Patents

Literature

227results about How to "Avoid electrification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

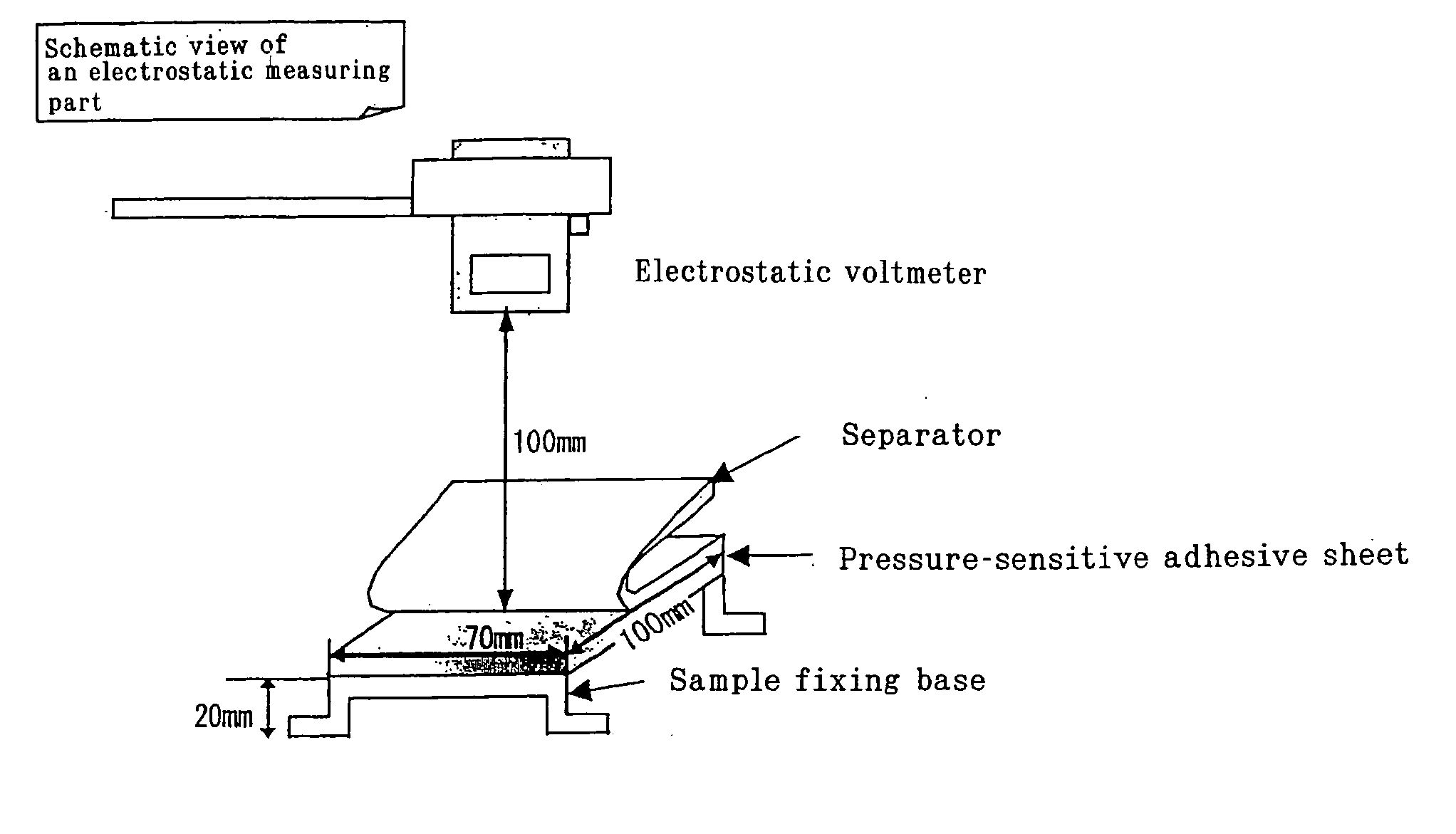

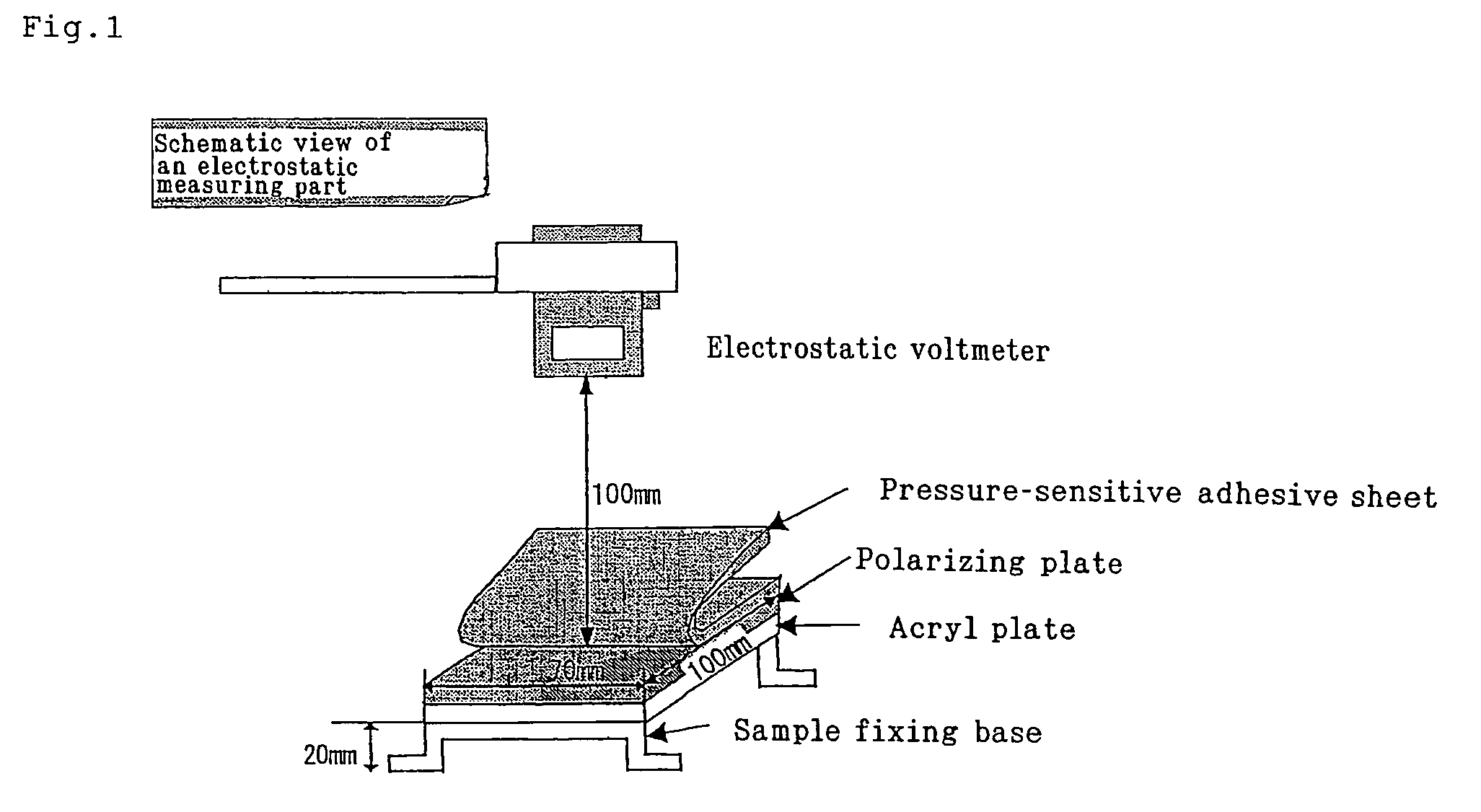

Pressure-sensitive adhesive composition, pressure-sensitive adhesive sheets and surface protecting film

InactiveUS20050197450A1Reduce stainsAvoid electrificationNon-macromolecular adhesive additivesEster polymer adhesivesTectorial membraneGlass transition

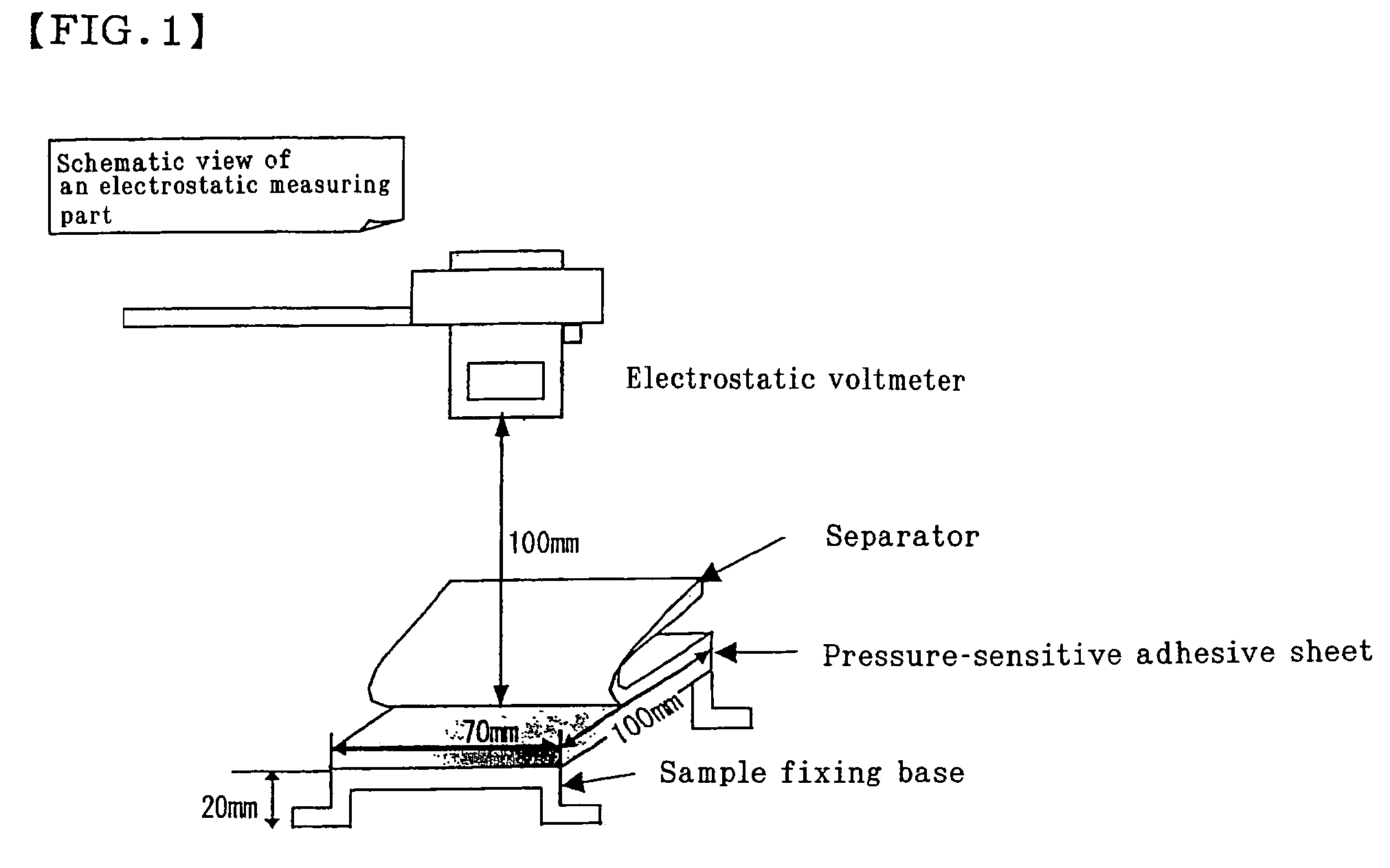

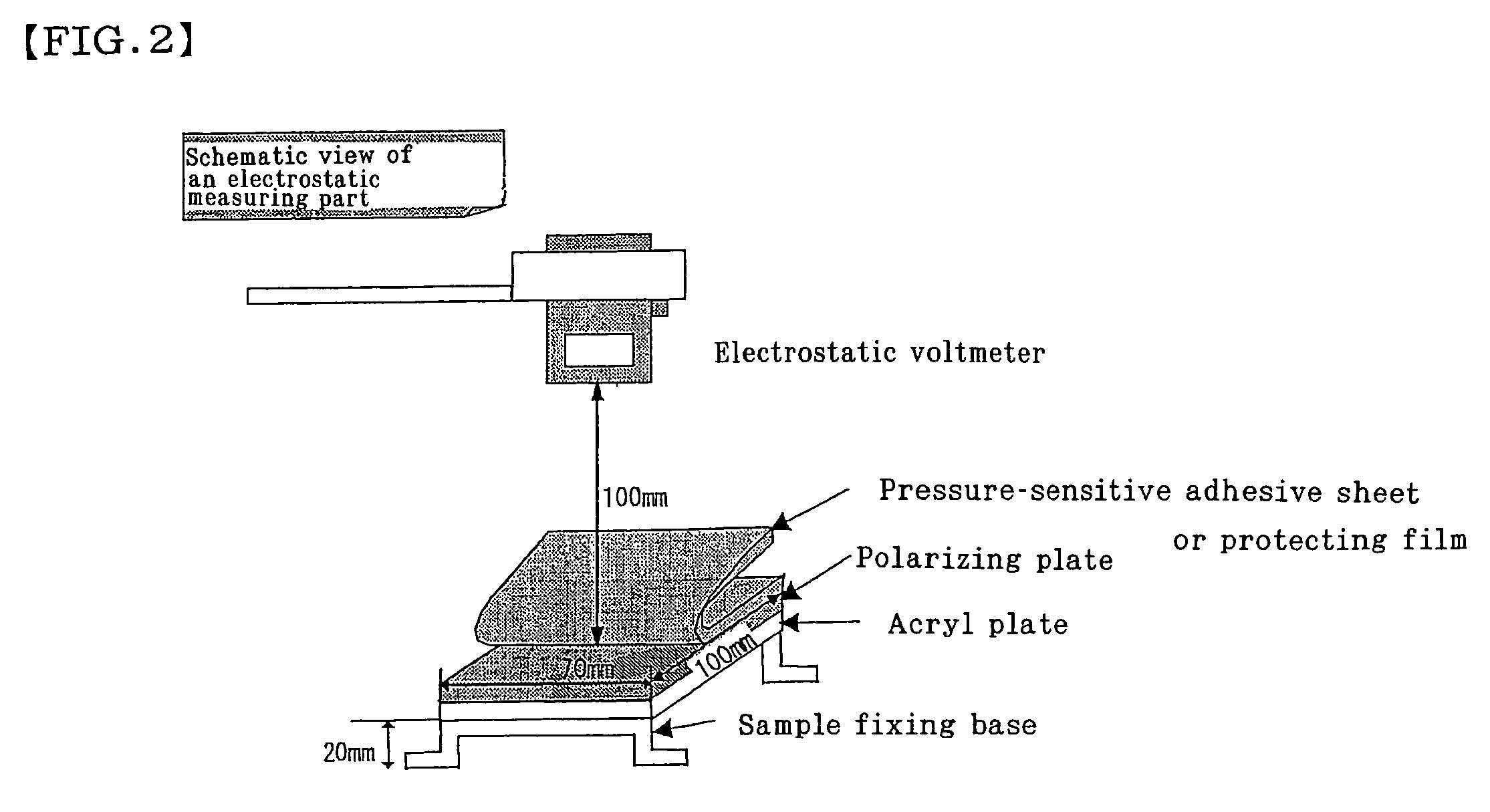

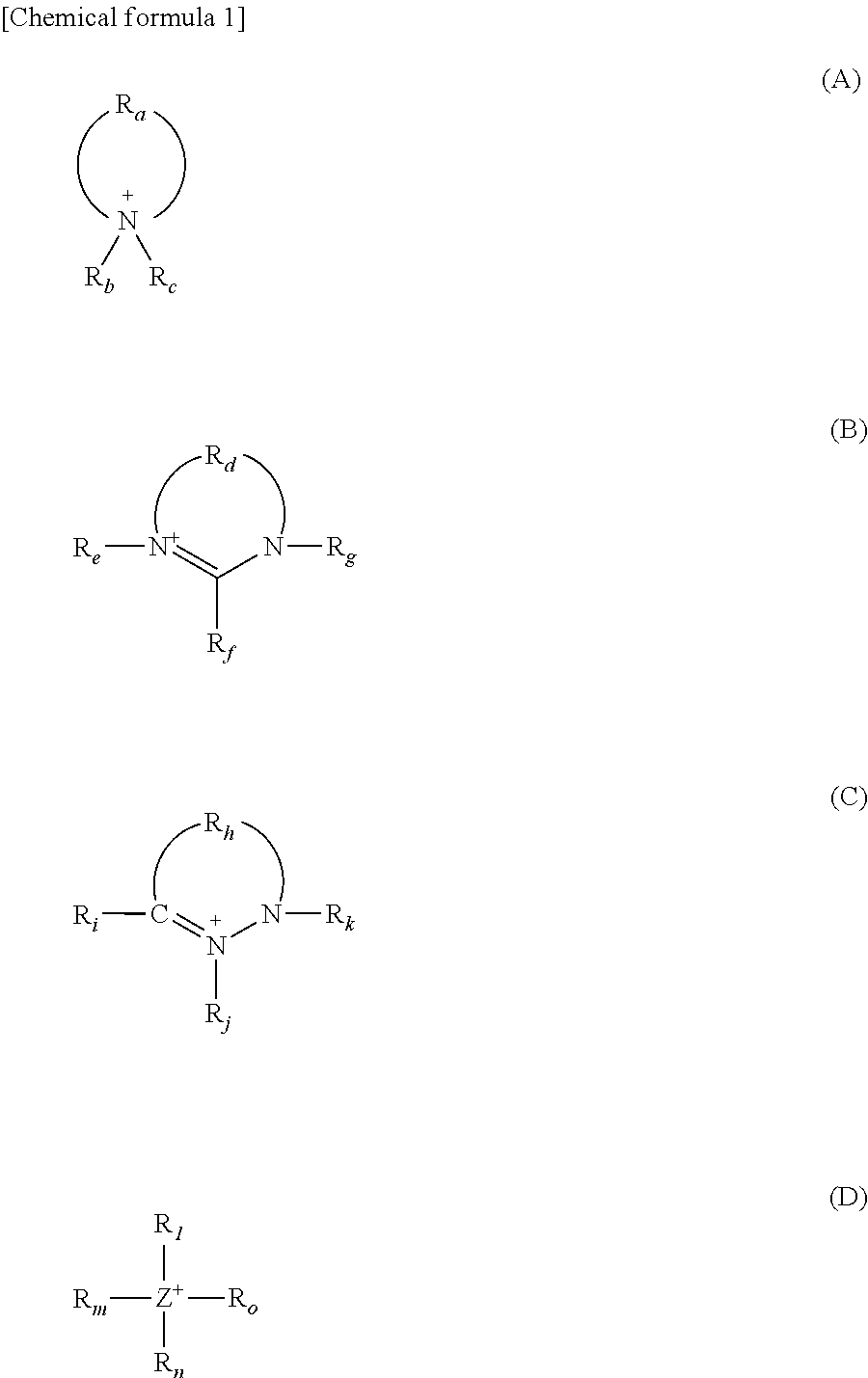

An object of the present invention is to provide a pressure-sensitive adhesive composition in which electrification of a pressure-sensitive adhesive sheet can be prevented upon peeling, and staining property on an adherend can be reduced, and an antistatic pressure-sensitive sheet and surface protecting film using this. There is provided a pressure-sensitive composition comprising an ionic liquid and a polymer having a glass transition temperature Tg of 0° C. or lower as a base polymer.

Owner:NITTO DENKO CORP

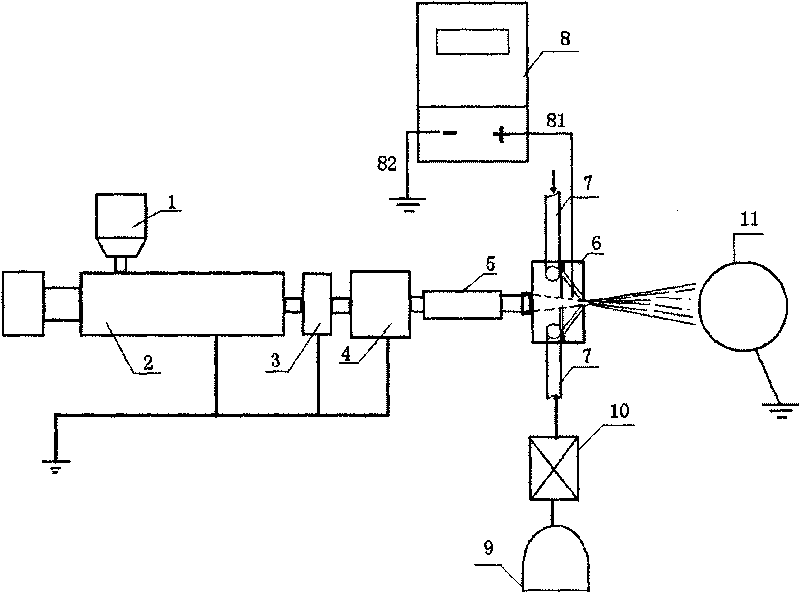

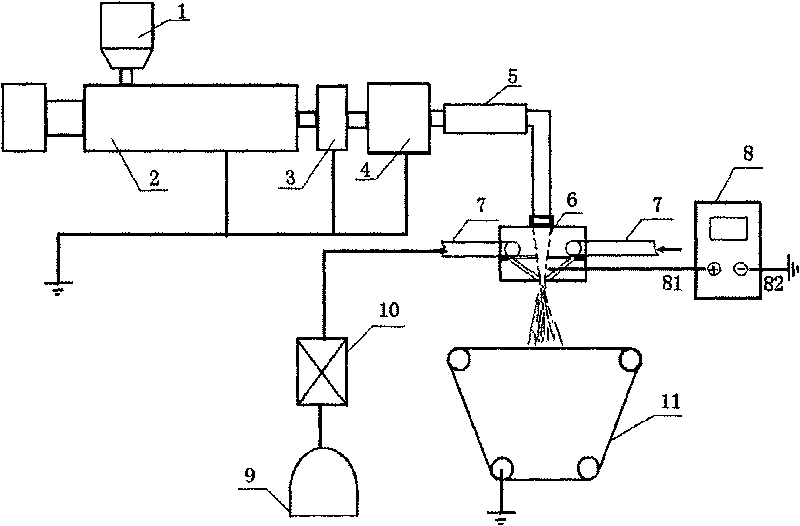

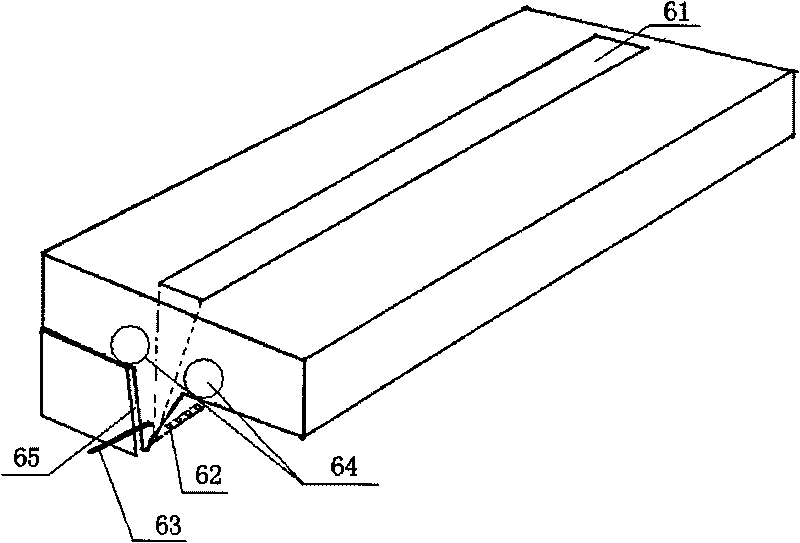

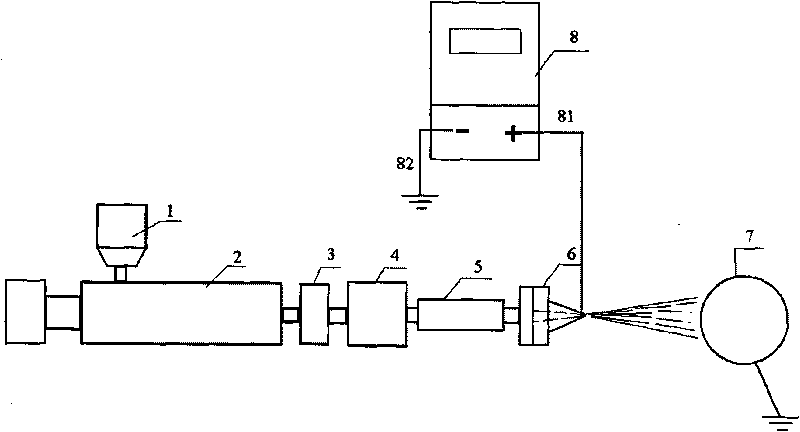

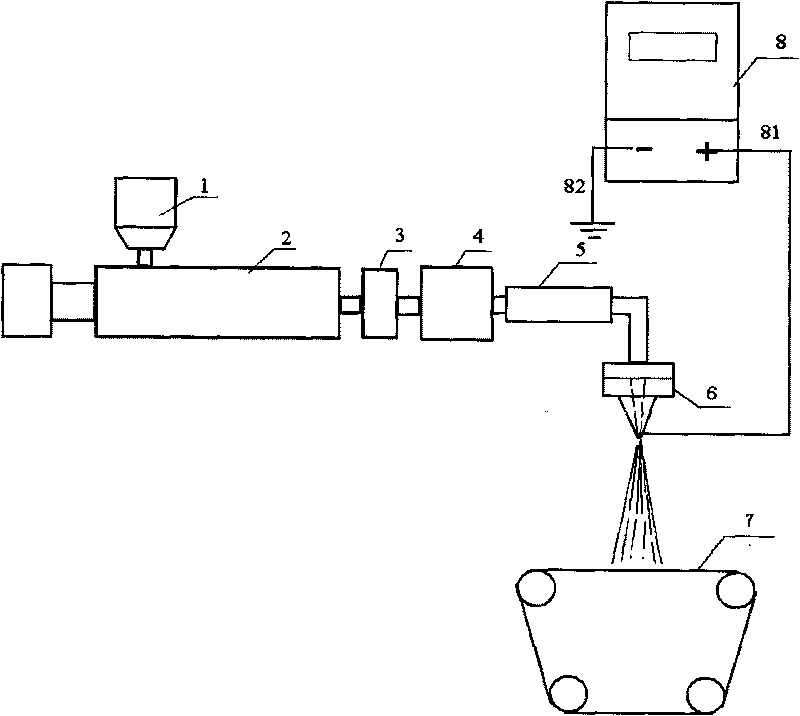

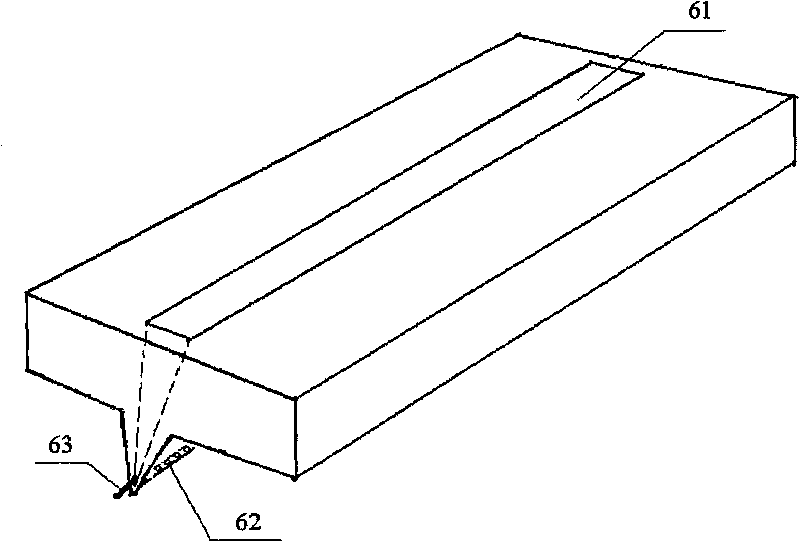

Device and method for manufacturing airflow melting electrostatic spinning nano-fiber non-woven fabric

InactiveCN101709534AThin diameterNarrow distributionSpinnerette packsSpinning head liquid feederFiberManufacturing technology

The invention relates to a device and a method for manufacturing an airflow melting electrostatic spinning nano-fiber non-woven fabric. The device for manufacturing the airflow melting electrostatic spinning nano-fiber non-woven fabric comprises a stock hoper, a screw extruder, a filter, a metering pump, a material path, a melt-blown die head, a hot-air pipeline, an air compressor, a heating device, a high voltage electrostatic generator and a receiving device. The material path is made of high thermal conductivity insulating ceramics. The method for manufacturing the nano-fiber non-woven fabric adopts the device disclosed by the invention and comprises the following processing steps: (1) preparing a polymer melt; (2) jetting nano-fibers by using airflow static electricity; and (3) moulding the non-woven fabric. The method for manufacturing the nano-fiber non-woven fabric of the invention adopts airflow-melting electrostatic spinning technology, avoids a problem of pollution of electrostatic spinning solvent, and is novel environment-friendly non-woven fabric manufacturing technology. In the manufacturing method, high voltage electrostatic is directly acted on the melt-blown die head; the melt has high and uniform charge; and simultaneously by utilizing drafting of the airflow, the prepared nano-fiber has the advantages of thin diameter and narrow distribution. The device can meet production requirements by improving the conventional melt-blown manufacturing device, and has low implementation cost and easy industrialization promotion.

