System for eliminating static

A technology for eliminating static electricity and static eliminators, applied in the direction of static electricity, circuits, electrical components, etc., can solve the problems of increasing energy consumption of CDA, adding rod-shaped static eliminators, increasing costs, etc., to meet the requirements of reducing the size of the installation space, reducing CDA usage, effect of reducing the number of installations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

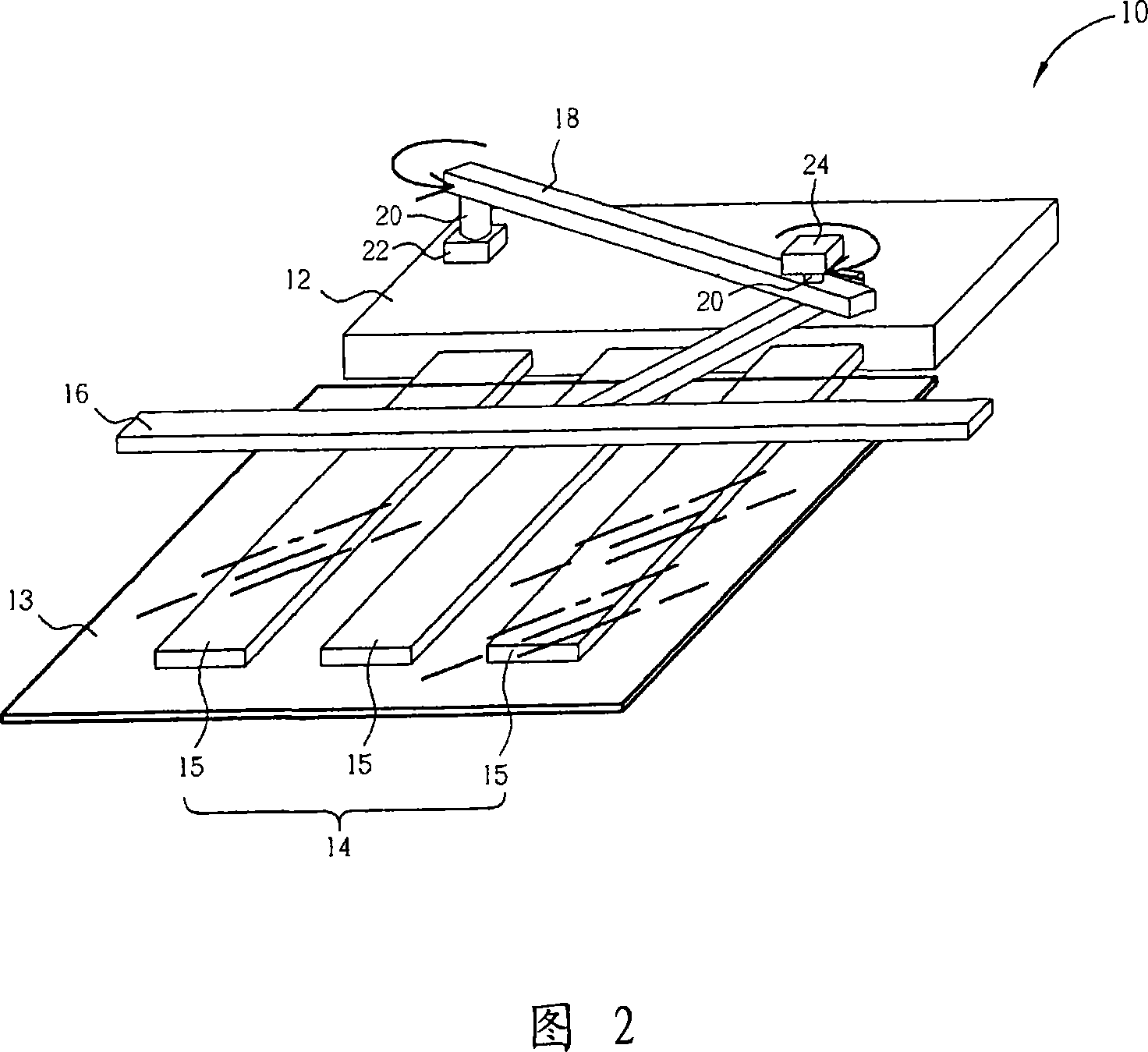

[0041] Fig. 2 is a schematic diagram of a system device for eliminating static electricity proposed by the first preferred embodiment of the present invention. As shown in Figure 2, the static elimination system 10 includes a mechanical arm 12, and the front end of the mechanical arm 12 has a gripper (fork) 14 for picking and placing the glass substrate 13, and the static eliminator 16 is connected by a connecting rod group 18 is erected on the mechanical arm 12. Wherein, the static eliminator 16 used in this preferred embodiment can be various types of static eliminator equipment such as rod type, fan type, high frequency type, and light irradiation type, and the clamping jaw 14 also includes a plurality of supporting arms (arm) 15, used to support the glass substrate 13. The connecting rod group 18 connected to the static eliminator 16 has two pivot points 20, and the connecting rod group 18 is controlled by the first servo motor 22 and the second servo motor 24 on the pivo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com