Working table device, film-forming device, optical element, semiconductor element and electronic device

A film-forming device and workbench technology, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, metal processing equipment, etc., can solve problems such as difficulty in forming uniform layers, short circuits in circuit patterns, film formation or drying effects of light-emitting layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

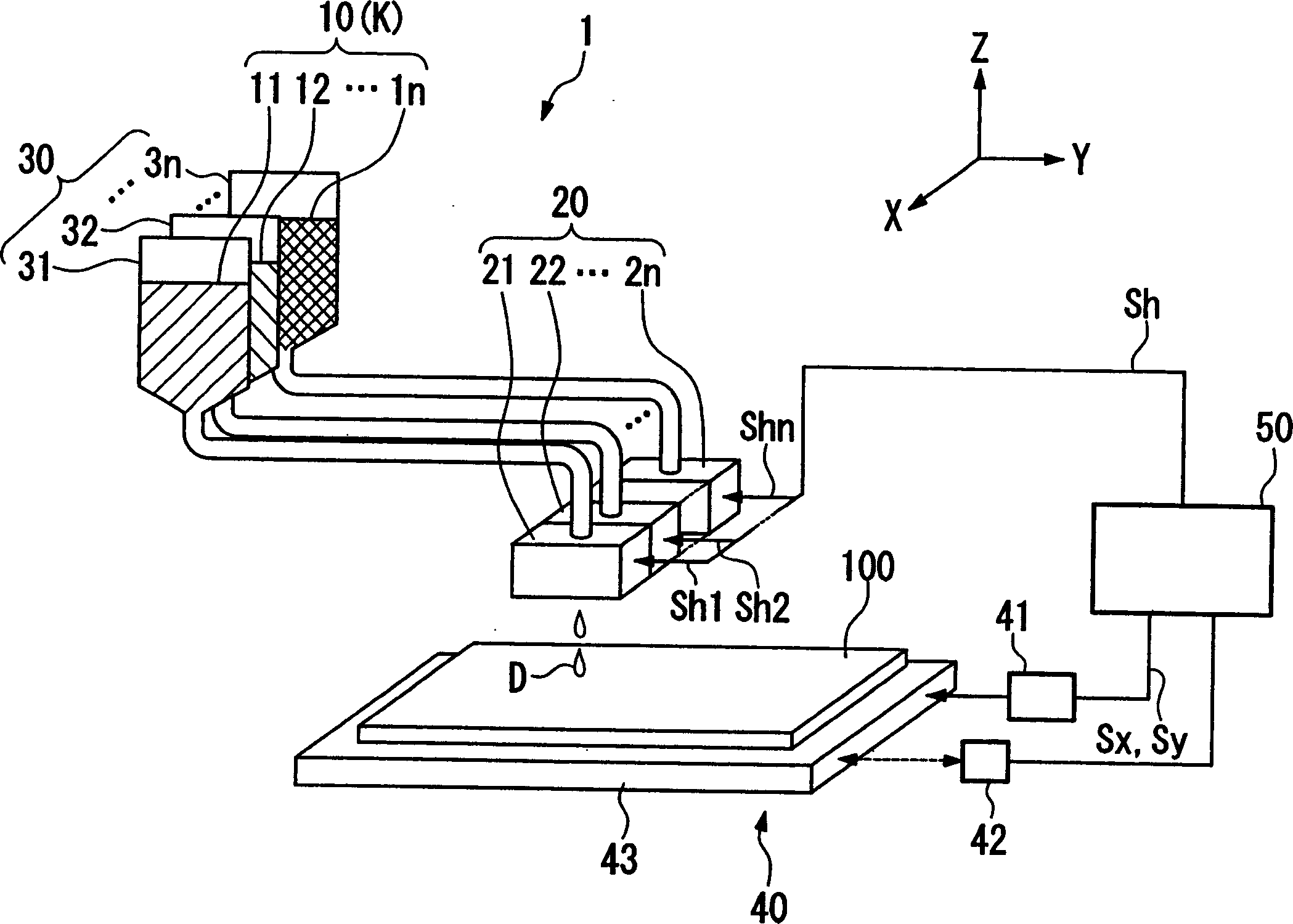

[0025] figure 1 It is a schematic diagram showing the film forming apparatus 1 of the present invention. The film forming apparatus 1 is an apparatus for forming a film by ejecting liquid droplets by an inkjet method, and includes an inkjet head 20 , a storage tank 30 , a stage device 40 , and a control device 50 .

