Patents

Literature

3826results about "Automatic clutches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

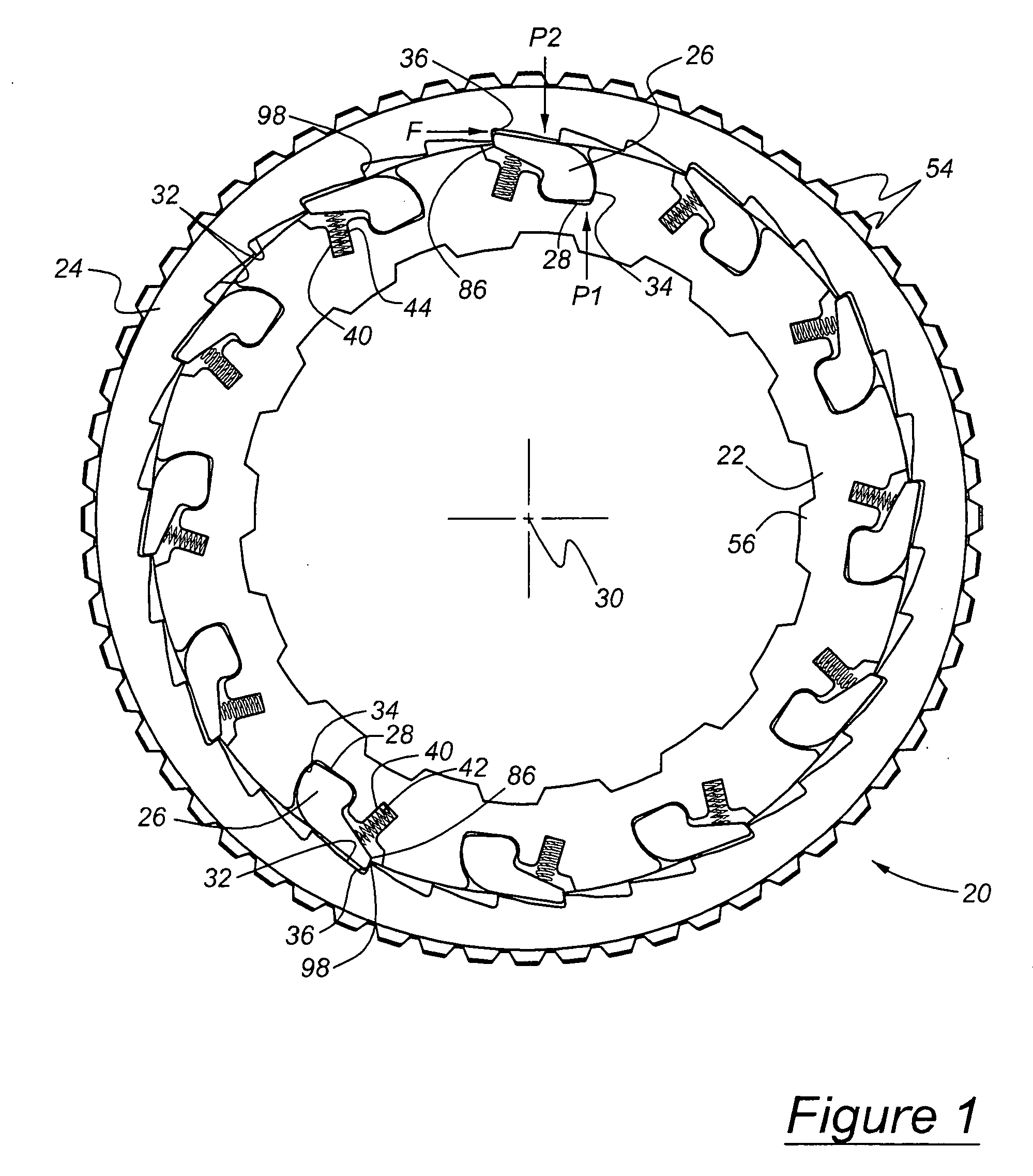

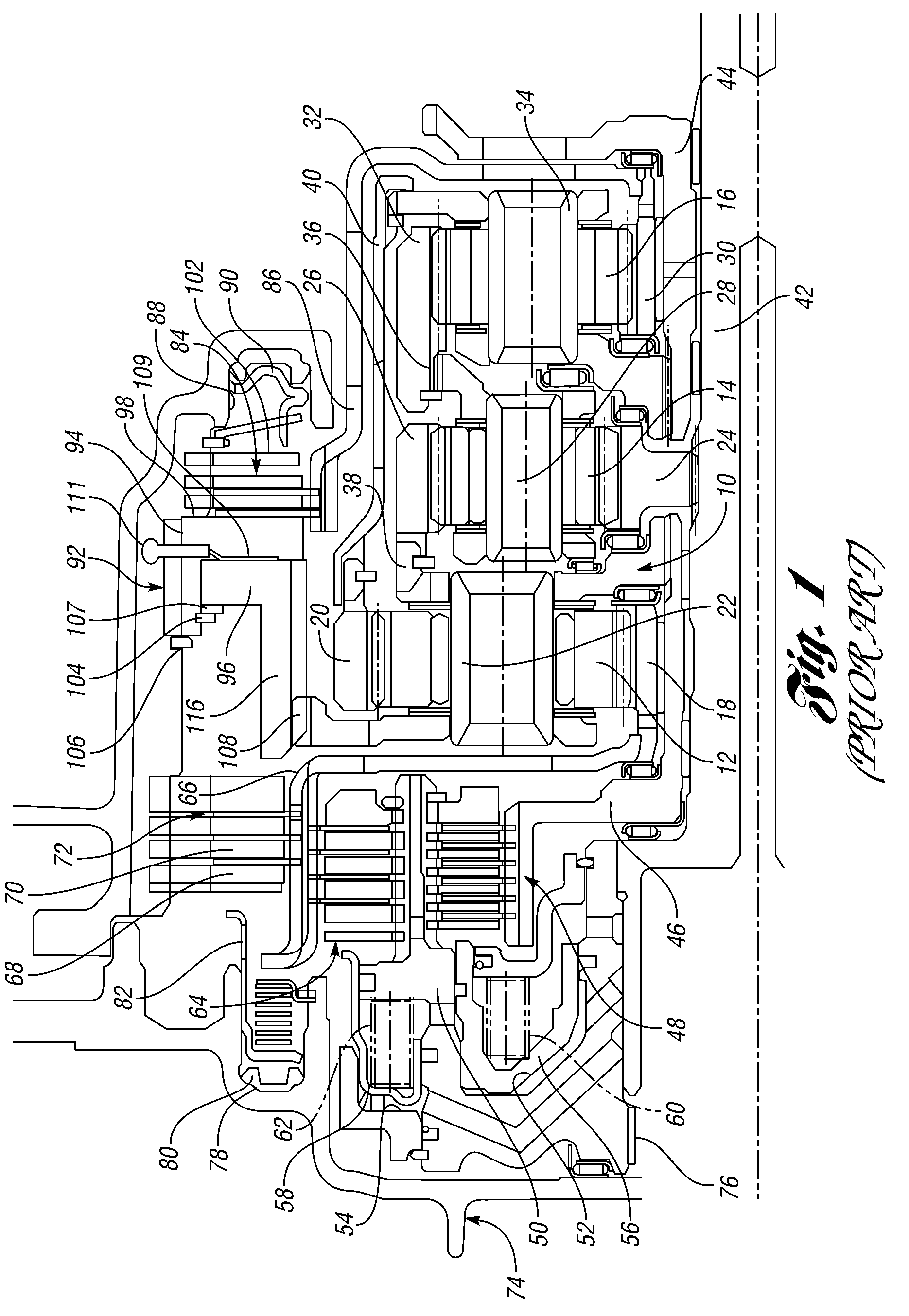

Overrunning coupling assembly and method for controlling the engagement of planar members

ActiveUS7258214B2Reduce complexityReduce controlFriction clutchesInterengaging clutchesEngineeringMechanical engineering

