Swirl vane and flue gas ammonia-injection and denitration device

A swirling blade and flue gas technology, applied in gas treatment, fluid flow, chemical instruments and methods, etc., can solve the problem of uneven mixing of reducing agent and flue gas, and achieve simple structure, low installation space requirements, and investment. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

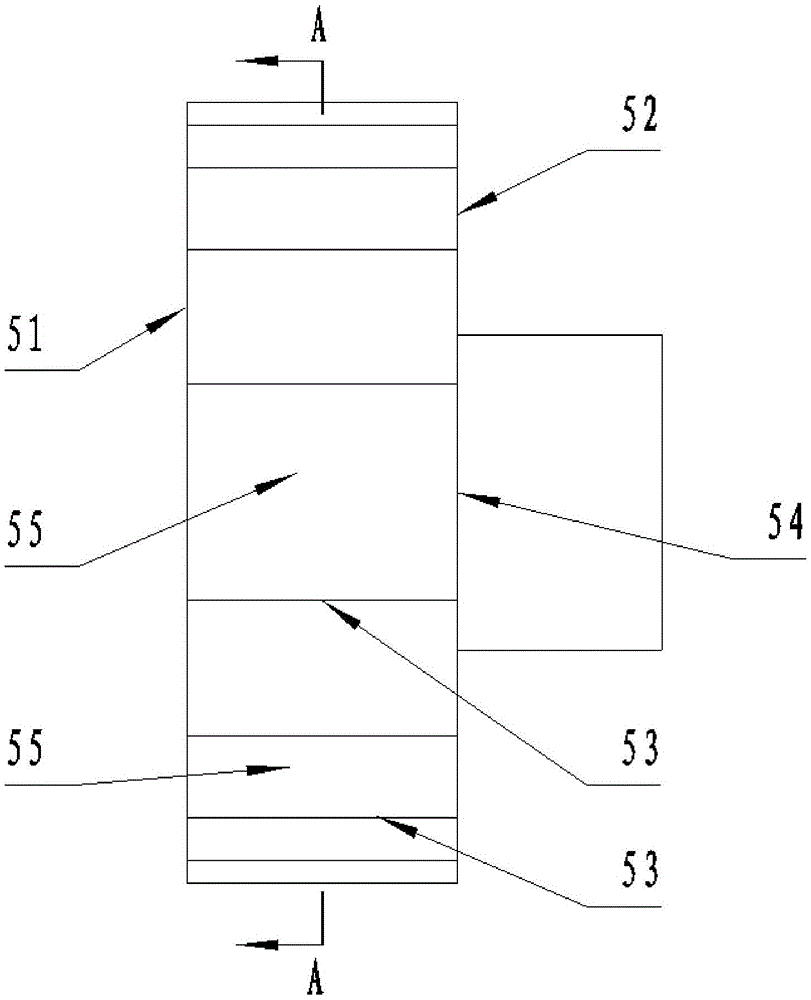

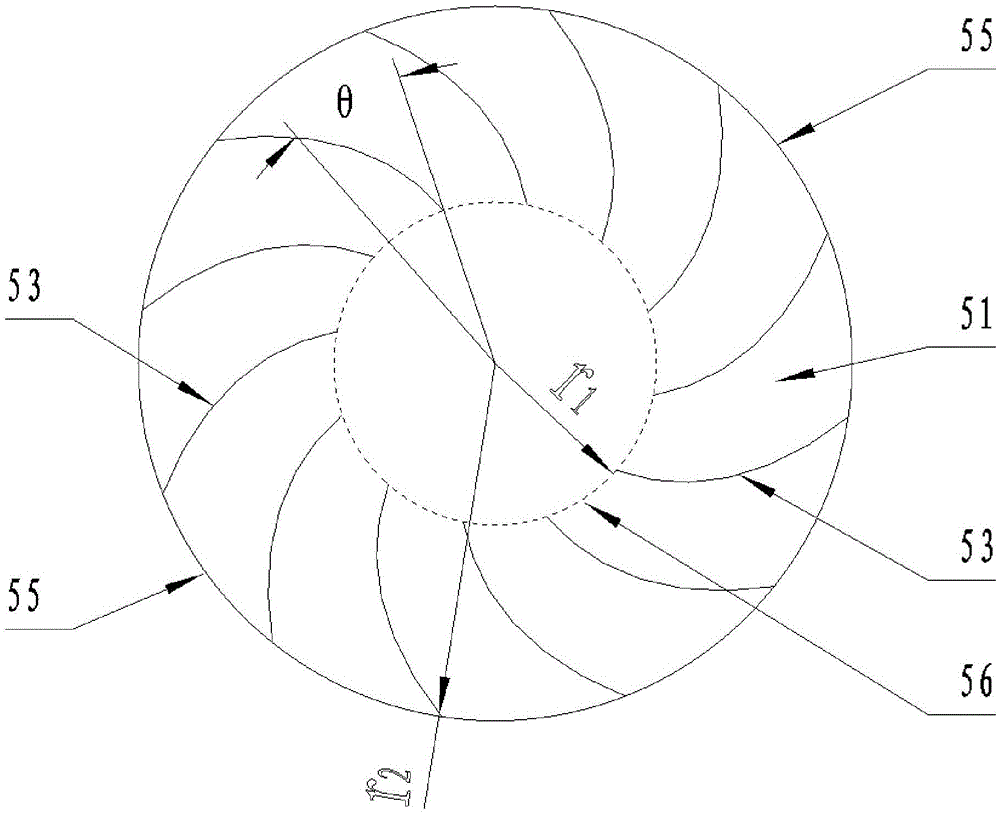

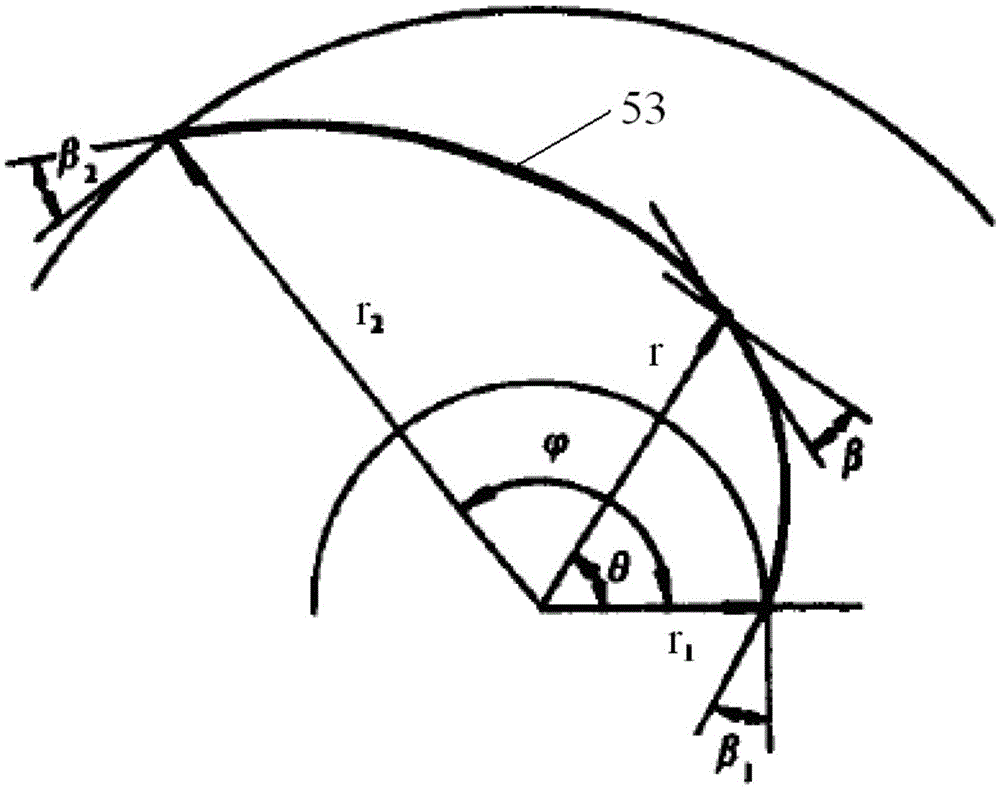

[0035] In order to make the concentration distribution of the gas components on the flue cross-section tend to be uniform, the present invention provides a swirl vane, which is a lateral air inlet structure, including two first partitions 51 and a second partition parallel to each other. Two baffles 52, a plurality of baffles 53 are uniformly distributed between the first baffle 51 and the second baffle 52, the middle part of the second baffle 52 contains an air outlet 54, the adjacent two baffles 53 Between the outer ends is the air inlet 55, and between the inner ends of the two deflectors 53 is the inner outlet 56, and the air flow can flow out of the swirl blade after passing through the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com