Owner:TIANJIN POLYTECHNIC UNIV

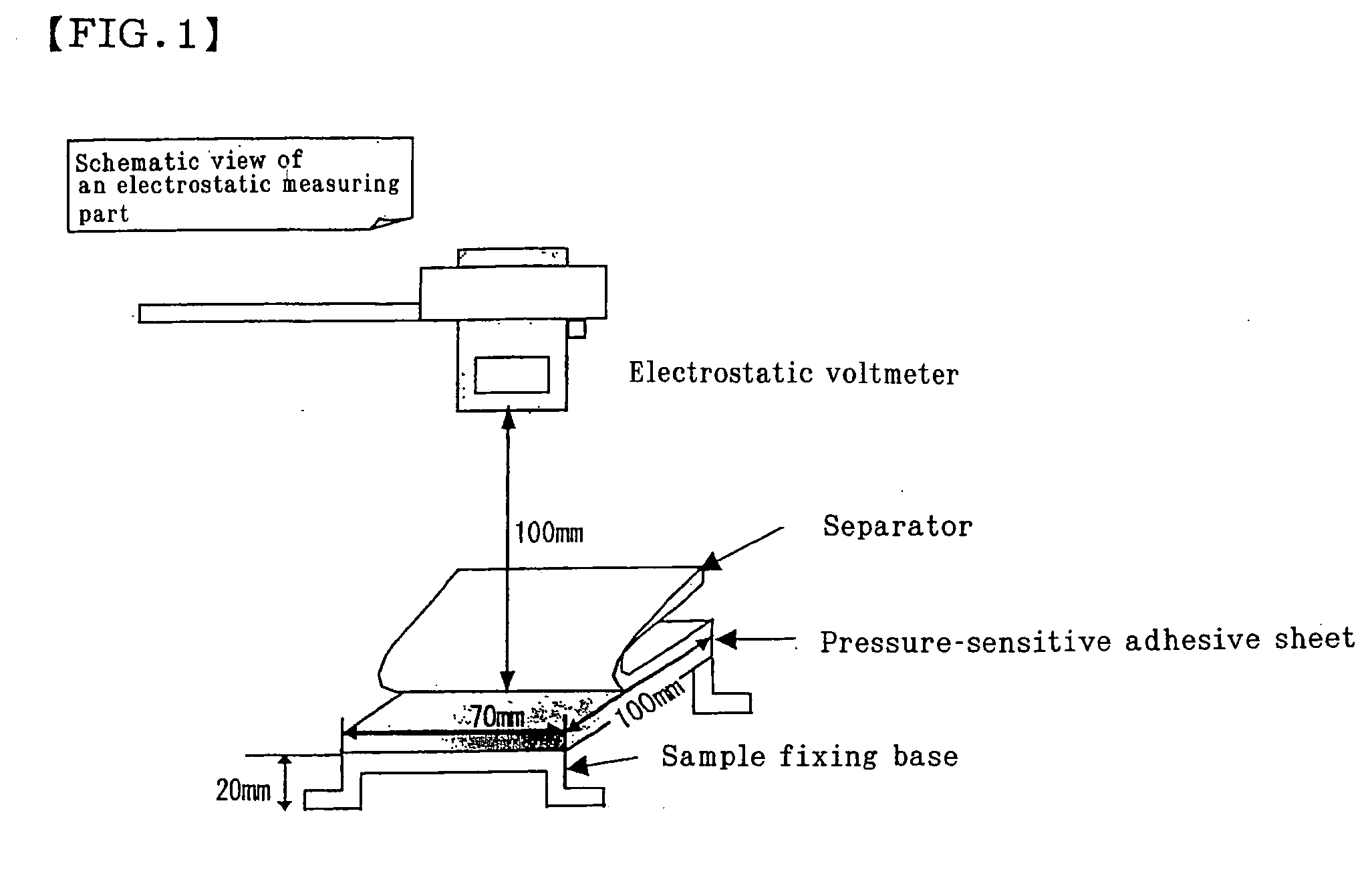

Pressure-sensitive adhesive composition and pressure-sensitive adhesive sheets

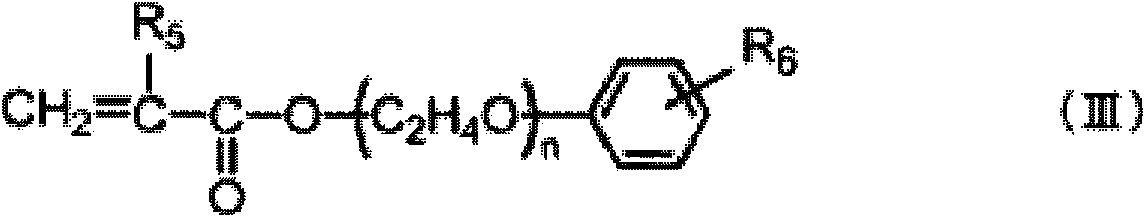

ActiveUS20050244633A1Excellent pressure-sensitive adhesive propertyStaining propertyNon-macromolecular adhesive additivesFilm/foil adhesivesCarbon numberMeth-

An object of the present invention is to provide an electrostatic pressure-sensitive adhesive composition which is excellent in antistatic property of pressure-sensitive adhesive sheets upon peeling, and has reduced stainability in an adherend (subject to be protected) and is excellent in adhesion reliance, and electrification preventing pressure-sensitive adhesive sheets and a surface protecting film using the same. There is provided a pressure-sensitive adhesive composition, which comprises a (meth)acryl-based polymer containing, as a monomer component, 15 to 100% by weight of a (meth)acrylic acid alkylene oxide adduct, 0 to 85% by weight of a (meth)acryl-based monomer having an alkyl group of a carbon number of 1 to 14 other than the adduct, and 0 to 85% by weight of other polymerizable monomer, and an alkali metal salt.

Owner:NITTO DENKO CORP

Pressure-sensitive adhesive composition, pressure-sensitive adhesive sheets, and surface protecting film

InactiveUS20050256251A1Reduce stainsAvoid electrificationNon-macromolecular adhesive additivesFilm/foil adhesivesCarbon numberTectorial membrane

An object of the present invention is to provide a surface protecting film which reduces staining on an adherend (subject to be protected) when applied to a surface protecting film of plastic products, and prevents electrification on an adherend (subject to be protected) which has not been electrification-prevented when a surface protecting film is peeled. There is provided a pressure-sensitive adhesive composition, which comprises a (meth)acryl-based polymer containing, as a main component, a (meth)acryl-based monomer having an alkyl group of a carbon number of 6 to 14, a polyether polyol compound and an alkali metal salt, wherein an acid value of the (meth)acryl-based polymer is 1.0 or lower, and the alkali metal is contained at an amount of less than 0.1 part by weight relative to 100 parts by weight of the (meth)acryl-based polymer.

Owner:NITTO DENKO CORP

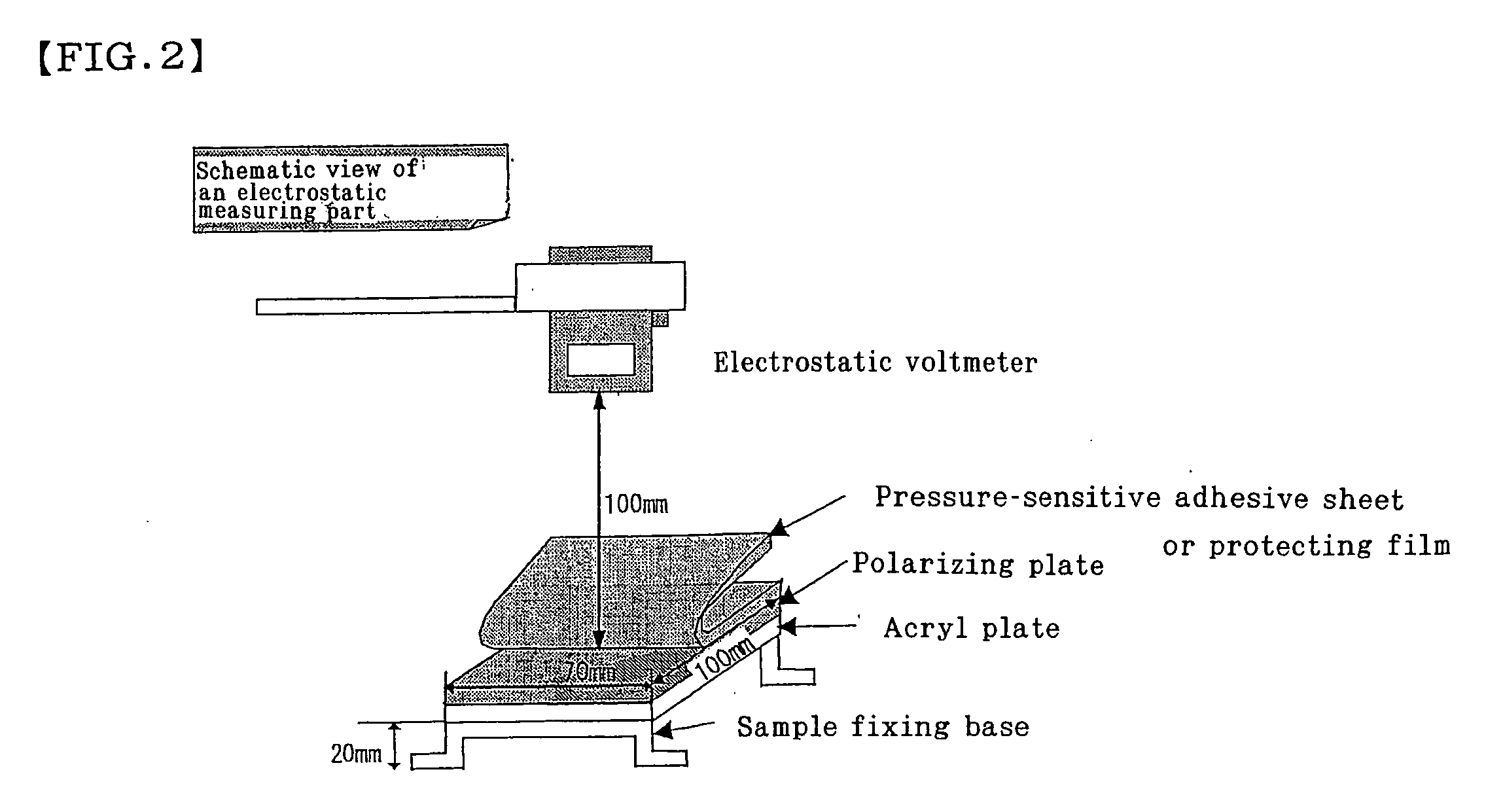

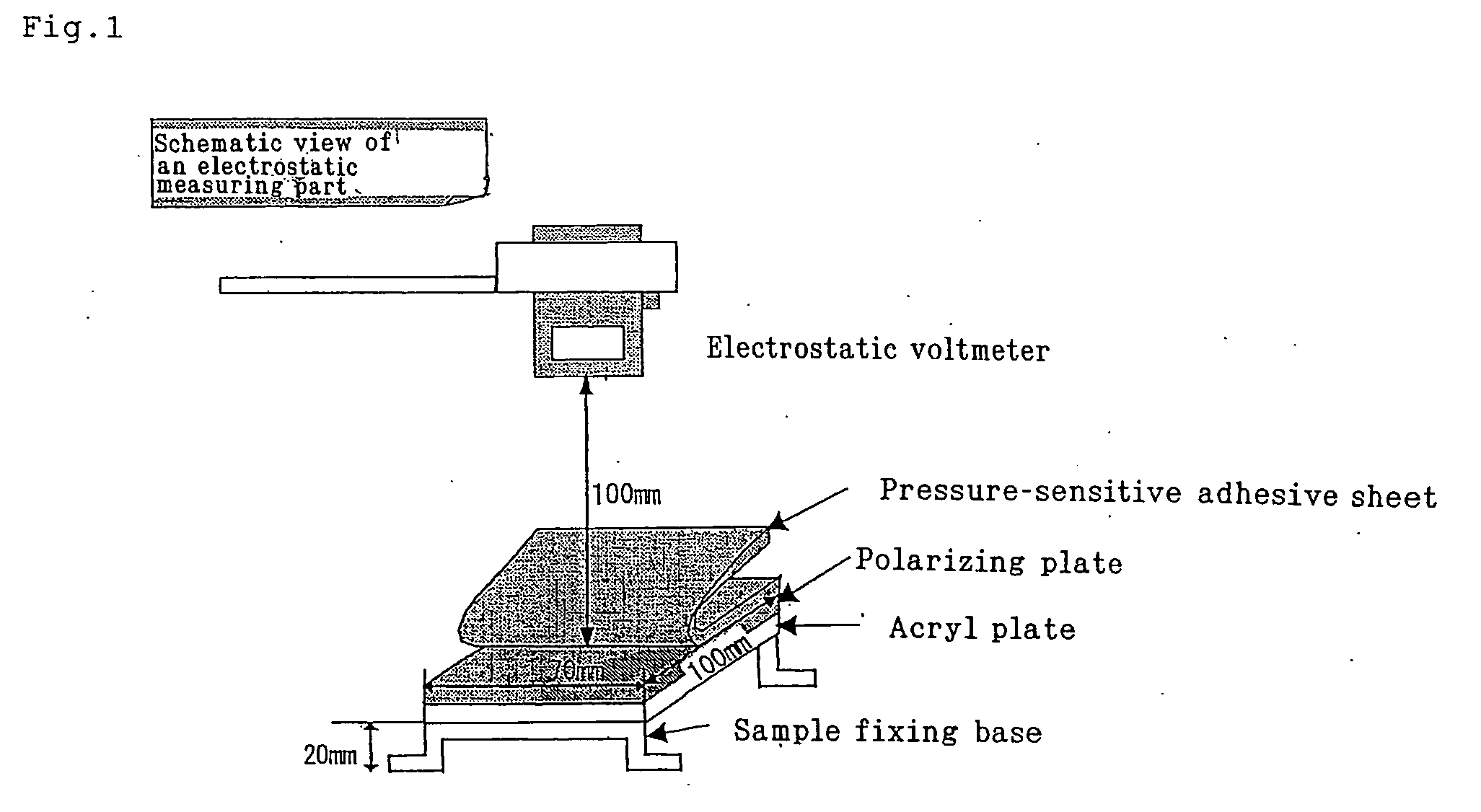

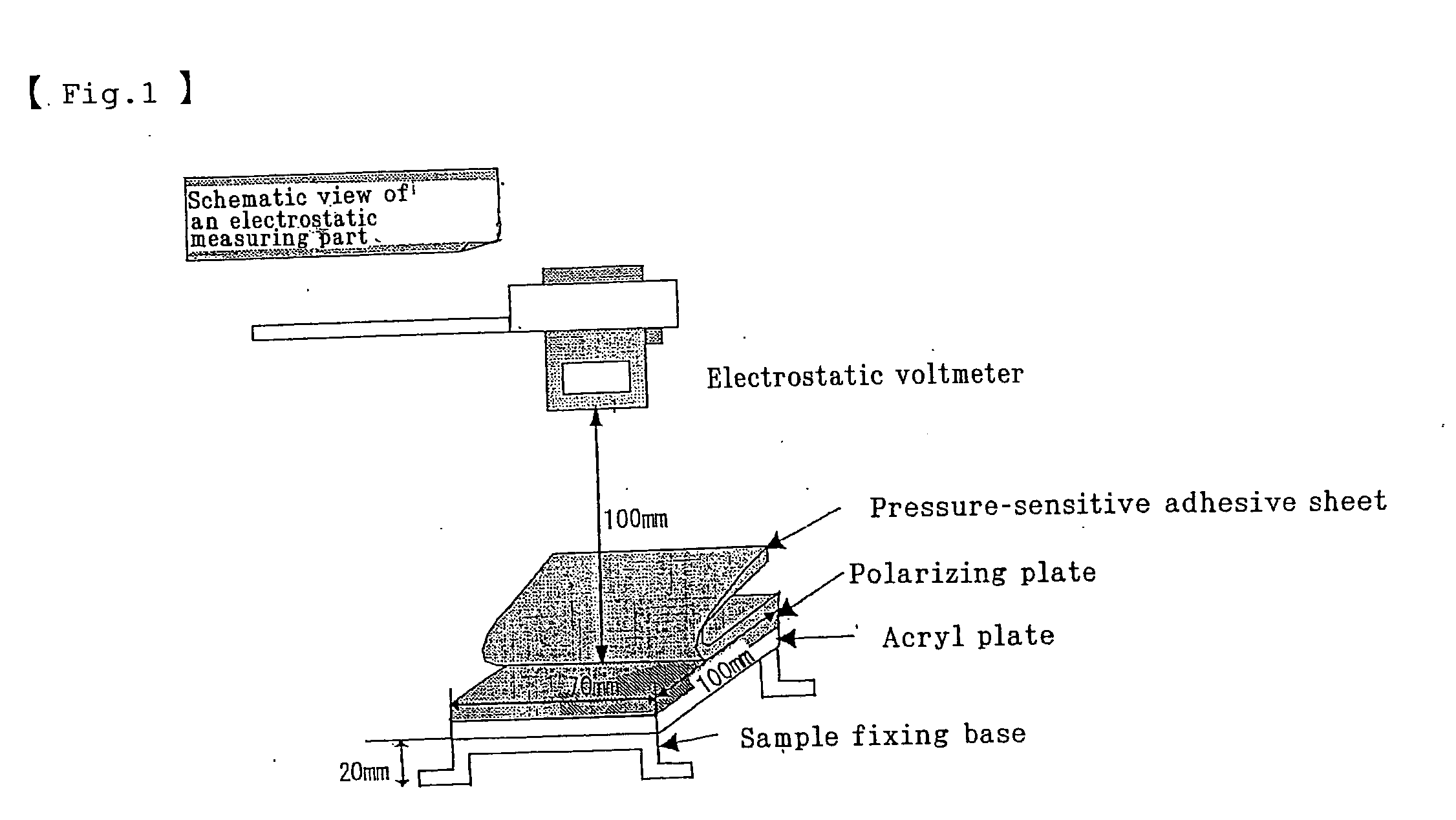

Laminated polarizing film

InactiveUS7038746B2Avoid electrificationSolve low usagePolarising elementsNon-linear opticsEngineeringBright spot

It is aimed to provide a laminated polarizing film having an antistatic function, where static electricity occurs less even if the protective film is peeled off to bond the laminated polarizing film to a liquid crystal cell, and where defects such as bright spots are not caused in display. The aim is achieved by a laminated polarizing film, wherein a reflective polarizing film and an absorptive polarizing film are laminated, and an antistatic layer is further laminated at least either on the outside of the reflective polarizing film or between the reflective polarizing film and the absorptive polarizing film.

Owner:SUMITOMO CHEM CO LTD

Extra-high voltage transformer oil and production process thereof

The invention relates to extra-high voltage transformer oil and a production process thereof. The extra-high voltage transformer oil comprises the following components in percentage by weight: 75wt%-85wt% of naphthenic-base base oil, 12wt%-22wt% of dodecyl benzene, 10ppm-200ppm of a metal de-activating agent and 0.1wt%-3wt% of a light stabilizer. Compared with the prior art, the extra-high voltage transformer oil is low in cost, simple in formula and production process, convenient to use, excellent in comprehensive performances and in particular suitable for being used as extra-high voltage transformer oil.

Owner:ANHUI KAIAO NEW ENERGY CO LTD

Device and method for manufacturing melting electrostatic spinning nano-fiber non-woven fabrics

InactiveCN101709535AAvoid electrificationRealize continuous productionSpinnerette packsSpinning head liquid feederSolventHigh voltage

The invention relates to a device and a method technique for manufacturing melting electrostatic spinning nano-fiber non-woven fabrics. The device for manufacturing the melting electrostatic spinning nano-fiber non-woven fabrics comprises a material storage tank, a screw extruder, a filter, a measuring pump, a material path, a spinning component, a receiving device and a high-voltage electrostatic generator; and the material path is made of high thermal conductivity insulating ceramics. The method for manufacturing the nano-fiber non-woven fabrics adopts the device for manufacturing the same and comprises the following process steps: (1) preparing a polymer melt; (2) jetting nano-fibers; and (3) molding the non-woven fabrics. By adopting a melting electrostatic spinning technique, the method for manufacturing the nano-fiber non-woven fabrics avoids the pollution problem caused by a solution electrostatic spinning solvent, which is a novel environment-friendly technique for manufacturing the non-woven fabric; and the device is reconstructed on the basis of the conventional screw extrusion melting spinning production equipment to meet the requirement on production, has a low implementation cost, and is easy for industrialized popularization.

Owner:TIANJIN POLYTECHNIC UNIV

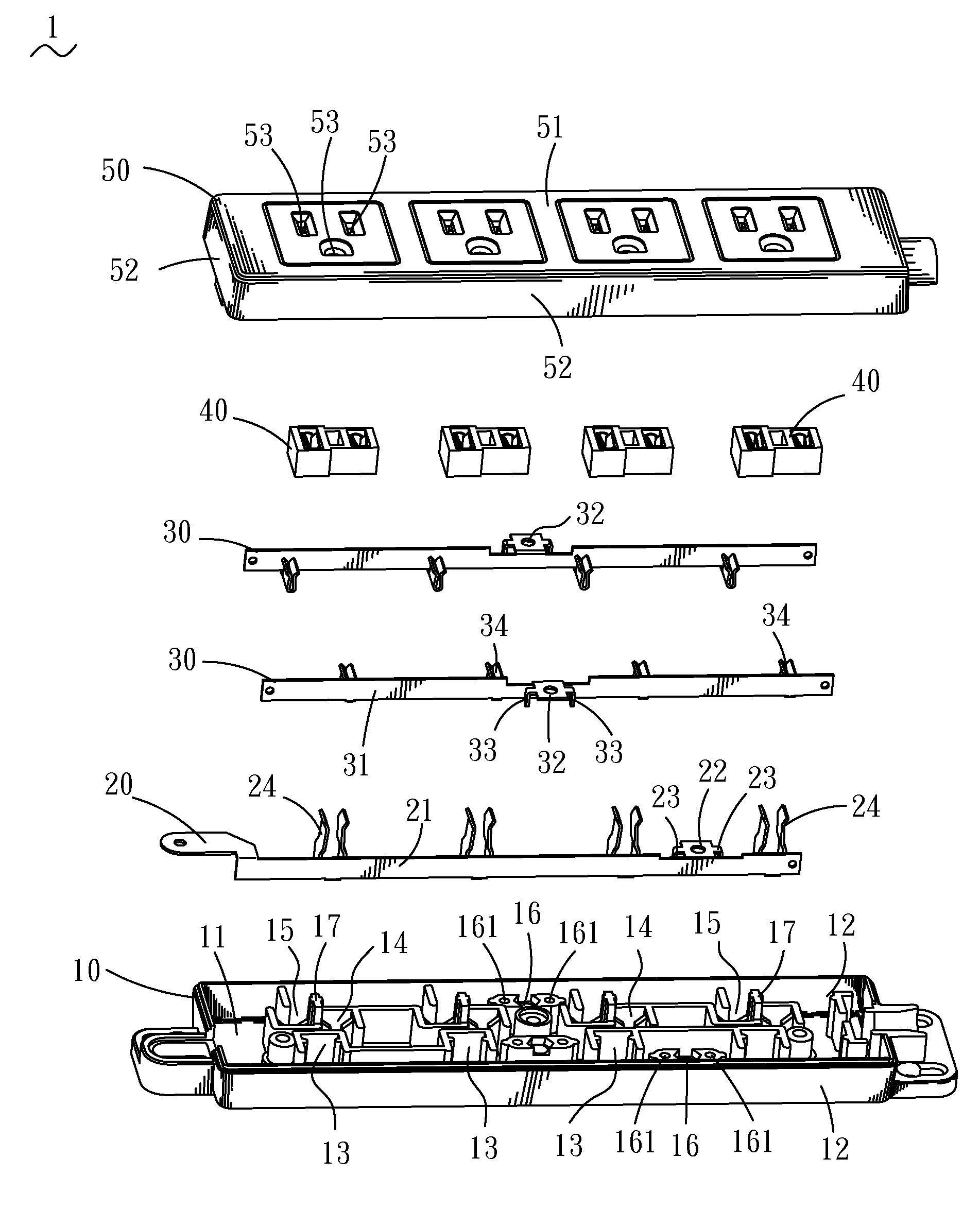

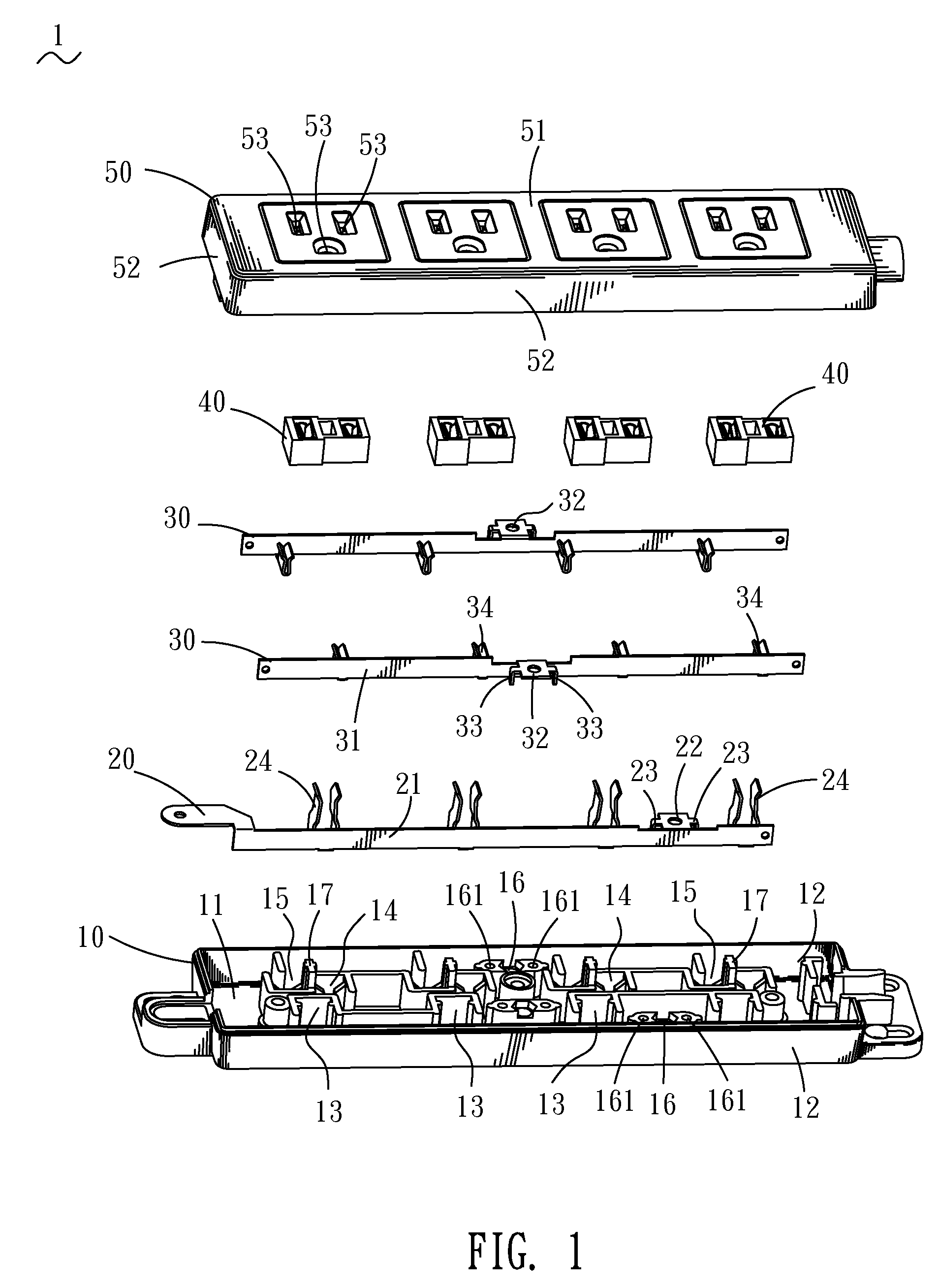

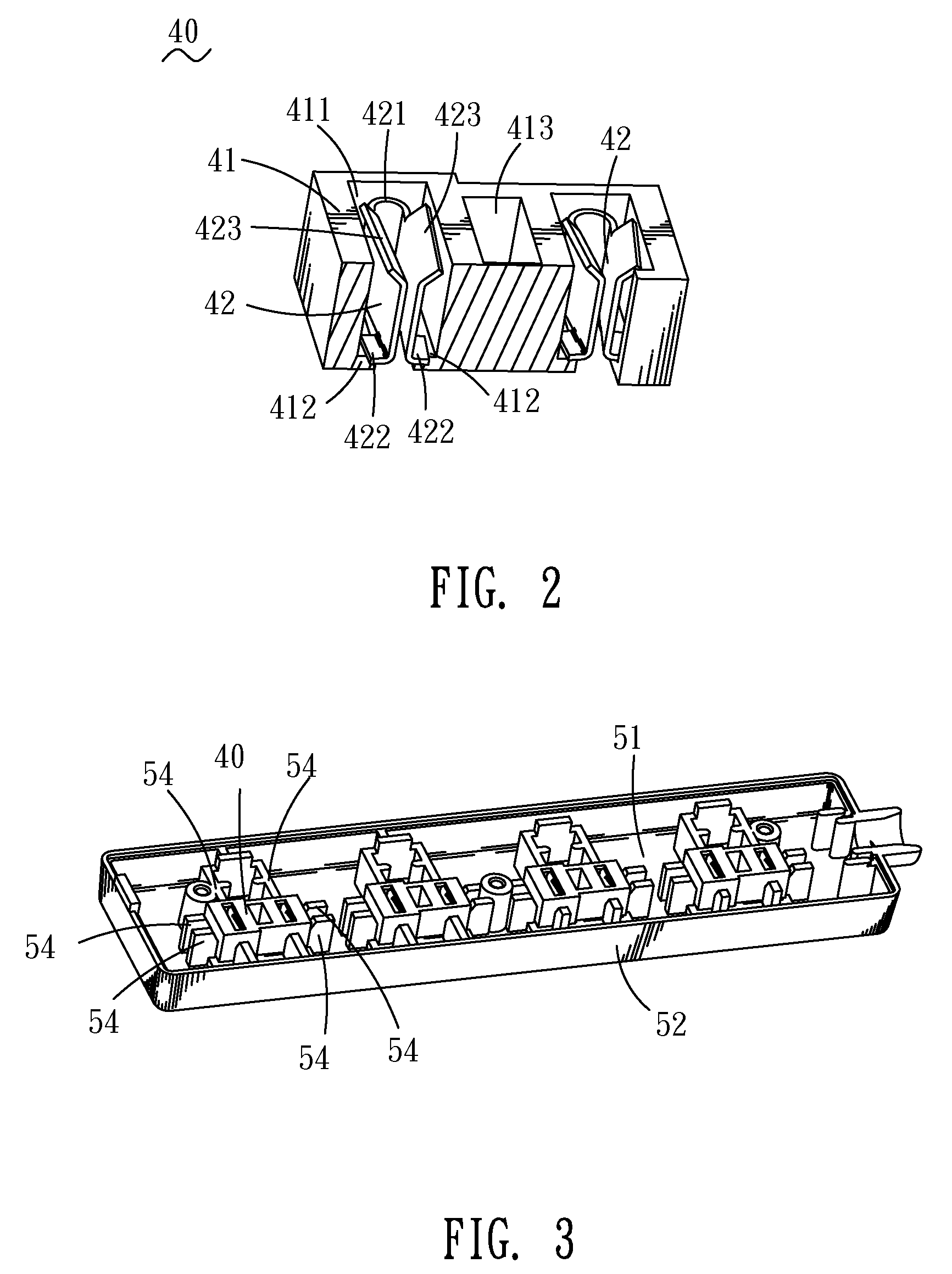

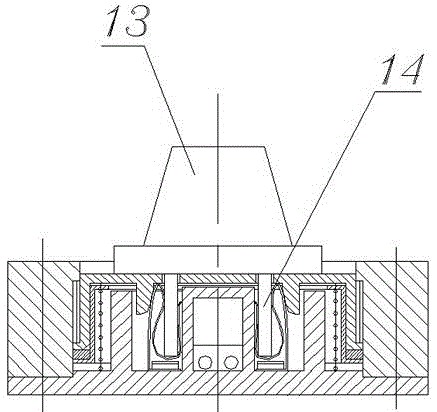

Safety socket

InactiveUS7753699B2Easy to manufactureEasy to assembleEngagement/disengagement of coupling partsTwo pole connectionsEngineeringBiomedical engineering

A safety socket adapted for receiving a terminal of a plug includes a socket housing with a plurality of electrodes being mounted thereon, a socket cover coupled with the socket housing and an insulating case mounted between the socket housing and the socket cover. The socket cover has a plurality of insertion holes corresponding to the electrodes. And the insulating case is located above the electrode for holding the terminal separated from the electrode and has a through hole aligned with the electrode and the insertion hole.

