Aligning control system and method for end surfaces of double-layer fabrics of sewing machine

A control system and sewing machine technology, applied in the direction of sewing machine components, program-controlled sewing machines, sewing equipment, etc., can solve problems such as the inability to use building blocks, achieve compact structure, low installation space requirements, and save labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

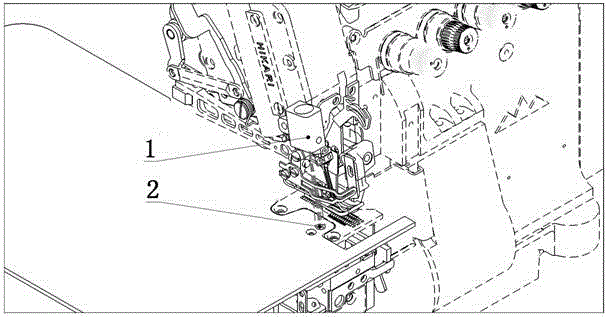

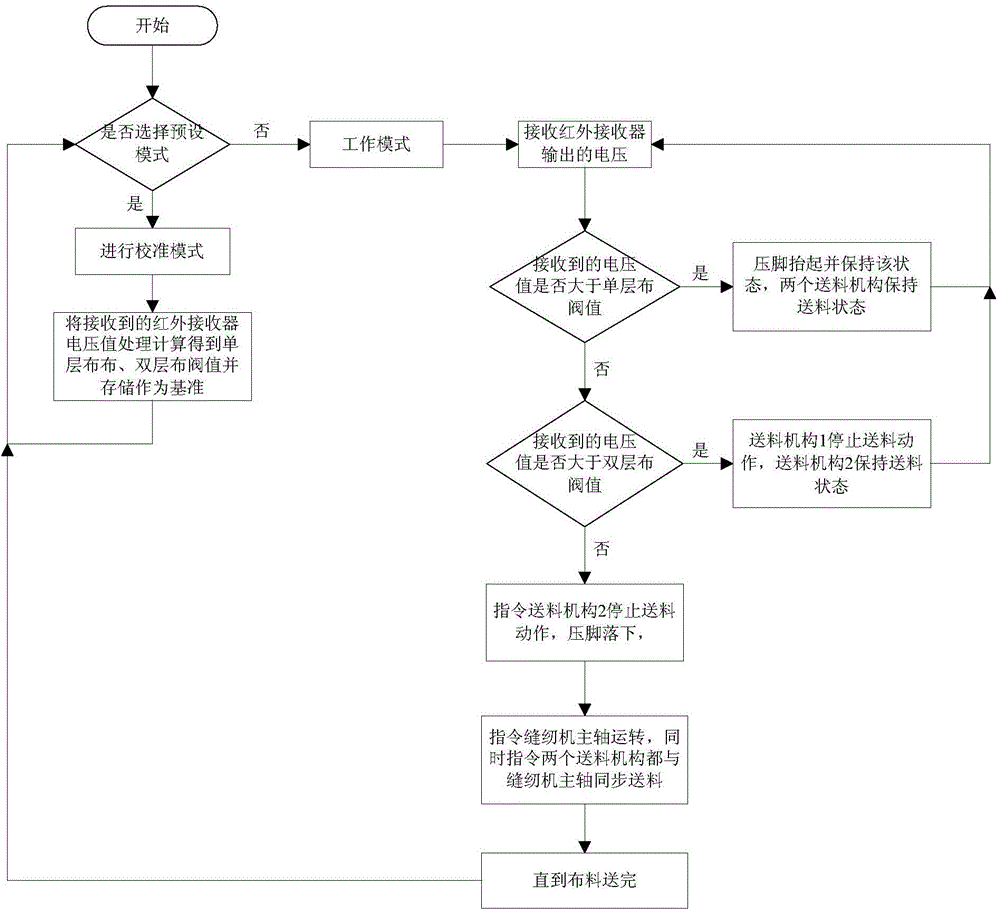

[0030] A double-layer cloth end face alignment control system for a sewing machine, the sewing machine includes a machine head, a sewing table and two feeding mechanisms, and also includes: used to identify whether the cloth is sent to the presser foot and whether the cloth sent to the presser foot is a single layer It is still a double-layer cloth sensing device; figure 1 As shown, the cloth sensing device includes an infrared emitter 1 or an infrared laser emitter 1 arranged on the machine head shell and an infrared receiver 2 arranged on the sewing table, the infrared emitter 1 or the infrared laser emitter 1 The transmitting end is facing the receiving end of the infrared receiver 2; the microcontroller is connected with the signal output end of the infrared emitter 1 or the infrared laser emitter 1, the infrared receiver 2, the control end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com