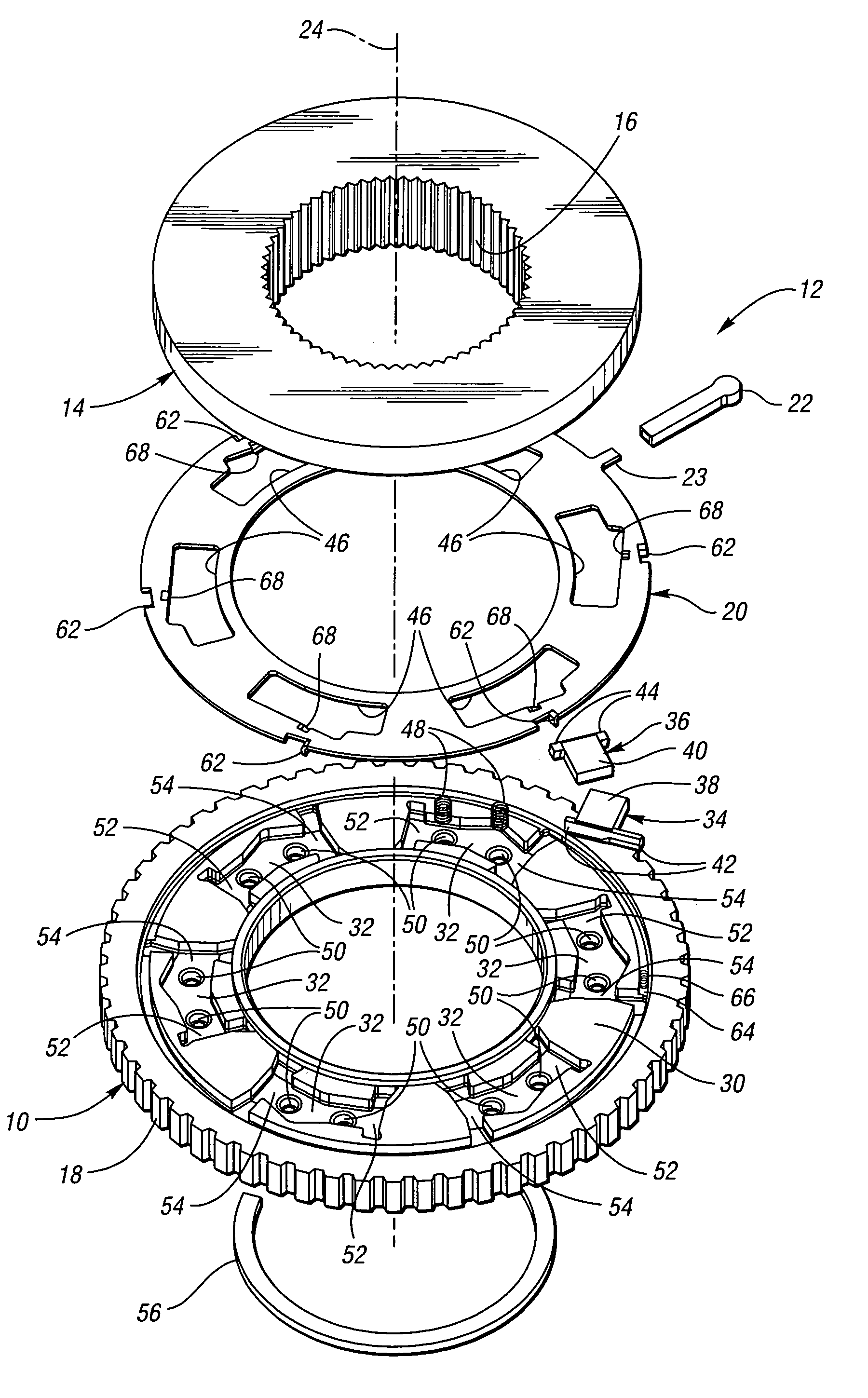

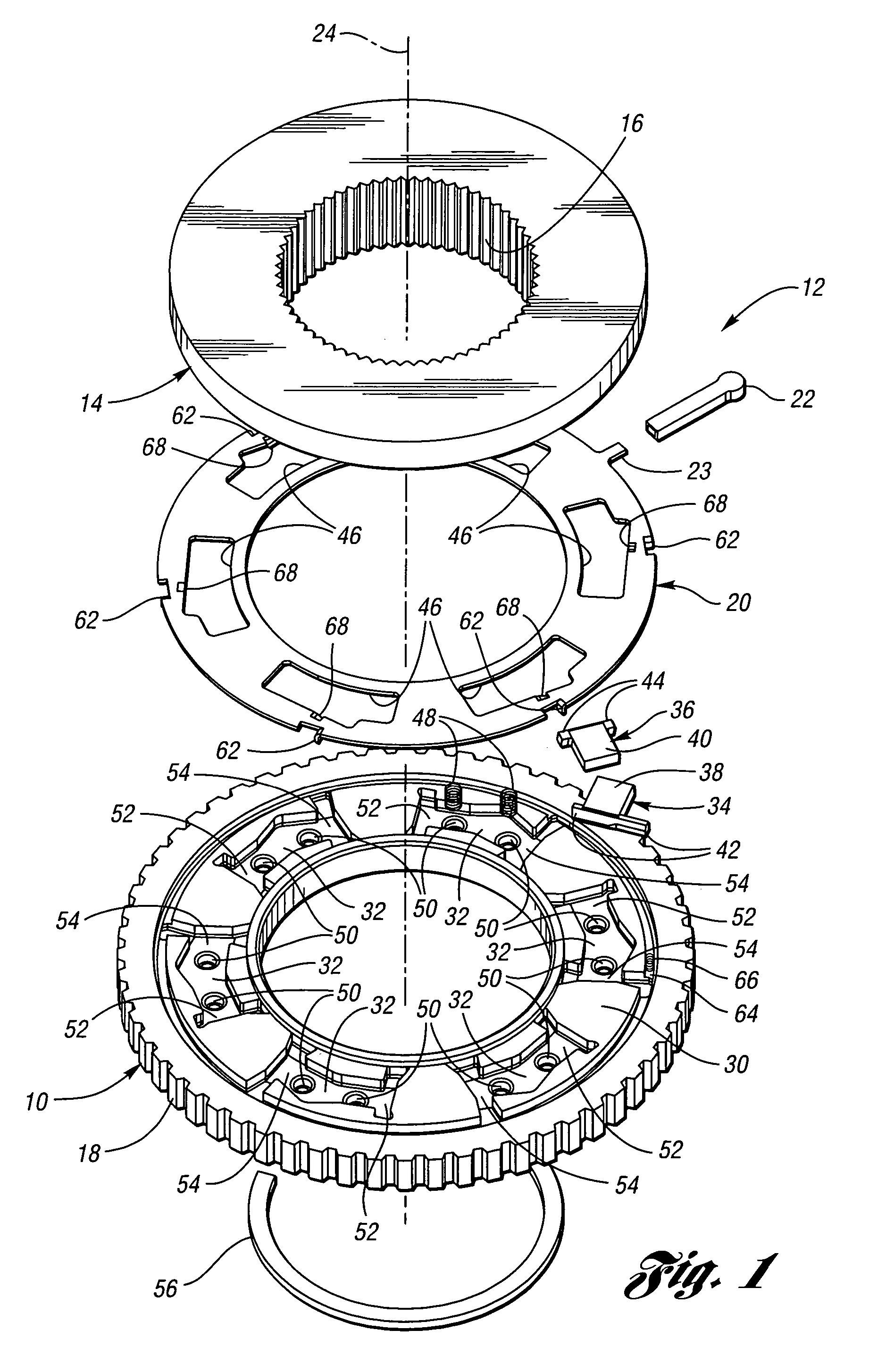

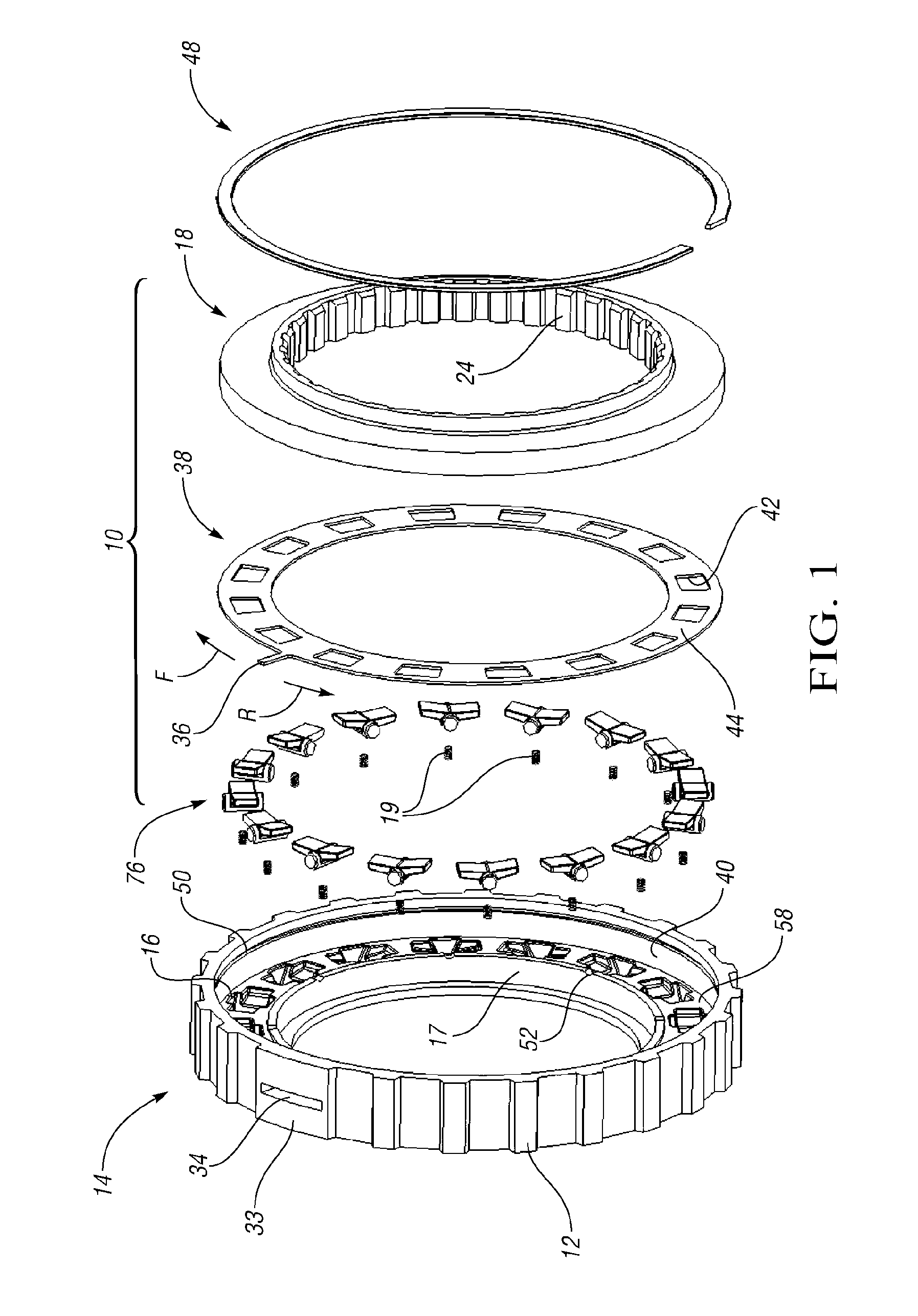

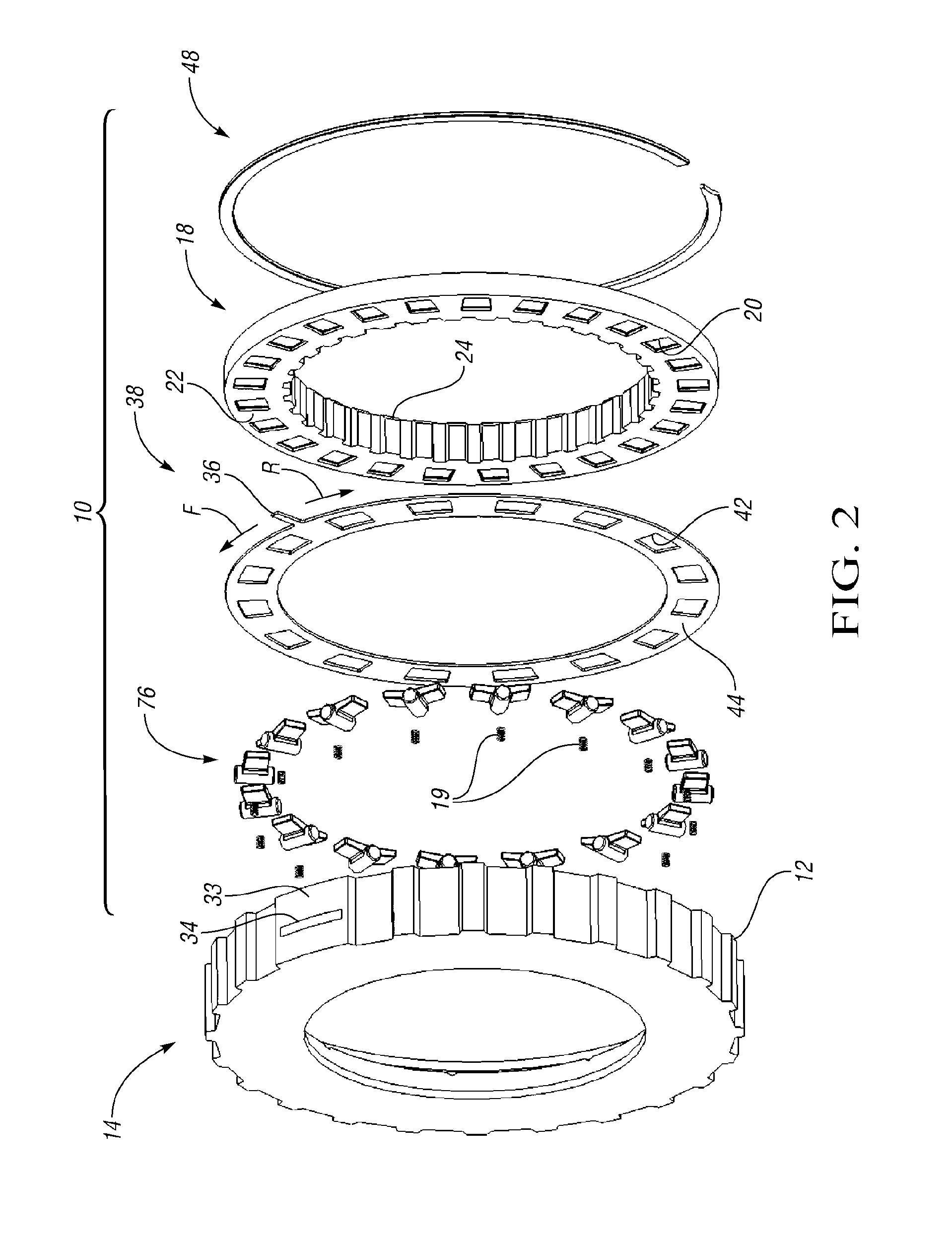

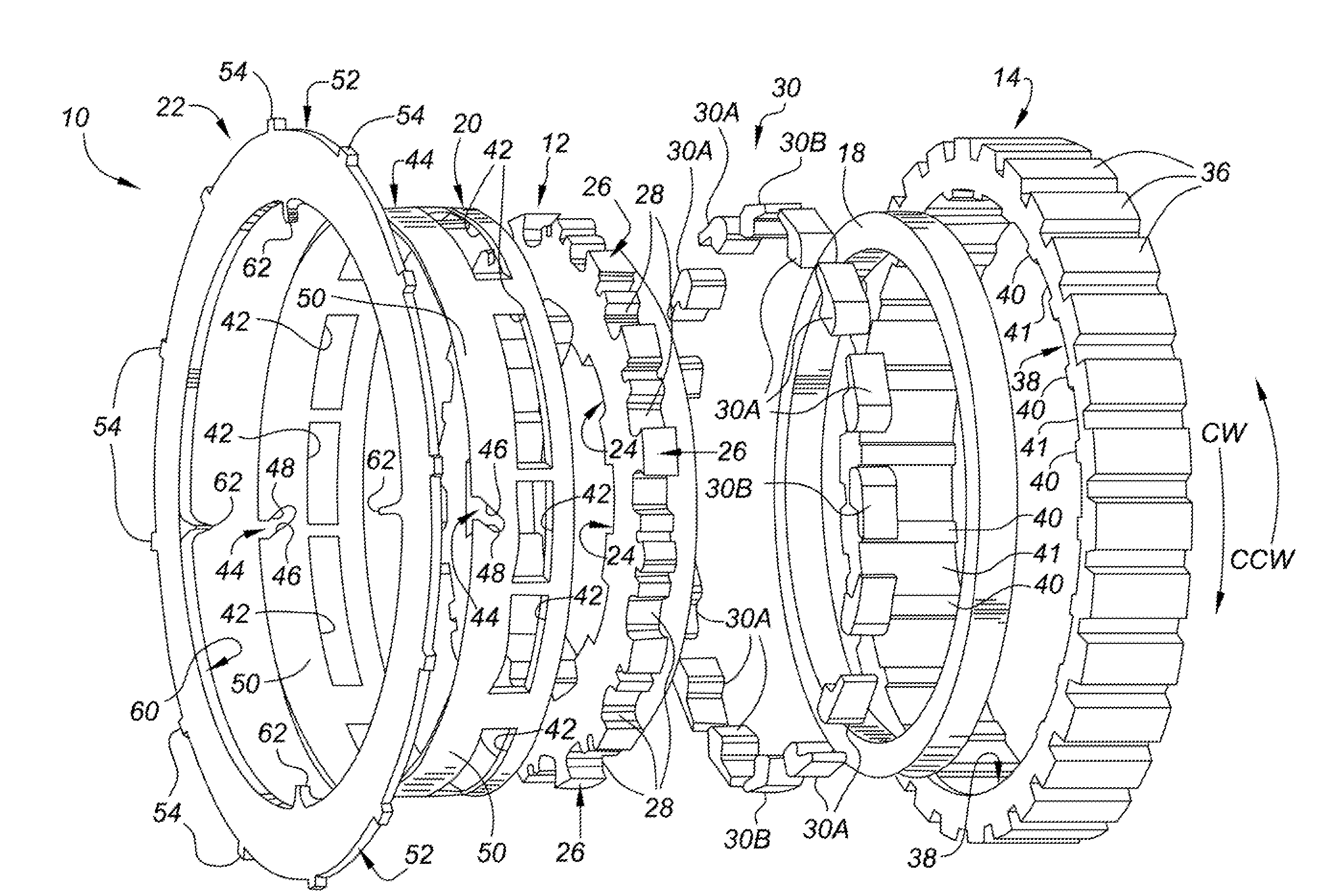

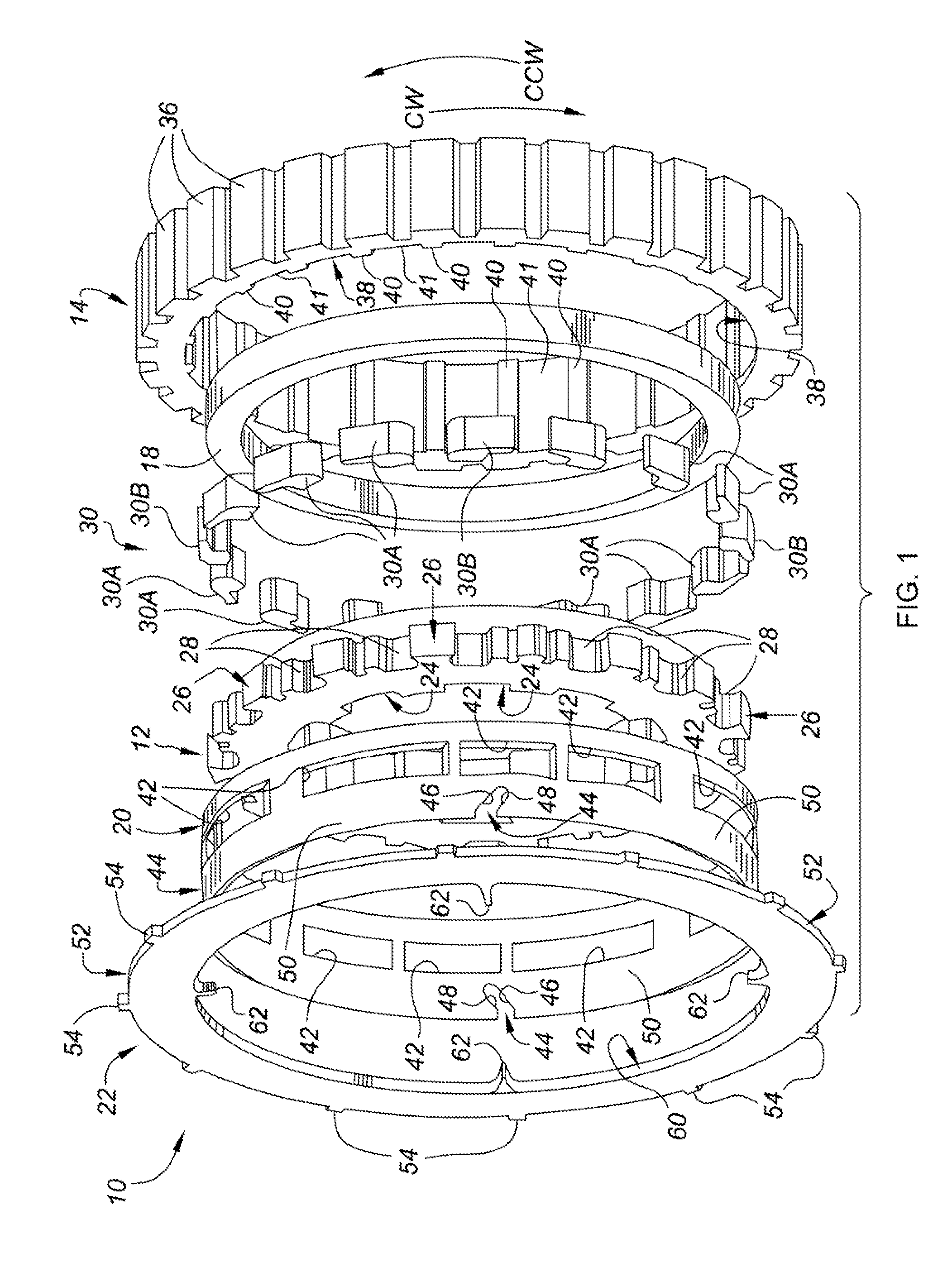

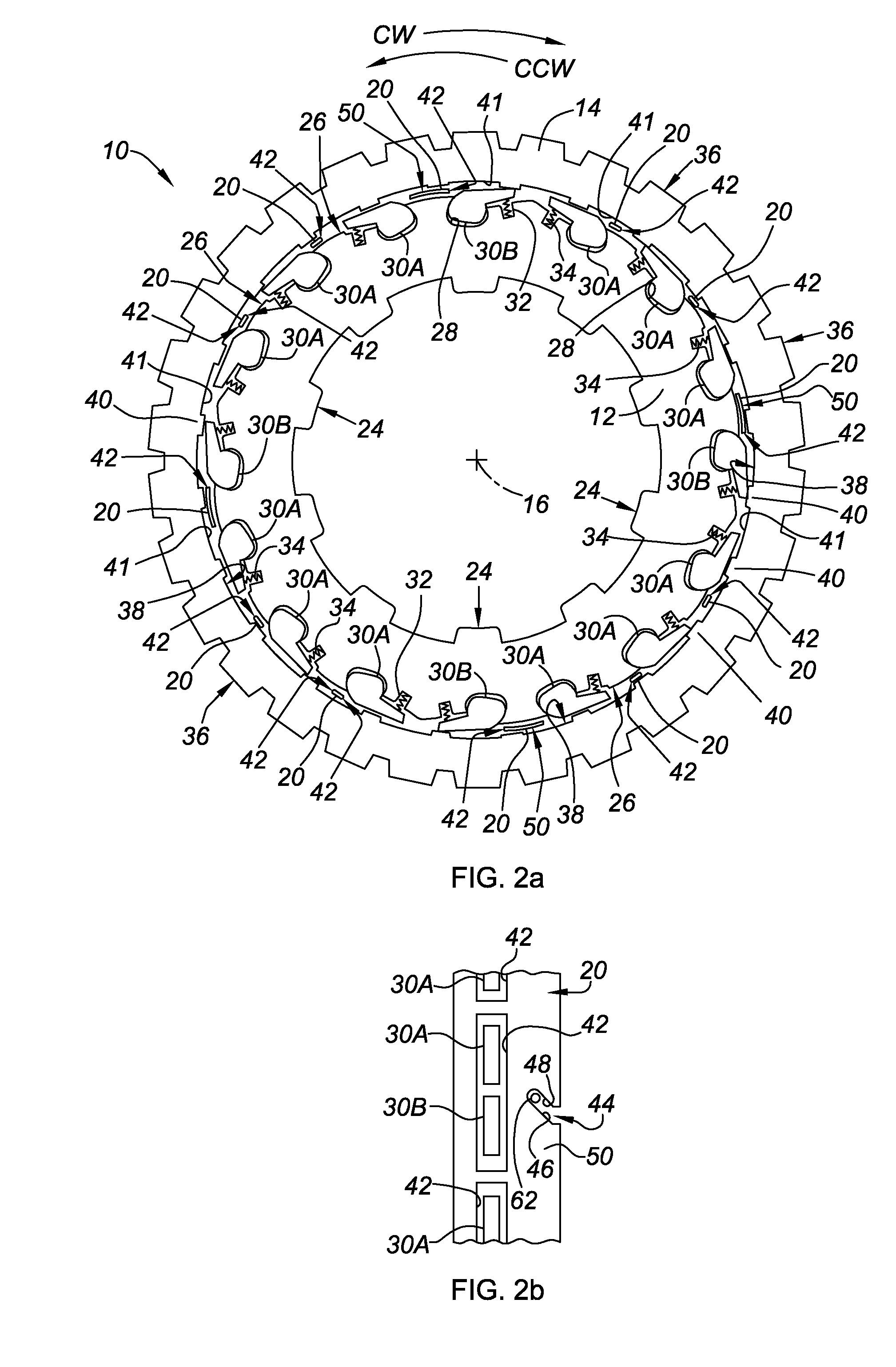

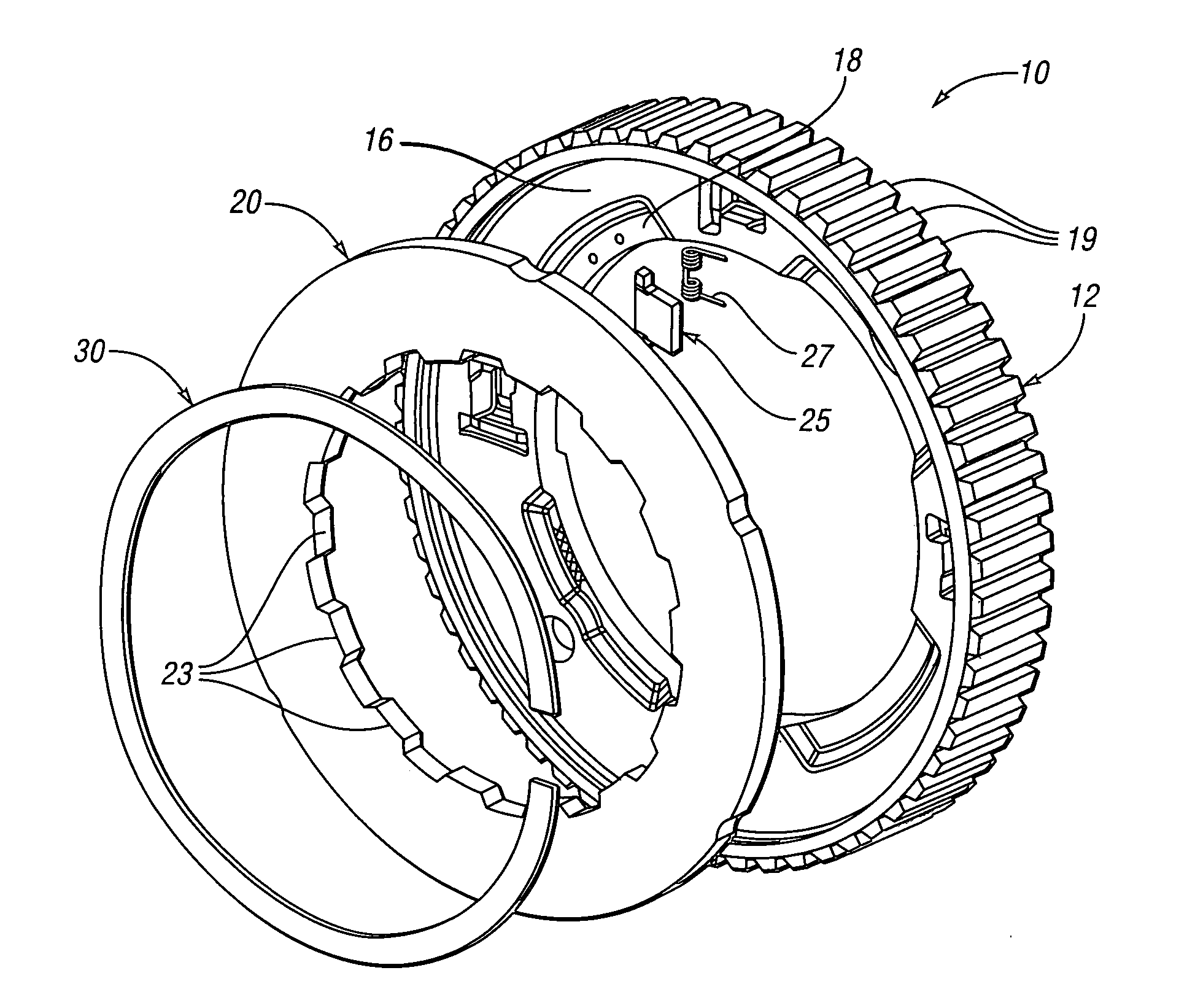

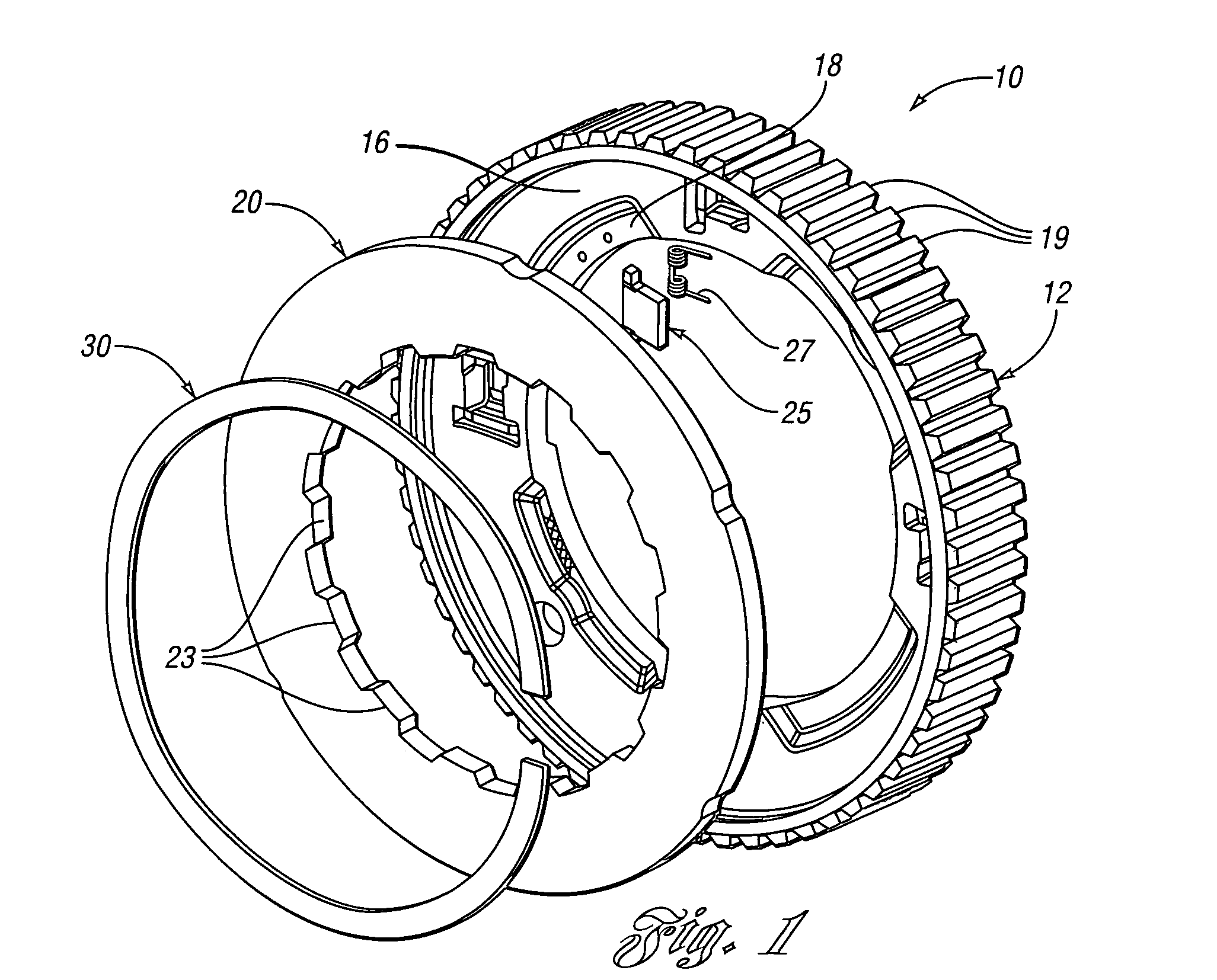

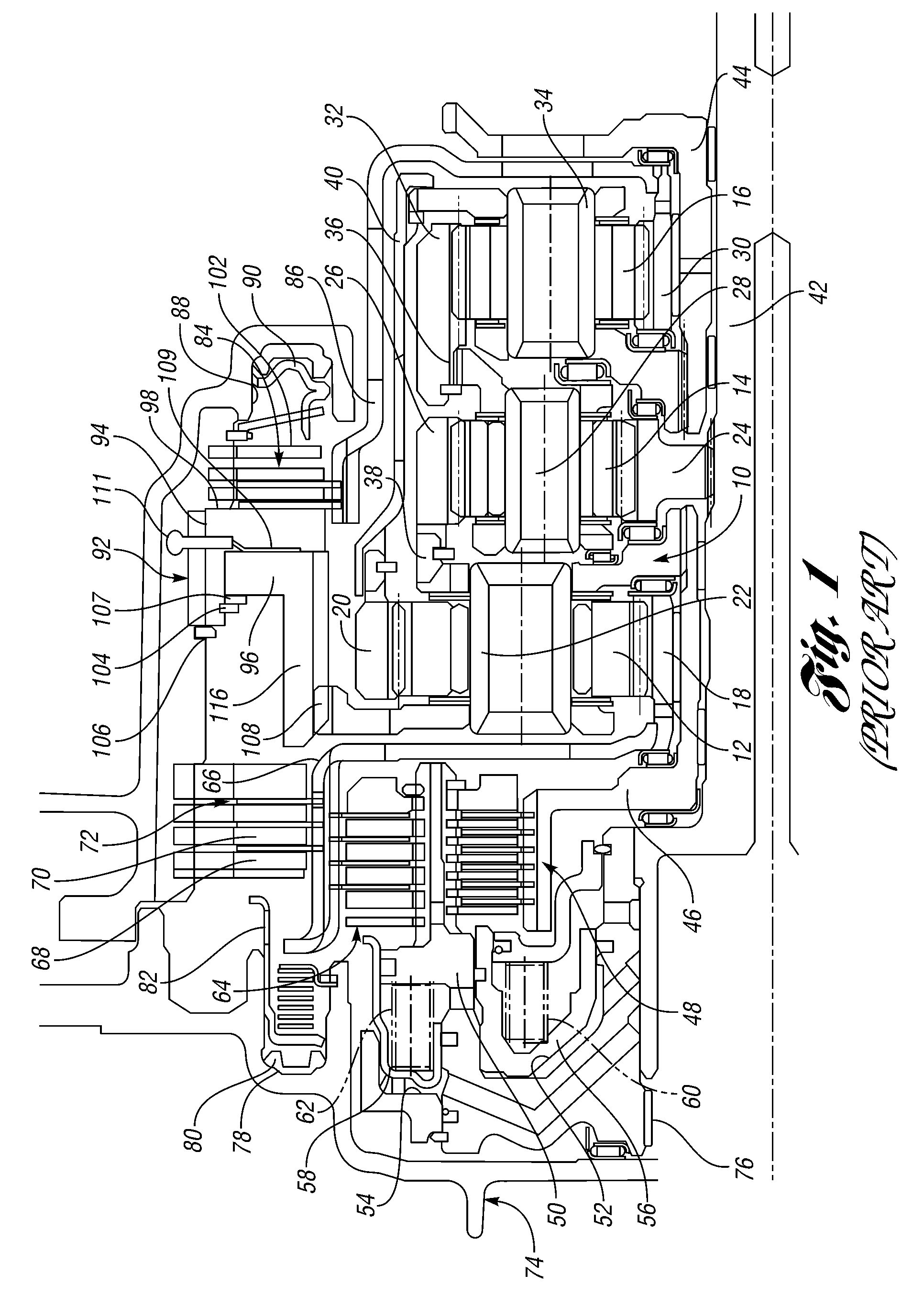

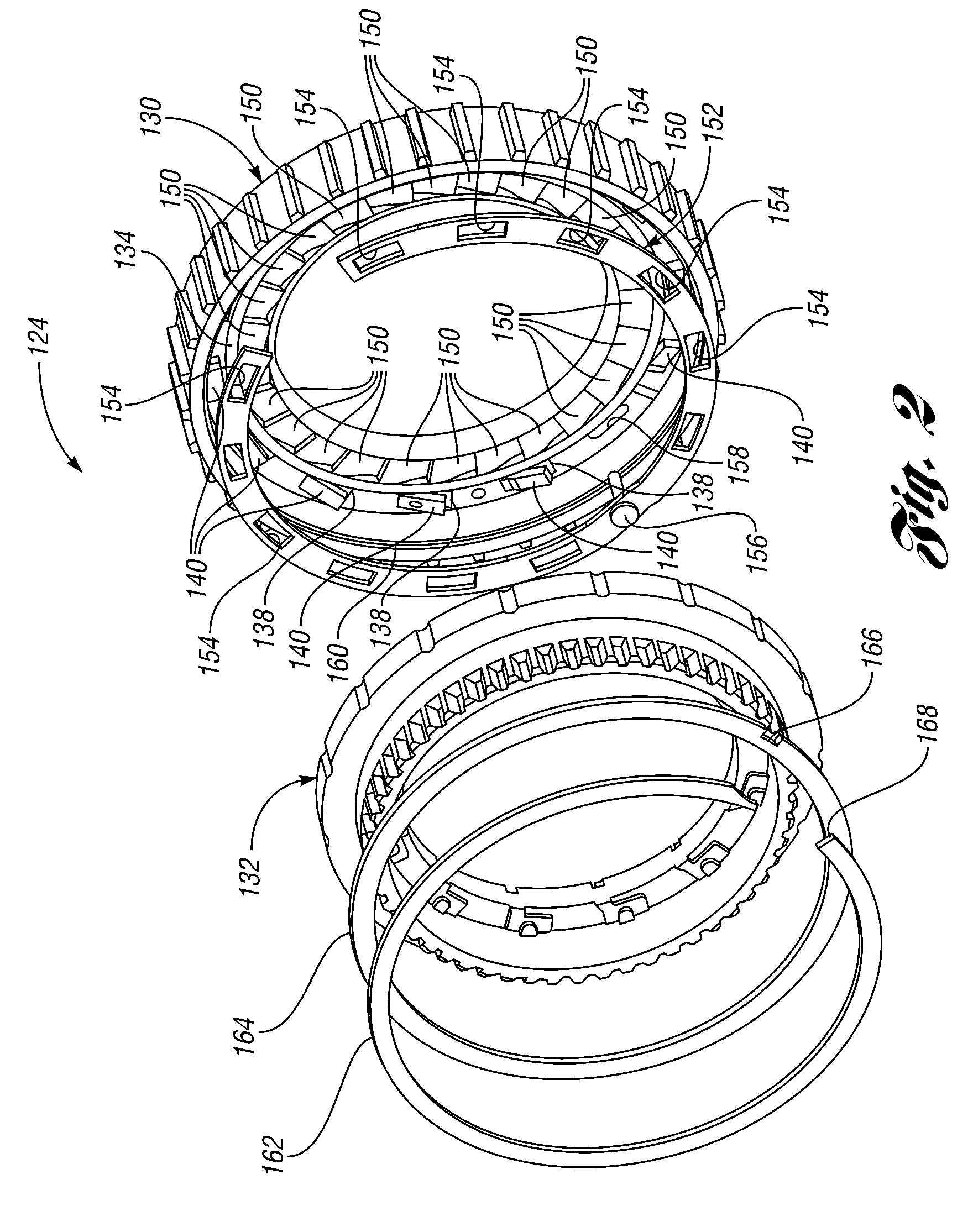

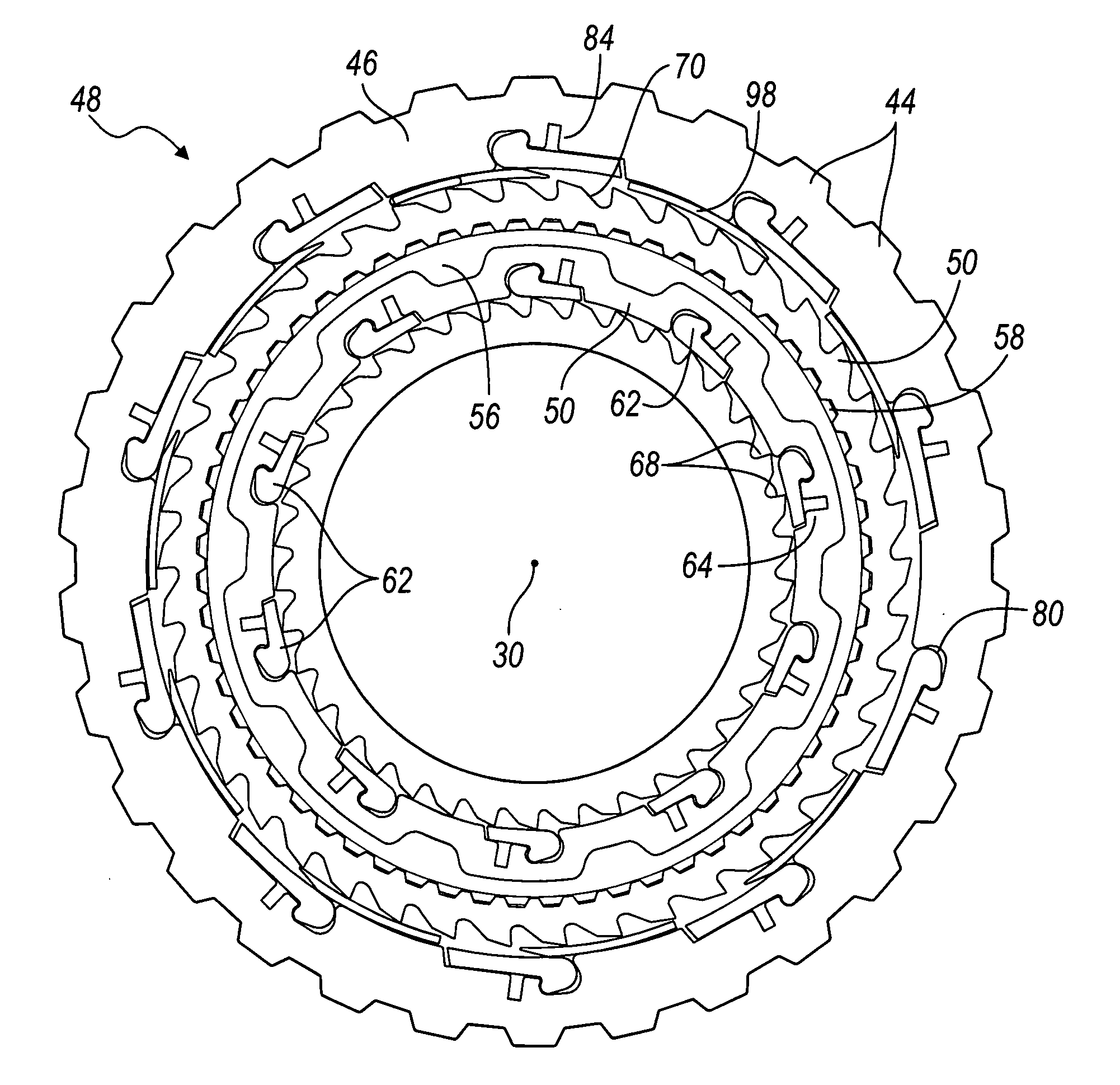

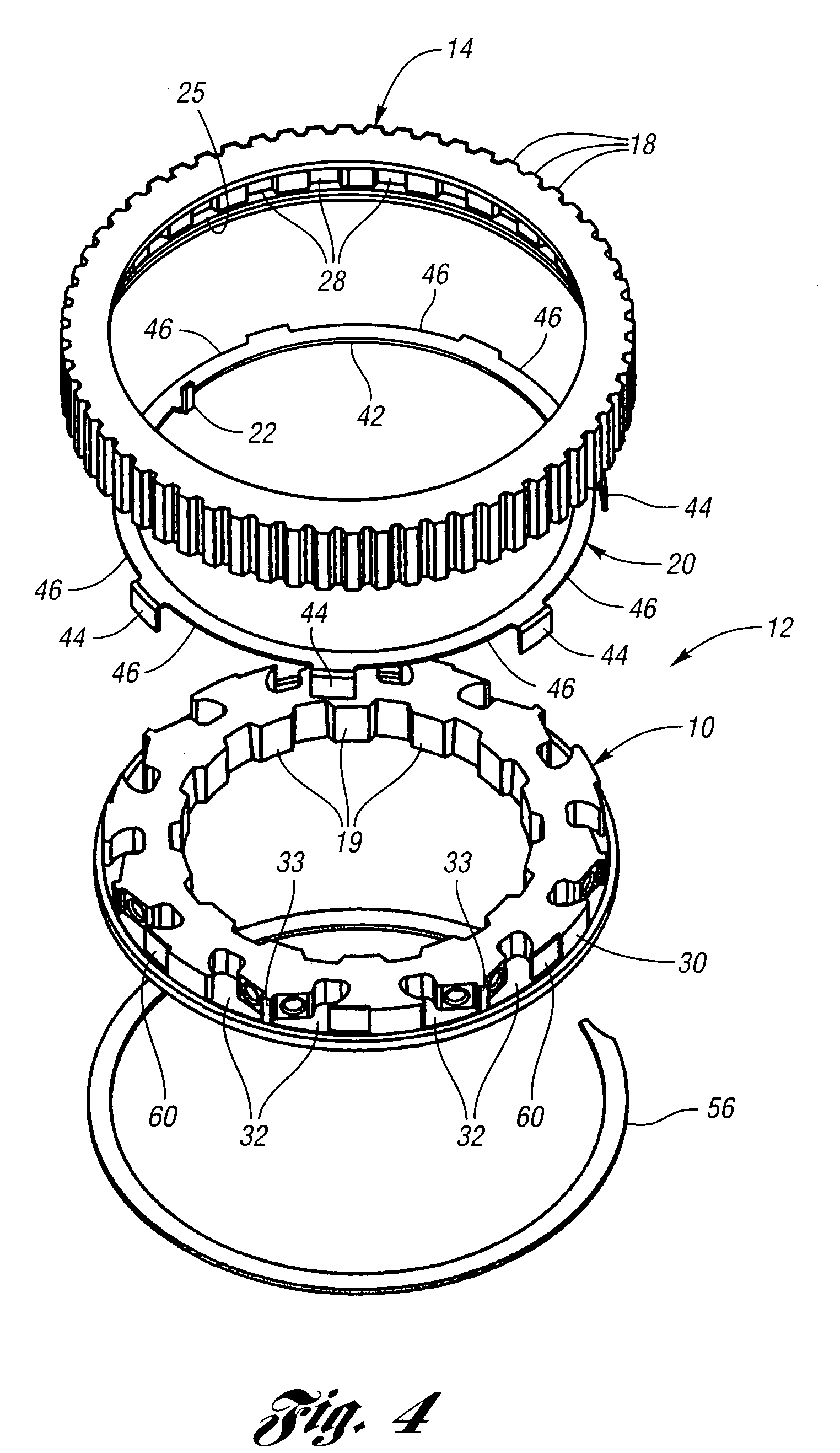

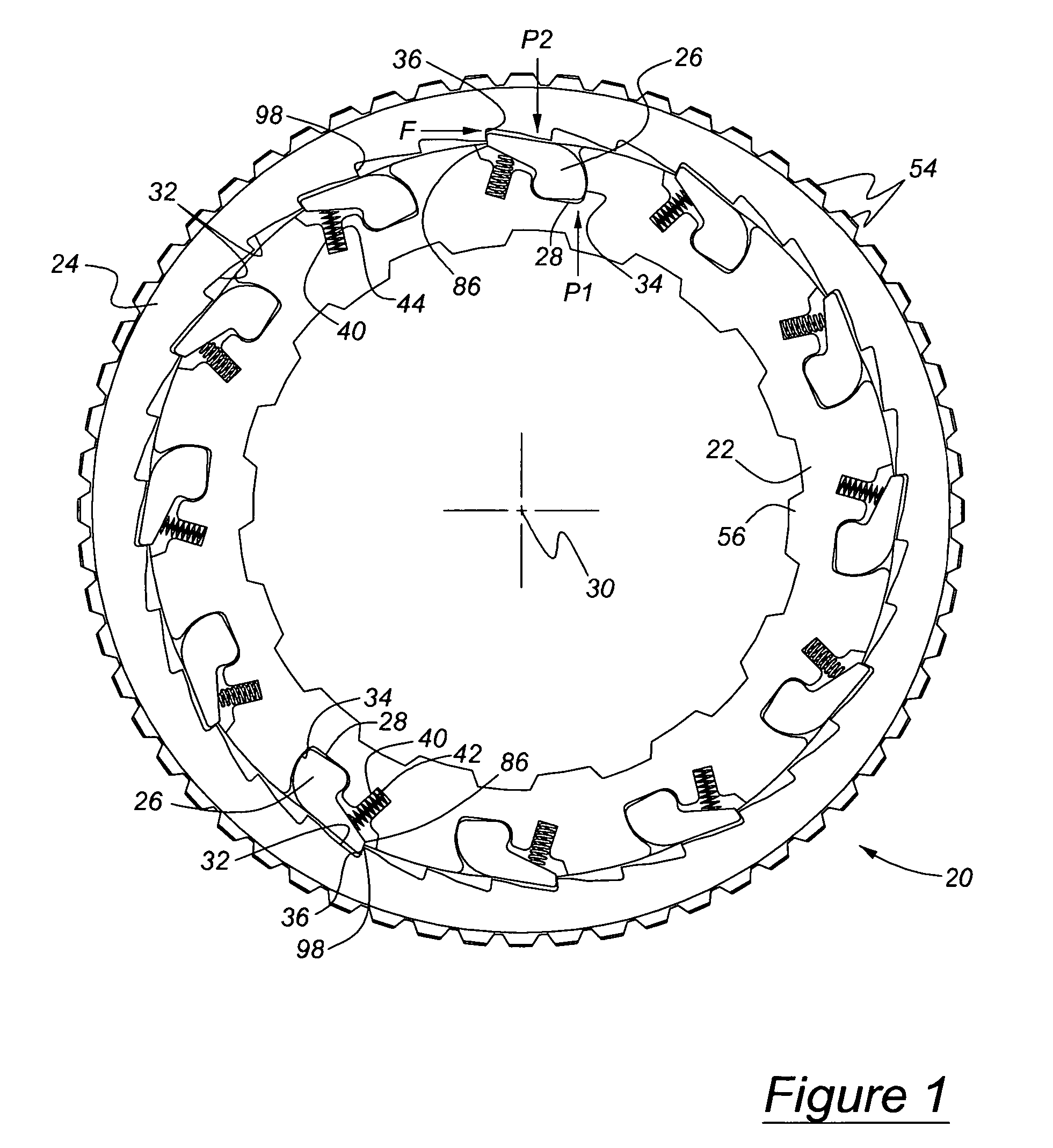

An overrunning coupling assembly and a method of controlling the engagement of planar first and second members are provided wherein two sets of opposed engaging struts are applied with one motion of a single control plate or member. The planar first and second members have inside surfaces extending generally normal to a first axis. The assembly includes free-floating, forward keys and free-floating, reverse keys opposed to the forward keys. The forward and reverse keys are movable between a notch-engaging, engaged position and a disengaged position in which the second member is permitted to free-wheel relative to the first member. The planar control member is disposed between the first and second surfaces and is controllably rotatable about the first axis between first and second angular positions relative to the first member.