Owner:WELL SHIN TECH

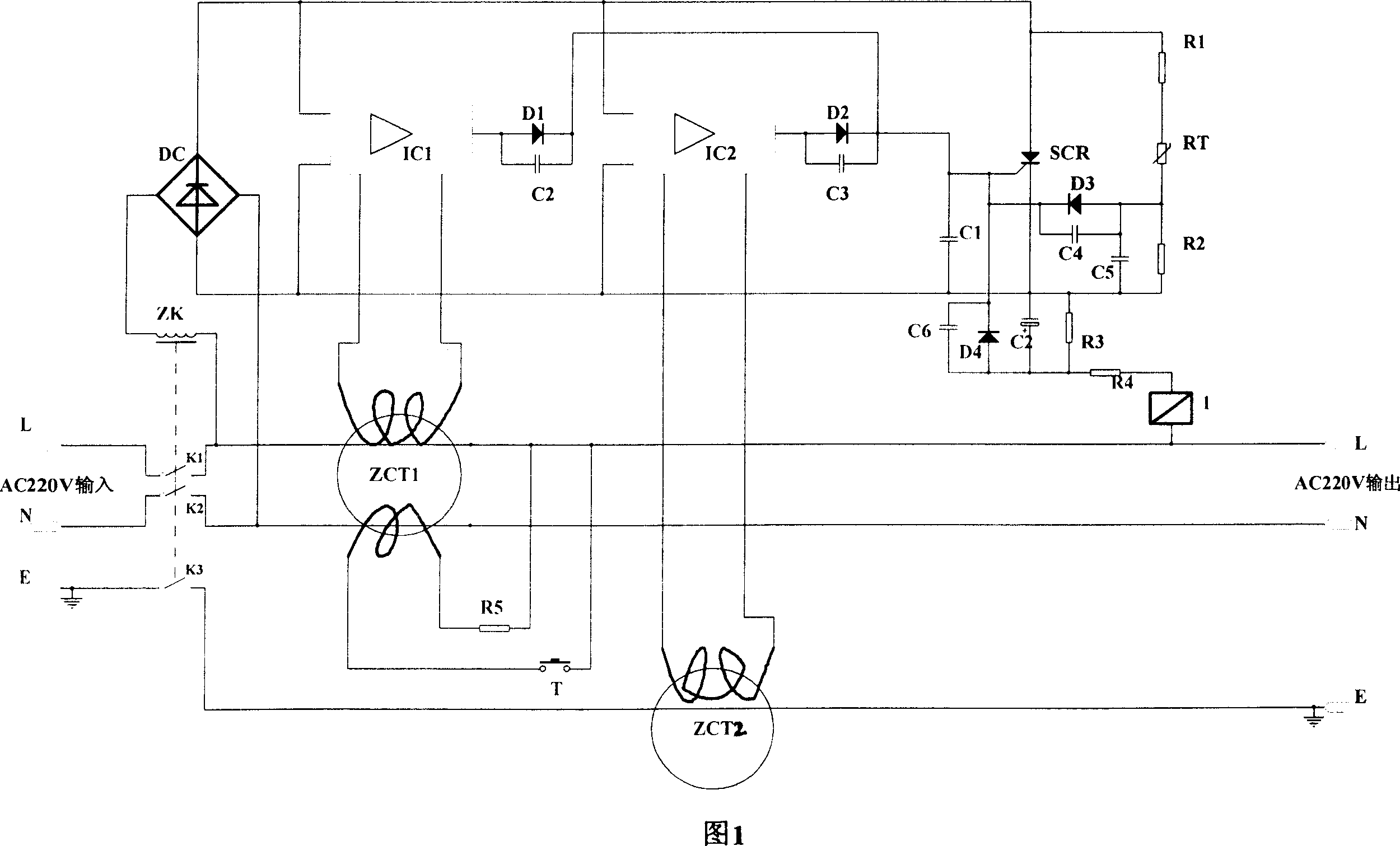

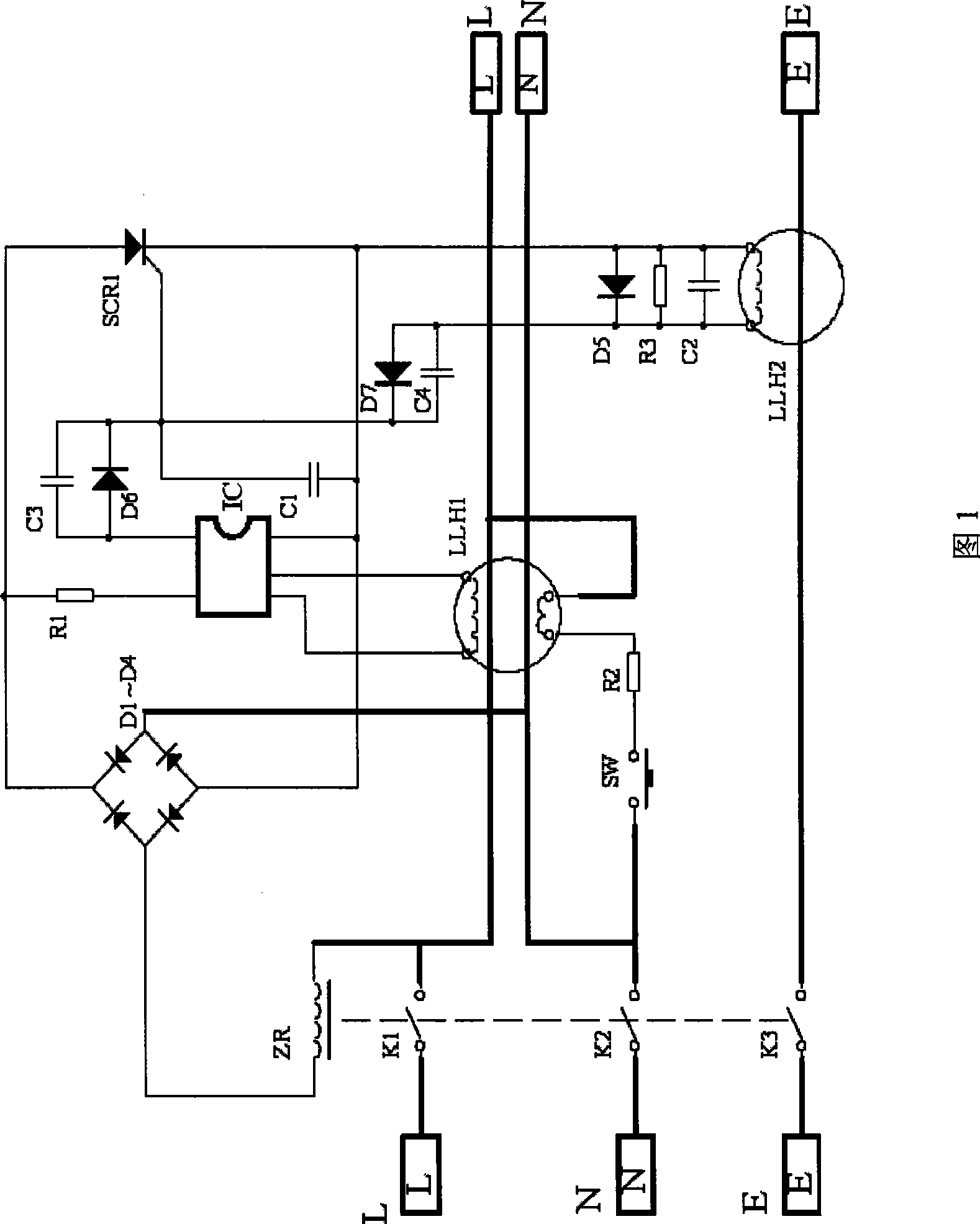

Full-function secure plug

InactiveCN101017947AAvoid electrificationEnsure personal safetyCoupling device detailsEmergency protective arrangements for automatic disconnectionThree-phaseGround line

The related all-purpose safe plug comprises: three poles every with switch; between phase and zero line, a zero-sequence current transformer, a test loop, an amplification circuit, a dc power, and a release device; a ground line connected by a movable contact spring and a fixed point; another zero-sequence current transformer in the ground line with secondary output end paralleled with another amplification circuit whose output serial connects with the trigger electrode of a thyristor. This invention can prevent electrification of three phase lines and over-temperature of plug self.

Owner:YUYAO JIARONG ELECTRONICS & ELECTRIC APPLIANCE CO LTD

Semiconductor embedded module and method for producing the same

ActiveUS8742589B2Avoid damageNot to damageSemiconductor/solid-state device detailsSolid-state devicesRedistribution layerDevice material

Owner:TDK CORPARATION

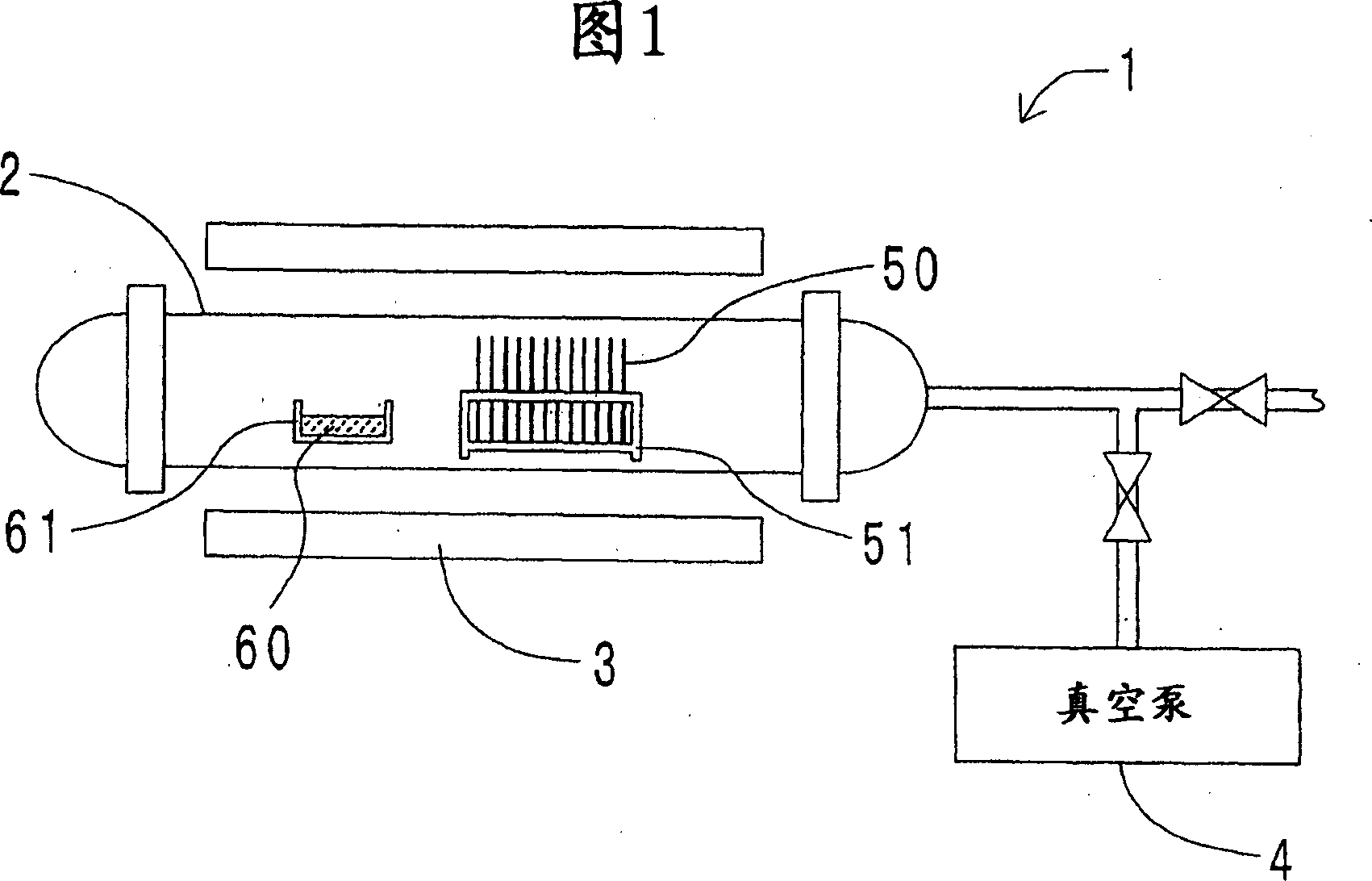

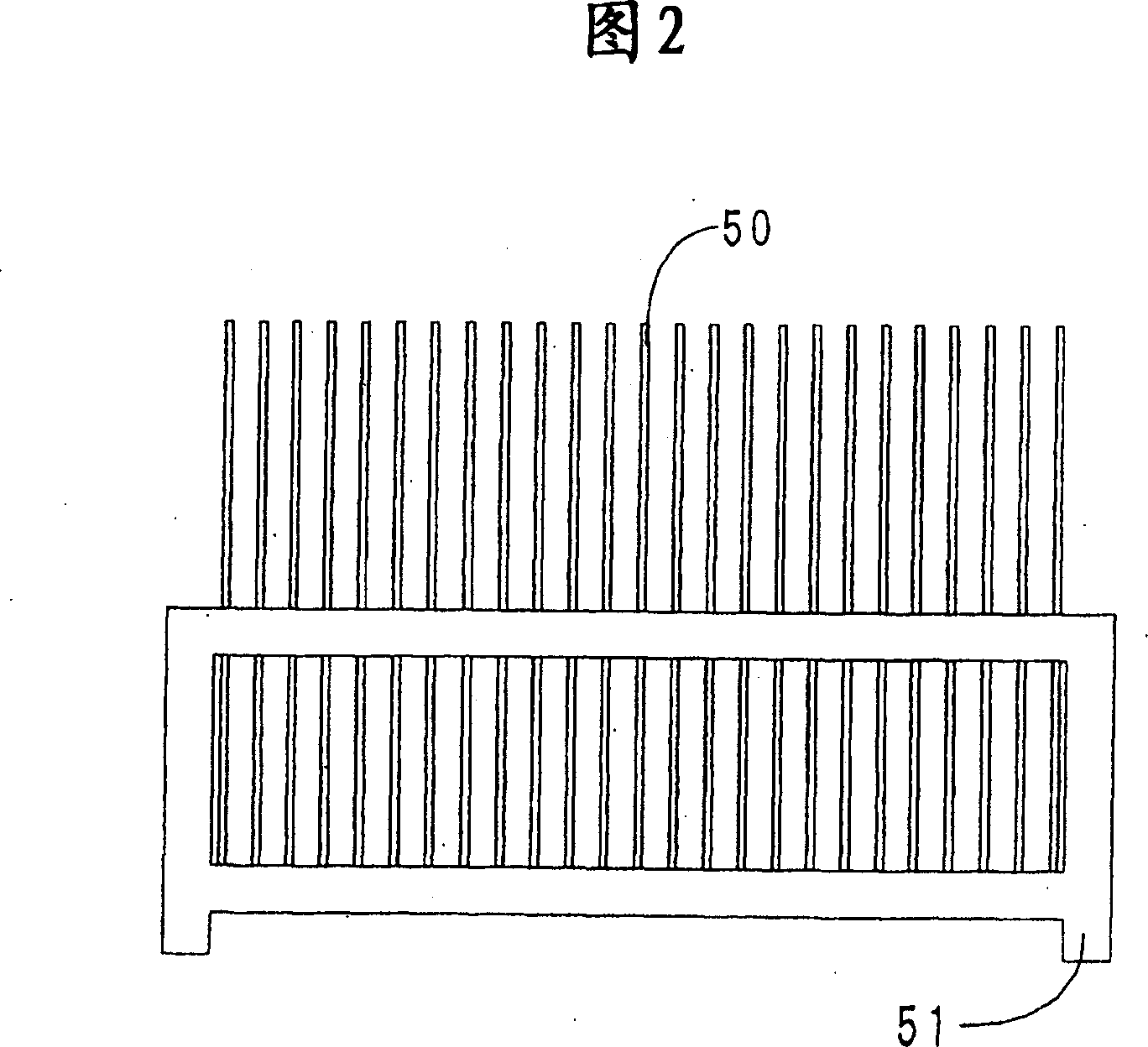

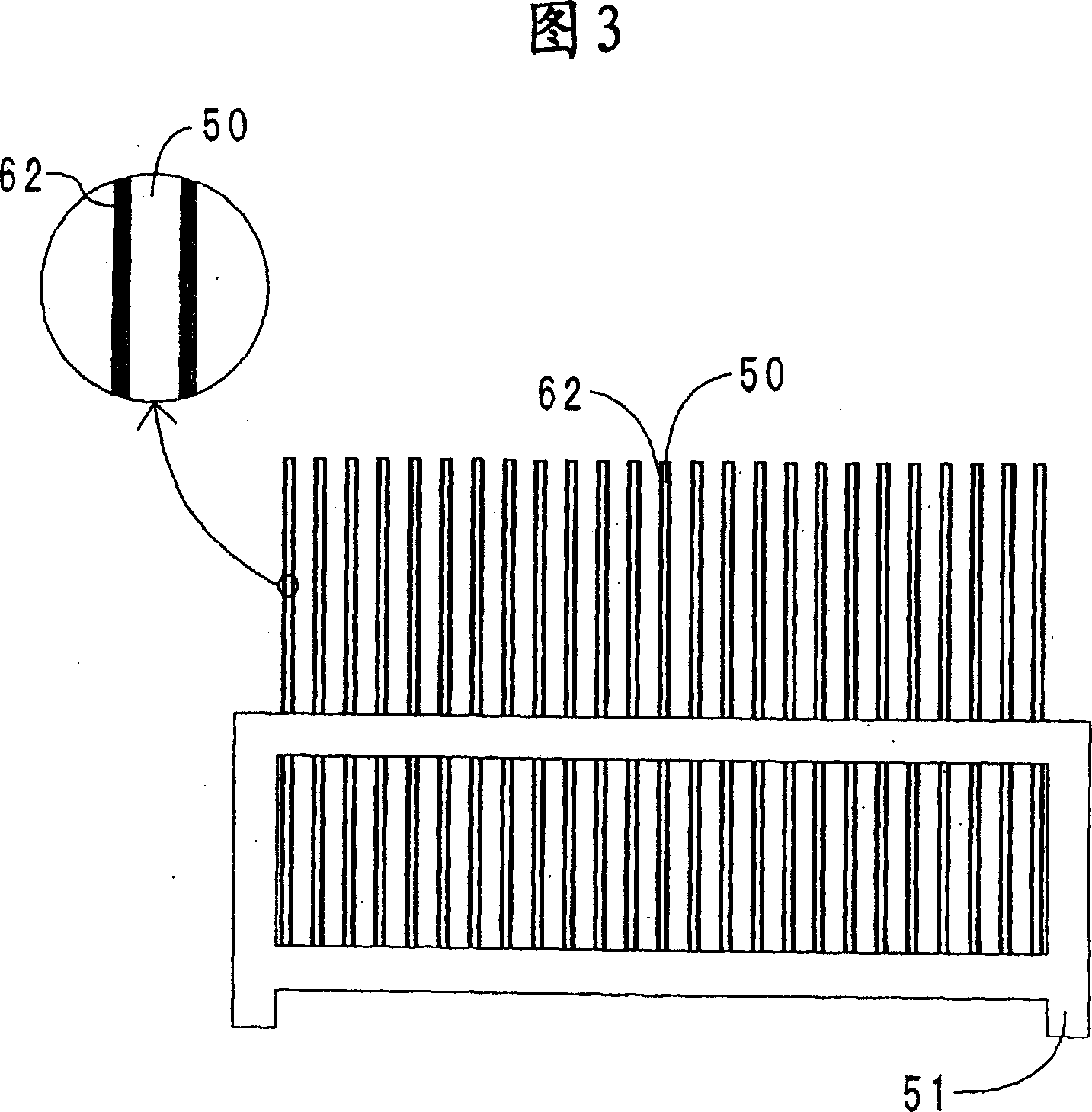

Charge restraining method and apparatus for piezoelectric oxide single crystal

InactiveCN1950549AEasy to operateControl the degree of restorationPolycrystalline material growthAfter-treatment detailsSingle crystalPiezoelectricity

To provide a processing method which can restrain the charging of lithium tantalate single crystal or lithium niobate single crystal without impairing the piezoelectricity. Moreover, to provide a processing apparatus which can carry out the processing method simply and easily. It is characterized in that a wafer 50, made from a lithium tantalate single crystal or a lithium niobate single crystal, and a reducing agent 60, including an alkali metal compound, are accommodated in a processing tank 2, and the inside of the processing tank 2 is held at a temperature of from 200 °C to 1000 °C under decompression, thereby reducing the wafer 50.

Owner:YAMAJIYU CERAMICS

Pressure-sensitive adhesive composition, pressure-sensitive adhesive sheets and surface protecting film

InactiveUS7691925B2Reduce stainsAvoid electrificationNon-macromolecular adhesive additivesInksGlass transitionIonic liquid

An object of the present invention is to provide a pressure-sensitive adhesive composition in which electrification of a pressure-sensitive adhesive sheet can be prevented upon peeling, and staining property on an adherend can be reduced, and an antistatic pressure-sensitive sheet and surface protecting film using this. There is provided a pressure-sensitive composition comprising an ionic liquid and a polymer having a glass transition temperature Tg of 0° C. or lower as a base polymer.

Owner:NITTO DENKO CORP

Antistatic agent and coating or molding synthetic resins

The object of the present invention is to provide an antistatic agent used for thermoplastic resin having aromatic ring(s) such as a styrene group resin, polyester resin, or the like A graft copolymer whose main chain is acrylic rubber and graft chain is of a polymer chain mainly consisting of a styrene group monomer or copolymer chain mainly consisting of a styrene group monomer and nitrile group monomer is used as said antistatic agent. Besides said graft copolymer, antistatic properties are is given to said thermoplastic resin by blending said thermoplastic resin with a compound having a hydrophilic group so as to be a blend polymer or a polymer alloy. Further, antistatic properties are given to a resin molded article by coating it with a paint containing hydrophilic polymer.

Owner:SUZUKA FUJI XEROX CO LTD

Optical film having adhesive agent, and optical laminated body in which same is used

ActiveCN103403117AInhibit electrificationGood durabilityNon-macromolecular adhesive additivesSynthetic resin layered productsAcrylic acidOptical film

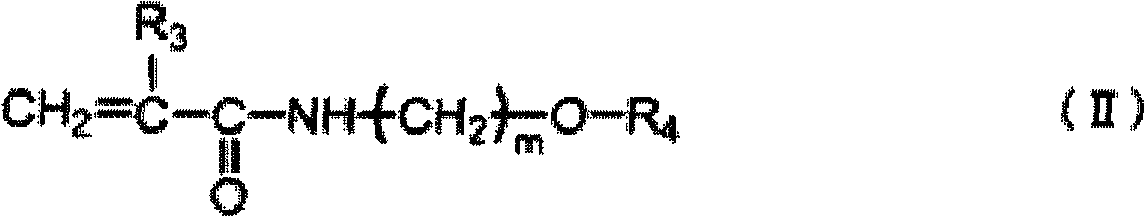

The present invention provides an optical film having an adhesive agent, the optical film being provided with an adhesive agent layer obtained using a composition in which 0.3 to 12 parts by weight of an ionizable compound and 0.1 to 5 parts by weight of a cross-linking agent are compounded with 100 parts by weight of an acrylic copolymer of a monomer mixture comprising 80 to 96 wt% of (A-1), 1 to 15 wt% of (A-2), 0.1 to 5 wt% of (A-3), and 0.5 to 5 wt% of (A-4). (A-1) is a compound of formula (I) (R1 is a hydrogen or methyl, and R2 is a C1-14 alkyl), (A-2) is an unsaturated monomer having an aromatic ring, (A-3) is a compound of formula (II) (R3 is a hydrogen or methyl, R4 is an alkyl, and m is 1 to 8), and (A-4) is an unsaturated monomer having a polar functional group.

