Thread plug-in mounting type load holding valve

A load-holding valve and threaded cartridge technology, which is applied in the field of hydraulic components, can solve problems such as the inability to realize the limitation of oil pressure rise, the increase in the number of opening and closing of the valve core, and the increase in equipment complexity, so as to improve the flexibility of use , reduce wear and impact collision damage, the effect of its own compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be described in further detail below in conjunction with the drawings and embodiments.

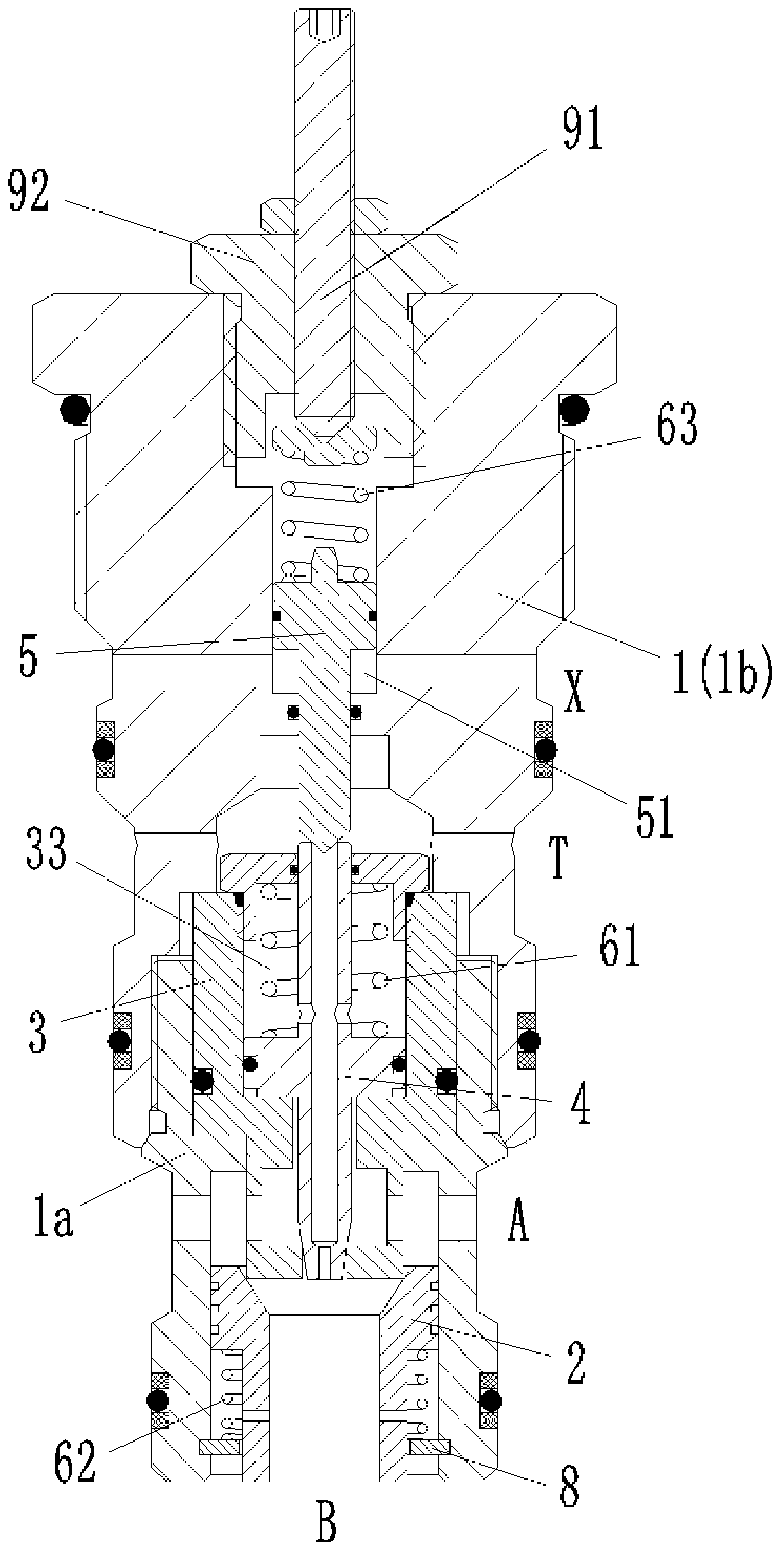

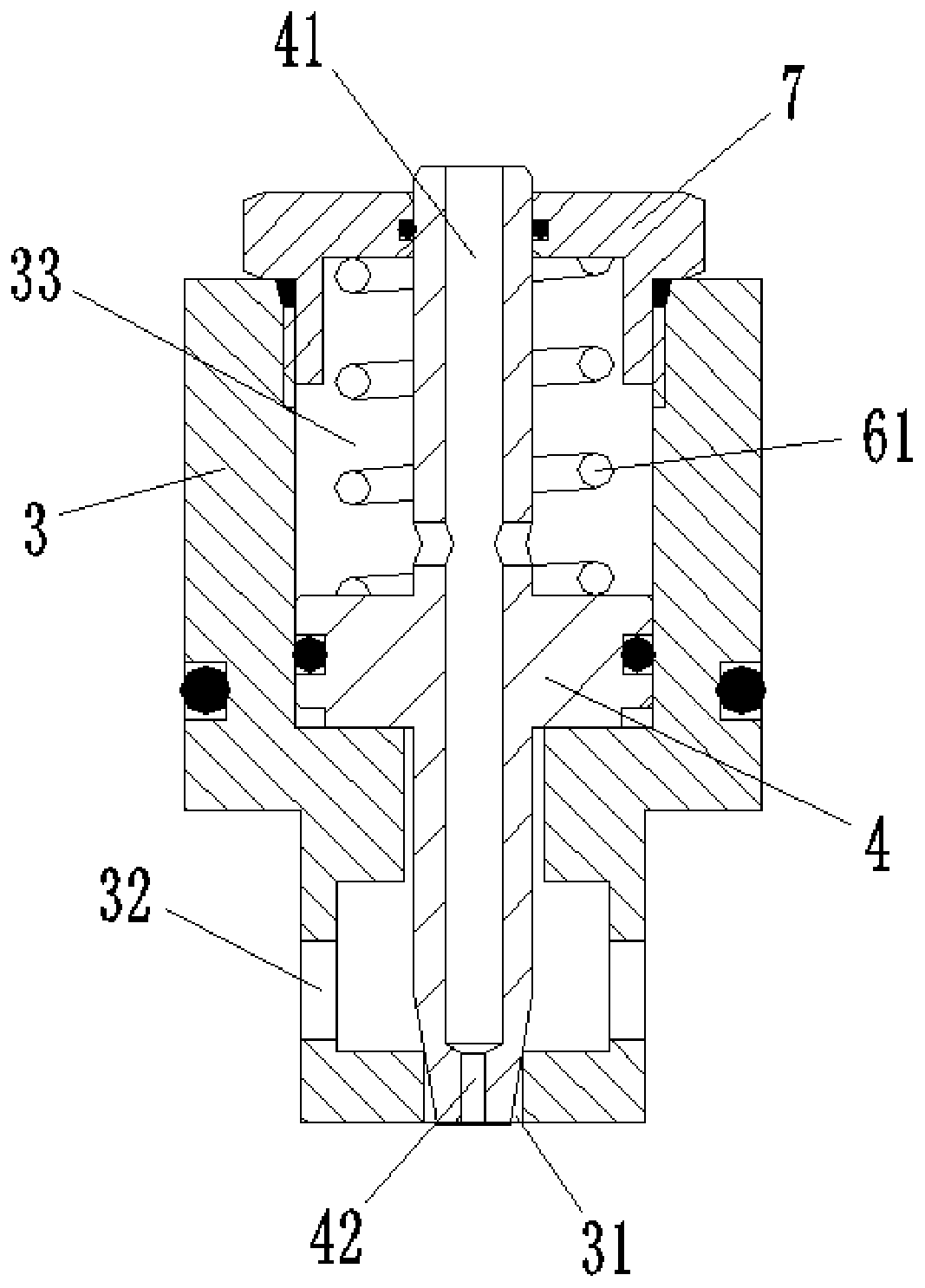

[0027] Combine figure 1 As shown, the threaded cartridge load holding valve of this embodiment includes a valve body 1, a one-way valve core 2, a valve seat 3, a flow control valve core 4, and a pilot valve core 5. Among them, the valve body 1 is a threaded cartridge valve body structure, and is provided with an oil inlet A, an oil outlet B, a control oil port X and an oil discharge port T. The one-way valve core 2, the valve seat 3, the flow control valve core 4 and the pilot valve core 5 are arranged inside the valve body 1 along the axial direction thereof.

[0028] The one-way valve core 2 is located near the oil outlet B and can move axially relative to the valve body 1. The upper end of the valve seat 3 maintains a fixed connection with the valve body 1, and the lower end forms a contact seal with the one-way valve core 2. Throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com