Patents

Literature

326 results about "Static eliminators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Optical fiber drawing cooling system

ActiveCN101531455AImprove cooling effectReduce whiplashGlass making apparatusGlass productionWater storage tankEngineering

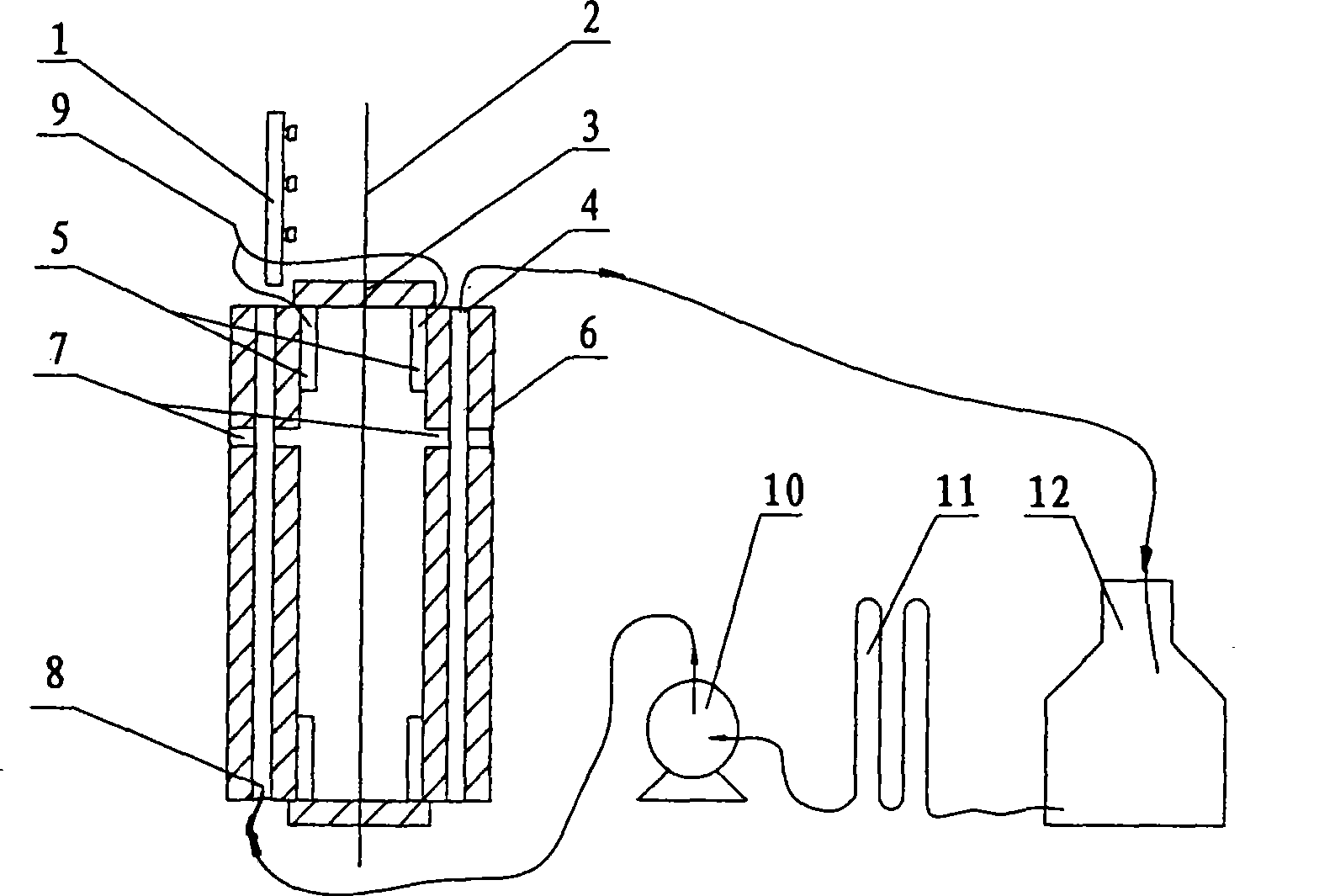

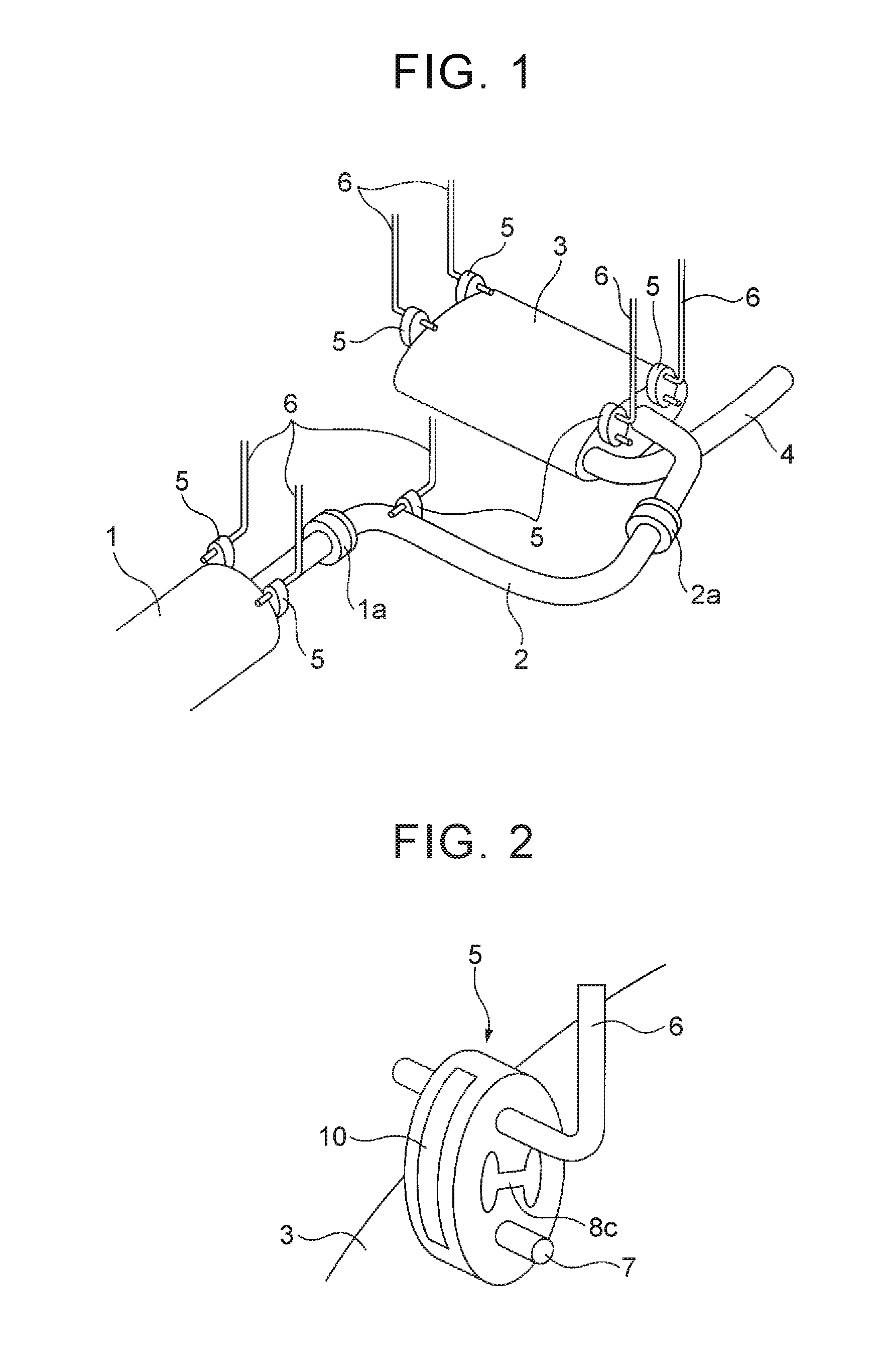

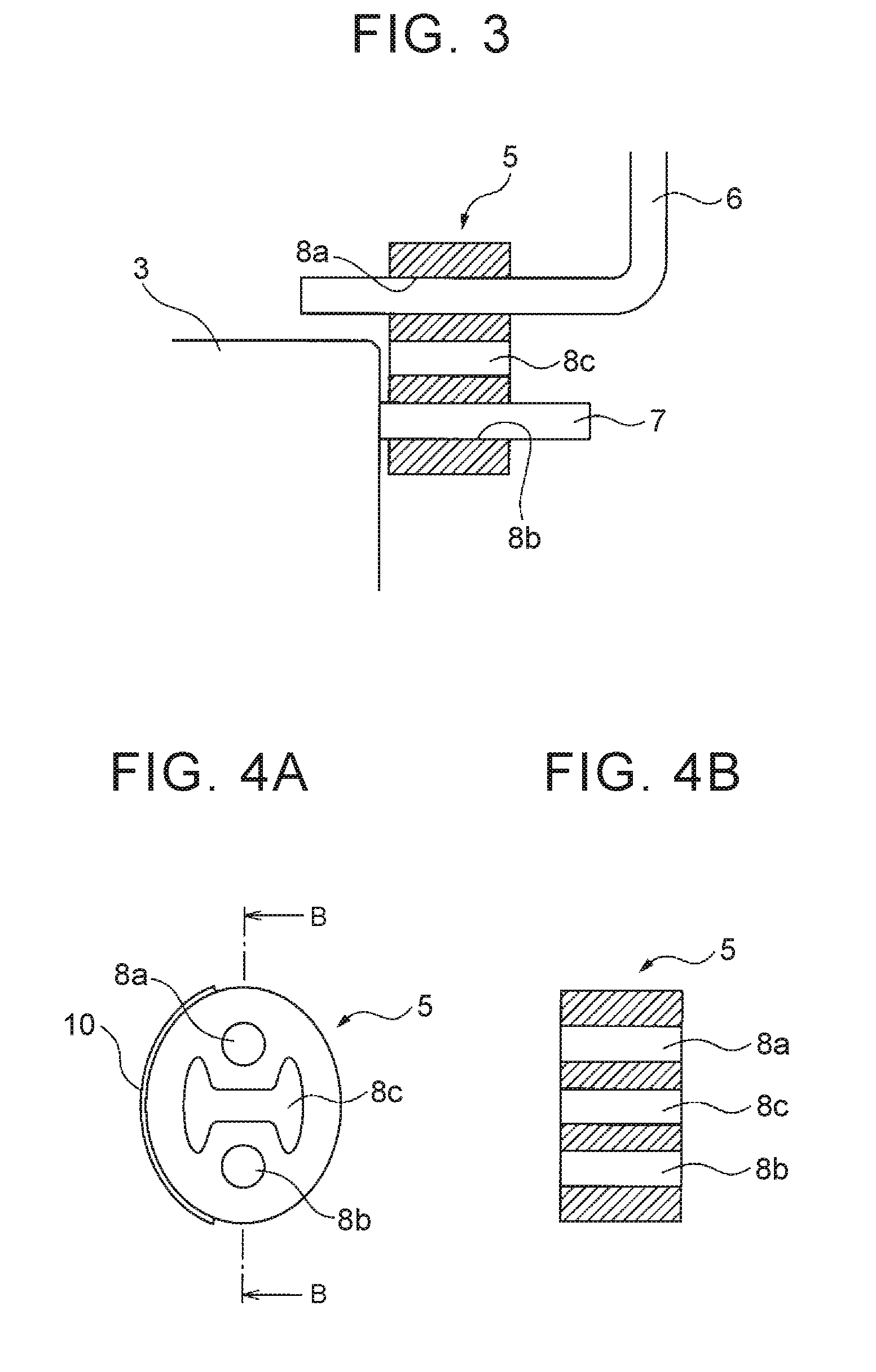

The invention discloses an optical fiber drawing cooling system, and relates to a bare optical fiber cooling system in a single mode optical fiber drawing process. The optical fiber drawing cooling system is used for reducing the temperature of an optical fiber before coated, is suitable for improving the optical fiber curing performance, and ensures that the single mode optical fiber is applied to an optical fiber communication system with high speed, high capacity and long distance. A structure of the optical fiber drawing cooling system consists of an antistatic device, a cooling tube body, a cooling water pipe, a gas pipeline and a cooling water circulation device, wherein the antistatic device consists of a static eliminator and a static transferring component; the cooling tube body is provided with an inner cavity which is suitable for passing through the optical fiber, and the outside of the inner cavity is provided with the cooling water pipe and a gas injection channel of cooling gas; an upper mouth and a lower mouth of the cooling tube body are provided with drain plugs with variable apertures; the cooling water pipe is arranged on the outside of the inner cavity of the cooling tube body; the cooling water circulation device comprises a cooling water storage tank, a cooling water pump and a refrigerator; and the gas injection channel of the cooling gas is positioned on the lateral part of the cooling tube body, communicated with the inner cavity of the cooling tube body, and is distributed on the periphery of the inner cavity.

Owner:四川天府江东科技有限公司

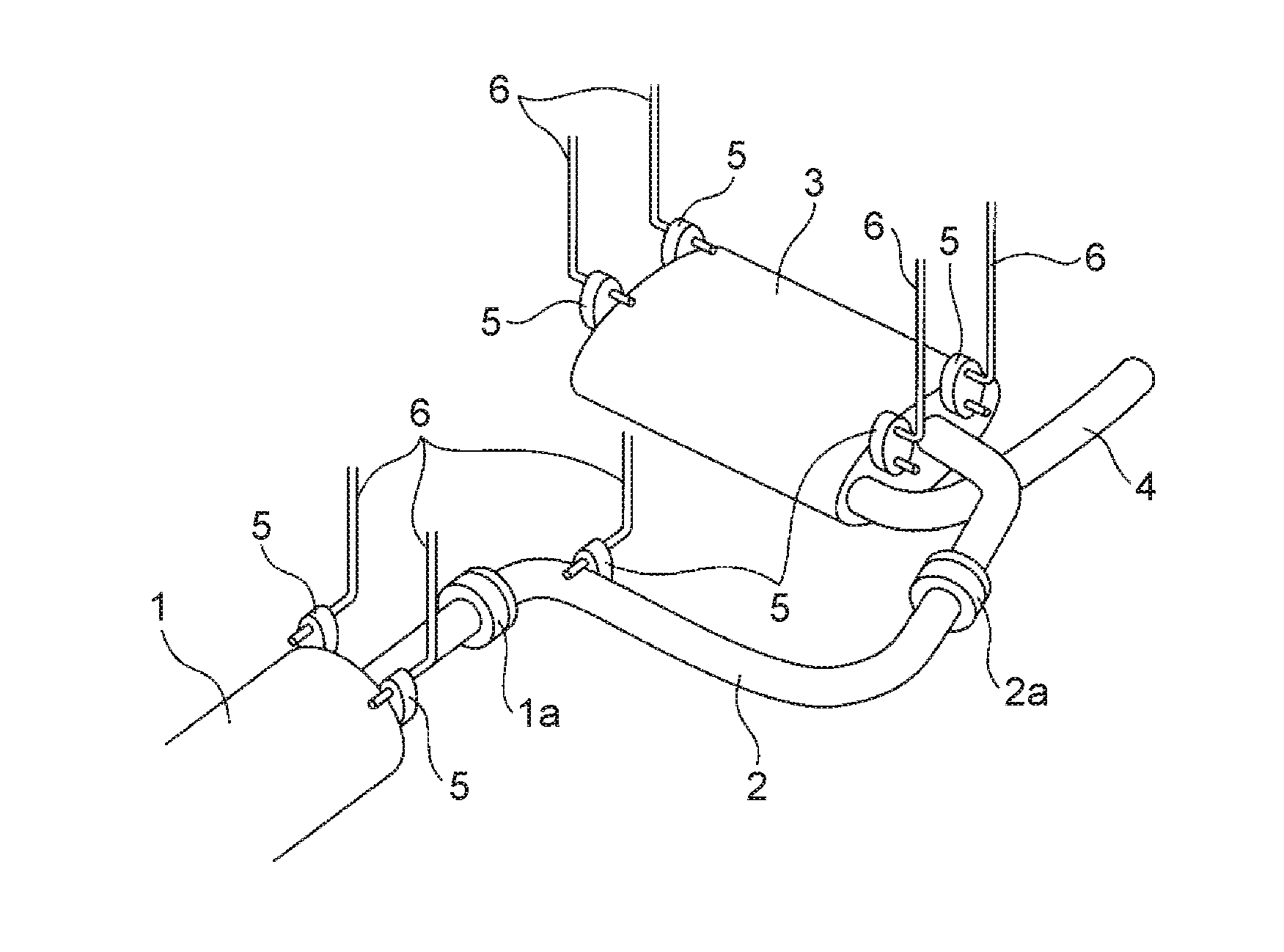

Pipe type static eliminator

InactiveCN1769761AImprove neutralization and elimination efficiencyPipeline systemsElectrostatic chargesElectricityPetroleum product

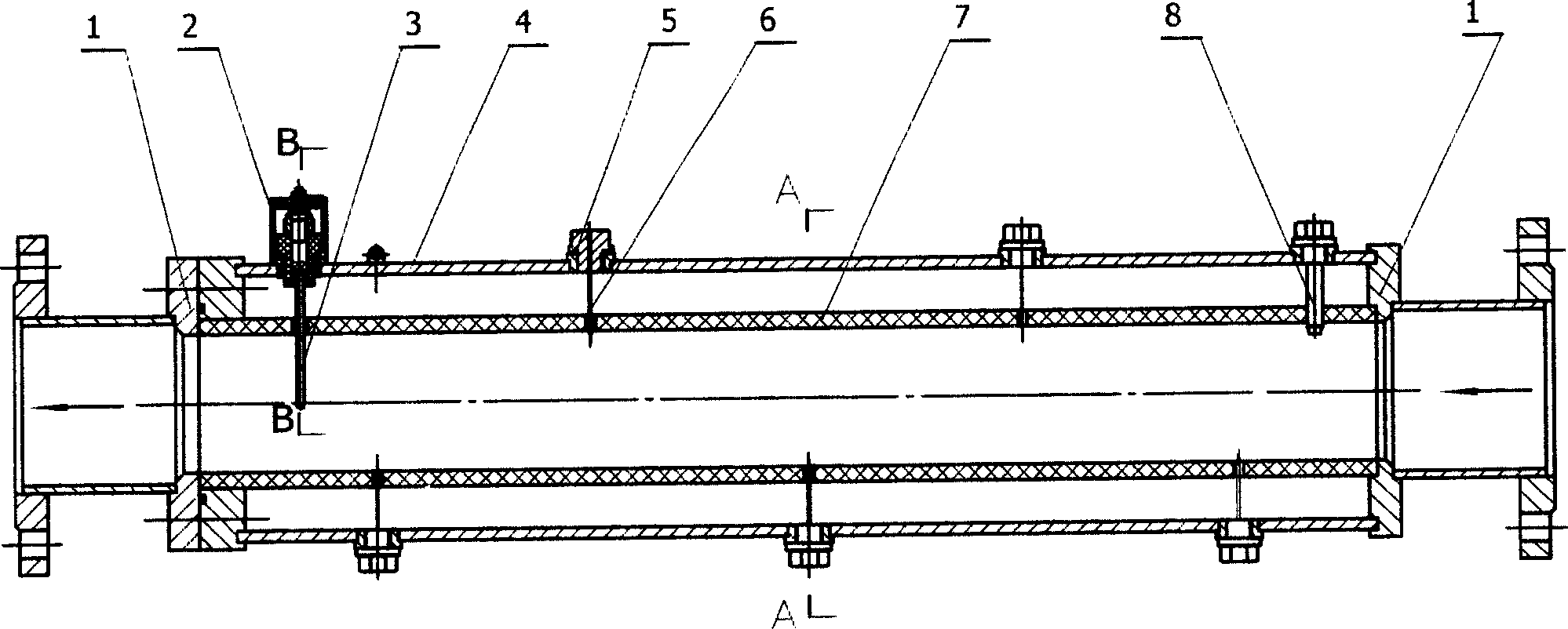

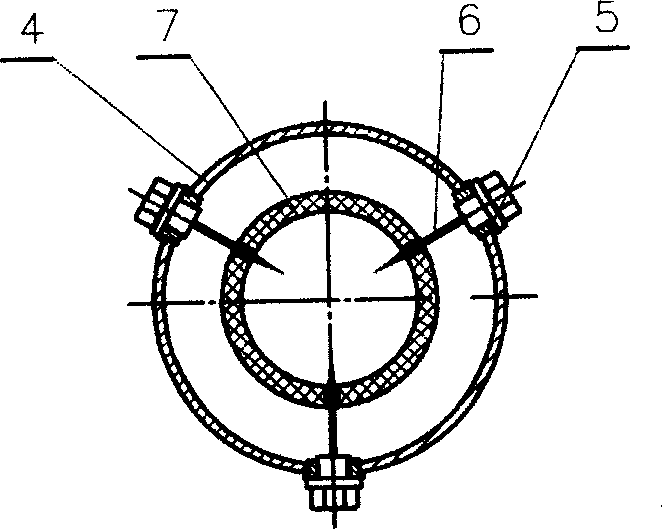

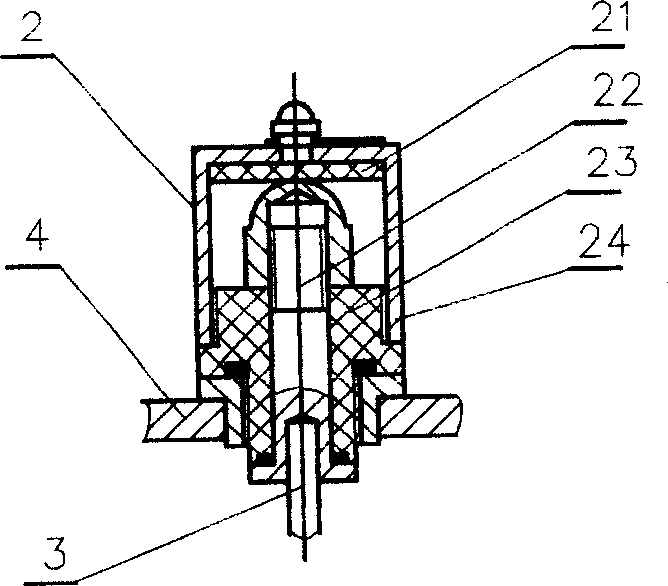

The invention discloses a pipe-type electrostatic eliminator of hydrocarbon liquid conveying system, which comprises the following parts: oil conveying pipe, erasing out-pipe, and erasing needle, wherein the erasing out-pipe is set beyond the oil conveying pipe at certain space, which is fixed on the conveying pipe with two ends supported by flange; the erasing needle is fixed on the erasing out-pipe, whose front plugs in the oil conveying pipe for 6-12 mm. The electrostatic monitor is set on the outlet side of electrostatic eliminator, which can monitor the eliminator working condition at random. The invention can eliminate the electrostatic charge of conveyed oil, which avoids the electrostatic accidents.

