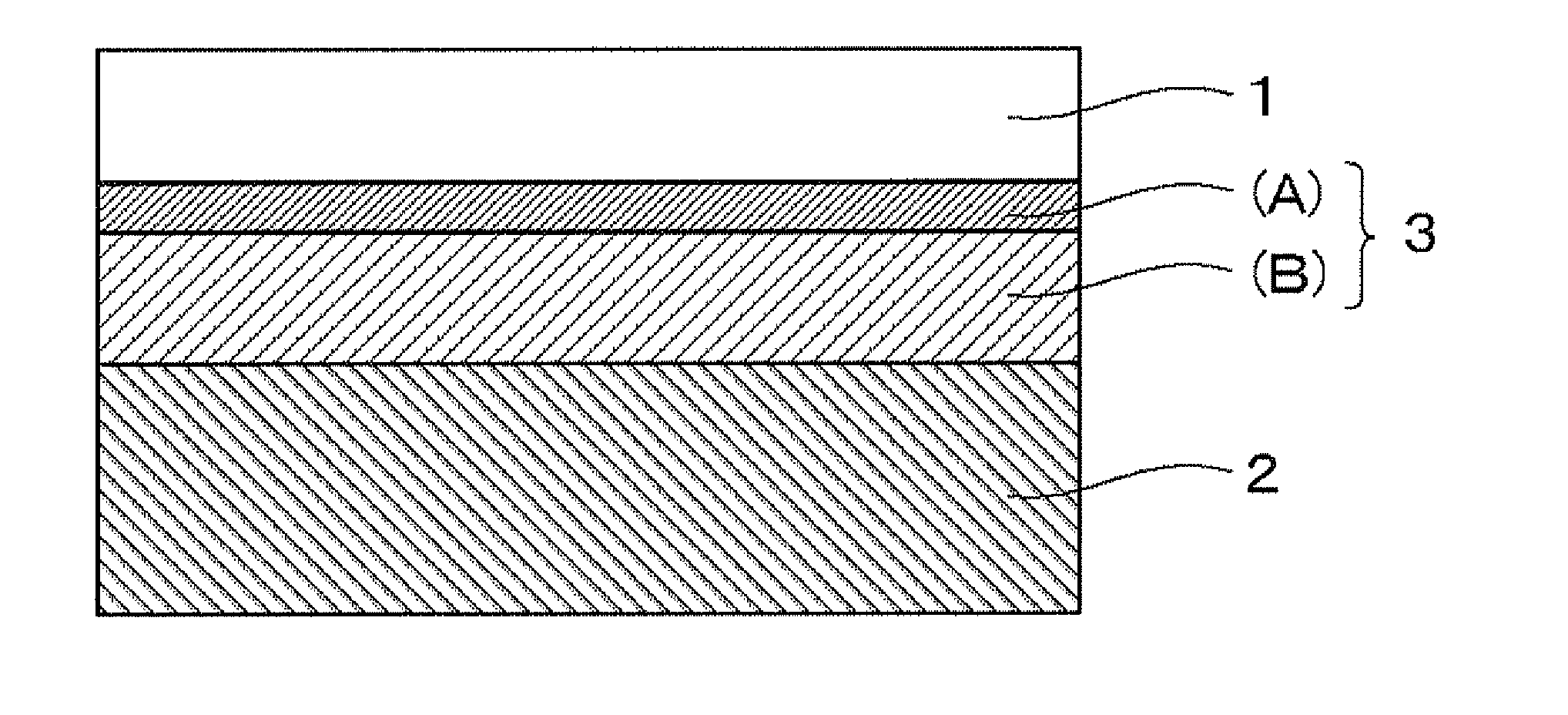

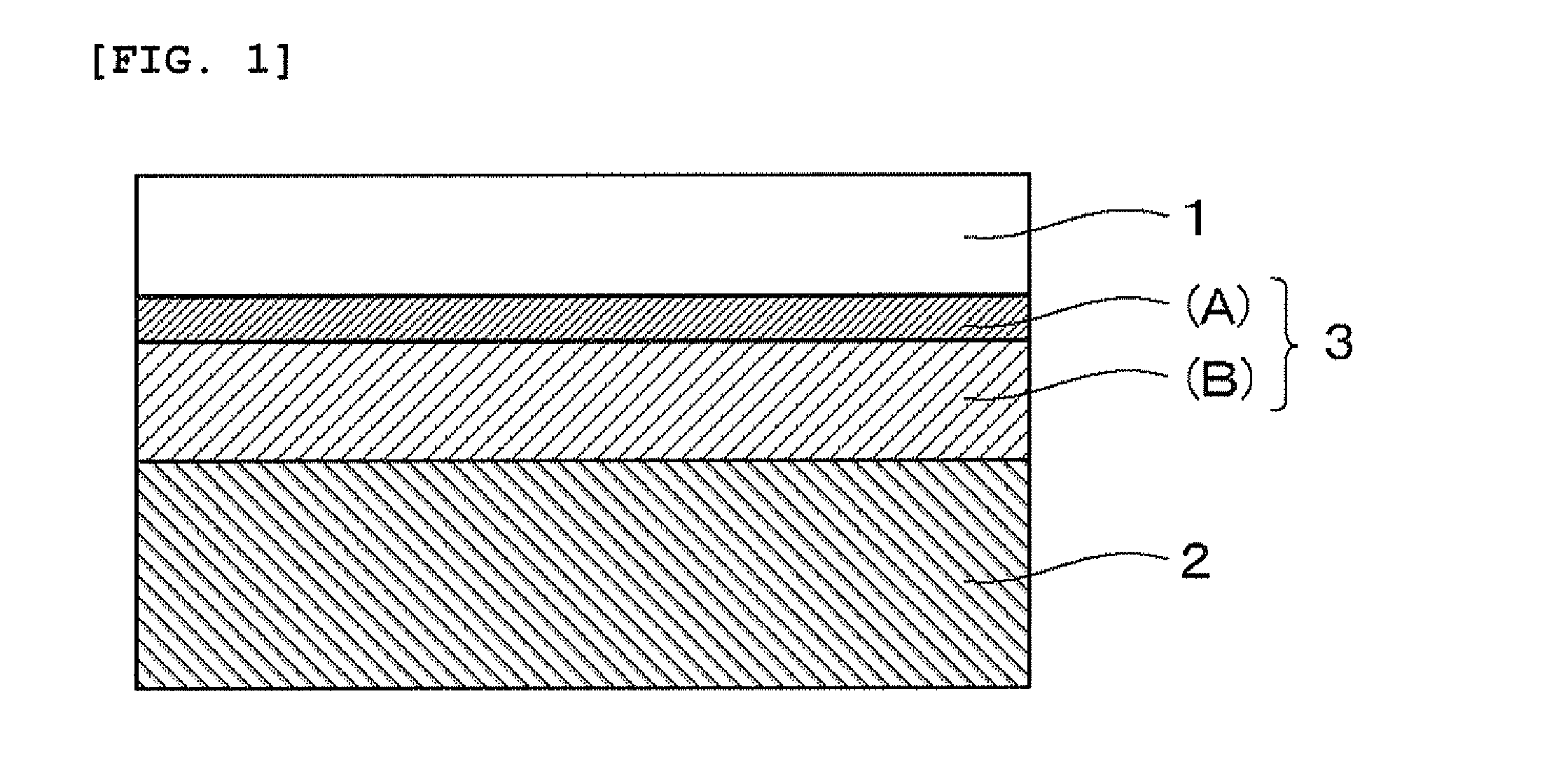

Temporary adhesive for wafer processing, member for wafer processing using the same, wafer processed body, and method for producing thin wafer

ActiveUS20130302983A1Easy to produceEasy to separateSynthetic resin layered productsSolid-state devicesWaferingAdhesive

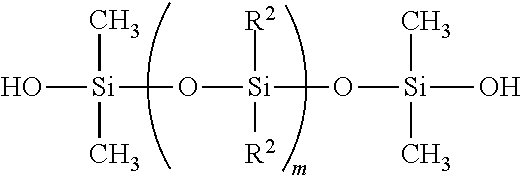

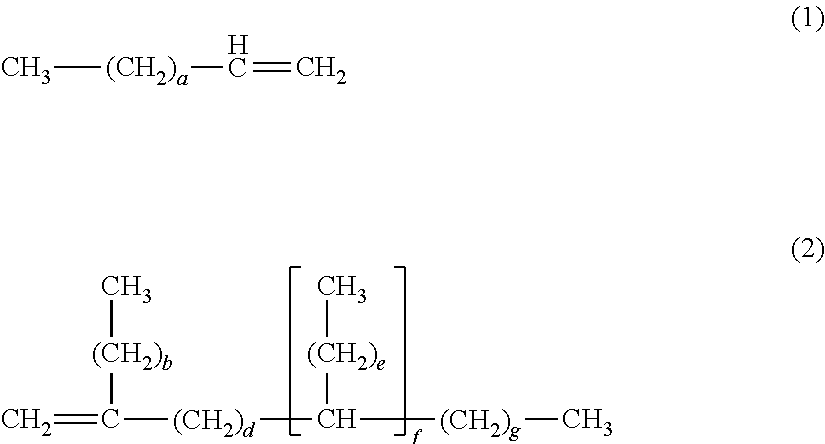

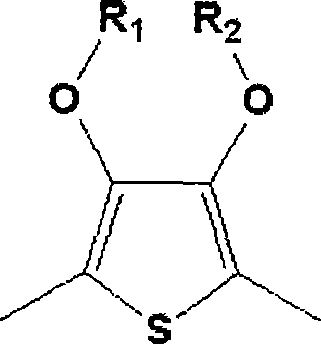

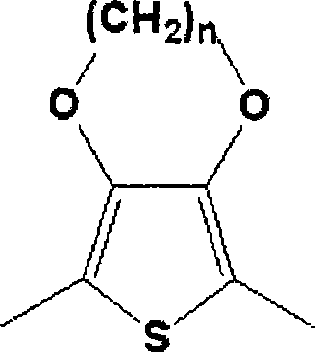

The present invention provided is the temporary adhesive for wafer processing which temporarily bonds a wafer having a circuit face on the front surface and a processing face on the back surface to a support, and includes a first temporary adhesive layer which is a layer (A) of a thermoplastic resin modified organopolysiloxane obtained by partial dehydration condensation of an organopolysiloxane resin containing a R21R22R23SiO1 / 2, and a SiO4 / 2 unit in a molar ratio of R21R22R23SiO1 / 2 unit / SiO4 / 2 unit of 0.6 to 1.7 and an organopolysiloxane represented by the following general formula (1), and a second temporary adhesive layer which is a thermosetting modified siloxane polymer layer (B) which is laminated on the first temporary adhesive layer and is releasably bonded to the support.

Owner:SHIN ETSU CHEM IND CO LTD

Anti-curling reinforcement device for area rug corners

InactiveUS20120285613A1Treating and preventing corner curlPreventing or eliminating curling at cornersLamination ancillary operationsLaminationEngineering

An anti-curling reinforcement device can be applied to corners of a rug, such as an area rug, to prevent the corners from curling. By adhering to the underside of the rug, and not the floor, the anti-curling reinforcement device does not damage the floor as may occur with double-sided carpet tape. The device utilizes a specially designed shape and structure that straightens and reinforces the corner to prevent further curling and possible damage to the rug. The device straightens, reinforces and adds weight to the rug corner to prevent curling, keeping the corner flat, and preventing possible damage to the rug as well as minimizing tripping hazards from curled corners.

Owner:BONGIOVANNI CHARLES MICHAEL +1

Easily peelable laminated film

InactiveUS20030152735A1Easily peelableEasily peelable laminatedSynthetic resin layered productsThin material handlingSurface layerEngineering

An easily peelable laminated film includes a laminate of a peelable surface layer (B) having a peeling strength of 5 to 100 g / cm with a base layer (A) containing a thermoplastic resin. The laminated film of the invention provides an easily peelable laminated film excellent in water resistance as a base materialfor, for example, concealing seals and labels for preventing re-pasting. The easily peelable laminated film of the invention requires no specific process to start peeling.

