Patents

Literature

329results about How to "Low installation space requirement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

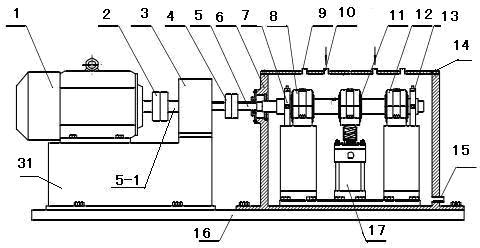

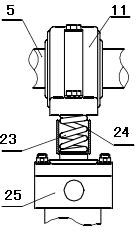

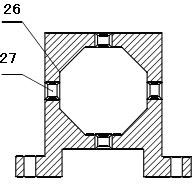

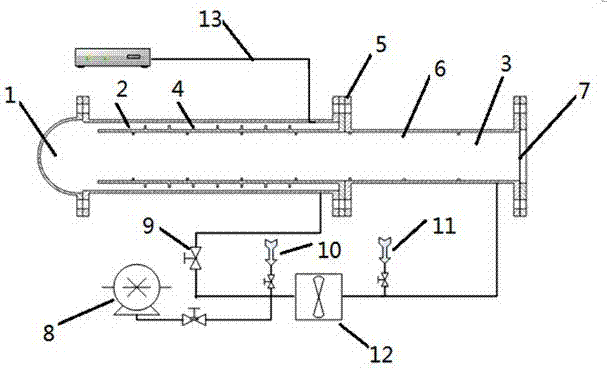

Comprehensive test stand for water-lubricated bearings for pumps

InactiveCN102607846AIncrease the maximum speedAccurate speed regulationMachine bearings testingVibration accelerationTransmission system

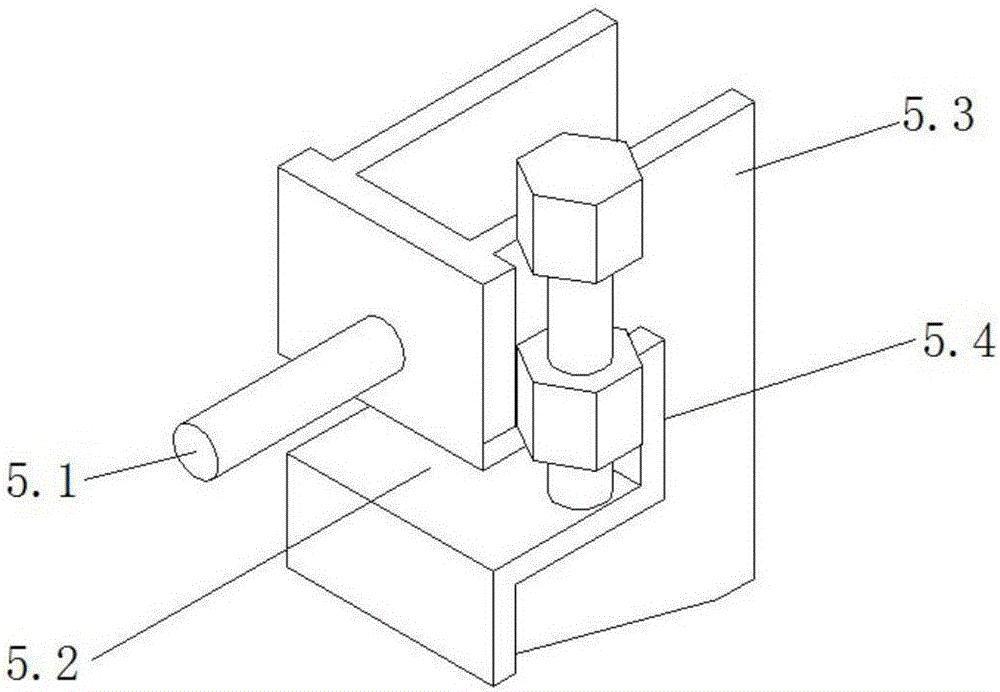

The invention discloses a comprehensive test stand for water-lubricated bearings for pumps. The comprehensive test stand comprises a driving transmission system, a main box, a bearing, a lubricating system, a loading system, a measuring system, a signal analyzing and processing system and the like, the driving transmission system consists of a variable-frequency motor, an elastic coupler, a step-up box and the like, the main box is a cube with a transparent top cover plate, and a spindle horizontally enters the box from a side wall, which is close to the end of the elastic coupler, of the main box. A pressure sensor, an eddy current sensor, a vibration acceleration sensor, a temperature sensor and the like are sequentially arranged and mounted on the spindle or around the spindle and used for acquiring displacement signals, rotation speed signals, phase signals, temperature signals, pressure signals, vibration signals and the like, and the sensed signals which are acquired by the various sensors in an online manner are transmitted to an upper computer to be processed, displayed and stored. The comprehensive test stand has the unique advantages of fine performance, high precision, low cost, environmental protection, zero pollution, friction reduction, energy conservation, noise and vibration reduction, fine fire resistance, easiness in maintenance and the like.

Owner:JIANGSU UNIV

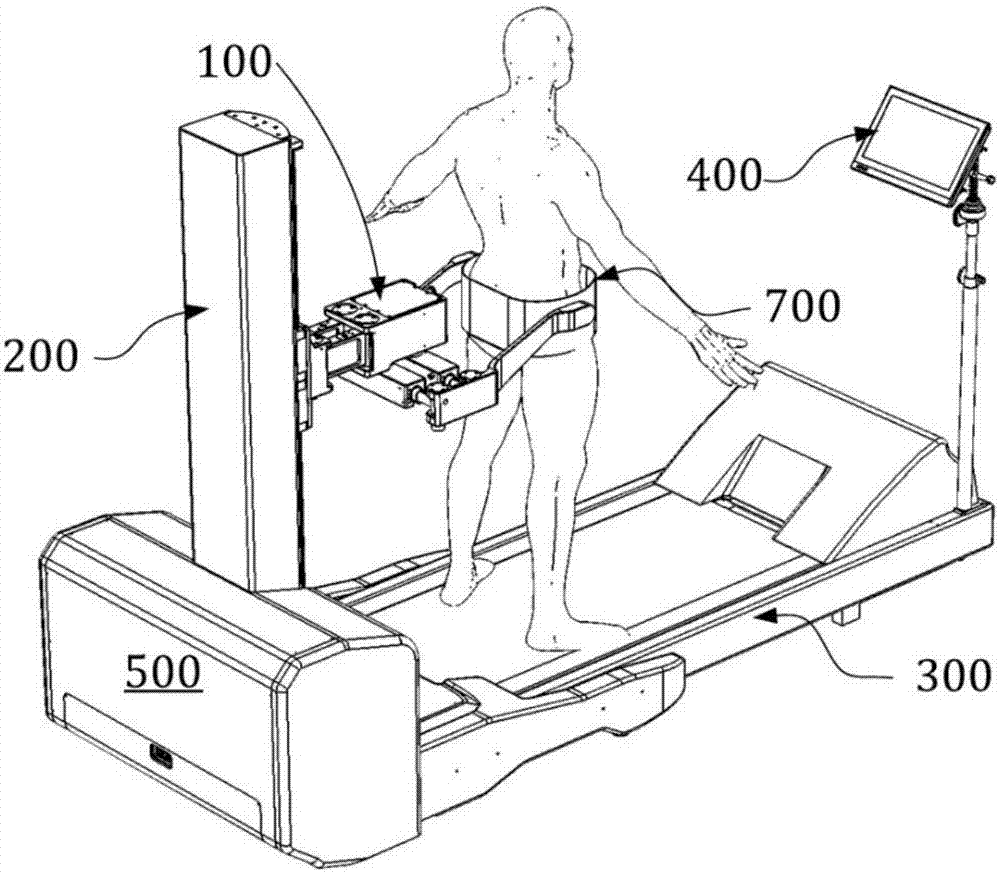

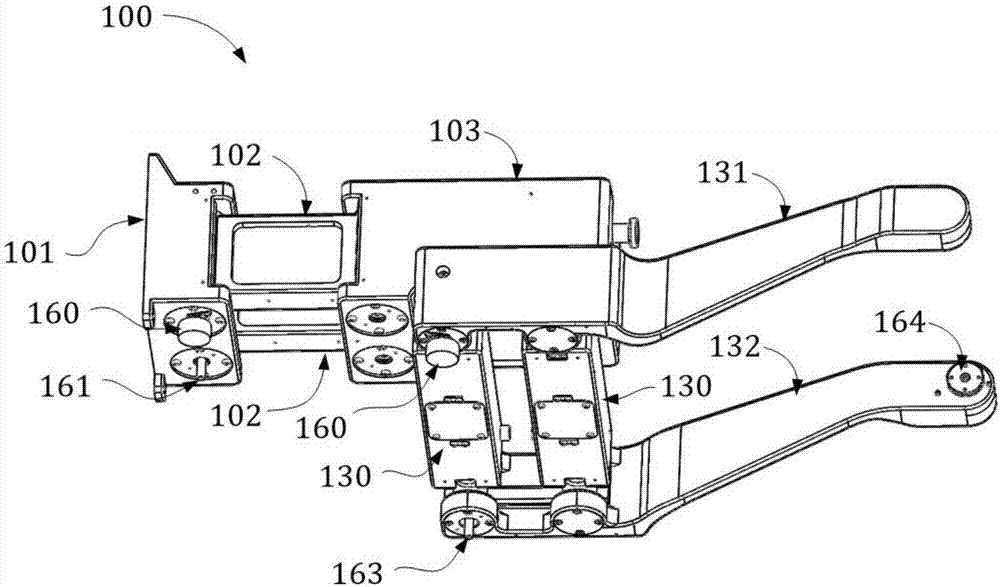

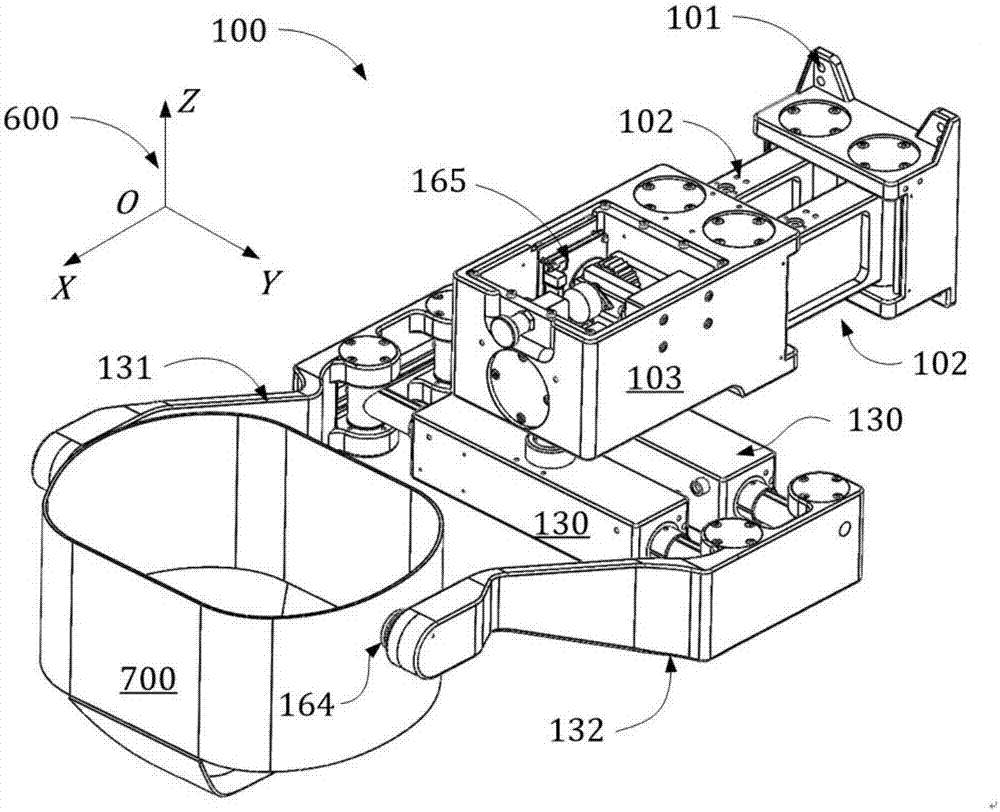

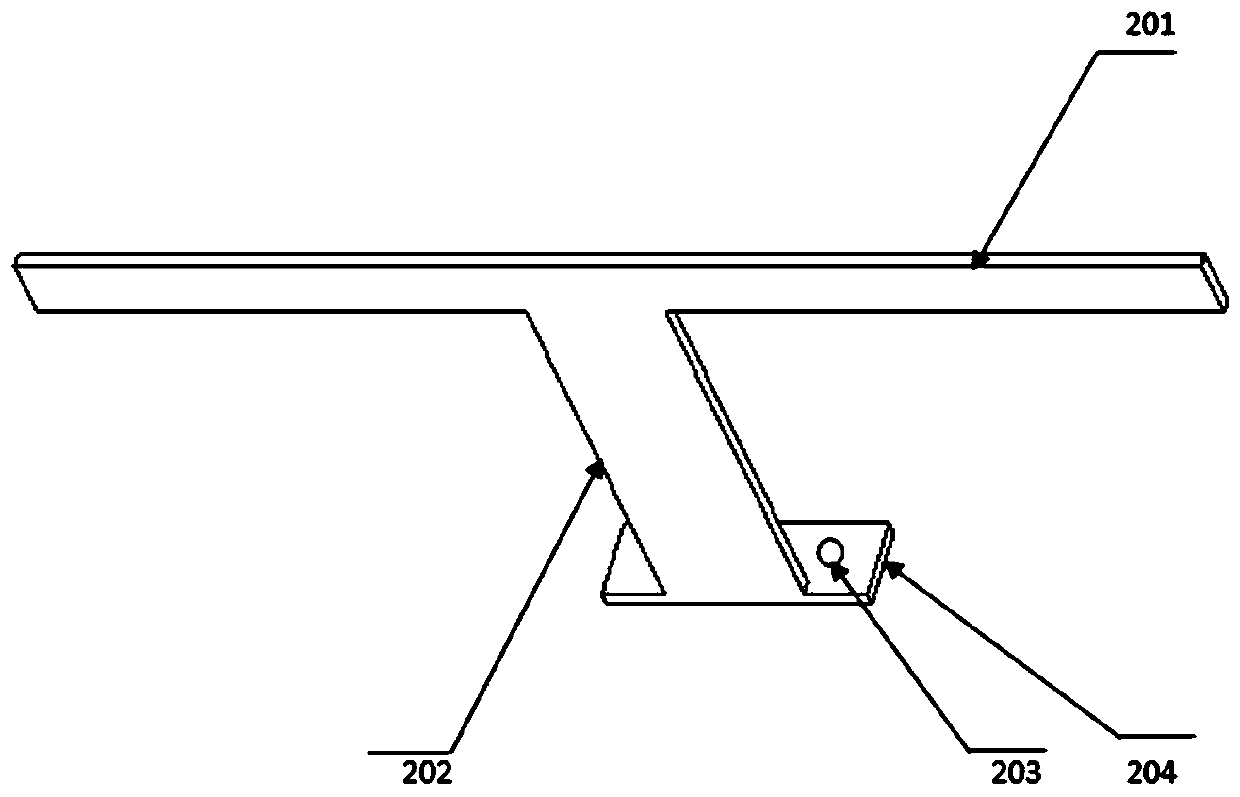

Device and method for rehabilitation training

ActiveCN107537136AEnsure safetyImprove dynamic performanceWalking aidsMovement coordination devicesEngineeringPelvis

The invention discloses a device and a method for rehabilitation training. The device comprises a pelvis mechanism unit, a stand column support mechanism unit, a treadmill unit, and a control unit. The stand column support mechanism unit is fixed on the treadmill unit. The pelvis mechanism unit is connected with the stand column support mechanism unit and can move axially along the stand column support mechanism unit. The pelvis mechanism unit comprises a first four-rod mechanism formed by a base, a first connecting rod, a second connecting rod, and a connecting box, and a second four-rod mechanism formed by a third connecting rod, a fourth connecting rod, a first supporting arm, and a second supporting arm. The first four-rod mechanism and the second four-rod mechanism are movably connected. A method for connecting a pelvis of a patient through the pelvis mechanism provides a weight reduction function. The pelvis structure has multiple degrees of freedom, and can swing with natural swing of a pelvis when a patient walks. Weight reduction supports on a pelvis position prevent pendulum effect caused by an overhanging weight reduction method, so that a body can naturally swing when walking.

Owner:SHANGHAI ELECTRICGROUP CORP

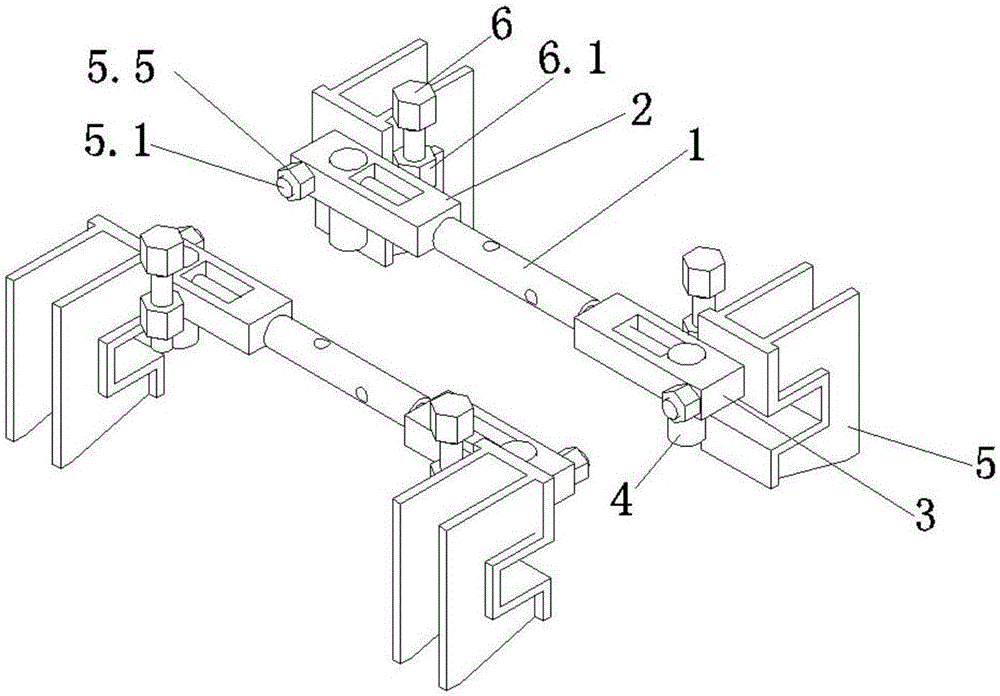

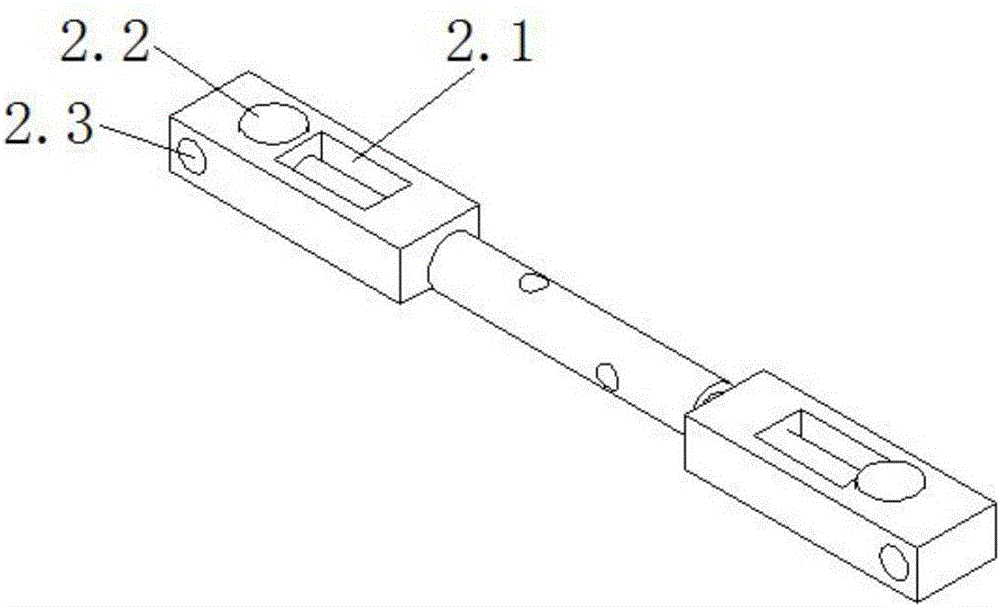

Locating and mounting method for H-shaped steel girder butting joints

ActiveCN106193622AFirmly connectedEliminate lateral misalignmentBuilding material handlingFlangeH shaped

Owner:CHINA FIRST METALLURGICAL GROUP

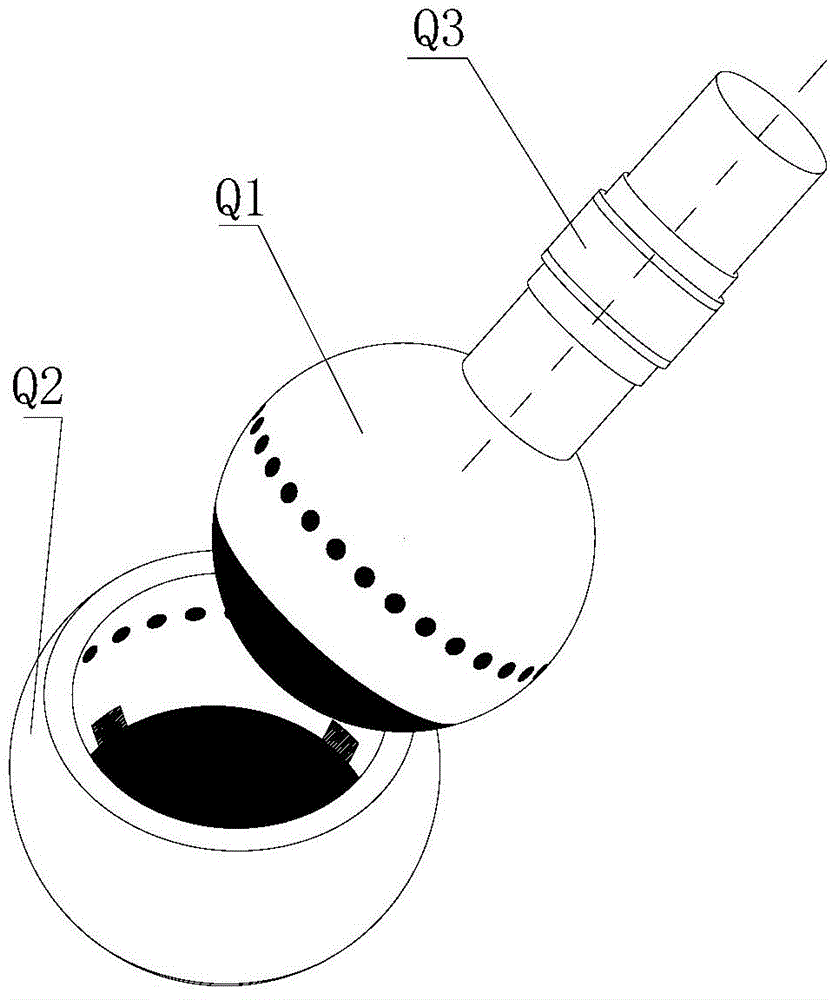

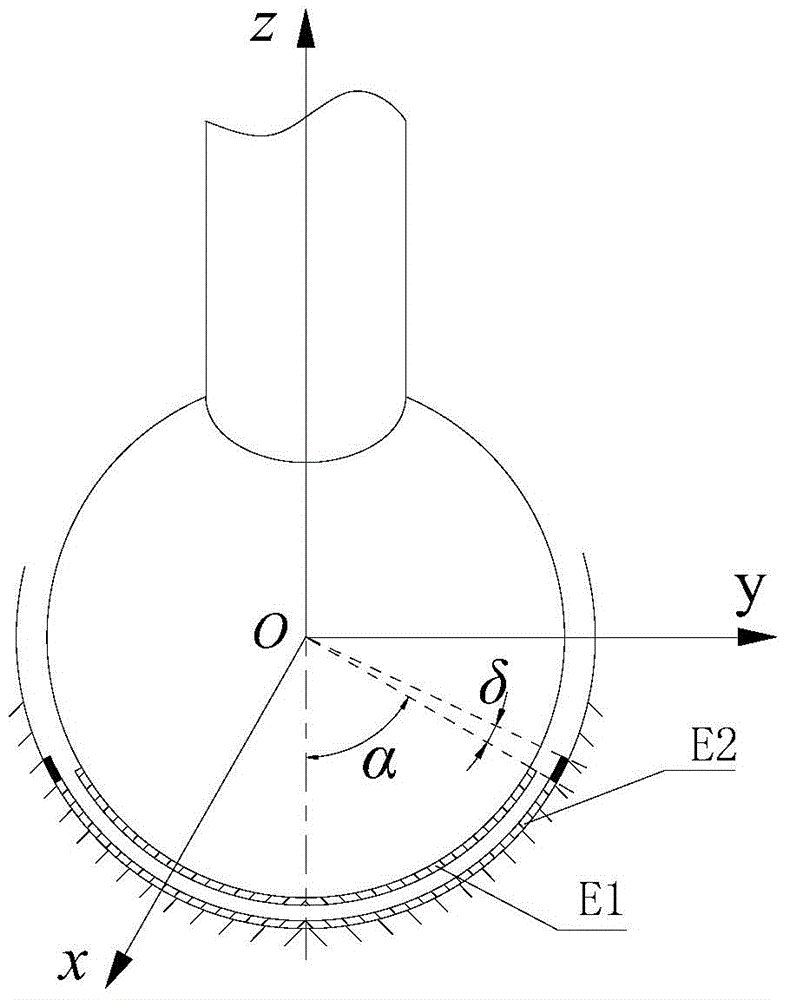

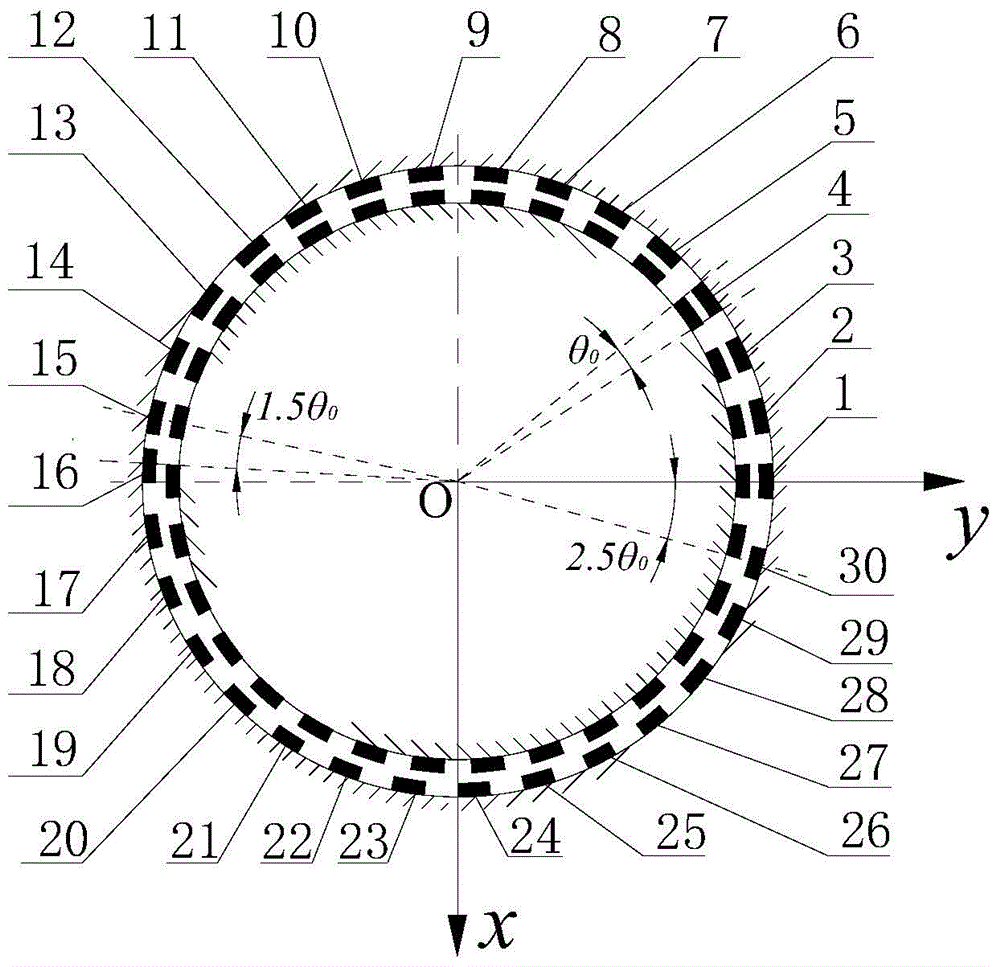

Spherical hinge movement direction measuring method based on spherical capacitor

ActiveCN104132675ARealize non-contact detectionHigh measurement accuracyIndication/recording movementConverting sensor output electrically/magneticallyCapacitanceThree degrees of freedom

The invention discloses a spherical hinge movement direction measuring method based on a spherical capacitor. The existing spherical hinge degree-of-freedom testing method needs construction of a complex system, and the related technology is not mature. An absolute rotary encoder measures the angle at which an output rod rotates around the axis thereof; the forward included angle between the output rod and a vertical shaft is solved according to the effective overlap area between a first spherical crown-shaped sensing capacitor electrode at the bottom of a ball head and a second spherical crown-shaped sensing capacitor electrode at the bottom of a ball socket; and the included angle between the projection of the output rod on the horizontal plane and a horizontal shaft is solved according to a fourth spherical crown-shaped capacitor electrode with the largest capacitance, capacitance change between the fourth spherical crown-shaped capacitor electrode and a corresponding third spherical crown-shaped capacitor electrode, and the serial numbers of arc sensing capacitor electrodes of which the capacitances are not equal to zero. According to the method, the three degrees of freedom of movement of a spherical hinge are solved based on the principle in which the change of area between polar plates of a spherical capacitor causes change of output capacitance. The algorithm is simple.