Owner:JIANGSU DONGQIANG

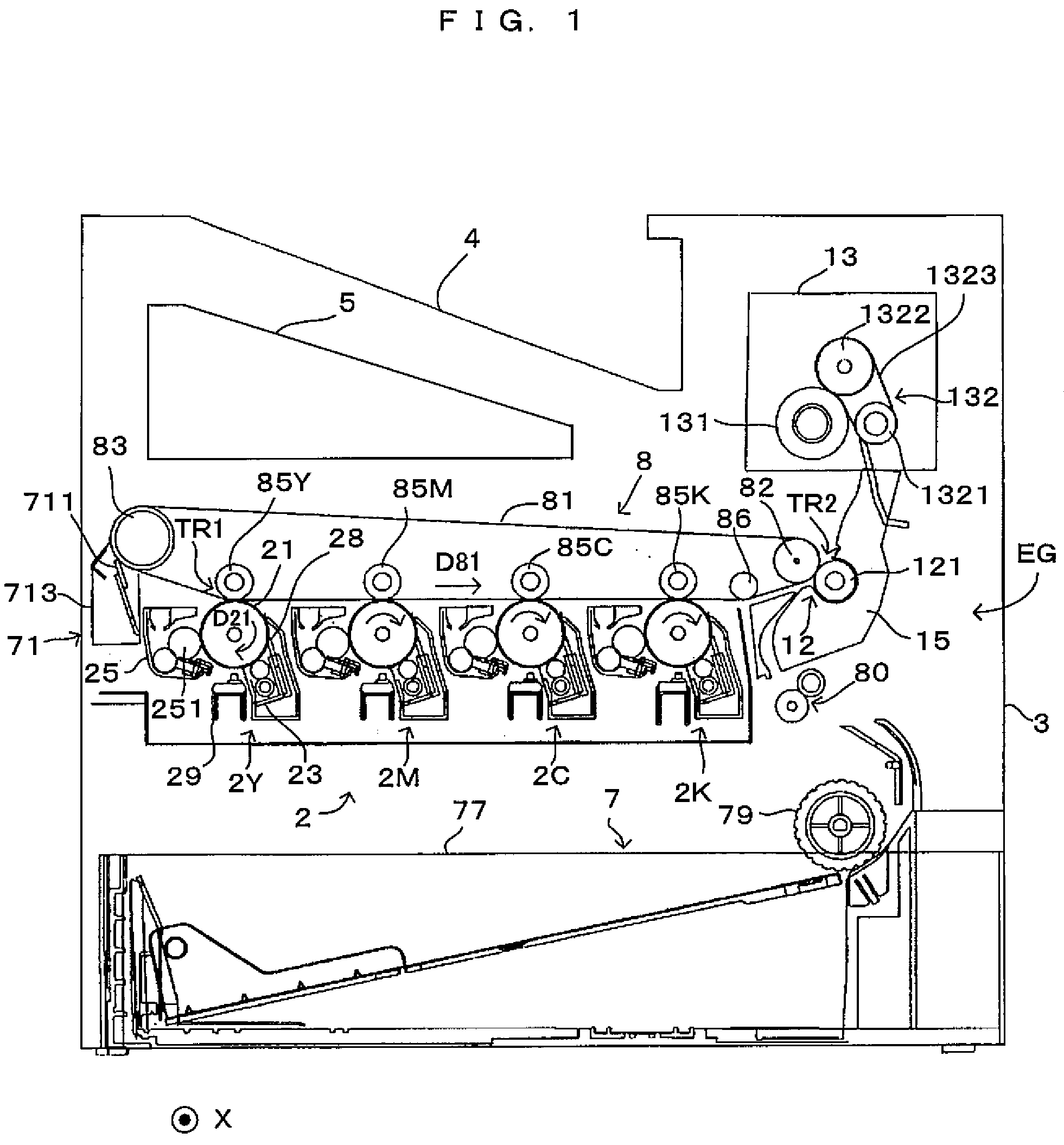

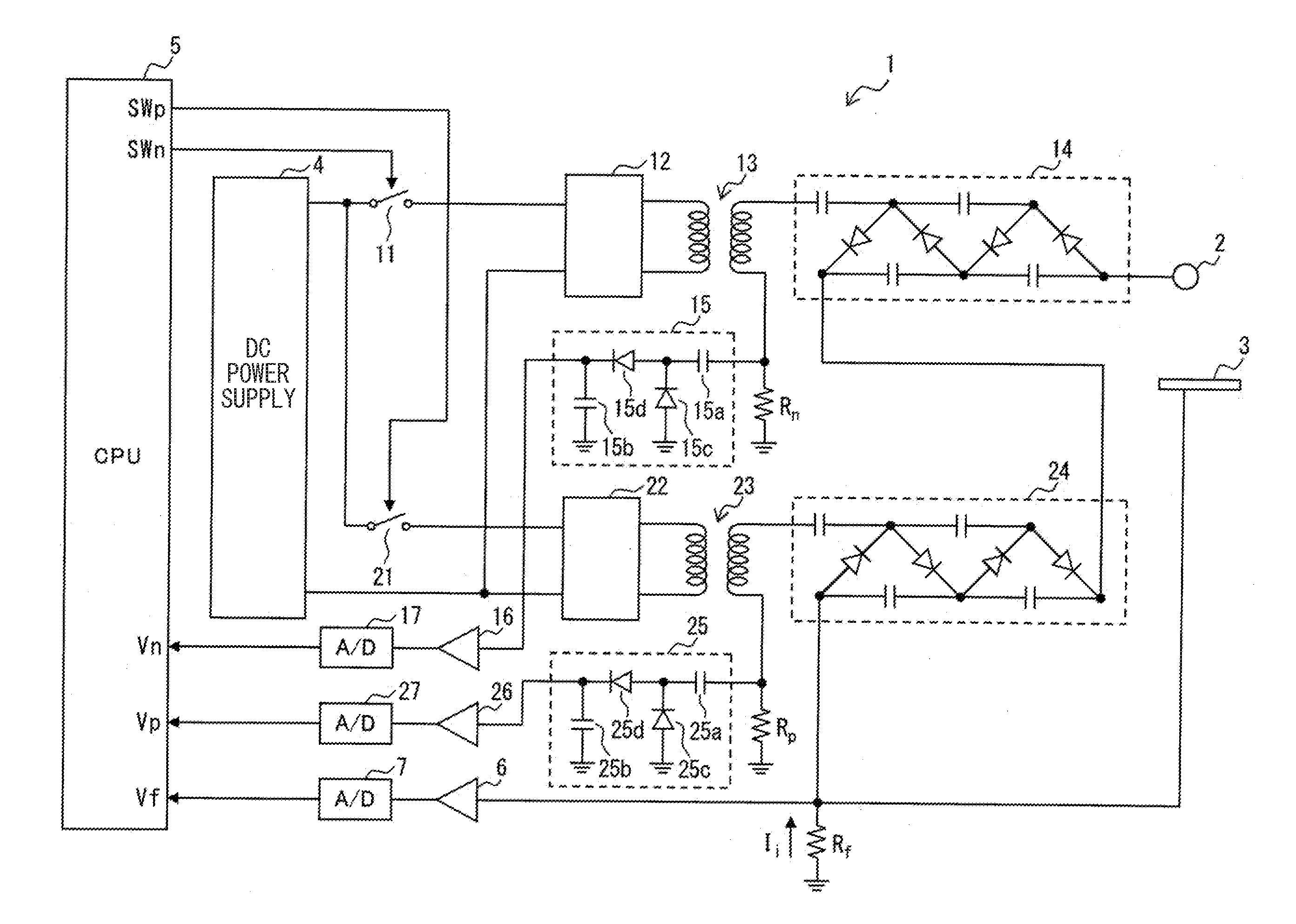

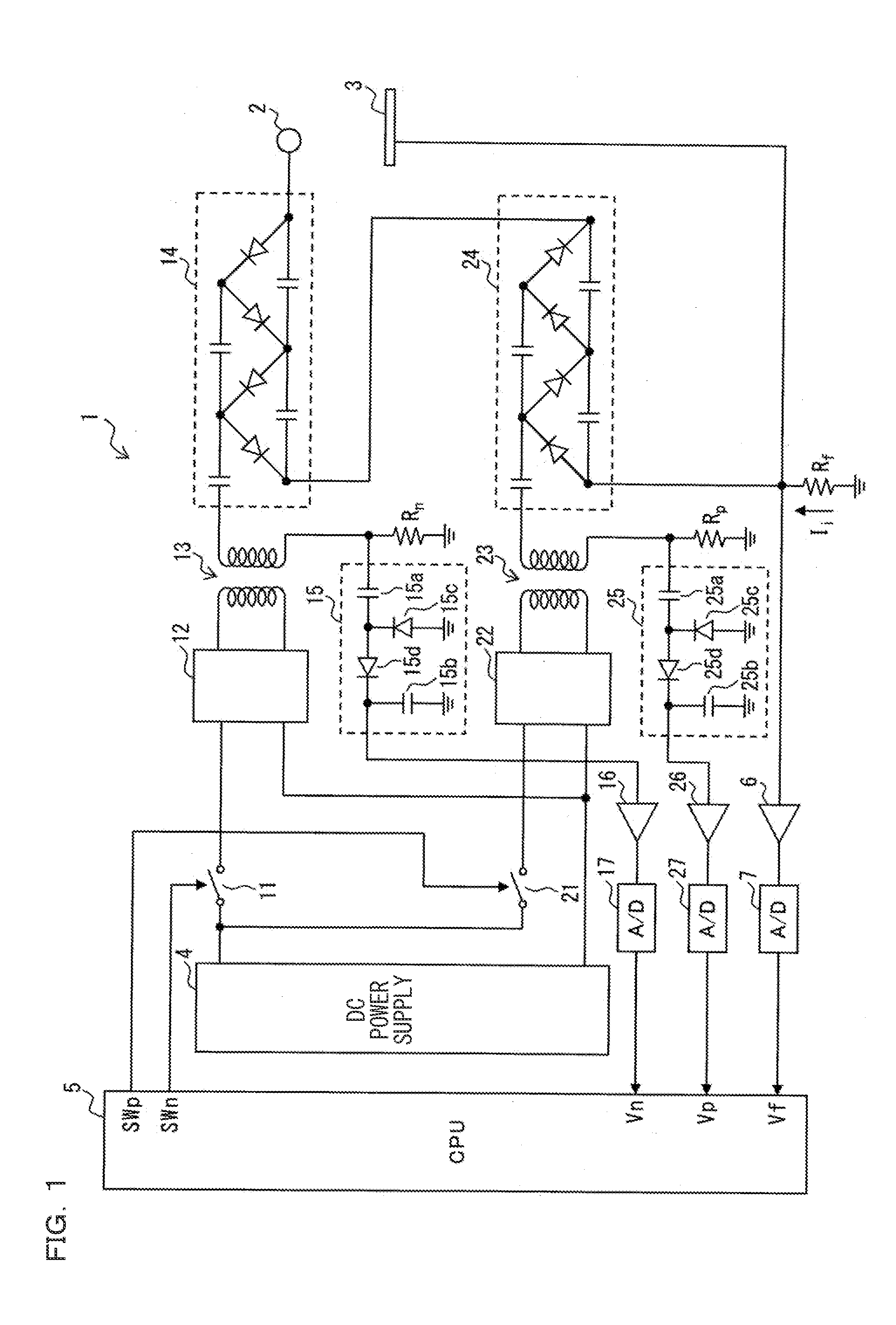

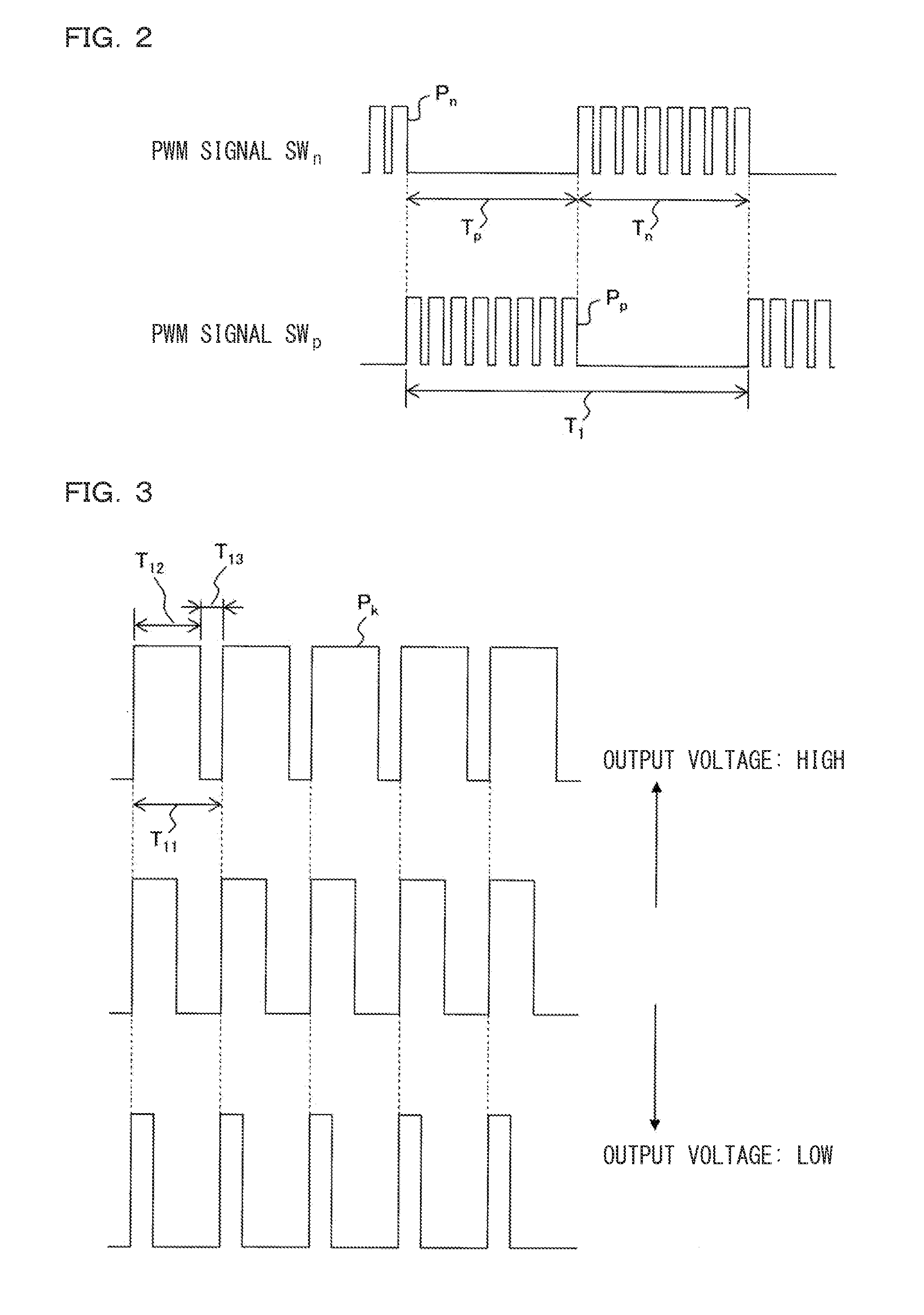

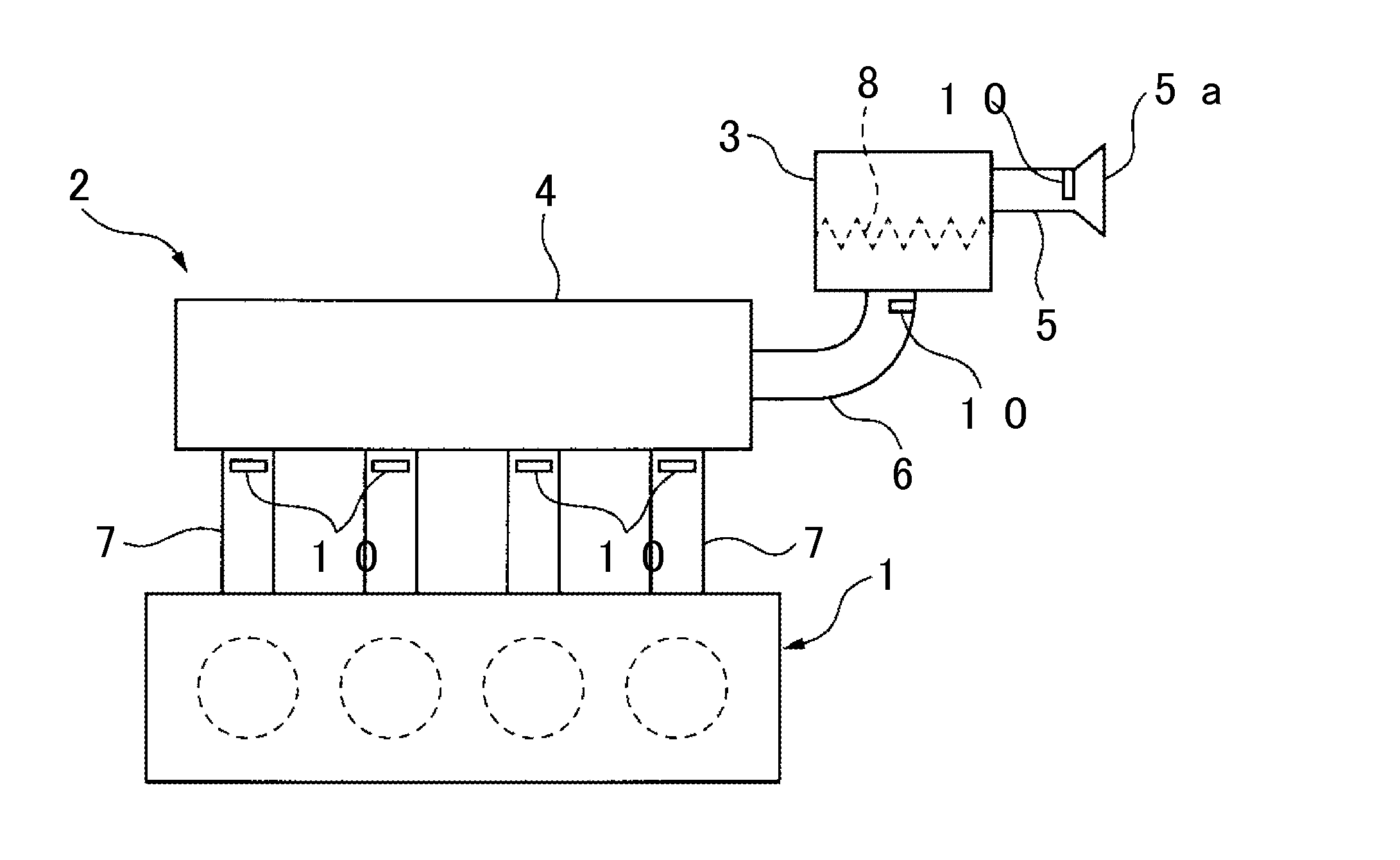

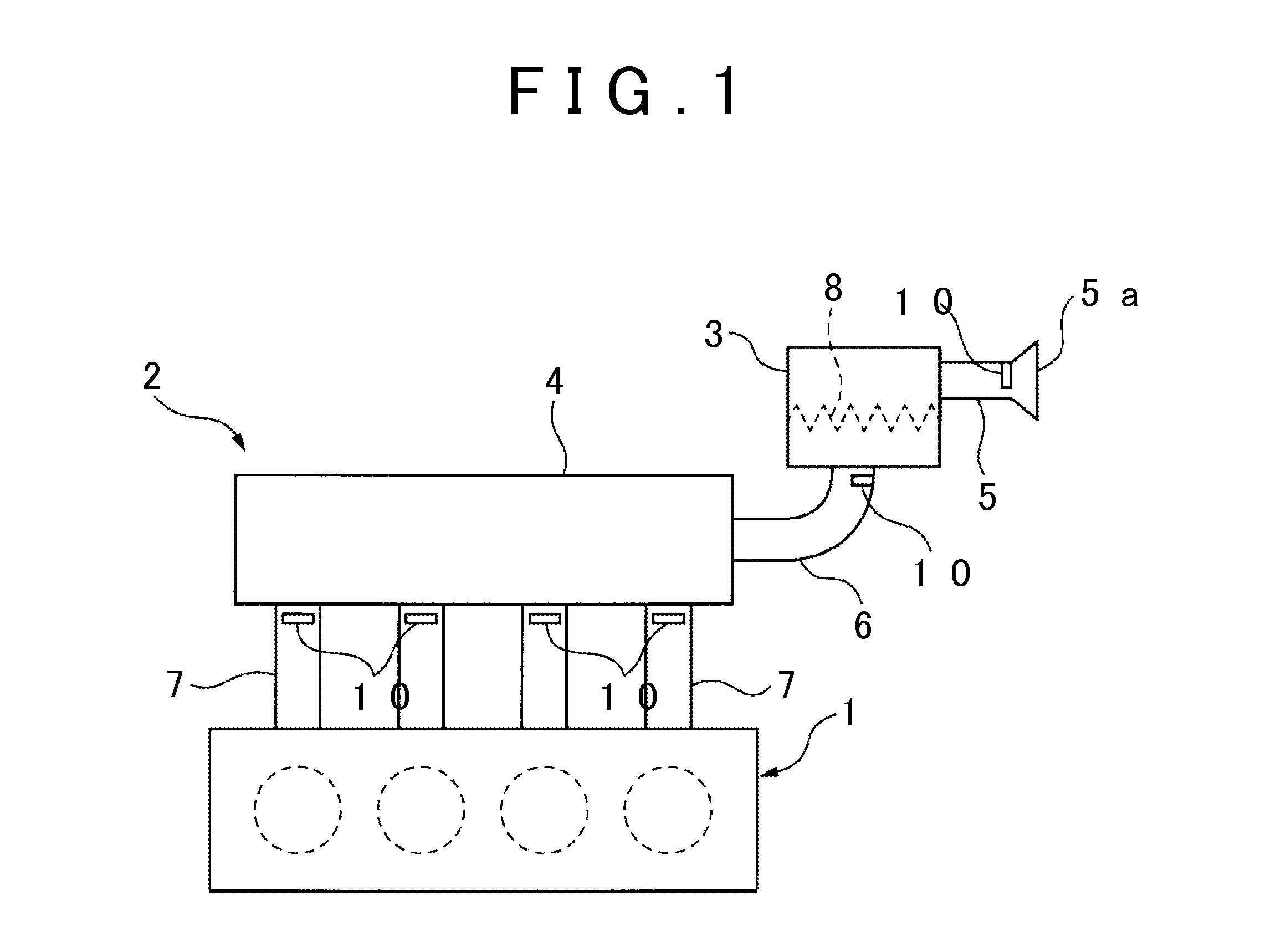

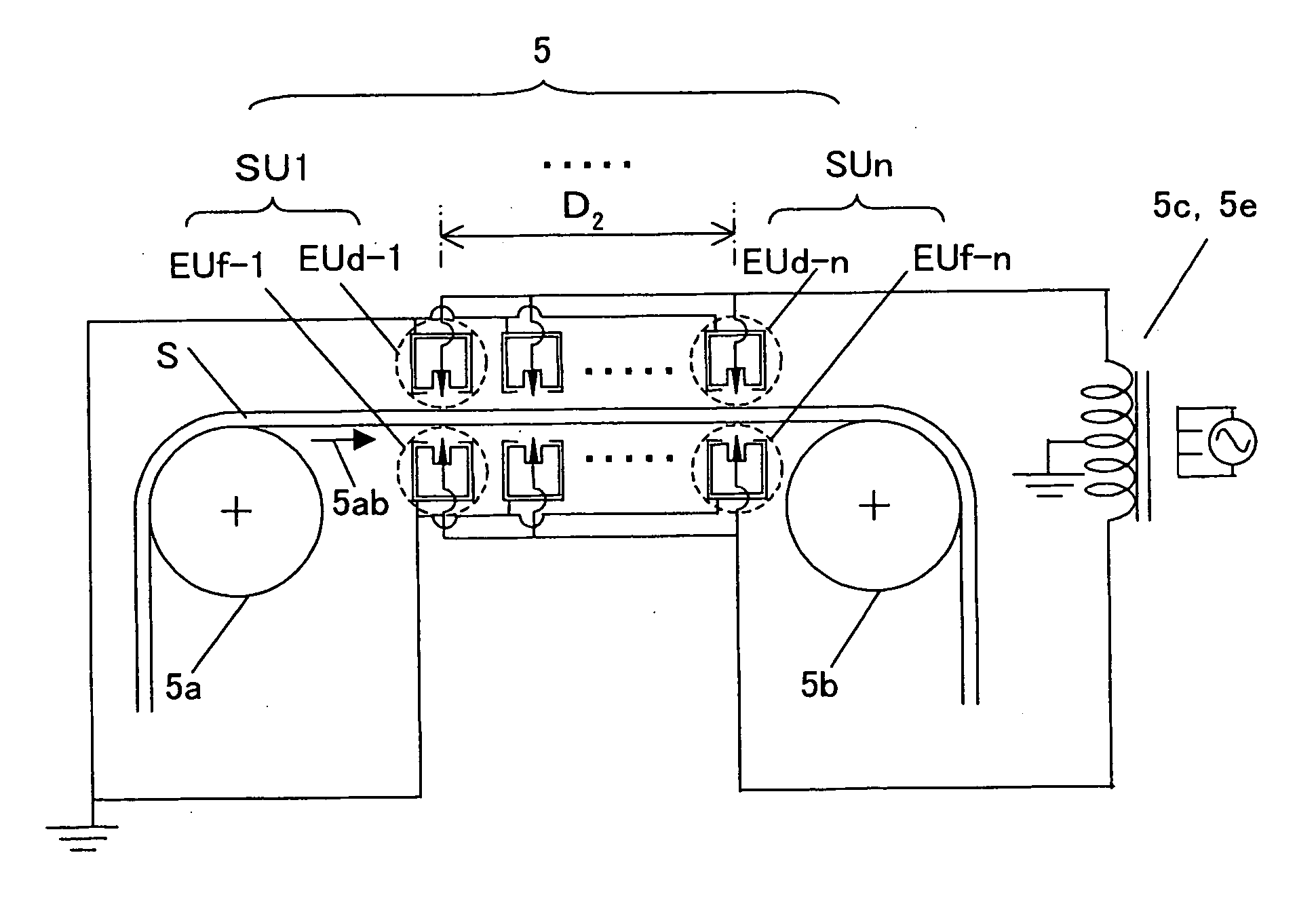

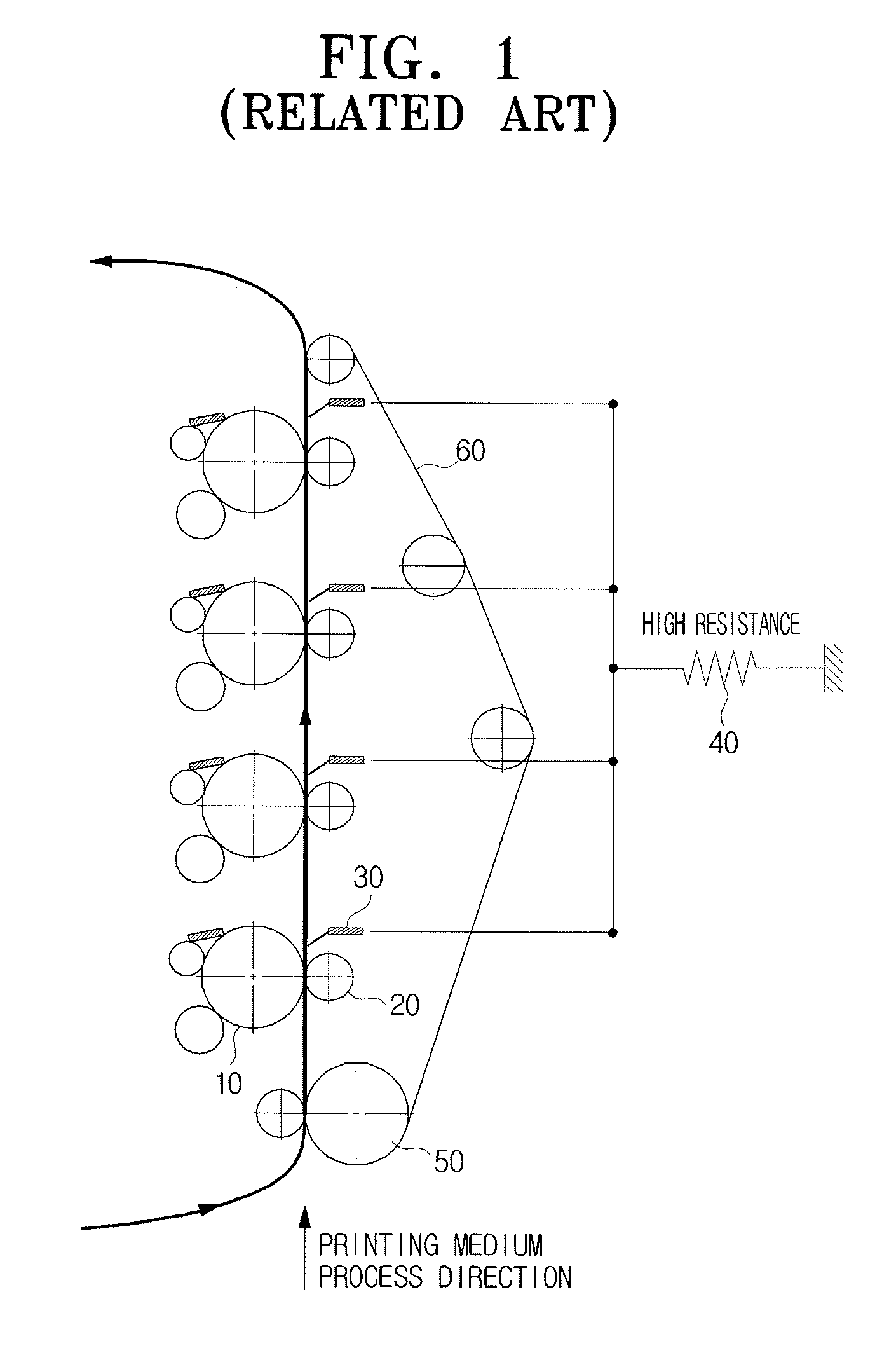

Image Forming Apparatus and Abnormality Determination Method for Such an Apparatus

InactiveUS20080085131A1Accurate detectionElectrographic process apparatusCorona dischargeLatent imageAC - Alternating current

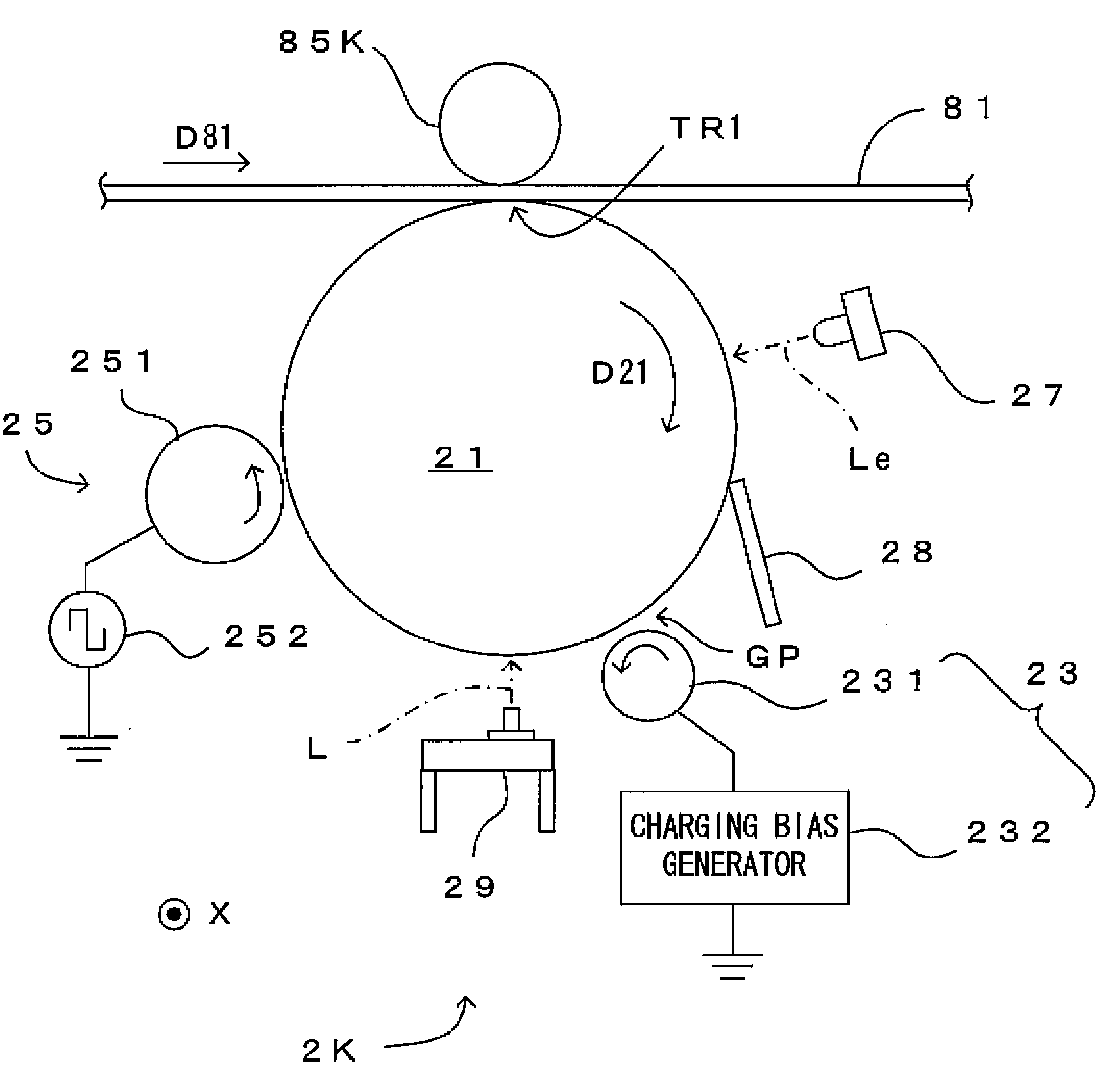

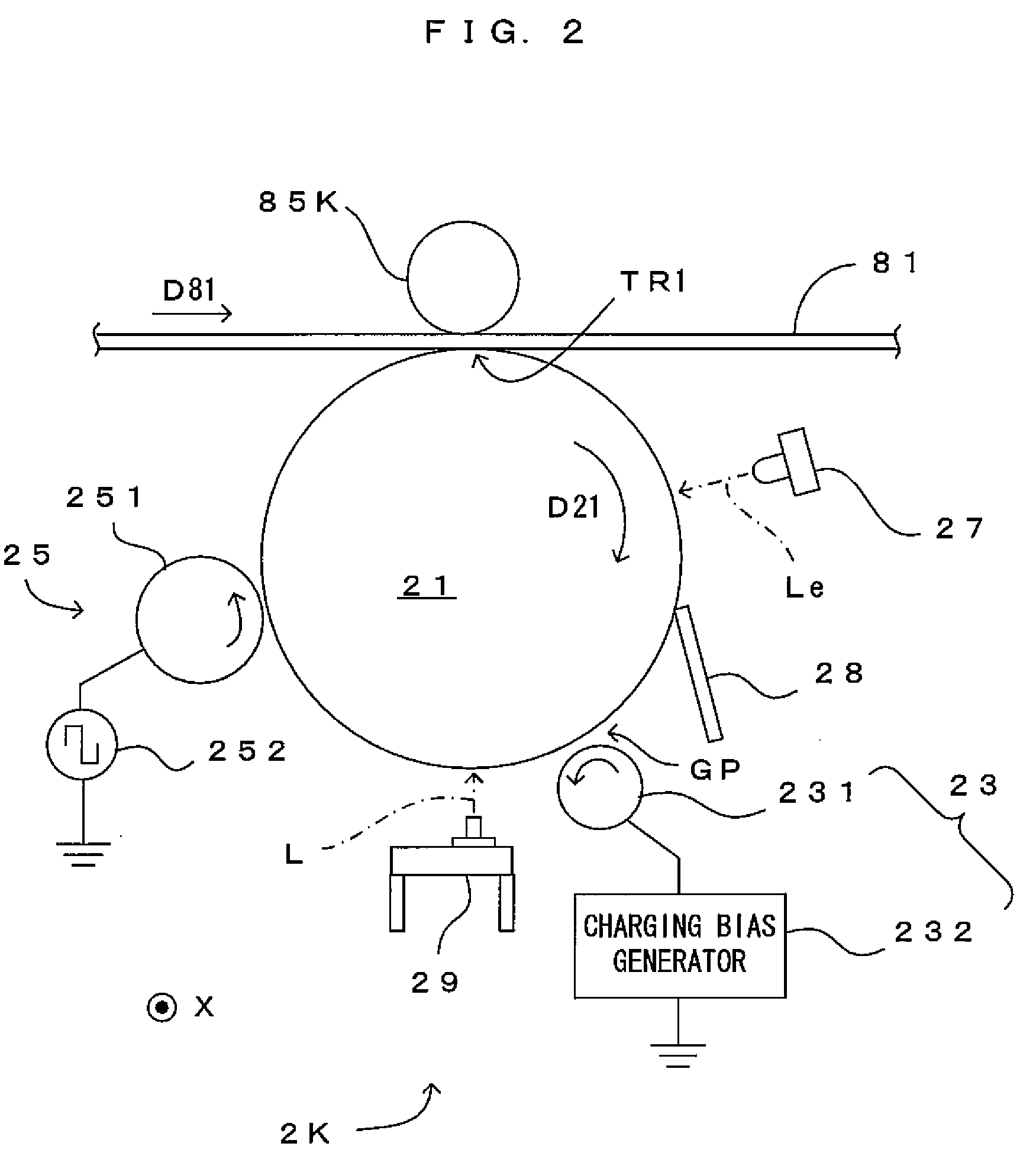

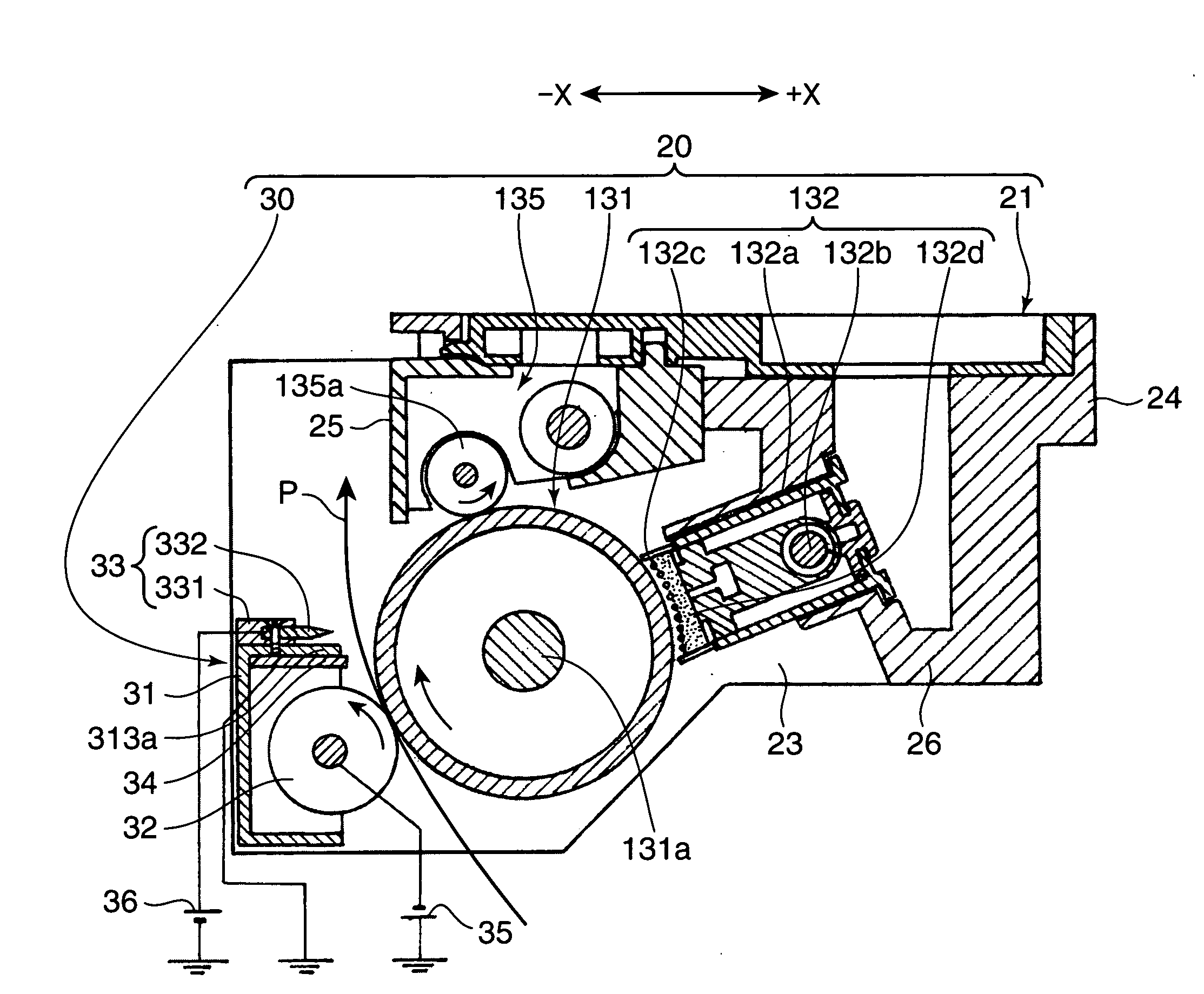

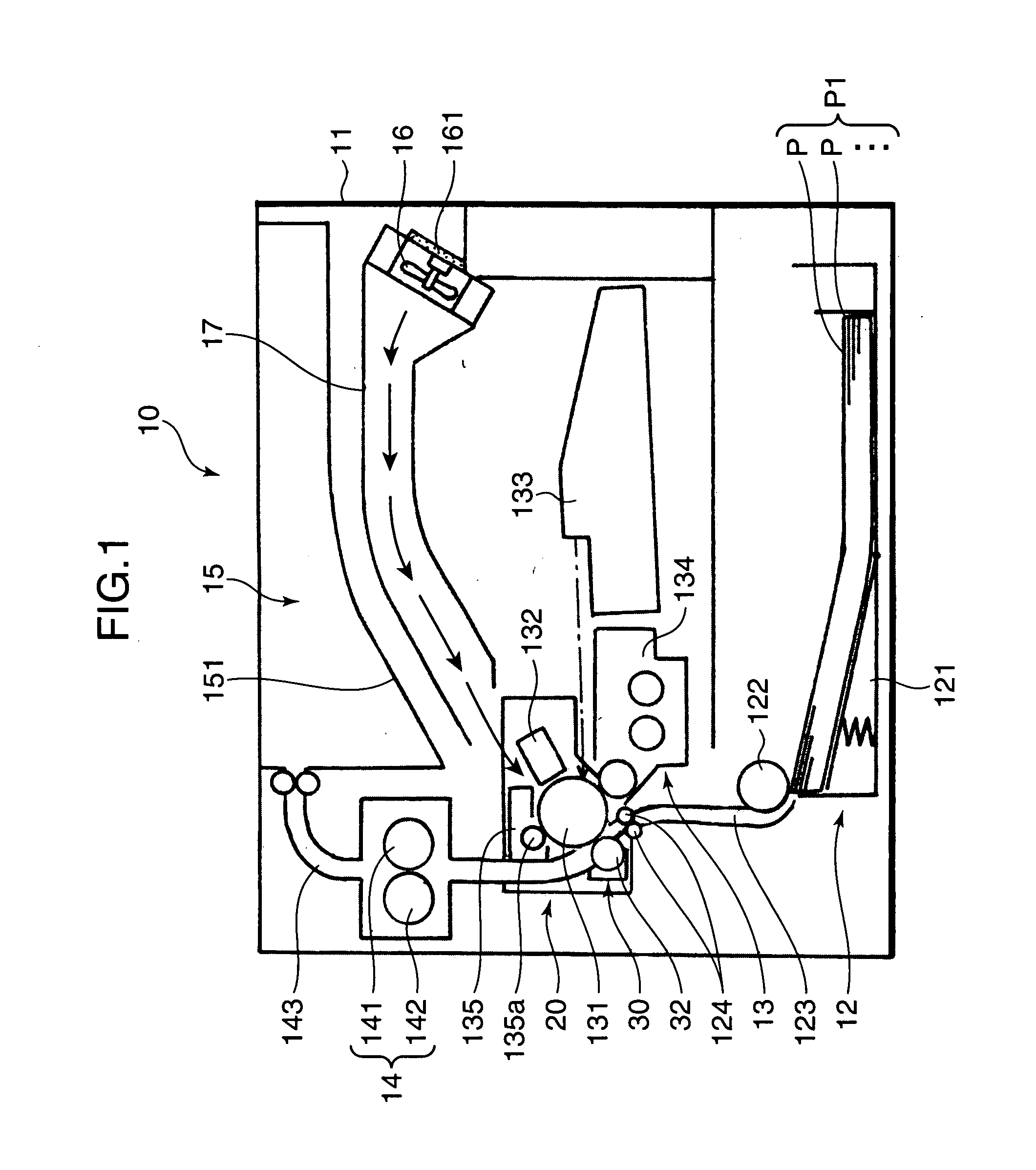

An image forming apparatus, includes: a plurality of image forming stations each including an electrostatic latent image carrier, a static eliminator that eliminates charges on the electrostatic latent image carrier, and a charging member that is arranged to face the electrostatic latent image carrier while defining a specified gap; a bias applicator that collectively applies charging bias voltages including alternating-current components to the charging members provided in collective bias image forming stations, the collective bias image forming stations being at least two of the plurality of image forming stations; a current sensor that collectively detects currents flowing in the charging members provided in the respective collective bias image forming stations; and a detector that detects an abnormal discharge in the gap between the electrostatic latent image carrier and the charging member based on a current detection result by the current sensor, wherein the detector selects one of the collective bias image forming stations as a selected image forming station, and determines presence or absence of the abnormal discharge in the gap between the electrostatic latent image carrier and the charging member in the selected image forming station based on the current detection result by the current sensor when the bias applicator applies the charging bias voltages to the charging members in the respective collective bias image forming stations while causing the static eliminator provided in the selected image forming station to operate and causing the static eliminators provided in the collective bias image forming stations other than the selected image forming station to stop operating.