Owner:YUPO CORP

Pressure-sensitive adhesive tape for battery

InactiveUS20130071740A1Prevent short-circuitingInhibit deteriorationLayered productsActive material electrodesEngineeringPressure sensitive

The present invention relates to a pressure-sensitive adhesive tape for battery containing: a substrate and a pressure-sensitive adhesive layer laminated on at least one surface of a substrate, in which the pressure-sensitive adhesive layer is laminated on the substrate, 0.5 mm or more inside from both edges of the substrate, and in which the pressure-sensitive adhesive tape has a 180° peeling pressure-sensitive adhesive force at 23° C. being 0.1 N / 10 mm or more, and has a slippage distance after a pressure-sensitive adhesive layer side of the pressure-sensitive adhesive tape is attached to a phenolic resin plate (attaching area: 10 mm×20 mm), followed by applying a load of 500 g thereto at 40° C. for 1 hour being 0.2 mm or less.

Owner:NITTO DENKO CORP

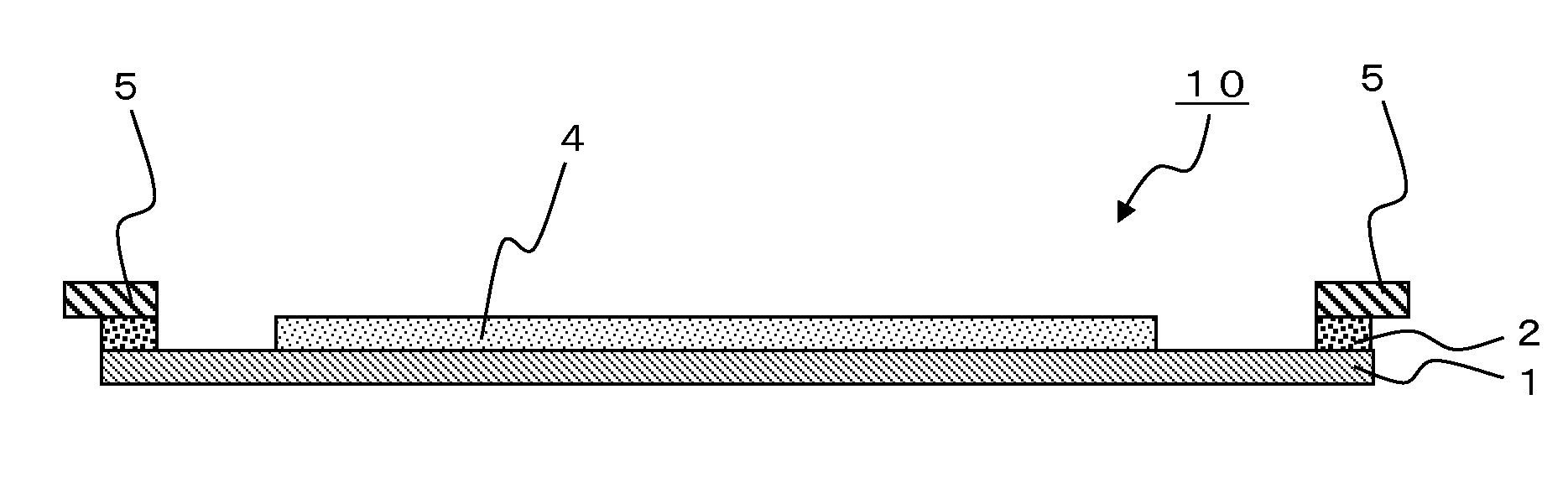

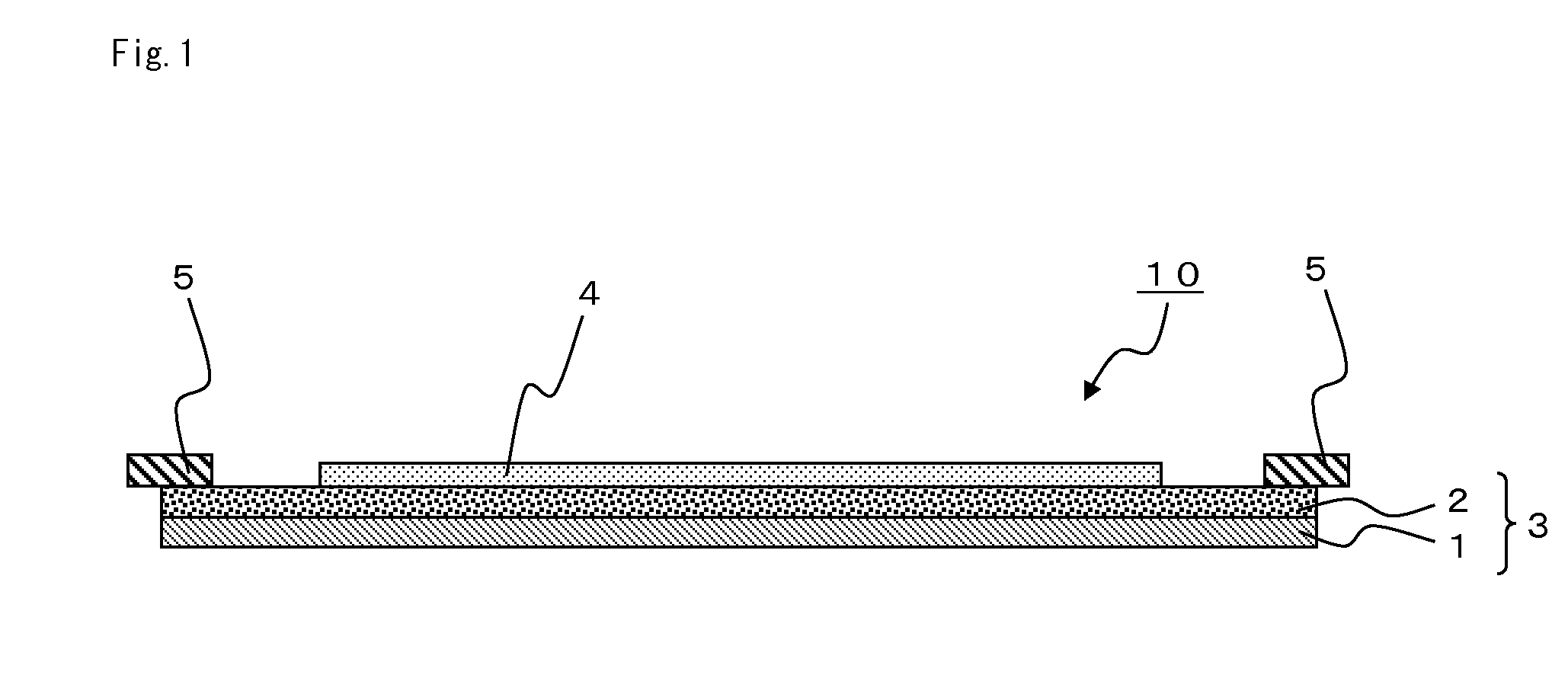

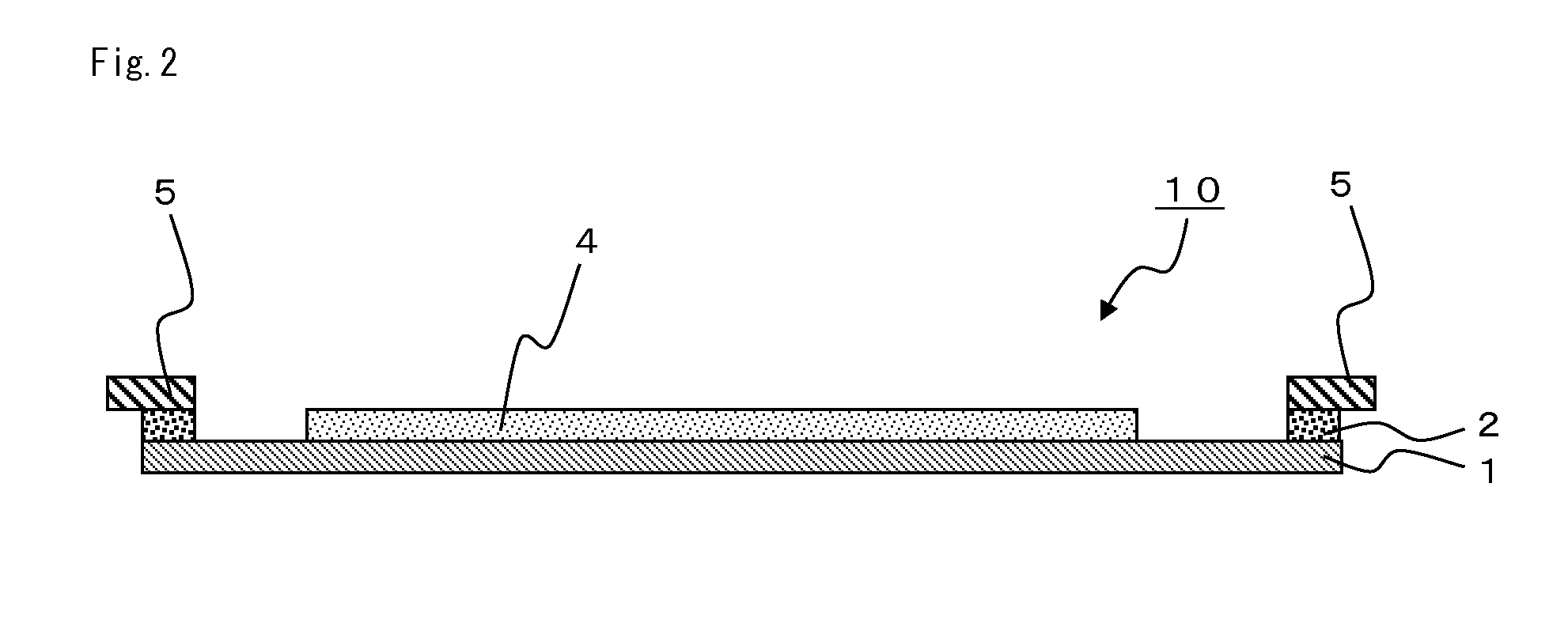

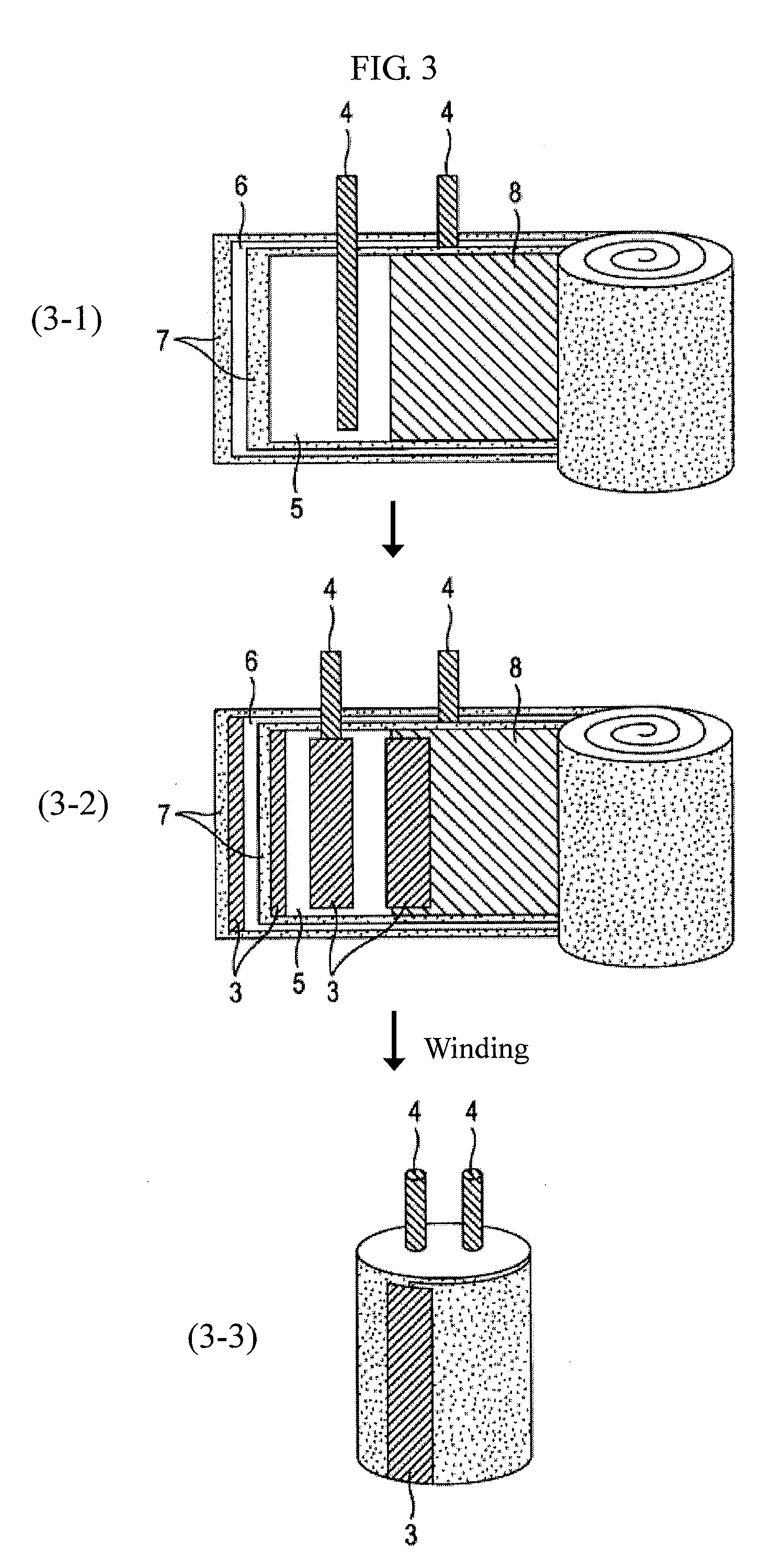

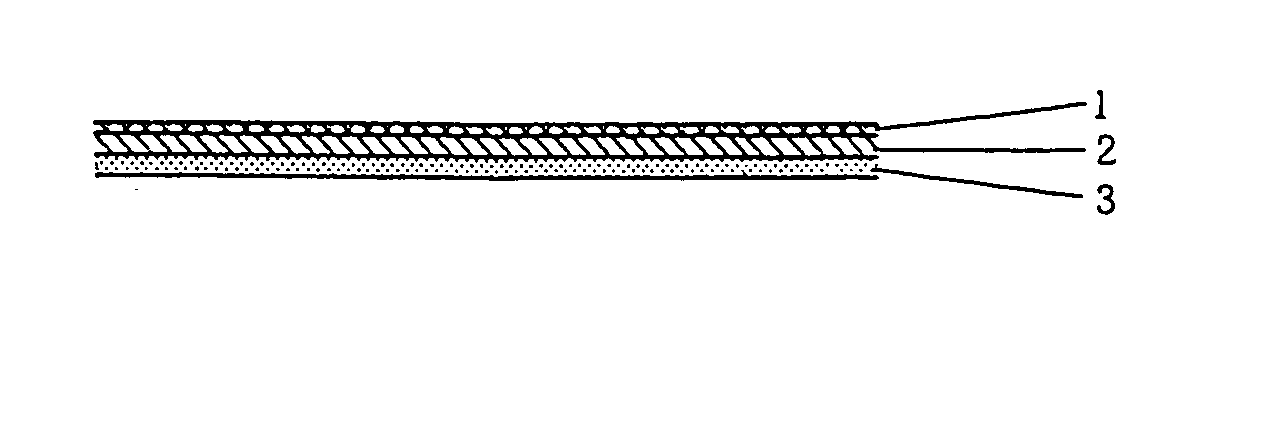

Wafer processing tape

ActiveUS20100227165A1Suppresses transfer marksChange sizeSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