Owner:MEANS IND INC

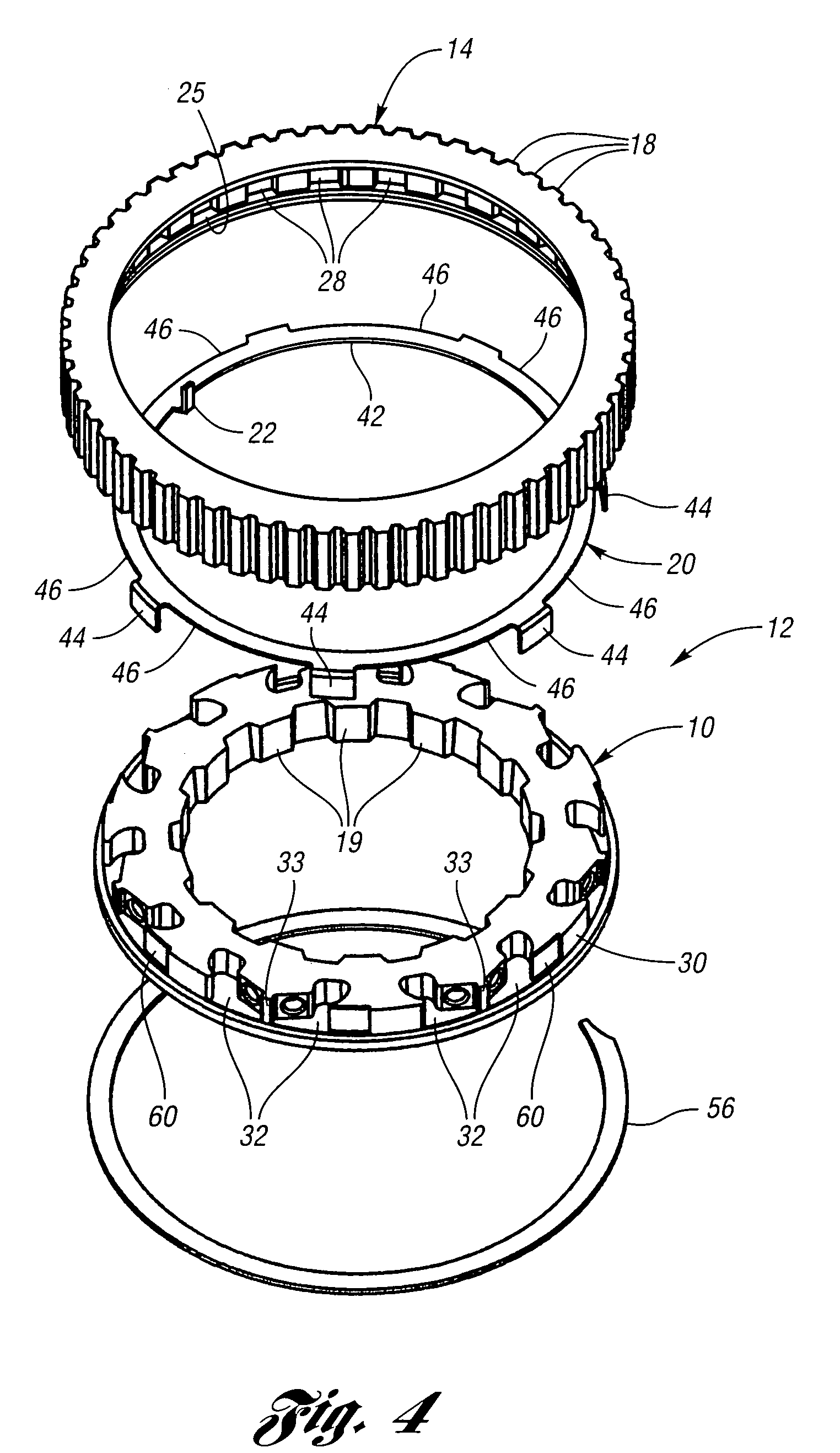

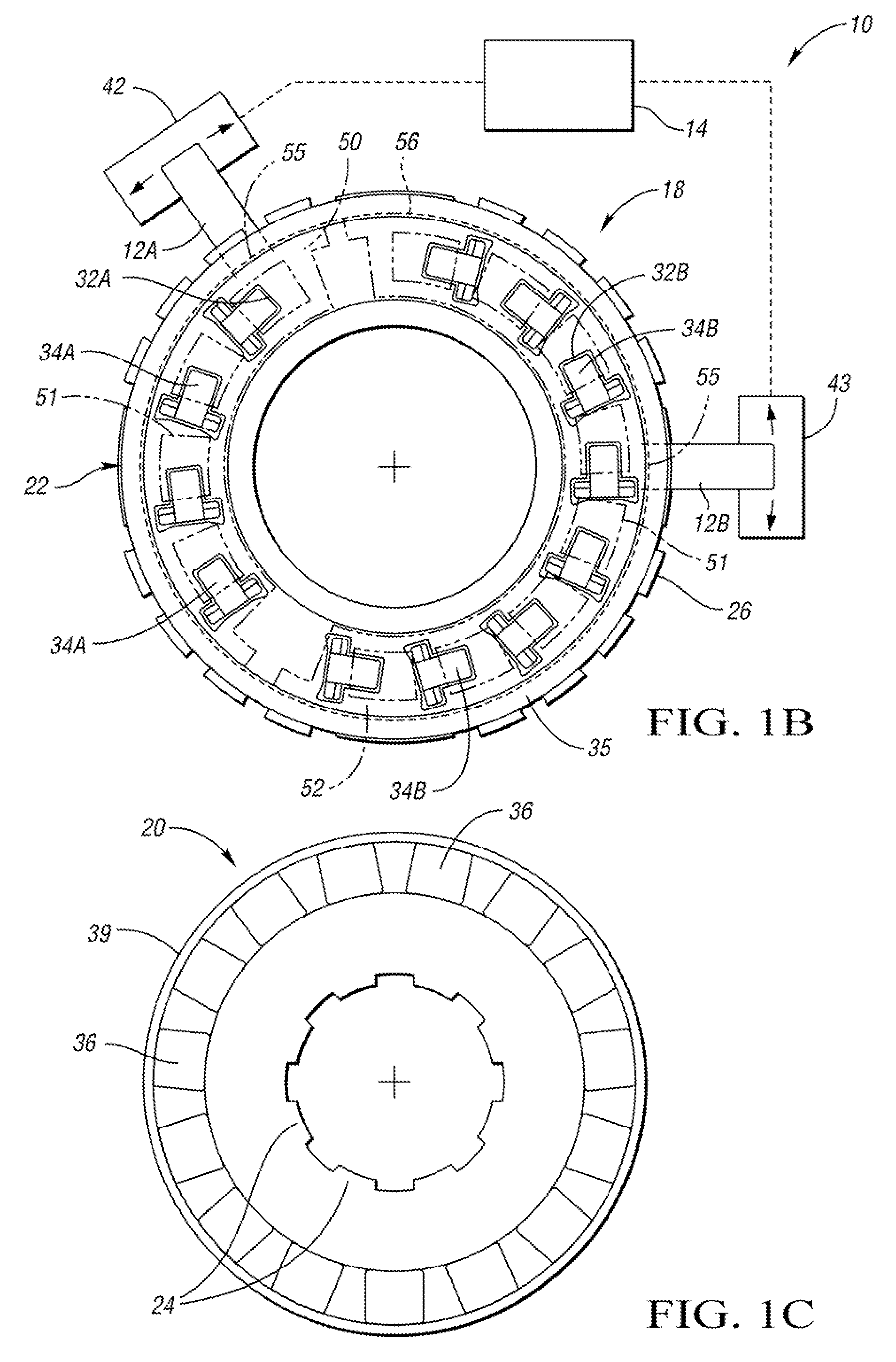

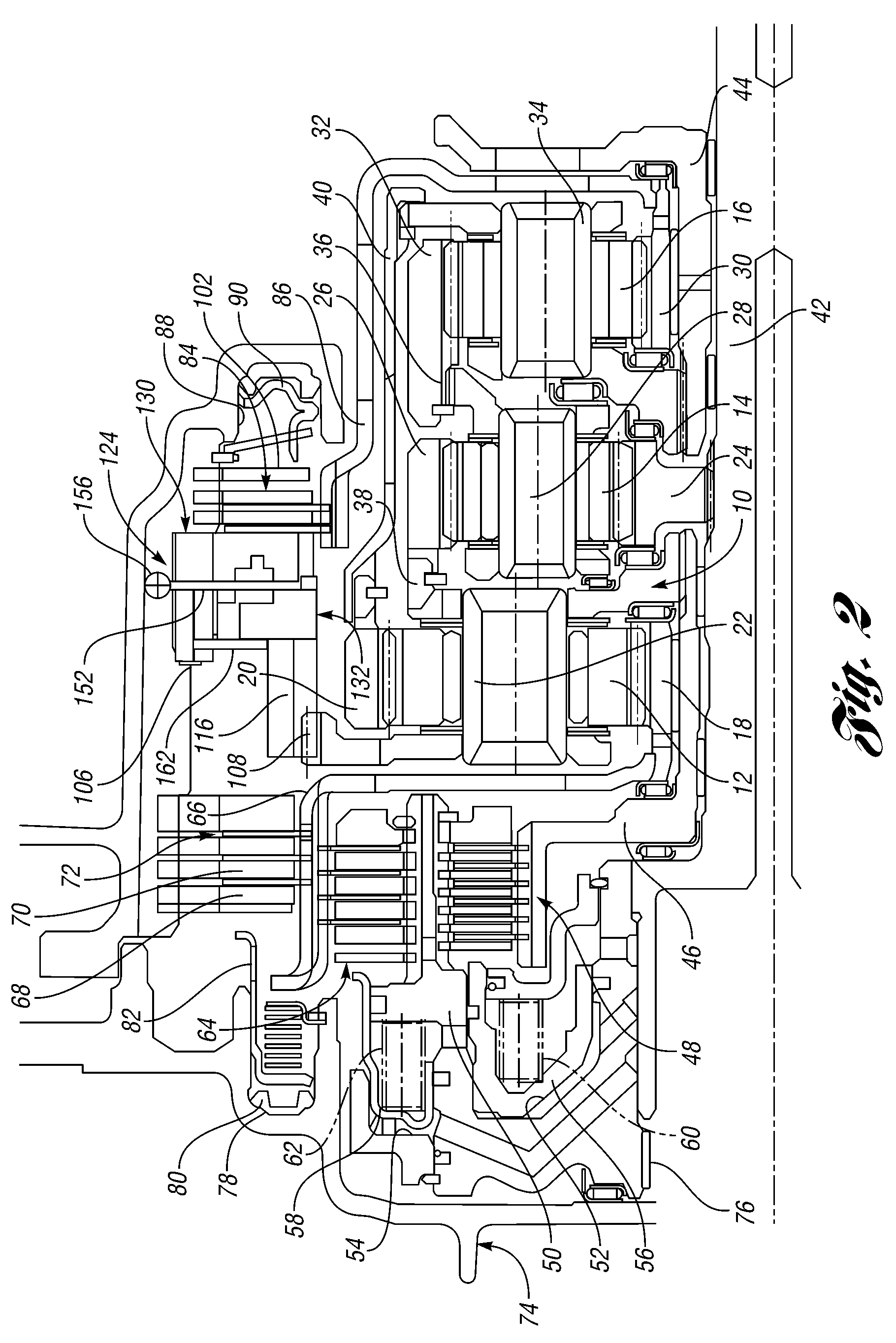

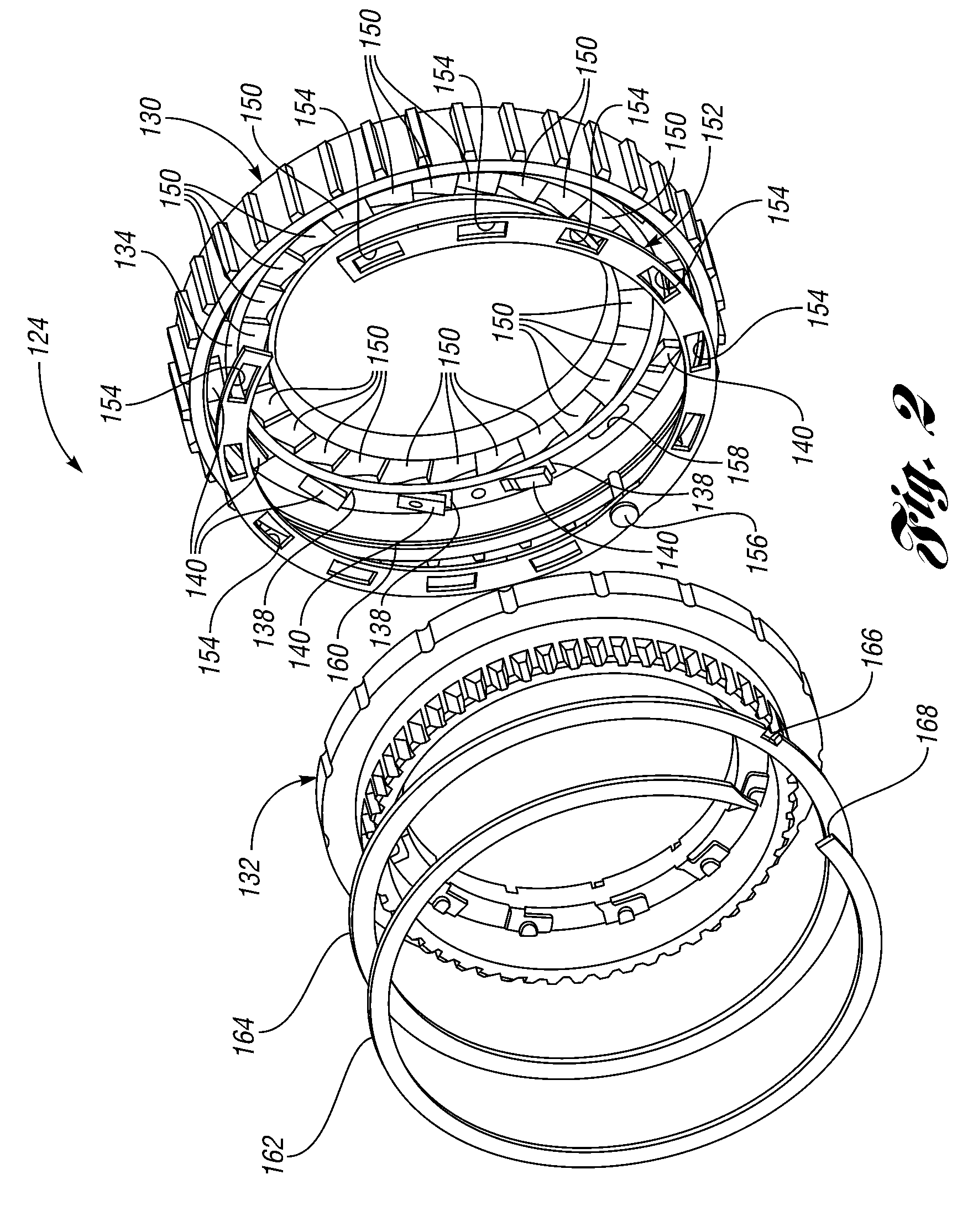

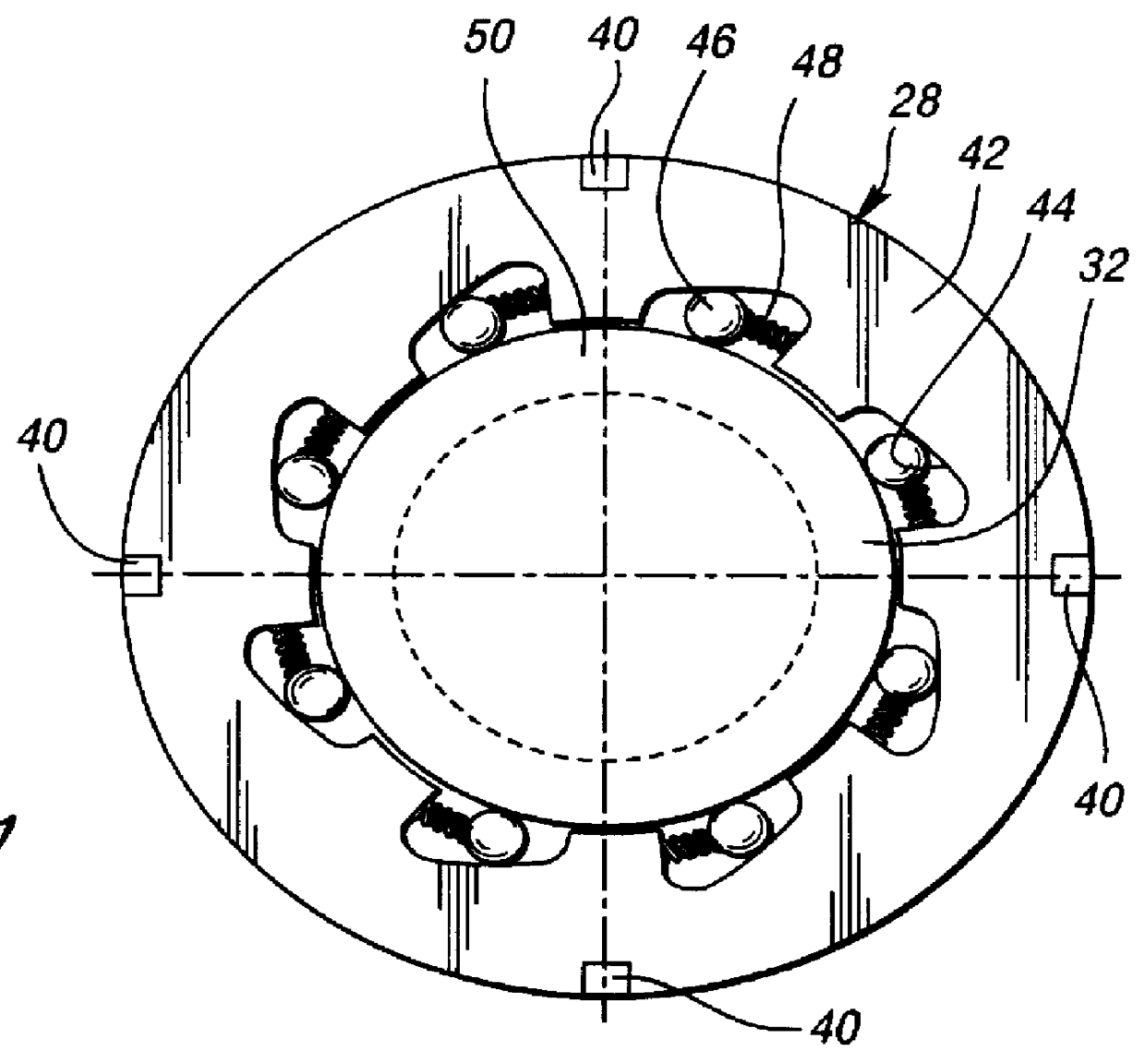

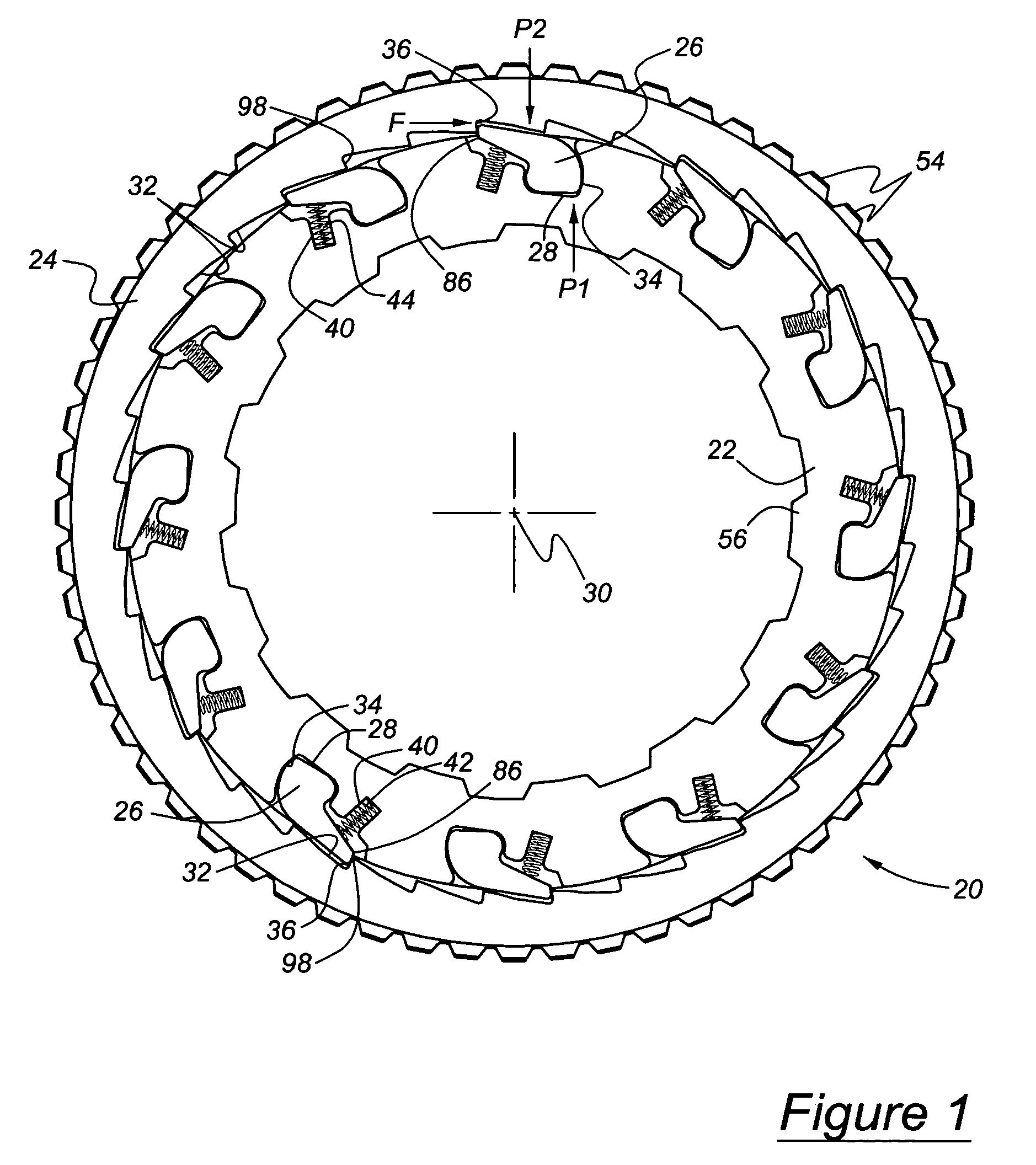

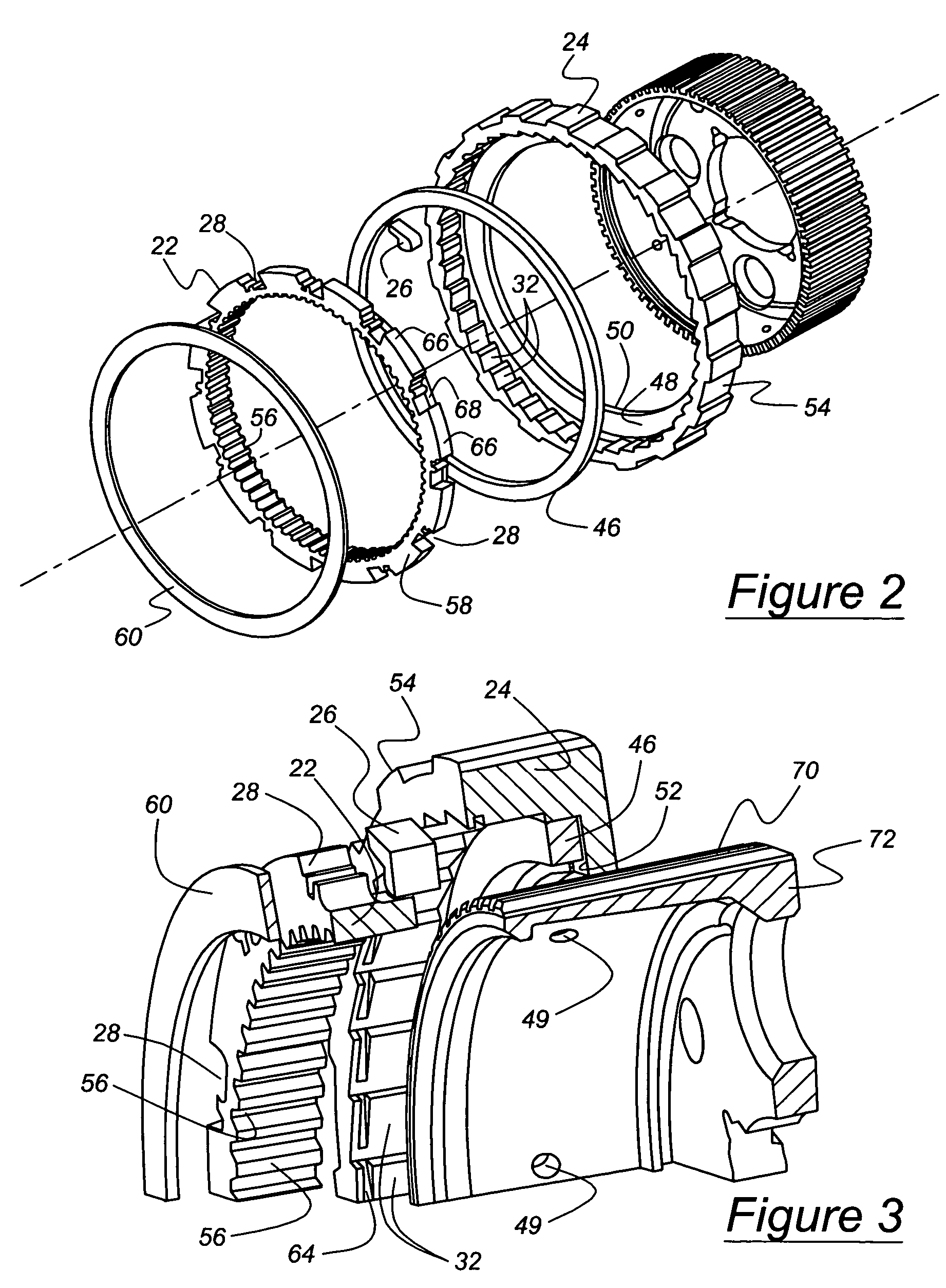

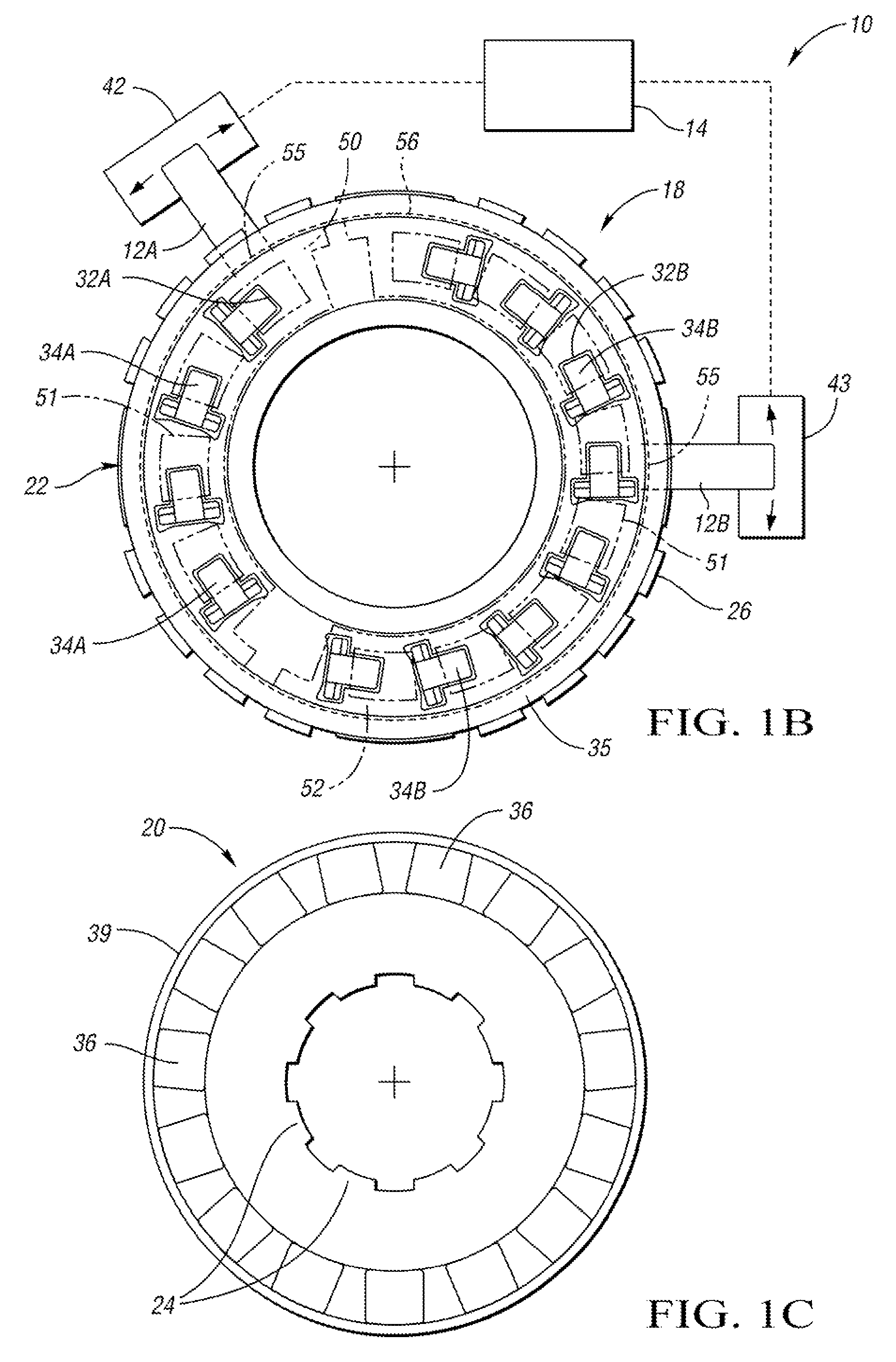

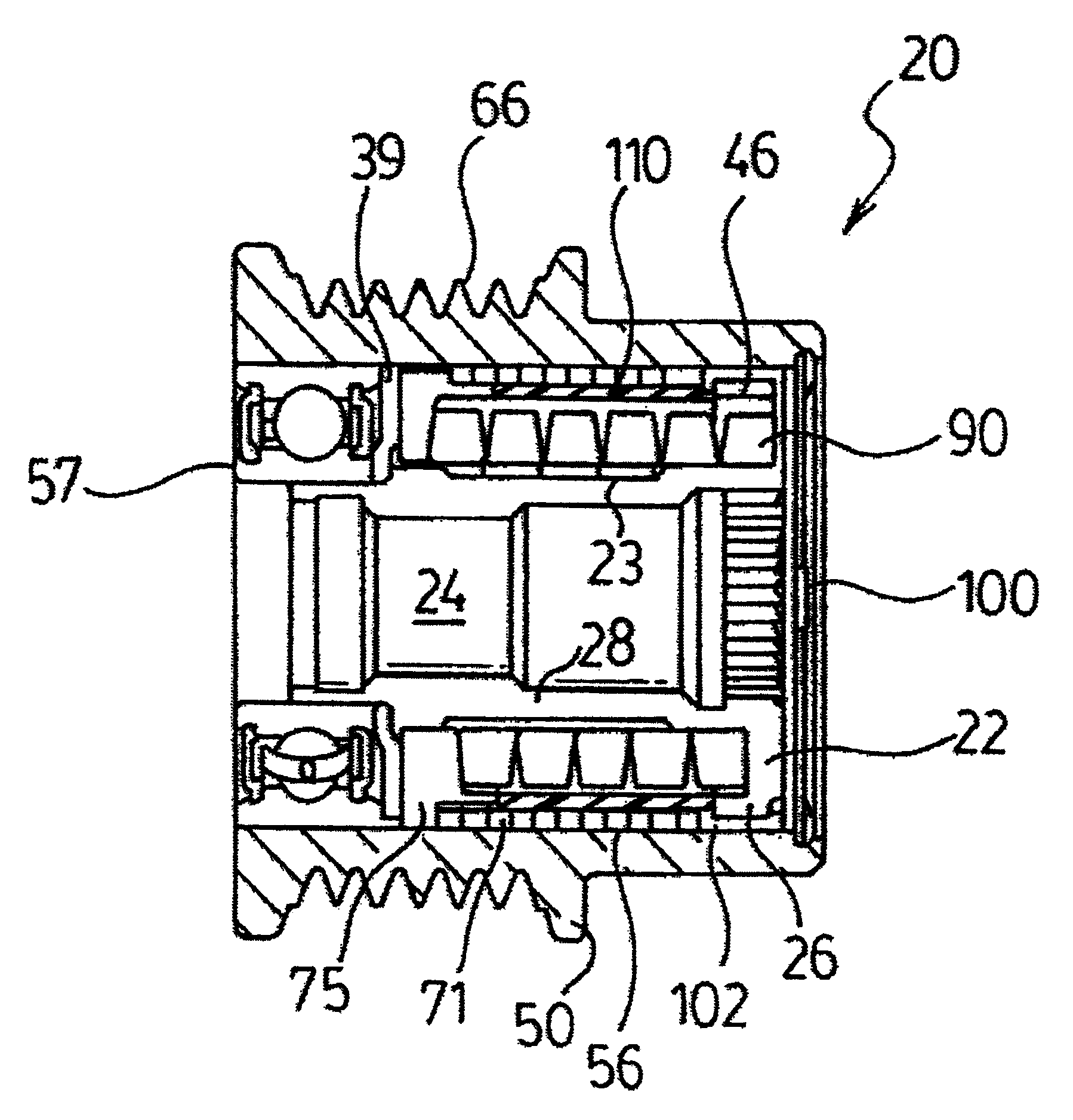

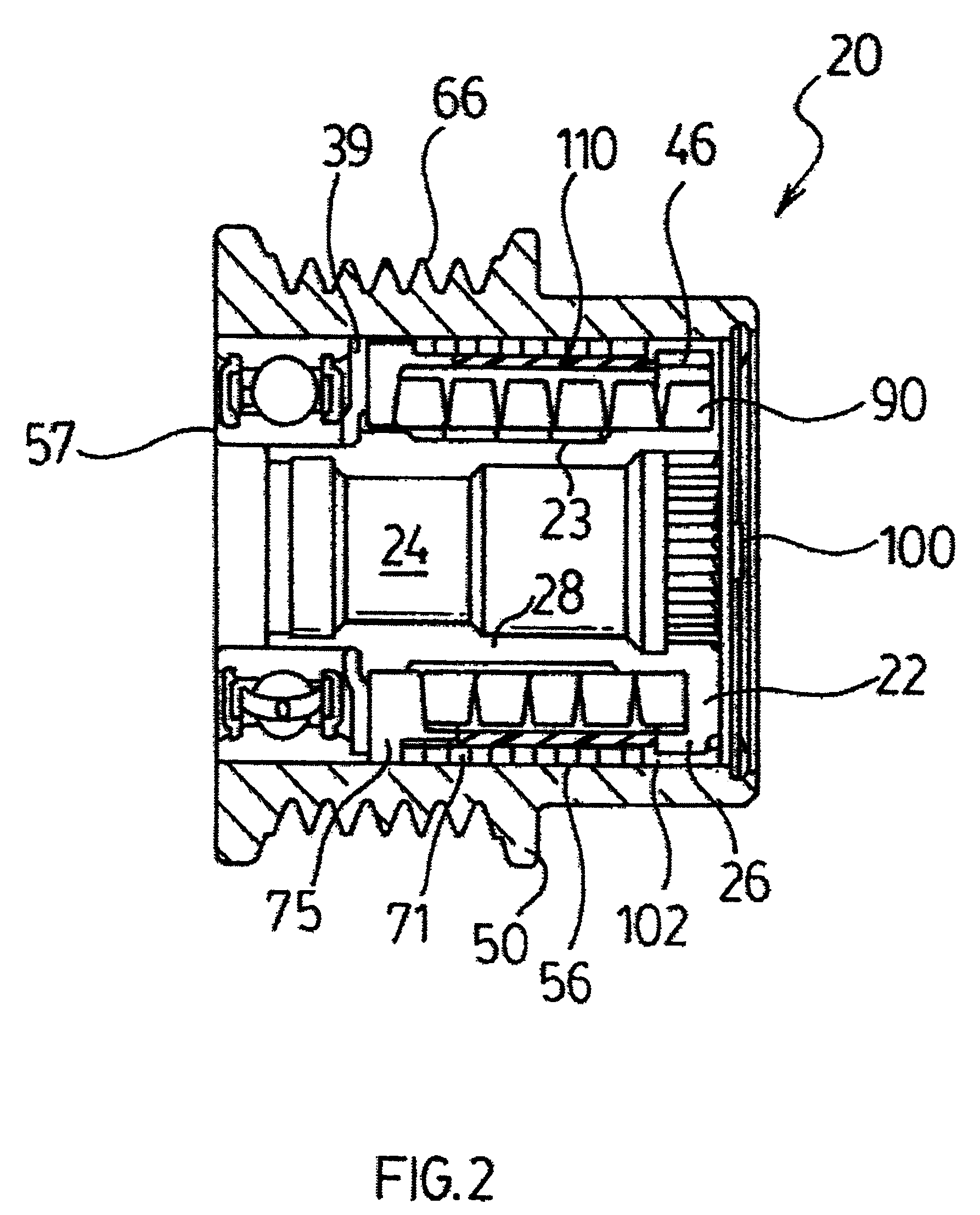

Overrunning radial coupling assembly and method for controlling the engagement of inner and outer members of the assembly

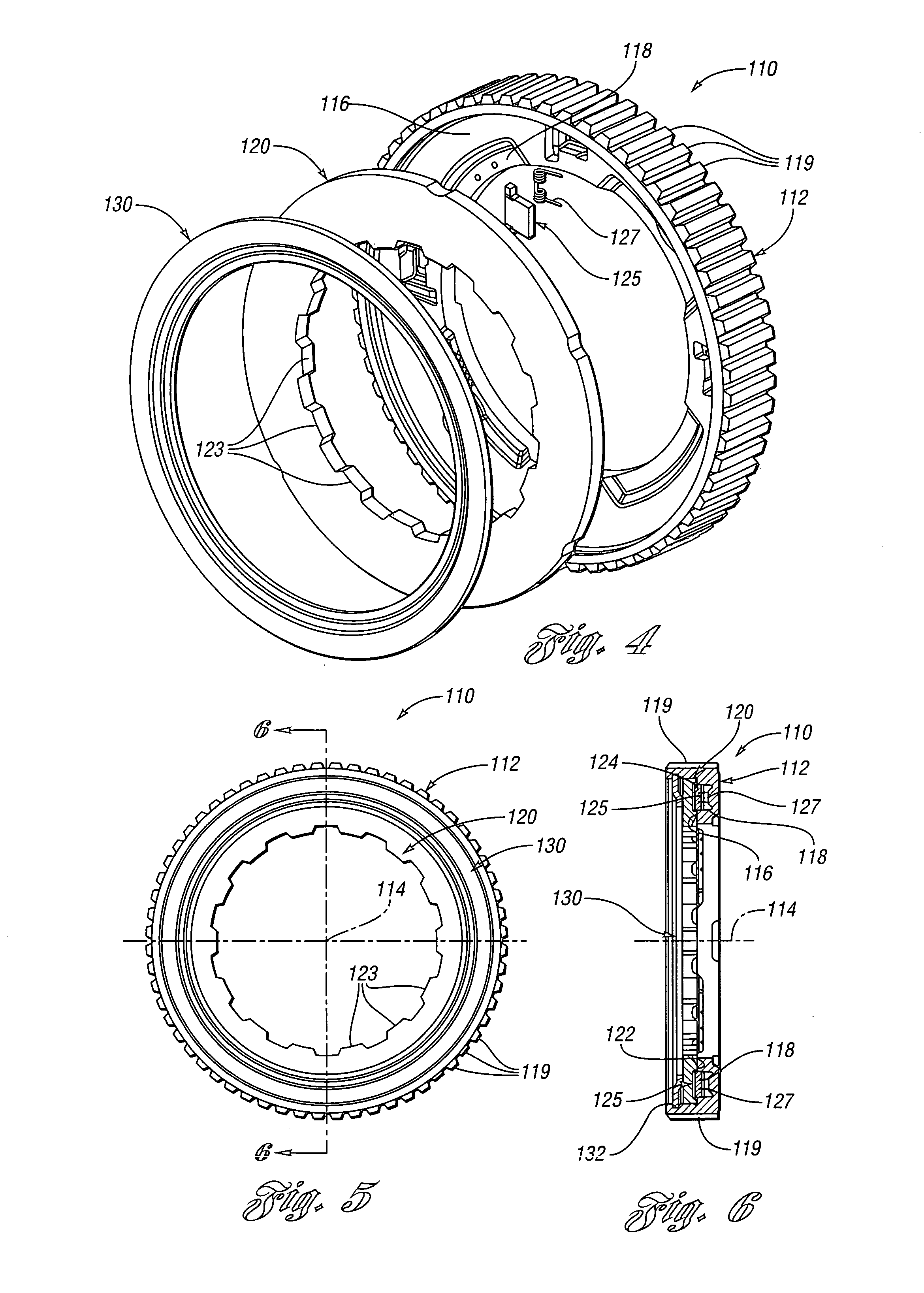

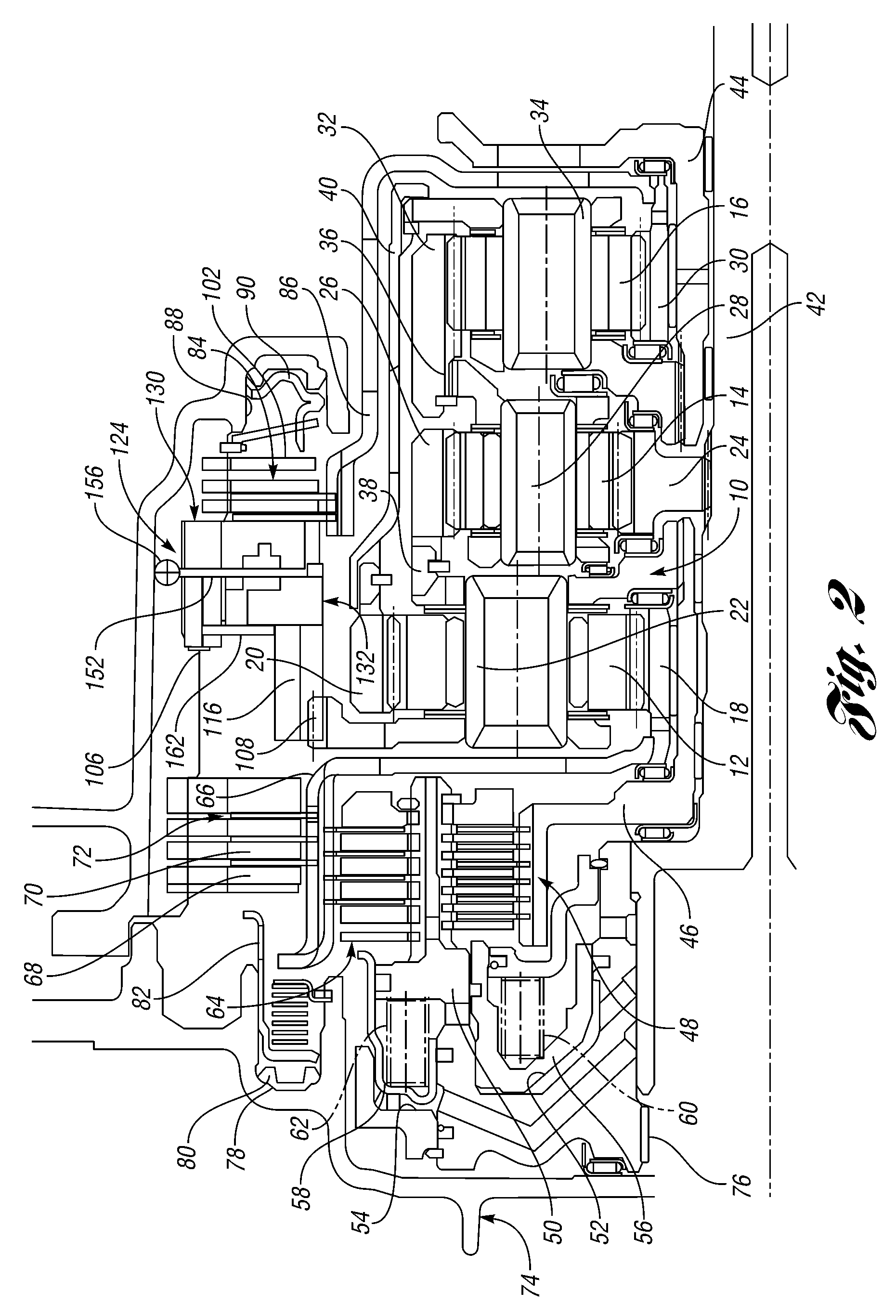

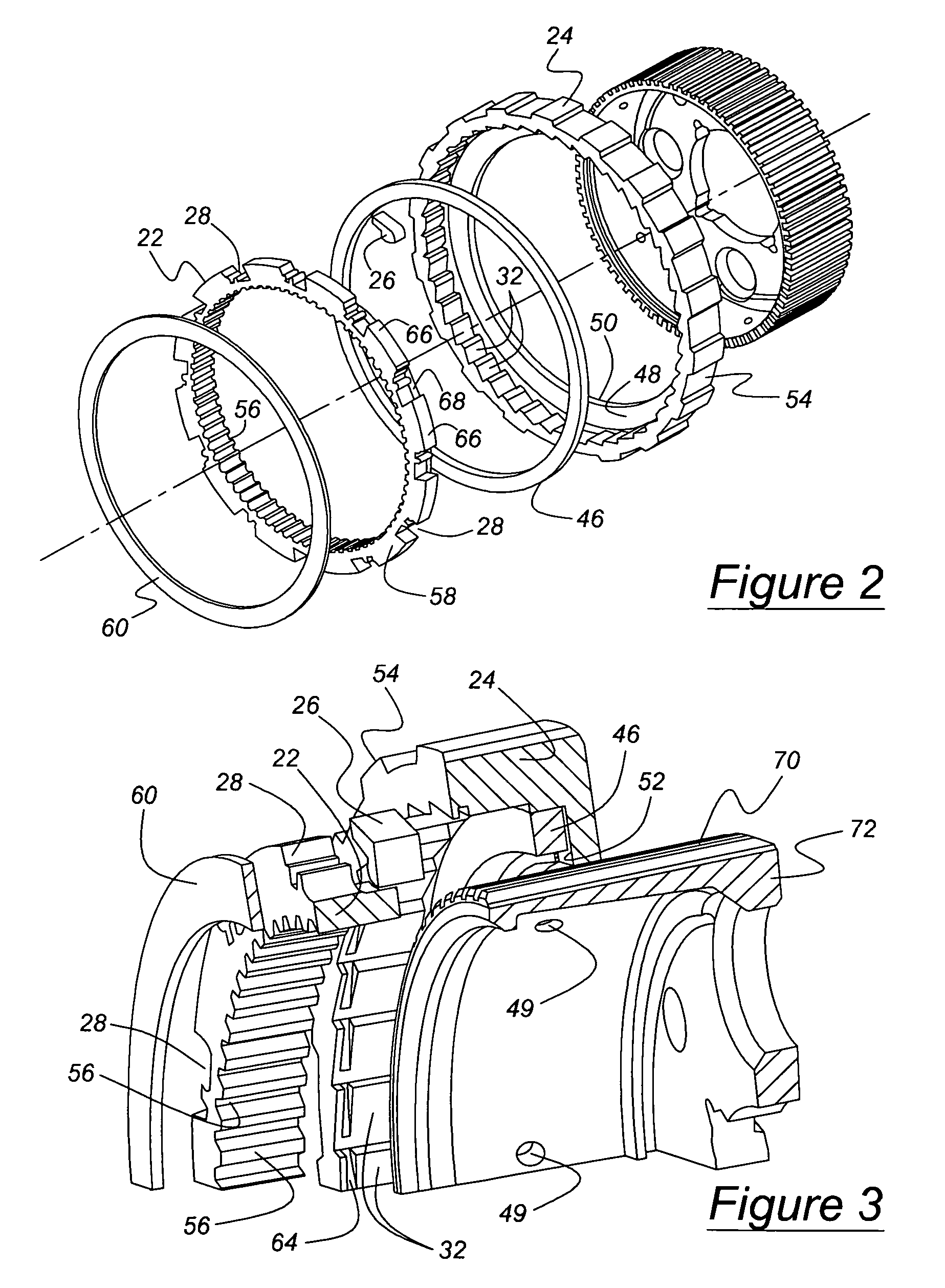

The overrunning radial coupling assembly or clutch and a method of controlling the engagement of inner and outer plates or members of the assembly are provided wherein adjacent engaging radial locking pawls are selectively controlled by a single, rotatable control plate or element to obtain full lock, one-way lock and one-way overrun conditions. The assembly includes free-floating, forward pawls and free-floating, reverse pawls adjacent to their respective forward pawls. The forward and reverse pawls are movable between a notch-engaging, engaged position (i.e., full lock condition) and a disengaged position in which the outer member is permitted to free-wheel relative to the inner member in the one-way overrun condition in one direction about a first axis and the outer member is locked to the inner member in the one-way lock condition in the opposite direction. A number of different embodiments of the assembly and method are provided.

Owner:MEANS IND INC

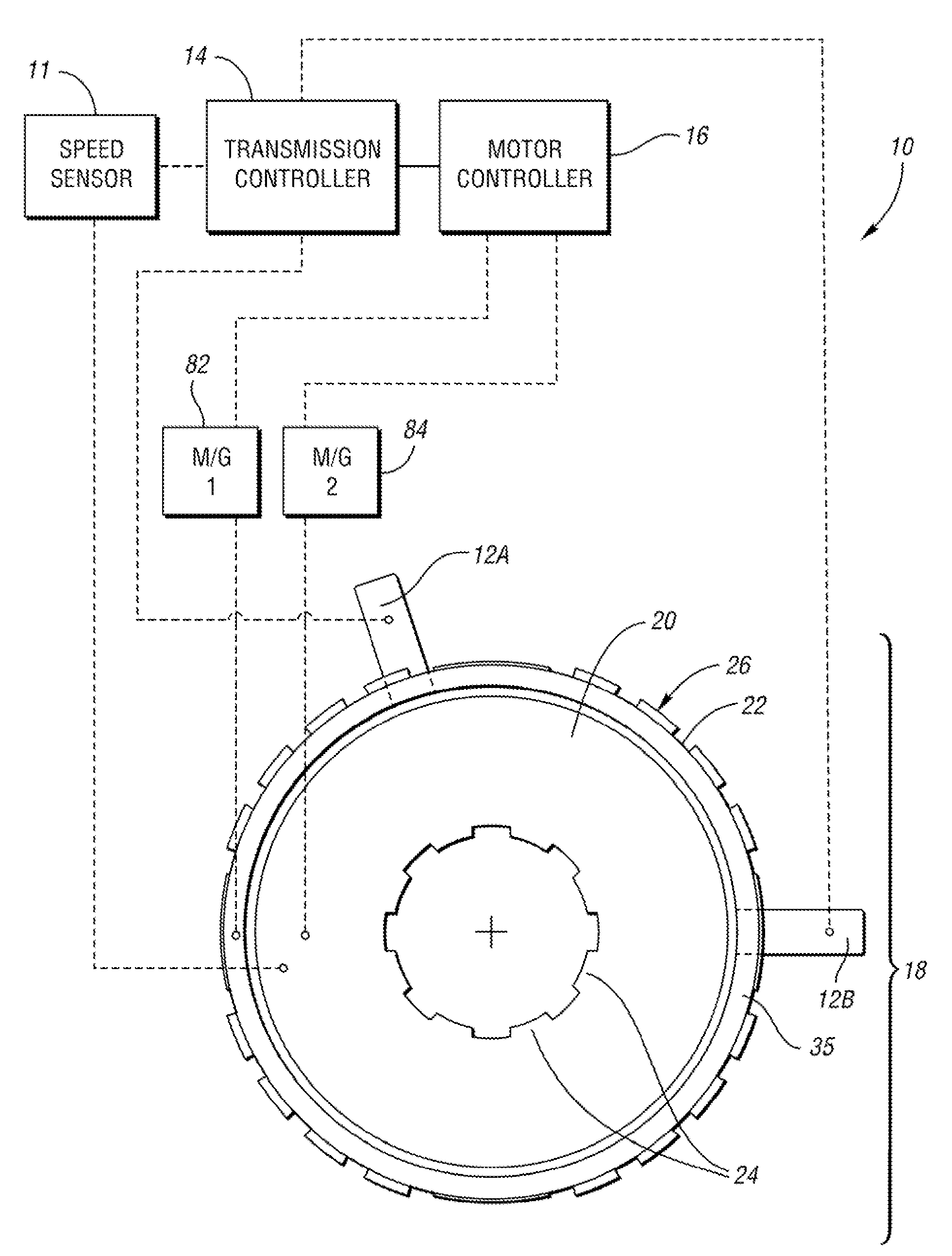

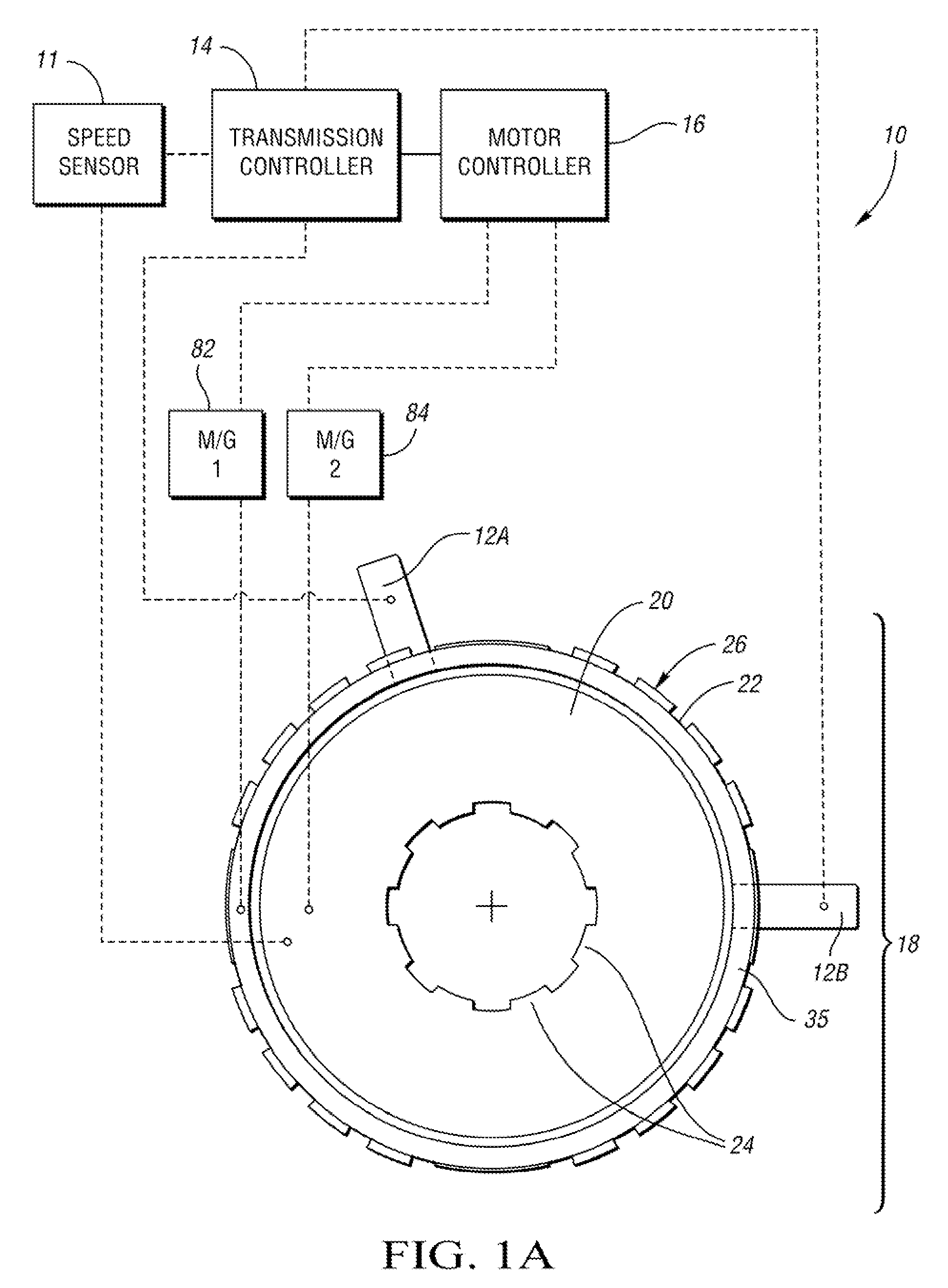

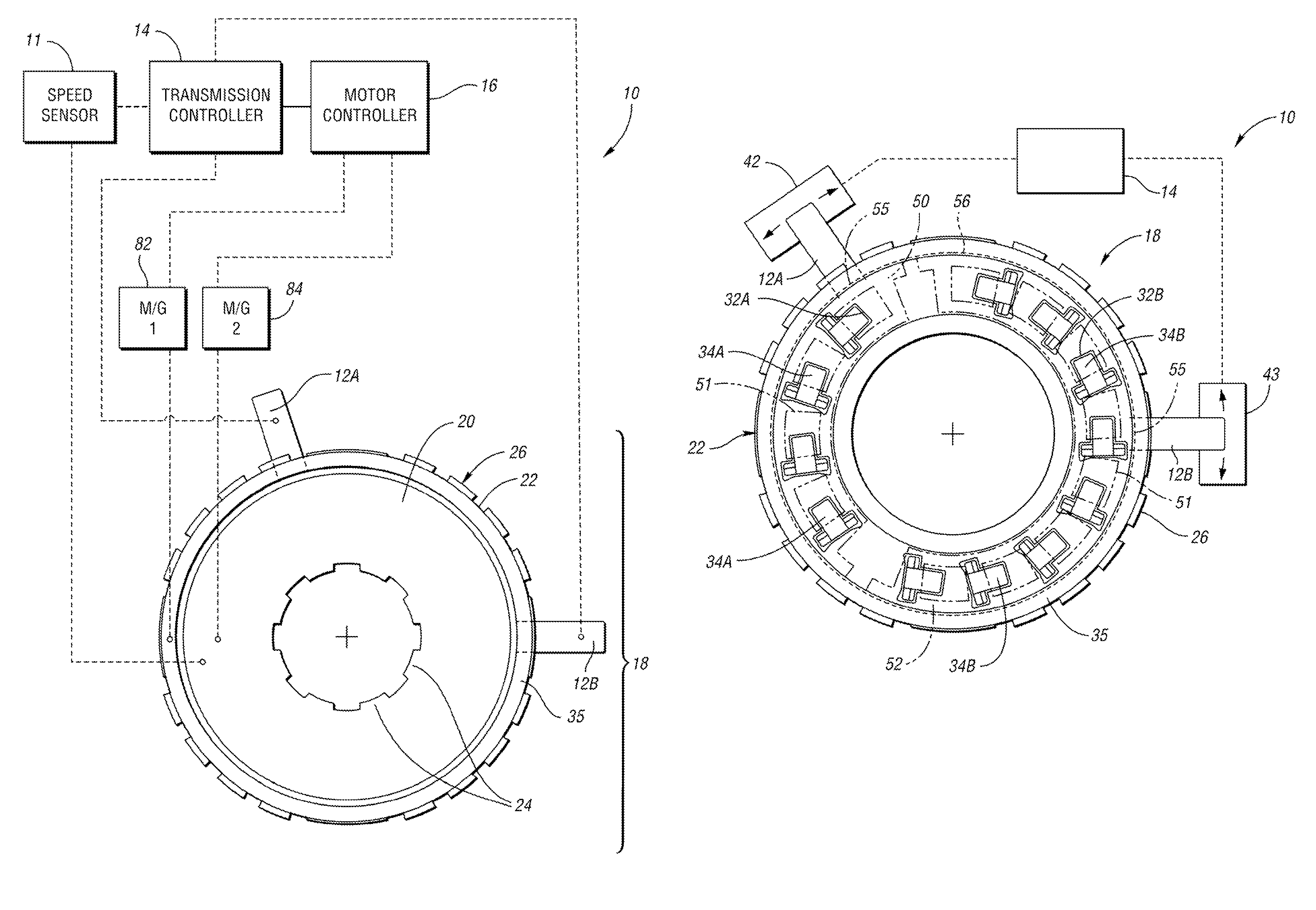

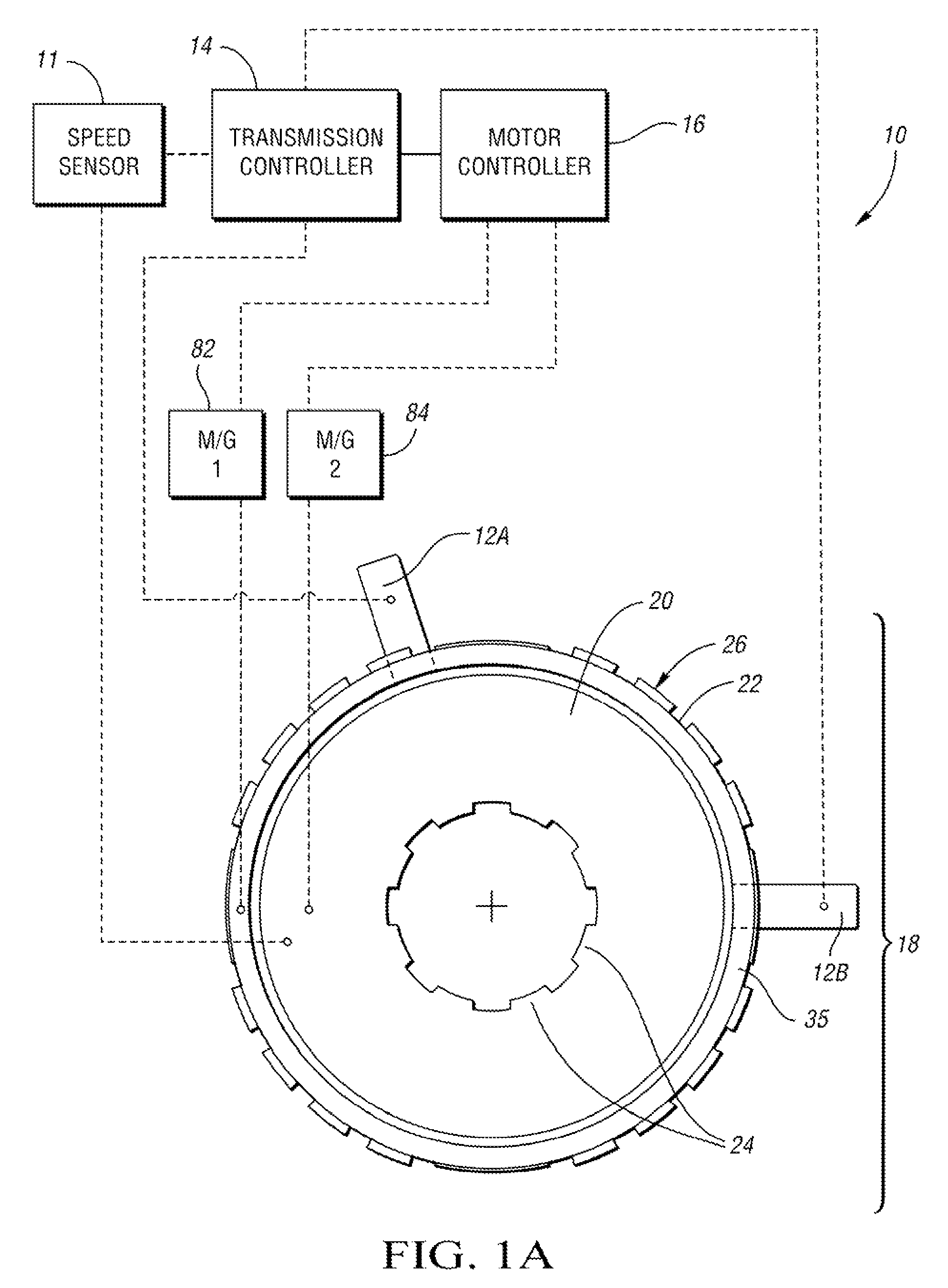

Selectable one-way clutch

A controllable selectable one-way clutch is provided for use within a hybrid transmission. The clutch comprises an outer and inner race, and a first and second selector plate. A transmission motor controller synchronizes the speeds of the races to facilitate application and release of the clutch, and a transmission controller communicates a signal to the clutch for re-positioning of the plates to apply and release the clutch. The clutch has three operational modes, including freewheeling and holding torque in one direction or both directions. A method is also provided for applying a selectable one-way clutch in a vehicle having a hybrid transmission with a motor controller and a transmission controller, including synchronizing the clutch speed using the motor controller, detecting the direction of the race speed difference, communicating the race speed difference to the transmission controller, and selecting between the clutch operational modes in response to the detected speed difference.

