Pipe type static eliminator

A static eliminator, pipeline-type technology, applied in the direction of static electricity, piping systems, electrical components, etc., can solve problems such as static electricity accidents, high static voltage, unavoidable static charge discharge accidents, etc., and achieve the effect of eliminating static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

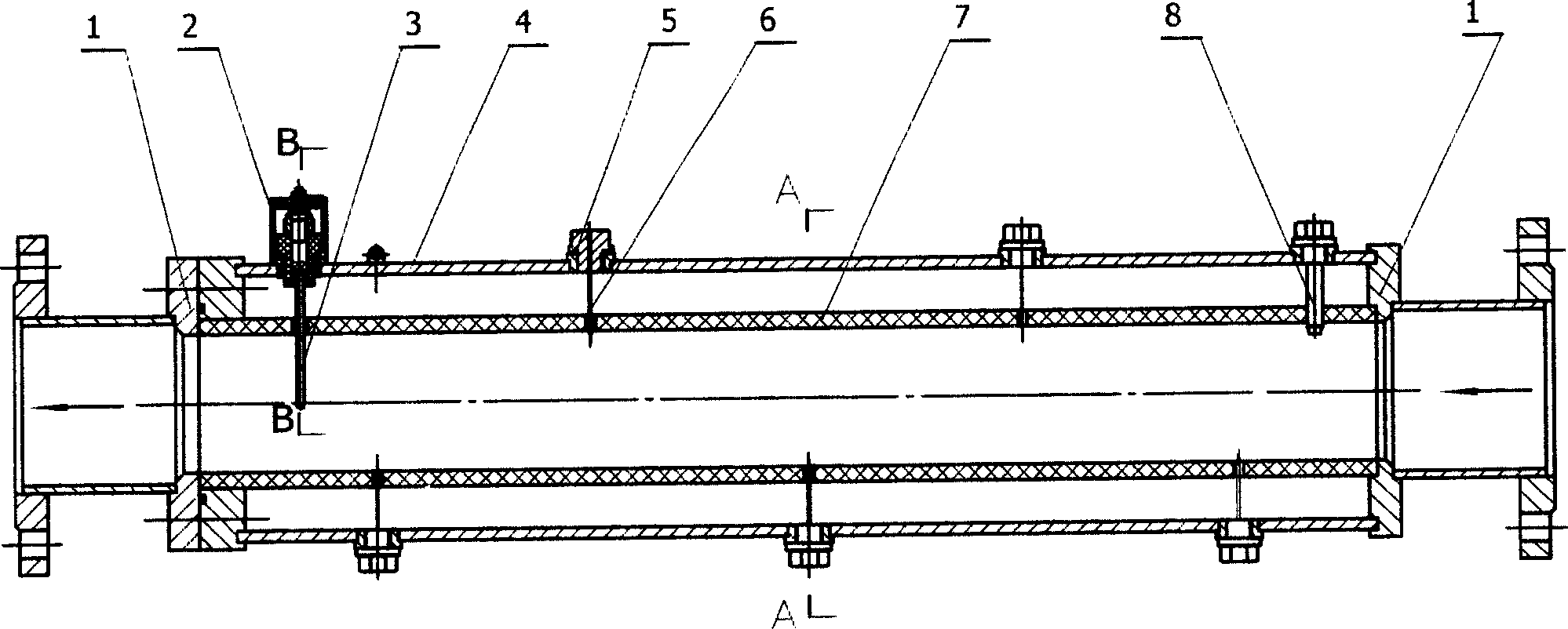

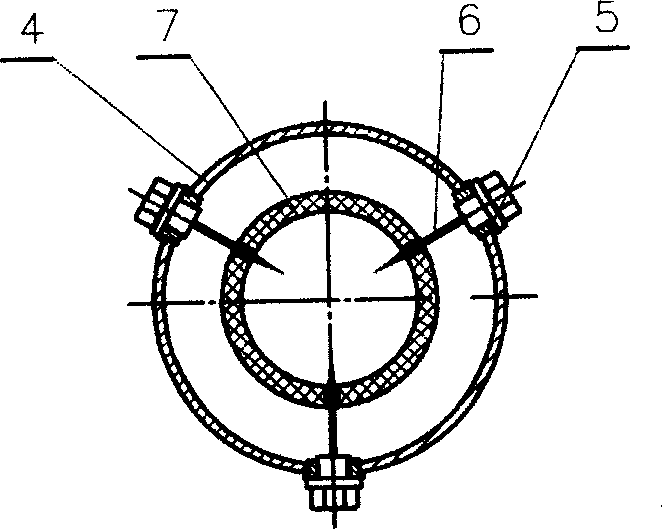

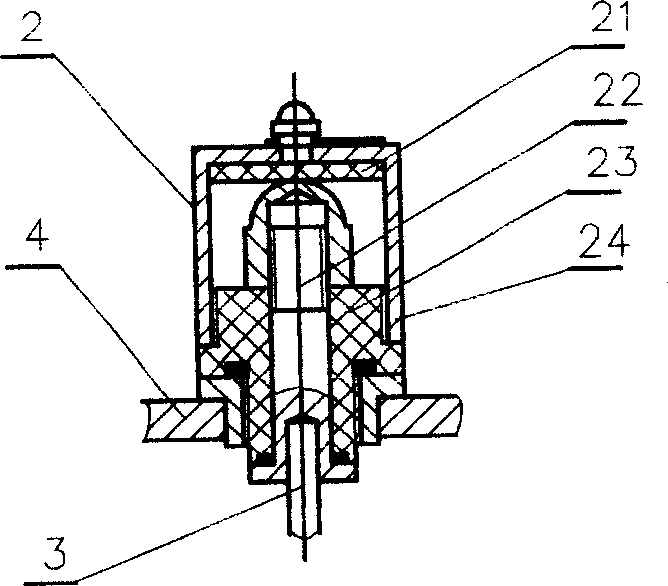

[0014] figure 1 Shown is the pipeline type static eliminator of the present invention, and the two ends of the oil delivery pipe 7 are fixedly connected with the support flange 1, and the oil delivery pipe 7 is an insulating oil delivery pipeline made of plastic; The outside of 1 is connected with a short oil pipe and a connecting flange at the end of the short pipe, and the connecting flange is used to connect the pipeline static eliminator of the present invention in series with the oil pipeline. On the outer side of the above-mentioned oil product delivery pipe 7, a discharge outer tube 4 is concentrically set. A space is formed between the inner wall of 4 and the outer wall of the oil delivery pipe 7, and its spacing is at least 30mm, and 35mm is adopted in this example. A positioning pin 8 is arranged on the position of the discharge outer tube 4 close to the oil product inlet to align and maintain the relative position between the discharge tube 4 and the oil delivery p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com