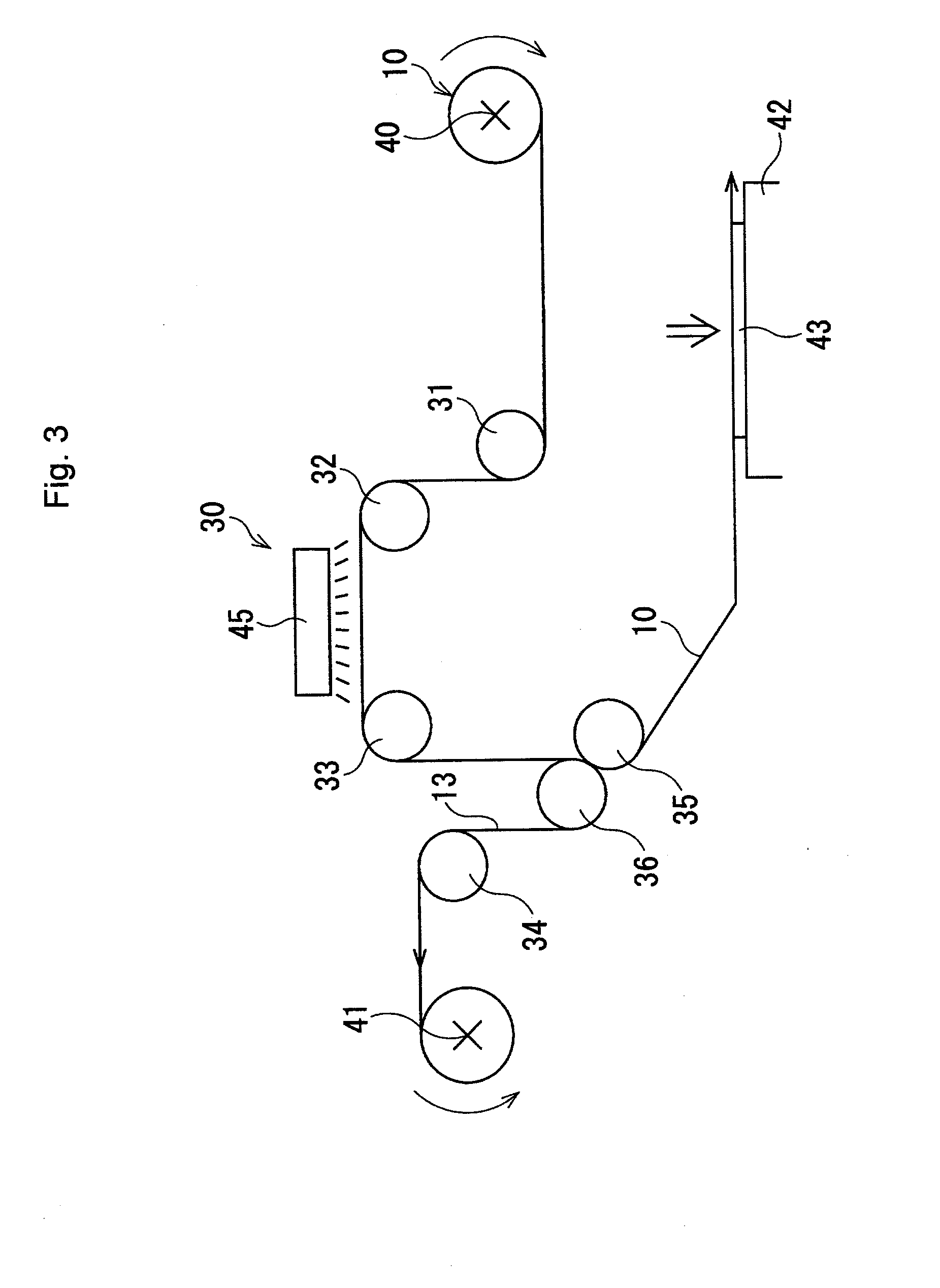

A wafer processing tape includes a release film having a large length; an adhesive layer formed on a first surface of the release film and having a predetermined planar shape; a pressure-sensitive adhesive film having a label portion and a surrounding portion surrounding outside the label portion; and a support member formed on a second surface of the release film opposite to the first surface on which the adhesive layer and the pressure-sensitive adhesive film are formed. The label portion has a predetermined planar shape and covers the adhesive layer so that the label portion contacts with the release film around the adhesive layer. The support member is disposed at both end portions of the release film in a short side direction of the release film. The support member has a coefficient of linear expansion of 300 ppm / ° C. or less.

Owner:FURUKAWA ELECTRIC CO LTD

Optical-use pressure-sensitive adhesive sheet

ActiveCN102051133AStripping does not produceImprove bond reliabilityMonocarboxylic acid ester polymer adhesivesOpticsConstant loadPeel force

The invention provides an optical-use adhesive sheet excellent in adhesiveness under bending, twisting or distorting stress. The optical-use adhesive sheet has an adhesive layer having a storage elastic modulus at 80 DEG C of at least 2.0X10 4 Pa and a loss elastic modulus at 80 DEG C of at least 1.0X10 4 Pa, the optical-use adhesive sheet is characterized in that the adhesive sheet has a peel force, as measured in the L-shape peel test, of at least 0.16 MPa, and has a peel distance, as measured in the constant-load peel test, of at most 50 mm. In the L-shape peel test, an L-shaped stainless steel clamp is adhered with an acrylicresin plate through the adhesive sheet, the acrylicresin plate and the stainless steel clamp are processed for 15 minutes at 50 DEG C under 5 atm, and then, the stainless steel clamp is drawn along a direction vertical to a surface of the acrylicresin plate so as to test the peel force. In the constant-load peel test, a double-faced adhesive sheet is adhered on the acrylicresin plate, then, the acrylicresin plate and the double-faced adhesive sheet are processed for 10 minutes at 50 DEG C under 5 atm, and then, a load of 100gf is applied along the direction vertical to the surface of the acrylicresin plate on a tail end in a length direction of the adhesive sheet so as to test the peel distance of the adhesive sheet after 3 hours.