Owner:SUMITOMO CHEM CO LTD

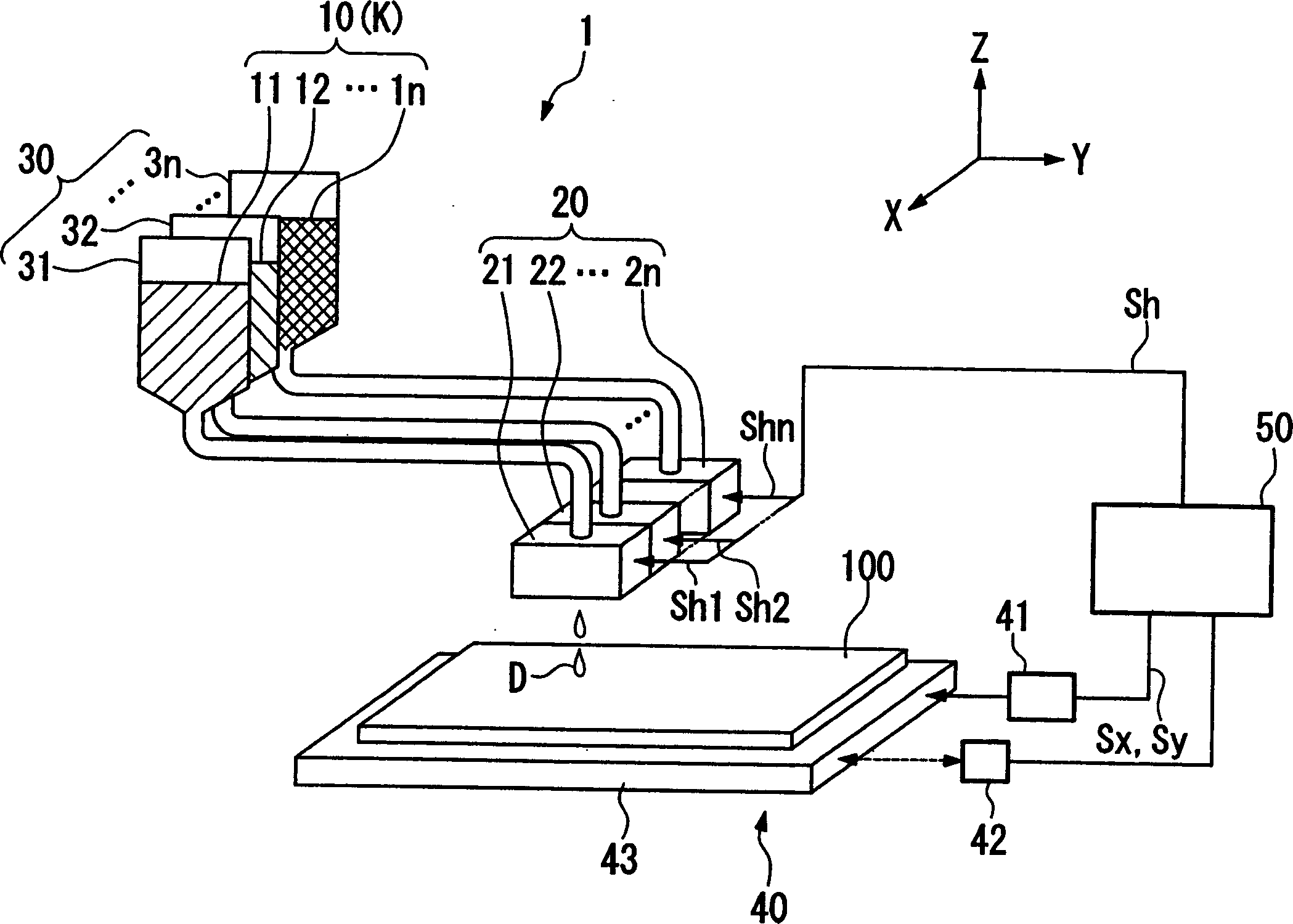

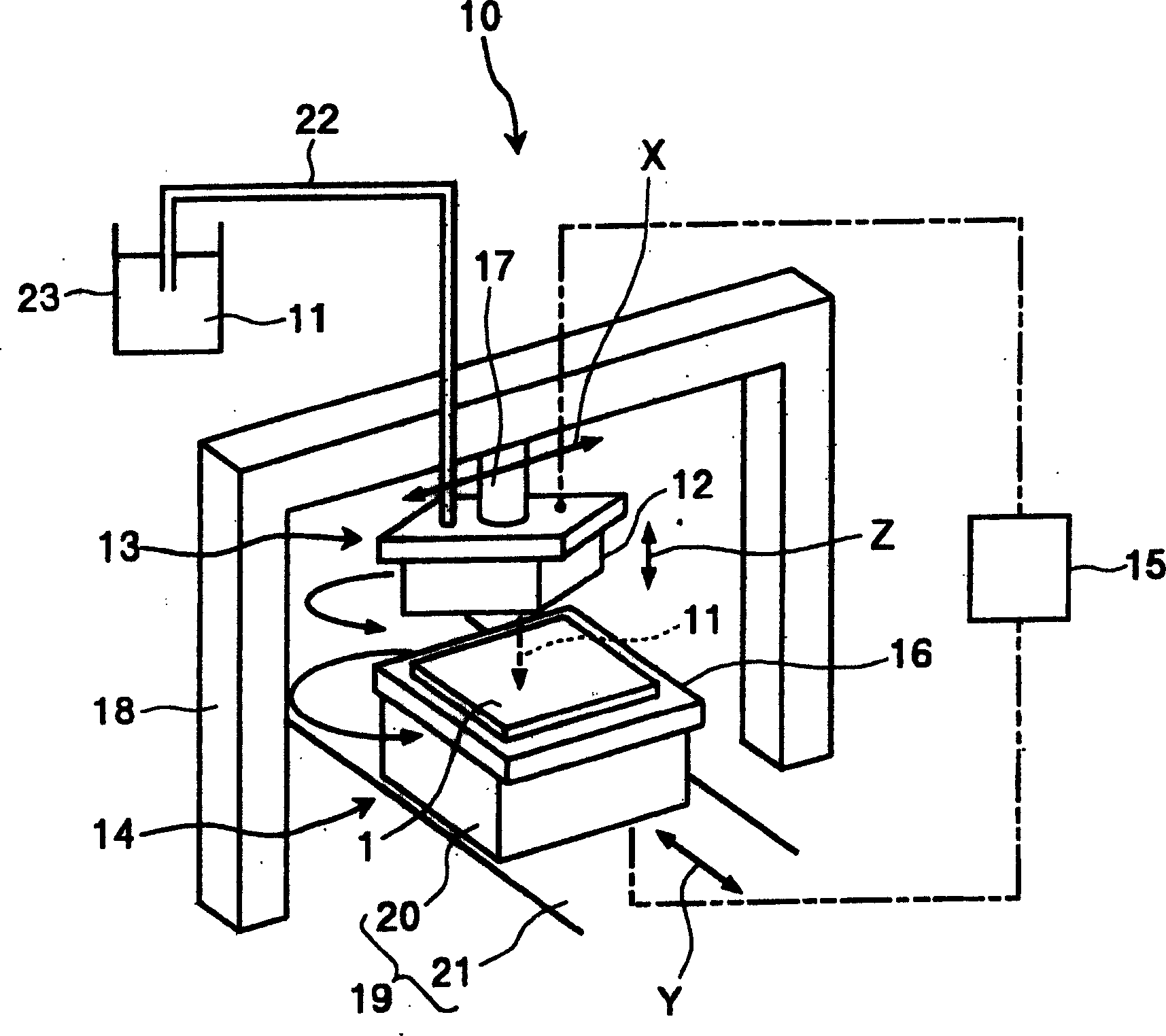

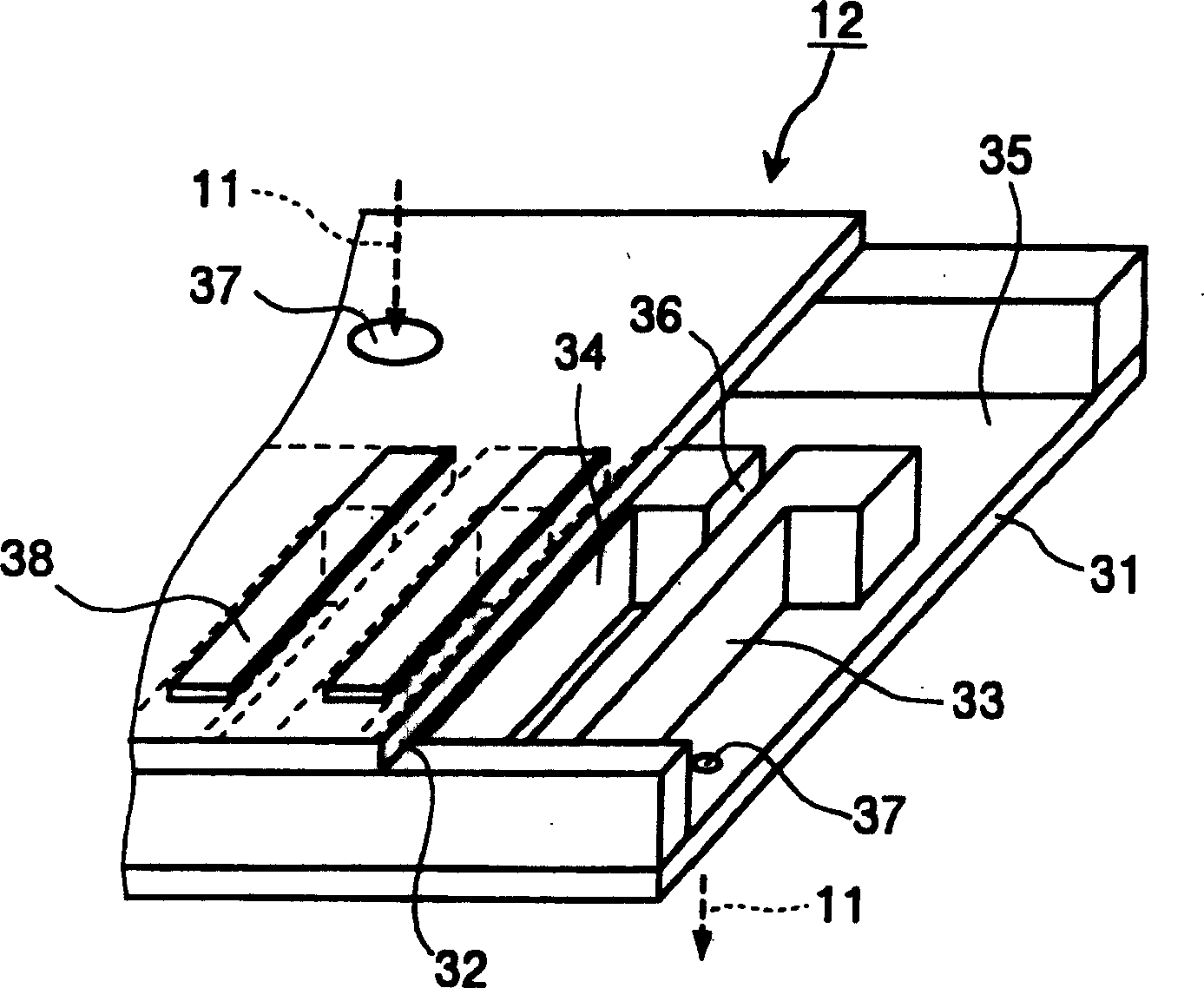

Working table device, film-forming device, optical element, semiconductor element and electronic device

InactiveCN1535823AAvoid electrificationPrevent sticking marksSleeve/socket jointsElectroluminescent light sourcesEngineeringSemiconductor components

Owner:SEIKO EPSON CORP

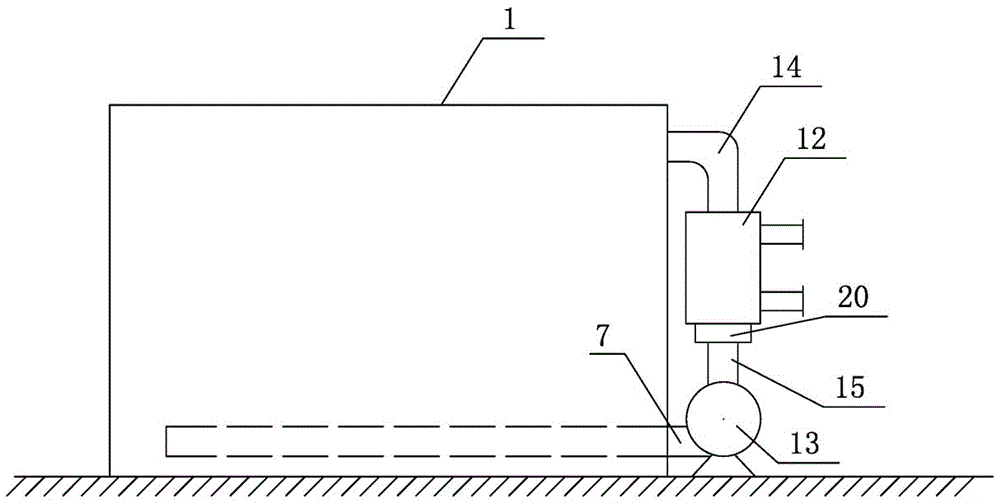

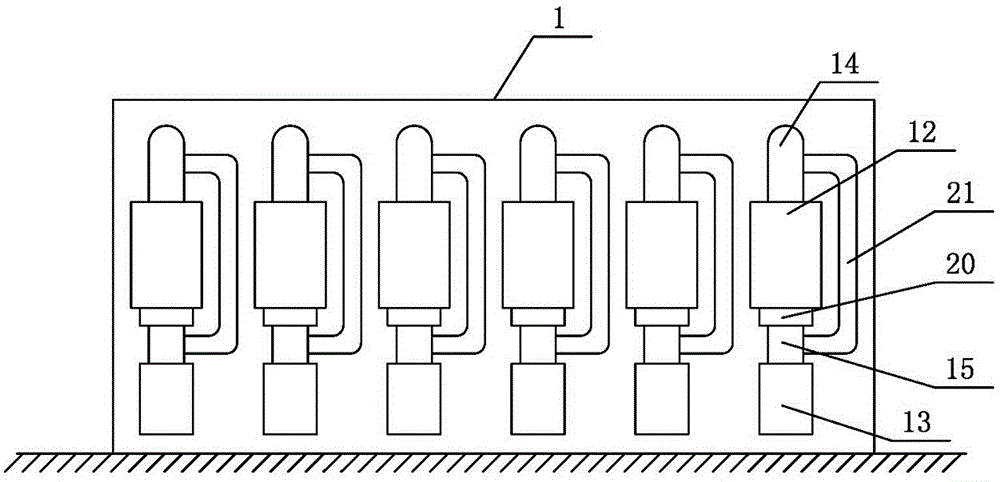

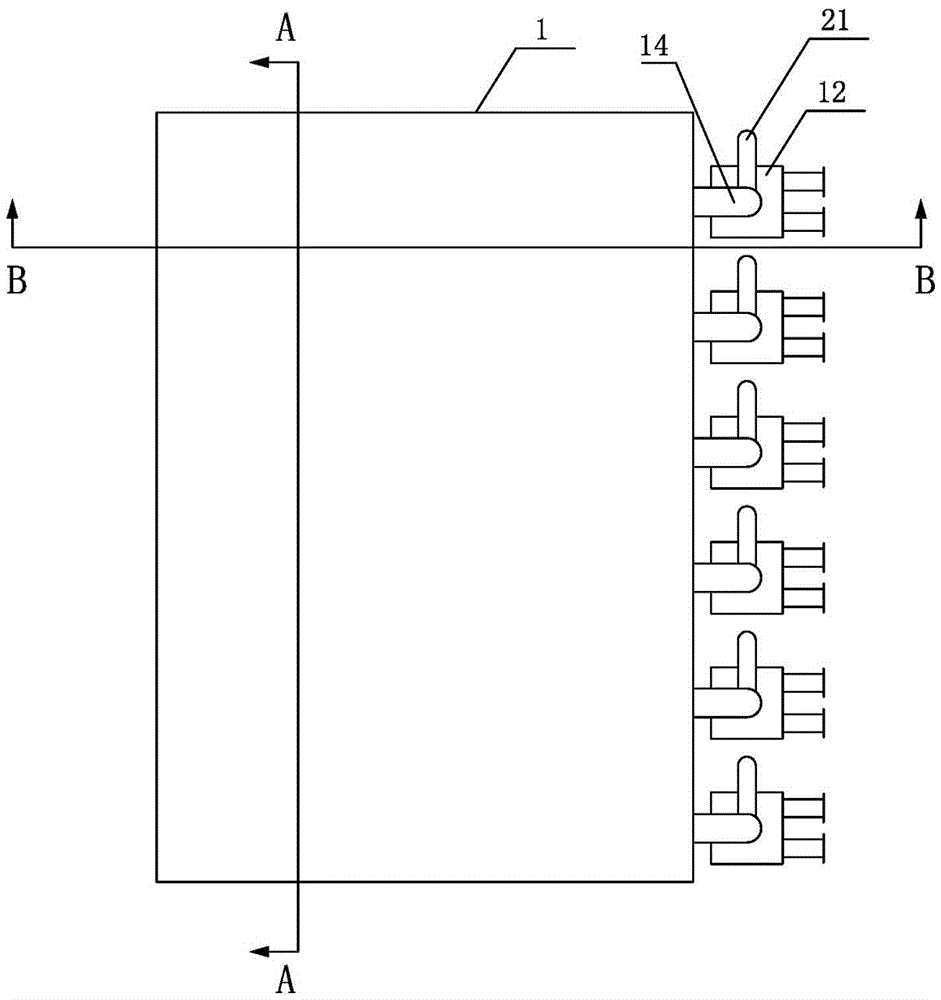

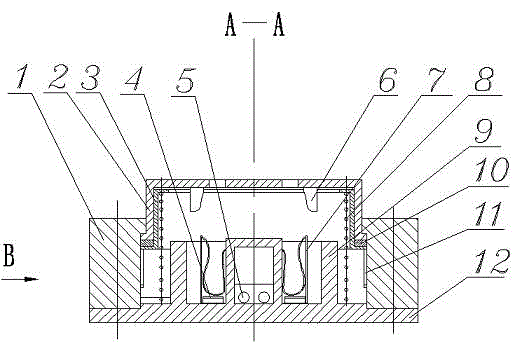

Solid electric heat accumulation device

ActiveCN105605957AAvoid electrificationReduce insulation costsHeat storage plantsControl systemEngineering

The invention relates to a solid electric heat accumulation device which comprises a thermal-insulation shell, a load-bearing wall, a resistance heater set, a heat accumulator, a thermal circulation system, a basic structure and a control system. The technical scheme is as follows: the resistance heater set directly powered by a power source is installed in each space established by the load-bearing wall in the thermal-insulation shell; the resistance heater set is formed by connecting a plurality of resistance heating units in series; the basic structure is composed of a cable trench, a load-bearing wall and a foundation; the heat accumulator is composed of a rectangular-solid assembly array; the rectangular-solid assembly is made of cast iron or refractory steel, the inside of which is provided with a heat accumulation material; and the thermal circulation system is a closed air duct formed by tightly connecting a circulating path, a heat exchanger, an air regulator and a fan component arranged on the external surface of the thermal-insulation shell, thereby completing the output of the heat energy to the heat user. Compared with the solid electric heat accumulation device manufactured by the prior art, the solid electric heat accumulation device provided by the invention can reduce the equipment volume, lowers the cost for electric heating components, and prevents the heat accumulator from being electrically charged.

Owner:SHENYANG SHIJIE ELECTRIC

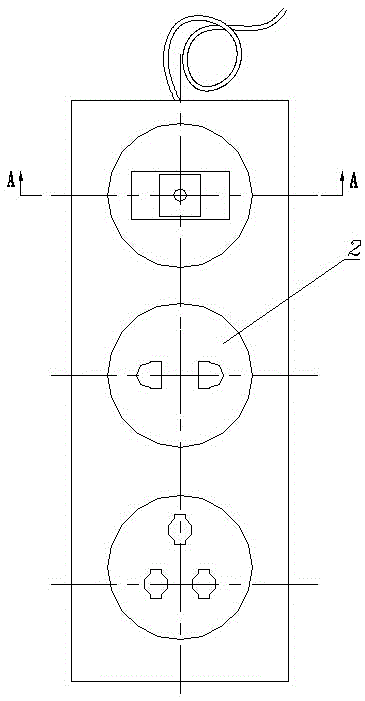

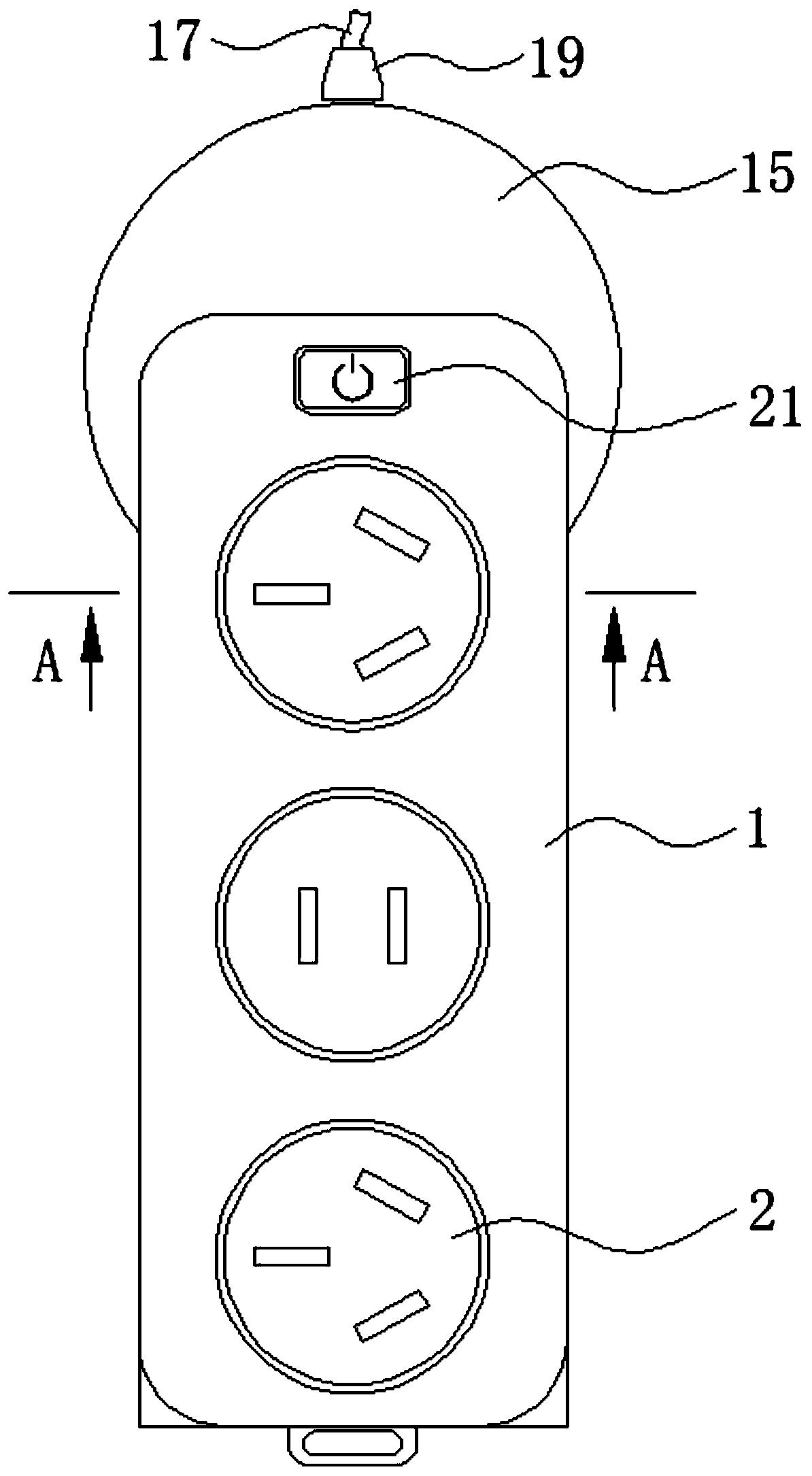

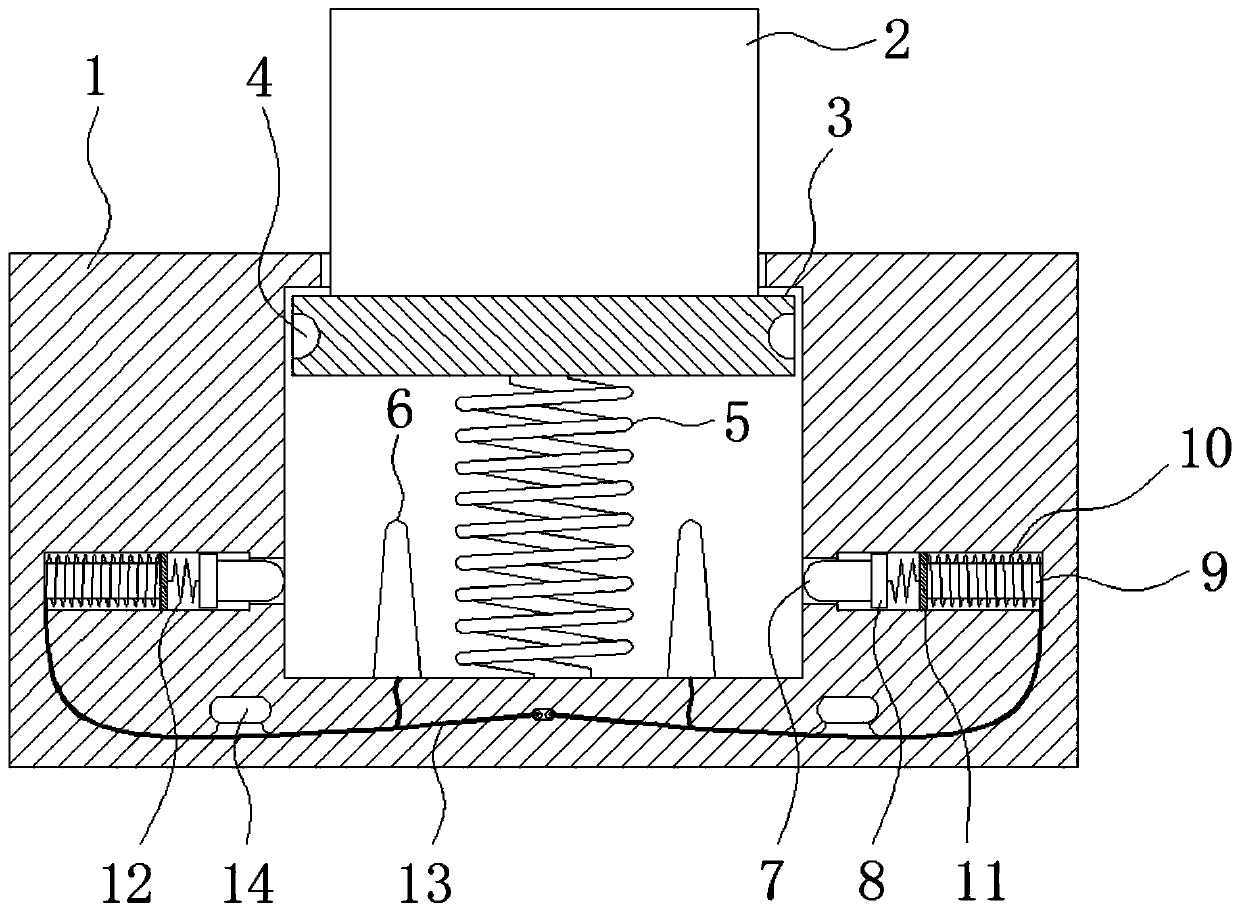

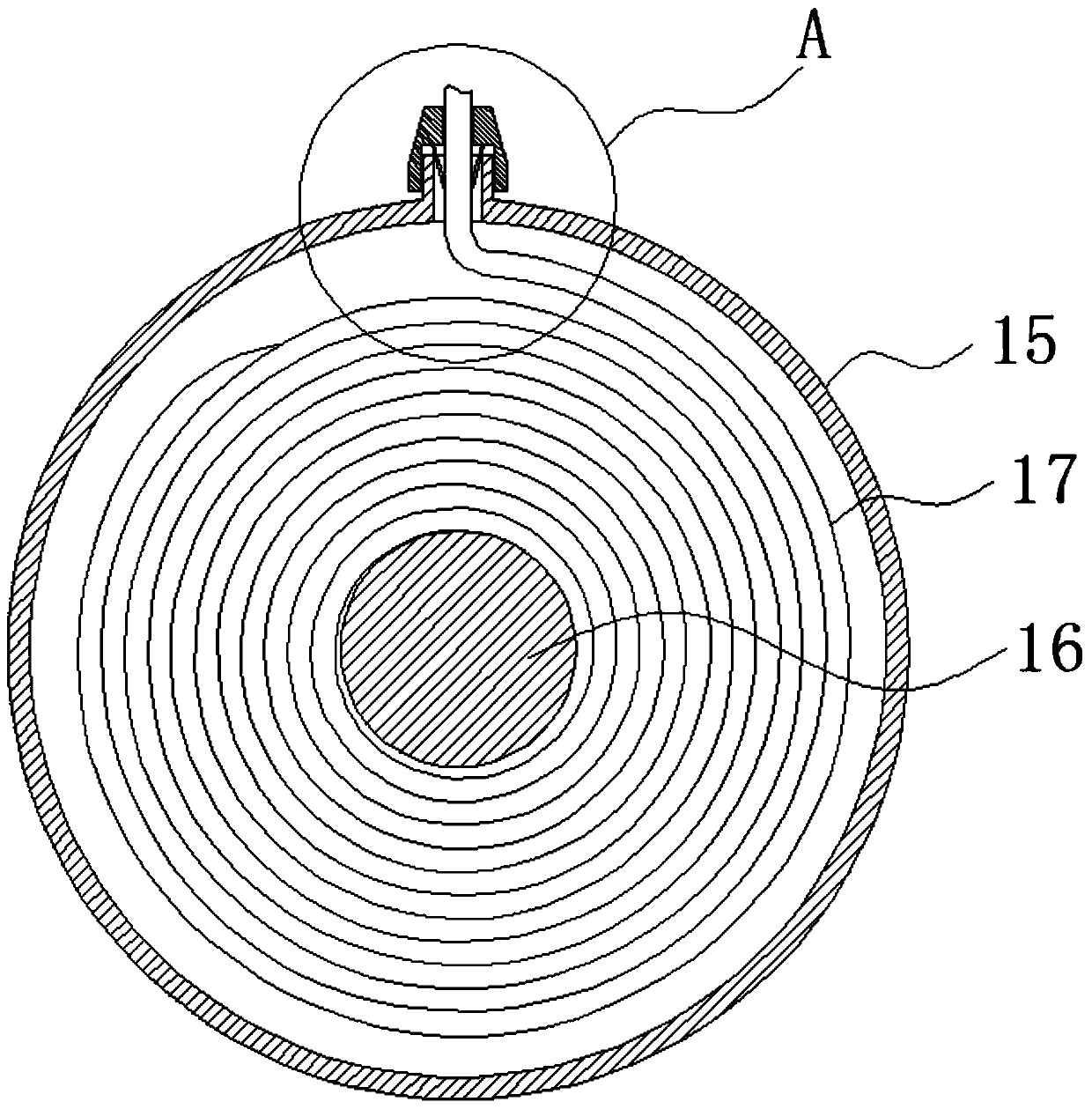

Convenient one-handed socket

The invention relates to a socket, in particular to a convenient one-handed socket, and belongs to electrical products. At least one window for placing a movable platform is formed in an upper cover of the socket, the movable platform can move up and down in the window, and plugholes are formed in the movable platform; a spiral spring is arranged on a base plate, the center line of the spiral spring is overlapped with that of the movable platform in positions, and the top of the spiral spring is in contact with the movable platform. The convenient one-handed socket is provided with the movable platform capable of lifting up and down, when a plug is inserted in the socket, the plug is pressed together with the platform, the plug is maintained at the lower limiting position of the platform together with the platform while switching on a power supply, and when the plug needs to be pulled out, the plug is held with only one hand to be pressed downwards, the platform can be bounced, so that the purpose of pulling out the plug with one hand is realized, and other tools are not needed; particularly, the convenient one-handed socket has higher practical value for inserting and pulling-out of the plug on the socket placed at a narrow spatial position, and the problem of electrification in inserting and pulling processes is avoided to realize safe operation.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

