Spherical honeycomb board-based automobile tail gas catalyzing unit

A technology for automobile exhaust and honeycomb panels, which is used in exhaust devices, machines/engines, air quality improvement, etc., can solve the problems of uneven distribution of flow velocity, difficult to withstand long-term impact of exhaust gas, troublesome fixing of porous baffles, etc. Convenience, reduced installation space requirements, reliable connection and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

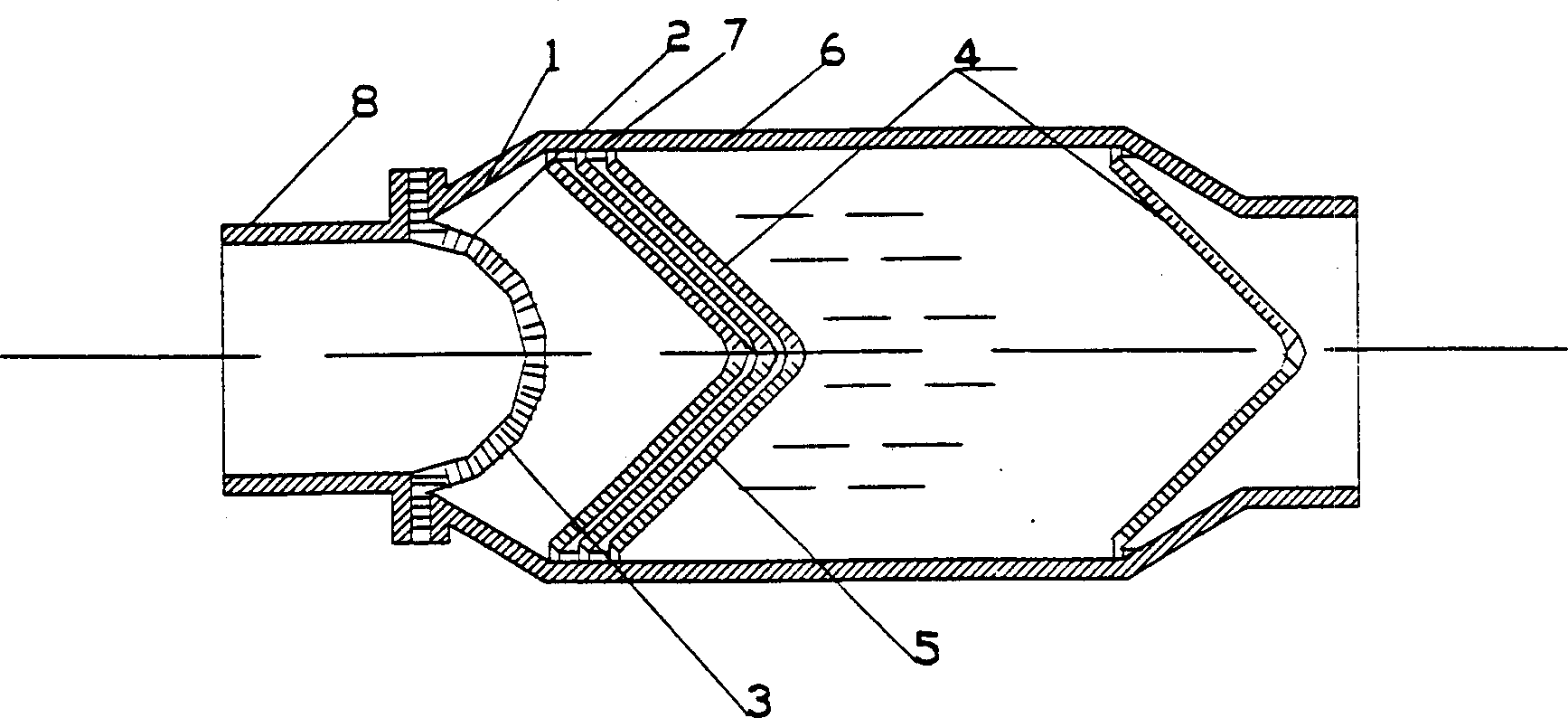

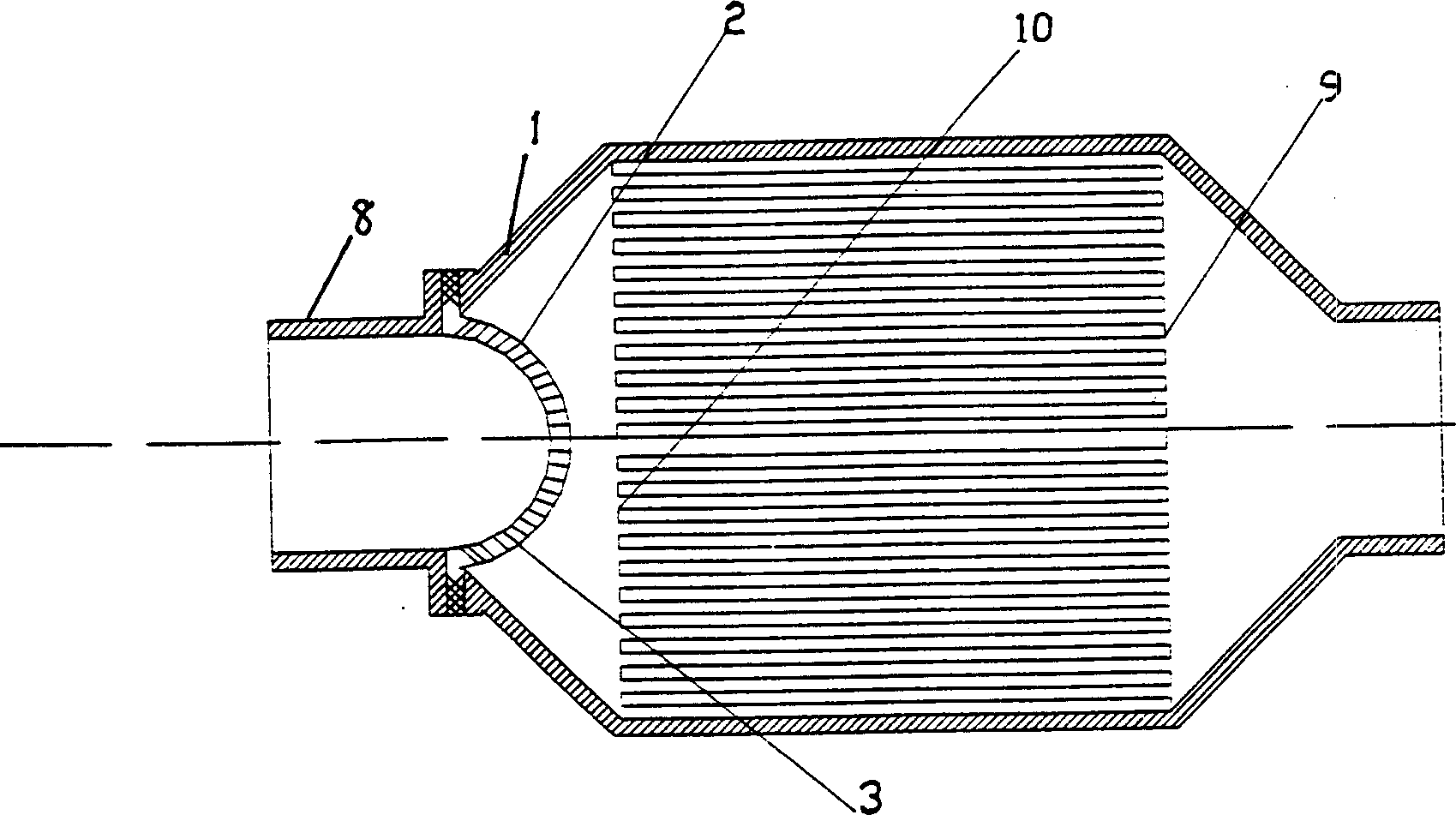

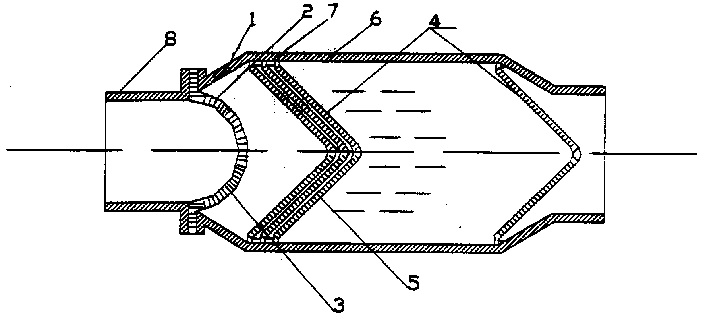

[0021] Such as figure 1 As shown, the present invention is mainly applied to automobile exhaust catalytic converters of gasoline engines, including an expansion section 1 and a main carrier section of the catalytic converter, a porous spherical arc honeycomb panel 2 is arranged on the inlet surface of the expansion section 1, the shell of the expansion section 1 and the spherical arc The honeycomb panel 2 and the exhaust pipe 8 are fixed by welding or flange connection. The spherical arc honeycomb panel 2 is densely covered with flow channels 3 perpendicular to the surface of the spherical arc, with substantially equal wall thickness and a diameter of 1mm. The wall surface of the runner 3 is coated with platinum, rhodium and other noble metal active layers. The main carrier section of the catalytic converter is composed of about 20 conical h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com