Owner:NITTO DENKO CORP

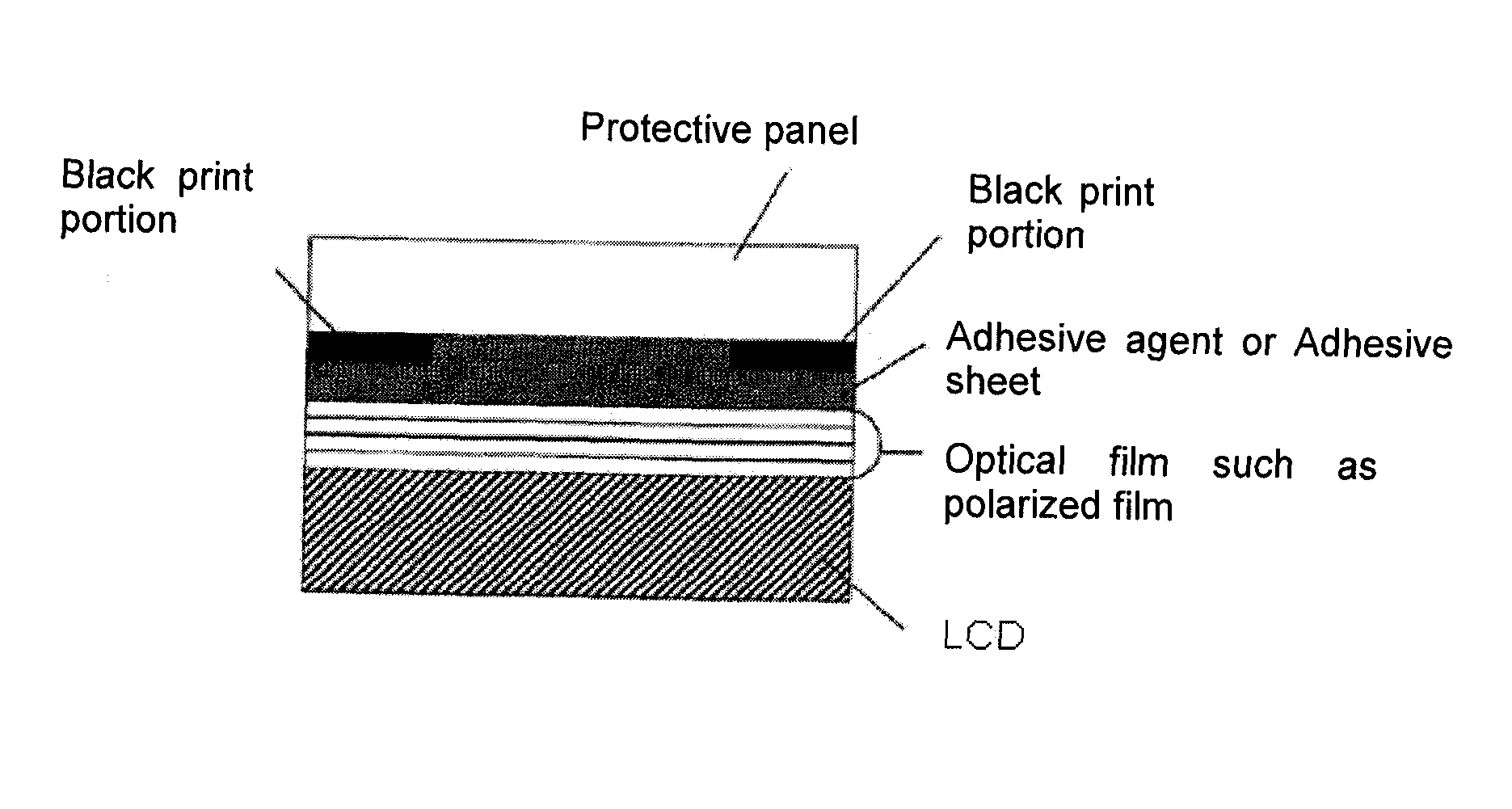

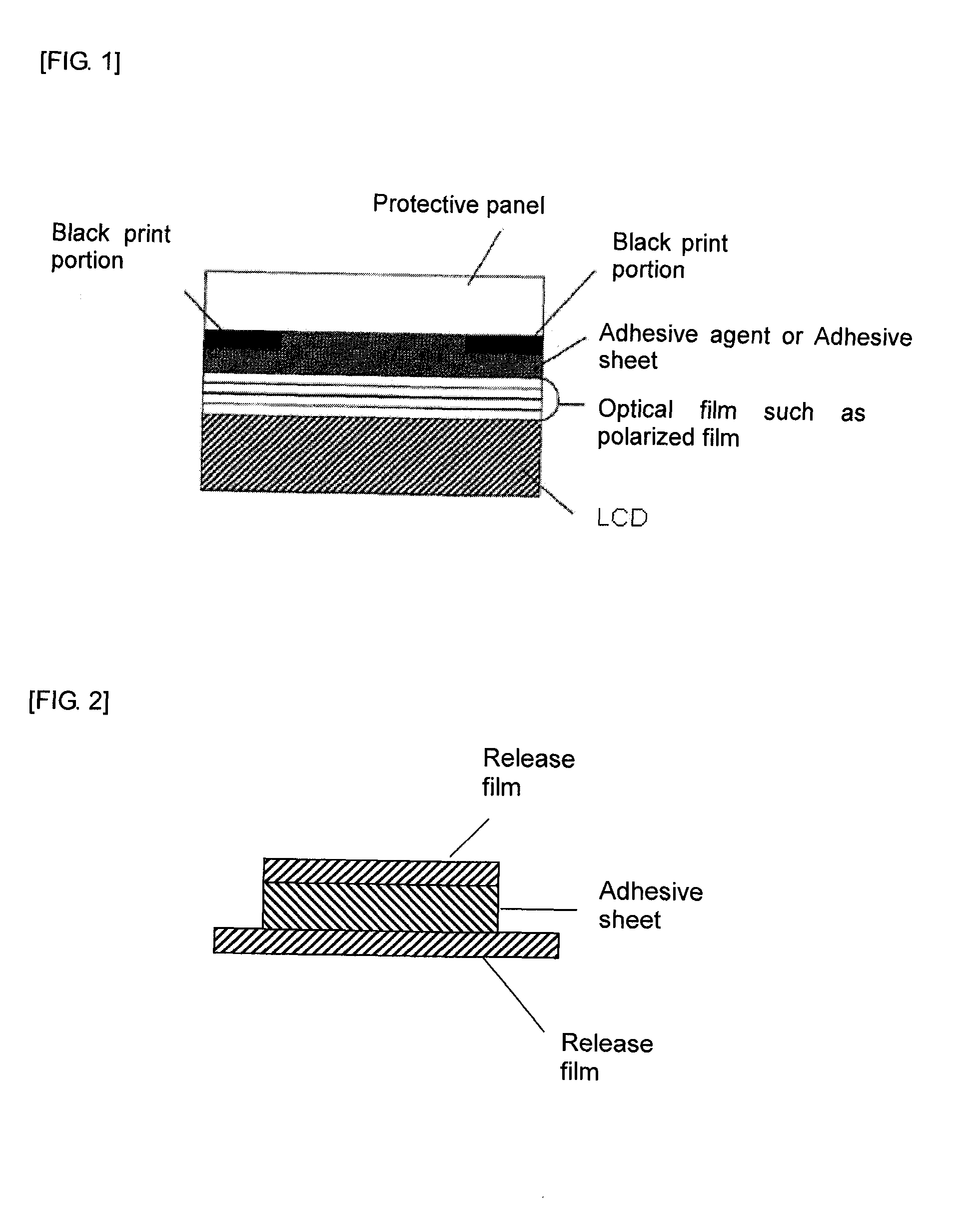

Transparent adhesive sheet and image display device

ActiveUS20110195240A1Synthetic resin layered productsEster polymer adhesivesDisplay deviceEngineering

Provided is a novel transparent adhesive sheet with which the cut edge is not sticky over time when a laminated body that has been bonded via the adhesive sheet is cut, which can be adhered without generating residual air bubbles, even when the surface of an adherend is uneven, and which can be adhered without foaming, even when the adherend is a material such as plastic that can generate outgas. Suggested is an adhesive sheet that has one or more layers of a first adhesive layer and one or more layer of a second adhesive layer that exhibit different viscoelastic behaviors, and has an integrated structure whereby these layers are laminated, with a dynamic shear storage modulus G′ of 2×104 to 5×105 Pa for G′(20° C.) and 1×104 to 1×105 Pa for G′(150° C.) when measured with a 1 Hz frequency temperature dispersion.

