Patents

Literature

827results about "Electrically actuated clutches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

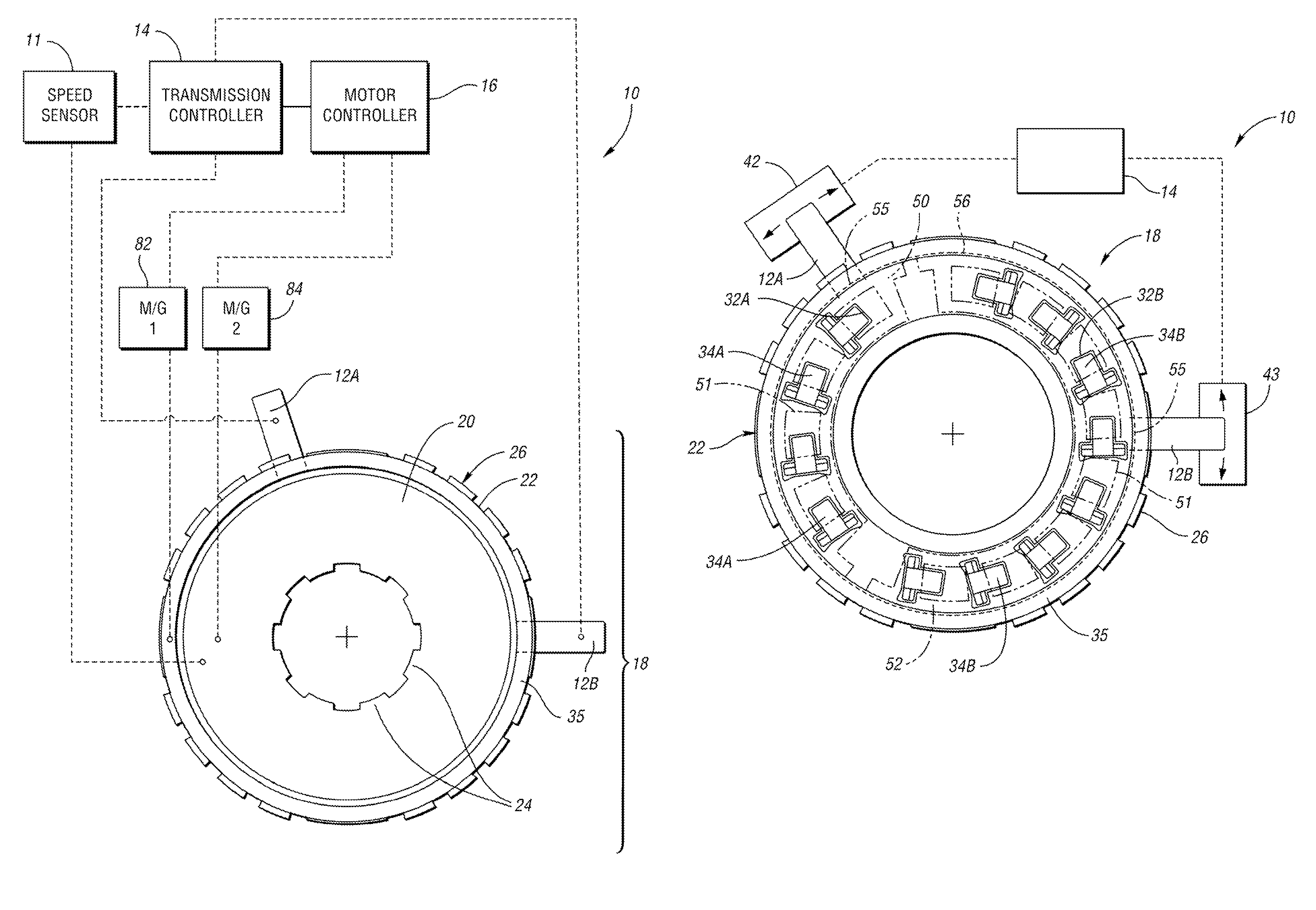

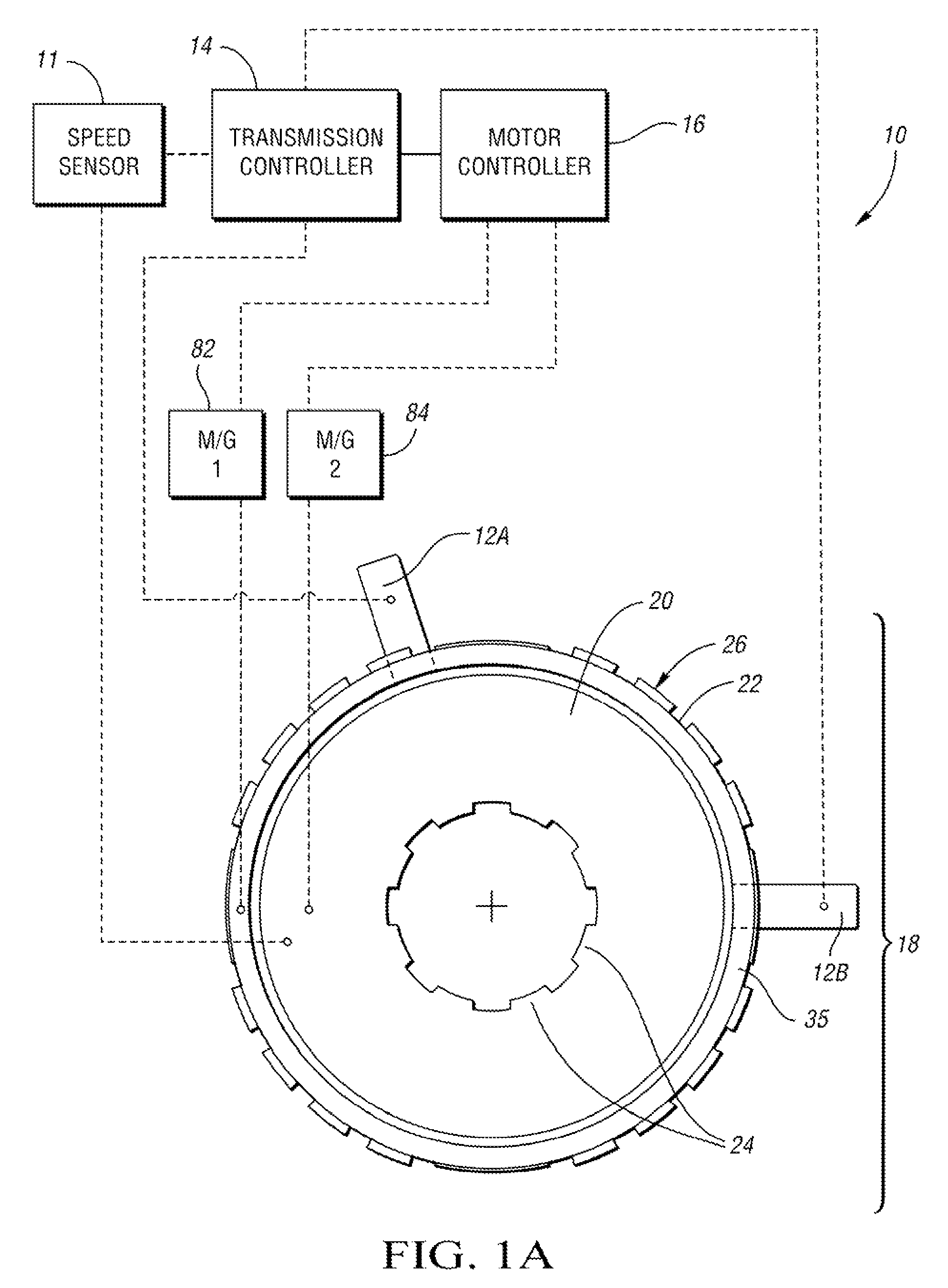

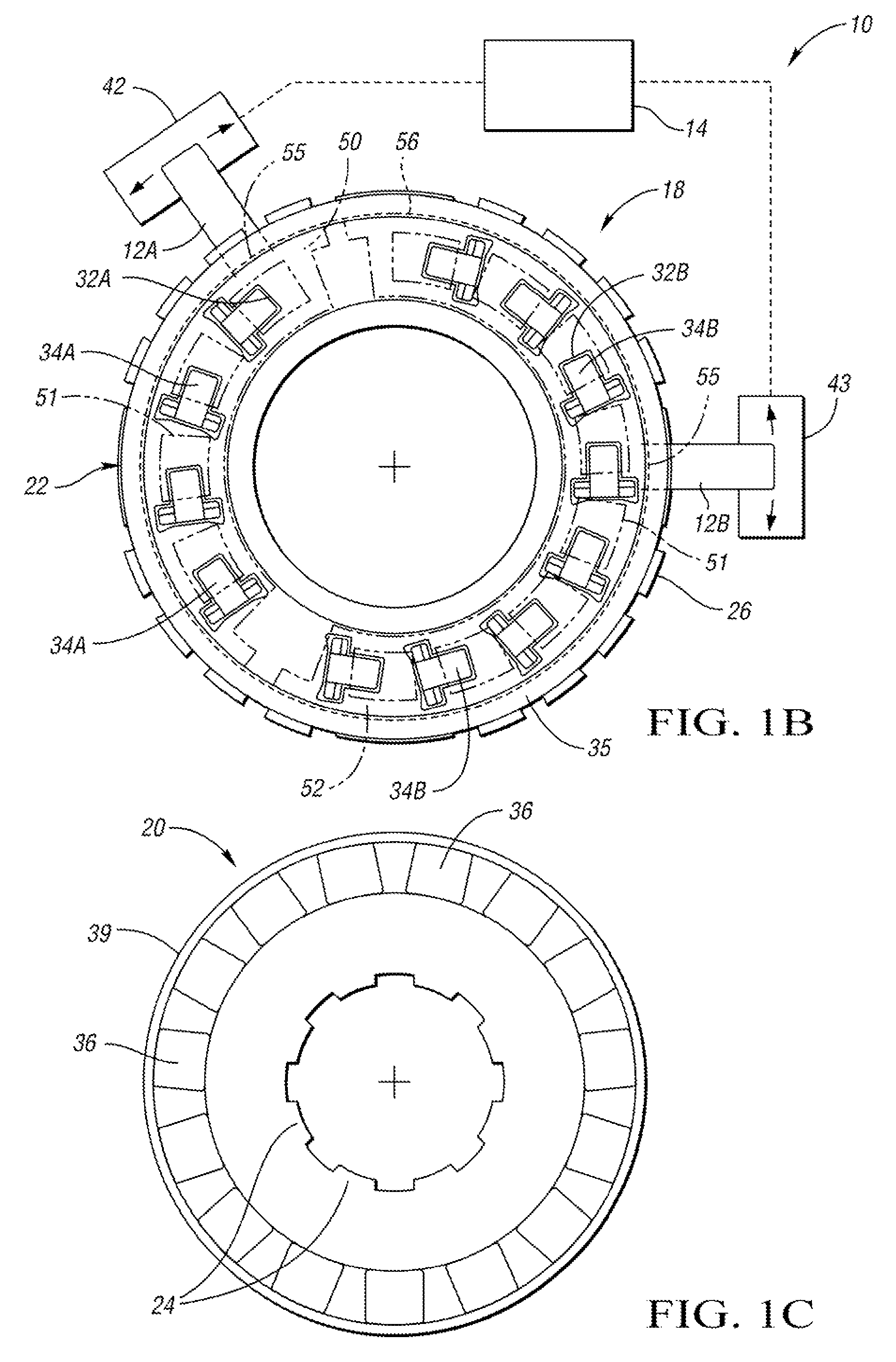

Selectable one-way clutch

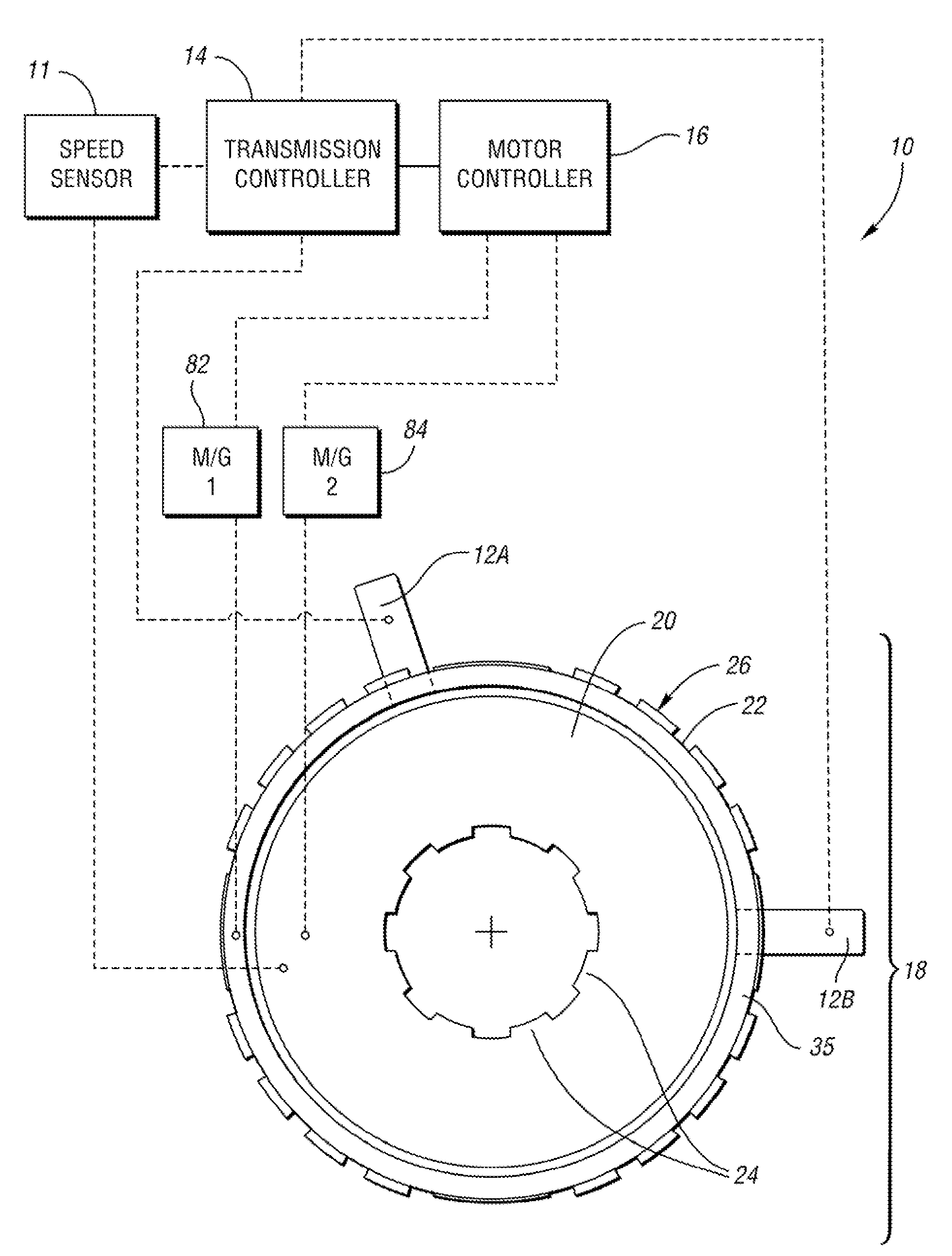

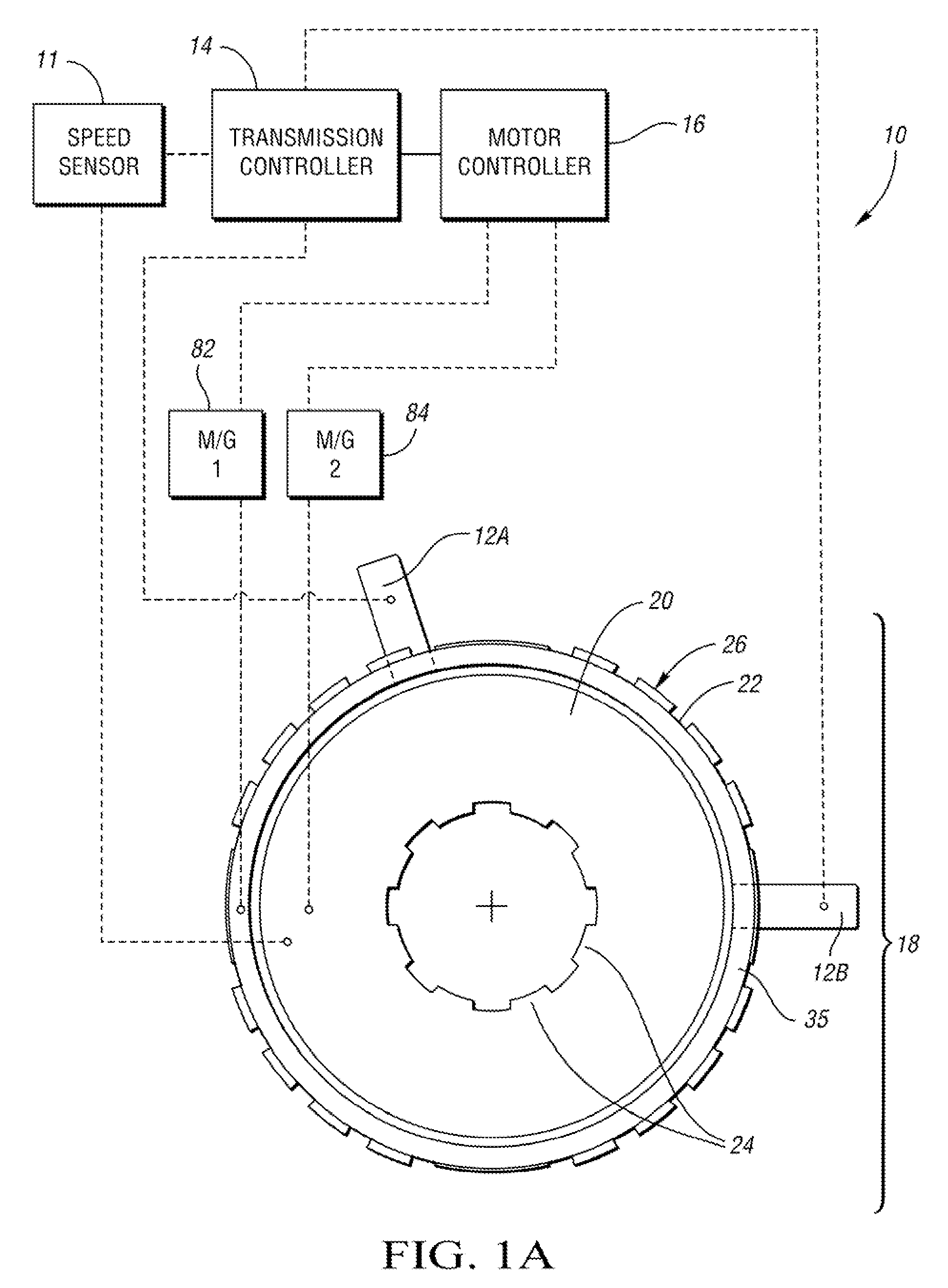

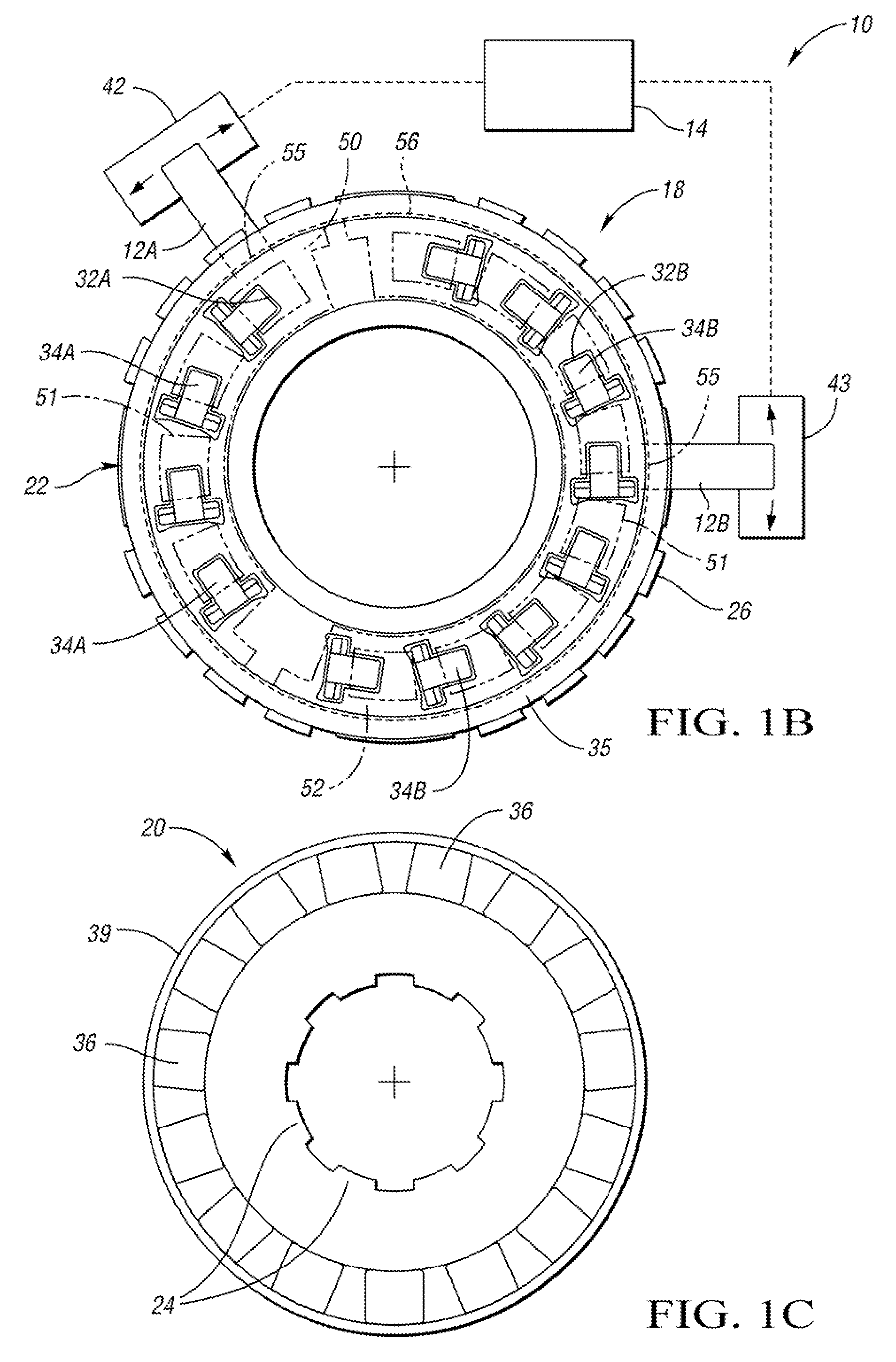

A controllable selectable one-way clutch is provided for use within a hybrid transmission. The clutch comprises an outer and inner race, and a first and second selector plate. A transmission motor controller synchronizes the speeds of the races to facilitate application and release of the clutch, and a transmission controller communicates a signal to the clutch for re-positioning of the plates to apply and release the clutch. The clutch has three operational modes, including freewheeling and holding torque in one direction or both directions. A method is also provided for applying a selectable one-way clutch in a vehicle having a hybrid transmission with a motor controller and a transmission controller, including synchronizing the clutch speed using the motor controller, detecting the direction of the race speed difference, communicating the race speed difference to the transmission controller, and selecting between the clutch operational modes in response to the detected speed difference.

Owner:GM GLOBAL TECH OPERATIONS LLC

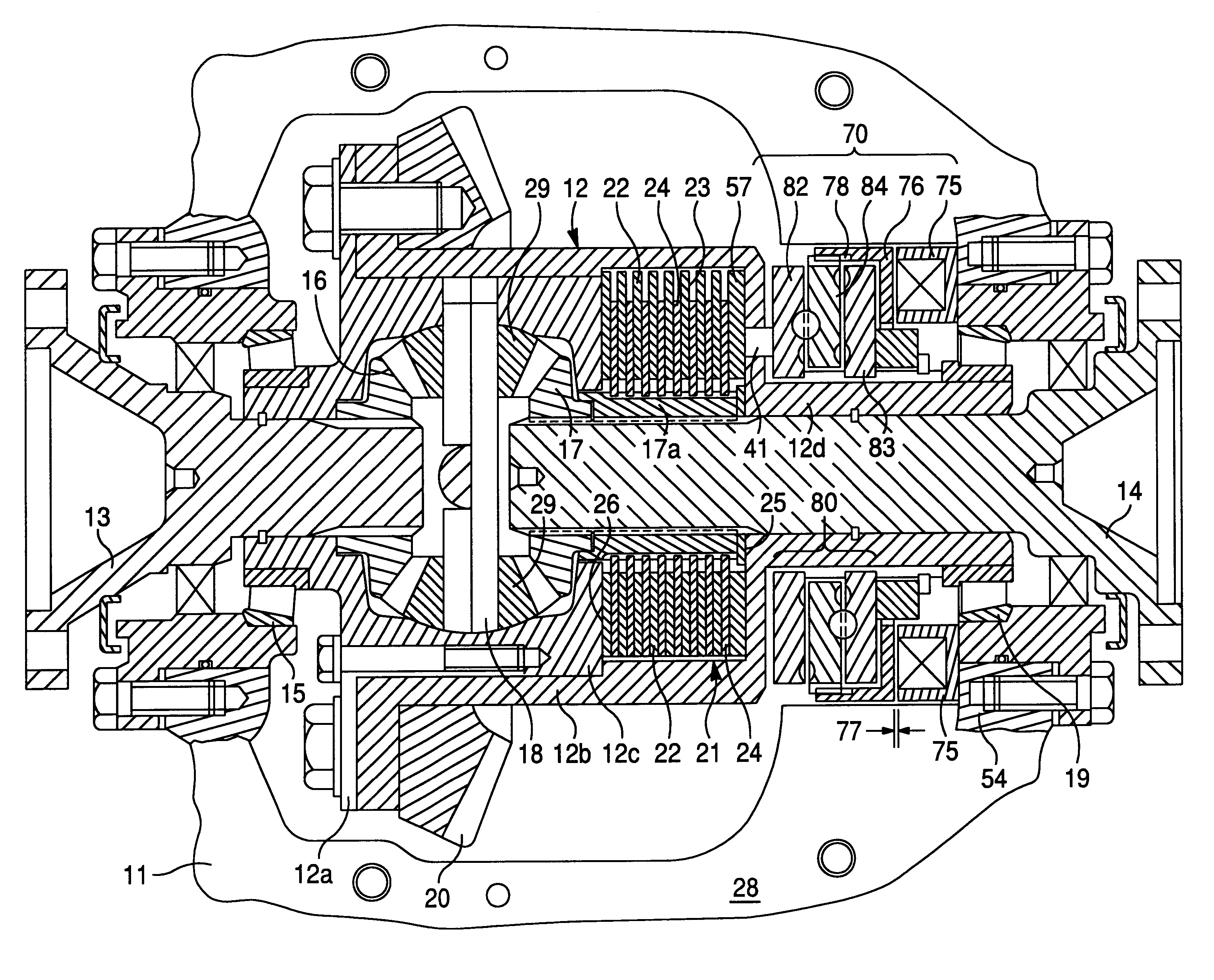

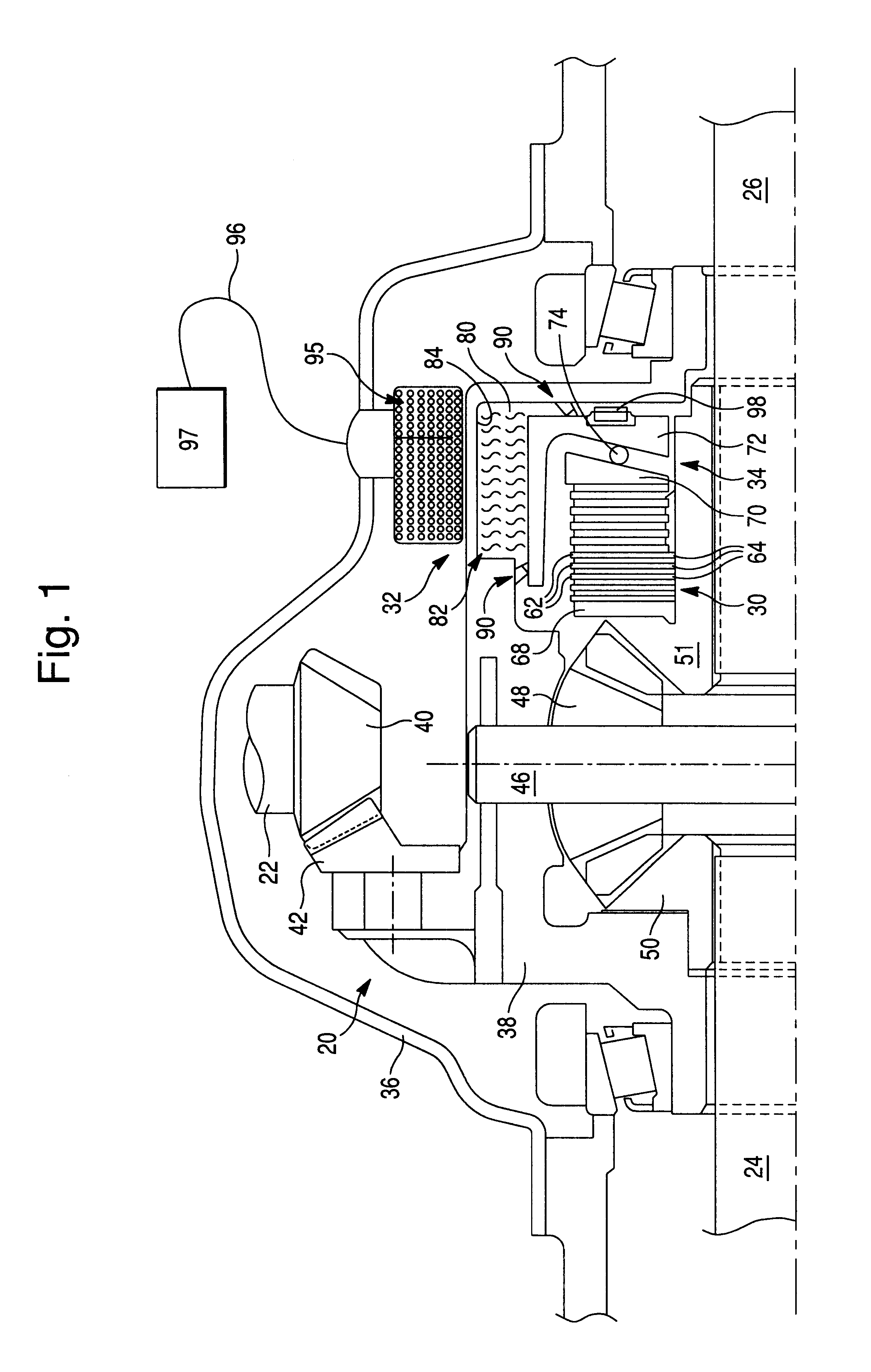

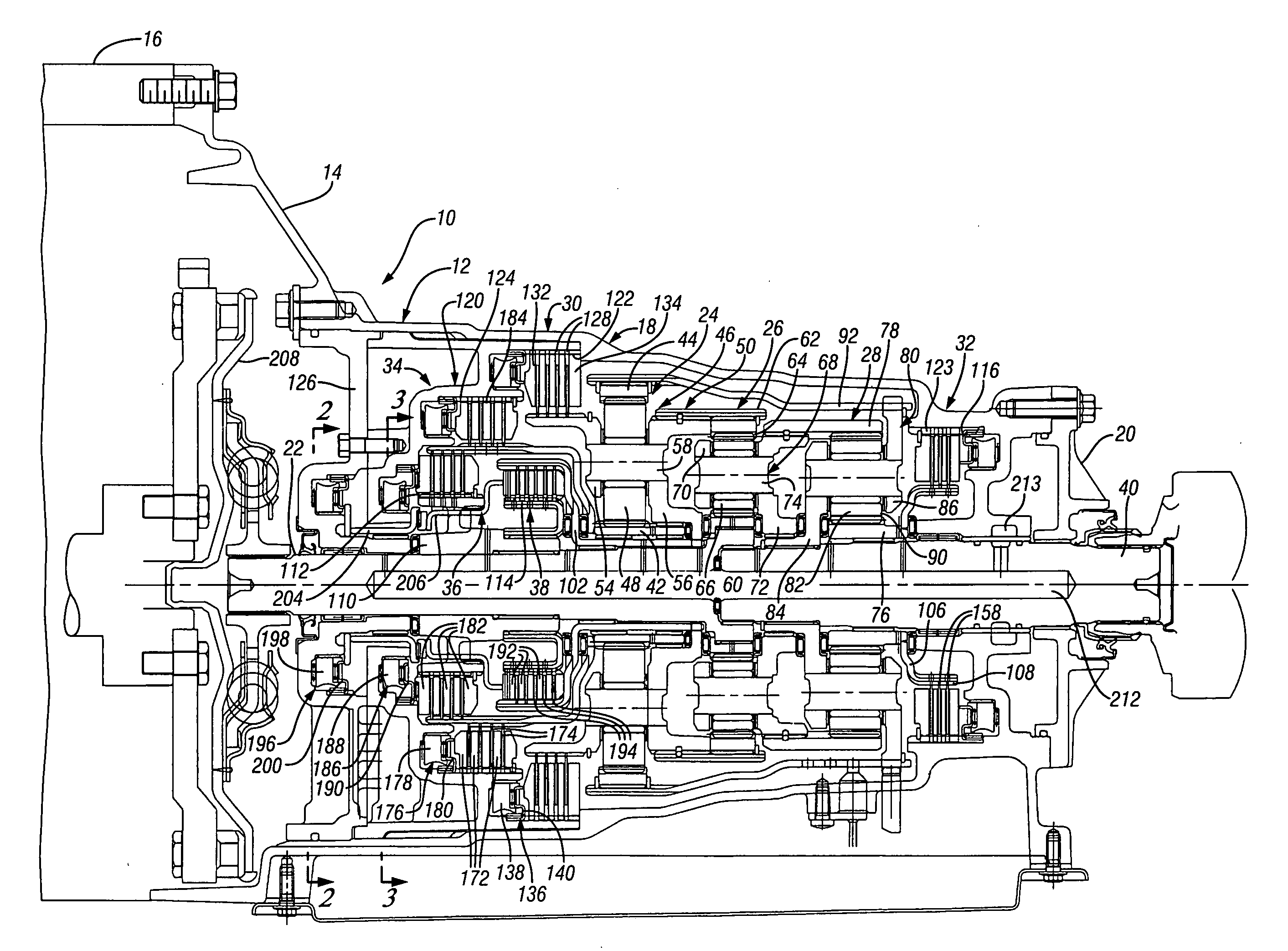

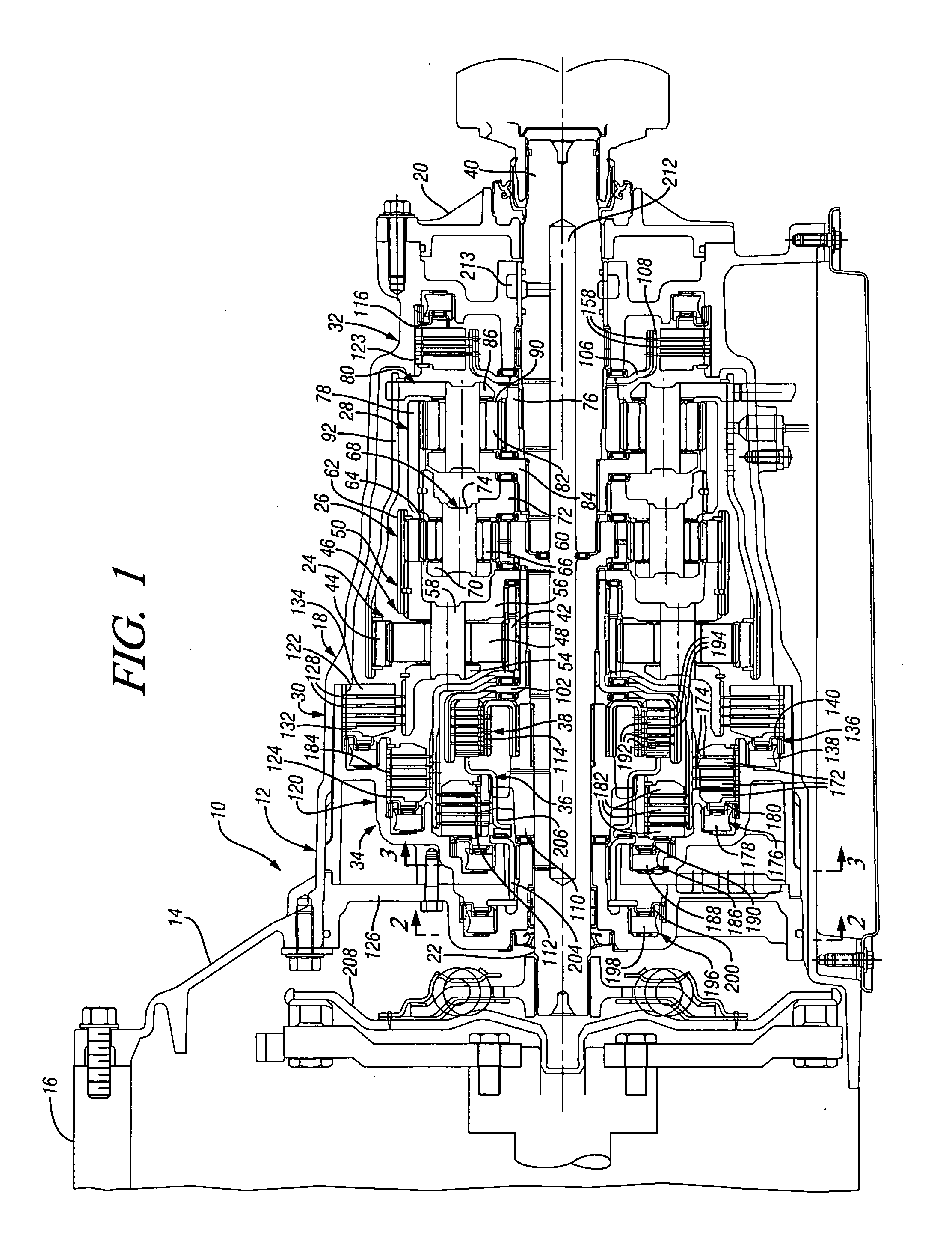

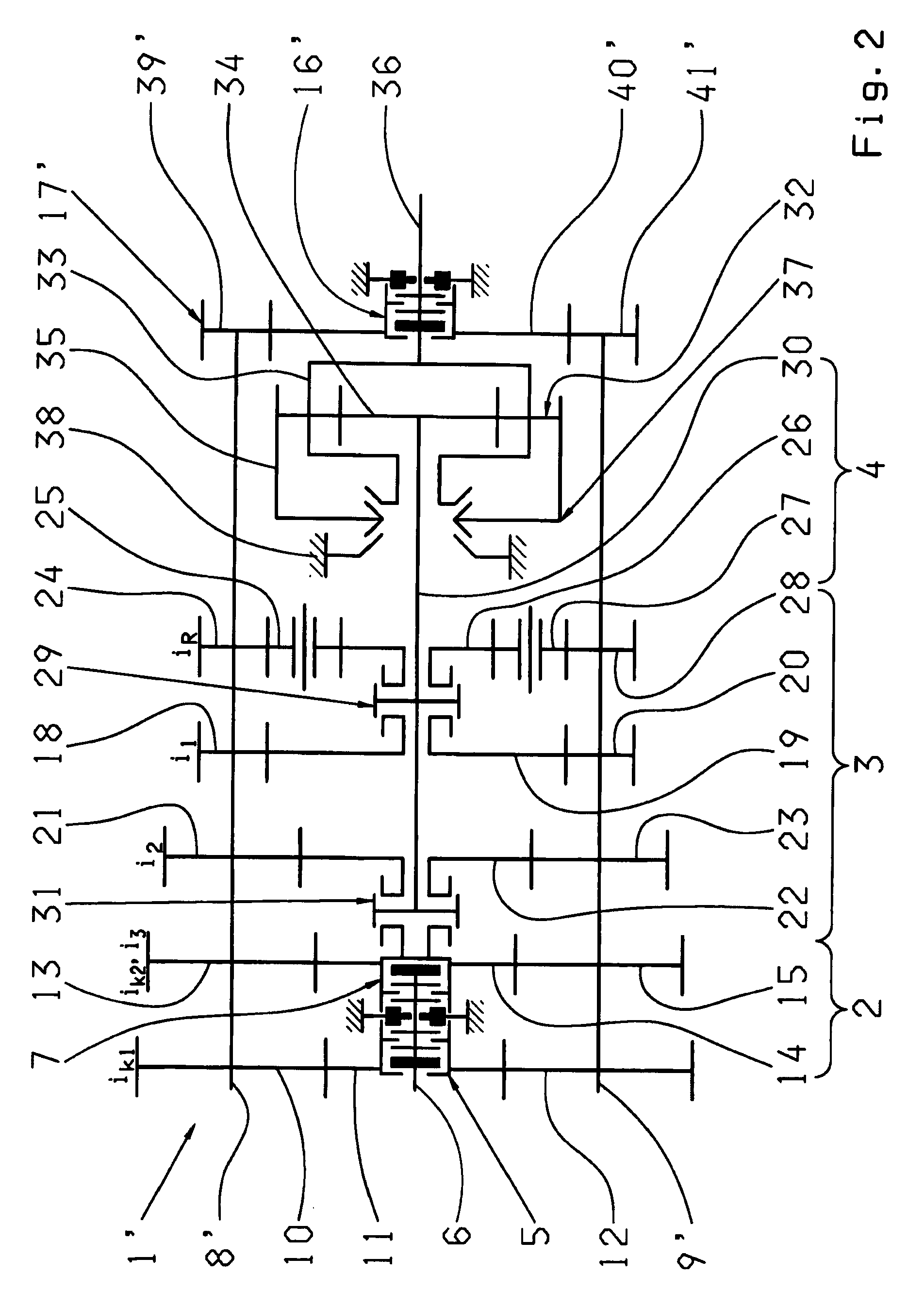

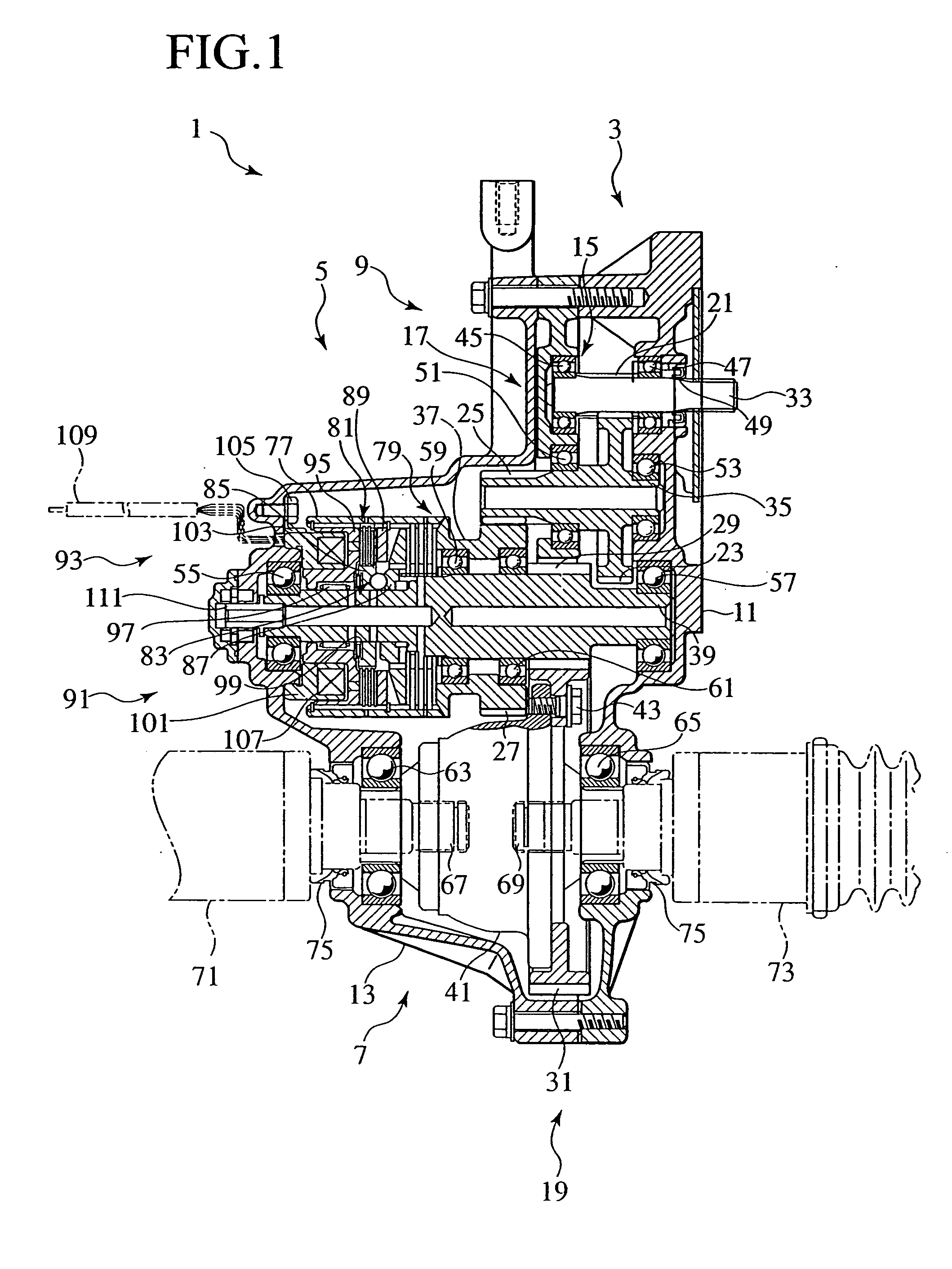

Electro-mechanical automatic transmission having dual input shafts

InactiveUS6044719APrevent rollbackImprove efficiencyRoad transportGear lubrication/coolingAutomatic transmissionEngineering

An electro-mechanical automatic transmission is provided including a first input shaft and a second input shaft concentric with the first input shaft. A plurality of drive gears are rotatably mounted to each input shaft and are provided with synchronizer devices for selectively engaging the drive gears to the input shafts. A driver shaft is provided with a plurality of driven gears in meshing engagement with the drive gears. The electro-mechanical automatic transmission is provided with a pair of electro-mechanical clutch actuators for selectively disengaging dual clutches which transmit engine torque to the input shafts, as well as an electro-mechanical shift actuator system which operatively engage the synchronizer devices for selectively engaging the drive gears.

