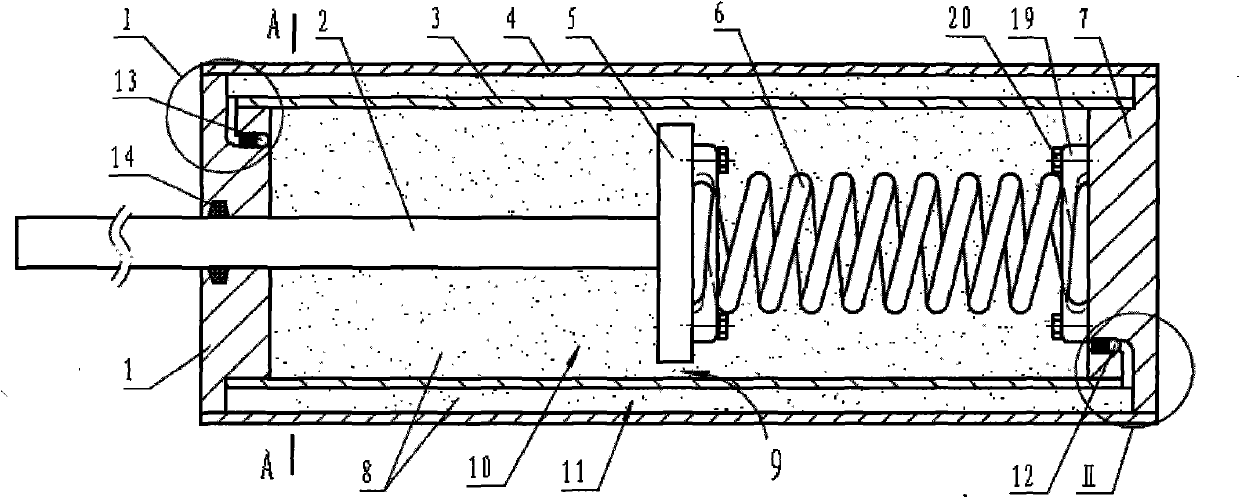

Composite damping single-piston rod viscous damper

A viscous damper and single-piston rod technology, applied in the field of viscous dampers, can solve problems such as structural sloshing, aggravated structure, growth, etc., and achieve the effects of reducing installation space requirements, shortening design length, and improving energy consumption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