Owner:SEIKO EPSON CORP

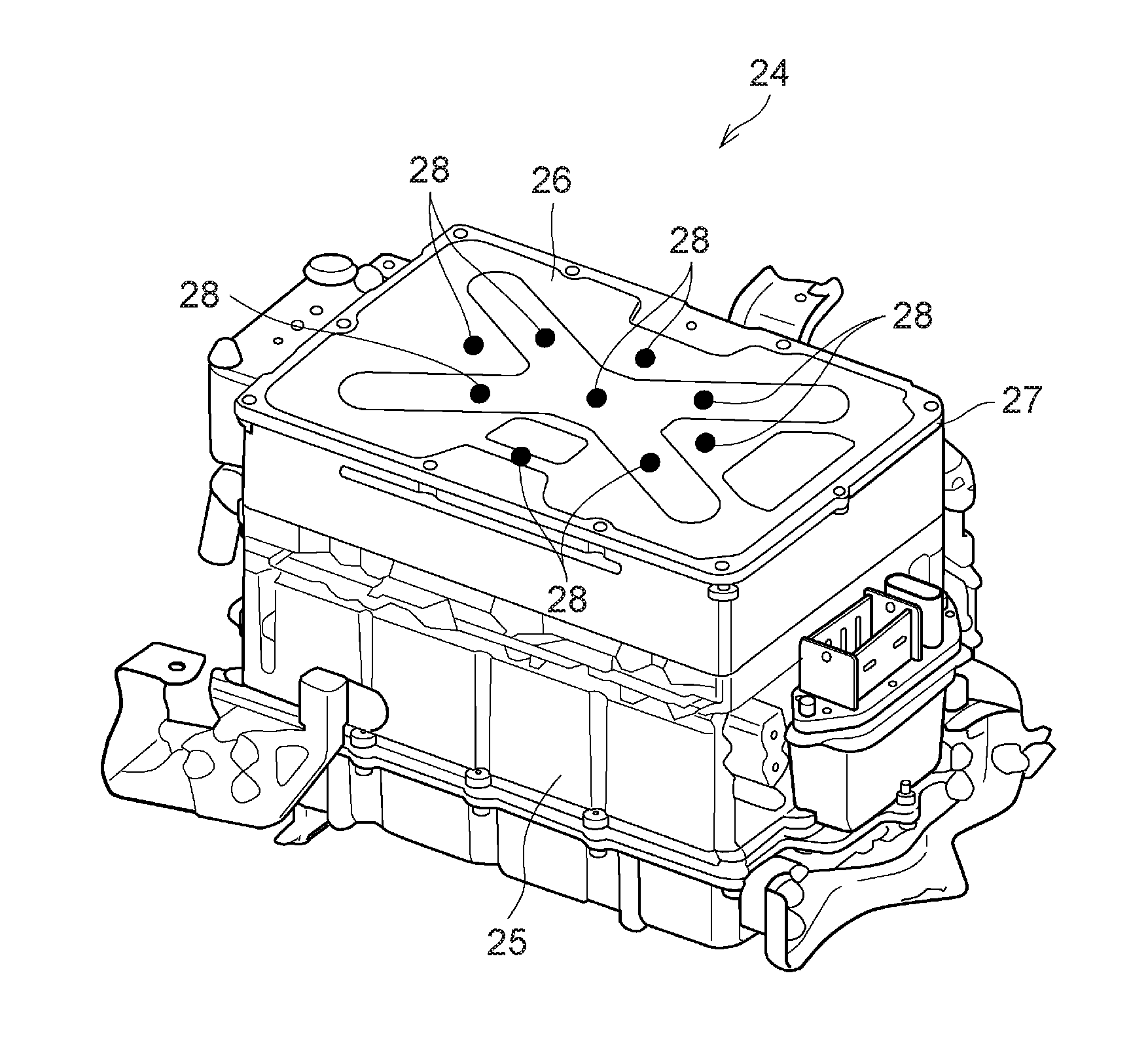

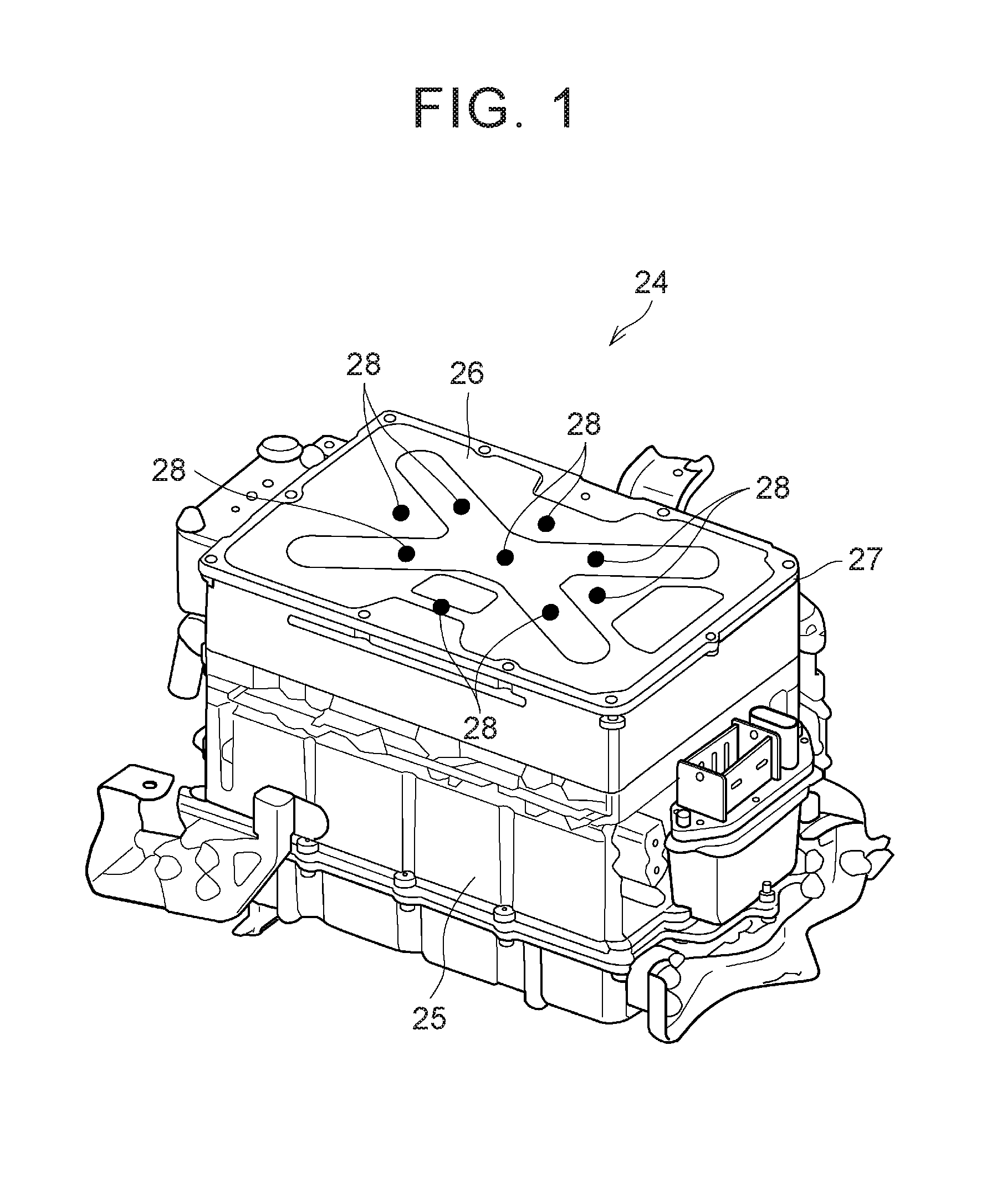

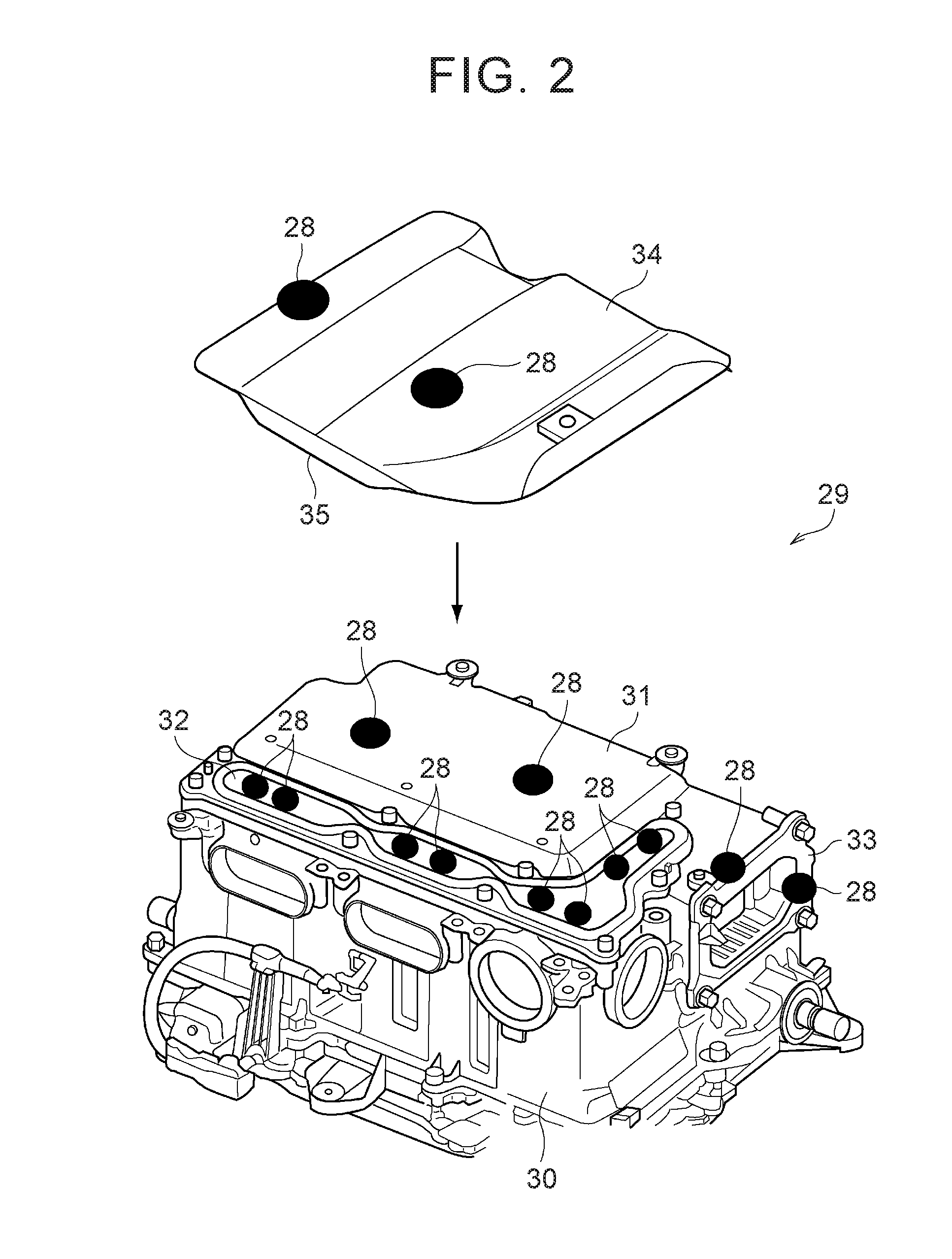

Vehicle

ActiveUS20160200270A1Lower performance requirementsSuppress mutationFinal product manufactureConversion constructional detailsElectric power systemDrive motor

A vehicle includes a power control unit having at least one of an inverter and a converter, a drive motor that produces torque for running the vehicle when electric power is supplied from the power control unit to the drive motor, a vehicle body kept insulated from a road surface, a case main body in which the power control unit is housed, a member that is connected to the case main body where the member is insulated from the case main body, or in a condition in which electric resistance is large, and a static eliminator that neutralizes and eliminates positive charges on the member and lowers a positive potential of the member, by self-discharge for producing negative air ions in outside air according to the positive potential of the member that is electrostatically charged.

Owner:TOYOTA JIDOSHA KK

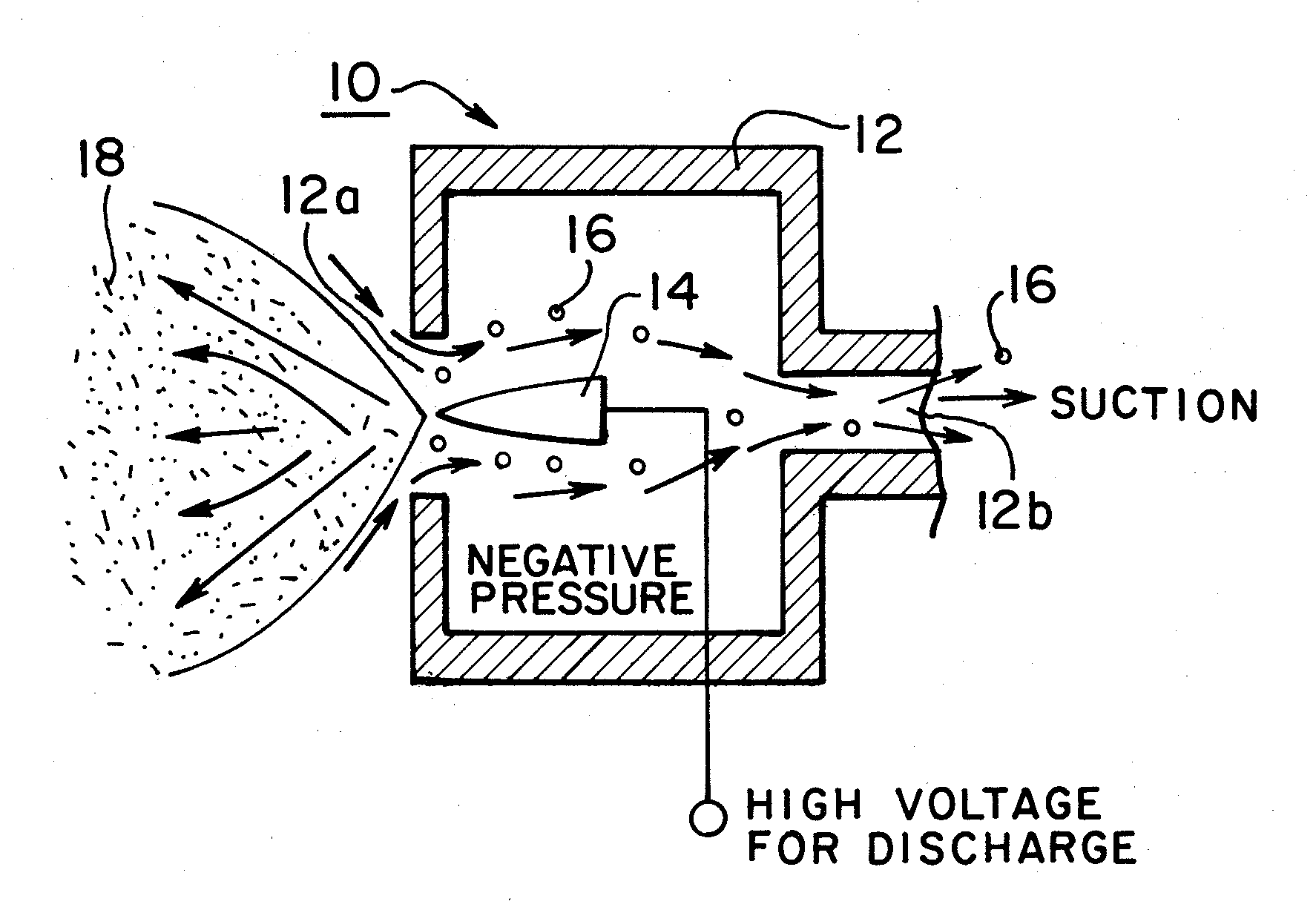

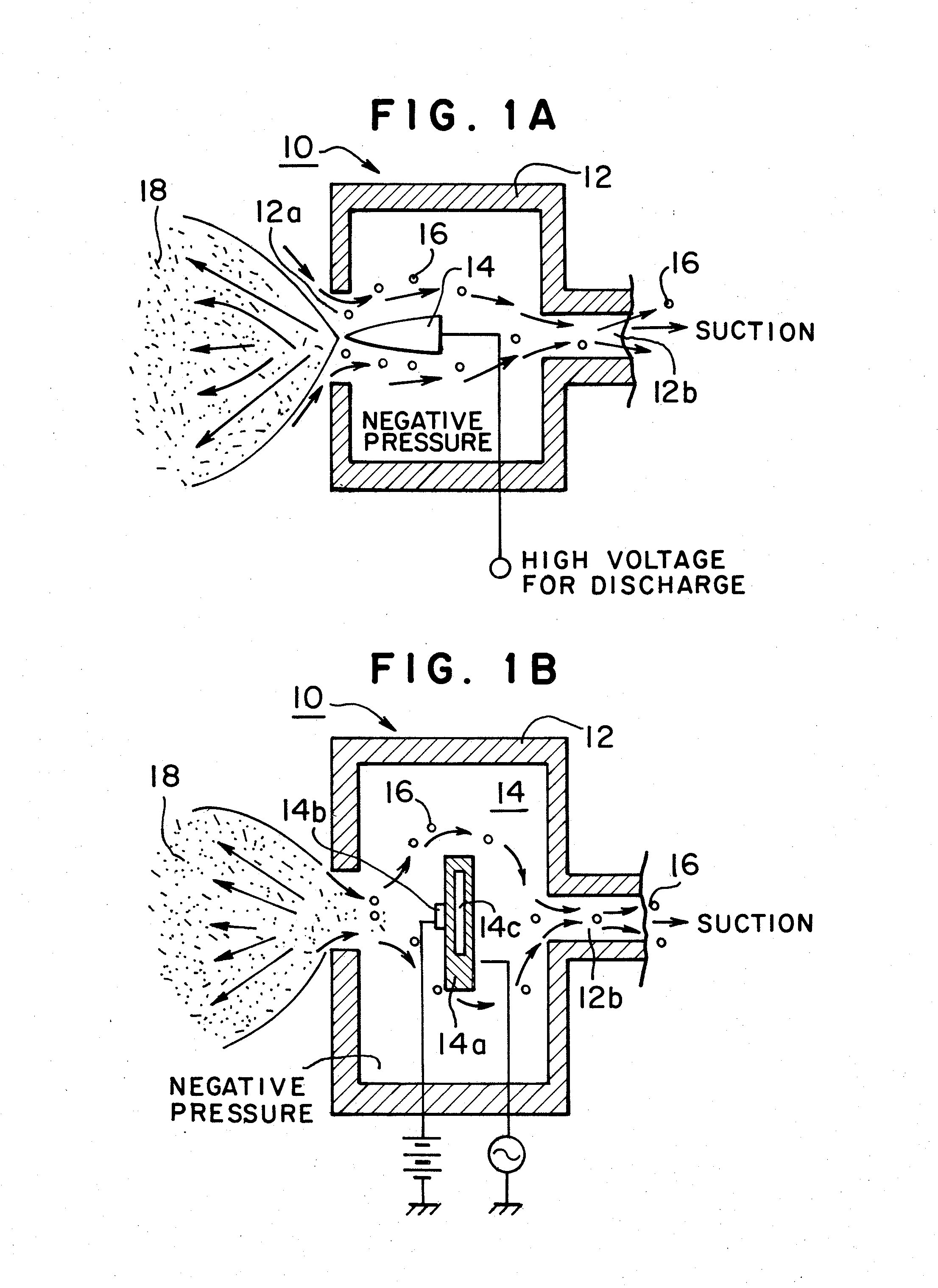

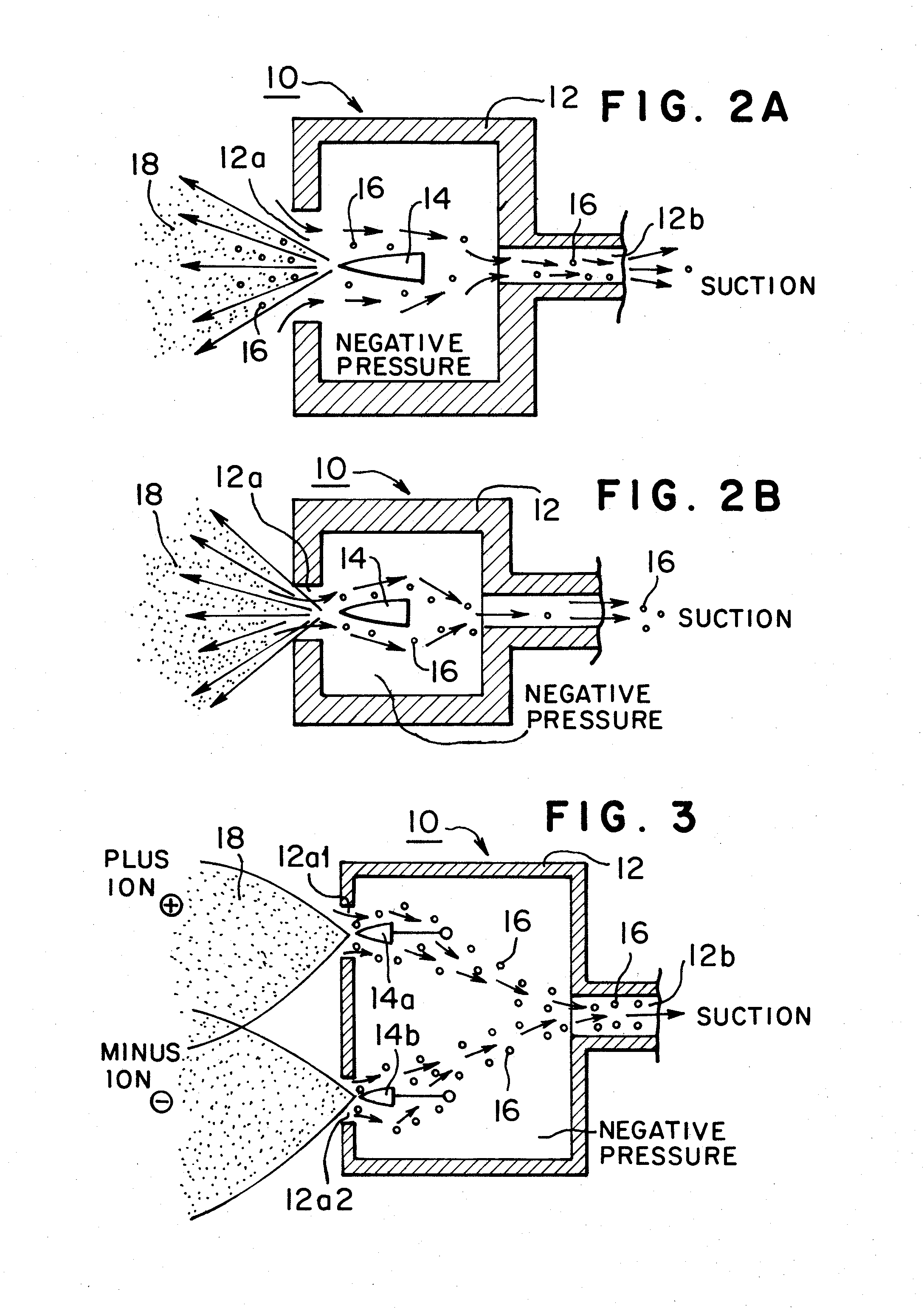

Ozone-less static eliminator

InactiveUS20100128408A1Avoid polluting the environmentElectrographic process apparatusCorona dischargeElectric dischargeOptoelectronics

A static eliminator comprises an electric discharge portion, and a case in which the discharge portion for emitting ions in front thereof is disposed. The case includes an ion emitting opening and an ozone, etc suction opening. The ozone, etc generated in the discharge portion is sucked through the ozone, etc suction opening resulting in sucking air from the ion emitting opening in a direction opposite to that of ion emission through the ion emitting opening.

Owner:TRINC

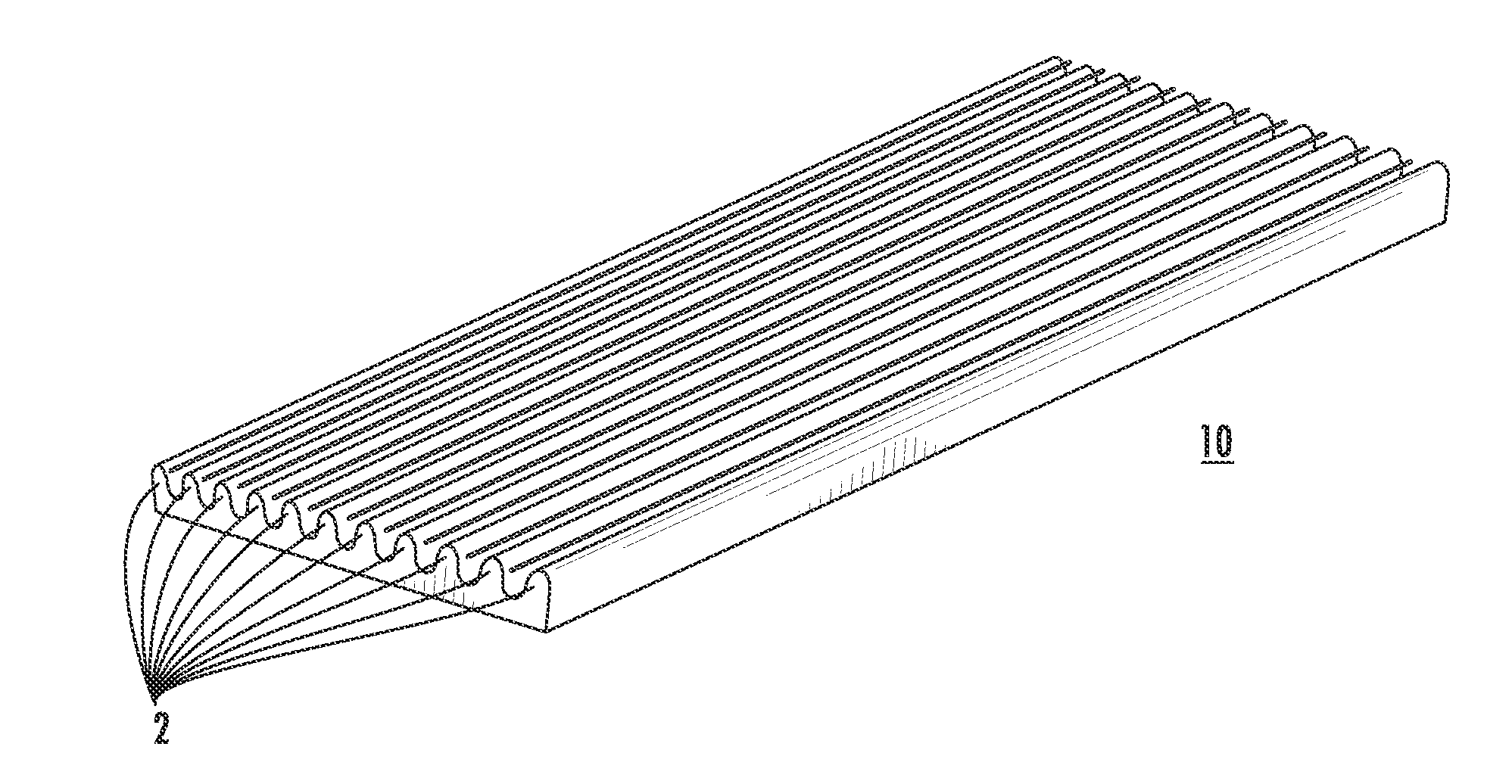

Protective ionizing surface for eliminating static

ActiveUS7684169B1Efficiently eliminates staticEliminates static without wearing out or being abradedElectrostatic chargesStatic eliminatorsBiomedical engineering

The present invention relates to a protective ionizing device, or protective static eliminator, and methods, systems, apparatus and kits using the device. The device has a surface having a series of (e.g., one or more) grooves or gaps, each groove defines a space; and a multiplicity of ionizing points suspended in the space, just below the upper surface of the device. The ionizing points can be suspended on braided microfibers, on an extruded surface in the groove, on an elastic cord, or on a wire core.The device is useful for the efficient elimination of static charge build-up on a surface of insulative material while maintaining and protecting the ionizing points.