Owner:FCA US

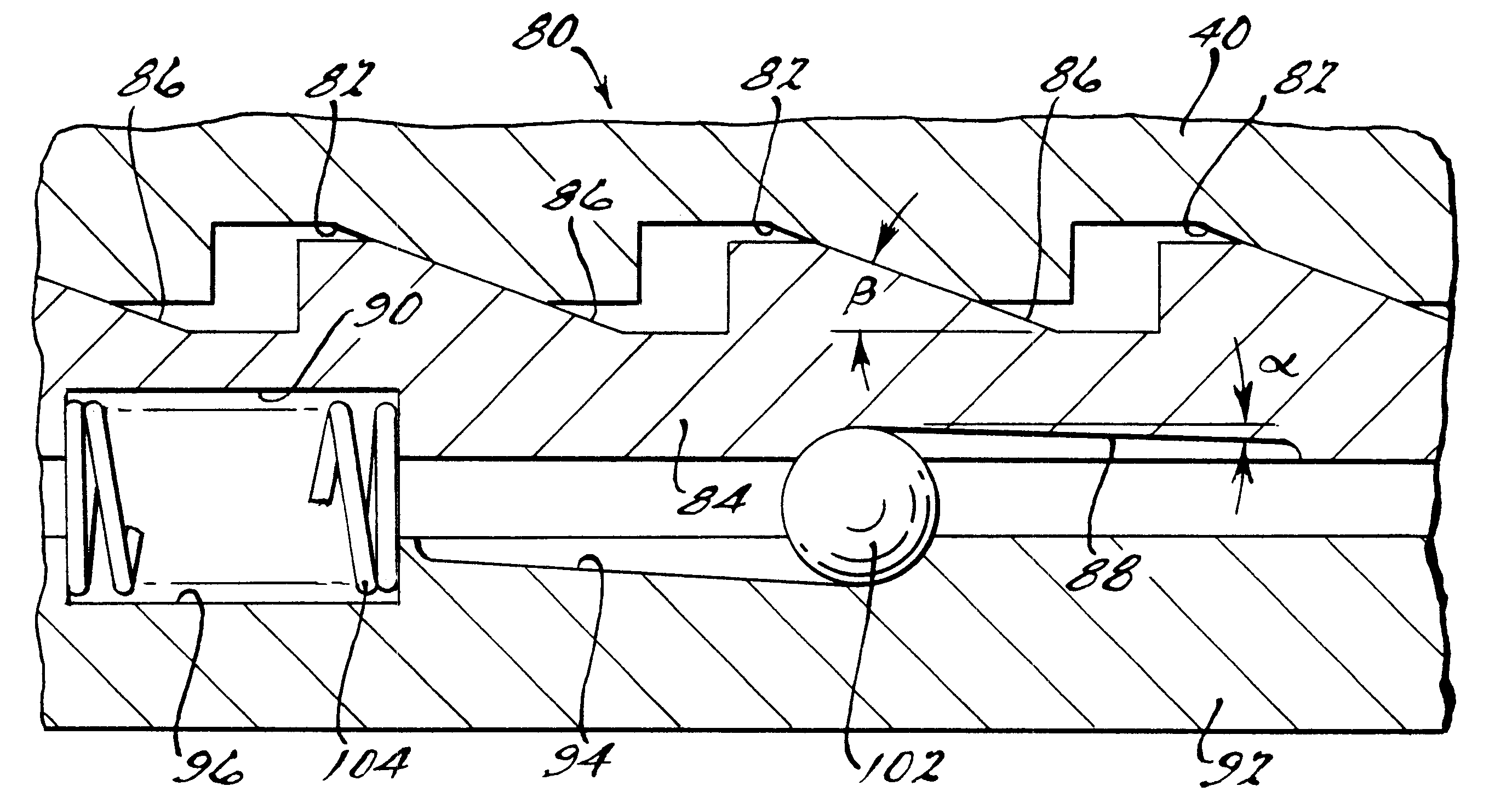

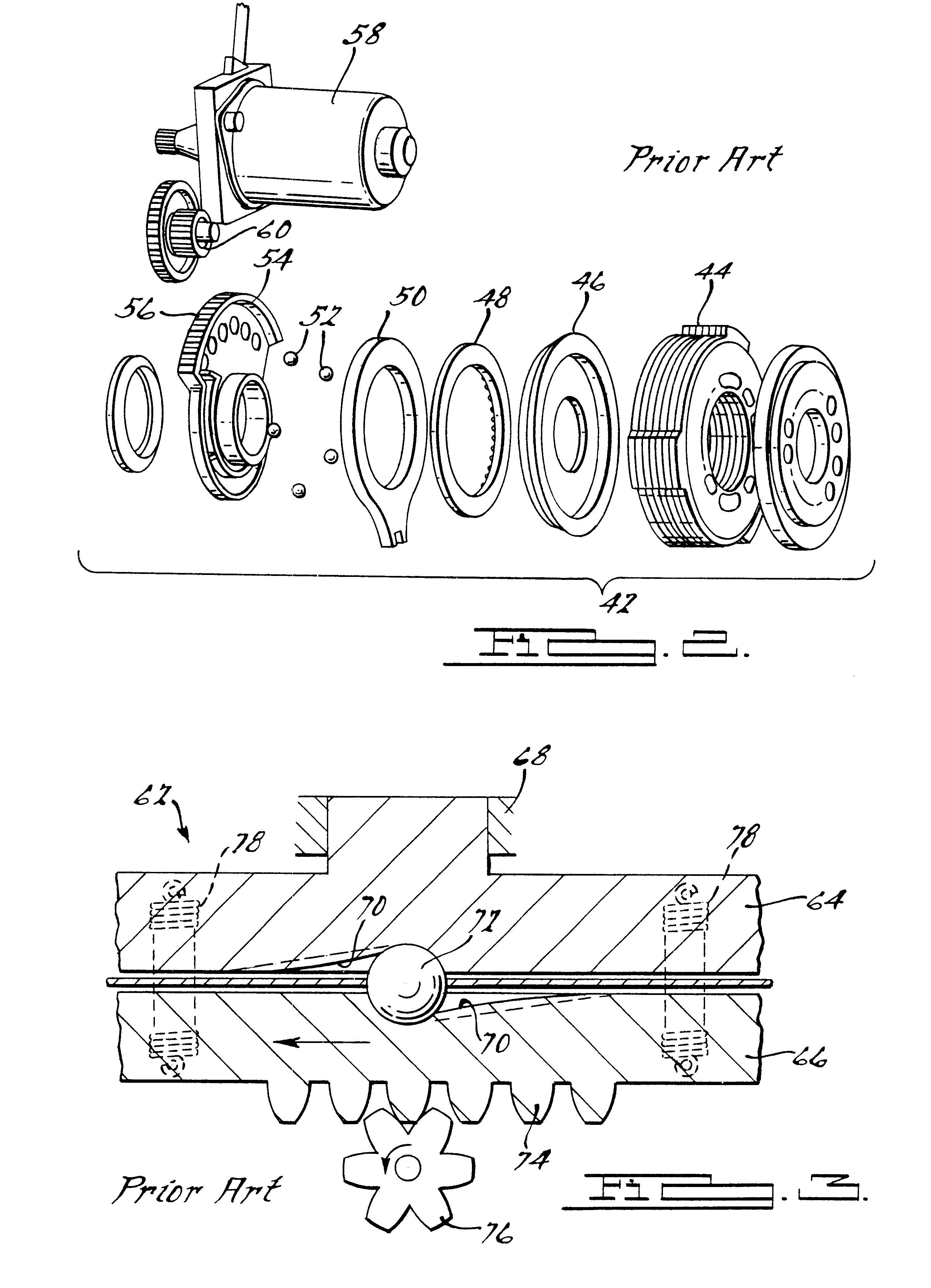

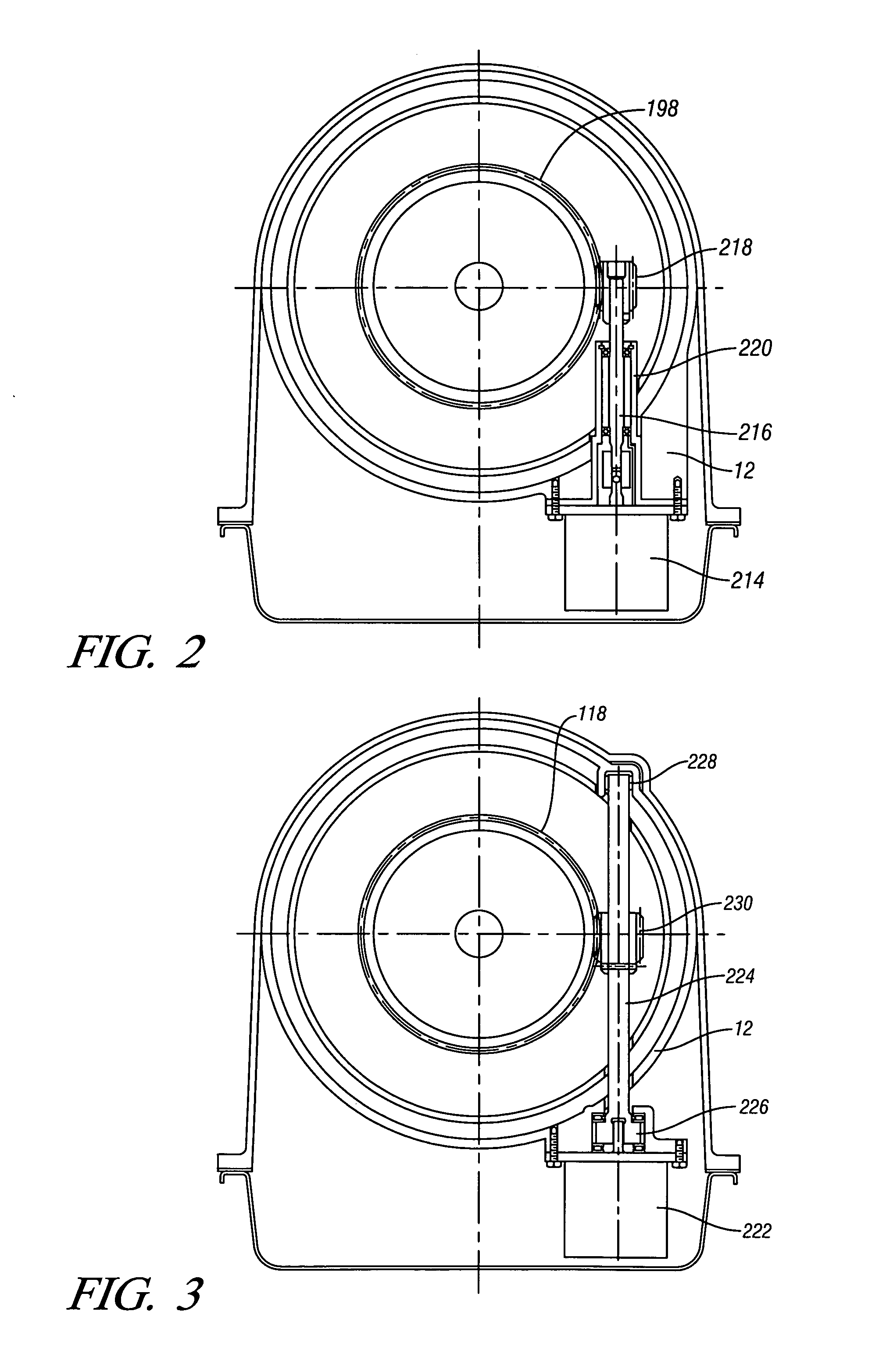

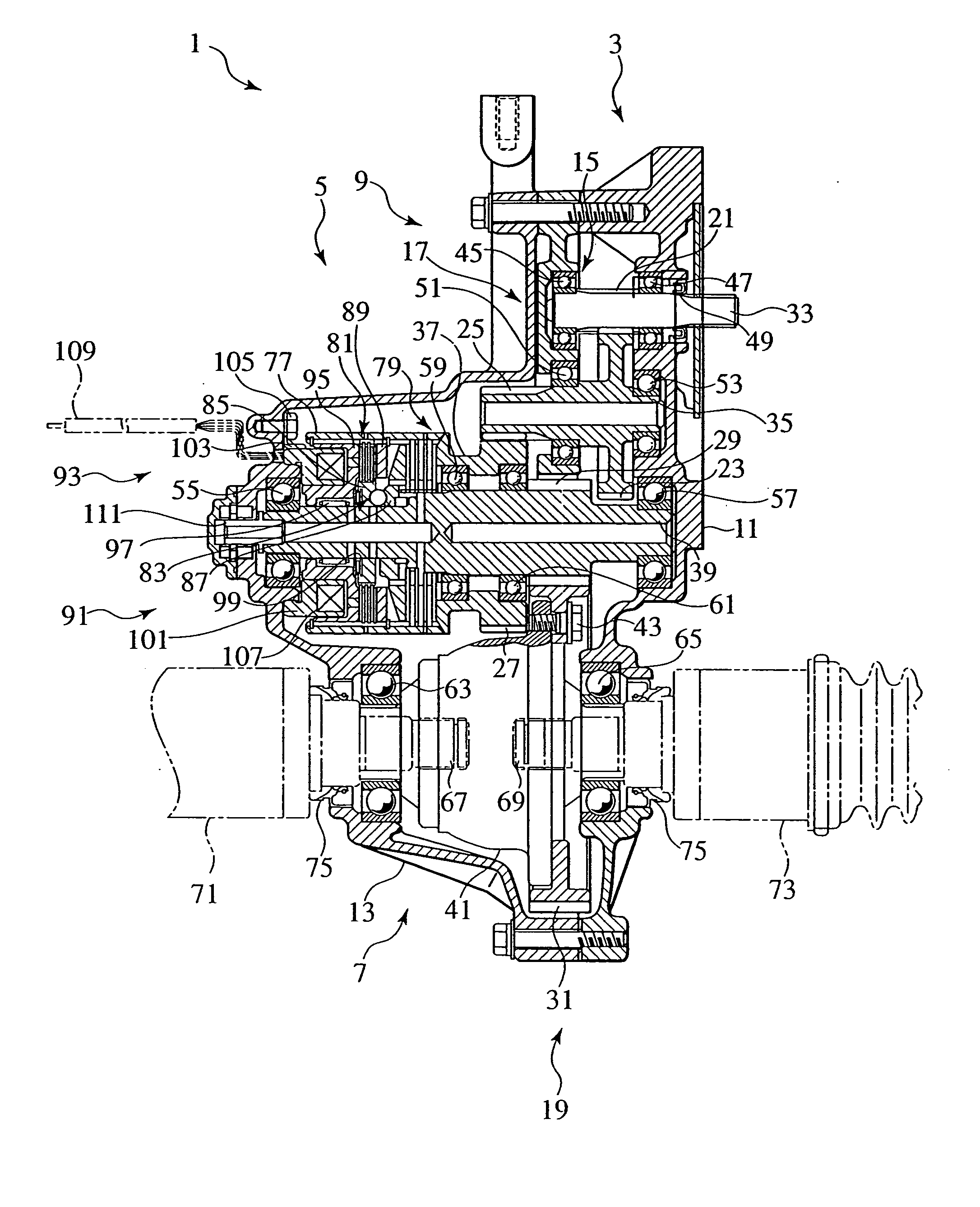

Dual ball ramp actuator for locking differential

A dual ball ramp actuator having a control ring acting with a pressure plates to supply an axial clutch clamping force to a differential clutch assembly where the ball ramp paths follow overlapping eccentric grooves that can be actuated in both the forward and reverse directions. The dual ramp feature doubles the effectiveness and sensitivity when compared to a single ramp system. The overlapping eccentric ball ramps increase (effectively double) the angular travel distance while reducing the ramp angle (in half). The forward and reverse feature provides clutch actuation in both the forward and reverse directions. The dual ramp, 3-piece sandwich construction permits the central control ring to roll up on two sets of balls on each side. This structure doubles the axial travel available to compress a disc pack and lock up the differential with the same ball ramp angle when compared to a single ramp system involving only two ramp plates.

Owner:DANA AUTOMOTIVE SYST GRP LLC

Selectable one-way clutch

A controllable selectable one-way clutch is provided for use within a hybrid transmission. The clutch comprises an outer and inner race, and a first and second selector plate. A transmission motor controller synchronizes the speeds of the races to facilitate application and release of the clutch, and a transmission controller communicates a signal to the clutch for re-positioning of the plates to apply and release the clutch. The clutch has three operational modes, including freewheeling and holding torque in one direction or both directions. A method is also provided for applying a selectable one-way clutch in a vehicle having a hybrid transmission with a motor controller and a transmission controller, including synchronizing the clutch speed using the motor controller, detecting the direction of the race speed difference, communicating the race speed difference to the transmission controller, and selecting between the clutch operational modes in response to the detected speed difference.