Owner:HANGZHOU DIANZI UNIV

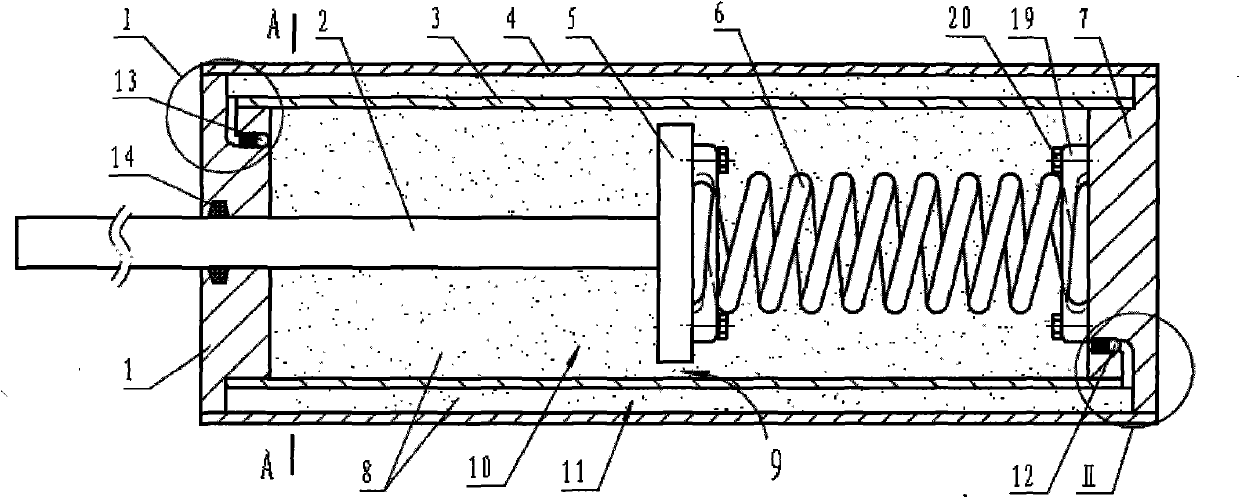

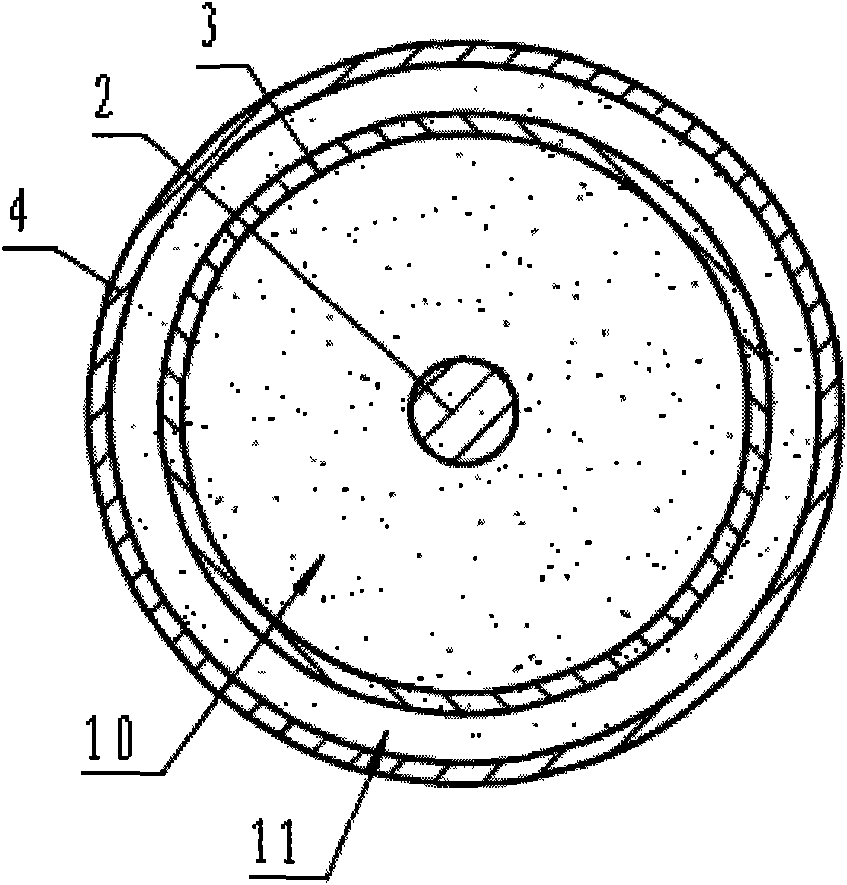

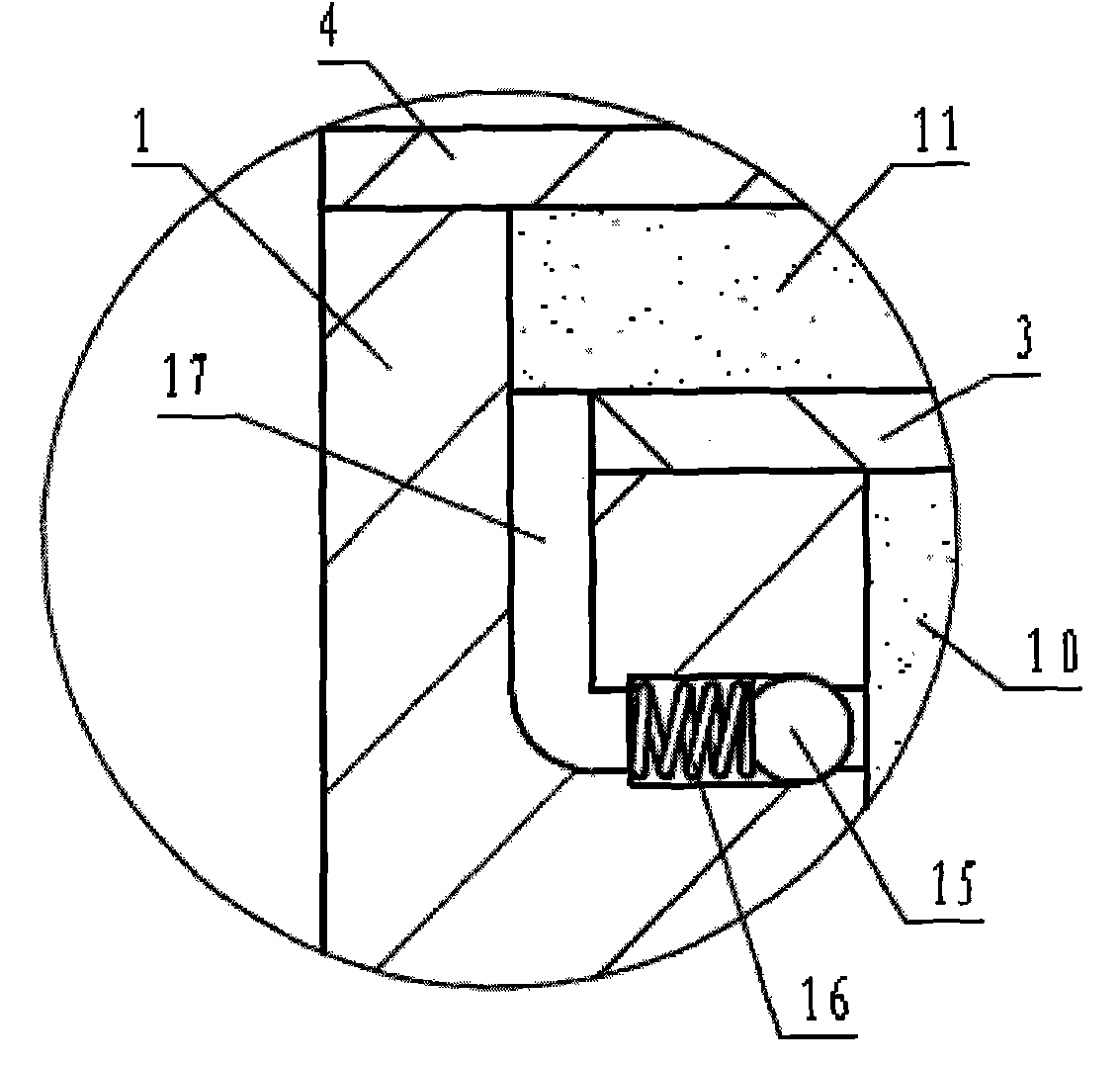

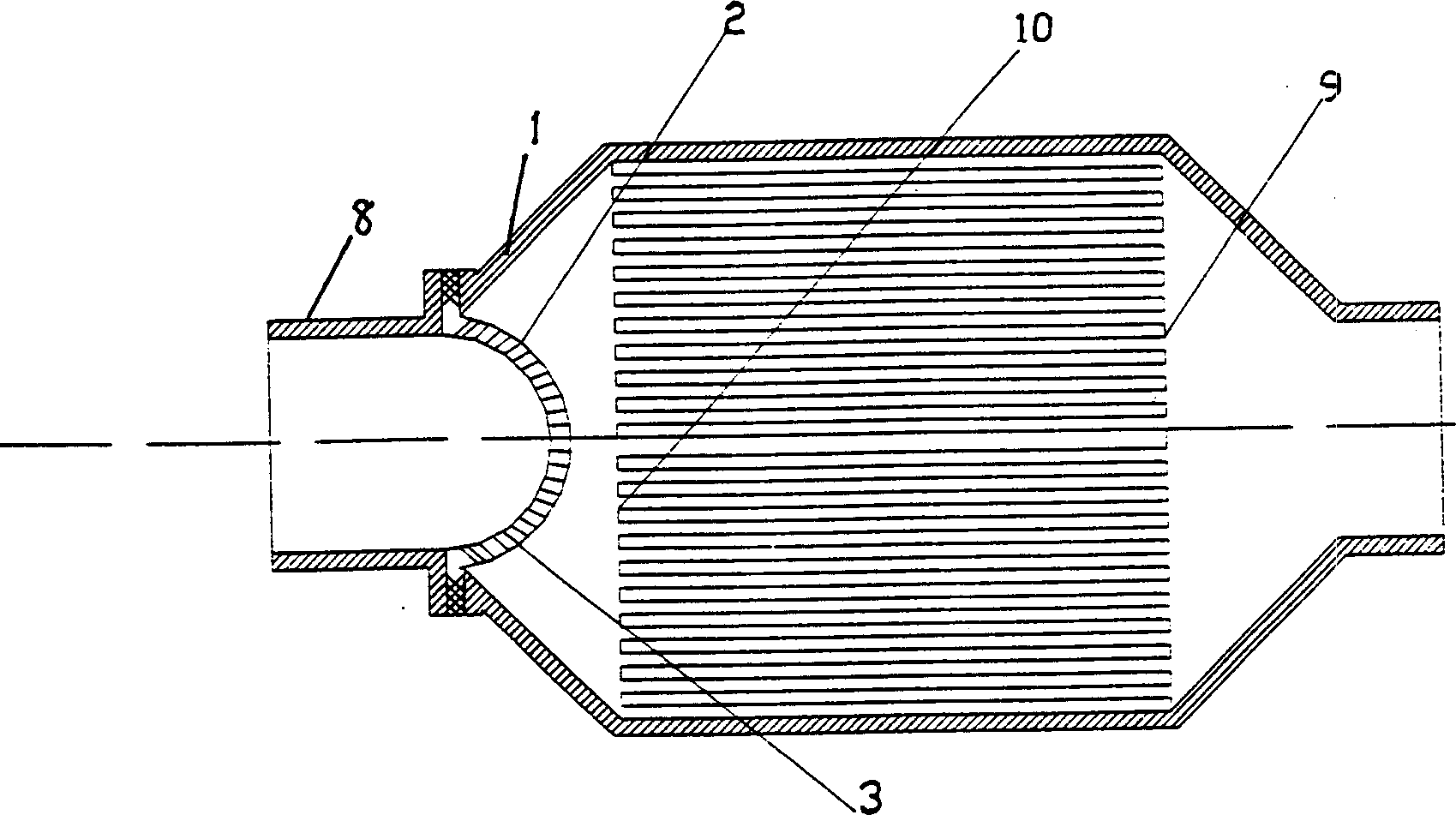

Composite damping single-piston rod viscous damper

InactiveCN101994775AShorten design lengthSmall aspect ratioSpringsShock absorbersViscous dampingBuilding unit

The invention relates to a vibration-proof building unit, in particular to a composite damping single-piston rod viscous damper. The damper is a single-piston rod viscous damper and is characterized in that: a piston rod (2) of the single-piston rod viscous damper passes through a left end cover (1) through a working cylinder (10) on the left of a piston (5); a cylindrical spiral spring (60 is arranged in the working cylinder (10) on the right of the piston (5); one end of the spring is fixed on a right end cover (7), while the other end is fixed to the end face of the piston (5); an outer cylinder barrel (4) is sleeved outside an inner cylinder barrel (3) of the working cylinder (10); the left end cover (1) and the right end cover (7) are respectively arranged at two ends of the outer cylinder barrel (4), so that a gap between the inner cylinder barrel (3) and the outer cylinder barrel (4) forms a compensation cylinder (11); one one-way valve (13) is arranged in the body of the left end cover (1); and another one one-way valve (12) is arranged in the body of the right end cover (7). The viscous damper can simultaneously provide viscous damping and elastic damping in the whole moving process of the piston.

Owner:GUANGZHOU UNIVERSITY

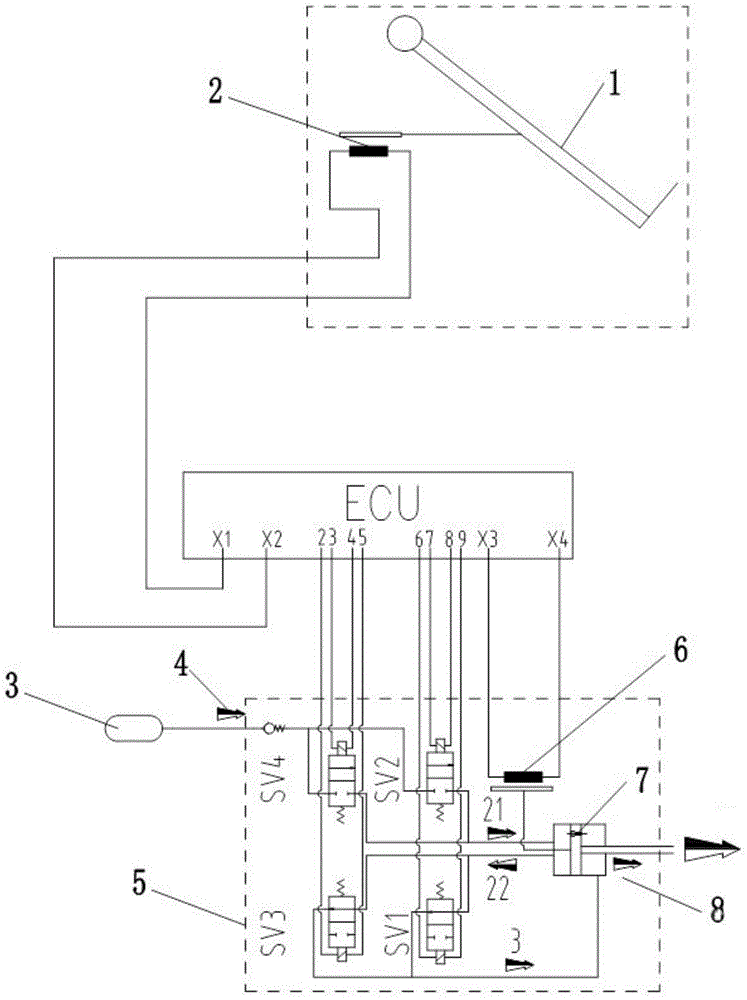

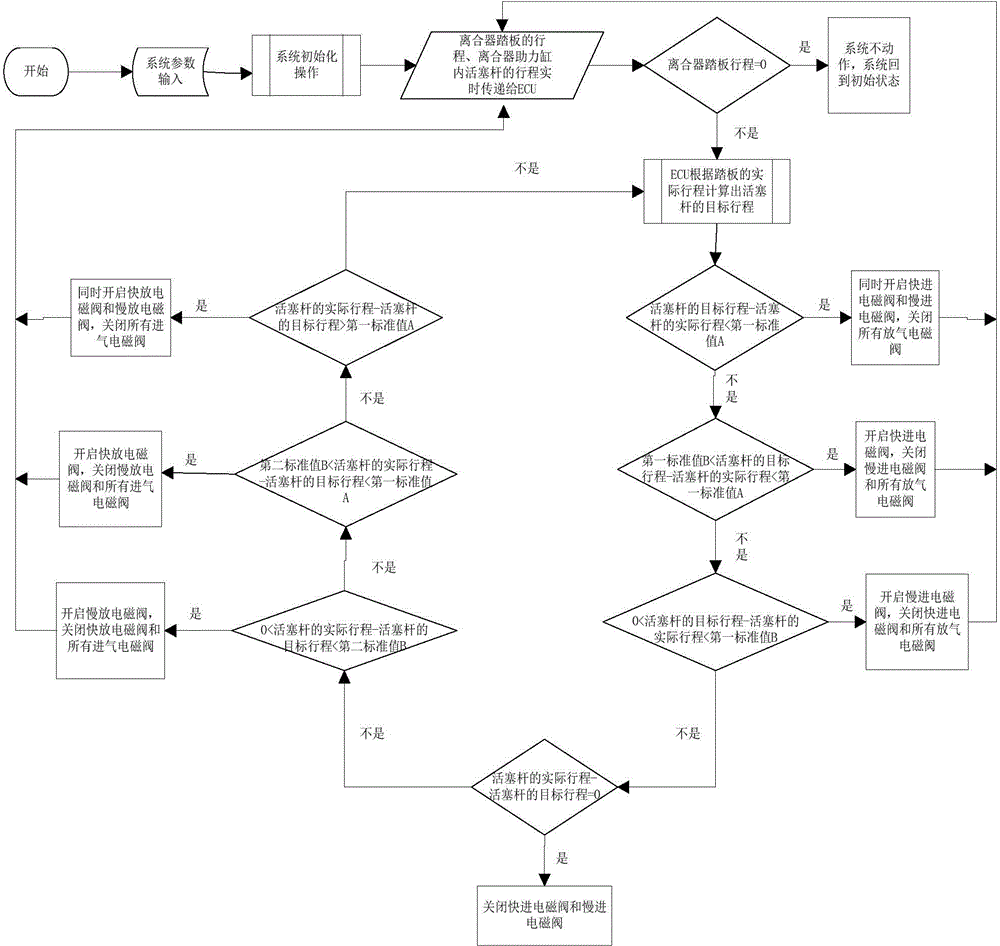

Electronic control pneumatic type clutch control system and method

The invention discloses an electronic control pneumatic type clutch control system and method. The control system comprises an electronic clutch pedal, an electronic control unit (ECU) and a pneumatic clutch actuator. The electronic clutch pedal is provided with a position sensor which is in communicating connection with the ECU. The pneumatic clutch actuator comprises a clutch assistance cylinder. A quick release electromagnetic valve, a fast forward electromagnetic valve, a slow release electromagnetic valve and a slow forward electromagnetic valve are arranged in the clutch assistance cylinder. The clutch assistance cylinder is provided with a first displacement sensor. The quick release electromagnetic valve, the fast forward electromagnetic valve, the slow release electromagnetic valve, the slow forward electromagnetic valve and the first displacement sensor are connected with the ECU in a communicating mode. According to the control method, the ECU controls the piston rod stroke in the clutch assistance cylinder by controlling opening and closing of the quick release electromagnetic valve, the fast forward electromagnetic valve, the slow release electromagnetic valve and the slow forward electromagnetic valve. The response time of the system can be effectively shortened, the fast response of clutch control is achieved, and a driver can control a vehicle conveniently.

Owner:ZF COMMERCIAL VEHICLE SYSTEMS (QINGDAO) CO LTD

Low-flow-resistant near-wall small-space annular shock wave focusing direct priming device

InactiveCN104500272ASimple structureIncrease the lengthIntermittent jet plantsRocket engine plantsShock waveShortest distance

The invention discloses a low-flow-resistant near-wall small-space annular shock wave focusing direct priming device which comprises a pulse detonation engine, an ignition system and feeding system. The pulse detonation engine comprises a main detonation chamber and a sealing cover, and an annular near-wall space passage is formed between the sealing cover and the main detonation chamber. The priming device has the advantages that the device is simple in structure, and the length of the pulse detonation engine is not increased; the high-temperature and high-pressure hot point generated by annular shock wave focusing is used as the ignition source of the main detonation chamber, the duration for transiting the pulse detonation engine from knock to detonation can be reduced effectively, and the flow resistance in the main detonation chamber is lowered; the annular near-wall space passage of the priming device is small and short, low in mounting space requirements, capable of generating high-intensity shock waves in a short distance and capable of effectively controlling the resistance loss of the pulse detonation engine, and the area of the annular near-wall space passage can be changed according to different detonation limits of different fuels.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

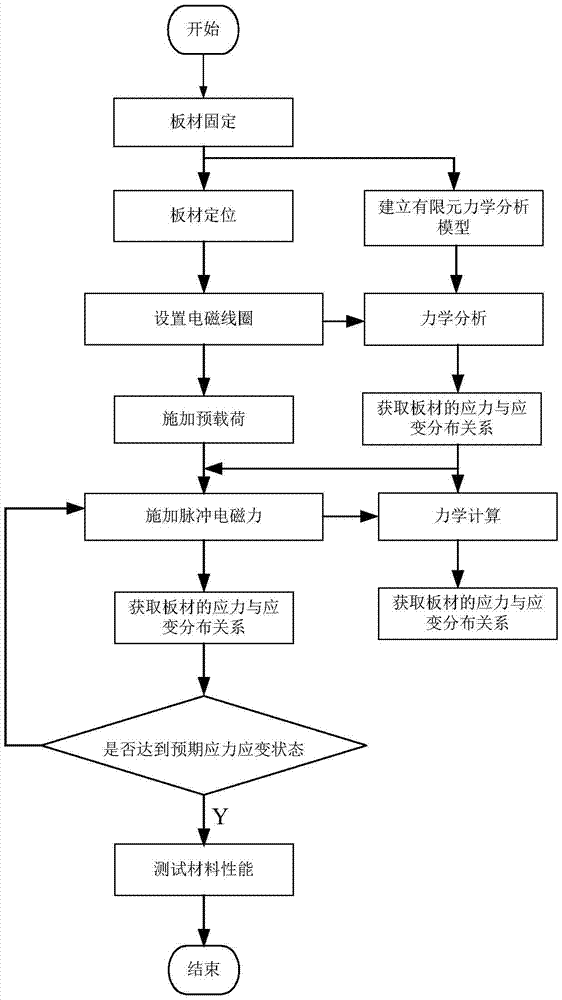

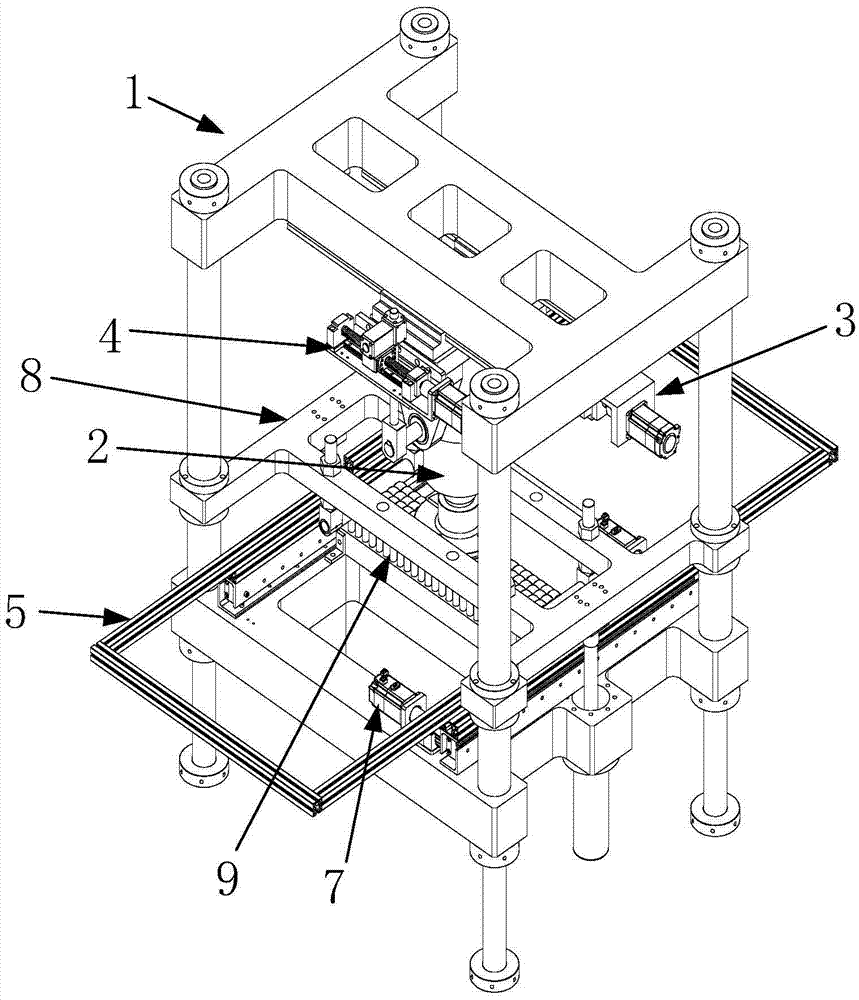

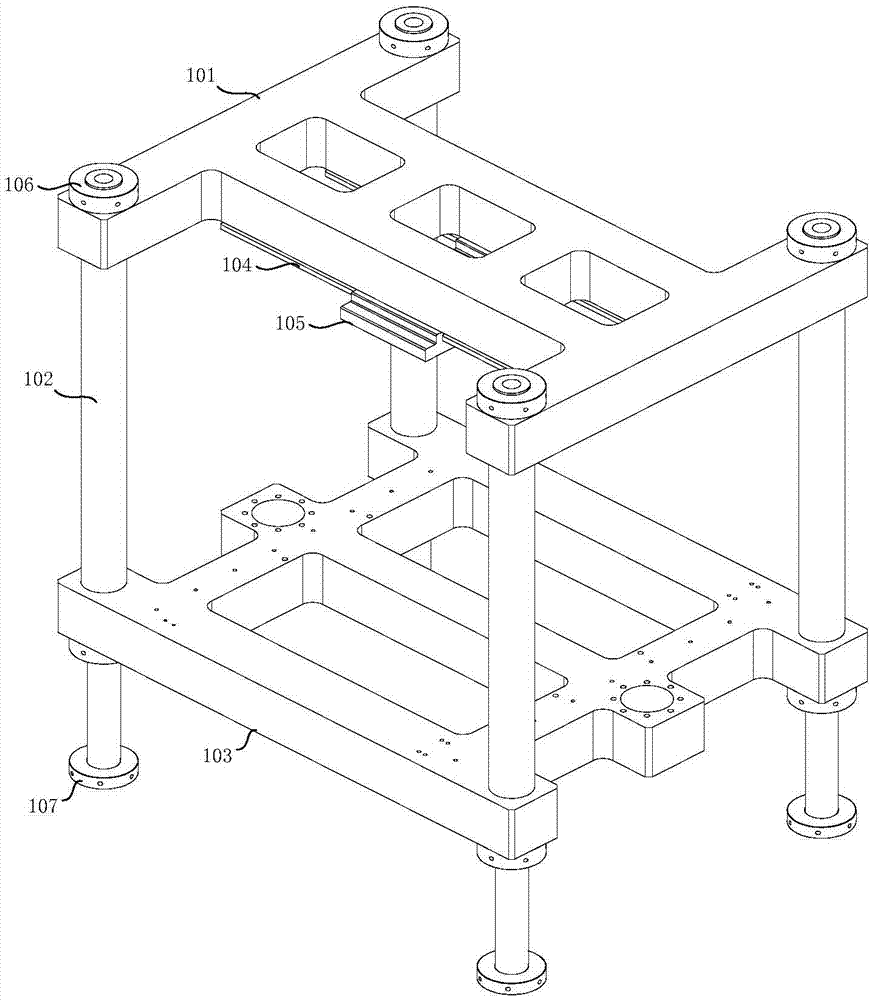

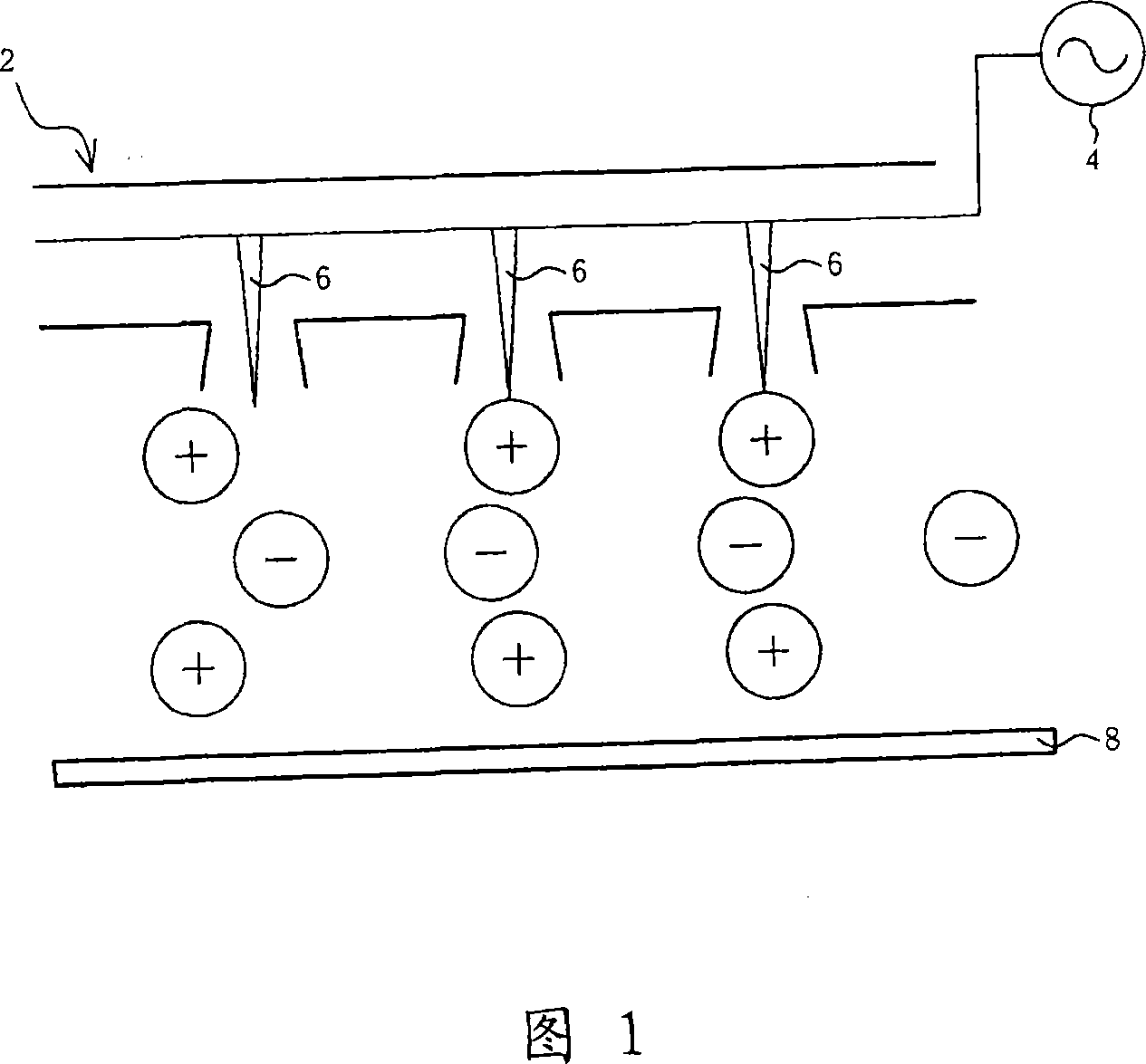

Method for adjusting shapes and performance of plates under combined action of prestress and pulse electromagnetic force