Owner:GM GLOBAL TECH OPERATIONS LLC

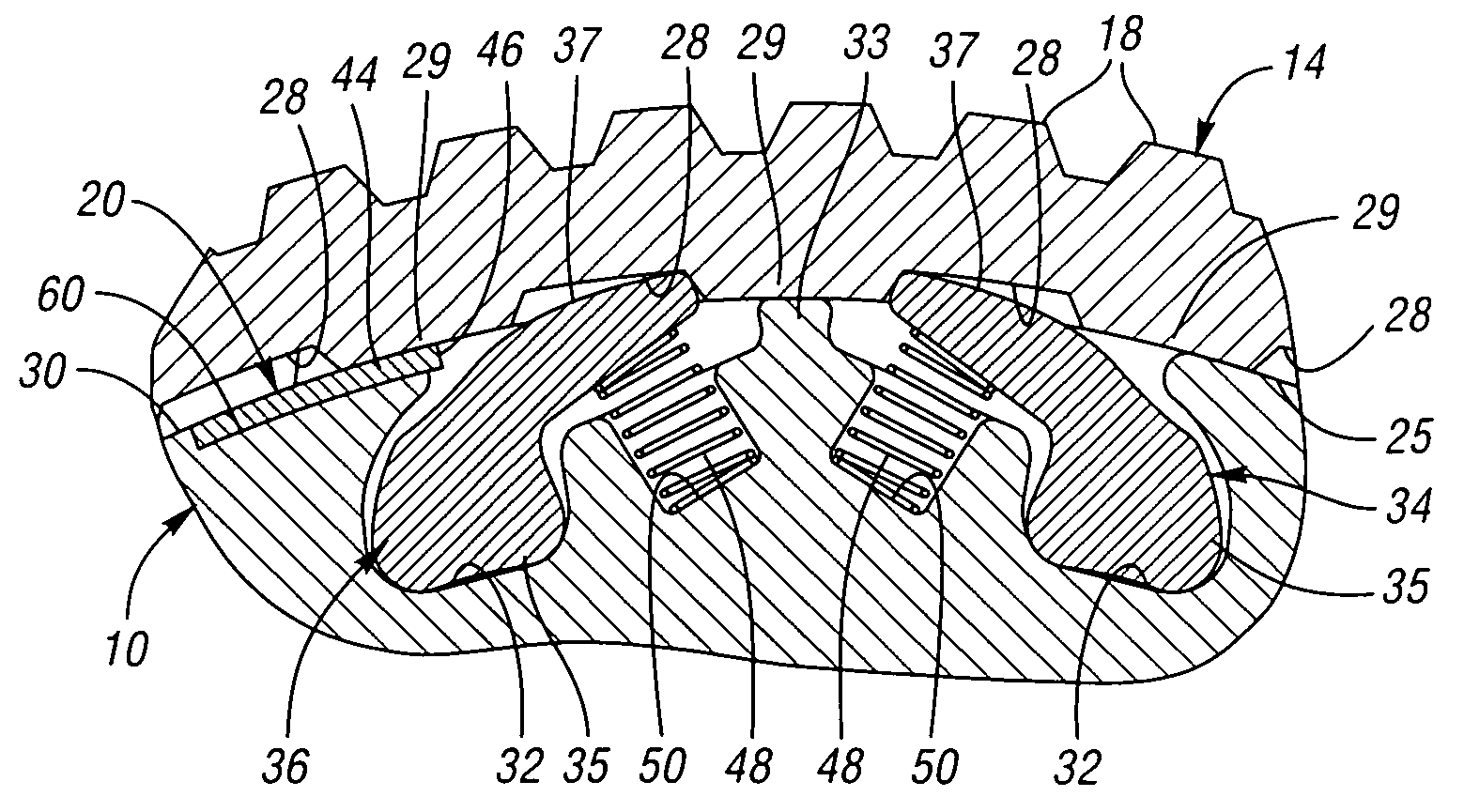

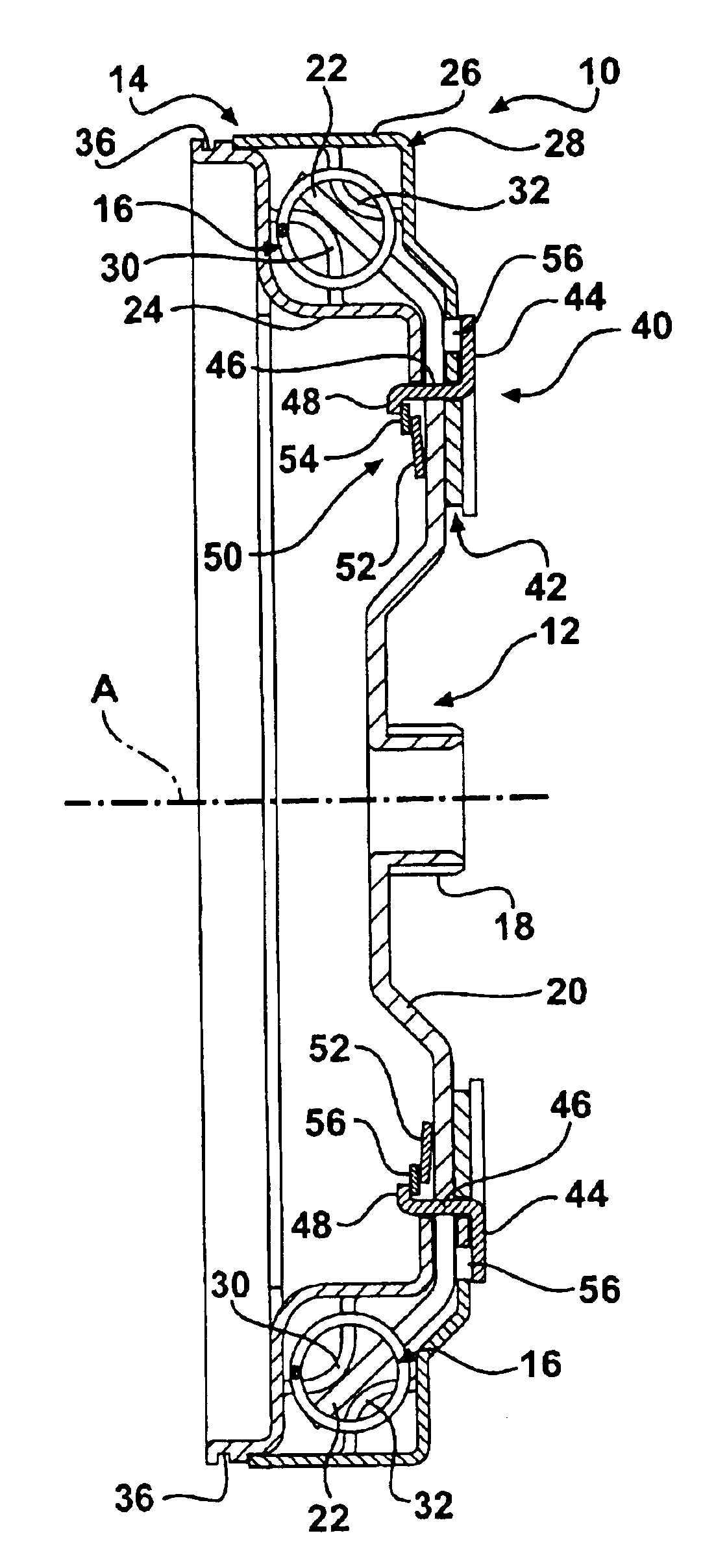

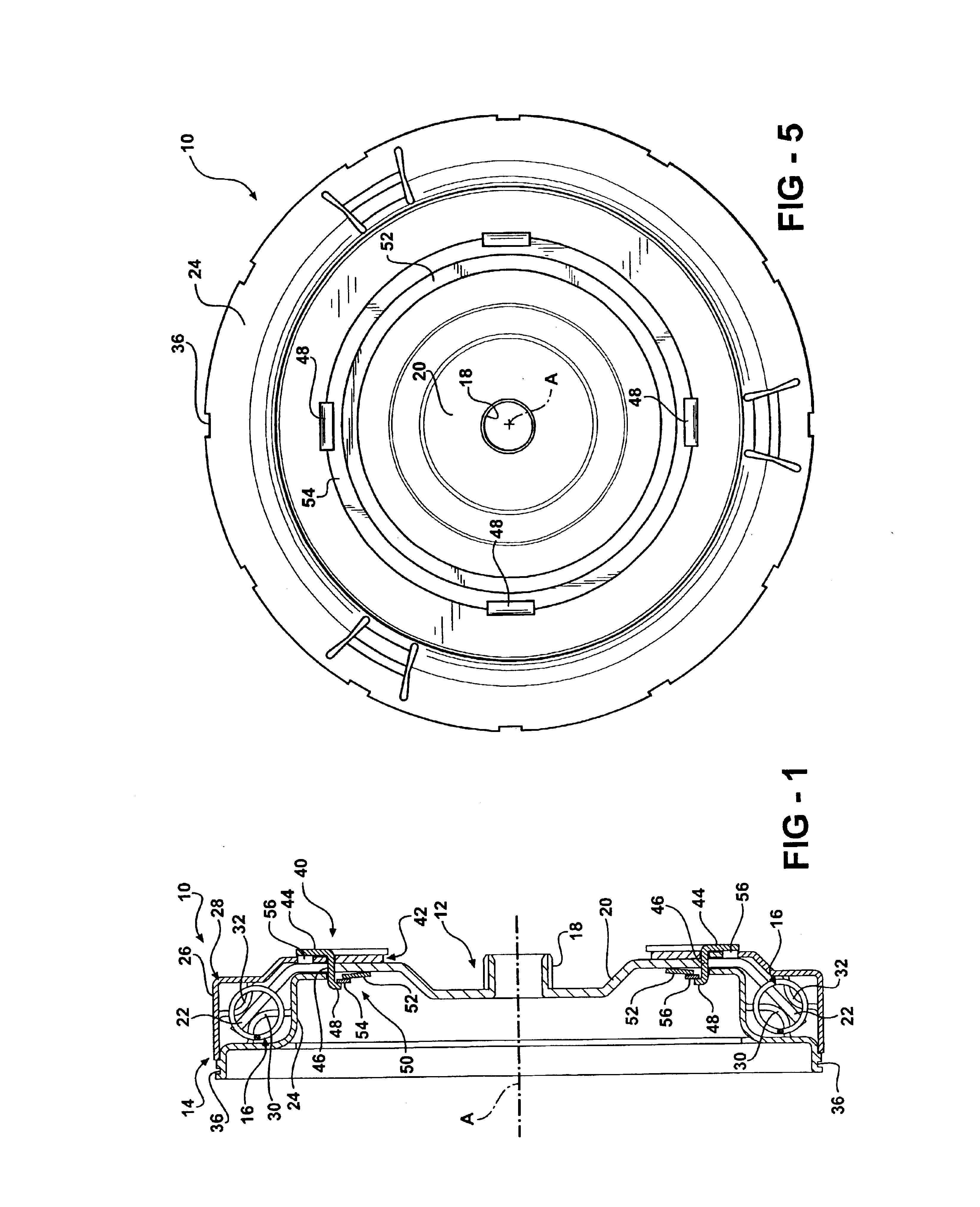

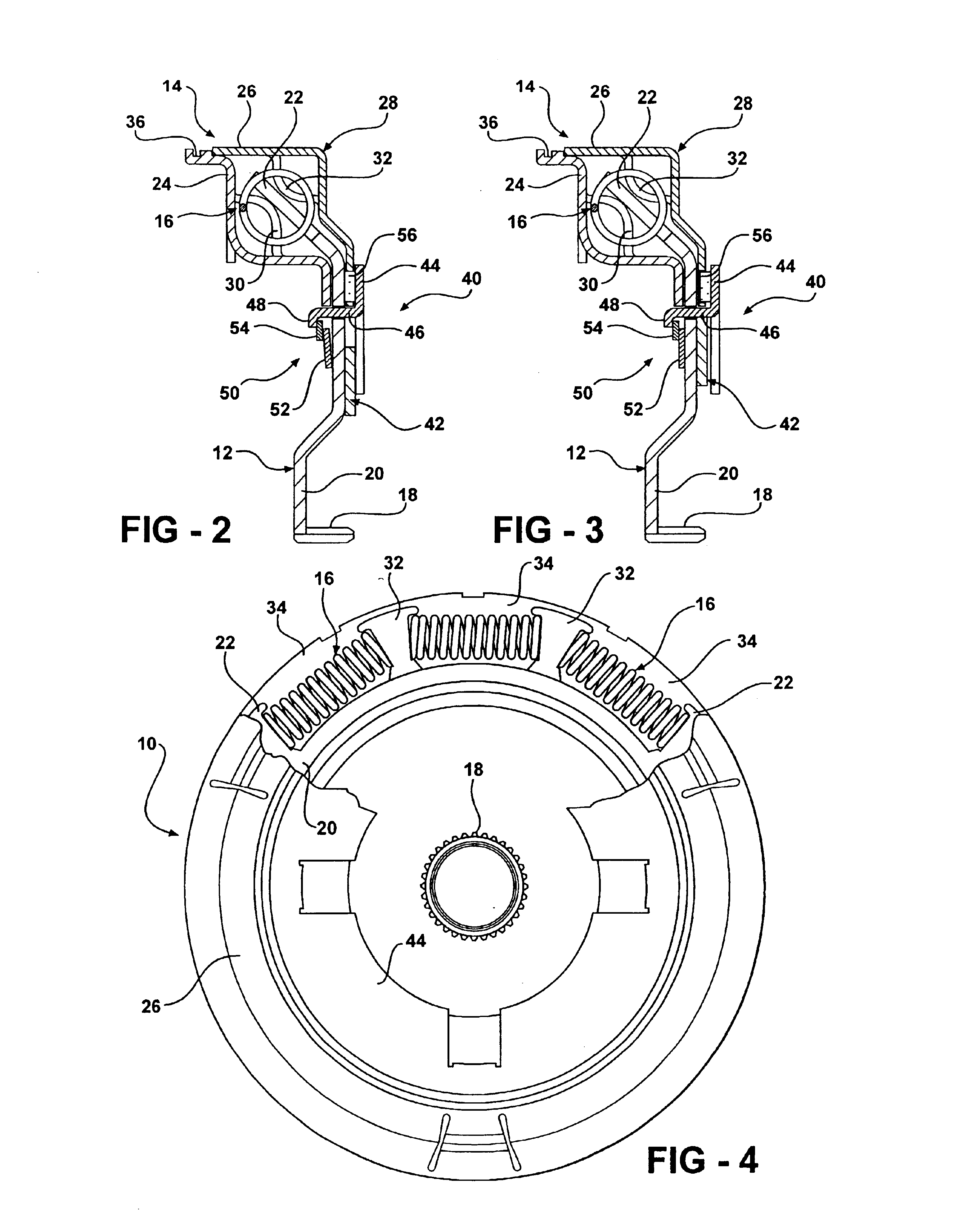

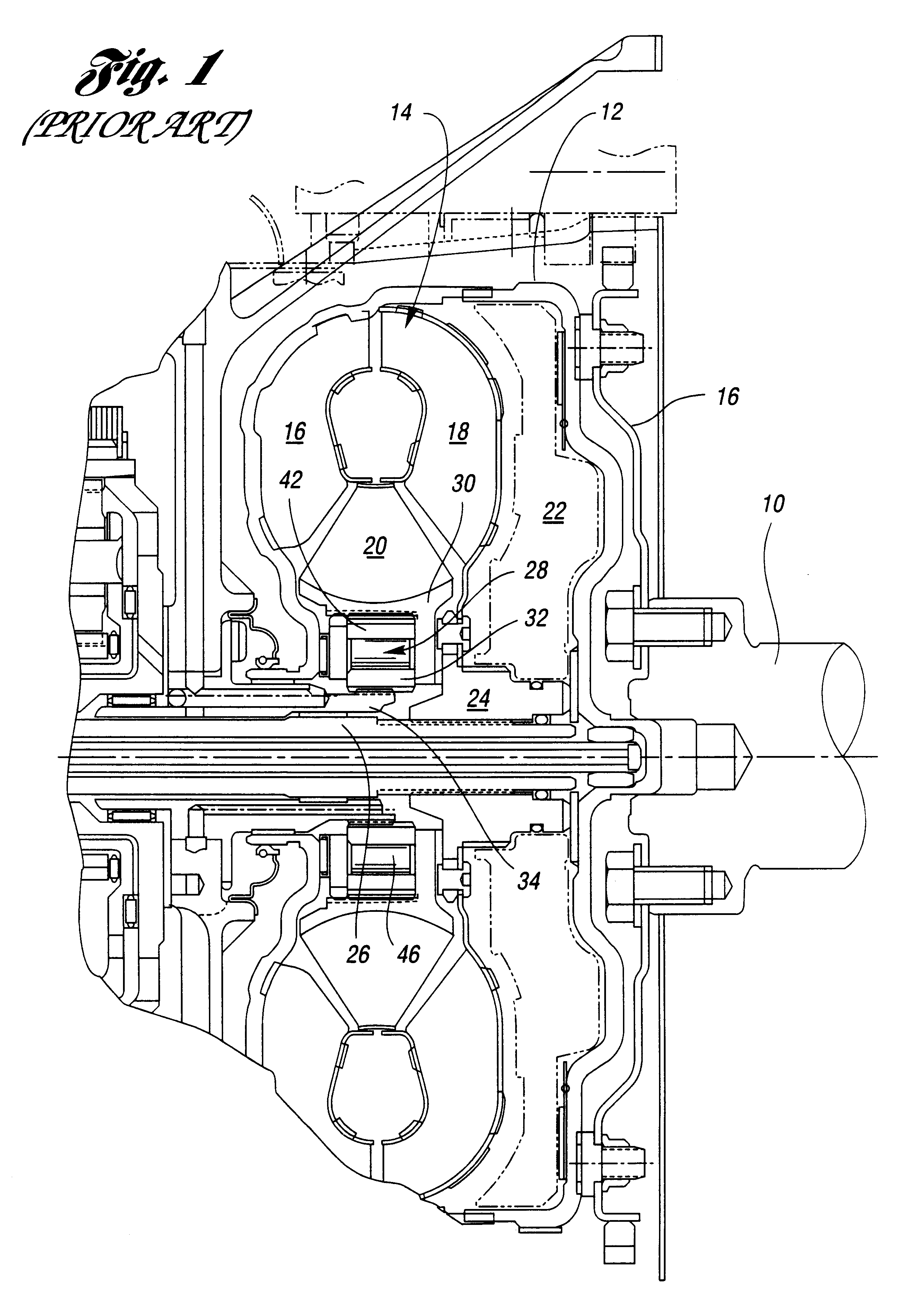

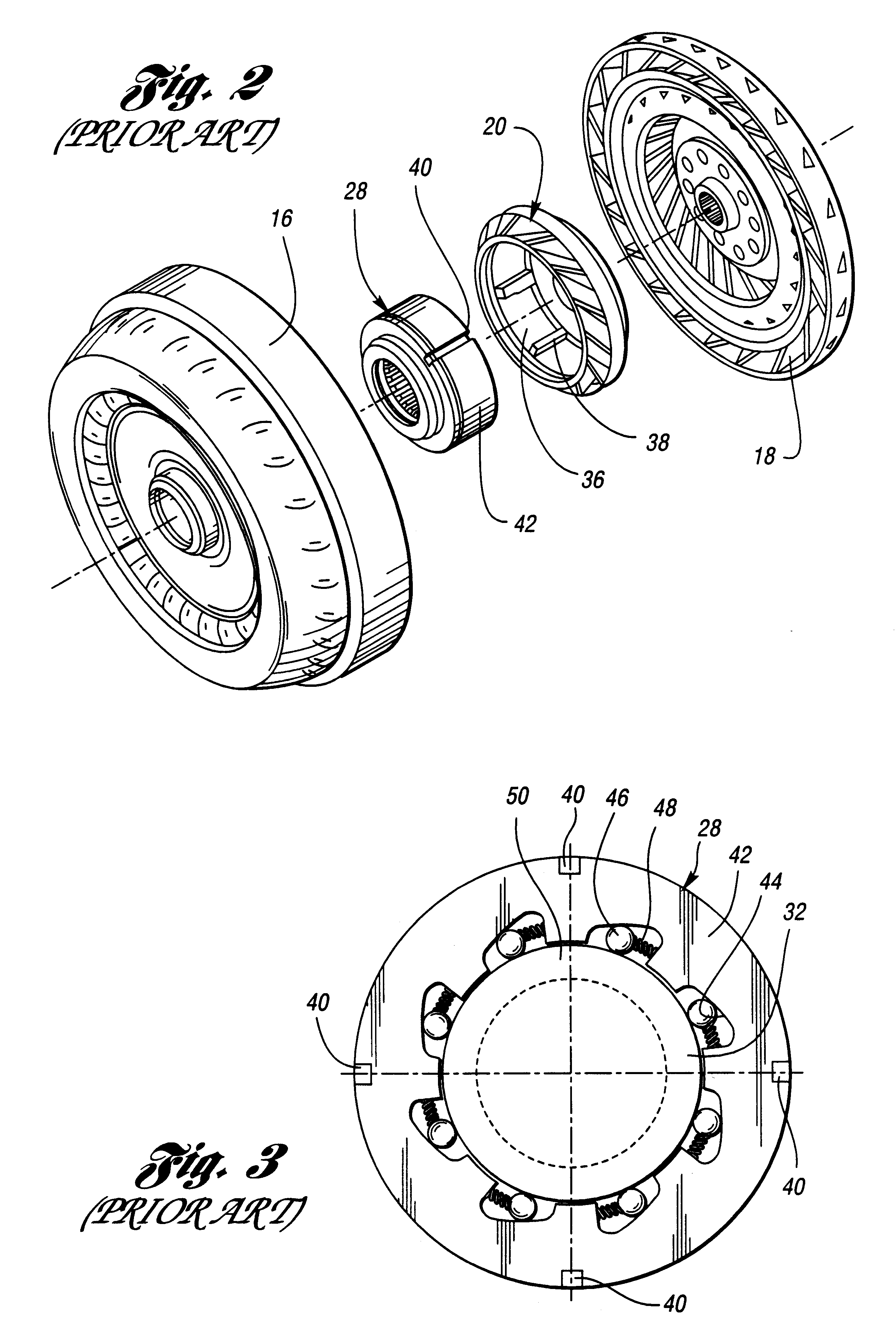

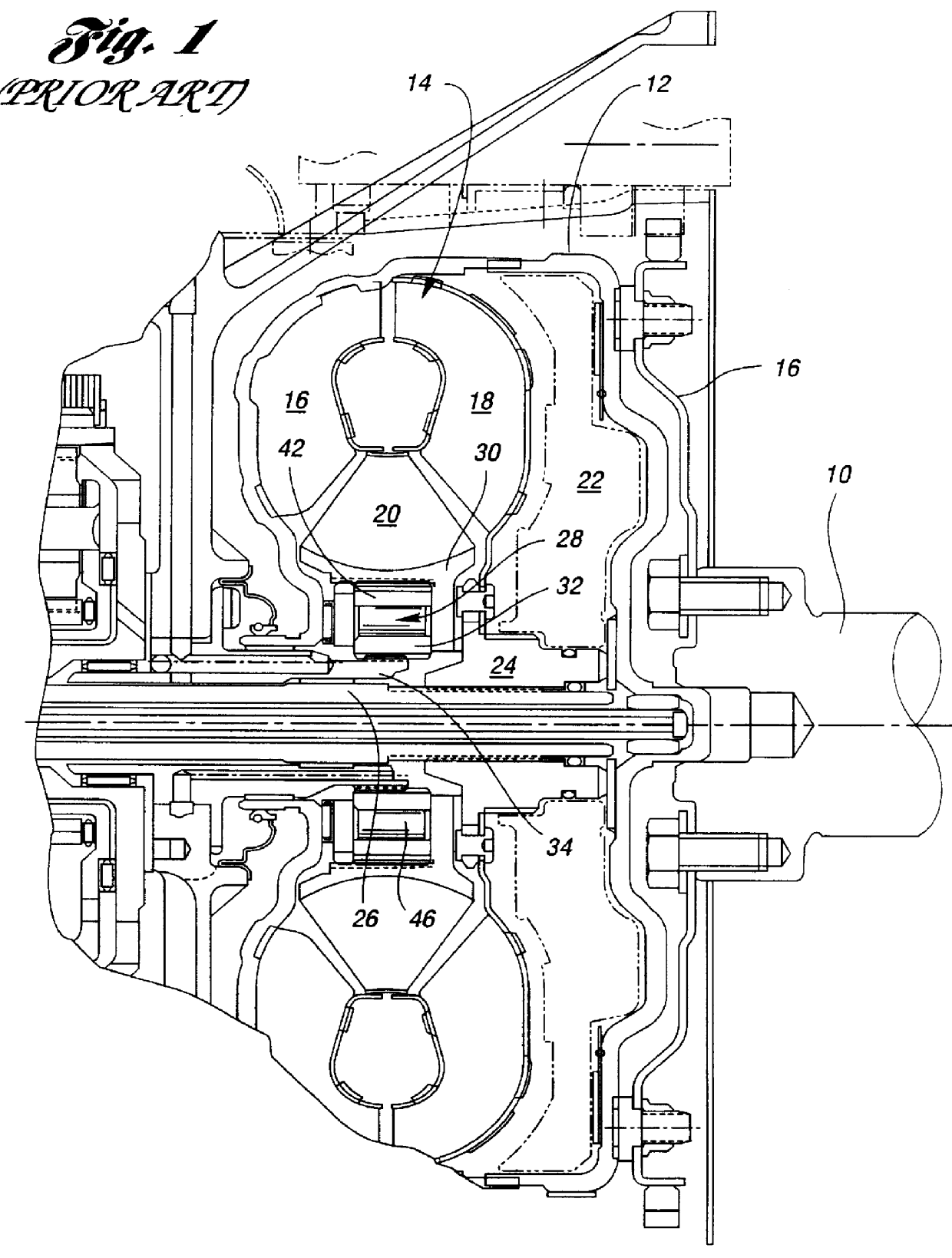

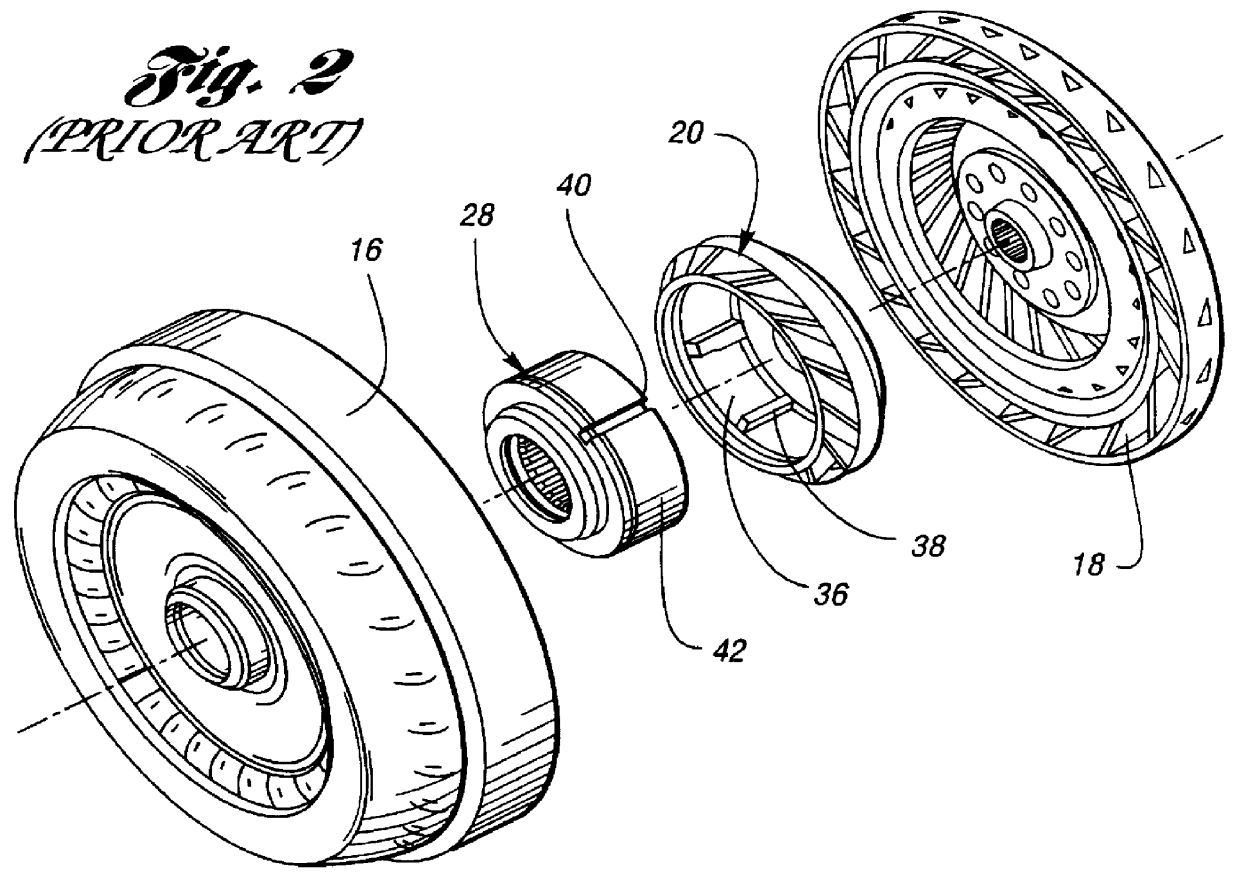

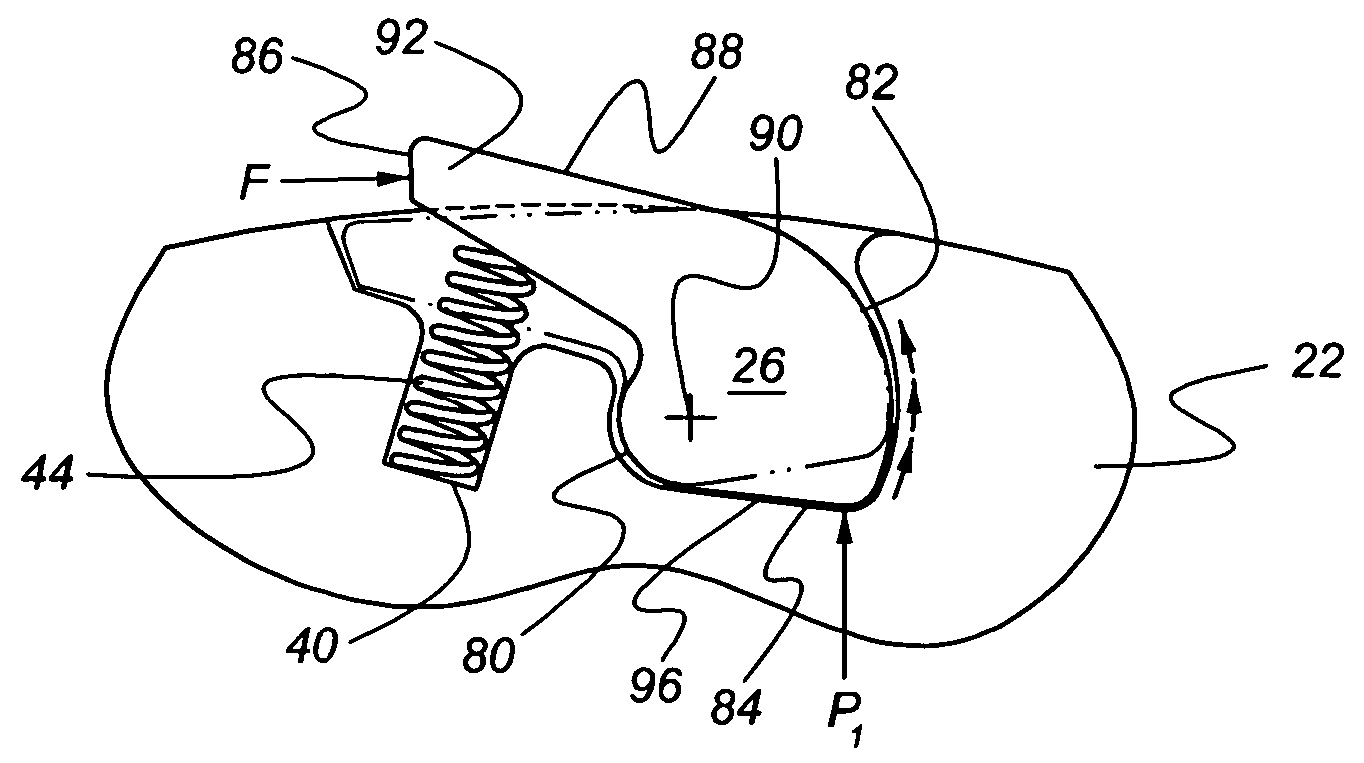

Torsional damper having variable bypass clutch with centrifugal release mechanism

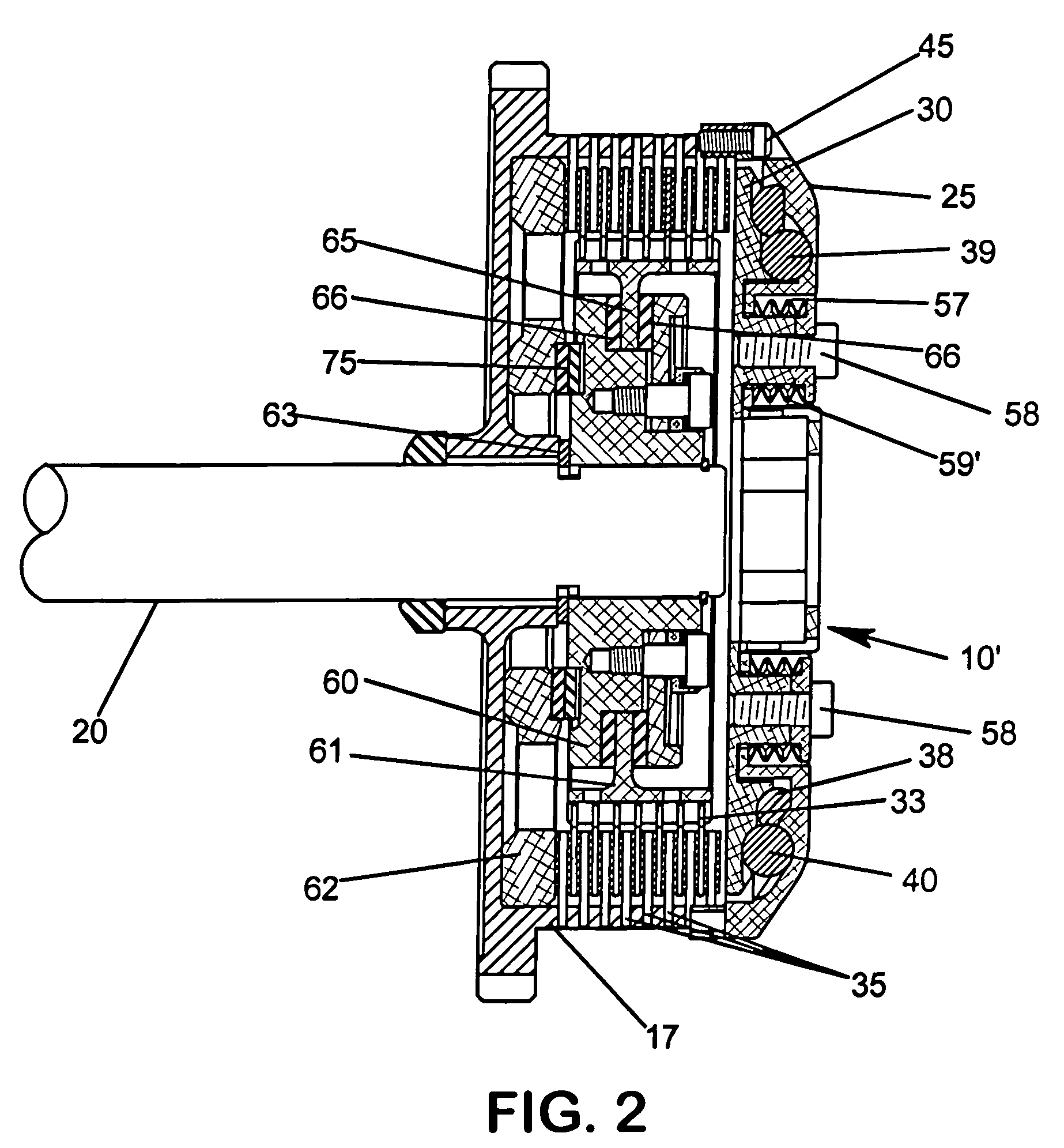

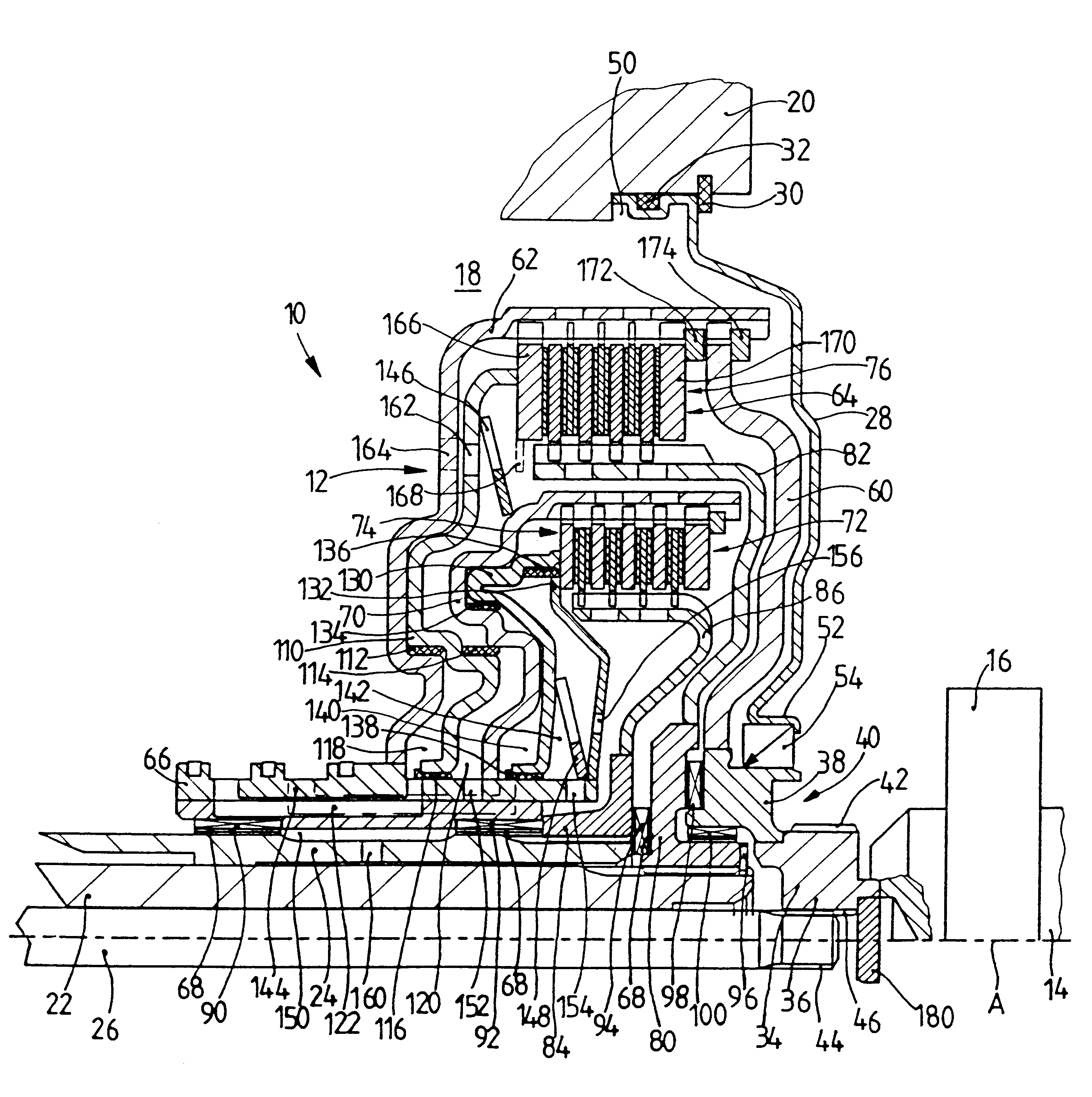

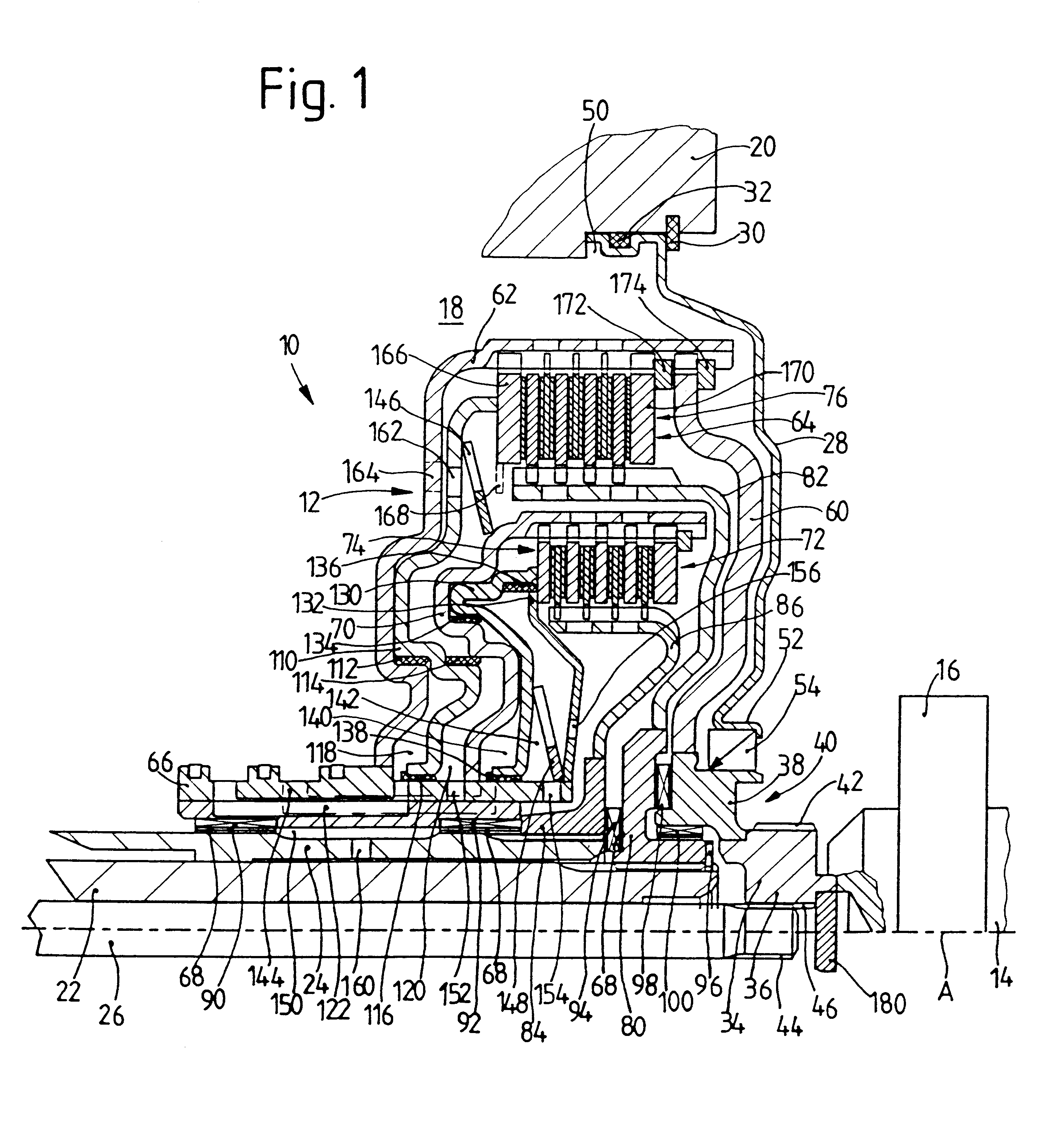

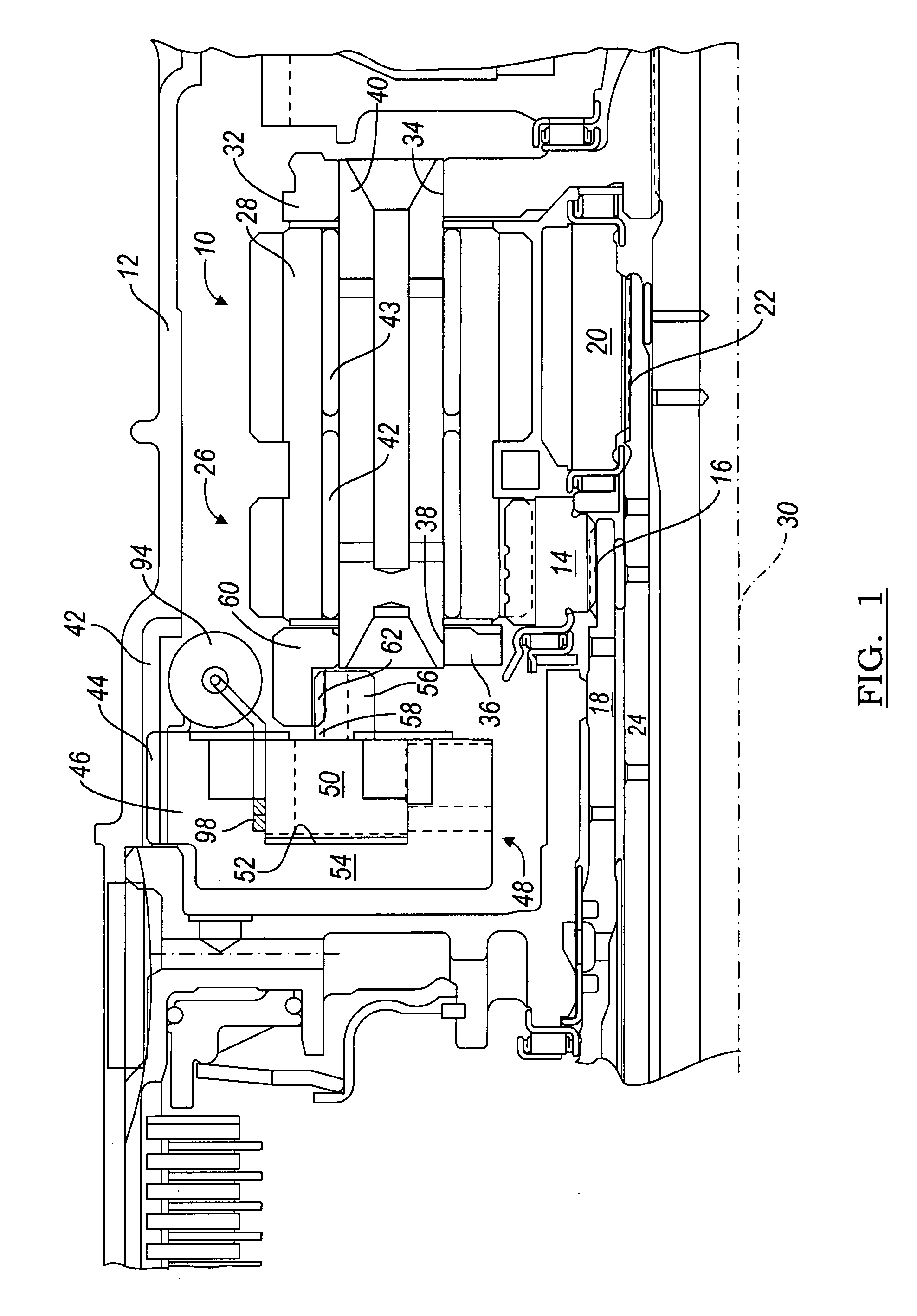

InactiveUS6854580B2Restraint torsionReduce torqueYielding couplingRotary clutchesCentrifugal forceControl theory

