Base plate bonding device and method

A substrate and base technology, used in optics, instruments, electrical components, etc., can solve problems such as destroying circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

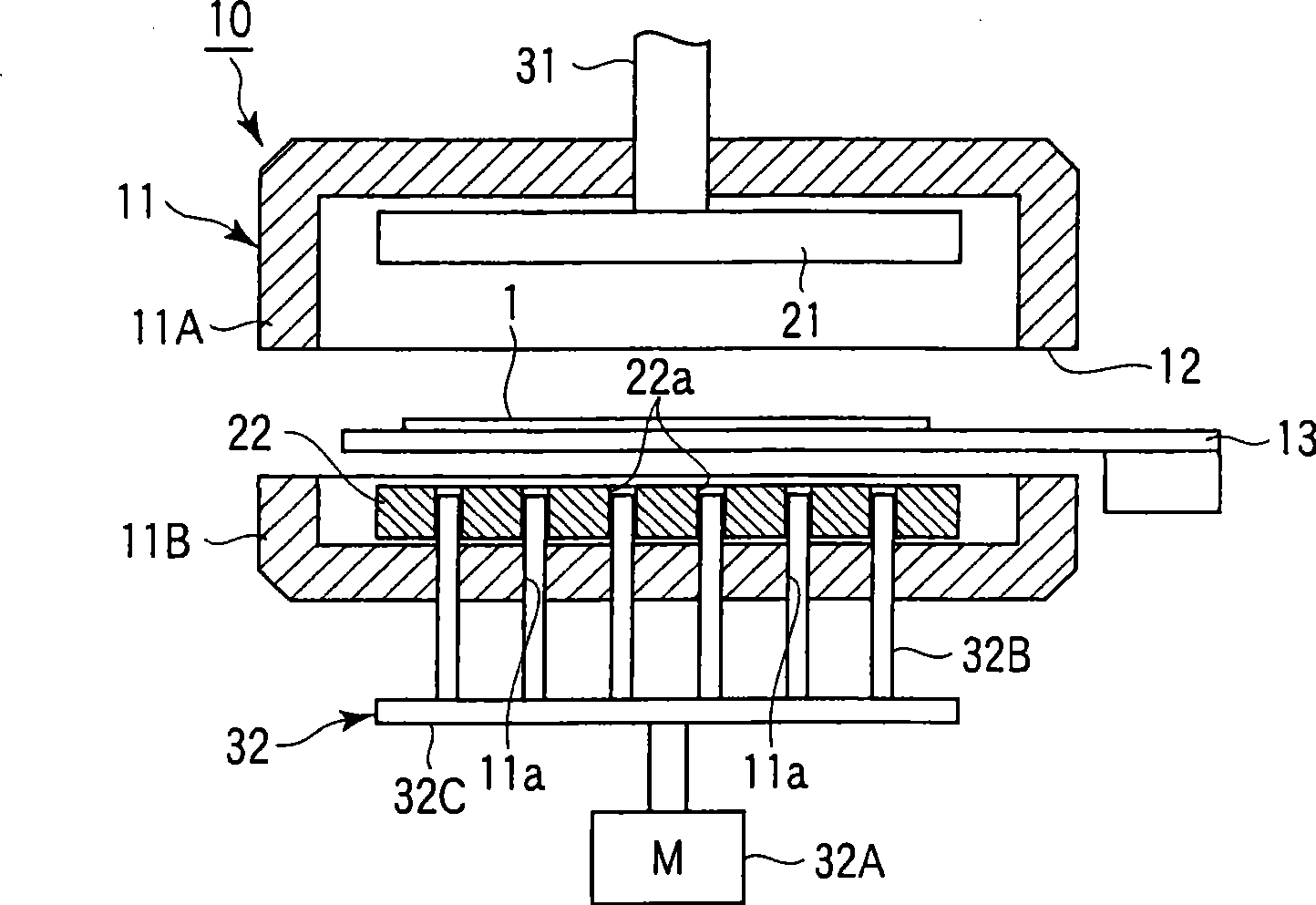

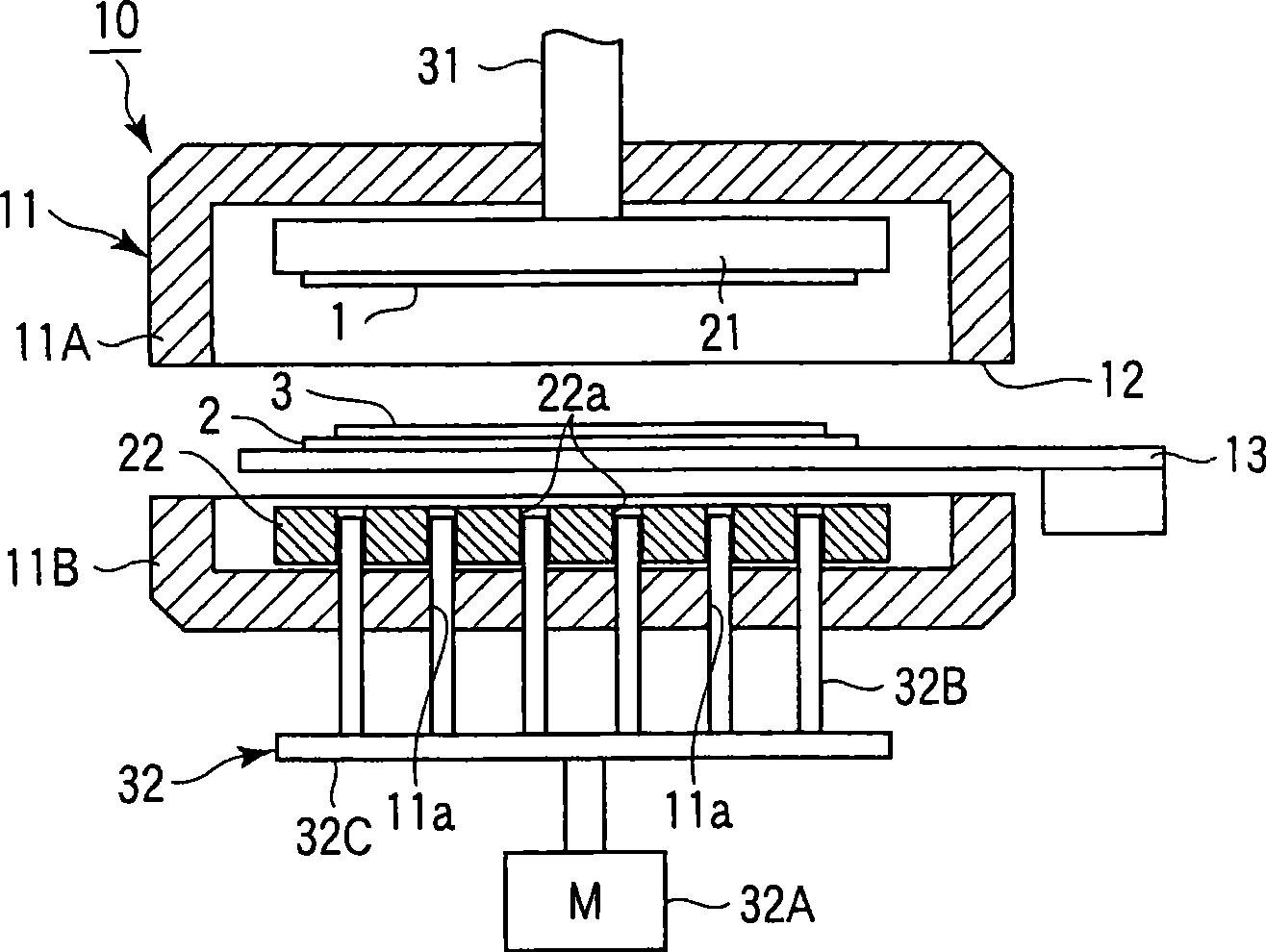

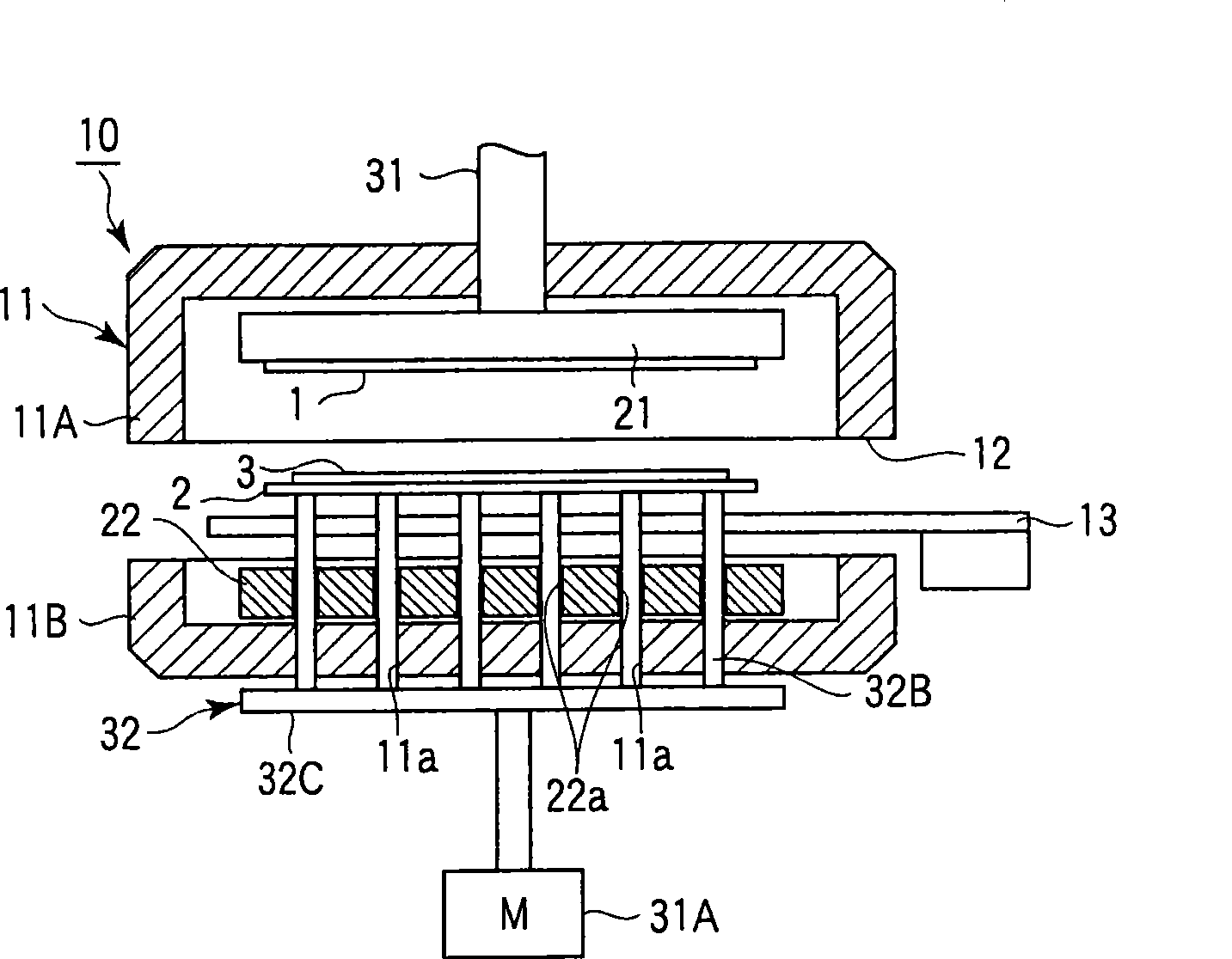

[0027] (Example 1)( Figure 1 to Figure 10 )

[0028] Substrate gluing device 10, such as Figure 1 to Figure 10 As shown, there is a vacuum chamber 11 (an upper chamber 11A and a lower chamber 11B) which can be opened and closed up and down, and a loading and unloading port 12 for loading and unloading the upper and lower substrates 1 and 2 is provided. The substrates 1 and 2 sucked and held by the robot arm 13 are loaded and unloaded from the loading and unloading port 12 of the vacuum chamber 11 into and out of the vacuum chamber 11 .