InactiveCN105436286AEmbody multidisciplinaryChange the organizational structureMetal working apparatusPre stressElectromagnetic interference

The invention discloses a method for adjusting the shapes and the performance of plates under the combined action of prestress and pulse electromagnetic force. The method comprises the steps of firstly clamping and fixing the plates and enabling the plates to be located above a die; arranging electromagnetic coils above the plates; carrying out preloading on the plates and establishing a finite element mechanical analysis model for obtaining the stress and strain distribution relationship of the plates; exerting the pulse electromagnetic force on each area of the plates through the electromagnetic coils by controlling the movement of the plates and the movement of the electromagnetic coils; obtaining the stress and strain distribution relationship of the plates again, judging the stress-strain state of the plates, and unloading the plates for carrying out rigidity and strength tests if the stress-strain state meets the expectation state; carrying out regional shape adjustment on the plates if the stress-strain state does not meet the expectation state. The method has the advantages that for the metal plates with certain initial prestress, traditional mechanical force and the pulse electromagnetic force are combined, through the impact waves generated by the pulse electromagnetic force, the interior structure of material is changed, and the interior stress-strain state of the plates is adjusted.

Owner:BEIHANG UNIV

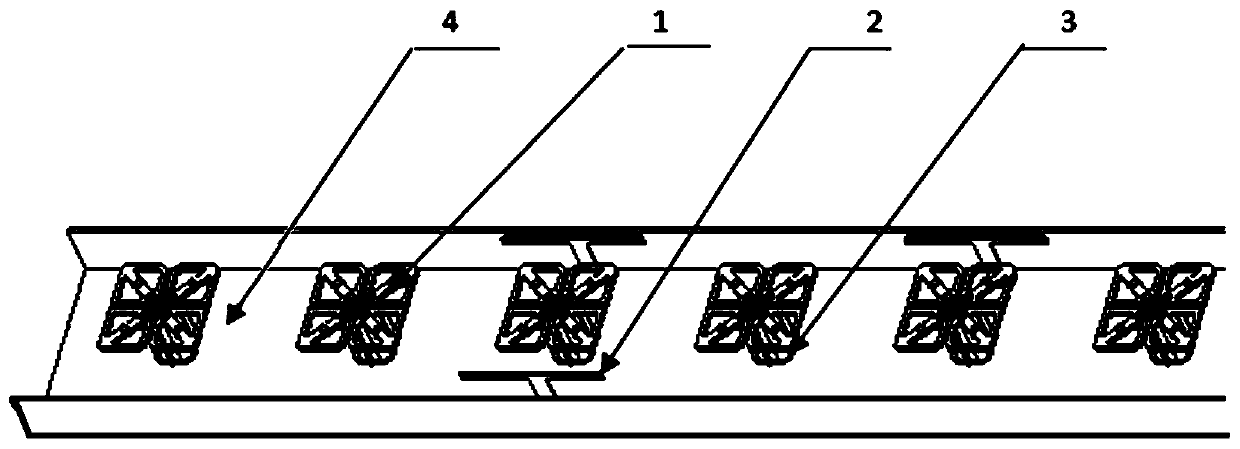

System for eliminating static

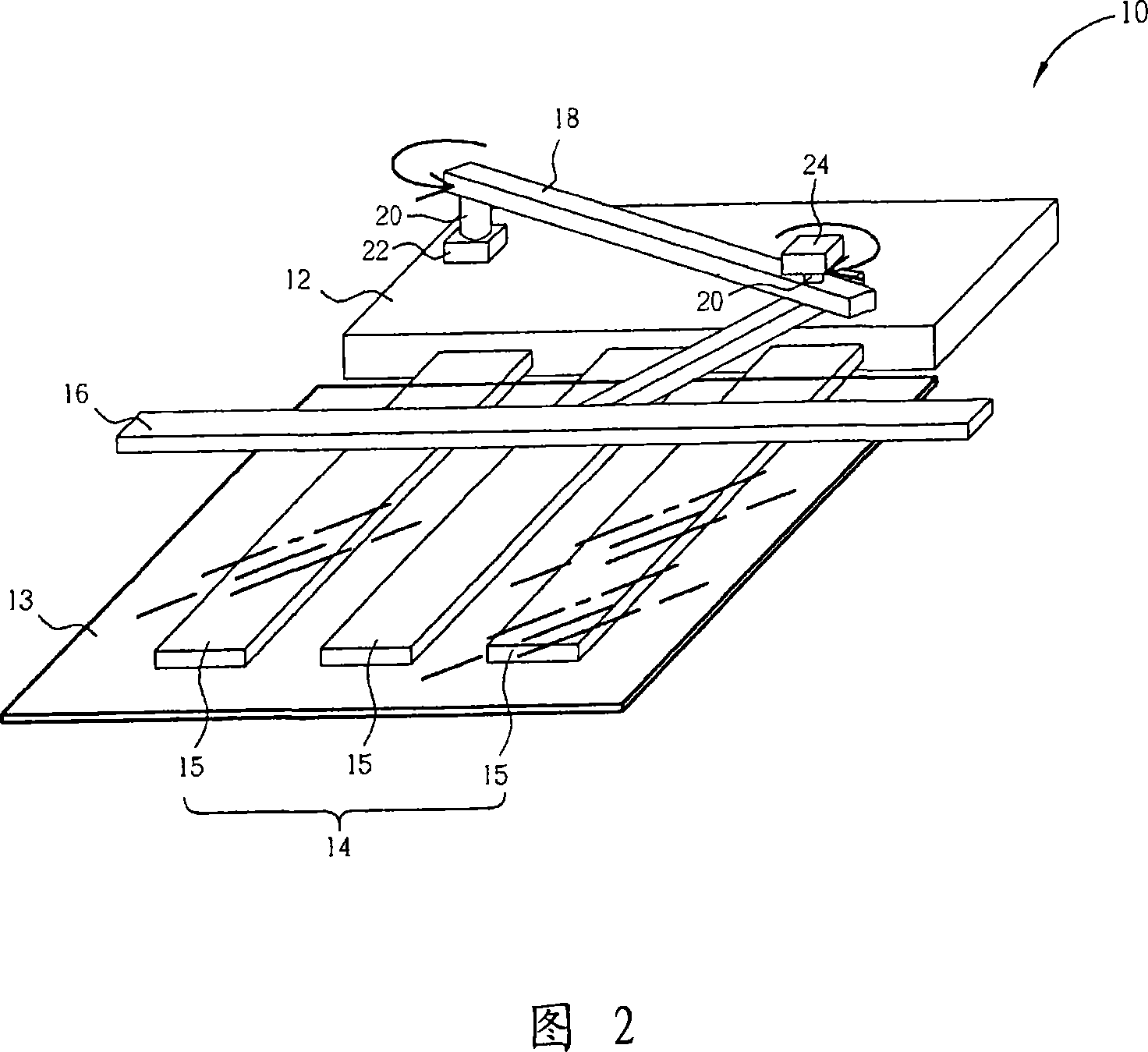

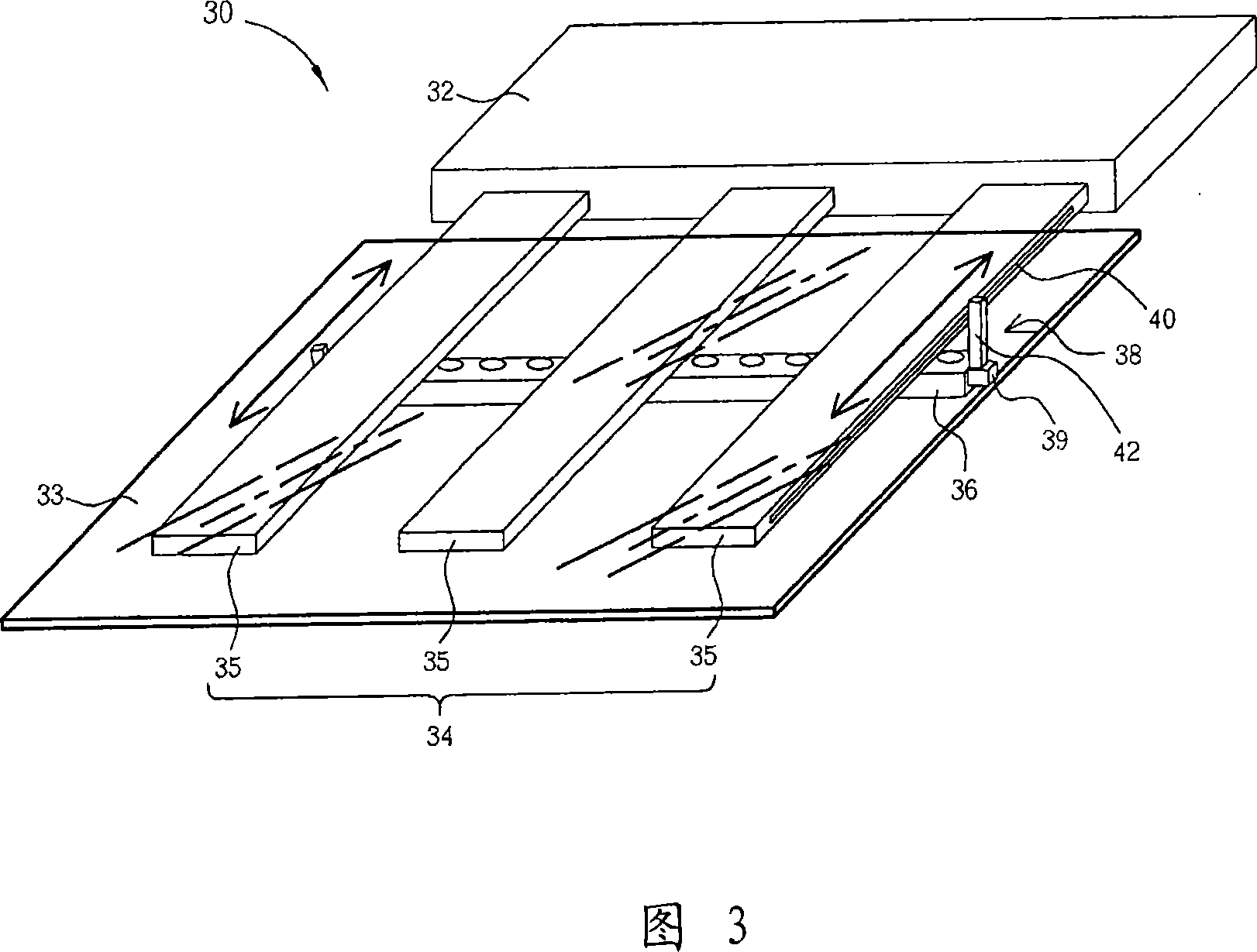

ActiveCN101197302AReduce the number of installationsReduce the use effectSemiconductor/solid-state device manufacturingCharge manipulationRobotic armStatic eliminators

A system for static elimination comprises an electric-manipulator, a grip jaw arranged in the front end of the electric-manipulator, a connecting rod set arranged on the electric-manipulator and a static eliminator arranged on the connecting rod set. The static eliminator can reciprocate in a fixed scope to eliminate static by the connecting rod set.

Owner:AU OPTRONICS CORP

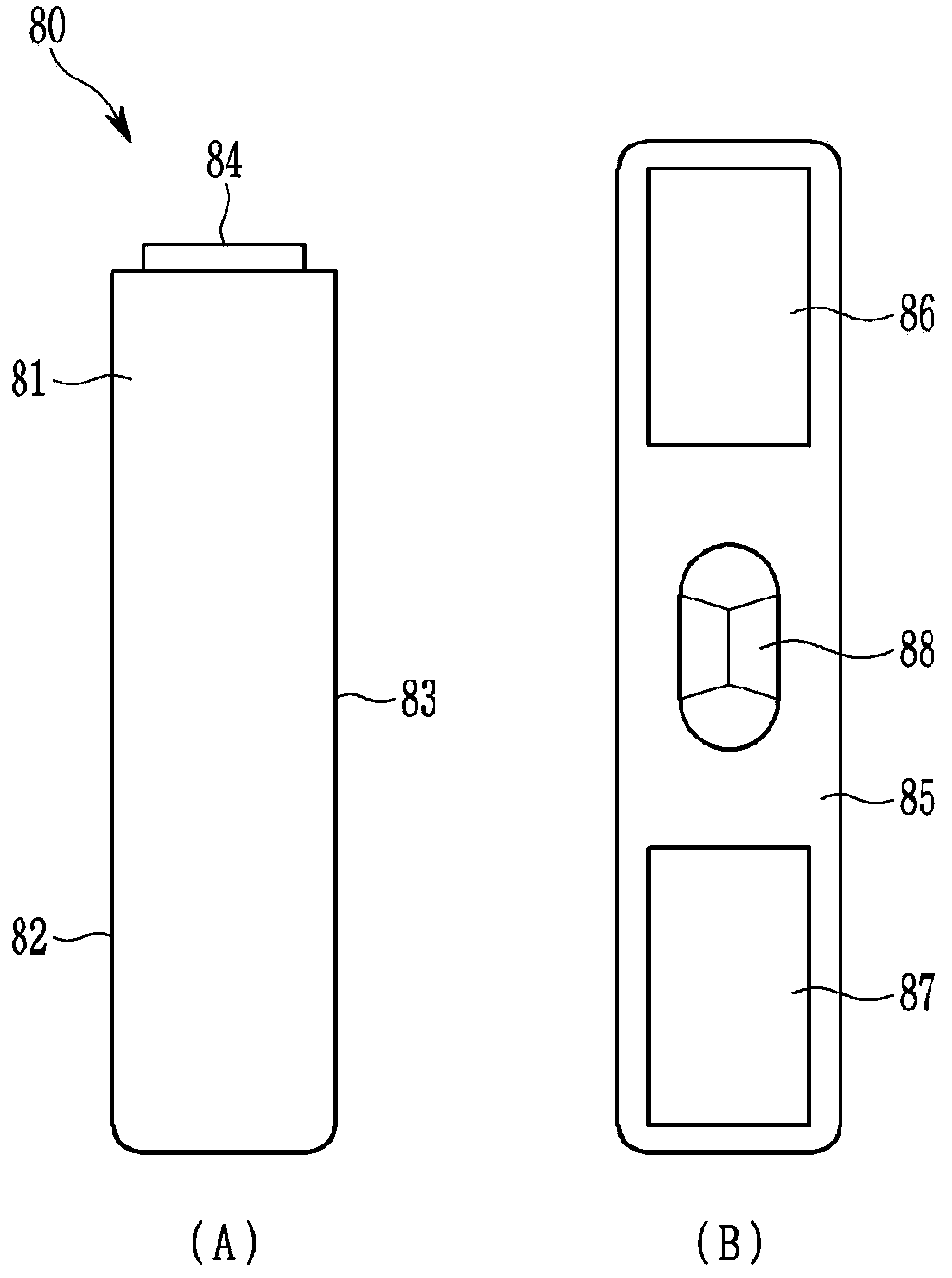

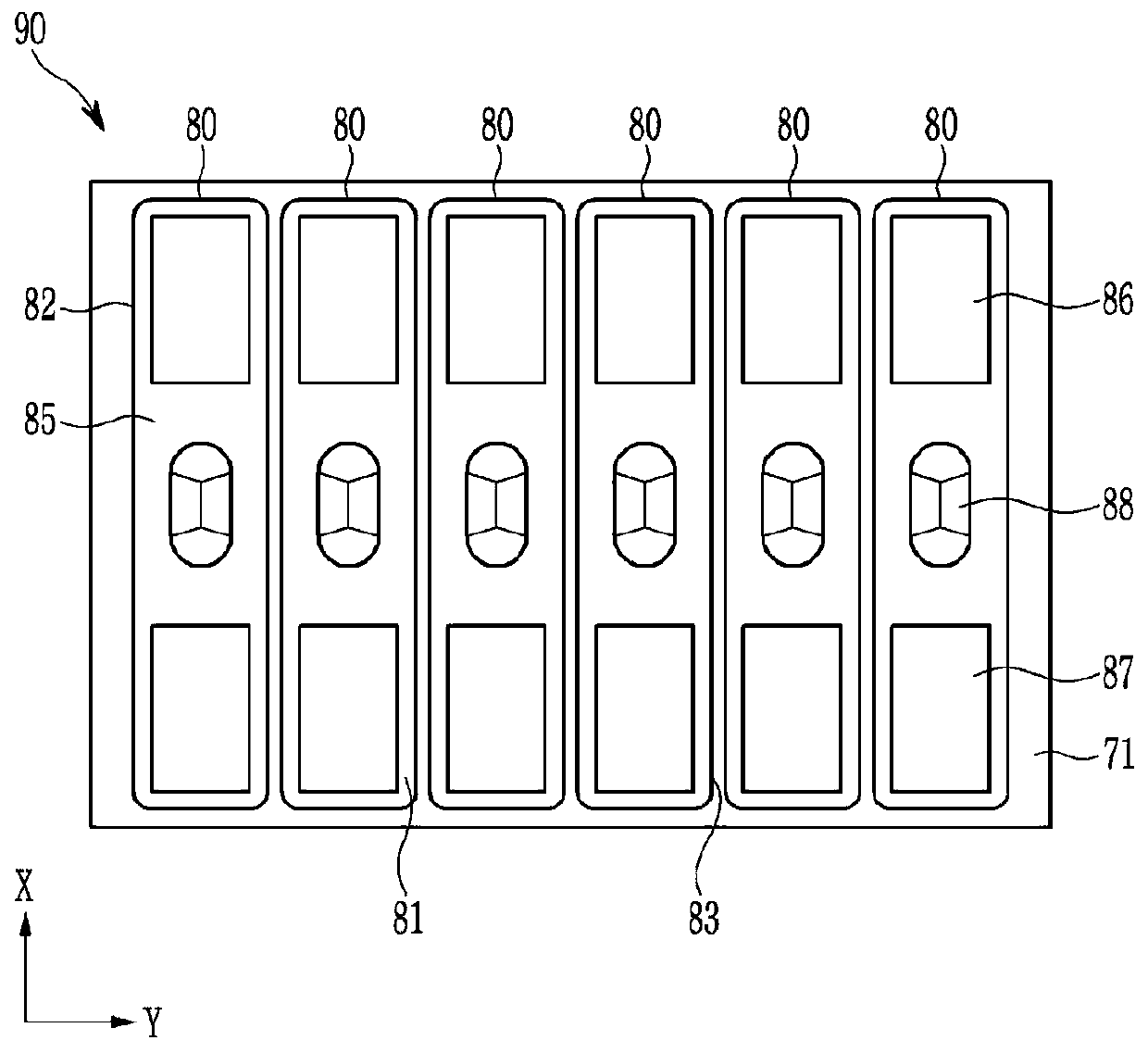

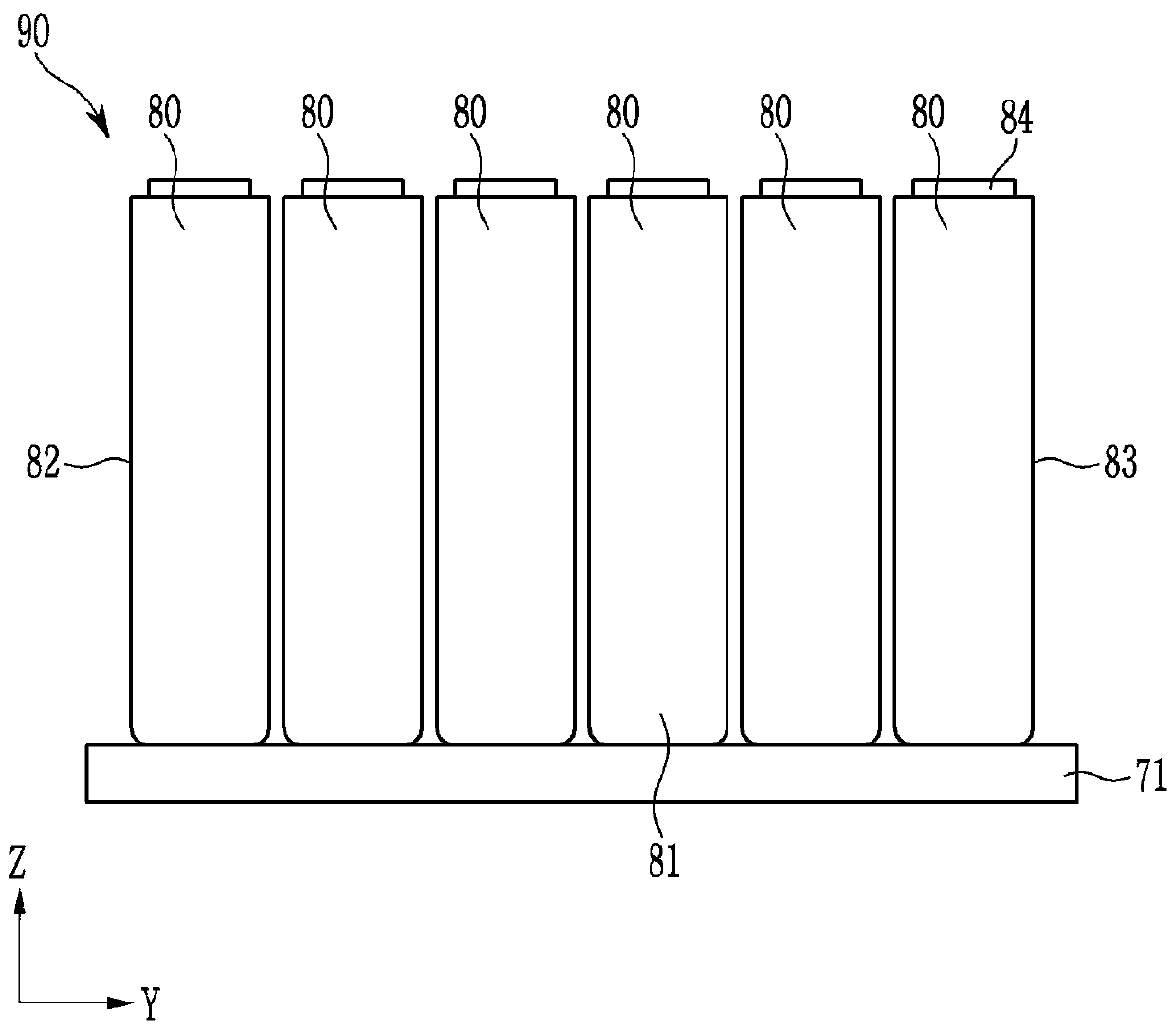

Battery system

ActiveCN110199406AImprove protectionLow installation space requirementBattery isolationVent arrangementsMechanical engineeringBattery system

The present invention relates to a battery system (100) that comprises at least one plurality of aligned battery cells (80) arranged in a first direction (y). Each of the battery cells (80) comprisesa vent hole (88). The battery system (100) further an extinguishing system (60) with a reservoir (61) for an extinguishing agent and at least one conduit means (62) for conducting the extinguishing agent, wherein the conduit means (62) is positioned such that it is hit by a vent-gas jet emitted by any of the vent holes (88) of the plurality of aligned battery cells (80) and wherein the at least one conduit means (62) is configured to be melted by the vent-gas jet. The invention further relates to a cooling circuit (70) for a battery system (100) comprising at least one plurality of aligned battery cells (80), each of the battery cells (80) comprising a vent hole (88). The cooling circuit (70) comprises a conduit means (72) configured for conducting an incombustible or flame-retardant coolant and an evaporator (71) that is in thermal contact with the a first plurality (91) of aligned battery cells (80) and that is configured for causing the coolant to absorb heat from the first plurality of aligned battery cells (80). The conduit means (72) is positioned such that it is hit by a vent-gas jet emitted by any of the vent holes (80) of the first plurality (91) of aligned battery cells (80) and is configured to be melted by the vent-gas jet.