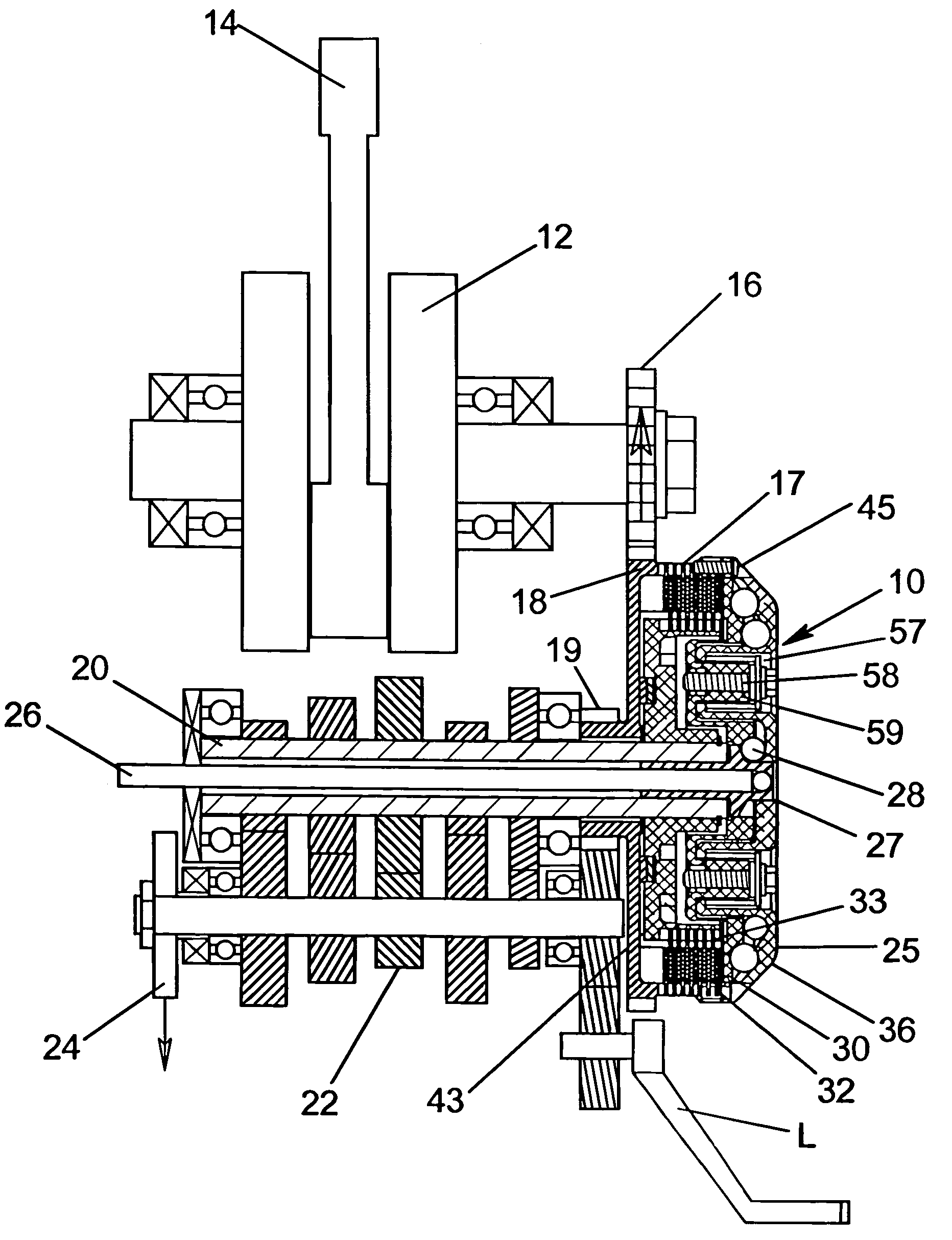

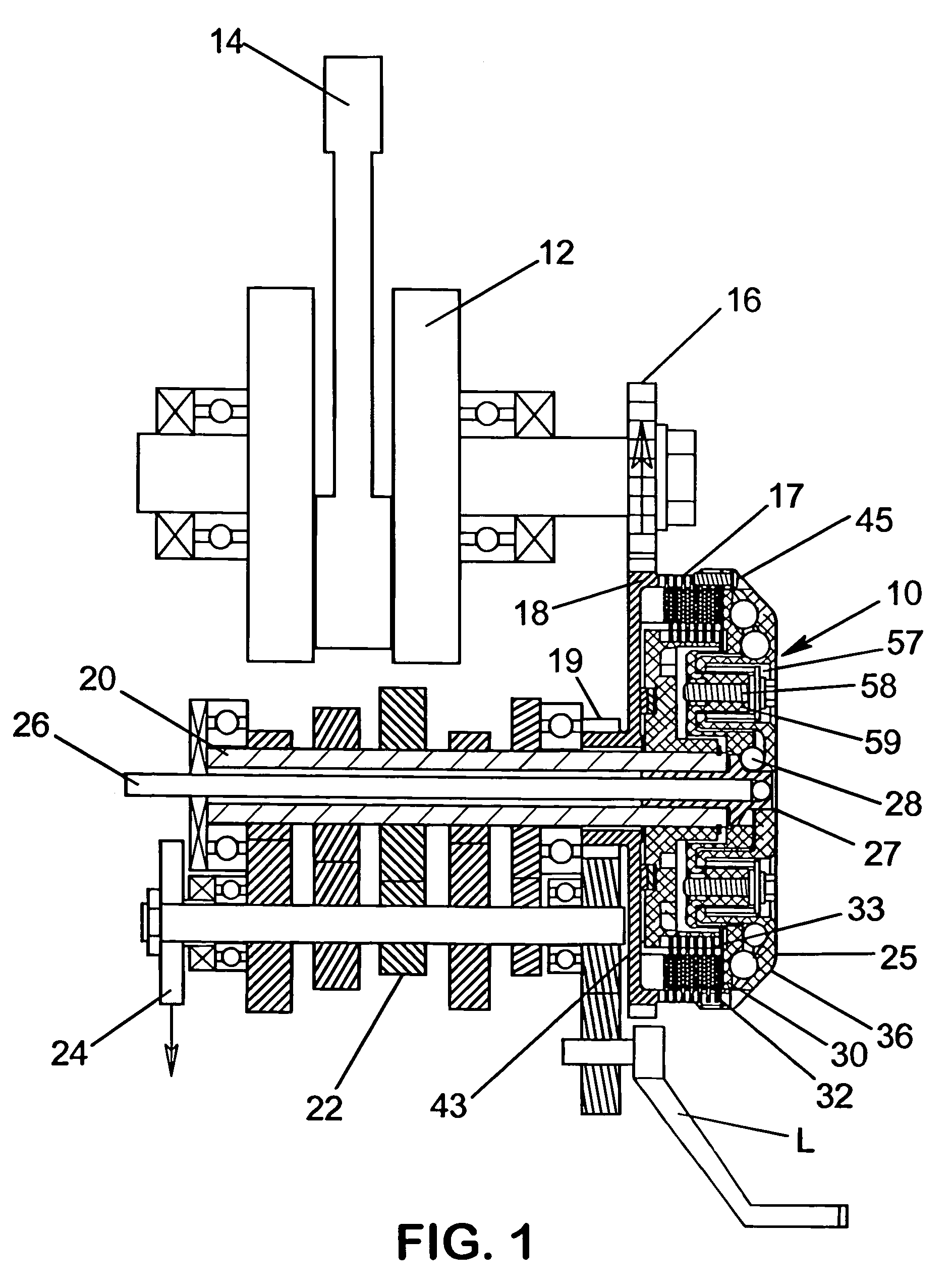

A torsional damper (10) rotatably supported for translating torque between a prime mover and the input of a transmission including a torque input member (12) that is operatively connected for rotation with the power take-off of a prime mover, an output member (14) operatively connected for rotation with the input to a transmission and a plurality of damping elements (16) interposed between the input member and the output member. The damping members (16) act to translate torque between the input and output members and to dampen torsional forces generated between the prime mover and the transmission. A bypass clutch (40) acts to translate torque directly between the input and output members thereby providing a path for partial torque translation that bypasses the damping elements at low rotational speeds of the input and output members. In addition, the torsional damper (10) includes a clutch release mechanism (42) that is responsive to centrifugal forces acting on the torsional damper to disengage the bypass clutch (40) to reduce the torque translated directly between the input and output members at high rotational speeds.

Owner:BORGWARNER INC

Series drive clutch

InactiveUS6846257B2Prevent rotationPlural diverse prime-mover propulsion mountingFluid clutchesCombustionEngineering

A clutch mechanism is disclosed for use with a hybrid electric vehicle wherein the electric motor-generator and engine are arranged in a series configuration. The clutch mechanism is positioned between and in communication with the electric motor-generator and engine to allow for either direct drive or a predetermined gear ratio between the electric motor-generator and engine. The electric motor-generator is preferably an integrated electric motor and generator. The engine is preferably a combustion engine.

Owner:NTN CORP

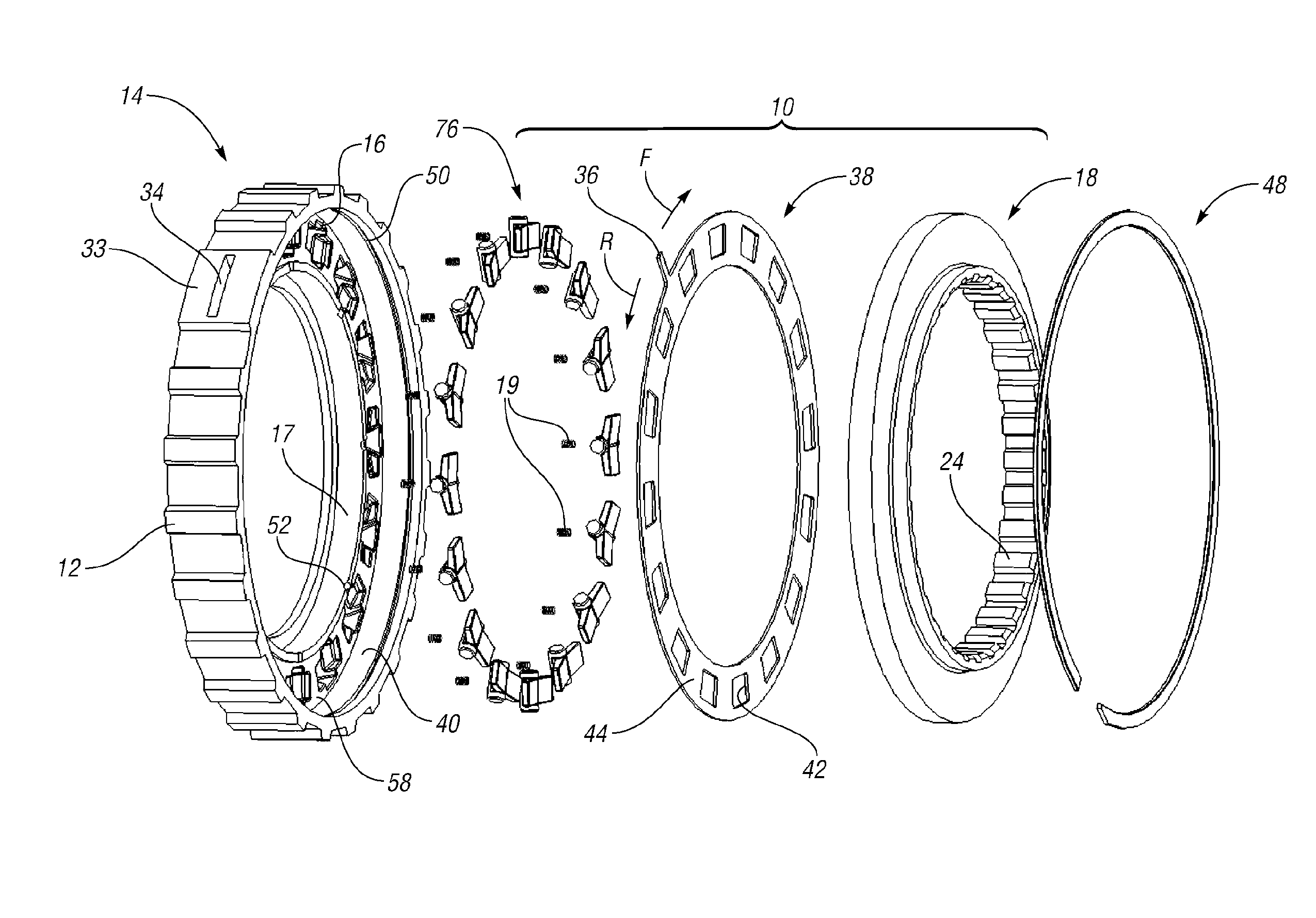

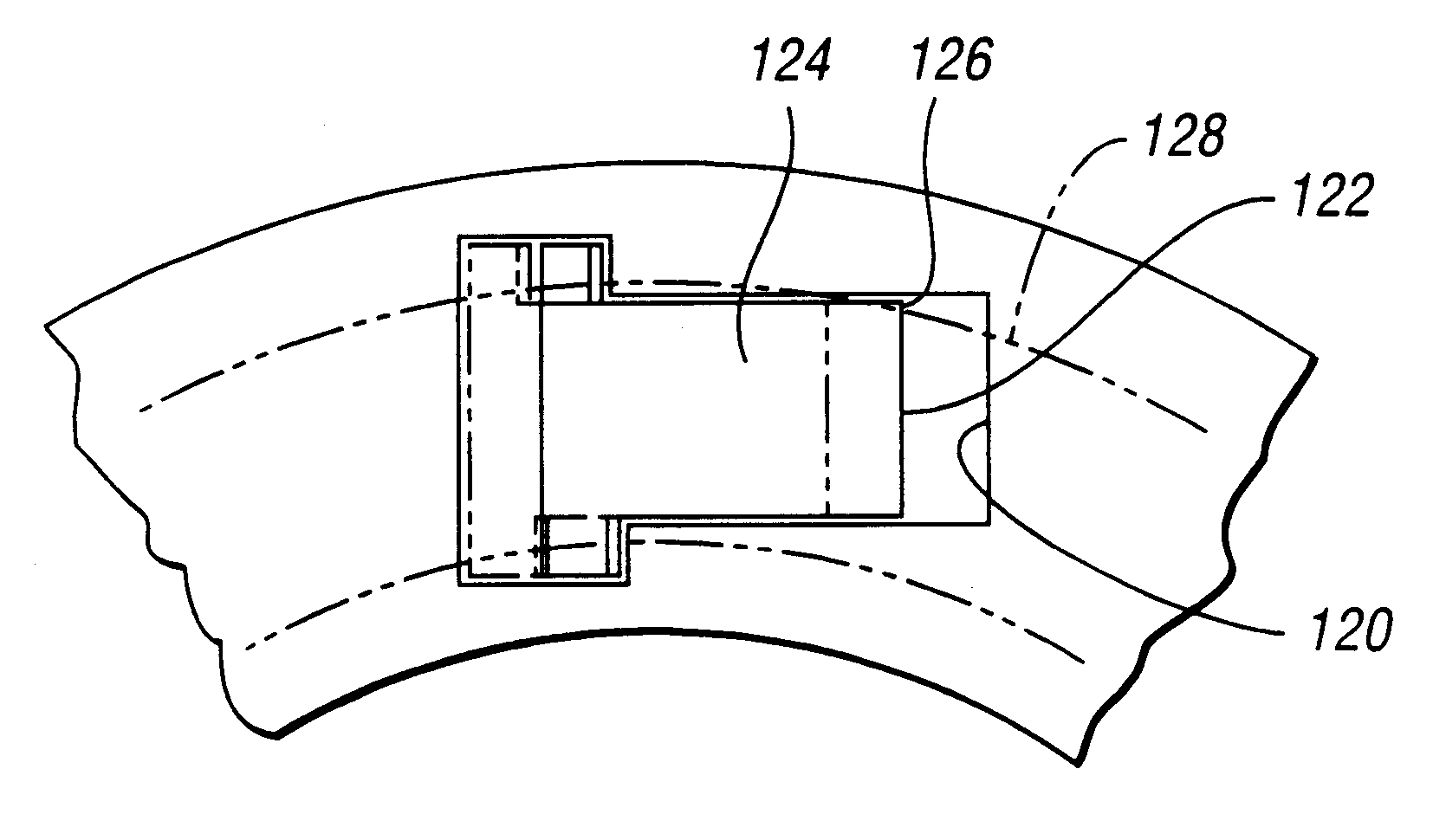

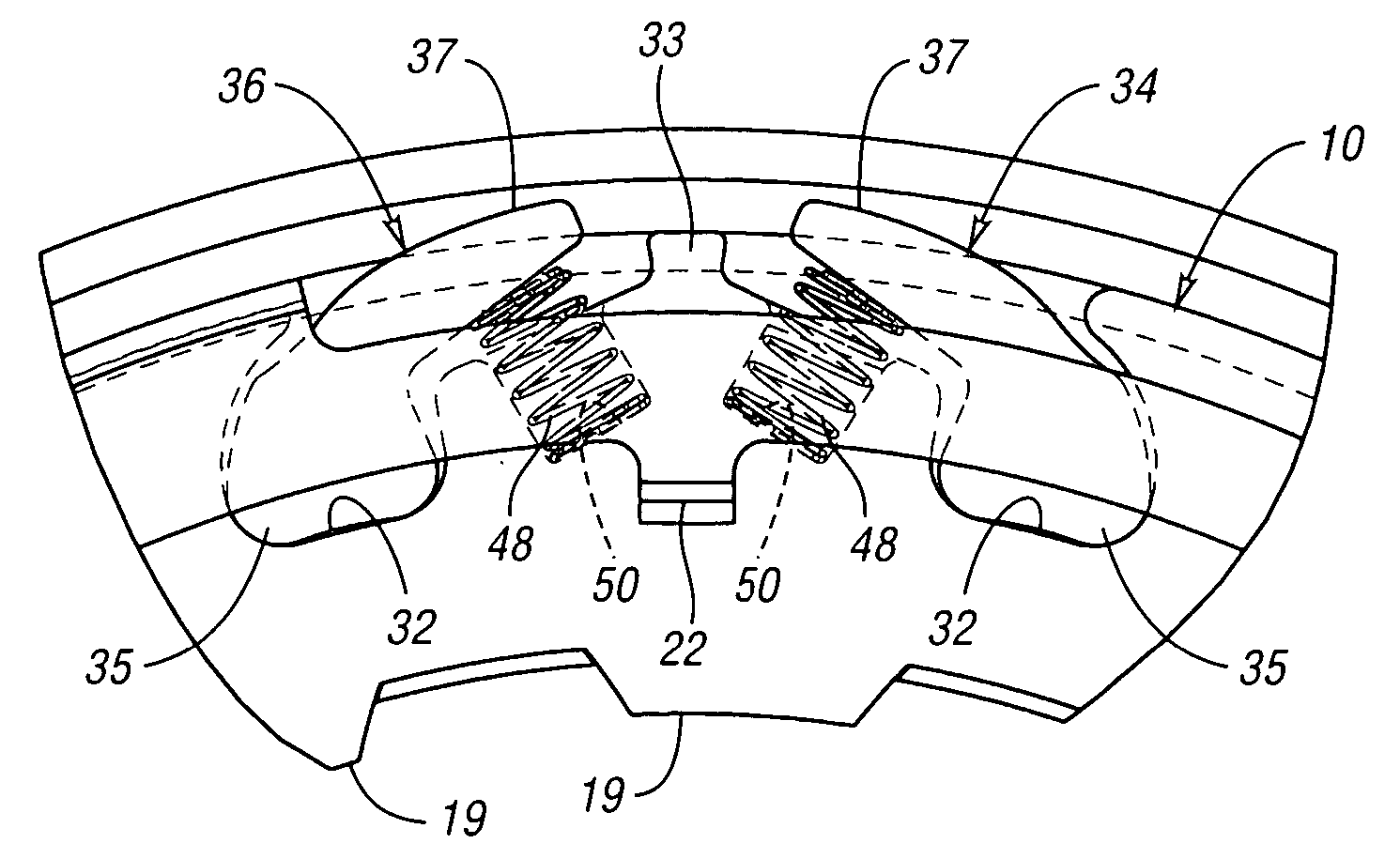

Selectable One-Way Clutch with Symmetrical Struts

ActiveUS20080169165A1Prevent rotationReduce bending stressFriction clutchesInterengaging clutchesControl theoryClutch

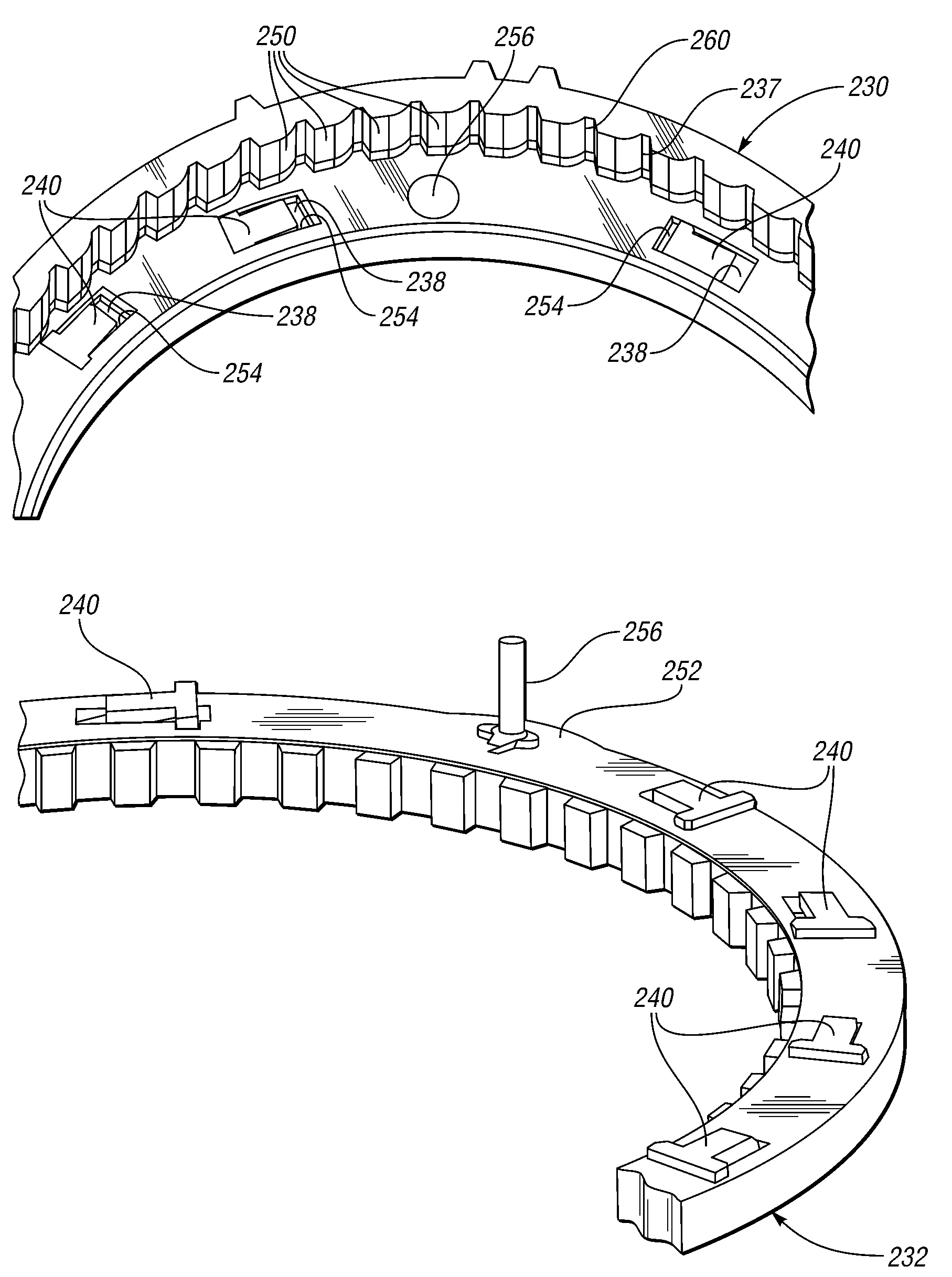

A selectable one-way clutch (SOWC) is provided for use with a vehicle transmission, and has a first race with a plurality of strut pockets, a moveable selector plate, symmetrical torque-holding elements or struts, and a second race that is rotatably engageable with a torque input device. The selector plate has a plurality of windows, and the struts selectively prevent rotation of the second race in either rotational direction depending on the position of the selector plate. The struts have a cylindrical portion and a pair of strut wings each having a free end. The strut wings connect to the cylindrical portion, and a different one of the free ends engages a strut pocket when an opposite strut wing is depressed in order to prevent rotation of the second race.

Owner:GM GLOBAL TECH OPERATIONS LLC

Centrifugal clutch and cover mount assembly therefor

InactiveUS7140480B2Withstand high pressureEasy to assembleMechanical actuated clutchesChain/belt transmissionCamCentrifugal clutch

Owner:DRUSSELL WILFLEY DESIGN LLC

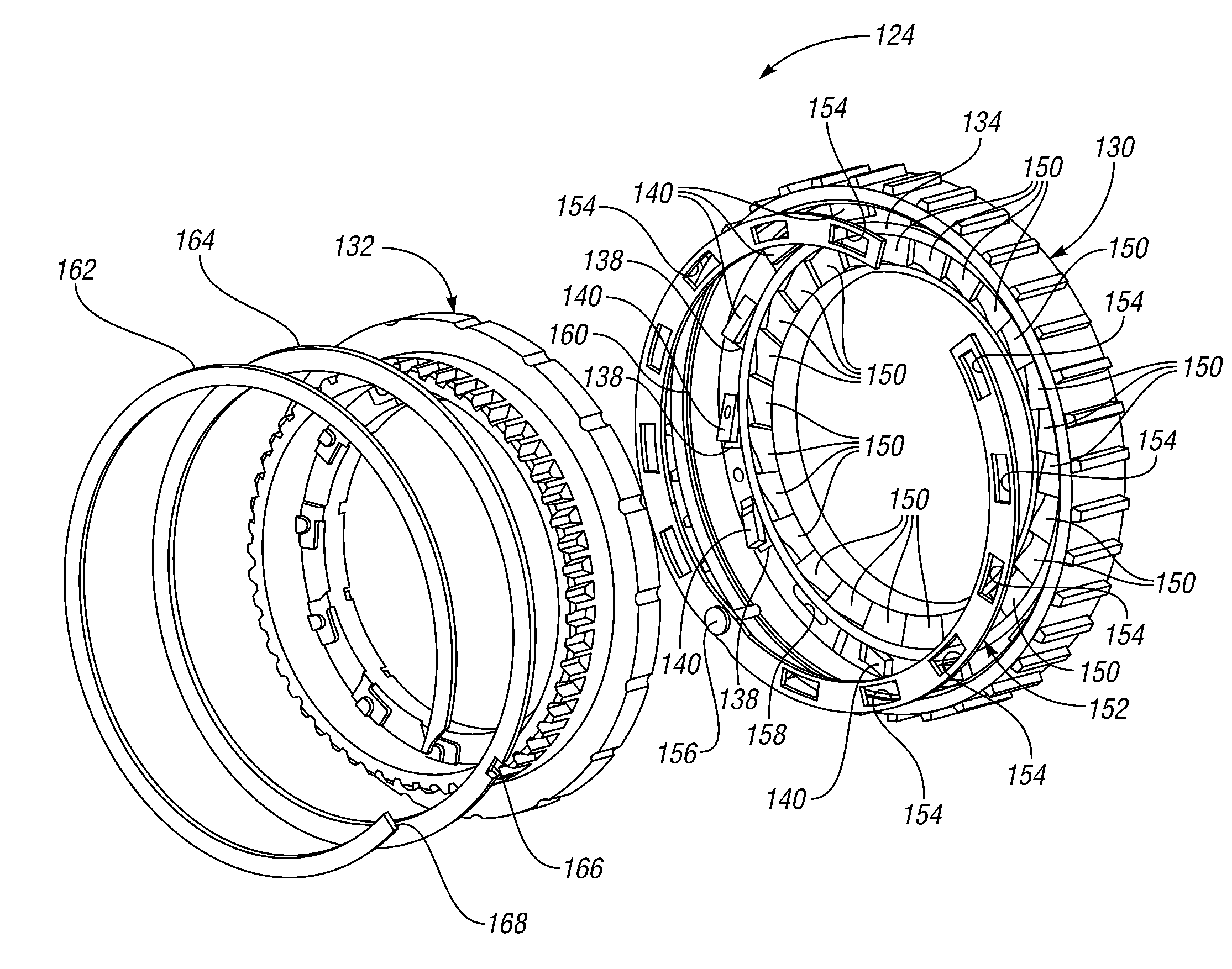

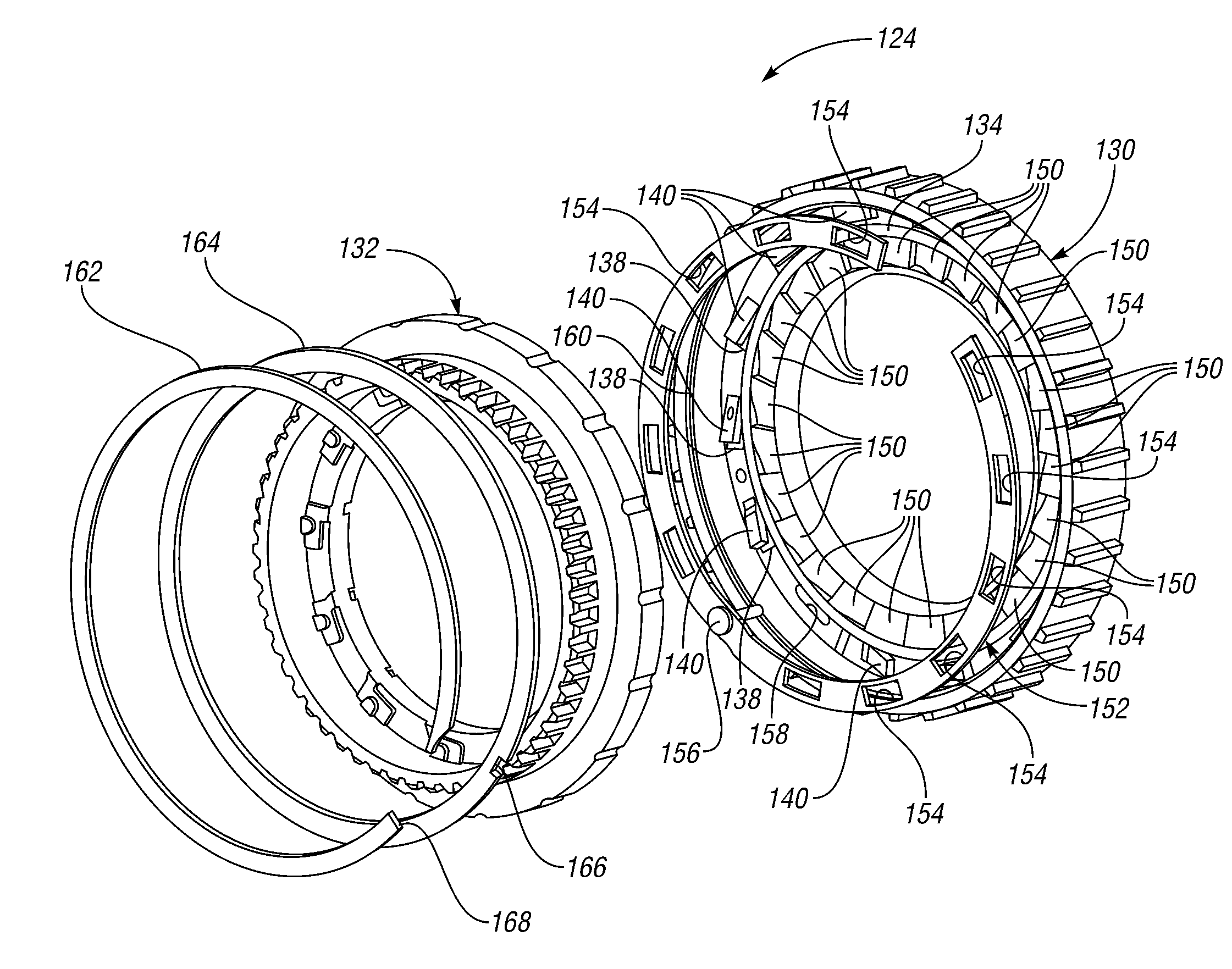

Selectable One-Way Rocker Clutch

The present invention provides a selectable one-way rocker clutch assembly having an inner race disposed radially within an outer race, first and second plurality of rockers, a selector ring and an apply plate. The inner race defines a plurality of pockets configured to operatively retain the first and second plurality of rockers. The first plurality of rockers is configured to resist rotation of the outer race relative to the inner race in a first direction. The second plurality of rockers is configured to resist rotation of the outer race relative to the inner race in a second direction. The selector ring is disposed radially between the inner race and outer race. The apply plate is configured to engage with the selector ring and, in so doing, rotate the selector ring to thereby selectively retract the first and / or second plurality of rockers and thus control the state of the rocker clutch assembly.

Owner:GM GLOBAL TECH OPERATIONS LLC

Dual-mode one-way torque transmitting device

InactiveUS20060185957A1Low costReduce hoop stressFluid actuated clutchesFriction clutchesDual modeEngineering

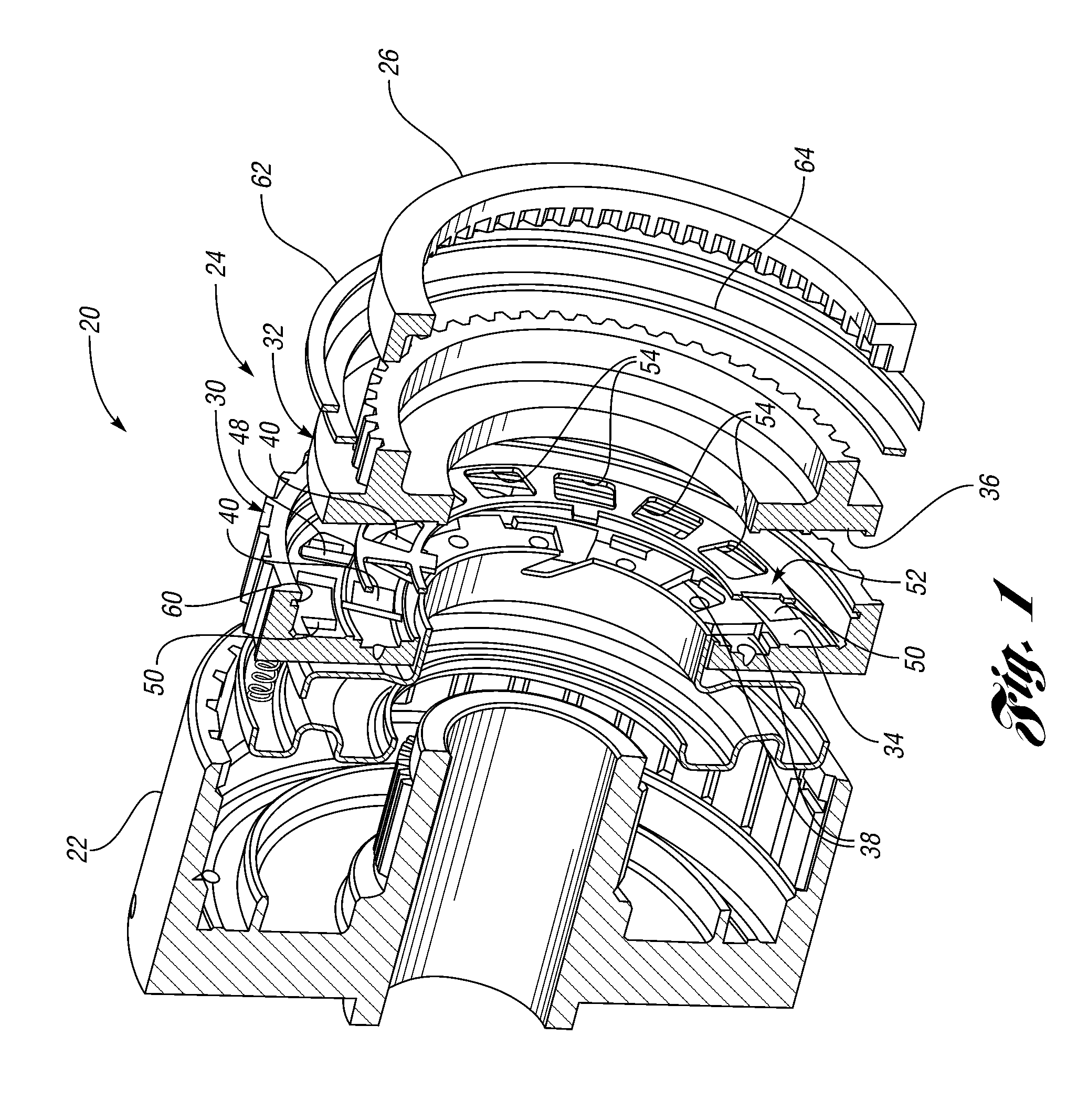

A dual mode one-way torque transmitting device includes an inner race having a first plurality of notches spaced about an axis. An intermediate race includes a second plurality of notches spaced about the axis, a first plurality of pockets spaced about the axis, and a first plurality of rockers, each rocker being located in a pocket of the intermediate race. A spring urges each rocker toward engagement with a notch on the inner race. An outer race includes a second plurality of pockets spaced about the axis, a second plurality of rockers, each rocker being located in a pocket on the outer race, and a plurality of actuators, each actuator alternately engages and disengages a rocker on the outer race and a notch on the intermediate race.

