Making method of haw crisp chips

The technology of hawthorn flakes and hawthorn is applied in the field of preparation of hawthorn flakes, which can solve problems such as inability to produce hawthorn flakes, and achieve the effects of increasing economic and social benefits of enterprises, crisp taste and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

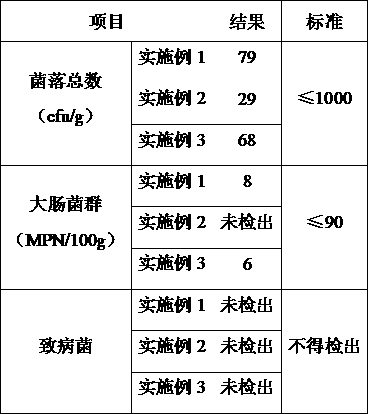

Examples

Embodiment 1

[0032] This embodiment provides a kind of preparation method of hawthorn chips, described method is carried out according to the following steps:

[0033] S01: Pretreatment of raw materials: Wash and remove the pitted fresh hawthorns that are fully mature, free from mildew, dry scars and injuries, and cut into 5 mm thin slices.

[0034] S011: Microwave treatment: microwave the hawthorn slices cut in step S01 for 80 s at a microwave power of 600 W;

[0035] S02: Ultrasonic hot water blanching: blanching the hawthorn slices after the microwave treatment in the step S011 for 55 s under the condition of ultrasonic power of 540 W and water temperature of 90°C;

[0036] S03: Vacuum pre-drying and wet equalization: The hawthorn slices blanched with ultrasonic hot water in the step S02 are quickly vacuum-dried, the drying temperature is controlled at 50°C, and the vacuum degree is 0.06 MPa to make the moisture The content is 30%; then put the dried hawthorn slices into a sealed bag, ...

Embodiment 2

[0041] This embodiment provides a kind of preparation method of hawthorn chips, described method is carried out according to the following steps:

[0042] S01: Pretreatment of raw materials: Wash and remove the pitted fresh hawthorns that are fully mature, free from mildew, dry scars and injuries, and cut into thin slices of 4 mm.

[0043] S011: Microwave treatment: microwave the hawthorn slices cut in step S01 for 60 s at a microwave power of 800 W;

[0044] S02: Ultrasonic hot water blanching: blanching the hawthorn slices after the microwave treatment in the step S011 for 60 s under the condition of ultrasonic power of 480 W and water temperature of 90°C;

[0045] S03: Vacuum pre-drying and wet equalization: The hawthorn slices blanched with ultrasonic hot water in the step S02 are quickly vacuum-dried, the drying temperature is controlled at 52°C, and the vacuum degree is 0.07 MPa to make the moisture The content is 35%; then put the dried hawthorn slices into a sealed bag,...

Embodiment 3

[0050] This embodiment provides a kind of preparation method of hawthorn chips, described method is carried out according to the following steps:

[0051] S01: Raw material pretreatment: Wash and remove the pitted fresh hawthorns that are fully mature, free from mildew, dry scars and injuries, and cut into 6 mm thin slices.

[0052] S011: Microwave treatment: microwave the hawthorn slices cut in step S01 for 90 s at a microwave power of 400 W;

[0053] S02: Ultrasonic hot water blanching: blanching the hawthorn slices after the microwave treatment in the step S011 for 40 s under the conditions of ultrasonic power of 600 W and water temperature of 85°C;

[0054] S03: Vacuum pre-drying and wet equalization: The hawthorn slices blanched with ultrasonic hot water in the step S02 are quickly vacuum-dried, the drying temperature is controlled at 55°C, and the vacuum degree is 0.05 MPa to make the moisture The content is 25%; then put the dried hawthorn slices into a sealed bag, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com