Owner:GM GLOBAL TECH OPERATIONS LLC

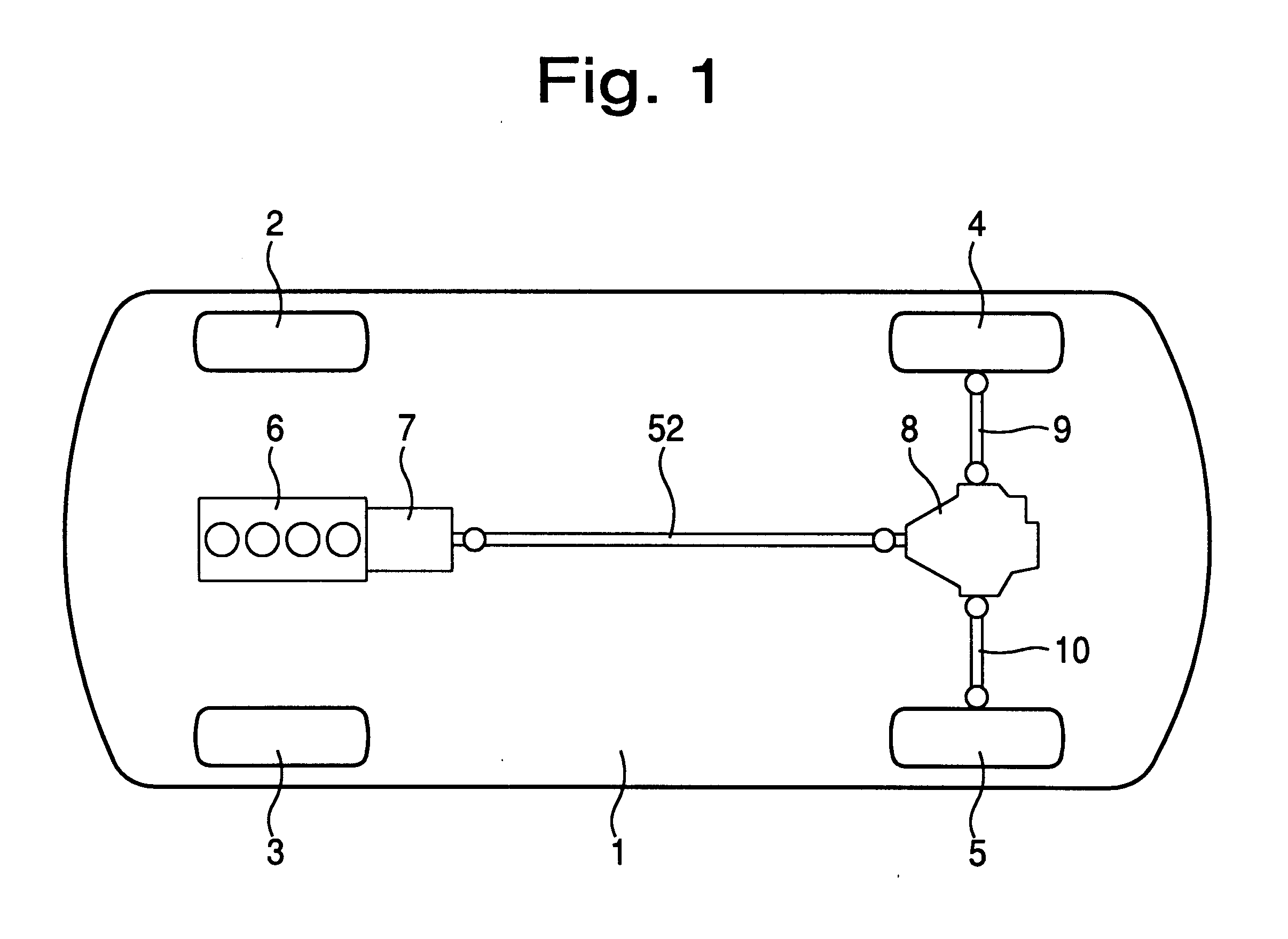

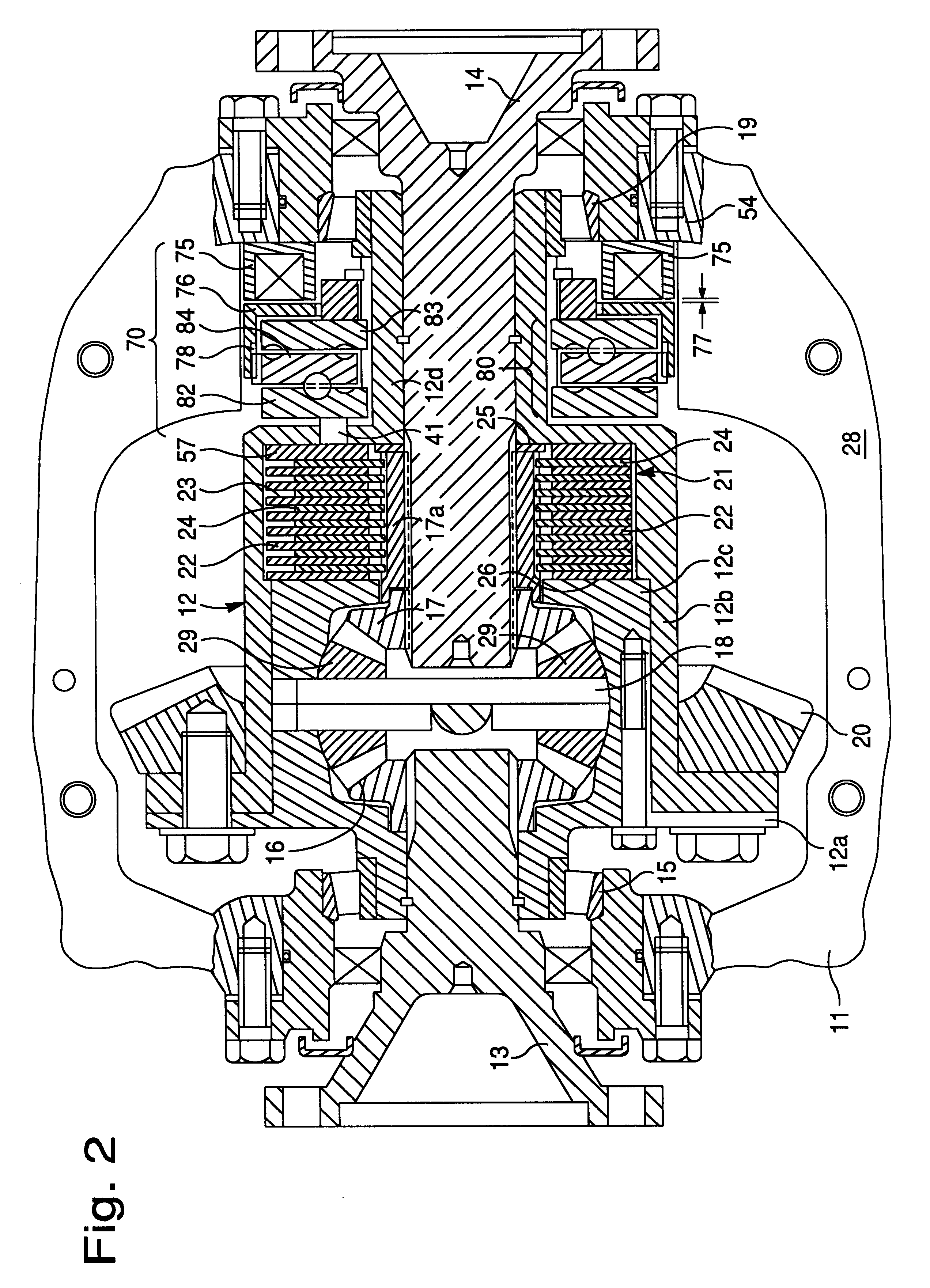

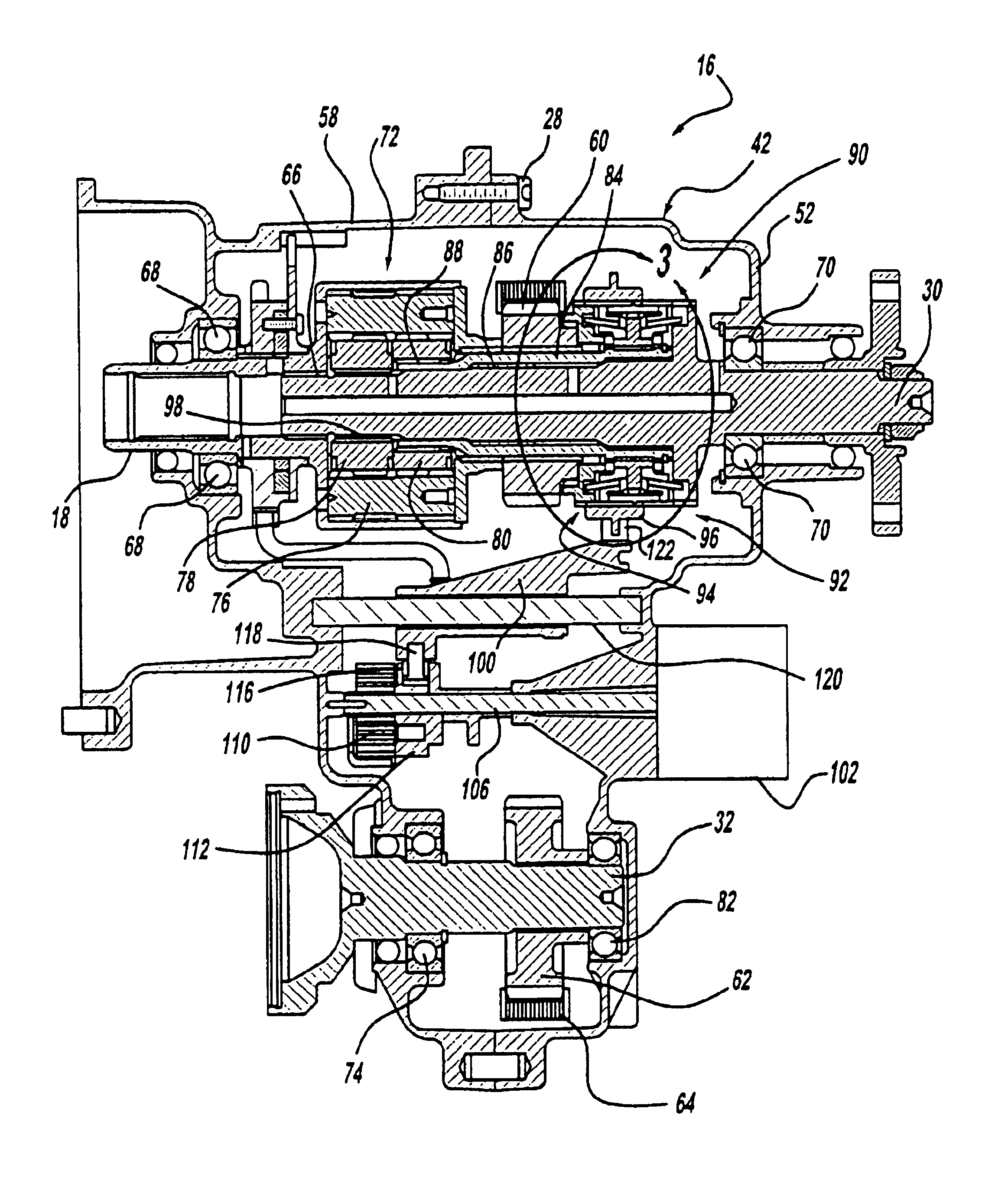

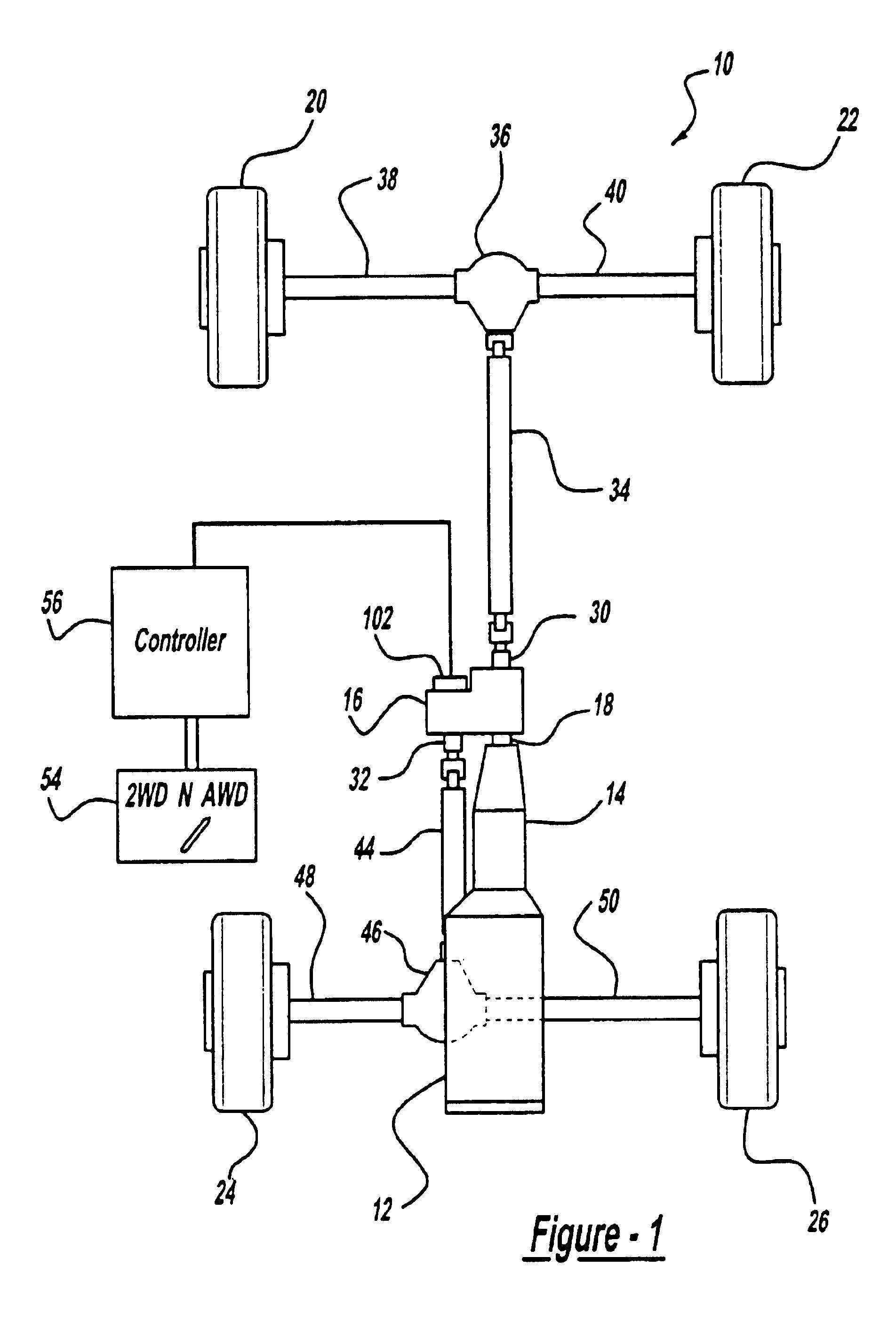

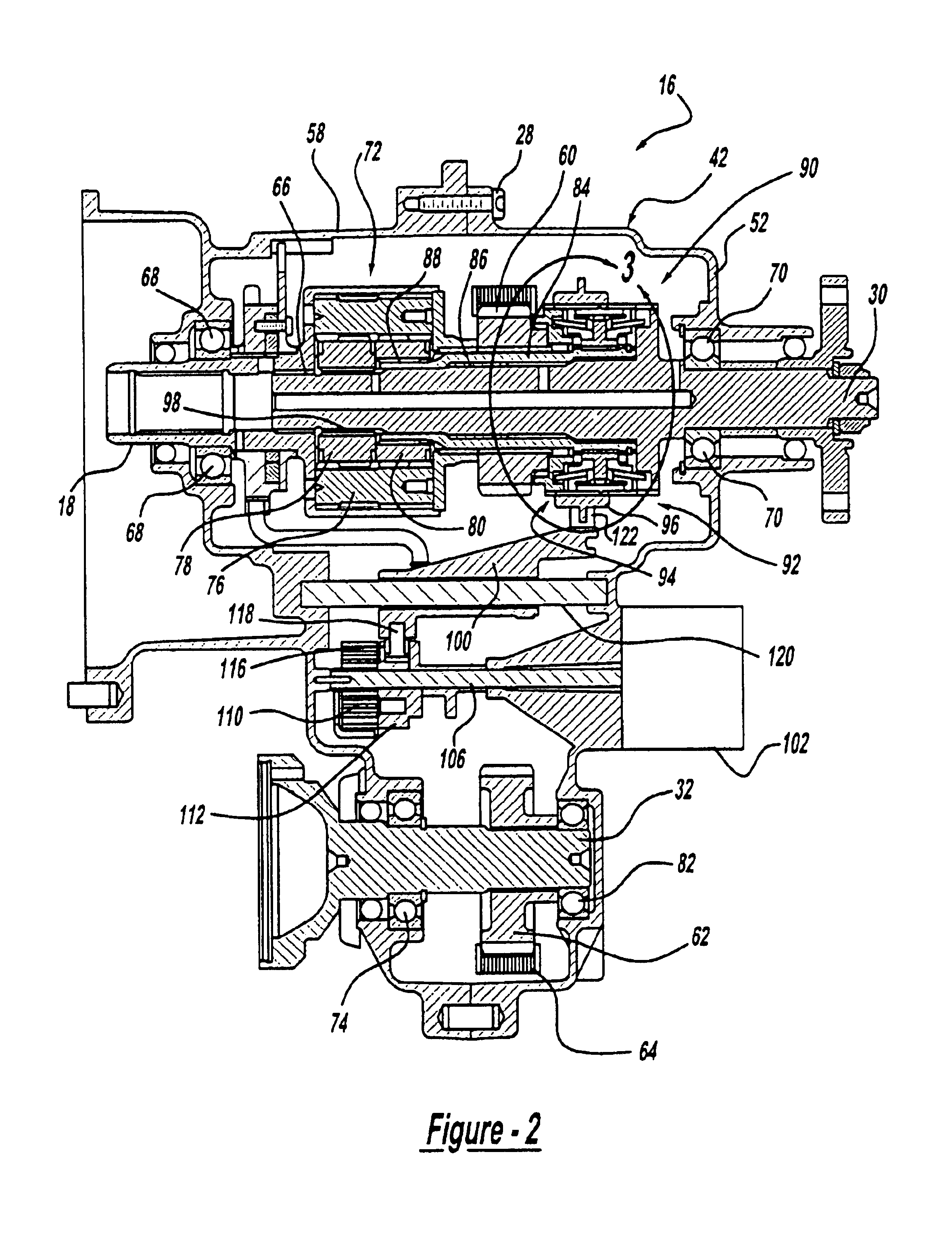

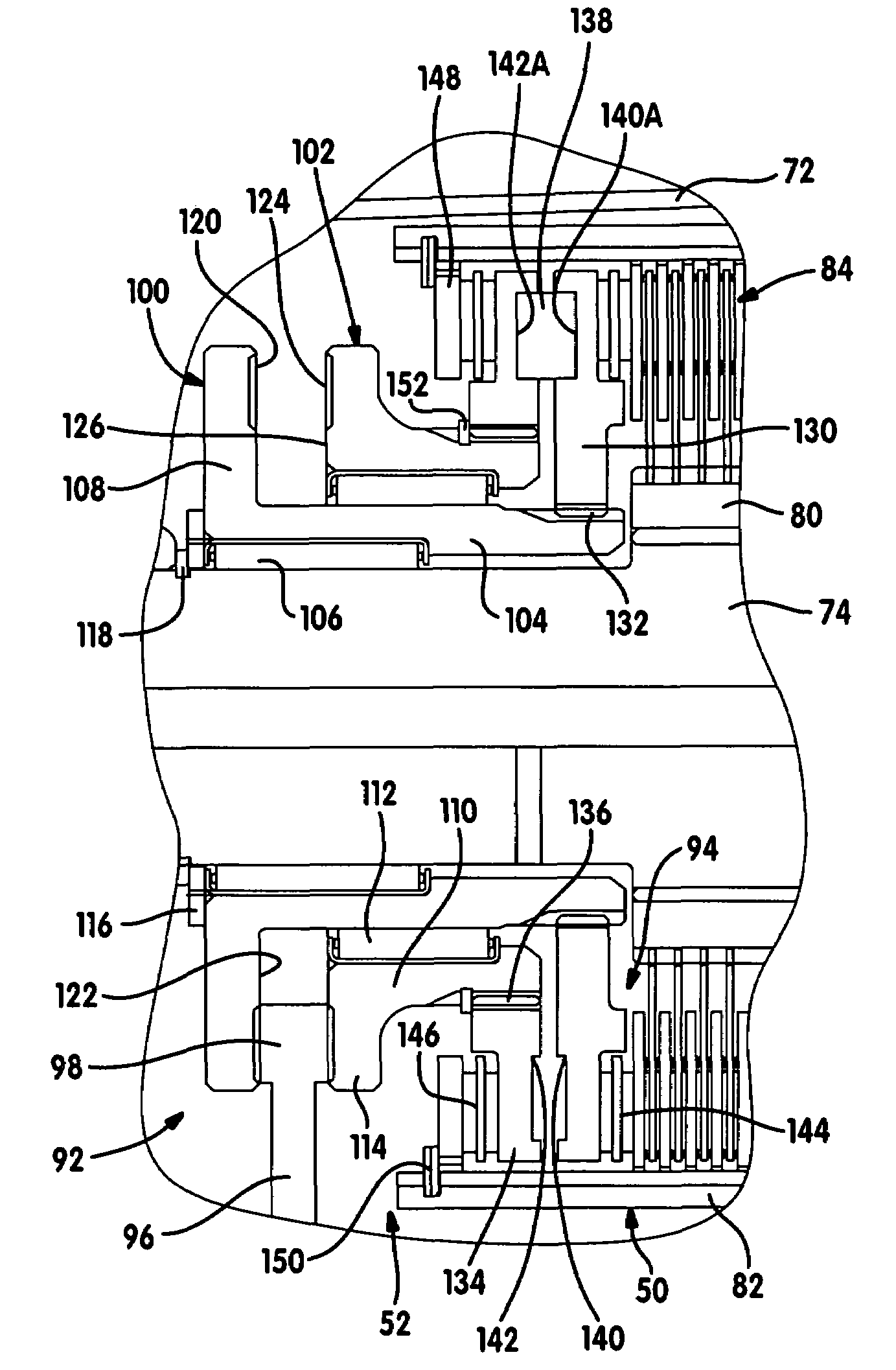

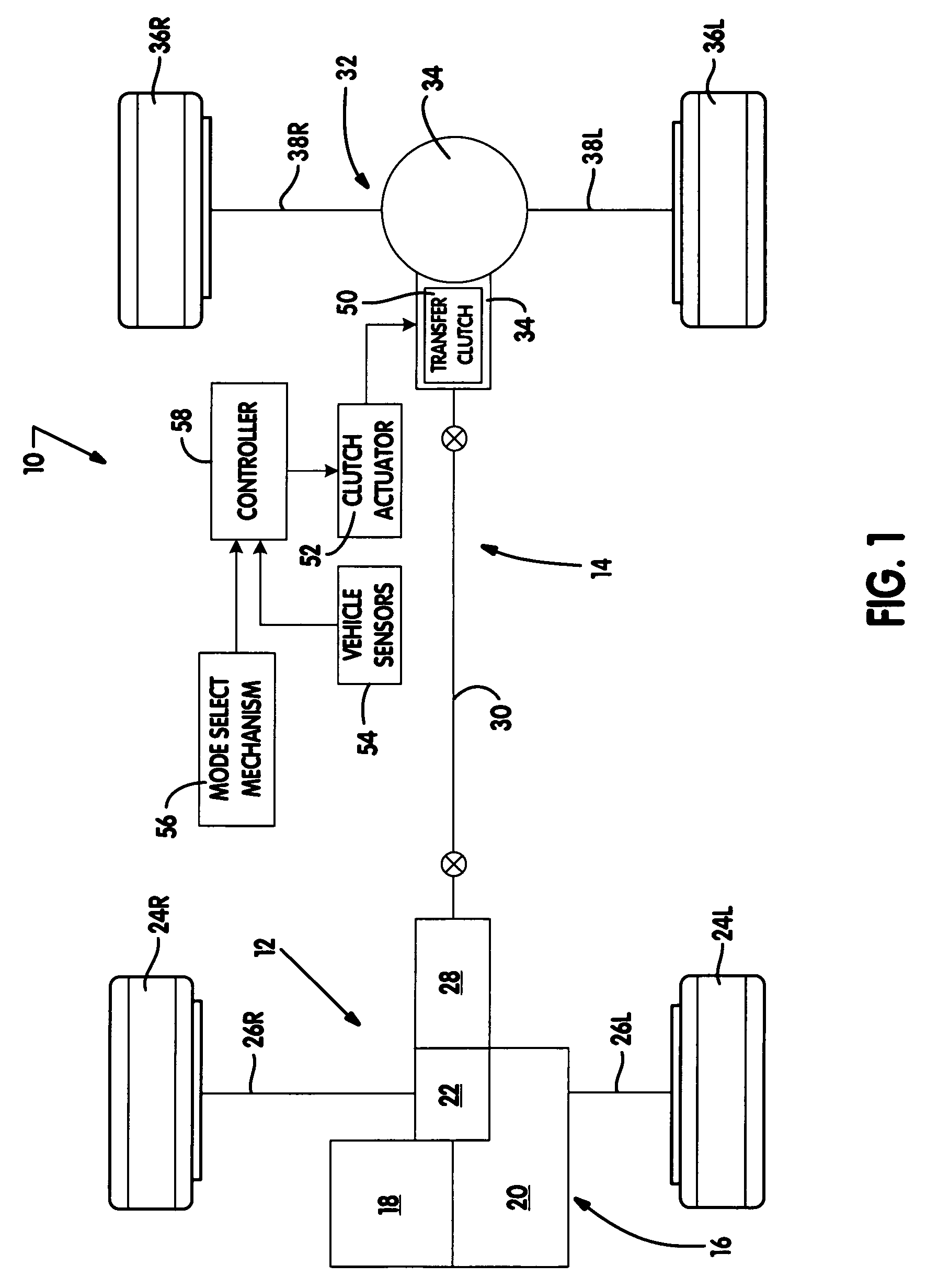

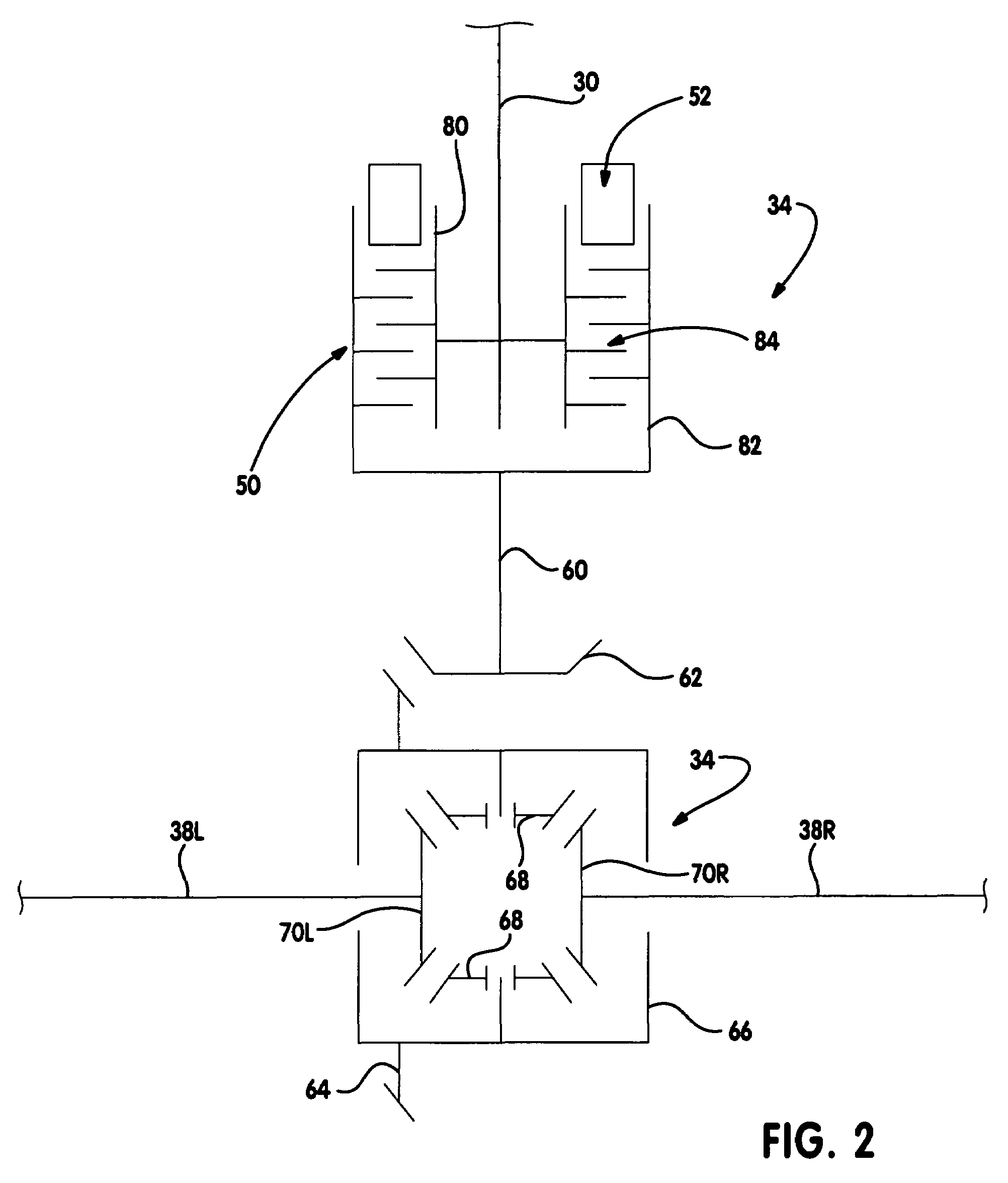

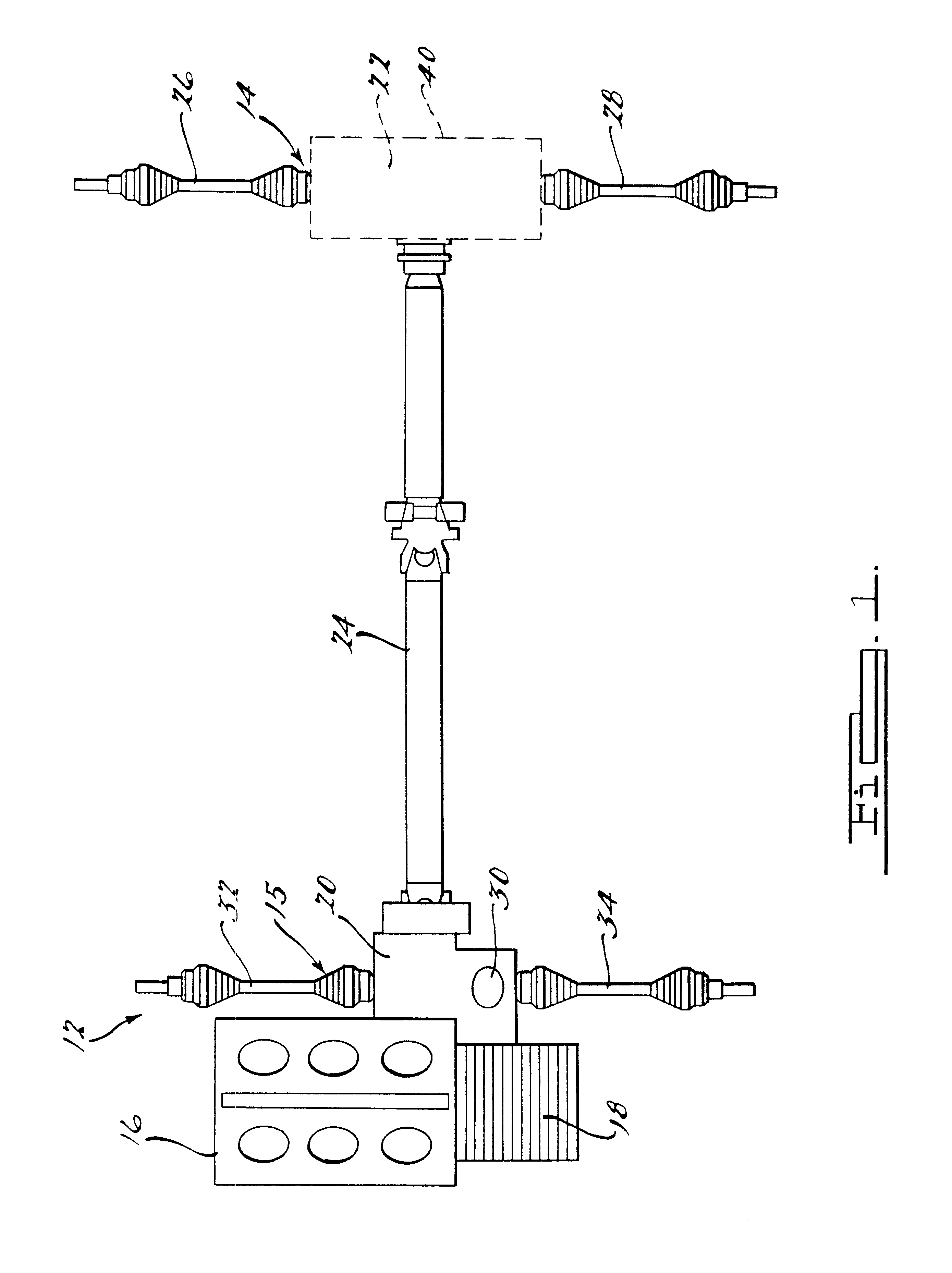

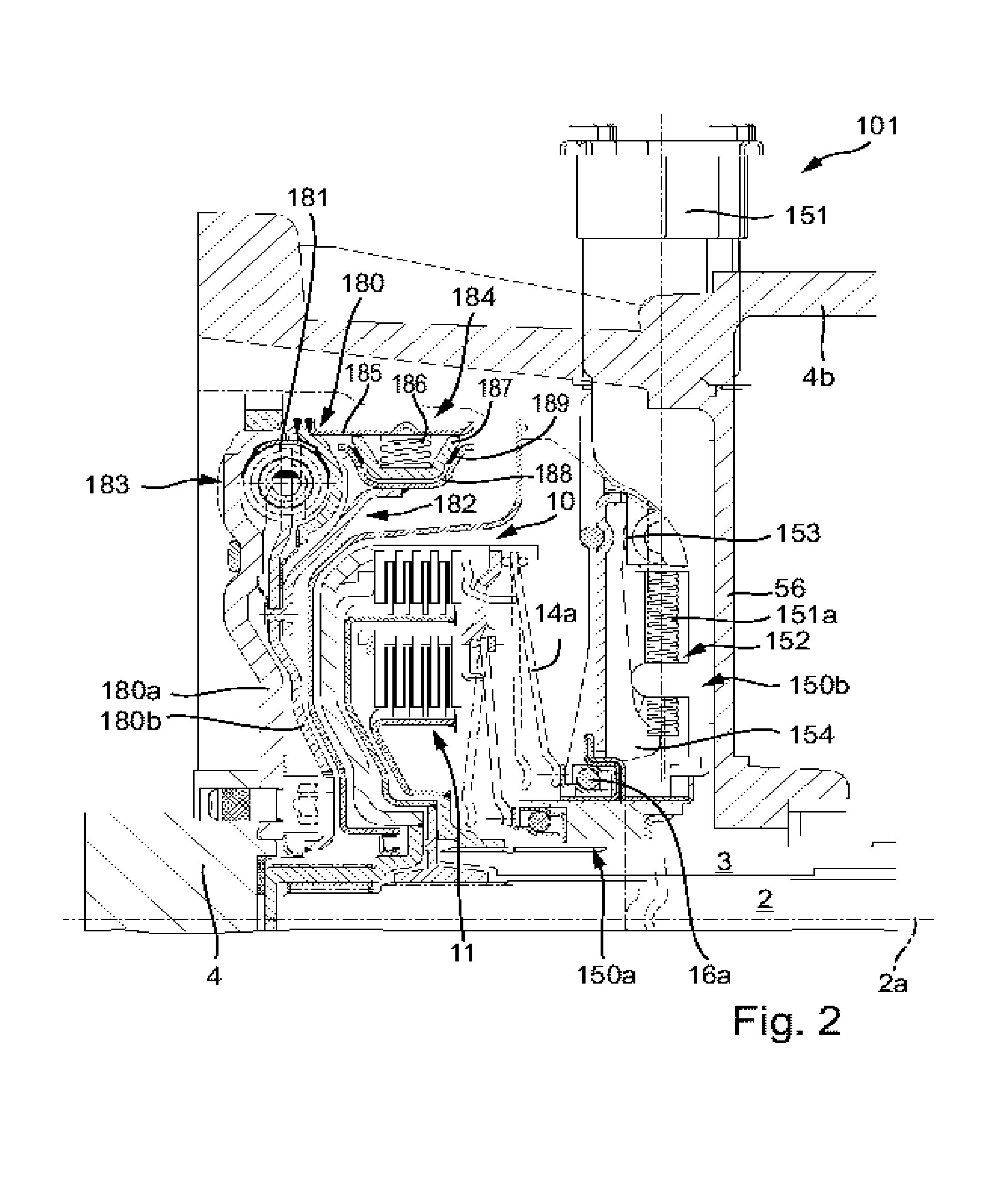

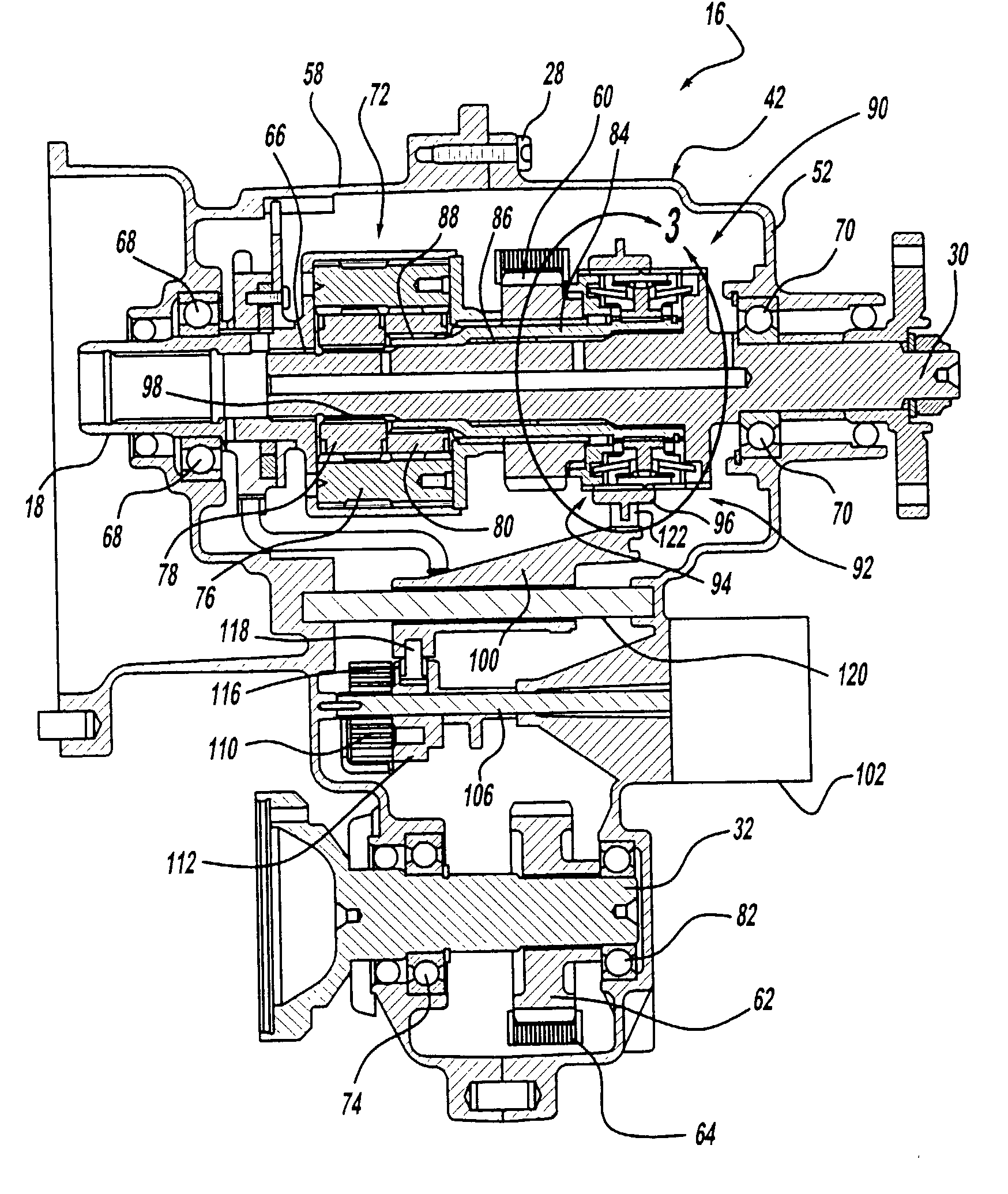

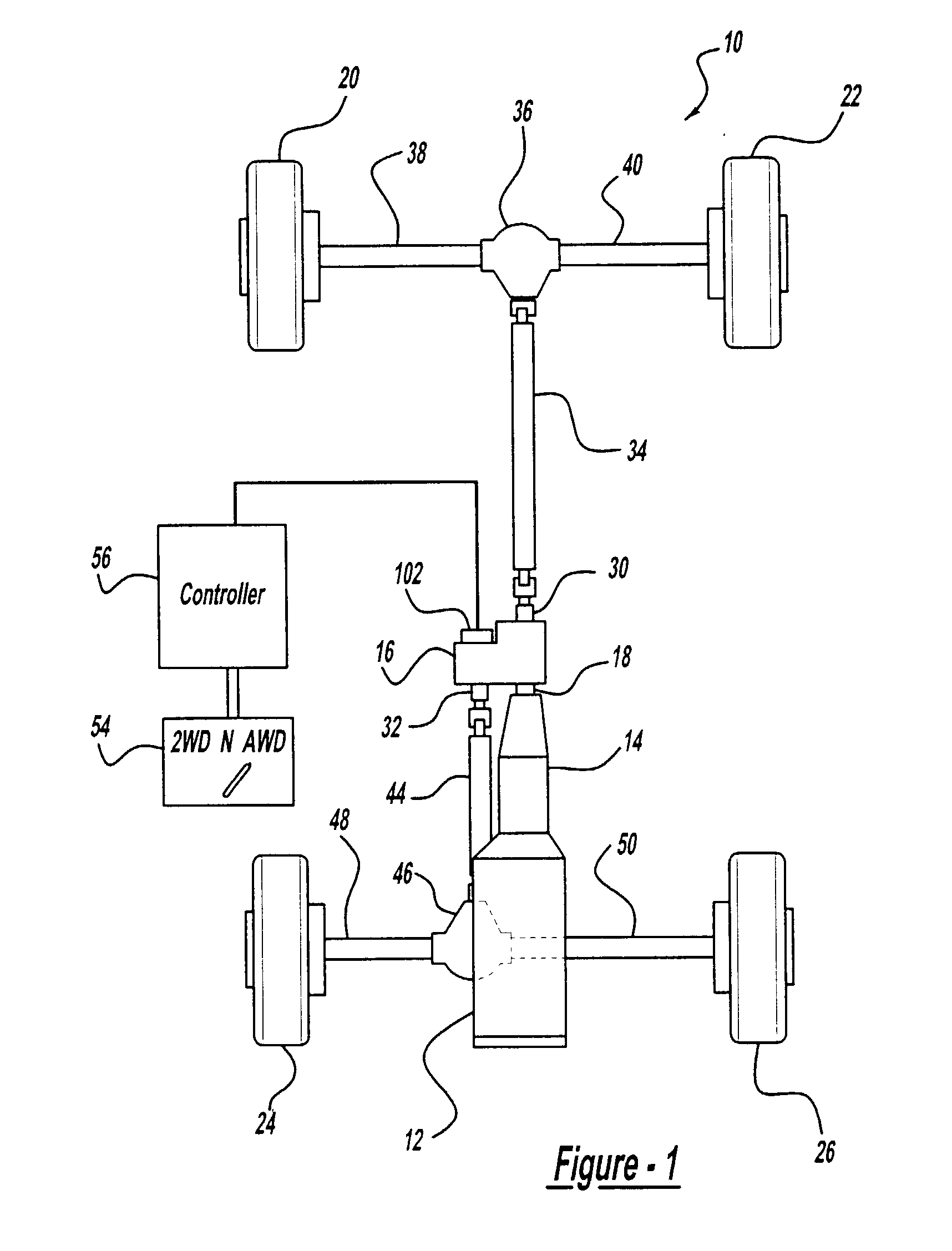

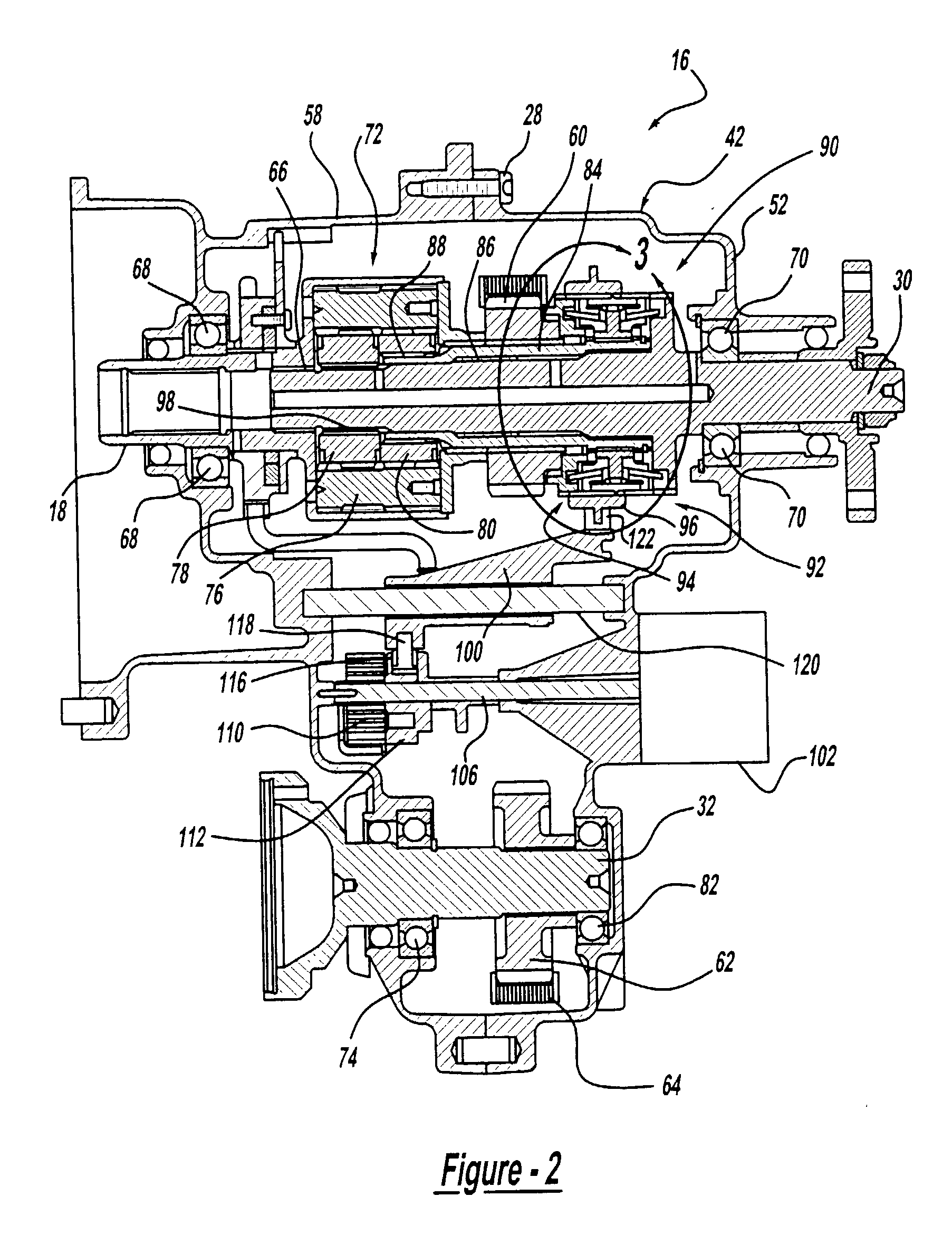

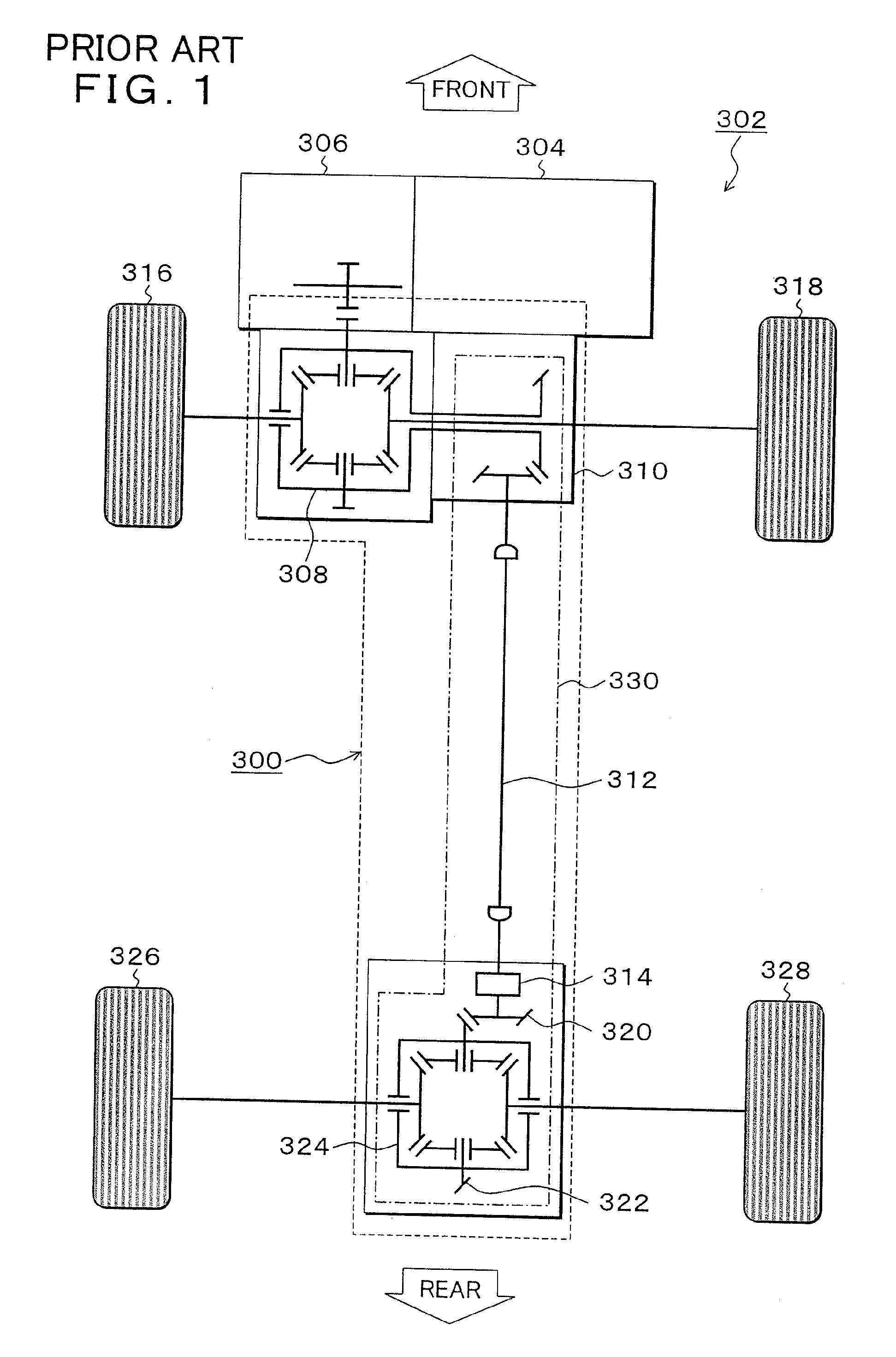

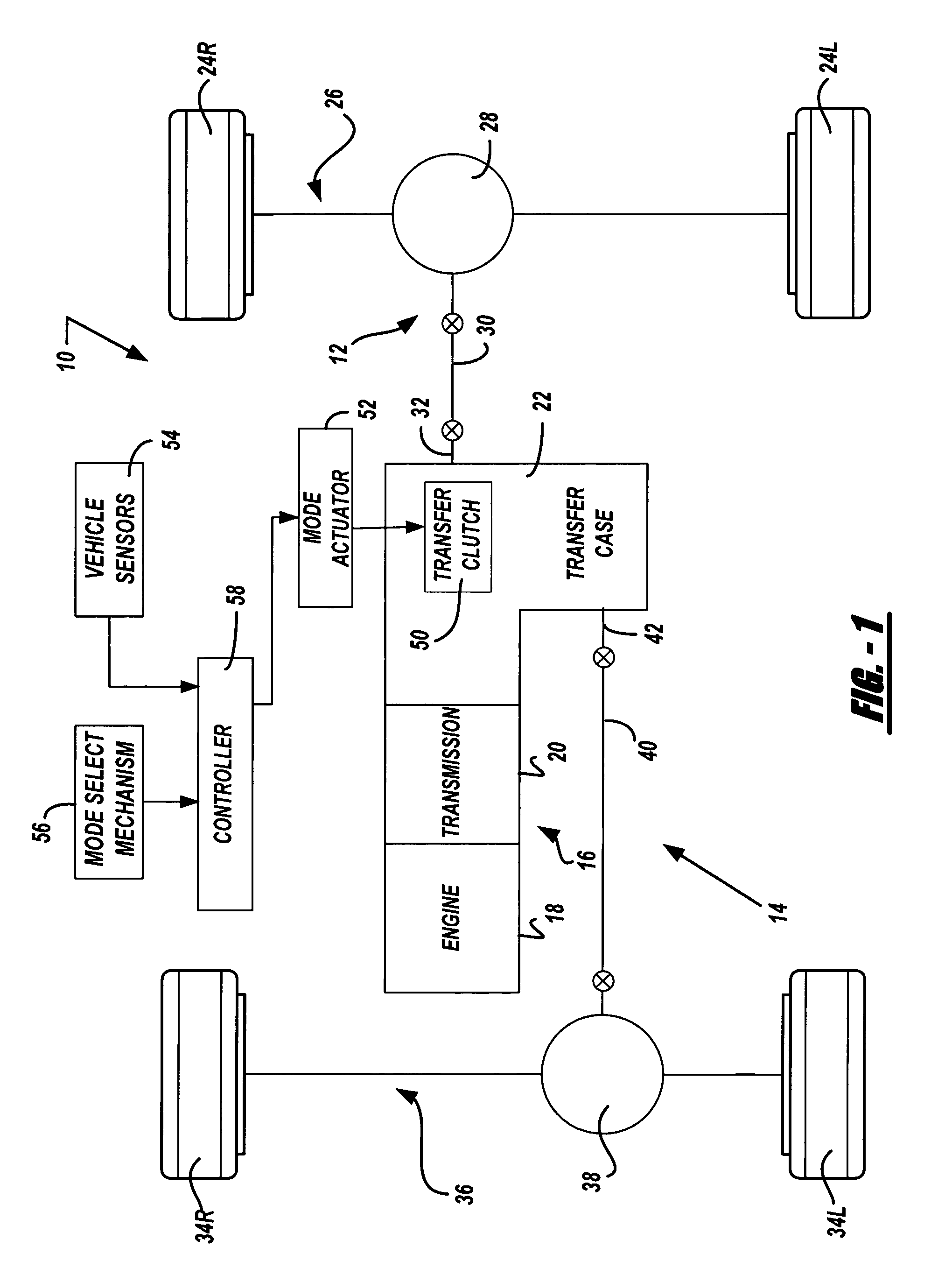

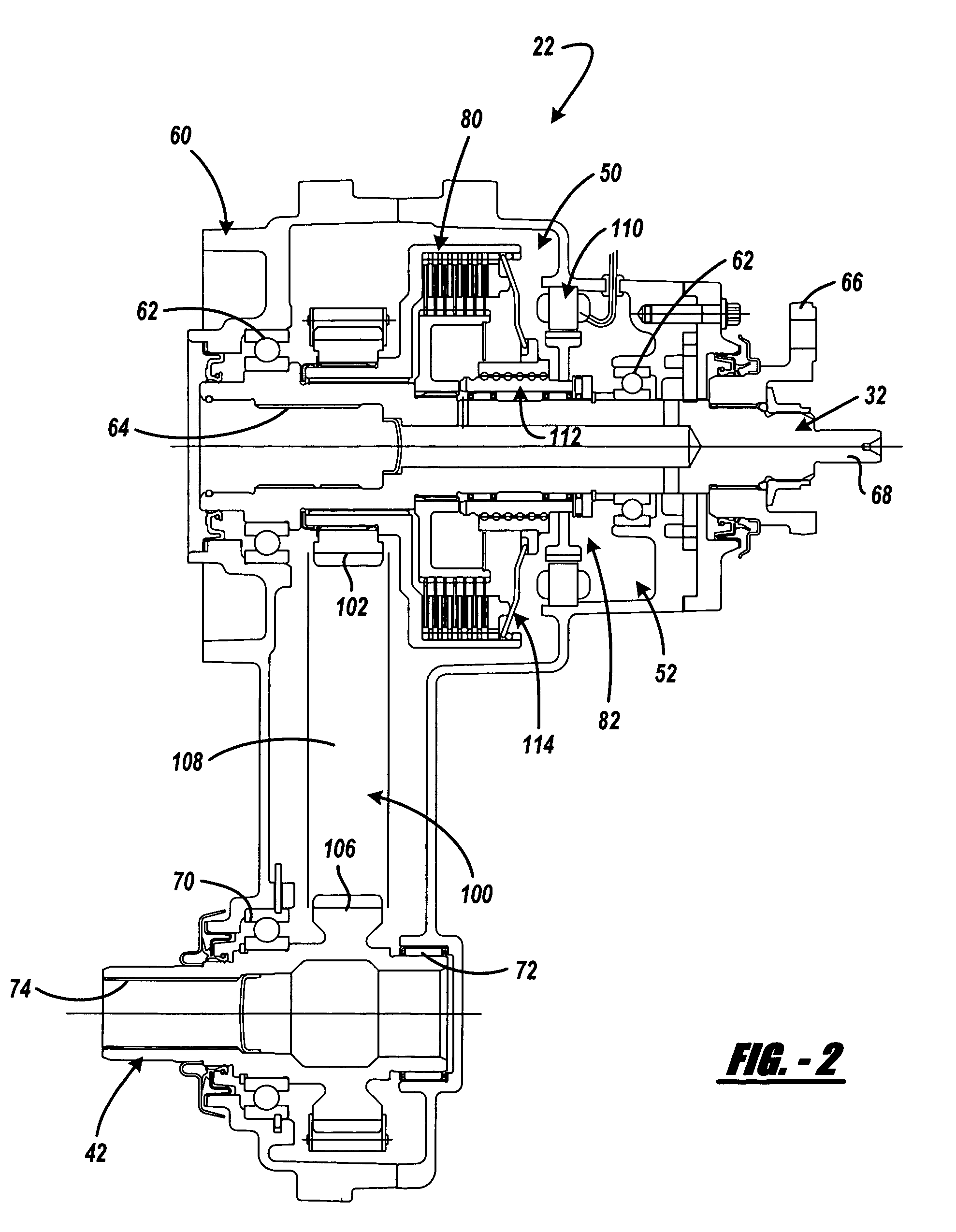

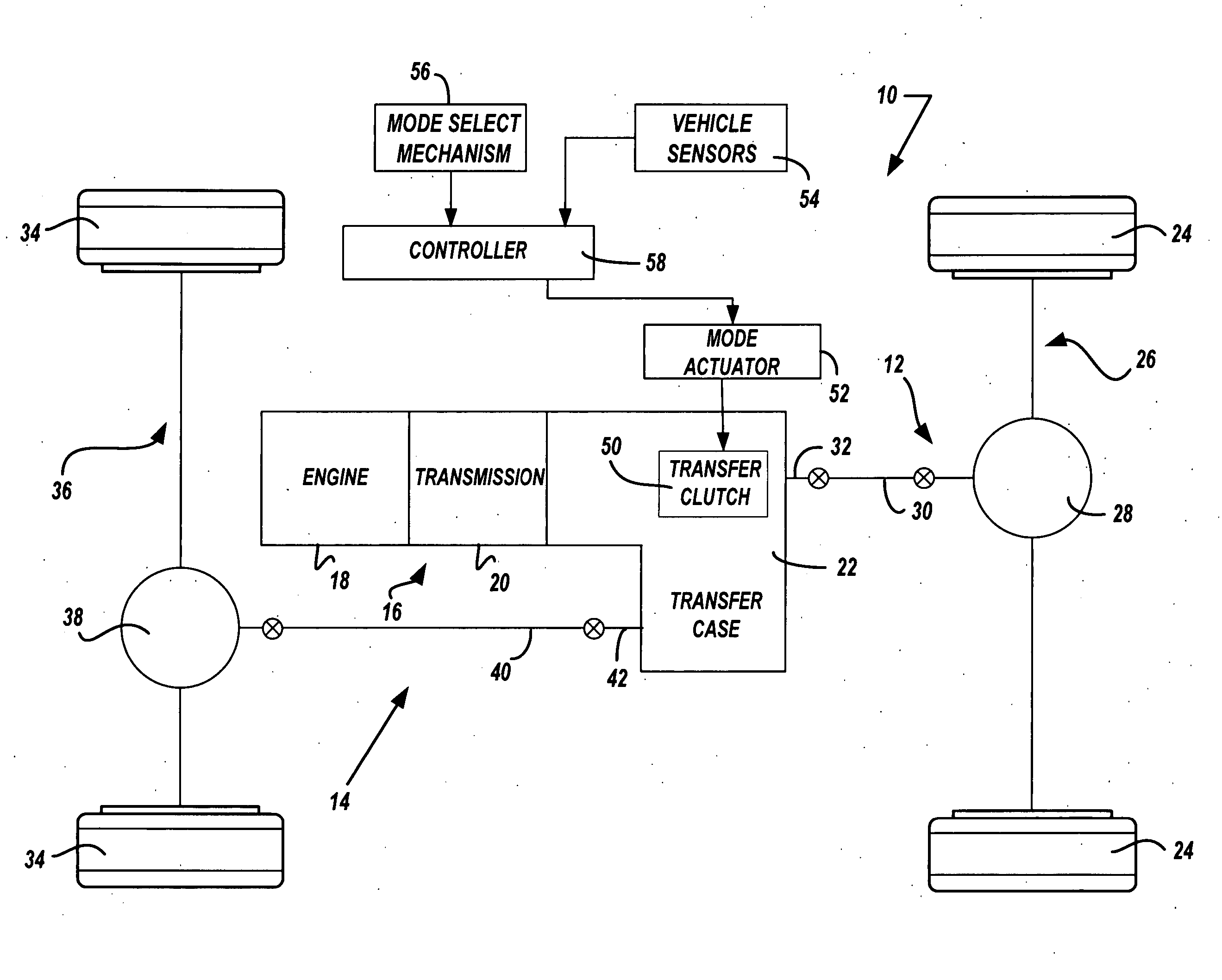

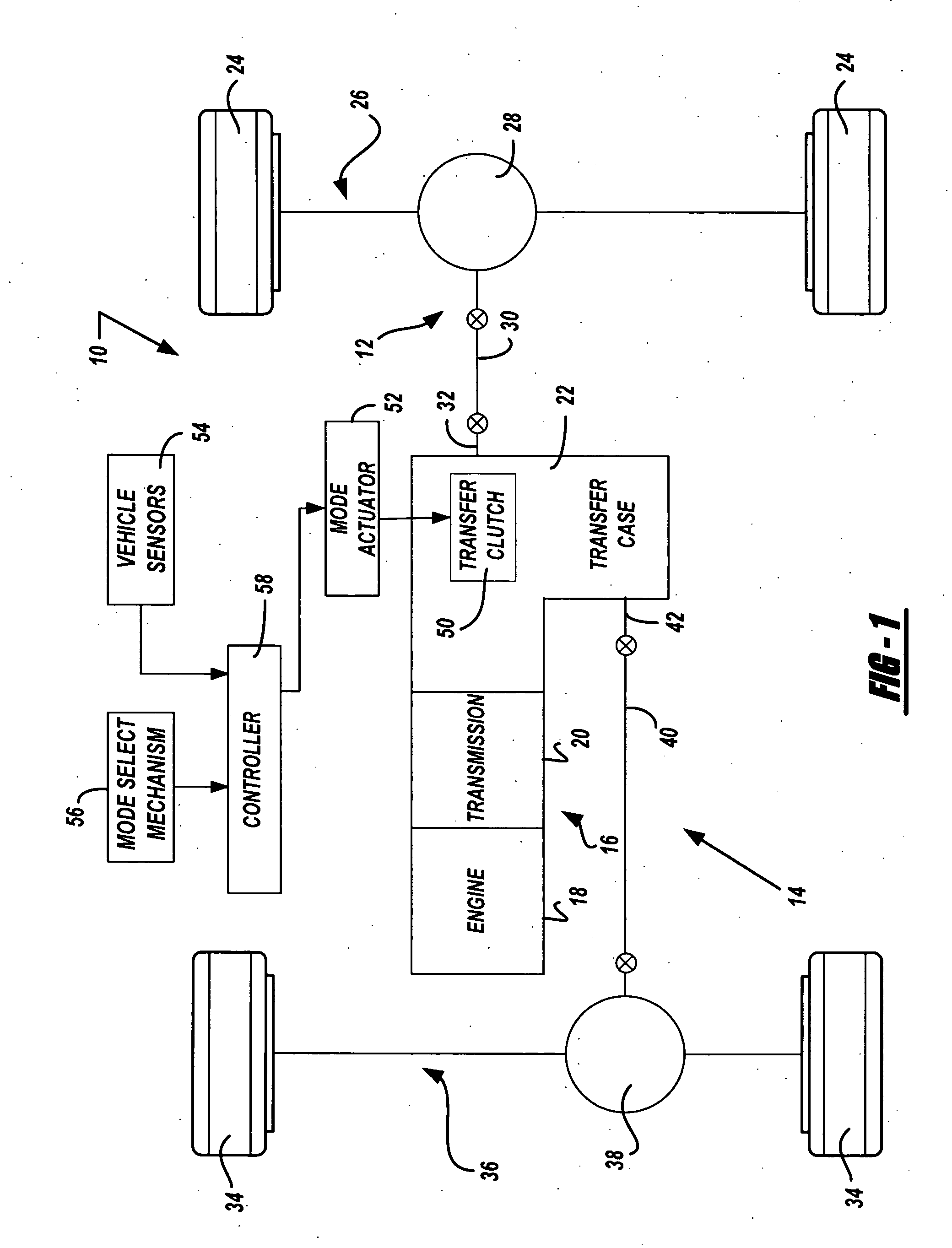

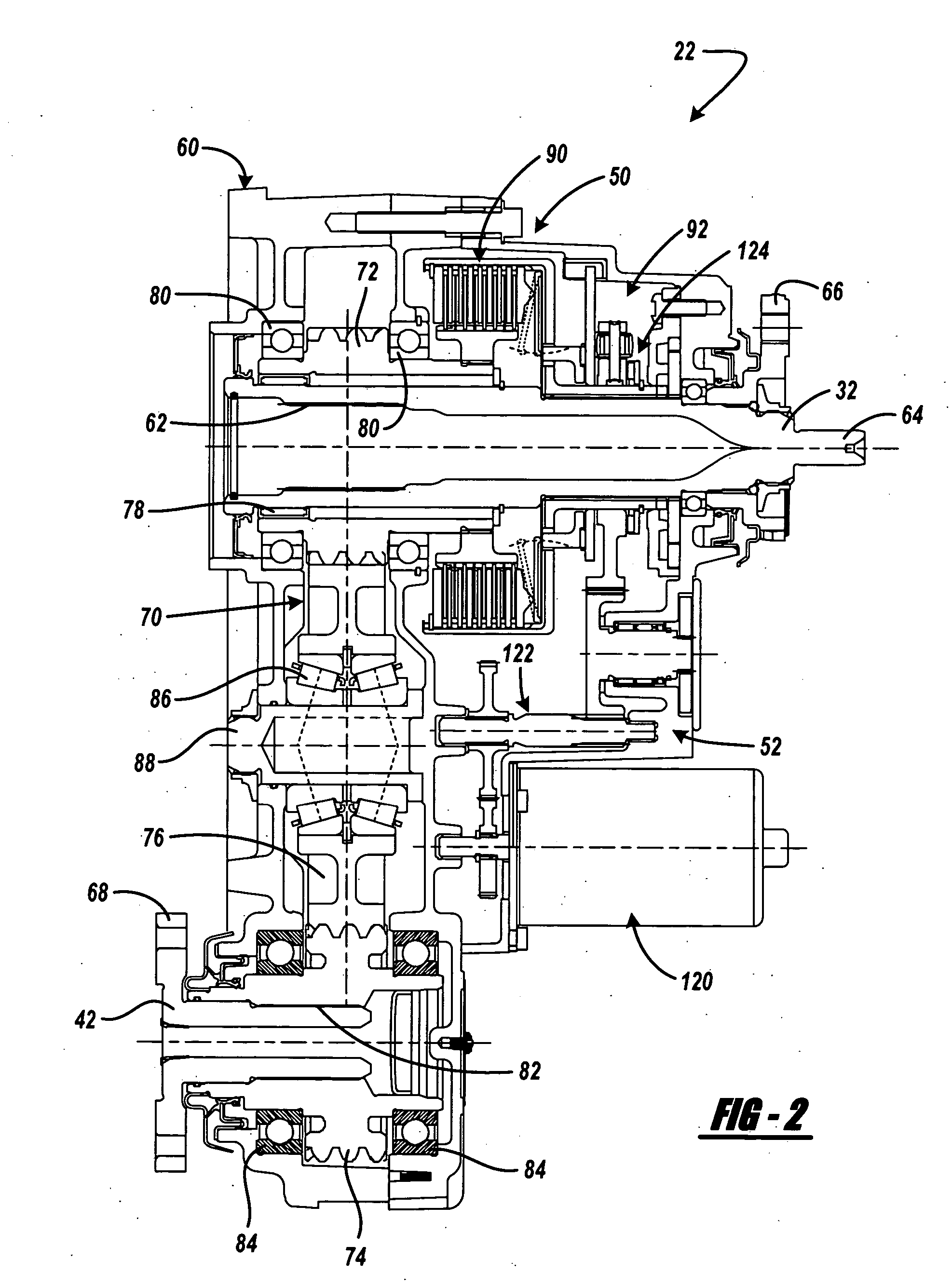

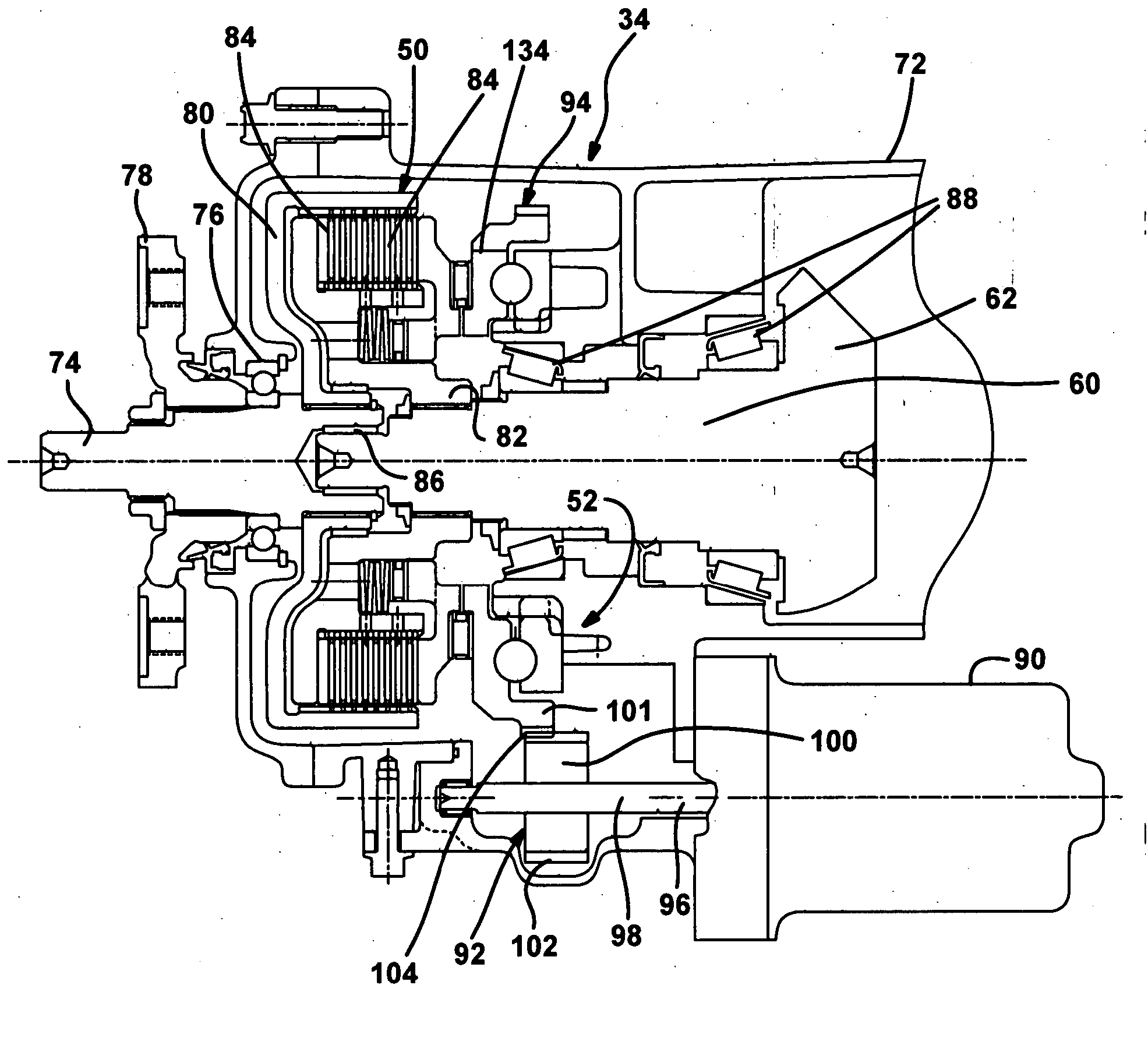

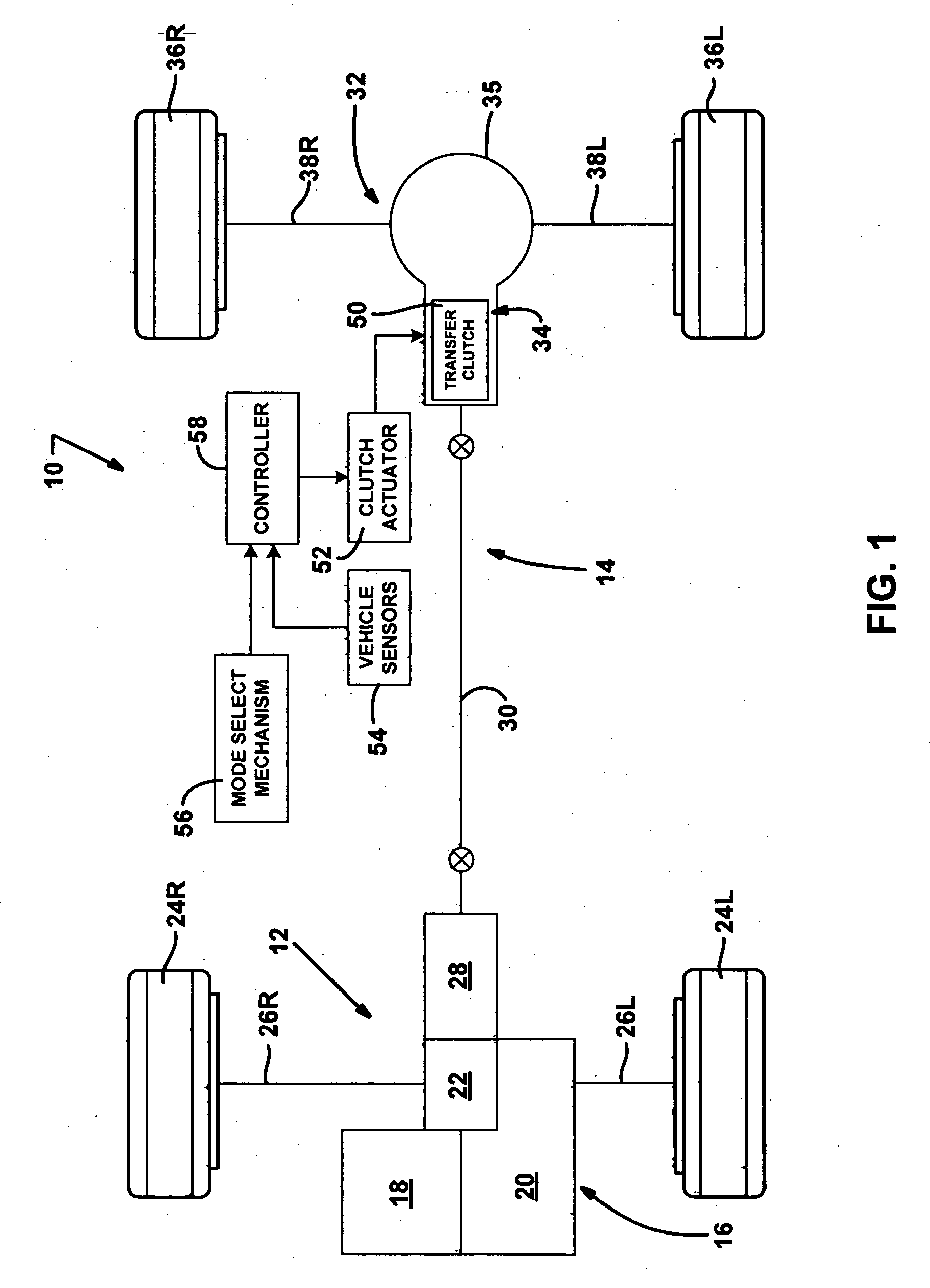

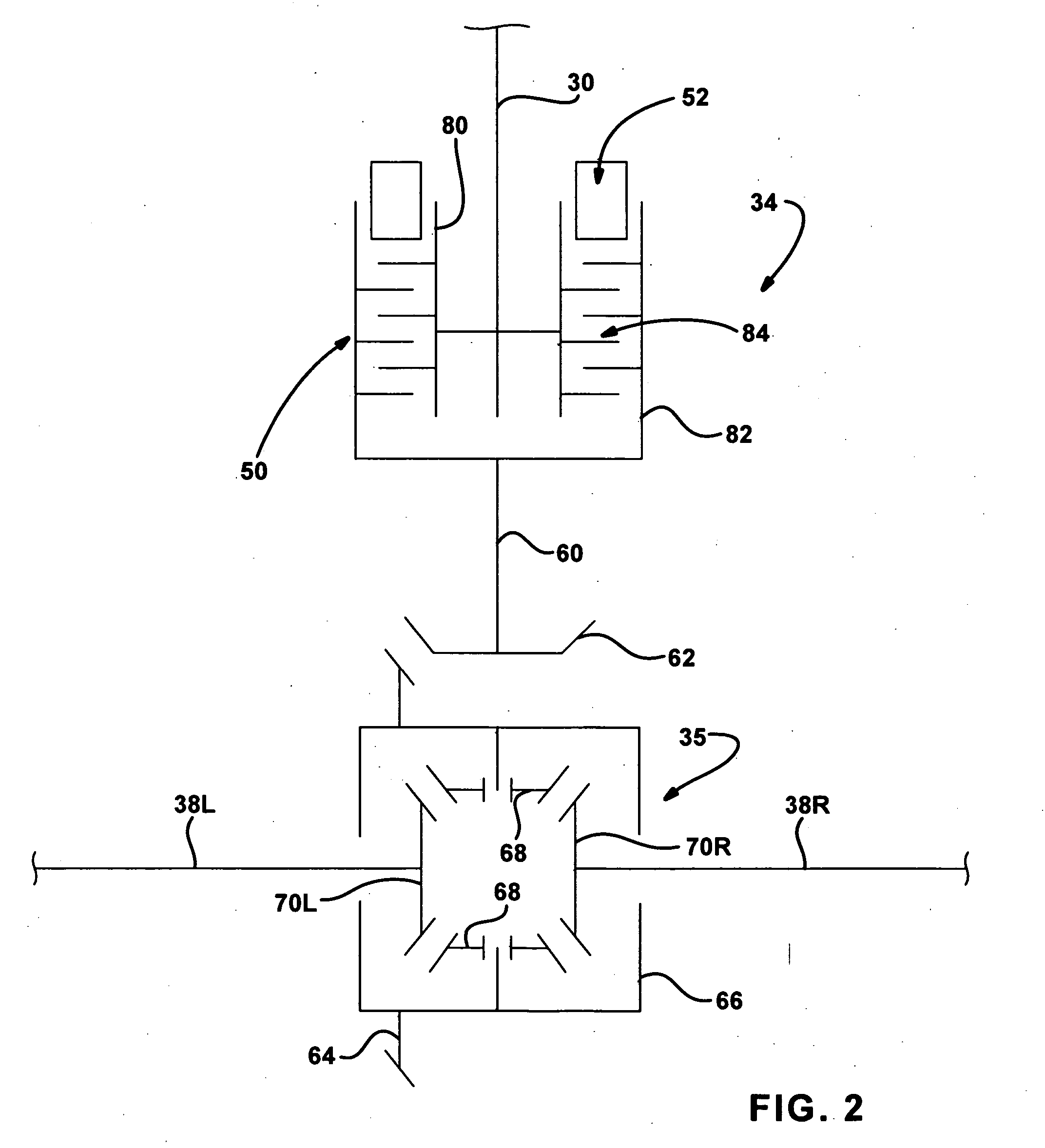

Transfer case with synchronizer clutch

InactiveUS6814682B2Mechanical actuated clutchesMagnetically actuated clutchesTransfer caseDrive shaft

A transfer case for a vehicle that allows shifting between AWD and two-wheel drive at any vehicle speed. The transfer case includes a center differential employing pinion and sun gears that allow a front drive shaft and a rear drive shaft to turn at different speeds to provide the all-wheel drive function. The transfer case further includes an electrically actuated synchronizer assembly that allows the speed of the front drive shaft to be synchronized to the speed of the rear drive shaft when shifting from two-wheel drive to all-wheel drive to provide the shift on the fly function. The synchronizer assembly also includes a neutral position where both the front drive shaft and the rear drive shaft are not engaged to the vehicle transmission to allow for vehicle towing.

Owner:BORGWARNER INC

Power-operated clutch actuator for torque transfer mechanisms

A torque transfer mechanism is provided for controlling the magnitude of a clutch engagement force exerted on a multi-plate clutch assembly that is operably disposed between a first rotary and a second rotary member. The torque transfer mechanism includes a power-operated face gear clutch actuator for generating and applying a clutch engagement force on the clutch assembly.

Owner:MAGNA POWERTRIAN INC (US)

Engagement mechanism with two stage ramp angle

InactiveUS6571928B1Minimizes the required angular rotation and torque necessaryMaximizing engagementMagnetically actuated clutchesFriction clutchesDrivetrainEngineering