Owner:ALPHA INNOVATION

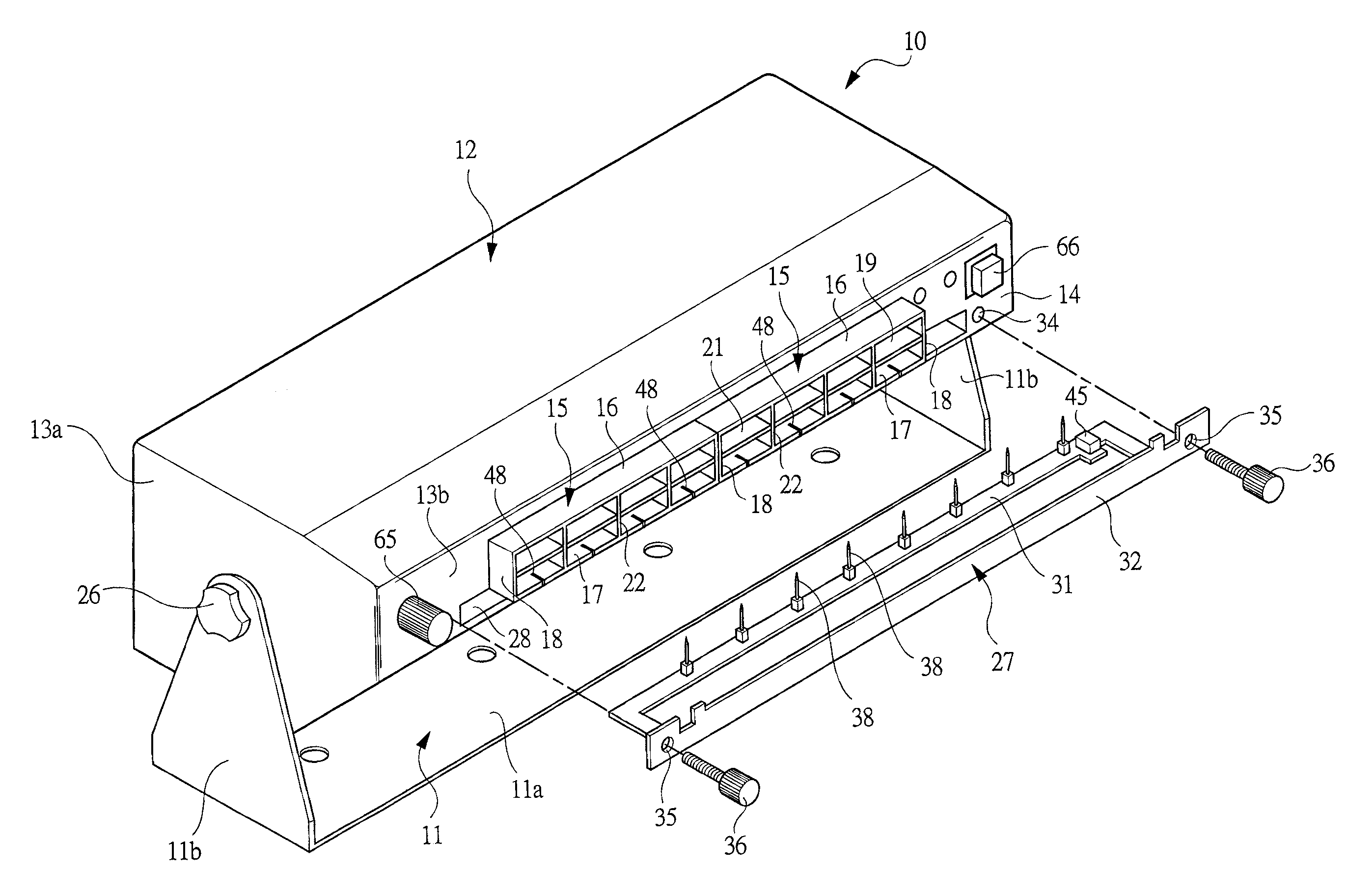

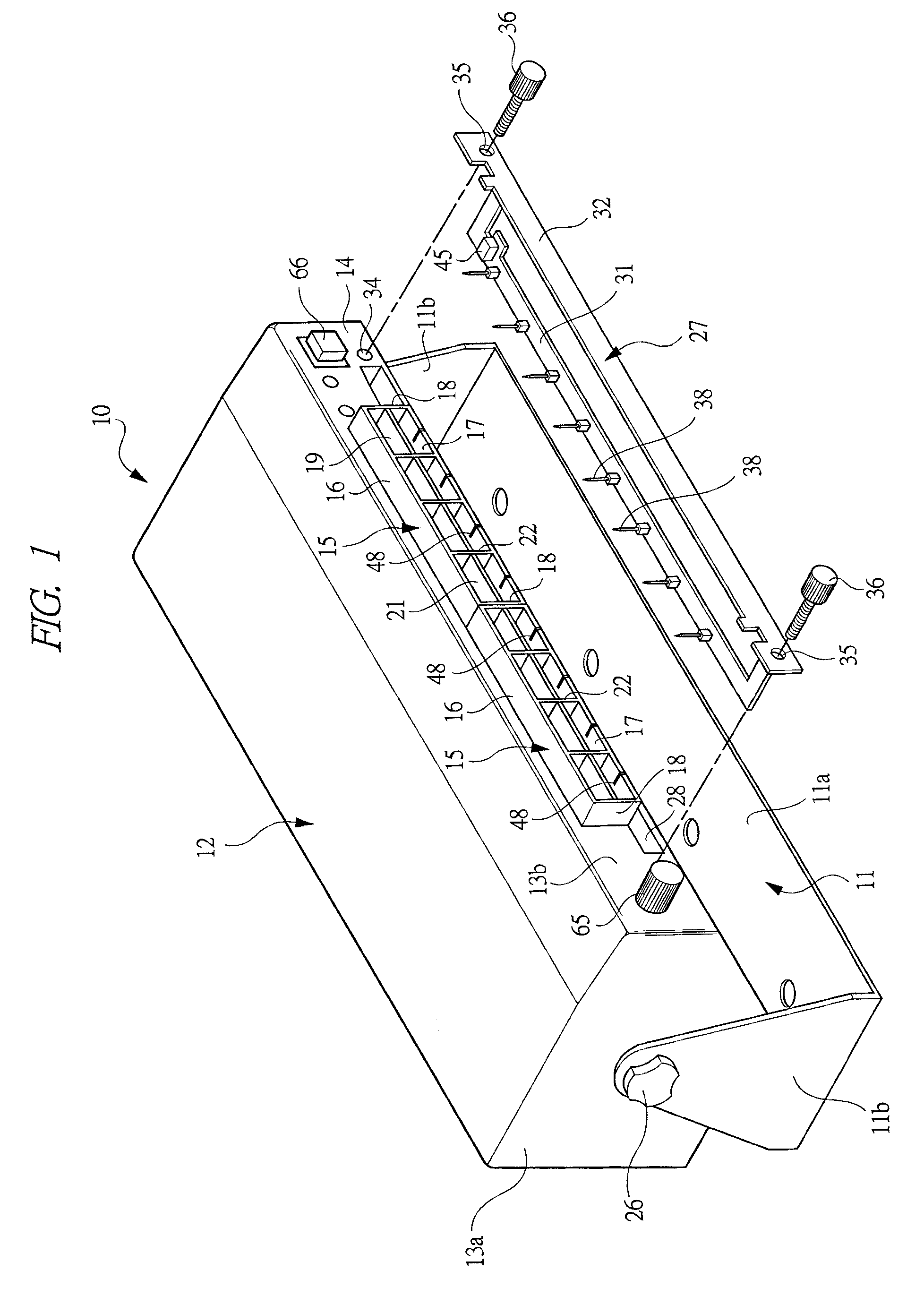

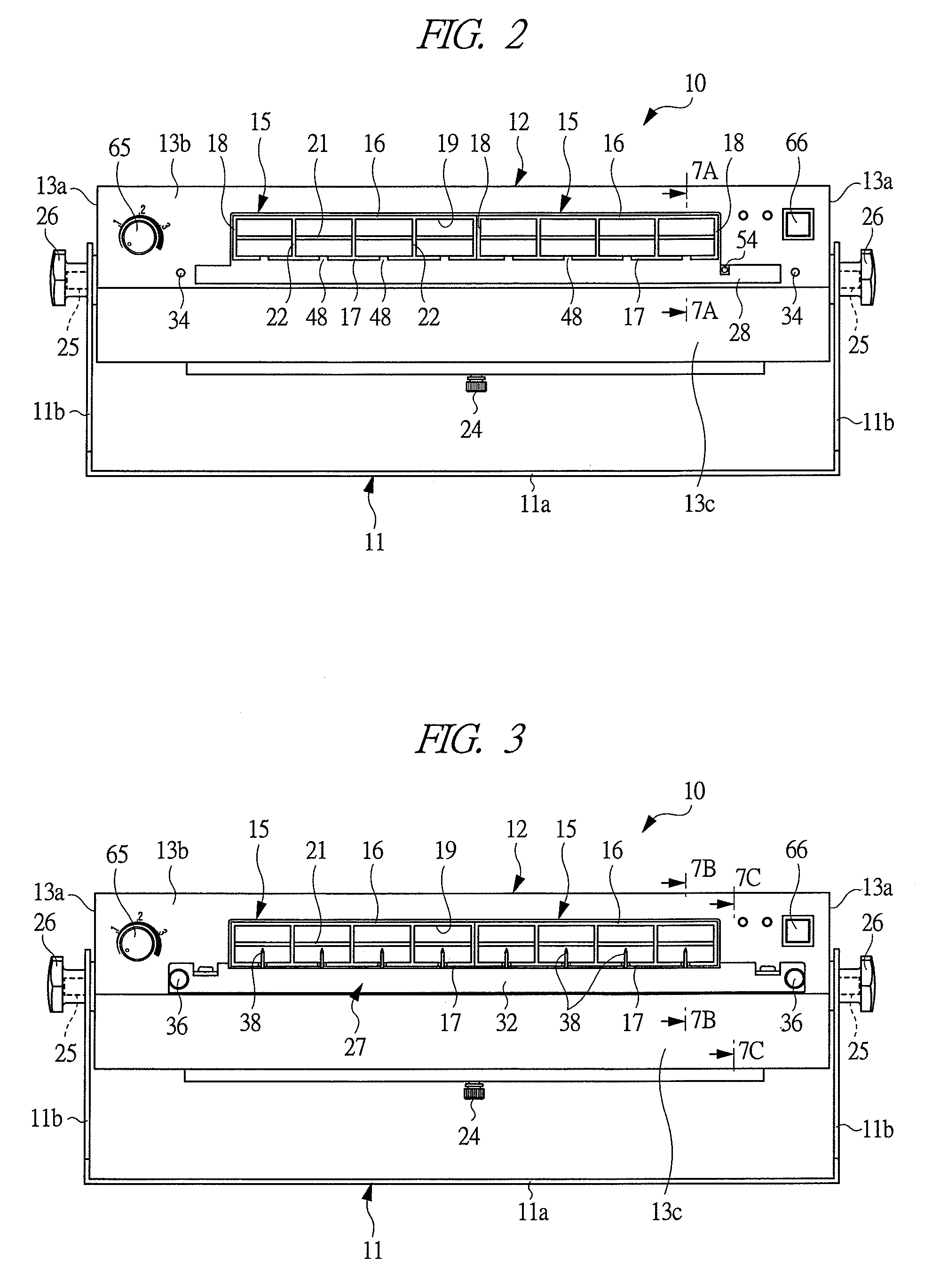

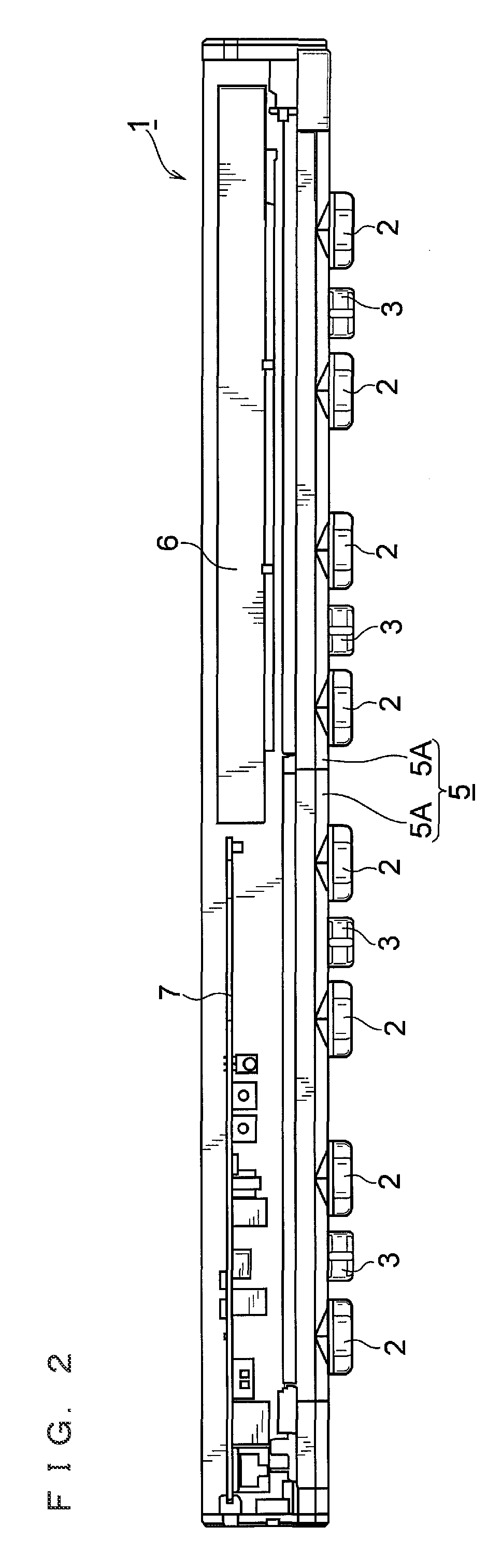

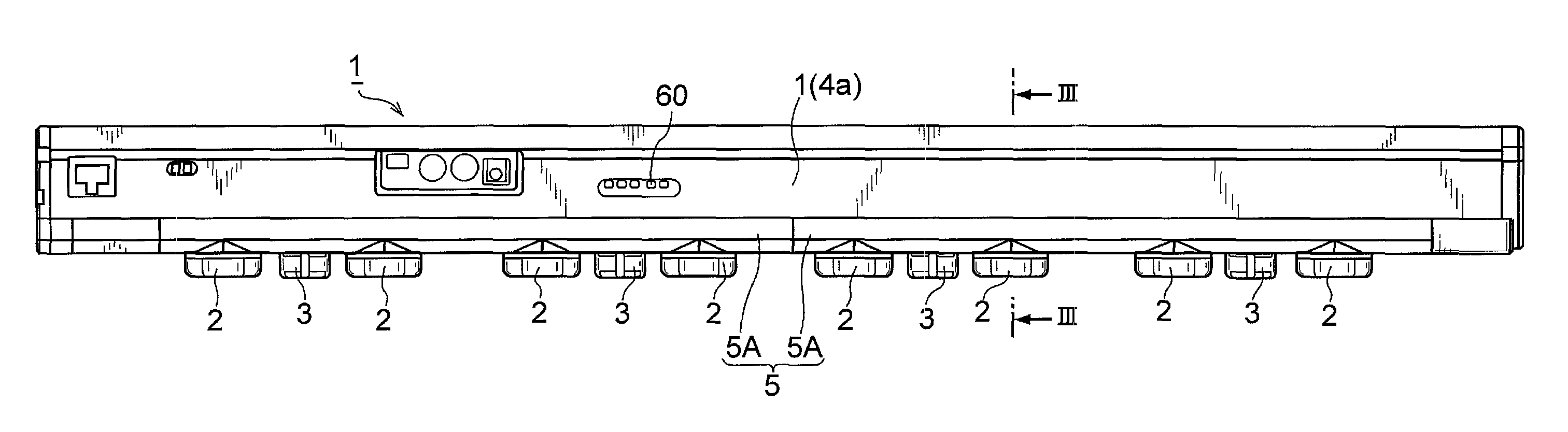

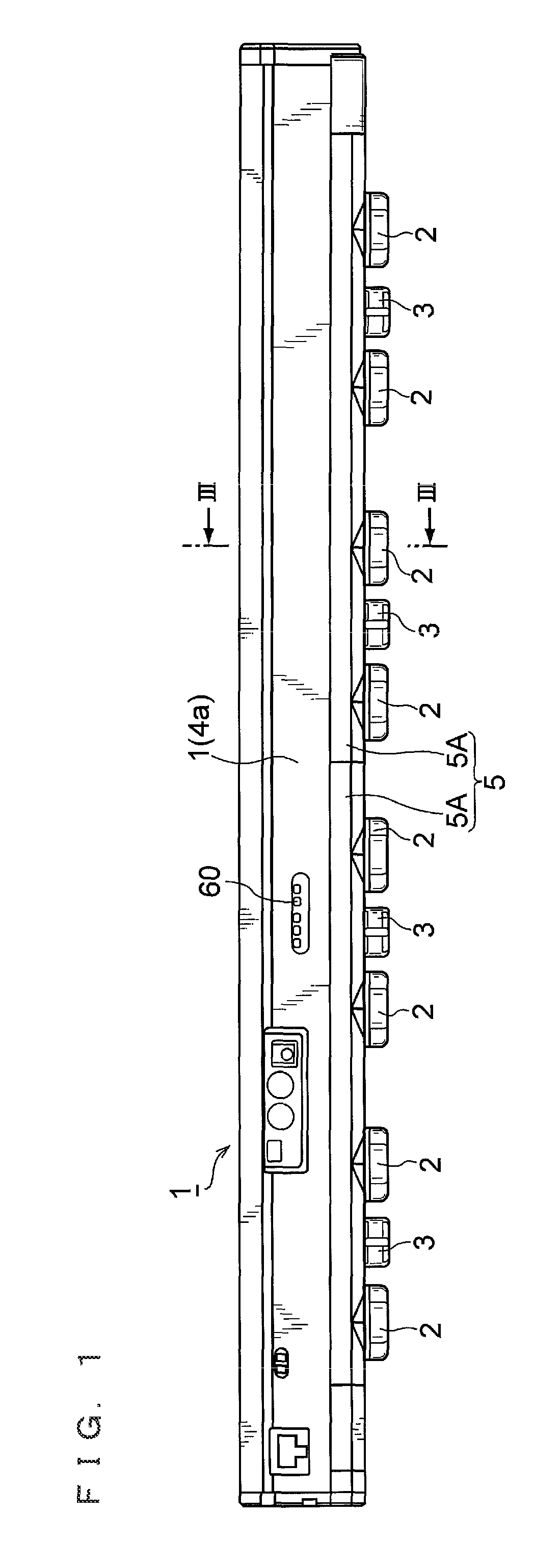

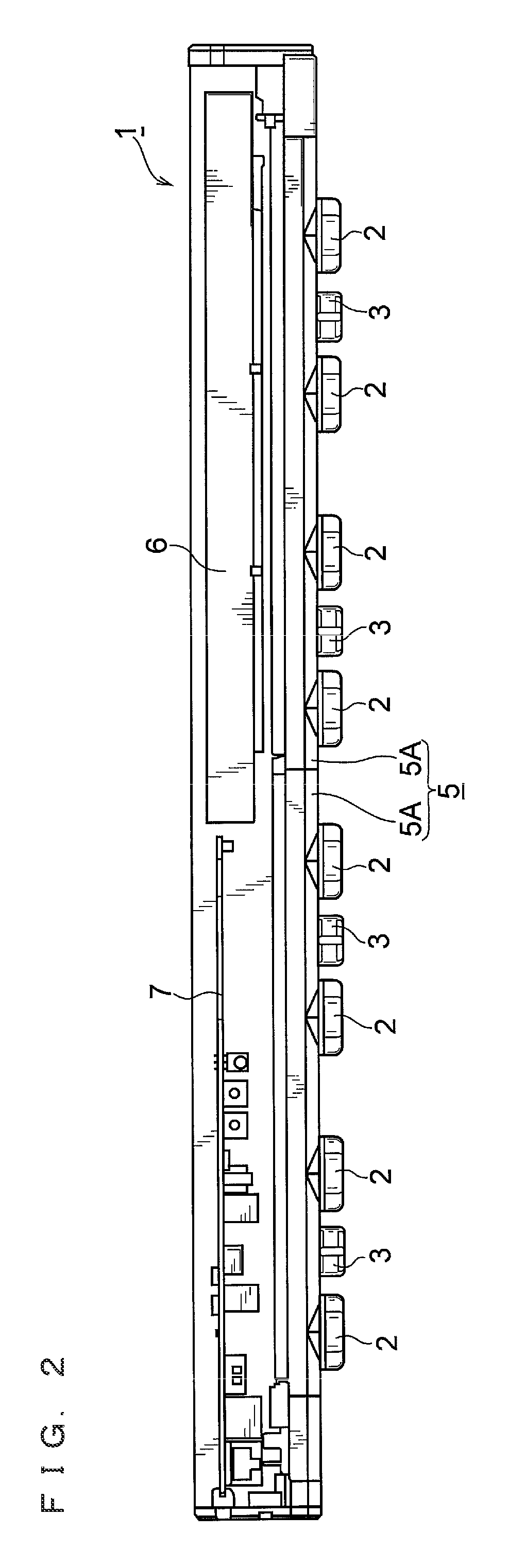

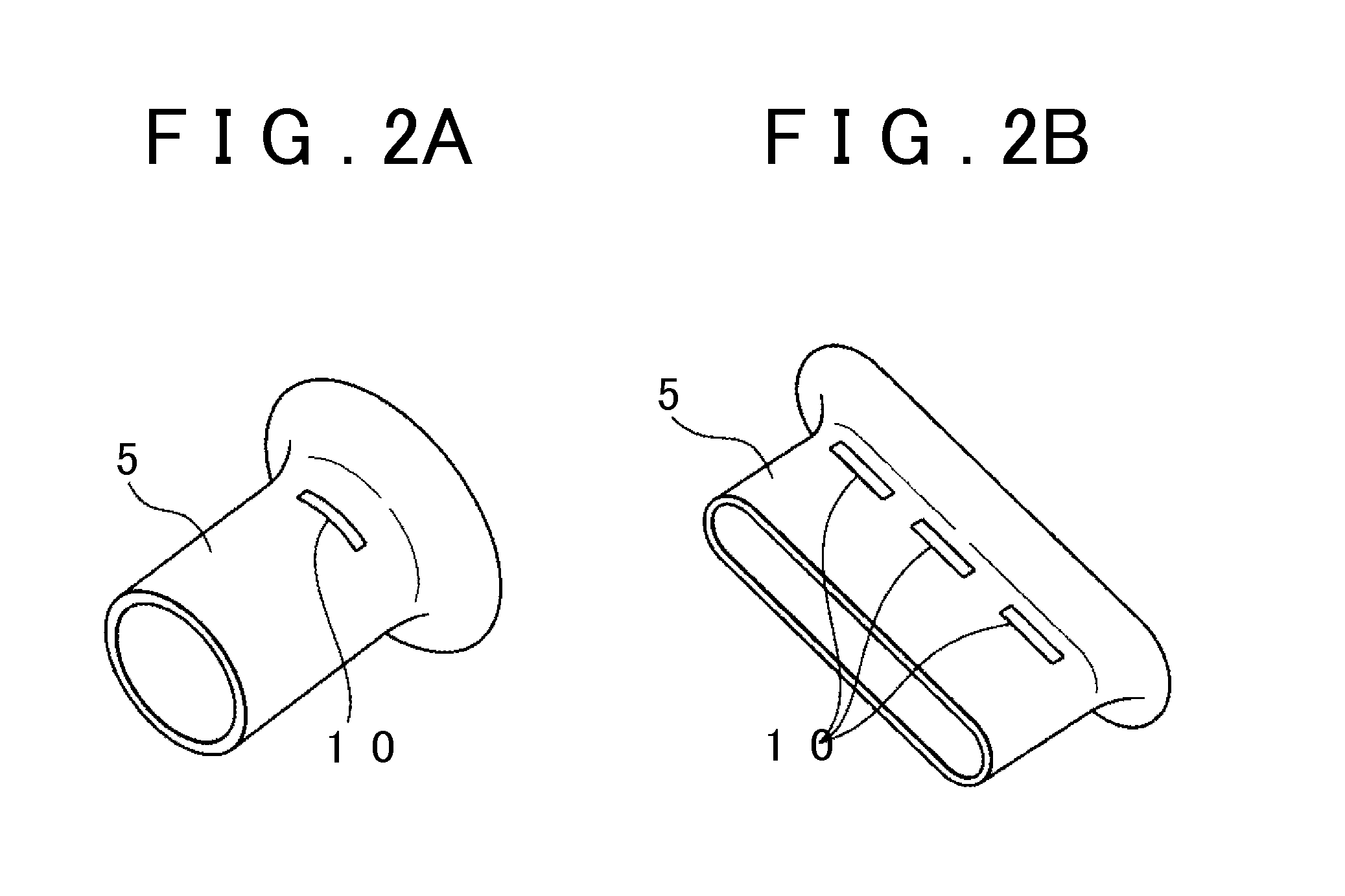

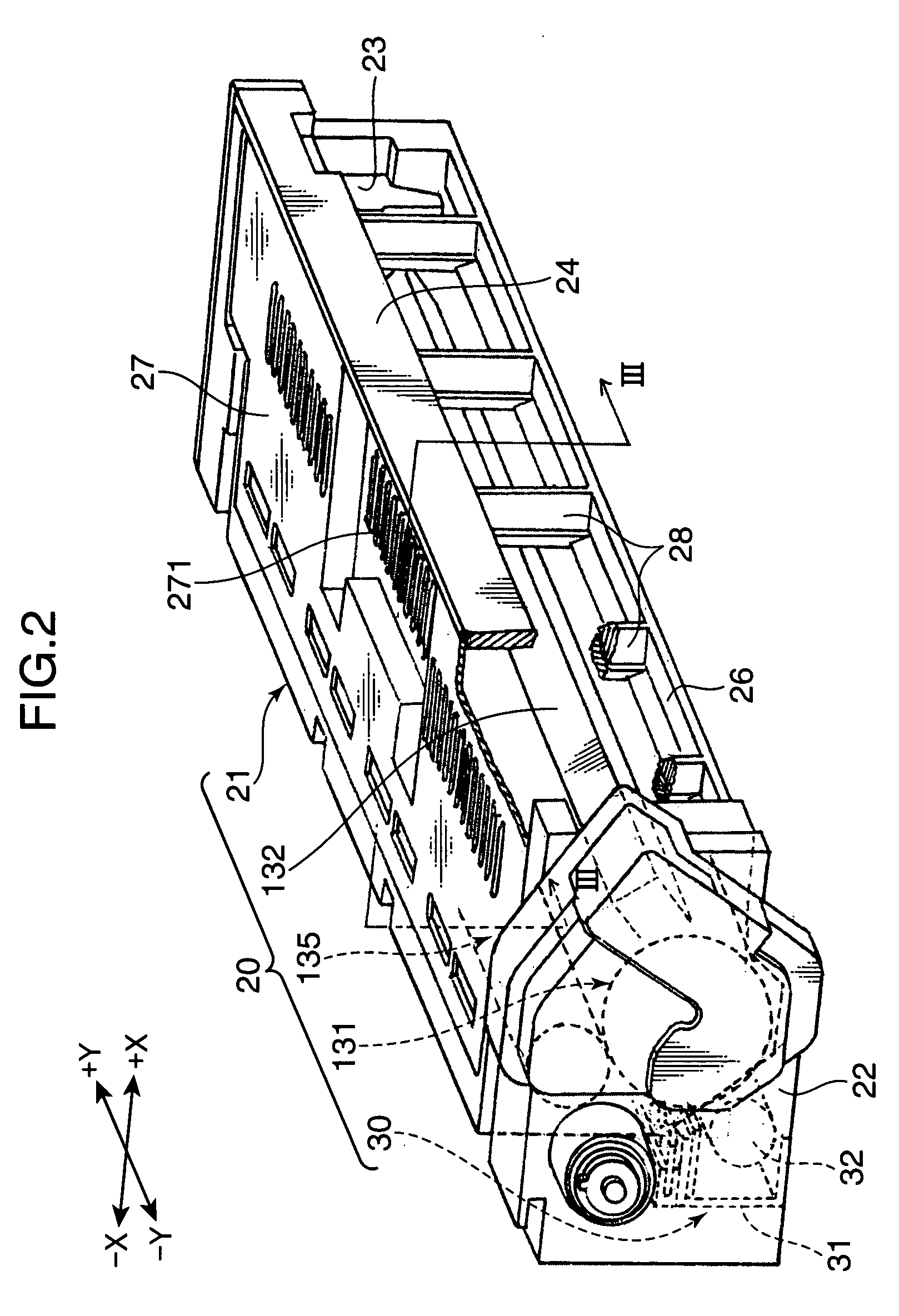

Static eliminator and electric discharge module

InactiveUS20090116162A1Improve maintainabilityEasy to cleanCorona dischargeRelaysElectric dischargeEngineering

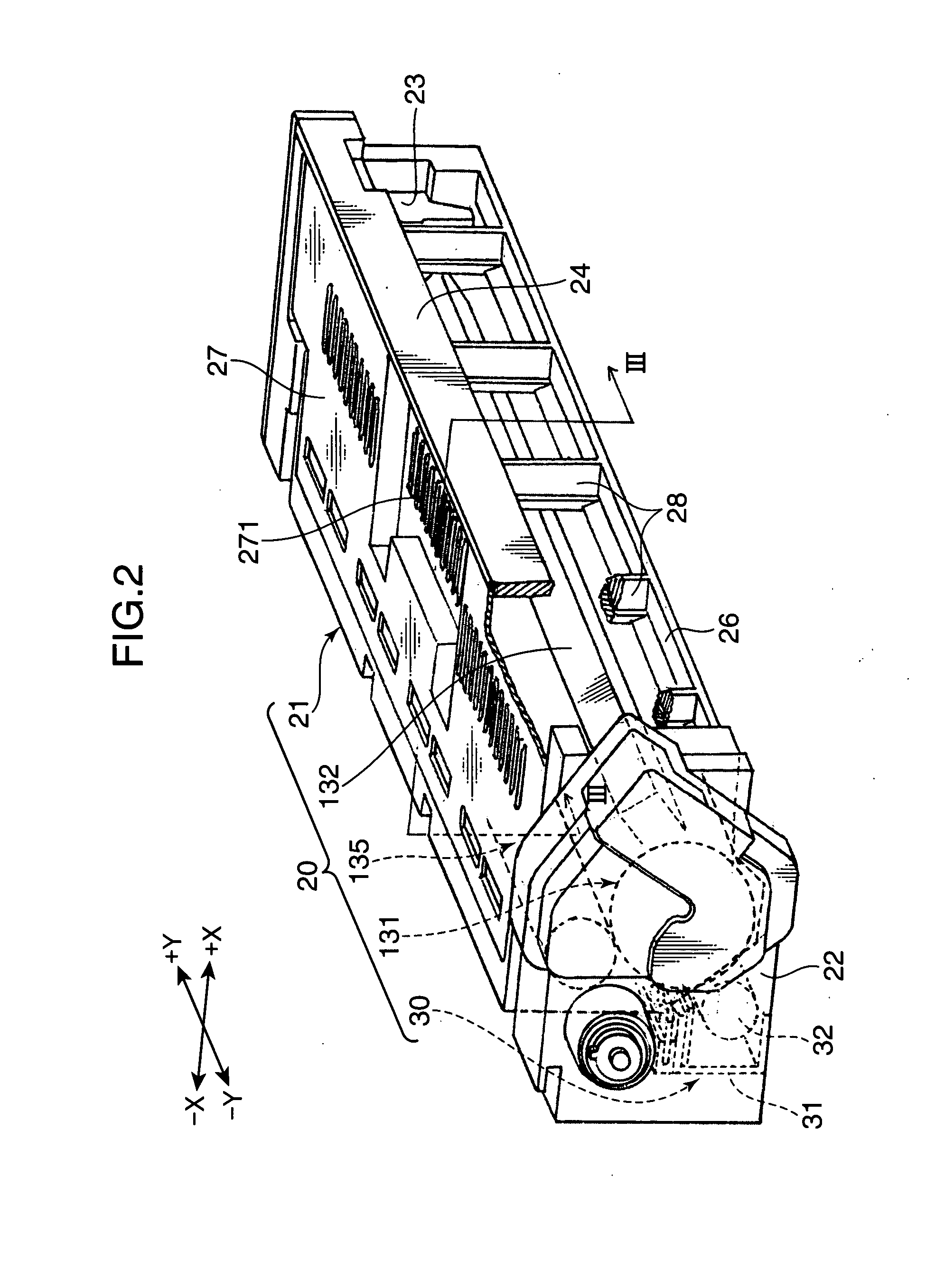

This static eliminator is used for eliminating static electricity from an object by ionizing the air to be blown to a charged object, and has a case 12 body provided with an air blow duct 15 for blowing out an ionized air, and an electric discharge module 27 being mounted detachably on the case body 12. The electric discharge module 27 has an electric discharge needle substrate 31 having a plurality of electric discharge needles 38 arranged straightly, and a surface panel 32 detachably mounted on the case body, and the electric discharge module 27 is mounted on the case body 12 by mean of a mounting screw member 36 in the portion of the surface panel 12. By dismounting the electric discharge module 27 from the case body 12, the electric discharge needles can be replaced.

