Thin-membrane shaper, electrooptics device and electronic equipment

A thin film and particle technology, applied in the field of thin film forming devices, can solve problems such as disorder, molecular orientation disorder, and inability to obtain a stable ejection state, and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Embodiments of the liquid crystal device for data writing according to the present invention will be described in detail below with reference to the accompanying drawings. Also, the present invention is not limited to this Example.

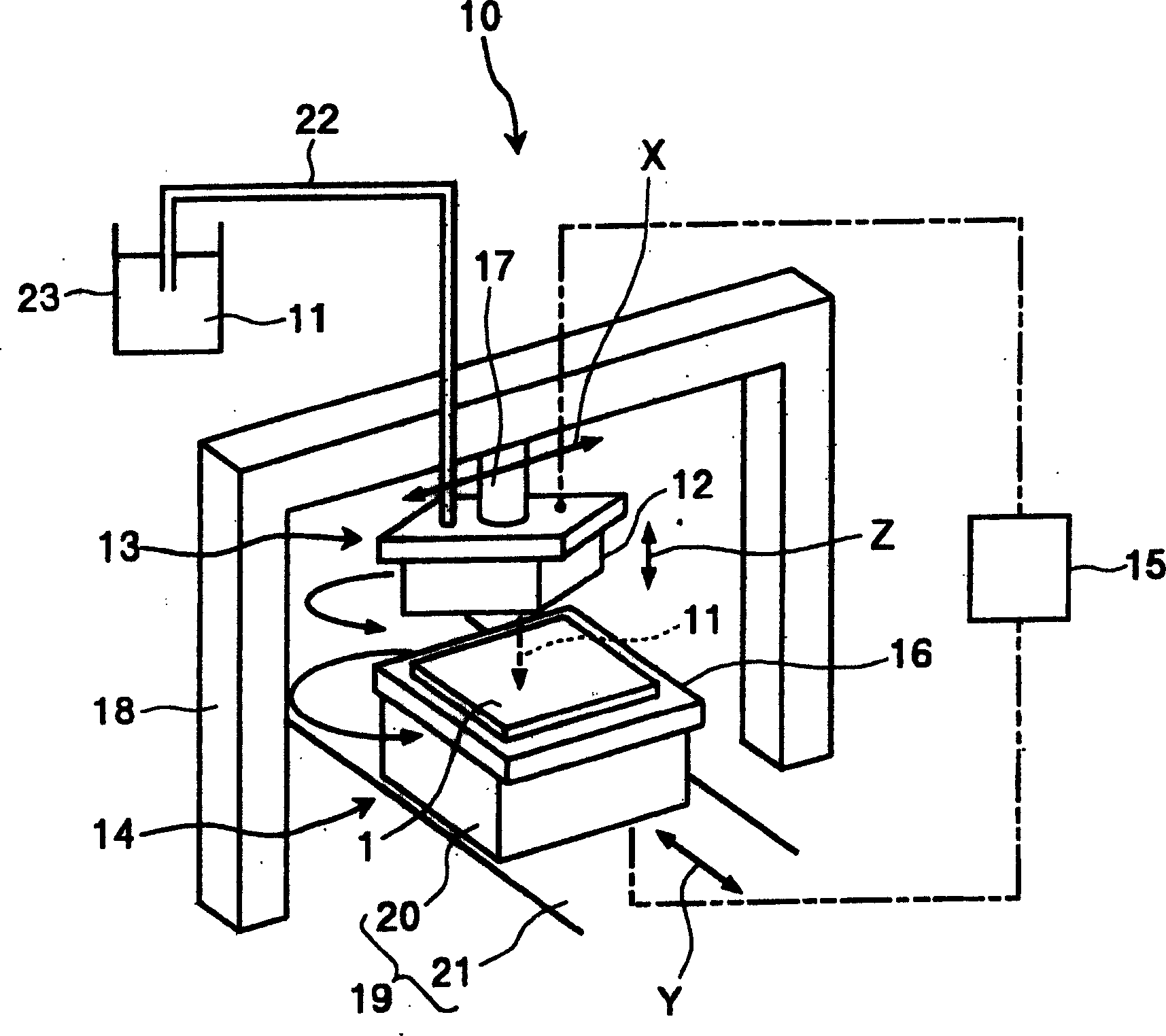

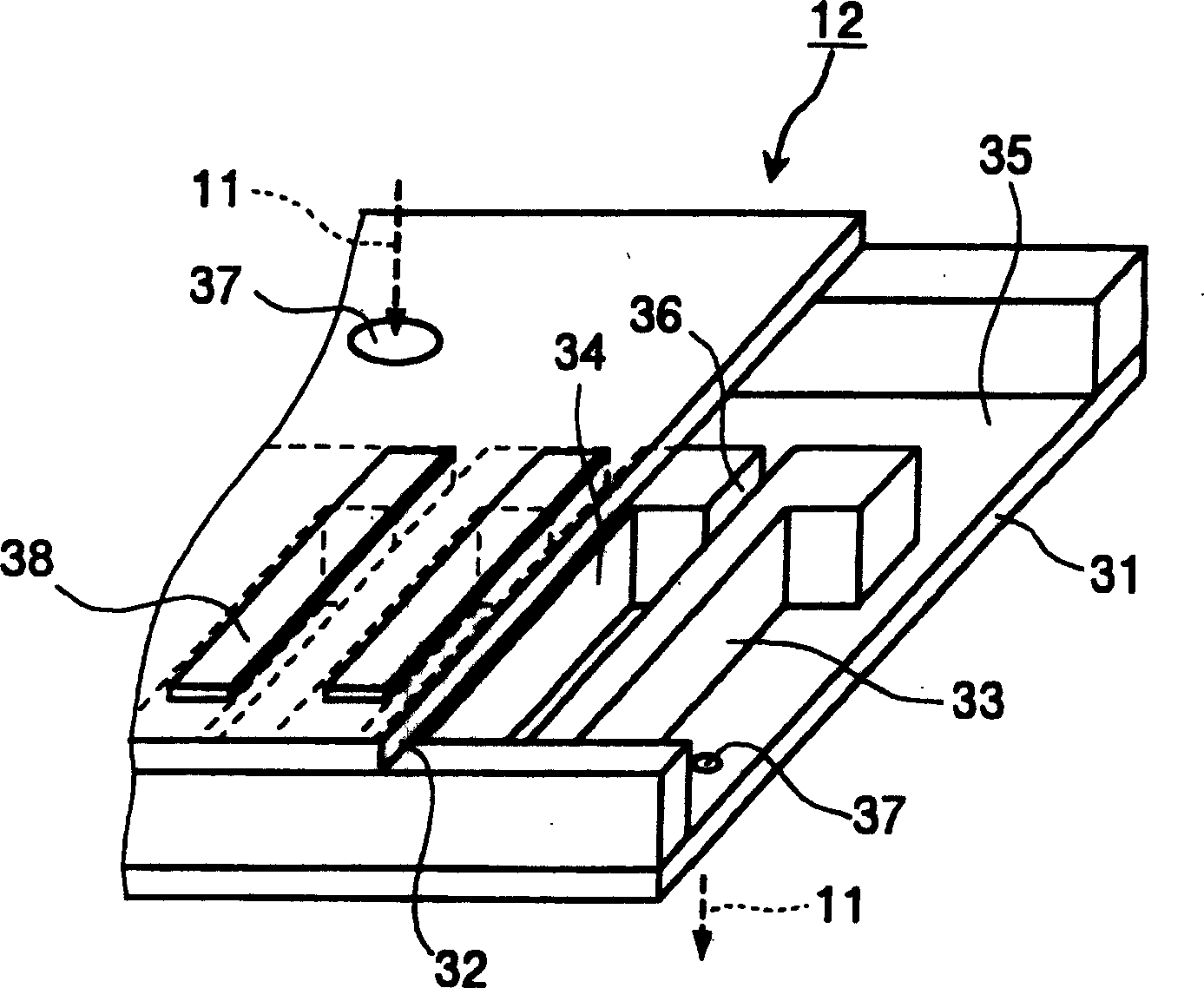

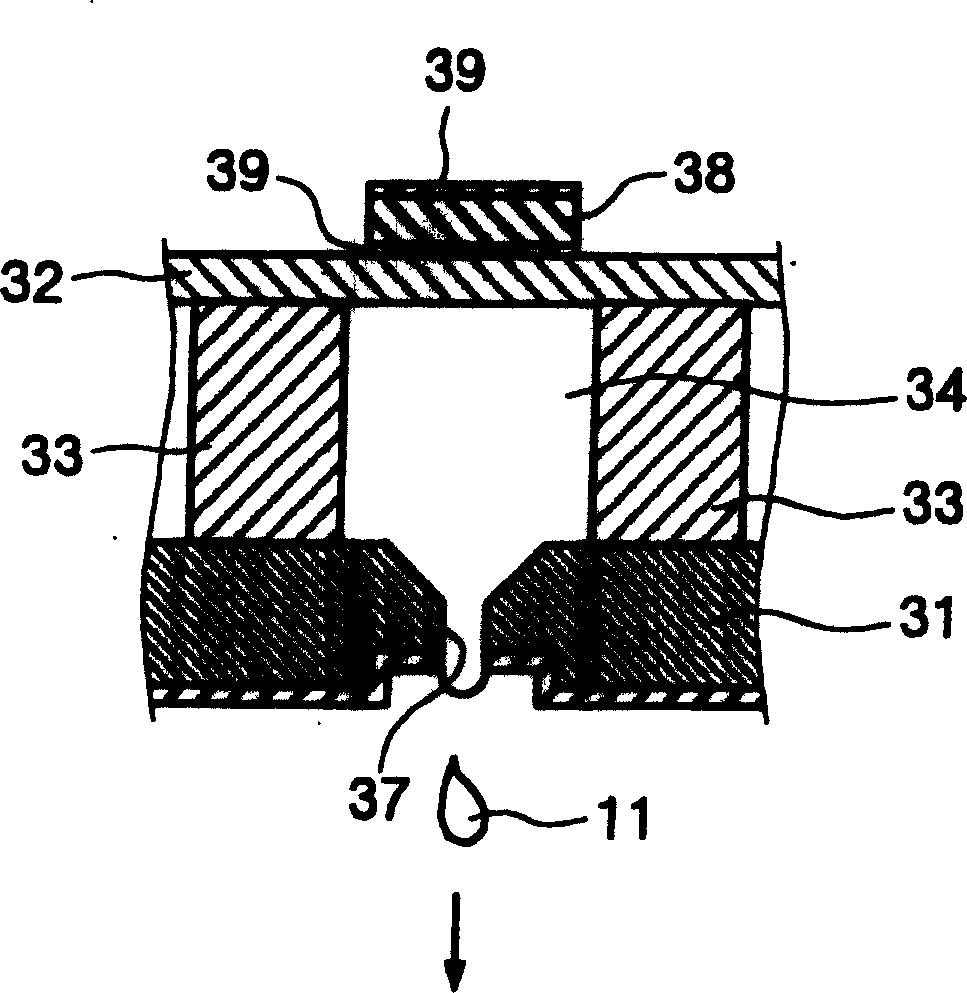

[0055] figure 1 It is a schematic diagram of the thin film forming apparatus of this invention. figure 2 and image 3 is a schematic diagram of a droplet ejection head. Figure 4 It is a configuration diagram of a liquid crystal panel.

[0056] First, refer to Figure 4 The configuration of the liquid crystal display panel as the electro-optical device of the present invention will be described. The liquid crystal display panel 100 of this embodiment has a first substrate 1 and a second substrate 4 facing each other, and liquid crystal display units 106 and 107 are respectively formed on the inner surfaces of the first substrate 1 and the second substrate 4 .

[0057] Specifically, as Figure 4 As shown, on the first substrate 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com