An engagement mechanism for use in a vehicle includes a housing. The engagement mechanism also includes a first ball ramp disc engaging the housing on one side. The first ball ramp disc includes a first ramp on the side engaging the housing. The first ball ramp disc also includes a second ramp having a predetermined angle on the side opposite of the side engaging the housing. The engagement mechanism further includes a ball ramp disc adjacent to the first ball ramp disc on a side opposite of the side engaging the housing which is rotatably driven. The engagement mechanism also includes a spring element arranged between the first ball ramp disc and the second ball ramp disc. The engagement mechanism is used to engage a friction clutch pack of a vehicle drivetrain system.

Owner:GKN DRIVELINE NORTH AMERICA

Motion transmitting apparatus

InactiveUS20020065171A1More versatileLess expensiveFluid actuated clutchesMagnetically actuated clutchesMobile vehicleCoil spring

A motion transmitting apparatus wherein an electric motor, an engine or another prime mover rotates an axially fixed first part relative to a coaxial axially movable non-rotatable second part. The structure which serves to move the second part axially in response to clockwise or counterclockwise rotation of the first part includes a follower borne by the first part and a helical spring having end convolutions affixed to the first part. The follower extends between two intermediate convolutions of the helical spring. If the apparatus is utilized in the power train of a motor vehicle, the axially movable part can serve to engage or disengage or change the extent of engagement of the friction clutch between the output element of the engine and the input element of the change-speed transmission.

Owner:SCHAEFFLER TECH AG & CO KG

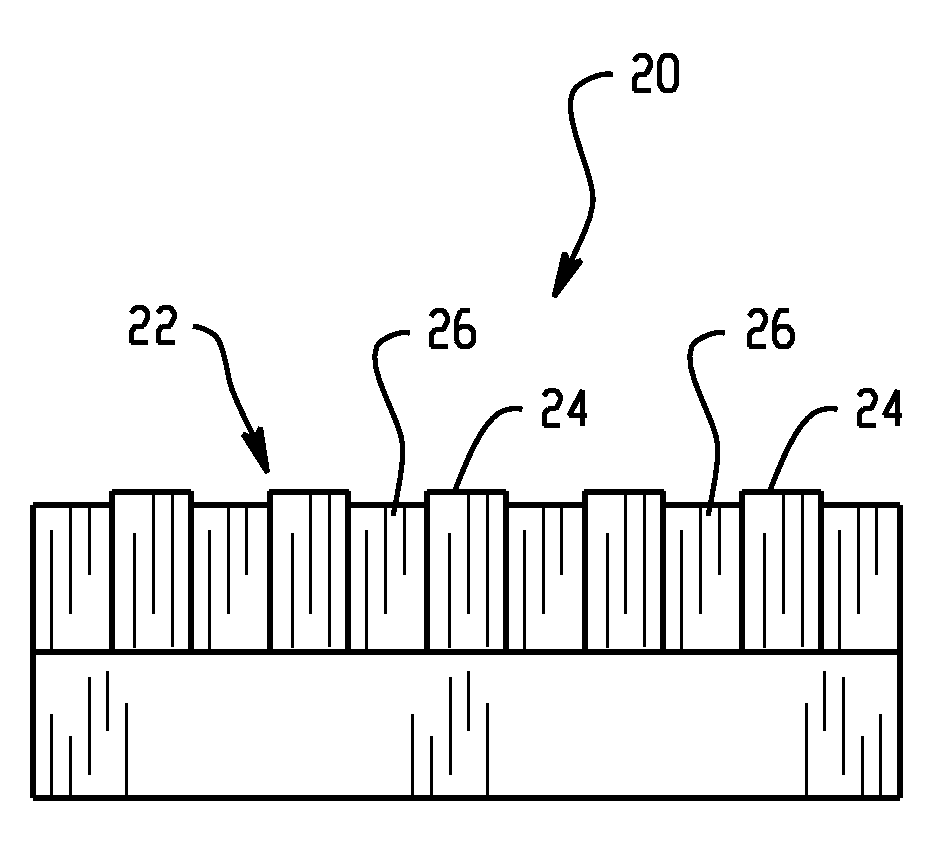

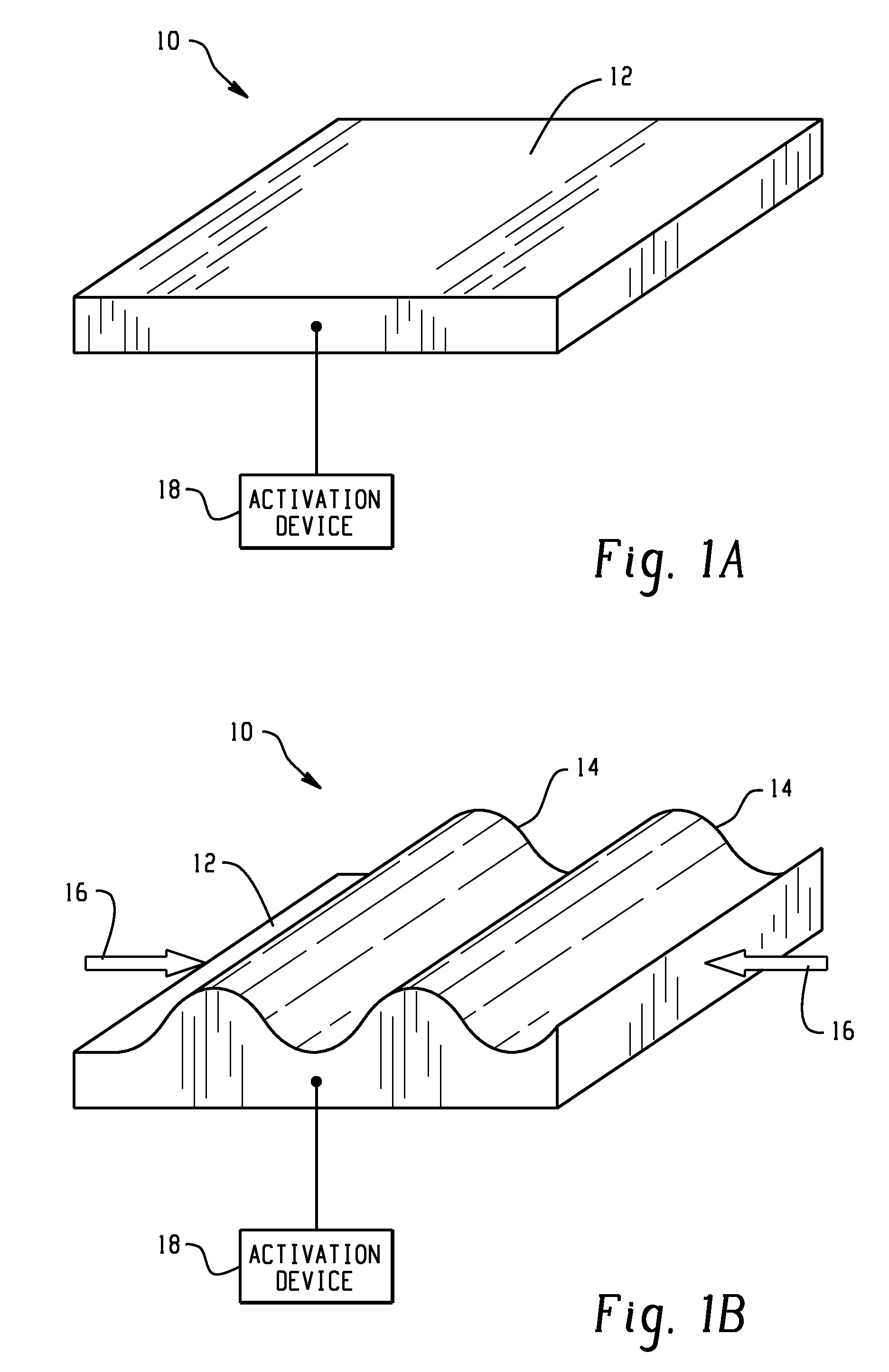

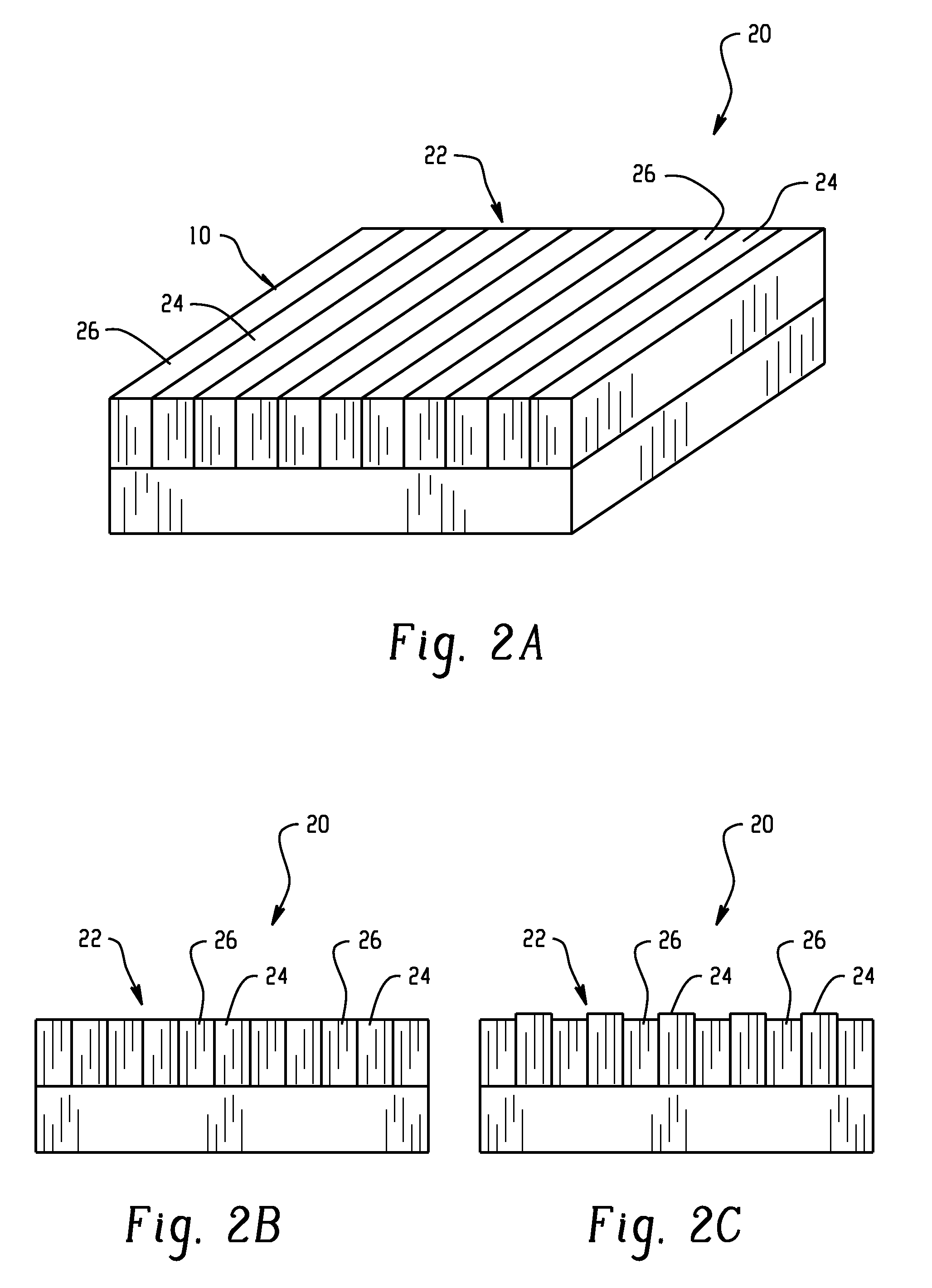

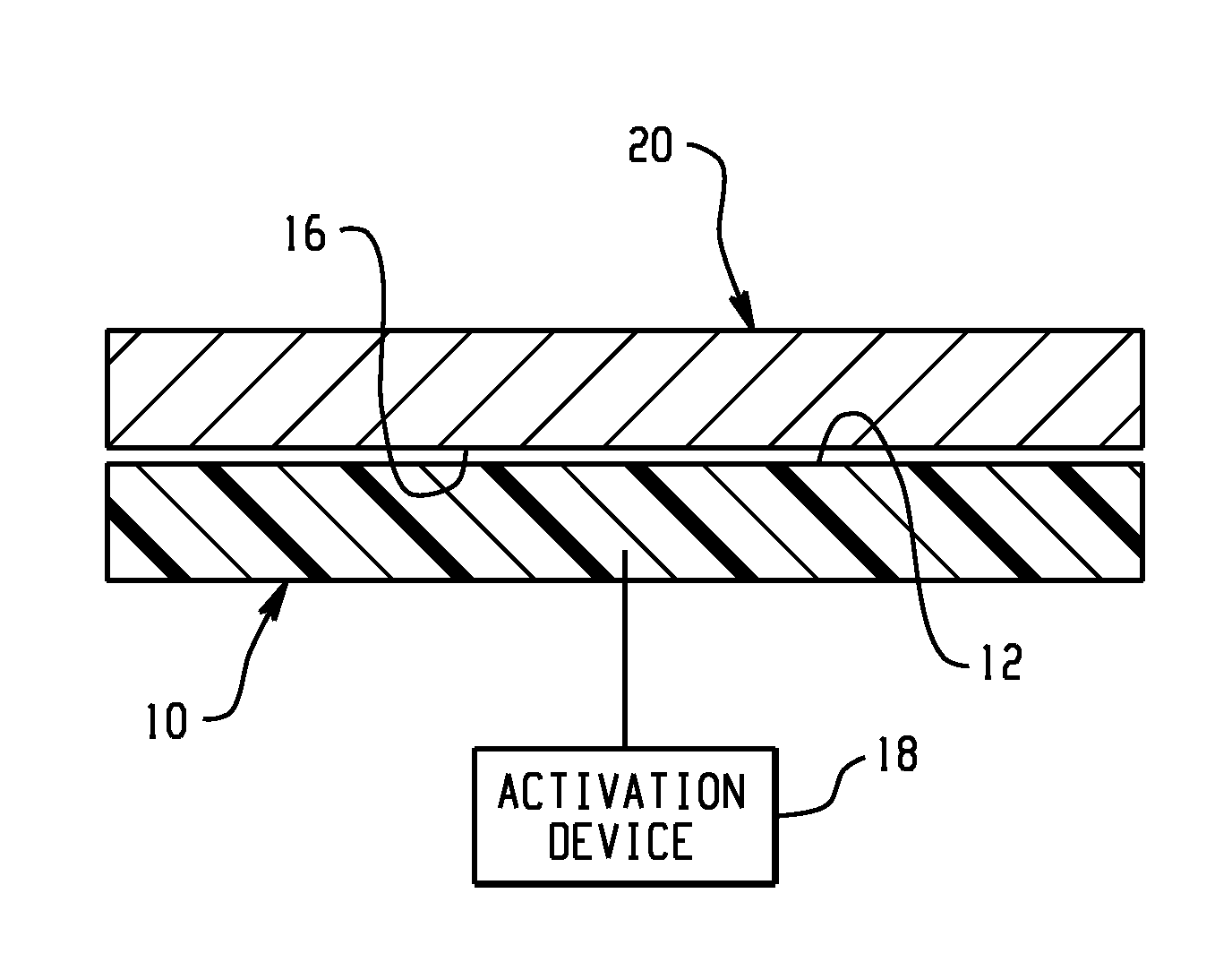

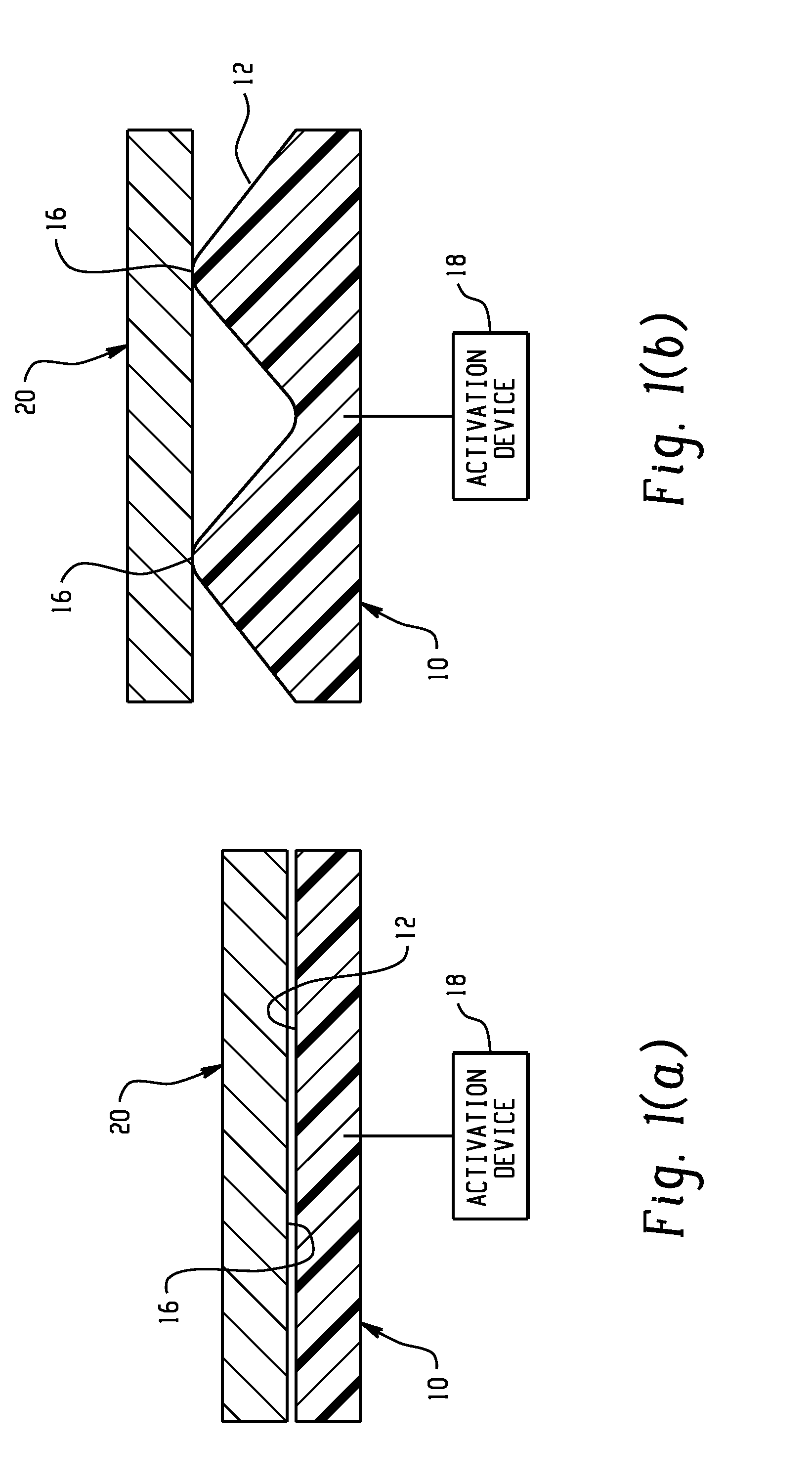

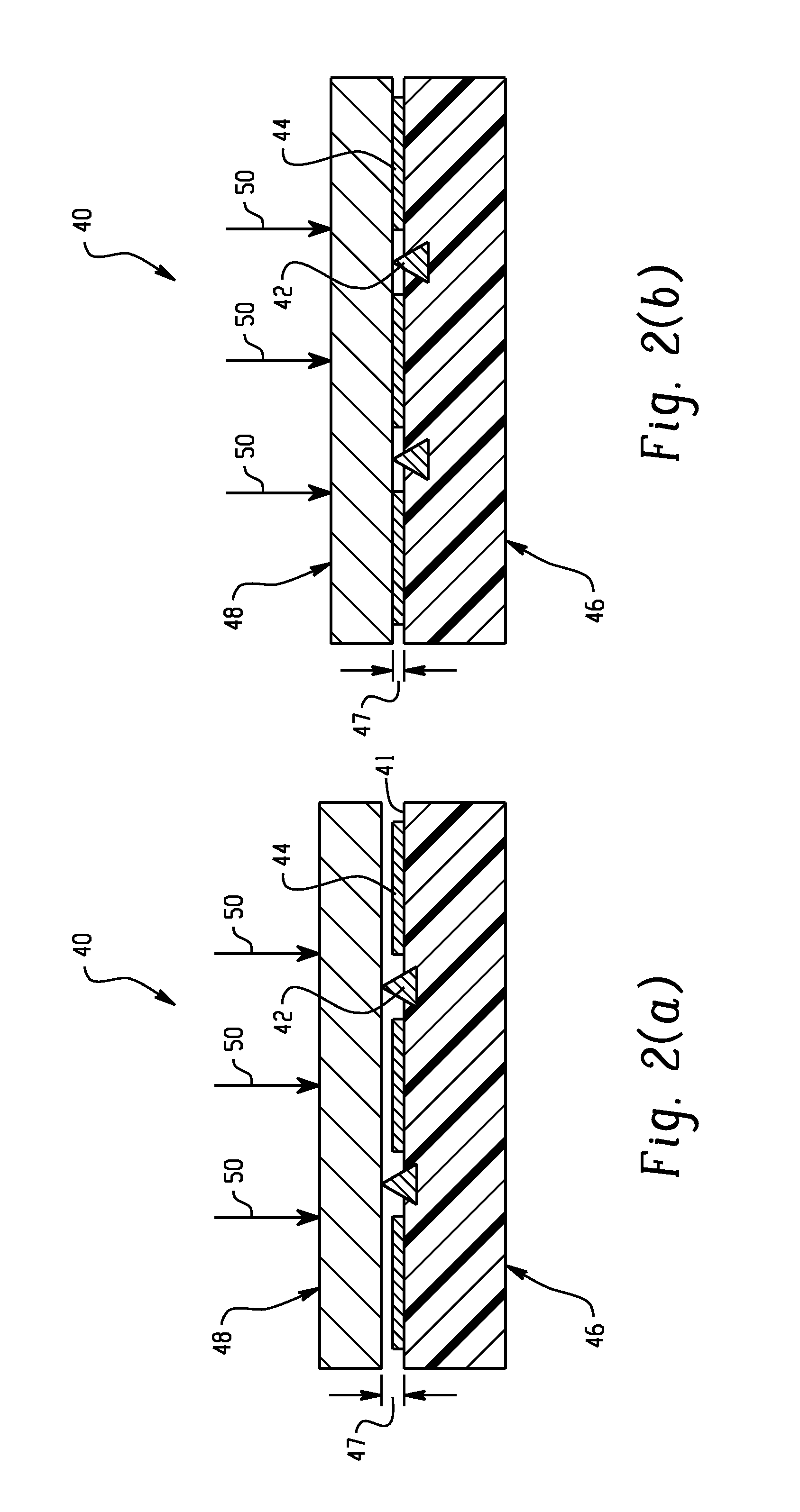

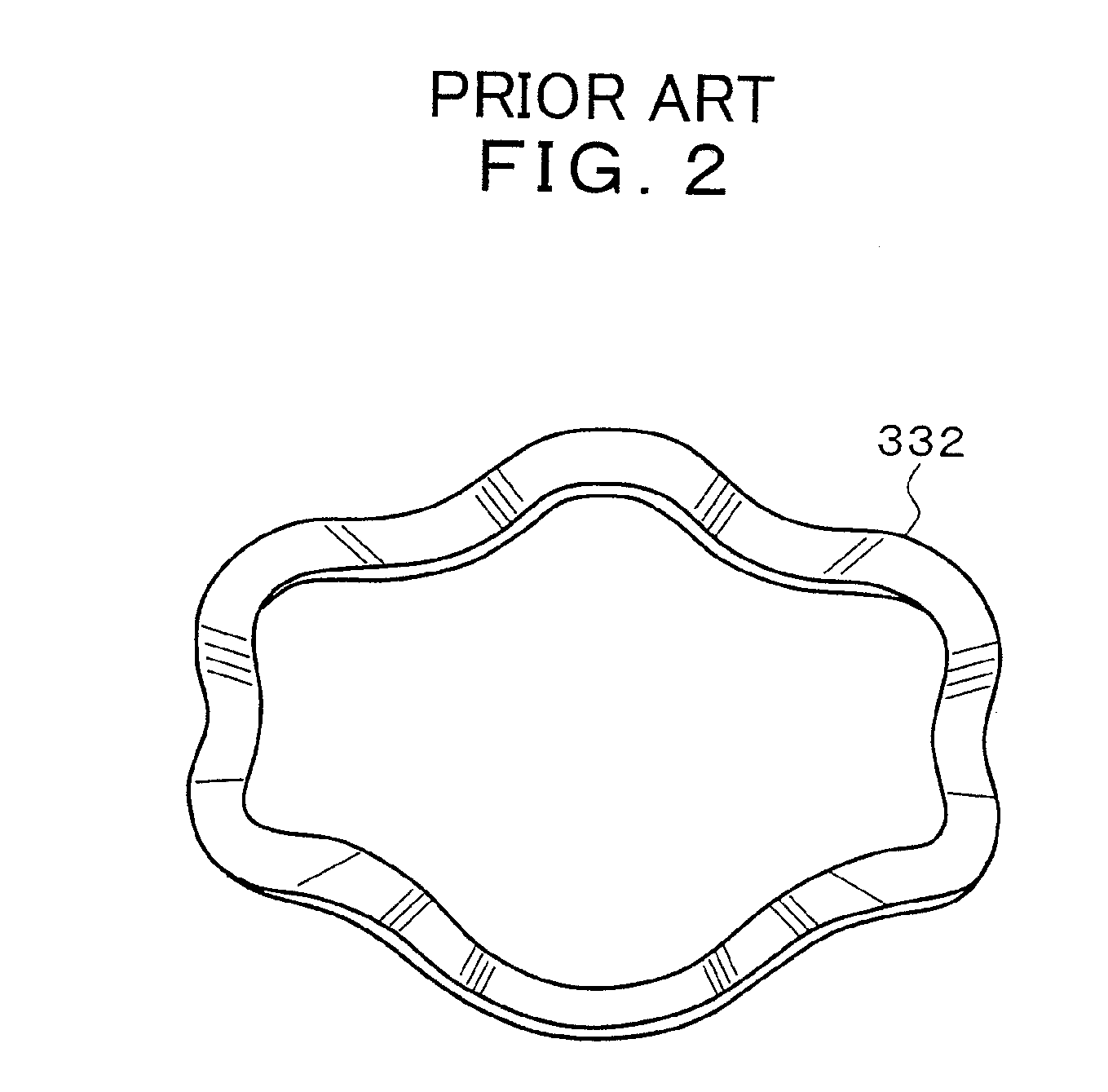

Active material based bodies for varying surface texture and frictional force levels

InactiveUS20090047197A1Efficient changeBacterial antigen ingredientsLavatory sanitoryEngineeringBiological activation

A device for selectively controlling and varying surface texture includes a body having at least one surface, and an active material in operative communication with the at least one surface, wherein the active material is configured to undergo a change in a property upon receipt of an activation signal, wherein the change in a property is effective to change a texture of the at least one surface.