Owner:KOGANEI

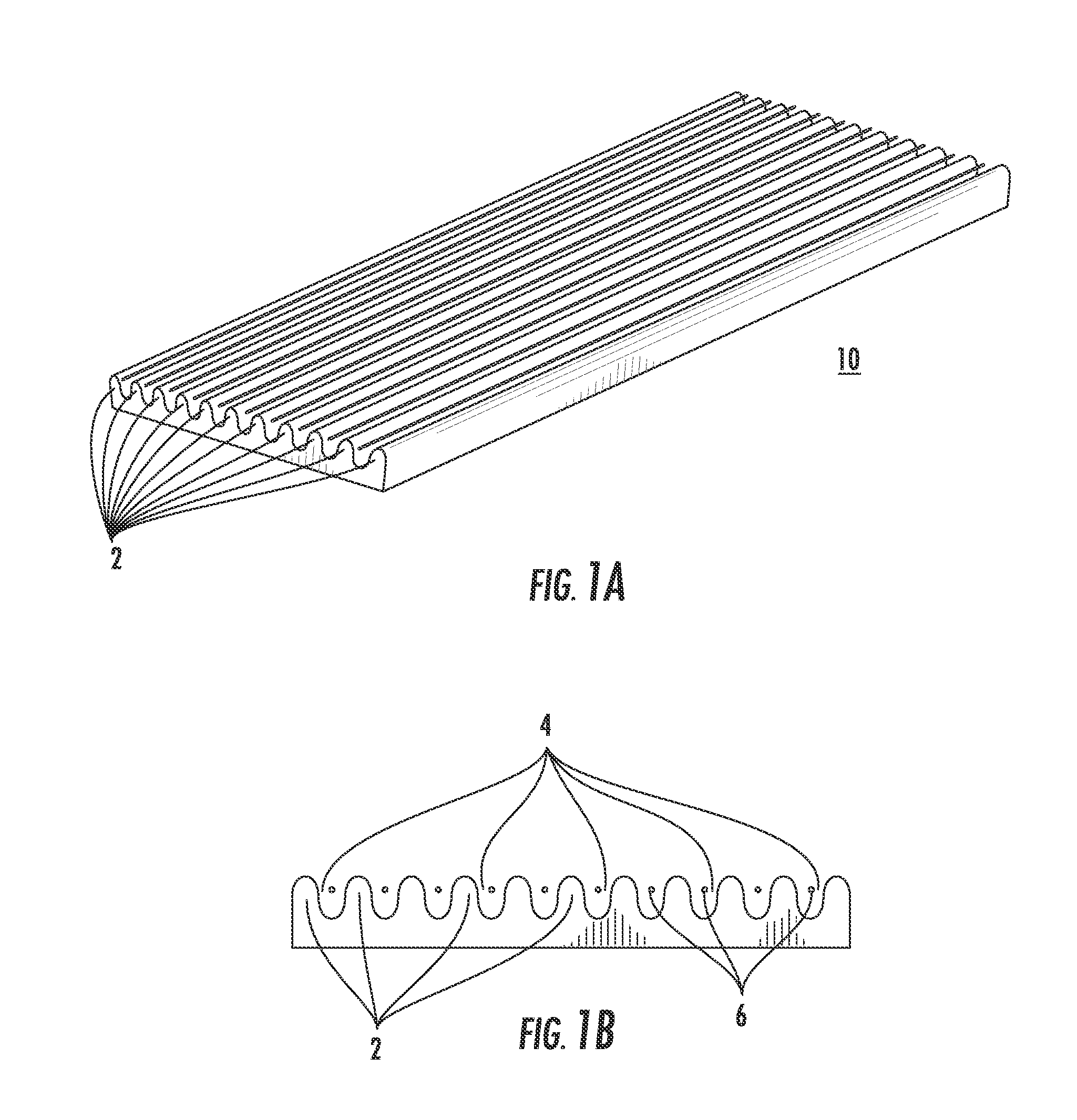

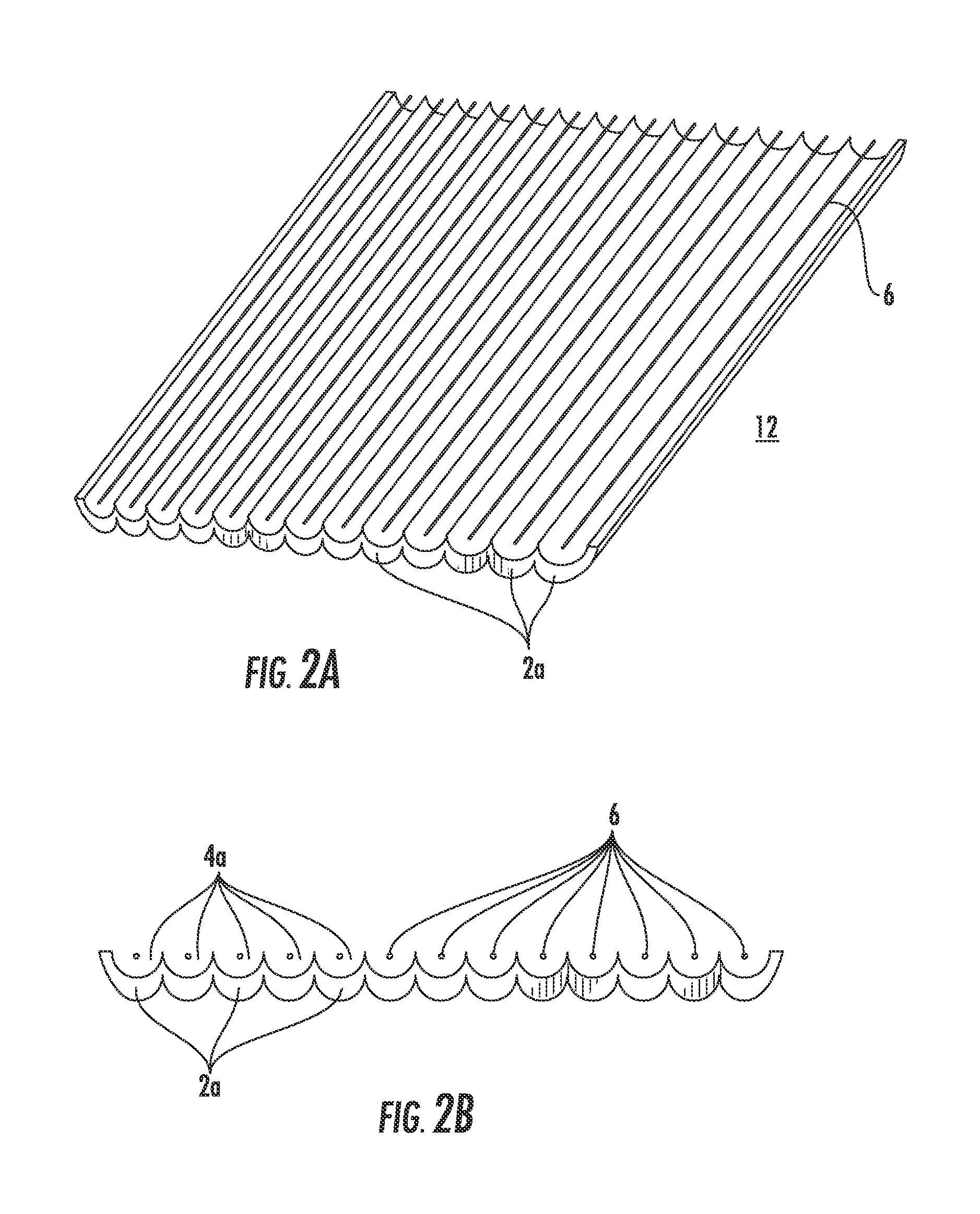

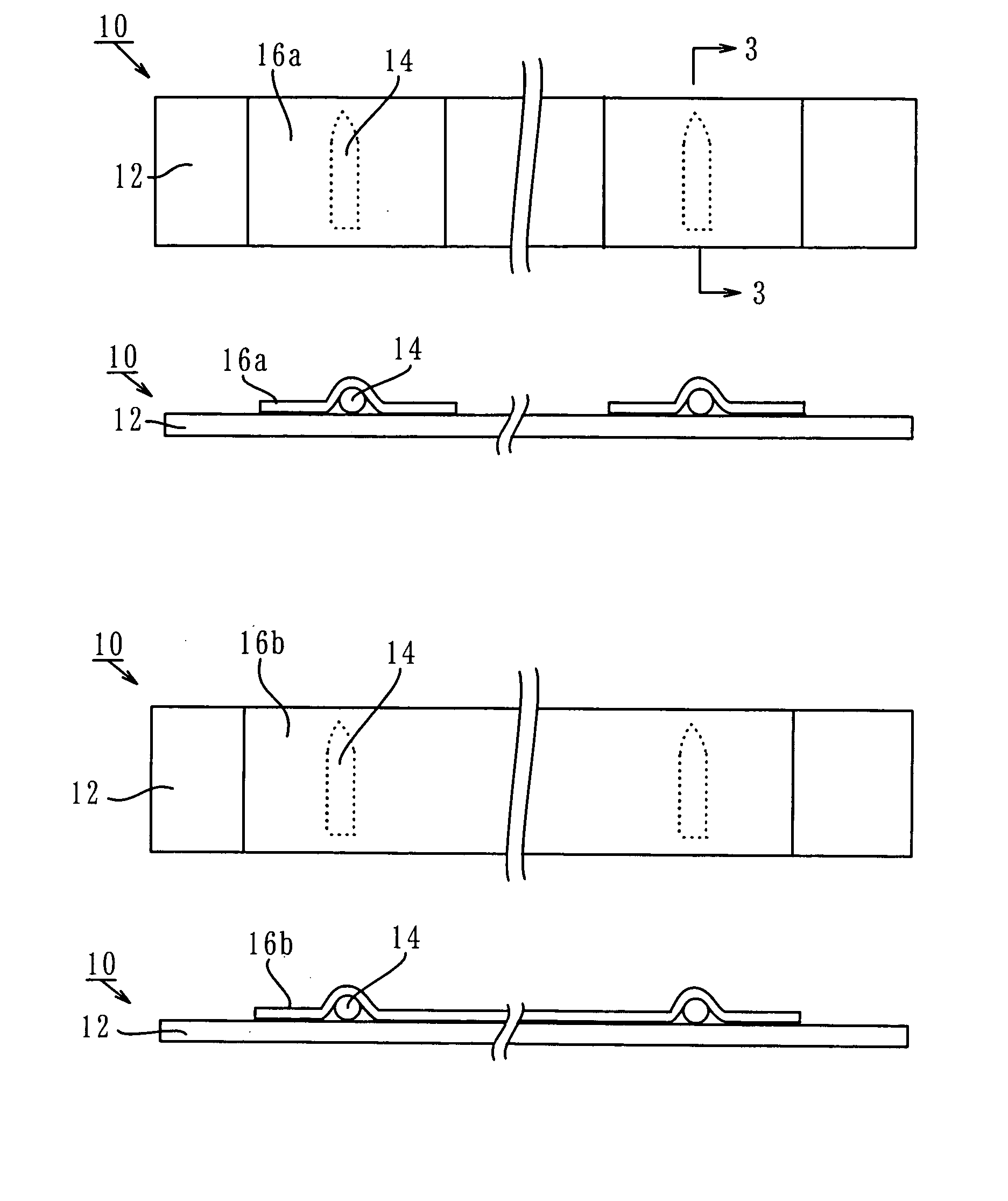

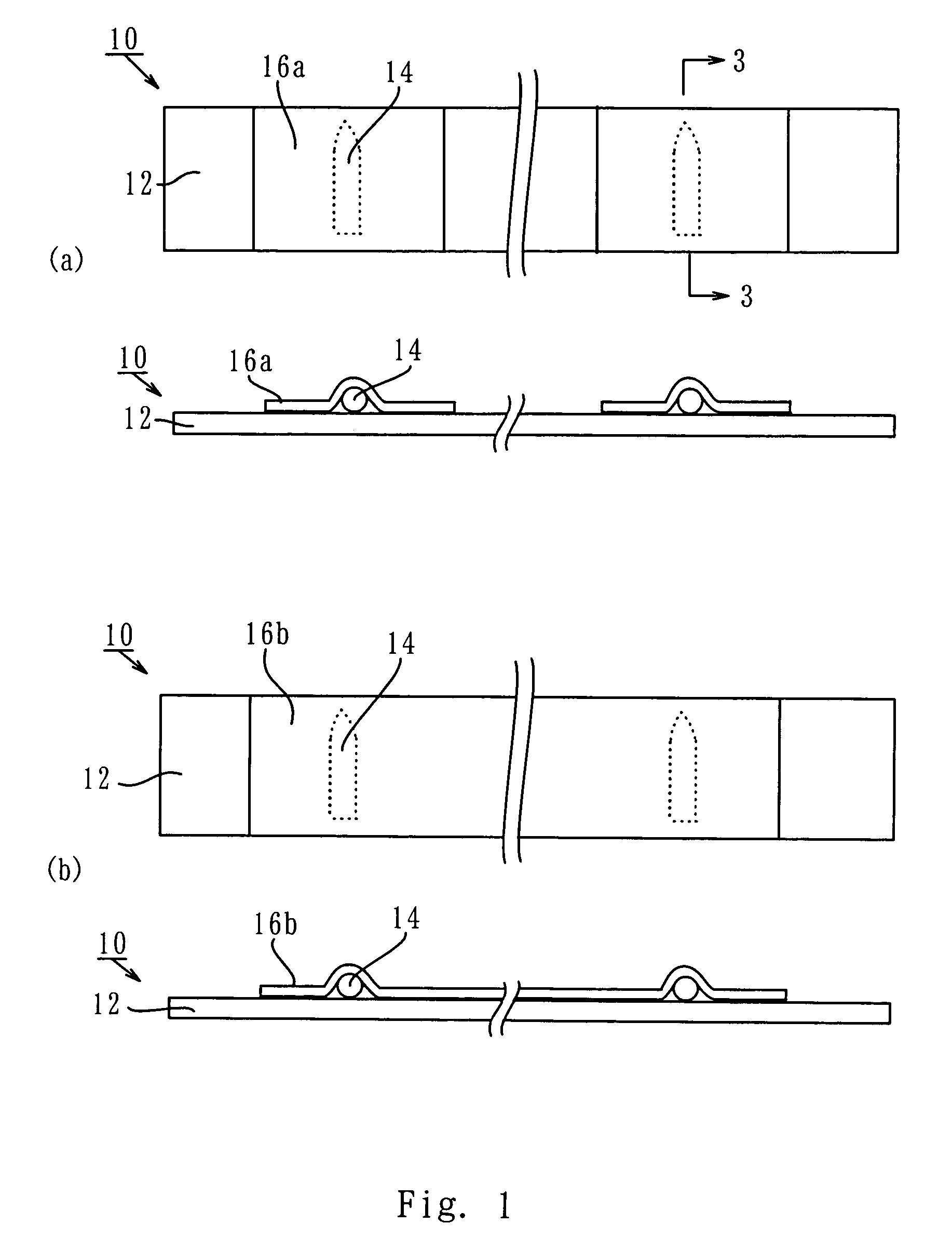

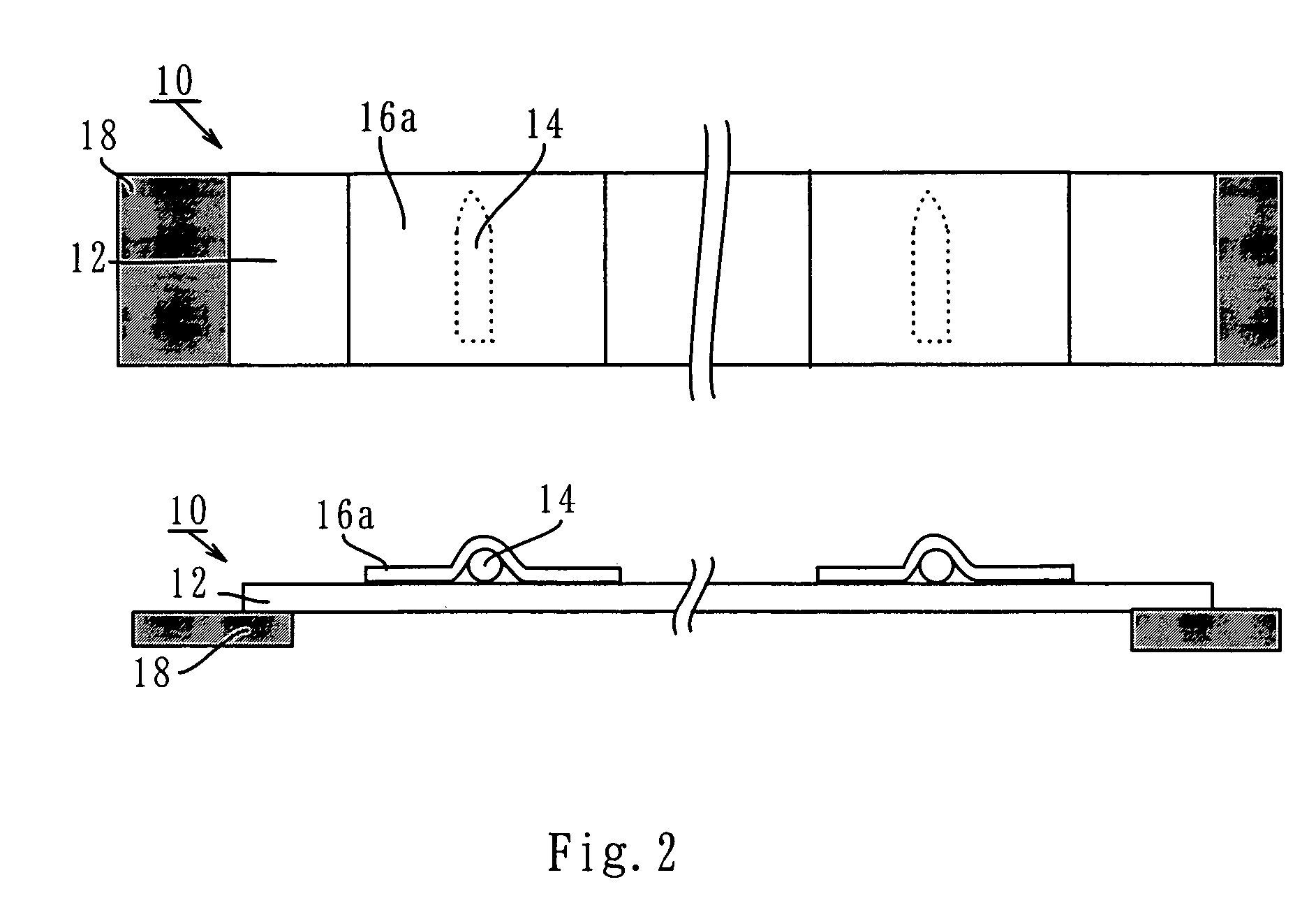

Static eliminator

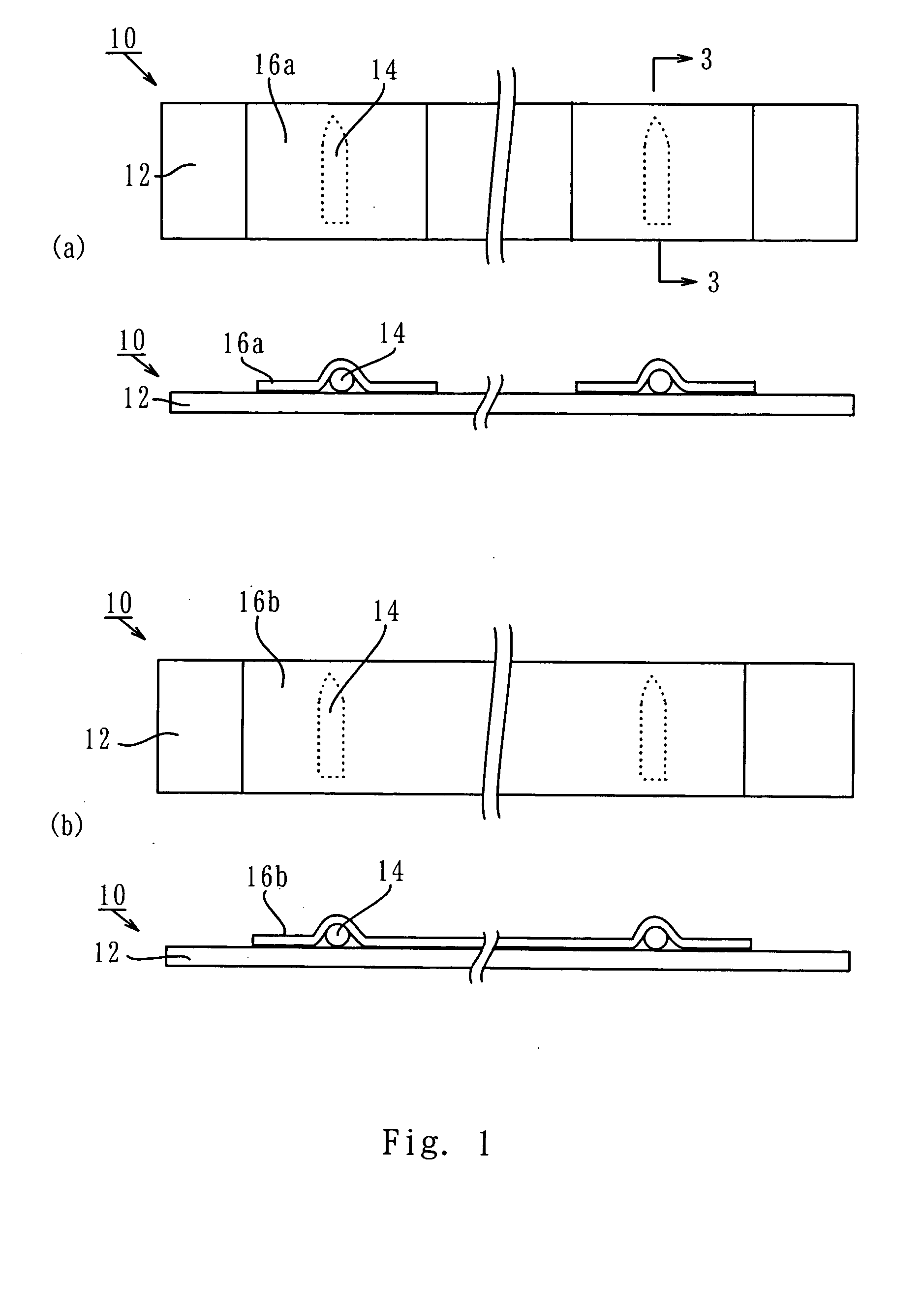

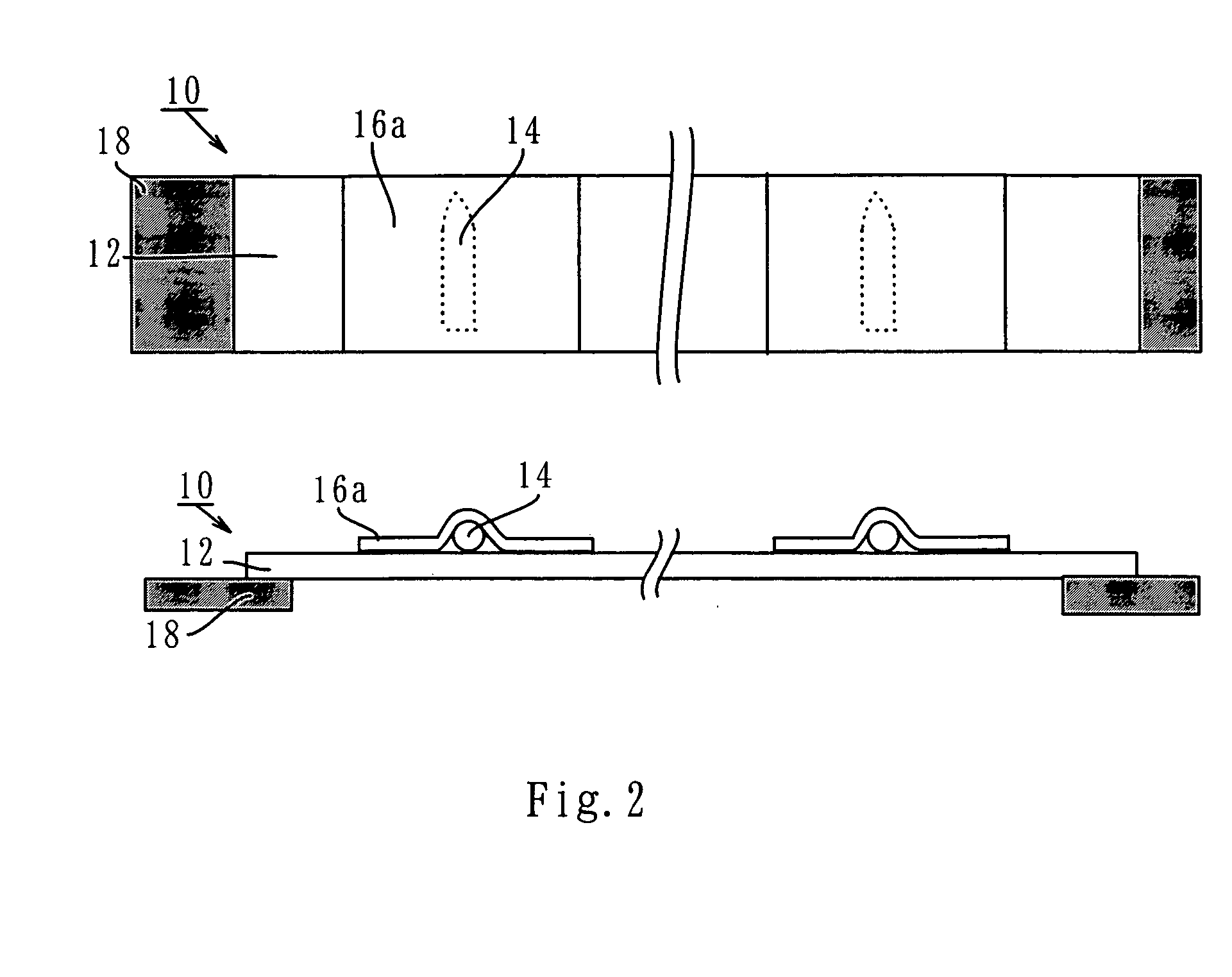

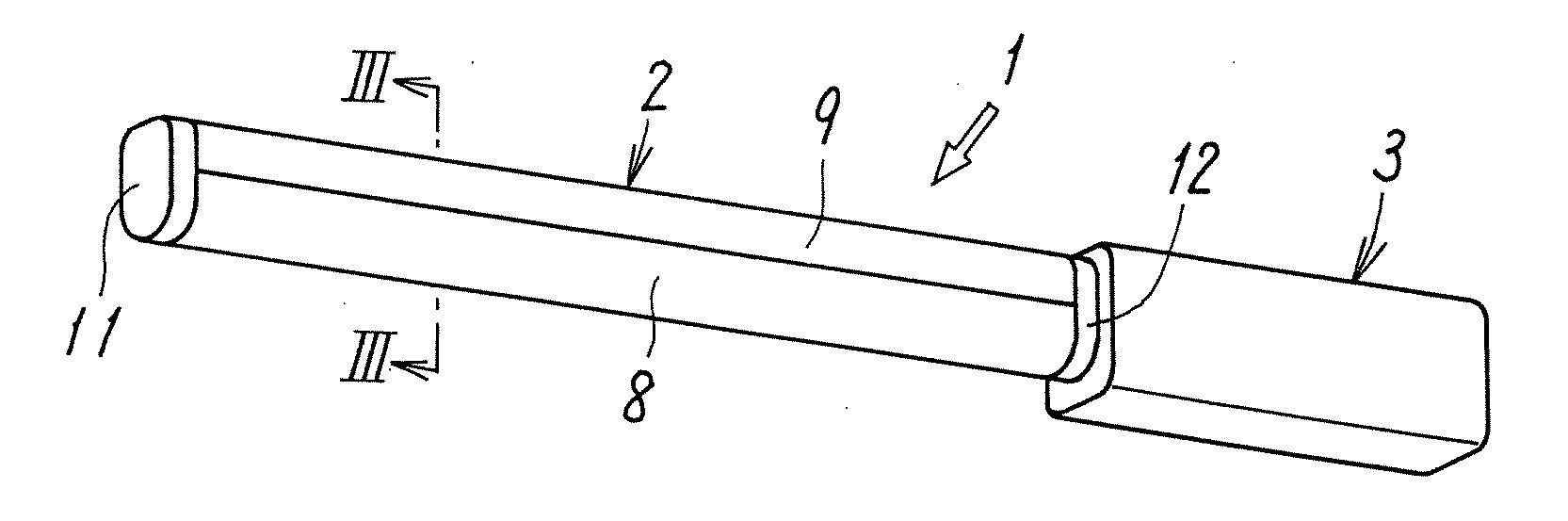

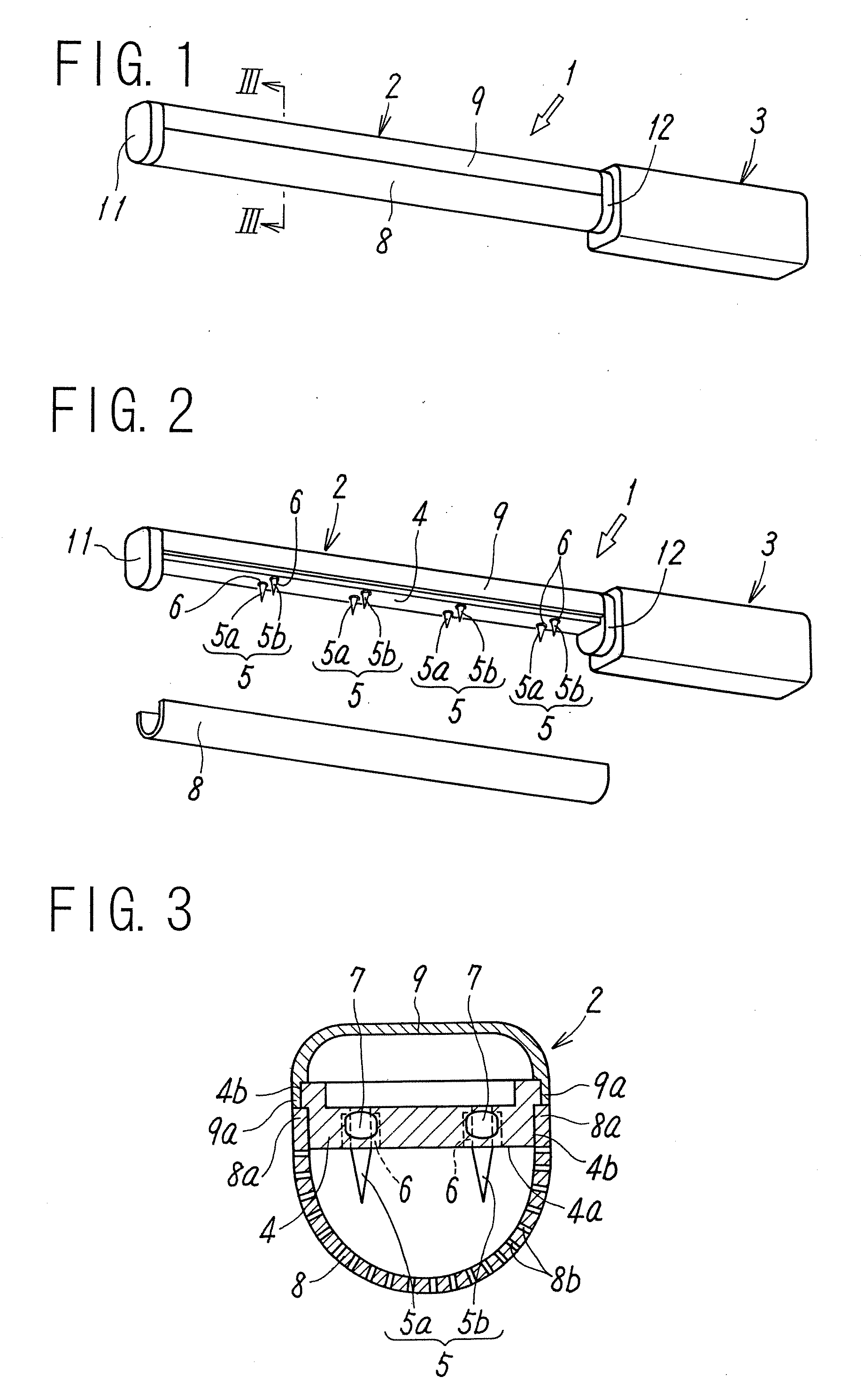

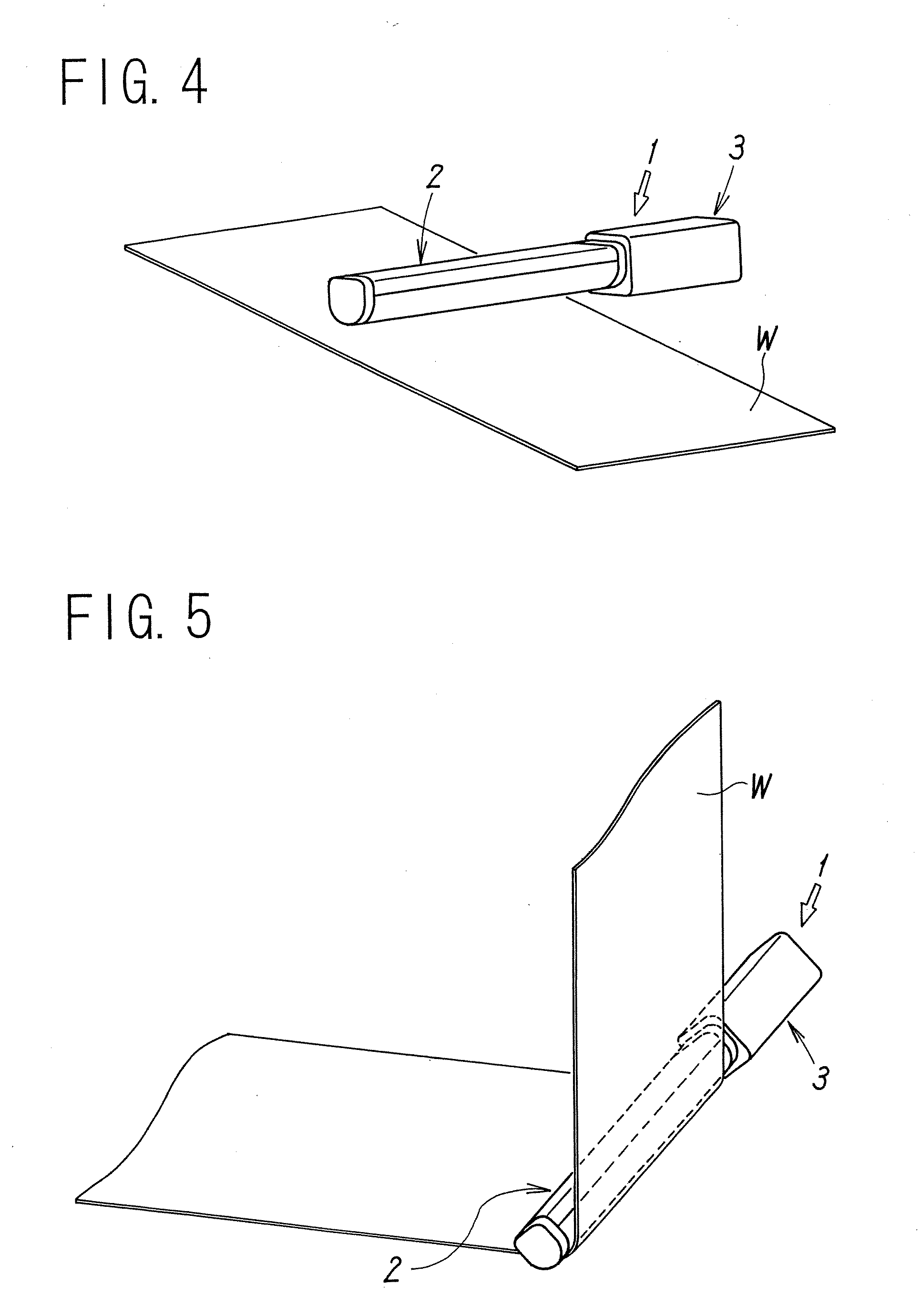

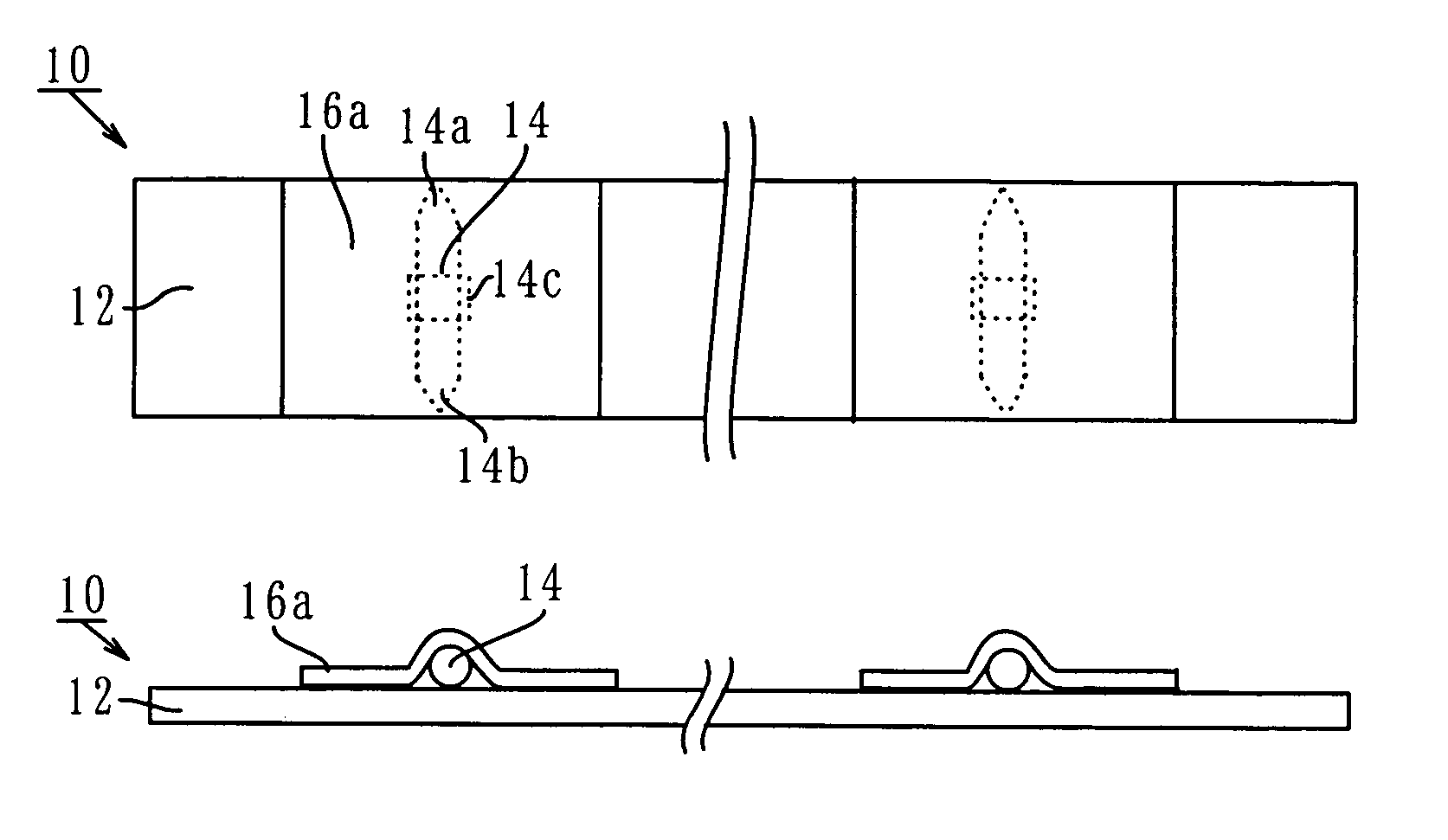

ActiveUS20050018375A1Emergency protective arrangement detailsArrangements responsive to excess voltageFiberElectrical conductor

There is provided a static eliminator which comprises an ion generating portion in the form of tape. There is also provided a self-discharged static eliminator comprising an conductor provided with discharge whiskers in which the conductor is applied with a predetermined voltage. There is also provided a DC type of self-discharged fiber-like static eliminator which comprises plus fiber electrodes applied with plus voltage, minus fiber electrodes applied with minus voltage, a support disposed between the plus and minus electrodes for supporting the plus and minus electrodes and provided with insulation reserving member for preventing the spark discharge or short due to the access of the plus and minus electrodes.

Owner:TRINC

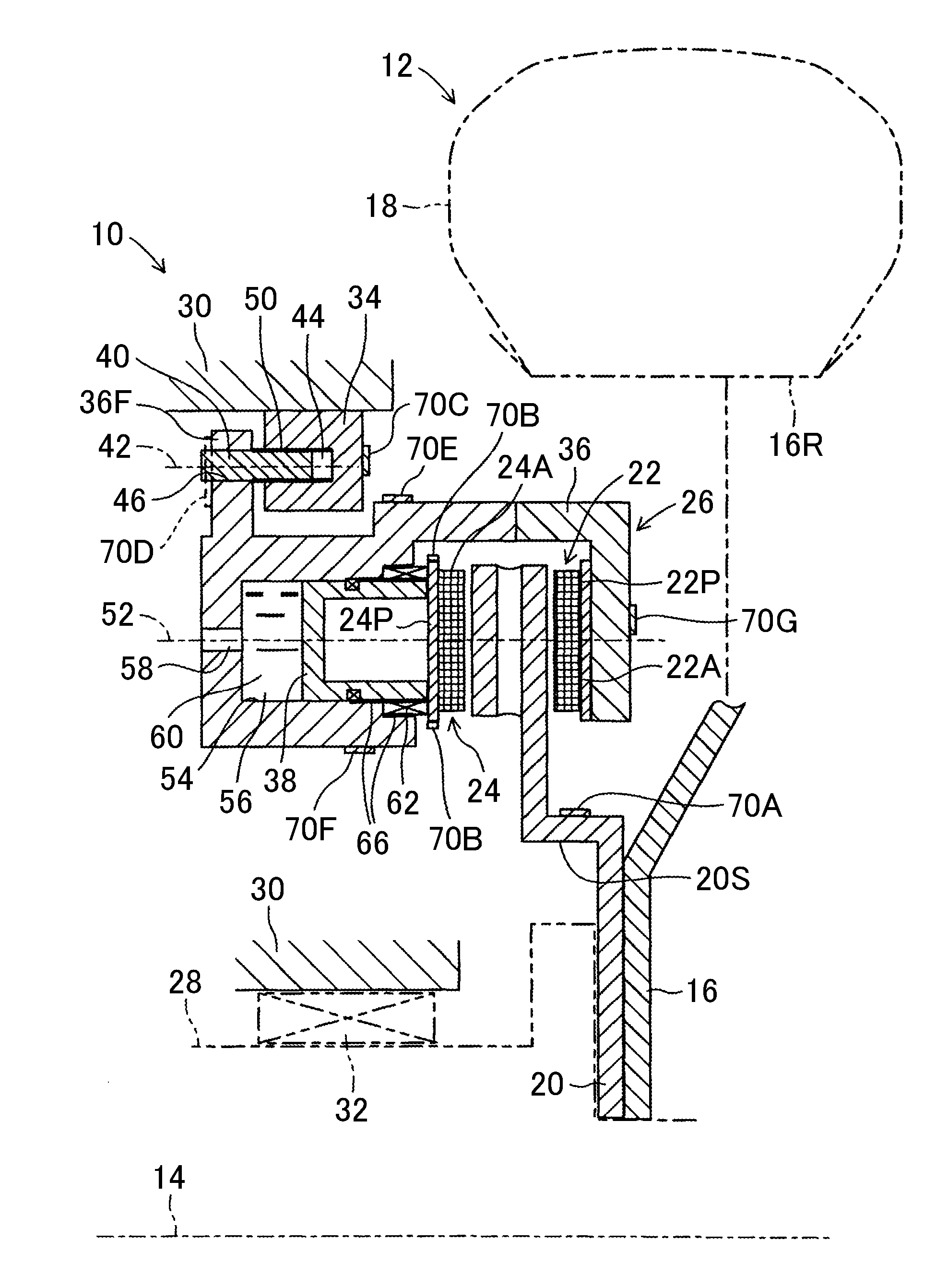

Static eliminator and discharge electrode unit built therein

ActiveUS8134821B2Strengthen electric fieldImprove elimination efficiencyEmergency protective arrangement detailsElectrostatic chargesEngineeringStatic eliminators

There is provided a static eliminator capable of weakening an electric field between a discharge electrode and a ground electrode, to generate a strong electric field between the discharge electrode and a workpiece, in which a first-stage circumferential chamber, a second-stage circumferential chamber and a first gas pool are arrayed in series along the longitudinal direction of a discharge electrode, the first gas pool is disposed in the mode of diametrically overlapping a gas outflow channel for shielding located on the inner circumferential side of the first gas pool, a gas is supplied to the first gas pool through the chambers disposed at multi-stages by means of the circumferentially spaced multi-stage orifices (the first and second chases), a ground electrode plate member in plate shape is buried in an insulating resin member on the bottom surface side of the half base in a position as high as where the first gas pool is located, and the ground electrode plate member includes a circular ring section concentric with the discharge electrode.

Owner:KEYENCE

Static eliminator

InactiveUS7948733B2Accurate detectionEliminate static electricityElectrostatic chargesStatic eliminatorsContamination

There is provided a static eliminator for accurately detecting a contamination condition of a discharge electrode, in which a target value as a target frame ground current value is changed from, for example, zero as a reference alternately to the plus side and the minus side to such a degree as not to affect the ion balance of a workpiece, and the follow-up time, namely a phase delay, with respect to the change in target value differs depending on the contamination condition of the discharge electrode, and becomes longer with the progress of the contamination, and by use of this characteristic, a plurality of thresholds are prepared and compared with a detected frame ground current value, so as to detect the contamination condition of the discharge electrode.

Owner:KEYENCE

Static Eliminator And Static Elimination Control Method

ActiveUS20120257318A1Suppress deterioration in ion balanceInhibit deteriorationEmergency protective arrangement detailsCorona dischargeCorona dischargeStatic eliminators

Provided is a static eliminator capable of holding ion balance uniform regardless of a distance from the static eliminator. The static eliminator includes: an electrode driving device that alternately and repeatedly applies, to a discharge electrode, a positive drive voltage and a negative drive voltage as drive voltages for corona discharge; decreases a ratio of the application time of the positive drive voltage while relatively increasing the voltage value of the positive drive voltage in a case of increasing positive ions, and increases the ratio of the application time of the positive drive voltage while relatively decreasing the voltage value of the positive drive voltage in a case of increasing negative ions.

Owner:KEYENCE

Antistatic thermal-transfer-printing label cloth as well as preparation method thereof

ActiveCN103572610AIncrease tightnessGood orientationFibre typesLiquid/gas/vapor removalAntistatic agentPolyethylene glycol

The invention relates to label cloth as well as a preparation method thereof, and particularly relates to antistatic thermal-transfer-printing label cloth as well as the preparation method thereof. The label cloth is 0.100-0.165mm thick, and the gram weight is 90-150g / <m2>. Base cloth is prepared by a PET (Polyethylene Glycol Terephthalate) material, the specification of the yarn of the base cloth prepared is 60-150D, the warp density is 85-160 / cm, and the weft density is 30-45 / cm. An antistatic agent is adhered to the base cloth, and the antistatic agent accounts for 0.5-1.5% of the weight of the base cloth. The preparation method comprises the following steps: weaving greige cloth; obtaining the base cloth for preparing the label cloth after weaving; dyeing and finishing, namely pre-treatment of dyeing and finishing, dyeing and pos-treatment of dyeing and finishing, wherein the pre-treatment of dyeing and finishing adopts an alkali desizing method and the pos-treatment of dyeing and finishing comprises a continuous sectional setting and pre-concentrating process; antistatic treatment, namely roasting for 1-2 minutes at 170-210 DEG C to dry and form the base cloth; and press-polishing treatment, namely by adopting a press-polishing process, installing an antistatic remover in a press-polishing machine, and preparing the label cloth through chemical and mechanical double antistatic removal. The label cloth is safe and convenient to operate and antistatic, and can be subjected to thermal transfer printing.

Owner:HUZHOU SINY LABEL MATERIAL

Static electricity eliminator

The invention provides a pulse AC static electricity eliminator, wherein generally a primary booster circuit formed by a transformer does not need better insulating property. In a static electricity eliminator, an output line of a positive polarity high pressure generating circuit is in connection with a negative polarity high pressure generating circuit to alternately apply positive and negative polarity high pressure to shared discharge electrodes. A grounding terminal of a second winding of a negative polarity transformer is grounding and the grounding terminal is not in connection with a negative polarity secondary boosting rectifier circuit.

Owner:KEYENCE

Vehicle engine exhaust system

ActiveUS20160186639A1Increase engine powerImprove driving stabilityTyre partsSilencing apparatusStatic eliminatorsSelf-discharge

A vehicle engine exhaust system includes an exhaust component and a non-conductive support member. The exhaust component is supported by a vehicle body via the non-conductive support member. The vehicle body and the exhaust component are positively charged. The vehicle engine exhaust system further includes a self discharge type static electricity eliminator that reduces, in a state where the self discharge type static electricity eliminator is installed on a non-conductive wall surface, an amount of electrification charge on the non-conductive wall surface within a limited area around a location where the self discharge type static electricity eliminator is installed. The self discharge type static electricity eliminator is installed on the non-conductive support member such that static electricity elimination is performed for the exhaust component.

Owner:TOYOTA JIDOSHA KK

Pattern defect inspection method and apparatus thereof

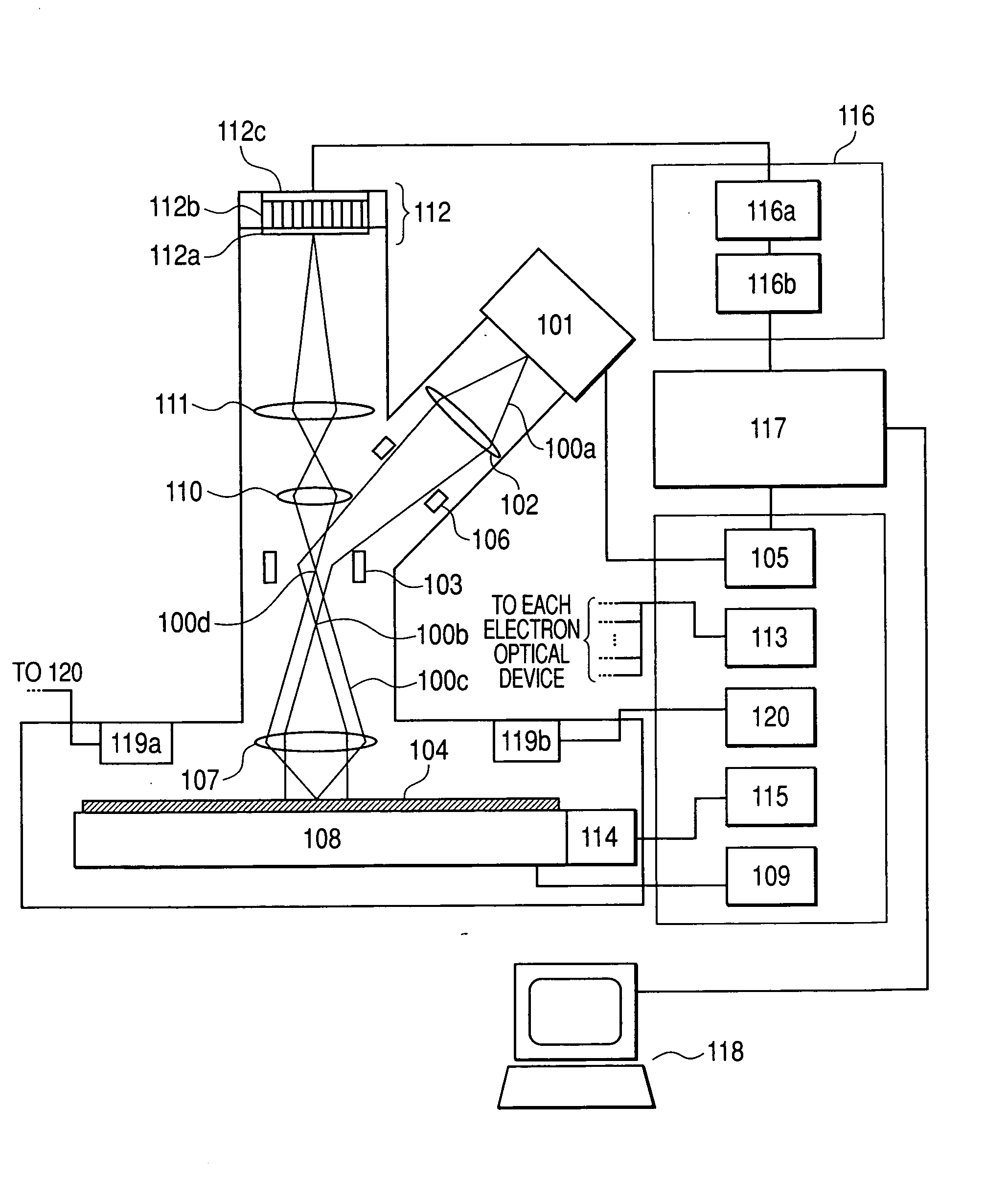

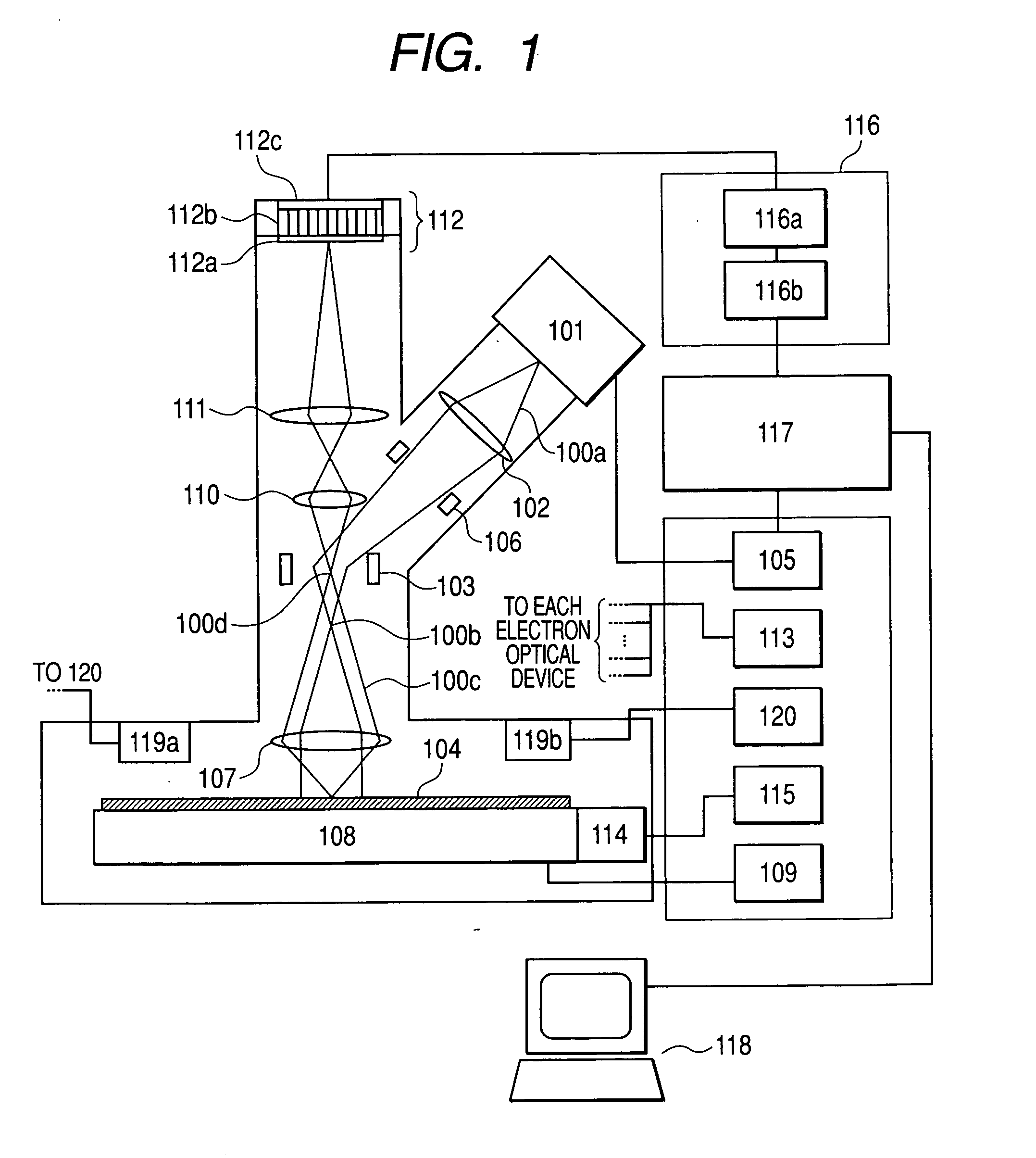

ActiveUS20070085005A1Reduce gradientReduced strengthMaterial analysis using wave/particle radiationElectric discharge tubesSecondary electronsStatic eliminators

In the present invention, the structure of an electrification control electrode is changed from a grid type to a slit type and thereby shadows are not formed when a wafer is irradiated with a beam. Further, a beam forming slit is disposed ahead of an electrification control slit, thus the electrification control slit is prevented from being irradiated with an electron beam for preliminary electrification, and thereby secondary electrons which disturb the control of the electrification are inhibited from being generated. The shape of the slit is designed so that the strength of an electron beam may gradually decrease toward both the ends of an electron beam irradiation region in the longitudinal direction thereof. Furthermore, a preliminary static eliminator to remove or reduce the unevenness in an electrification potential distribution which has undesirably been formed earlier is disposed.

