Antistatic silicone release coating films

A silicone and antistatic technology, applied in the direction of film/sheet release liner, film/sheet adhesive, layered products, etc., to reduce product pollution, good adhesion, stable release characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0023] Hereinafter, the present invention will be described in more detail with reference to preferred embodiments of the present invention.

[0024] Those skilled in the art should understand that each embodiment is only intended to describe the present invention in more detail, and the scope of the present invention is not limited by these embodiments.

[0025] The polyester film used in the present invention is not limited to a specific type, and a known conventional polyester film can be used as a base film for antistatic coating. In the present invention, the exemplary polyester film is a polyester resin polyester film, such as polyethylene terephthalate, polybutylene terephthalate, polyethylene naphthalate, and the like. It should be noted that the substrate of the antistatic coating composition of the present invention is not limited to a polyester sheet or film.

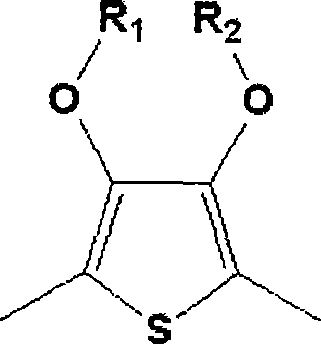

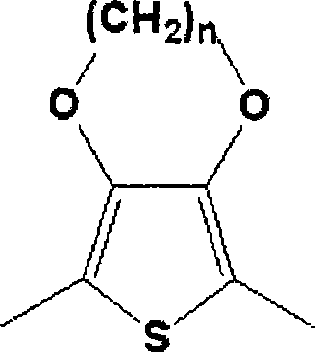

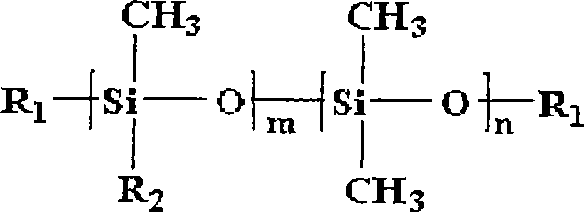

[0026] The polyester constituting the film of the present invention is obtained by polycondensing an aromatic ...

Embodiment approach 1

[0053] First, a silicone release type containing 0.05 parts by weight of conductive polymer resin based on 100 parts by weight of organopolysiloxane, 0.05 parts by weight of silane coupling agent, 5 parts by weight of organohydrogen polysiloxane, and 50 ppm of platinum chelate catalyst The composition is prepared by diluting the composition in water, and the composition has a total solid content of 2% by weight. The composition was then coated on the corona discharge-treated surface of a polyester film with a thickness of 10 microns. After coating the film with the composition, the film was dried with a hot air dryer at 180° C. for 10 seconds to produce an antistatic silicone release film having a layer coated with an antistatic silicone release composition.

Embodiment approach 2

[0055] The antistatic silicone release film was prepared in the same manner as in the above-mentioned Embodiment 1, except that 0.1 parts by weight of the conductive polymer resin was added to the composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com