Owner:GM GLOBAL TECH OPERATIONS LLC

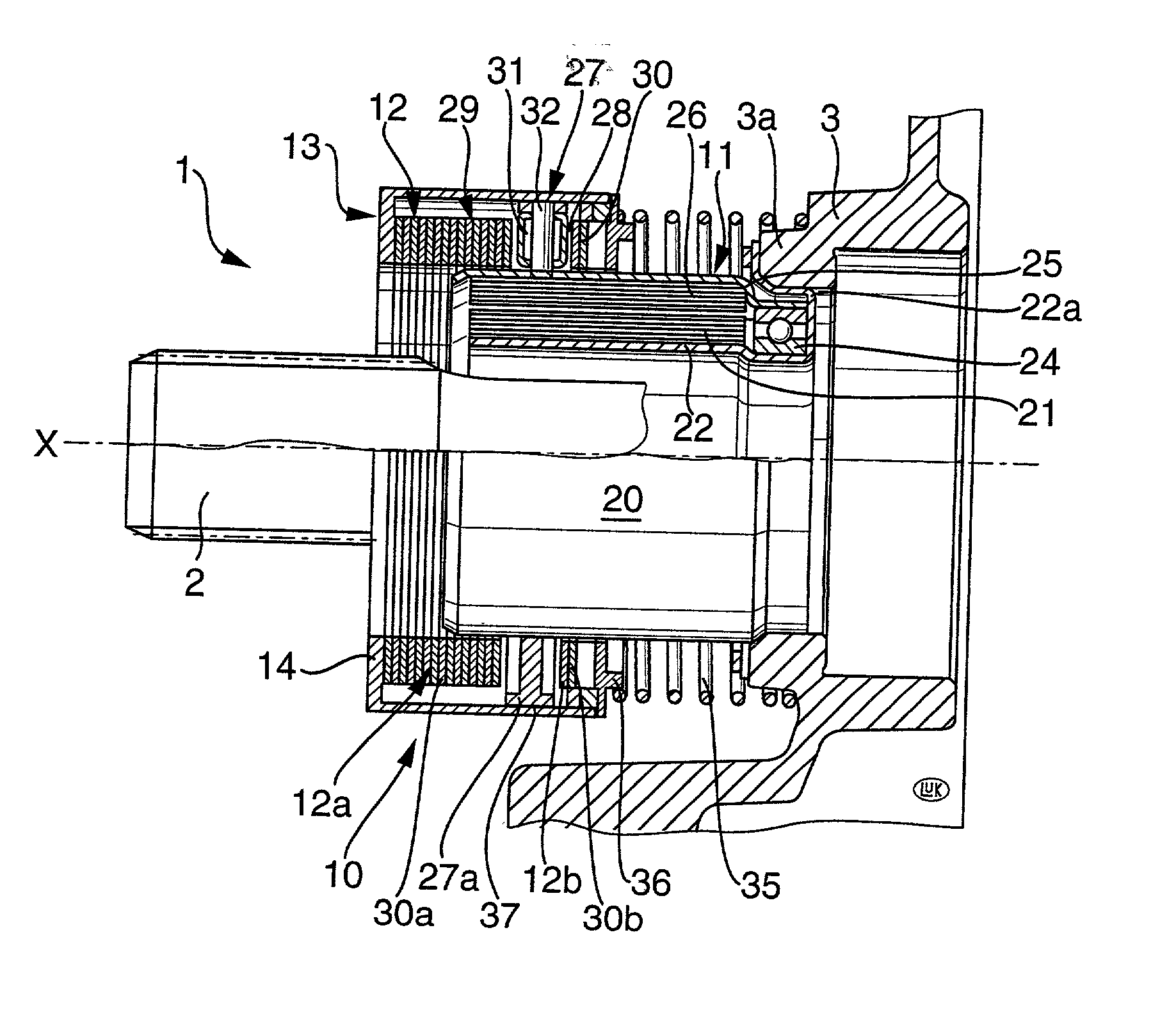

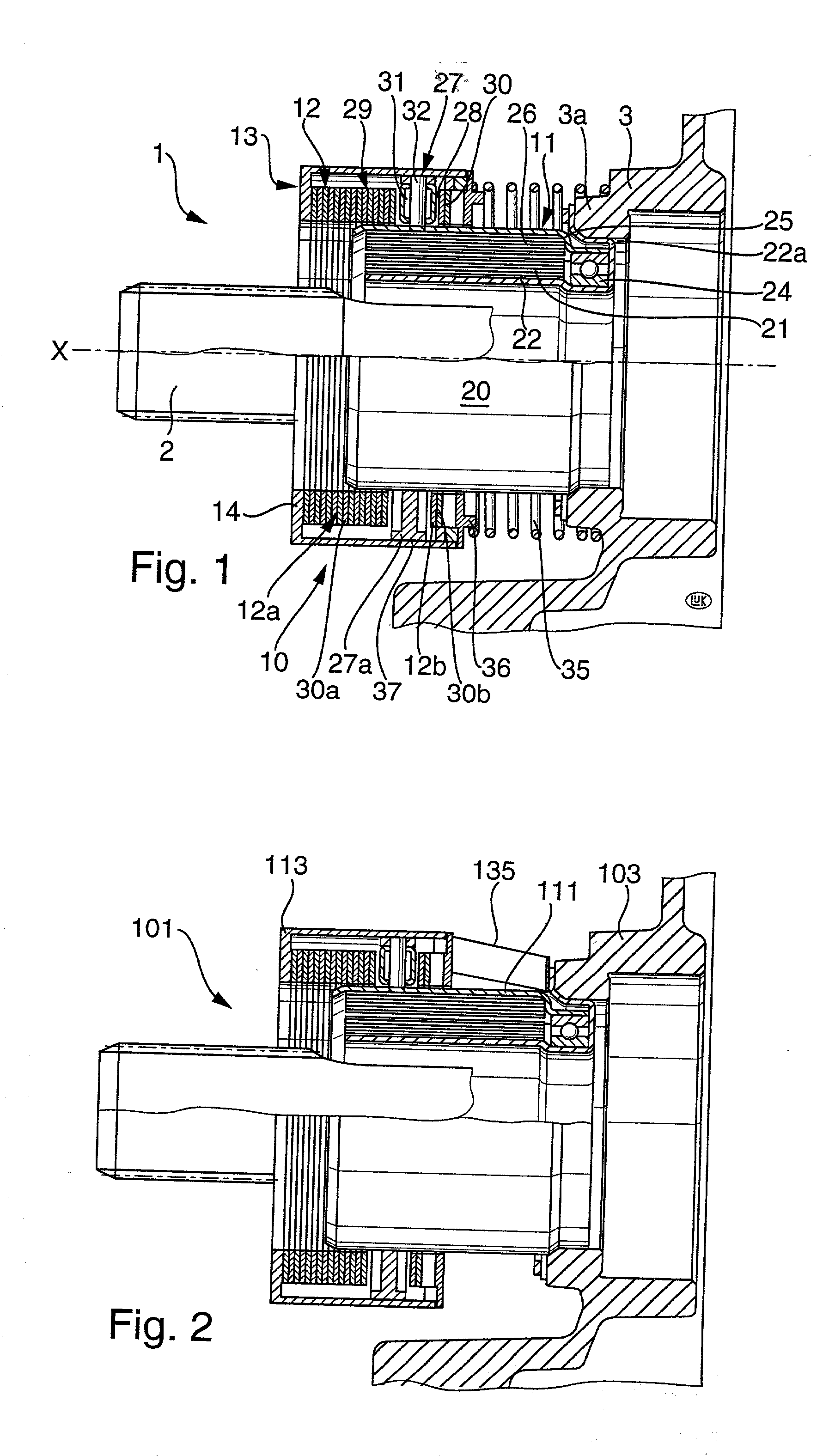

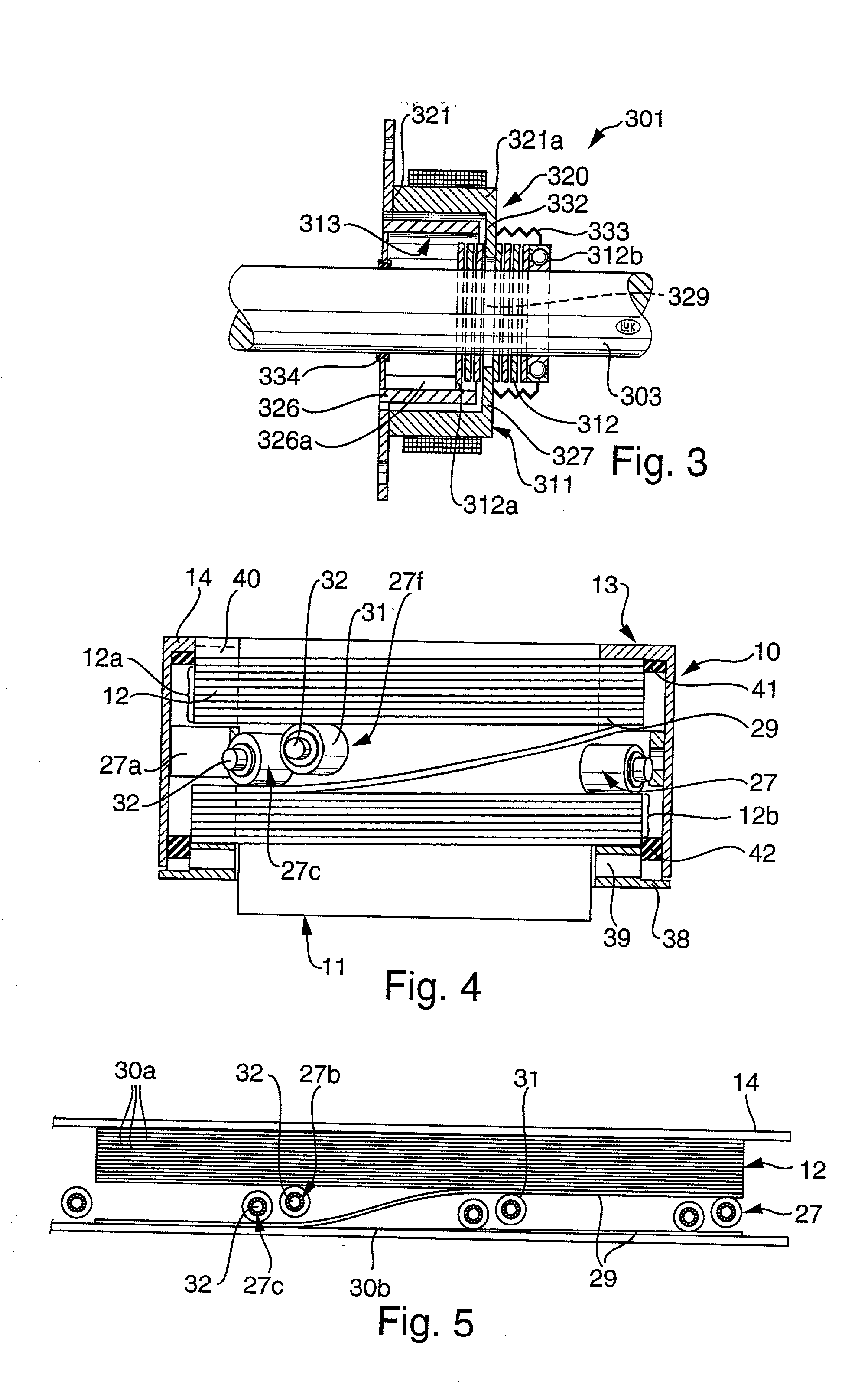

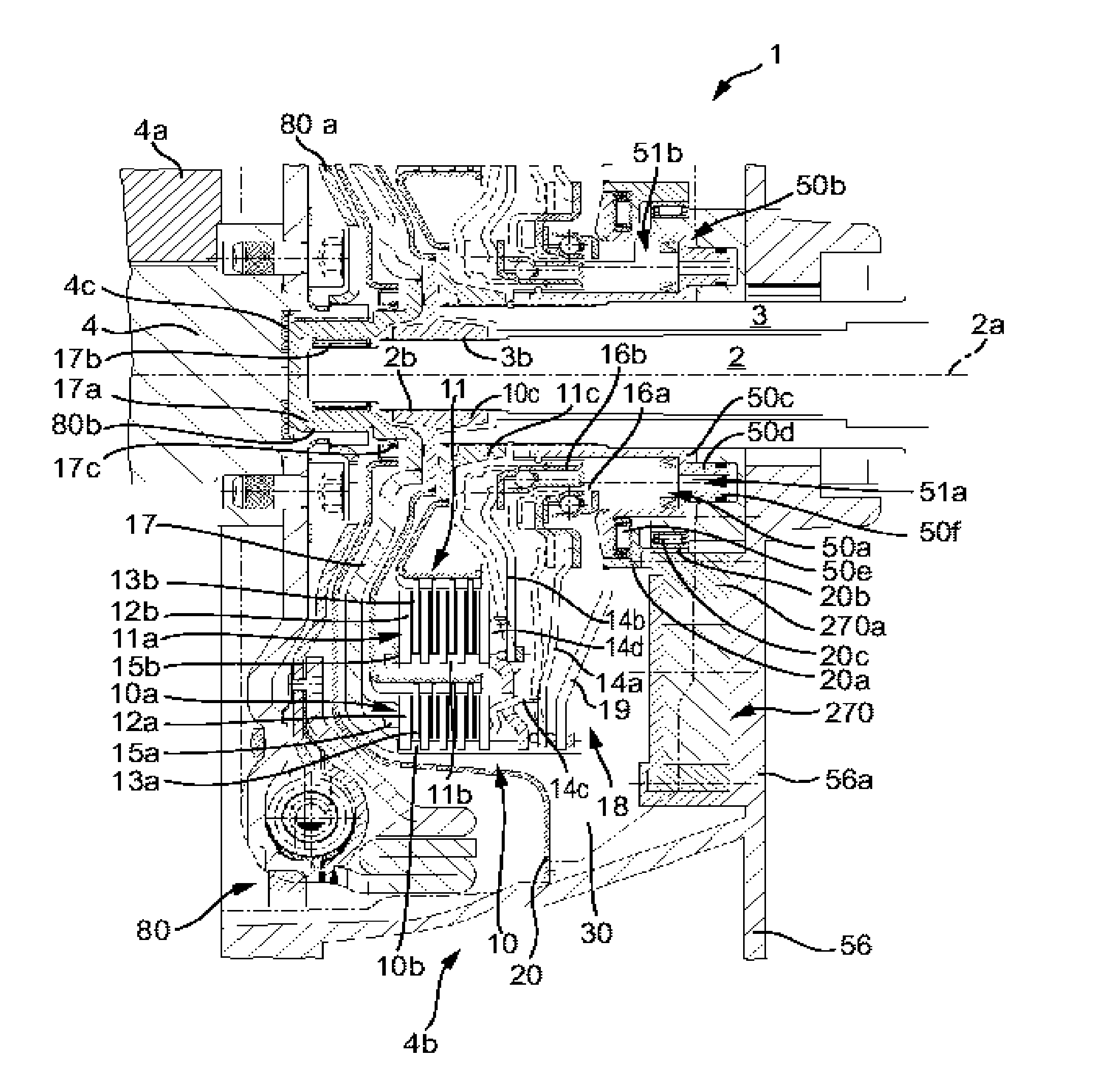

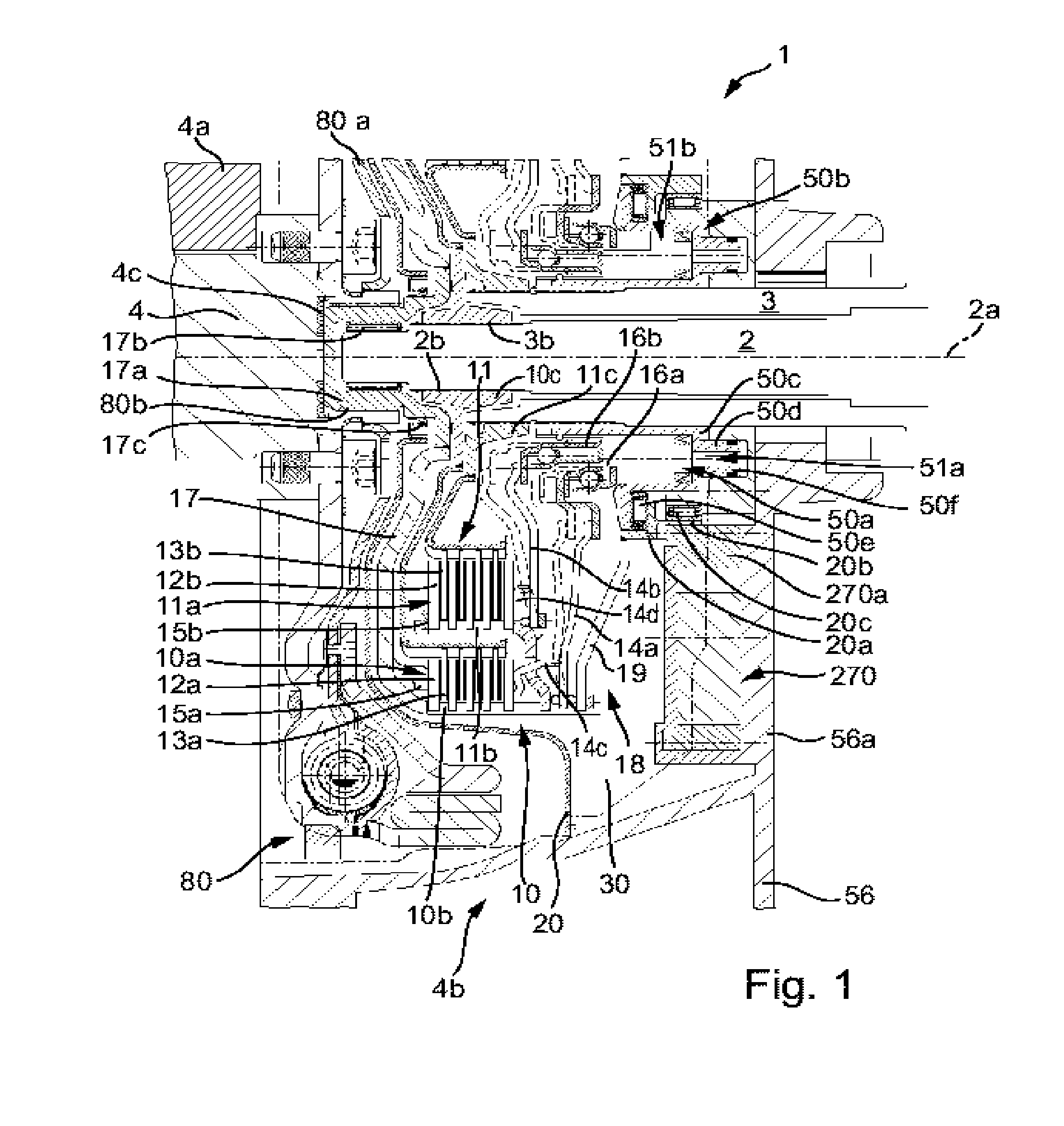

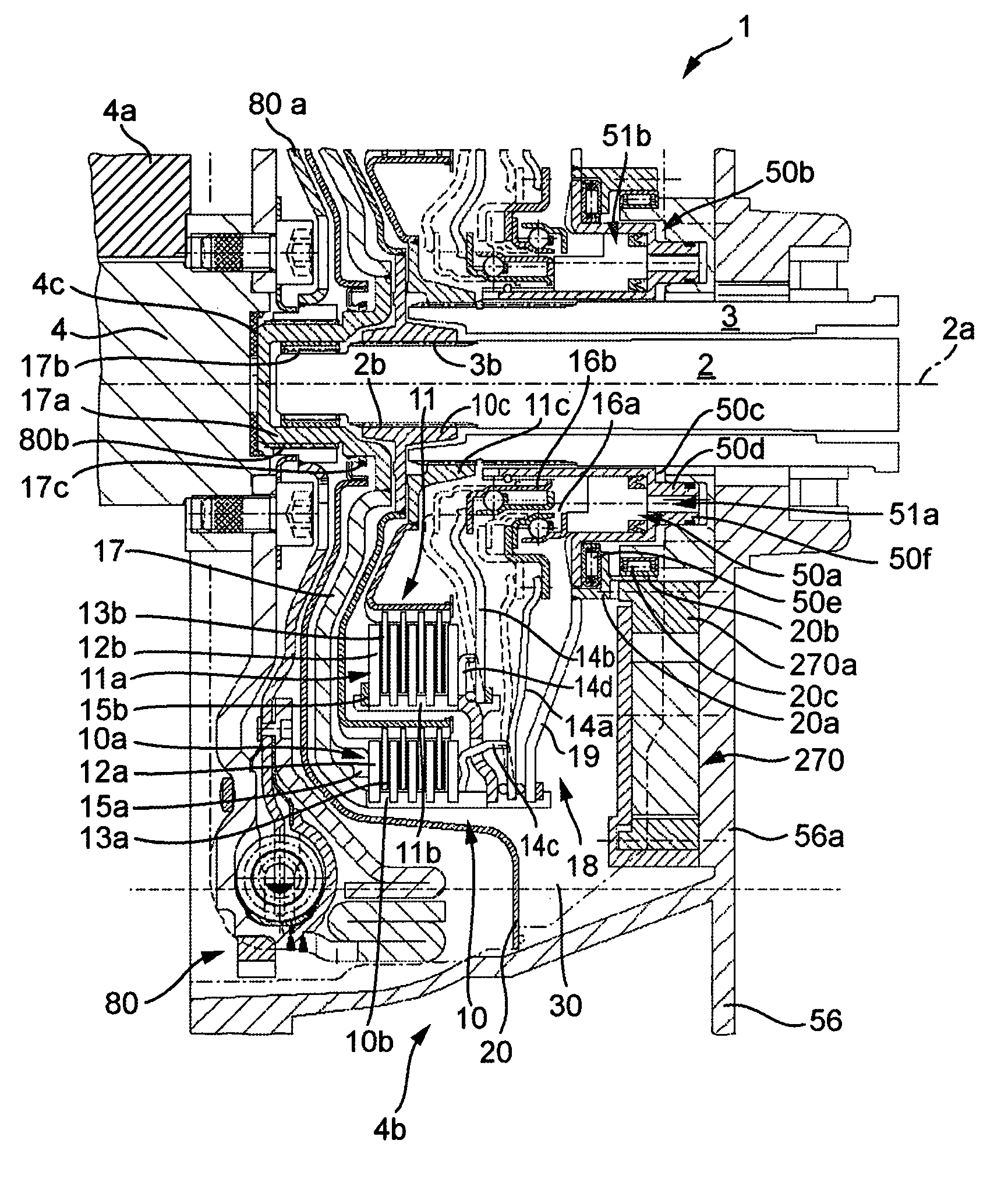

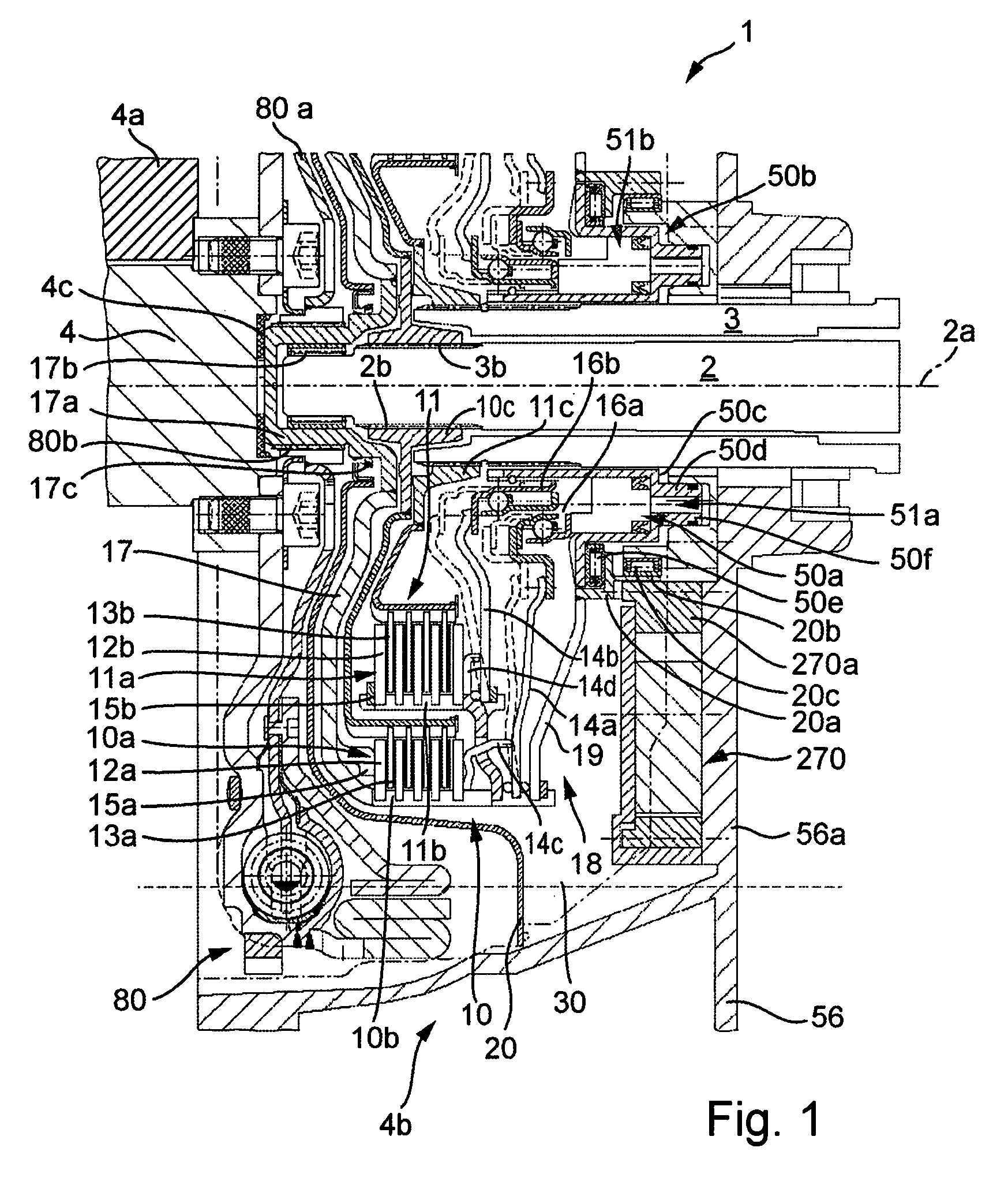

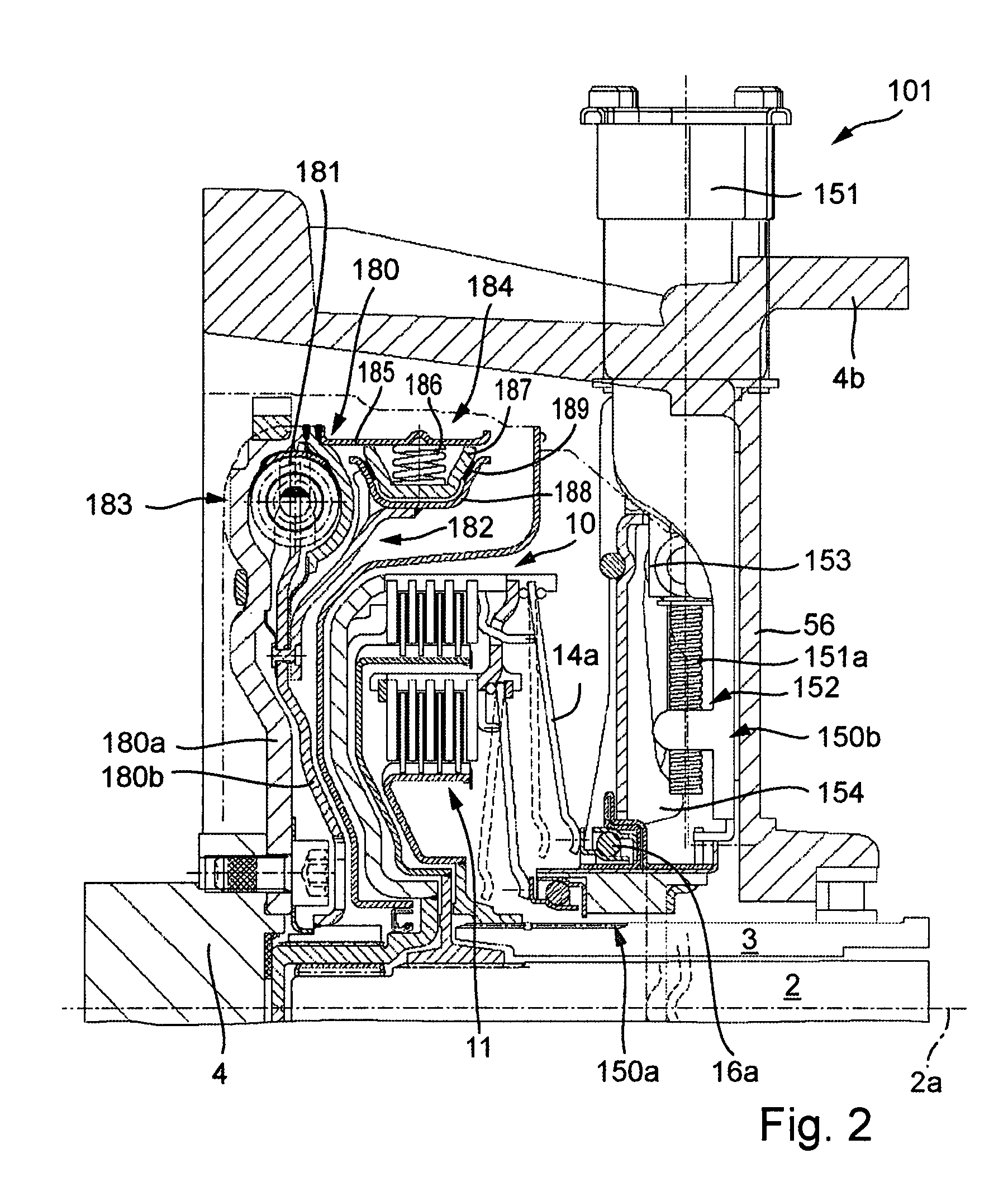

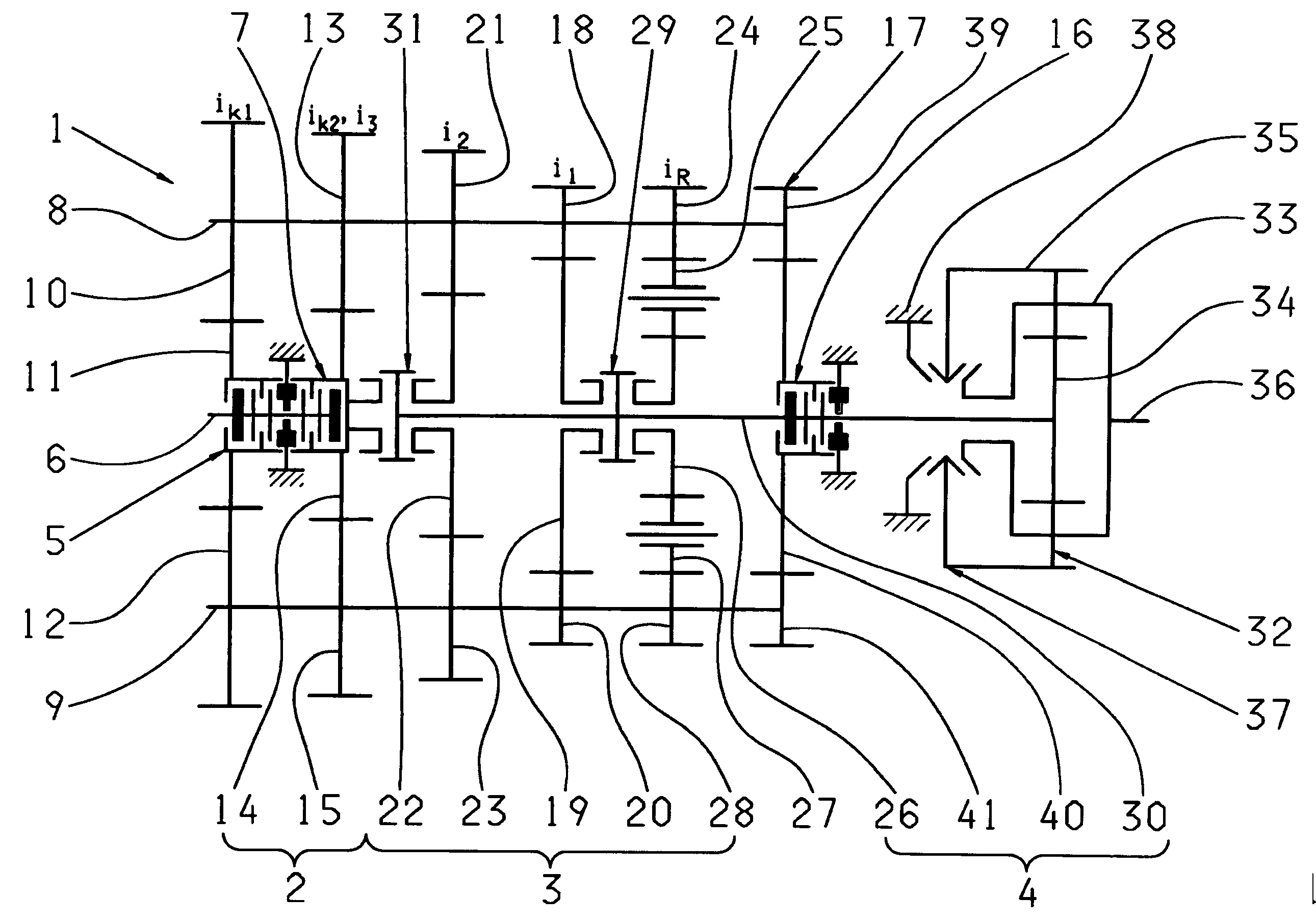

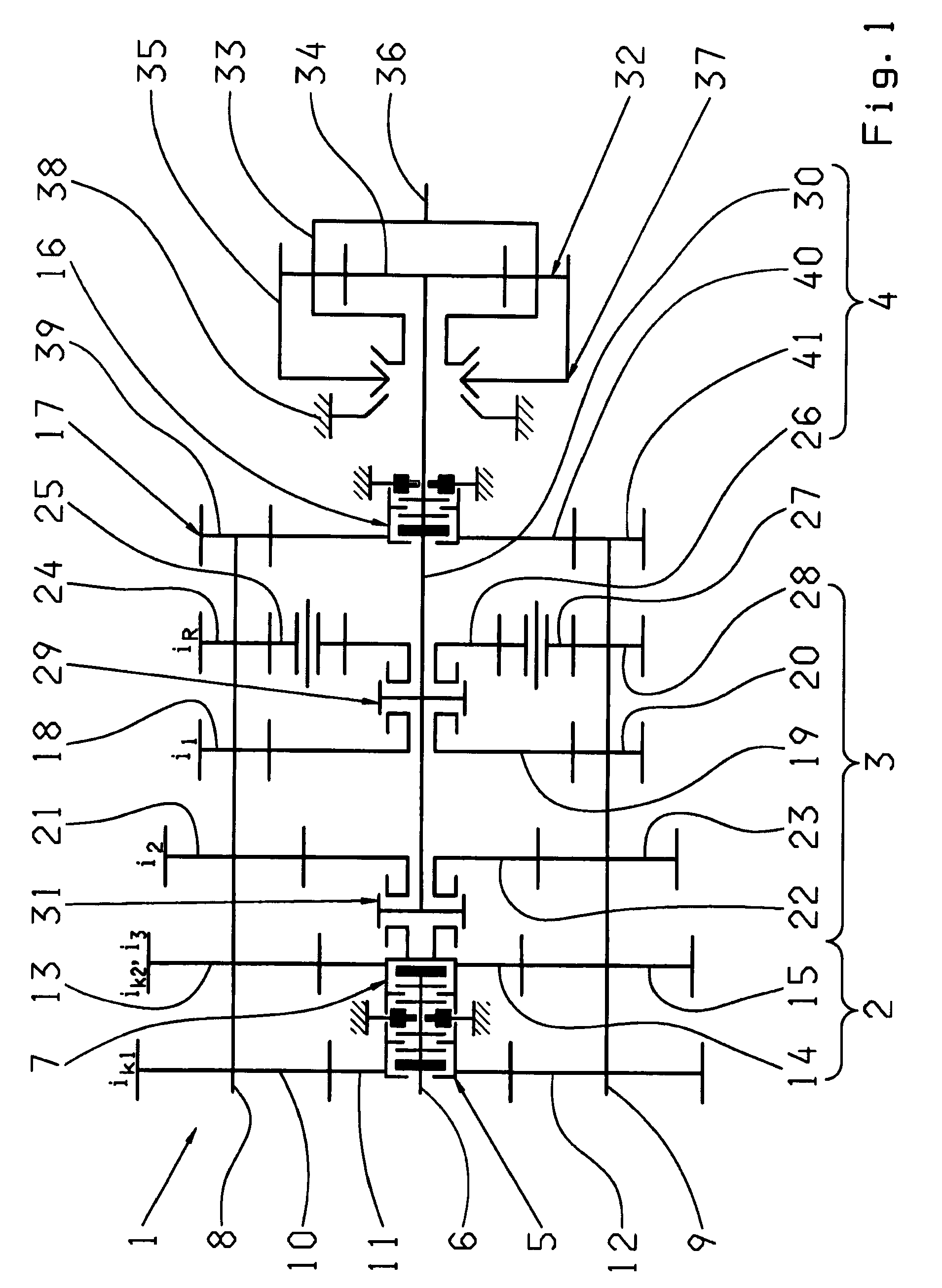

Torque transmitting unit and drive train for it

ActiveUS20050139442A1Reduce and eliminate torsional vibrationSustained beneficialFluid actuated clutchesFriction clutchesTorque transmissionInternal combustion engine

The invention relates to a torque transmission device, especially for a drive train comprising an internal combustion engine and a twin-clutch transmission having two transmission input shafts and one transmission output shaft, each transmission input shaft being connectable to an internal combustion engine via a clutch of the torque transmission device.