Owner:SAMSUNG SDI CO LTD

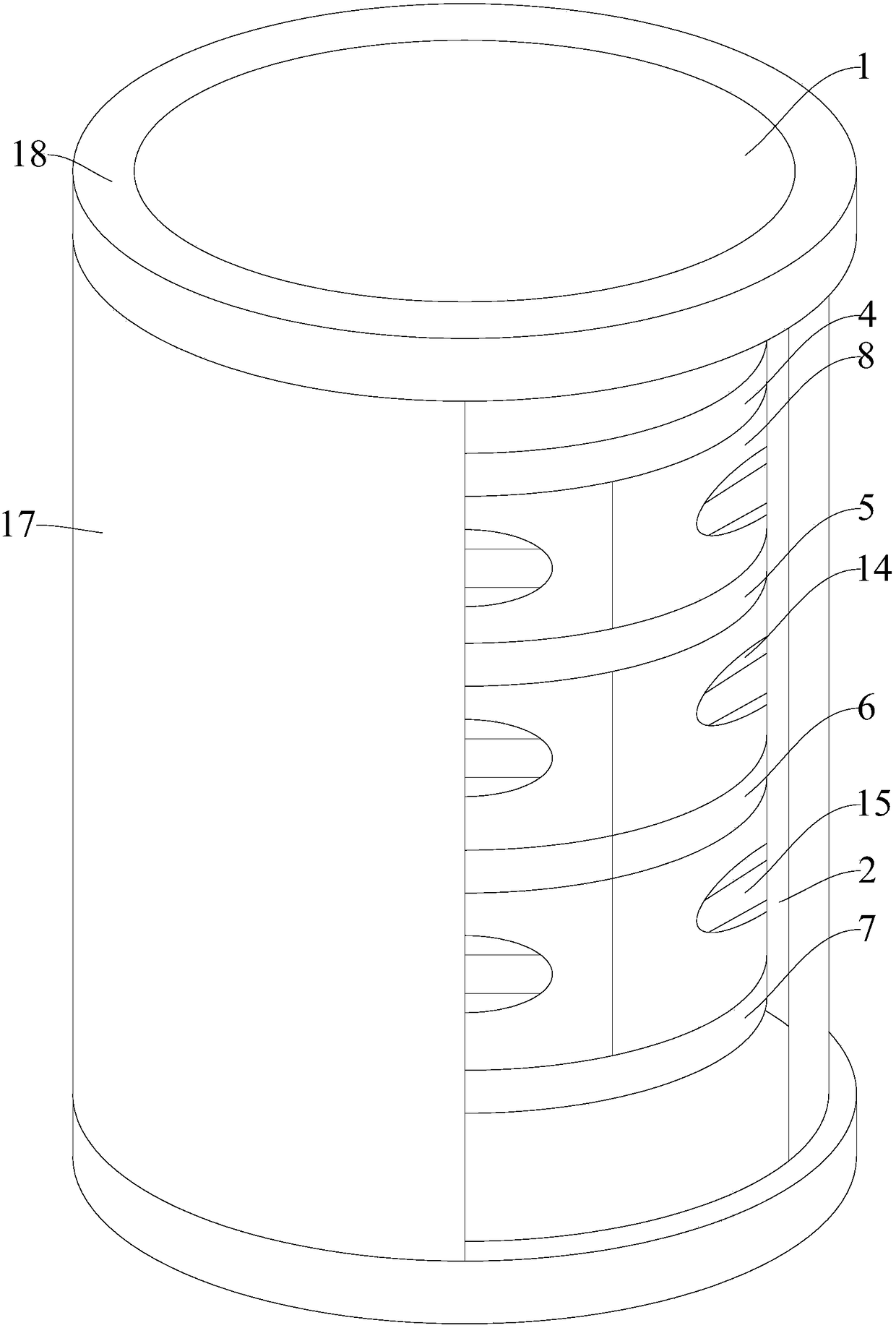

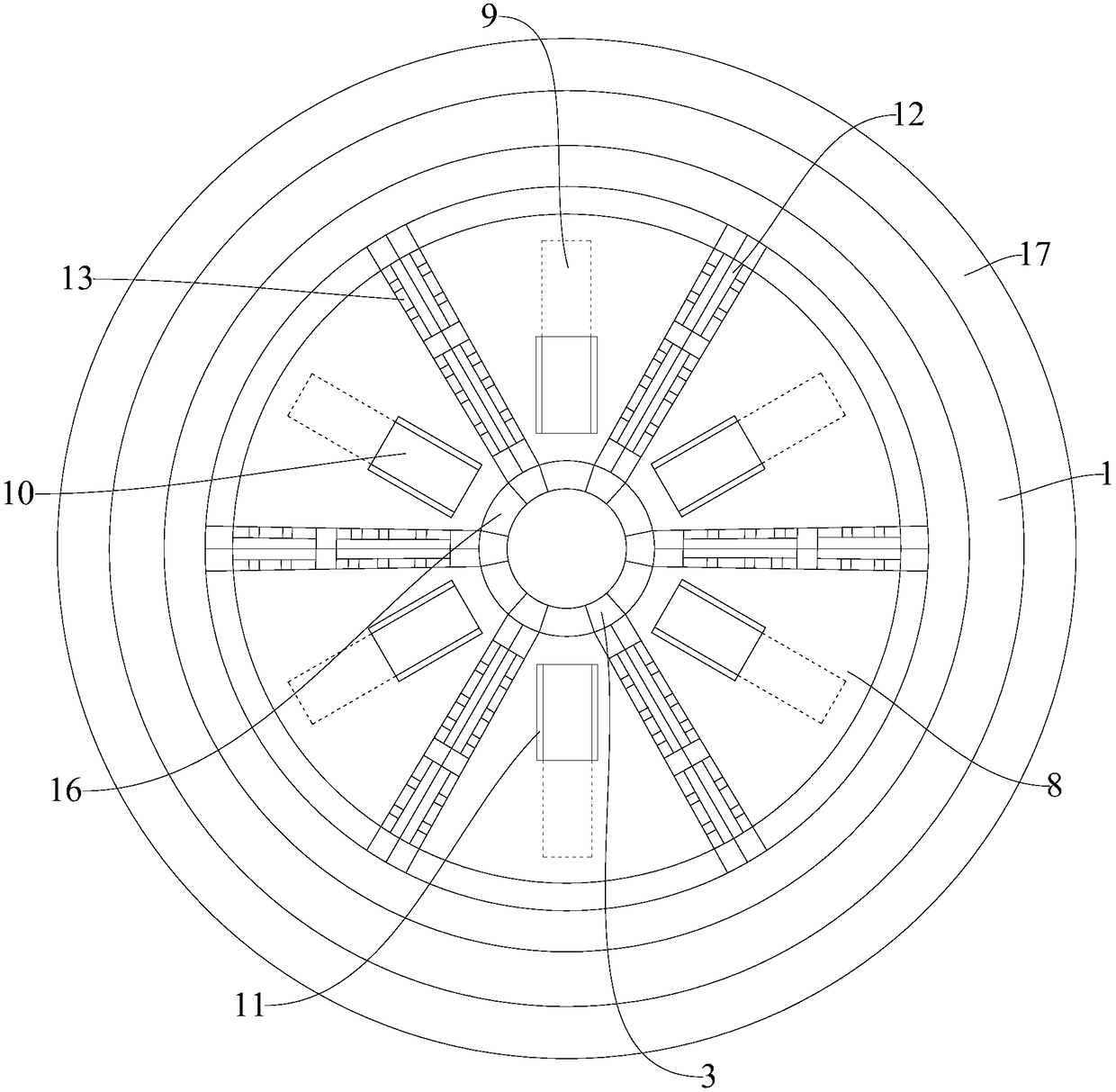

Low-voltage power distribution cabinet with internal rotary installation mechanism

InactiveCN108258587ANumber of lift switches installedReasonable switch layoutSubstation/switching arrangement casingsLow voltageEngineering

The invention relates to the technical field of low-voltage power distribution equipment, in particular to a low-voltage power distribution cabinet with an internal rotary installation mechanism. Thelow-voltage power distribution cabinet comprises a main cabinet body having a cylindrical structure; and an operation port is formed in the front side of the main cabinet body. According to the low-voltage power distribution cabinet, a plurality of hollow-structure limiting plates are welded and fixed at an internal longitudinal rotating shaft; and the limiting plates at different positions form an accommodation chamber inside the main cabinet body. Connecting sliding pieces arranged at the upper surfaces and lower surfaces of switch mounting bases are inserted into insides of assembling portsto realize movable connection with the limiting plates. Control switches are installed at inner sides of the switch mounting bases to increase the switch mounting number of the distribution cabinet,so that the switch layout inside the distribution cabinet becomes reasonable. A cabinet door is arranged at the operation port at the outer side of the main cabinet body in a sliding connection manner, the requirement on the mounting space by the distribution cabinet is reduced substantially and the occupied external space is reduced.

Owner:安徽乾轩信息科技有限公司

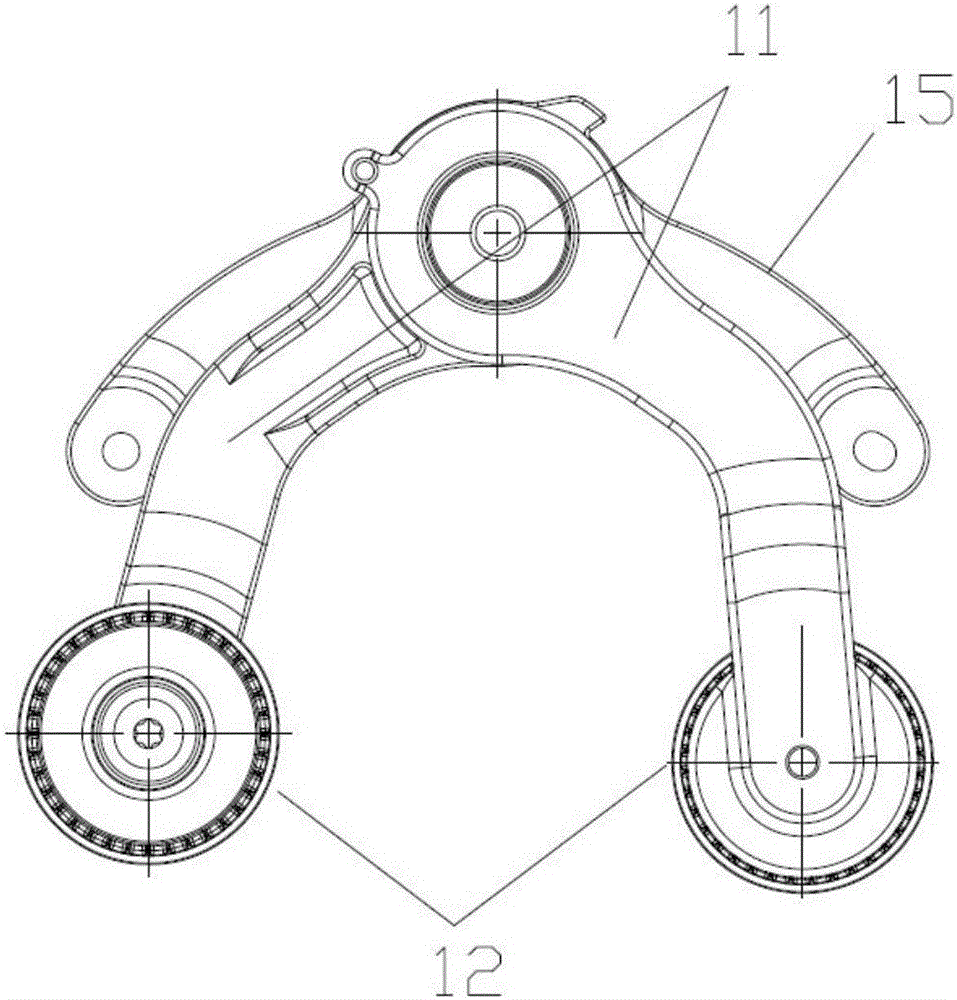

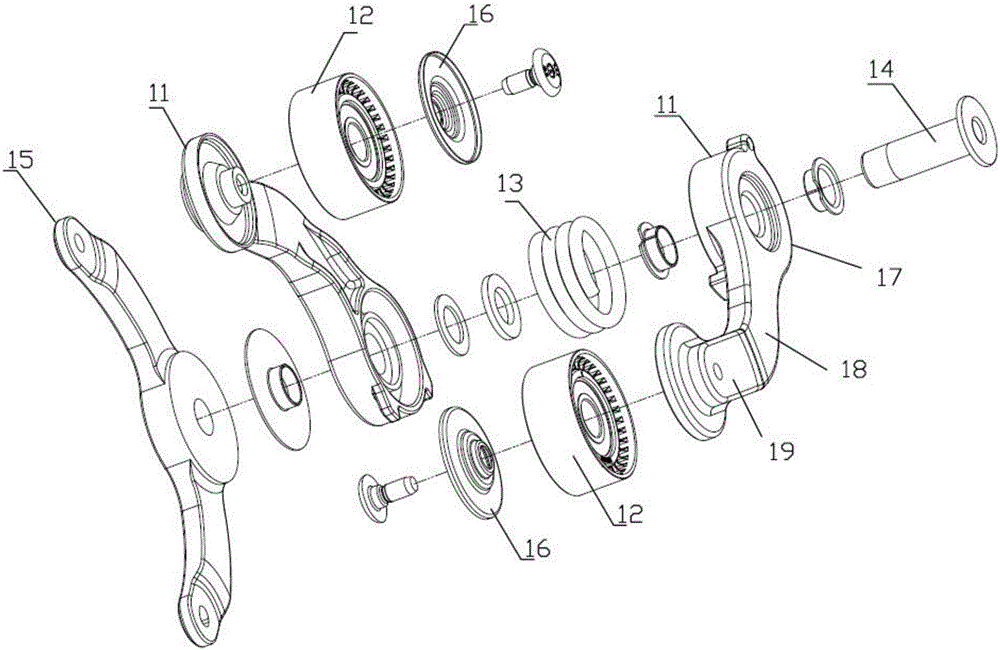

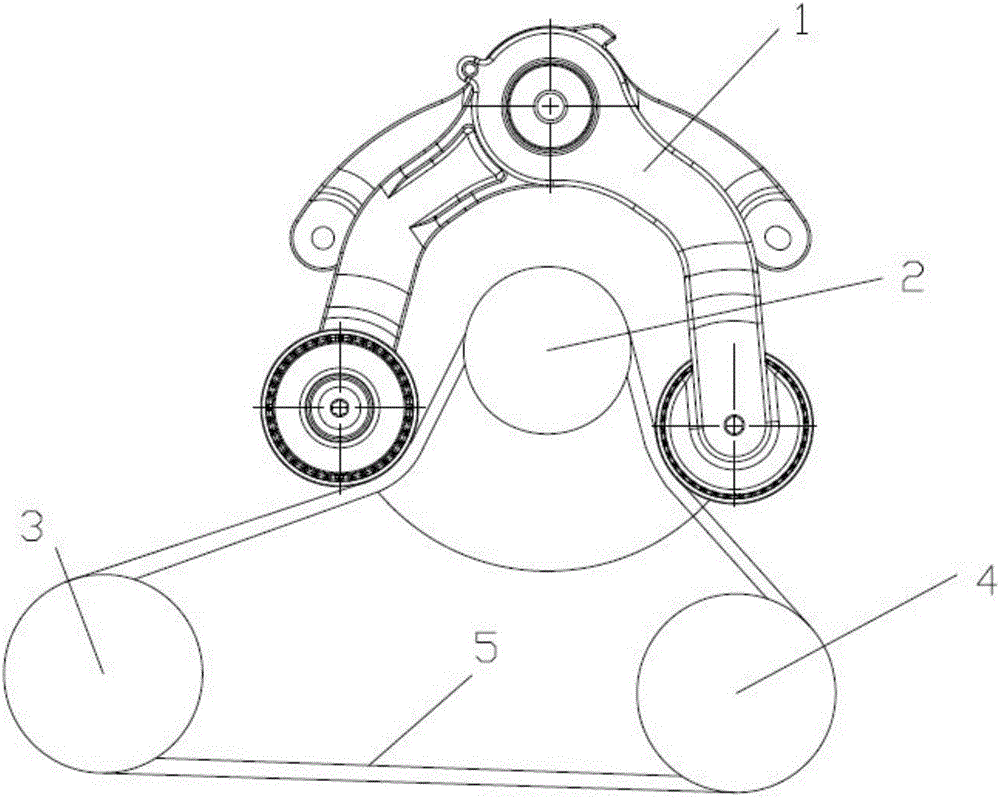

Two-way tensioner applied to BSG wheel system and vehicle engine system

The invention discloses a two-way tensioner applied to a BSG wheel system, and is suitable for a hybrid power engine. The tensioner adopts two tensioner arms arranged in a swing manner, and the internals are connected through a torsion spring to generate elastic tension to realize tensioning of two edges of a motor so as to adapt to interchange of elastic edges of transmission belts on the left and right two sides of the motor due to different working states; and the tensioner is fast in response, is convenient for quick start and stop of the engine, and prevents accidents. The two-way tensioner is compact in structure, convenient for installation and low in control mounting requirements.

Owner:LITENS AUTOMOTIVE PARTS (SUZHOU) CO LTD

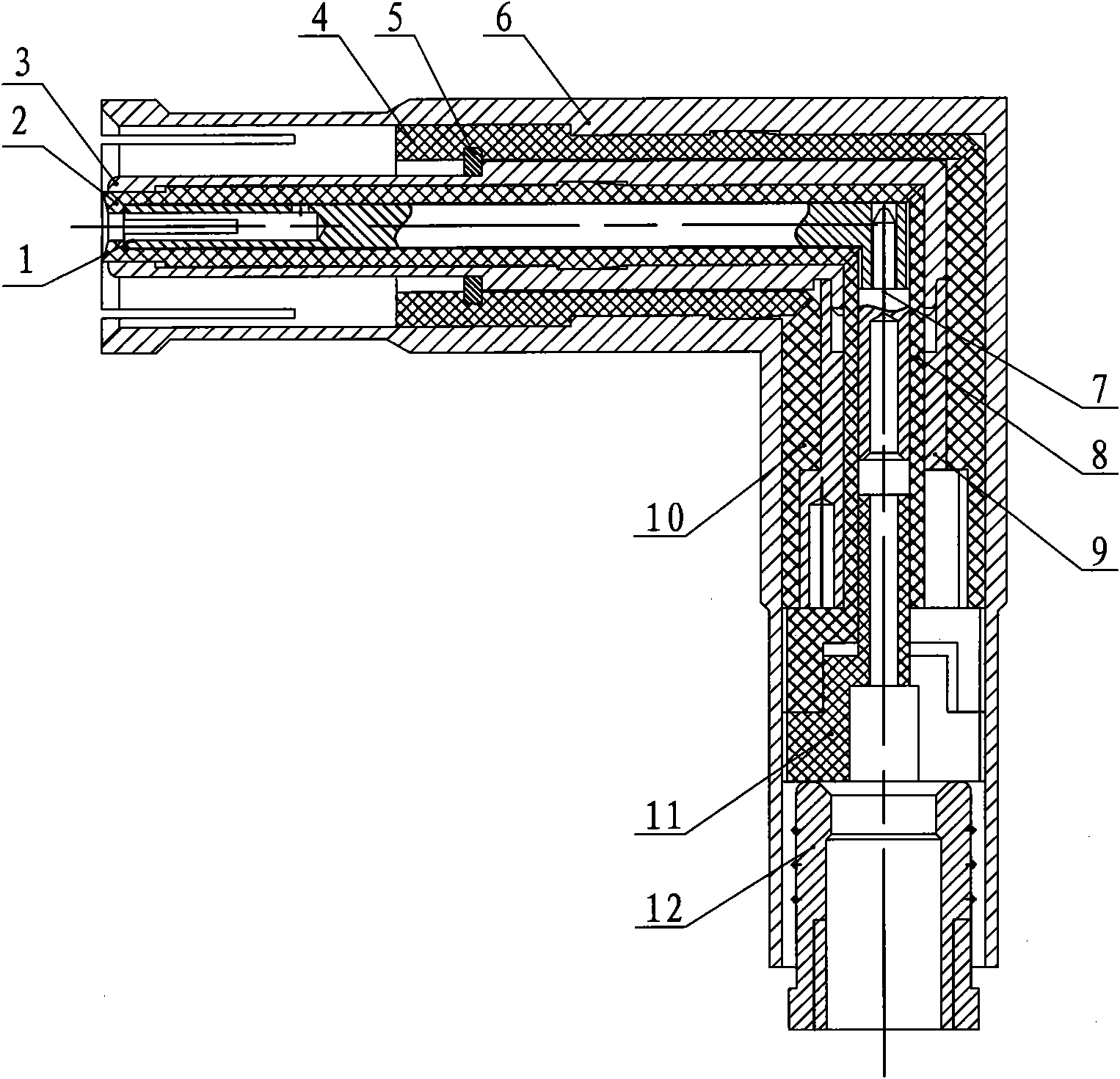

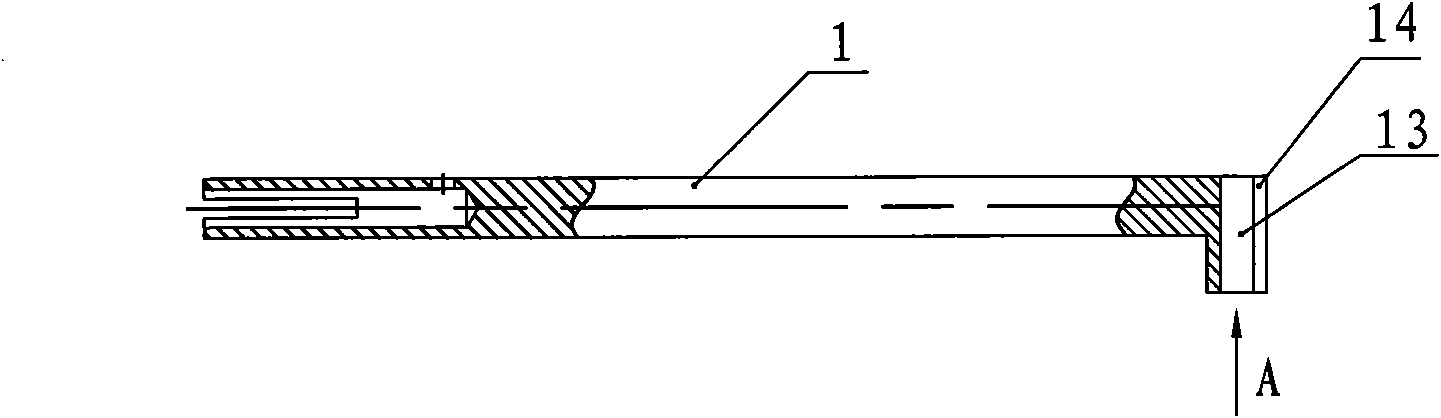

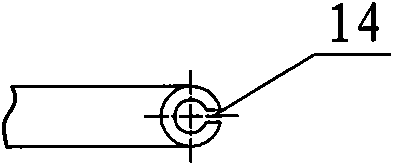

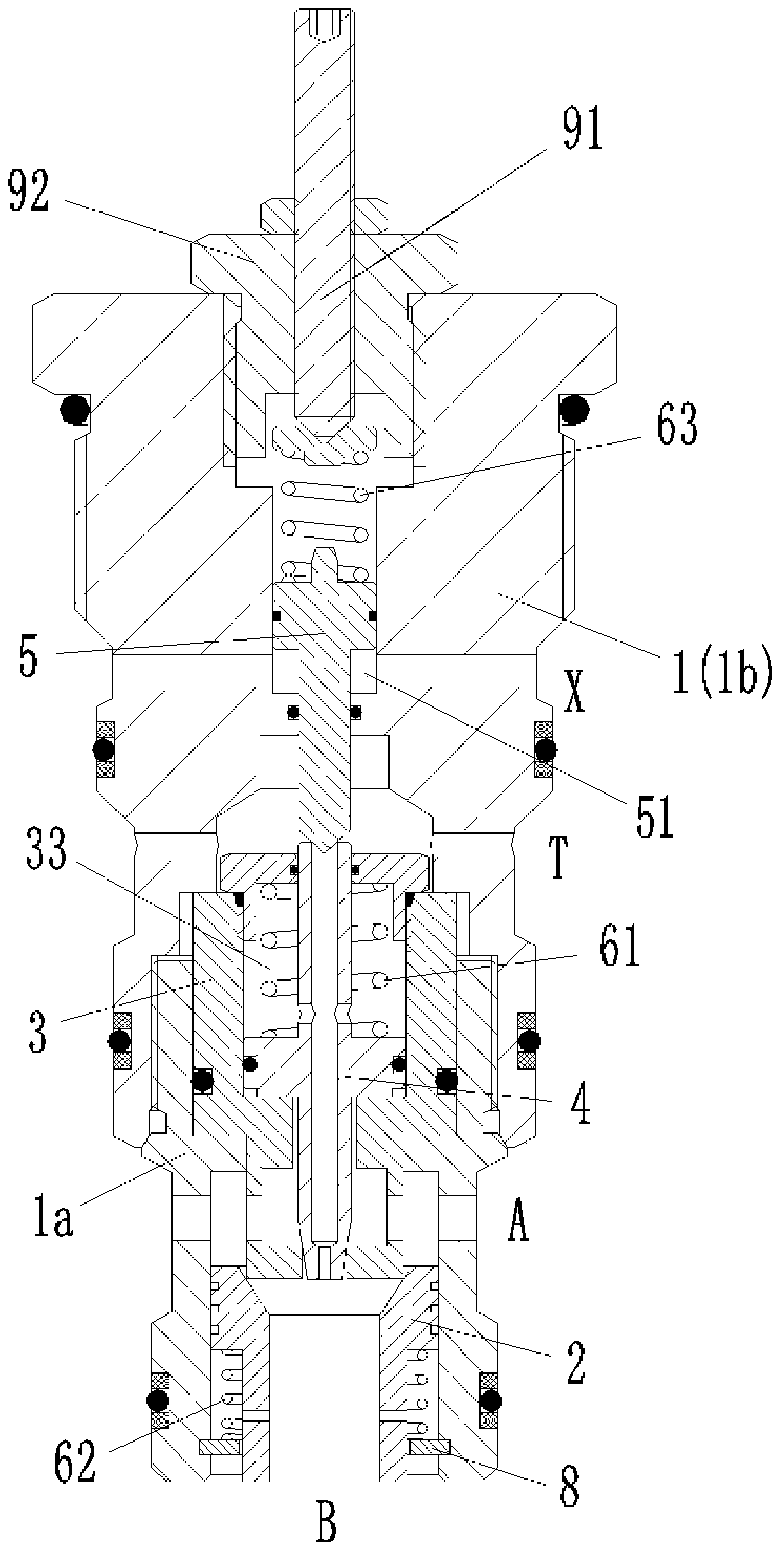

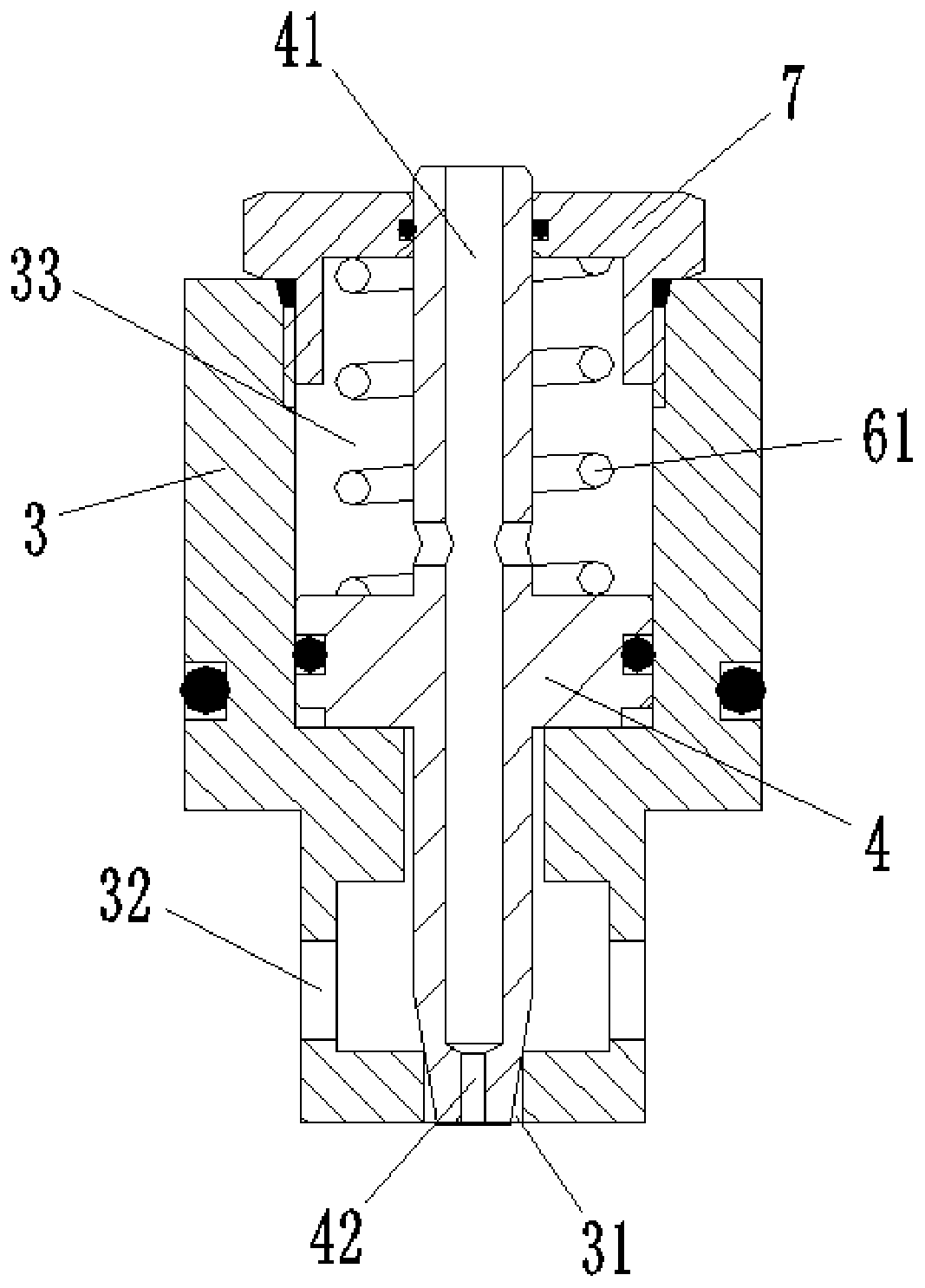

Tri-coaxial contact element

InactiveCN101662114ALow installation space requirementGood consistency of characteristic impedanceSecuring/insulating coupling contact membersCoupling contact membersElectrical conductorEngineering