Owner:FORD GLOBAL TECH LLC

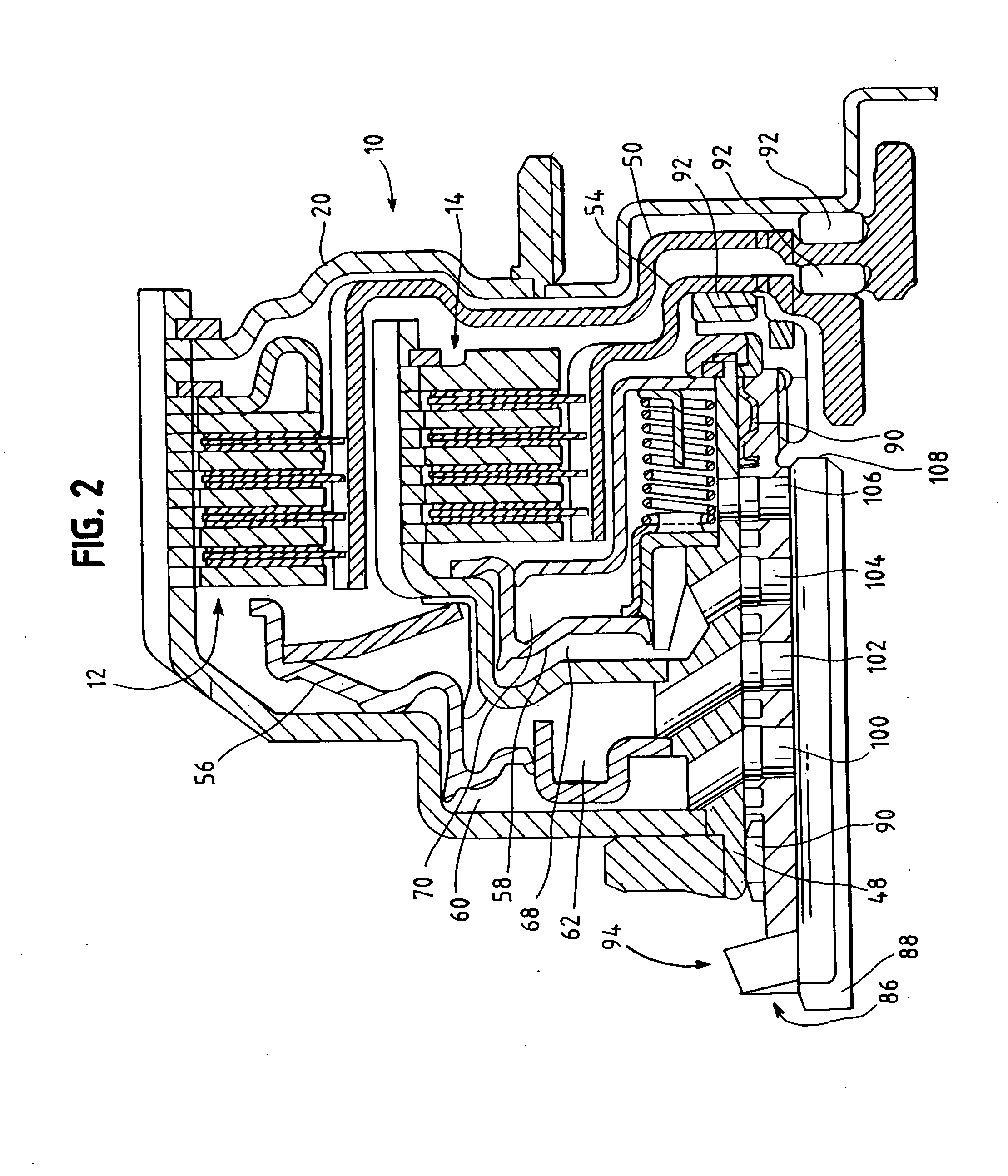

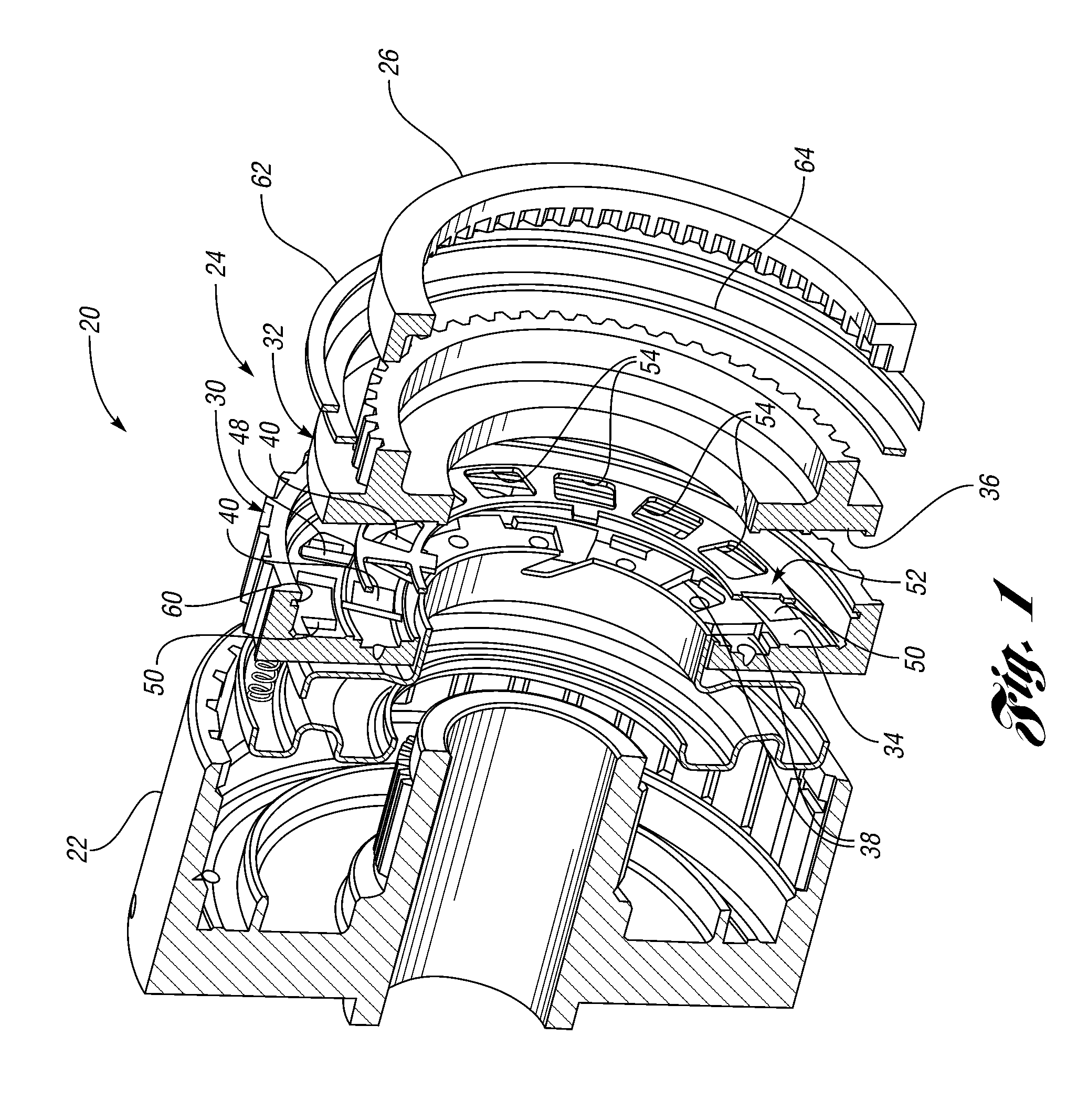

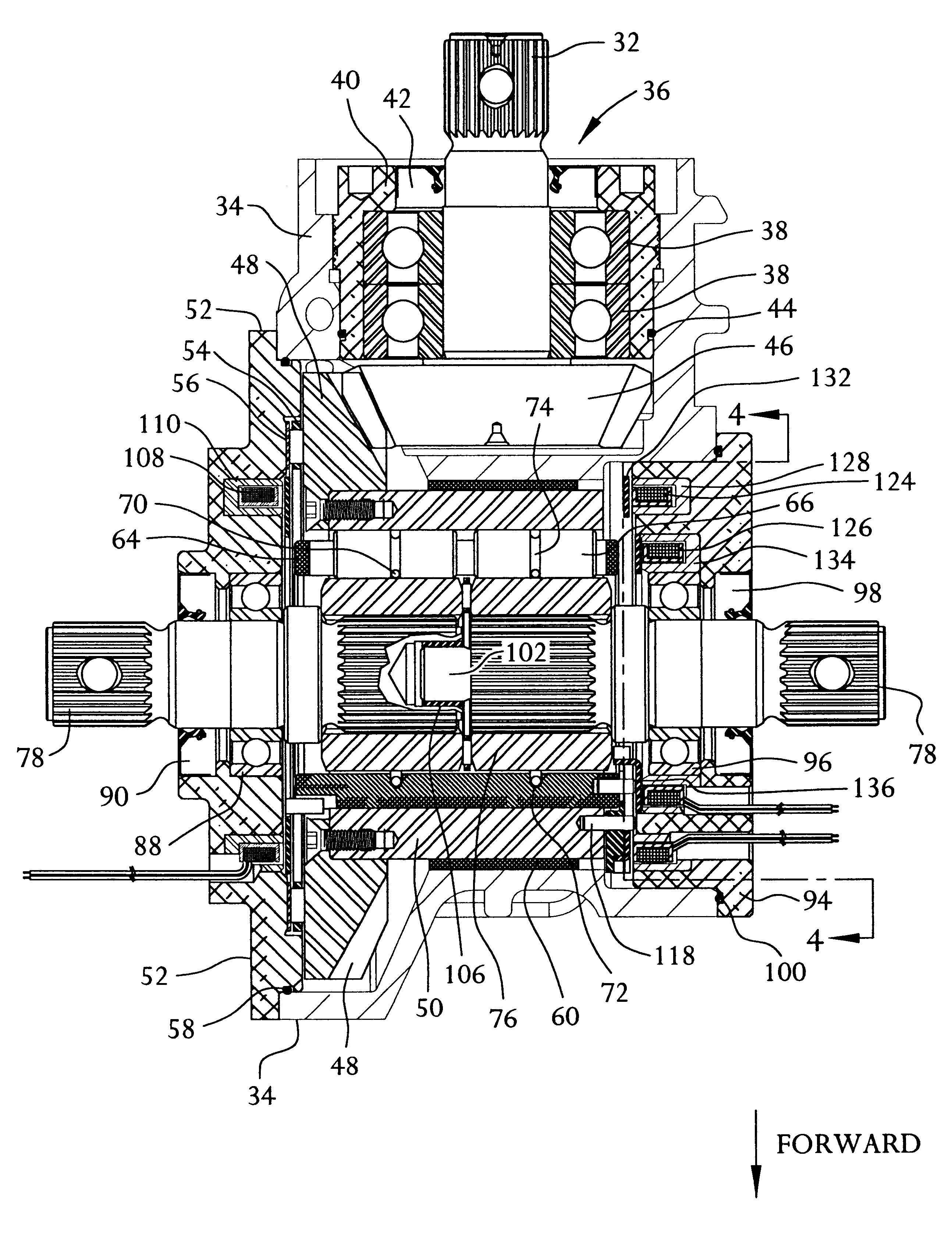

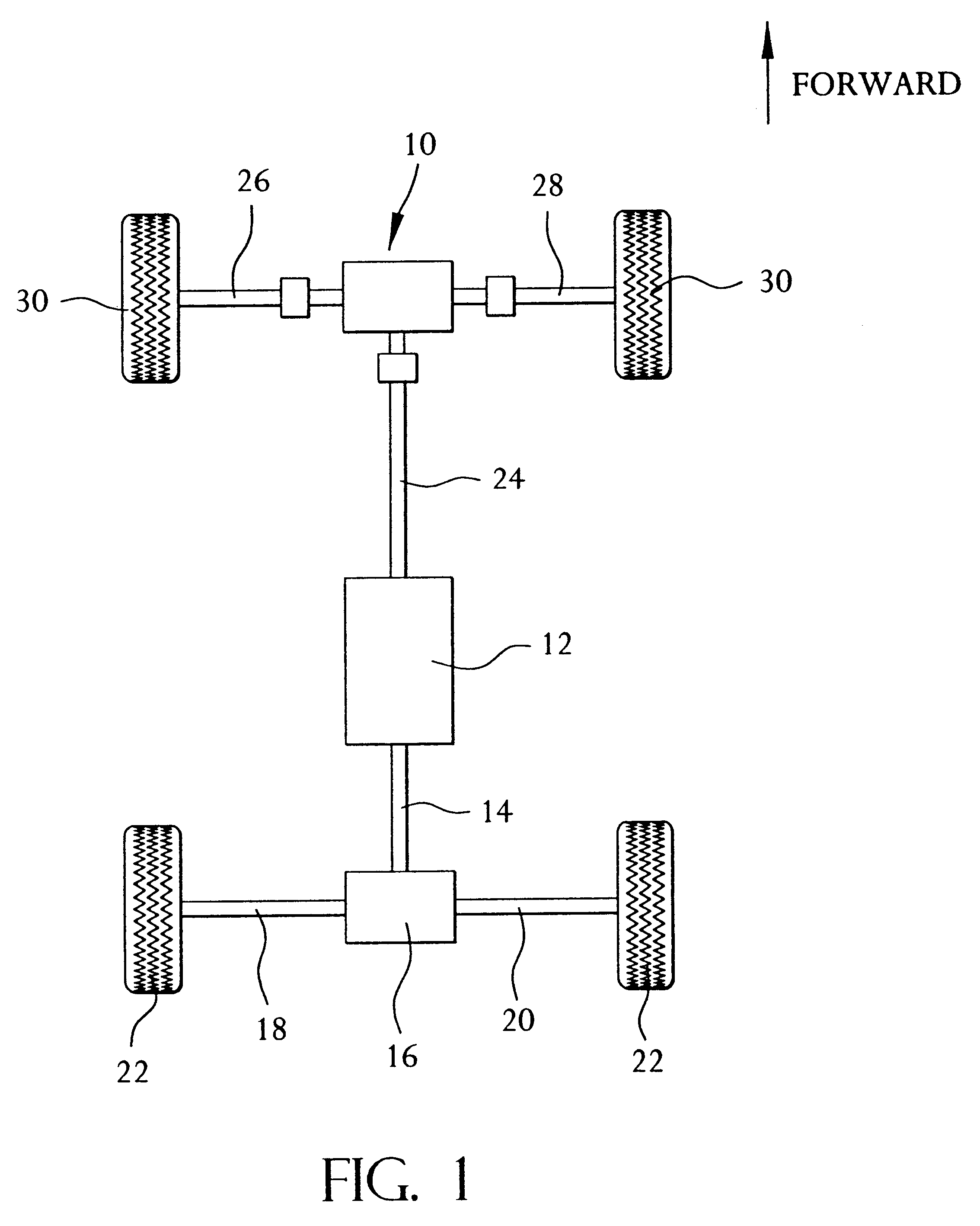

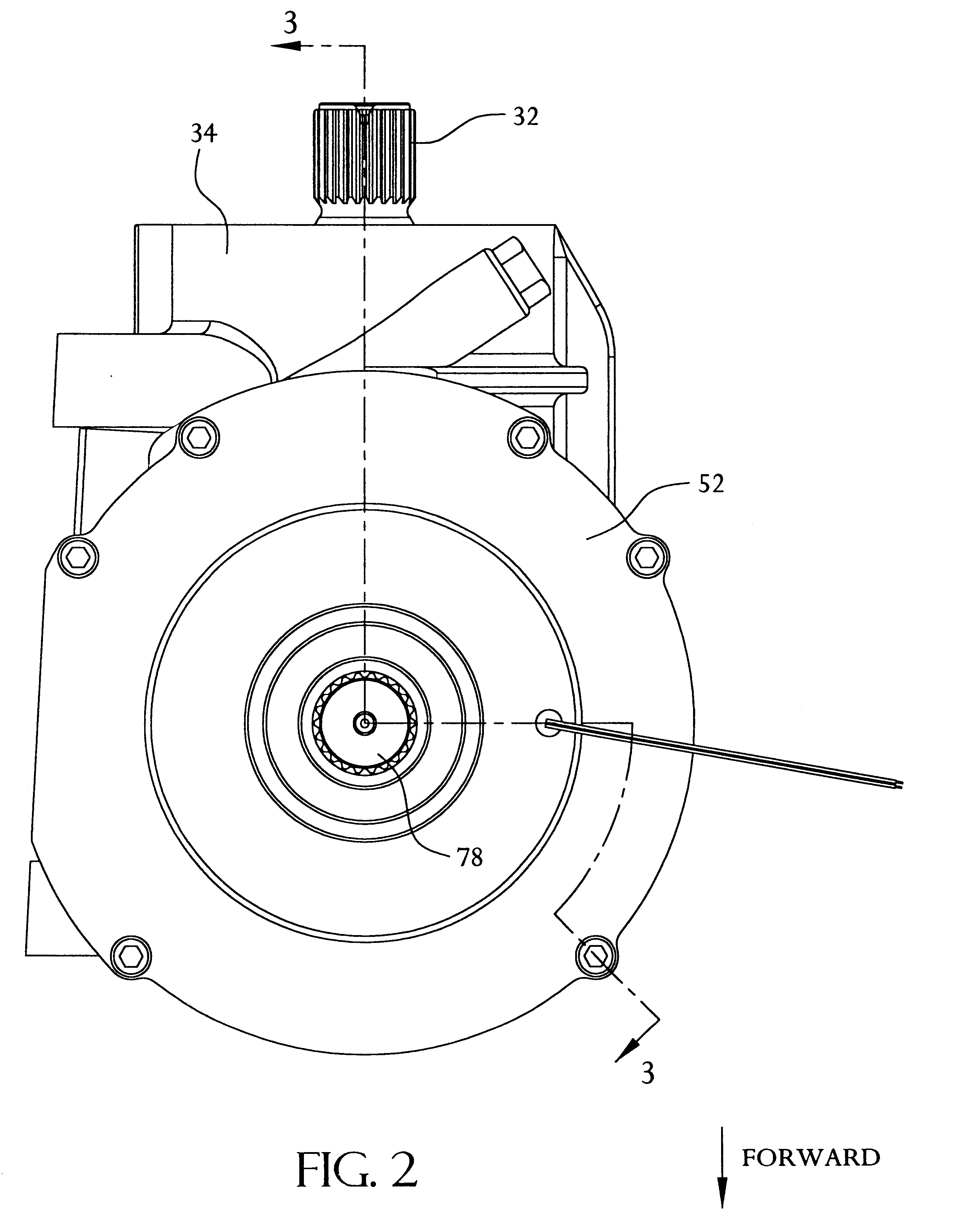

Controllable overrunning coupling assembly

A controllable overrunning coupling assembly includes a control member mounted for controlled shifting movement between a first pair of coupling faces of first and second coupling members relative to reverse pockets formed in one of the coupling faces. The first pair of coupling faces oppose each other and are oriented to face axially along a common rotational axis. The control member is operable for controlling position of only reverse struts in the reverse pockets without controlling the position of forward rockers in forward pockets formed in a coupling face of a second pair of coupling faces of the coupling members that oppose each other and are oriented to face radially with respect to the rotational axis.

Owner:MEANS IND INC

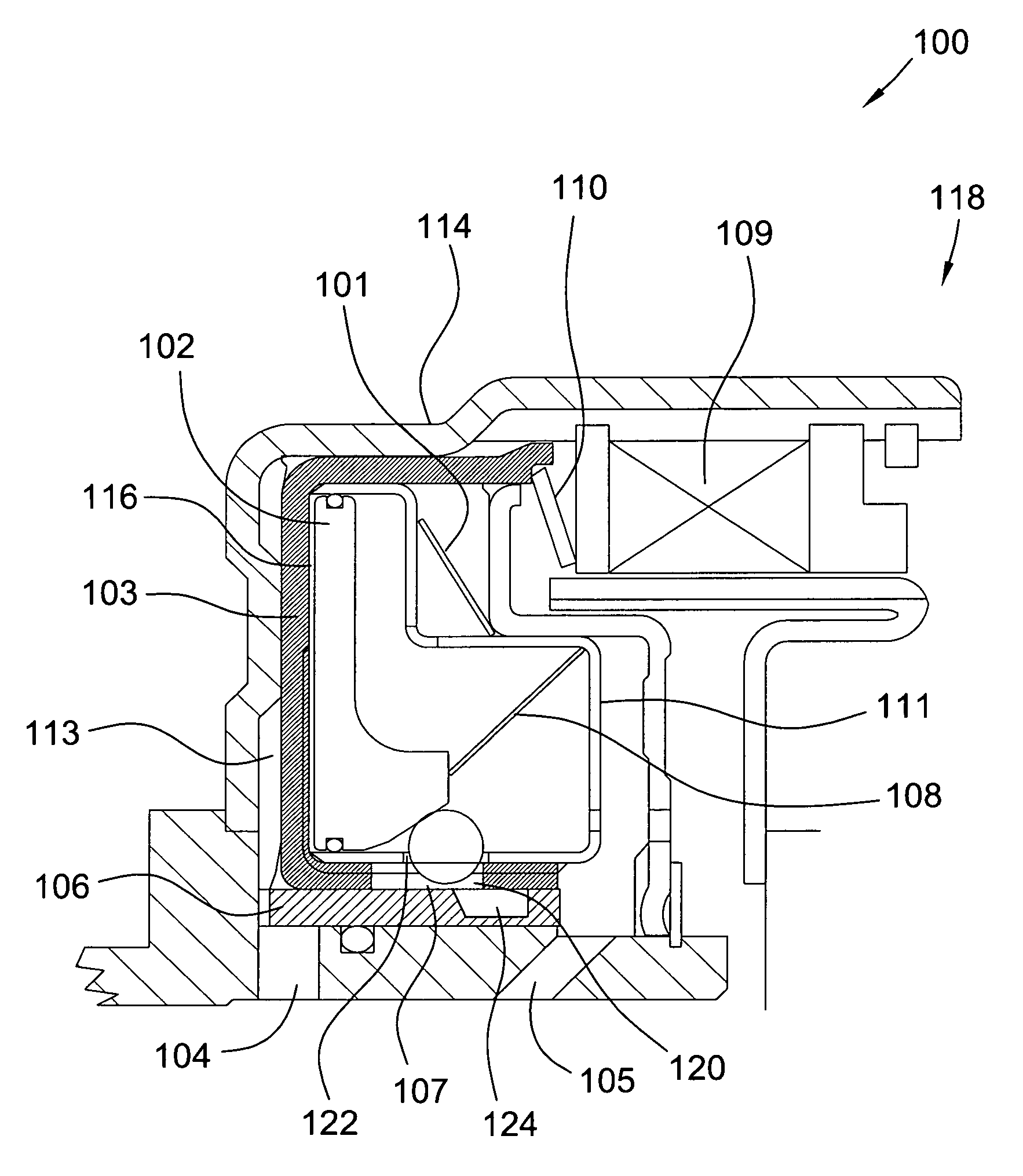

Oil management system for dual clutch transmissions

InactiveUS20050067251A1Solve the lack of balanceReduce flow of fluidFluid actuated clutchesGear lubrication/coolingEngineeringCentrifugal force

The present invention provides an improved fluid management system for dual and other multiple clutch assemblies having fluid-operated pistons and fluid operated balance chambers offsetting the undesired pressures exerted by fluids within the piston chamber induced by centrifugal forces. Among other improvements, the system provides an effective and cost efficient arrangement of fluid supply channels and supply openings capable of maintaining desired fluid levels in the balance chambers under low, otherwise insufficient, flow rate conditions. In another aspect, the system provides a reservoir for the balance chambers under conditions where the fluid flow is stopped or interrupted.

Owner:BORGWARNER INC

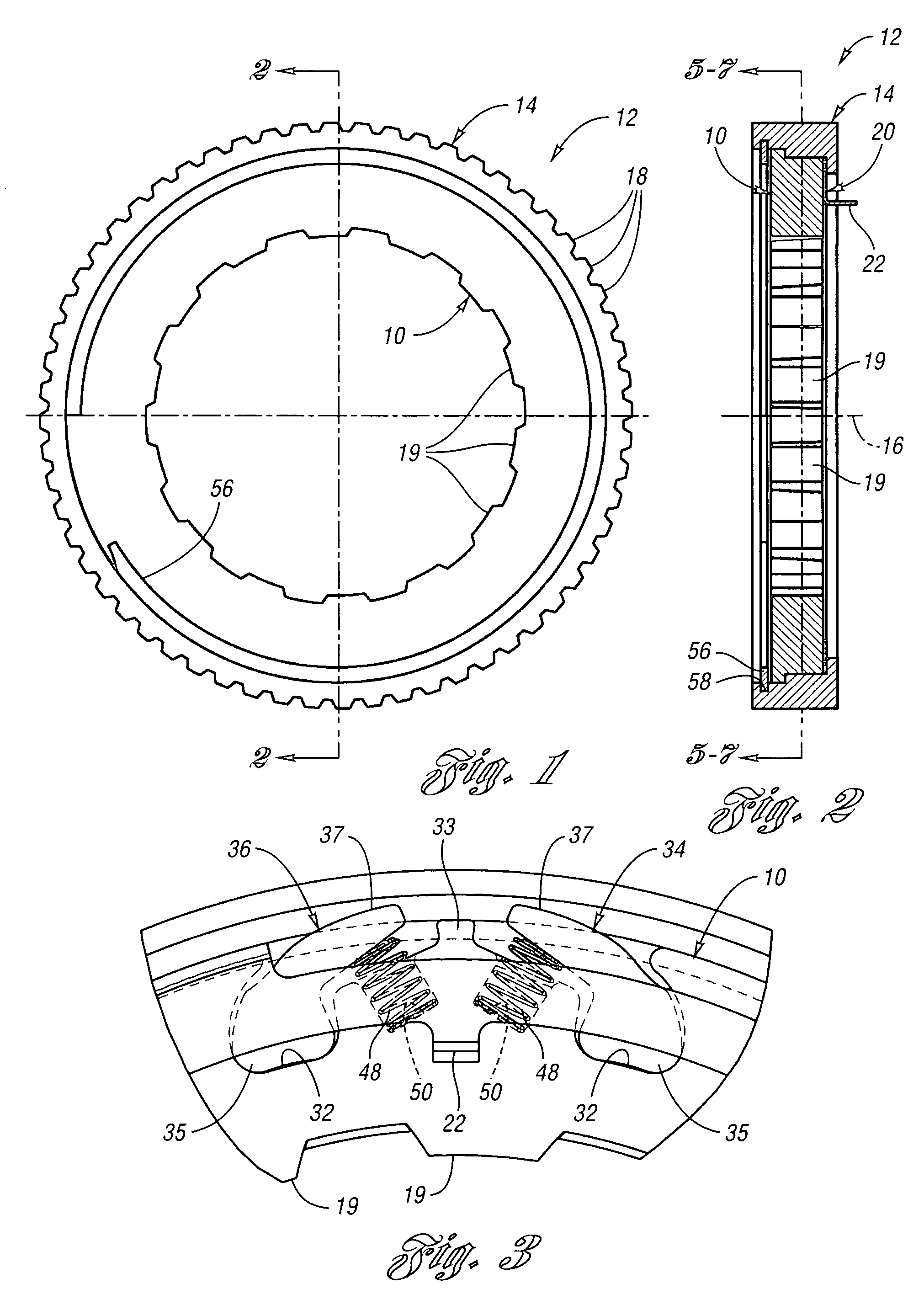

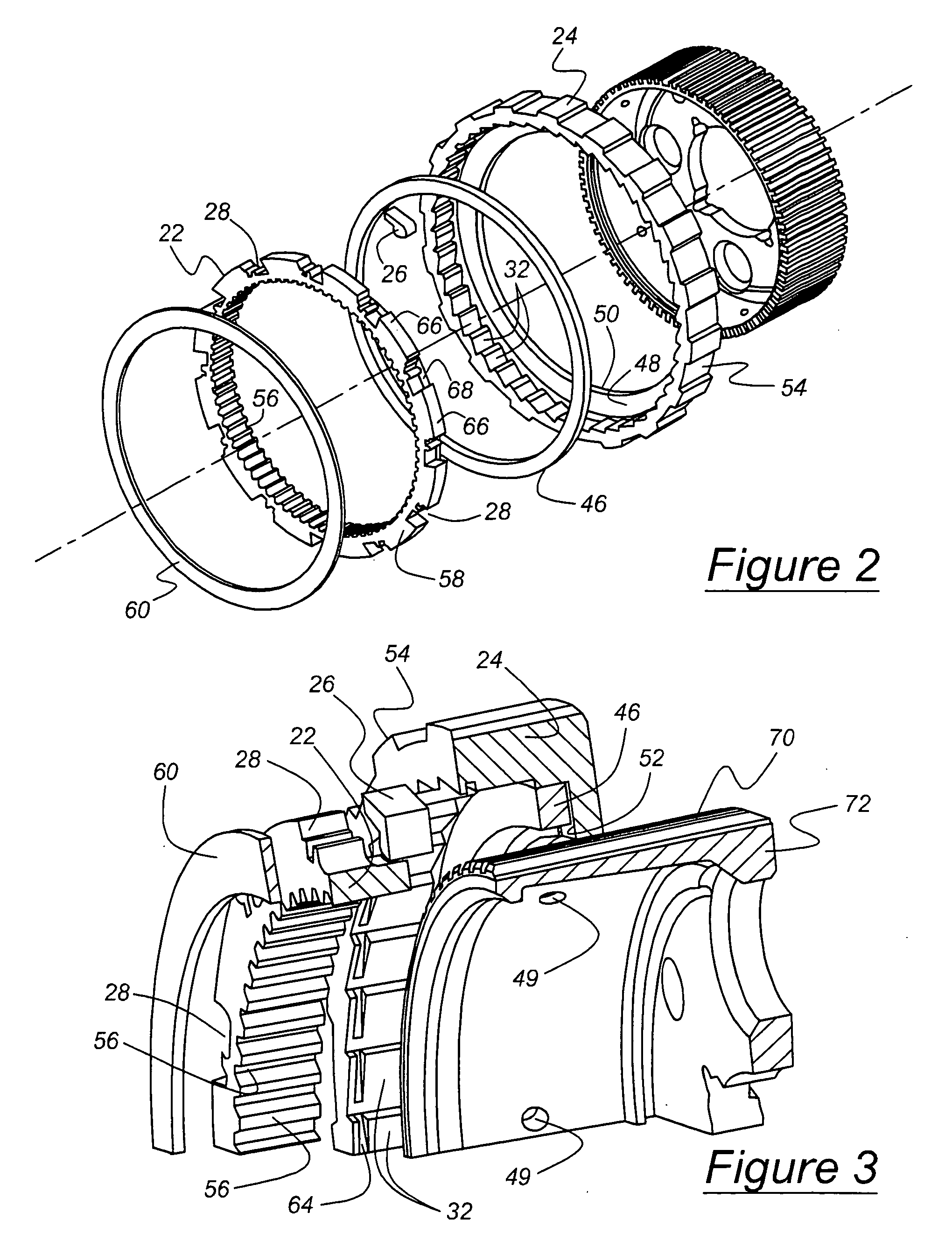

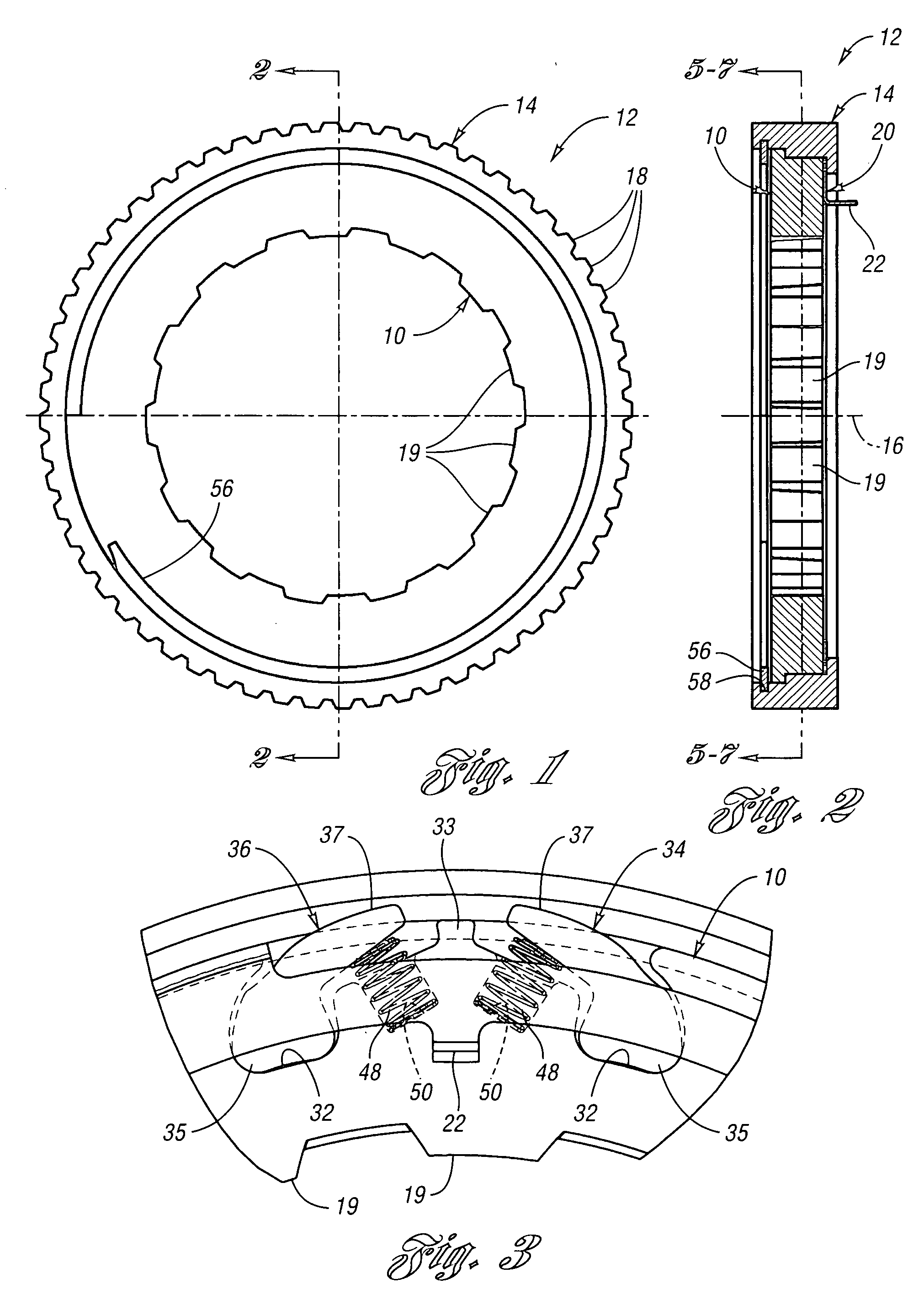

Overrunning coupling assembly

InactiveUS6186299B1Reduce wearLower requirementFriction clutchesInterengaging clutchesForward slidingCoupling

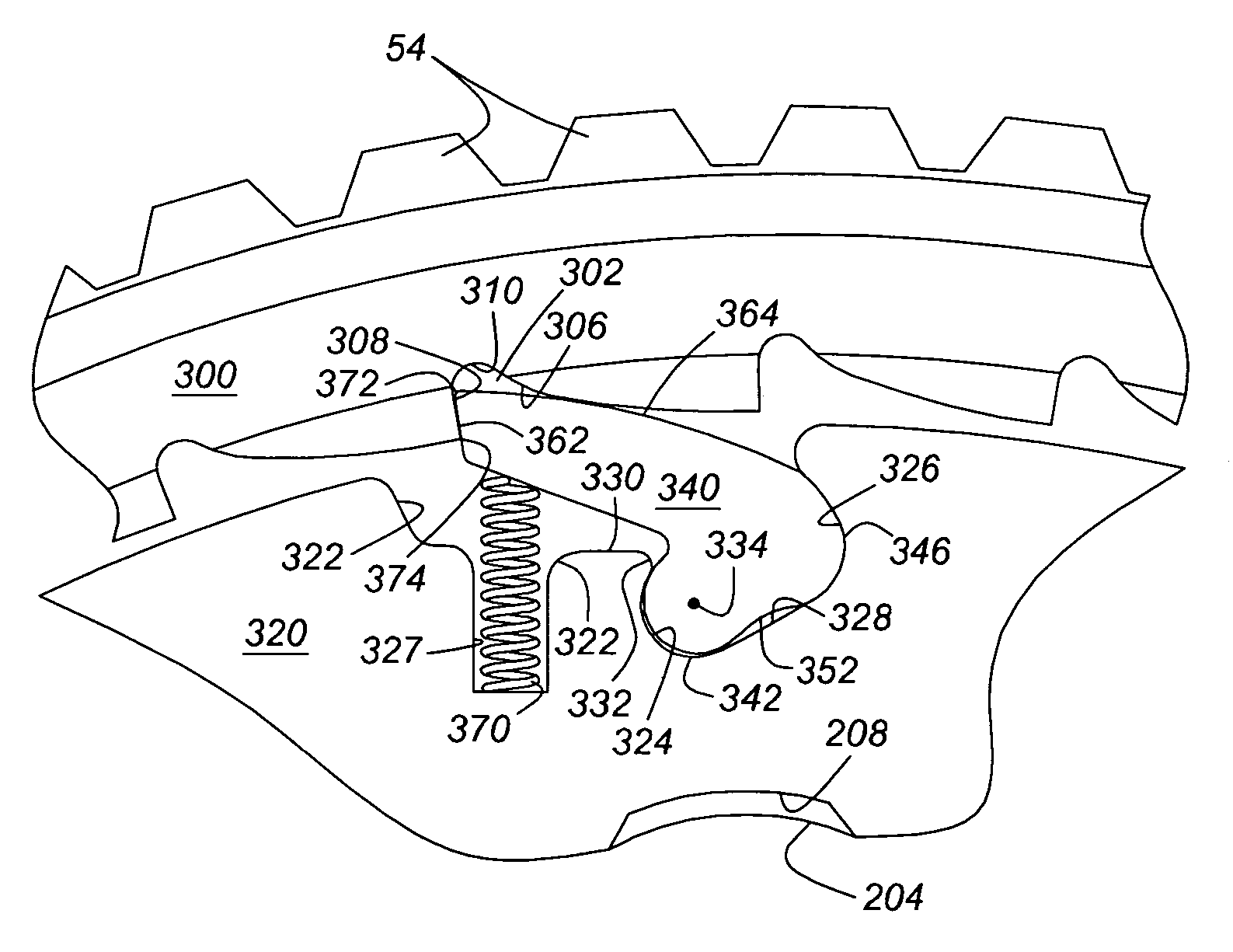

An overrunning coupling assembly includes a notch plate and an annular coupling pocket plate positioned in face-to-face relationship with respect to each other along a common axis. The pocket plate has strut pockets disposed at angularly spaced positions about the common axis. The notch plate has notch recesses at angularly spaced positions about the common axis and positioned in juxtaposed relationship with respect to the strut pockets. Torque-transmitting struts are positioned in each of the strut pockets. Each strut has first and second ears at one edge thereof for enabling pivotal motion of the struts about an ear axis intersecting the ears. The opposite edge of each strut is movable between disengaged and engaged positions with respect to one of the notch recesses whereby one-way torque transfer may occur between the plates. A lubricant flows between the notch plate and pocket plate. A spring is positioned in each strut pocket and biases the respective strut toward the notch plate. Each spring engages the respective strut intermediate the ear axis and the opposite edge. Each strut pocket provides sufficient clearance forward of the respective opposite edge of the strut to allow forward sliding movement of the respective strut during overrunning to cause the engagement of the respective spring and strut to occur nearer the ear axis, thereby reducing the length of a moment arm about which the spring acts upon the strut which enables frictional forces of the flowing lubricant to hold the strut in its disengaged position to prevent the strut from slapping against the notch recesses as the notch plate and pocket plate are respectively counterrotated.

Owner:MEANS IND INC

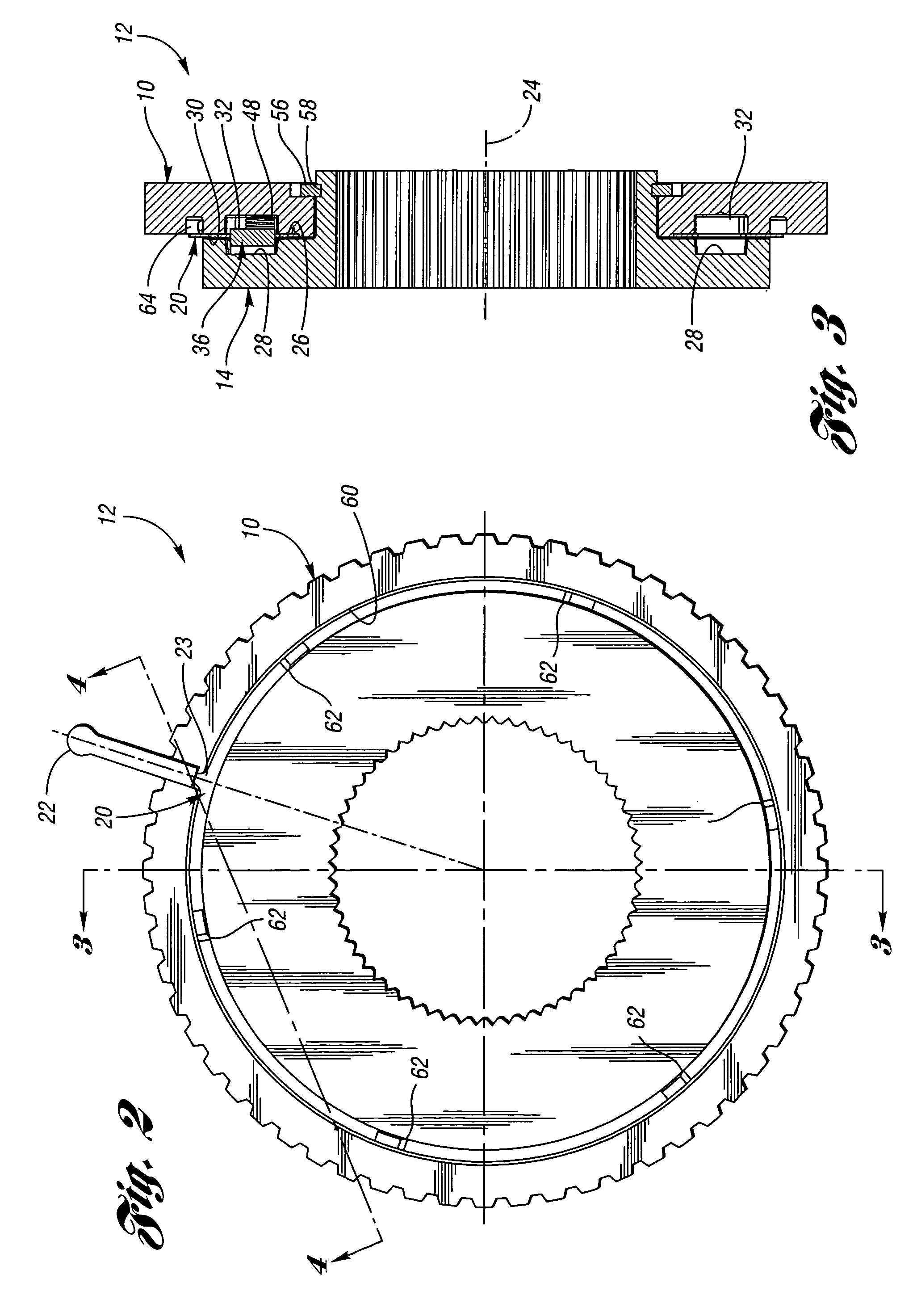

Overrunning coupling assembly having improved shift feel and/or noise reduction

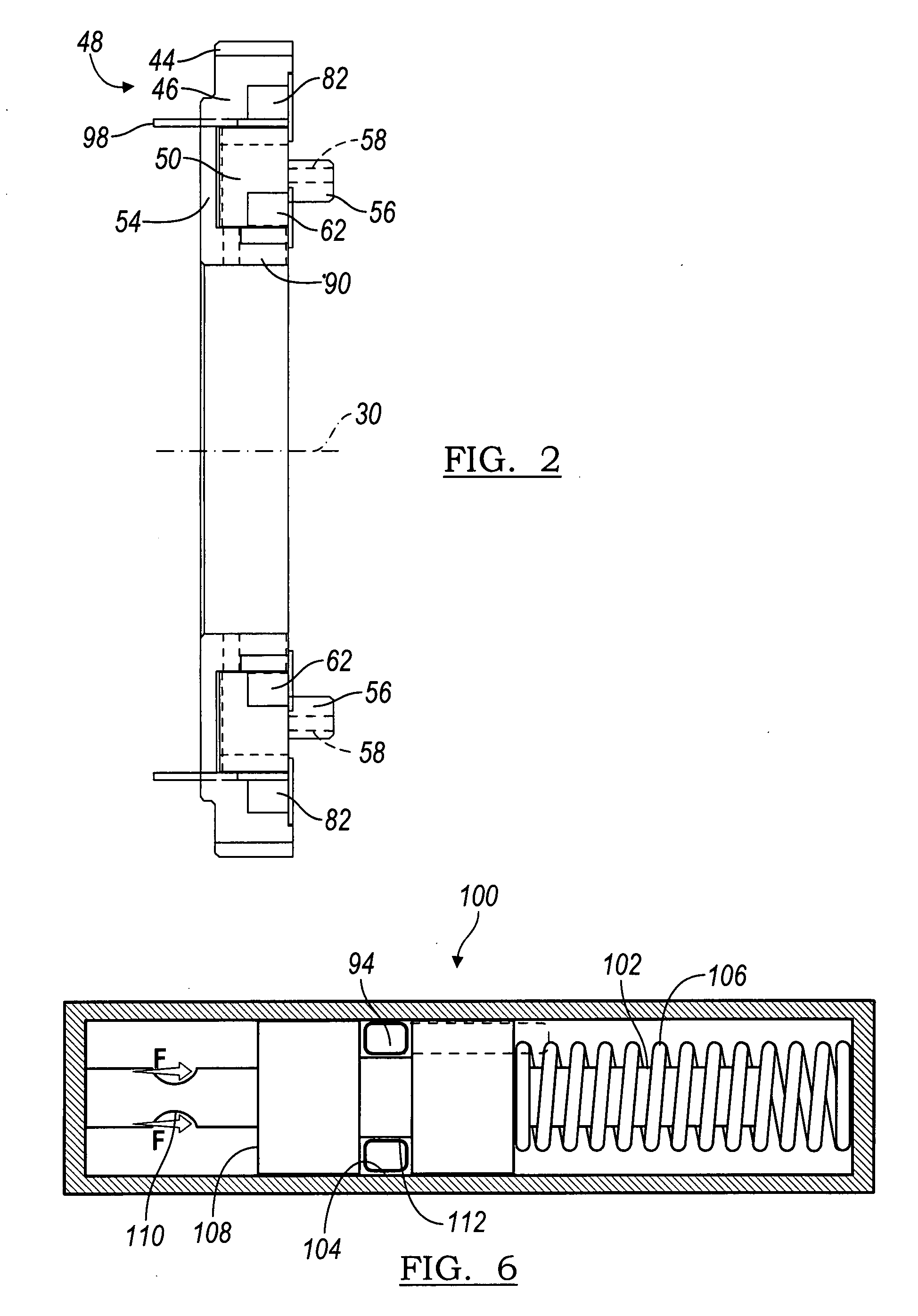

ActiveUS7275628B2Improved shift feel and noise reductionReduce axial forceRotating vibration suppressionFluid actuated clutchesWave shapeCoupling

An overrunning coupling assembly having improved shift feel and / or noise reduction is provided. The assembly includes planar first and second members rotatable about a first axis. In a locked position, torque transfer is permitted between the first and second members in a first direction about the first axis. In a disengaged position, the first and second members are permitted to free-wheel relative to each other in a second direction opposite the first direction. A compliant retaining device retains the first and second members together and absorbs axial impact loads. The retaining device is less compliant in the locked position than in the disengaged position to decrease axial force at time of axial impact and improve shift feel and / or noise reduction. In a first embodiment, the retaining device includes a wave spring. In a second embodiment, the retaining device includes a stepped weir plate.

Owner:MEANS IND INC

Controllable Overrunning Coupling Assembly

ActiveUS20090211863A1Improved overrunningFriction clutchesInterengaging clutchesRotational axisCoupling

A controllable overrunning coupling assembly includes a control member mounted for controlled shifting movement between a first pair of coupling faces of first and second coupling members relative to reverse pockets formed in one of the coupling faces. The first pair of coupling faces oppose each other and are oriented to face axially along a common rotational axis. The control member is operable for controlling position of only reverse struts in the reverse pockets without controlling the position of forward rockers in forward pockets formed in a coupling face of a second pair of coupling faces of the coupling members that oppose each other and are oriented to face radially with respect to the rotational axis.

Owner:MEANS IND INC

Overrunning Coupling Assembly

ActiveUS20090159391A1Improved overrunningEasy to assembleFriction clutchesInterengaging clutchesCouplingControl theory

An overrunning coupling assembly includes a control element mounted for controlled shifting movement between coupling faces of annular coupling members relative to a first set of pockets in the first member. The control element is operable for controlling position of only reverse struts in the first set of pockets without controlling the position of forward struts in a second set of pockets in the coupling face of the second member. The control element allows at least one of the reverse struts to engage at least one of a set of locking formations on the coupling face of the second coupling member in a first position of the control element. The control element maintains the reverse struts in their pockets in a second position of the control element.