Owner:SCHAEFFLER TECH AG & CO KG

Locking differential with clutch activated by magnetorheological fluid

InactiveUS6428441B1Magnetically actuated clutchesFriction clutchesElectromagnetic couplingLimited-slip differential

A limited slip differential includes a friction clutch mechanism, an electromagnetic coupling, and a camming mechanism disposed between the friction clutch mechanism and the electromagnetic coupling. The camming mechanism converts shearing forces within the electromagnetic coupling to an axial force applied to engage the clutch mechanism. The camming mechanism includes annular discs having axially inclined ramps, and a roller bearing for movement along the ramps to provide for variable spacing between the annular discs, wherein increased spacing is used to apply the axial force.

Owner:TORQUE TRACTION TECH INC

Active material based bodies for varying frictional force levels at the interface between two surfaces

A device for selectively controlling and varying a frictional force level at an interface between two bodies, includes a first contact body having at least one surface, a second contact body having at least one surface in physical communication with the first contact body, and an active material in operative communication with a selected one or both of the first contact body and the second contact body, wherein the active material is configured to undergo a change in a property upon receipt of an activation signal wherein the change in a property is effective to change the frictional force level at the interface between the at least one surface of the first contact body and the at least one surface of the second contact body.

Owner:GM GLOBAL TECH OPERATIONS LLC

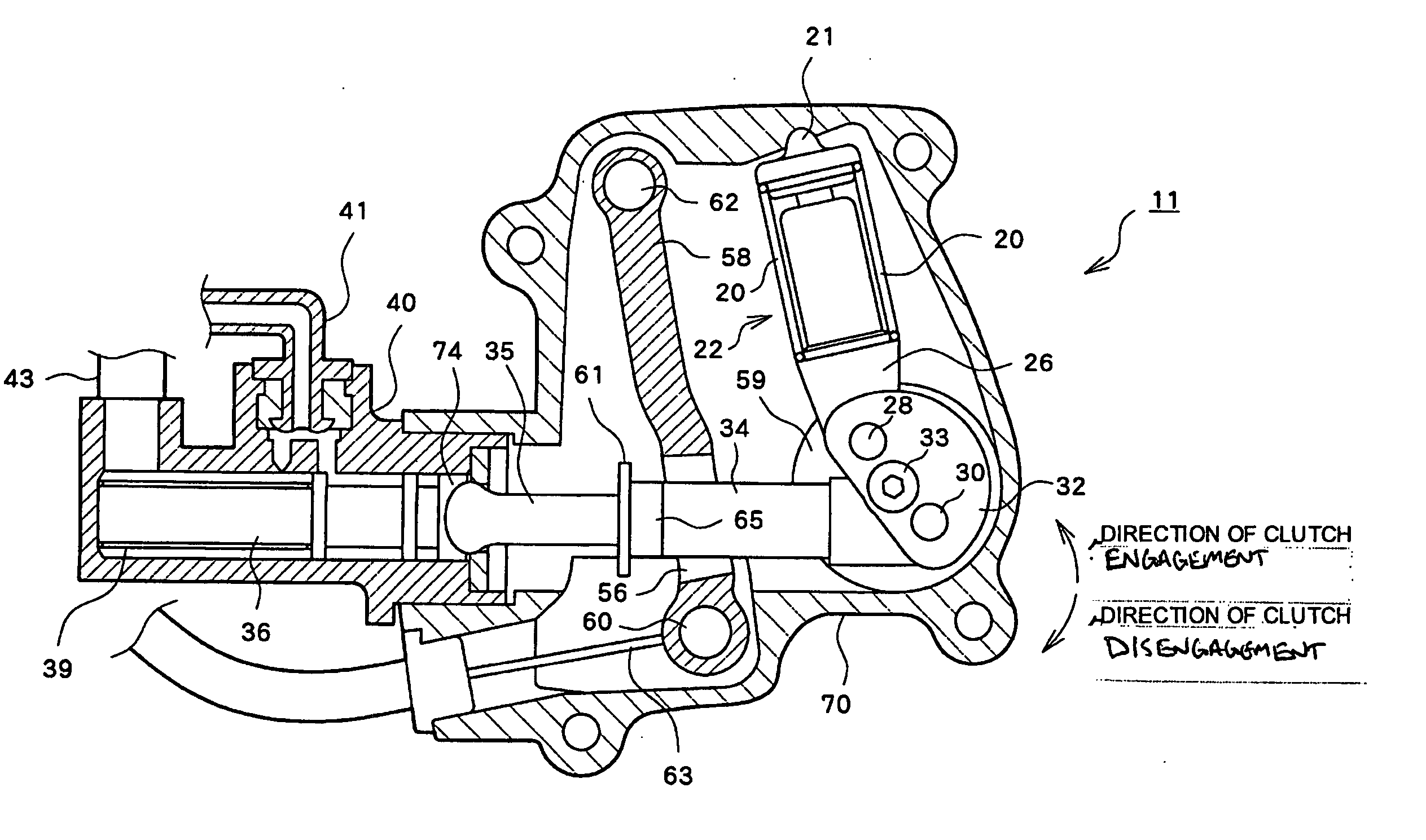

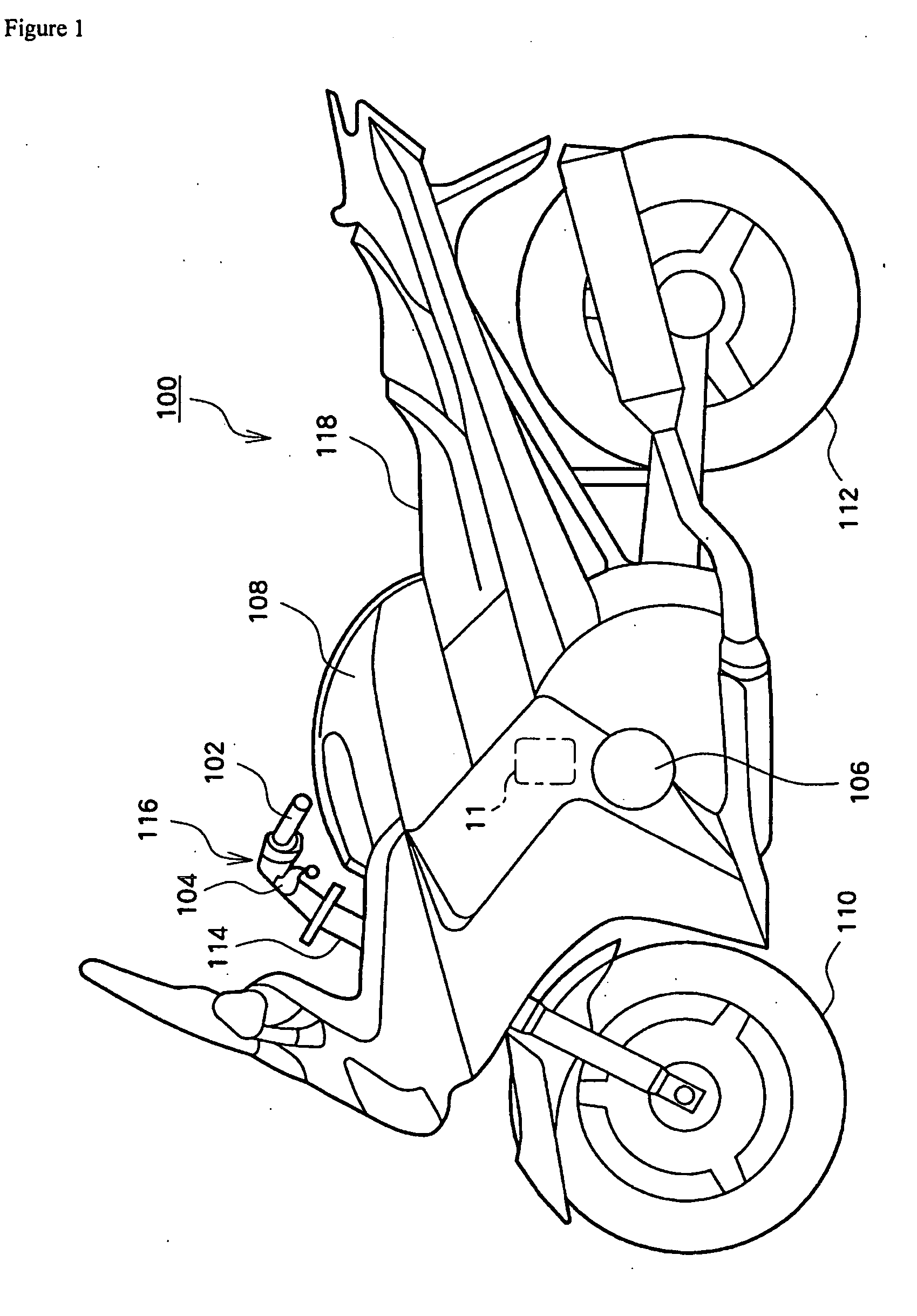

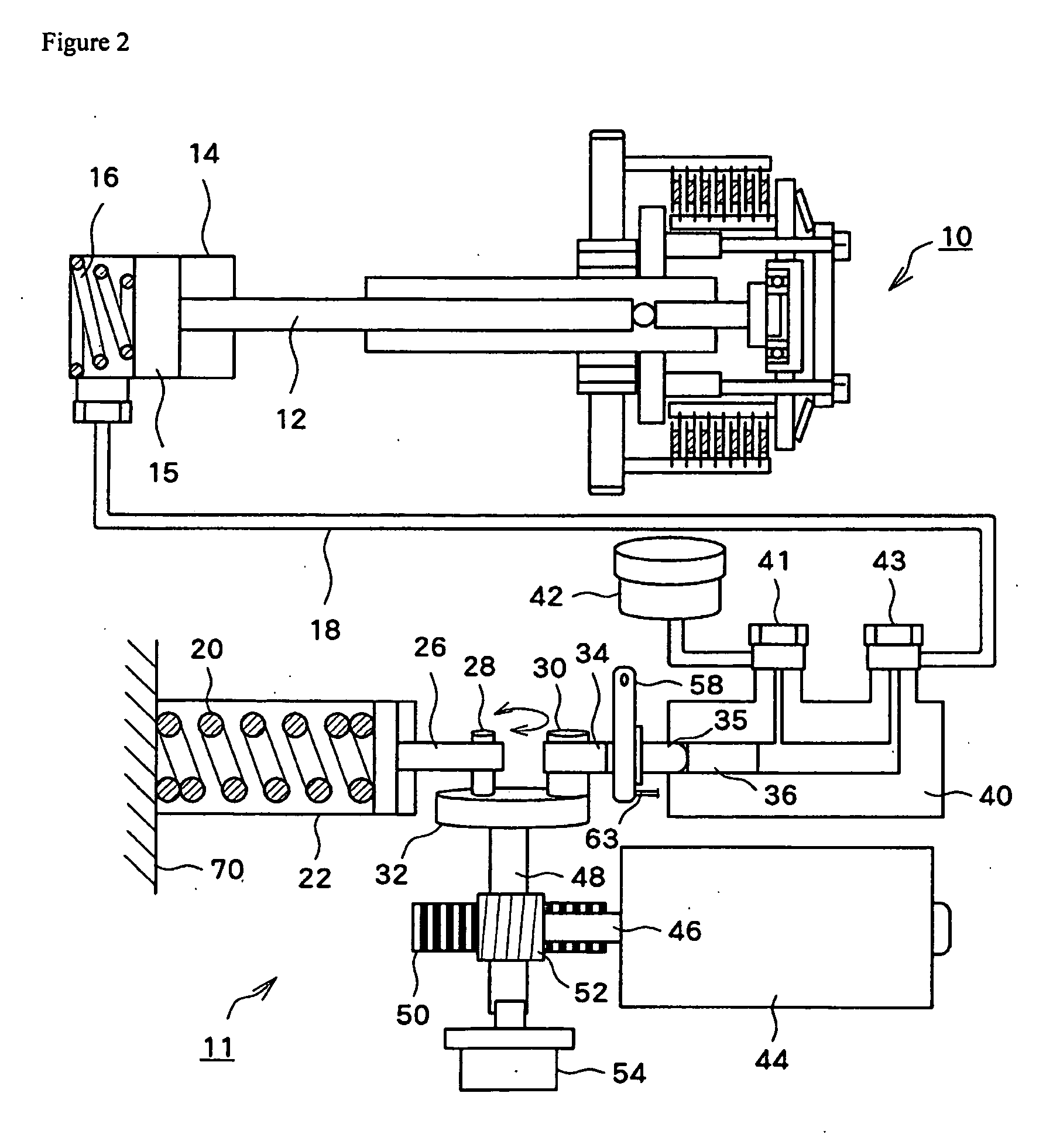

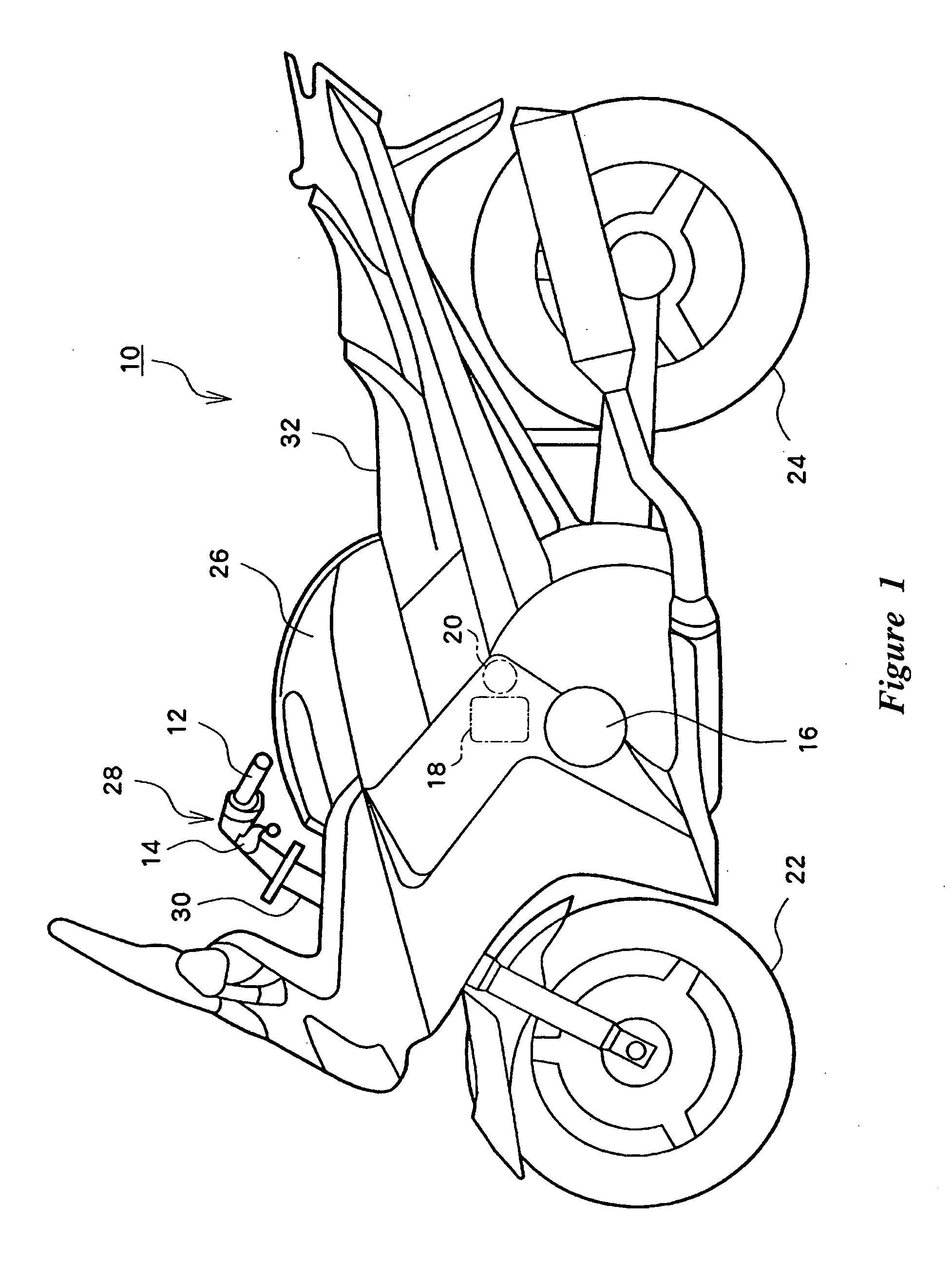

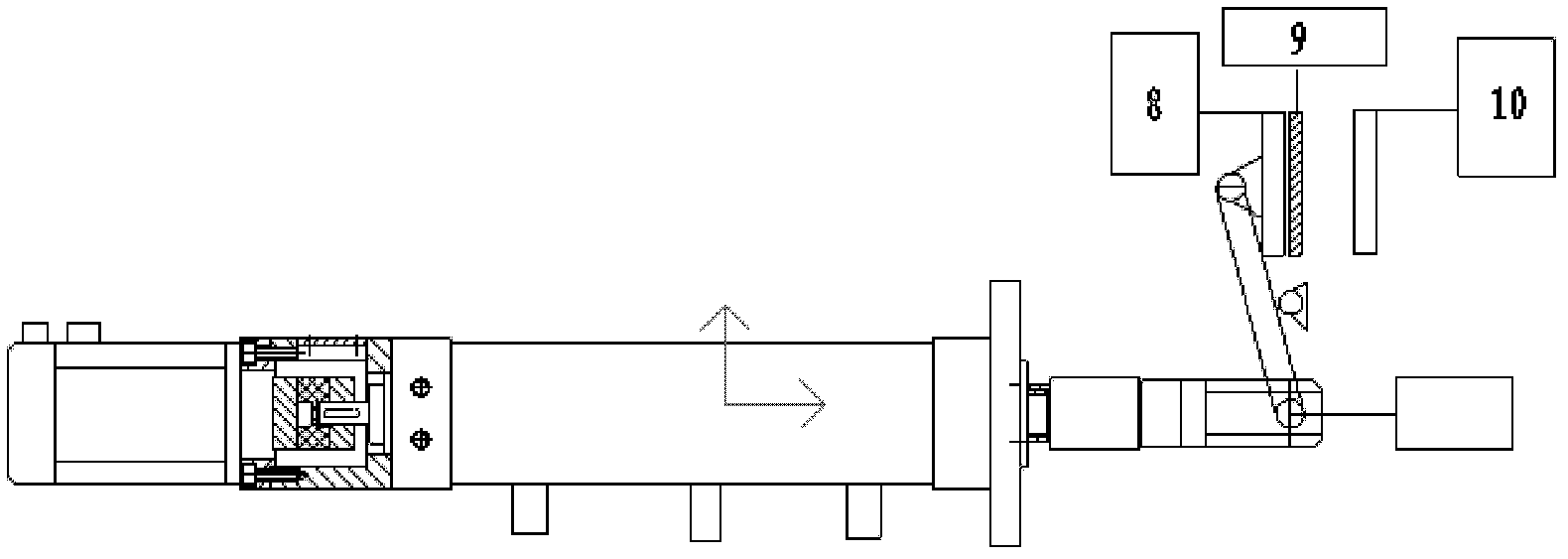

Clutch actuator for straddle-type vehicle

ActiveUS20060169562A1No torqueSmall sizeFluid actuated clutchesFriction clutchesCoil springEngineering

A clutch actuator is provided to stabilize a state of clutch engagement. A rotating member is rotationally driven on a rotating shaft by a motor. A clutch operating member includes two ends. One end of the clutch operating member is pushed by a push force of a clutch spring and the other end is pivotally supported on the rotating member by a shaft. The clutch operating member disengages the clutch when moved in a direction against the force of the clutch spring. An auxiliary biasing mechanism also acts on the rotating member. One end of the auxiliary biasing member is supported on a vehicle side and the other end is pivotally supported on the rotating member by a shaft. The auxiliary biasing member can include a compressible coil spring. The rotating member rotates in a first direction to move the clutch operating member in a direction of clutch engagement. When the clutch is engaged, the combined torque on the rotating member, which is produced by forces asserted by the auxiliary biasing mechanism and the clutch operating member, bias the rotating member in the first direction.

Owner:YAMAHA MOTOR CO LTD

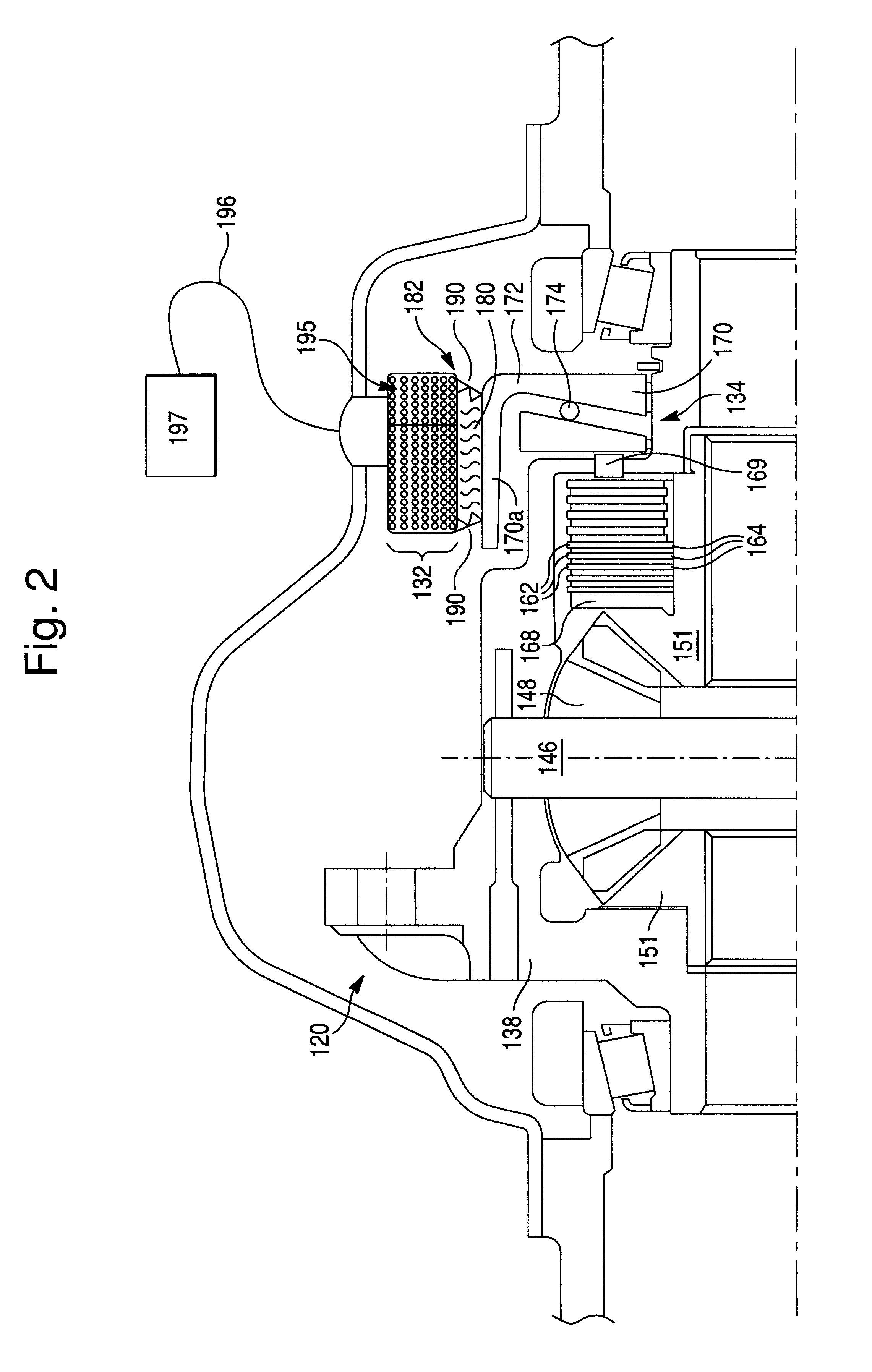

Transfer case with synchronizer clutch

InactiveUS20030211913A1Mechanical actuated clutchesMagnetically actuated clutchesTransfer caseDrive shaft

A transfer case for a vehicle that allows shifting between AWD and two-wheel drive at any vehicle speed. The transfer case includes a center differential employing pinion and sun gears that allow a front drive shaft and a rear drive shaft to turn at different speeds to provide the all-wheel drive function. The transfer case further includes an electrically actuated synchronizer assembly that allows the speed of the front drive shaft to be synchronized to the speed of the rear drive shaft when shifting from two-wheel drive to all-wheel drive to provide the shift on the fly function. The synchronizer assembly also includes a neutral position where both the front drive shaft and the rear drive shaft are not engaged to the vehicle transmission to allow for vehicle towing.

Owner:BORGWARNER INC

Torque transmitting unit and drive train for it

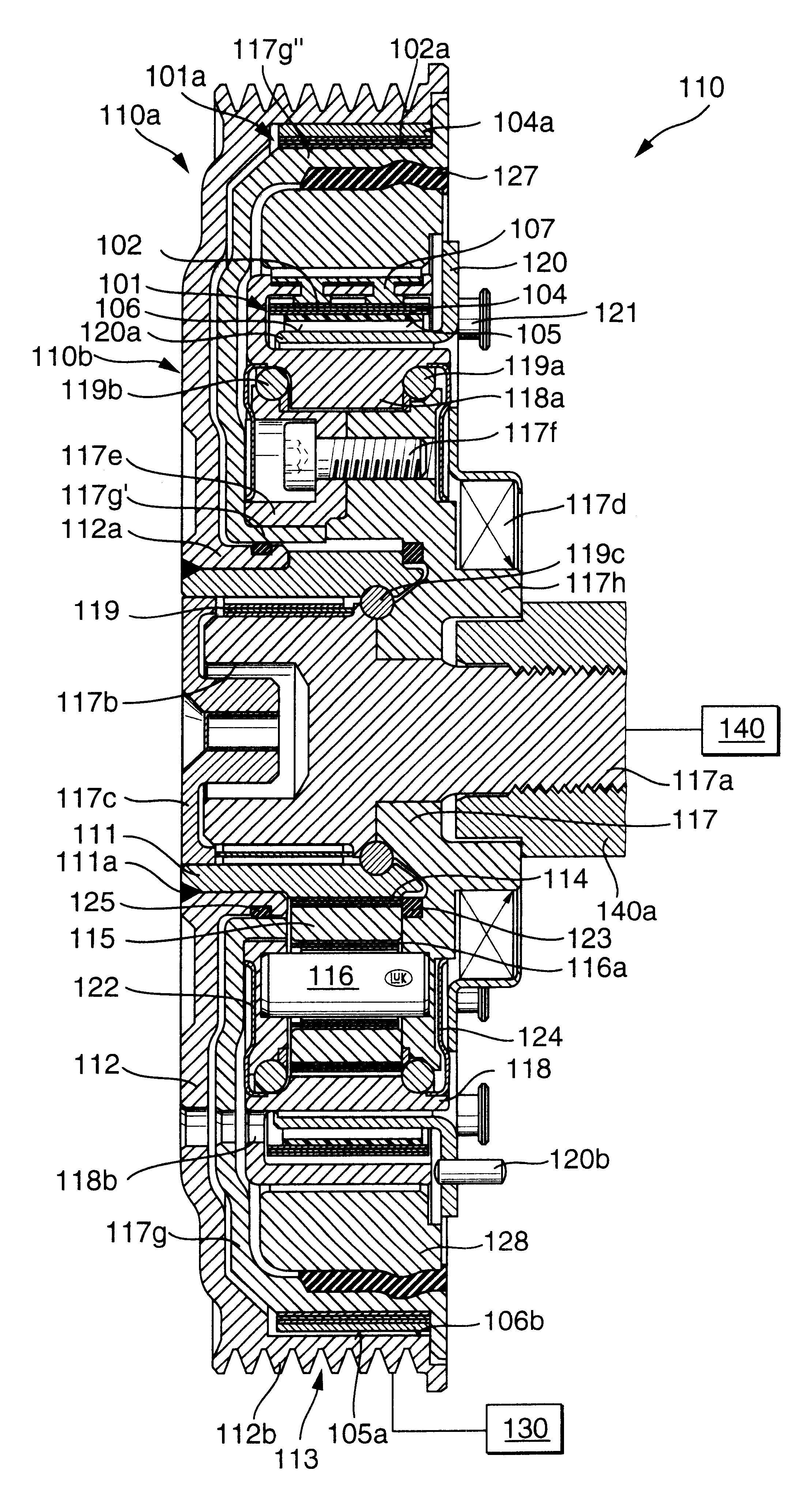

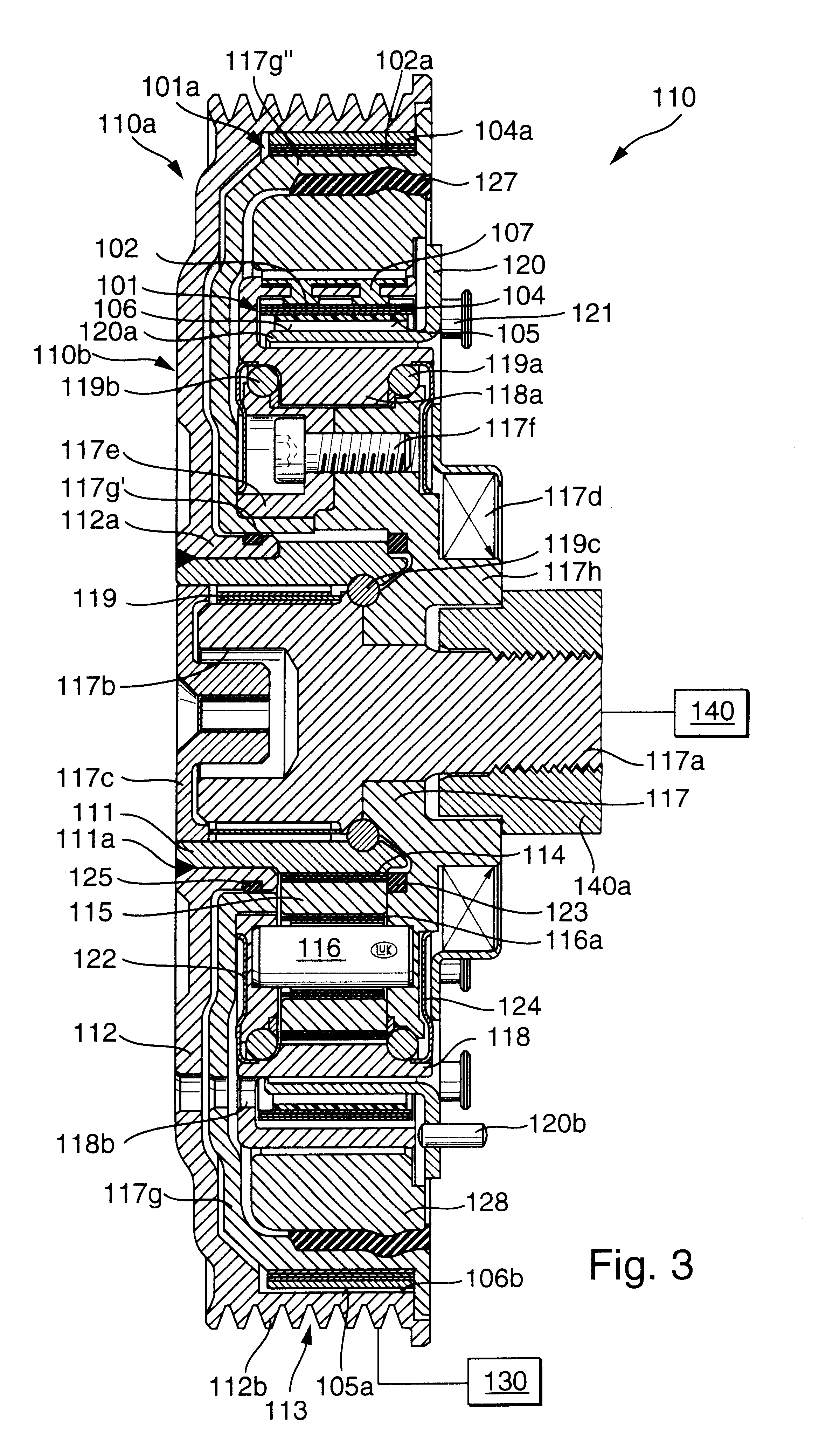

ActiveUS7287634B2Increase output powerSimple and safe operation of clutchFluid actuated clutchesFriction clutchesTorque transmissionEngineering

The invention relates to a torque transmission device, especially for a drive train comprising an internal combustion engine and a twin-clutch transmission having two transmission input shafts and one transmission output shaft, each transmission input shaft being connectable to an internal combustion engine via a clutch of the torque transmission device.

Owner:SCHAEFFLER TECH AG & CO KG

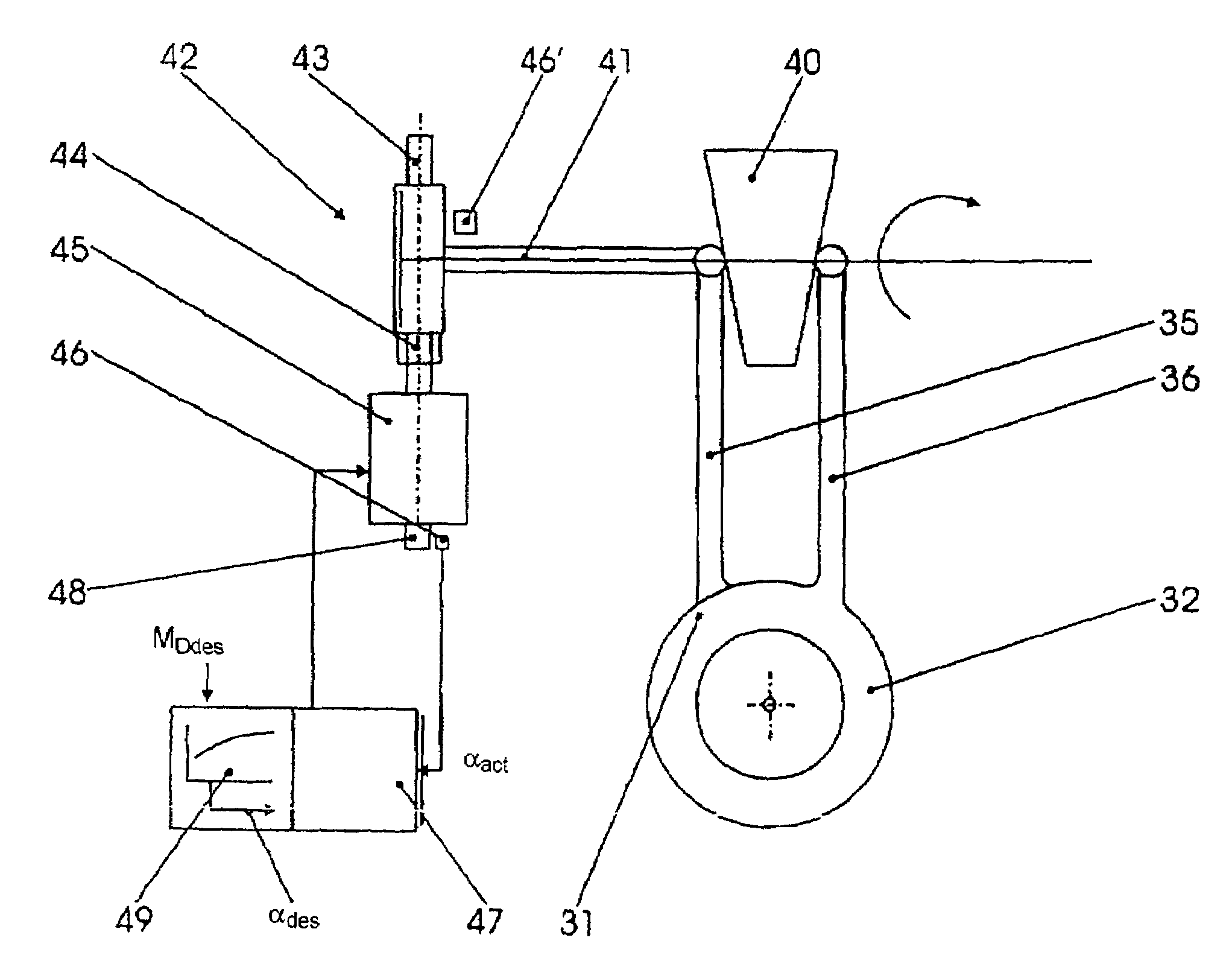

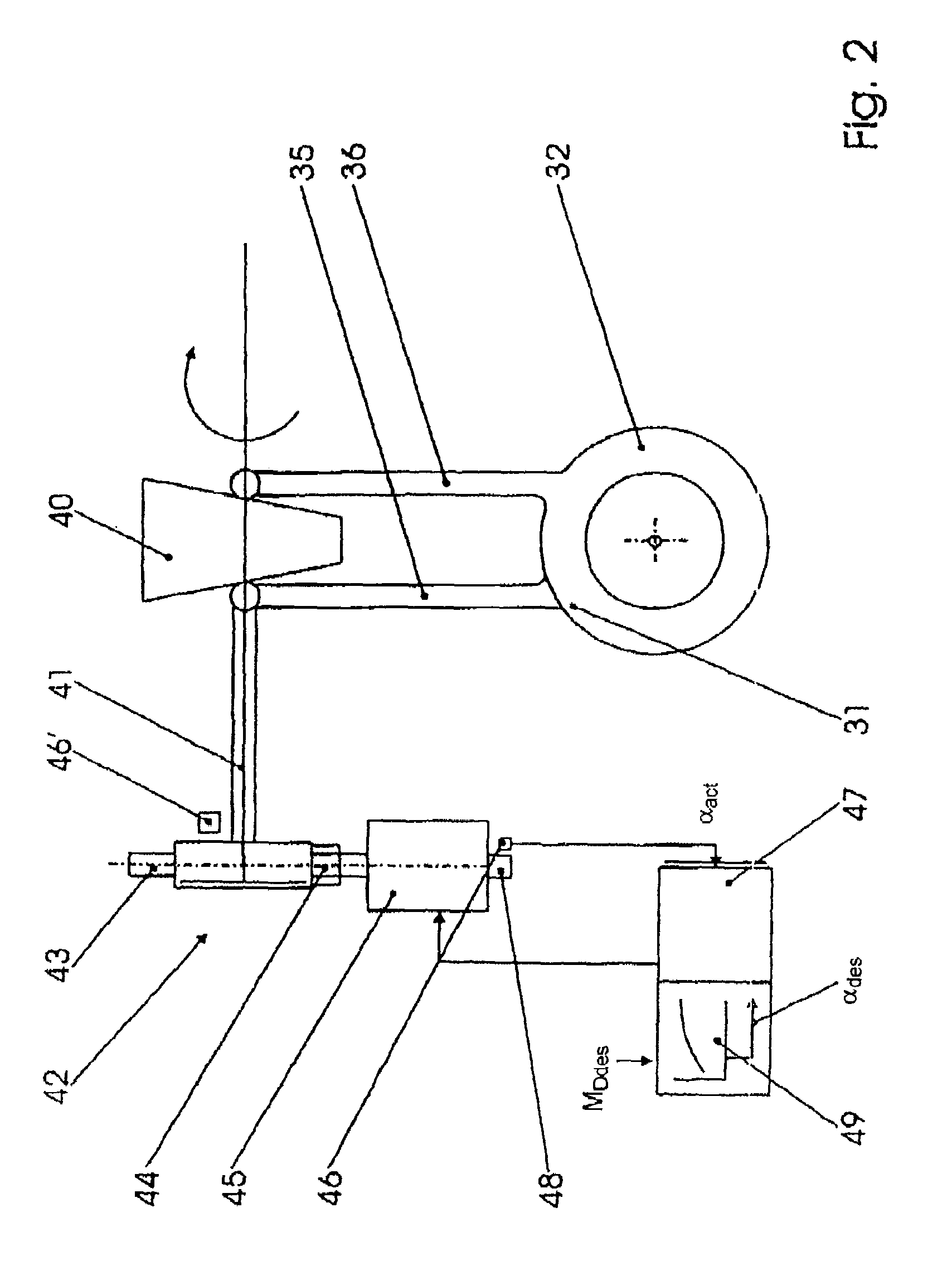

Device and method for adjusting the torque transmitted by a friction clutch

InactiveUS7032733B2Certain elastic flexibilityEliminate disadvantagesMechanical actuated clutchesDigital data processing detailsActuatorControl theory

A device for setting the torque transmitted by a friction clutch (12), having an actuator chain which comprises an electric motor (45), a step-down gear (42) and a mechanism for converting the rotational movement into a displacement of a pressure plate (29) of the clutch (12), so as to enable the torque which is transmitted to be set precisely and rapidly even given high friction. For this purpose, the electric motor (45) and / or step-down gear (42) is / are affected by friction, the conversion mechanism (31, 32, 35, 36, 40) and / or the friction clutch (12) itself is / are affected by elasticity, and, to set the torque (Md) of the friction clutch (12), a position regulator (47) which is operatively connected to the electric motor (45) and a sensor (46; 46′) which determines the position of one of the links of the actuator chain (45, 42, 41, 40, 36, 35, 32, 31, 29) are provided, the sensor being present at a location upstream of a substantial part of the elasticity in the force-flow direction. The corresponding control and calibrating method is also developed.

Owner:MAGNA STEYR POWERTRAIN

Torque-transmitting mechanisms for a planetary transmission

InactiveUS20050279601A1Optimization mechanismMechanical actuated clutchesToothed gearingsTorque transmissionEngineering

A power transmission includes a plurality of torque-transmitting mechanisms, such as clutches and brakes. Each clutch and / or brake includes an apply piston, which is operatively drivingly connected with a stationary portion of the transmission and a rotating gear member having a cam surface formed thereon to enforce axial movement of each apply piston to thereby enforce engagement of the respective torque-transmitting mechanisms.