Owner:HITACHI HIGH-TECH CORP

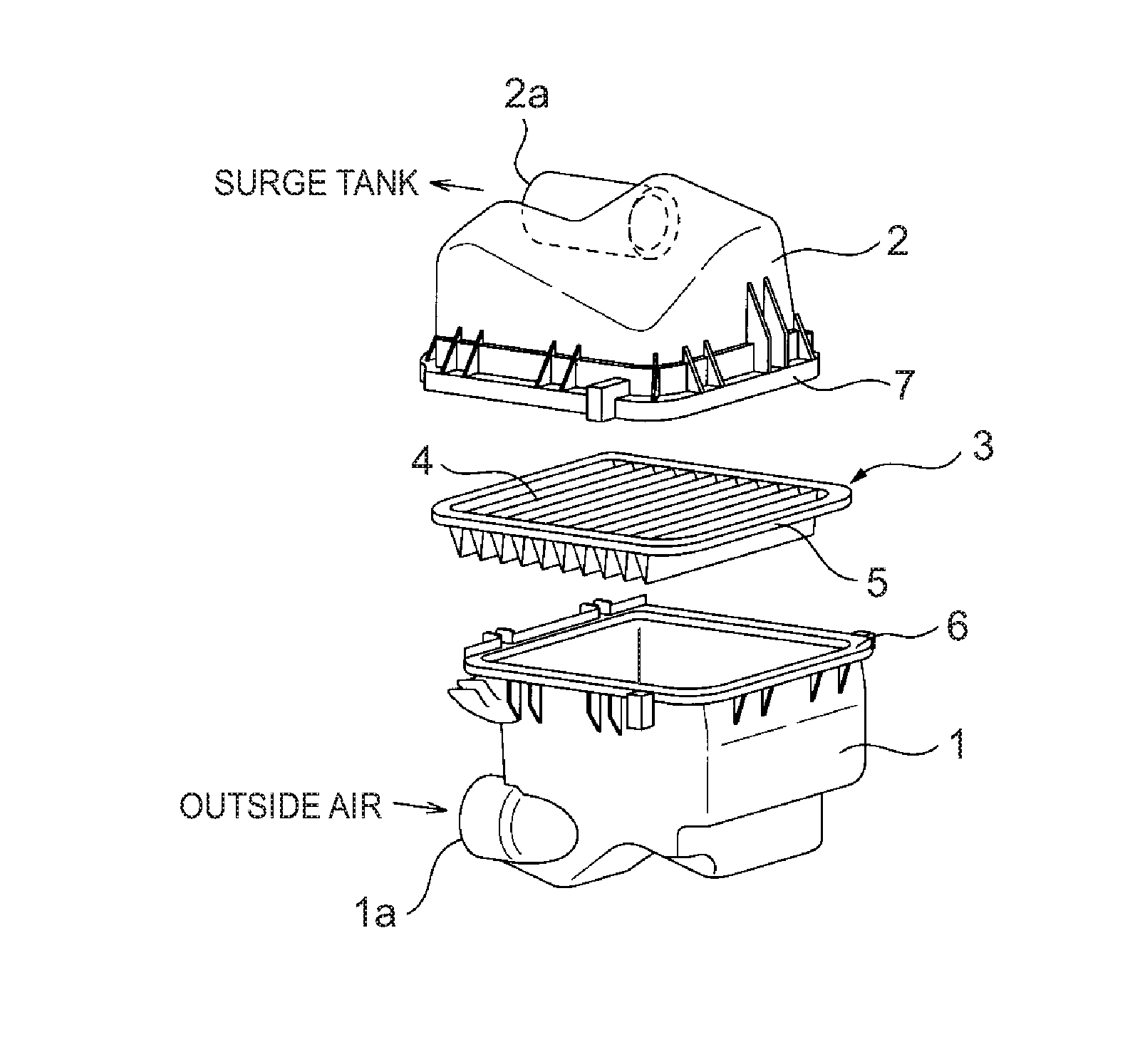

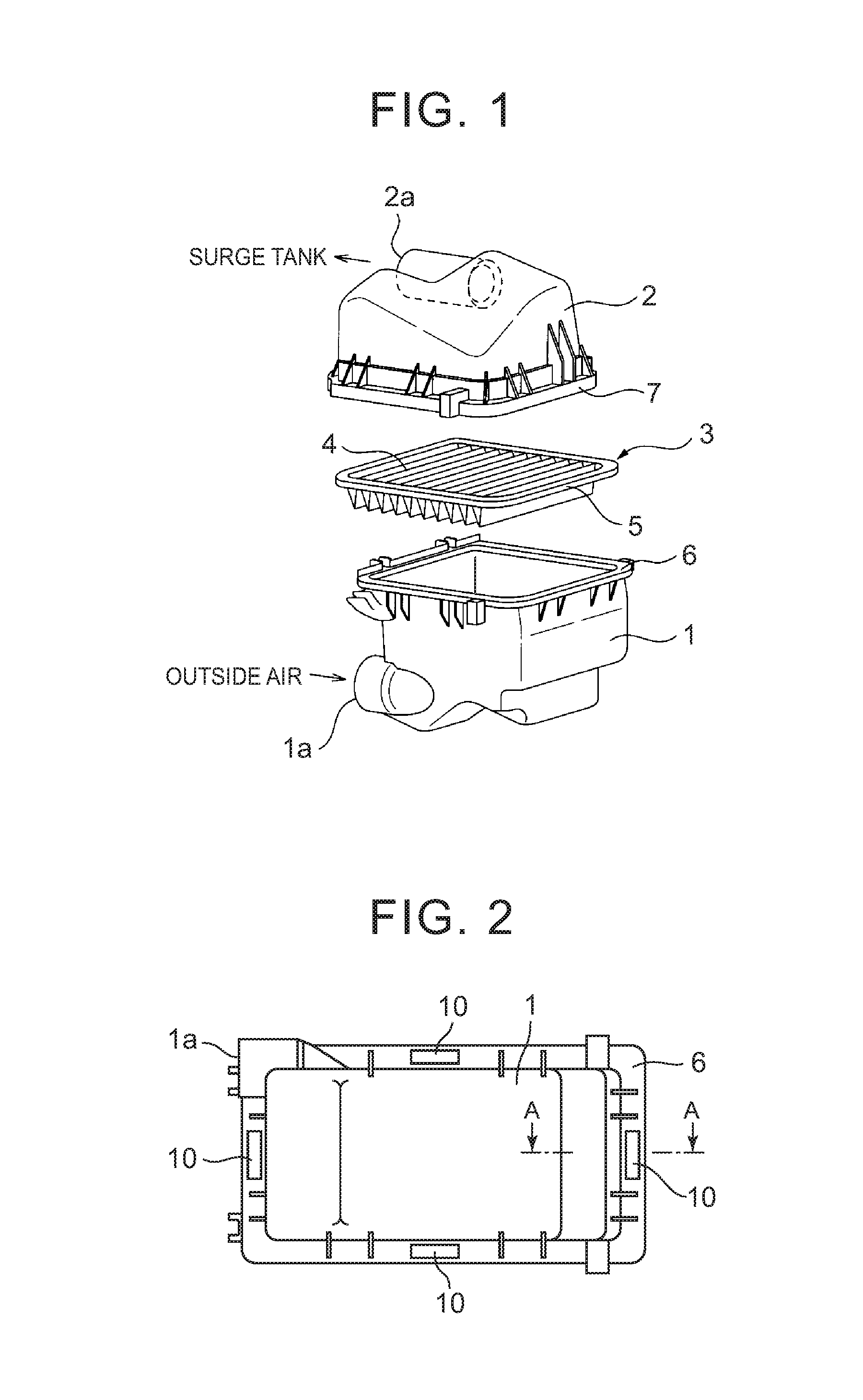

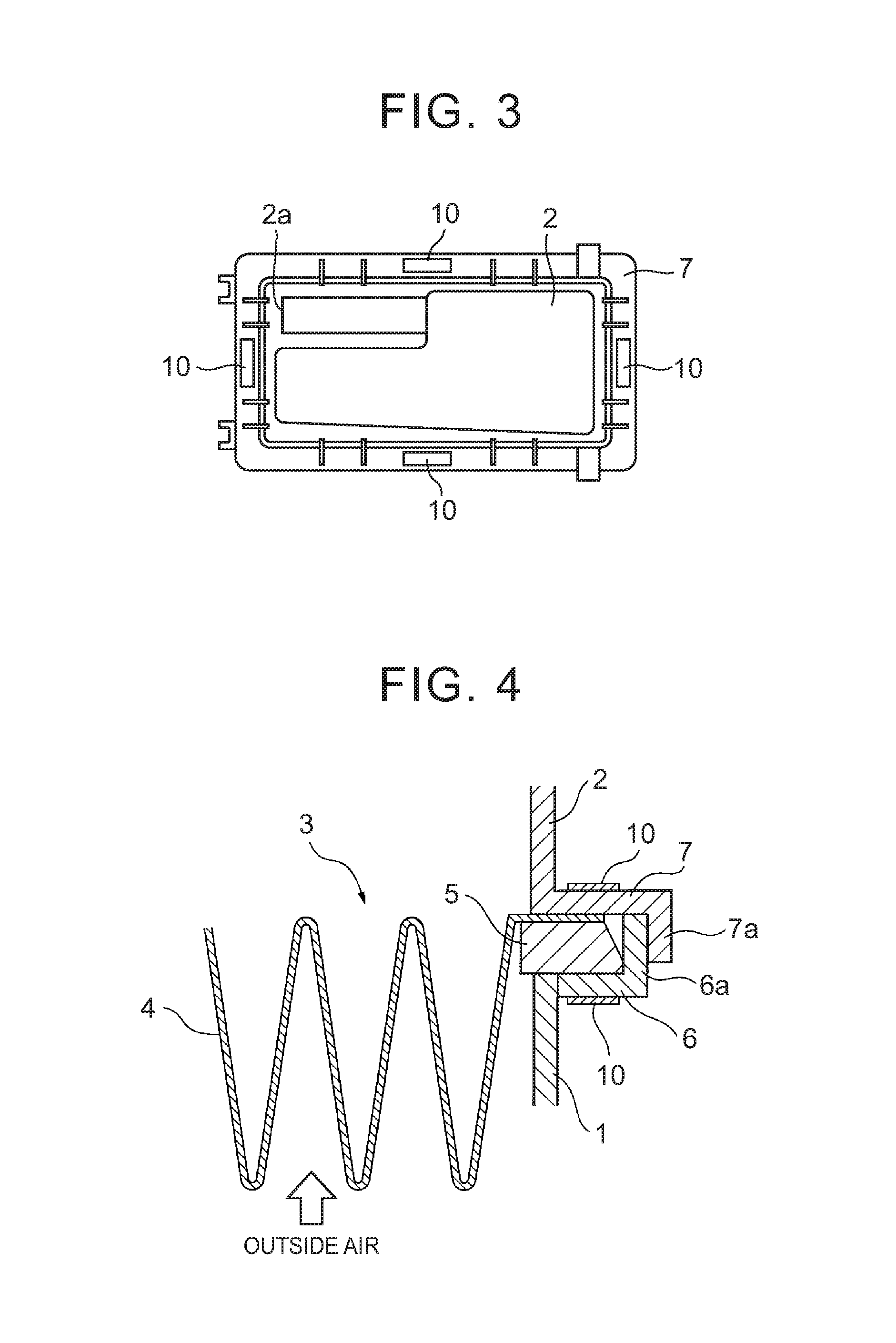

Intake device for vehicle

ActiveUS20160108868A1Improve air intake efficiencyFluid dynamicsMachines/enginesEngineeringStatic eliminators

An intake device for a vehicle, in which an intake passage wall surface defining an intake passage is charged with positive charges, includes: a self-discharge static eliminator that is provided on the intake passage wall surface and that decreases an electrification charge amount on that part of the intake passage wall surface which is within a limited range around a mounting part of the self-discharge static eliminator, by providing the self-discharge static eliminator on the intake passage wall surface.

Owner:TOYOTA JIDOSHA KK

Neutralization apparatus

ActiveUS20100073842A1Eliminate the problemElimination of static electricity from a work can be effectively and surly performedCorona dischargeRelaysElectricityStatic eliminators

A static eliminator that can be placed at a close distance capable of eliminating static electricity while preventing furious elevation of the surface electric potential of a work when the static eliminator is placed at a close distance to the work. A cover formed by an electro conductive porous material covering discharge needles is attached to a holding member in which a plurality of the discharge needles are provided and air blowing openings for ejecting air around the discharge needles are provided. The cover evenly discharges ionized air from the surface of the cover, and is electrically connected to ground to have a function for absorbing a part of generated ions.

Owner:SMC CORP

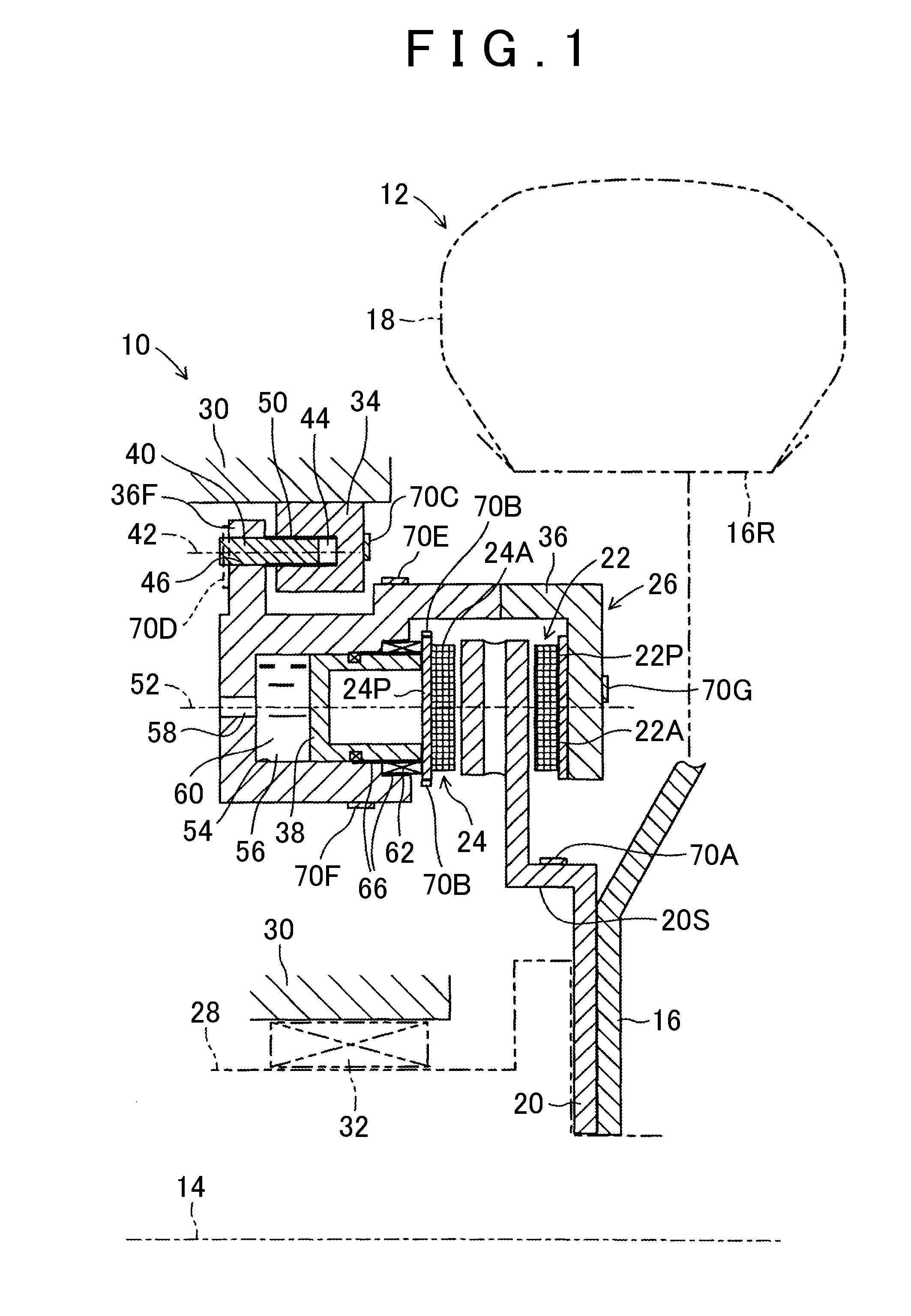

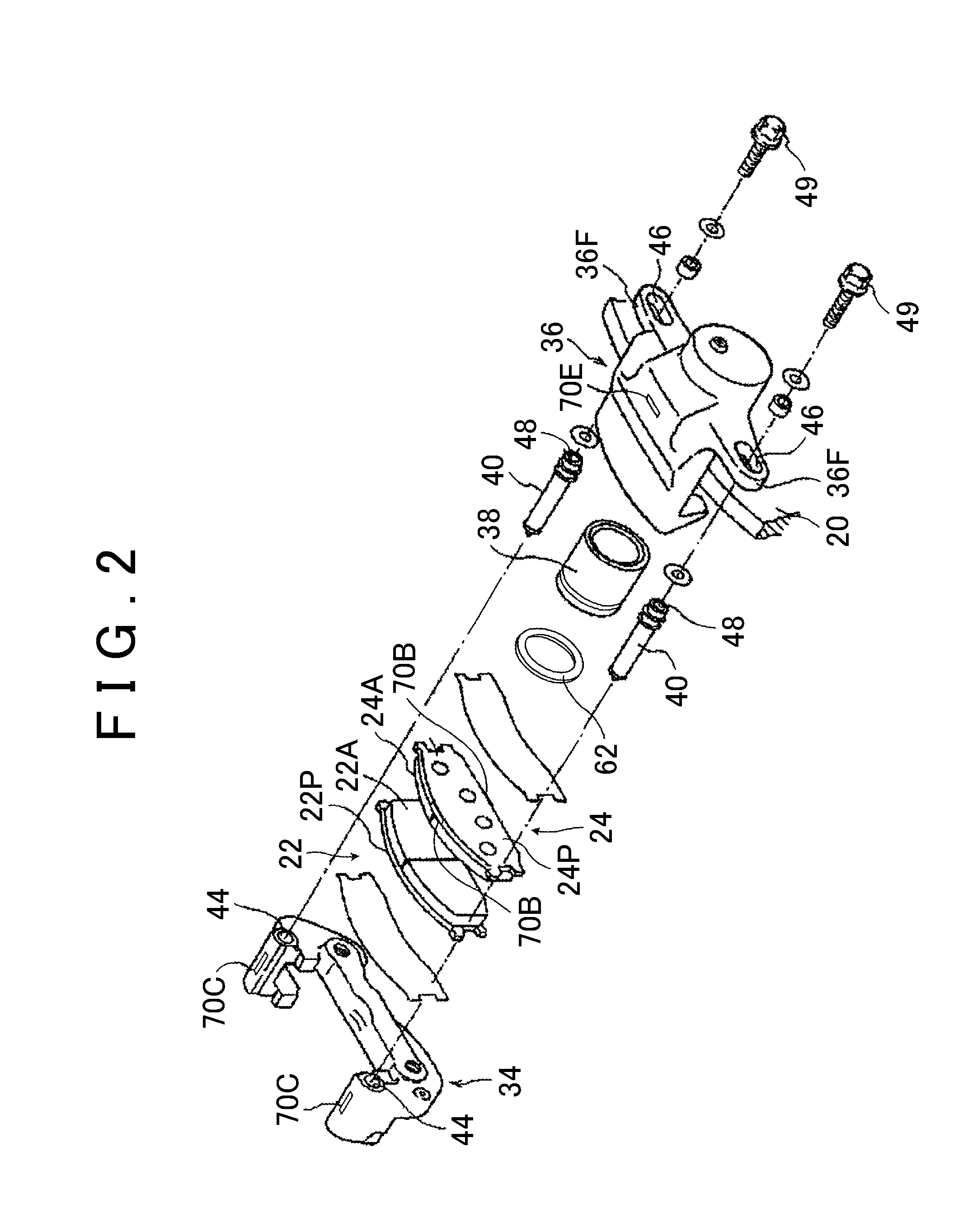

Braking force generation device of vehicle

ActiveUS20160230824A1Reduce chargeReduce in quantityBraking element arrangementsAxially engaging brakesForce generationEngineering

A braking force generation device of a vehicle includes a rotary member, a frictional member, a pressing device, and a self-discharge type static charge eliminator provided on a surface of a particular member. The self-discharge type static charge eliminator changes air around the self-discharge type static charge eliminator into negative air ions, according to the quantity of positive charge carried by the particular member, and eliminate charge by causing the negative air ions to attract the positive charges of the particular member for neutralization, so as to reduce a quantity of charge of the particular member, and thereby reduce a quantity of charge of the lubricant.

Owner:TOYOTA JIDOSHA KK

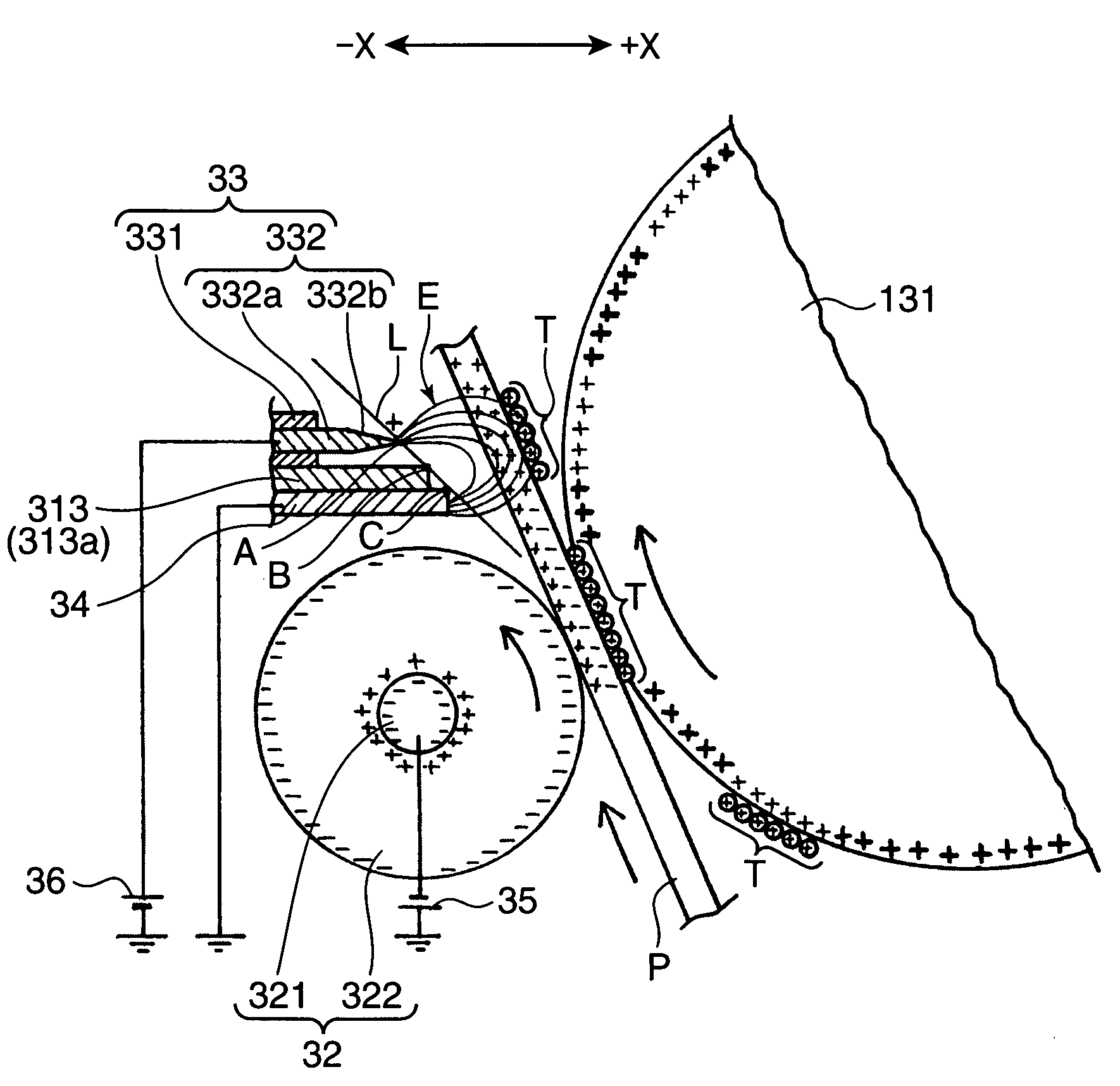

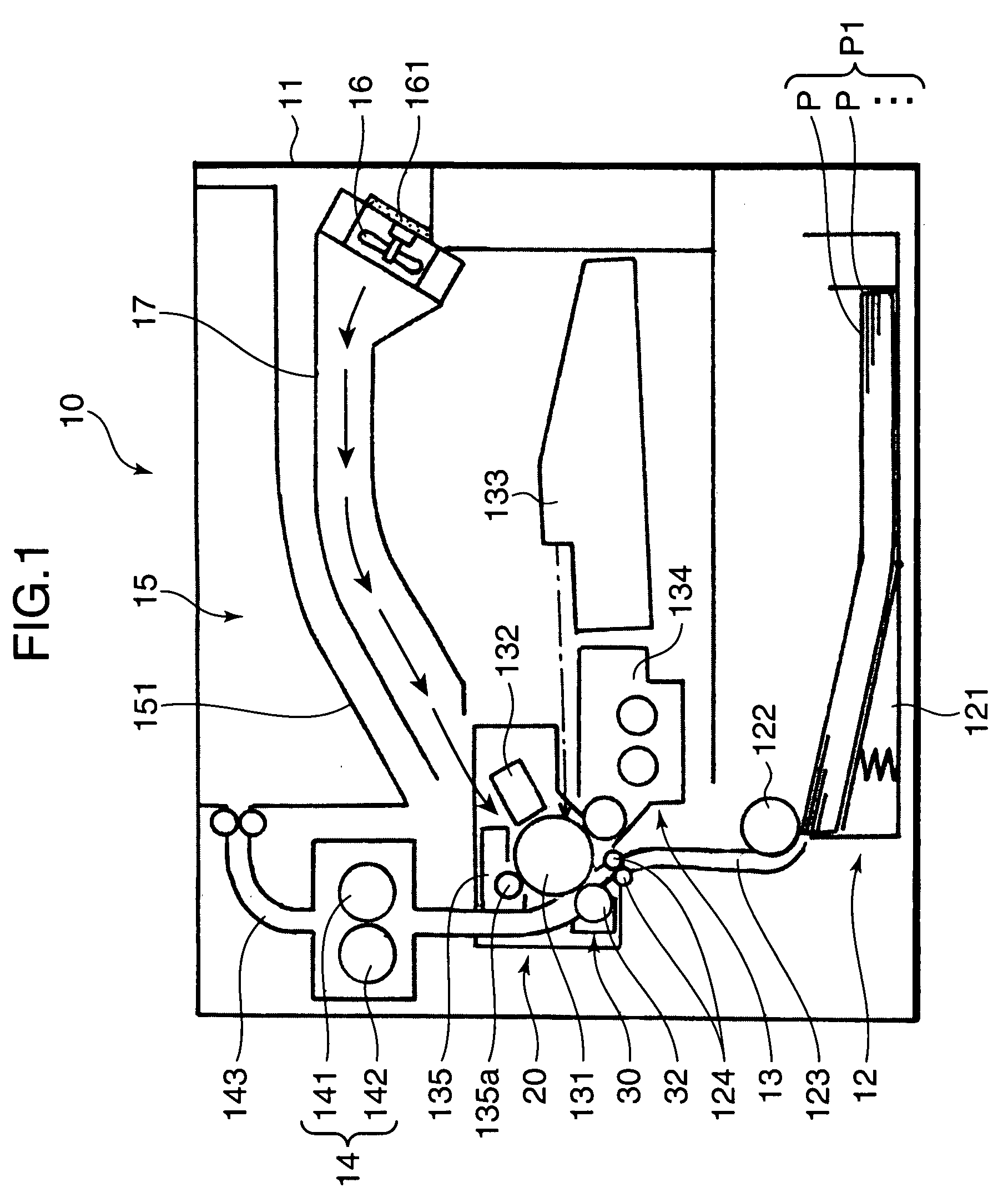

Image forming apparatus with static charge eliminator for discharging an electric charge on a transfer sheet

An image forming apparatus comprises: a revolving image bearing member on which a toner image is formed; a transfer member that is provided at a position facing the surface of the image bearing member and transferring the toner image electrostatically on a transfer sheet traveling between the image bearing member and the transfer member; a static charge eliminator generating an electric field for discharging the electric charge on the transfer sheet for separation of the transfer sheet carrying the transferred toner image from the image bearing member; and a conductive member that is provided between the static charge eliminator and the transfer member.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Impurity-removing cleaning machine

ActiveCN108035133AEasy to changeEasy to cut offMechanical cleaningPressure cleaningPulp and paper industryHearing perception

The invention provides an impurity-removing cleaning machine. The impurity-removing cleaning machine comprises a rack, a thread residue removing device, a cloth shaking mechanism, a static eliminator,a cleaning device and a dust collecting device; the thread residue removing device includes a thread cutting mechanism, a mobile frame and a supporting platform; the cloth shaking mechanism and the static eliminator are disposed between a first support roller and a second support roller; the cleaning device includes a housing, a first fan blade, a second fan blade, a third fan blade and a first suction fan; and the dust collecting device includes an air suction opening, an air suction tube, a second air suction fan and a dust collecting box. According to the impurity-removing cleaning machineof the present invention, the thread residue removing device can remove redundant thread residues at two sides of a textile; the cloth shaking mechanism and the static eliminator are used in cooperation, so that impurities attached onto the textile can be shacked off more easily; the cleaning device is provided with a dust removal fan and a dust removal brush, and hearing rollers can dry the textile, and therefore, dust can fall off more easily, and dust removal is more thorough; and therefore, the quality of the textile can be ensured, and the health of staff can be ensured.

Owner:青岛凯尊帽业有限公司

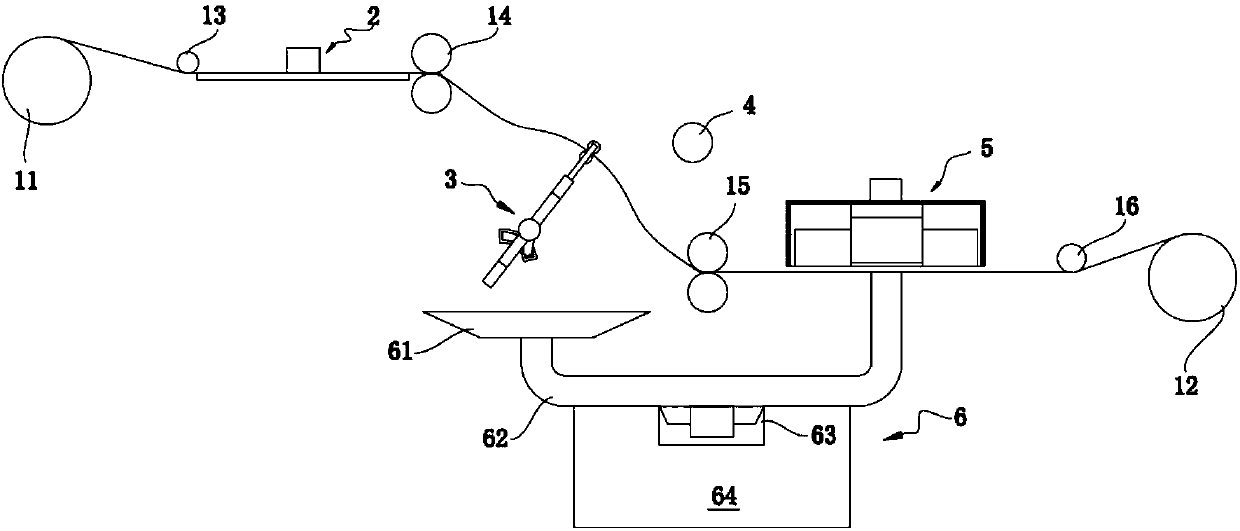

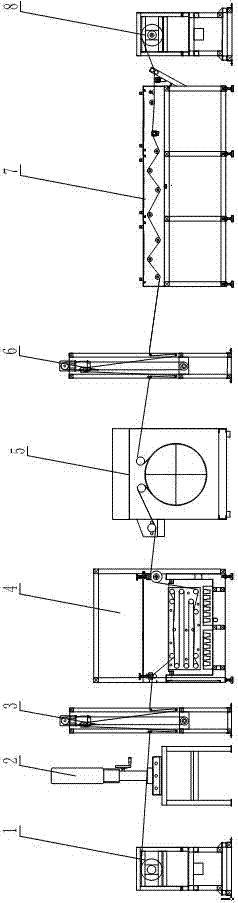

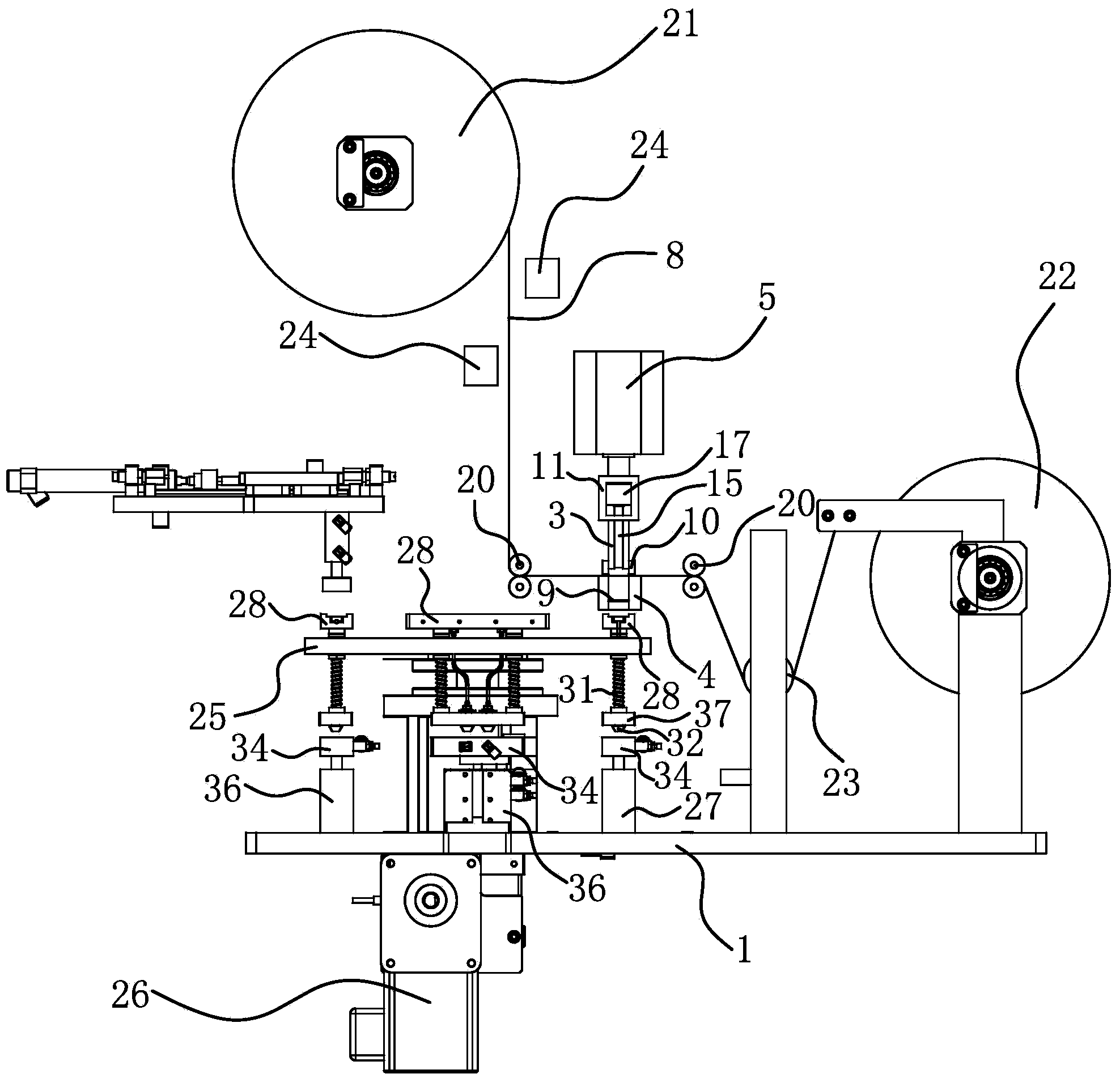

Automatic processing system for rolled cloth

InactiveCN103086186AImprove processing efficiencyImprove processing qualityArticle deliveryWebs handlingUltrasonic weldingMegasonic cleaning

The invention relates to an automatic processing system for rolled cloth. The automatic processing system comprises a programmable control device. The programmable control device is respectively connected with an unrolling rectification device, an ultrasonic welding device, a feeding tension damping device, an ultrasonic cleaning device, a drying device, a discharge tension damping device, a flattening machine and a rolling rectification device to control the whole production process, wherein the unrolling rectification device, the ultrasonic welding device, the feeding tension damping device, the ultrasonic cleaning device, the drying device, the discharge tension damping device, the flattening machine and the rolling rectification device are sequentially arranged along the cloth conveying direction. The unrolling rectification device and the rolling rectification device are respectively provided with a photoelectric rectification sensor, the feeding tension damping device and the discharge tension damping device are respectively provided with a tension sensor, the drying device is provided with a temperature sensor, and the flattening machine is provided with a static electricity eliminator. By means of the automatic processing system for the rolled cloth in the structure, the production process can be monitored in real time, rapid adjustment can be carried out, meanwhile, cleanliness of the production process is improved, and therefore processing efficiency and processing quality of the rolled cloth are improved.