Owner:MEANS IND INC

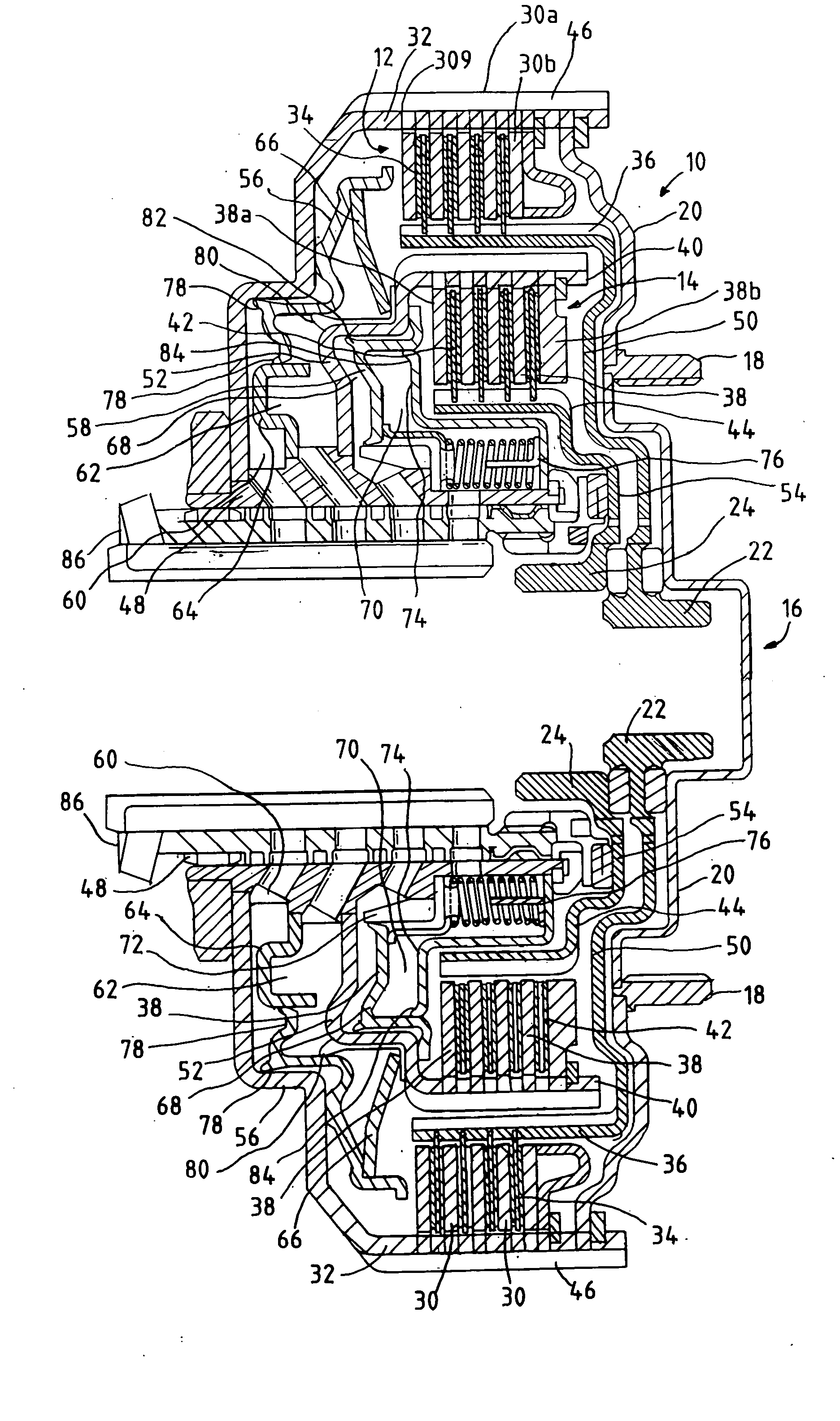

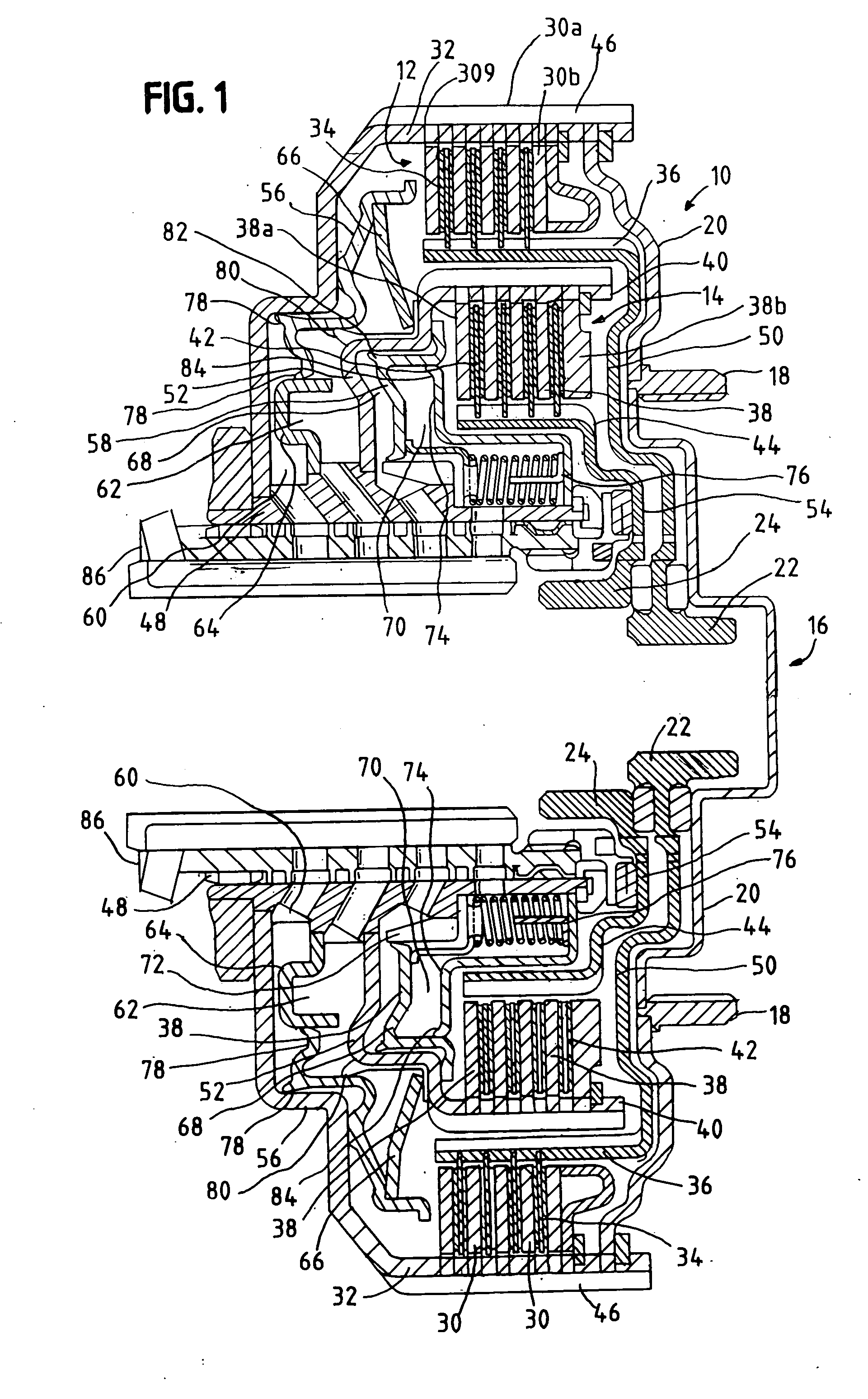

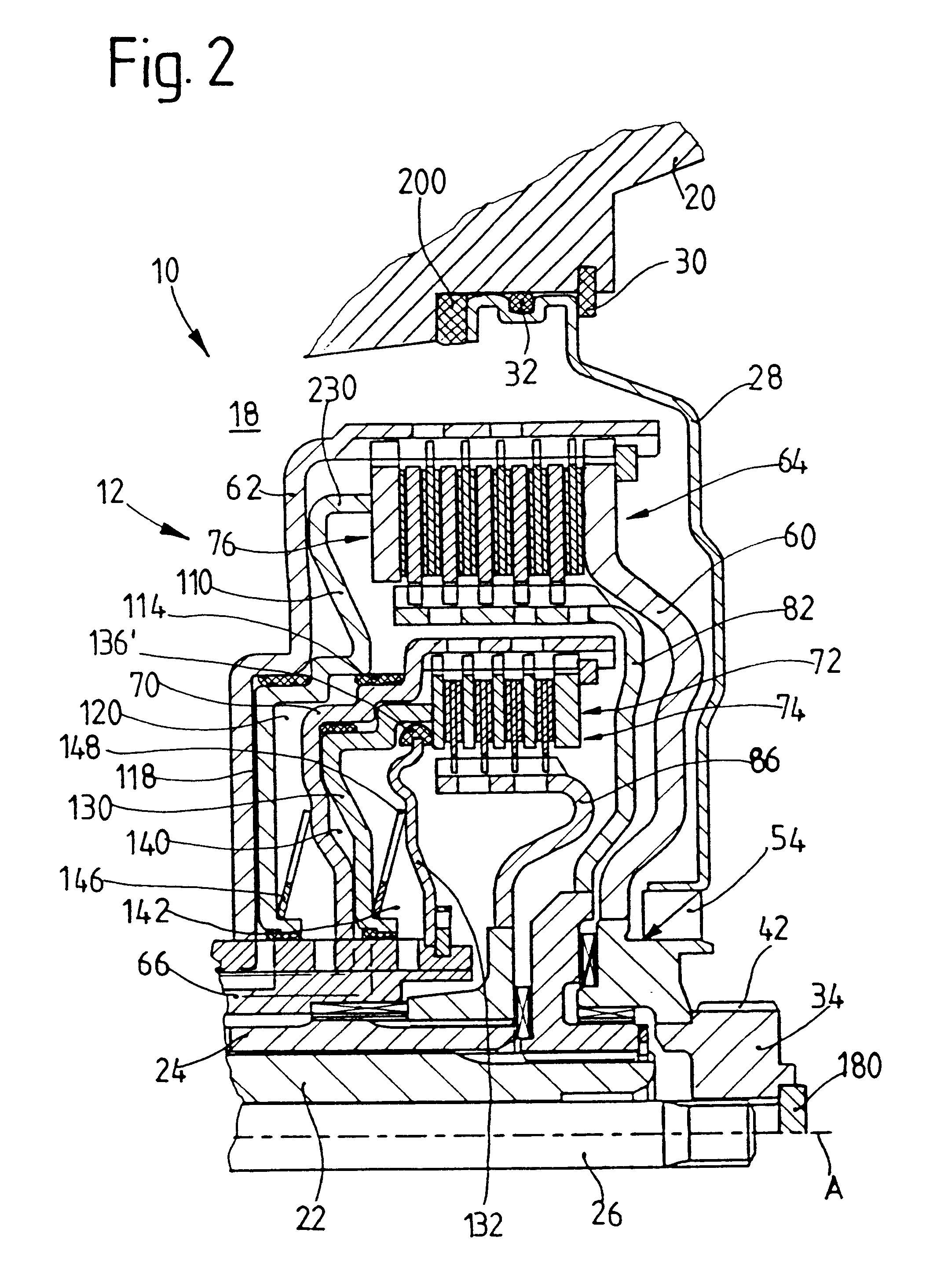

Multiple-clutch device

InactiveUS6523657B1Large massLarge heat capacityRoad transportFluid actuated clutchesMobile vehicleDrivetrain

The invention is directed to a multiple-clutch device, such as a double-clutch device, for arranging in a drivetrain of a motor vehicle between a drive unit and a transmission, wherein the clutch device has a first clutch arrangement associated with a first transmission input shaft of the transmission and a second clutch arrangement associated with a second transmission input shaft of the transmission for transmitting torque between the drive unit and the transmission. According to one aspect of the invention, it is suggested that plates in a plate stack of a clutch arrangement constructed as a plate clutch arrangement which have at least one friction facing can be brought into frictional engagement with plates having no friction facing, wherein at least one of the plates not having a friction facing is thicker in axial direction than friction facing carrying elements of adjacent plates having at least one friction facing. Alternatively or in addition, it is suggested that at least one plate which has at least one friction facing of sintered material and at least one plate which has at least one friction facing made of another friction facing material are provided in the plate stack, wherein the other friction facing material has a progressive frictional coefficient curve (dlambd / dDELTAN) in relation to a slip speed (DELTAN).

Owner:ZF FRIEDRICHSHAFEN AG +1

Selectively controlled rocker one-way clutch

ActiveUS20080185253A1Easy to assembleSignificantly reducing backlashToothed gearingsFriction clutchesEngineeringClutch

An overrunning clutch assembly includes a first ring having pockets spaced mutually about an axis, rockers each located in a pocket, springs each urging a rocker to pivot in a respective pocket, and first notches arranged around the axis. A second ring includes second pockets spaced mutually about the axis, second rockers each located in a second pocket such that at least one second rocker is engageable with a notch, second springs each urging a second rocker toward engagement with a notch, and second notches around the axis, at least one rocker being engageable with at least one second notch. A control member moves about the axis alternately to prevent the first rockers from engaging the second notches and to permit the first rockers to engage the second notches.

Owner:FORD GLOBAL TECH LLC

Controllable or selectable bi-directional overrunning coupling assembly

An overrunning coupling assembly includes a control element mounted for controlled shifting movement between coupling faces of annular coupling members relative to a first set of pockets in the first member. The control element is operable for controlling position of only reverse struts in the first set of pockets without controlling the position of forward struts in a second set of pockets in the coupling face of the second member. The control element allows at least one of the reverse struts to engage at least one of a set of locking formations on the coupling face of the second coupling member in a first position of the control element. The control element maintains the reverse struts in their pockets in a second position of the control element.

Owner:MEANS IND INC

Overrunning coupling assembly

InactiveUS6116394AReduce wearEliminate lubrication control requirementRotary clutchesFriction clutchesCouplingTrunnion

An overrunning coupling assembly includes a notch plate and an annular coupling pocket plate positioned in face-to-face relationship with respect to each other along a common axis. The pocket plate includes strut pockets disposed at angularly spaced positions about the axis. The notch plate includes notch recesses at angularly spaced positions about the common axis and positioned in juxtaposed relationship with respect to the strut pockets. The notch plate includes an inner circumferential rail at a radially inward side of the notch recesses and an outer circumferential rail at a radially outward side of the notch recesses. Torque-transmitting struts are positioned in the strut pockets. Each strut has first and second ears at one edge thereof for enabling pivotal motion of the struts about an ear axis intersecting the ears. The opposite edge of each strut is engageable with one of the notch recesses whereby one-way torque transfer may occur between the plates. Each opposite edge has first and second corners. Each strut pocket is sufficiently enlarged to allow pivotal movement of each strut about a strut axis which is parallel with the common axis, thereby enabling one of the first and second corners to be selectively supported by one of the inner and outer circumferential rails to prevent the struts from slapping against the notch recesses as the notch plate and pocket plate are respectively counterrotated.

Owner:MEANS IND INC

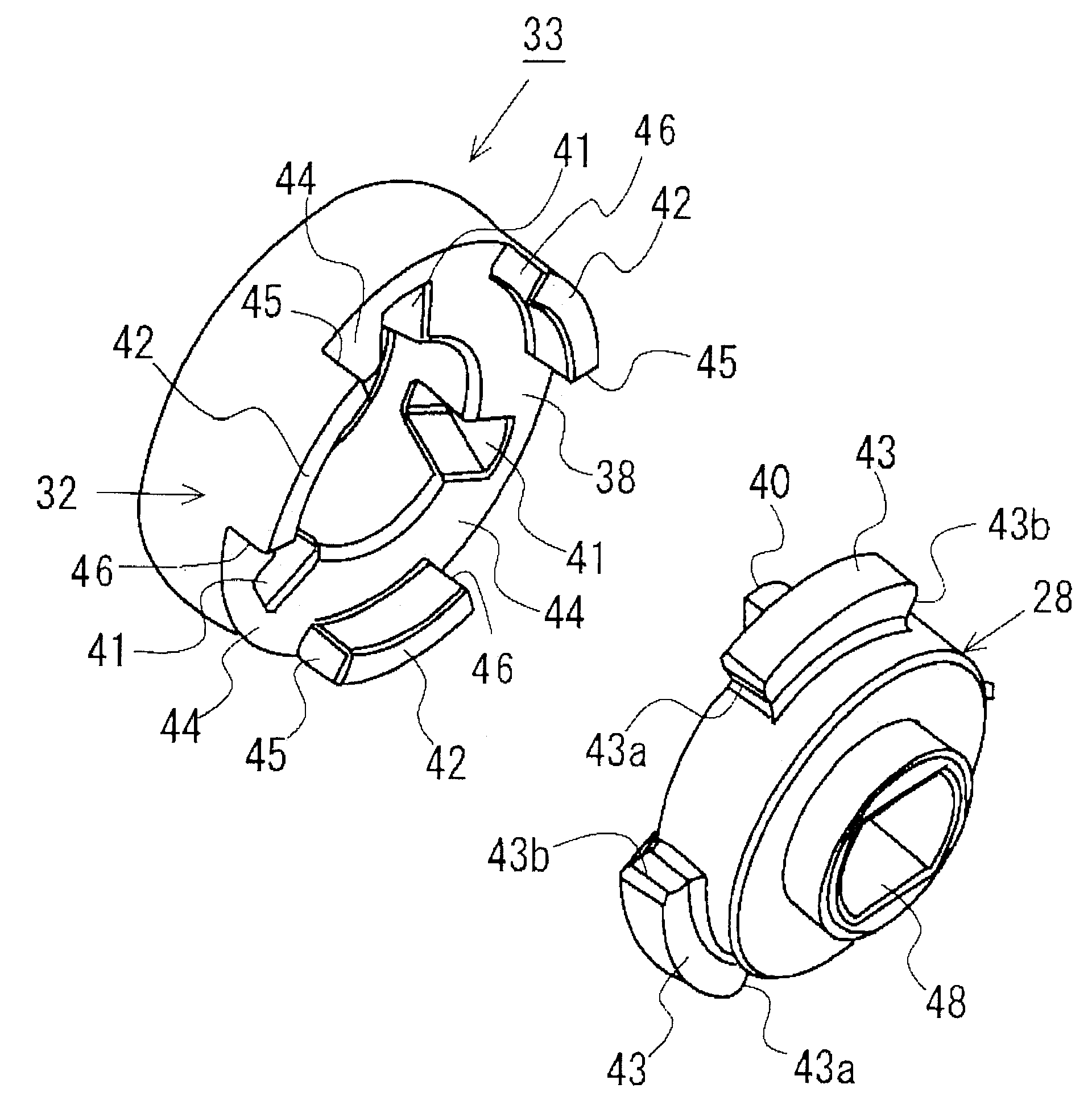

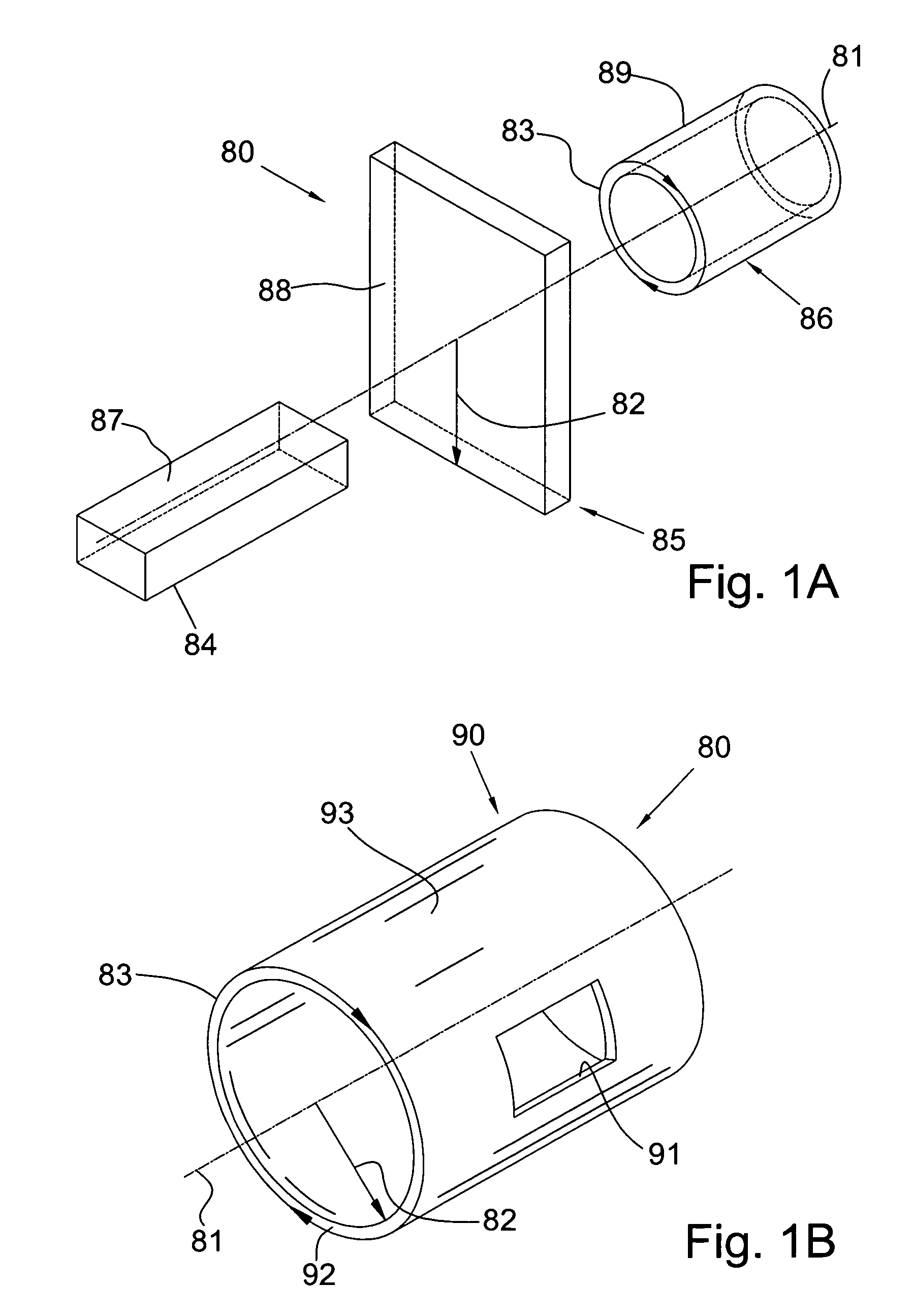

Shaft coupling, and function unit drive device for an image forming device comprising the same

InactiveUS7603059B2Suppress couplingReliable transmissionFriction grip releasable fasteningsCorona dischargeCouplingImage formation

Inner circumference projections of a driven coupling are engaged with inner circumference recesses of a drive coupling. Outer circumference projections of the driven coupling are engaged with outer circumference recesses of the drive coupling. A chamfered portion formed at each tip of the rotational leading-side side surface of the inner circumference projections is capable of contact with the leading-side side surface of each inner circumference recess. A rotational trailing-side circumferential end face of each outer circumference projection and a rotational trailing-side circumferential end face of each outer circumference recess are in surface-to-surface contact with each other. As a result, the drive coupling and the driven coupling can rotate integrally without rattling in the rotational direction.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Bi-directional overrunning clutch

InactiveUSRE38012E1Prevent rotationYielding couplingFluid couplingsElectronic control systemDrive shaft

A bi-directional overrunning clutch is disclosed for controlling torque transmission between a secondary drive shaft and secondary driven shafts. The overrunning clutch includes a pinion input shaft in a differential housing that engages with a clutch housing rotatably disposed within the differential housing. At least one race is located adjacent to the clutch housing and is engaged with an output shaft. A cage is located between the race and the clutch housing. The cage is movable with respect to the clutch housing. A <DEL-S DATE="20030304" ID="DEL-S-00001" / >first<DEL-E ID="DEL-S-00001" / > coil is mounted within the differential housing adjacent to the cage and is adapted to produce an electromagnetic field when energized which causes the cage to drag with respect to the clutch housing. The dragging of the cage with respect to the clutch housing positions <INS-S DATE="20030304" ID="INS-S-00001" / >rolls within <INS-E ID="INS-S-00001" / >the cage to engage the clutch housing with the race when wheels on a primary drive shaft lose traction. <DEL-S DATE="20030304" ID="DEL-S-00002" / >A<DEL-E ID="DEL-S-00002" / > <INS-S DATE="20030304" ID="INS-S-00002" / >If desired a <INS-E ID="INS-S-00002" / >second coil <DEL-S DATE="20030304" ID="DEL-S-00003" / >is<DEL-E ID="DEL-S-00003" / > <INS-S DATE="20030304" ID="INS-S-00003" / >may be <INS-E ID="INS-S-00003" / >mounted within the differential housing adjacent <DEL-S DATE="20030304" ID="DEL-S-00004" / >adjacent<DEL-E ID="DEL-S-00004" / > to the cage. The second coil is adapted to produce an electromagnetic field when energized which advances cage with respect to the clutch housing causing the clutch housing to engage with the races. When the second coil is activated, the output shaft drives the pinion input shaft producing engine braking. An electronic control system is utilized to control the energizing of the coils.

Owner:HILLIARD

Overrunning clutch

ActiveUS7100756B2Significantly reducing backlashEasy to assembleFriction clutchesInterengaging clutchesEngineeringClutch

A one-way clutch includes a first race having a plurality of pockets, each pocket defining a pivot center, a second race including a plurality of notches, a plurality of rockers, each rocker being supported on a respective pocket for pivoting movement about a pivot center relative to the second race, and a spring for urging a rocker toward engagement with a notch.

Owner:FORD GLOBAL TECH LLC

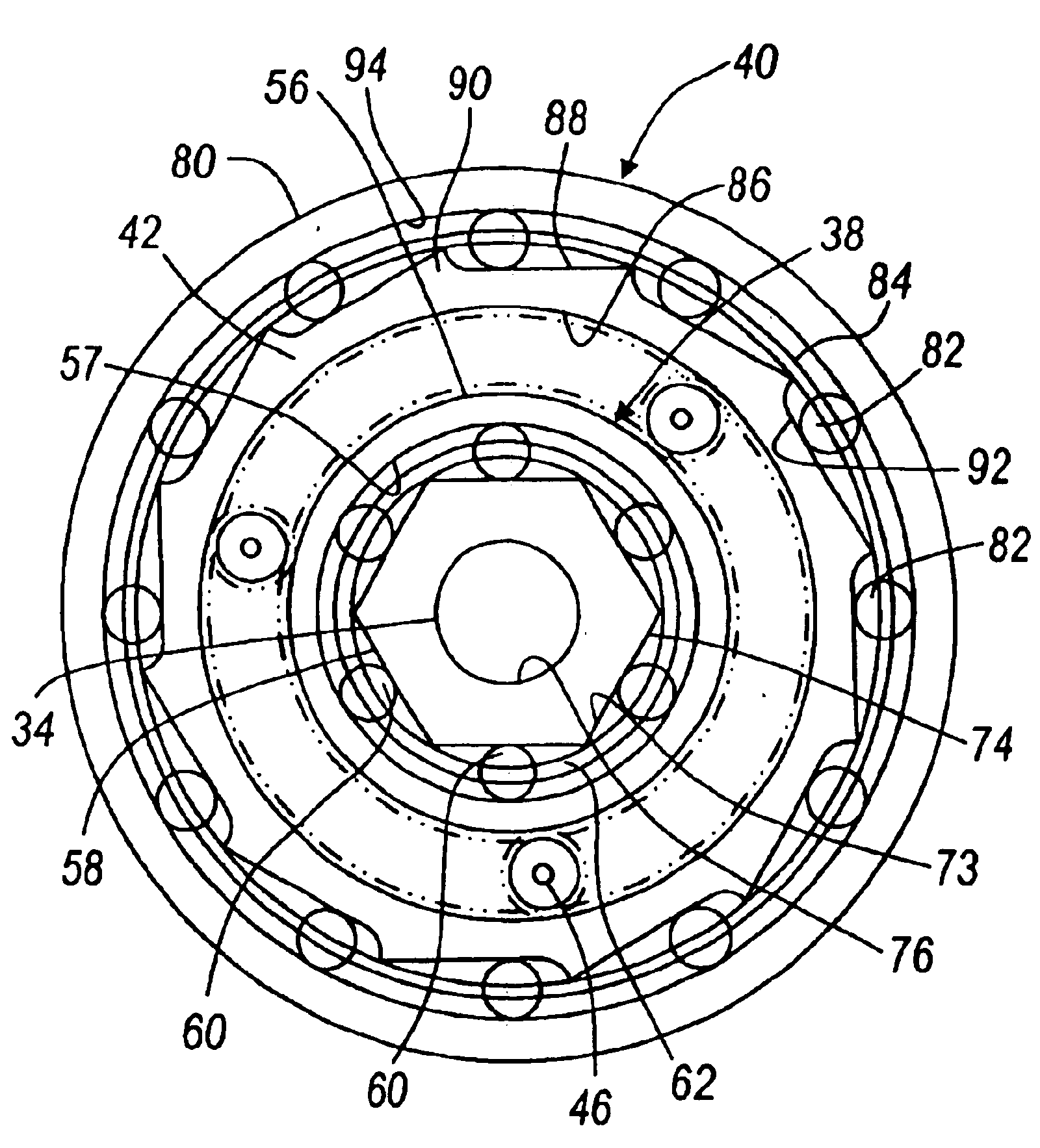

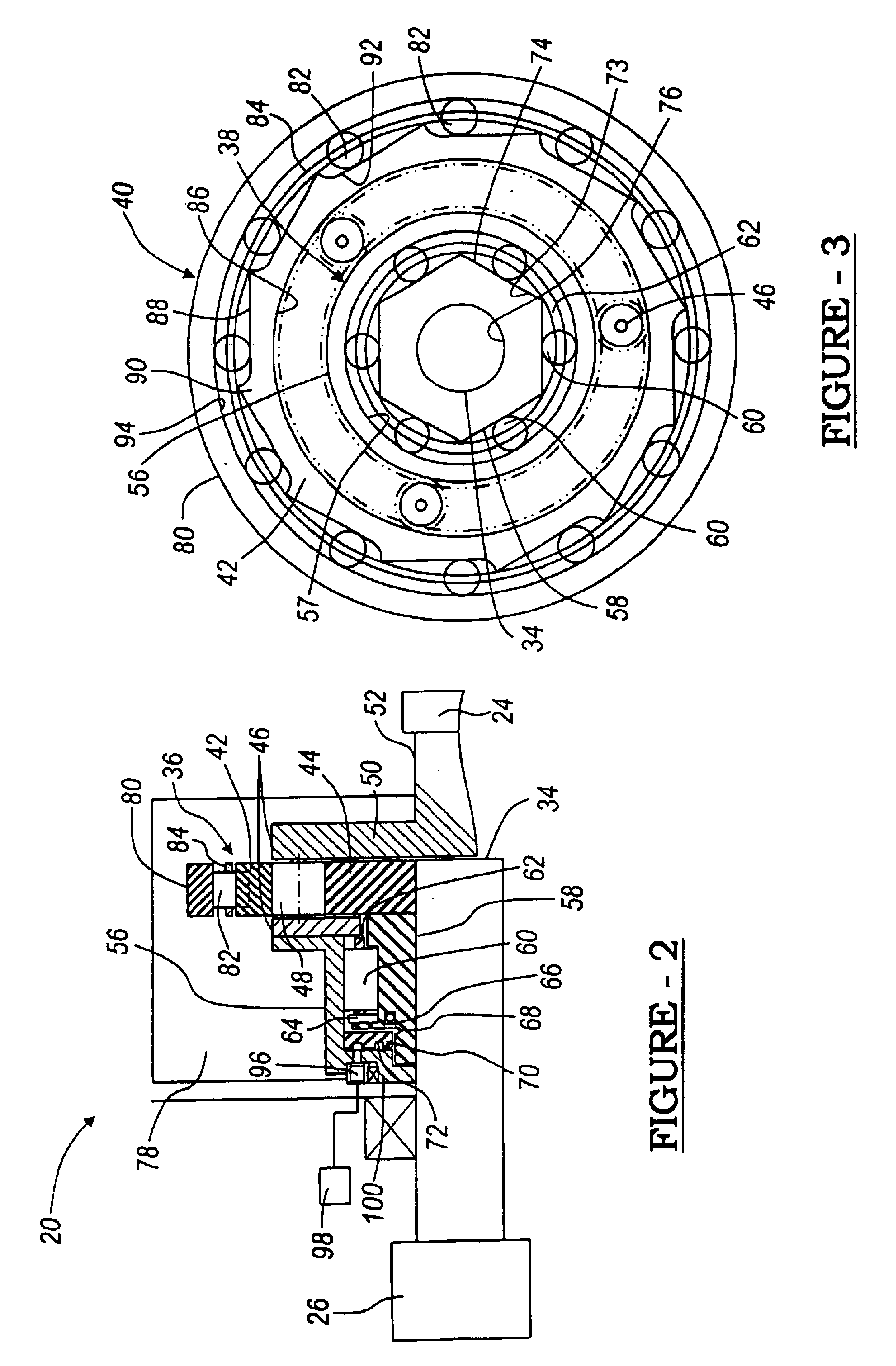

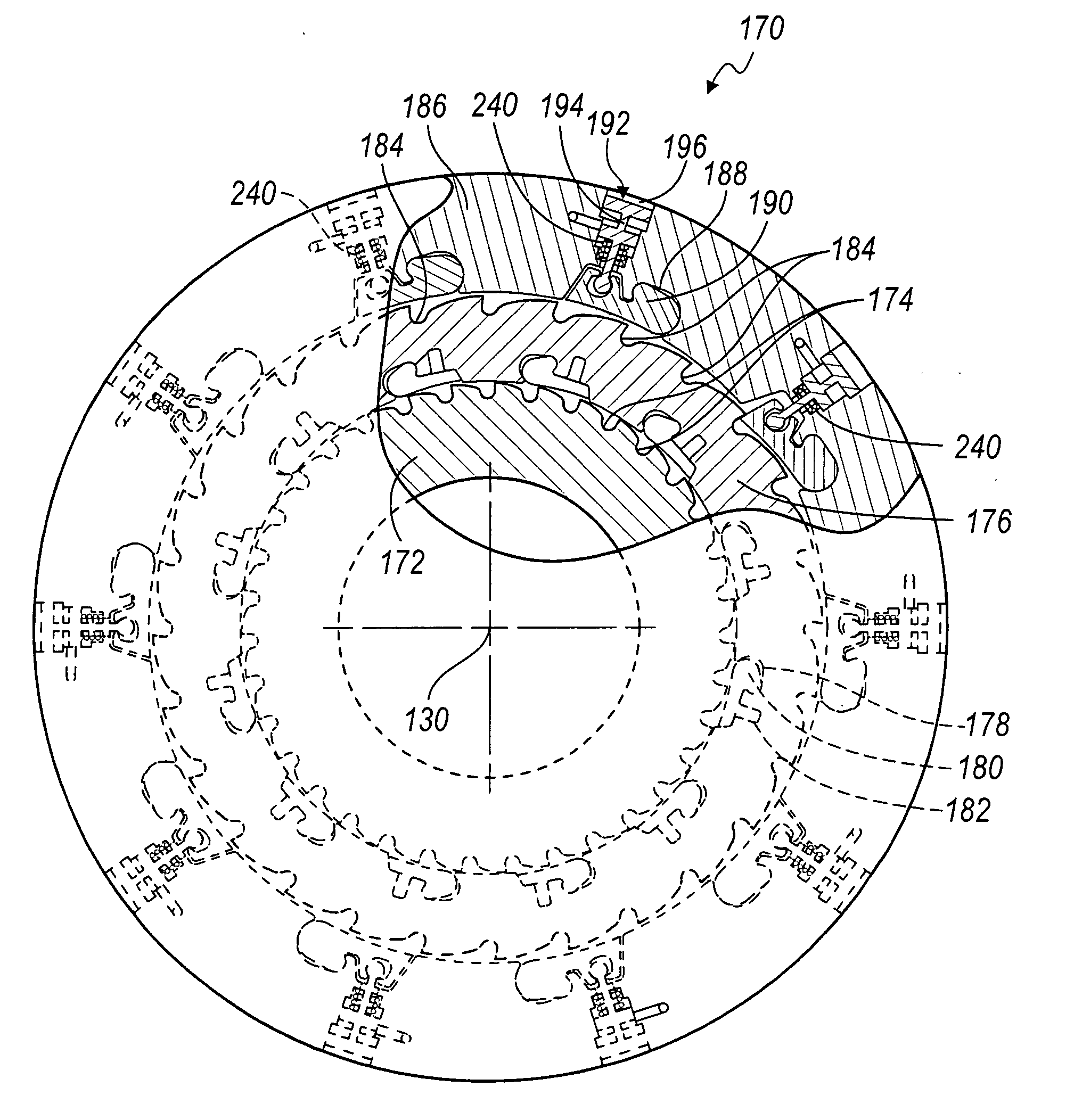

Overrunning radial coupling assembly and method for controlling the engagement of inner and outer members of the assembly

ActiveUS20060278487A1Prevent rotationFriction clutchesInterengaging clutchesCouplingRotation control

The overrunning radial coupling assembly or clutch and a method of controlling the engagement of inner and outer plates or members of the assembly are provided wherein adjacent engaging radial locking pawls are selectively controlled by a single, rotatable control plate or element to obtain full lock, one-way lock and one-way overrun conditions. The assembly includes free-floating, forward pawls and free-floating, reverse pawls adjacent to their respective forward pawls. The forward and reverse pawls are movable between a notch-engaging, engaged position (i.e., full lock condition) and a disengaged position in which the outer member is permitted to free-wheel relative to the inner member in the one-way overrun condition in one direction about a first axis and the outer member is locked to the inner member in the one-way lock condition in the opposite direction. A number of different embodiments of the assembly and method are provided.

Owner:MEANS IND INC

Ratcheting one-way clutch having rockers

ActiveUS7455157B2Prevent chafing and wearPrevent removalFriction clutchesInterengaging clutchesEngineeringCam

An overrunning clutch includes a cam plate formed with cams angularly spaced about a central axis, and a rocker plate that includes pockets angularly spaced about the central axis. Each pocket includes a first concave surface having a center located within the pocket and through which a pivot axis passes. Each pocket contains a rocker that includes a first convex surface complementary to, and at least partially surrounded by the first concave surface. Springs, supported on the rocker plate, each urge a rocker to pivot about the pivot axis toward the cam plate.

