Measuring method for leakage current of zinc oxide arrester

A technology of leakage current and measurement method, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as general economy, impossibility, and damage to invisible equipment, so as to improve measurement accuracy, avoid safety hazards, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

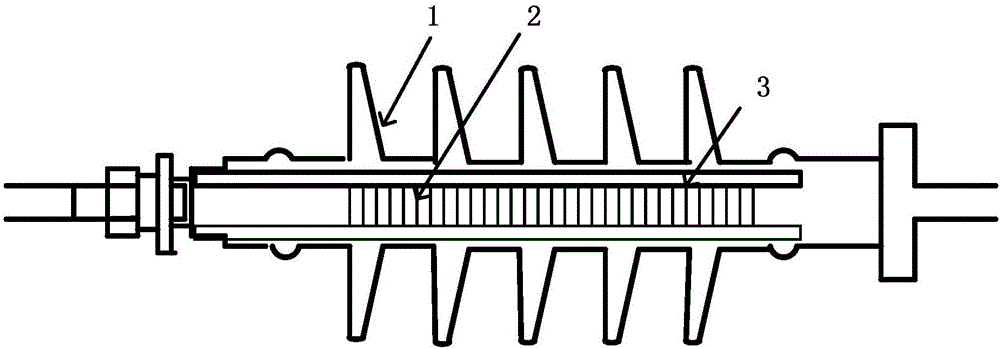

[0019] Such as Figure 1 to Figure 3 Shown: the zinc oxide arrester leakage current measurement method of this embodiment includes the following steps:

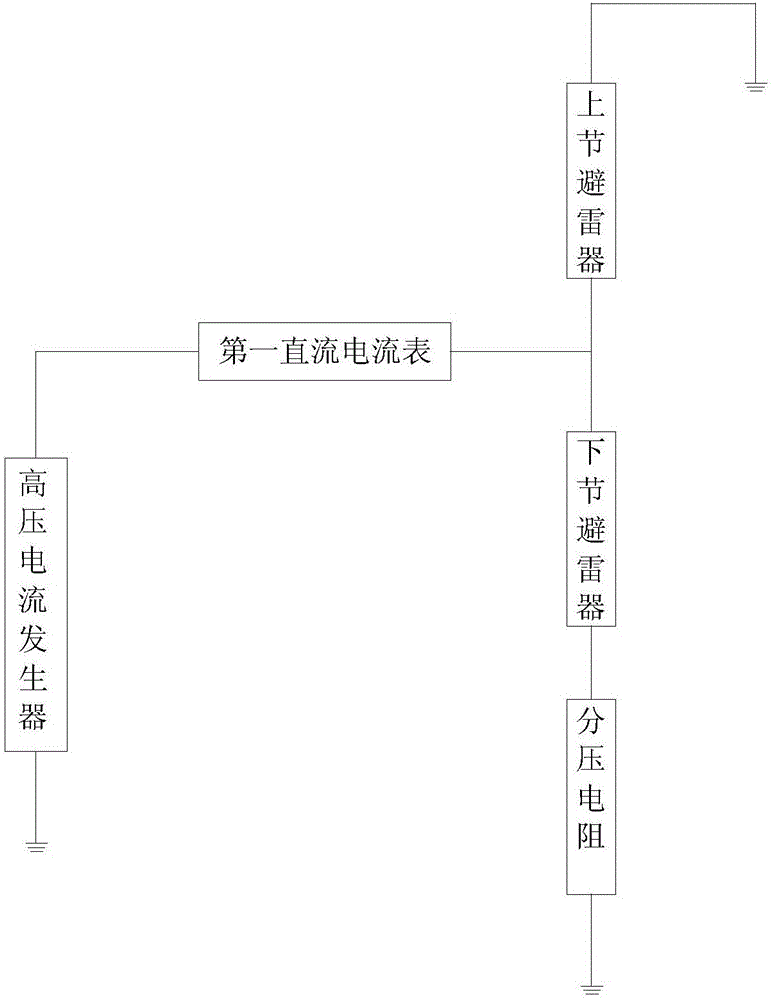

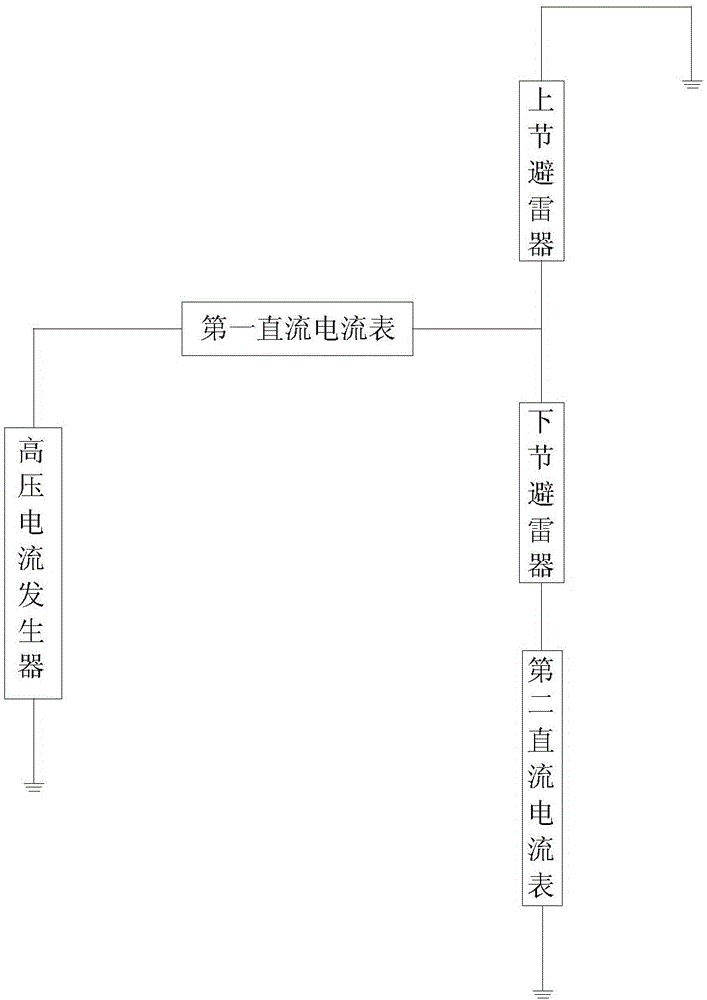

[0020] A: Connect the high voltage output terminal of the DC high voltage generator to the "-" terminal of the first DC ammeter, and connect the "+" terminal of the first DC ammeter to the connection point of the upper section lightning arrester and the lower section lightning arrester. The voltage test terminal of the generator is connected to a DC microammeter, and the terminal of the DC high voltage generator is grounded.

[0021] B: Connect the voltage divider resistor with the resistance value of 25kΩ~35kΩ in parallel with the discharge counter and connect it to the lower end of the lightning arrester in the lower section, and the end of the voltage divider resistor is grounded; the setting of the voltage divider resistor increases the operating voltage of the arrester in the lower section and makes it flow through the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com