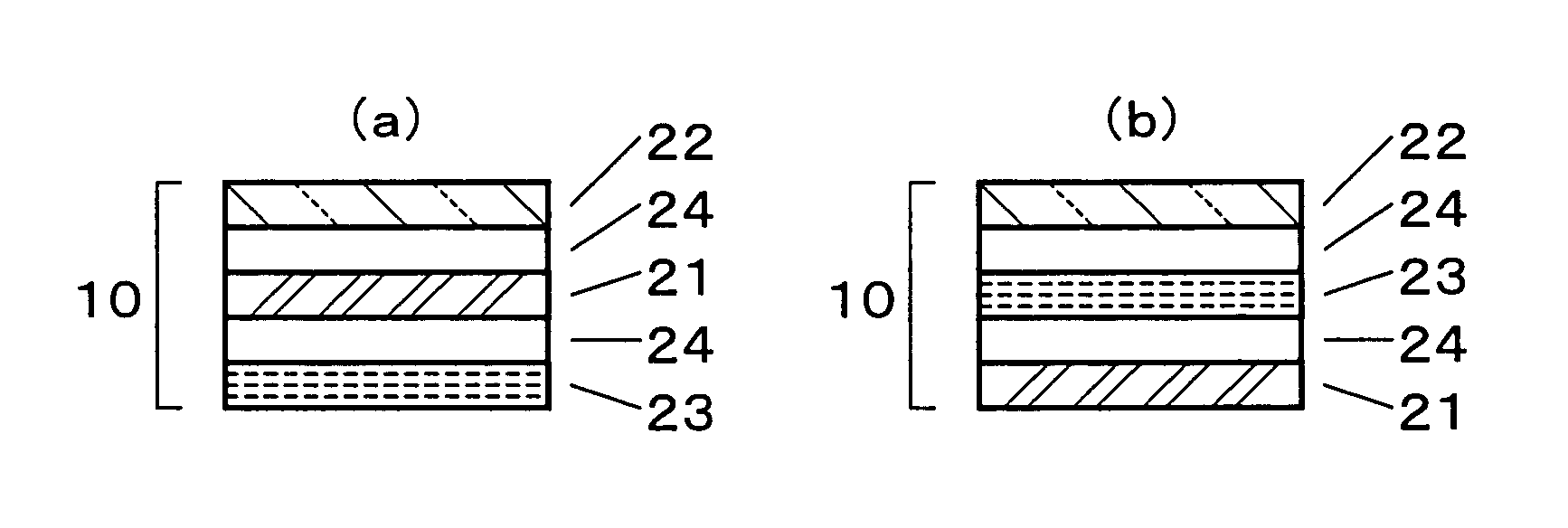

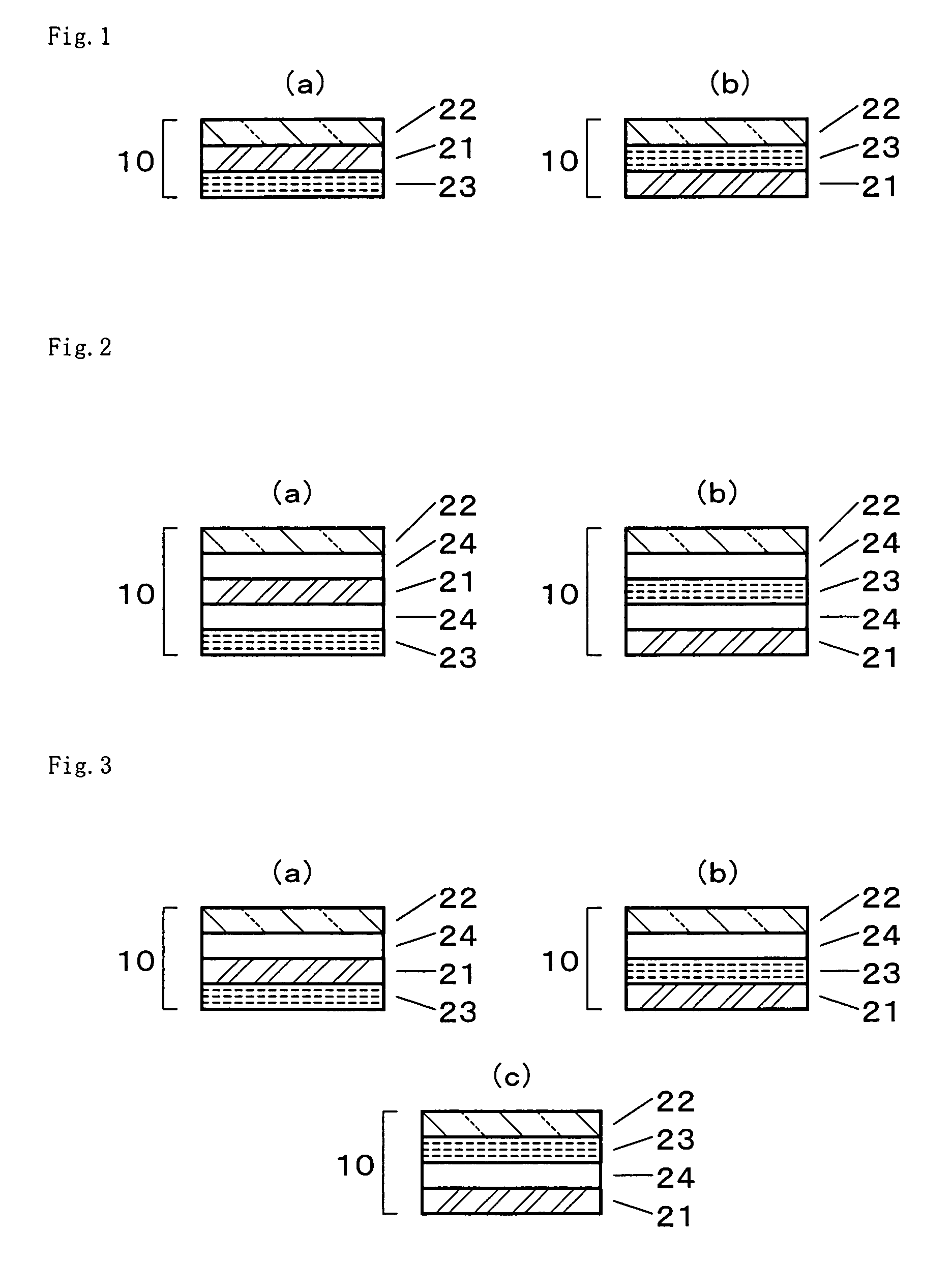

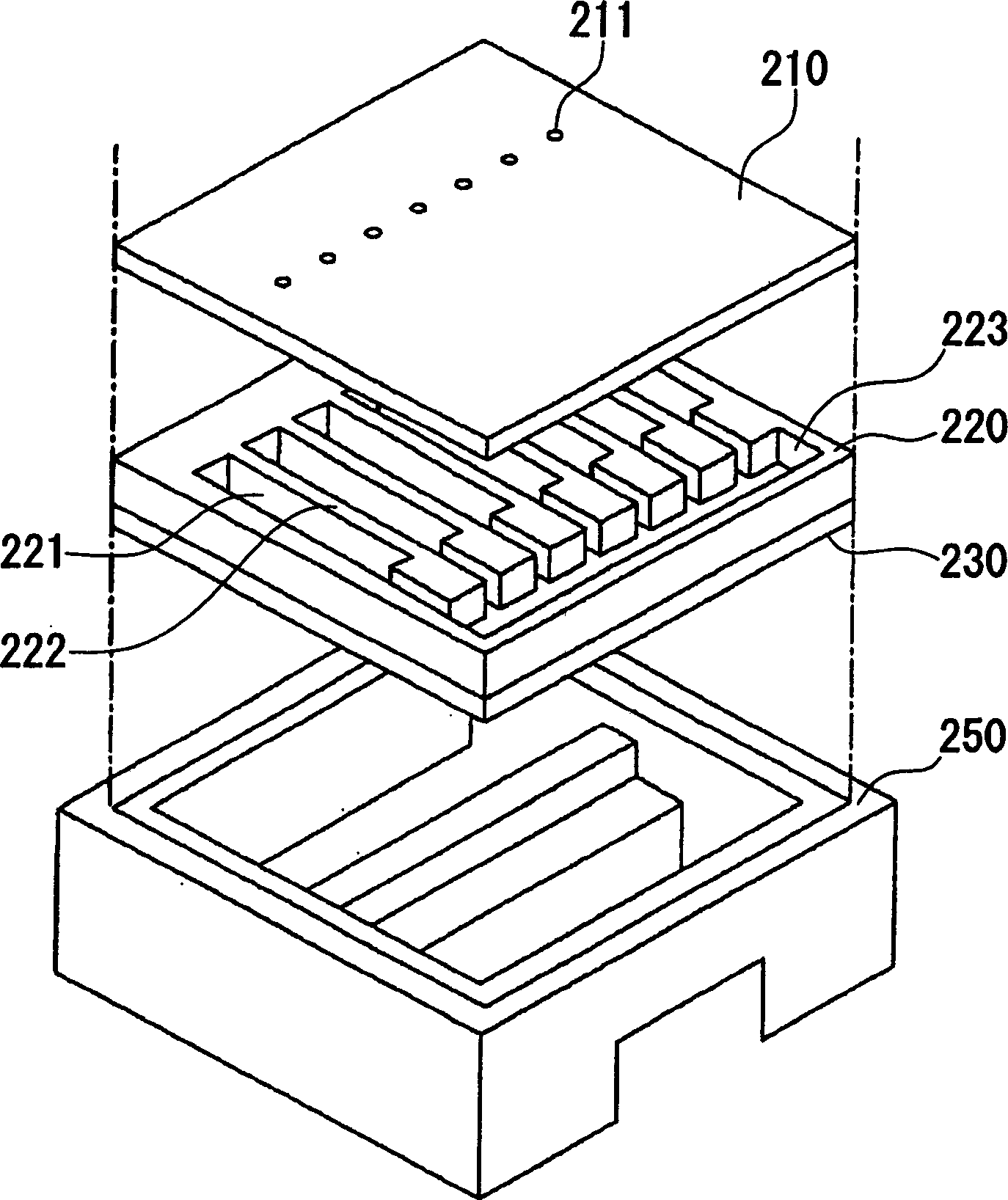

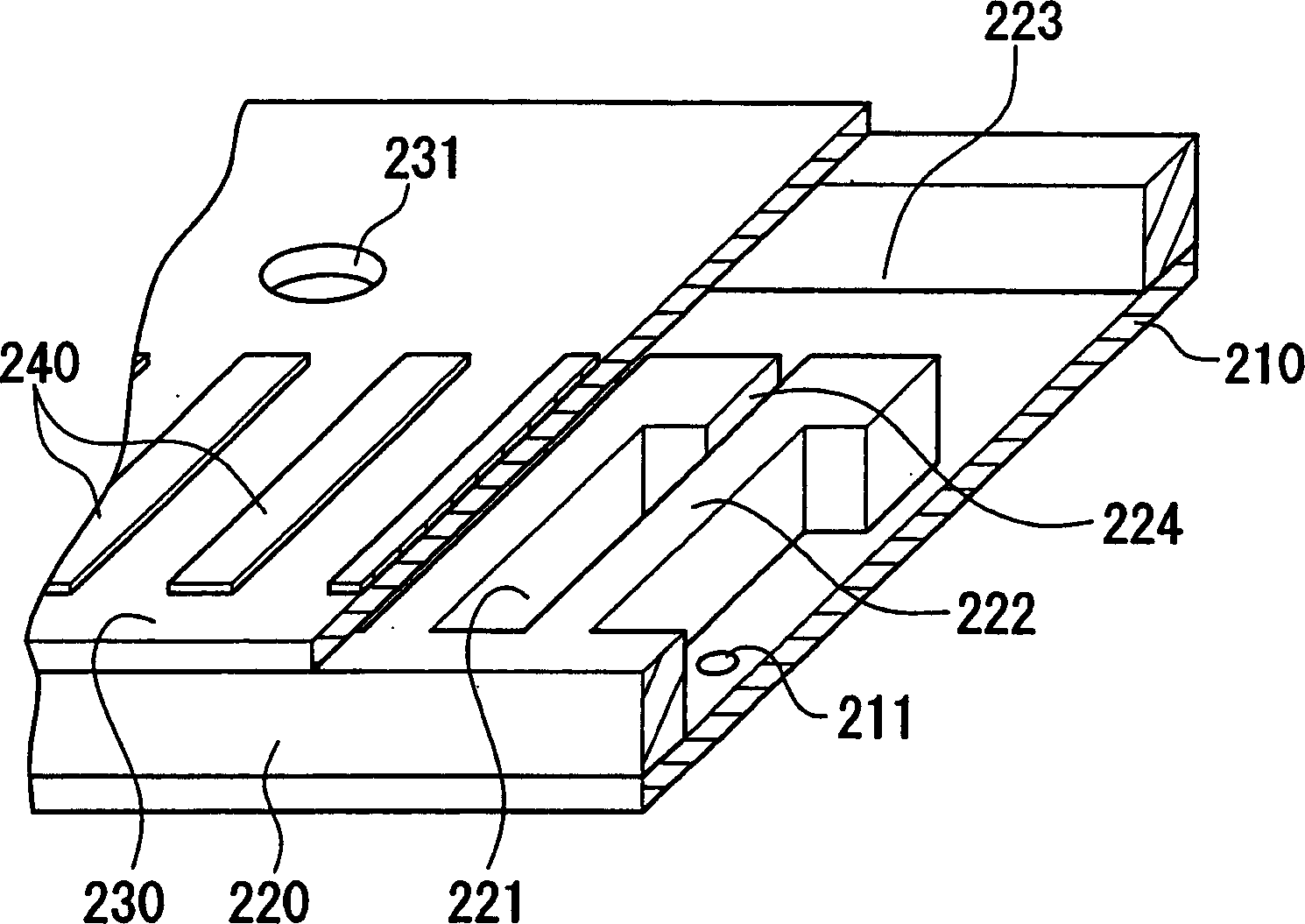

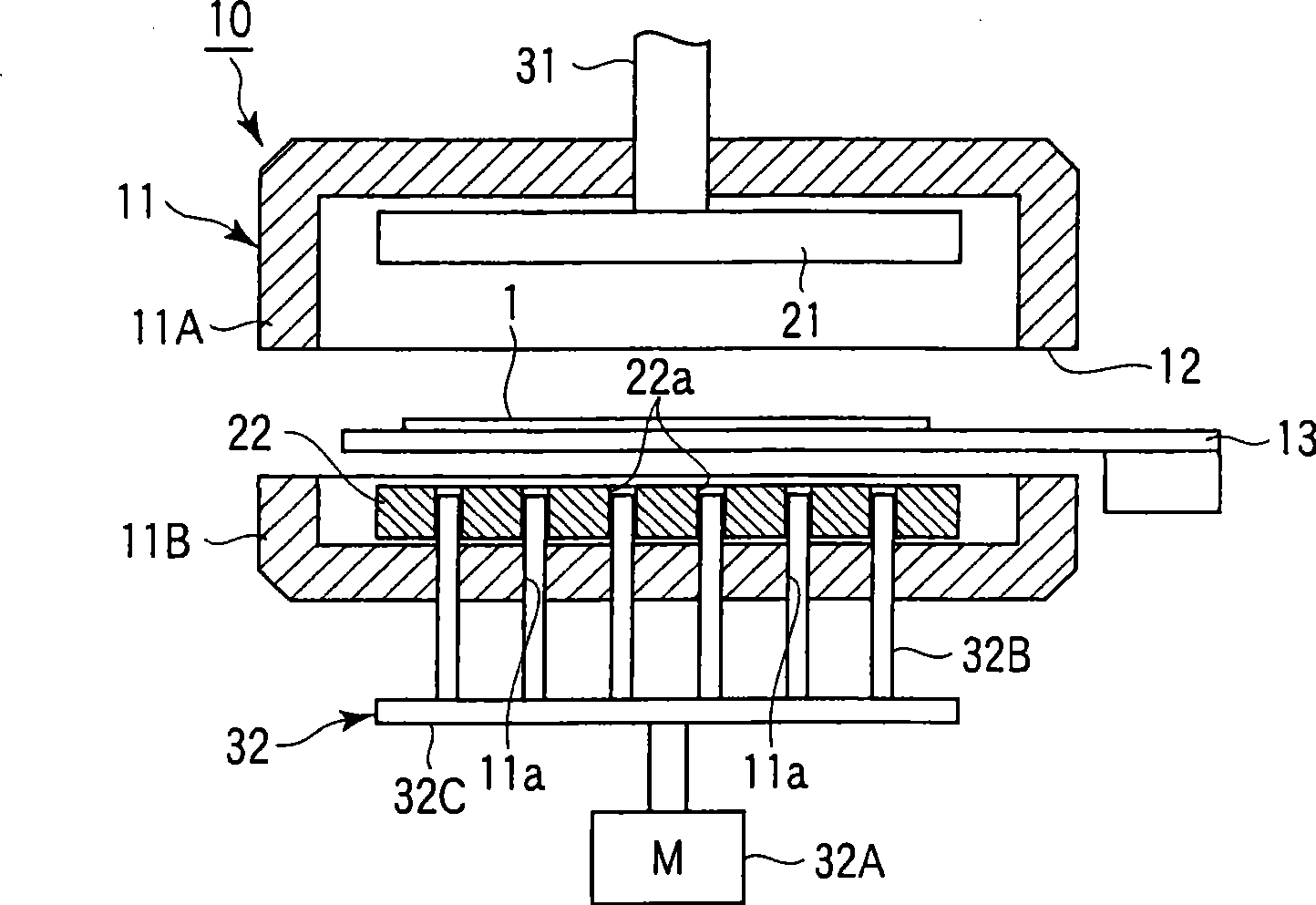

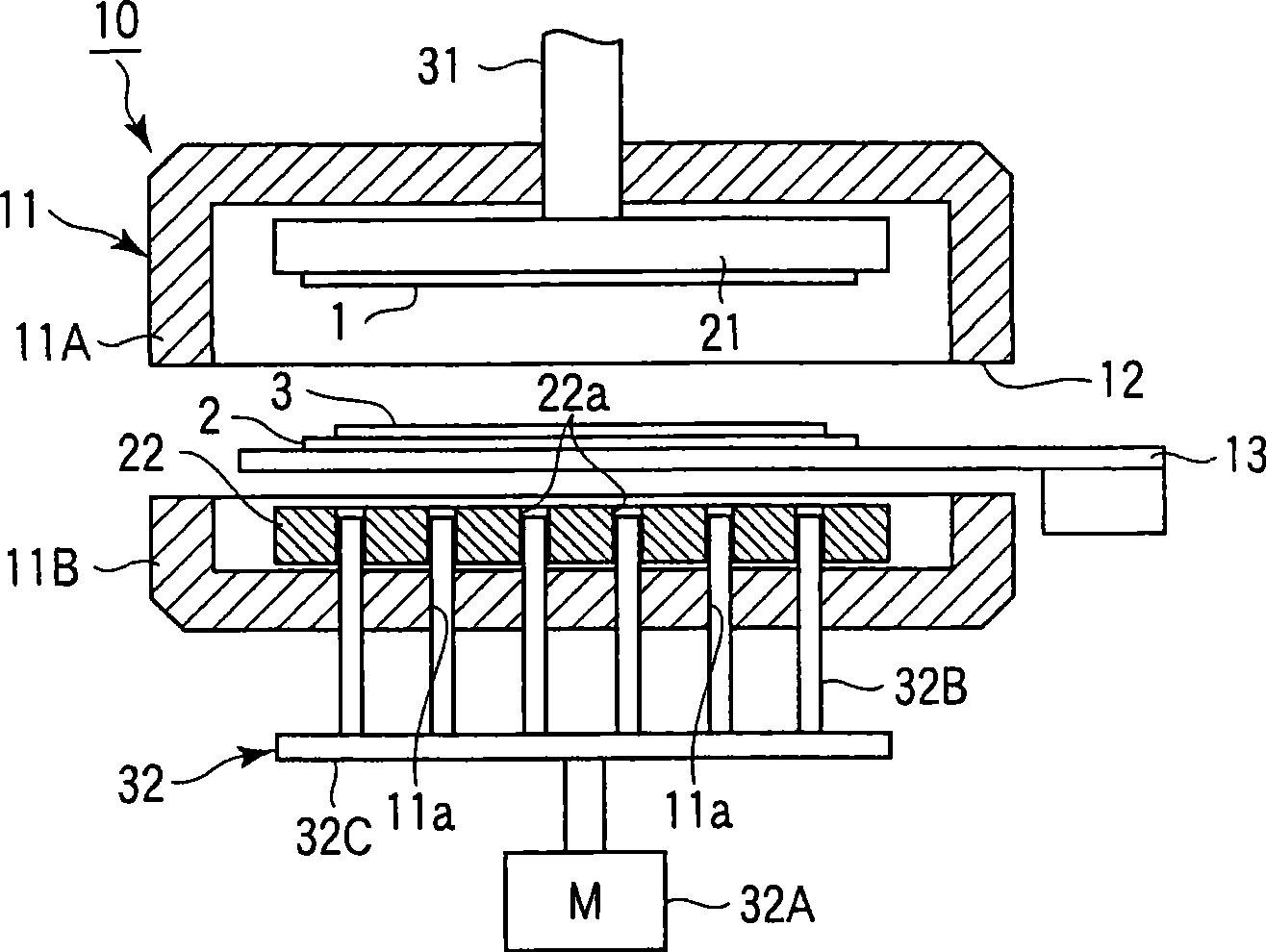

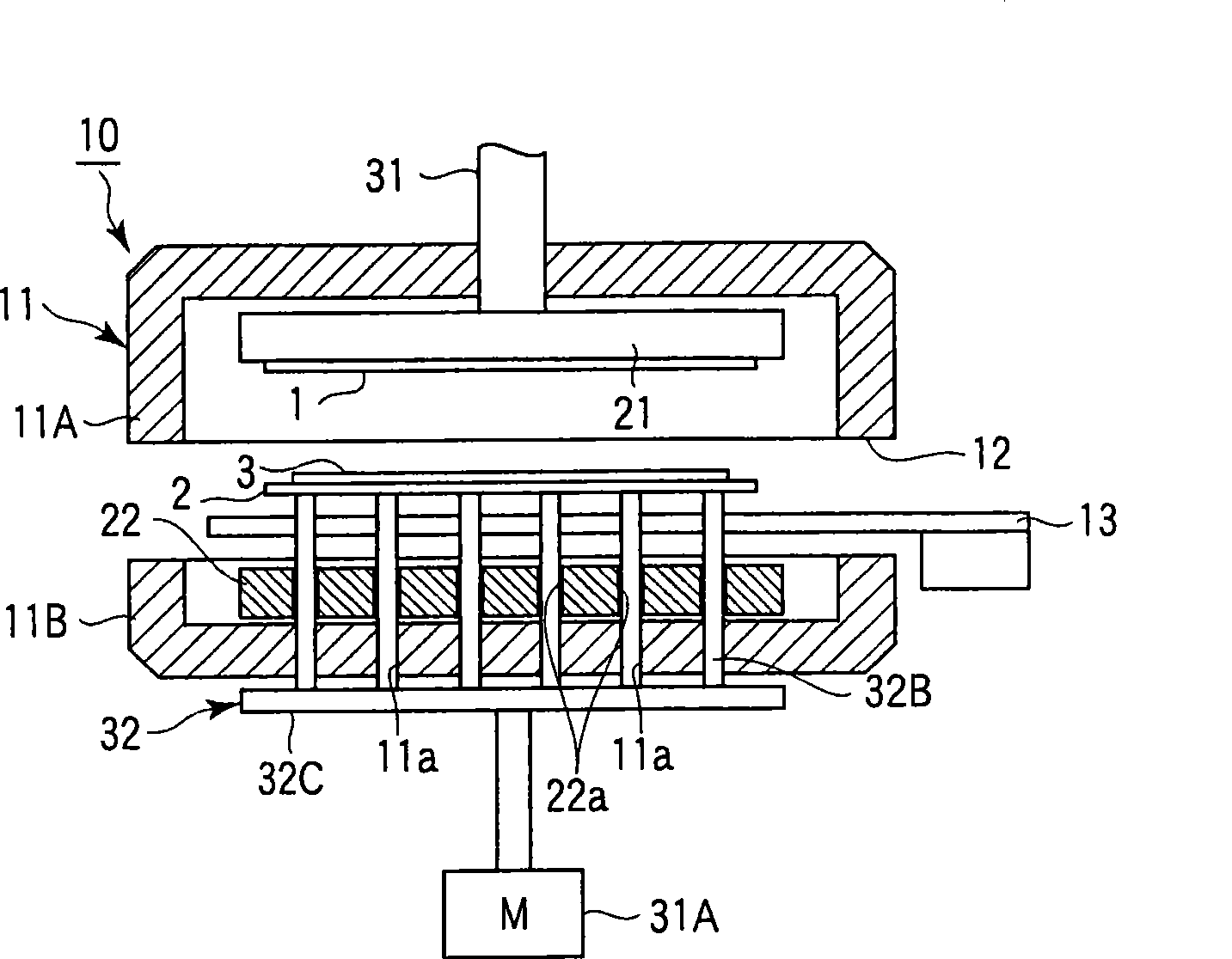

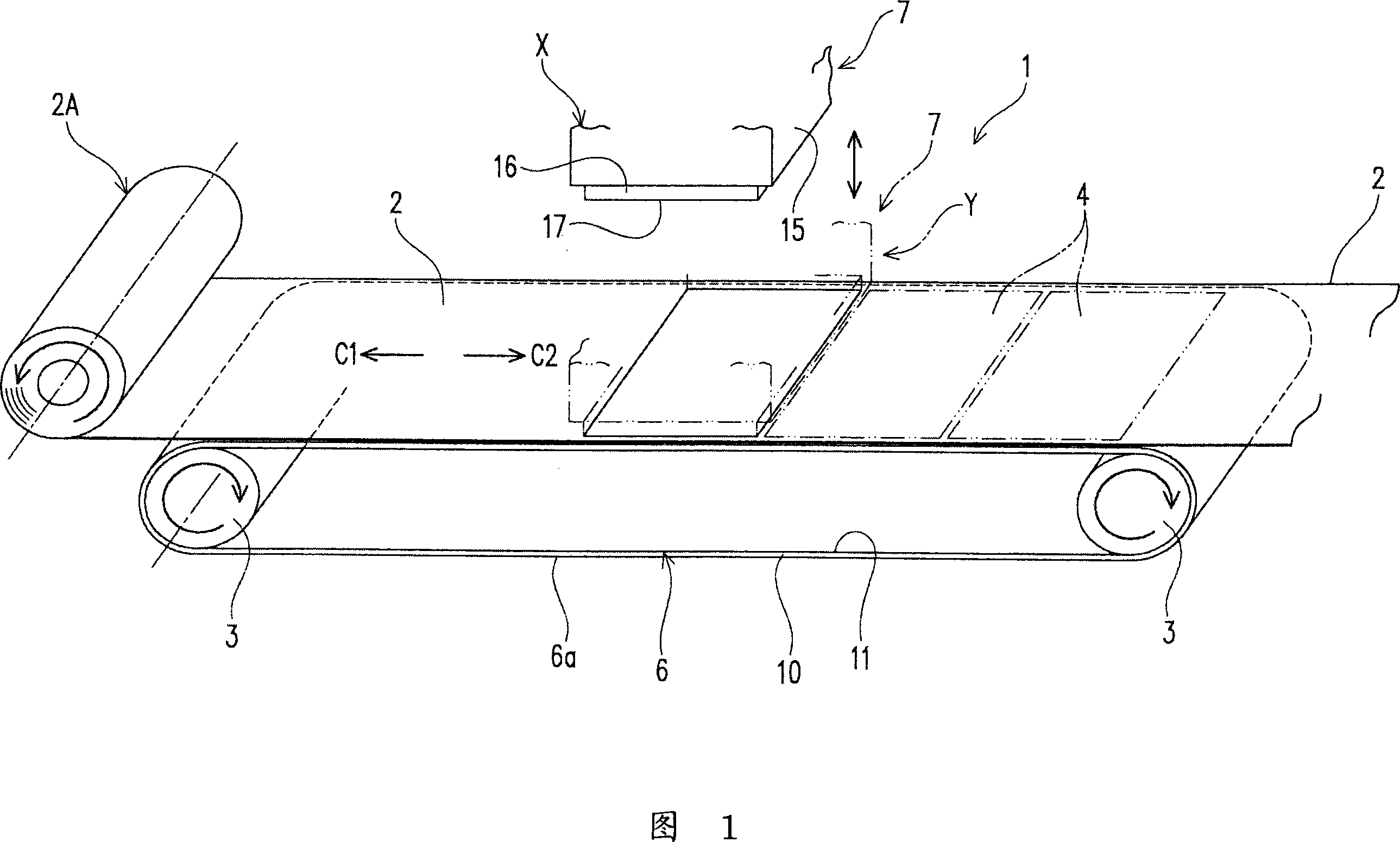

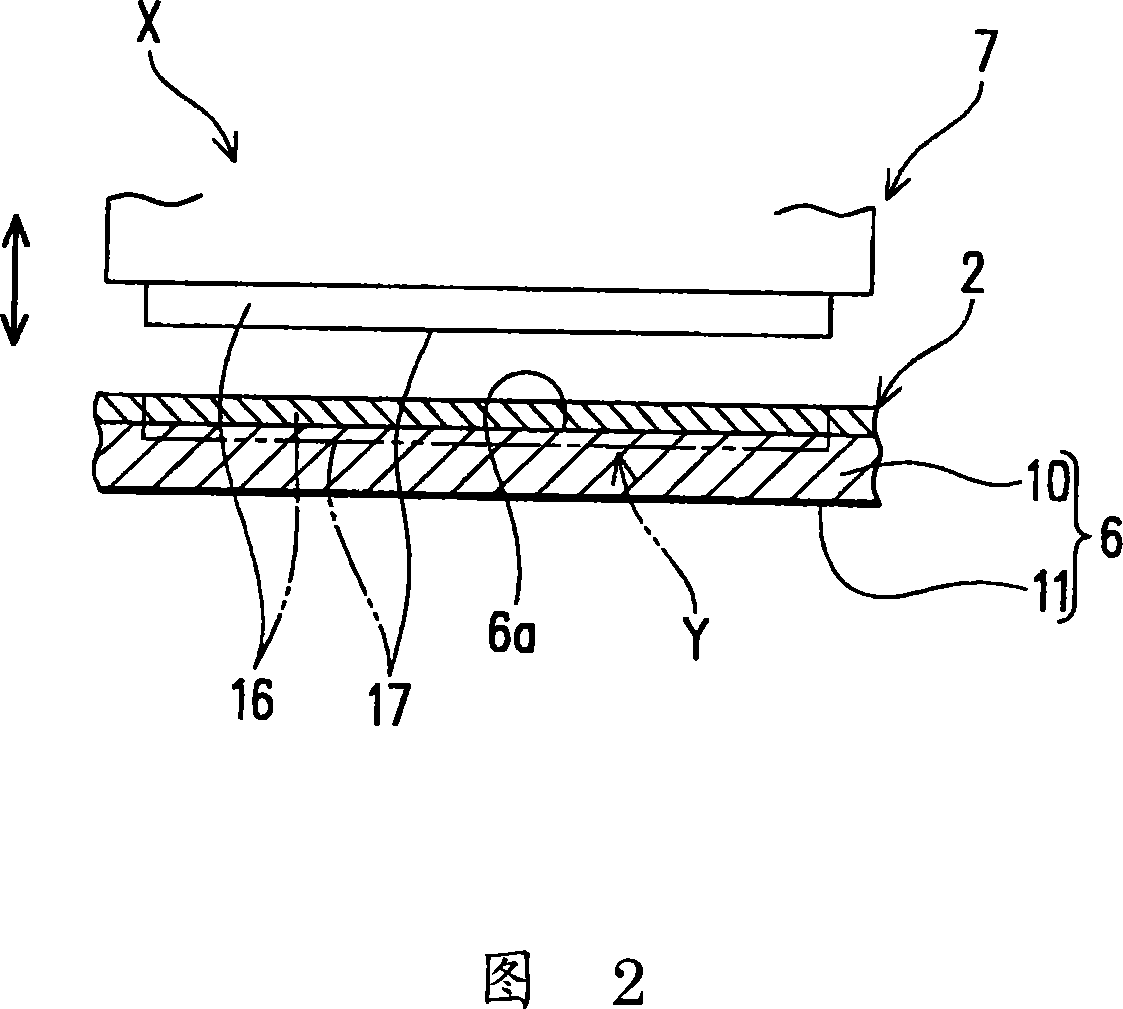

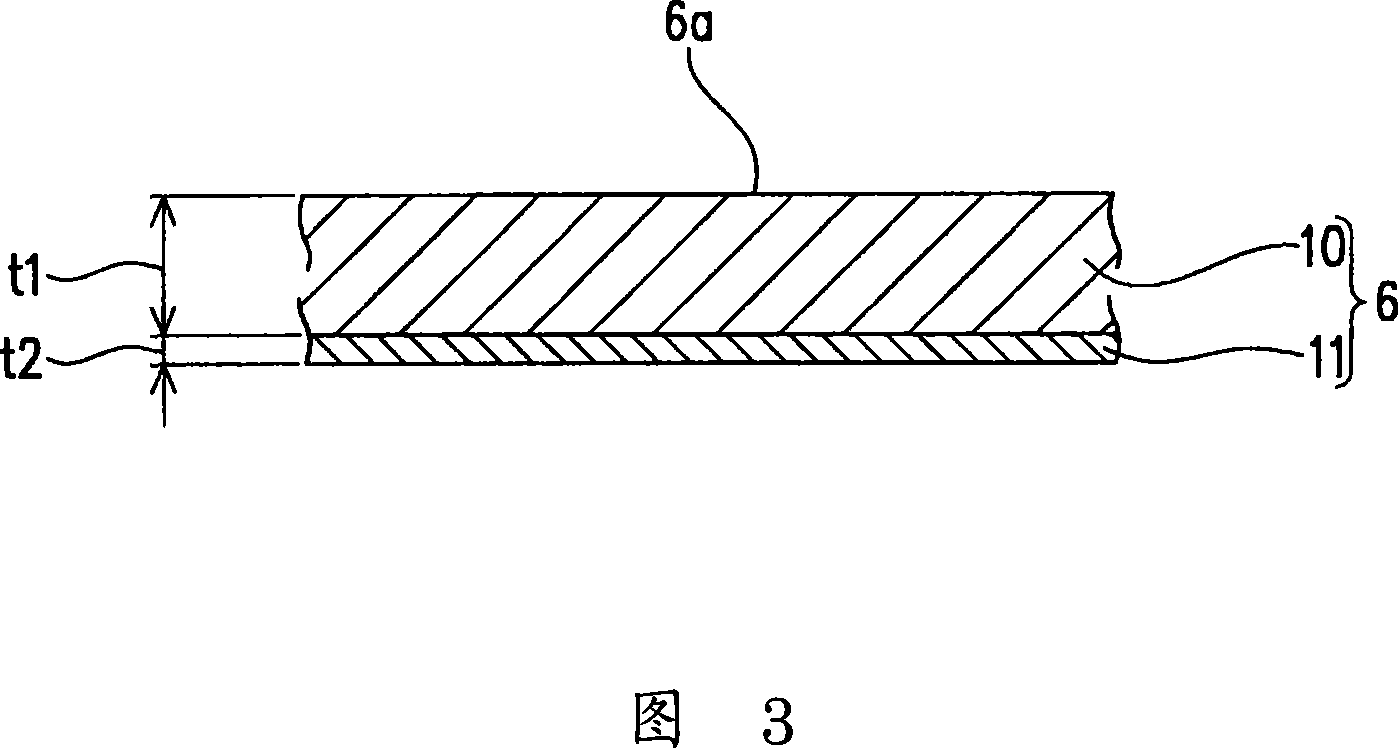

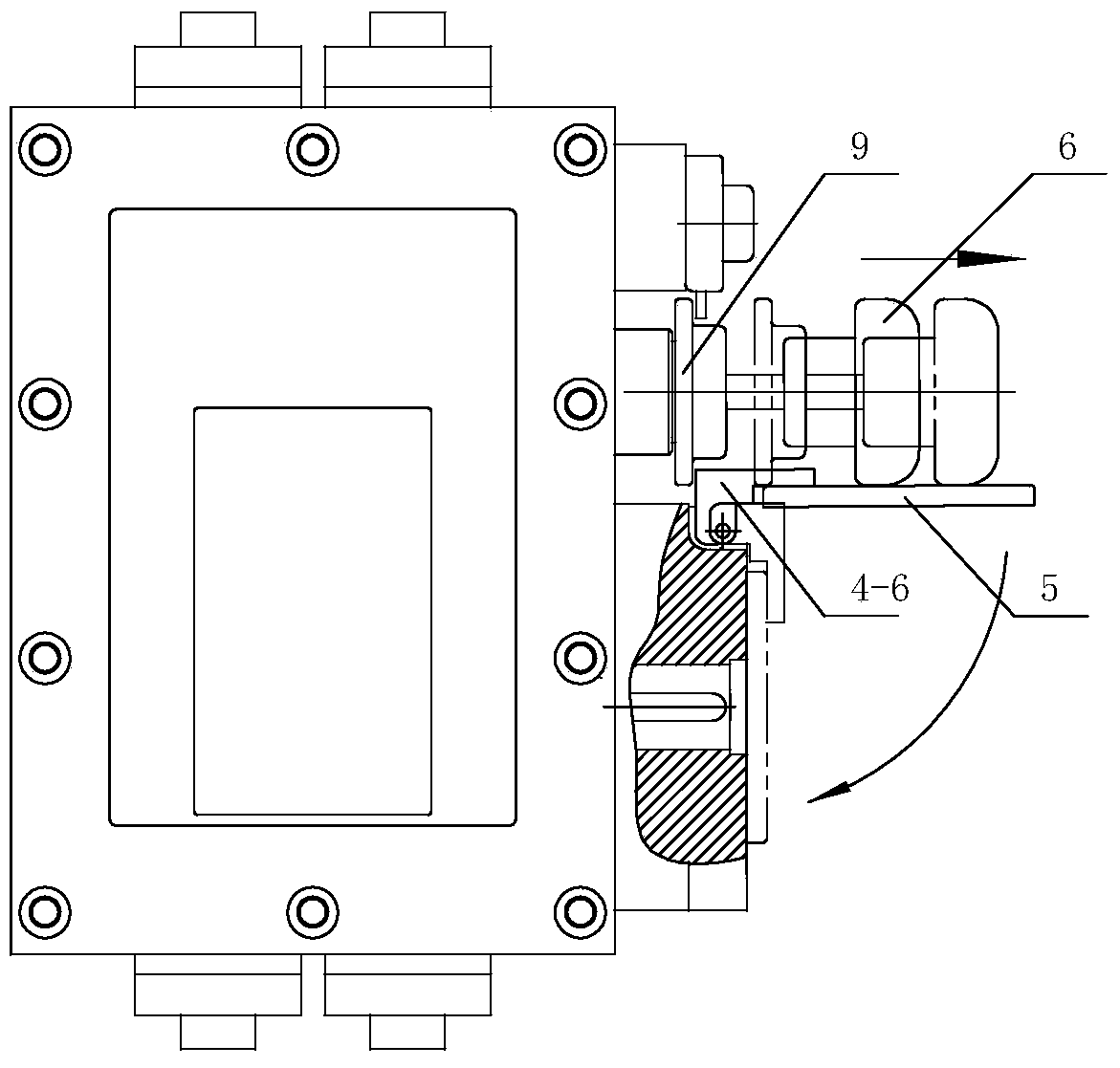

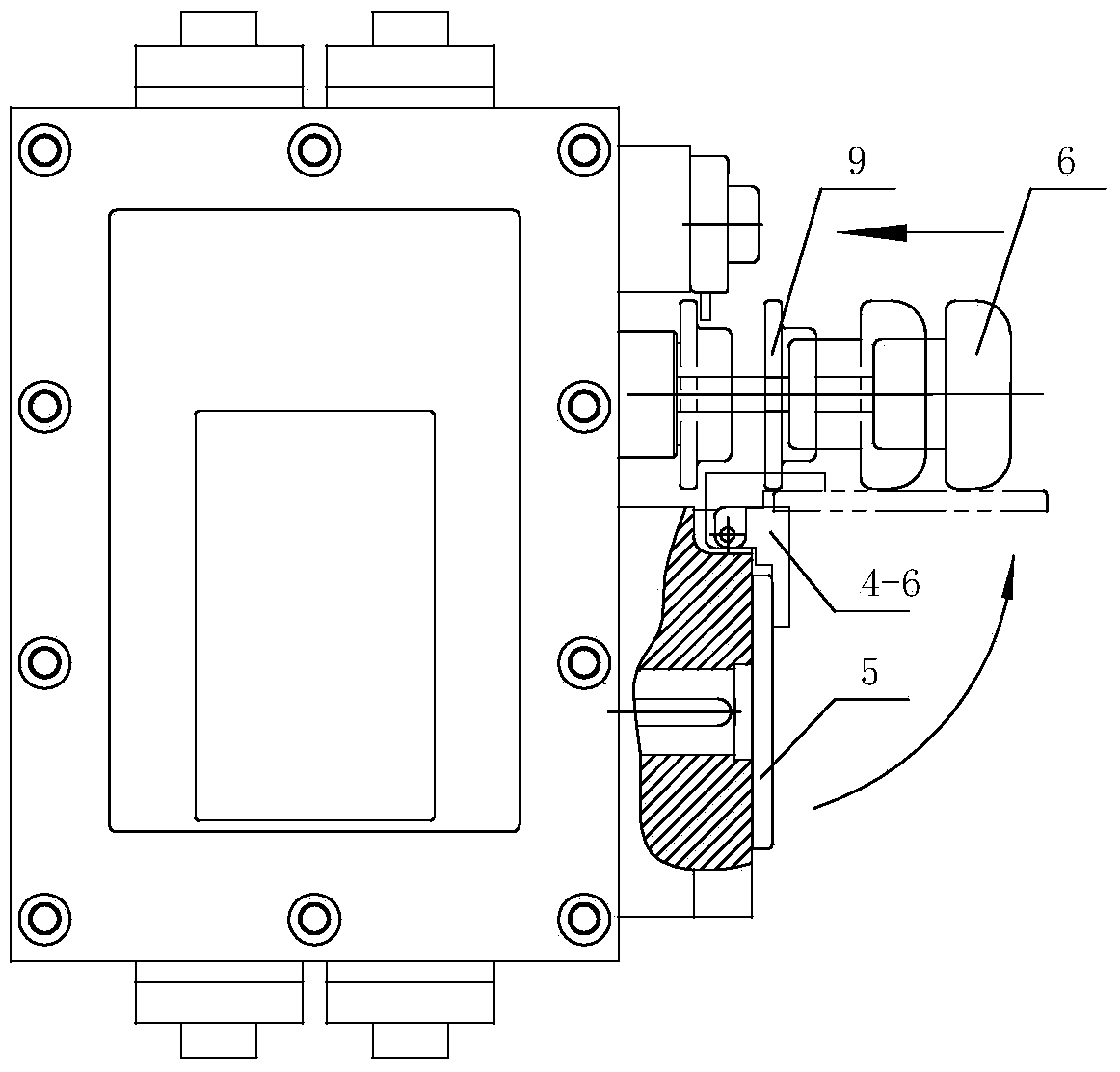

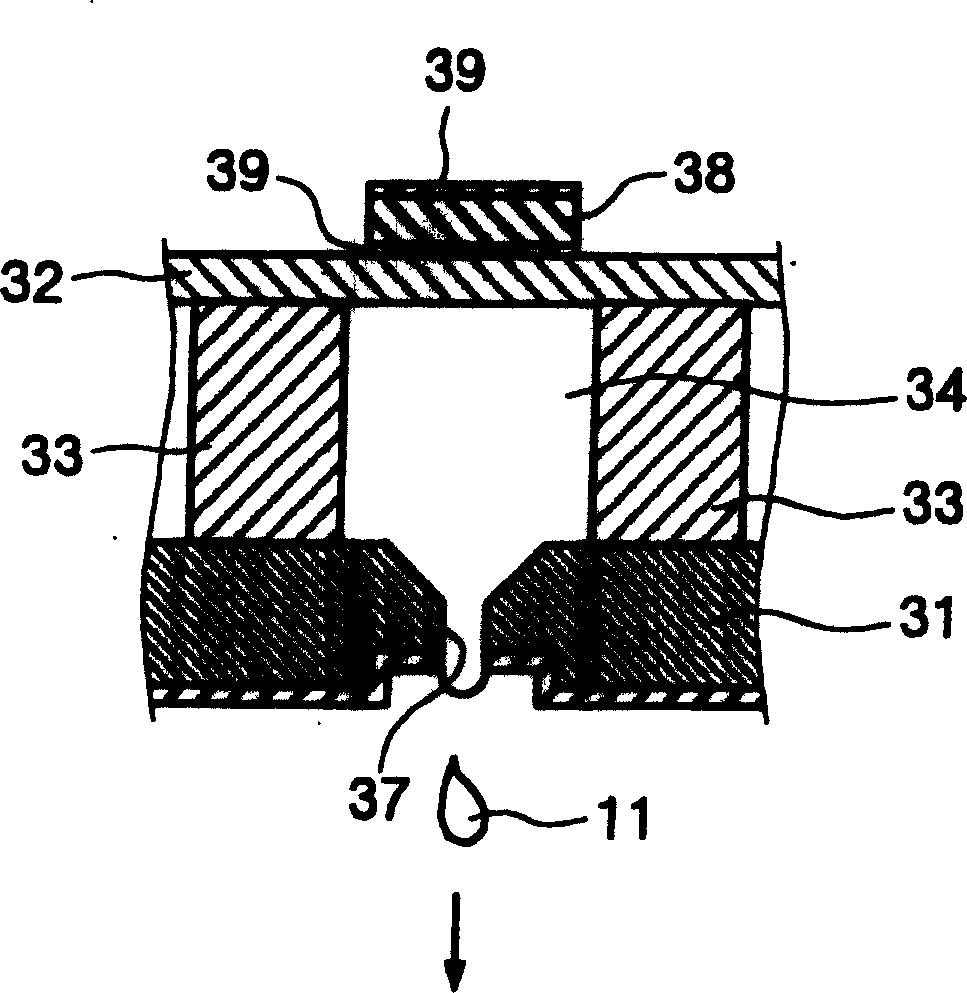

Base plate bonding device and method

InactiveCN101419356AAvoid electrificationPrevent electrification damageSemiconductor/solid-state device manufacturingNon-linear opticsEngineeringAtmospheric pressure

The invention provides a substrate gluing device and method, which can prevent substrate electrification when two glued substrates are taken out from worktables so that the quality is improved. The substrate gluing device (10) has a member reducing the contact areas of upper and lower substrates (1, 2) and upper and lower worktables (21, 22) after gluing the upper substrate (1) and the lower substrate (2) and before recovering the atmospheric pressure inside a vacuum chamber (11).

Owner:SHIBAURA MECHATRONICS CORP

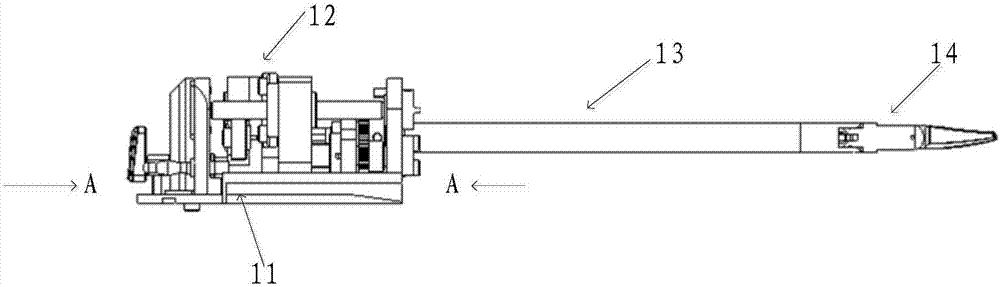

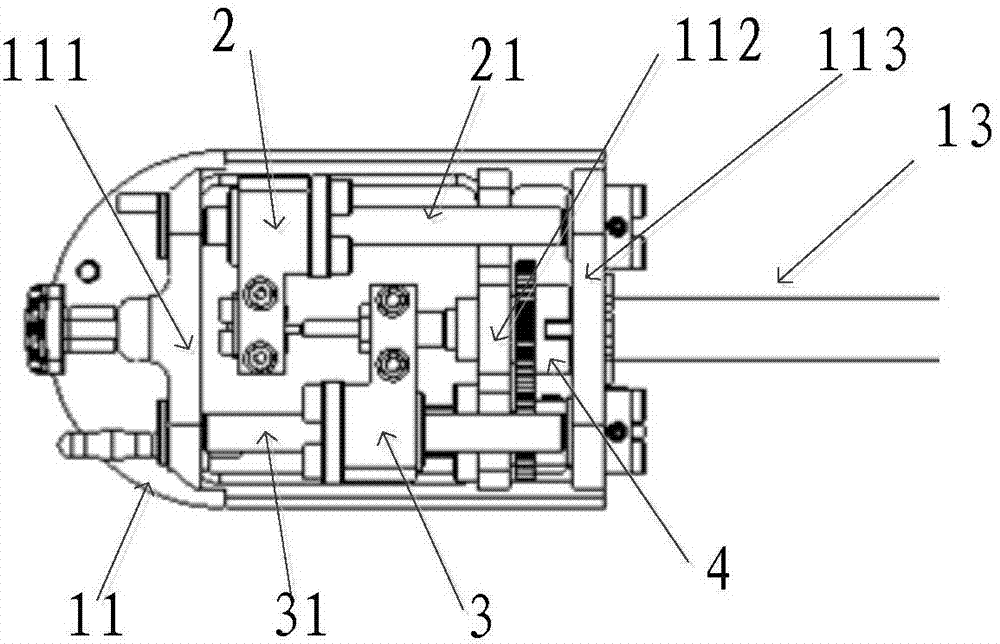

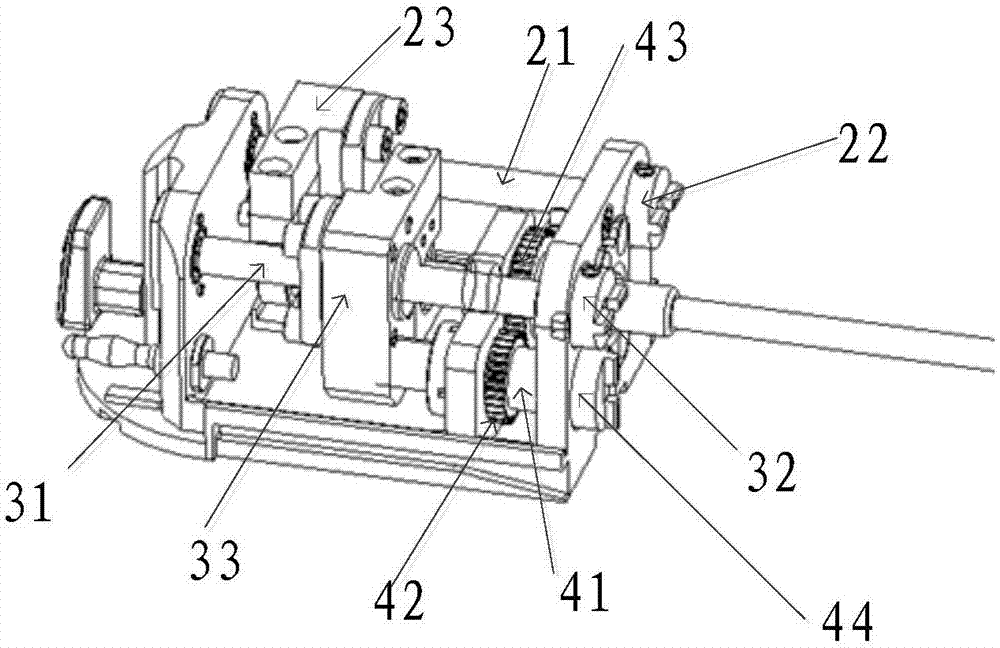

Surgical instrument for minimally invasive surgical robot and minimally invasive surgical robot

ActiveCN107320184AEliminate potential safety hazardsAvoid safety hazardsSurgical robotsLess invasive surgerySurgical robot

The invention discloses a surgical instrument for a minimally invasive surgical robot and a minimally invasive surgical robot. The surgical instrument comprises a base, a front-end driving portion, a guide rod portion and a tail-end execution portion. The front-end driving portion comprises an opening-closing driving device, a deflection driving device and a rotation driving device. The opening-closing driving device is mounted on the base through a first transmission shaft, the deflection driving device is mounted on the base through a second transmission shaft, the rotation driving device comprises a driving gear and a driven gear, and the driving gear is mounted on the base through a third transmission shaft.

Owner:CHENGDU BORNS MEDICAL ROBOTICS INC

Blanking device for optical film and blanking method for optical film

InactiveCN101077586APrevents electrification of optical filmsEasy to manufactureMetal working apparatusEngineeringOptical film

The invention provides a blanking apparatus of optical membrane and blanking method of optical membrane. The said blanking apparatus can prevent the dust adhere to the optical membrane by suppressing generating statical electricity on blanking optical membrane. The blanking apparatus of optical membrane comprises mat and blanking cutter for loading optical membrane to blank the optical membrane loaded on the mat, wherein the surface opposite to the blanking cutter contact surface on the said mat is performed conduction treatment.

Owner:NITTO DENKO CORP

Omnipotence safety plug