Owner:MAXCLEAN WUXI TECH

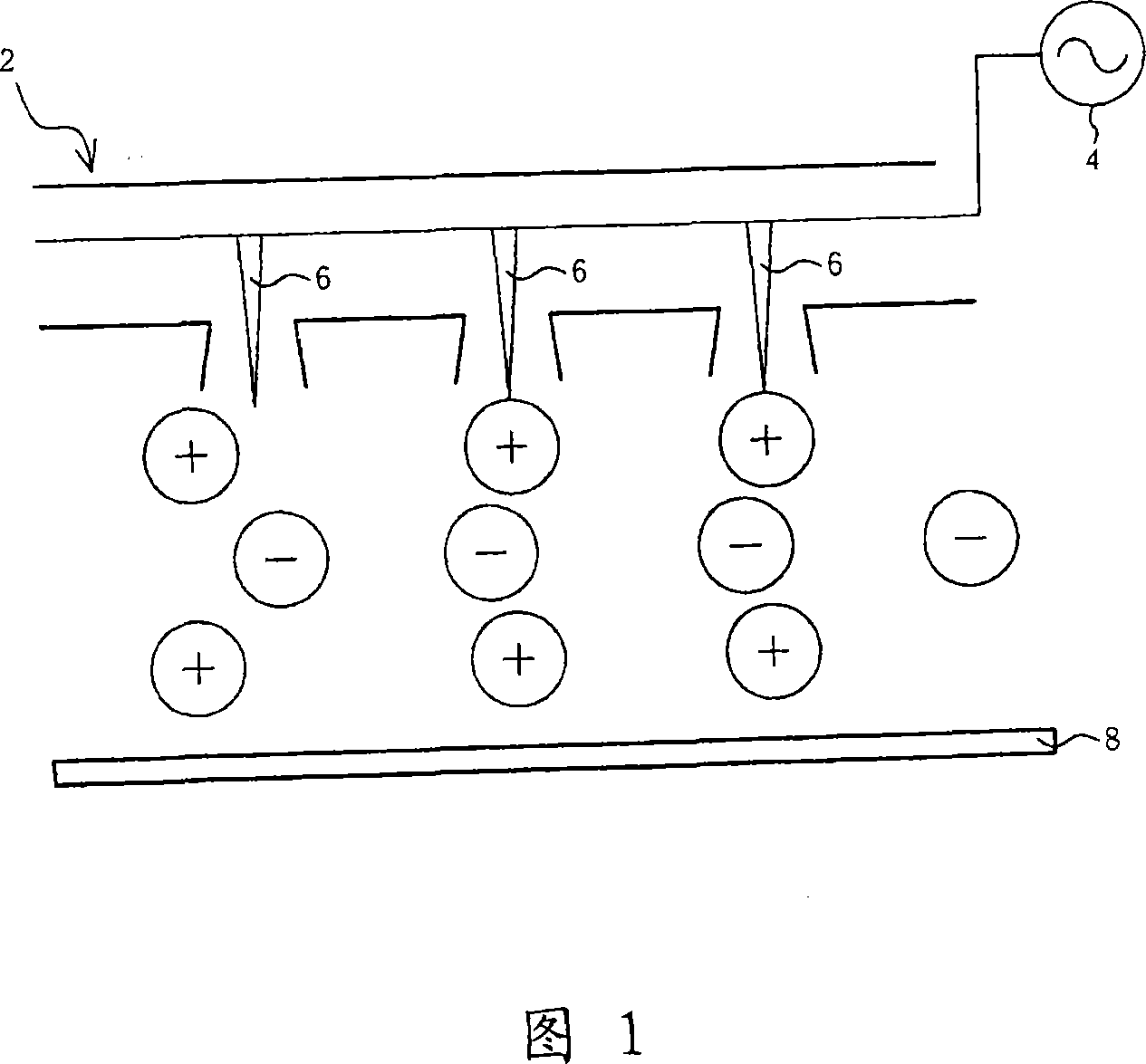

System for eliminating static

ActiveCN101197302AReduce the number of installationsReduce the use effectSemiconductor/solid-state device manufacturingCharge manipulationRobotic armStatic eliminators

A system for static elimination comprises an electric-manipulator, a grip jaw arranged in the front end of the electric-manipulator, a connecting rod set arranged on the electric-manipulator and a static eliminator arranged on the connecting rod set. The static eliminator can reciprocate in a fixed scope to eliminate static by the connecting rod set.

Owner:AU OPTRONICS CORP

Image forming apparatus

An image forming apparatus comprises: a revolving image bearing member on which a toner image is formed; a transfer member that is provided at a position facing the surface of the image bearing member and transferring the toner image electrostatically on a transfer sheet traveling between the image bearing member and the transfer member; a static charge eliminator generating an electric field for discharging the electric charge on the transfer sheet for separation of the transfer sheet carrying the transferred toner image from the image bearing member; and a conductive member that is provided between the static charge eliminator and the transfer member.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Static eliminator

ActiveUS7248454B2Emergency protective arrangement detailsArrangements responsive to excess voltageFiberElectrical conductor

There is provided a static eliminator which comprises an ion generating portion in the form of tape. There is also provided a self-discharged static eliminator comprising an conductor provided with discharge whiskers in which the conductor is applied with a predetermined voltage. There is also provided a DC type of self-discharged fiber-like static eliminator which comprises plus fiber electrodes applied with plus voltage, minus fiber electrodes applied with minus voltage, a support disposed between the plus and minus electrodes for supporting the plus and minus electrodes and provided with insulation reserving member for preventing the spark discharge or short due to the access of the plus and minus electrodes.

Owner:TRINC

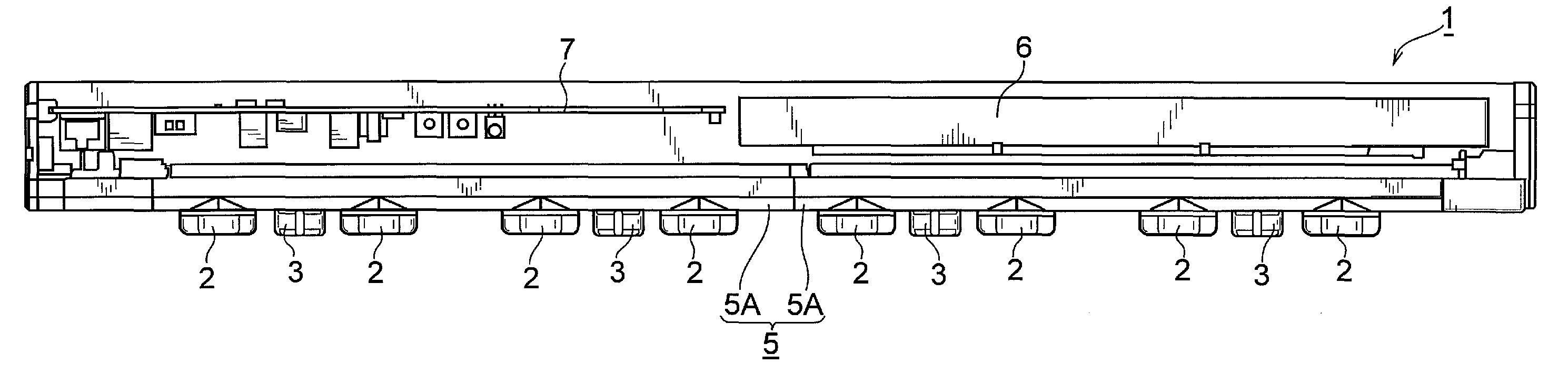

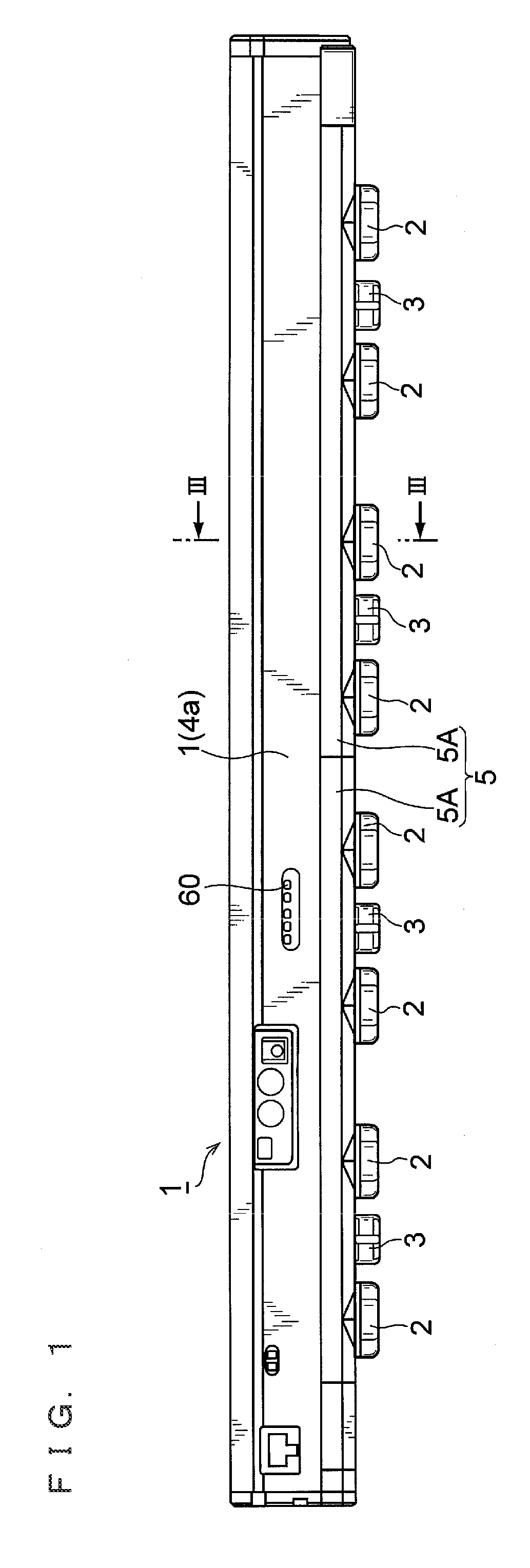

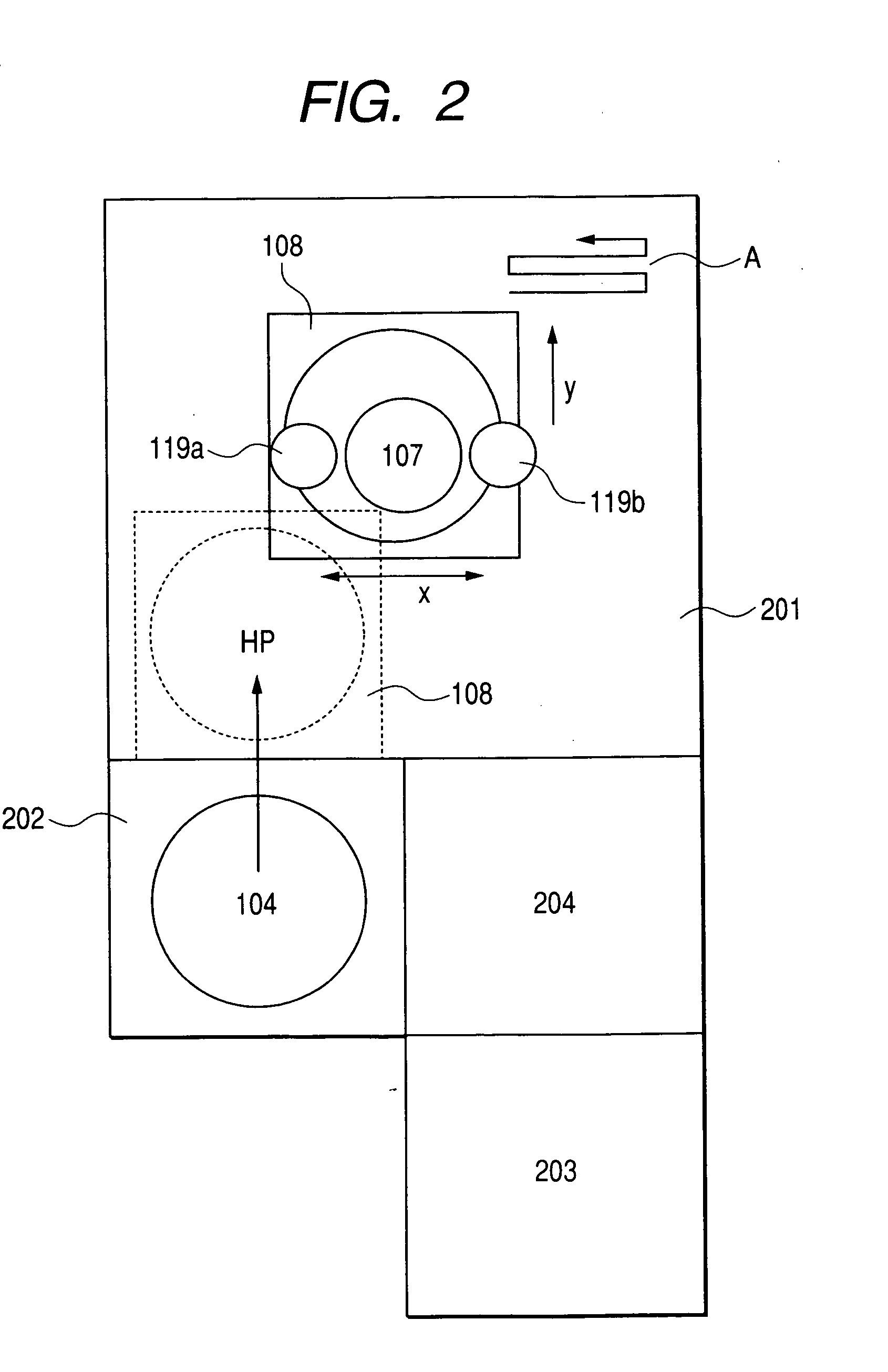

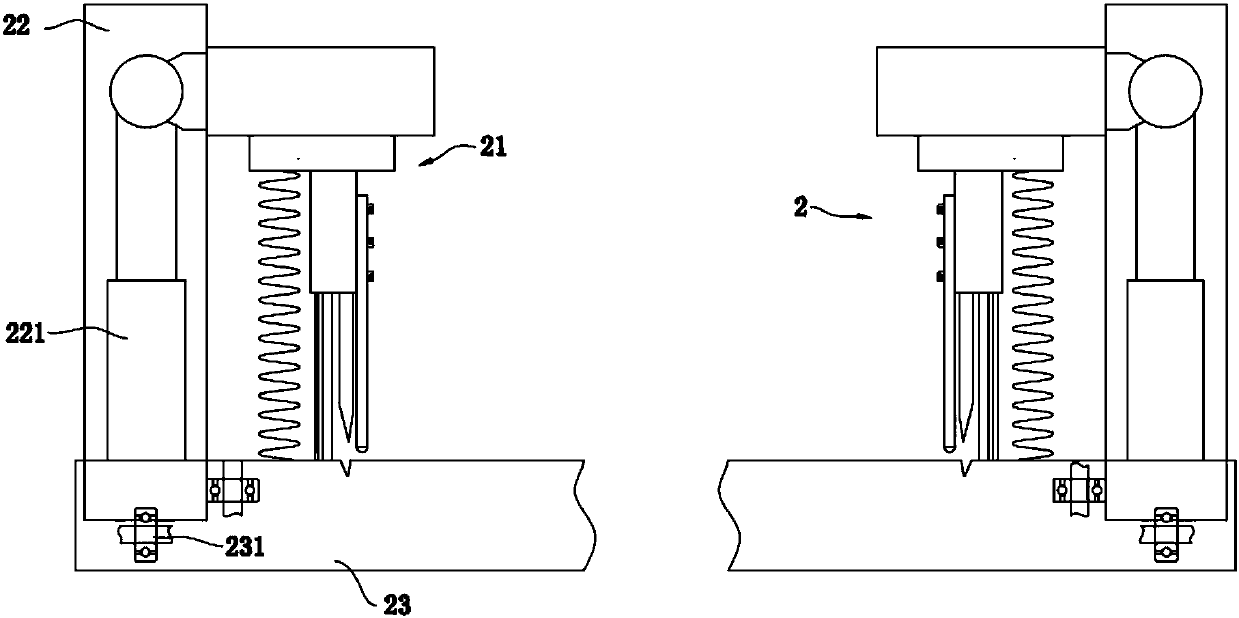

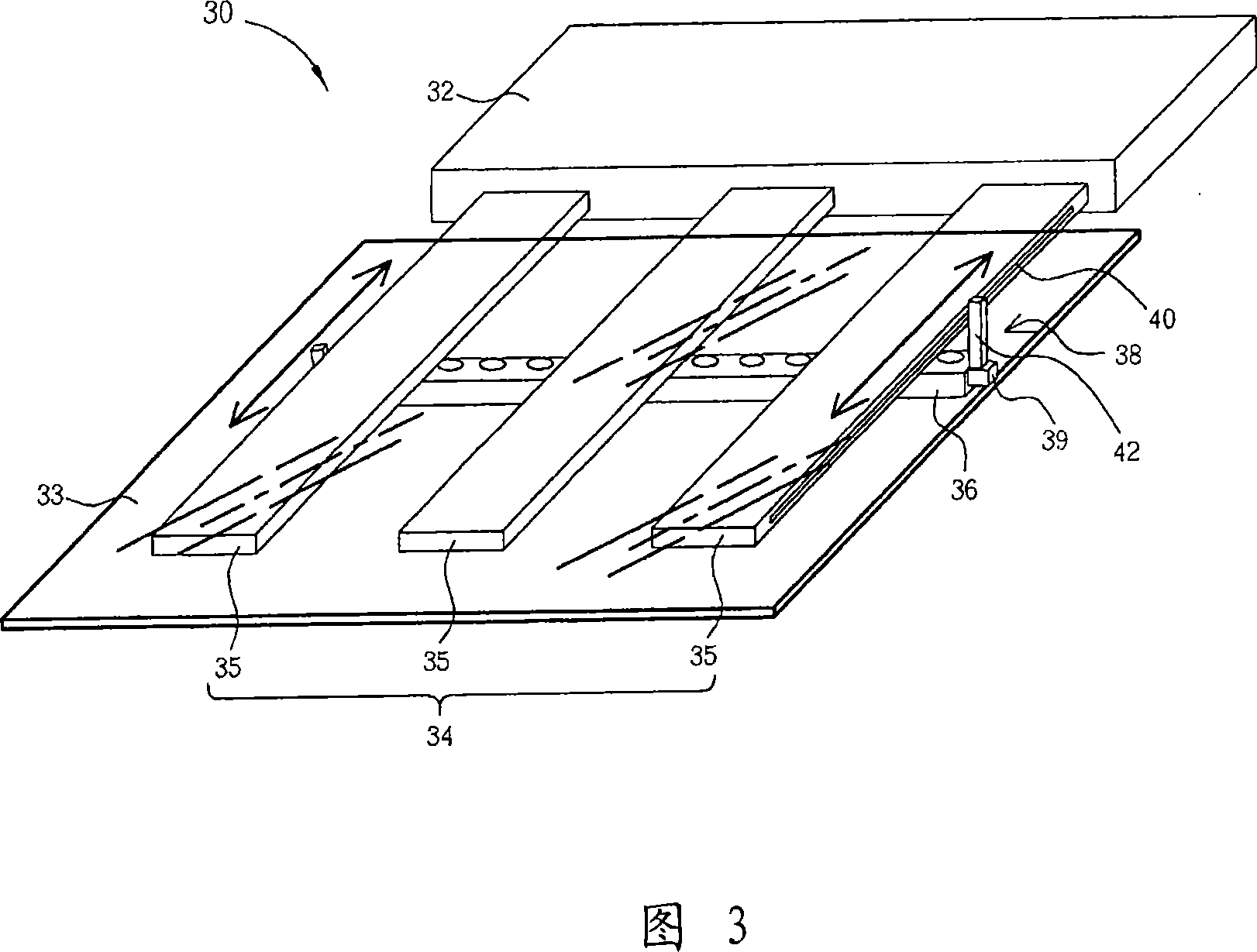

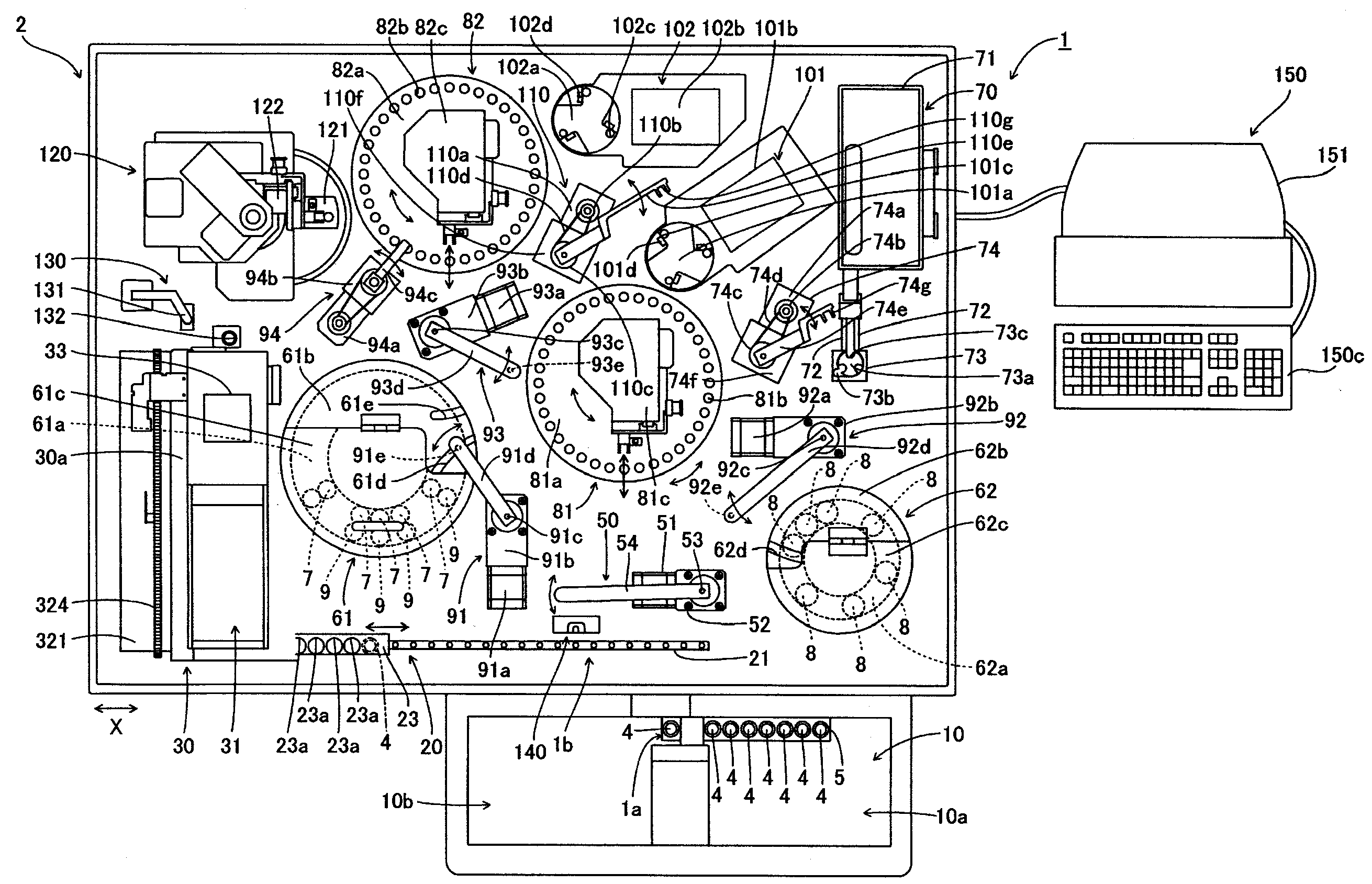

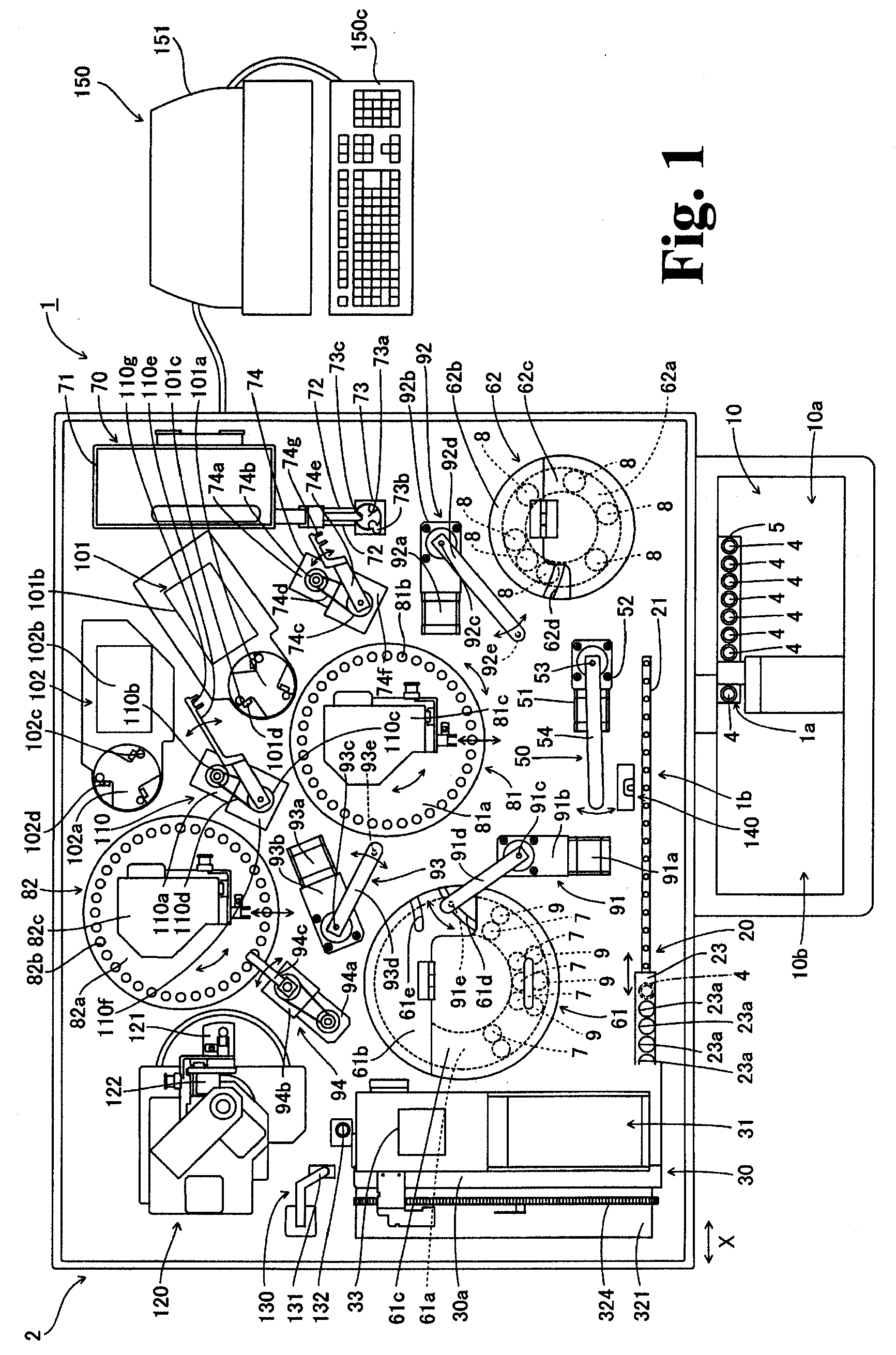

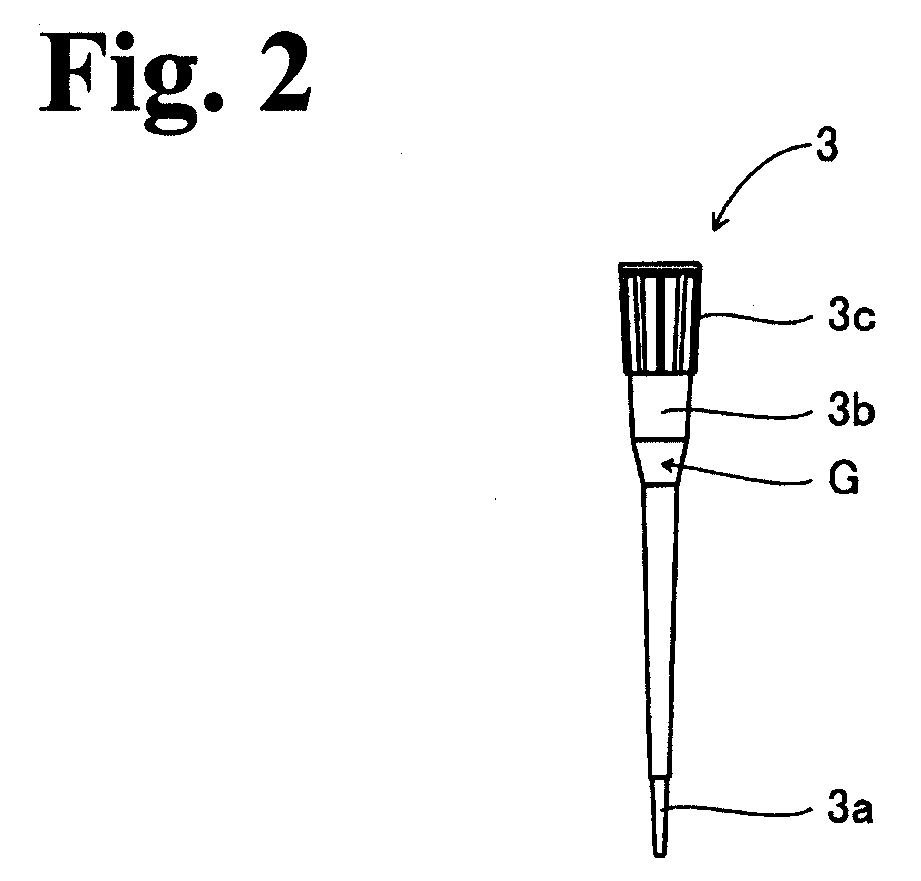

Pipette tip supplier and sample analyzer

InactiveUS20090081081A1Analysis using chemical indicatorsLaboratory glasswaresPipetteStatic eliminators

The present invention is to present a pipette tip supplier and a sample analyzer which are capable of increasing an efficiency of eliminating electrification charge of the pipette tip than ever before. The pipette tip supplier comprises: a tip supply mechanism section 32 for containing pipette tips 3; a tip storing section 34 for storing pipette tips 3 supplied from the tip supply mechanism section 32; a static eliminator fan 33 for performing an eliminating operation for eliminating electrification charge of the pipette tips 3 being stored in the tip storing section 34; and a separating mechanism section 36 for performing a separating operation for separating the pipette tips 3 being stored in the tip storing section 34 one by one.