Owner:GENERAL MOTORS COMPANY

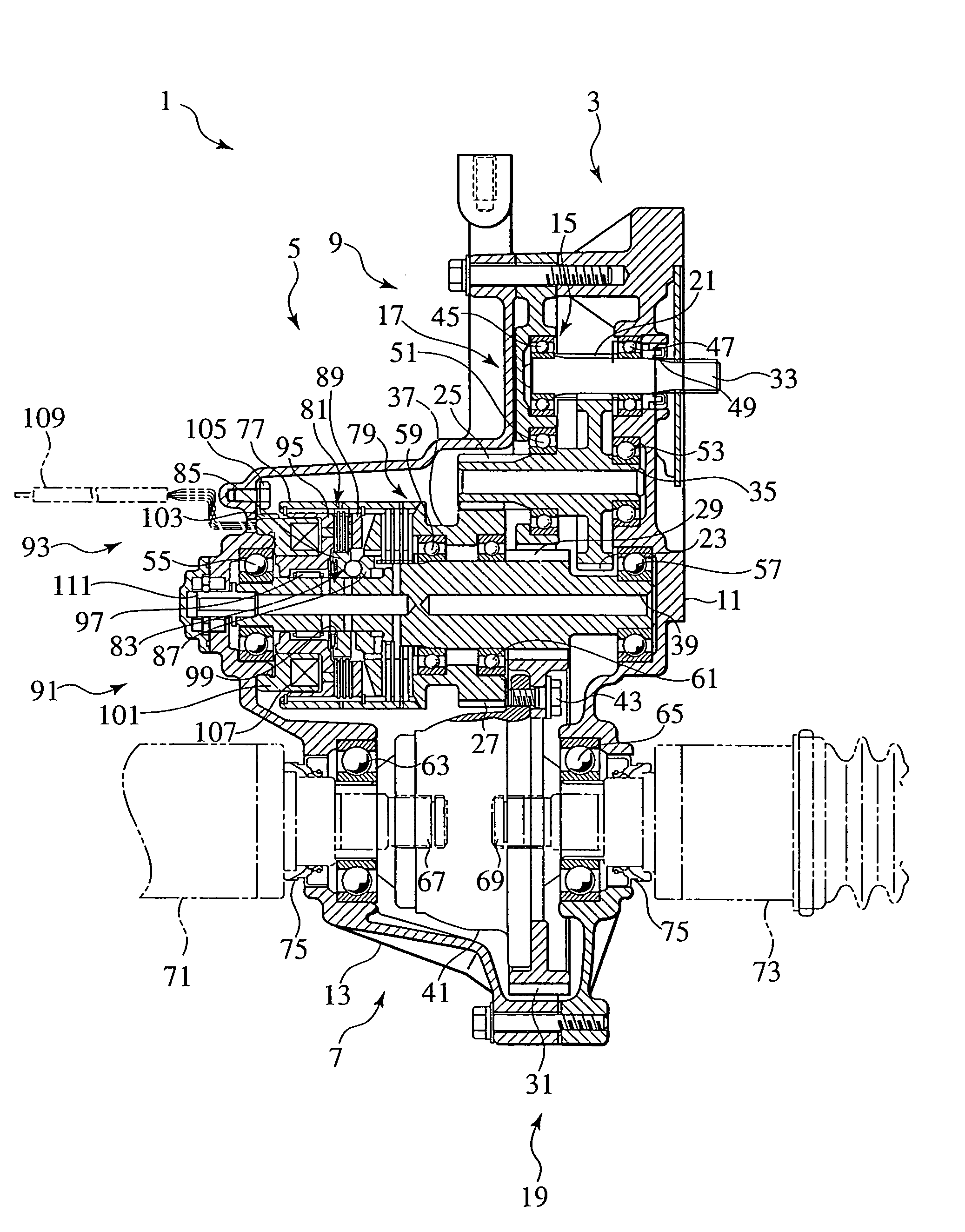

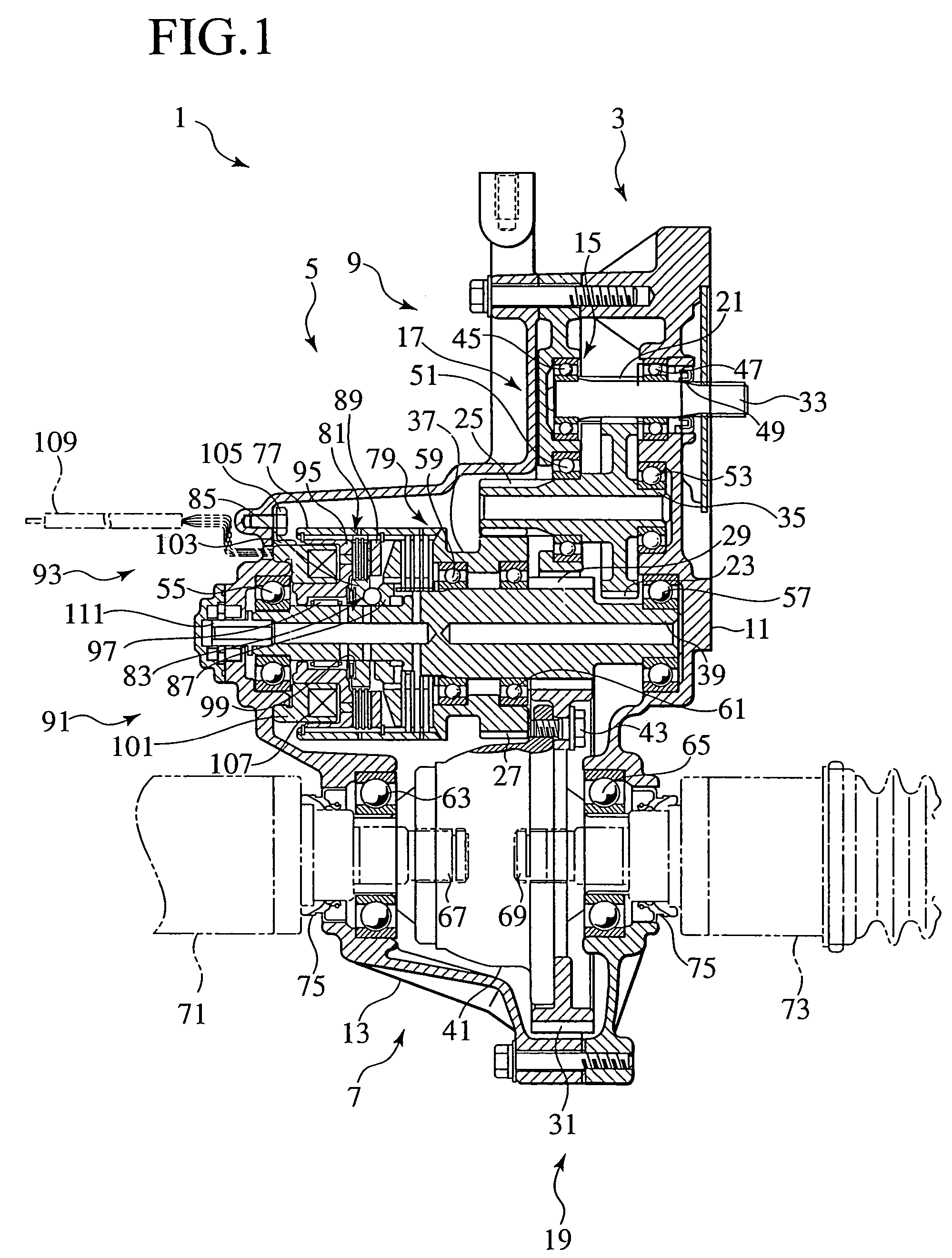

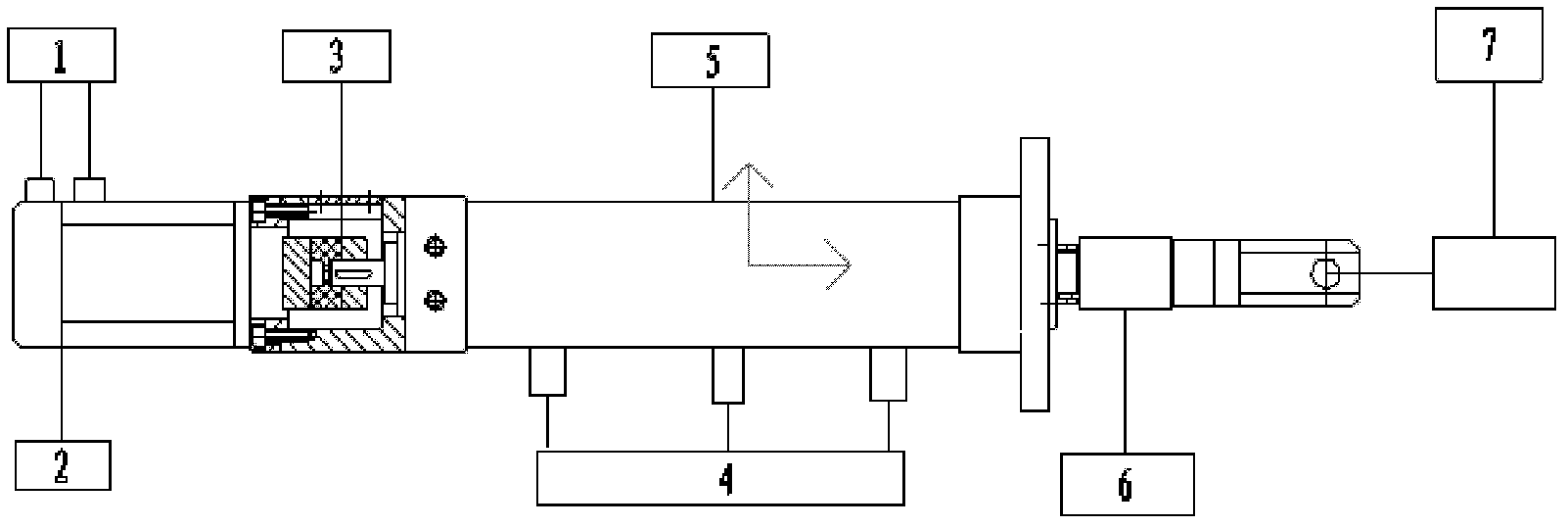

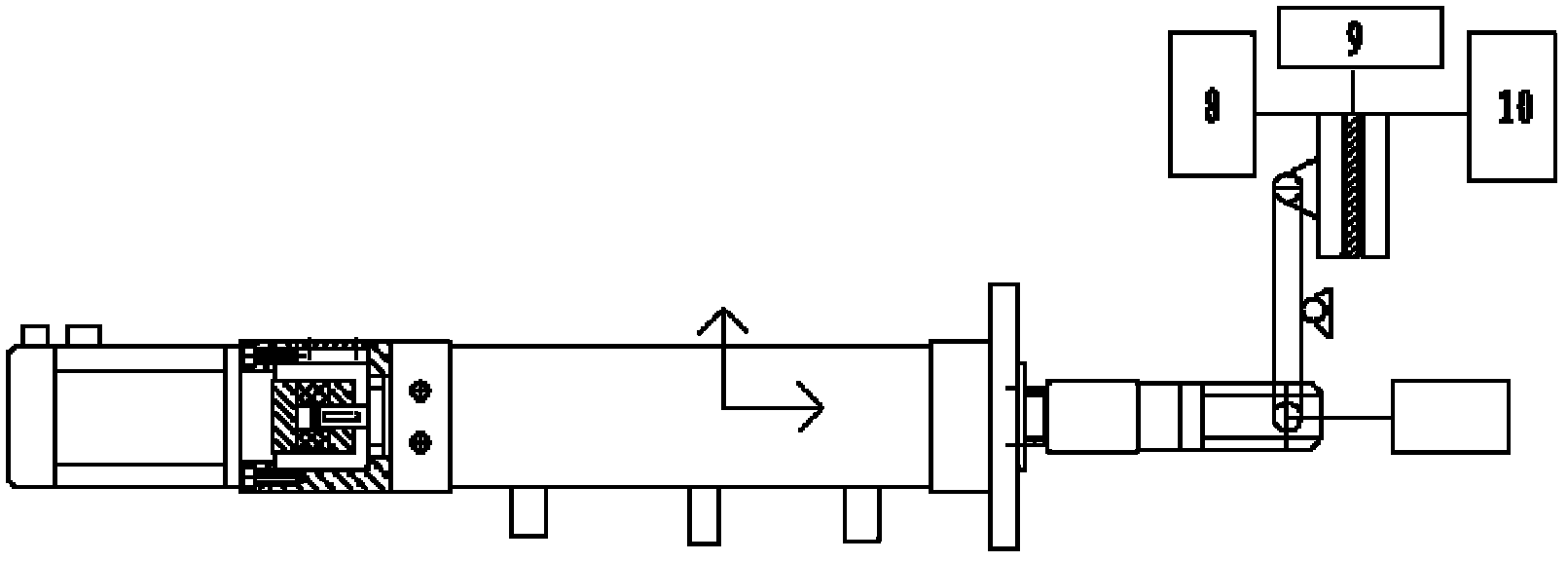

Transmission actuator

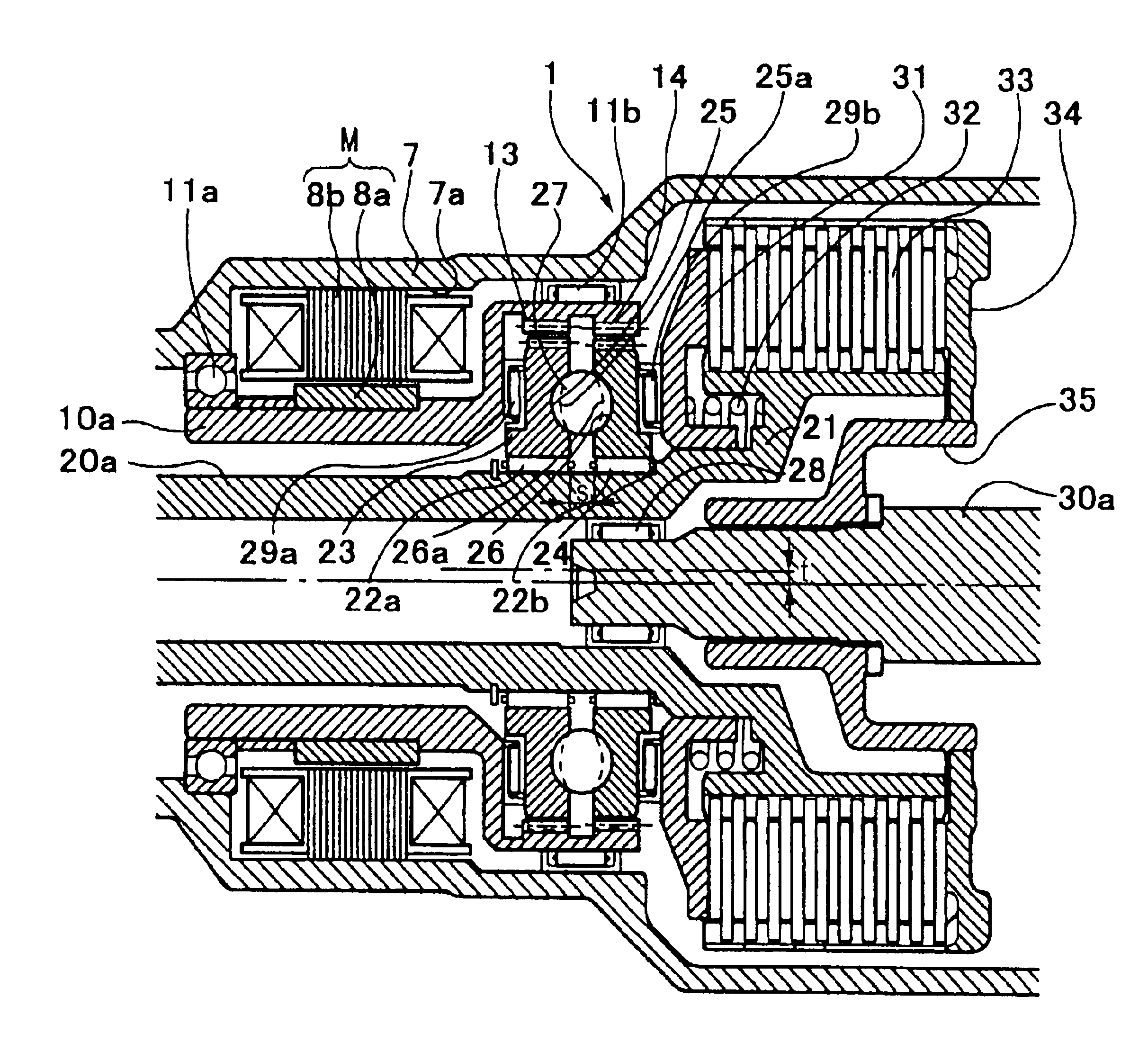

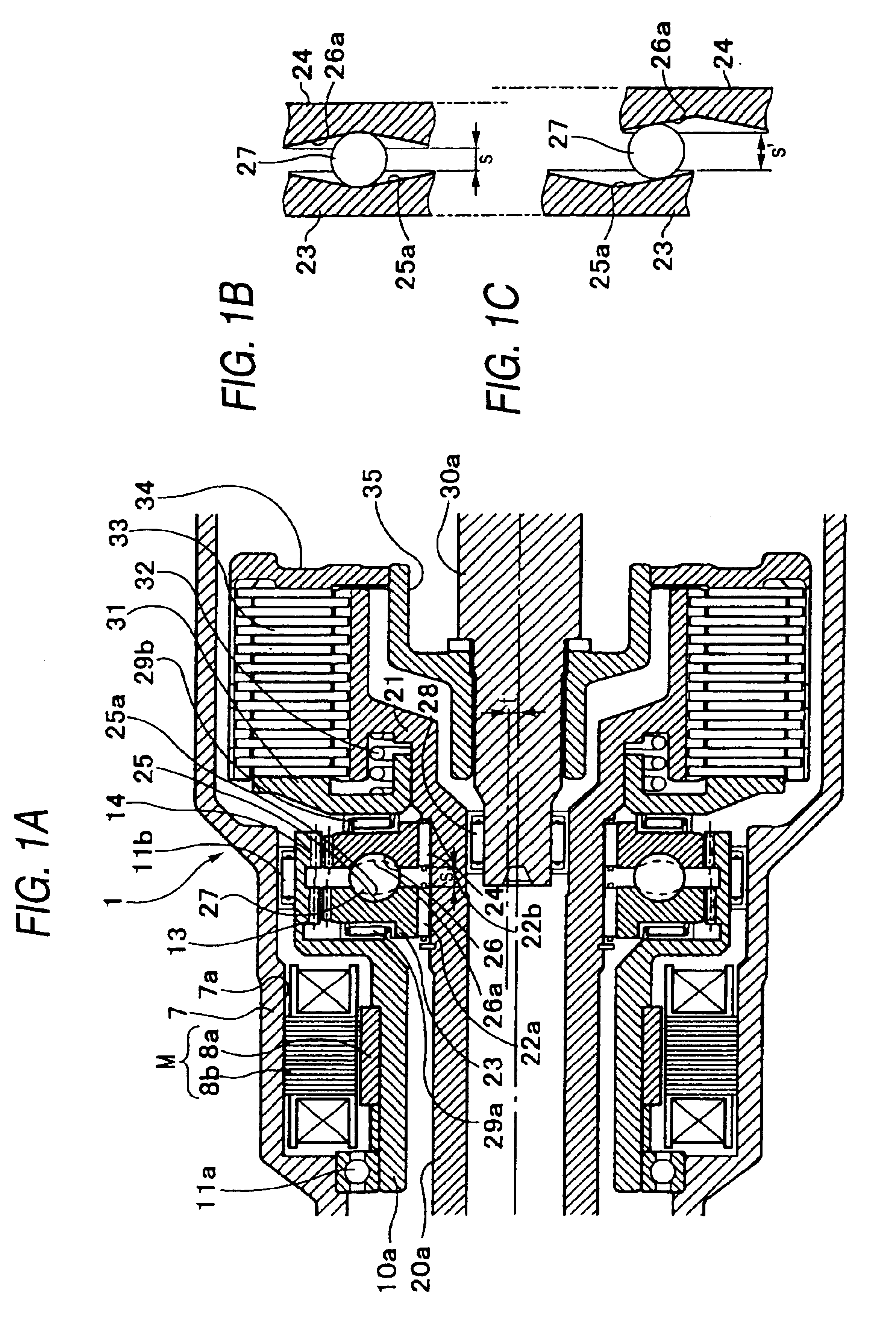

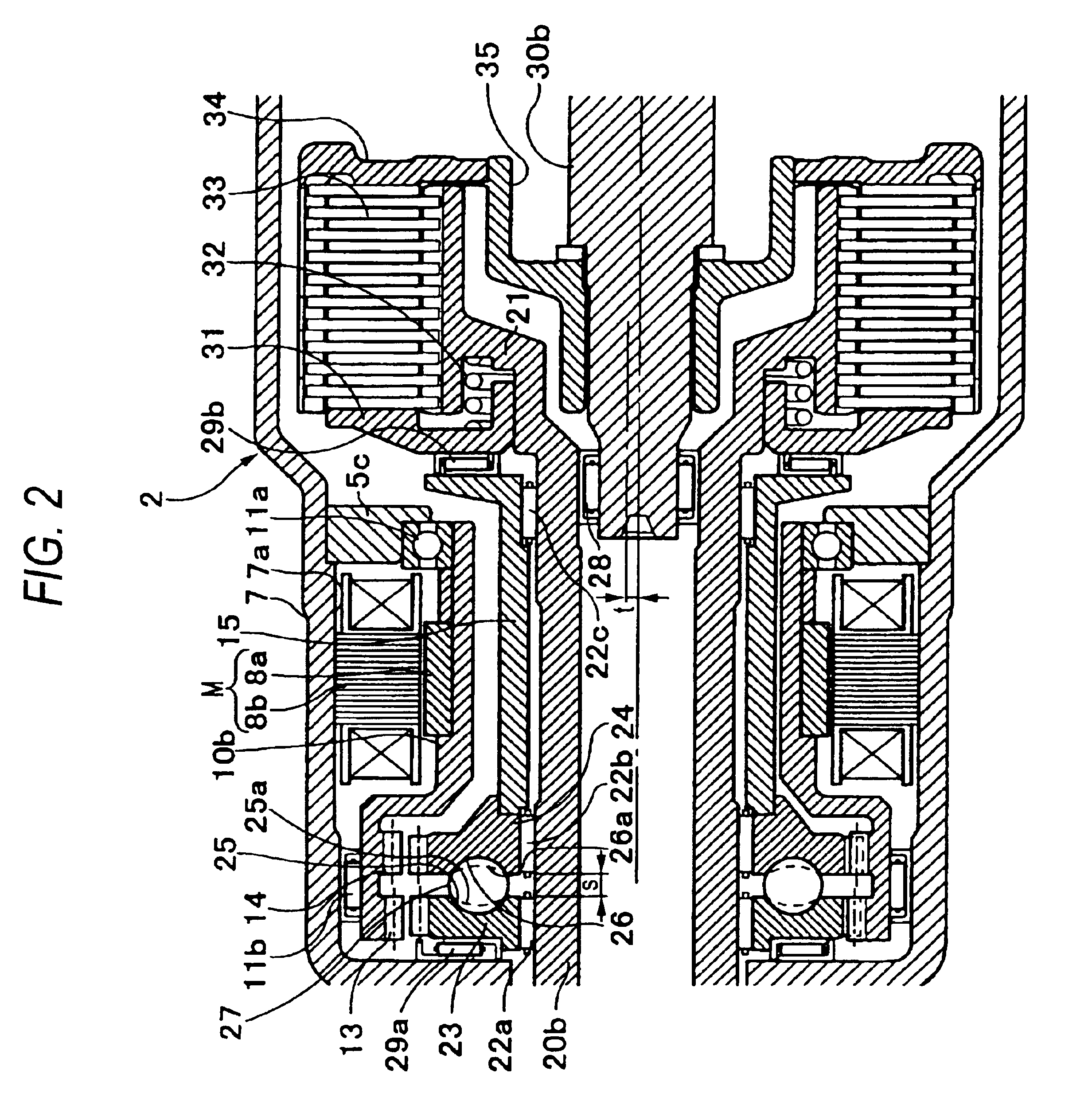

ActiveUS6951521B2Less spaceGood response in transmittingToothed gearingsMagnetically actuated clutchesTransmitted powerDrive shaft

A transmission actuator has a torque generating mechanism for generating a torque from a drive shaft, a speed reduction mechanism for multiplying a torque from the torque generating mechanism through a differential motion produced by a difference in gear ratio between a gearset of a first internally toothed gear and a first externally toothed gear and a gearset of a second internally toothed gear and a second externally toothed gear, a motion direction changing mechanism for converting the torque multiplied into a thrust and a friction engagement mechanism for transmitting power from an input shaft to an output shaft by virtue of the thrust so converted, wherein the drive shaft is made hollow so that the input shaft and the output shaft are disposed in a hollow portion of the drive shaft.

Owner:HONDA MOTOR CO LTD

Driving force transmitting device for four-wheel drive vehicle

InactiveUS20090229905A1Decreases oil viscosity resistanceDecreases friction lossFluid actuated clutchesRoad transportFriction torqueDrag torque

A driving force transmission device for four-wheel-drive vehicle based on the two-wheel drive of front wheels is provided. In the case of the two-wheel drive of front wheels, a multi-disc clutch mechanism for controlling the driving force distribution to a rear wheel output shaft, and a disconnection / connection mechanism for disconnecting and connecting a rear wheel differential and a right rear wheel drive shaft are provided, and in the two-wheel drive of front wheels, the dragging torque of the multi-disc clutch mechanism is made smaller than the friction torque of a rear wheel driving force transmission section, and the front wheel differential and the right rear wheel drive shaft are disconnected by the disconnection / connection mechanism, thereby the rotation of the rear wheel driving force transmission section is stopped.

Owner:UNIVANCE CORP

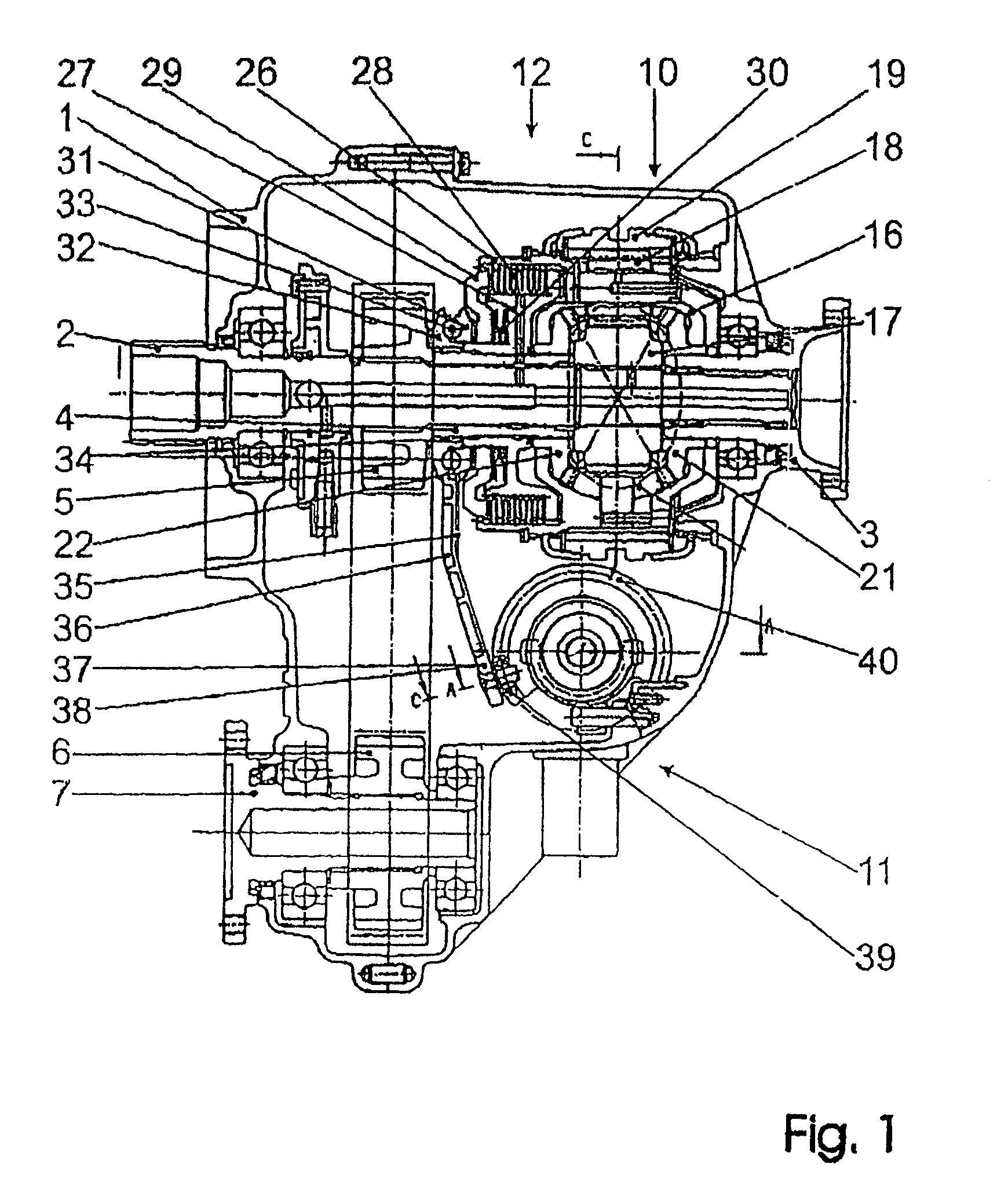

Multi-group transmission of a motor vehicle

InactiveUS20090272211A1Low costSave spaceMechanical actuated clutchesMagnetically actuated clutchesDrivetrainDrive shaft

A multi-group transmission of a motor vehicle which includes at least two transmission groups arranged in a drivetrain and a way for supporting traction force during gearshifts such that traction-force gearshifts are maintained with improved shifting comfort at comparatively low cost, little design effort and compact installation space demands. At least one electromagnetic clutch is a change-under-load unit by which, bypassing the force flow of at least one main group made as a gear-change transmission, an active connection can be formed between a driveshaft and a main transmission shaft or a transmission output shaft. During a gearshift operation, an active connection is temporarily made between a driveshaft and a main transmission shaft or a transmission output shaft by way of at least one electromagnetic clutch designed as a change-under-load unit.

Owner:ZF FRIEDRICHSHAFEN AG

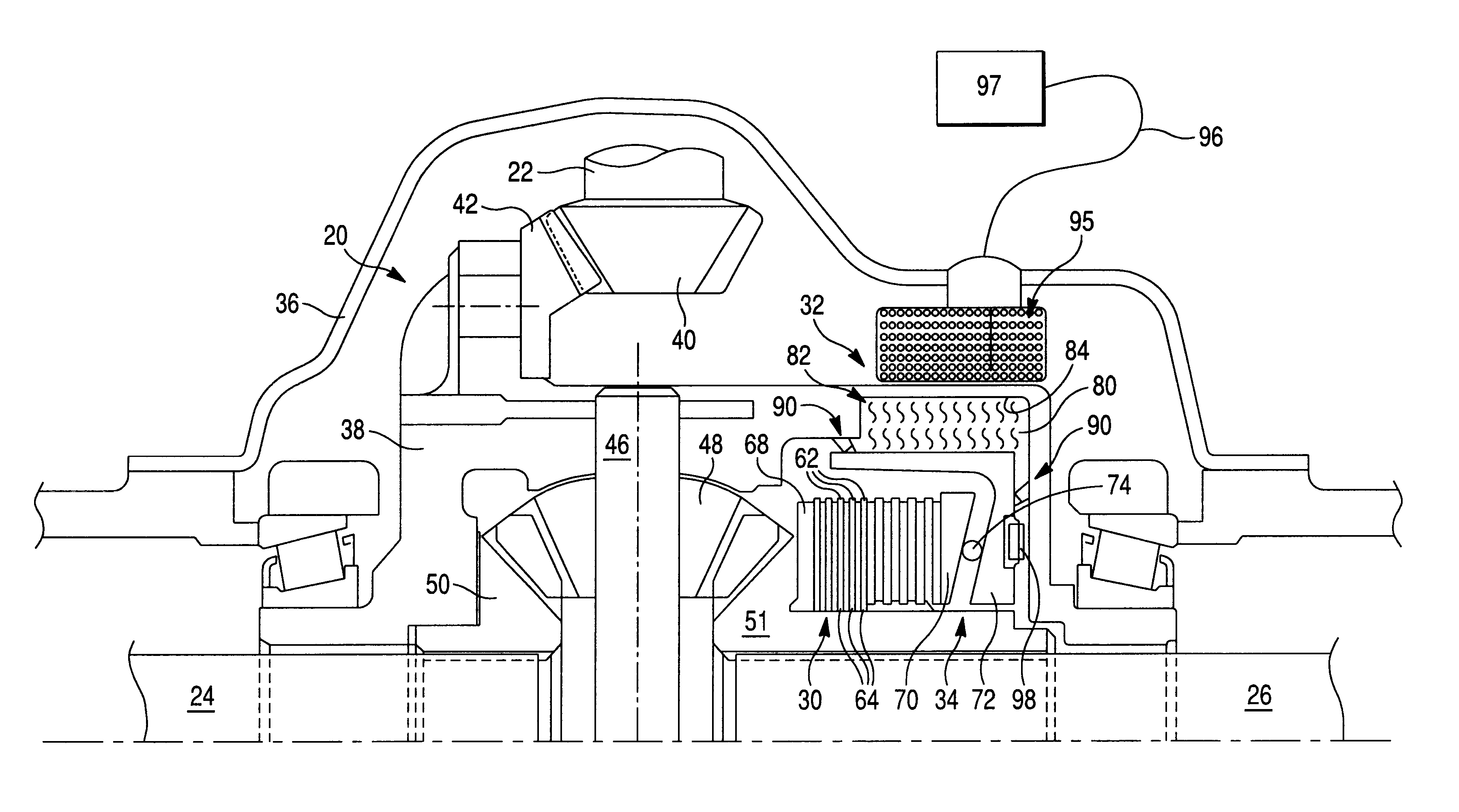

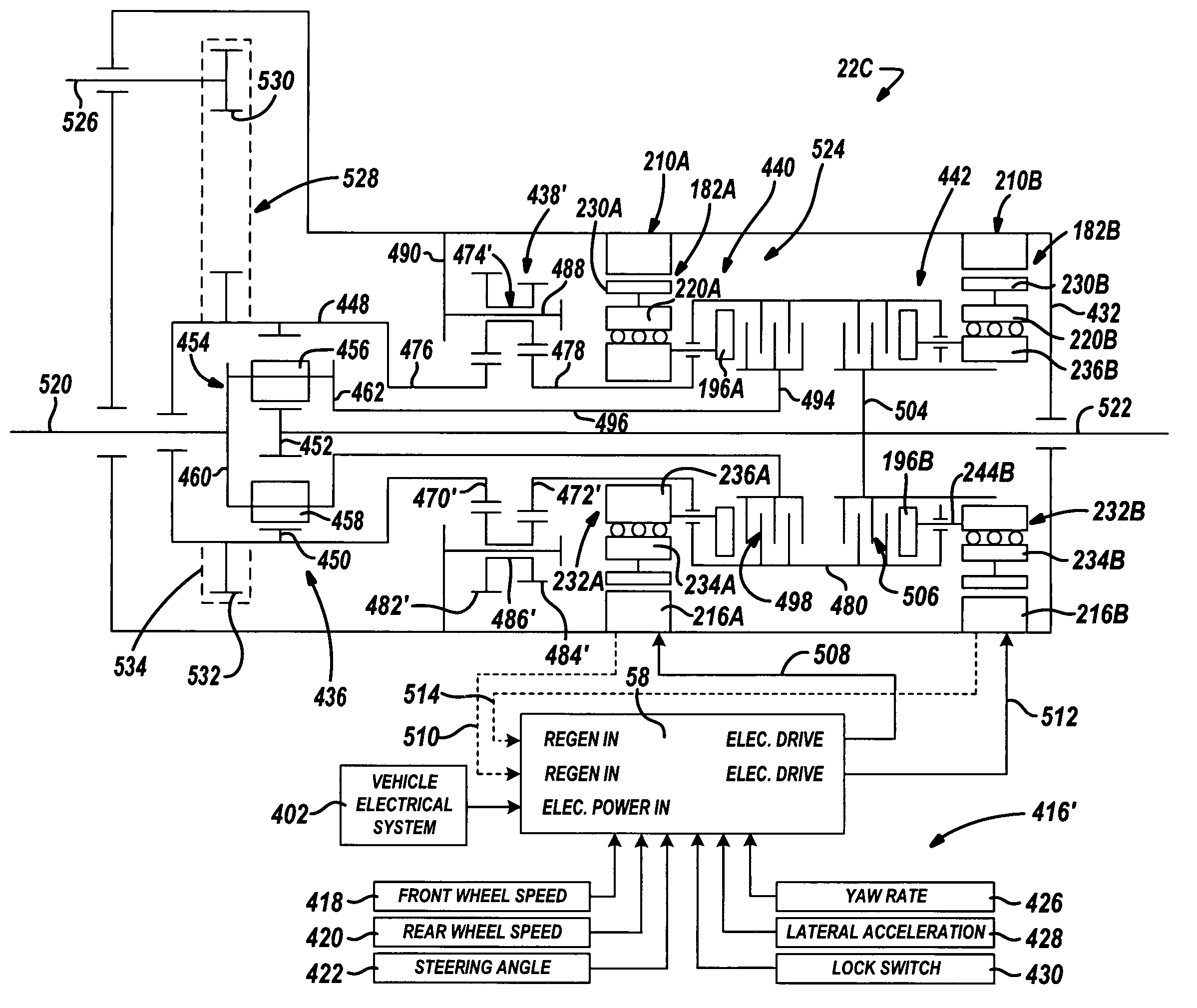

Torque vectoring device having an electric motor/brake actuator and friction clutch

InactiveUS7175557B2Reduced Power RequirementsReduce electricity demandMagnetically actuated clutchesEngine controllersLinear motionDual mode

