High-efficiency and stable full-automatic plunger type PTFE strip extruder

A fully automatic, plunger technology used in the field of extruders to improve efficiency, reduce impact and reduce installation space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

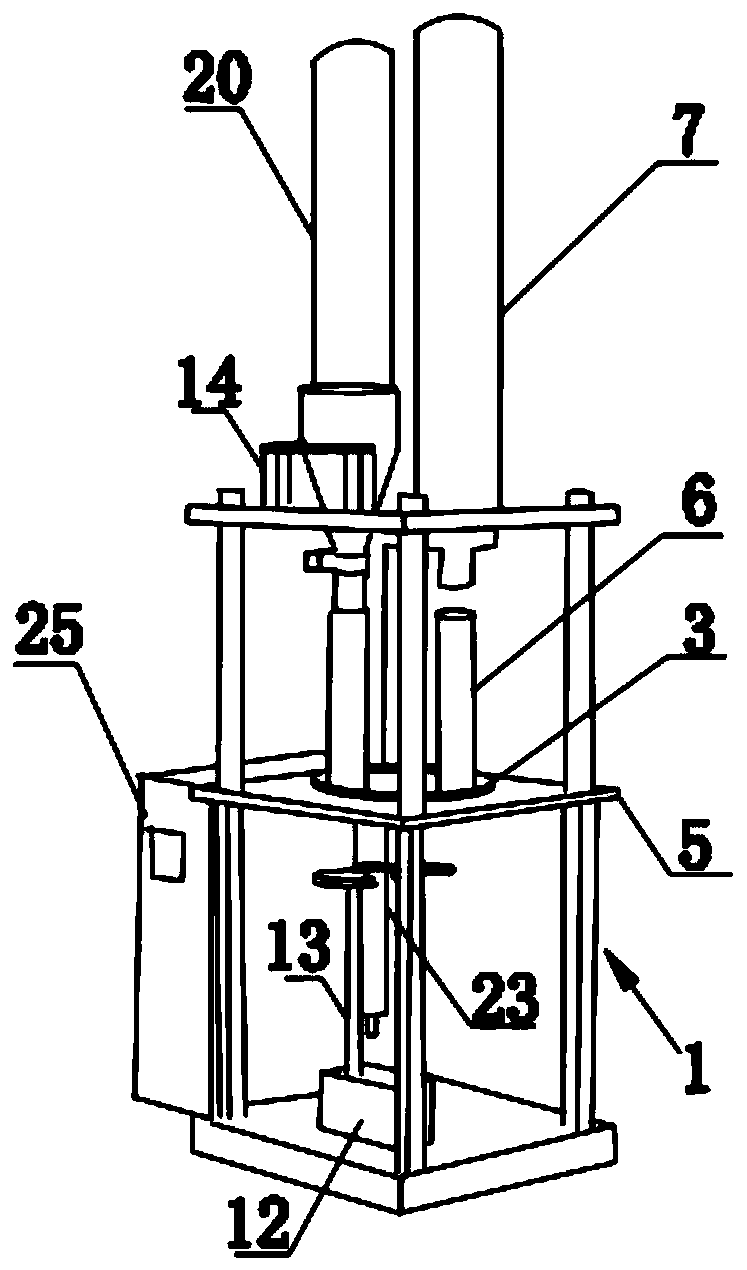

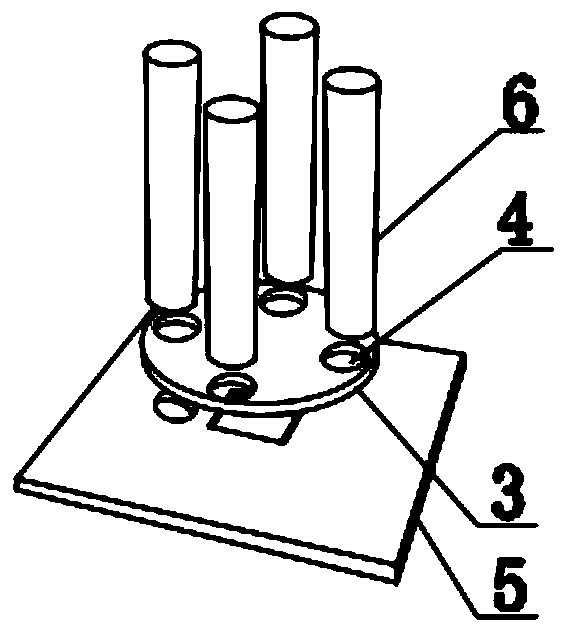

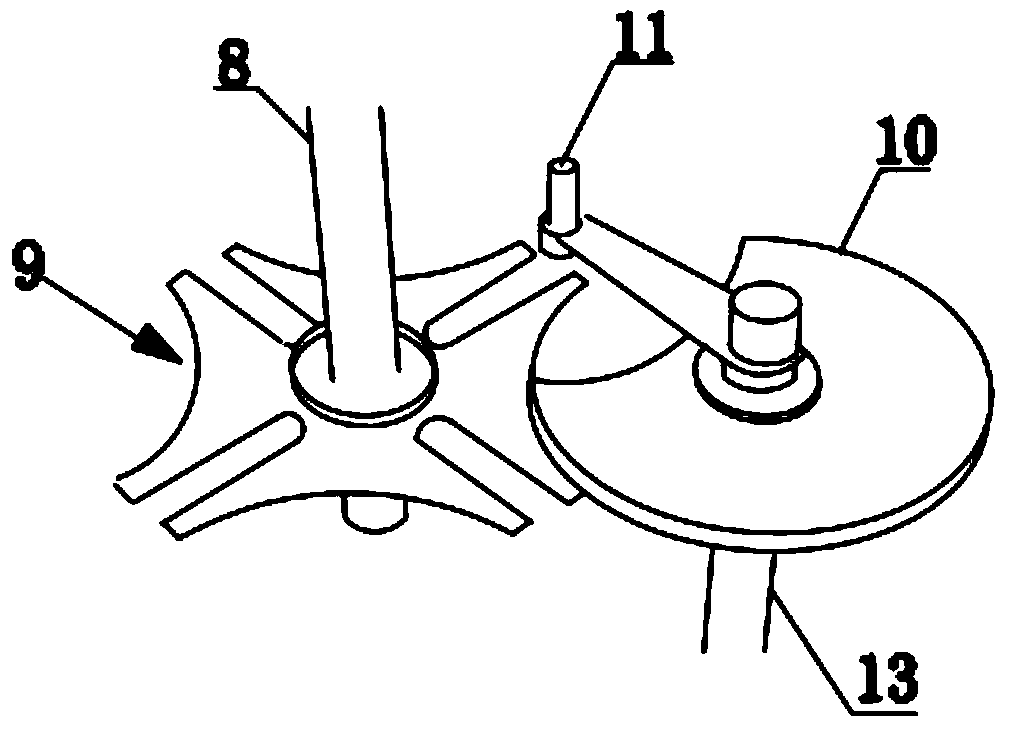

[0043] An efficient and stable full-automatic plunger-type PTFE strip extruder, including a frame 1, a silo 2 for feeding, and an automatic weighing feed for automatically and accurately outputting the materials in the silo Mechanism, the pre-pressing device for receiving the material in the automatic weighing and feeding mechanism and pre-pressing the material into a green body, and the long strip extrusion mechanism for extruding the green body made by the pre-pressing device , the pre-pressing device includes a circular conveying mechanism, the circular conveying mechanism includes a turntable 3 for driving the injection cylinder, equidistant along the circumference of the turntable is provided with through holes 4 for placing the injection cylinder, in The bottom of the turntable is provided with a bearing plate 5 for carrying the turntab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com