Locating and mounting method for H-shaped steel girder butting joints

An installation method and node positioning technology, which are applied in the construction, building structure, processing of building materials, etc., can solve the problems such as the time required cannot be accurately predicted, the continuity of the operation process is restricted, and the overlapping time is long. Simple, low-cost, easy-to-make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

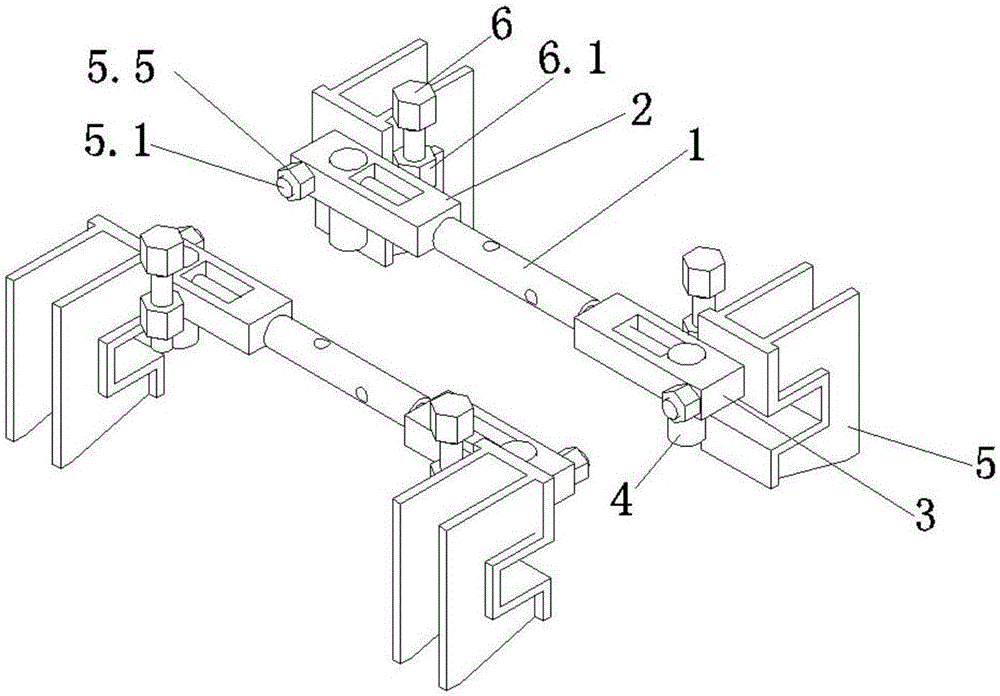

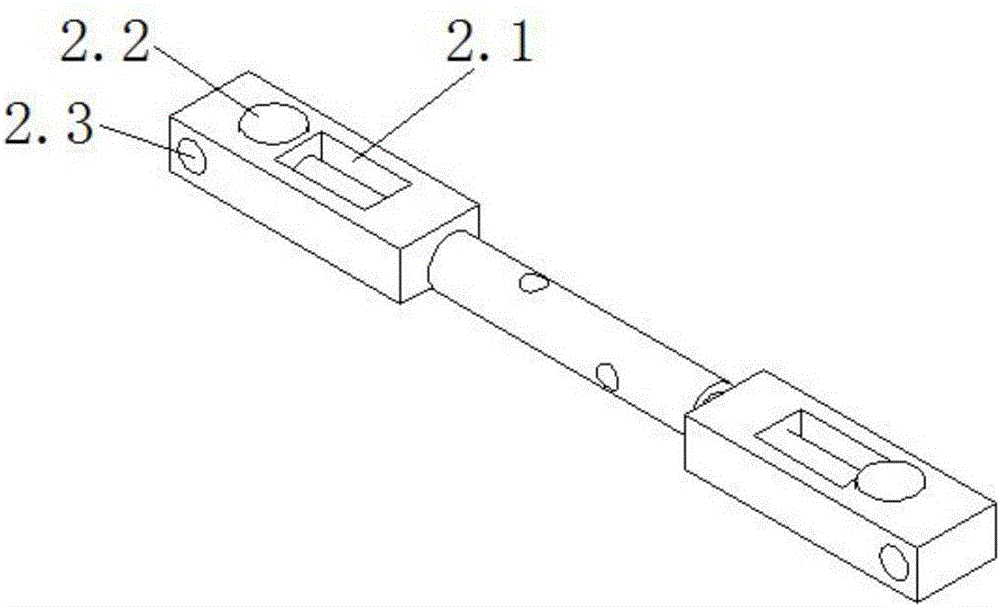

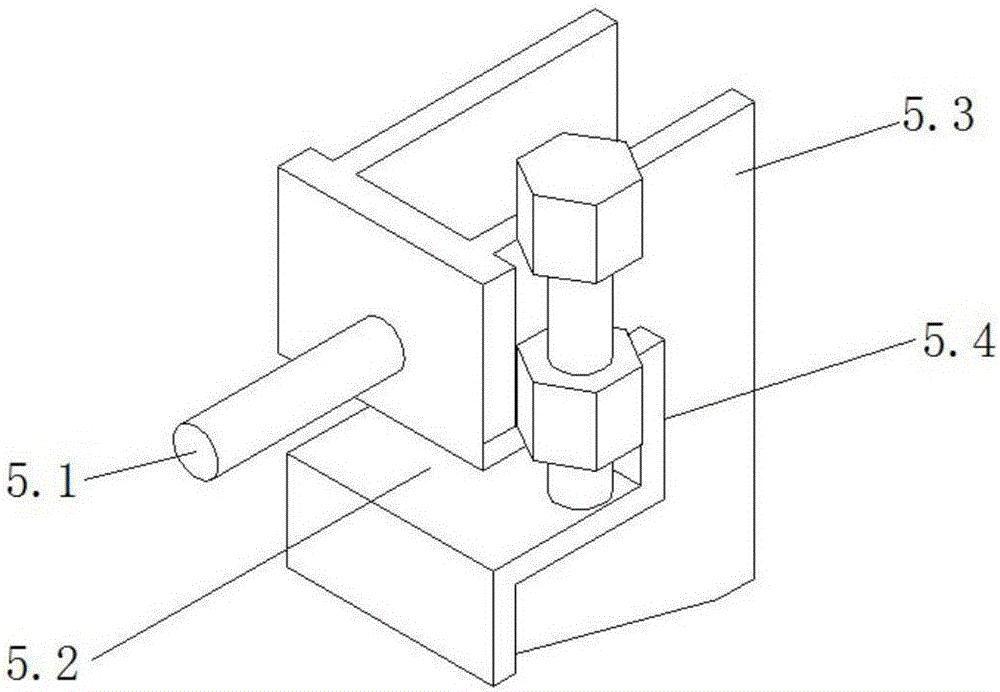

[0037] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0038] Taking the butt joint of steel beam one 7 and steel beam two 8 as an example, the present invention provides a method for positioning and installing an H-shaped steel beam joint joint, which specifically includes the following steps:

[0039] Step 1. Pre-install the connecting plate 10 through the hinge 9 on both sides of the web of the steel beam 7. A part of the connecting plate 10 overlaps with the web of the steel beam 7. The bolt holes opened on the connecting plate 10 are aligned with the steel beam. - Alignment of the bolt holes opened on the web;

[0040] Step 2: Lift steel beam 1 7 to the steel beam 2 8 with lifting equipment for docking. 8 There is a gap of 5~10mm between the butt ends; at the same time, the connecting plate 10 is unfolded, and the other part of the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com