Owner:SYSMEX CORP

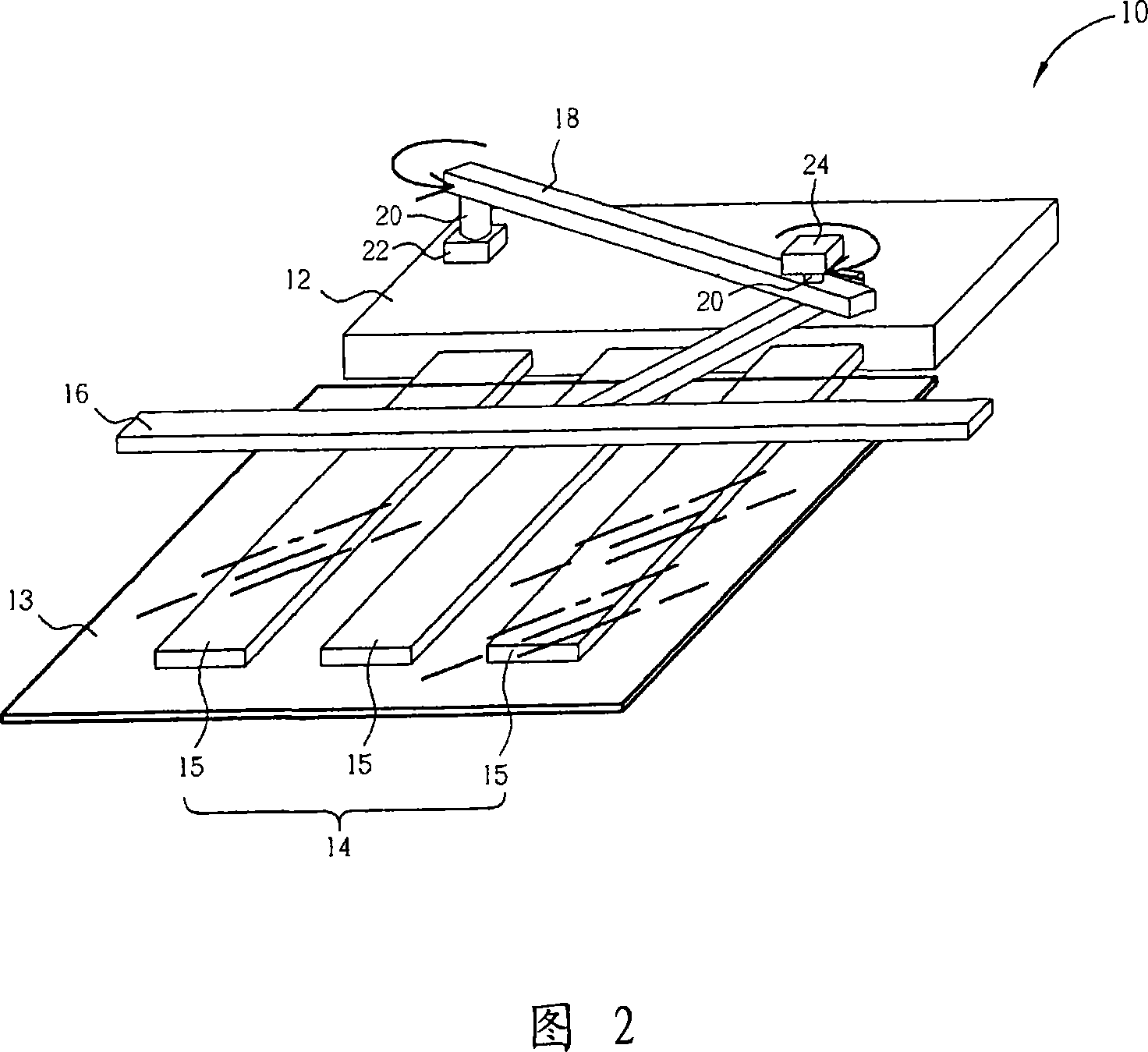

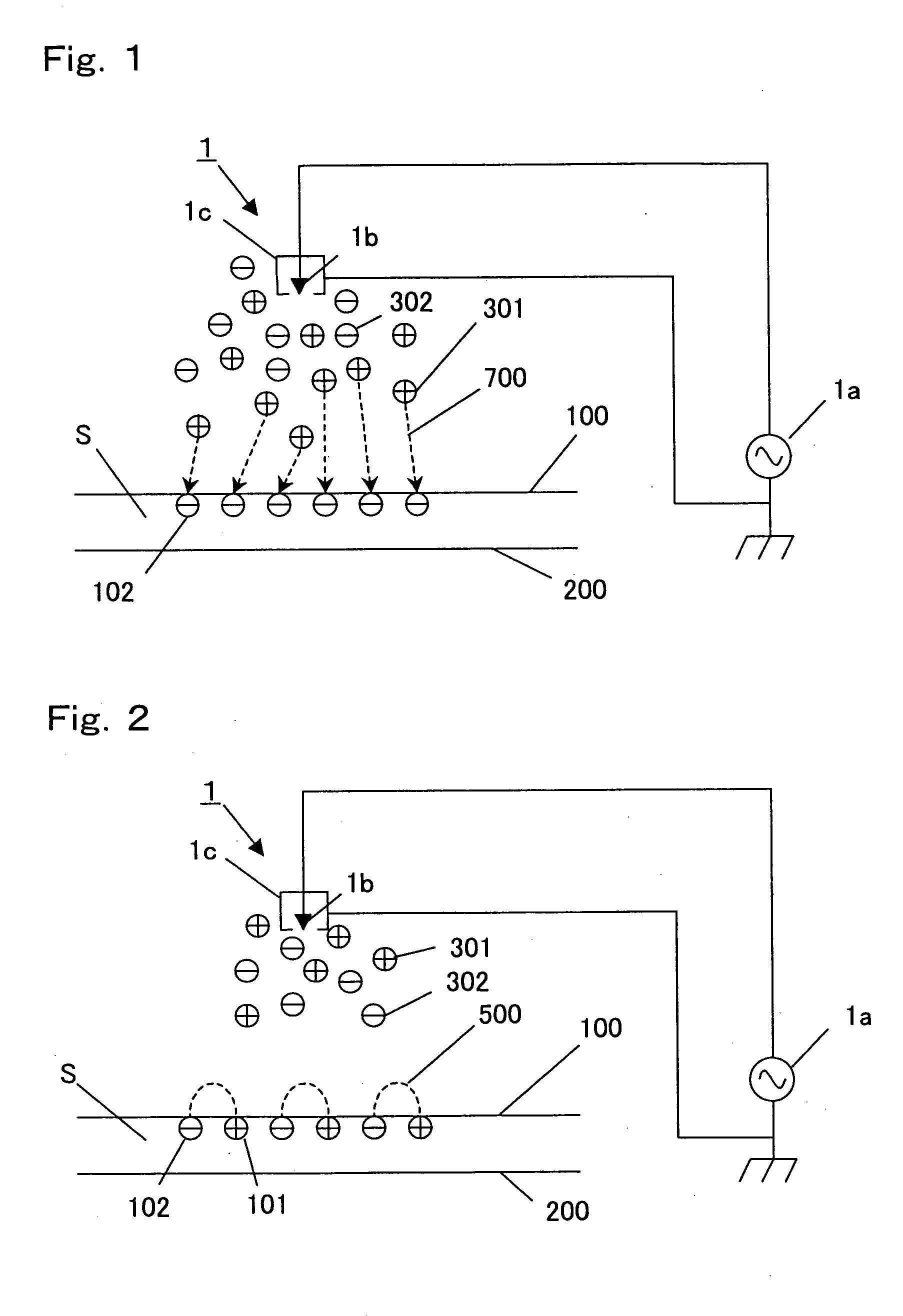

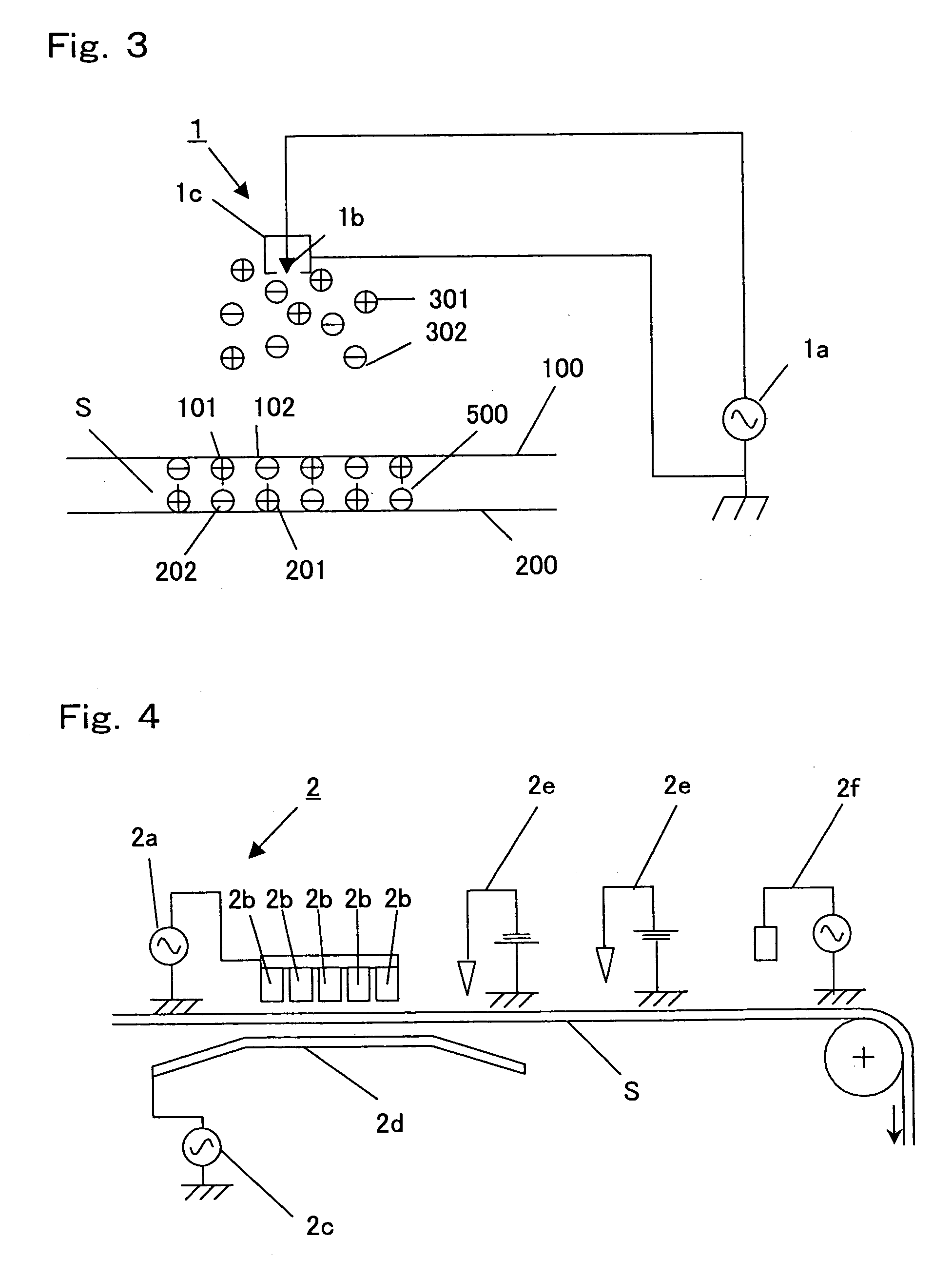

Static eliminator and a static eliminating method for an insulating sheet, a method for producing an insulating sheet, and an insulating sheet

InactiveUS20050030694A1Easy to eliminateSmall differenceEmergency protective arrangement detailsElectrostatic chargesElectrical polarityEngineering

At least 2 sets of ion-generating means are provided to face each other through a space having an insulating sheet, and the first and second surfaces of the sheet are simultaneously irradiated with monopolar ion clouds substantially opposite to each other in polarity generated from the ion-generating means and subsequently irradiated with monopolar ion clouds reverse in polarity to that of the previously applied ion clouds, to eliminate the positive and negative charges of both the surfaces of the insulating sheet.

Owner:TORAY IND INC

Intake system of vehicle

ActiveUS20160186703A1Improve air intake efficiencyDispersed particle filtrationMachines/enginesEngineeringStatic eliminators

An intake system of a vehicle, includes an air cleaner case, an air filter that is arranged inside the air cleaner case and positively charged, and a self discharge type static eliminator that decreases an amount of electrification charge on a wall surface of the air cleaner case within a limited range about a location where the self discharge type static eliminator is installed, when the self discharge type static eliminator is installed on the wall surface of the air cleaner case. An peripheral edge part of the air filter is held by an air filter holding part of the air cleaner case. The self discharge type static eliminator is installed on an outer wall surface of the air filter holding part of the air cleaner case.

Owner:TOYOTA JIDOSHA KK

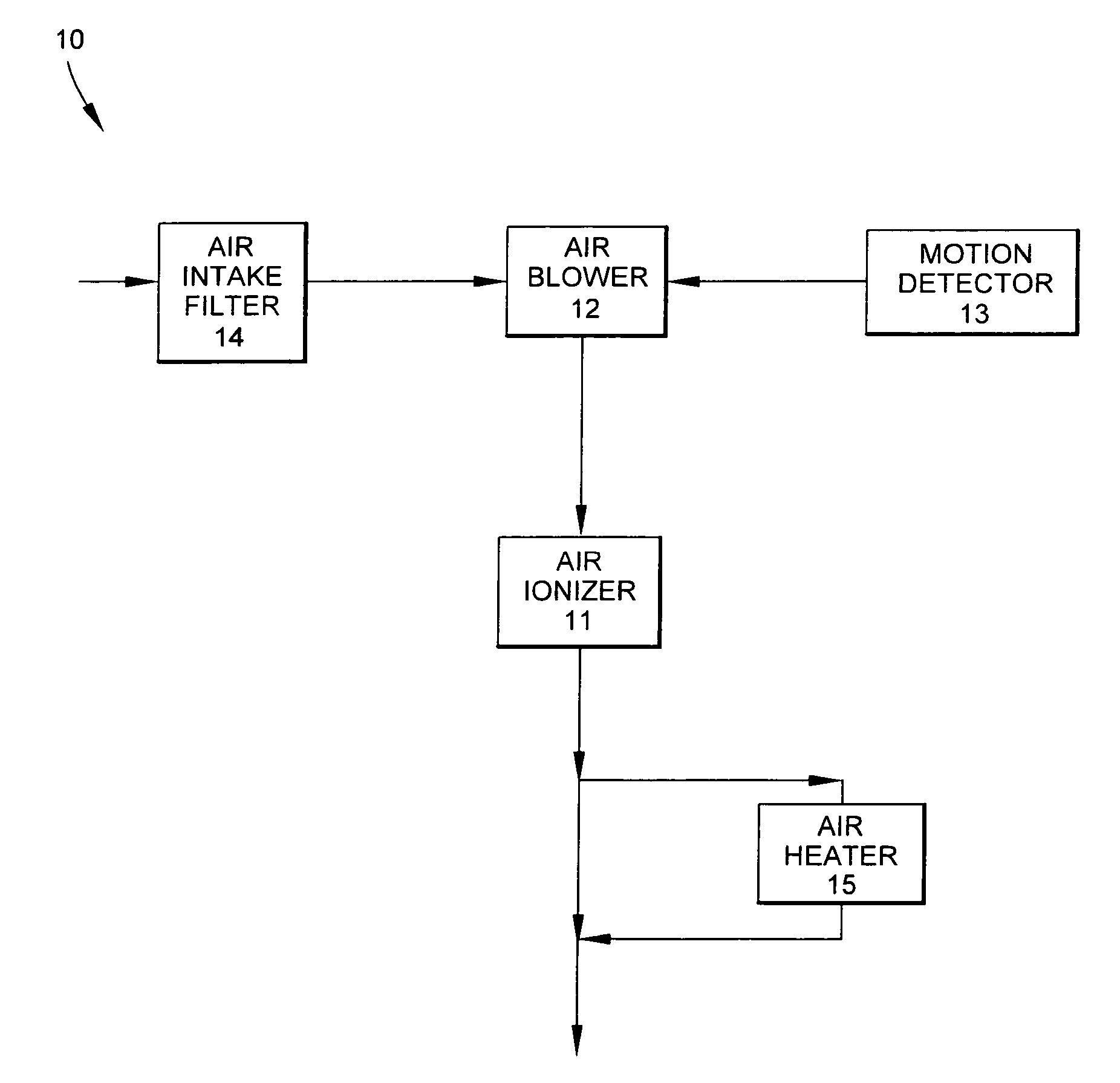

Static electricity eliminator

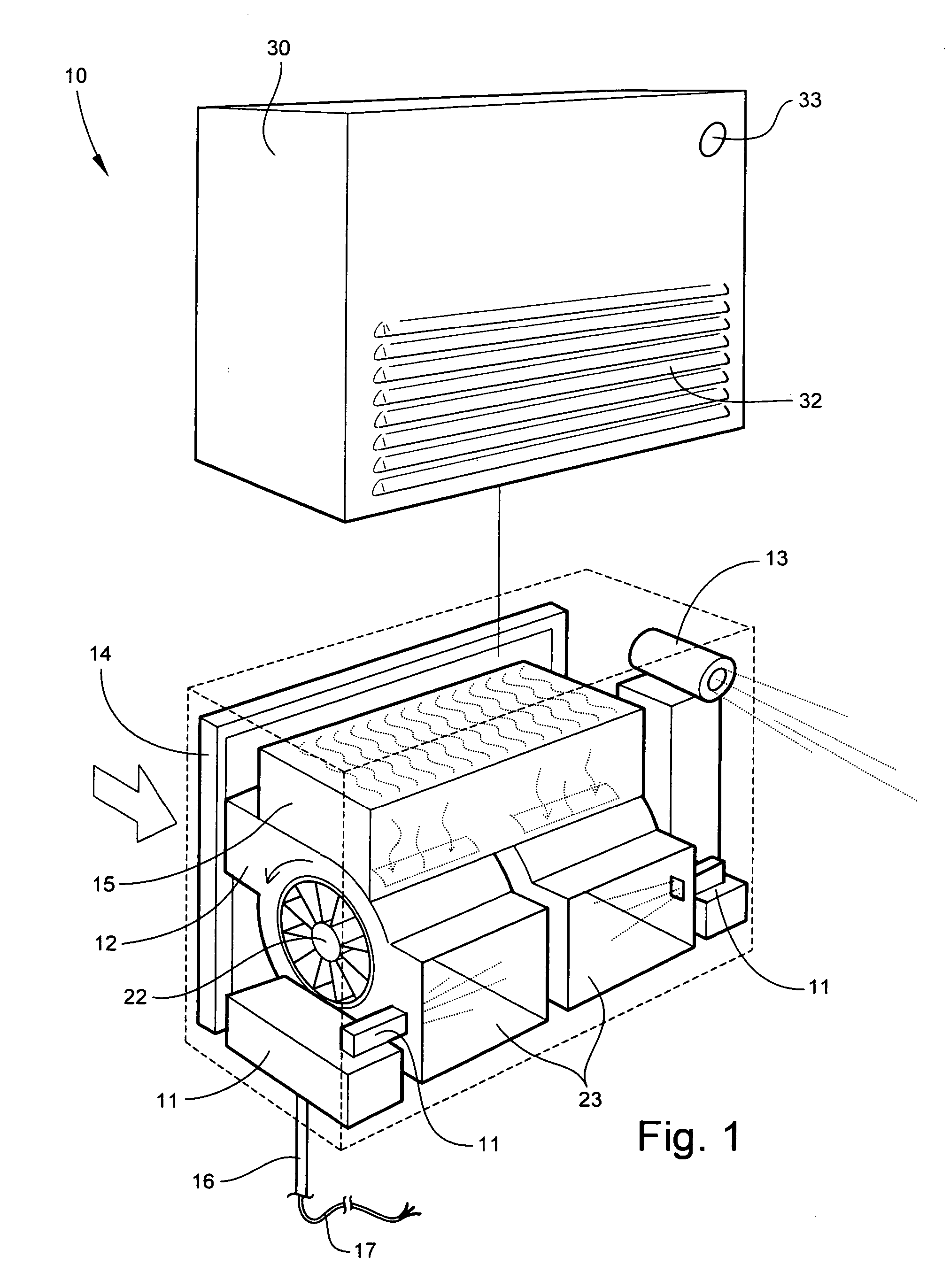

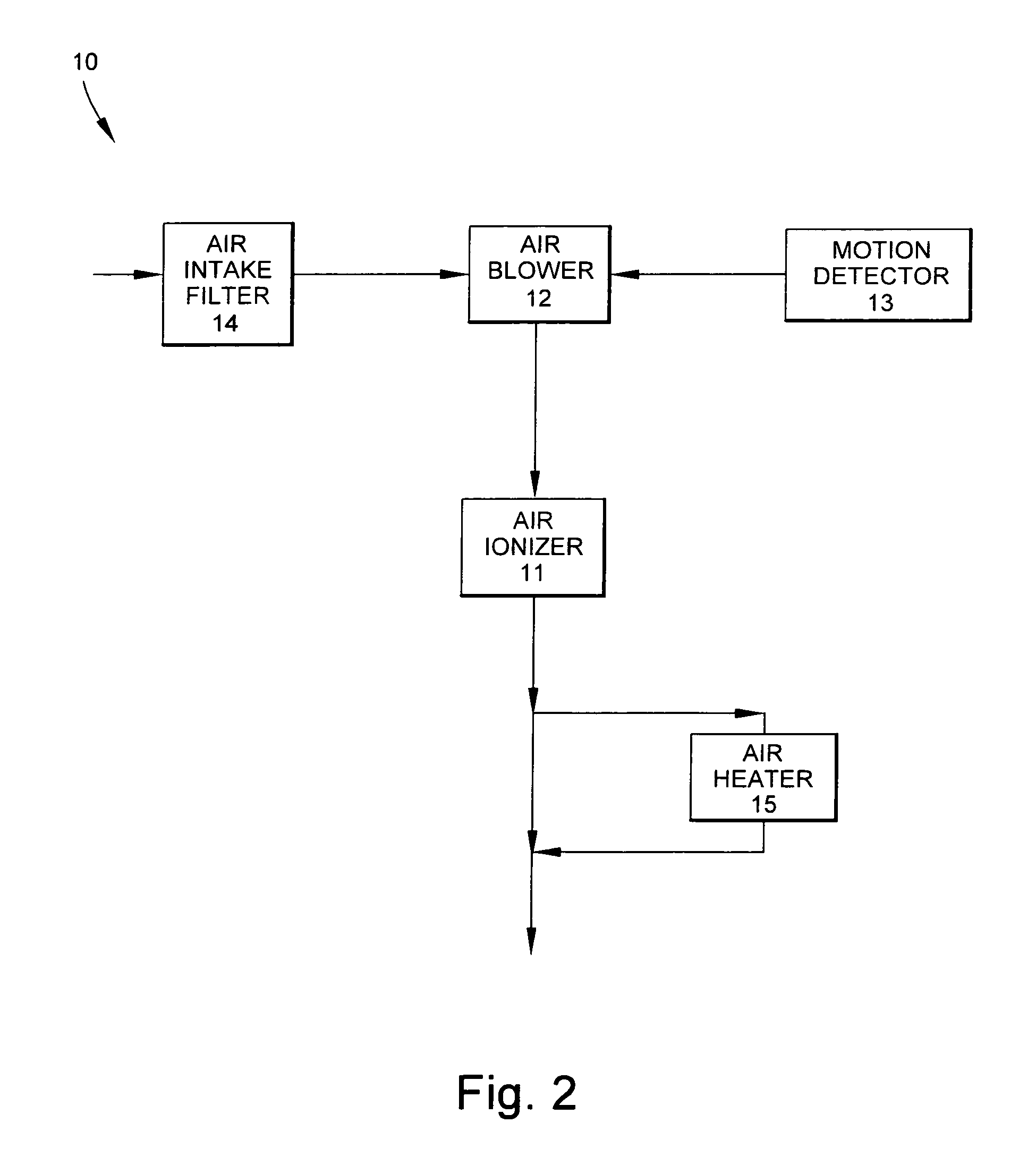

InactiveUS20060176642A1Reduce riskLiquid transferring devicesParticle charging/ionising stationsMotion detectorEngineering

An apparatus for reducing static electricity includes an ionizer that generates ions for neutralizing static electricity, a blower that produces a current of air for moving the ions to a desired location, and a motion detector operatively connected to the blower. Upon detecting motion, the motion detector activates the blower, which disperses ions to reduce static electricity at the desired location. The apparatus can include a heater for heating the current of ionized air. In addition, the motion detector can be operatively linked to the ionizer and heater so that they are also activated upon detection of motion. The blower can be linked to a timer such that it runs for a predetermined amount of time upon activation by the motion detector, or the blower can run continuously until the motion detector no longer detects any motion. The apparatus is particularly useful for reducing static electricity around fuel dispensers.

Owner:GEORGE KENT J +2

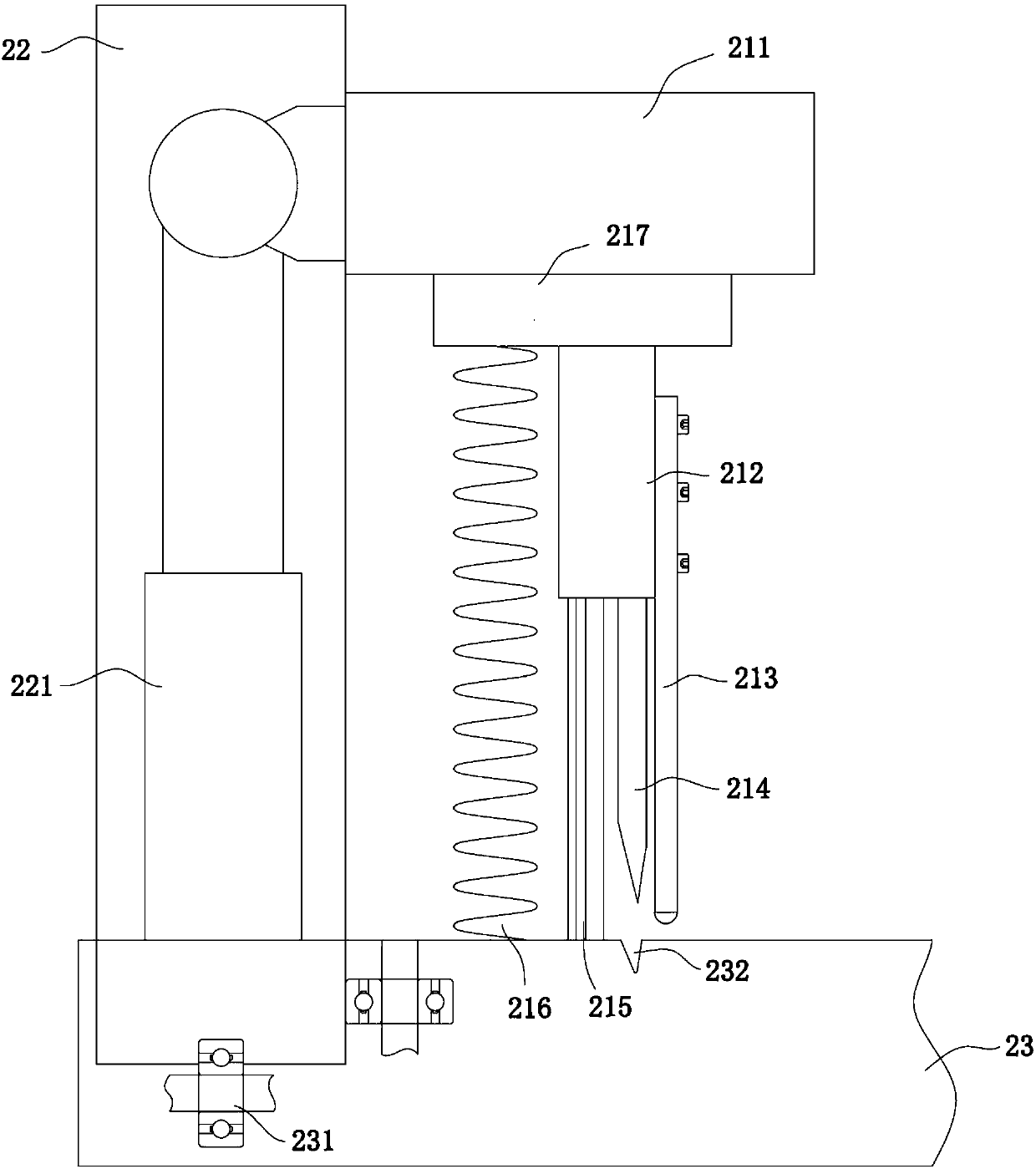

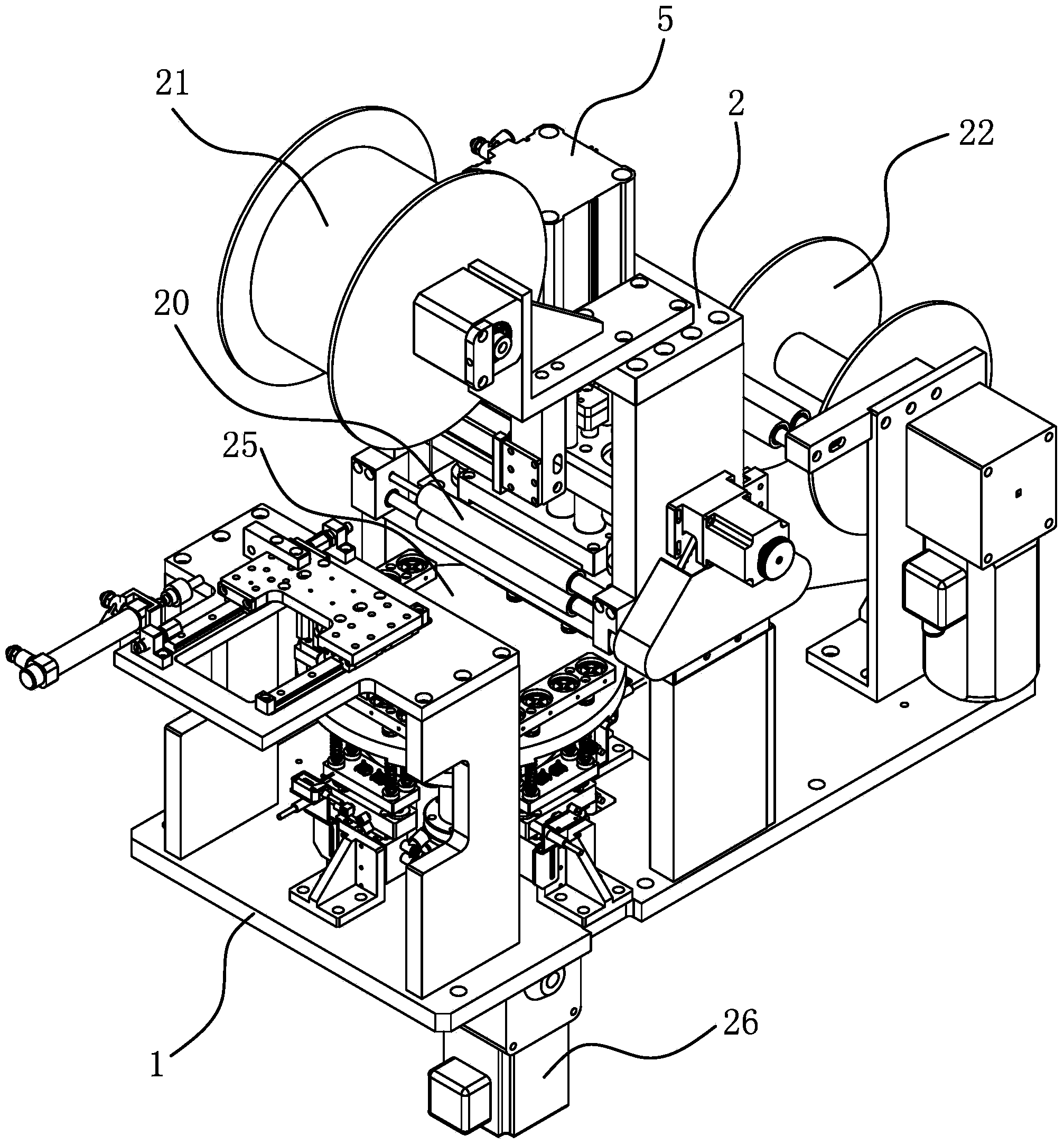

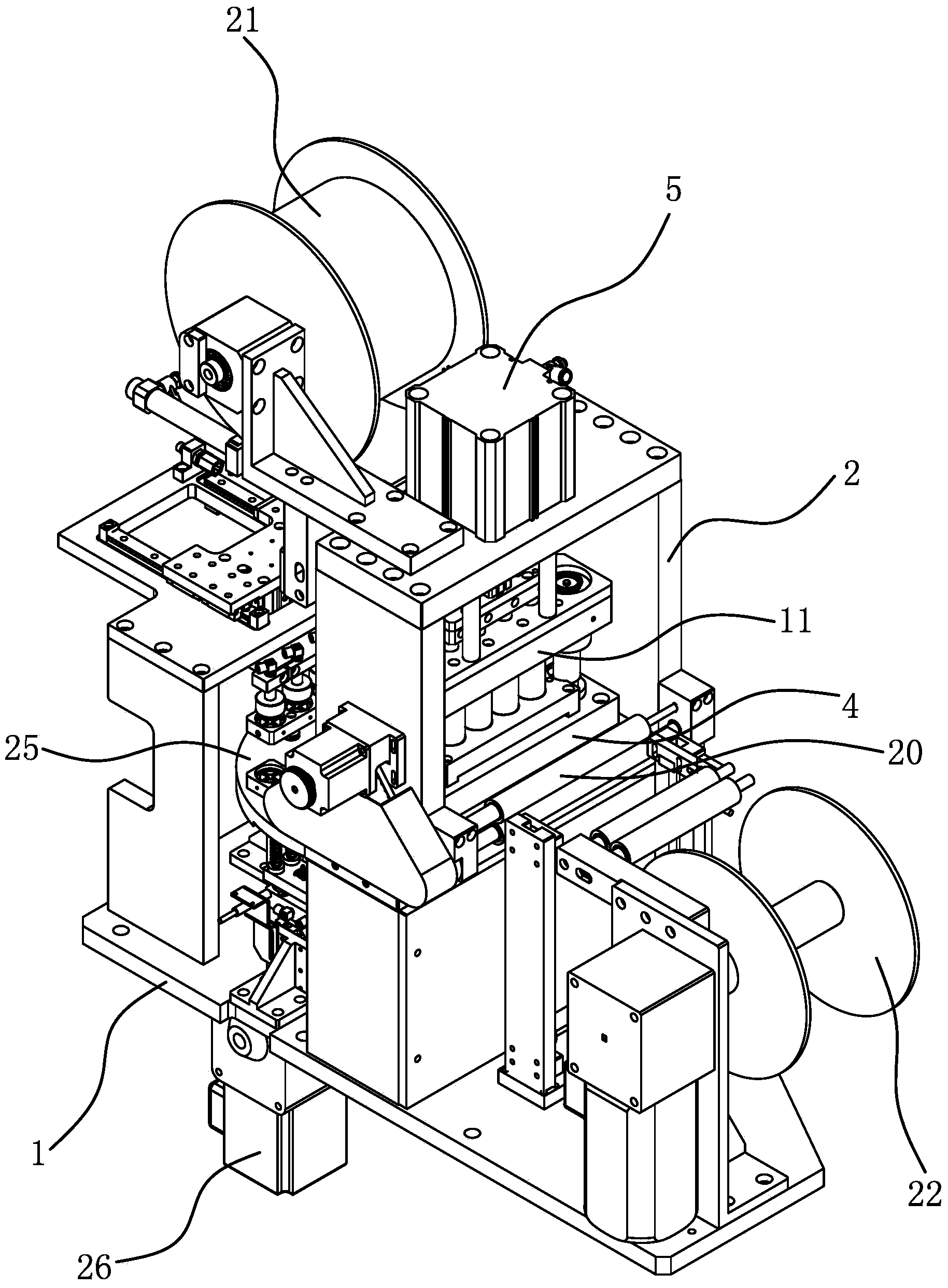

Punching device for medical precision filtering membrane

ActiveCN103586937AReduce the possibilityRaise the possibilityMetal working apparatusElectrostatic chargesPunchingEngineering

The invention provides a punching device for a medical precision filtering membrane, and belongs to the technical field of machines. The punching device resolves the problems that an existing punching device is utilized to punch a membrane, and a filtering membrane belt easily has the problem of producing static electricity in a conveying process and a repeated punching process. The punching device for the medical precision filtering membrane comprises a fixed support, a punching rod and a female die, wherein a punching hole is formed in the female die, the female die is fixedly connected with the fixed support, and the fixed support is provided with a first driving piece enabling the punching rod to move upwards and downwards and capable of being embedded into the punching hole. The punching device further comprises a discharging pressure head and an air electrostatic eliminator, the punching rod is of a tubular shape, the discharging pressure head is arranged in the punching rod and located at a lower port, an air-blowing port is formed in the lower end face of the discharging pressure head, and an air outlet of the air electrostatic eliminator is communicated with the air-blowing port. According to the punching device for the medical precision filtering membrane, by elimination of static electricity, the possibility that the filtering membrane is clamped in the female die is greatly reduced.

Owner:MAIDER MEDICAL IND EQUIP

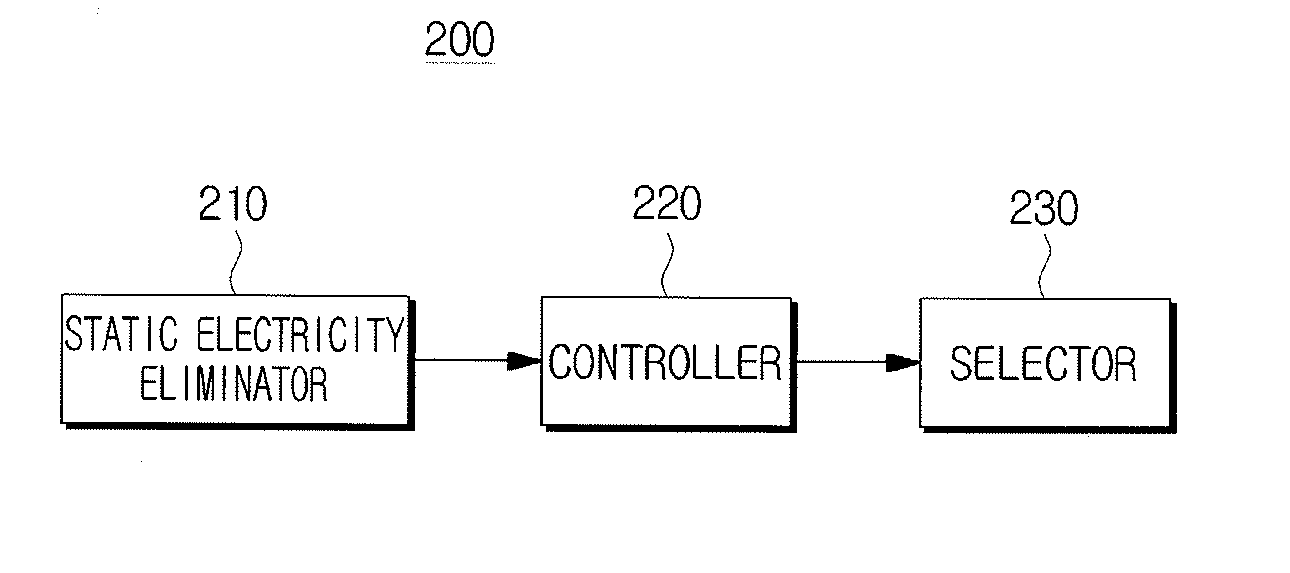

Image forming apparatus and method thereof

ActiveUS20080317485A1Improve printing qualityEliminate residual chargeElectrographic process apparatusElectrical resistance and conductanceImage formation

An image forming apparatus includes a static electricity eliminator to remove residual charge from a printing medium. A selector is provided to connect the static electricity eliminator to ground through a selected resistance, and a controller is provided to control the selector depending on printing medium characteristics. The resistance in the ground path connected to the static electricity eliminator is changed according to printing medium characteristics such that elimination of residual charge is effective over a range of printing media having different printing medium characteristics.

Owner:HEWLETT PACKARD DEV CO LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com