InactiveCN101431203AGuarantee personal safetyAvoid electrificationCoupling device detailsEmergency protective arrangements for automatic disconnectionInductorInstrument transformer

An all-function safety plug comprises a phase pole, a zero pole, a ground pole, a zero sequence current mutual inductor, a test loop, an amplifying circuit, a direct-current power supply, a controlled silicon, and a release; the phase pole, the zero pole and the ground pole are provided with switches; the zero sequence current mutual inductor is arranged between a phase line and a zero line; a ground wire is connected with a static contact by a movable contact elastic trip; the zero sequence current mutual inductor passes through the ground wire; the output end of the zero sequence current mutual inductor in the ground wire is connected with a capacitor and a resistor in parallel; one output end of a ground wire mutual inductor is connected with the triggering electrode of another controlled silicon, while the other output end of the ground wire mutual inductor is connected with the cathode of a rectification circuit; and the anode and the cathode of the controlled silicon is connected with the anode and the cathode of the rectification circuit. The plug has the advantages that by another controlled silicon, even if the ground wire is electrified unexpectedly under the condition that the controlled silicon between the phase line and the zero line or the amplifying circuit are in failure, the power supply can still be immediately cut off, thereby stably and reliably preventing the ground wire to be electrified, and ensuring the personnel safety of users. Furthermore, the zero sequence mutual inductor between the phase line and the zero line does not interfere with the zero sequence mutual inductor of the ground wire, so that the reliability is good. In addition, the cost is saved.

Owner:钱加灿

Antistatic release film and manufacture method thereof

ActiveCN102390149APrevent charging of substrateHigh fastnessSynthetic resin layered productsPolyethylene terephtalateChemistry

The invention discloses an integrative antistatic release film with an antistatic function and a release function as well as a manufacture method of the film. The release film comprises a substrate and an antistatic coating I, wherein the substrate consists of a polyethylene glycol terephthalate (PET) film, and the antistatic coating I is coated on the substrate and consists of ethyl silicate systems. The PET film and oxhydryl (OH) in organic siloxane absorb moistures (the combination of H3O<+> and OH<->) in the air, and the surface resistance of the release film is reduced, so the release function is realized, the substrate electrification is prevented, in addition, the antistatic coating consisting of the ethyl silicate systems has good electric conductivity, the static on the surface of the release film can be brought away, and the static removal effect is reached and is very stable and good. Further, the integrative antistatic release film and the manufacture method have the advantages that the firmness of the surface of each layer is high, the friction resistance is realized, in addition, the manufacture process is simple, and the production cost is low.