A tri-coaxial contact element is formed by sequential connection of an inner conductor layer, an inner dielectric body layer, a middle conductor layer, an outer dielectric body layer and an outer conductor from inside to outside; an abutting end is an elastic jack, and the other end is a lead compression jointing end; the tri-coaxial contact element formed by the connection of the inner conductorlayer, the inner dielectric body layer, the middle conductor layer, the outer dielectric body layer and the outer conductor has a right angle bent type structure; the lead compression jointing end thereof is simultaneously provided with a rear dielectric body and a connecting sleeve, wherein the rear dielectric body is installed inside the outer conductor, the small end presses the tail end of theinner conductor layer; the connecting sleeve is installed at the tail end of the rear dielectric body and is pressed tightly. The tri-coaxial contact element is compact in structure, extremely good in the consistency of characteristic impedance on a contact element, simultaneously has the characteristics of small standing-wave ratio, good transmission property and the like, and is suitable for being used as the contact element needing to conduct right angle bent type line outgoing.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

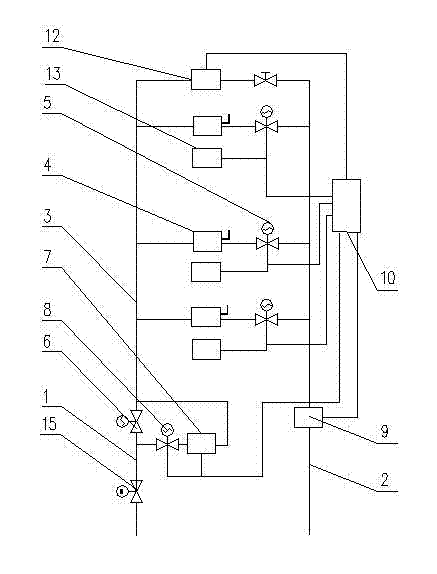

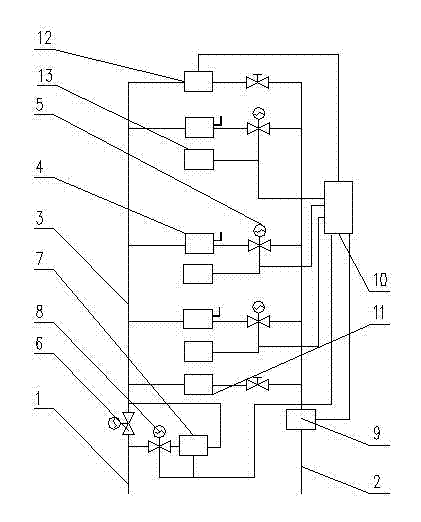

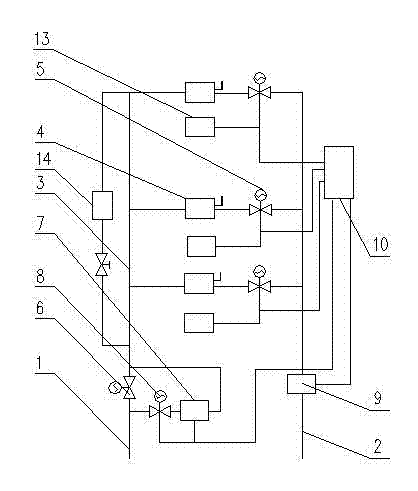

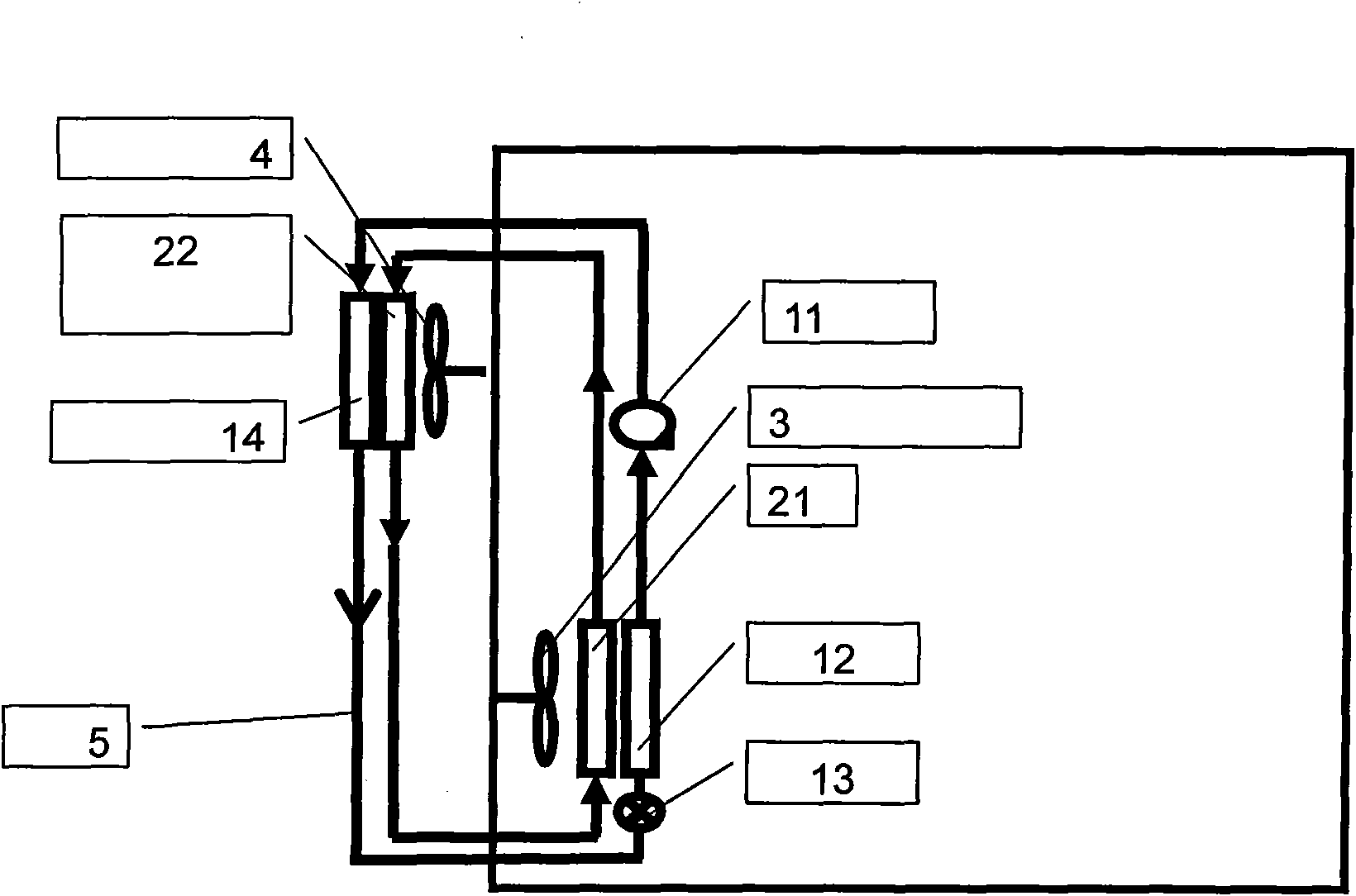

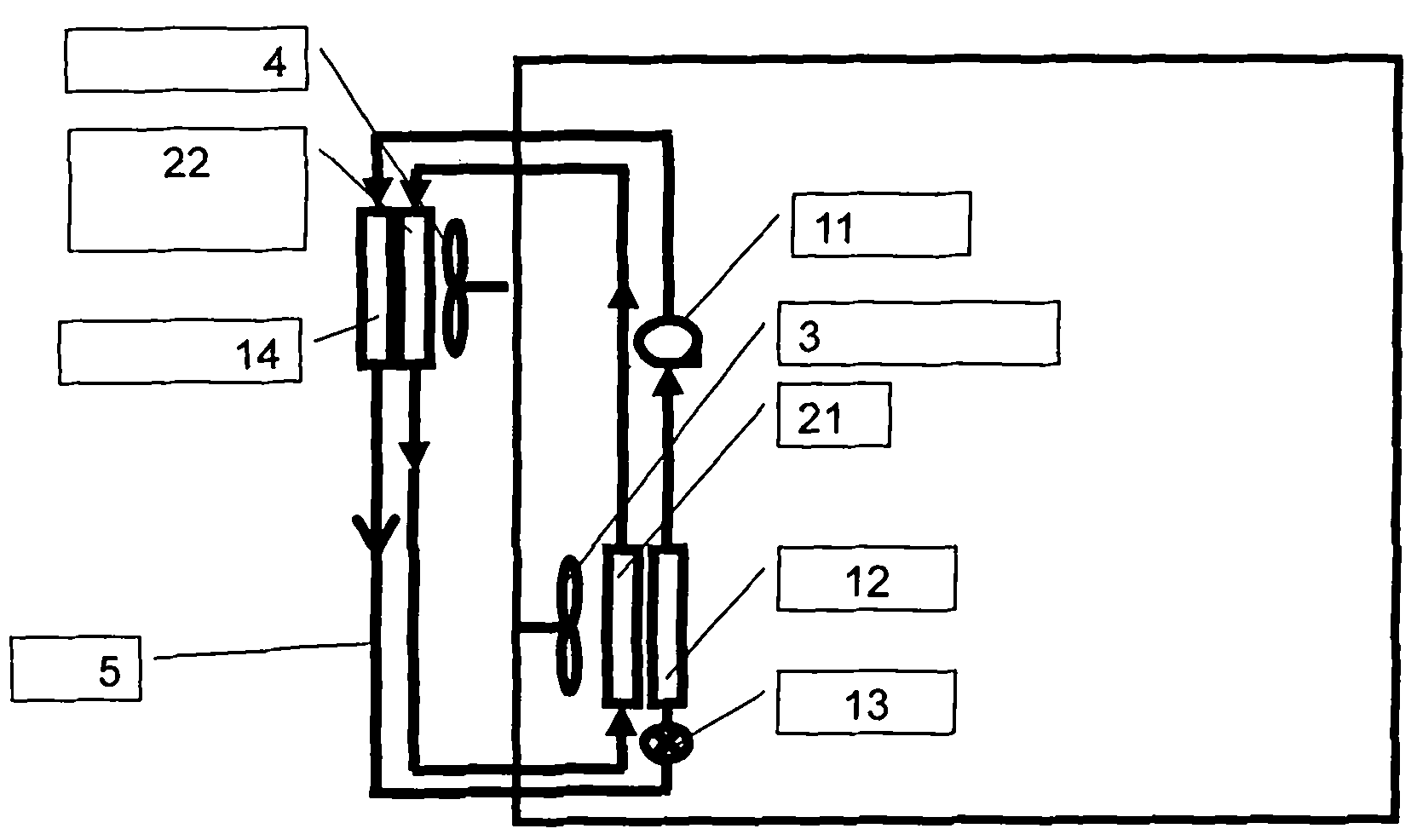

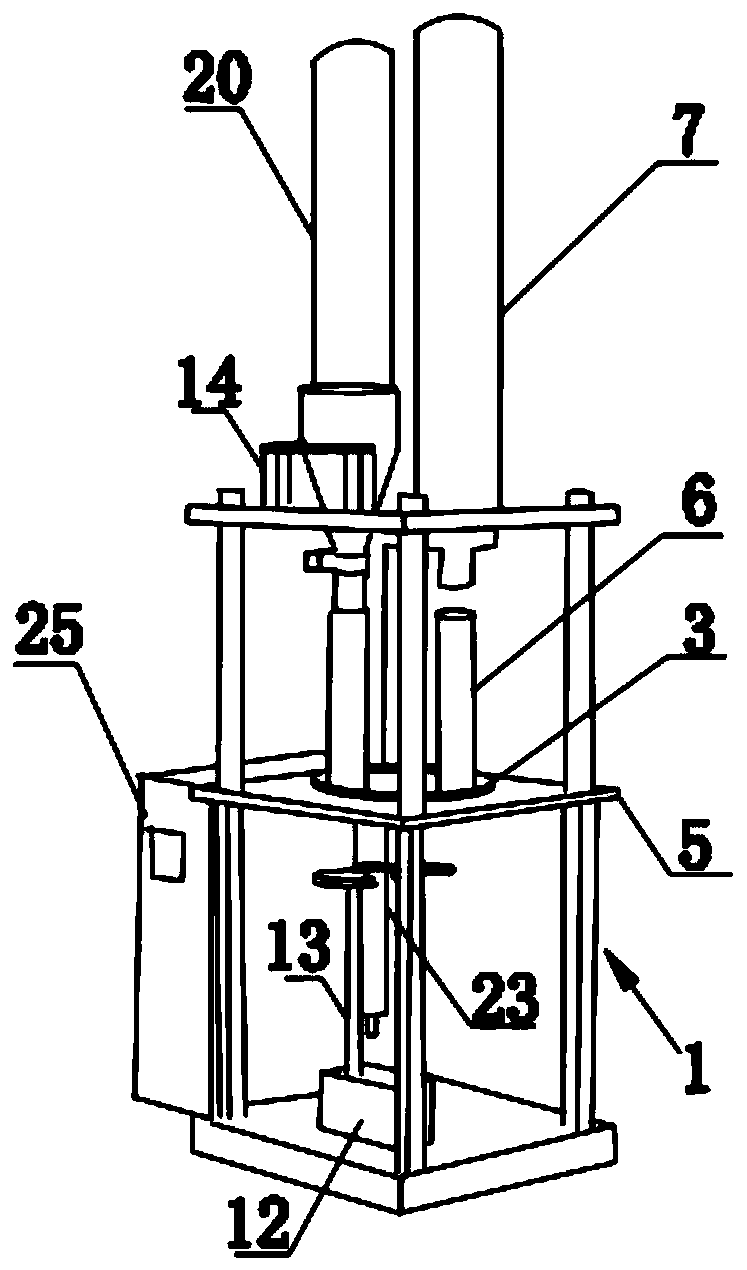

Multifunctional household-based heat metering distribution management device and metering method

InactiveCN102226549AReduce in quantityHousehold metering is easyLighting and heating apparatusSpace heating and ventilation detailsMeasurement deviceProcess engineering

The invention relates to a multifunctional household-based heat metering distribution management device and a metering method, the existing heat metering device has the defects such as large installation occupy space, large error, multiple user limitations and the like. The device comprises a water supply main pipe (1) and a backwater main pipe (2), wherein a group of user pipes (3) are connected in parallel between the water supply main pipe and the backwater main pipe, each user pipe (3) is connected with a radiator (4), the radiator (4) is connected with an intelligent valve (5), the intelligent valve is connected with indoor temperature setting metering equipment (13), a total heat meter (9) is installed on the backwater main pipe, a pressure measurement device is connected between the water supply main pipe and the backwater main pipe, the intelligent valve (5), and the total heat meter (9) and the pressure measurement device are all connected with a center controller (10). The device in the invention is used for household-based heat metering.

Owner:何学新

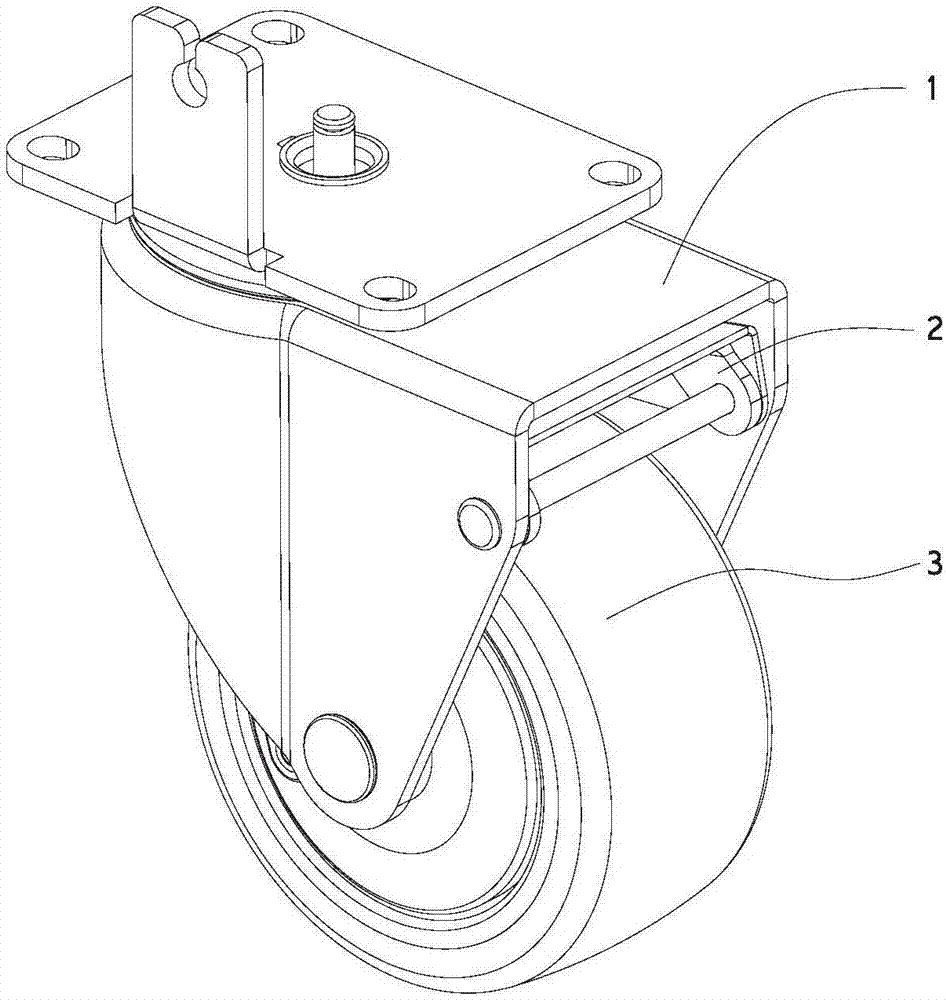

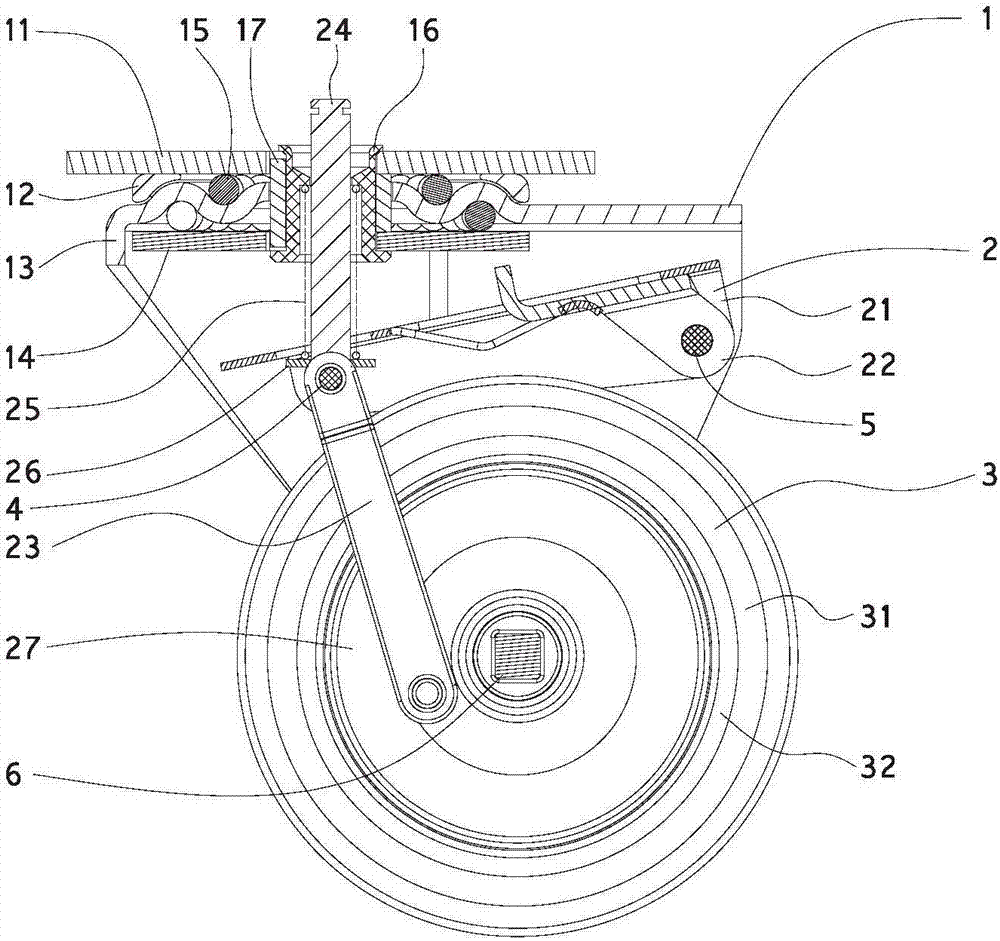

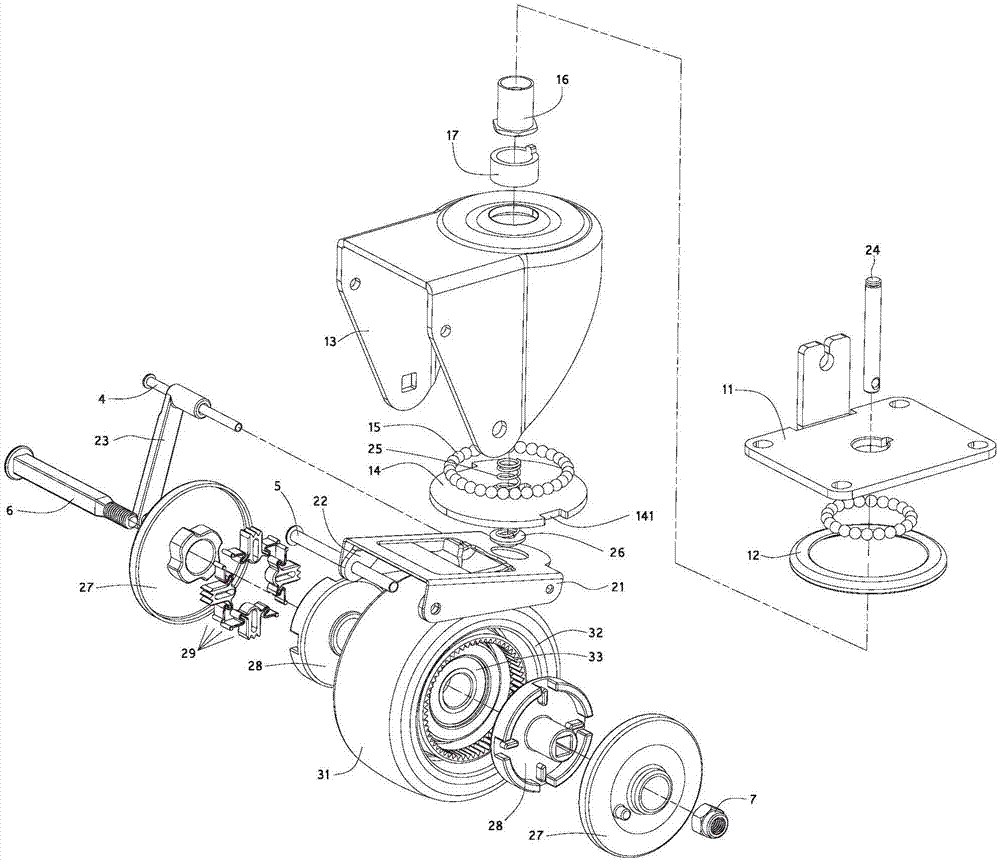

Universal caster with brake device

PendingCN107284134ALow installation space requirementNovel and reliable structureCastorsRolling resistance optimizationEngineeringSpace requirements

The invention discloses a universal caster with a brake device. The universal caster comprises a support component and a wheel component, the support component comprises a mounting support and a wheel support, the mounting support is rotatably mounted on the wheel support, the wheel component comprises a tire and a hub, a tire is mounted on the hub, and the hub is mounted on the wheel component. The universal caster further comprises a brake component, the brake component comprises a driving part, a rotating disk, a cam mechanism and a brake part, wherein the driving part is associated with the rotating disk to drive the rotating disk to move, and the rotating disk is associated with the brake part through the cam mechanism to drive the brake part to move, so that the brake part is switched between a first position and a second position. At the first position, the brake part is matched with the hub, so that the universal caster is in a brake state. At the second position, the brake part is disengaged with the hub, so that the universal caster is in a movable state. The universal caster is convenient to operate and low in mounting space requirement.

Owner:SHANGHAI HONGYAN RETURNABLE TRANSIT PACKAGINGS CO LTD

Double-cold source integrated air-conditioning system

InactiveCN102401438ACompact designLow installation space requirementSpace heating and ventilation safety systemsLighting and heating apparatusEvaporationEngineering

The invention relates to a double-cold source integrated air-conditioning system, which comprises a refrigeration air-conditioning subsystem, a heat pipe subsystem, an evaporation fan and a condensation fan, wherein the refrigeration air-conditioning subsystem comprises a compressor, an evaporator, a condenser and an expansion valve; the expansion valve, the evaporator, the compressor and the condenser are connected sequentially; the heat pipe subsystem comprises a heat pipe indoor heat exchanger and a heat pipe outdoor heat exchanger; the heat pipe indoor heat exchanger is connected with the heat pipe outdoor heat exchanger; an air outlet of the evaporation fan is opposite to the evaporator and the heat pipe indoor exchanger; and an air outlet of the condensation fan is opposite to the condenser and the heat pipe outdoor exchanger. Compared with the prior art, the double-cold source integrated air-conditioning system has the advantages of compact design, good energy-saving effect and the like, and is easy to control and convenient to overhaul.