Owner:FORD GLOBAL TECH LLC

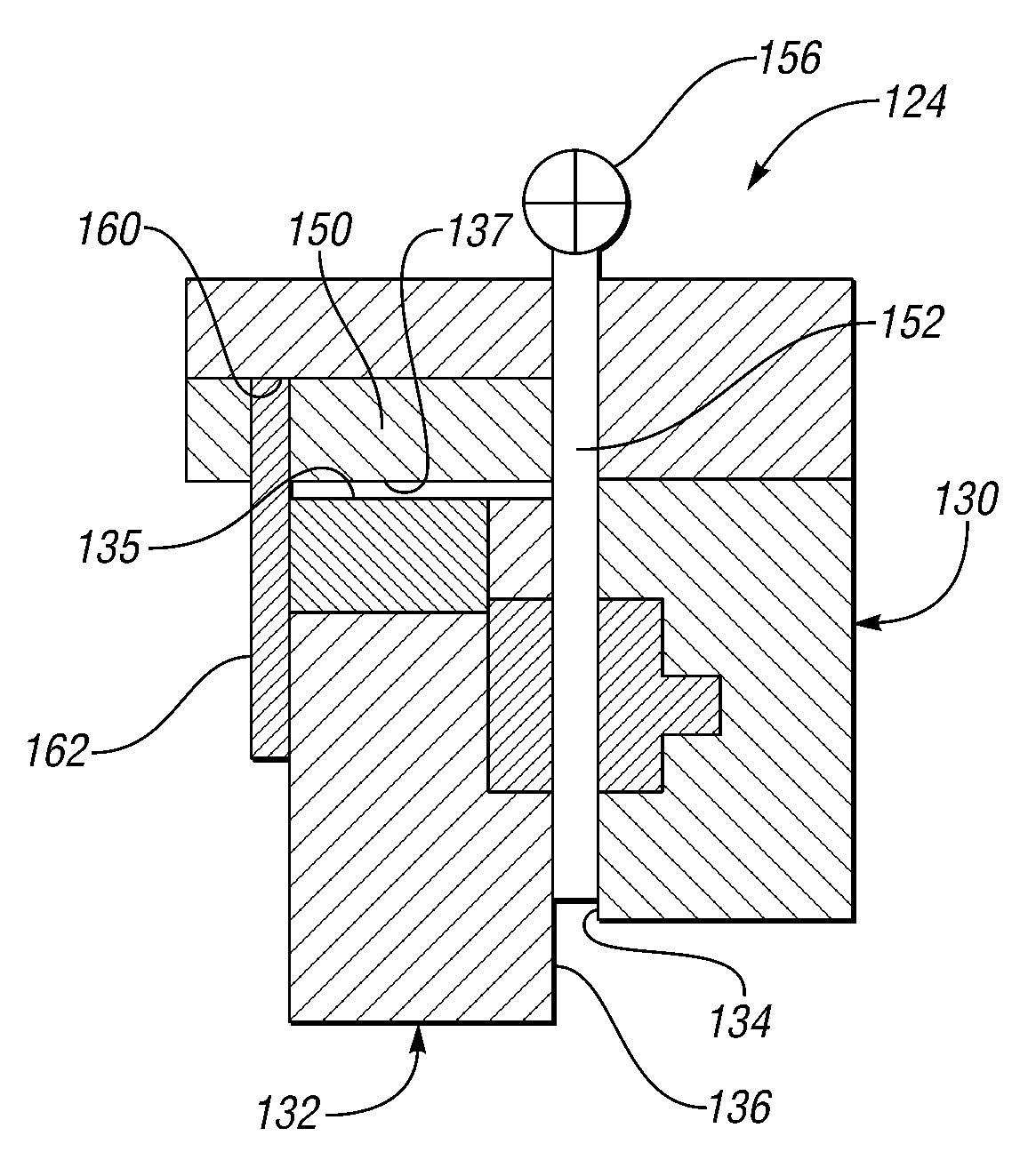

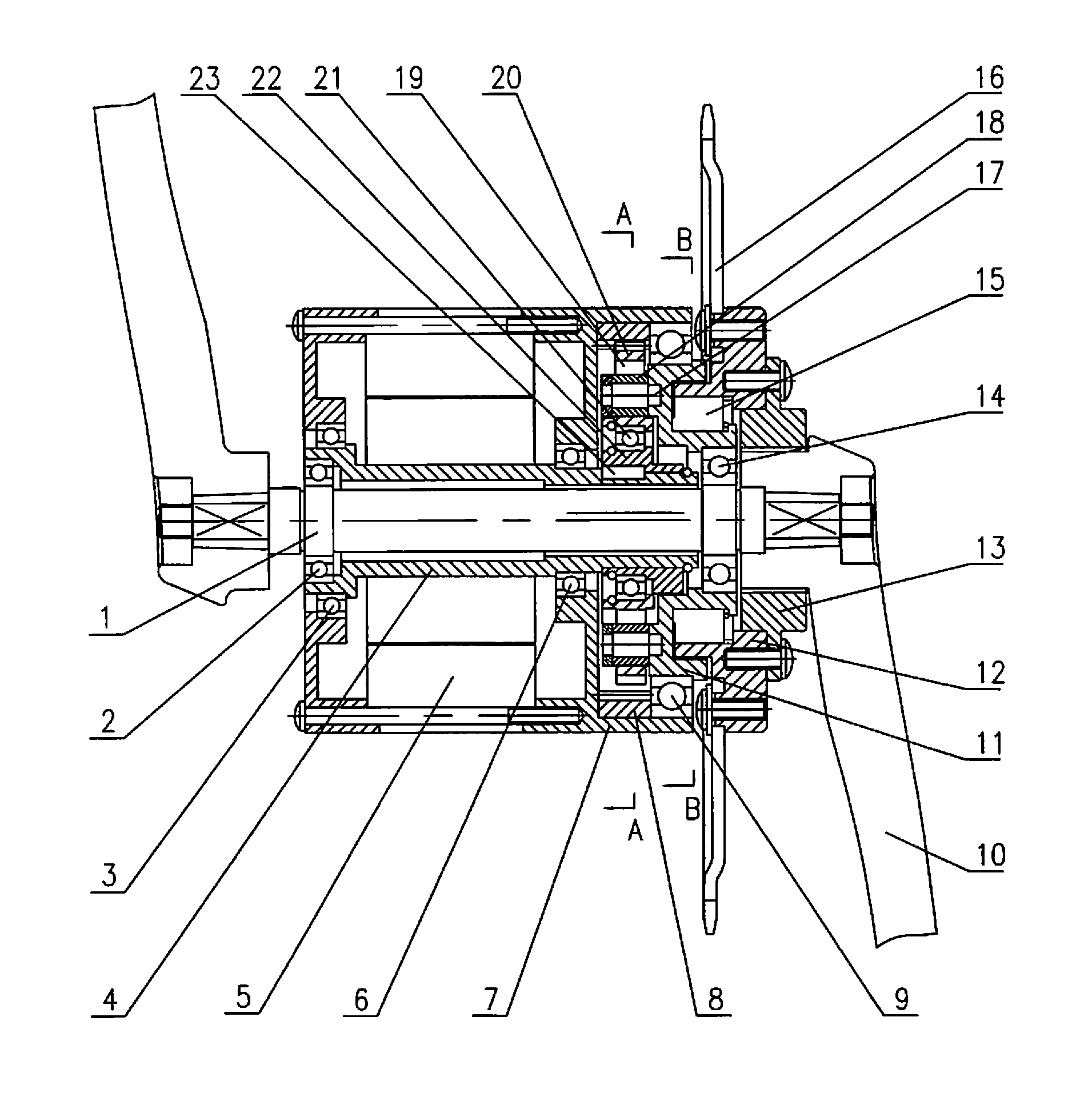

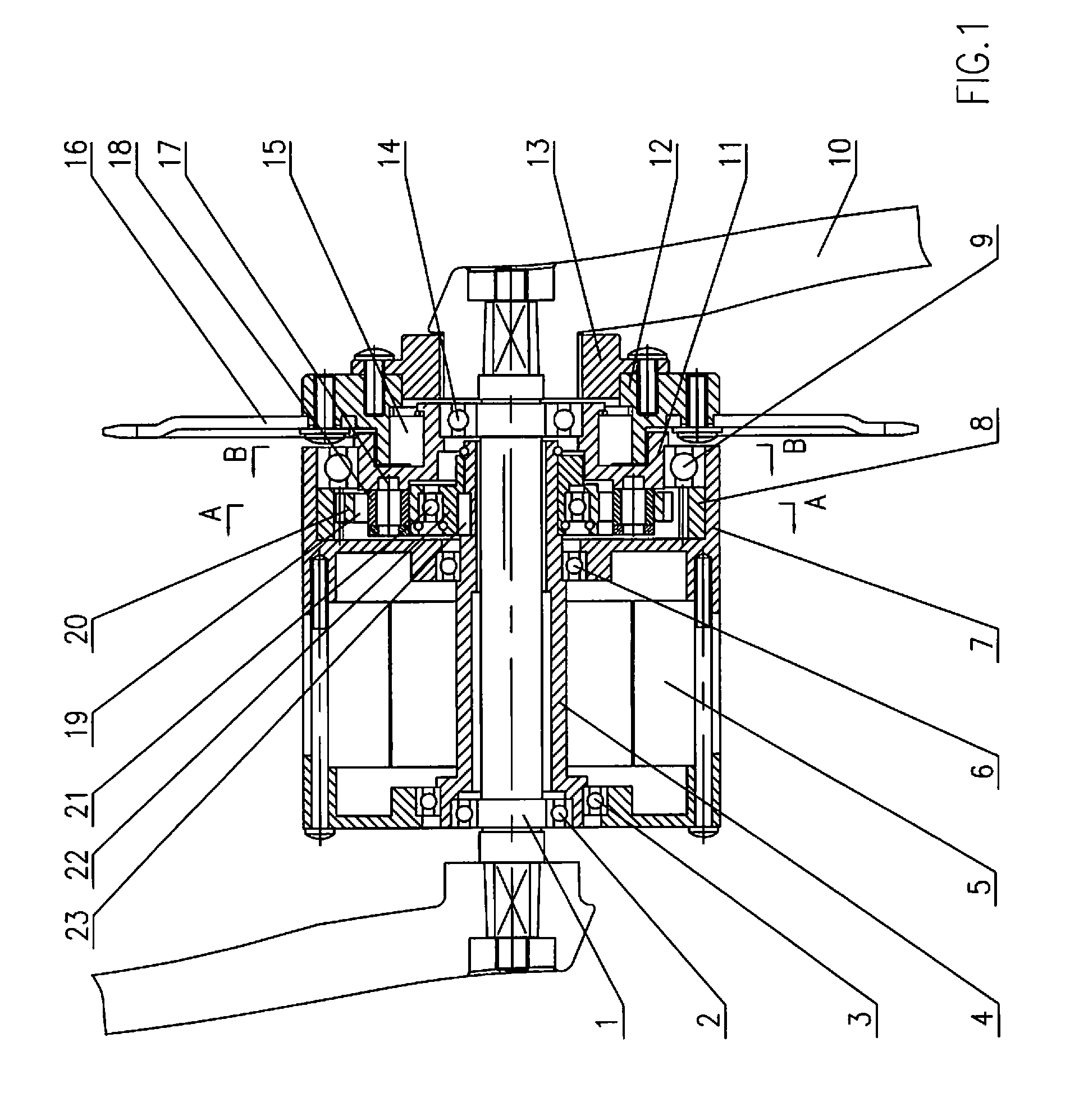

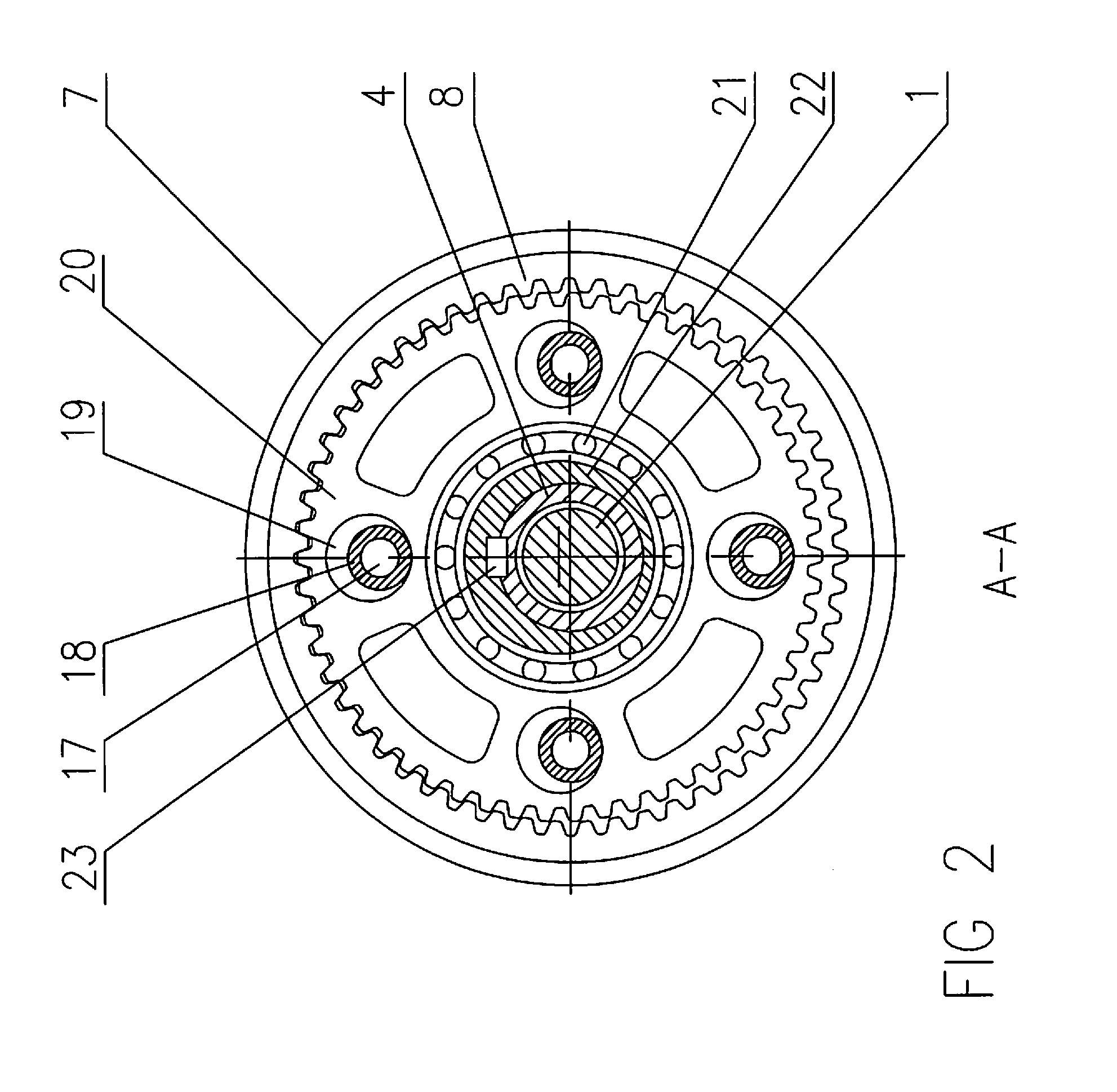

Motor having an integrated torque sensor

A motor unit comprises a housing for containing a motor, a motor shaft for receiving a motor provided driving force, a torque sensor mechanism for detecting torque, and a controller for controlling power to the motor in response to a detected amount of torque. An actuator couples the torque sensor to a sensor of the controller. The actuator is configured to move relative to the controller sensor thereby causing the sensor to produce a signal indicative of the detected level of torque. The controller is contained within the housing of the motor. The motor unit may also have an auxiliary shaft for receiving an externally provided driving force with a first torque transmission path for transferring the externally provided driving force to a drive mechanism and a second torque transmission path for transferring the motor provided driving force to said drive mechanism. A first one way drive means is provided in the first torque transmission path between the auxiliary shaft and the drive mechanism such that when the drive mechanism is being driven by the motor provided driving force through the second torque transmission path, the auxiliary shaft is able to freewheel. The motor unit can drive any apparatus, but may be used in a pedal driven apparatus such as a bicycle where an externally provided driving force is provided by manually operable pedals of said apparatus which are fixed for rotation with the auxiliary shaft. In this case, the auxiliary shaft comprises a pedal spindle of the bicycle and the drive mechanism comprises a sprocket or belt drive.

Owner:FOSTER ASSETS CORPORATION

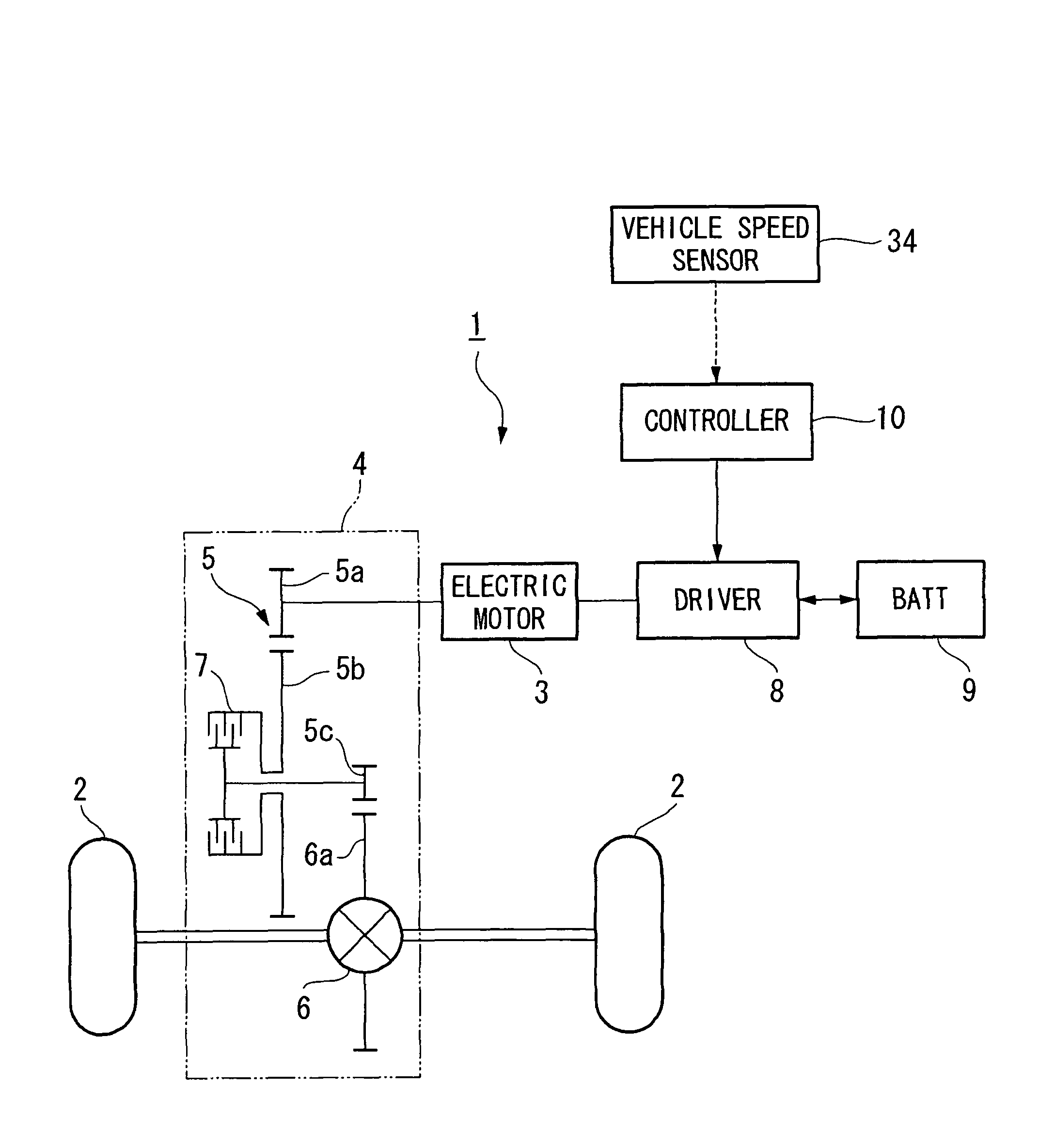

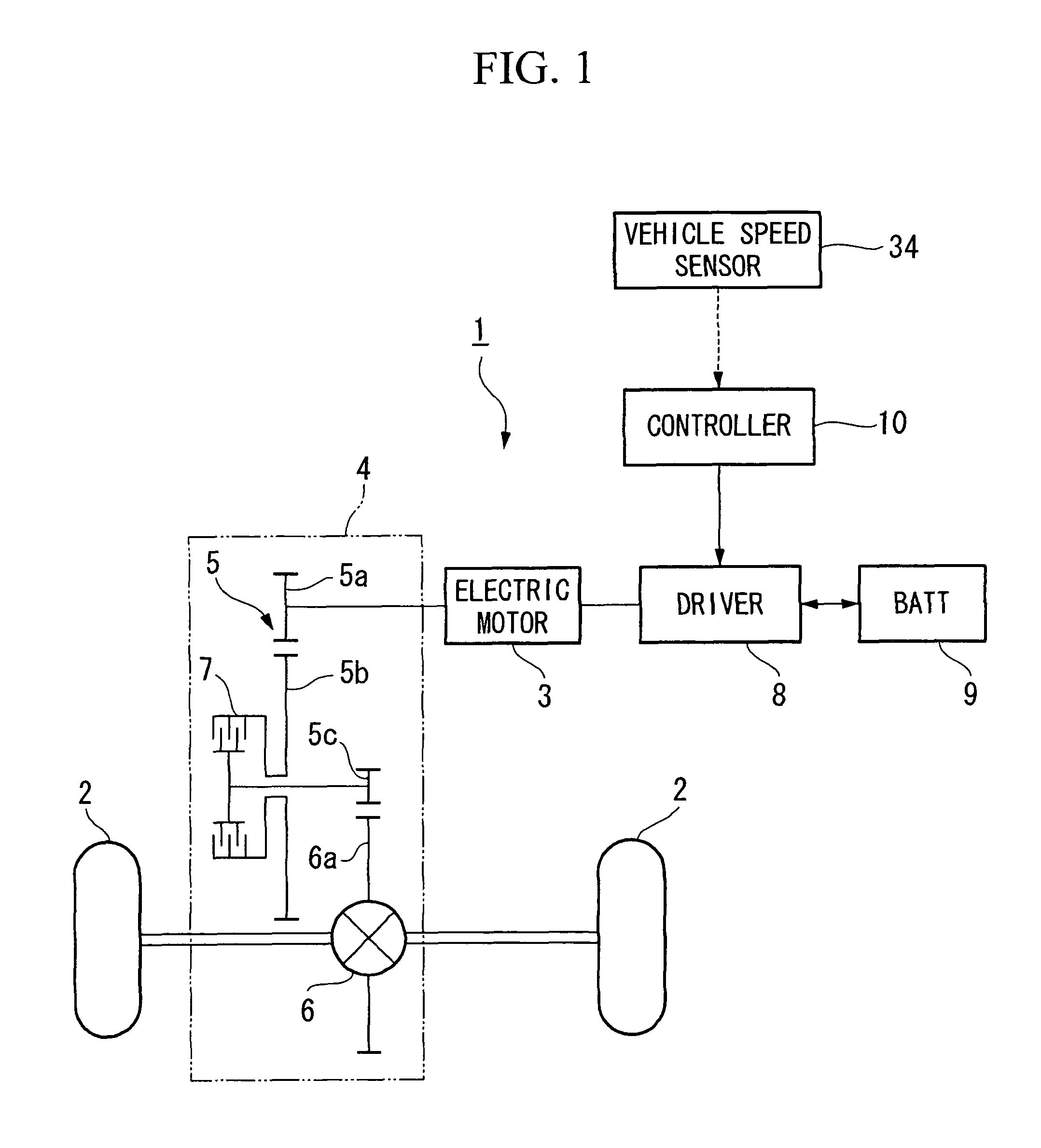

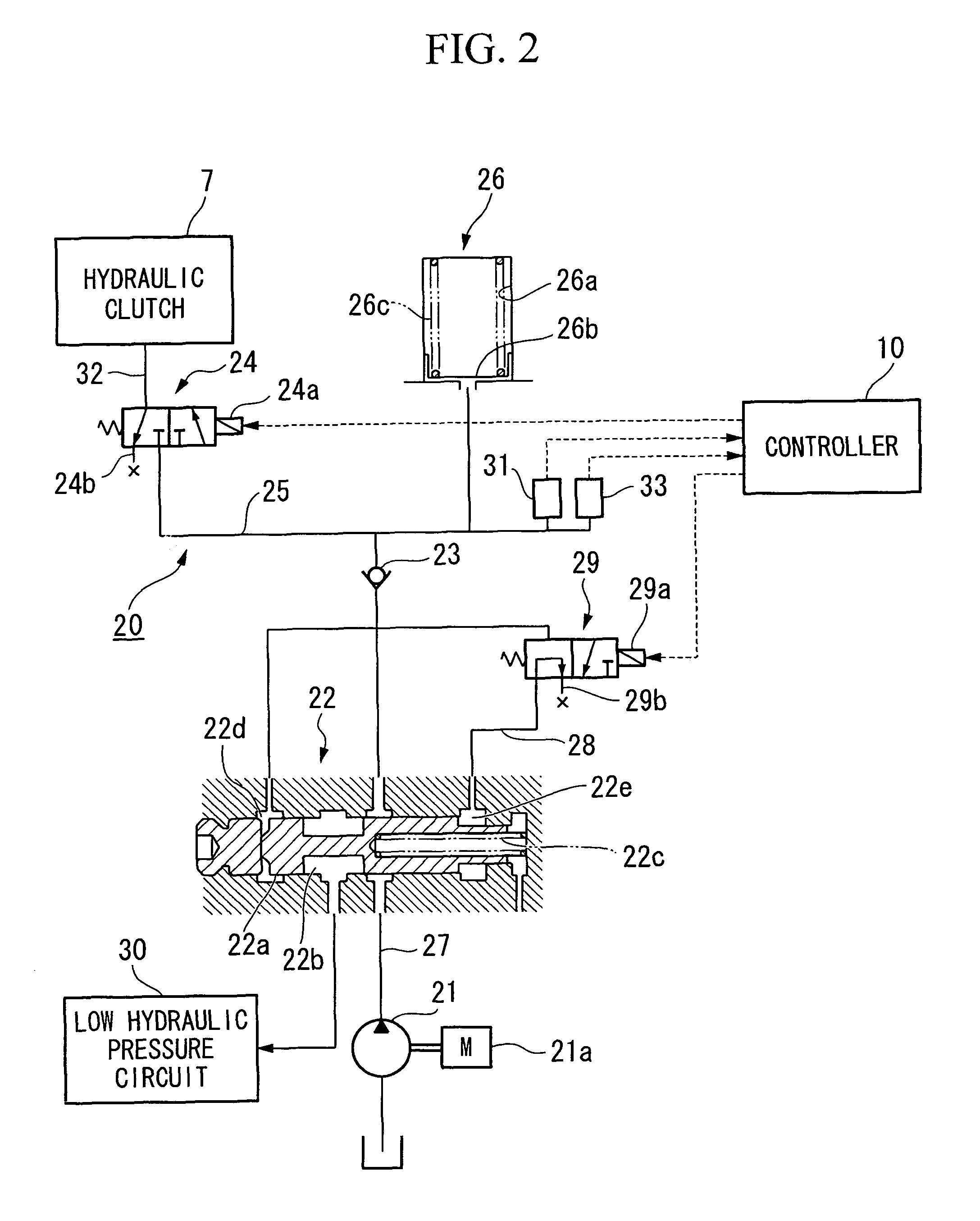

Control unit for an electric oil pump

InactiveUS7909729B2Reduce power consumptionReduce operating frequencyGearingFluid actuated clutchesFluid supplyControl unit

A control unit for an electric oil pump of the present invention includes: a one-way valve that permits circulation of operating fluid from the electric oil pump to the friction engagement device and blocks circulation in the opposite direction; an accumulator that is connected to a fluid supply path joining the one-way valve to the friction engagement device and accumulates hydraulic pressure required for operating the friction engagement device; a hydraulic pressure measuring device that measures hydraulic pressure inside the fluid supply path; a vehicle speed measuring device that measures a vehicle speed of the vehicle; and a pressure setting device that sets a first predetermined pressure based on the vehicle speed measured by the vehicle speed measuring device.

Owner:HONDA MOTOR CO LTD

Selectable one-way clutch

A controllable selectable one-way clutch is provided for use within a hybrid transmission. The clutch comprises an outer and inner race, and a first and second selector plate. A transmission motor controller synchronizes the speeds of the races to facilitate application and release of the clutch, and a transmission controller communicates a signal to the clutch for re-positioning of the plates to apply and release the clutch. The clutch has three operational modes, including freewheeling and holding torque in one direction or both directions. A method is also provided for applying a selectable one-way clutch in a vehicle having a hybrid transmission with a motor controller and a transmission controller, including synchronizing the clutch speed using the motor controller, detecting the direction of the race speed difference, communicating the race speed difference to the transmission controller, and selecting between the clutch operational modes in response to the detected speed difference.

Owner:GM GLOBAL TECH OPERATIONS LLC

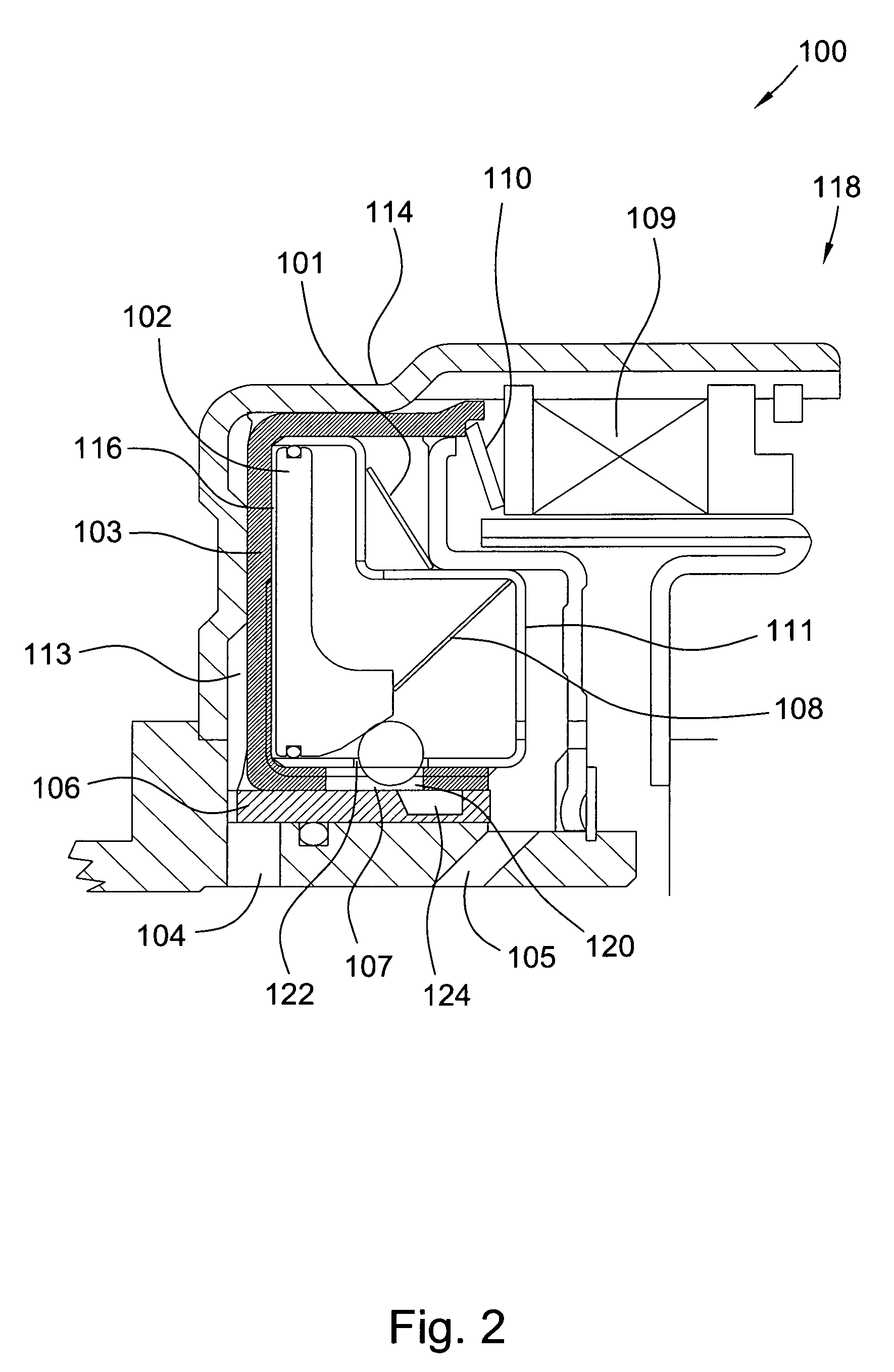

Clutch and brake latch mechanism

A clutch including: a first piston displaceable to operate a clutch pack; a second piston; a first fluid chamber partially formed by the pistons, wherein the second piston is displaceable by fluid pressure in the first fluid chamber; and a locking means fixable by the second piston to hold the pack closed. In a preferred embodiment, the locking means includes at least one displaceable ball. In another preferred embodiment, in response to a loss of fluid pressure in the first chamber, the second piston is displaceable to enable displacement of the locking means to open the pack. In a further preferred embodiment, the clutch includes a second chamber, separate from the first chamber and partially formed by the first piston. The first piston is displaceable in response to fluid pressure in the second chamber. The pack remains closed after a loss or reduction of fluid pressure in the second chamber.

Owner:SCHAEFFLER TECH AG & CO KG

Torque limited decoupler

A decoupler assembly is provided for allowing an alternator to be rotatably driven by a serpentine belt in an engine of an automotive vehicle and for allowing the speed of the belt to oscillate relative to the alternator. A hub is fixedly carried by a drive shaft from the alternator for rotation therewith. A pulley is rotatably journaled to the hub by a ball bearing assembly. A bare, helical clutch spring is operatively coupled between the hub and pulley for transferring rotational movement from the pulley to the hub during acceleration of the pulley relative to the hub by the serpentine belt and for allowing the hub to overrun the pulley during deceleration of the pulley relative to the hub. A torque limiter, preferably a spring or sleeve, is wrapped about the torsion limiting outward expansion of the torsion isolating the torsion spring from torques above a predetermined limit.

Owner:LITENS AUTOMOTIVE INC

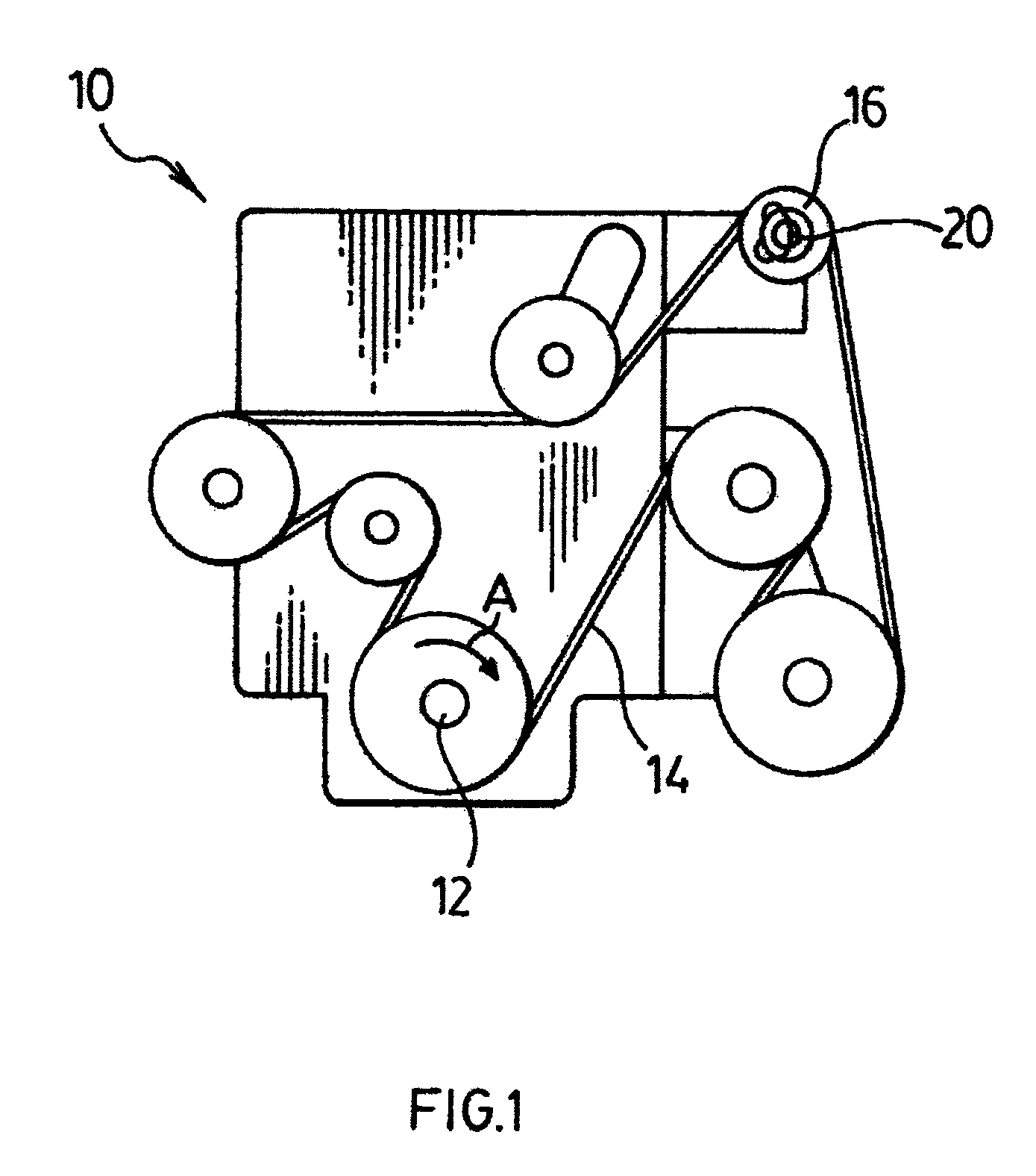

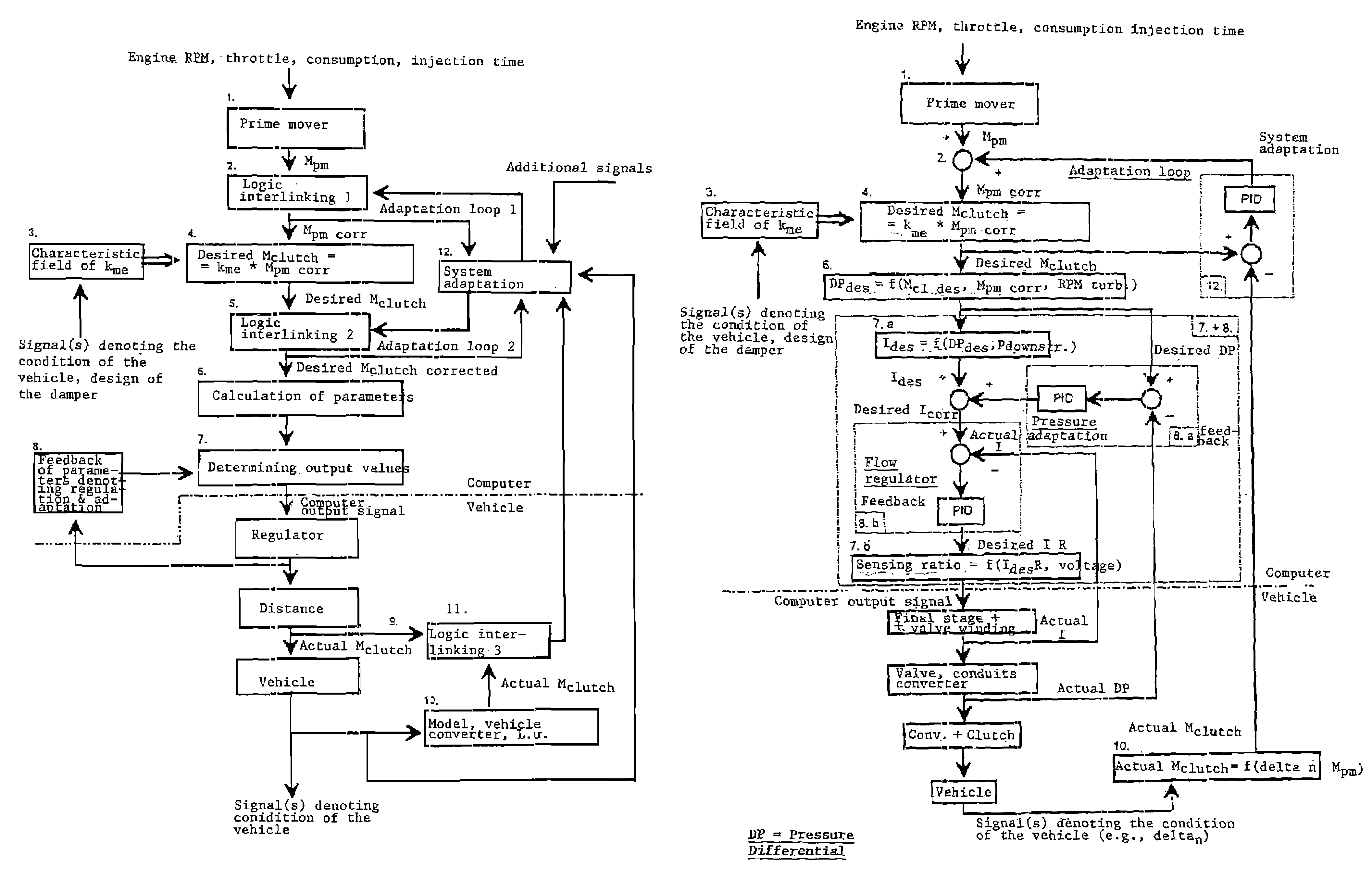

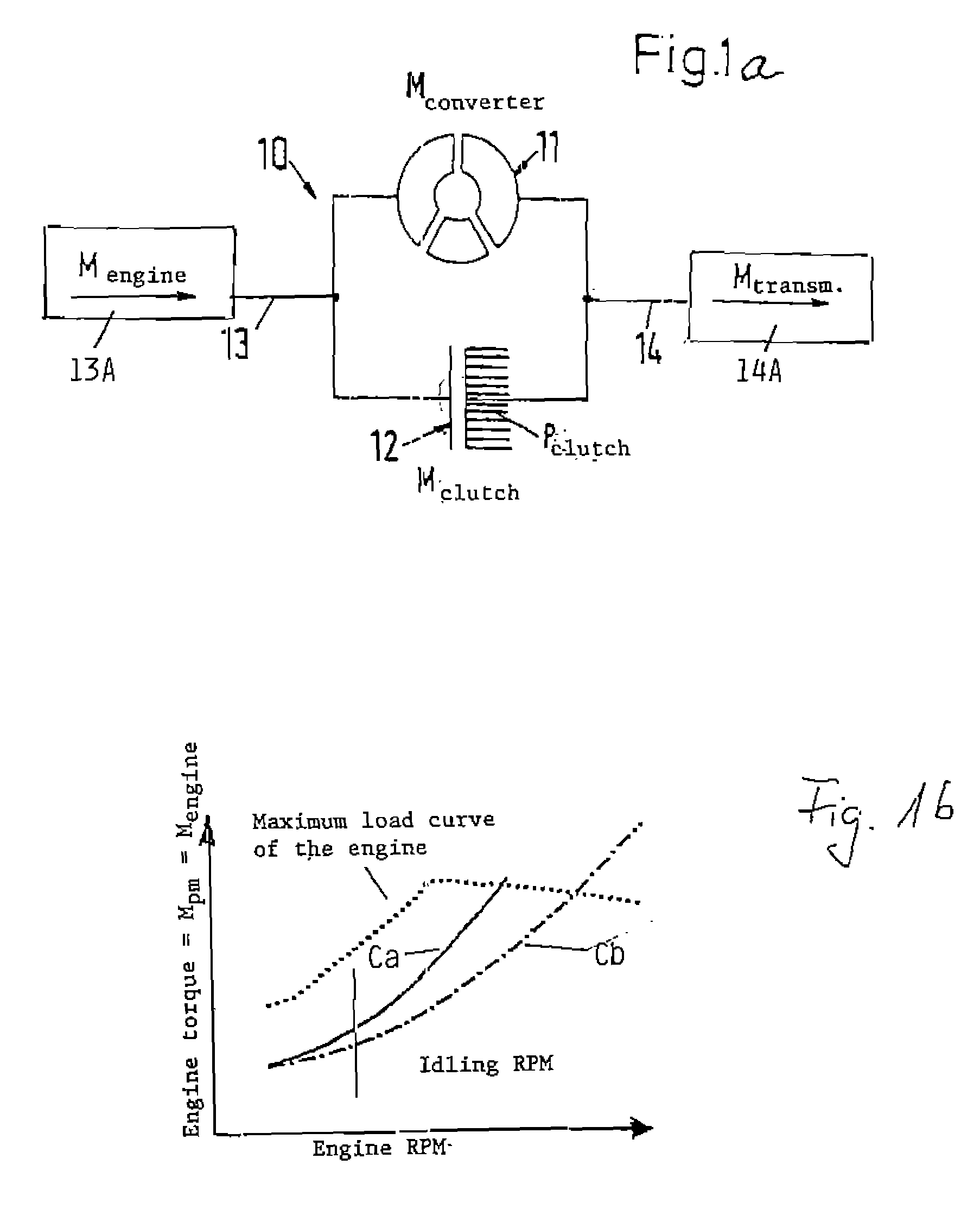

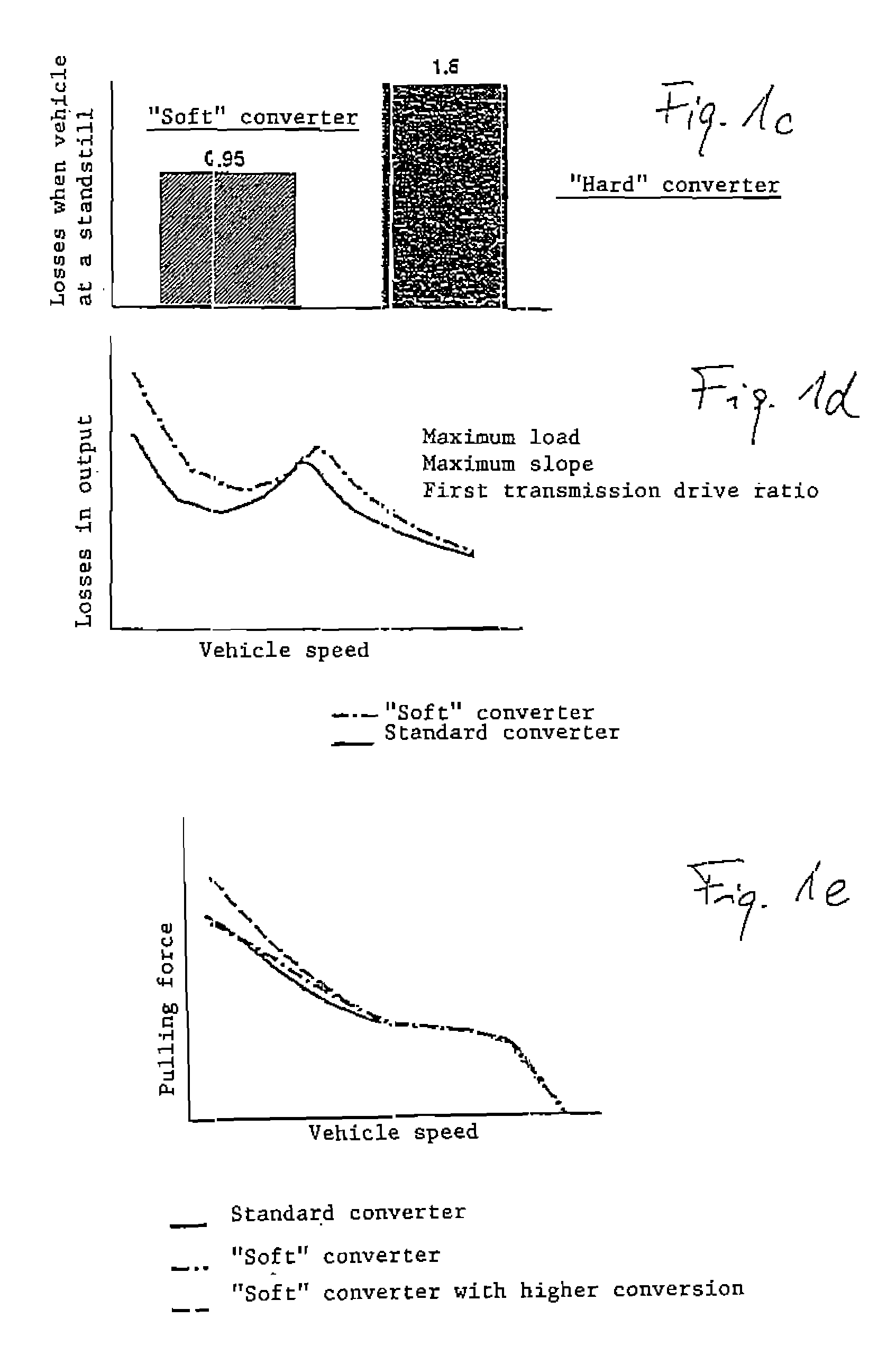

Method of and apparatus for transmitting torque in vehicular power trains

InactiveUS7286922B1Reduce capacityMechanical actuated clutchesDigital data processing detailsMobile vehicleAutomatic transmission

The magnitude of torque which can be transmitted by a bypass clutch between the housing and the turbine of a torque converter between a prime mover, such as an engine, and an automatic transmission in the power train of a motor vehicle is selectively regulatable by a computerized regulating unit. The regulation involves the transmission of torque by the clutch in dependency upon the magnitude of the torque being transmitted by the output element of the engine and ascertaining as well as adaptively applying to the clutch a variable force so that the clutch can transmit a predetermined torque. This entails automatic selection of a minimum slip between a torque receiving and a torque transmitting part of the power train. Compensation, particularly long-range compensation, is carried out for the existence of possible differences between the predetermined and actual torques being transmitted by the clutch.

Owner:LUK GETRIEBE SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com