Owner:FOSHAN NANHAI DISTRICT XINYONGTAI ADHESIVE PROD CO LTD

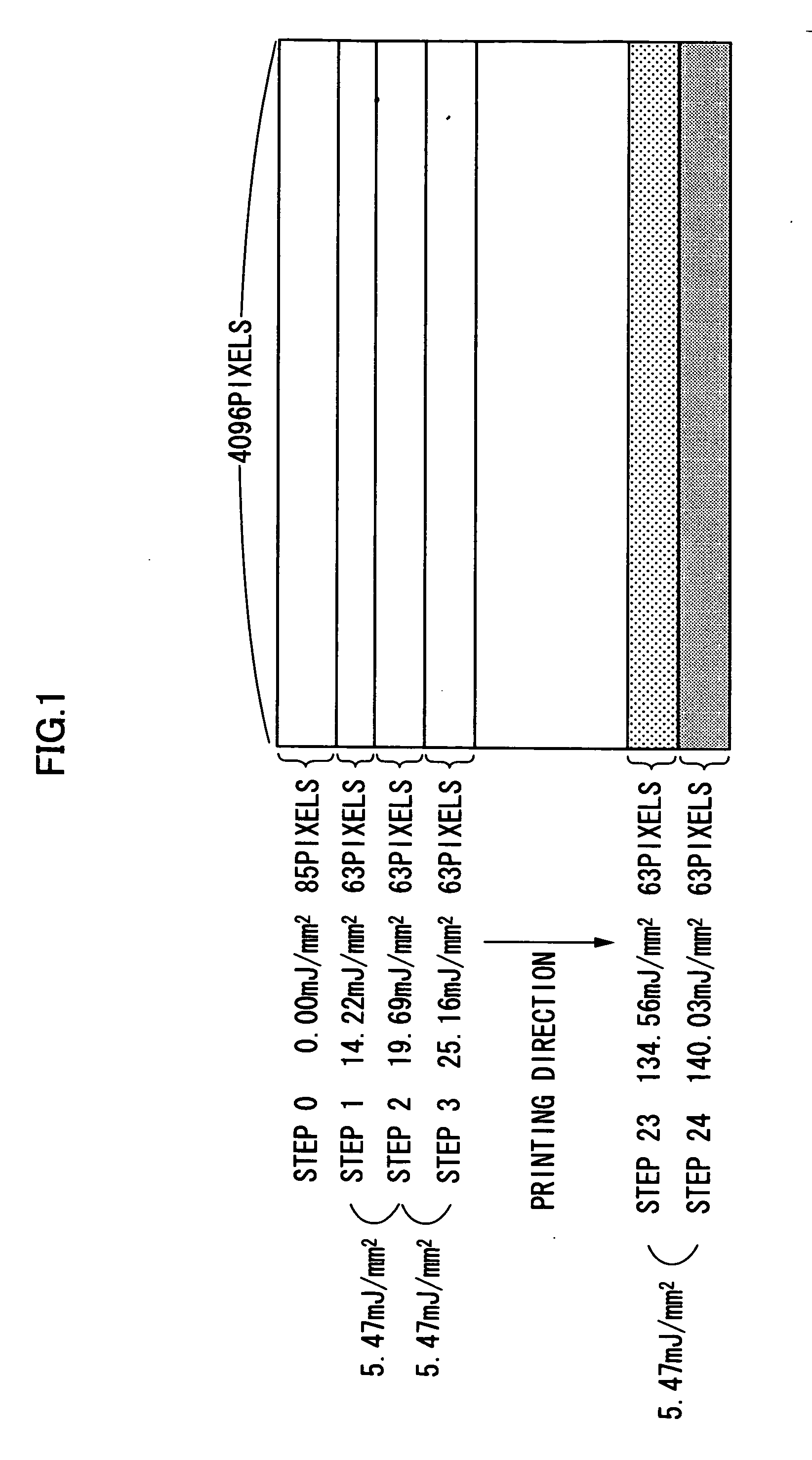

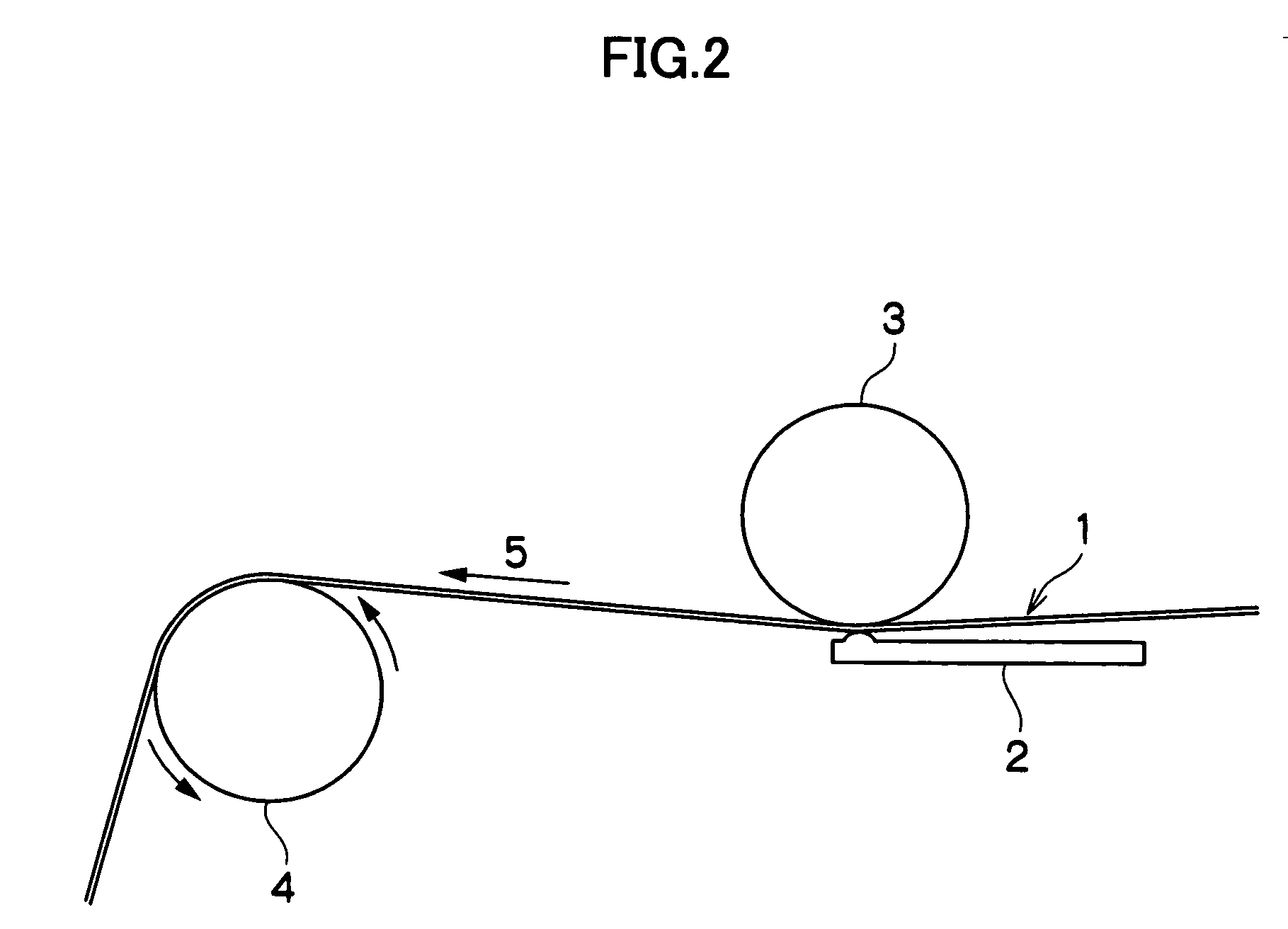

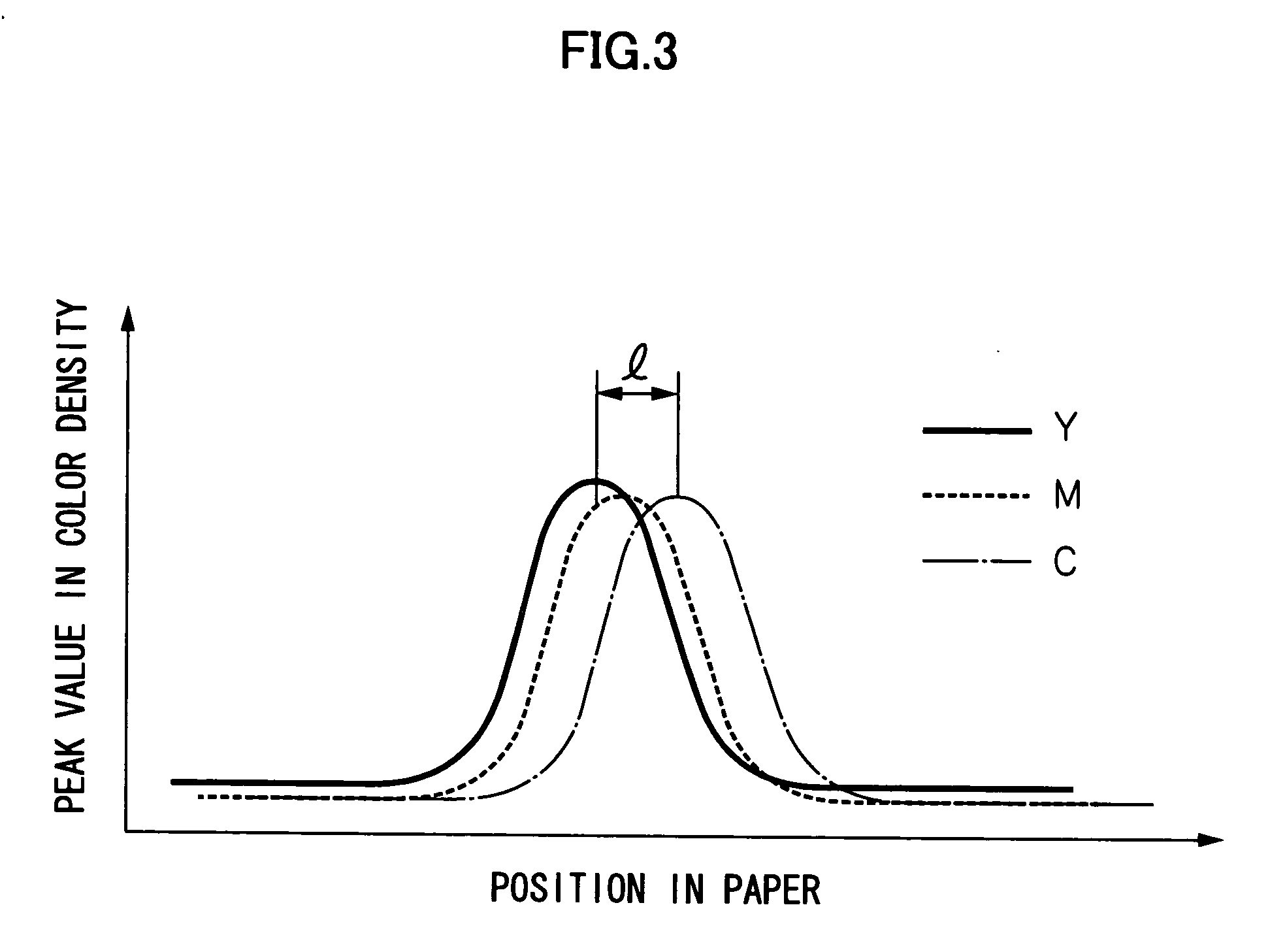

Heat-sensitive recording material, heat-sensitive recording method and method for manufacturing heat-sensitive recording material

ActiveUS20070032381A1Reduce transportationGood transportabilityPattern printingDiazo compound compositionsThermodynamicsEngineering

A heat-sensitive recording material including at least one heat-sensitive recording layer and a protective layer provided in this order on a support, wherein the protective layer contains a compound represented by the following Formula (1) and / or a compound represented by the following Formula (2), a method for manufacturing the heat-sensitive recording material, and a heat-sensitive recording method using the heat-sensitive recording material provided.

Owner:FUJIFILM CORP +1

Pressure-sensitive adhesive composition and pressure-sensitive adhesive sheets

ActiveUS8153251B2Maintain good propertiesReduced stainabilityNon-macromolecular adhesive additivesFilm/foil adhesivesCarbon numberOxygen

An object of the present invention is to provide an electrostatic pressure-sensitive adhesive composition which is excellent in antistatic property of pressure-sensitive adhesive sheets upon peeling, and has reduced stainability in an adherend (subject to be protected) and is excellent in adhesion reliance, and electrification preventing pressure-sensitive adhesive sheets and a surface protecting film using the same. There is provided a pressure-sensitive adhesive composition, which comprises a (meth)acryl-based polymer containing, as a monomer component, 15 to 100% by weight of a (meth)acrylic acid alkylene oxide adduct, 0 to 85% by weight of a (meth)acryl-based monomer having an alkyl group of a carbon number of 1 to 14 other than the adduct, and 0 to 85% by weight of other polymerizable monomer, and an alkali metal salt.

Owner:NITTO DENKO CORP

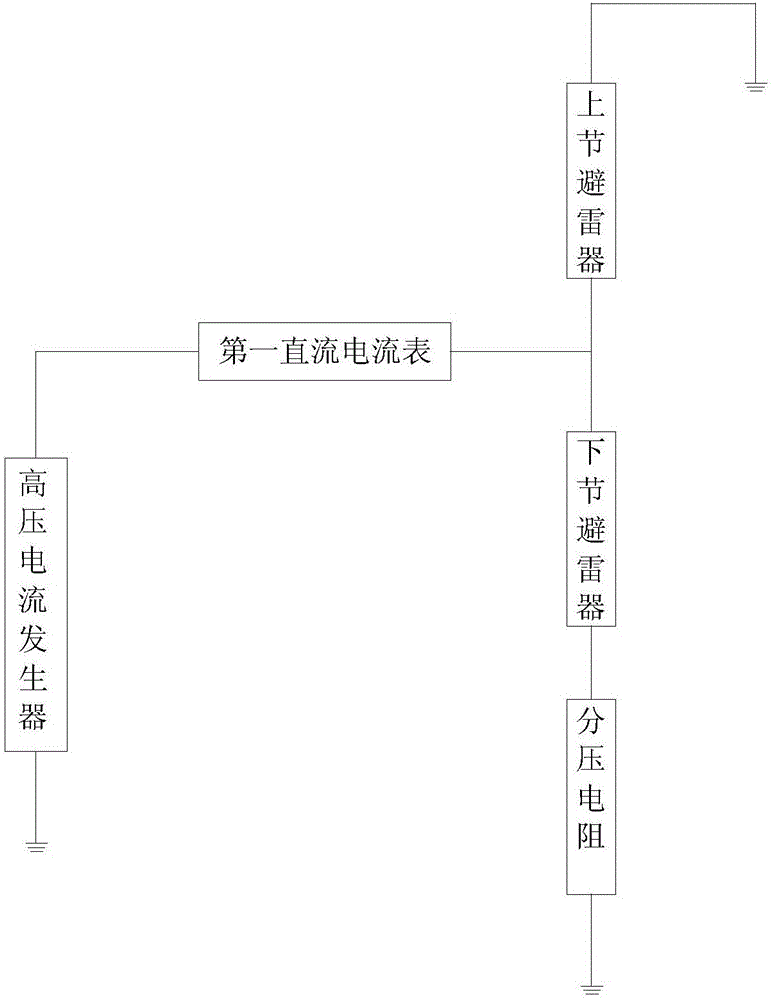

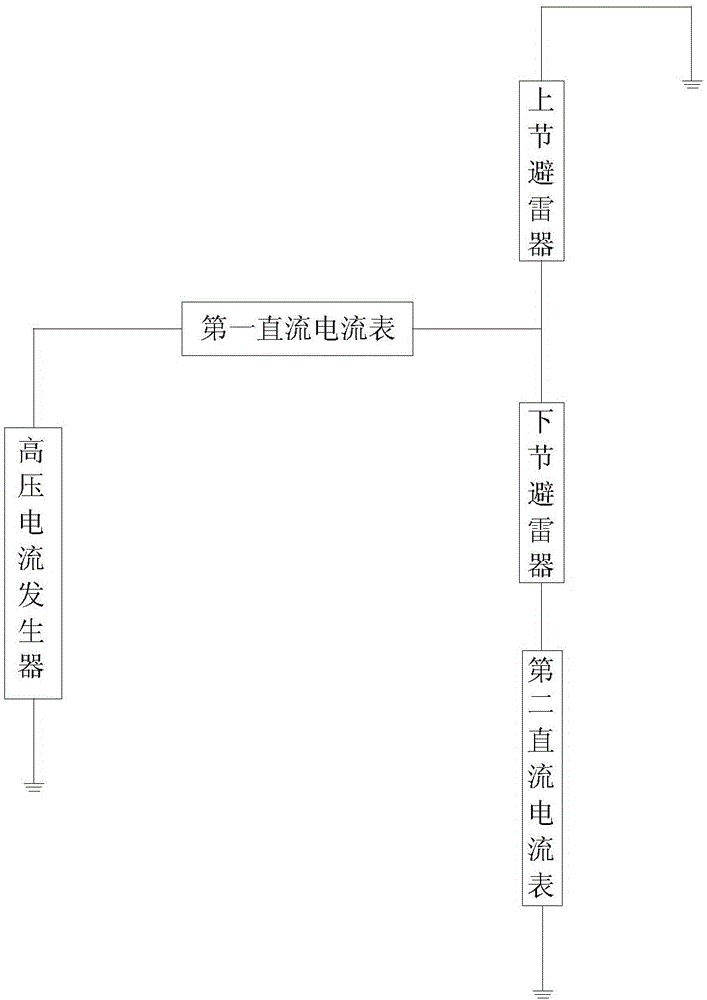

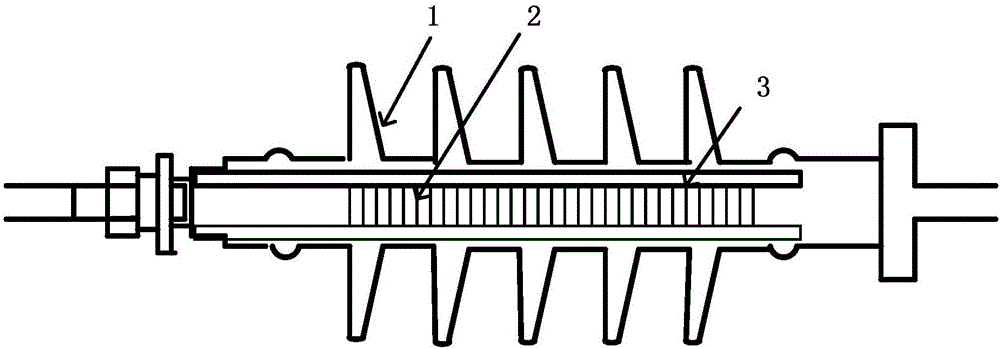

Measuring method for leakage current of zinc oxide arrester

InactiveCN106501584AVerification statusAvoid safety hazardsCurrent/voltage measurementElectrical testingEngineeringHigh pressure

The invention discloses a measuring method for a leakage current of a zinc oxide arrester. The measuring method comprises the steps of: connecting a high-voltage output end of a DC high voltage generator with a ''-'' wiring end of a first DC ammeter, connecting a ''+'' wiring end of the first DC ammeter to a joint of an upper segment lightning arrester and a lower segment lightning arrester, connecting a voltage testing end of the DC high voltage generator with a DC microammeter, and grounding the tail end of the DC high voltage generator; connecting a voltage-dividing resistor with a resistance value ranging from 25 kilo-ohm to 35 kilo-ohm with a discharge counter in parallel and then connecting the voltage-dividing resistor with the lower end of the lower segment lightning arrester, and grounding the tail end of the voltage-dividing resistor; disconnecting the lower segment lightning arrester from the discharge counter, initiating the DC high voltage generator, and taking the reading of the DC microammeter as 1mA voltage of the upper segment lightning arrester when the reading of the first DC ammeter reaches 1mA. The measuring method avoids the potential safety hazards of high-altitude disconnection and connection of high-voltage lead wire operation, and improves the working efficiency and measurement precision.