Owner:SHANGHAI AEROSPACE AUTOMOBILE ELECTROMECHANICAL CO LTD

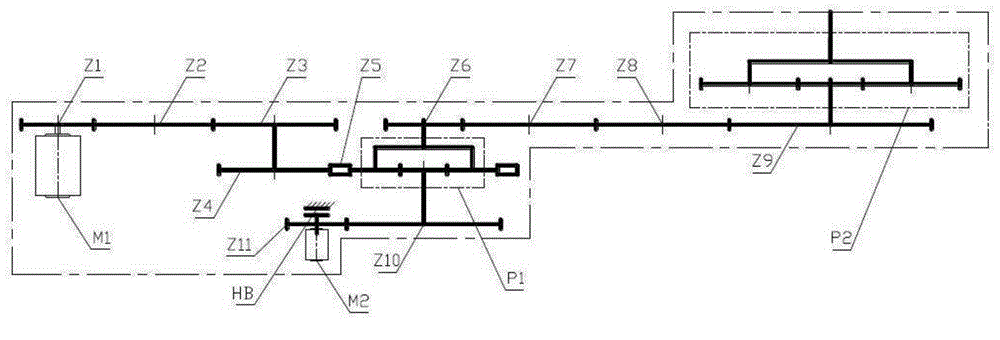

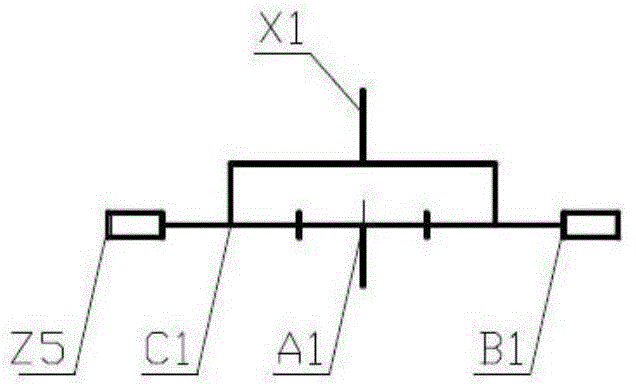

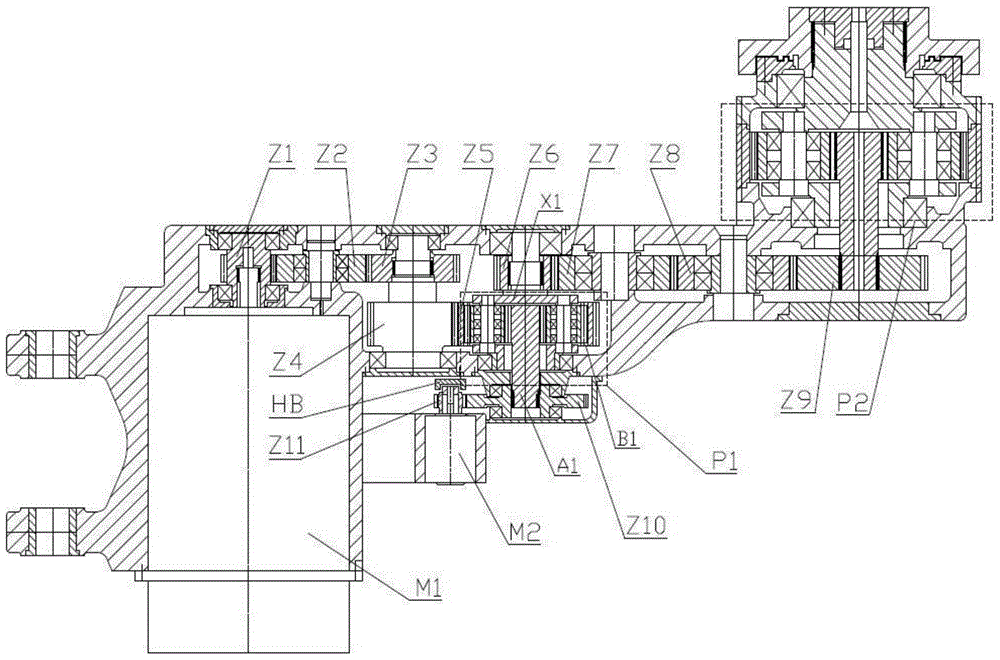

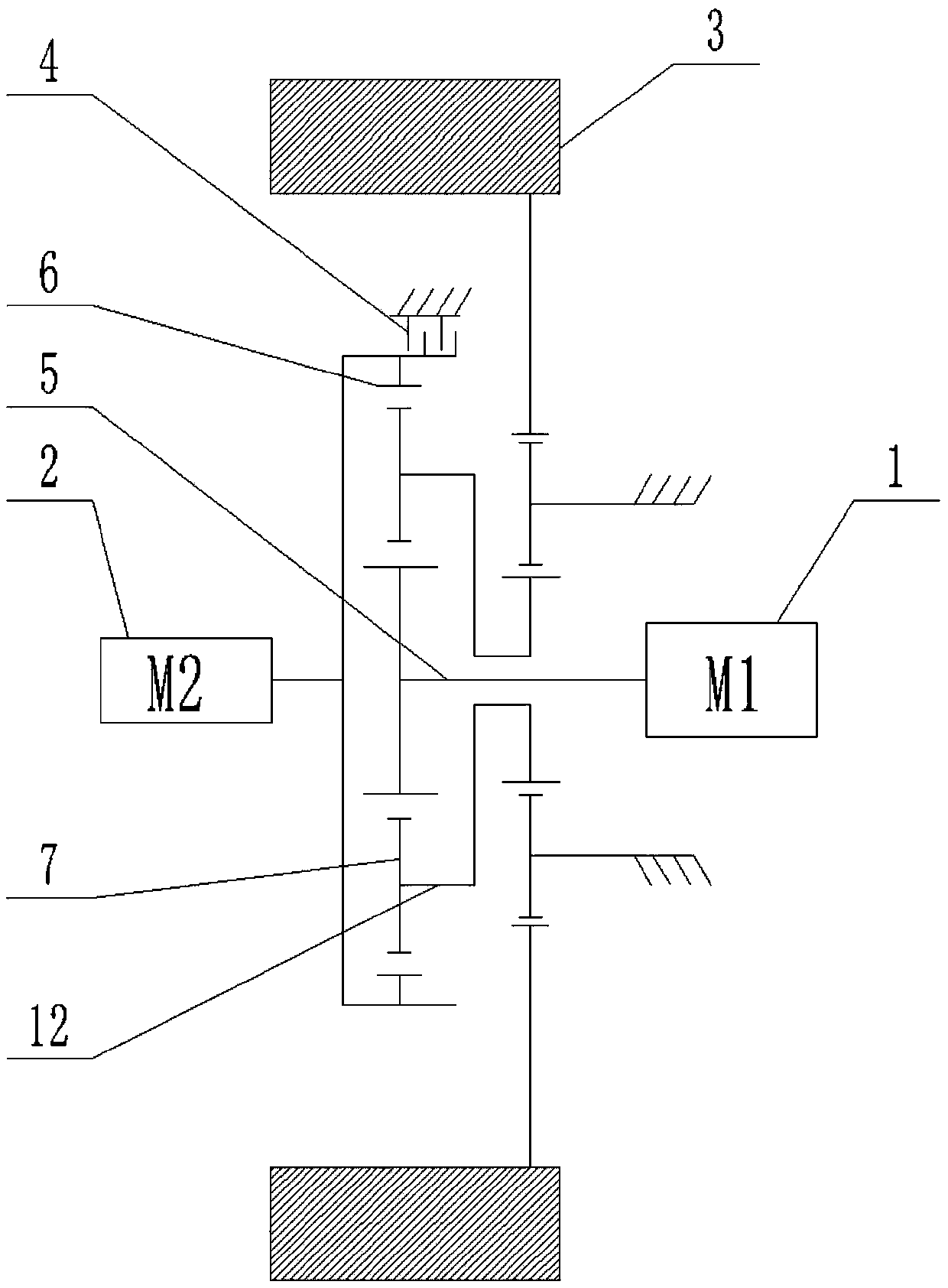

Coal cutter infinitely-variable-speed cutting transmission system based on rotation speed coupling

InactiveCN104455224AStepless adjustment of cutting speedIncrease peak cut powerToothed gearingsMotor speedCoupling

The invention discloses a coal cutter infinitely-variable-speed cutting transmission system based on rotation speed coupling. The system comprises a cutting motor, a variable-speed motor, a differential planetary gear train, a cutting part planetary reducer and a cutting drum. The differential planetary gear train is mainly composed of a planetary carrier, a gear ring, a sun gear and a planetary gear, and gears are arranged on the inner ring and the outer ring of the gear ring receptively. The cutting motor is meshed with the outer ring of the gear ring on the differential planetary gear train through a gear pair for transmission. The variable-speed motor is connected with the sun gear on the differential planetary gear train in a transmission mode through a motor reducer. The differential planetary gear train is connected with the cutting part planetary reducer in a transmission mode through a gear pair. By additionally arranging the differential planetary gear train and a motor speed regulation system, the cutting rotating speed of the drum can be regulated in a stepless mode within a certain range. Compared with a traditional transmission system, the system has the advantages of being small in size change and cost increase, wide in application range and low in installation space requirement.

Owner:CHONGQING UNIV

Antenna array, base station antenna and antenna index improving method

InactiveCN110854550AImprove horizontal wave width convergenceImprove the convergence of high-frequency horizontal wave widthAntenna supports/mountingsRadiating elements structural formsMiniaturizationHigh frequency radiation

The invention relates to the technical field of wireless communication, and discloses an antenna array, a base station antenna and an antenna index improving method. The antenna array comprises high-frequency radiation units and is characterized by further comprising coupling boundaries, wherein the coupling boundaries are of a metal sheet structure, and the coupling boundaries are arranged on oneside or two sides of at least one high-frequency radiation unit. According to the antenna array, the base station antenna and the antenna index improving method provided by the invention, the coupling boundaries are set based on a surface current coupling technology, and the surface current of the high-frequency radiation units is coupled to the coupling boundaries through beam forming, so that the coupling boundaries generate weak radiation and synthesize a narrow beam with the high-frequency antenna array, and the high-frequency horizontal wave width convergence of the antenna is improved.The antenna array has low requirements for the installation space by arranging the sheet-shaped coupling boundaries, the high-frequency horizontal wave width convergence can be improved under the condition that the occupied space is small, the miniaturization and light weight of the antenna can be achieved, and the windward area and weight of the antenna can be reduced.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

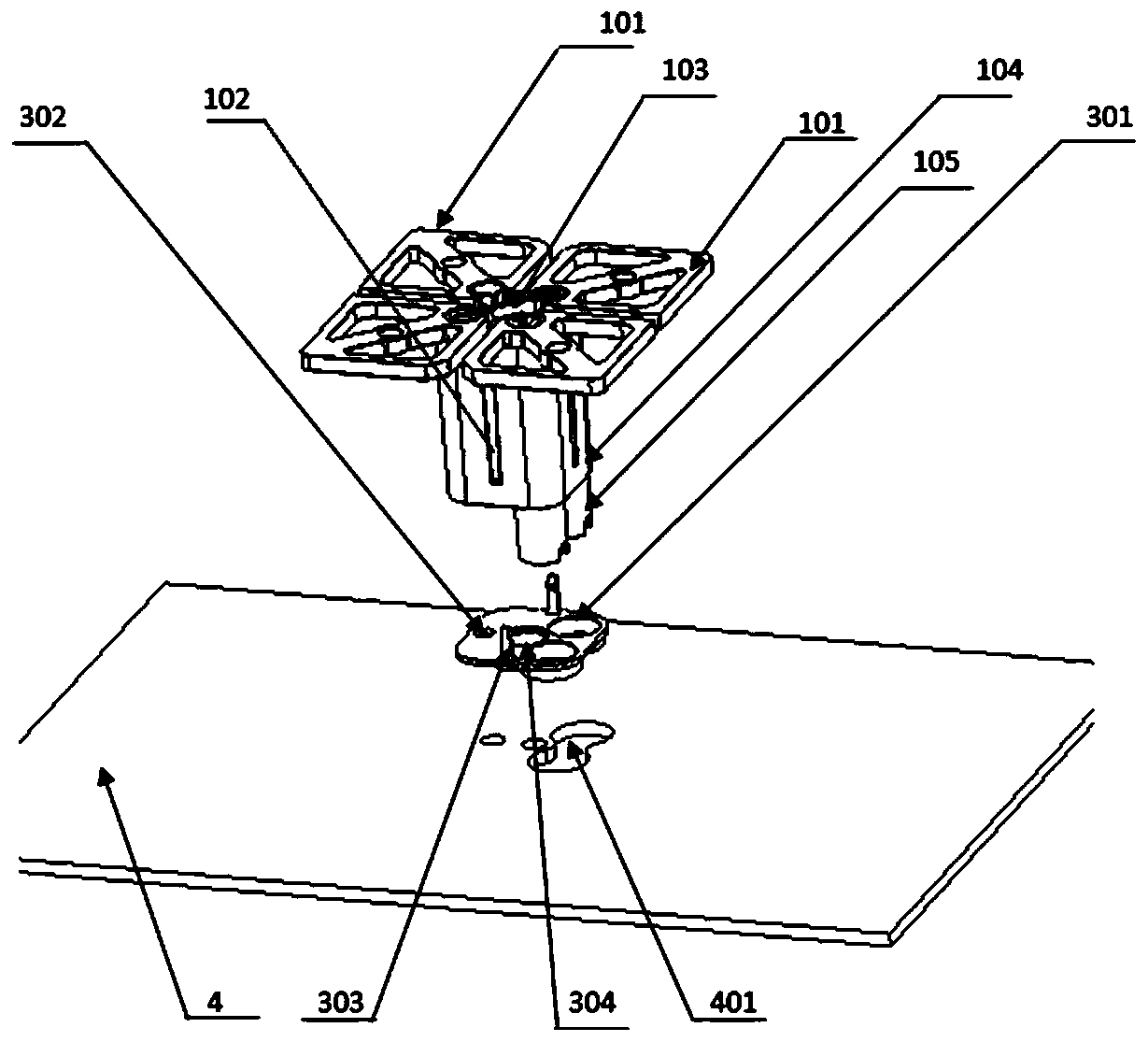

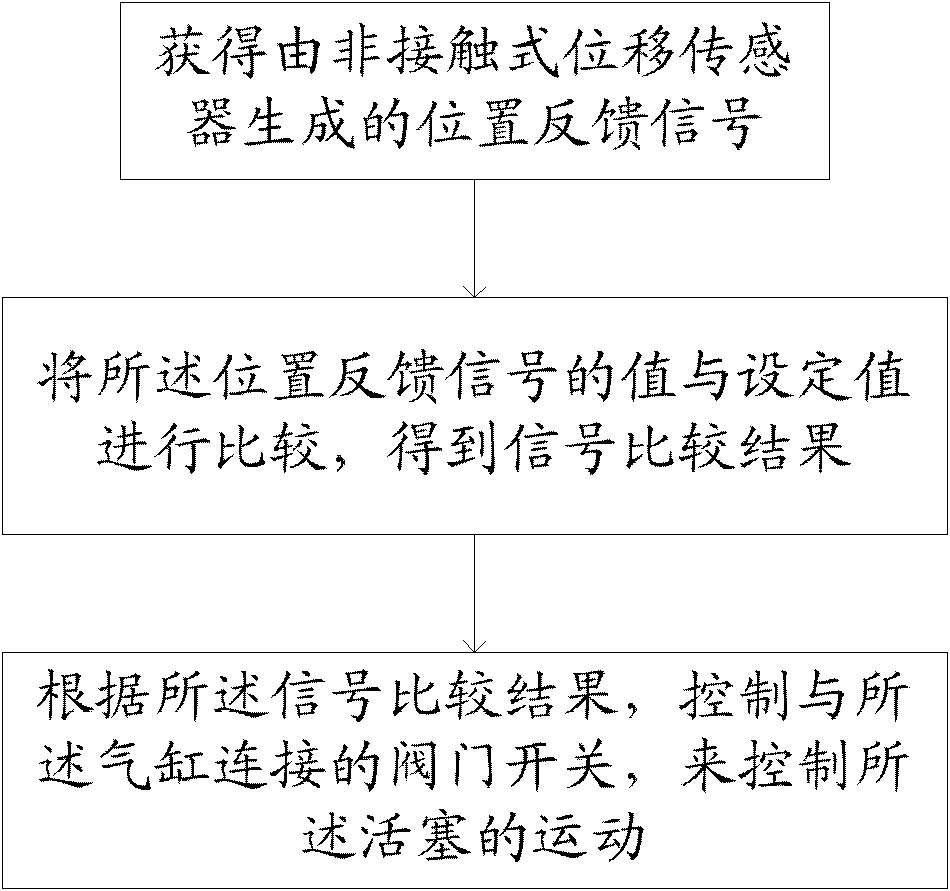

Servo control method, apparatus and system

ActiveCN102799194AReduce mechanical connectionsReduce wearControl using feedbackEngineeringControl theory

An embodiment of the invention provides a servo control method, a servo control apparatus and a servo control system for controlling the position of a piston in a pneumatic executive component, wherein the servo control method comprises the following steps of: acquiring a position feedback signal through a non-contact displacement sensor outside the pneumatic executive component, and obtaining the position of the piston; comparing the value of the position feedback signal with a preset value to obtain a signal comparison result; and controlling the movement of the piston through controlling the valve which is connected with the pneumatic executive component according to the signal comparison result. Due to the adoption of the non-contact displacement sensor in the invention, the precise control to the position of the piston is realized, and the problems, such as loss caused by the manner that a contact sensor is connected with a piston rod to detect the position of the piston so as to control the movement of the piston, are conquered.

Owner:SMC CHINA

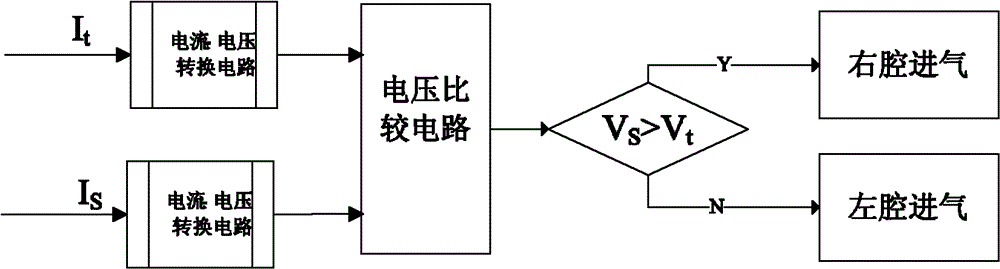

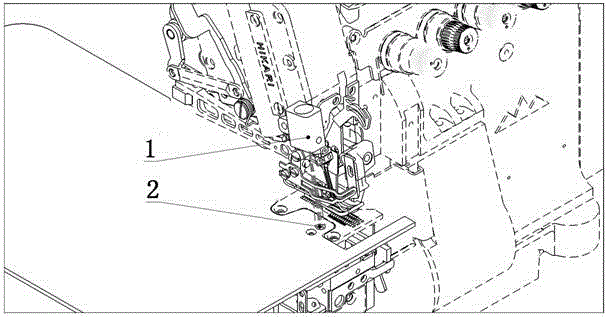

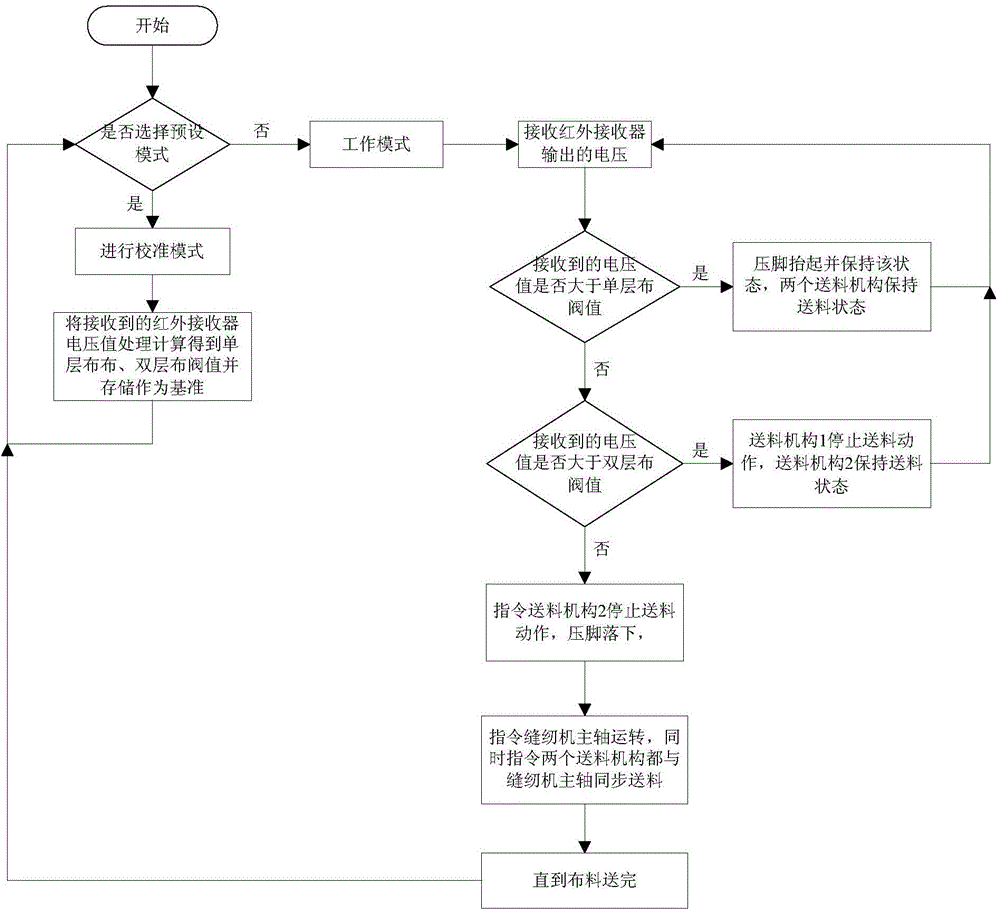

Aligning control system and method for end surfaces of double-layer fabrics of sewing machine

InactiveCN104480645ACompact structureReduced installation space requirementsProgramme-controlled sewing machinesWork-feeding meansInfrared emitterVoltage

The invention provides aligning control system and method for end surfaces of double-layer fabrics of a sewing machine, and belongs to the technical field of the sewing machines. The aligning control system for the end surfaces of the double-layer fabrics of the sewing machine is characterized in that the sewing machine comprises a machine head, a sewing stand, two feeding mechanisms, a fabrics sensor and a microcontroller, wherein the fabrics sensing device is used for recognizing whether fabrics are conveyed to a pressing pin as well as recognizing the number of the layers of the fabrics conveyed to the pressing pin; the microcontroller is respectively connected with a signal output end of an infrared emitter or an infrared laser emitter and an infrared receiver, the control end of the pressing pin, and the control ends of the two feeding mechanisms; the microcontroller is used for comparing the received voltage with a voltage threshold stored after being corrected during presetting, recognizing whether the fabrics are conveyed to a pressing pin as well as recognizing the number of the layers of the fabrics conveyed to the pressing pin, and controlling the pressing pin to raise and lower down and turn on and off the two feeding mechanisms according to the comparing result. The system is compact in structure, and low in requirement on a mounting space, replaces manual aligning, and realizes a full-automatic sewing machine.

Owner:上海富山精密机械科技有限公司

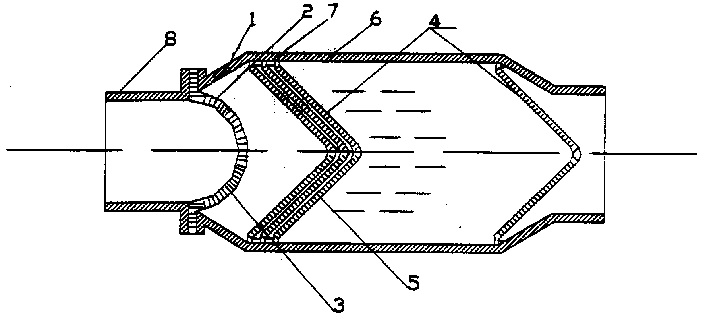

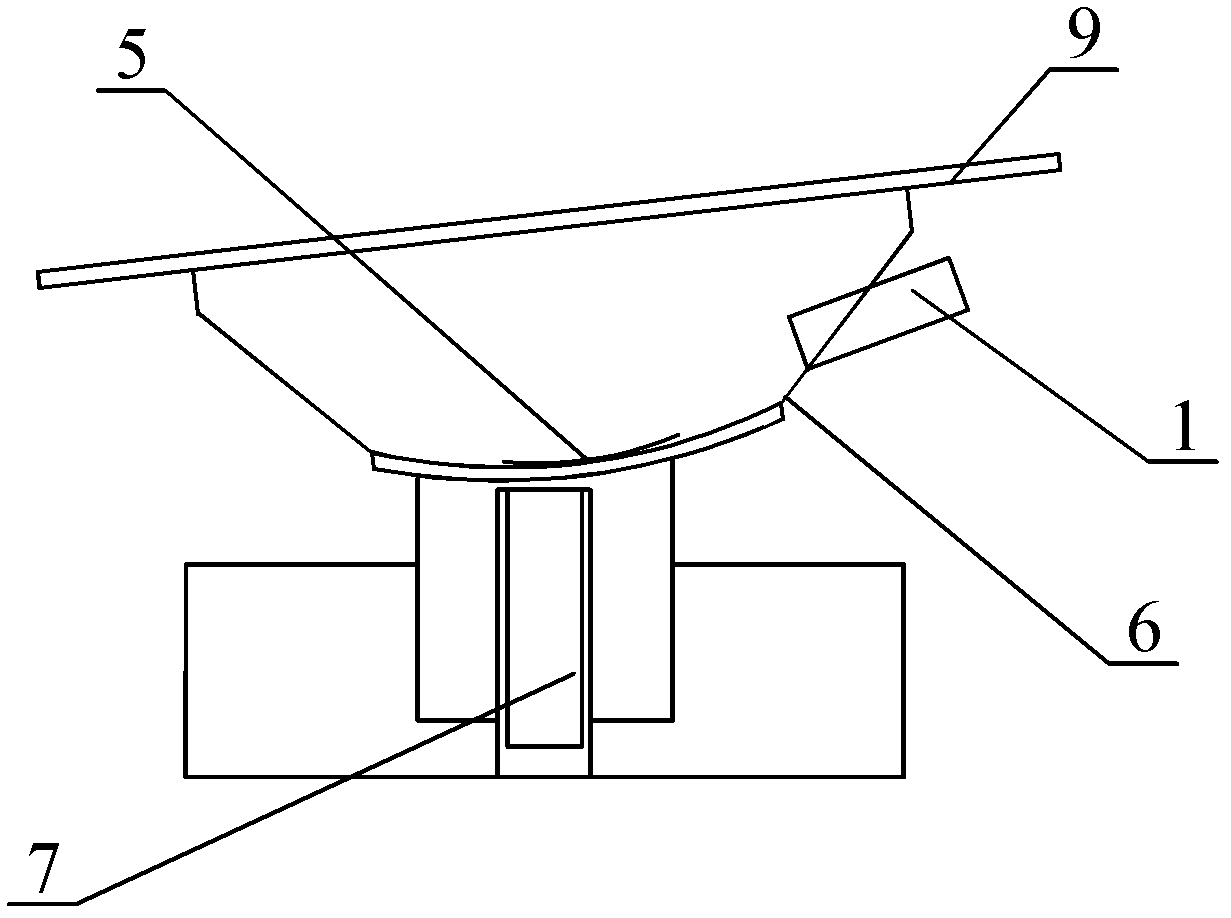

Spherical honeycomb board-based automobile tail gas catalyzing unit

InactiveCN1403691ATemperature rises fastHeating fastExhaust apparatusSilencing apparatusGasolineHoneycomb

The automobile tail gas catalyzing unit includes an expanding section and a main carrier section. The expanding section is provided with porous spherical honeycomb board in the inlet plane fixed to the conic casing and tail gas tube and the spherical honeycomb board has dense flow channels with maximum angle to the axis being the expanding angle of the said section. The main carrier section consists of conic honeycomb sheets arranged discretely with flow channel direction perpendicular to the surface. The present invention may be used in gasoline engine catalyzing device and diesel engine catalyzing device and can homogenize tail gas flow rate, raise mass transfer rate, reduce the radius of the catalyzing device and reduce the harmful exhaust.