[0026] In addition, the substrate 100 used in the present invention is a thin plastic or film-like flexible substrate, that is, a so-called flexible substrate, which is placed on the table device 40, and the liquid droplets ejected by the inkjet nozzle 20, etc. It lands thereon to form a film such as a light-emitting layer or a conductive layer.

[0027] Furthermore, as the material of the substrate 100 , transparent materials such as plastics such as polyolefin, polyester, polyacrylate, polycarbonate, polyethersulfone, and polyetherketone can be used.

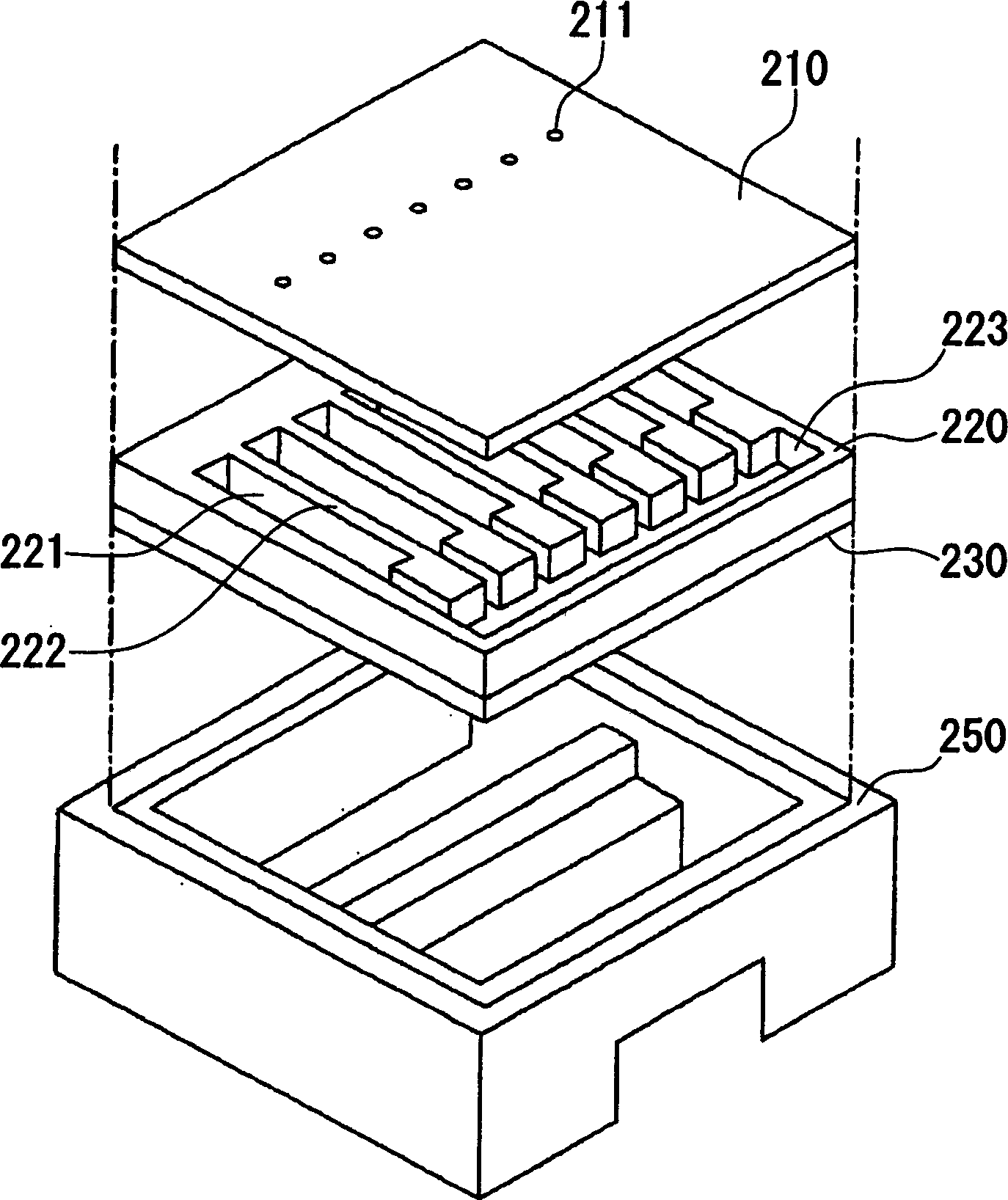

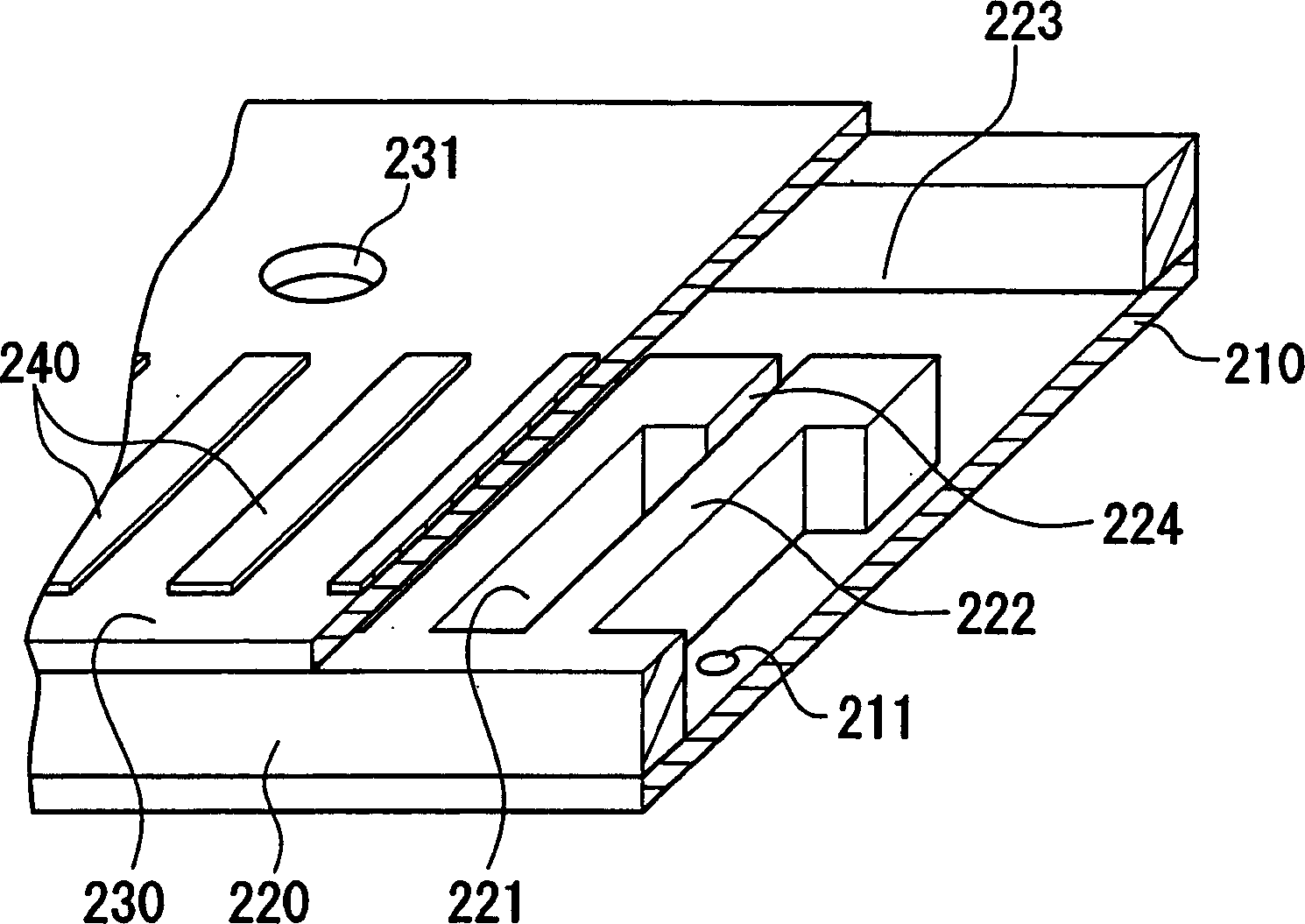

[0028] The inkjet heads 20 (21 to 2n: n is an arbitrary natural number) each have the same structure, and can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com