Multi-stage sequence triggered emergency system capable of automatically shearing tubular column and sealing borehole

An emergency system and pipe string technology, applied in the field of emergency systems, can solve the problems of reducing the hydraulic pressure of the hydraulic system, reducing the shearing capacity of the ram, and not being able to unlock normally, so as to prevent false triggering, improve system stability, and valve types. little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

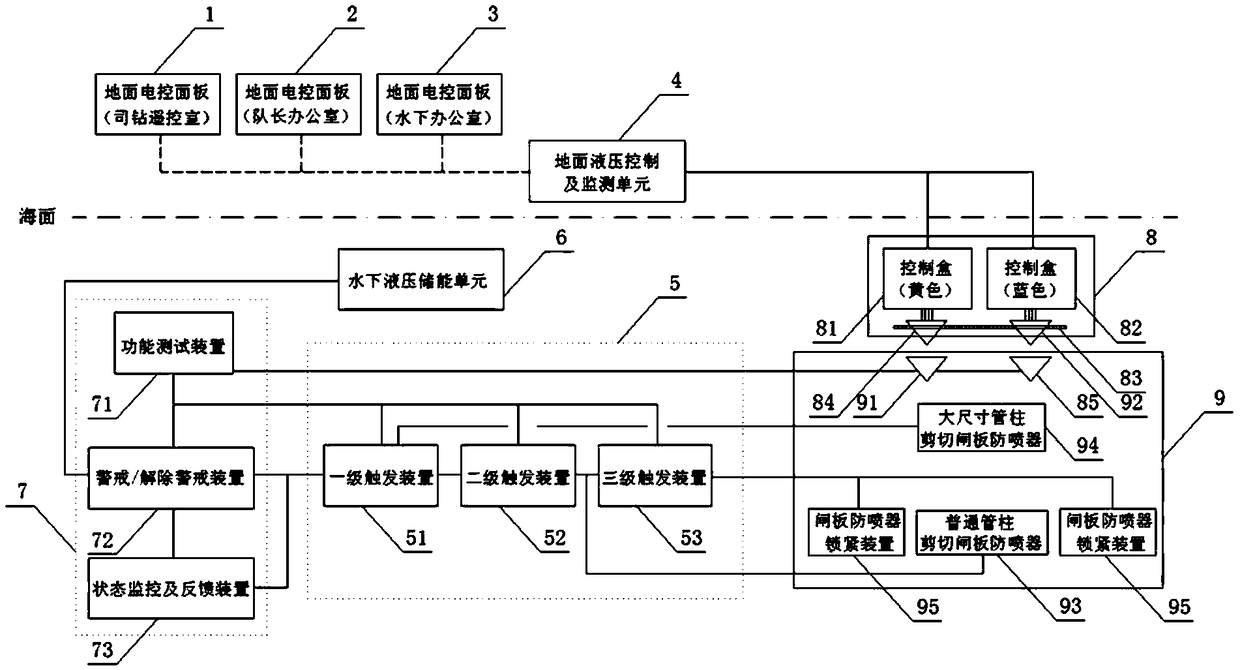

[0058] refer to figure 1 , the emergency system capable of automatically cutting the pipe string and sealing the wellbore triggered by multi-stage sequence of the present invention includes: ground electric control panel (ground electric control panel 1, ground electric control panel 2, ground electric control panel 3), Surface hydraulic control and monitoring unit 4 , lower riser assembly 8 , lower blowout preventer assembly 9 , multi-stage sequentially triggered hydraulic actuator valve group 5 , underwater hydraulic energy storage unit 6 and underwater robot operation panel 7 .

[0059] The structure of each part is described in detail below.

[0060] 1. Ground electric control panel

[0061] There are at least two groups of ground electric control panels, which are recorded as ground electric control panel 1, ground electric control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com