Owner:SHANGHAI JIAO TONG UNIV

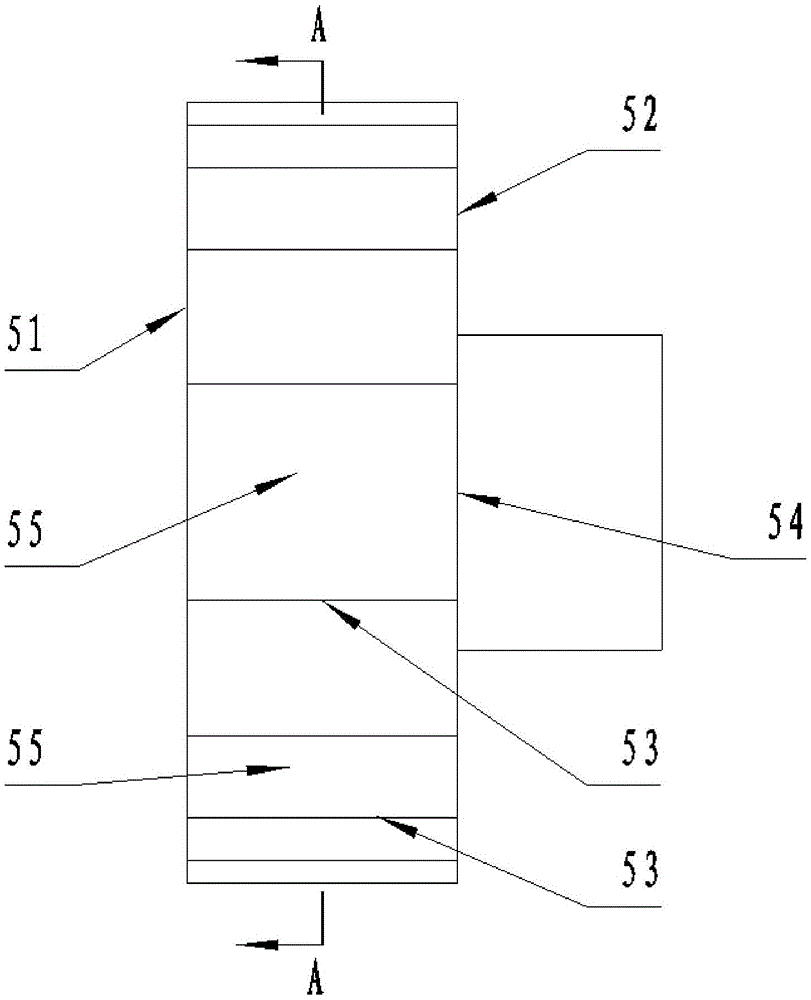

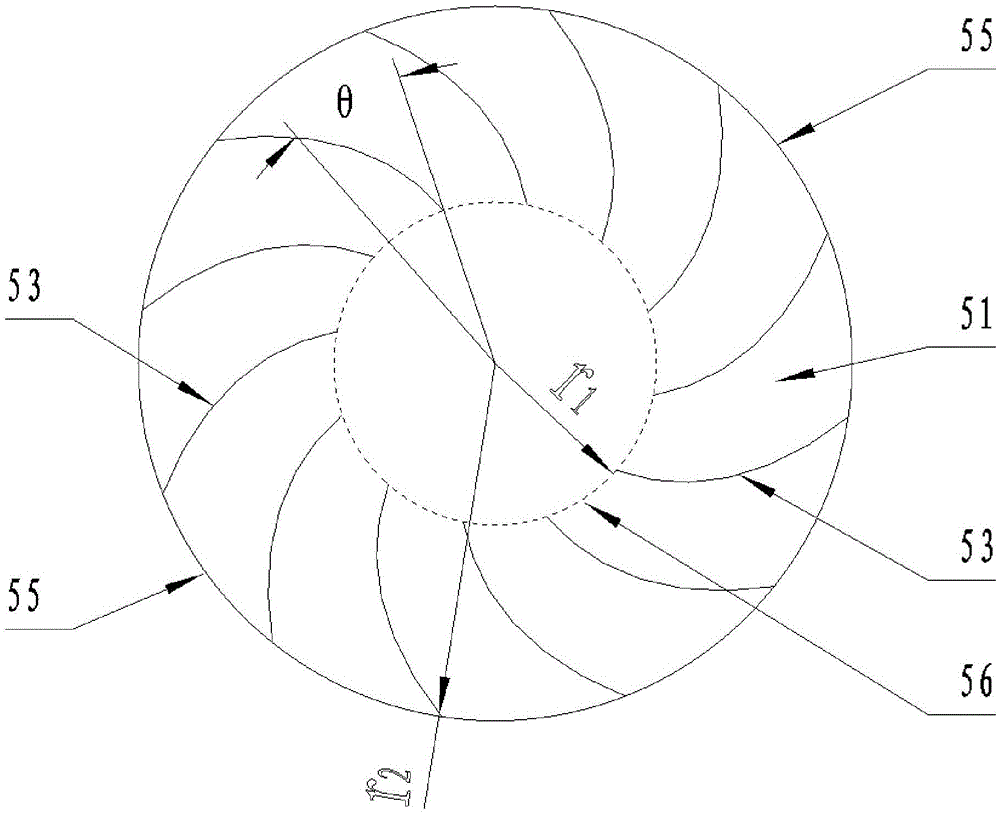

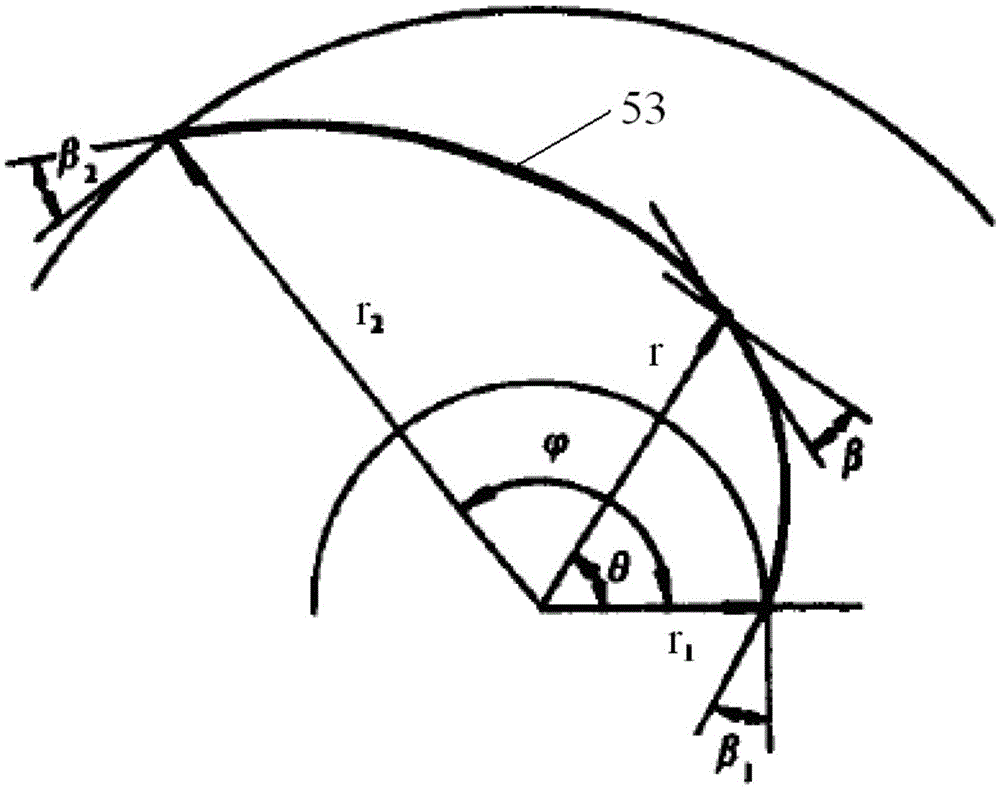

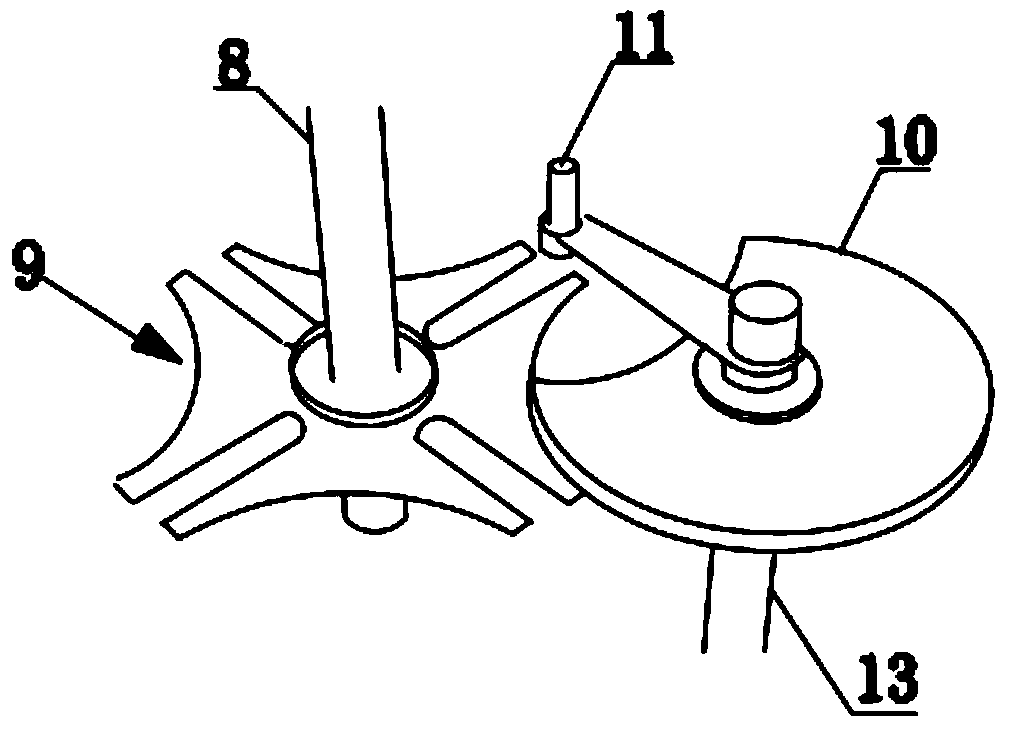

Swirl vane and flue gas ammonia-injection and denitration device

ActiveCN105465109ARealize automatic controlLow investment costGas treatmentDispersed particle separationControl flowFlue gas

The invention provides a swirl vane and a flue gas ammonia-injection and denitration device. The swirl vane comprises a first partition plate (51) and a second partition plate (52) which are parallel to each other, wherein a plurality of flow deflectors (53) are arranged between the first partition plate (51) and the second partition plate (52); the middle part of the second partition plate (52) is provided with an air outlet (54); an air inlet (55) is arranged between outer ends of adjacent two flow deflectors (53); an inner outlet (56) is arranged between inner ends of the two flow deflectors (53); and gas flow can sequentially pass through the air inlets (55), the inner outlets (56) and the air outlet (55), and then flows out of the swirl vane. After being optimized, the swirl vane can enable the gas component concentration distribution on a flue section to be uniform in case of not needing to additionally applying power and energy. On the primes of not increasing NOx measuring points, the effect of automatically control flow of a reducing agent is brought into play, and optimized operation of a denitration system is realized.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +1

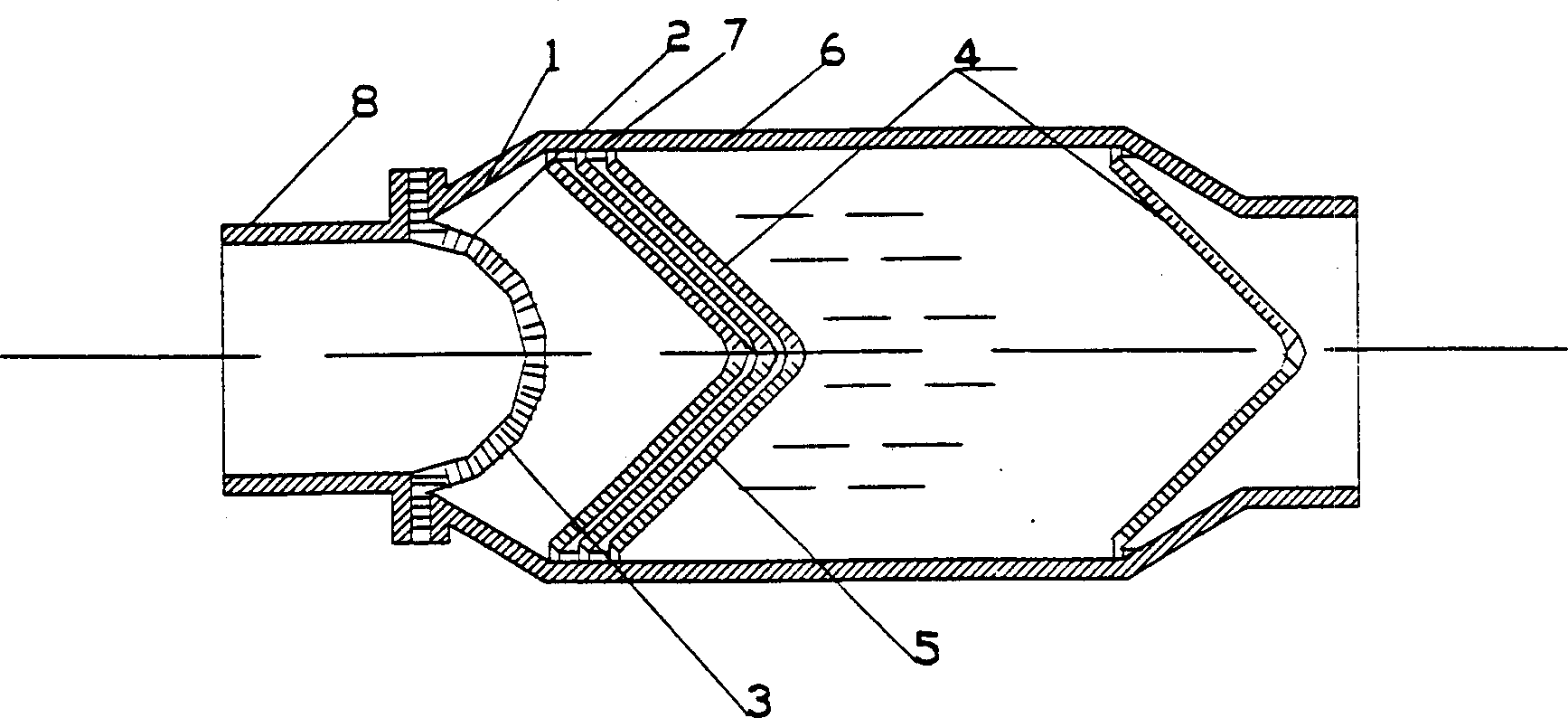

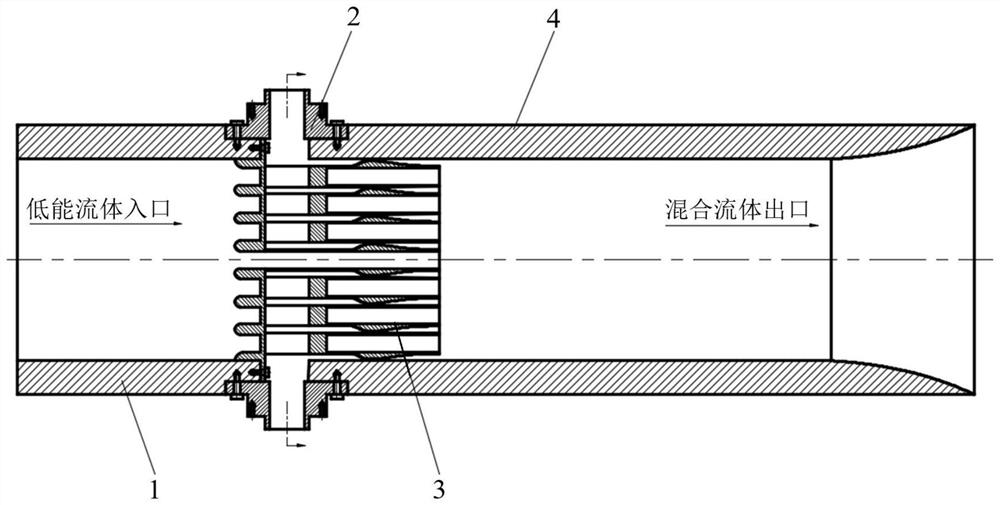

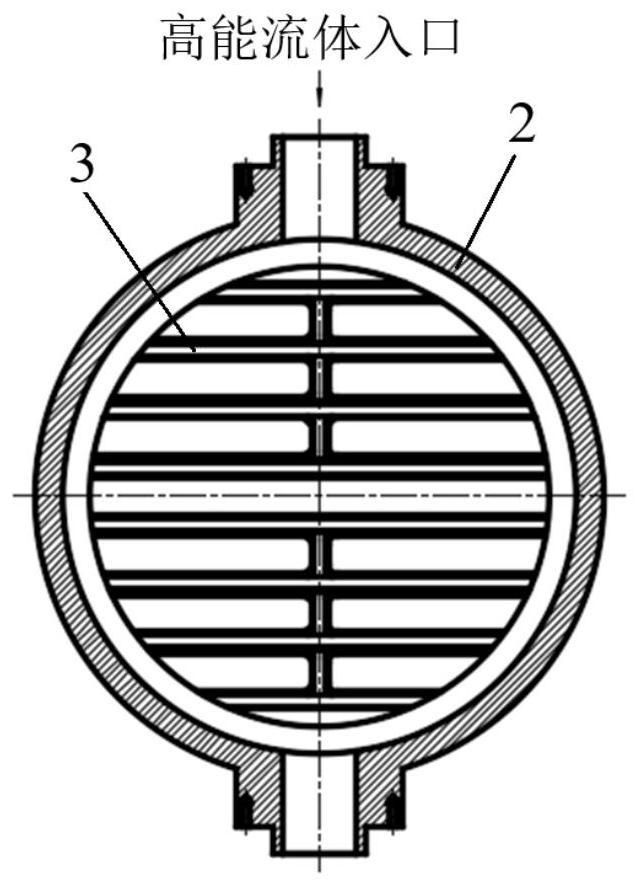

Distributed two-dimensional spray pipe ejector device

ActiveCN111911465AEnough storage spaceIncrease contact surfaceJet pumpsMachines/enginesEngineeringMechanical engineering

The invention discloses a distributed two-dimensional spray pipe ejector device. The distributed two-dimensional spray pipe ejector device uses a pipeline connection mode, and sequentially comprises alow-energy fluid inlet section, a high-energy fluid inlet section and a mixed fluid outlet section which are connected in sequence, wherein an two-dimensional spray pipe ejector is arranged in a pipeline near the high-energy fluid inlet section; a through hole is formed in the surface of the high-energy fluid inlet section and communicates with an external high-pressure tank; the low-energy fluidinlet section, the high-energy fluid inlet section and the mixed fluid outlet section share the same central axis; the two-dimensional spray pipe ejector comprises linear spray pipe unit bodies arranged in parallel; the spray pipe unit bodies are connected through reinforcing ribs; part of the reinforcing ribs are of hollow structures; high-energy fluid enters the spray pipe unit bodies from thethrough hole of the high-energy fluid inlet section and is sprayed out from outlets of the spray pipe unit bodies; and spray pipes are arranged in the spray pipe unit bodies. The distributed two-dimensional spray pipe ejector device is suitable for fluid ejection control of gas and liquid, and has the advantages that the ejection efficiency is improved; the appearance dimension of the ejector device is reduced; and the space installation requirement of the ejector device is lowered.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

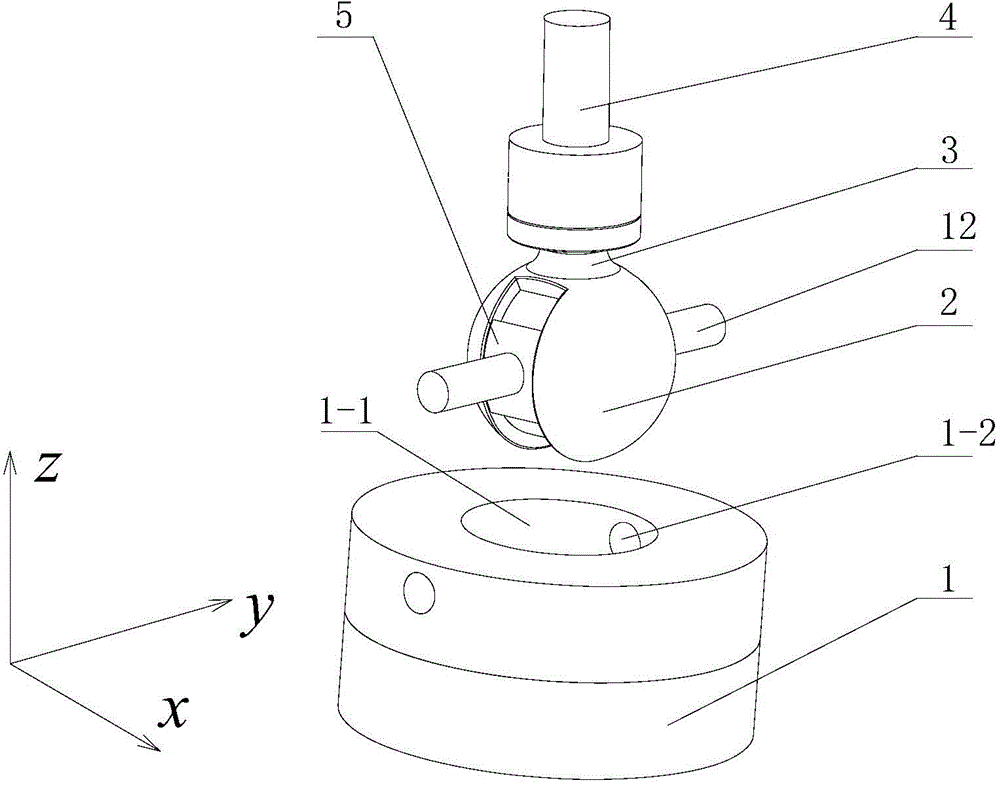

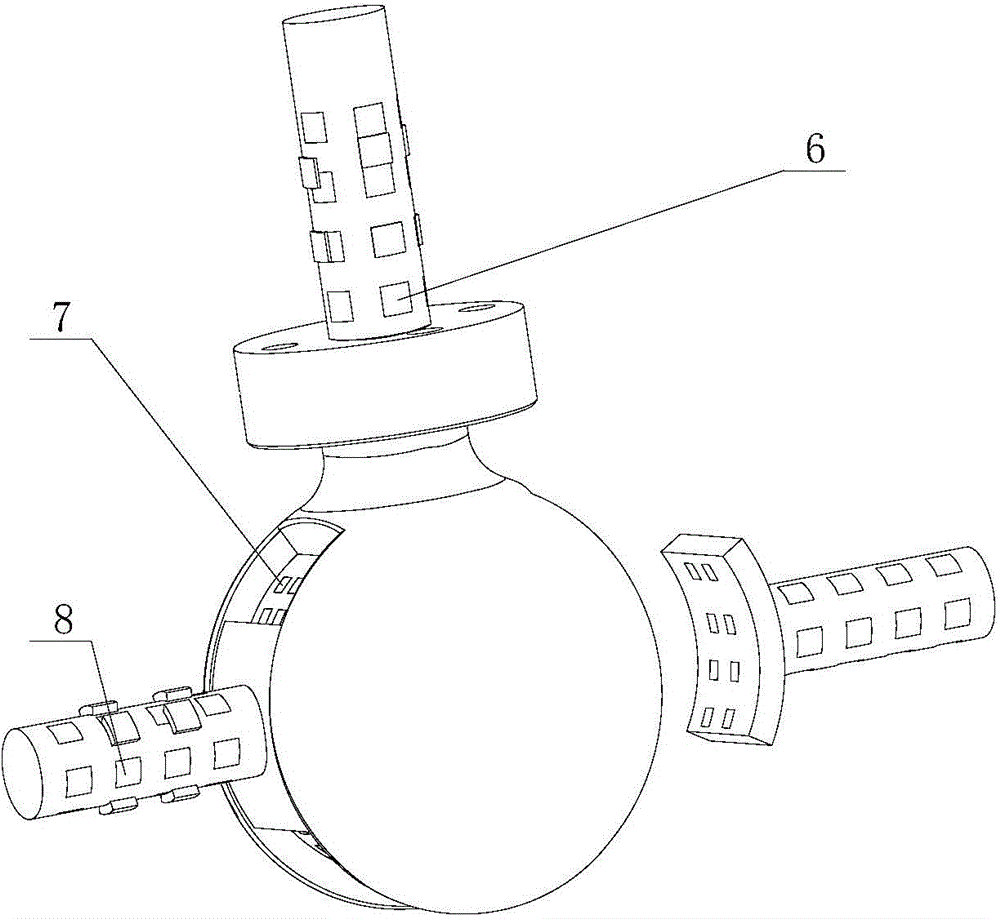

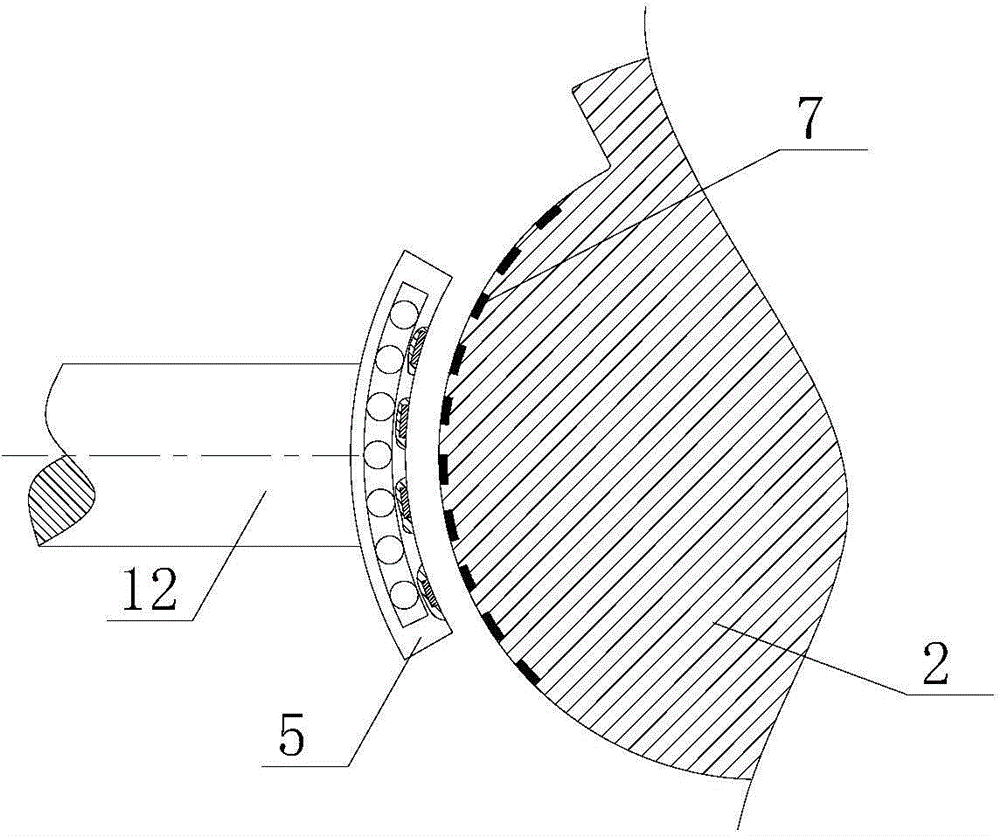

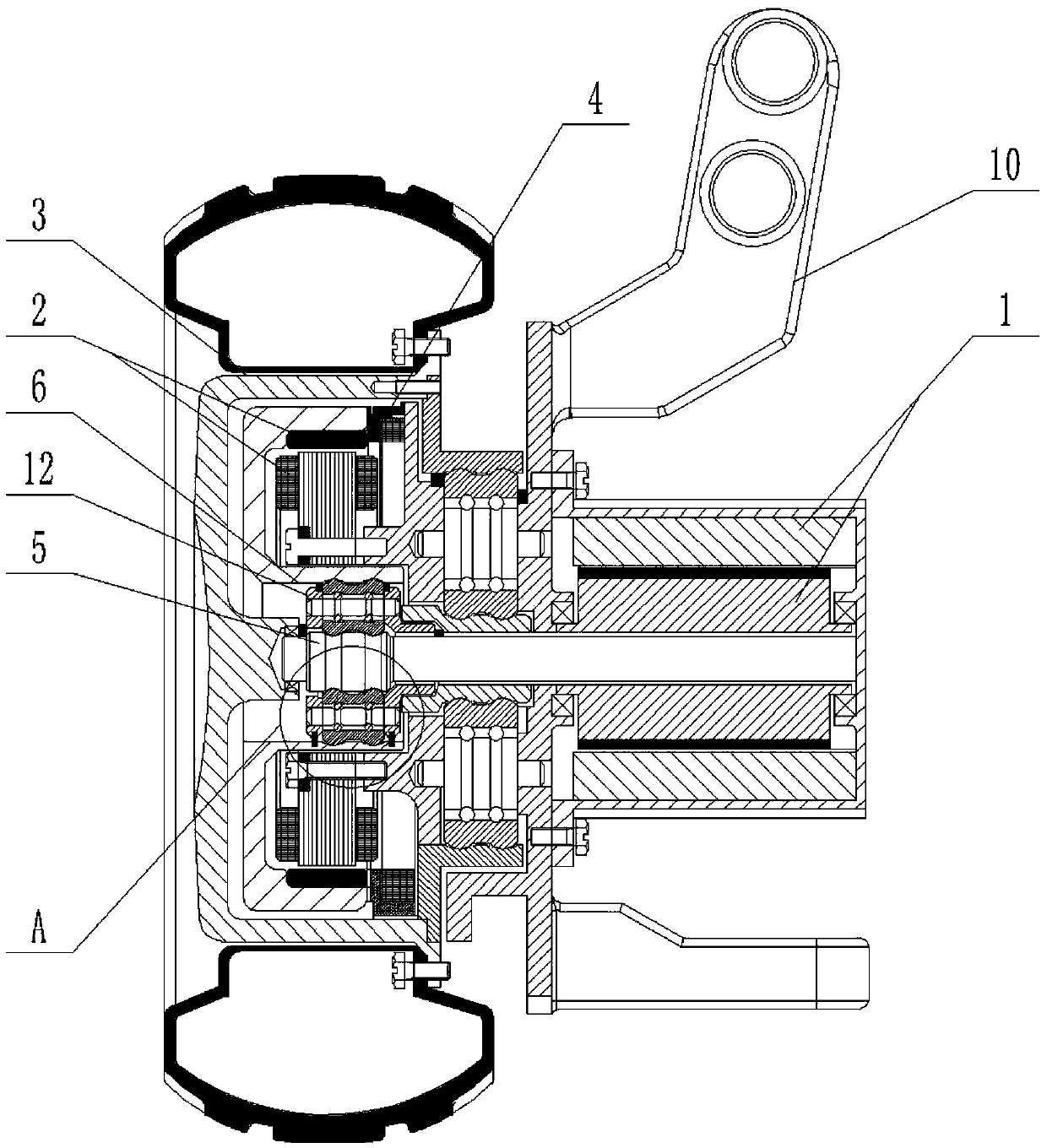

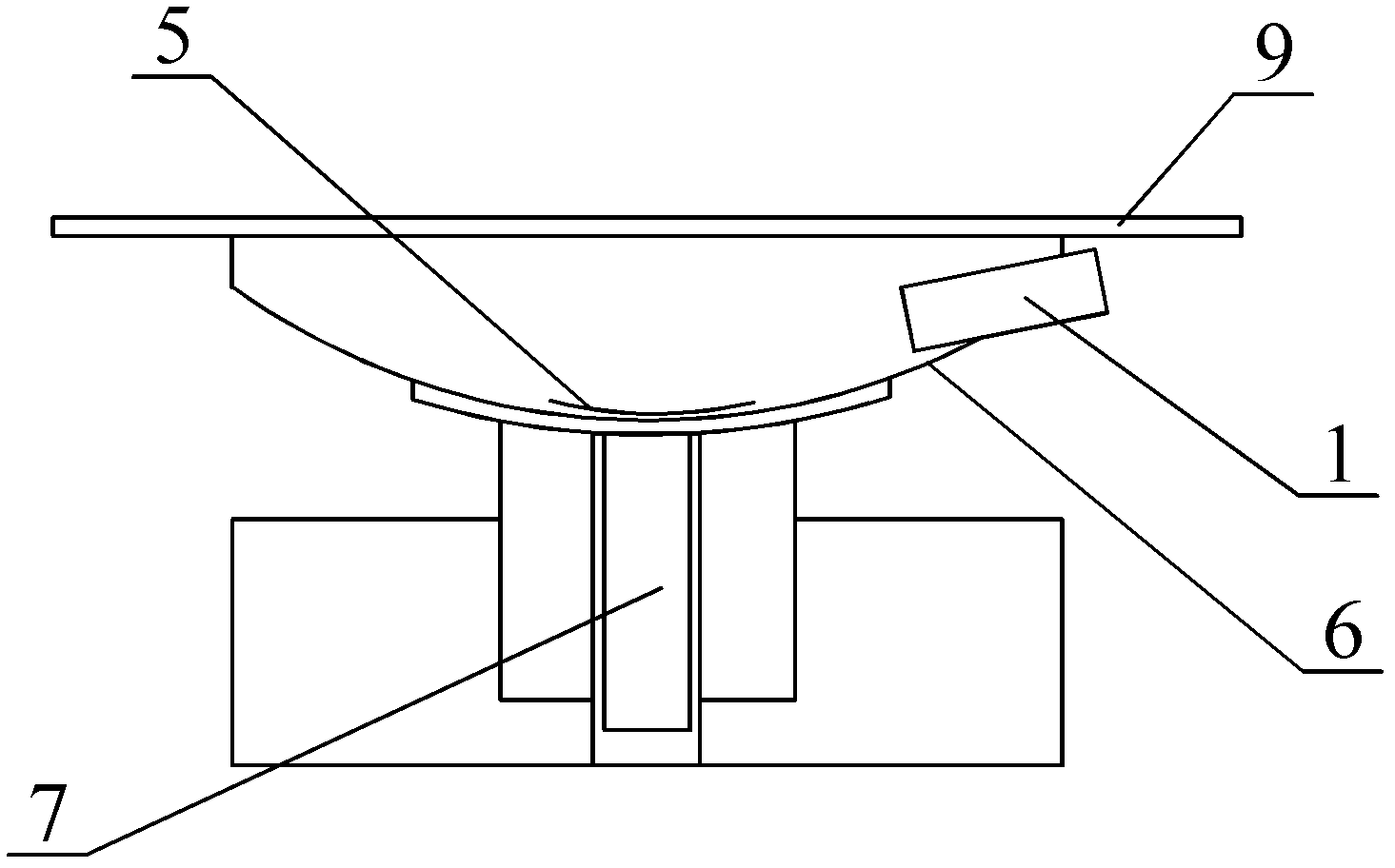

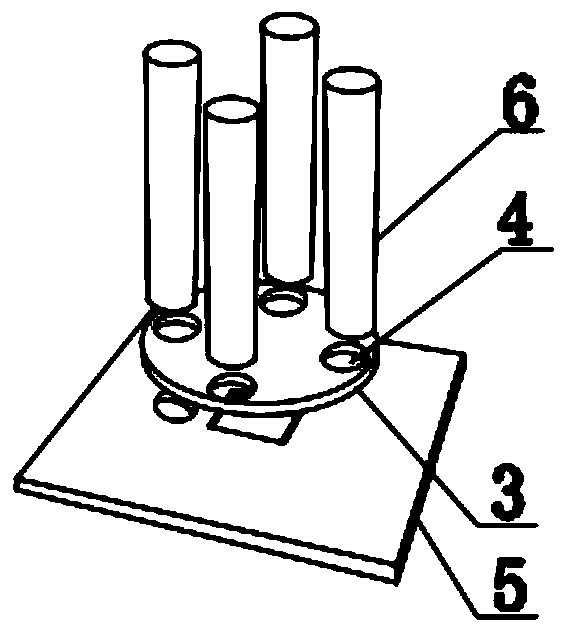

Ball hinge capable of measuring spatial revolution angle and offset in three degrees of freedom