Owner:STATE GRID CORP OF CHINA +1

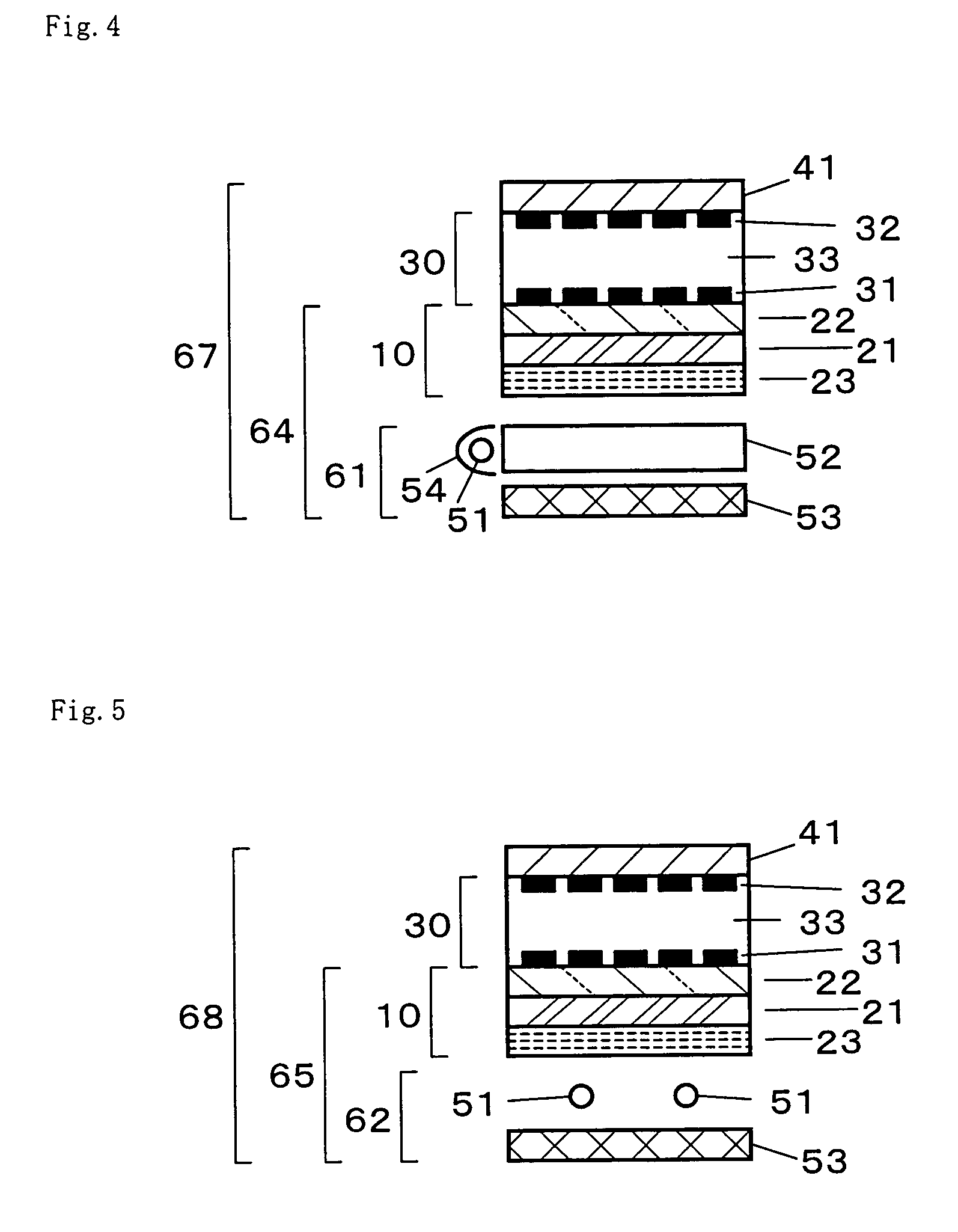

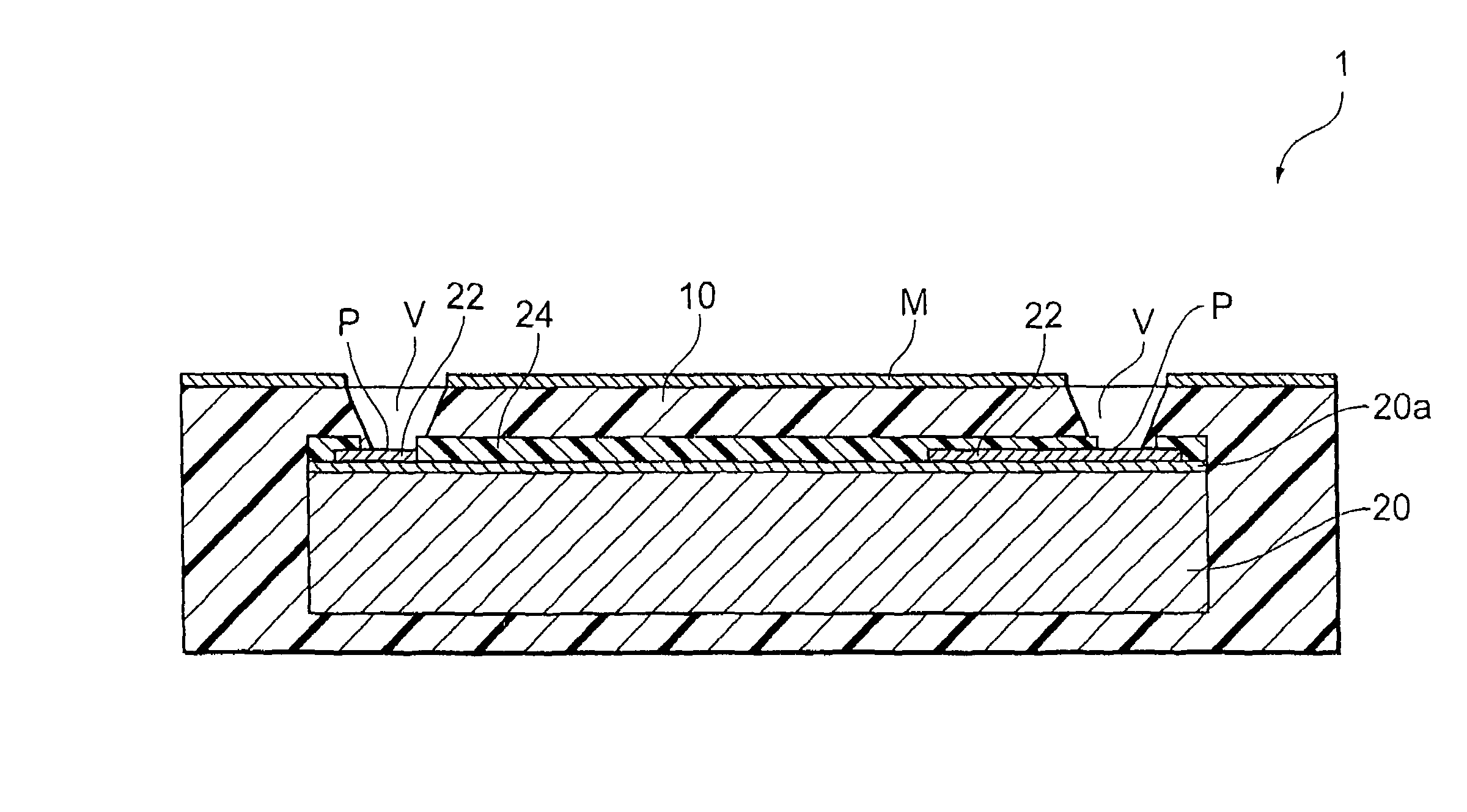

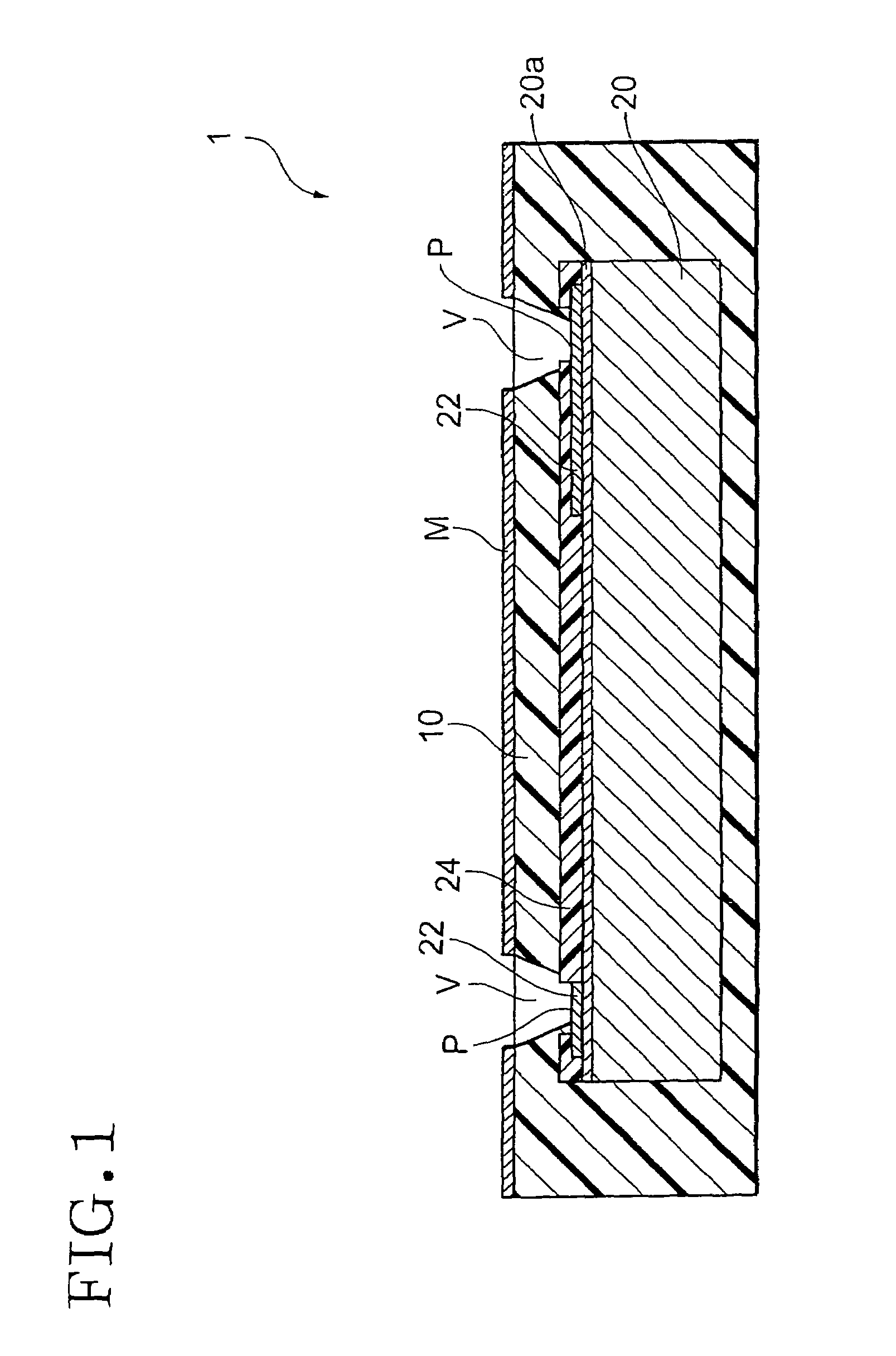

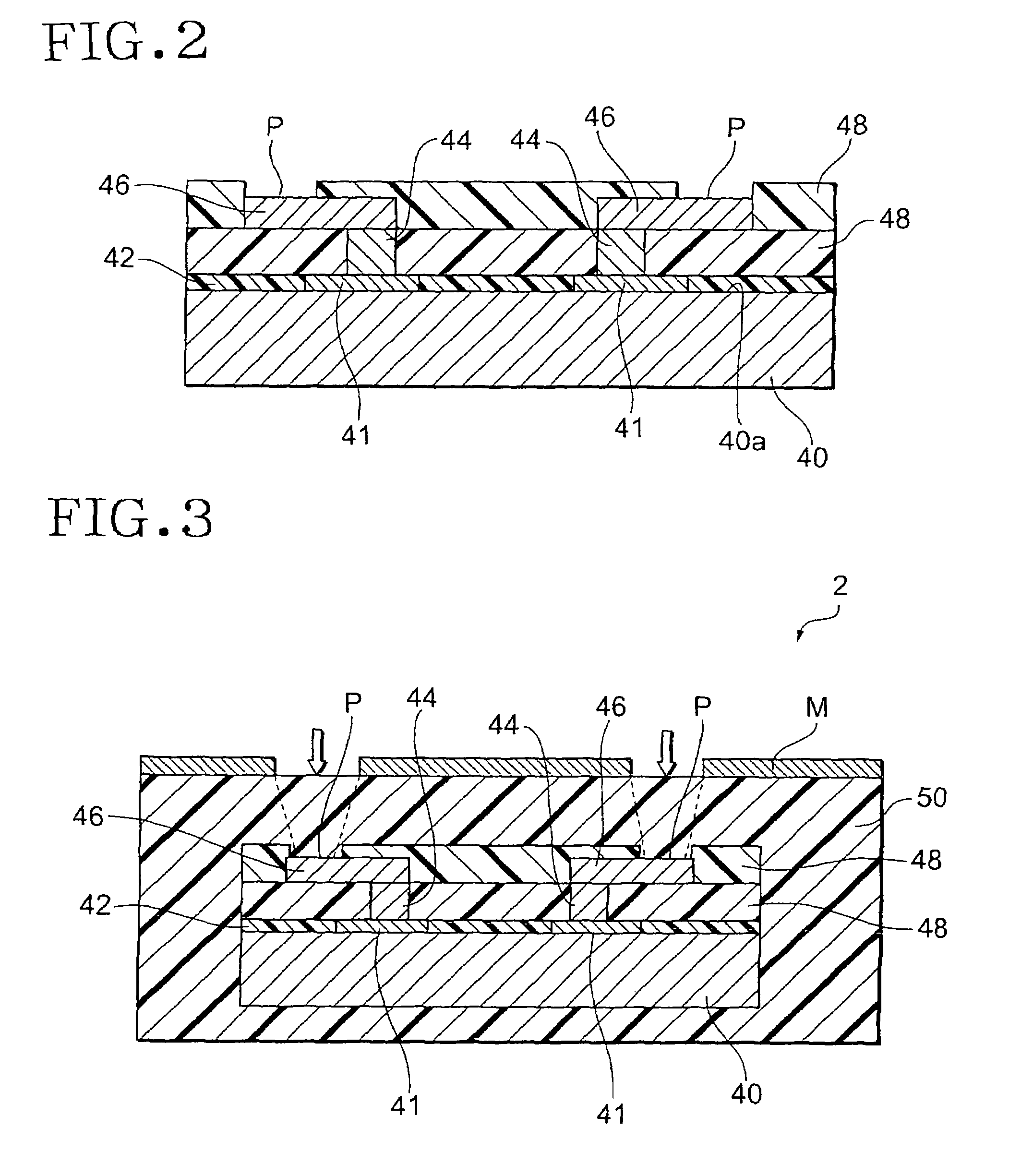

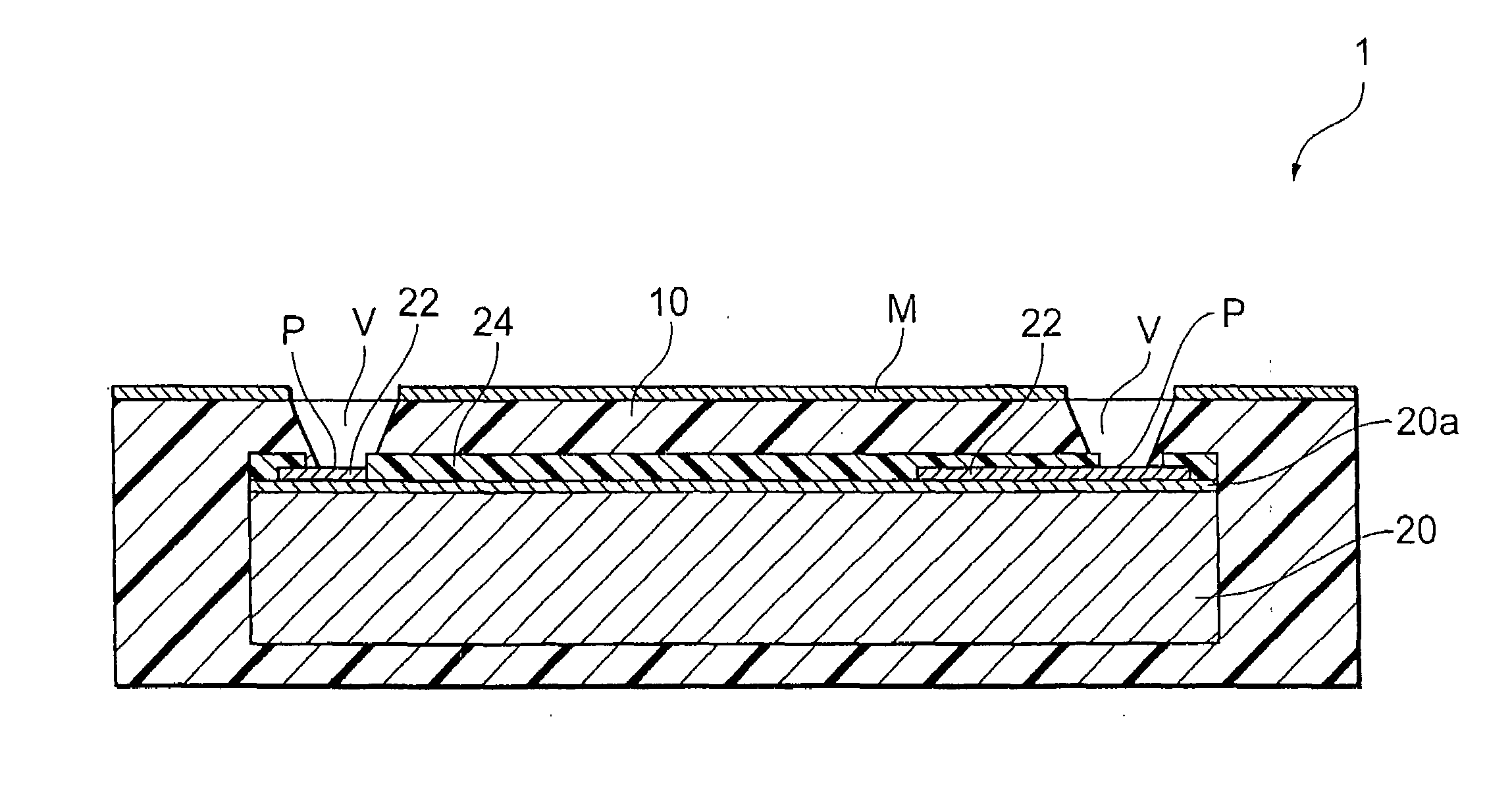

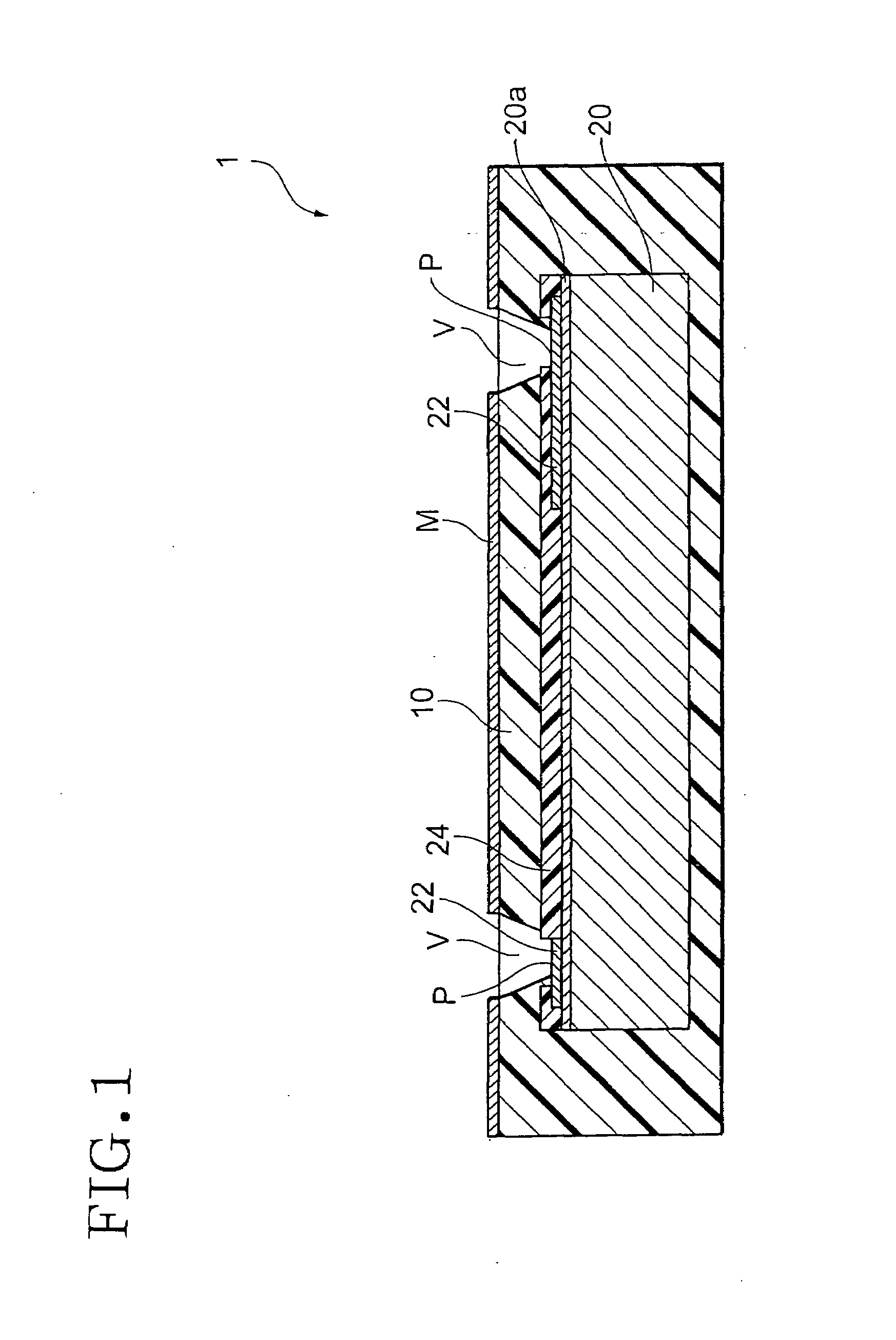

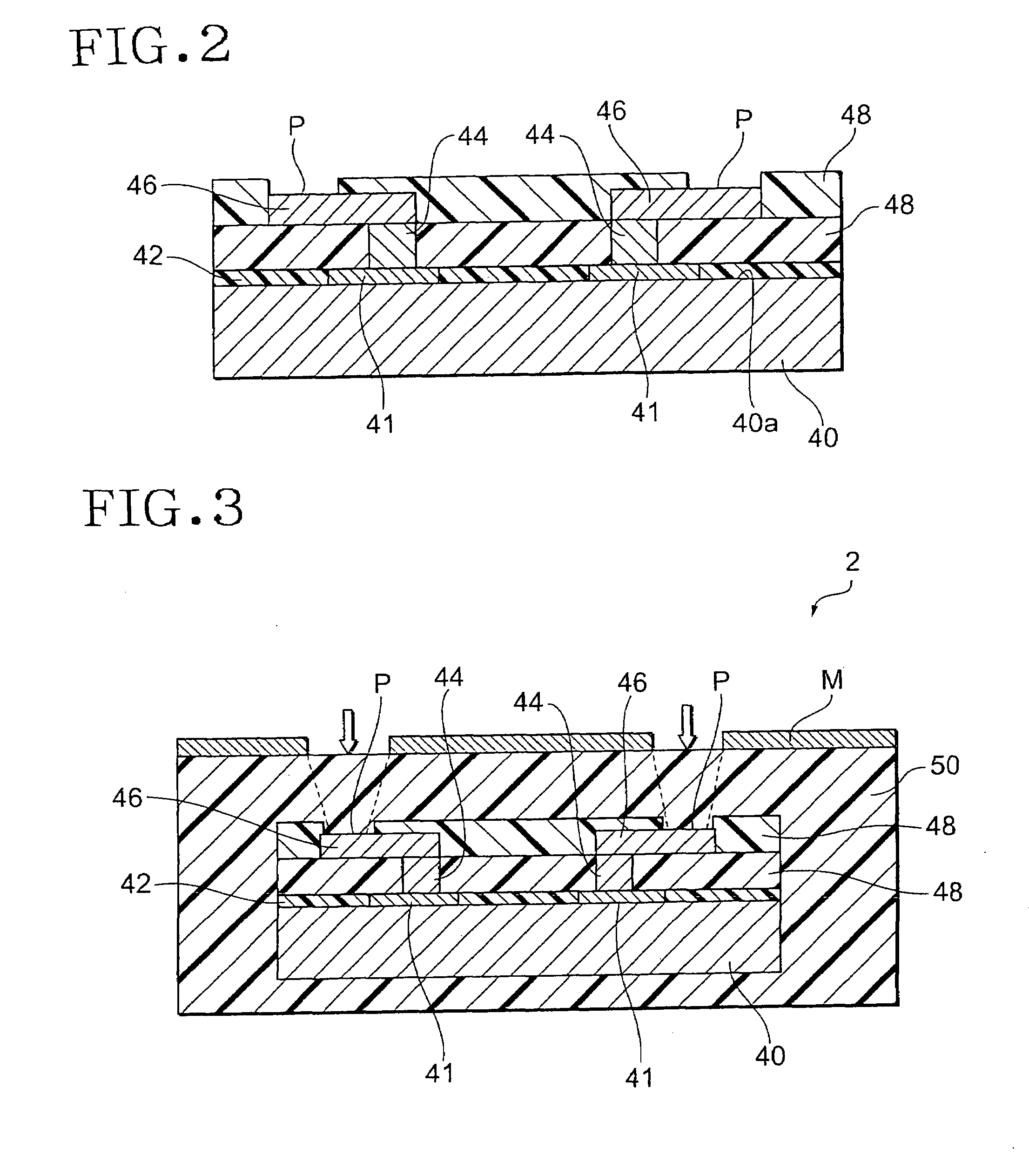

Semiconductor embedded module and method for producing the same

ActiveUS20100013103A1Efficient productionAvoid electrificationSemiconductor/solid-state device detailsSolid-state devicesRedistribution layerEngineering

A semiconductor embedded module 1 of the present invention has a configuration in which a semiconductor device 20, which is an electronic component such as a semiconductor IC (die) in a bare chip state, is embedded in a resin layer 10 (second insulating layer). In the semiconductor device 20, a redistribution layer 22 is connected to land electrodes. A protective layer 24 (first insulating layer) is provided on the redistribution layer 22, and is provided with openings such that external connection pads P of the redistribution layer 22 are exposed. Also, the resin layer 10 is formed to cover the protective layer 24, and vias V are formed at the positions of the respective external connection pads P of the redistribution layer 22. The grinding rate of the resin layer 10 is larger than that of the protective layer 24.

Owner:TDK CORPARATION

Anti-forgetting safety power strip based on electromagnetic transformation

ActiveCN110829118AAvoid electrificationAvoid clutter scattered on the groundIncorrect coupling preventionCoupling contact membersStructural engineeringElectric shock

The invention provides an anti-forgetting safety power strip based on electromagnetic transformation, and relates to the power strip technology field. The anti-forgetting safety power strip based on electromagnetic transformation comprises a frame body. A socket is slidably connected to a top of the frame body, a limiting seat is fixedly installed at a bottom end of the socket, semicircular grooves are arranged in two sides of the limiting seat, a first spring is fixedly connected to a bottom end of the limiting seat, an electric shock rod is fixedly installed at the bottom end of an internalportion of the frame body, and telescopic rods are slidably connected to the two sides of the limiting seat in the frame body. By using the anti-forgetting safety power strip based on the electromagnetic transformation, a user can be reminded that the power strip is not electrified; a phenomenon that a user forgets to press a power button and does not electrify an electric appliance is avoided; redundant electric wires can be automatically wound, extruded and fixed to keep a certain length; and the phenomenon that the electric wires are scattered on the ground disorderly due to a fact that theelectric wires are too long is avoided, and a safe, clean and tidy state is achieved.

Owner:佛山市顺德区富斯特电器科技有限公司

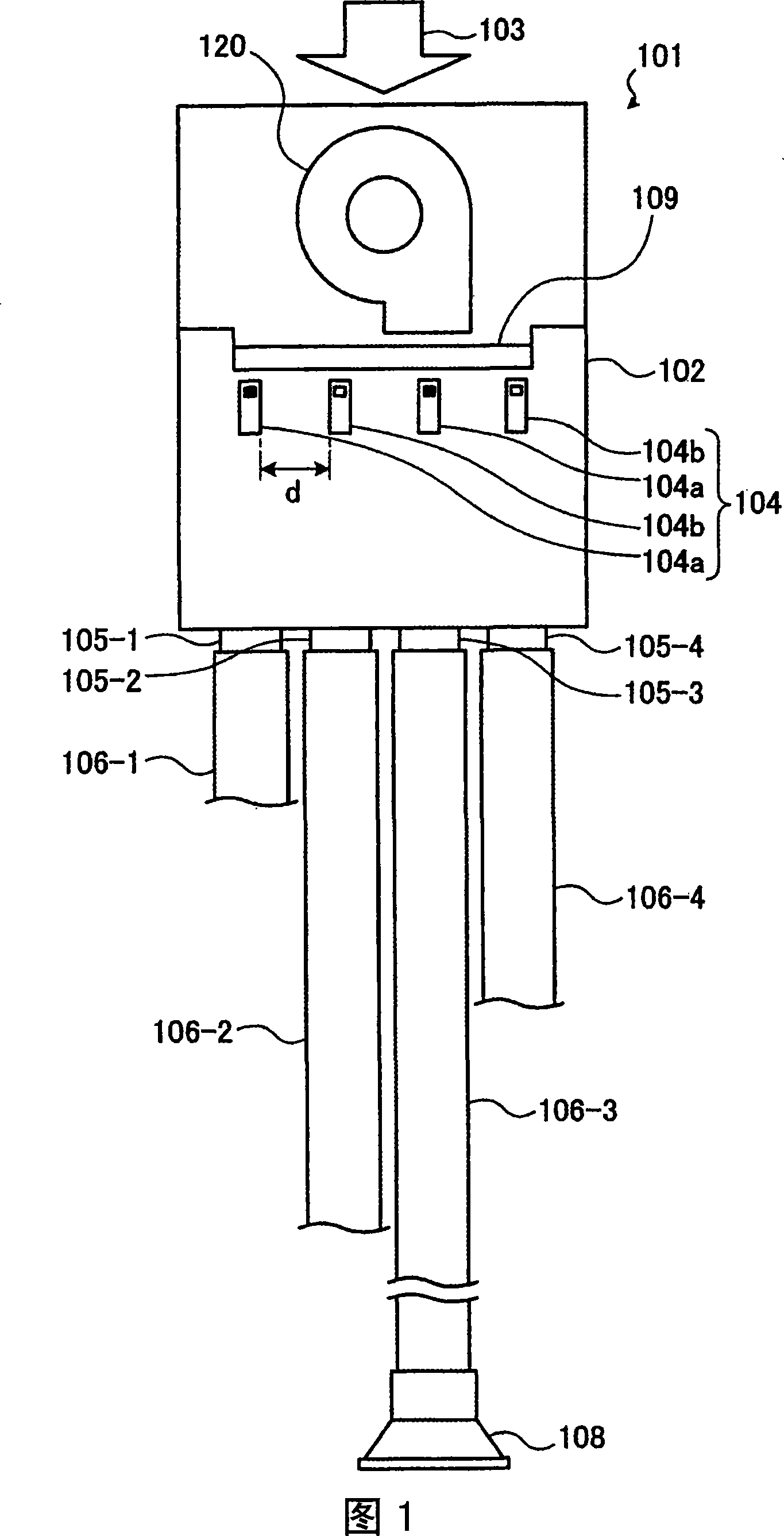

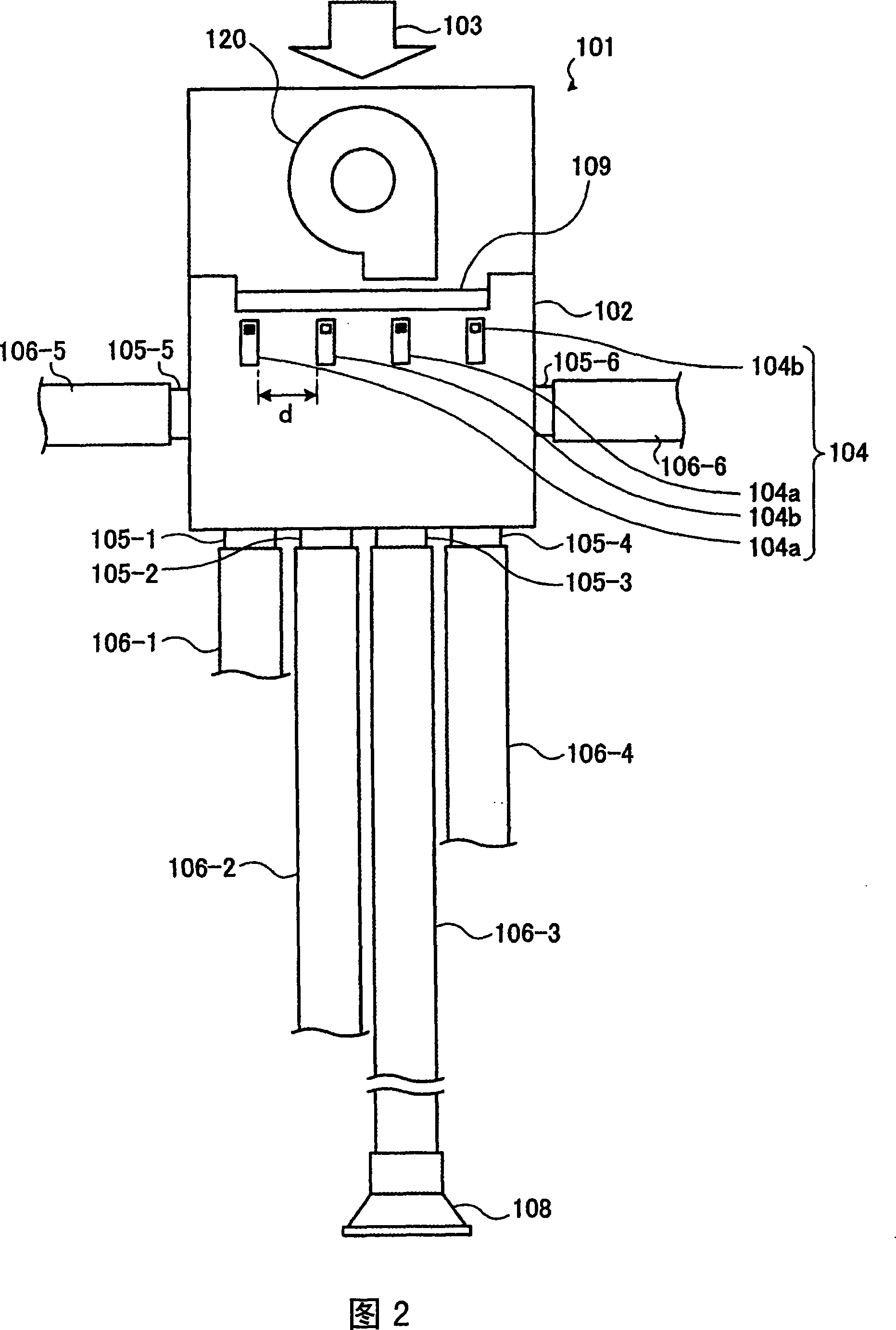

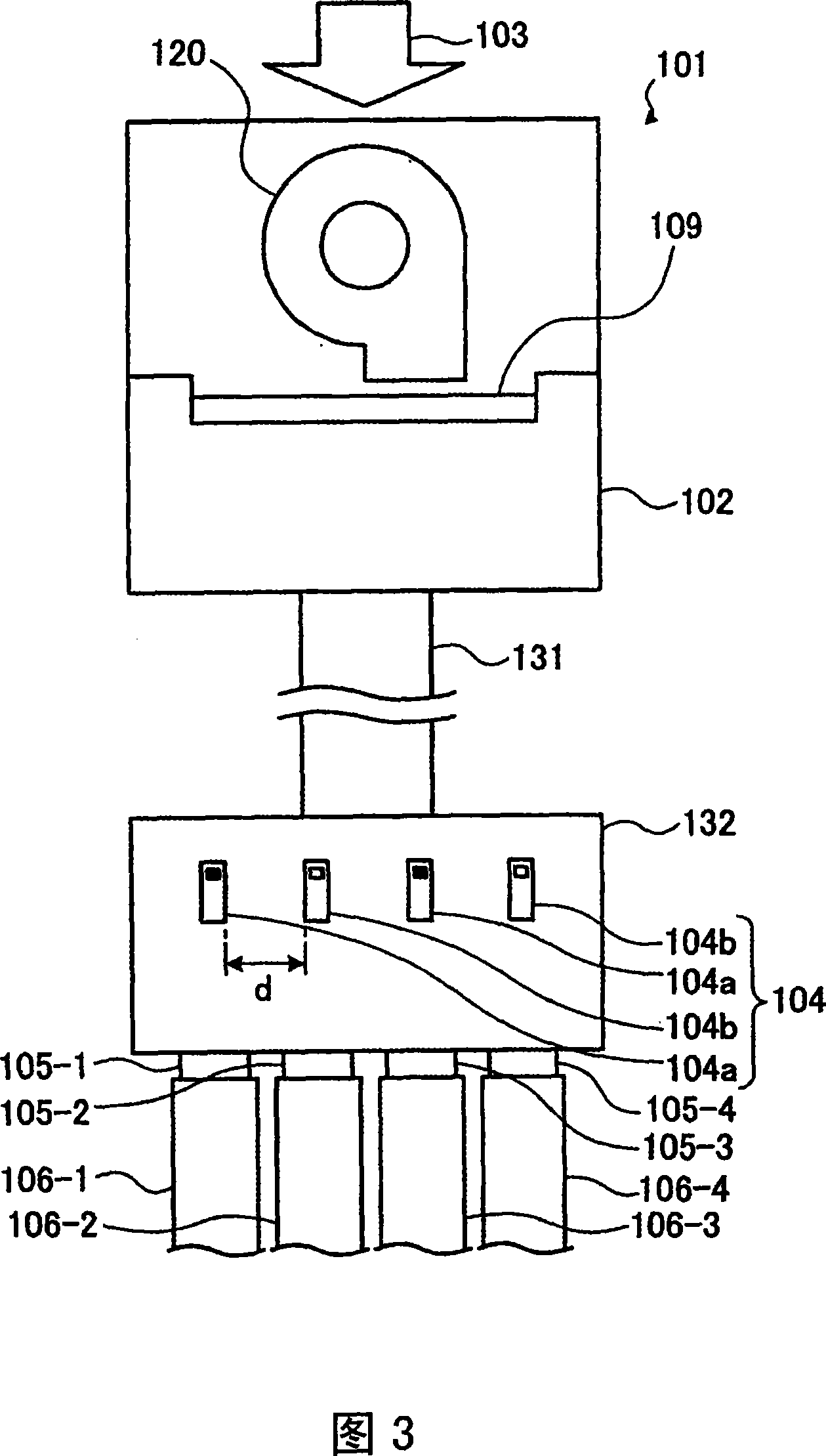

Air ion conveyance device and air ion conveyance system

InactiveCN101175510ASmall attenuationUniform supplyElectrical apparatusLighting and heating apparatusEngineeringAir conditioning

The present invention provides an air ion conveyance device as well as an air ion conveyance system, for example, for an air conditioning facility and conveys air ions to rooms of a house etc. The air ion conveyance device has an air ion production device unit, air ducts, and a control device. The air ion production device unit is provided in a housing of a centralized ventilation device and has positive ion production devices and negative ion production devices that are alternately arranged with a spacing in between, the positive ion production devices generating positive ions in air fed from the outside, the negative ion production devices generating negative ions in the air. The air ducts are connected to joints provided at the housing and individually conveys air to rooms. The control device controls the air ion production device unit. The control device regulates, according to a request from each room, whether or not to produce air ions or the amount of production of ions.

Owner:THE SHIMIZU CONSTRUCTION CO LTD +1

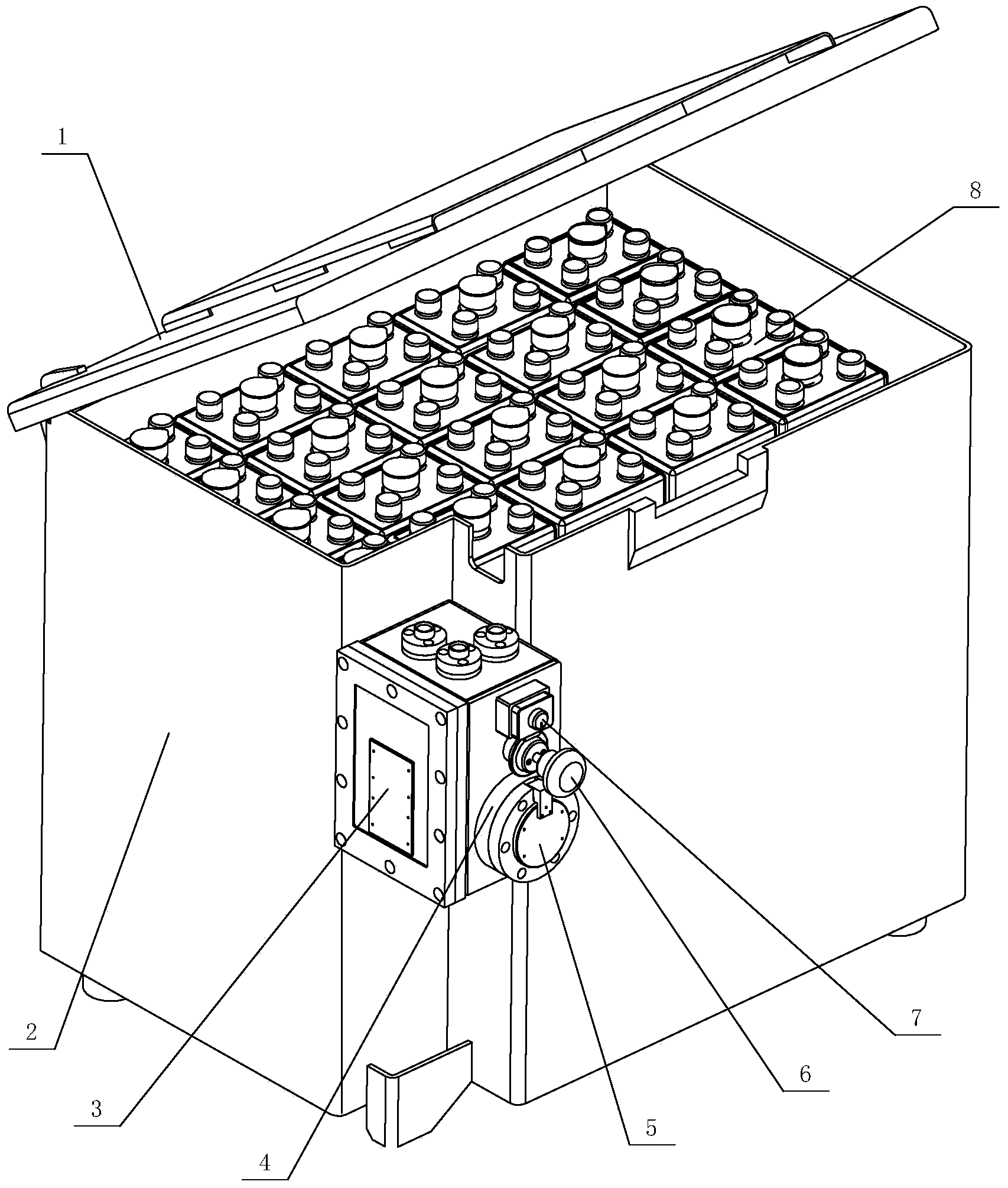

Anti-explosion power supply device of electric vehicle

ActiveCN104078642AImprove safety performanceEasy to operateCoupling device detailsCell component detailsBreakout boxElectric vehicle

The invention discloses an anti-explosion power supply device of an electric vehicle. The anti-explosion power supply device comprises a power supply box body (1), a box cover (1), a storage battery (8), a connection box (3) and a charging socket assembly (4), wherein a main power supply switch (6) is connected with the connection box (3); the charging socket assembly (4) is hinged with a socket cover plate (5) capable of separating the outside; a first electromechanical interlocking device is arranged between the main power supply switch (6) and the socket cover plate (5); a second electromechanical interlocking device is arranged between the charging socket assembly (4) and the storage battery (8). By using the structure, the phenomenon that the charging socket is charged when the charging socket is not charged or the main power supply switch is turned off can be avoided, so that the safety performance is greatly improved.

Owner:NINGBO RUYI

Thin-membrane shaper, electrooptics device and electronic equipment

InactiveCN1530225AAvoid electrificationAvoid mixingLiquid surface applicatorsPositive displacement pump componentsThin membraneEngineering

There is provided a thin film fabrication apparatus that has a substrate stage, a droplet discharge head, a tank, and a tube. The substrate stage holds a substrate. The droplet discharge head is disposed above the substrate stage and discharges liquid crystal on the substrate. The tank contains the liquid crystal. The tube connects the tank and the discharge head to supply the liquid crystal from the tank to the discharge head. The tube and the tank are configured from antistatic material. The droplet discharge head is a piezojet type, and at least a part of the area in contact with the liquid crystal is configured from antistatic material.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com