Owner:MITSUBISHI CHEM CORP

Pressure-sensitive adhesive members and processes for producing the same

InactiveUS20040224117A1Lightly peelableRetention stabilityLamination ancillary operationsAdhesive articlesFractionationElution

Owner:NITTO DENKO CORP

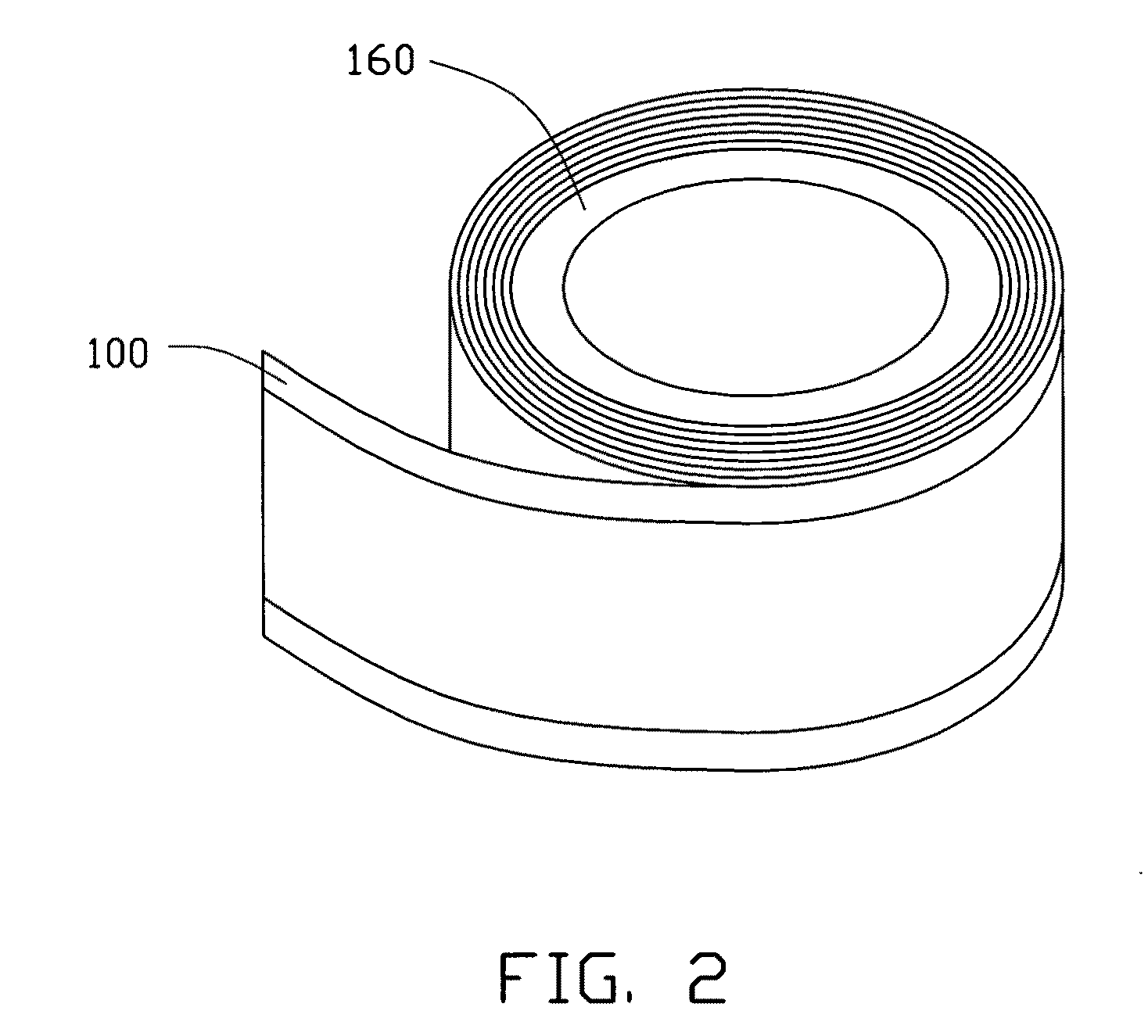

Protective device for protecting carbon nanotube film and method for making the same

ActiveUS20100310809A1Material nanotechnologyLamination ancillary operationsTectorial membraneCarbon nanotube

A protective device includes a base film, a first carbon nanotube film, and a first protecting film. The first protecting film includes a release layer. The first carbon nanotube film is located between the base film and the first protecting film and in contact with the release layer. The carbon nanotube film is capable of being released from the release layer. The present disclosure also relates to a roll of protective device, and a method for making the protective device.

Owner:TSINGHUA UNIV +1

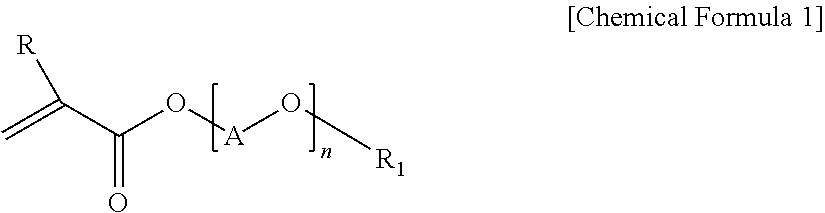

Adhesive composition and surface-protective adhesive film

ActiveCN103305157AAnti-residue propertiesGood residual effectEster polymer adhesivesPressure sensitive film/foil adhesivesLow speedPolymer science

The invention provides an adhesive composition and a surface-protective adhesive film, which have excellent electrical resistance and excellent adhesive balance, durability and rework performance during peeling in high speed and low speed. The adhesive composition contains (A) acrylate monomer (methyl) containing alkyl carbons of C4-C10, (B) comonomer containing hydroxyl, (C) comonomer containing carboxyl and (D) acrylic polymer of copolymer of poly alkylene glycol single (meth) acrylate monomer. The adhesive composition further contains (E) over three-functional isocyanate compound, (F) crosslinking inhibitor, (G) Crosslinking catalyst, (H) antistatic agent and (I) polyether modified siloxane compound, wherein the acid value of the acrylic polymer ranges from 0.01-8.0.

Owner:FUJIMORI KOGYO CO LTD

Adhesive sheet and release sheet

ActiveUS20070224378A1Reduce warpageReduce the impactAdhesive articlesSynthetic resin layered productsBiomedical engineeringRelease agent

There is provided an adhesive sheet comprising an adhesive base sheet, an adhesive layer, and a release sheet laminated in sequence from the adhesive base sheet. The release sheet comprises a release agent layer and a release base material laminated in sequence from the adhesive layer. A release force between the release sheet and the adhesive layer is decreased by an external stimulus.

Owner:LINTEC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com