ActiveCN104454963ARealize non-contact detectionLow installation space requirementPivotal connectionsCapacitanceThree degrees of freedom

The invention discloses a ball hinge capable of measuring a spatial revolution angle and offset in three degrees of freedom. A traditional ball hinge is complex in angle measurement way and difficult to ensure high measurement precision. Two arc-shaped sliding blocks of the ball hinge disclosed by the invention are connected with a sliding slot of a ball head through a rolling pair; two pin shafts fixed on the two arc-shaped sliding blocks are supported in a pin shaft hole in a ball socket base respectively; a ball head connecting rod is fixed with the ball head, and a supporting hole of an output rod is supported on the ball head connecting rod; a capacitance electrode array is arranged at the bottom of the sliding slot; four second capacitance electrode groups are arranged on the pin shafts; four third capacitance electrode groups are arranged on the ball head connecting rod; and capacitance sensing electrode pairs are arranged on inner sides of the arc-shaped sliding blocks, the hole wall of the pin shaft hole of a ball socket and the hole wall of the supporting hole in the output rod. The ball hinge disclosed by the invention can realize non-contact type detection of the spatial revolution angle and offset of the ball hinge; and furthermore, an algorithm is simple, and the precision is high.

Owner:HANGZHOU DIANZI UNIV

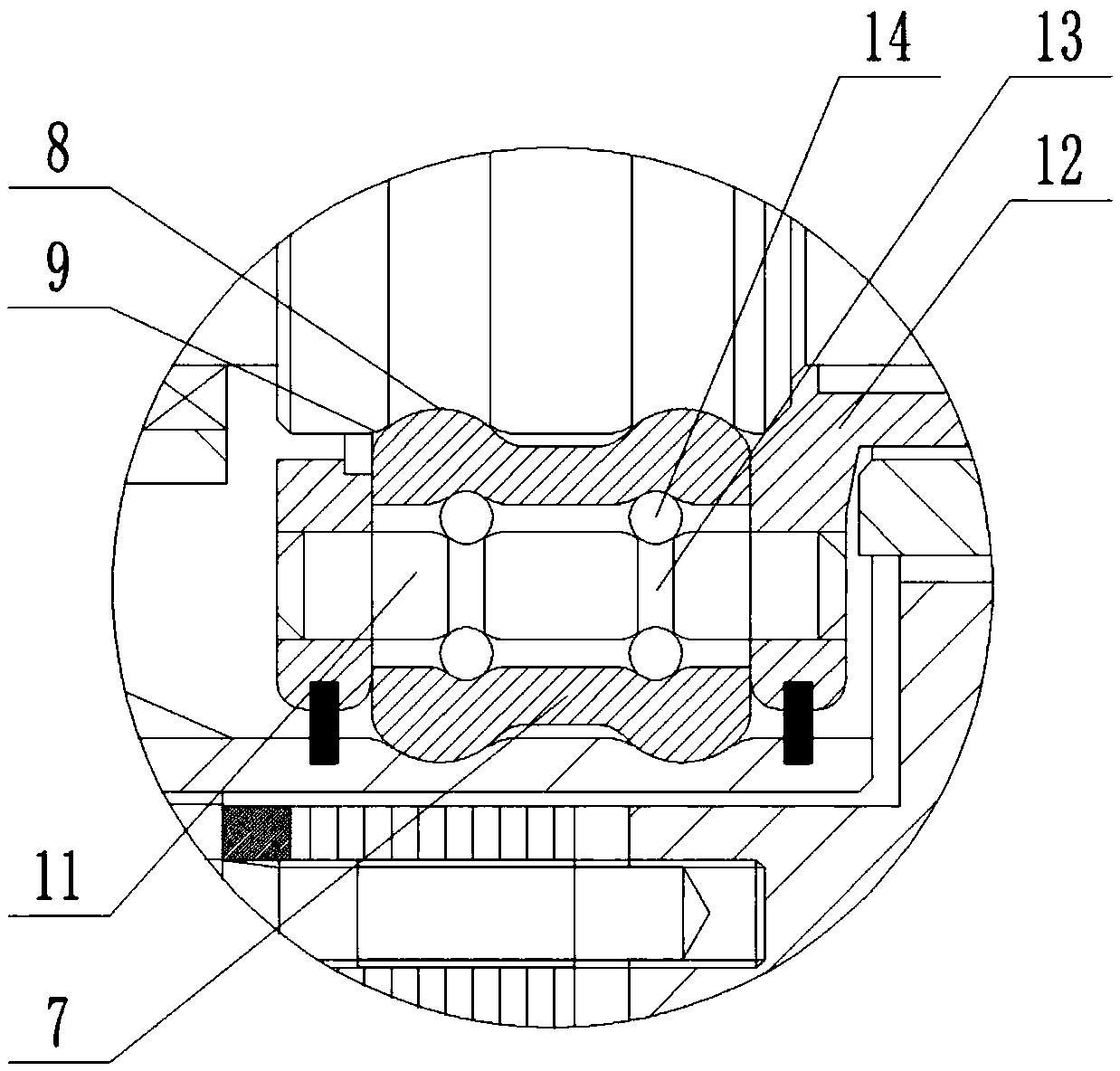

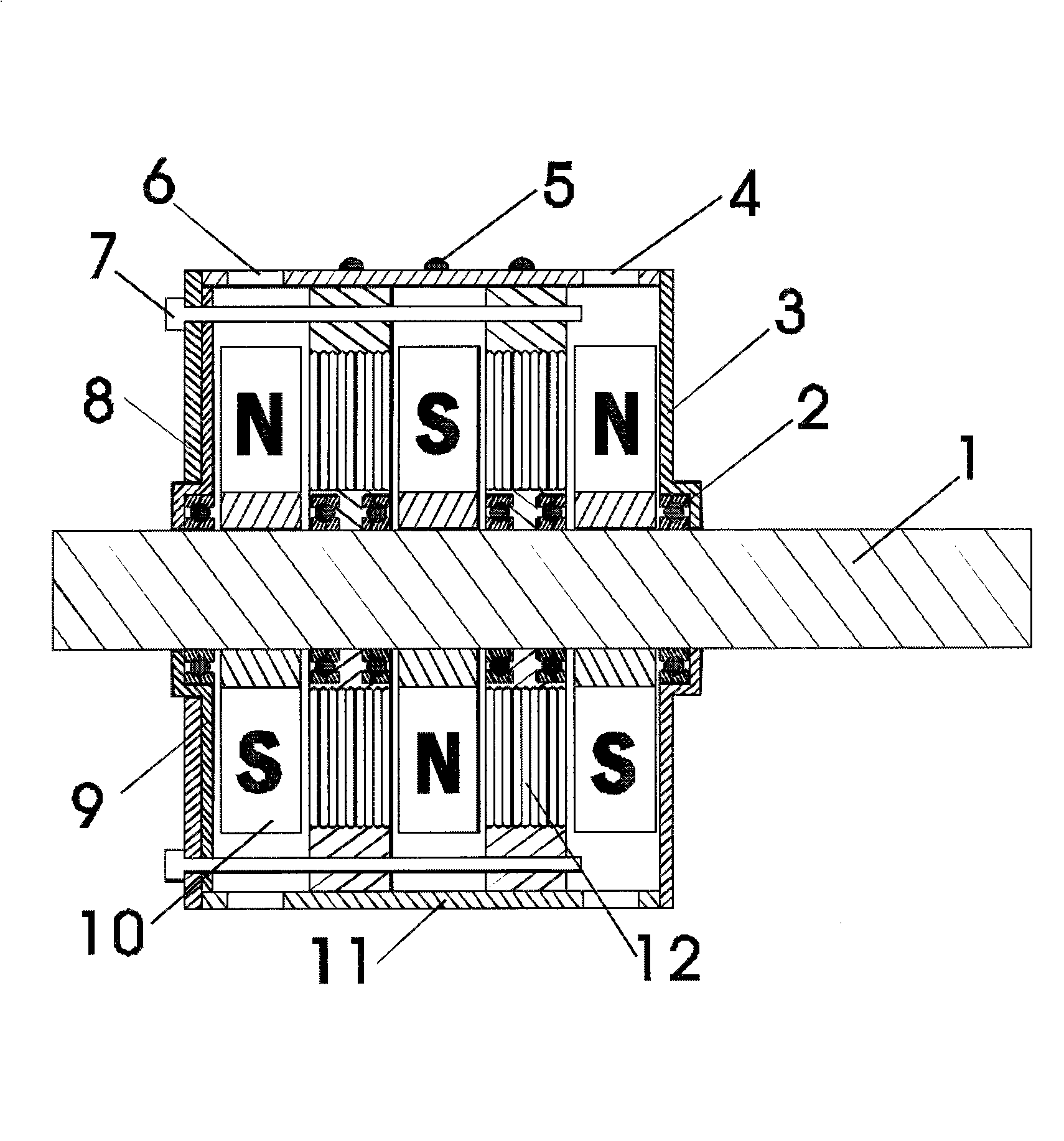

Double-motor coupling planetary traction transmission shaft bearing type deceleration electric hub

InactiveCN109532462ARealize stepless speed regulationSufficient powerMotor depositionControl devicesReduction driveCoupling

The invention discloses a double-motor coupling planetary traction transmission shaft bearing type deceleration electric hub, which comprises a hub, a planetary traction transmission shaft bearing type speed reducer arranged in a hub cavity, a first motor and a second motor. Any sequence combination of a sun gear, a planet carrier and an outer ring in the planetary traction transmission shaft bearing type speed reducer respectively corresponds to a power input end, a power output end and an intermediate transmission part in the planetary traction transmission shaft bearing type speed reducer,the first motor is used for driving the power input end to provide power and driving the hub to rotate through the power output end, and the second motor is used for driving the intermediate transmission part for speed coupling. According to the planetary traction transmission shaft bearing type speed reducer, the cooperation of the two motors is realized through the planetary traction transmission shaft bearing type speed reducer, so that each motor can always work in a high-efficiency working range, the working efficiency of the hub is improved, and the purposes of saving energy and prolonging endurance mileage are achieved.

Owner:CHONGQING UNIV

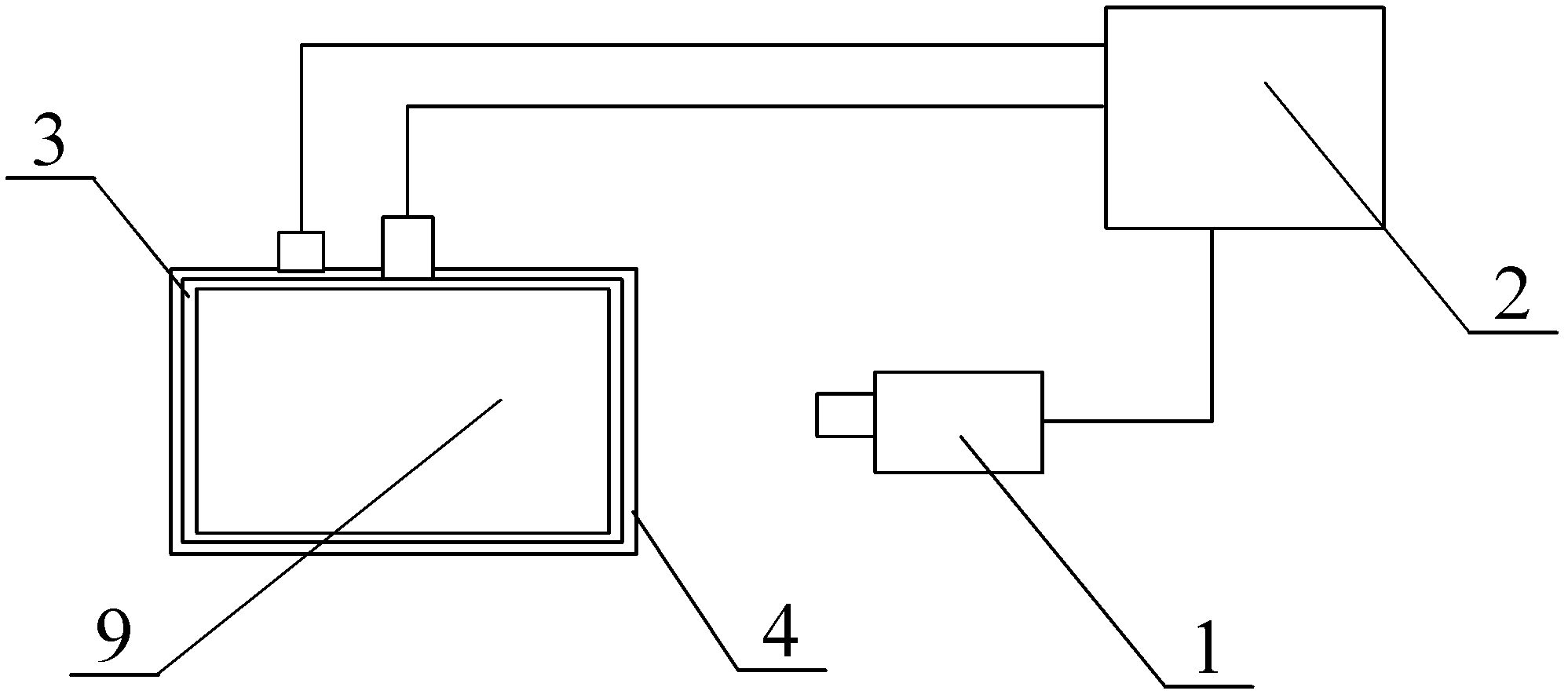

Back projection system applied to device with transparent desktop

InactiveCN102495517ALow installation space requirementLow costTelevision system detailsProjectorsInteraction systemsBack projection

The invention relates to a back projection system applied to a device with a transparent desktop. The back projection system comprises a projector, a control main machine, a reflection mirror and a back projection film, the control main machine is connected with the projector, the back projection film is arranged at the back surface of the transparent desktop, the reflection mirror is arranged below the back projection film, a projection opening of the projector faces to the reflection mirror, and images projected by the projector are reflected to the back projection film through the reflection mirror. Through the back projection system of the structure, the frames projected by the projector are reflected to the back projection film through the reflection mirror, thus a reflection mirror needs to be arranged below the transparent desktop only so as to effectively reduce requirements of a display on an installation space and the cost of a household touch induction interaction system, and also ensure that display effect is clear, a display size can be freely regulated, energy is saved, environment is protected and an application range is wider.

Owner:协晶电子科技(上海)有限公司

High-efficiency and stable full-automatic plunger type PTFE strip extruder

The invention relates to the technical field of extruding machines, in particular to a high-efficiency and stable full-automatic plunger type PTFE strip extruder. The high-efficiency and stable full-automatic plunger type PTFE strip extruder comprises a rack, a material bin, an automatic weighing and feeding mechanism, a pre-pressing and blank-forming device and a long-strip extruding mechanism, wherein the pre-pressing and blank-forming device comprises a circulation conveying mechanism, a material injecting cylinder and a pre-pressing driving system; the high-efficiency and stable full-automatic plunger type PTFE strip extruder further comprises a first detection element arranged at the pre-pressing and blank-forming device and a second detection element arranged at the long-strip extrusion mechanism; and the high-efficiency and stable full-automatic plunger type PTFE strip extruder further comprises a controller which saves manpower consumption, reduces the influence of manual operation on the PTFE fiber finished product, improves the quality of the PTFE long fiber product, is small in occupied area and simple to operate, achieves integration, greatly improves the production efficiency, greatly improves the stability, and greatly improves the production processing efficiency.

Owner:QINGDAO UNIV

Thread plug-in mounting type load holding valve

ActiveCN110792650ACompact structureIncreased flexibility of useOperating means/releasing devices for valvesServomotor componentsControl valvesOil intake

The invention belongs to the technical field of hydraulic elements and discloses a thread plug-in mounting type load holding valve. A valve body is provided with an oil inlet, an oil outlet, a controloil opening and an oil unloading opening. A one-way valve element is located at the oil outlet and can move axially relative to the valve body. The lower end of a valve seat makes contact with the one-way valve element in a sealed manner. A flow control valve element is located in the valve seat and can axially move relative to the valve seat. An axial hole is formed in the lower end of the valveseat, and the lower end of the flow control valve element makes contact with the axial hole in a sealed manner. A control cavity is formed by the flow control valve element and the valve seat. A first spring is arranged in the control cavity and generates pressing force on the flow control valve element. A valve hole and a damping hole are formed in the flow control valve element, the damping hole communicates with the oil outlet and the valve hole, and the valve hole communicates with the oil unloading hole and the control cavity. The upper end of a pilot valve element forms a control oil cavity with the valve body and communicates with the control oil opening, and the lower end of the pilot valve element makes contact with the valve hole in a sealed manner. The thread plug-in mounting type load holding valve is easy to integrate and long in service life and has a safety overflow function and a micro moving function.

Owner:江苏军源装备制造有限公司

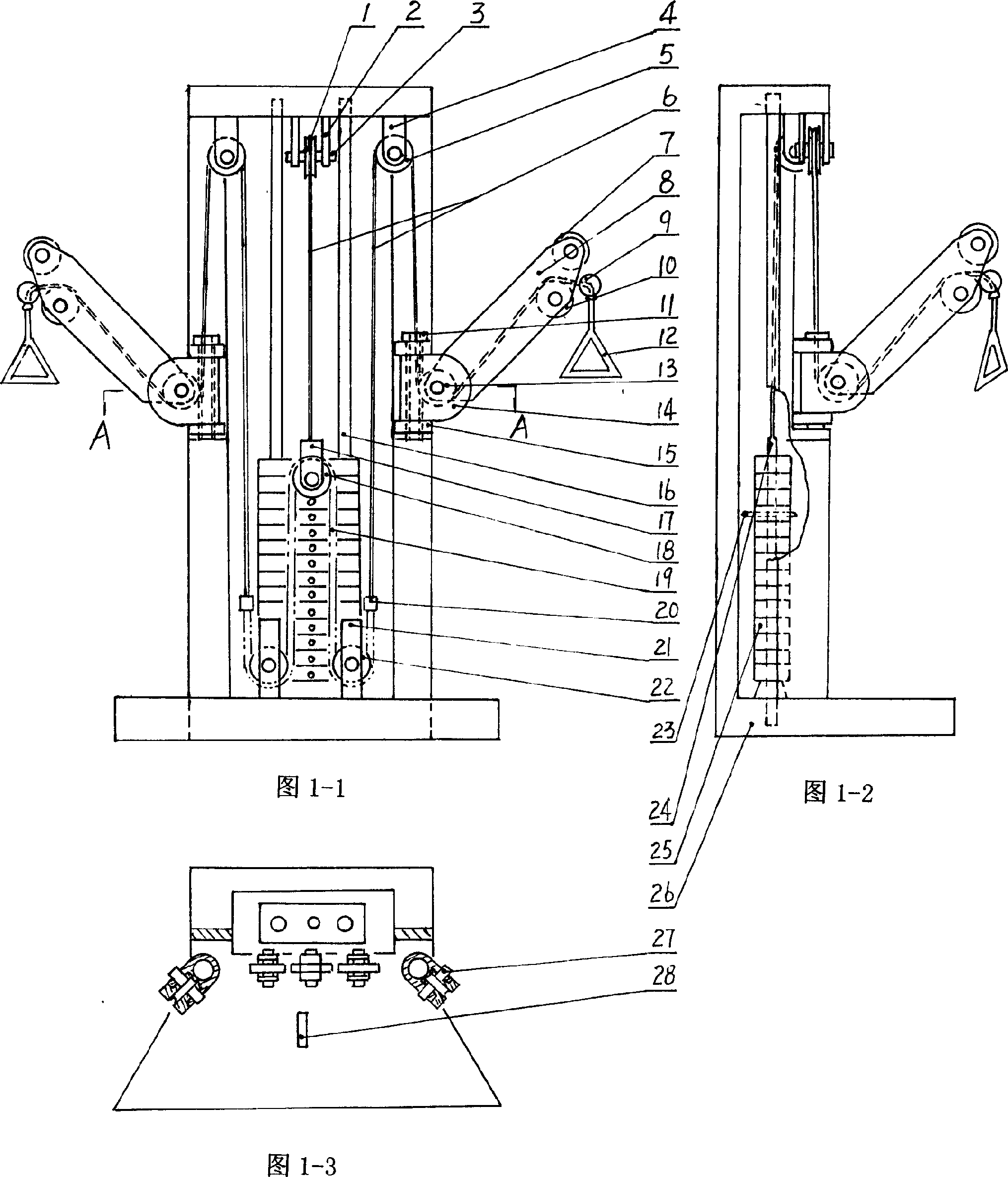

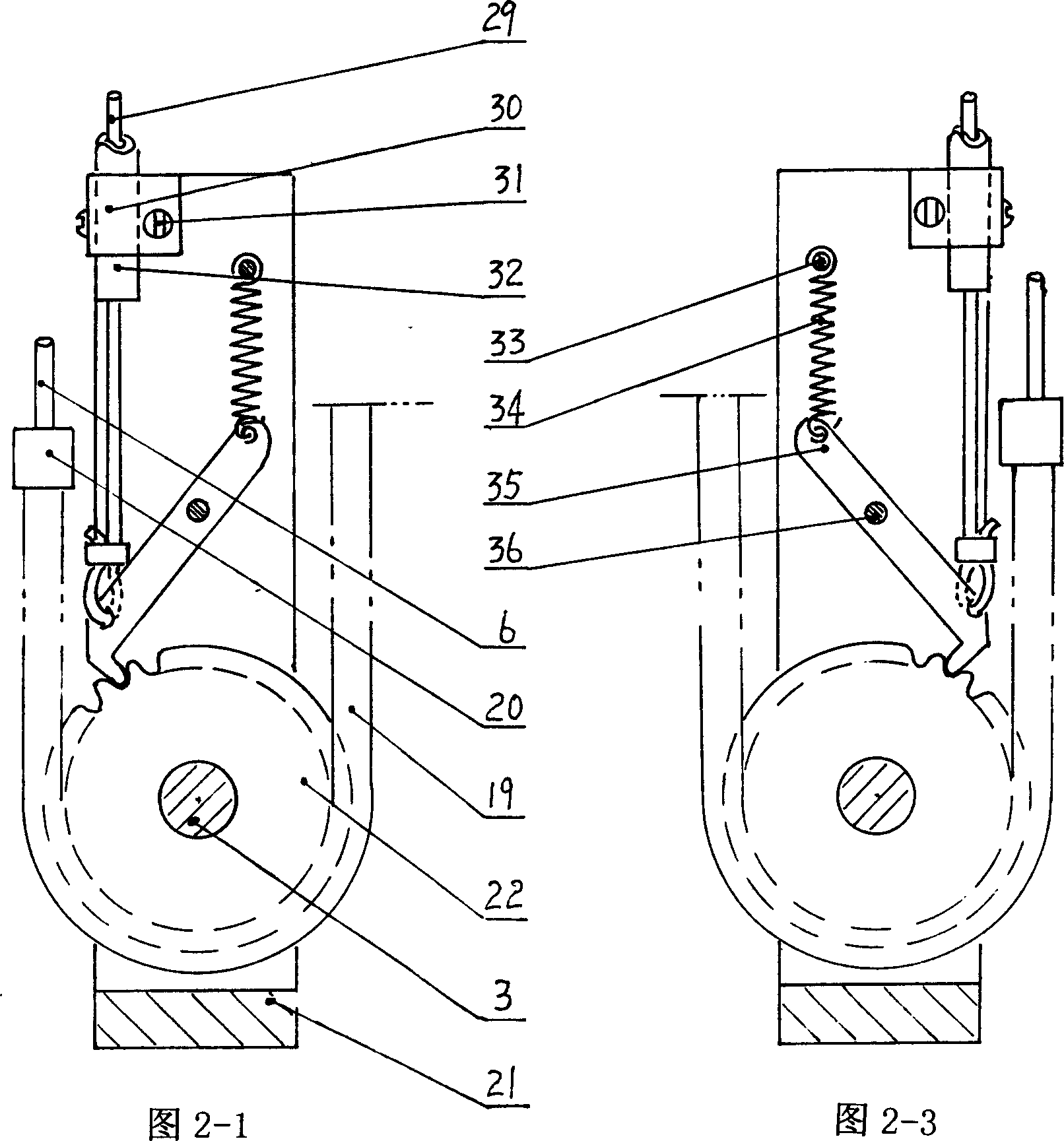

Multifunctional body-building equipment and operation guide

The multifunctional sports equipment consists of mainly frame, balance weight mechanism, actuating part, regulating mechanism, auxiliary mechanism and locking mechanism, and is characterized by its increased regulating mechanism and locking mechanism. The regulating mechanism of the multifunctional sports equipment is used to realize the conversion between the pulling mode and the pushing mode, and the locking mechanism is used to lock the balance weight. The conversion method among different sports modes and the operation of the locking mechanism are also provided.

Owner:张烝诚

Three-phase direct-current brushless deep-water motor

InactiveCN101540535AImprove work efficiencyImprove job stabilitySupports/enclosures/casingsThree-phaseEngineering

The invention provides a three-phase direct-current brushless deep-water motor, comprising a motor housing composed of a front shroud, a back shroud and a housing, wherein a main shaft is installed on the front shroud and the back shroud via a bearing, magnetic steel rotor disks and coil stator disks are installed inside the motor housing, a water inlet and a water outlet are installed on the housing, the magnetic steel rotor disks are fixedly installed on the main shaft, the coil stator disks are fixed on the motor housing, and the magnetic steel rotor disks and the coil stator disks are in alternative arrangement. The three-phase direct-current brushless deep-water motor in the invention has simple structure, easy processing and low cost, and the biggest feature is that a waterproof housing does not be needed. The internal structure of the motor and the structure of the existing submersible motor are completely different. The invention can be applied to small submarine, submarine mine, diving pusher and other deepwater machines.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com