Coal cutter infinitely-variable-speed cutting transmission system based on rotation speed coupling

A technology of stepless speed regulation and speed coupling, which is applied in the direction of transmission, gear transmission, mechanical equipment, etc., can solve the problem of large installation space of high-power frequency converters, so as to alleviate adverse effects, improve utilization rate, and save energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

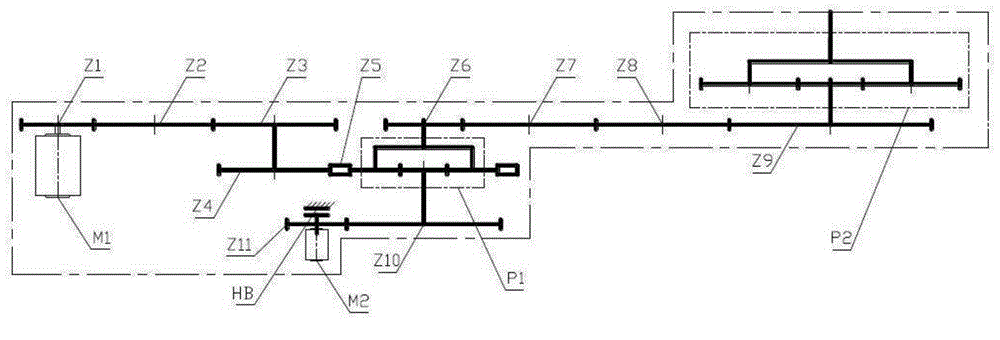

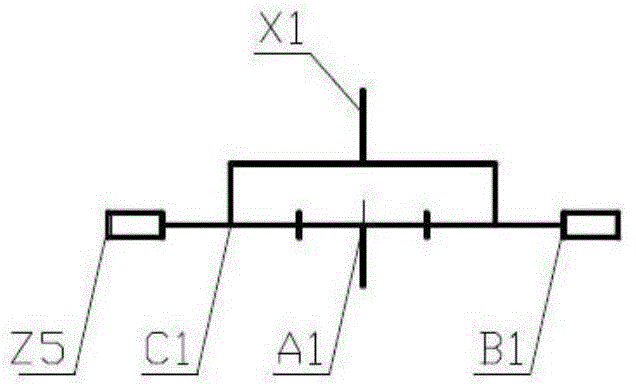

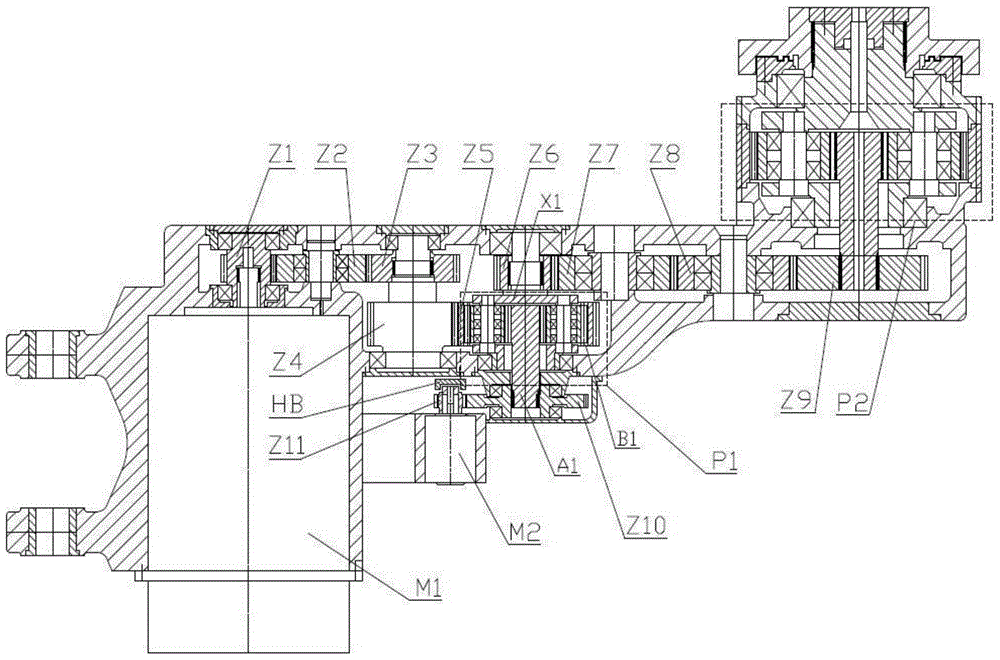

[0025] like figure 1 As shown, the coal shearer stepless speed regulation cutting transmission system based on speed coupling in this embodiment includes a cutting motor M1, a speed regulating motor M2, a differential planetary gear train P1, a cutting part planetary reducer P2 and a cutting Cutting drum; the differential planetary gear system P1 is mainly composed of a planetary carrier X1, a ring gear, a sun gear A1 and a planetary gear C1, and the inner and outer rings of the ring gear are correspondingly provided with internal teeth B1 and external teeth Z5; The cutting motor M1 meshes with the ring gear outer gear Z5 on the differential planetary gear train P1 through a gear pair, and the speed regulating motor M2 is connected to the sun gear A1 on the differential planetary gear train P1 through a motor reducer. , the differential pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com