[0029] The vacuum chamber 11 is provided with upper and lower workbenches 21 and 22 . The upper and lower workbenches 21, 22 form a rectangular disc shape made of aluminum alloy. The upper and lower substrates 1, 2 are formed of rectangular glass substrates.

[0030] The upper workbench 21 is raised and lowered relative to the lower workbench 22 by the upper elevating device 31, and an upper substrate adsorption device (not shown) such a...

Embodiment 2

[0062] (Example 2)( Figure 11 ~ Figure 13 )

[0063] The difference between Embodiment 2 and Embodiment 1 is that after the upper substrate 1 and the lower substrate 2 are glued together, before the atmospheric pressure is restored in the vacuum chamber 11, the contact area between the upper and lower substrates 1, 2 and the upper and lower worktables 21, 22 is reduced. As an apparatus, the substrate detachment dedicated apparatus 40 was used.

[0064] The substrate detaching device 40 includes a lifting actuator 41 composed of a liquid cylinder (or a motor) and a plurality of push rods 42 arranged on the lower table 22 that are lifted and lowered by the lifting actuator 41 . The ejector rod 42 passes through the through hole 11b provided in the lower chamber 11B in a sealed manner, and further penetrates the through hole 22b formed in the lower table 22 .

[0065] In the gluing process of the upper and lower substrates 1, 2, such as Figure 11 As shown, the above-mentione...

Embodiment 3

[0071] (Example 3)( Figure 14 ~ Figure 16 )

[0072] The difference between Embodiment 3 and Embodiment 1 is that after the upper substrate 1 and the lower substrate 2 are glued together, before returning to the atmospheric pressure in the vacuum chamber 11, the contact area between the upper and lower substrates 1, 2 and the upper and lower worktables 21, 22 is reduced. As an apparatus, the substrate detachment dedicated apparatus 50 was used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com