Method for adjusting shapes and performance of plates under combined action of prestress and pulse electromagnetic force

A technology of pulsed electromagnetic and combined action, applied in metal processing, metal processing equipment, manufacturing tools, etc., to achieve the effect of improving energy utilization, prolonging action time, and optimizing material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be described in further detail below in conjunction with the accompanying drawings.

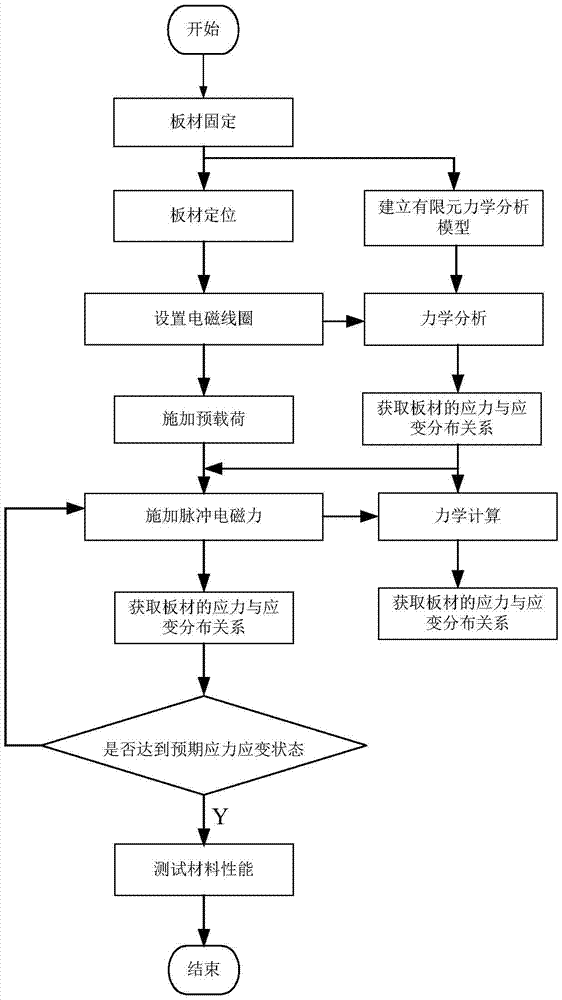

[0067] The shape adjustment and tonality method of the plate under the composite action of prestress and pulsed electromagnetic force of the present invention, for large metal plates, such as figure 1 As shown, it is specifically realized by the following methods:

[0068] Step 1: Clamp and fix the front and rear sides of the sheet in the X-axis direction through the clamping mechanism.

[0069] Step 2: Set the front end of the sheet over the mould.

[0070] Step 3: Place the solenoid over the front end of the sheet.

[0071] Step 4: Establish a finite element mechanical analysis model.

[0072] The finite element mechanical analysis model including mold, blank holder and plate is established by finite element software.

[0073] Step 5: Preload the plates;

[0074] Preload the sheet by pre-stretching, pre-bending, or applying pre-stretching and pre-bendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com