Owner:MAGNA POWERTRAIN USA

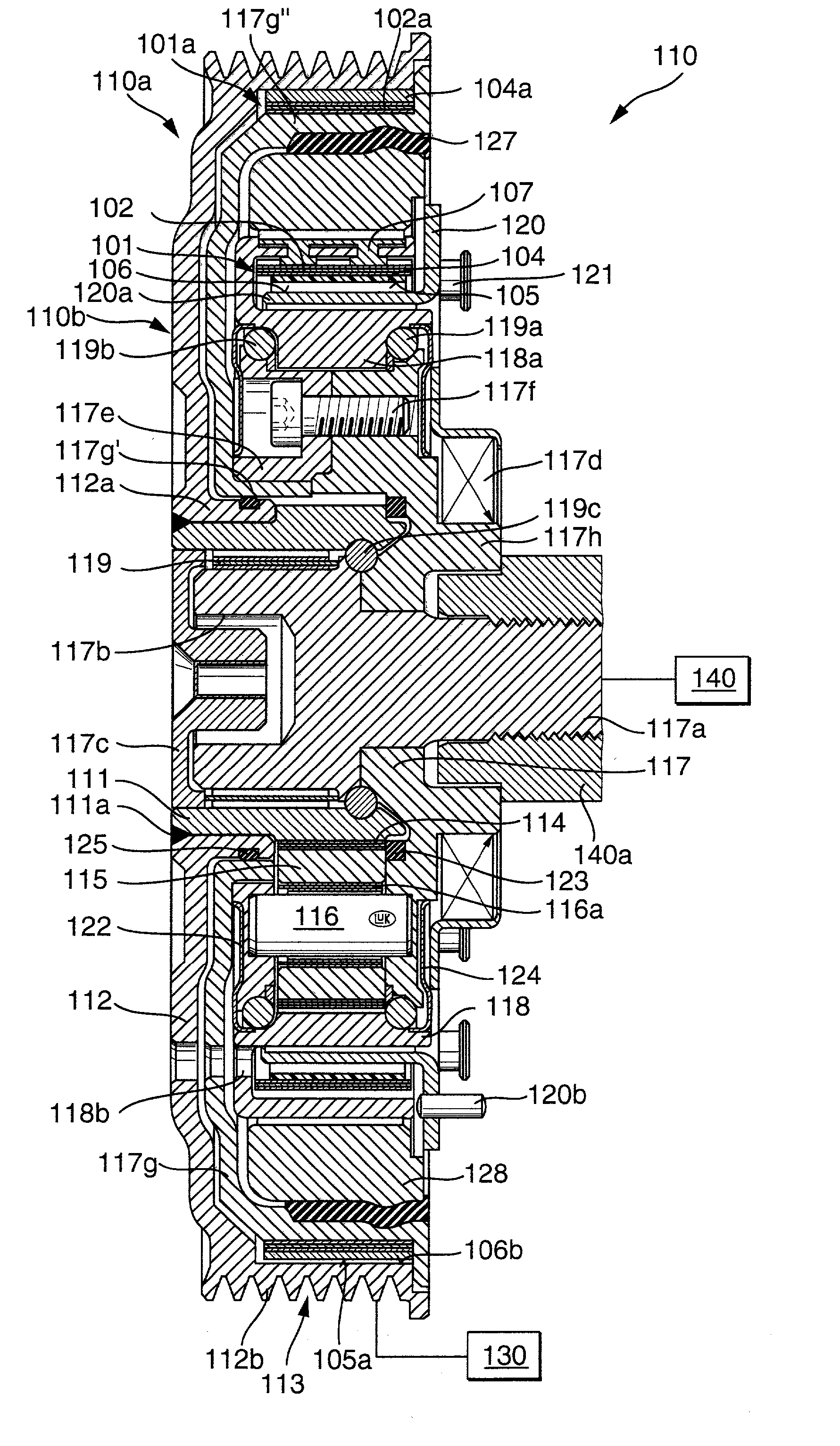

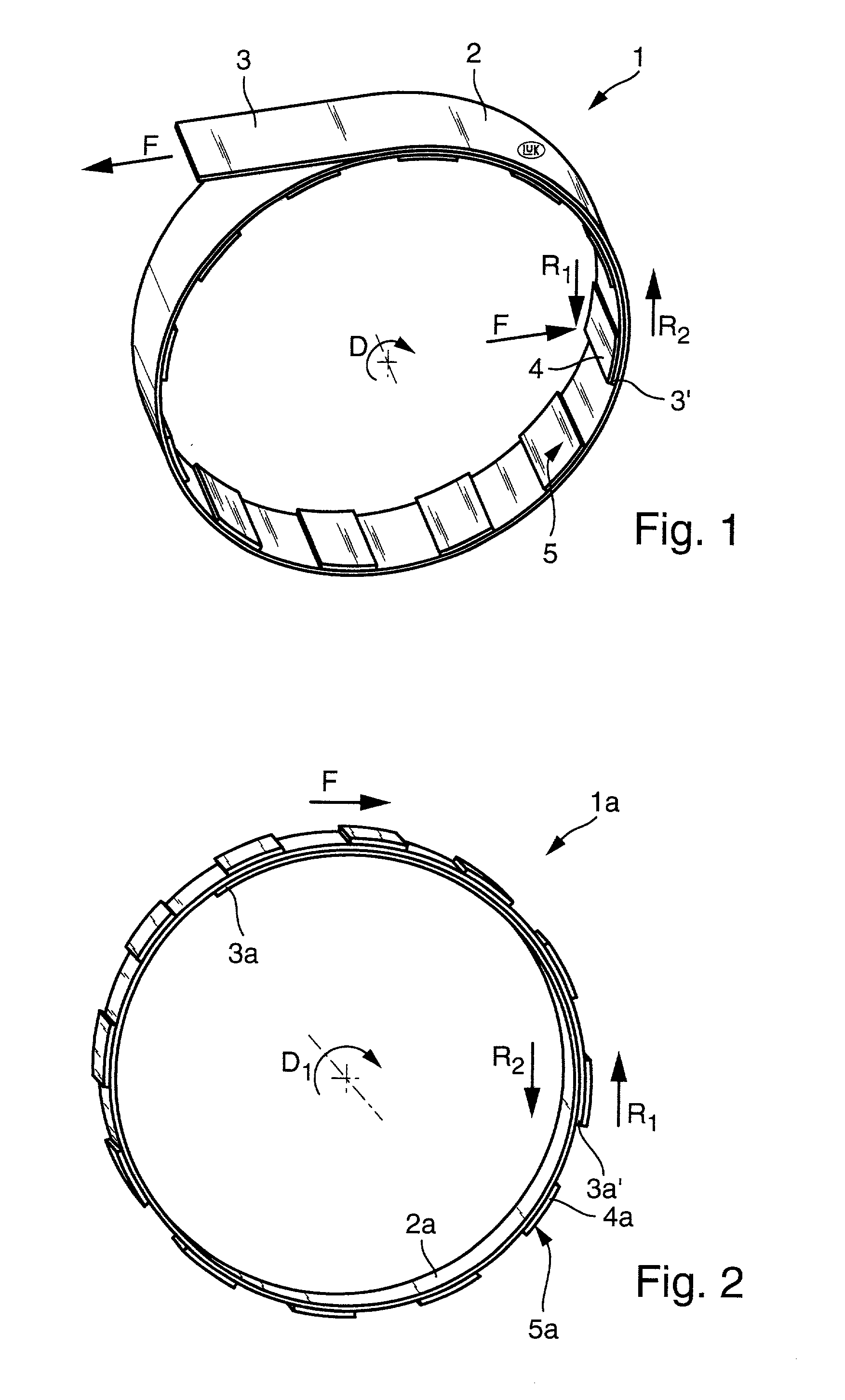

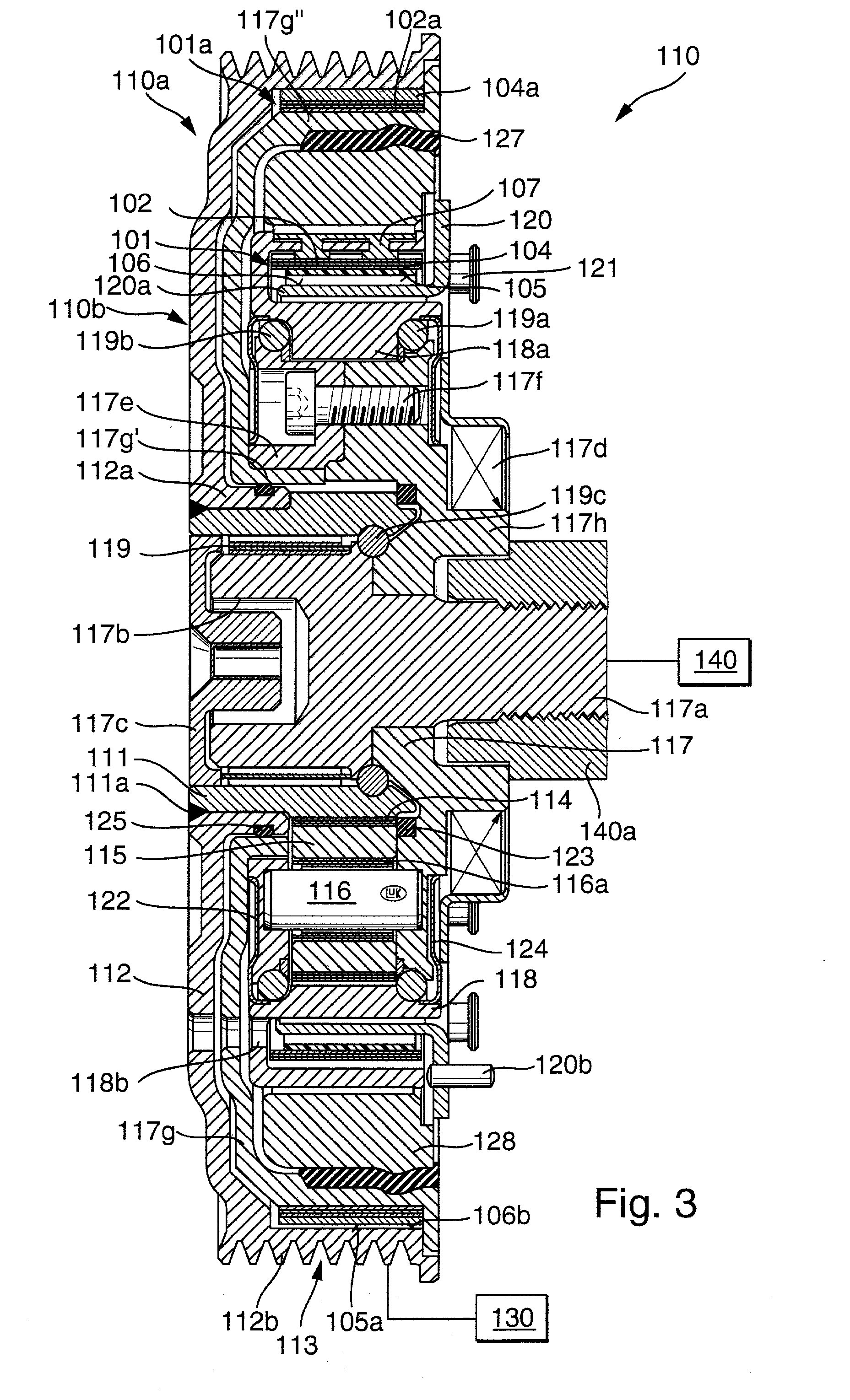

Transmission for use in the power trains of motor vehicles

InactiveUS6582333B2Less expensivePower operated startersSewing-machine control devicesFreewheelMobile vehicle

The power train of a motor vehicle has an engine which normally drives the wheels and can be started by an electric motor which acts as a generator once the engine is started. The torque transmitting connection between the crankshaft of the engine and a shaft of the motor includes a planetary and one or more freewheels of the type employing an elongated belt surrounding a rotary part and being surrounded by the internal surface of a hollow part. The belt or belts can be urged into or released from frictional engagement with one of the adjacent surfaces by centrifugal force and / or by an electromagnet.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

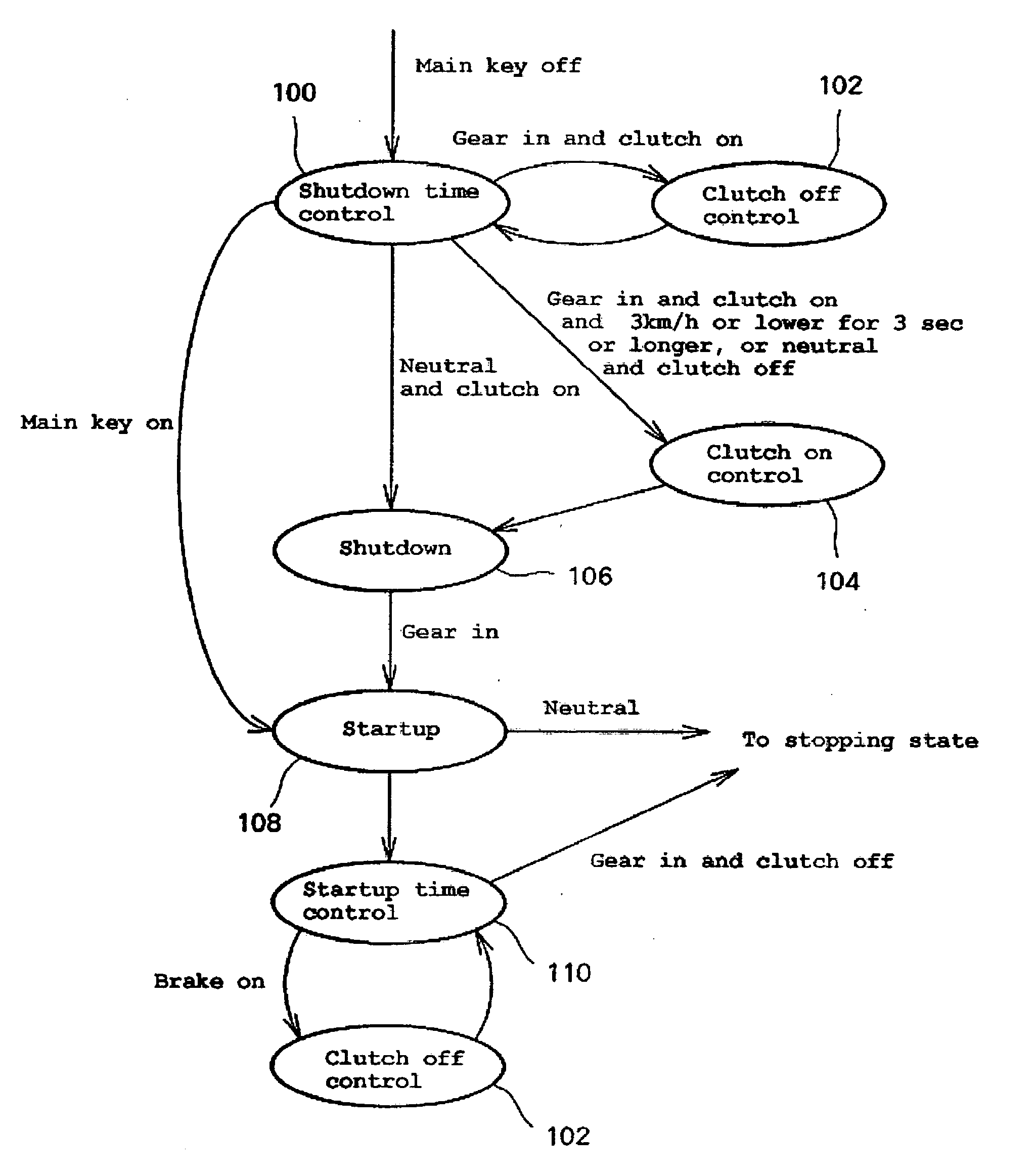

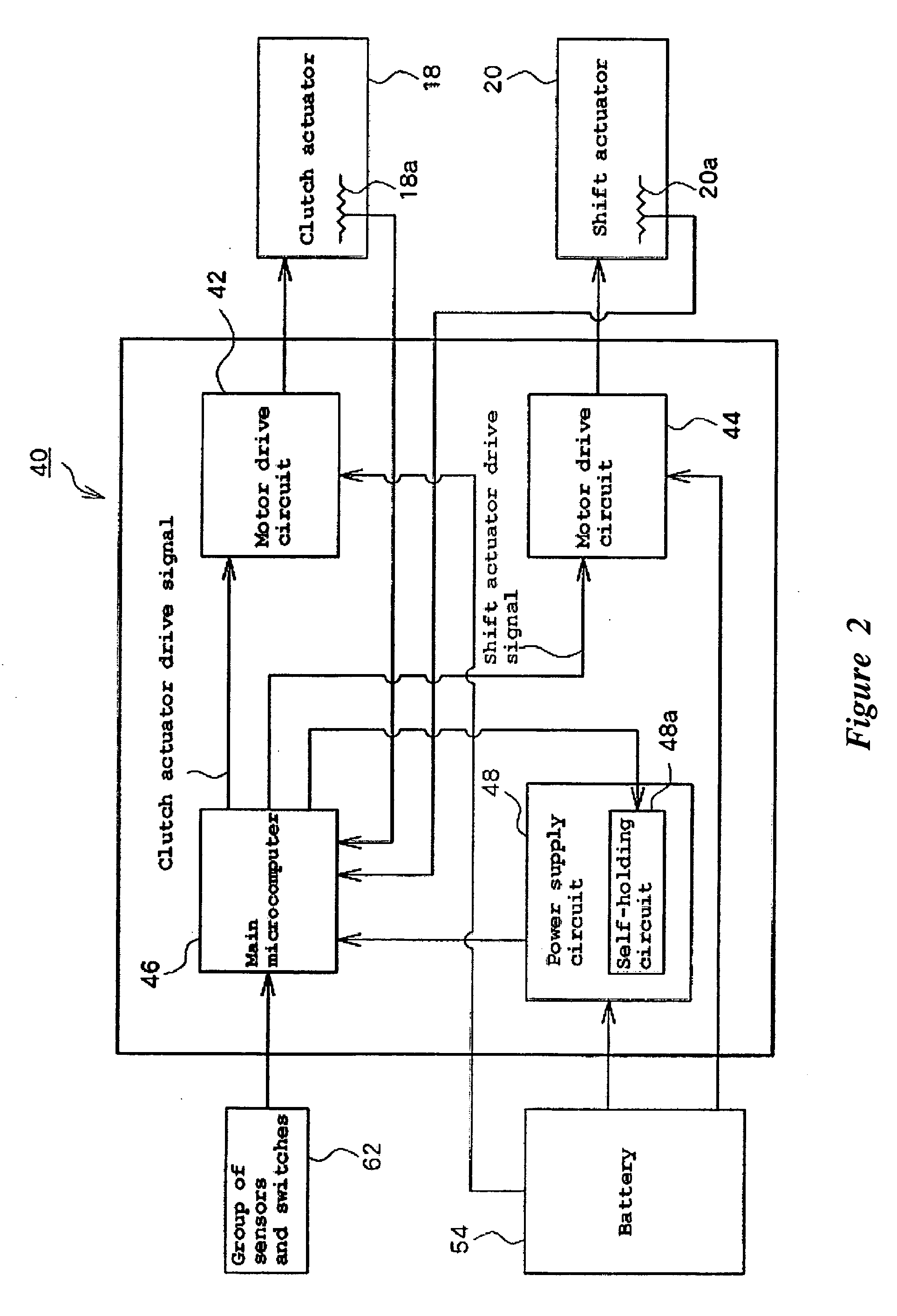

Gear change control device and method

A gear change control device is provided for a straddle-type vehicle having a clutch and a transmission. The device includes a clutch actuator configured to engage and disengage the clutch. A transmission actuator is configured to change a gear of the transmission. At least one sensor is configured to sense an operational condition of the straddle type vehicle. At least one switch is configured to generate a gear change command. A controller is operatively connected to the clutch actuator, the transmission actuator, the at least one sensor, and the at least one switch. The controller is configured to change gears in response to the gear change command and during the gear change reengage the clutch under either a first control routine or second, different control routine based upon the operational condition of the straddle-type vehicle determined by the at least one sensor.

Owner:YAMAHA MOTOR CO LTD

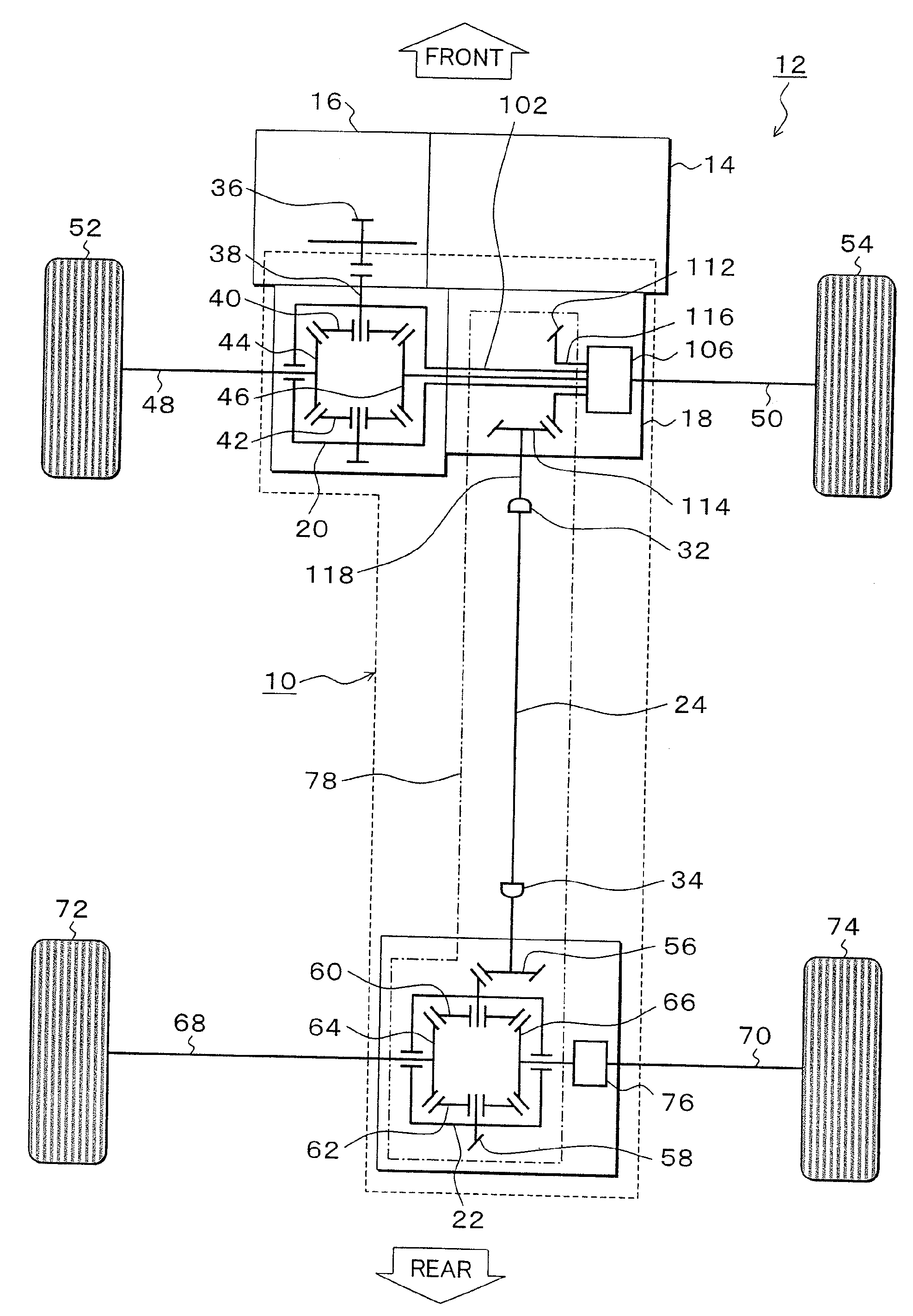

Power transmission system and operation method therefor

InactiveUS7086978B2Small sizeLight weightGear lubrication/coolingEngine controllersDrivetrainEngineering

Owner:TOCHIGI FUJI IND CO LTD

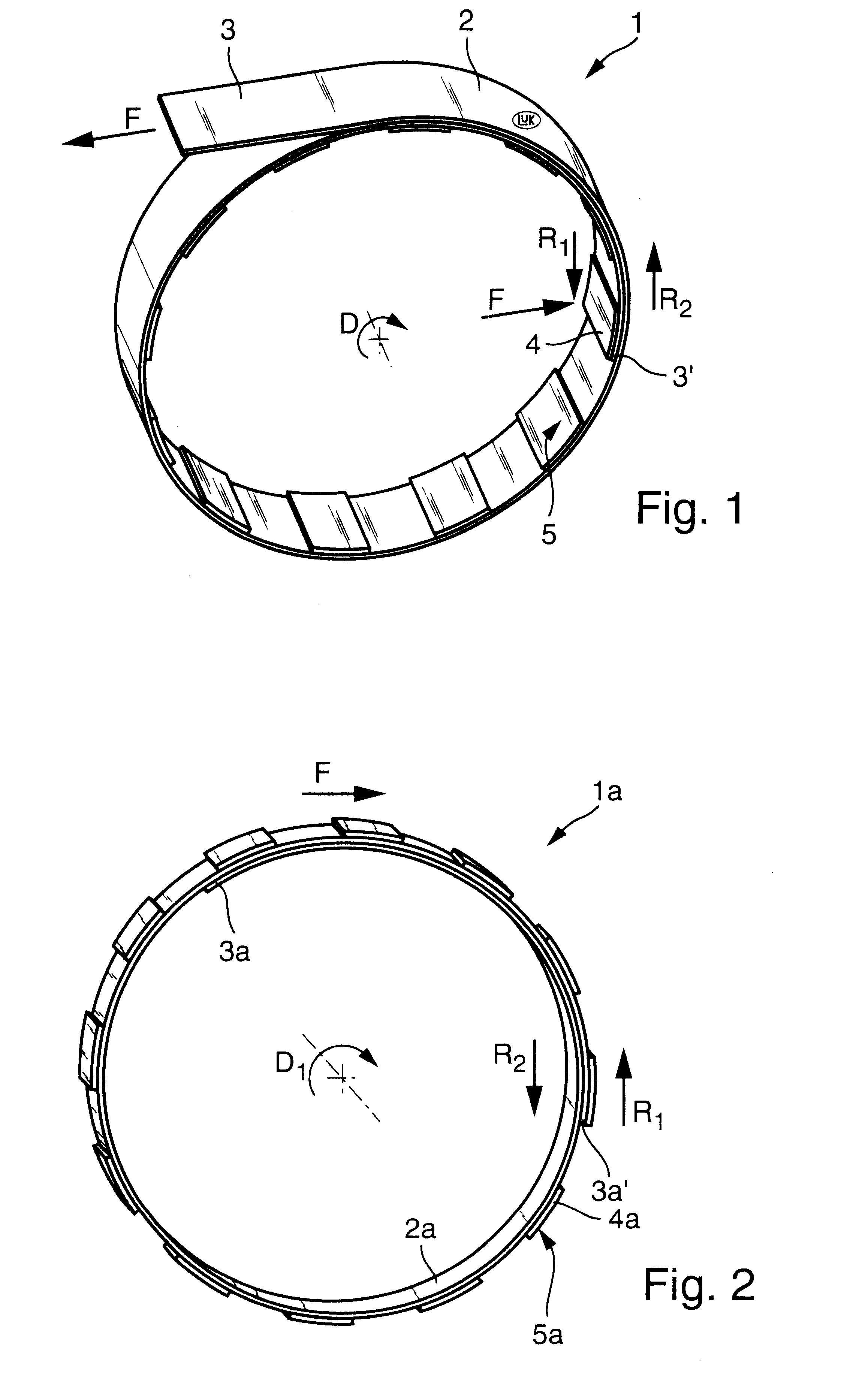

Transmission for use in the power trains of motor vehicles

The power train of a motor vehicle has an engine which normally drives the wheels and can be started by an electric motor which acts as a generator once the engine is started. The torque transmitting connection between the crankshaft of the engine and a shaft of the motor includes a planetary and one or more freewheels of the type employing an elongated belt surrounding a rotary part and being surrounded by the internal surface of a hollow part. The belt or belts can be urged into or released from frictional engagement with one of the adjacent surfaces by centrifugal force and / or by an electromagnet.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

On-demand transfer case

InactiveUS20050023063A1Limit slippingMechanical actuated clutchesMagnetically actuated clutchesTransfer caseActuator

A torque transfer mechanism is provided for controlling the magnitude of a clutch engagement force exerted on a multi-plate clutch assembly that is operably disposed between a first rotary and a second rotary member. The torque transfer mechanism includes a clutch actuator for generating and applying a clutch engagement force on the clutch assembly.

Owner:MAGNA DRIVETRAIN OF AMERICA

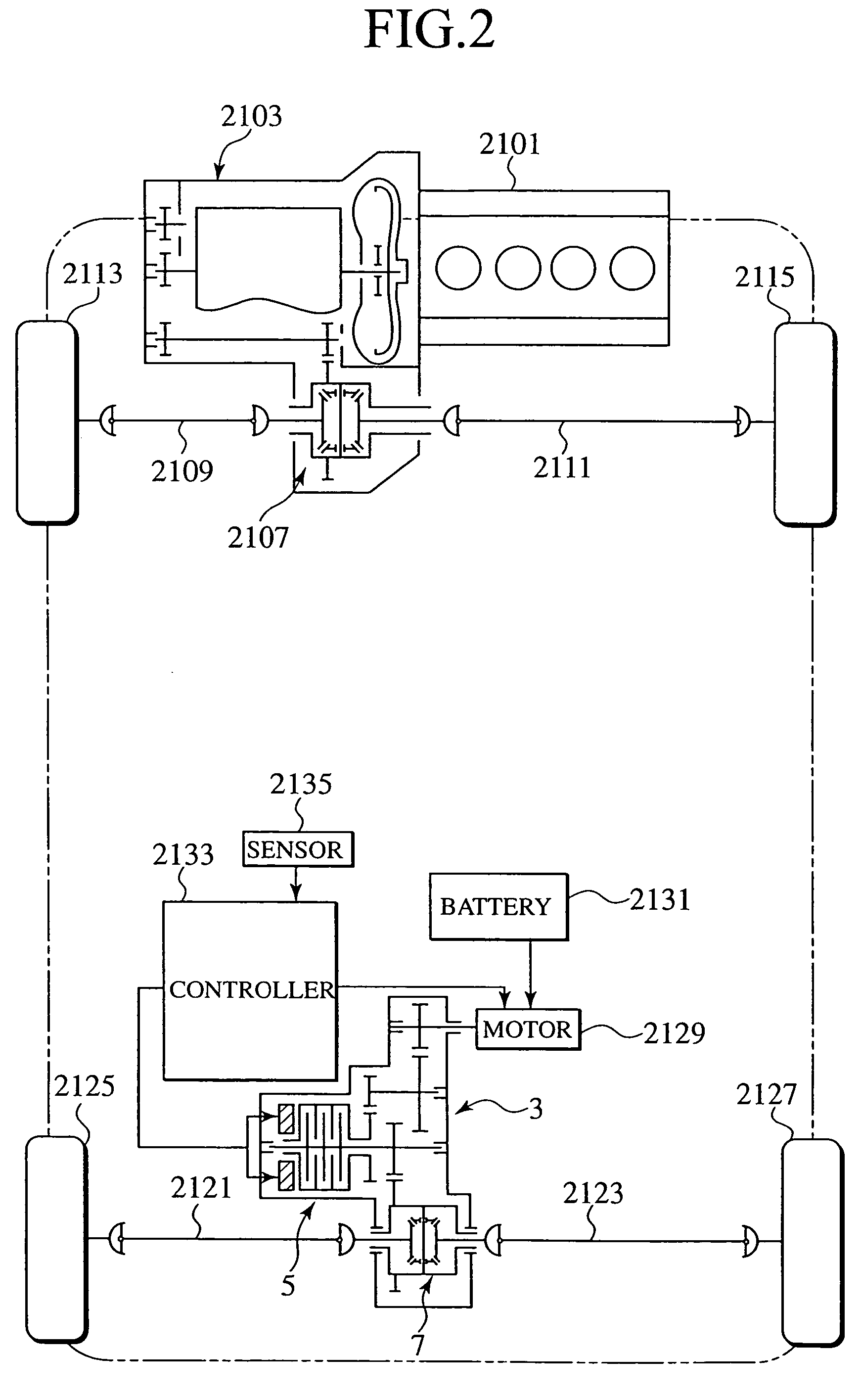

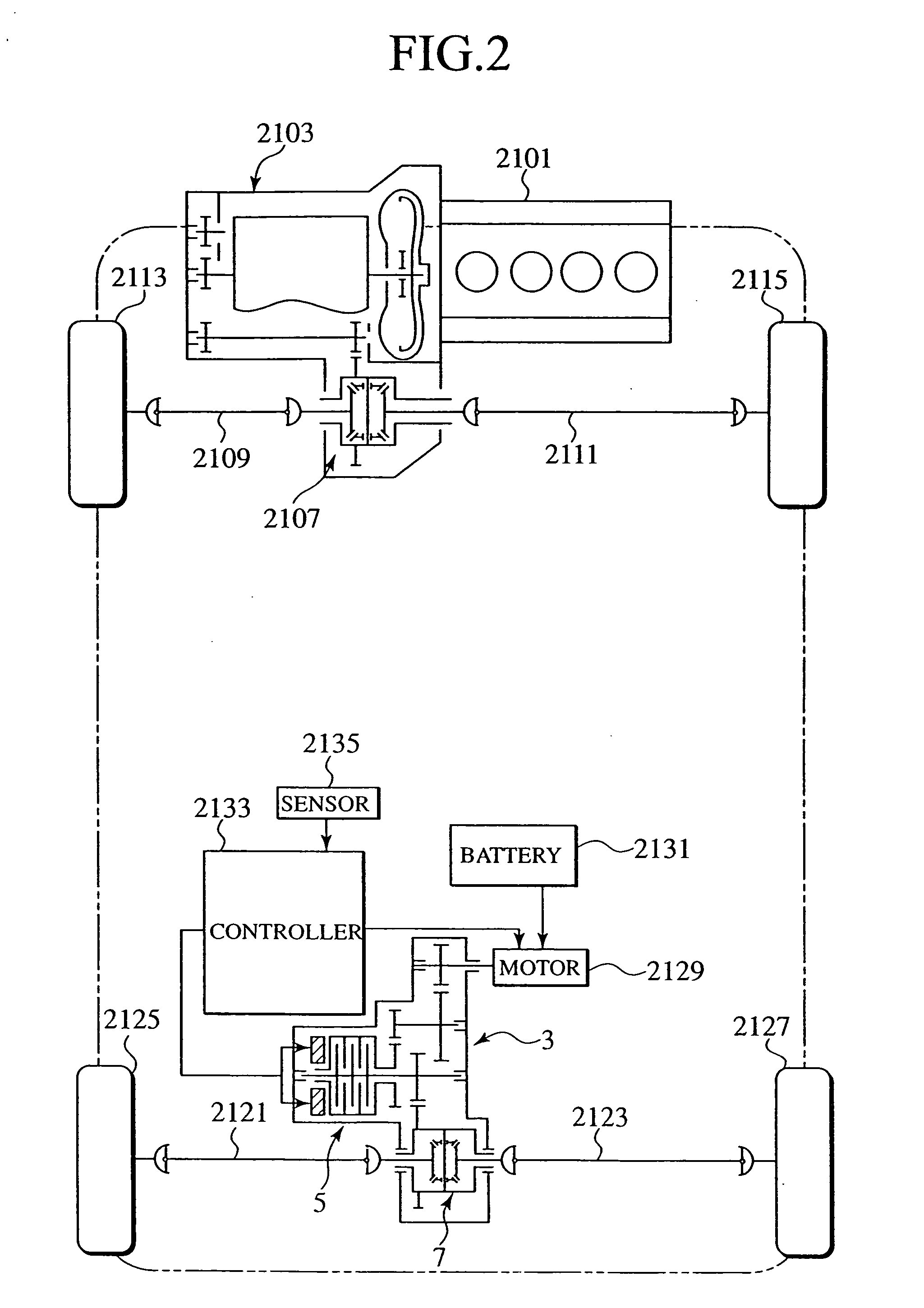

Power transmission system and operation method thereof

InactiveUS20060166777A1Small sizeLight weightGear lubrication/coolingEngine controllersDrivetrainEngineering

Between a speed reducing mechanism (15, 17, 19) for speed-reducing drive power of an electric motor and a differential apparatus (7) for distributing speed-reduced drive power to axle ends is disposed a clutch (5) configured for interruptive transmission of drive power.

Owner:TOCHIGI FUJI IND CO LTD

A speed-based clutch control method

InactiveCN102278391AObvious advantageObvious benefitsElectrically actuated clutchesMicrocontrollerClutch control

The invention relates to a control method of a clutch based on revolving speed and belongs to the field of clutch control. The control method provided by the invention is characterized that a clutch MAP figure control strategy is adopted in slipping stage of a clutch, the MAP figure lookup calculation is carried out according to the revolving speed difference of an output torque of the clutch and the input shaft of the clutch and the output shaft of the clutch, thereby controlling the position of the clutch; and driving intention of a driver is judged to output a clutch rotation speed target value curve according to the size and variable rate of an engine throttle; the D-value of the target value and actual value of the clutch revolving speed is calculated by virtue of PID (proportion integration differentiation), the position of the clutch is subjected to fine tuning, thereby meeting different driving intentions and travelling conditions. Compared with fuzzy control and a neural network, the control method provided by the invention has the advantages of small computational load, simple structure, and strong control instantaneity, and overcomes the delay problem of a controller singlechip caused by complicated control, and overcomes the influence from the variation in load of vehicles on the combined process; the dynamic property and economy of the automobile are unified by virtue of building MAP on a great deal calibration test, and the relation of the parameter characteristic and control objective in control process is clear and definite.

Owner:BEIJING UNIV OF TECH

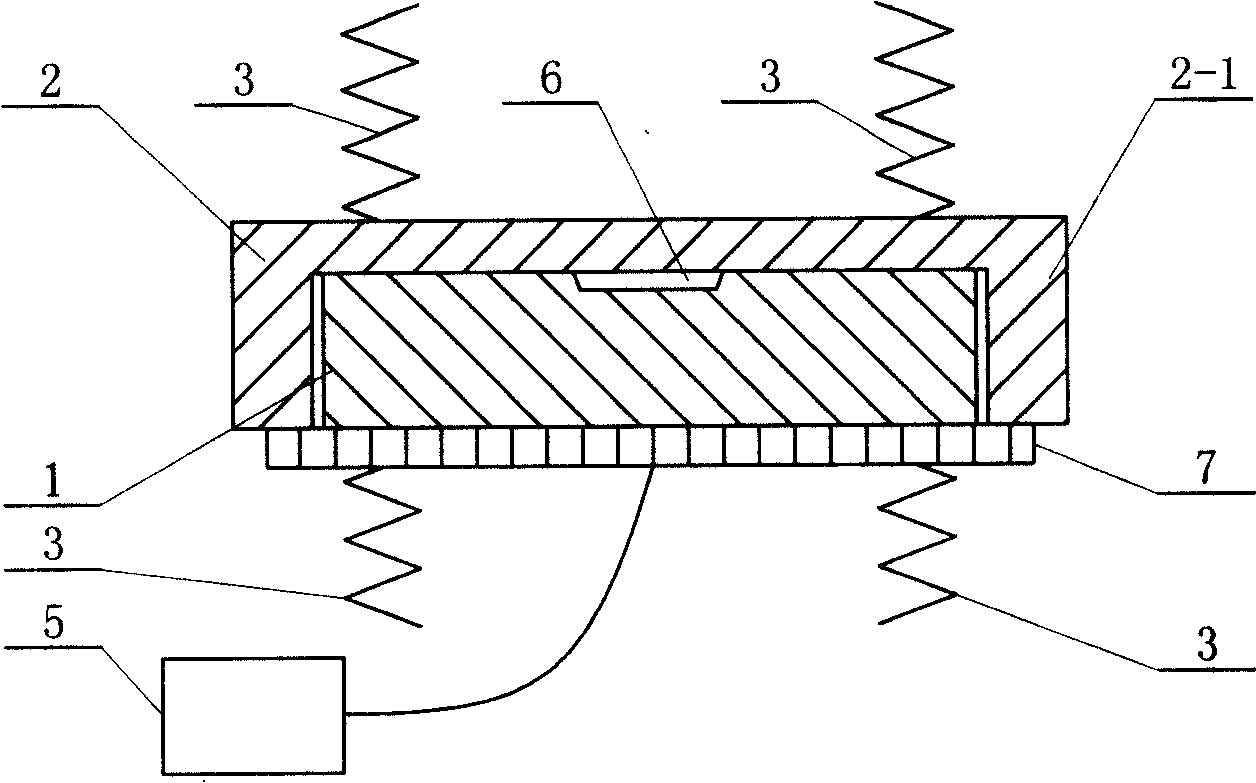

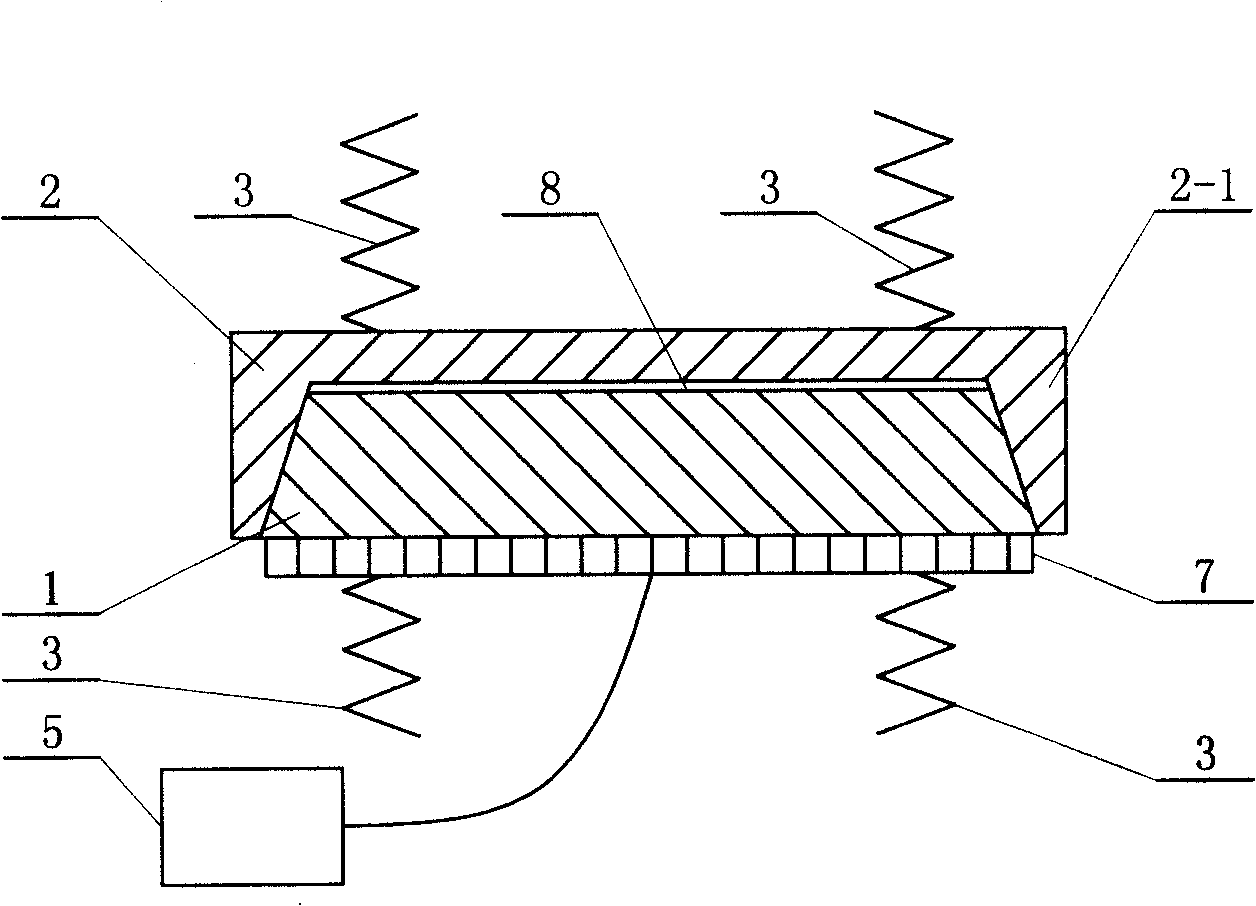

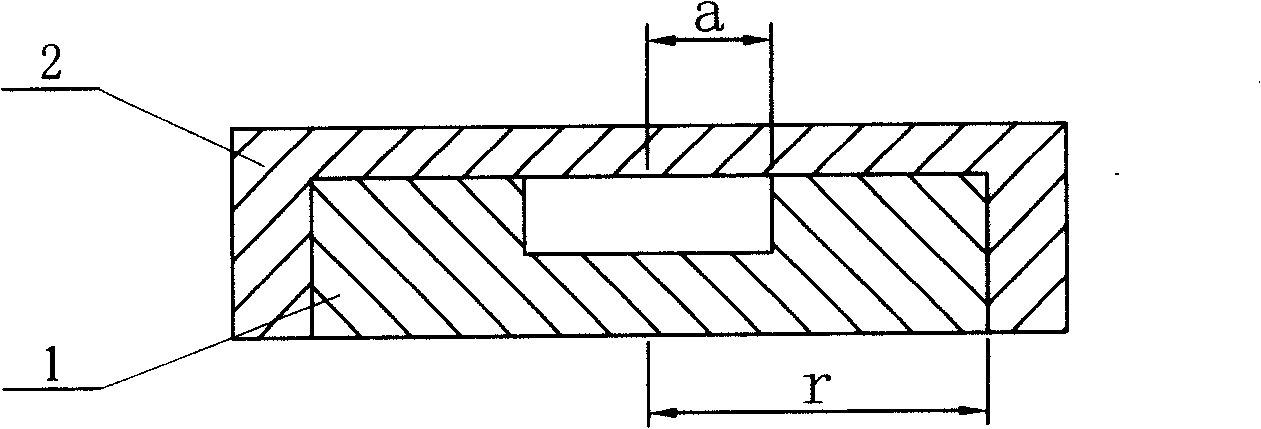

Clutch based on ultrasonic suspending force control

InactiveCN100424369CSimple structureOverall small sizePiezoelectric/electrostriction/magnetostriction machinesMagnetically actuated clutchesTransmitted powerElectromagnetic interference

The invention discloses a clutch based on ultrasonic suspending force control, which is composed of active rotating disc, passive rotating disc, piezoelectric ceramic piece, back-moving spring and high-frequency electric source. The passive rotating disc couples to the circular ring of the active rotating disc. The end face of the active rotating disc contacts to an end face of the passive rotating disc. The piezoelectric ceramic piece is fixed on the other end face of the passive rotating disc. The high-frequency electric source connects to the receiving terminal of the piezoelectric ceramic piece. The back-moving spring is set on active rotating disc or passive rotating disc to keep a certain distance between the active rotating disc and passive rotating disc. Another embodiment is that: the inner surface of the circular ring 2-1 is taper shaped; the flange of 1 is taper shaped; the inner surface of the 2-1 contacts to the flange of 1. The invention applies the ultrasonic suspending force as drive force for separation and applies friction moment to transmit power.

Owner:HARBIN INST OF TECH

Power-operated clutch actuator for torque transfer mechanisms

A torque transfer mechanism is provided for controlling the magnitude of a clutch engagement force exerted on a multi-plate clutch assembly that is operably disposed between a first rotary and a second rotary member. The torque transfer mechanism includes a power-operated clutch actuator for generating and applying a clutch engagement force on the clutch assembly.

Owner:MAGNA POWERTRAIN USA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com