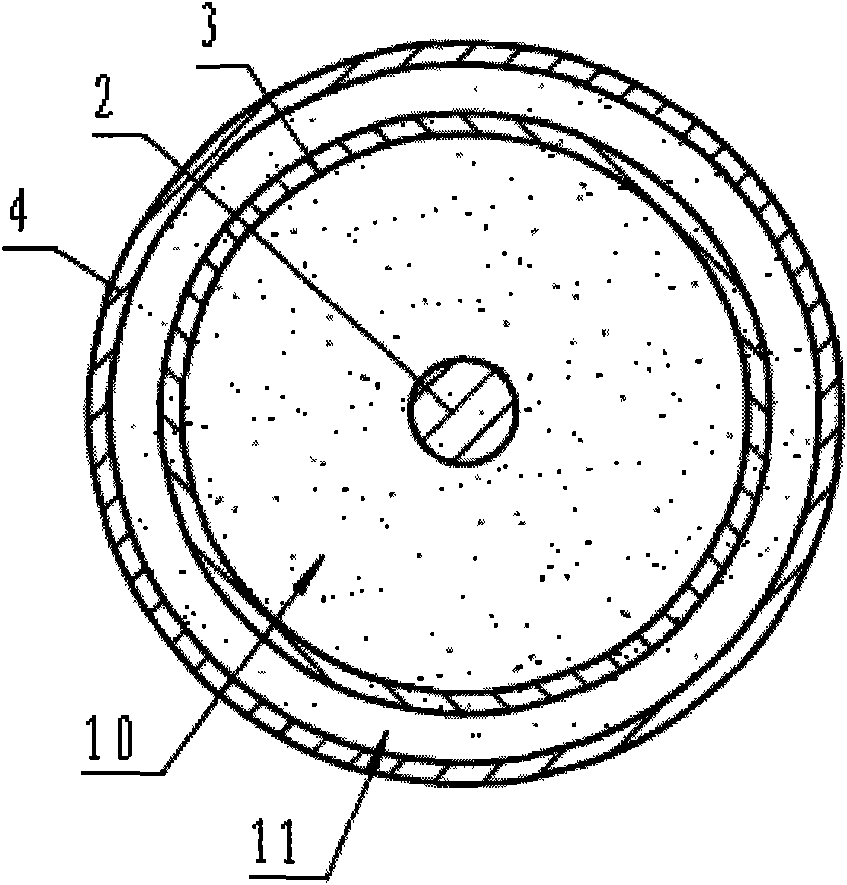

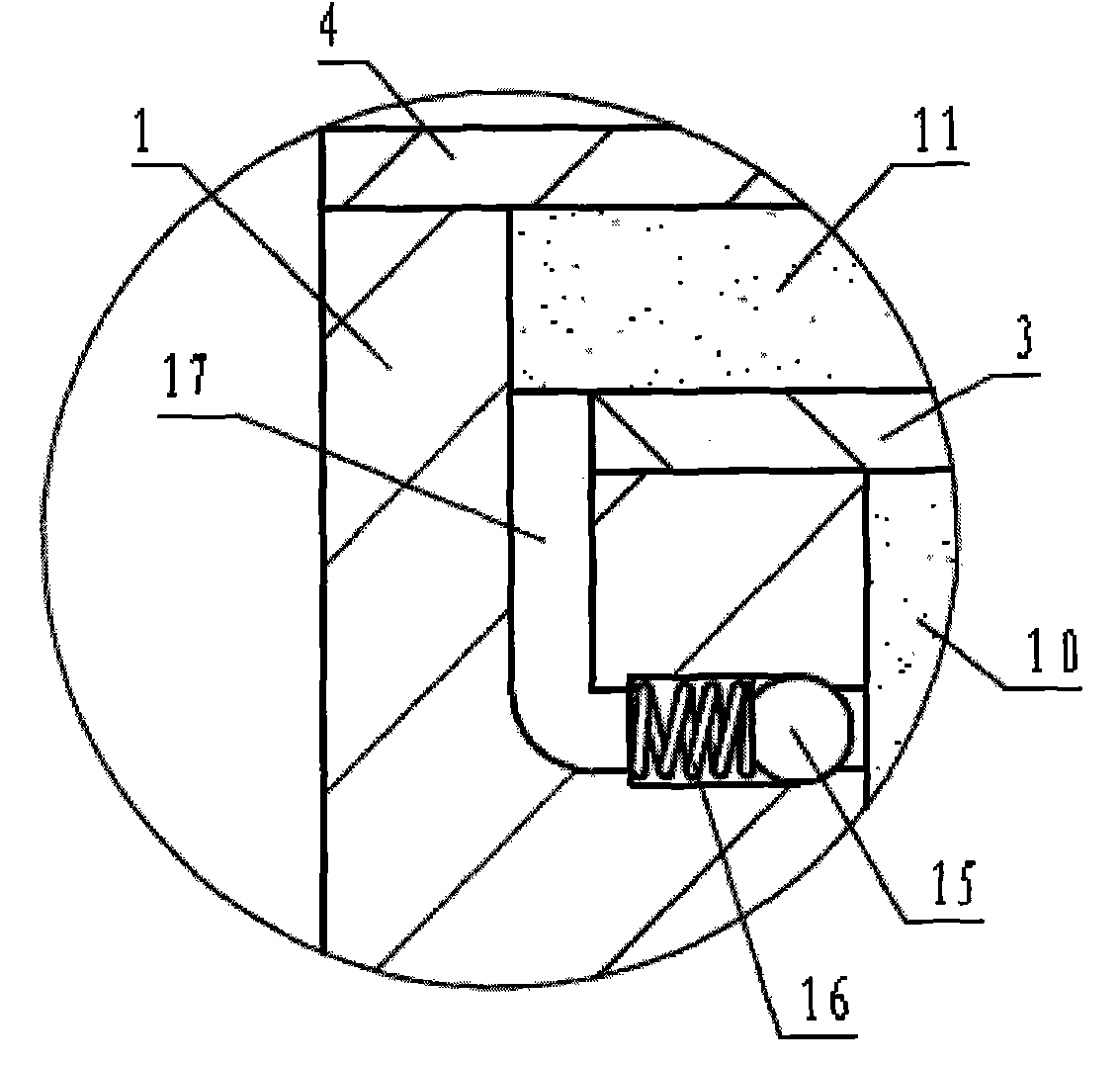

[0020] see Figure 1~4 , the outer cylinder 4 is set outside the inner cylinder 3, and the two ends of the outer cylinder 4 are respectively embedded with a left cylinder cover 1 and a right cylinder cover 7, so that the inner cylinder 3 forms a working cylinder 10, and the inner cylinder 3 and the outer cylinder A compensation cylinder 11 is formed between the cylinders 4; the piston 5 is located in the working cylinder 10, and there is a viscous damping gap 9 between the inner cylinder 3; the piston rod 2 passes through the left end cover 1 through the working cylinder 10 on the left side of the piston 5 , a sealing ring 14 is provided between the piston rod 2 and the left end cover 1; a cylindrical coil spring 6 is provided in the working cylinder 10 on the right side of the piston 5, one end of the spring is clamped on the right end cover by a fixing device, and the other end is held by a fixing device Clamp the end face of the piston 5; the left end cover 1 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com